Konica Minolta FS-105 Manual

SERVICE MANUAL

MODEL

FS-105

JUNE 1998

CSM-FS105

CONTENTS

TABLE OF CONTENTS |

|

SAFETY PRECAUTIONS........................................................ |

v |

FS-105 |

|

SPECIFICATIONS ................................................................. |

1 |

Type ............................................................................... |

1 |

Functions ....................................................................... |

1 |

Stapler Kit ...................................................................... |

1 |

Machine Data ................................................................. |

1 |

Maintenance .................................................................. |

1 |

Operating Environment ................................................. |

1 |

CENTER CROSS SECTION ................................................. |

3 |

DRIVE SYSTEM DIAGRAM .................................................... |

4 |

Paper Conveyance System Drive .................................. |

4 |

Stapler Unit Drive ........................................................... |

4 |

EXTERNAL SECTION ........................................................... |

5 |

Construction .................................................................. |

5 |

Disassembly and Reassembly .................................... |

5 |

CONVEYANCE SECTION ..................................................... |

8 |

Construction .................................................................. |

8 |

Mechanisms .................................................................. |

8 |

Disassembly and Reassembly .................................. |

11 |

Paper Feed Motor (M801) Control ............................... |

13 |

Conveyance Drum (M807) Control .............................. |

14 |

Tray Up/Down (M804) Control ..................................... |

15 |

PAPER EXIT/STAPLER UNIT SECTION ............................. |

16 |

Construction ................................................................ |

16 |

Mechanisms ................................................................ |

16 |

Disassembly and Reassembly .................................. |

18 |

Paper Alignment Control ............................................. |

20 |

Paper Exit (M805) Control ............................................ |

21 |

Paper Stacking Control ............................................... |

22 |

Stapler Movement (M806) Control ............................... |

24 |

Stapler Control ............................................................. |

25 |

OTHER CONTROL FUNCTIONS ....................................... |

27 |

Power On Operation .................................................... |

27 |

DIAGRAMS |

|

ELECTRICAL PARTS LAYOUT DIAGRAM .......................... |

28 |

CONNECTOR LAYOUT DIAGRAM ...................................... |

29 |

iii

This page left blank intentionally.

iv

FS-105

PRODUCT SPECIFICATIONS

Type

Type: Drum inverting type, multi-tray finisher

Functions

Kinds of copy paper: Same as main body

Copy paper size: A11x17R, 8.5x14R, 8.5x11, 8.5x11R, 8.5x5.5, 8.5x5.5R, 5.5x8.5R

Modes |

|

|

: Available |

: Not available |

|||||||

Mode |

Tray |

|

Tray 1 |

|

Tray 2 |

|

Tray 3 |

||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Through mode |

|

|

|

|

|

|

|

|

|

|

|

Offset mode |

|

|

|

|

|

|

|

|

|

|

|

Staple mode |

|

|

|

|

|

|

|

|

|

|

|

Sheet capacity |

|

|

|

|

|

|

|

|

|

|

|

Tray |

Mode |

|

Small sizes |

|

Middle sizes |

|

Large sizes |

|

Special paper |

||

|

|

|

|

||||||||

Tray 1 |

Through mode |

|

100 |

|

100 |

|

|

100 |

|

|

10 |

Tray 2, |

Through mode |

|

300 |

|

500 |

|

|

300 |

|

|

– |

Tray 3 |

Offset mode |

|

– |

|

500 |

|

|

300 |

|

|

– |

|

Staple mode |

|

|

|

|

|

|

|

|

– |

|

|

|

25 sets (Note) |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

The above numbers apply for same-size paper (22 lb. ,standard paper) stacked continuously.

Small sizes |

: 5.5x8.5R |

Middle sizes |

: 8.5x11, 8.5x11R, 8.5x5.5, 8.5x5.5R |

Large sizes |

: 11x17R, 8.5x14R |

Special paper : Other than standard paper (thin paper, thick paper, blueprint masters, OHP film etc.)

Note: The maximum capacity (500 or 300 sheets) should not

be exceeded. |

|

Paper weight |

|

Tray 1: |

14 - 54 lb. |

Tray 2/3: |

16 - 44 lb. |

Copy paper curling: |

10 mm maximum |

Curling |

Copy paper (5 sheets) |

Offset amount: 30 mm (offset/group mode)

Stapler Kit

Number of copies that can be stapled together:

50 maximum (22 lb. fine quality paper, thickness 5 mm maximum)

Staple position:

A = 9 mm (non-adjustable)

B = 10 mm (±3 mm adjustable) C = 90 mm (±4 mm adjustable)

Stapler capacity:

5000 staples/cartridge

Machine Data

Power source: 24 V DC / 5 V (supplied from main body)

Max. power consumption:

100 VA (FS-105 only)

Weight: approximately 72 lb. (with base)

Machine dimensions

Unit: inches |

21.5 |

10.4 |

24.5 |

.6 |

23 |

1

FS-105

Maintenance

Maintenance: Same as main body

Operating Environment

Temperature: |

50°F ~ 91°F |

Humidity: |

20% to 80% RH |

Note: The contents of this manual may be changed without prior notice.

2

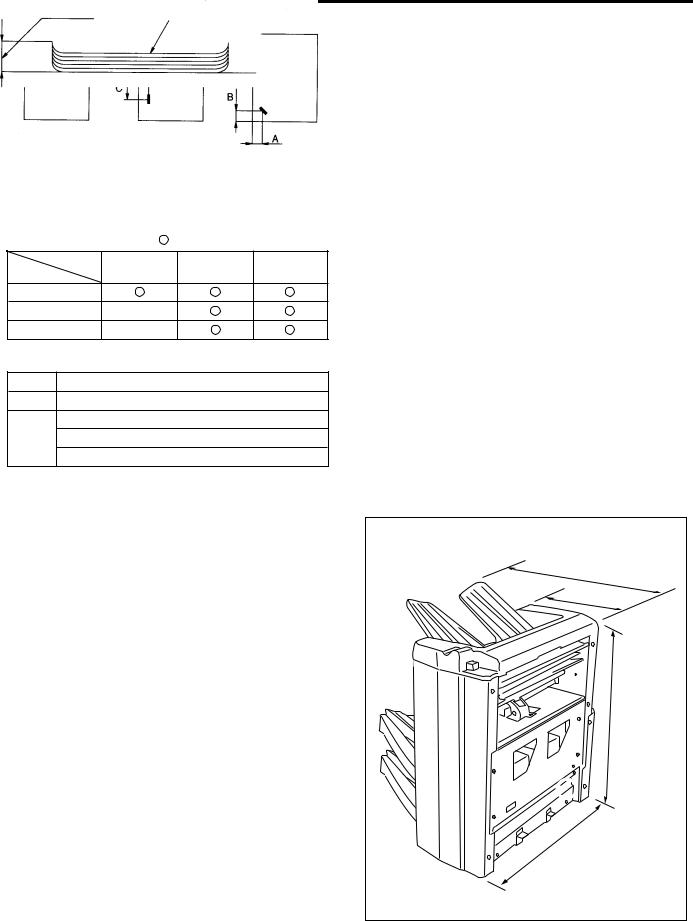

FS-105

CENTER CROSS-SECTIONAL DRAWING

Paper exit roller

Tray 1 |

|

Conveyance rollers |

Switching |

guide |

|

|

Conveyance drum |

Tray 2

Paper exit roller (A)

Stapler unit

Tray 3 |

Exit lever |

|

Paper exit roller (A)

3

FS-105

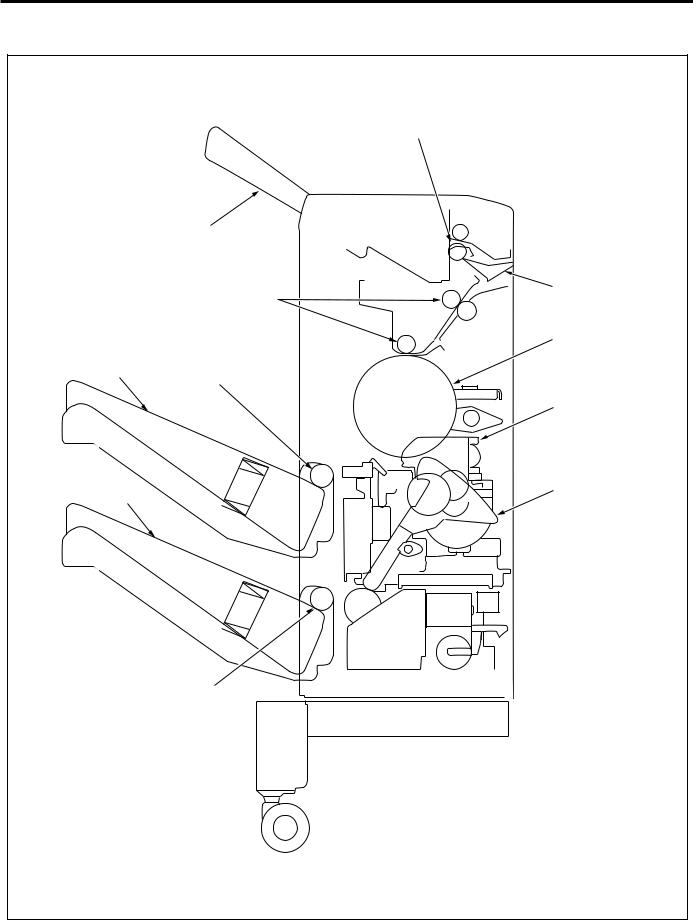

DRIVE SYSTEM DRAWING

Paper Conveyance System Drive

Conveyance rollers

Lift wire (rear)

Paper exit roller

Conveyance drum

drive motor (M807)

Paper exit roller (A)

Tray 2 motor (M810)

Timing belt

Tray 3 motor |

Paper exit roller (A) |

|

(M811) |

||

|

Paper feed motor (M801)

Conveyance drum

Tray up/down motor (M804)

Lift wire (front)

Stapler Unit Drive

Alignment motor |

Alignment plate |

Stapler unit (rear) |

|

||

(rear)(M808) |

(rear) |

|

|

|

|

|

Alignment plate |

Stapler unit (front) |

|

|

|

|

(front) |

|

|

Exit lever |

|

|

Alignment motor |

Stapler movement |

|

motor (M806) |

|

|

(front)(M809) |

|

|

|

|

|

|

Paper exit motor |

|

|

(M805) |

|

|

4 |

FS-105

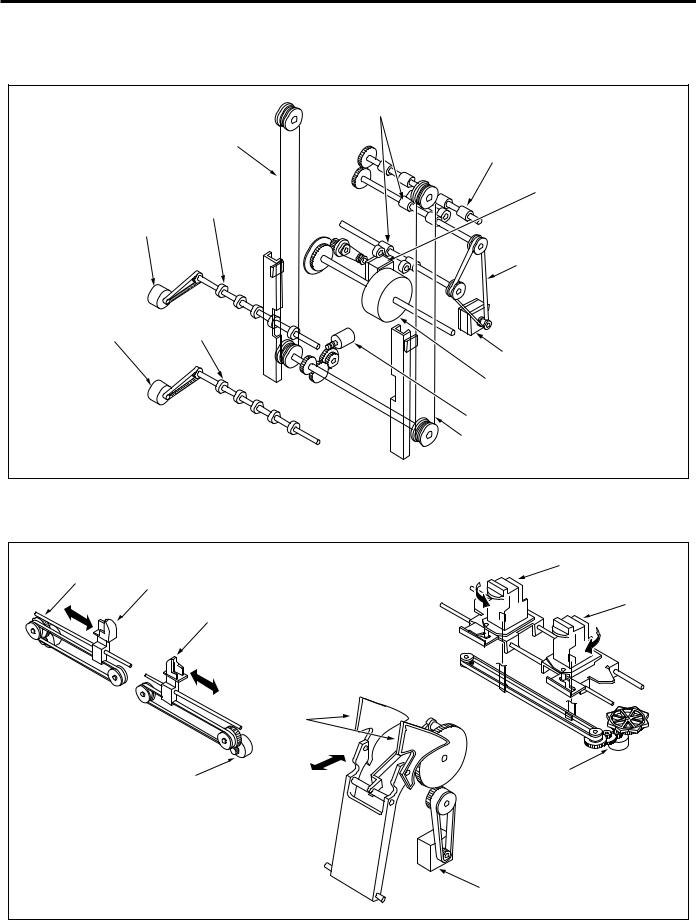

EXTERNAL SECTION

Construction

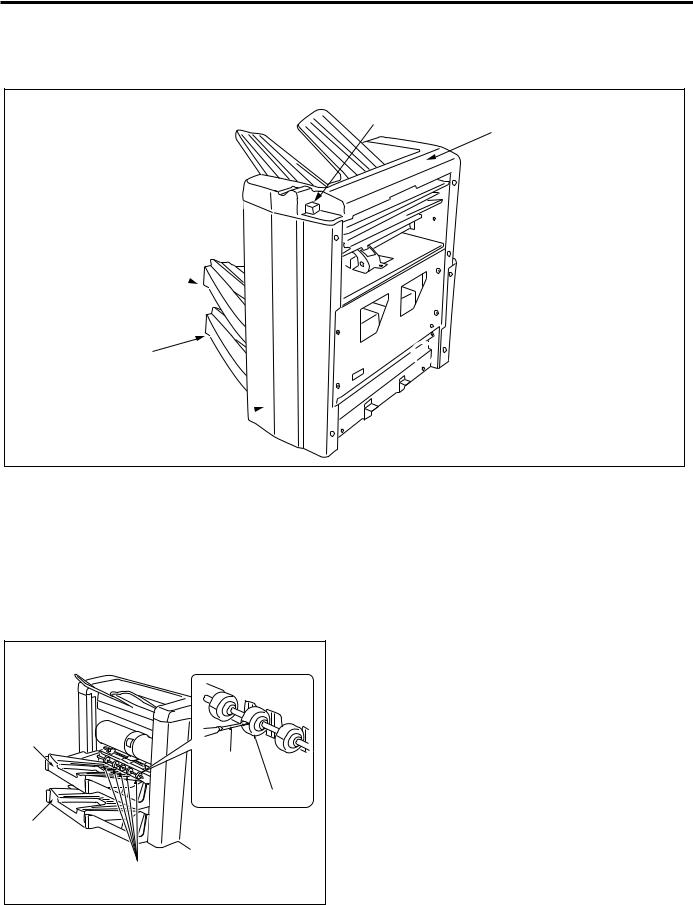

Release lever

Top cover

Tray 1

Upper rear cover

Upper rear cover

Tray 2

Rear cover

Rear cover

Tray 3

Front cover

Disassembly and Reassembly

Replacing the paper exit roller (A) (for tray 2)

Caution: Be sure that the power cord has been unplugged from the power outlet.

Caution: Be sure that the power cord has been unplugged from the power outlet.

Procedure

(1)Insert a flatbladed screwdriver or similar tool into the joint of a paper exit roller (A), pry the roller open, and remove it. Remove all paper exit rollers (A) (5 rollers) in this way.

Tray 2 |

Flatblade |

screwdriver |

Paper exit rollers (A) |

Tray 3 |

Paper exit roller (A) |

(2)To install new rollers, snap two roller parts (top and bottom) onto the exit roller shaft (5 locations).

5

FS-105

Replacing the paper exit roller (A) (for tray 3)

Procedure

(1)Use the operation panel on the main body to specify tray 3 and raise tray 2 to the topmost position.

(2)Turn the power OFF of the main body and unplug the power cord from the power outlet.

Caution: Be sure that the power cord has been unplugged from the power outlet.

Caution: Be sure that the power cord has been unplugged from the power outlet.

(3)Insert a flatbladed screwdriver or similar tool into the joint of apaper exit roller (A), pry the roller open, and remove it. Remove all paper exit roller (A) (5 rollers) in this way.

Tray 2 |

|

|

Flatblade |

Tray 3 |

screwdriver |

Paper exit roller (A) |

Paper exit rollers (A) |

|

(4)To install new rollers, snap two roller parts (top and bottom) onto the exit roller shaft (5 locations).

Removing and Reinstalling tray 2

Caution: Be sure that the power cord has been unplugged from the power outlet.

Caution: Be sure that the power cord has been unplugged from the power outlet.

Procedure

(1)Remove the two set screws, then remove the connector cover.

Tray 2 |

Set screws |

Tray 3 |

Connector cover |

(2) Disconnect the two connectors (CN728, CN751).

Connector |

(CN728) |

Tray 2 |

Connector |

(CN751) |

(3)Remove the two set screws, then remove the stopper bracket (front).

(4)Lift the front side of tray 2 up, then rotate it towards the rear and remove it.

6

FS-105

|

Stopper bracket |

|

(front) |

|

Set |

|

screws |

Tray 3 |

Tray 2 |

|

(5) Reinstall tray 2 in the opposite sequence to removal.

Removing and Reinstalling tray 3

Caution: Be sure that the power cord has been unplugged from the power outlet.

Caution: Be sure that the power cord has been unplugged from the power outlet.

Procedure

(1)Remove tray 2.

(2)Remove the two set screws, then remove the connector cover. (Refer to “Removing and Reinstalling tray 2”.)

(3)Disconnect the two connectors (CN729, CN752). (Refer to “Removing and Reinstalling tray 2”.)

(4)Remove the two set screws, then remove the stopper bracket (front). (Refer to “ Removing and Reinstalling tray 2”.)

(5)Lift the front side of tray 3 up, then rotate it towards the rear and remove it. (Refer to “ Removing and Reinstalling tray 2”.)

(6)Reinstall tray 3 in the opposite sequence to removal.

Removing and Reinstalling the external covers

Caution: Be sure that the power cord has been unplugged from the power outlet.

Caution: Be sure that the power cord has been unplugged from the power outlet.

Procedure

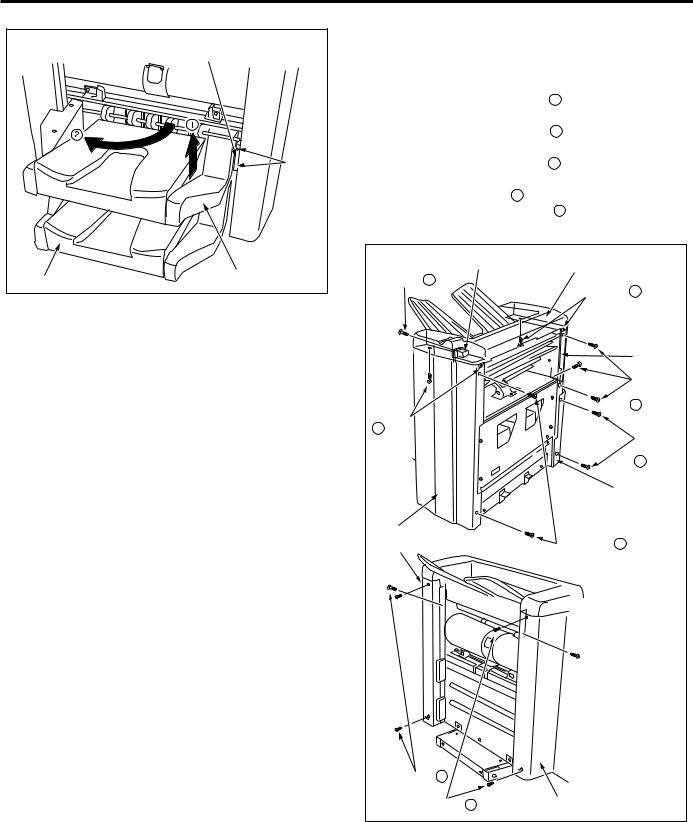

(1)Remove the four set screws A , then remove the front cover.

(2)Remove the five set screws B , then remove the rear cover.

(3)Remove the three set screws C , then remove the upper rear cover.

(4)Remove the set screw D, then remove the release lever.

(5)Remove the four set screws E , then release the top cover.

Release lever |

Top cover |

|

|

|

|

|

|

Set screw D |

Set screws |

E |

|

|

|||

|

|

|

Upper rear |

|

|

|

cover |

|

|

|

Set |

Set |

|

|

screws |

|

|

C |

|

screws |

|

|

|

E |

|

|

Set |

|

|

|

|

|

|

|

screws |

|

|

|

B |

|

|

Rear |

|

|

|

cover |

|

Front cover |

|

|

|

Rear |

Set screws |

A |

|

|

|

|

|

cover |

|

|

|

Set screws B |

|

|

|

Set screws A |

Front cover |

|

|

(6)Reinstall the external covers in the opposite sequence to removal.

7

Loading...

Loading...