Page 1

Body Shop Manual

FOREWORD

This Body Shop Manual illustrates body structures and

service procedures for the CARNIV AL/SEDONA.

This manual illustrates the replacement of major body

panels, plastic parts, body dimensions, sealing treatment

etc., in a systematic manner which is necessary for effective

and lasting body repairs.

You are encouraged to become familiar with this manual

and understand each section in order to perform proper

repair procedures. Keep this manual in a convenient

location so that it is readily available.

All information in this manual including specifications,

data and illustrations is made based on the vehicles built at

the time the manual was printed.

Information regarding the removal/replacement of

components not specifically covered in this manual can be

found in the CARNIVAL/SEDONA Service Manual.

Information regarding electrical harness routing/

connections, etc. can be found in the CARNIV AL/SEDONA

Electrical T roubleshooting Manual.

The descriptions and specifications contained in this manual

were in effect at the time this manual was approved for

printing. Kia Motors Corporation reserves the right to

discontinue models at any time, or change specifications

or design without notice and without incurring obligation.

CONTENTS

Title Group

General Information

Body Construction

Body Dimensions

Body Panel Repair Procedure

Body Sealing Locations

Corrosion Protection

Body Modification Tools

Plastic Parts

GI

BC

BD

BP

BS

CP

BT

PP

Kia Motors Corporation

SEOUL, KOREA

CAUTION :

Severe engine and transaxle damage may result

from the use of poor quality fuels and lubricants

that do not meet Kia specifications. You must

always use high quality fuels and lubricants that

meet the specifications described on the

specification section in the relevant group of the

Workshop Manual.

Copyright c 2005, Kia Motors Corporation

Printed in Korea, September 2005

Pub. No. : A4DB-EG56A (English)

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system or transmitted in

any form or by any means without the prior written permission of Kia Motors Corporation.

Page 2

IMPORTANT SAFETY NOTICE

Proper service methods and repair procedures are essential for safe, reliable operation of all

motor vehicles as well as personal safety of the operator. The service procedures and

descriptions in this shop manual provide general directions for a service and repair.

Procedure, techniques, tools, and parts for service including the skill of the technician vary.

It is impossible to provide advice or caution as to each case in this manual.

Accordingly, anyone who intends to use a replacement part, service procedure, or tool, which is

not recommended by the vehicle manufacturer, must first assure thoroughly that neither their

personal safety nor the safe operation of the vehicle will be first jeopardized by the replacement

part, service procedure, or tool they select.

IN THIS MANUAL

WARNING :

CAUTION :

NOTE :

The following list contains some general WARNINGS that you should follow while working on a

vehicle.

Always wear safety glasses for eye protection.

Use safety stands whenever a procedure requires you to be under the vehicle.

Make sure that the ignition switch is always in the OFF position, unless otherwise required by

the procedure.

Set the parking brake when working on the vehicle. If you have an automatic transaxle, set in

park unless instructed otherwise for a specific operation

Place supporters against the front and rear surfaces of the tires to help prevent the vehicle

from moving

Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide

poisoning.

Keep yourself and your clothing away from moving parts when the engine is running,

especially the drive belts.

To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust

manifold, tail pipe, catalytic converter and muffler.

Do not smoke while working on a vehicle.

To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing

before beginning to work on a vehicle.

When it is necessary to work under the hood, keep hands and other objects clear of the

radiator fan blades! Your vehicle may be equipped with a cooling fan that may turn on, even

though the ignition switch is in the OFF position. For this reason care should be taken to

ensure that the radiator fan electric motor is completely disconnected when working under the

hood and the engine is not running.

Remind you to be especially careful in those areas where carelessness can

cause personal injury.

To prevent you from making errors that could damage the vehicle as well as

personal injury.

Gives you added information that will help you complete a particular procedure.

Page 3

General

Information

FUNDAMENTAL PROCEDURES

VEHICLE PROTECTION..................................GI - 2

A WORD ABOUT SAFETY ...............................GI - 2

WELDING PROCEDURES ..............................GI - 3

BOD Y FRAME STRAIGHTENER.....................GI - 3

ELECTRICAL PROCEDURES ........................GI - 3

FOR BEST RESULTS

DISASSEMBLY.................................................GI - 4

PREPARATION OF ASSEMBLY .......................GI - 6

ASSEMBLY.......................................................GI - 7

RUSTPROOF TREA TMENT AFTER

ASSEMBLY.......................................................GI - 8

VEHICLE LIFT (2-SUPPORT TYPE) AND

SAFETY STAND POSITIONS

...................GI - 9

GI

JACK SUPPORT POSITIONS ..................GI - 10

BODY COLORS AND MAJOR

SPECIFICATIONS

..........................................GI - 11

Page 4

GI-2 GENERAL INFORMATION

FUNDAMENT AL PR OCEDURES

VEHICLE PROTECTION

1. Cover the seats before performing any procedure to

keep them from getting dirty .

2. Cover all glasses, seats and mats with a heat resistant

cover when welding.

BVQGI6001

3. Protect moldings, garnishes and ornaments.

A WORD ABOUT SAFETY

1. Wear the appropriate safety equipment that is

necessary for the procedure being performed.

Safety glasses

Mask

Face shield

2. When welding or performing other procedures that

require the use of an open flame near the fuel tank,

disconnect and remove the tank and fuel pipe, and

cap the pipe to prevent fuel leakage.

Ear protectors

Gloves

Safety shoes

BVQGI6002

BVQGI6003

Page 5

GENERAL INFORMATION GI-3

WELDING PROCEDURES

Observe the following tips when welding.

1. Wear appropriate eye protection.

2. Carefully follow the manufacturers operating

instructions for the welding machine you are using.

3. Do not weld, smoke or allow open flames around

volatile chemicals, cleaners or solvents or in any area

where they have just been used.

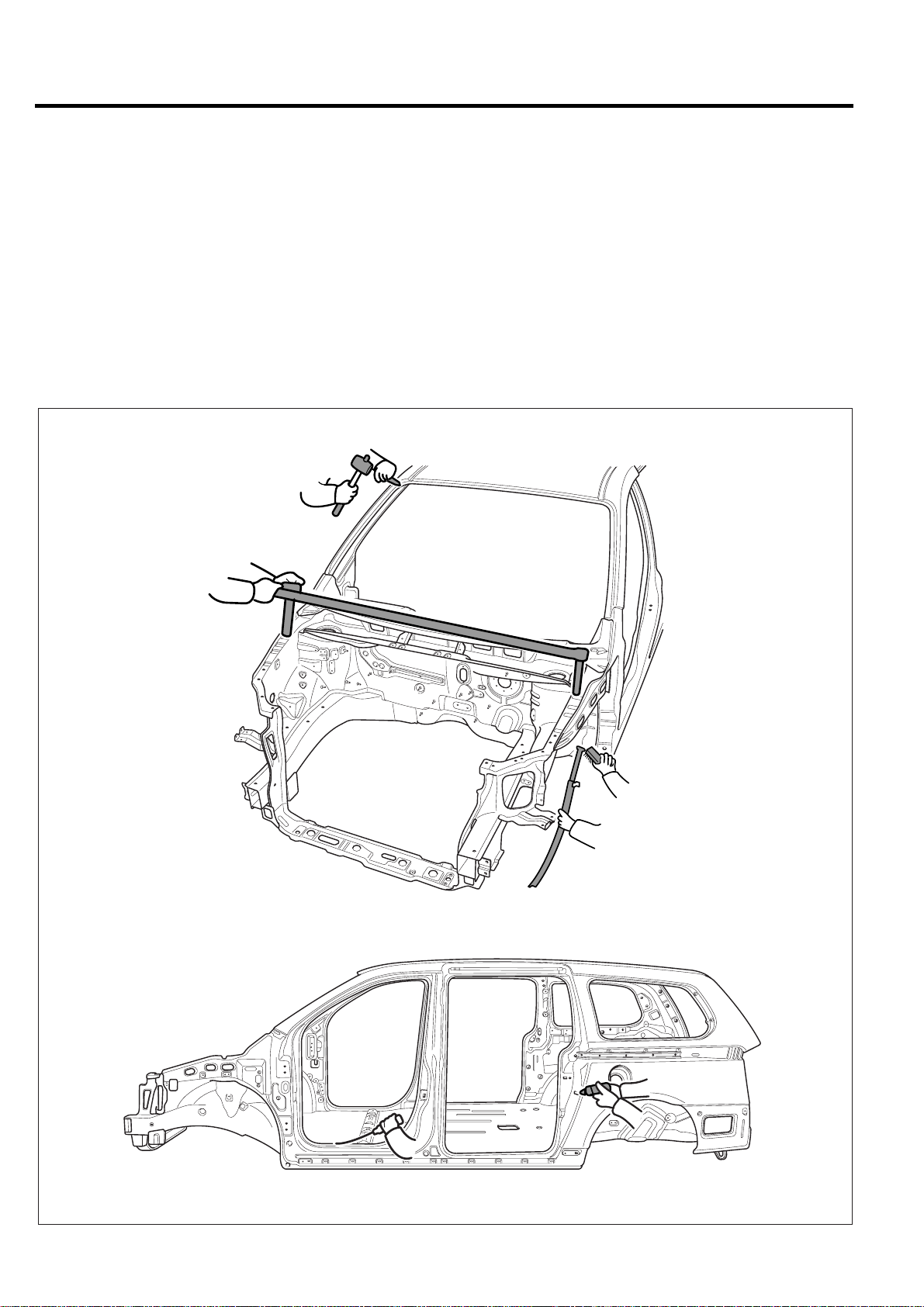

BODY FRAME STRAIGHTENER

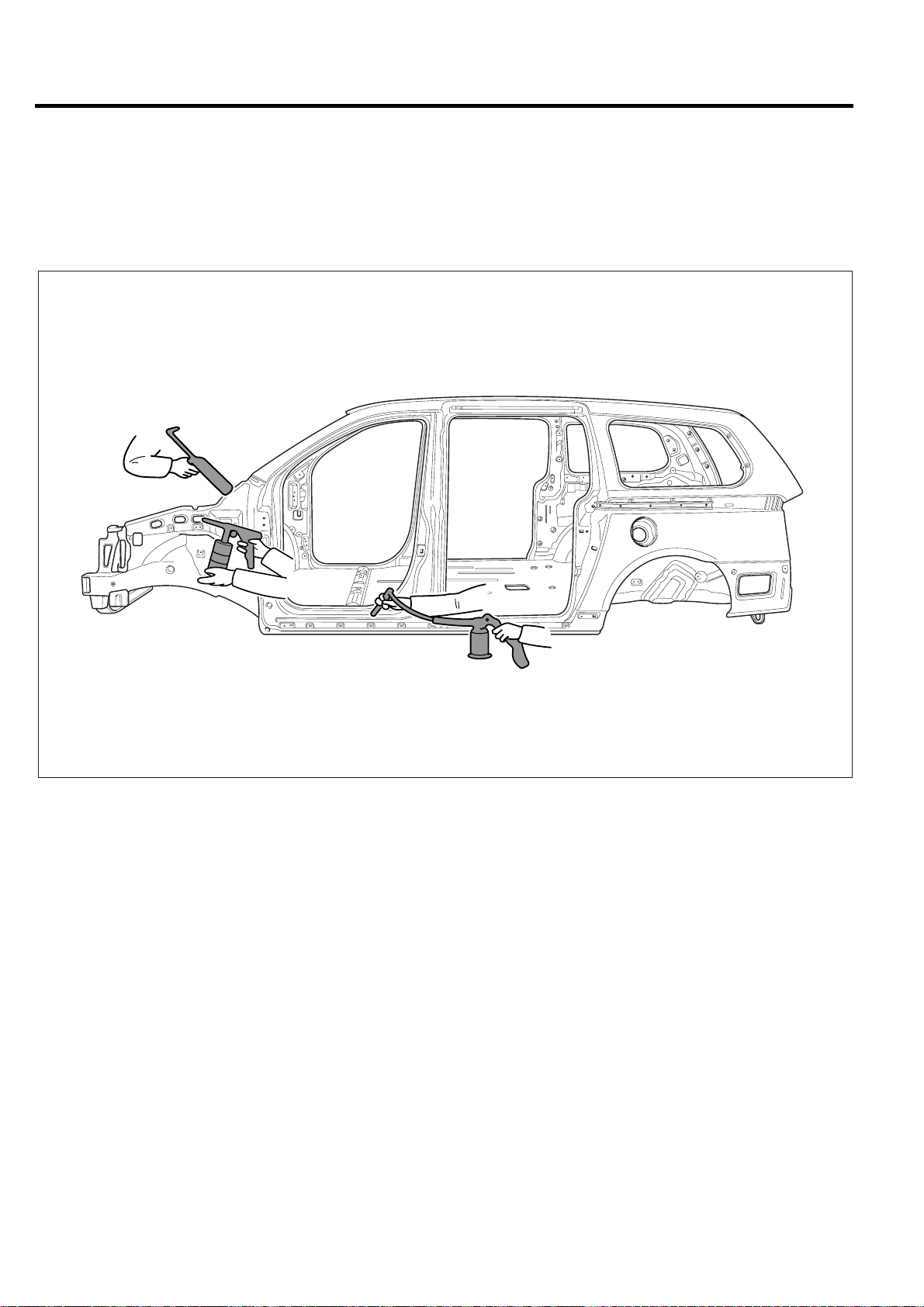

When using a frame straightener, do not enter the area

where the body is being straightened by the chain.

ELECTRICAL PROCEDURES

1. Disconnect the negative battery terminal.

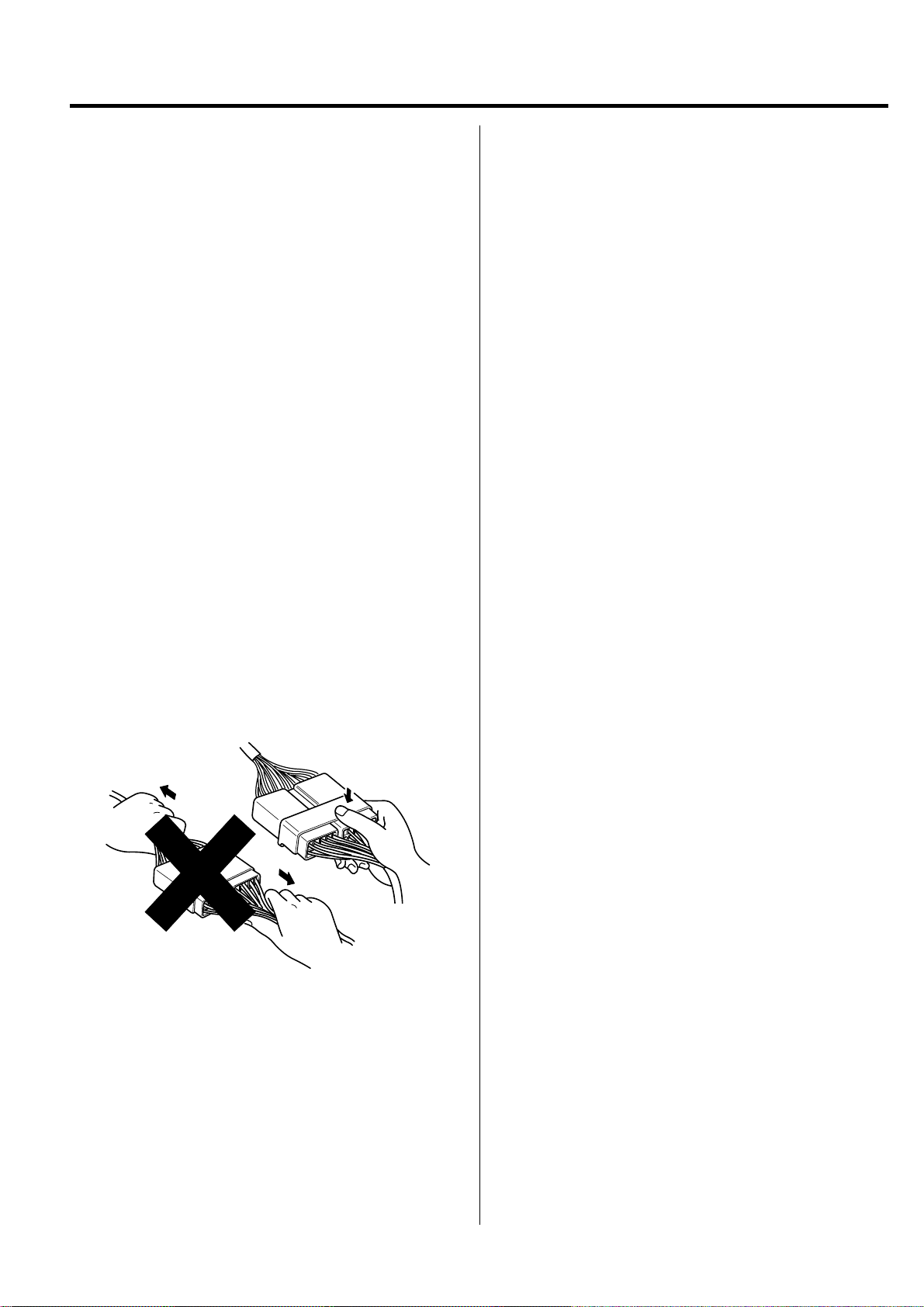

2. Do not pull on wires when disconnecting electrical

connectors. Be careful to hold the connector itself when

disconnecting it.

3. Insert the connector until it "licks" when connecting

the connector.

4. Handle all electrical components with care.

BVQGI6004

Page 6

GI-4 GENERAL INFORMATION

FOR BEST RESUL TS

DISASSEMBLY

Measuring dimensions before beginning

Measure the dimensions of the damaged area according to the body dimension drawings before disassembling and repairing.

Adjust dimensions with body frame adjuster if deformed.

Selecting cutting area

Select a cutting area that is easily accessible and that is prone to the least amount of distortion when welding.

Select an area that would allow the new part to overlap repair area by 1.2~2.0 in (30~50 mm).

Protecting body from damage

Secure the body with clamps and jacks to prevent damage to the body when working on it.

BVQGI6005

Page 7

GENERAL INFORMATION GI-5

Disassembling related parts

Use caution when removing body molding and trim from

the area to be worked.

Apply masking tape where needed to prevent damage to

the part being removed or to the vehicle body.

Before starting repairs, check if pipes, hoses or electrical

components are present near damaged area.

Wire harness

Repair work area

Cutting area

BVQGI6006

Page 8

GI-6 GENERAL INFORMATION

PREPARATION OF ASSEMBLY

Applying spot sealer

Remove paint from the surf ace of new parts and body to be spot welded, and apply spot sealer for rustproofing.

Selecting a welding method

If the thickness of the area to be welded with the panels overlapped is greater than 0.1 in (3 mm), do plug welding using a

carbon arc welding machine.

Protecting body from damage

Secure the body with clamps and jacks to prevent damage to the body when working on it.

Thicker than

0.1 in (3mm)

Machining holes for plug welding

Drill a hole of approximately 0.2~0.24 in (5~6 mm) in

diameter in those areas which are not suitable for spot

welding.

BVQGI6008

BVQGI6007

Adjusting a new part

The new part should be cut larger than the repair area,

overlapping the repair area by 1.2~2.0 in (30~50 mm).

1.2~2.0 in

(30~50 mm)

Overlap

body side to modify

new part to modify

1.2~2.0 in

(30~50 mm)

Overlap

BVQGI6009

Page 9

GENERAL INFORMATION GI-7

ASSEMBLY

Measuring dimensions before welding

When assembling a new part, assemble it according to the body dimensions given in Section 31, and start welding after

checking the gaps with nearby parts.

Caution when welding

The number of welding points should be determined based on the criteria below:

Spot welding Plug welding

Increase the number of

spot welds by 30%.

Pitch:

2.0 in (50 mm)

Old part

Pitch:

1.4 in (35 mm)

Repair part

Pitch: Same number of

welds as original part.

Repair part

more than

0.1 in (3 mm)

BVQGI6010

Caution when spot welding

The tip of the spot welding machine should be maintained to a minimum of 0.1 in (3 mm) because it greatly affects welding

strength. When possible , spot welding should be done between the existing spot welded points .

Before and after spot welding, weld a test piece(test pin) of the same material as the body panel, and check the welding

strength.

0.1 in

(3 mm)

Good

No good

Using a hammer and a chisel

Existing welded spots

New welded spots

0.1 in

(3 mm)

Center

diameter

Using a test piece(test pin)

Nugget diameter

to be 4/5 of chip

diameter

BVQGI6011

Page 10

GI-8 GENERAL INFORMATION

RUSTPROOF TREATMENT AFTER ASSEMBLY

Body sealing

Apply body sealer where necessary.

Applying rustproof material

Apply rustproofing material(wax, oil, etc.) behind welded area.

Applying undercoat

Apply undercoat on the body where necessary .

BVQGI6012

Page 11

GENERAL INFORMATION GI-9

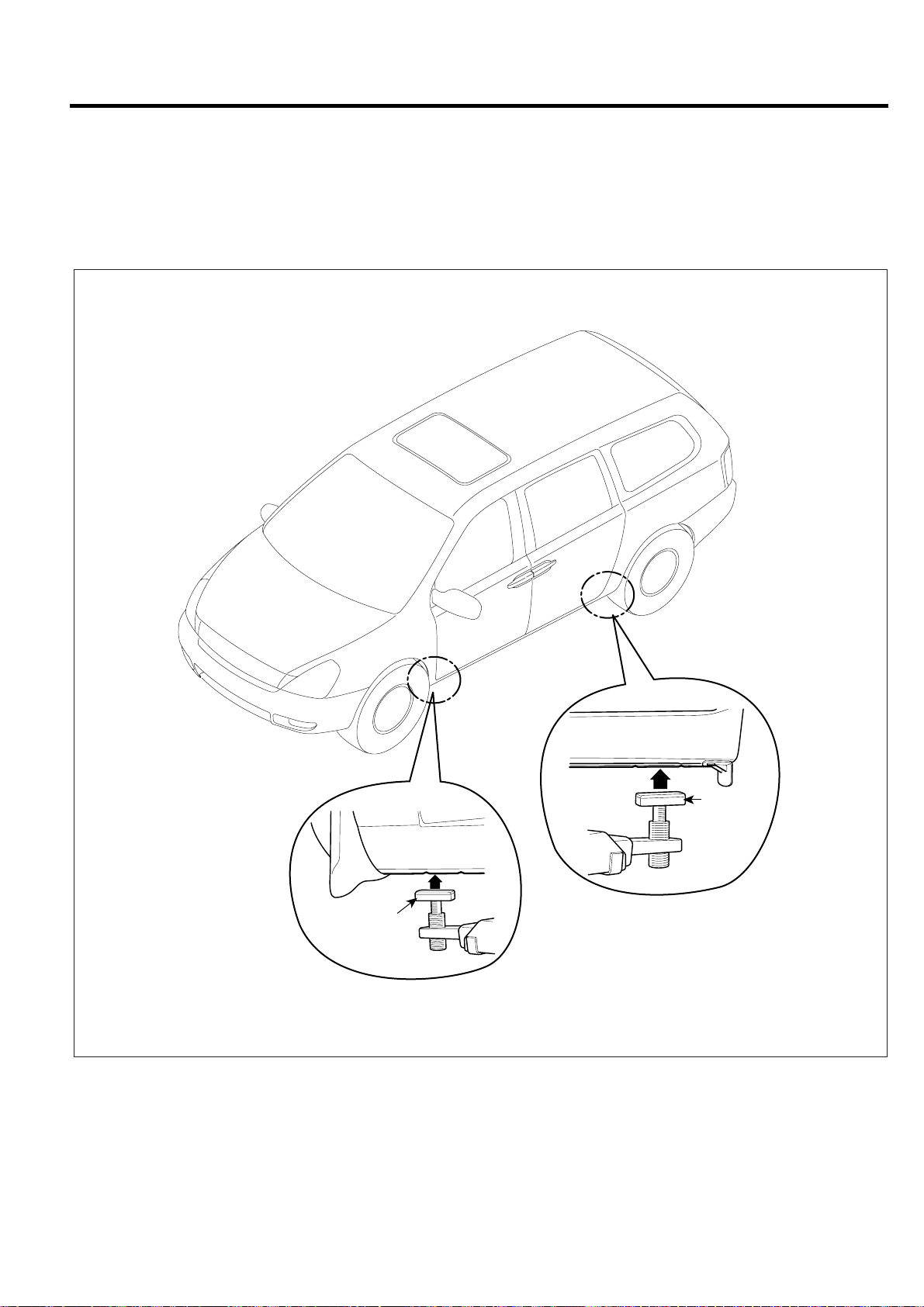

VEHICLE LIFT (2-SUPPORT TYPE) AND SAFETY STAND POSITIONS

1. Place the lift blocks under the support points as shown in the illustration

2. Raise the hoist a few inches and rock the v ehicle to be sure it is firmly supported.

3. Raise the hoist to full height to inspect the lift points for secure support.

Lift Block

Lift Block

[Front]

[Rear]

BVQGI6013

Page 12

GI-10 GENERAL INFORMATION

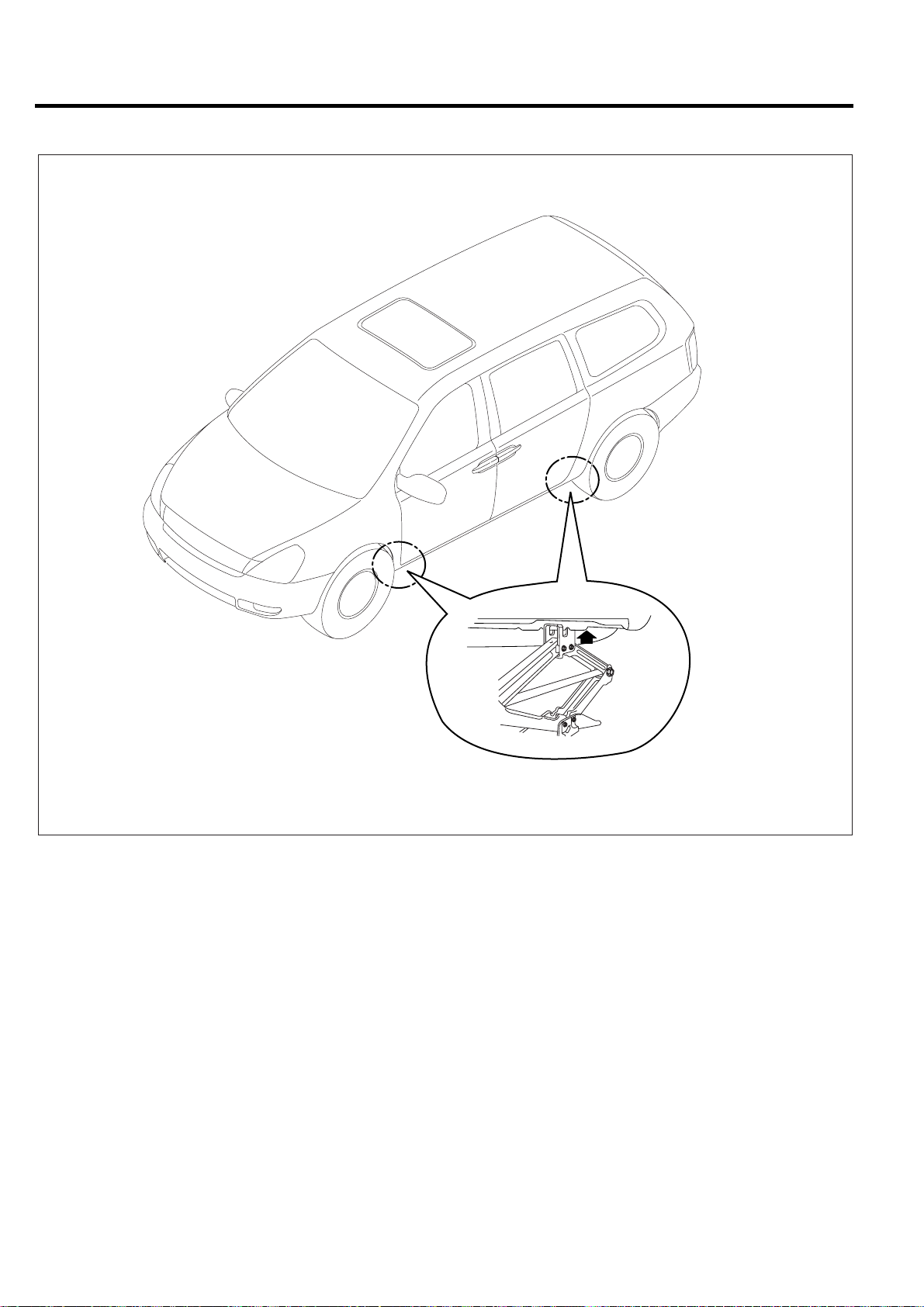

JACK SUPPORT POSITIONS

BVQGI6014

Page 13

GENERAL INFORMATION GI-11

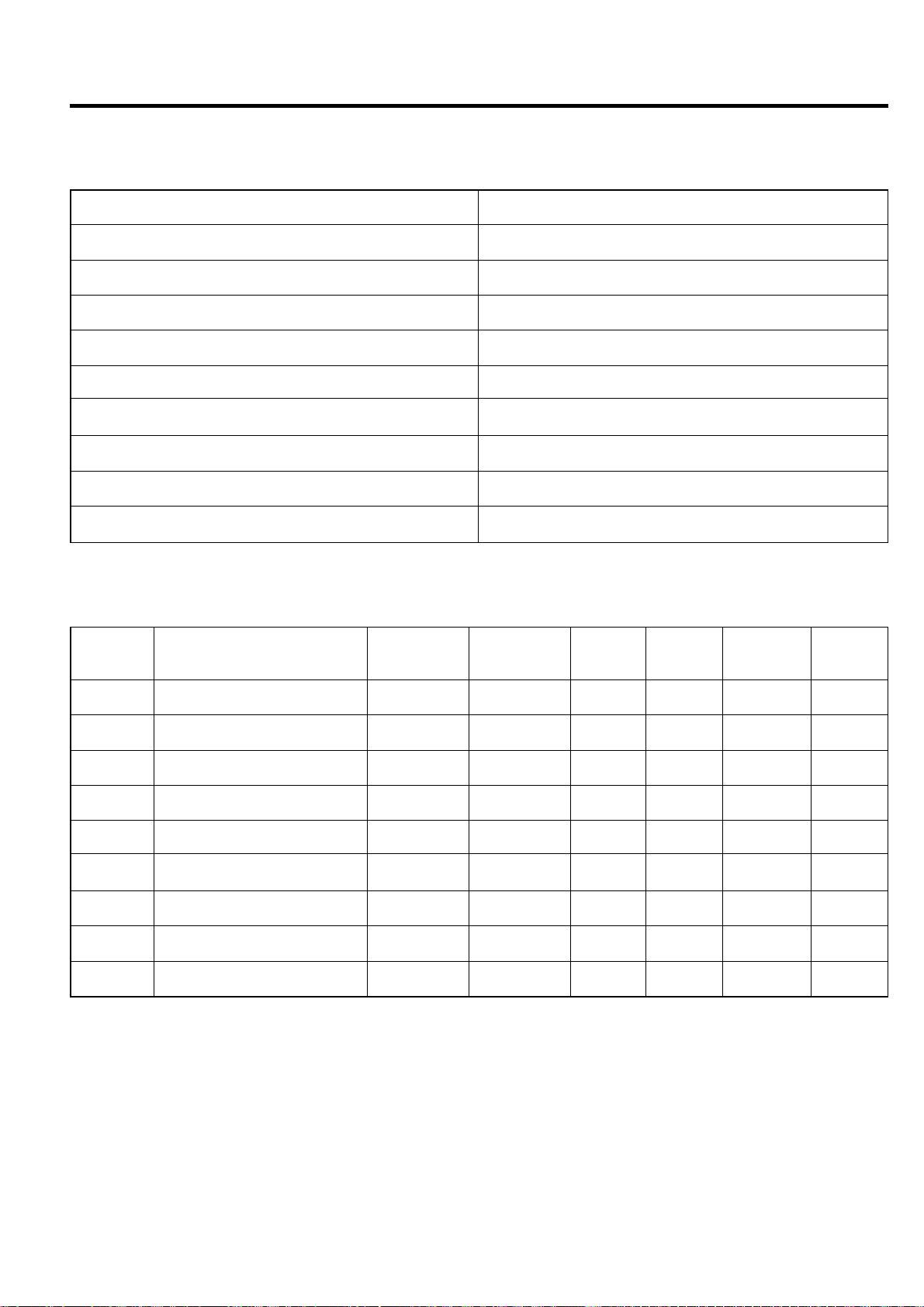

BODY COLORS AND MAJOR SPECIFICATIONS

KIA COLOR CODES

Kia code Paint color

7P

J9

K5

K9

6C

7V

9B

U4

UD

PAINT MANUFACTURE CODES

Kia code

Color name Dupont

Spies

Hecker

Cherry Kiss Cocktail

Evening Sailing Gold

V elvet Indigo Blue

Crystal Blue

Clear Silver

Olive Gray

Midnight Black

White Pearl

Clear White

Standox BASF

Akzo

Nobel

PPG

7P

J9

K5

K9

6C

7V

9B

U4

UD

Cherry Kiss Cocktail

Evening Sailing Gold

V elvet Indigo Blue

Crystal Blue

Clear Silver

Olive Gray

Midnight Black

White Pearl

Clear White

X3089

X3088

X3090

X3091

X1135

X2188

M0510

M7817

F2756

769042

769041

769043

769044

746556

760711

75343

744249

755719

7P

J9

K5

K9

6C

7V

9B

U4

UD

7P

J9

K5

K9

6C

7V

9B

U4

UD

KIA9322

KIA9106

KIA9546

KIA9545

KIA9742

KIA9741

KIA9411

KIA9405

KIA4004

7P

J9

K5

K9

6C

7V

9B

U4

UD

Page 14

Body

Construction

BODY COMPONENTS .................................BC - 2

ZINC-GALVANIZED STEEL PANELS ....BC - 4

HIGH STRENGTH STEEL PANELS .......BC - 6

BC

Page 15

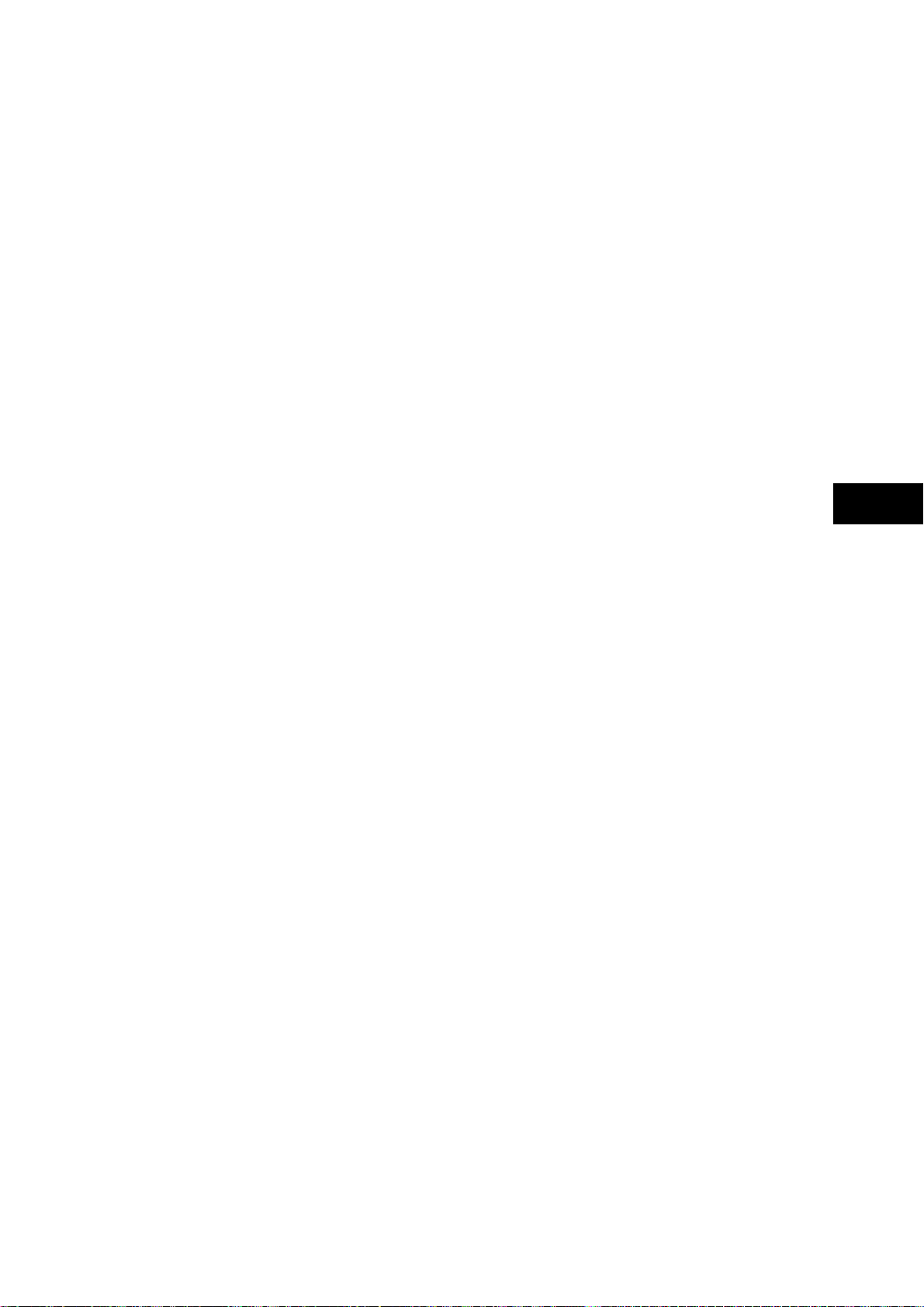

BC-2 BODY CONSTRUCTION

BOD Y COMPONENTS

Body construction will sometimes differ depending on specifications and country of destination. Theref ore, please k eep in

mind that the information contained herein is based on vehicles for general destination.

61

67

64

111

62

66

17

65

63

107

68

105

108

109

90

92

72

16

14

22

6

13

20

7

95

23

15

91

110

94

93

96

21

19

106

97

32

33

18

12

10

100

101

99

30

11

31

102

52

37

38

35

36

25

26

71

81

79

29

34

9

8

27

70

69

112

78

77

40

76

80

50

103

5153

46

39

98

24

28

41

104

45

84

86

75

42

60

43

89

85

44

87

49

47

48

88

59

58

56

57

55

54

82

83

1

4

5

2

3

73

74

BVQBC6001

Page 16

BODY CONSTRUCTION BC-3

1. Radiator support side member assembly

2. Head lamp support panel

3. Fender mounting braket assembly

4. Radiator support side member assembly

5. Radiator support lower outer member assembly

6. Radiator upper center member assembly

7. Radiator center stay member assembly

8. Dash panel assembly

9. Dash rainforcement assembly

10. Dash lower member assembly

11. Dash lower outer member assembly

12. Dash lower outer center member assembly

13. Fender apron inner lower panel assembly

14. Fender apron inner upper panel assembly

15. Front shock absorber housing panel assembly

16. Front shock absorber housing upper panel

17. Fender apron inner front support

18. Engine mounting bracket assembly

19. Front side inner member assembly

20. Front side member inner reinforcement assembly

21. Front side member inner rear reinforcement assembly

22. Front side member outer member assembly

23. Side cross front member

24. Center floor panel

25. Front seat cross front member assembly

26. Front seat cross rear member assembly

27. Console mounting front bracket assembly

28. Console mounting rear bracket assembly

29. Center floor side member

30. Center floor side member reinforcement assembly

31. Center floor side member upper reinforcement

32. No.1 cross member reinforcement

33. No.1 cross member reinforcement

34. No.1 cross member support reinforcement

35. No.1 cross member assembly

36. No.3 cross member assembly

37. No.3 cross member assembly

38. No.3 cross member assembly

39. Side sill inner upper panel

40. Side sill inner lower panel

41. Side sill inner rear panel

42. Rail guide lower panel assembly

43. Rear floor panel

44. Rear floor extension assembly

45. Rear floor side reinforcement

46. Rear floor side panel assembly

47. Rear floor rear panel

48. Rear floor rear cross member assembly

49. Rear towing hook bracket assembly

50. Rear floor side member

51. Rear floor side member extension assembly

52. Rear floor side front reinforcement assembly

53. Rear floor side rear reinforcement assembly

54. No.4 cross member assembly

55. No.5 cross member assembly

56. No.6 cross member

57. No.6 cross gusset

58. Back panel

59. Rear transverse member

60. Rear transverse side member

61. Roof panel

62. Roof front lower rail assembly

63. Roof No.2 rail

64. Roof No.2 rail

65. Room lamp mounting bracket

66. Roof rear upper rail assembly

67 Roof rear lower rail

68. Sun roof rack front bracket assembly

69. Cowl top outer panel

70. Cowl top outer reinforcement

71. Cowl inner lower panel assembly

72. Fender panel

73. Hood outer panel

74. Hood inner panel

75. Front door outer panel

76. Front door inner panel

77. Front door quadrant channel

78. Front door reinforcement beam

79. Front door belt outer rail

80. Front door belt inner rail

81. Front door frame assembly

82. Rear door outer panel

83. Rear door inner panel

84. Rear door belt outer rail

85. Rear door belt inner rail assembly

86. Rear door outer rail

87. Rear door beam

88. Tail gate outer panel

89. Tail gate inner panel

90. Front inner upper pillar assembly

91. Side inner upper reinforcement assembly

92. Front inner lower pillar assembly

93. Center pillar inner panel assembly

94. Front seatbelt upper mounting bracket assembly

95. Front pillar inner lower reinforcement assembly

96. Sill side outer front reinforcement

97. Quarter inner front reinforcement

98. Rear side belt upper mounting reinforcement assembly

99. Quarter inner panel

100. Quarter inner belt reinforcement assembly

101. Wheel house outer panel

102. Rear wheel house inner panel assembly

103. Quarter inner rear lower extension assembly

104. D pillar reinforcement gusset assembly

105. Front side outer panel

106. Front side outer panel

107. Fender rear upper reinforcement

108. Front pillar outer upper reinforcement

109. Front pillar outer lower reinforcement

110. Front side outer panel

111. Quarter outer rear upper extension

112. Rear combination lamp housing panel

Page 17

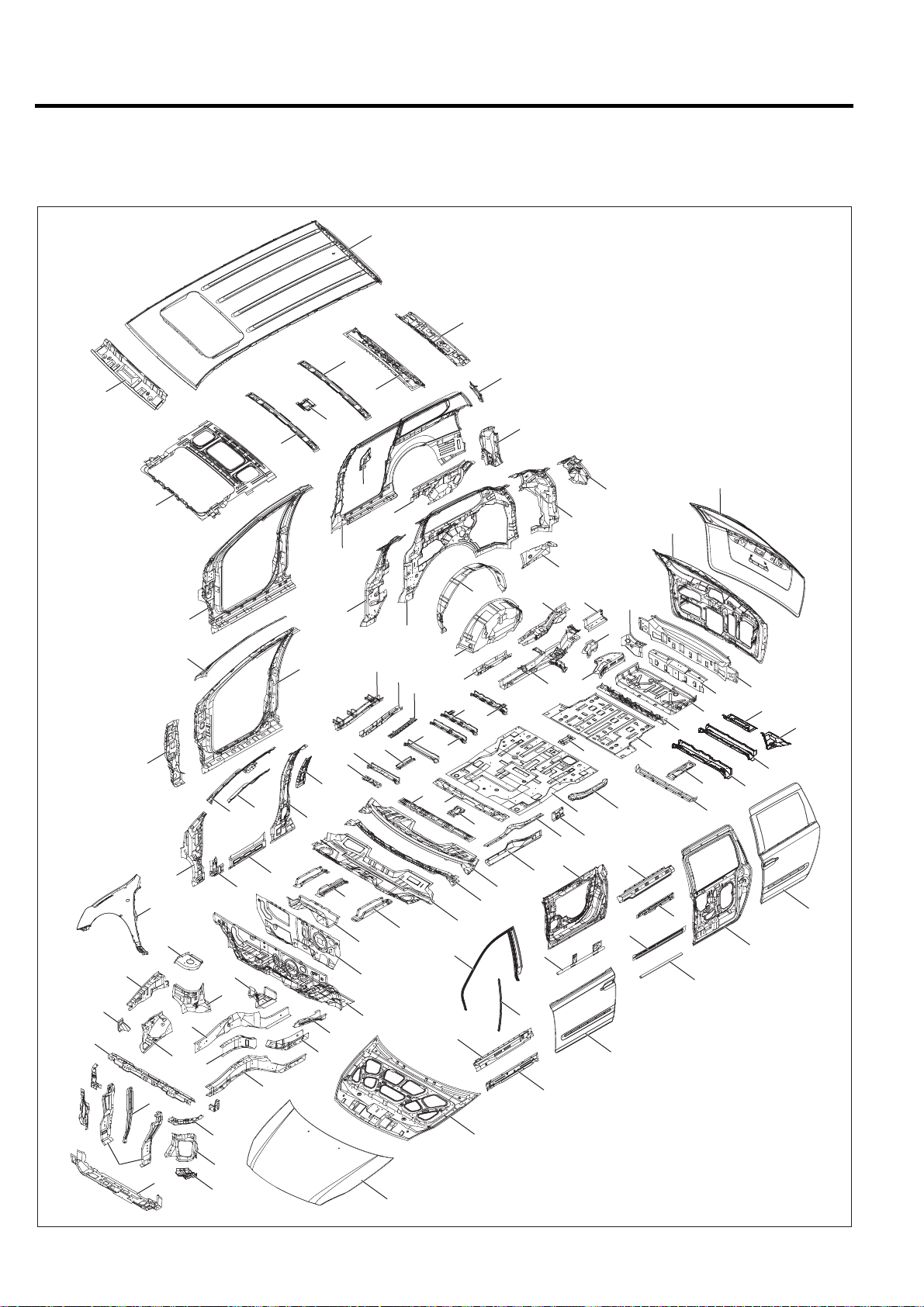

BC-4 BODY CONSTRUCTION

ZINC-GAL VANIZED STEEL PANELS

Becavanized steel panel has excellent resistance, it tis used in areas which have a high possibility of painting deficiency

below.

61

111

112

17

44

47

49

88

58

56

57

55

54

48

82

83

107

89

106

103

101

105

108

109

72

16

14

6

7

13

23

15

22

20

110

32

93

96

12

18

21

19

10

99

30

11

31

102

52

37

38

35

36

71

29

9

8

70

69

53

78

40

76

50

39

46

24

28

41

45

43

42

75

1

4

5

2

3

73

74

BVQBC6002

Page 18

BODY CONSTRUCTION BC-5

1. Radiator support side member assembly

2. Head lamp support panel

3. Fender mounting braket assembly

4. Radiator support side member assembly

5. Radiator support lower outer member assembly

6. Radiator upper center member assembly

7. Radiator center stay member assembly

8. Dash panel assembly

9. Dash rainforcement assembly

10. Dash lower member assembly

11. Dash lower outer member assembly

12. Dash lower outer center member assembly

13. Fender apron inner lower panel assembly

14. Fender apron inner upper panel assembly

15. Front shock absorber housing panel assembly

16. Front shock absorber housing upper panel

17. Fender apron inner front support

18. Engine mounting bracket assembly

19. Front side inner member assembly

20. Front side member inner reinforcement assembly

21. Front side member inner rear reinforcement assembly

22. Front side member outer member assembly

23. Side cross front member

24. Center floor panel

25. Front seat cross front member assembly

26. Front seat cross rear member assembly

27. Console mounting front bracket assembly

28. Console mounting rear bracket assembly

29. Center floor side member

30. Center floor side member reinforcement assembly

31. Center floor side member upper reinforcement

32. No.1 cross member reinforcement

33. No.1 cross member reinforcement

34. No.1 cross member support reinforcement

35. No.1 cross member assembly

36. No.3 cross member assembly

37. No.3 cross member assembly

38. No.3 cross member assembly

39. Side sill inner upper panel

40. Side sill inner lower panel

41. Side sill inner rear panel

42. Rail guide lower panel assembly

43. Rear floor panel

44. Rear floor extension assembly

45. Rear floor side reinforcement

46. Rear floor side panel assembly

47. Rear floor rear panel

48. Rear floor rear cross member assembly

49. Rear towing hook bracket assembly

50. Rear floor side member

51. Rear floor side member extension assembly

52. Rear floor side front reinforcement assembly

53. Rear floor side rear reinforcement assembly

54. No.4 cross member assembly

55. No.5 cross member assembly

56. No.6 cross member

57. No.6 cross gusset

58. Back panel

59. Rear transverse member

60. Rear transverse side member

61. Roof panel

62. Roof front lower rail assembly

63. Roof No.2 rail

64. Roof No.2 rail

65. Room lamp mounting bracket

66. Roof rear upper rail assembly

67 Roof rear lower rail

68. Sun roof rack front bracket assembly

69. Cowl top outer panel

70. Cowl top outer reinforcement

71. Cowl inner lower panel assembly

72. Fender panel

73. Hood outer panel

74. Hood inner panel

75. Front door outer panel

76. Front door inner panel

77. Front door quadrant channel

78. Front door reinforcement beam

79. Front door belt outer rail

80. Front door belt inner rail

81. Front door frame assembly

82. Rear door outer panel

83. Rear door inner panel

84. Rear door belt outer rail

85. Rear door belt inner rail assembly

86. Rear door outer rail

87. Rear door beam

88. Tail gate outer panel

89. Tail gate inner panel

90. Front inner upper pillar assembly

91. Side inner upper reinforcement assembly

92. Front inner lower pillar assembly

93. Center pillar inner panel assembly

94. Front seatbelt upper mounting bracket assembly

95. Front pillar inner lower reinforcement assembly

96. Sill side outer front reinforcement

97. Quarter inner front reinforcement

98. Rear side belt upper mounting reinforcement assembly

99. Quarter inner panel

100. Quarter inner belt reinforcement assembly

101. Wheel house outer panel

102. Rear wheel house inner panel assembly

103. Quarter inner rear lower extension assembly

104. D pillar reinforcement gusset assembly

105. Front side outer panel

106. Front side outer panel

107. Fender rear upper reinforcement

108. Front pillar outer upper reinforcement

109. Front pillar outer lower reinforcement

110. Front side outer panel

111. Quarter outer rear upper extension

112. Rear combination lamp housing panel

Page 19

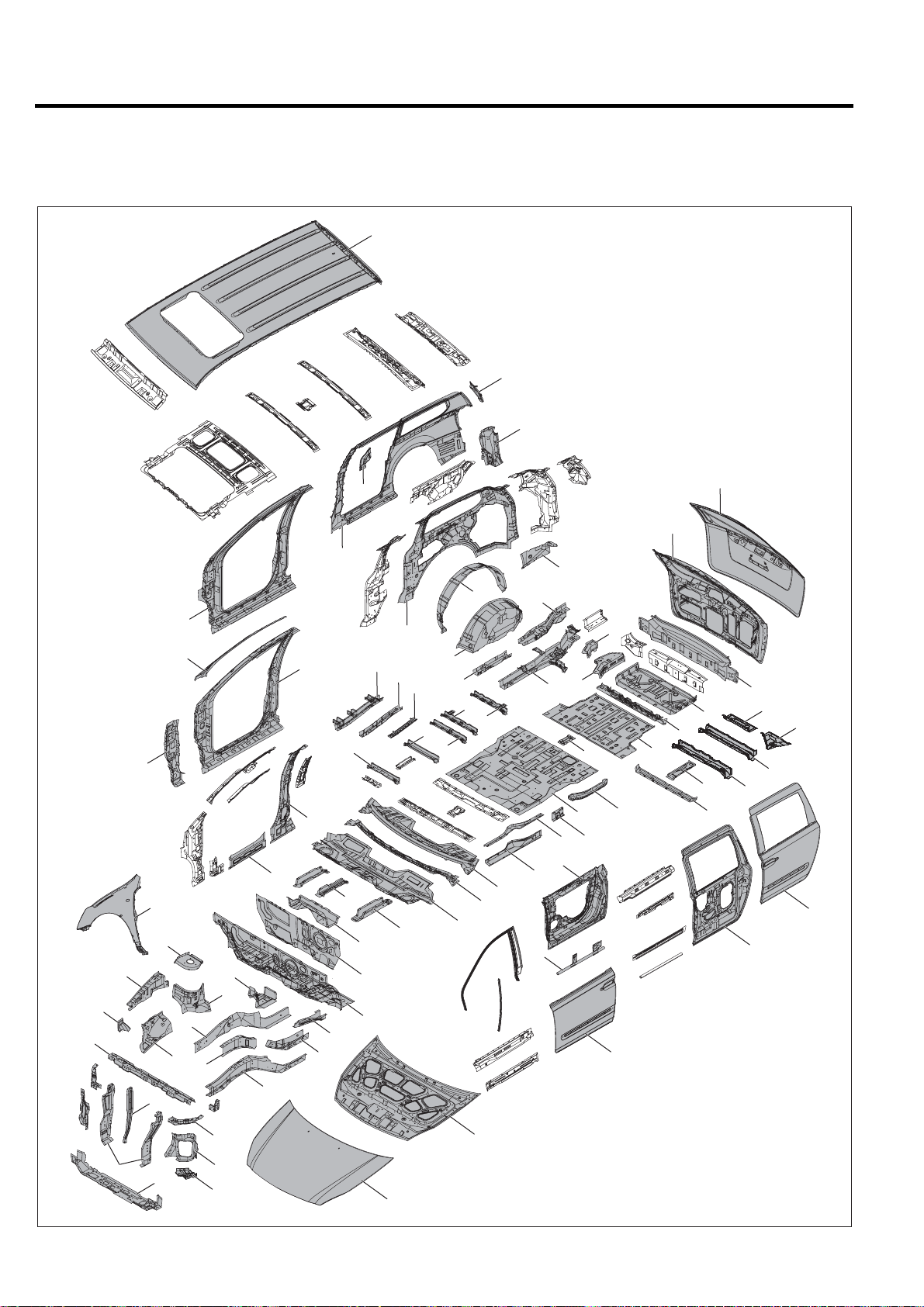

BC-6 BODY CONSTRUCTION

HIGH STRENGTH STEEL P ANELS

Because high strength steel panel has excellent resistance, it is used in areas which have a high posibility of painting

deficiency below .

61

67

64

111

66

63

14

109

68

72

92

108

15

93

97

12

10

85

47

48

88

59

56

57

54

82

104

101

45

29

30

9

35

26

36

52

37

38

50

46

43

41

84

86

8

13

20

1

4

5

3

75

BVQBC6003

Page 20

BODY CONSTRUCTION BC-7

1. Radiator support side member assembly

2. Head lamp support panel

3. Fender mounting braket assembly

4. Radiator support side member assembly

5. Radiator support lower outer member assembly

6. Radiator upper center member assembly

7. Radiator center stay member assembly

8. Dash panel assembly

9. Dash rainforcement assembly

10. Dash lower member assembly

11. Dash lower outer member assembly

12. Dash lower outer center member assembly

13. Fender apron inner lower panel assembly

14. Fender apron inner upper panel assembly

15. Front shock absorber housing panel assembly

16. Front shock absorber housing upper panel

17. Fender apron inner front support

18. Engine mounting bracket assembly

19. Front side inner member assembly

20. Front side member inner reinforcement assembly

21. Front side member inner rear reinforcement assembly

22. Front side member outer member assembly

23. Side cross front member

24. Center floor panel

25. Front seat cross front member assembly

26. Front seat cross rear member assembly

27. Console mounting front bracket assembly

28. Console mounting rear bracket assembly

29. Center floor side member

30. Center floor side member reinforcement assembly

31. Center floor side member upper reinforcement

32. No.1 cross member reinforcement

33. No.1 cross member reinforcement

34. No.1 cross member support reinforcement

35. No.1 cross member assembly

36. No.3 cross member assembly

37. No.3 cross member assembly

38. No.3 cross member assembly

39. Side sill inner upper panel

40. Side sill inner lower panel

41. Side sill inner rear panel

42. Rail guide lower panel assembly

43. Rear floor panel

44. Rear floor extension assembly

45. Rear floor side reinforcement

46. Rear floor side panel assembly

47. Rear floor rear panel

48. Rear floor rear cross member assembly

49. Rear towing hook bracket assembly

50. Rear floor side member

51. Rear floor side member extension assembly

52. Rear floor side front reinforcement assembly

53. Rear floor side rear reinforcement assembly

54. No.4 cross member assembly

55. No.5 cross member assembly

56. No.6 cross member

57. No.6 cross gusset

58. Back panel

59. Rear transverse member

60. Rear transverse side member

61. Roof panel

62. Roof front lower rail assembly

63. Roof No.2 rail

64. Roof No.2 rail

65. Room lamp mounting bracket

66. Roof rear upper rail assembly

67 Roof rear lower rail

68. Sun roof rack front bracket assembly

69. Cowl top outer panel

70. Cowl top outer reinforcement

71. Cowl inner lower panel assembly

72. Fender panel

73. Hood outer panel

74. Hood inner panel

75. Front door outer panel

76. Front door inner panel

77. Front door quadrant channel

78. Front door reinforcement beam

79. Front door belt outer rail

80. Front door belt inner rail

81. Front door frame assembly

82. Rear door outer panel

83. Rear door inner panel

84. Rear door belt outer rail

85. Rear door belt inner rail assembly

86. Rear door outer rail

87. Rear door beam

88. Tail gate outer panel

89. Tail gate inner panel

90. Front inner upper pillar assembly

91. Side inner upper reinforcement assembly

92. Front inner lower pillar assembly

93. Center pillar inner panel assembly

94. Front seatbelt upper mounting bracket assembly

95. Front pillar inner lower reinforcement assembly

96. Sill side outer front reinforcement

97. Quarter inner front reinforcement

98. Rear side belt upper mounting reinforcement assembly

99. Quarter inner panel

100. Quarter inner belt reinforcement assembly

101. Wheel house outer panel

102. Rear wheel house inner panel assembly

103. Quarter inner rear lower extension assembly

104. D pillar reinforcement gusset assembly

105. Front side outer panel

106. Front side outer panel

107. Fender rear upper reinforcement

108. Front pillar outer upper reinforcement

109. Front pillar outer lower reinforcement

110. Front side outer panel

111. Quarter outer rear upper extension

112. Rear combination lamp housing panel

Page 21

Body

Dimensions

GENERAL

MEASUREMENT METHOD .......................BD - 2

PROJECTED DIMENSIONS ............................BD - 2

ACTUAL-MEASUREMENT DIMENSIONS......BD - 3

MEASUREMENT POINT..................................BD - 3

FRONT BODY .................................................BD - 4

SIDE BODY (FRONT) ...................................BD - 6

SIDE BODY (REAR) .....................................BD - 8

INTERIOR A .....................................................BD - 10

INTERIOR B .....................................................BD - 12

INTERIOR C .....................................................BD - 14

REAR BODY ....................................................BD - 16

UNDER BODY

(PROJECTED DIMENSIONS)

UNDER BODY

(STRAIGHT-LINE DIMENSIONS)

.........................................................BD - 2

...................BD - 18

............BD - 21

BD

Page 22

BD-2 BODY DIMENSIONS

GENERAL

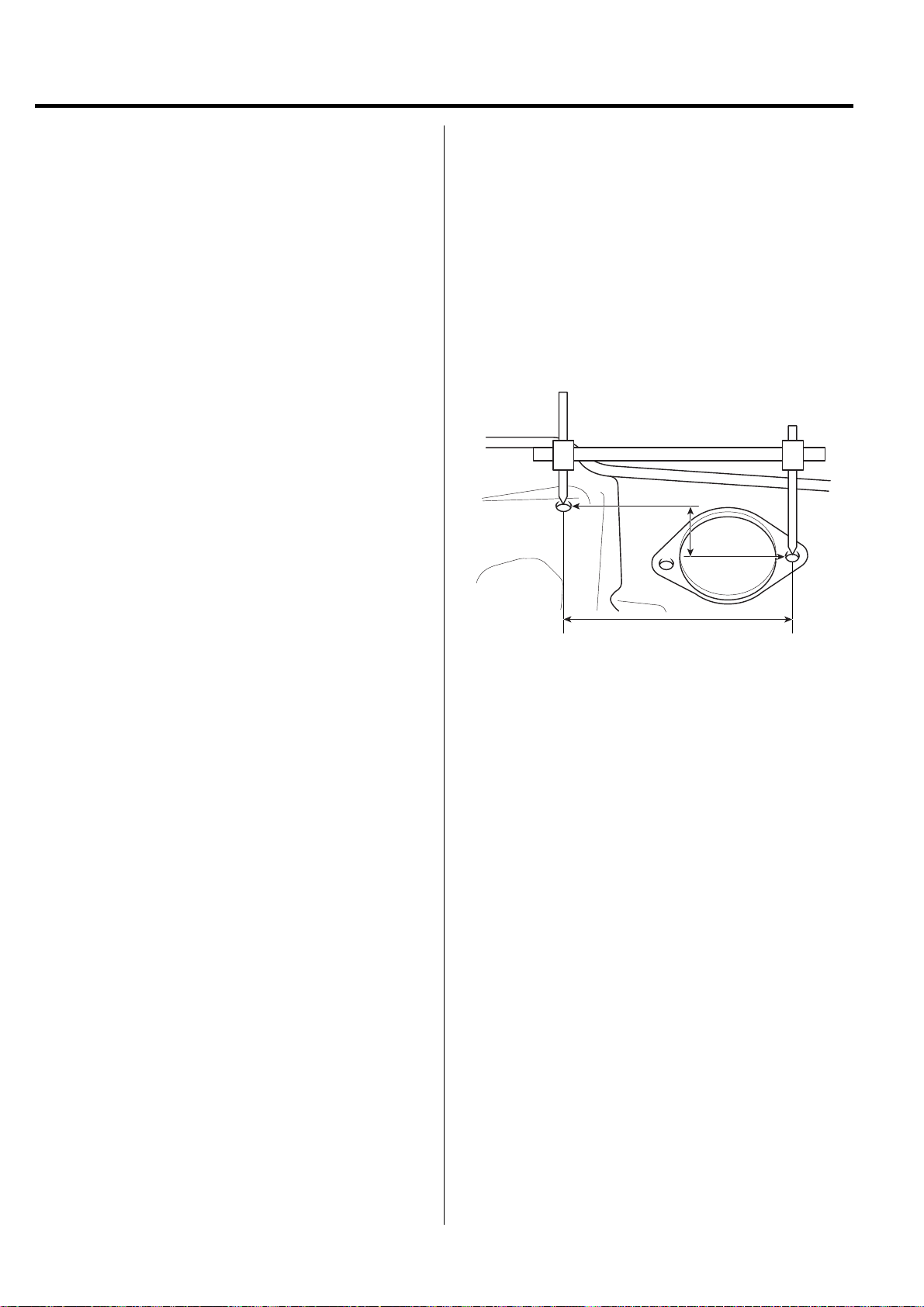

1. Basically, all measurements in this manual are taken

with a tracking gauge.

2. When a measuring tape is used, check to be sure

there is no elongation, twisting or bending.

3. For measuring dimensions, both projected dimension

and actual-measurement dimension are used in this

manual.

MEASUREMENT METHOD

PROJECTED DIMENSIONS

1. These are the dimensions measured when the

measurement points are projected into the reference

plane, and are the reference dimensions used for body

alterations.

2. If the length of the tracking gauge probes are

adjustable, make the measurement by lengthening one

probe by the amount equivalent to the difference in

height of the two surfaces.

Height

Projected Dimension

BMCBD6001

Page 23

BODY DIMENSIONS BD-3

N

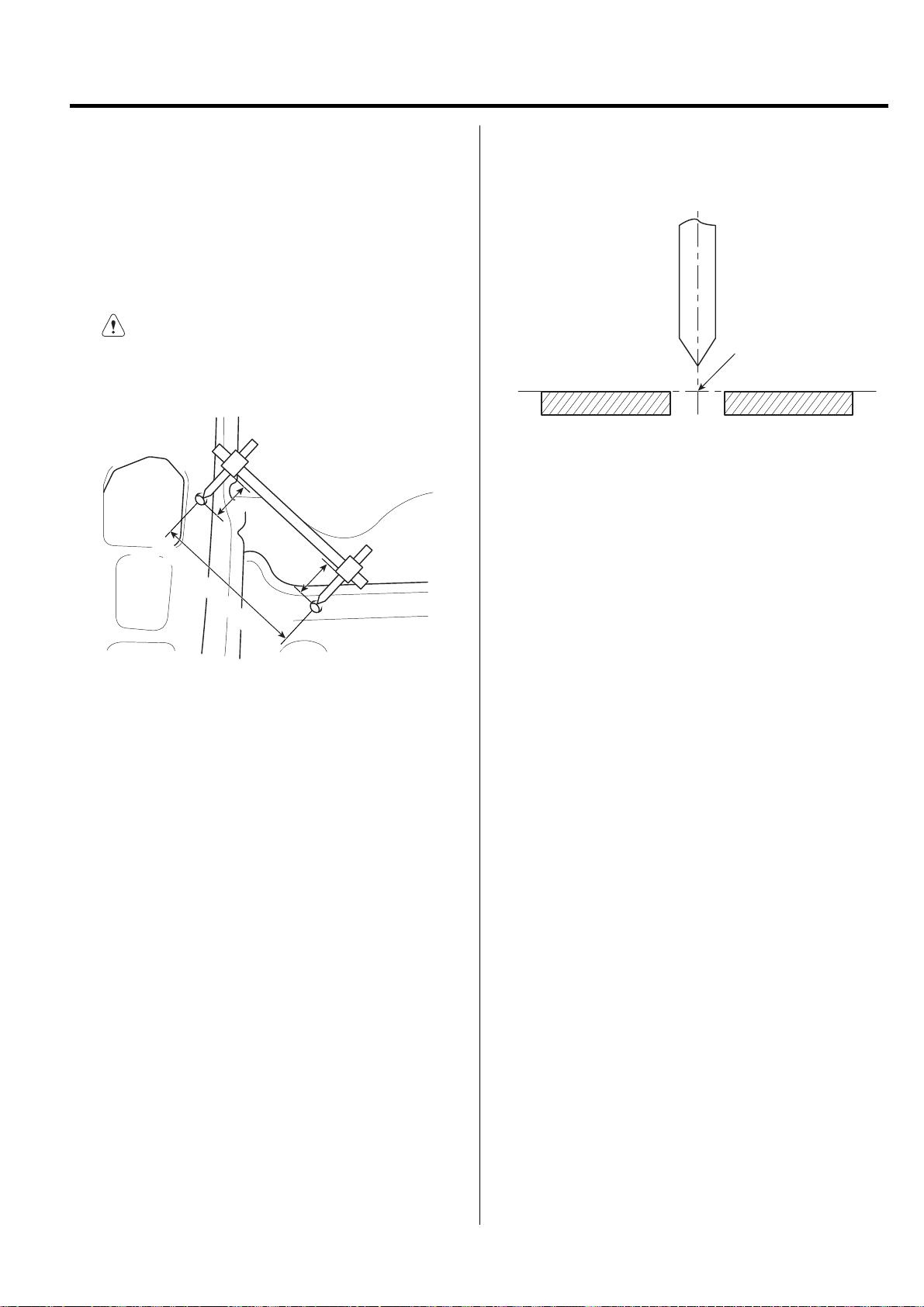

ACTUAL-MEASUREMENT DIMENSIONS

1. These dimensions indicate the actual linear distance

between measurement points, and are the reference

dimensions for use if a tracking gauge is used for

measurement.

2. Measure by first adjusting both probes to the same

length (A=A')

CAUTIO

Check the probes and gauge itself to make sure

there is no free play .

A

Actually-Measured Dimension

A'

MEASUREMENT POINT

1. Measurements should be taken at the hole center.

Hole Center

BMCBD6003

BMCBD6002

Page 24

BD-4 BODY DIMENSIONS

FRONT BODY

H'

H

G'

A'

D'

B'

C'

F'

* These dimensions indicated in this figure are actual-measurement dimensions.

E'

E

C

F

D

B

G

A

BVQBD6100

Point symbol

Length(mm)

Point symbol

Length(mm)

A-A'

1660

G-G'

1552.1

A-B

584.4

H-H'

1273

A-B'

584.4

H-G

1562.5

B-B'

1484.8

H-G'

1562.5

C-C' D-D' E-E' F-F'

1071.1 1310.5 1104.1 1120

Page 25

BODY DIMENSIONS BD-5

A

A,A'

BVQBD6101

Hood hinge mounting hole (ø12)

D

D,D'

BVQBD6104

B

B,B'

BVQBD6102

Fender mounting hole (ø8)

E

E

BVQBD6105

C

C,C'

BVQBD6103

Radiator upper member mounting

hole (ø8)

E'

E'

BVQBD6106

Front strut mounting hole (ø14)

F

F,F'

BVQBD6107

Front bumper bracket mounting

hole (ø9)

Transaxle bracket mounting hole

(ø12)

G

G,G'

BVQBD6108

Location notch

Engine bracket mounting hole

(ø18)

H

H,H'

BVQBD6109

Location notch

Page 26

BD-6 BODY DIMENSIONS

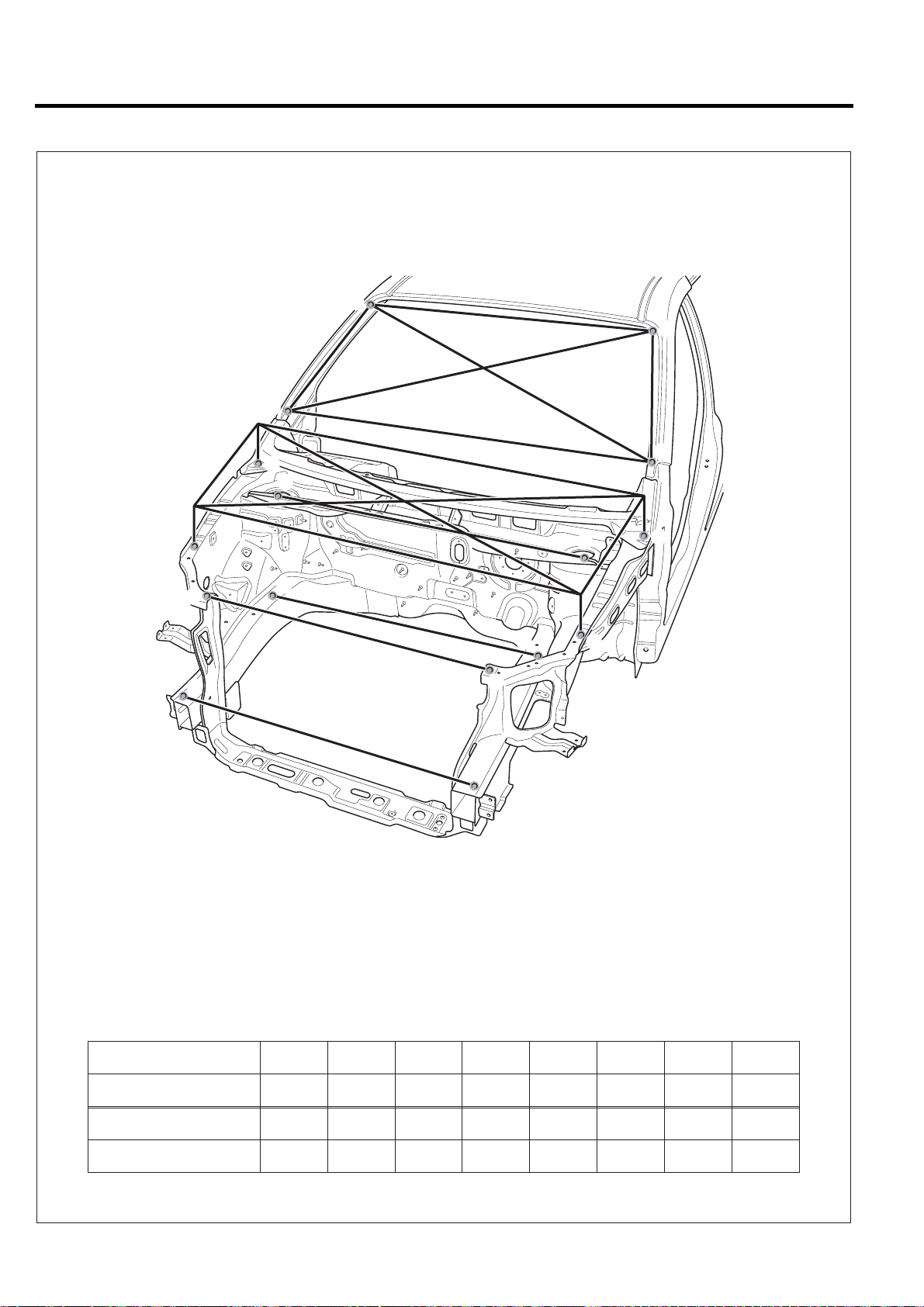

SIDE BODY (FRONT)

B

E

A

* These dimensions indicated in this figure are actual-measurement dimensions.

C

D

BVQBD6200

Point symbol

Length(mm)

Point symbol

Length(mm)

A-B

1244.9

A-E

2079.4

A-C A-D B-C C-D B-E C-E D-E

1119.4 1119.0 536.4 301.7 1005.8 1005.8 1126.2

Page 27

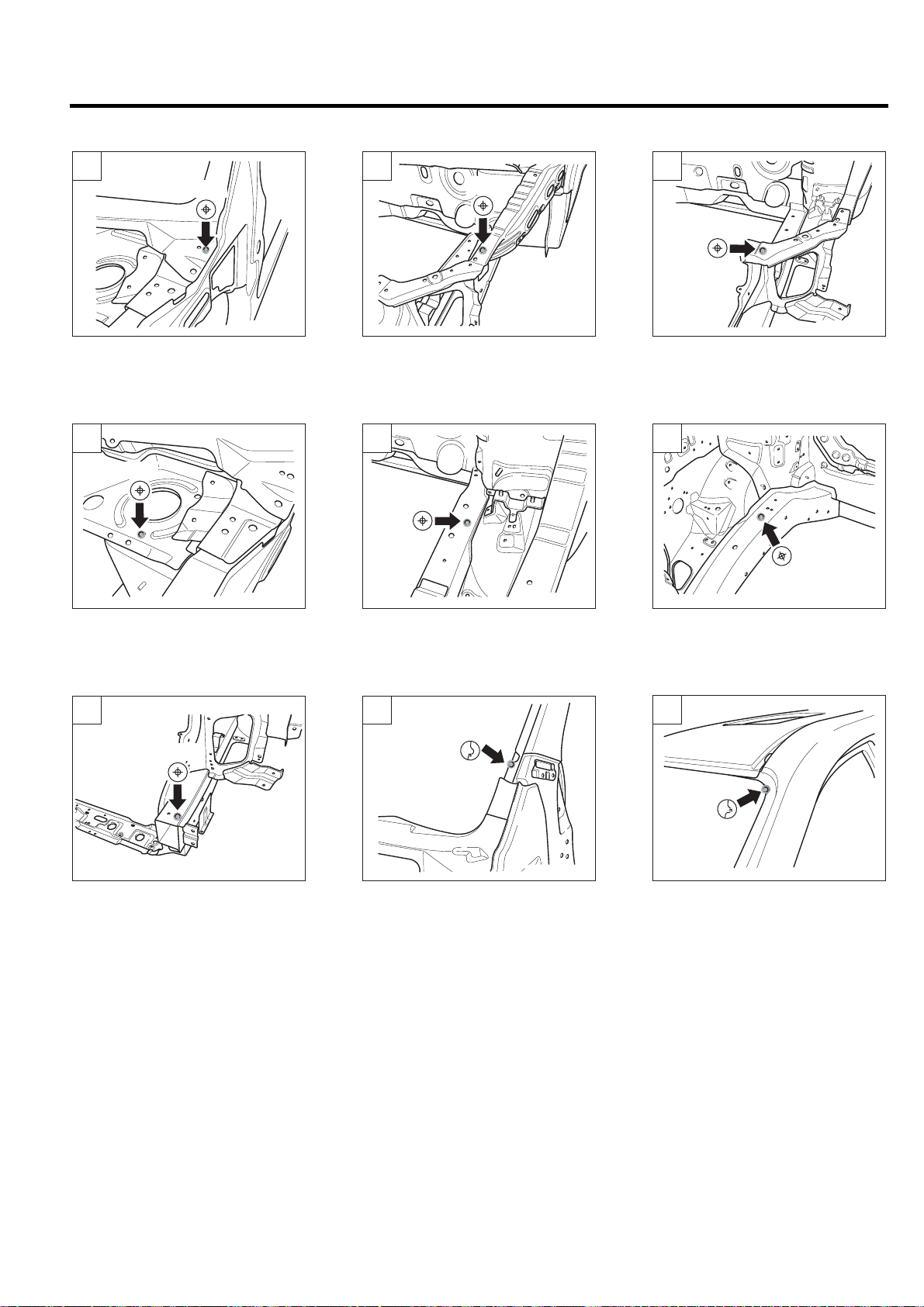

BODY DIMENSIONS BD-7

A

A

BVQBD6201

Tooling hole (ø16)

D

D

BVQBD6204

B

B

BVQBD6202

Front fender mounting hole (ø10)

E

E

BVQBD6205

C

C

BVQBD6203

Front door hinge mounting hole

(ø13)

Front fender mounting hole (ø10)

Front door switch mounting hole

(R9.2X9.2)

Page 28

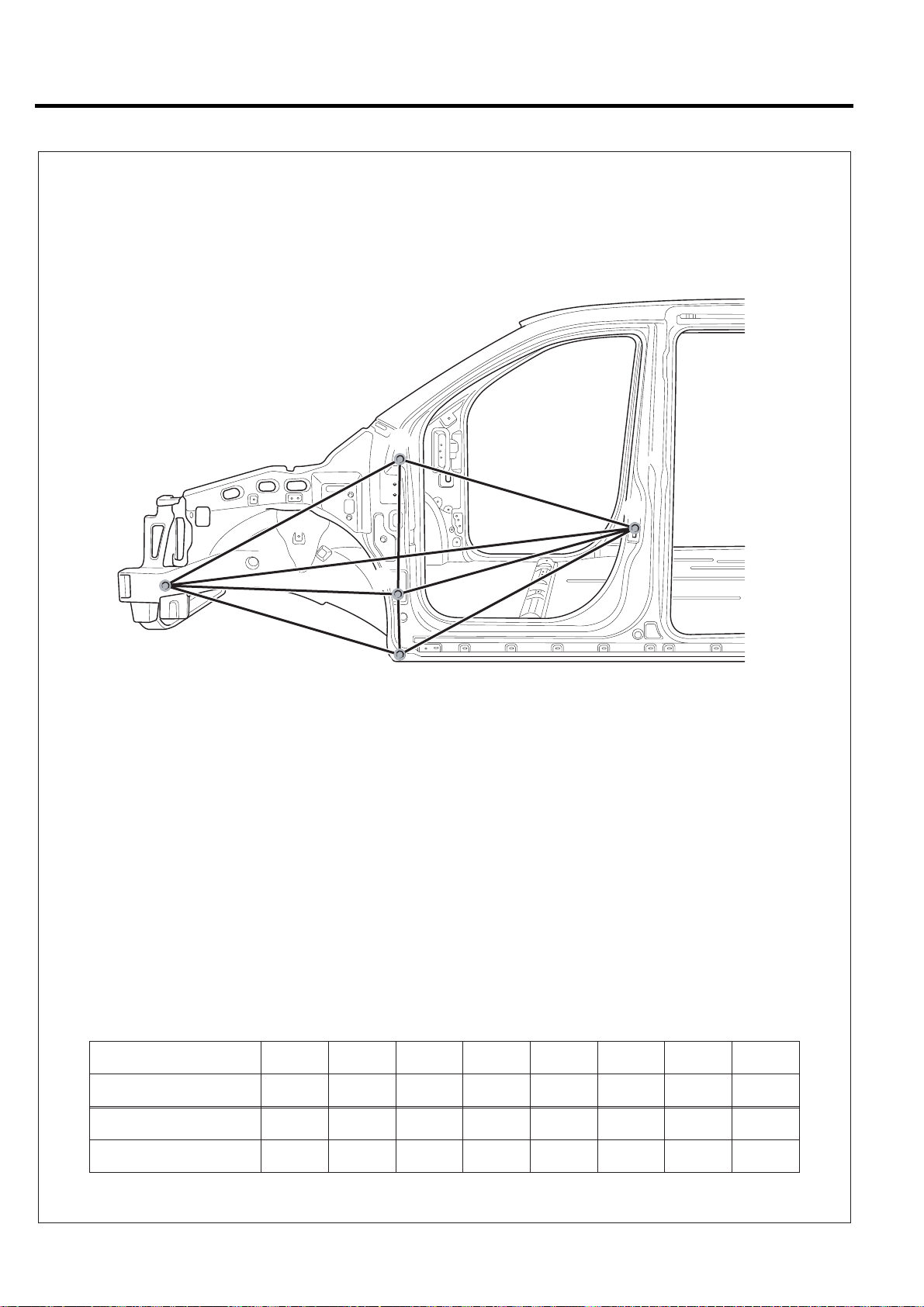

BD-8 BODY DIMENSIONS

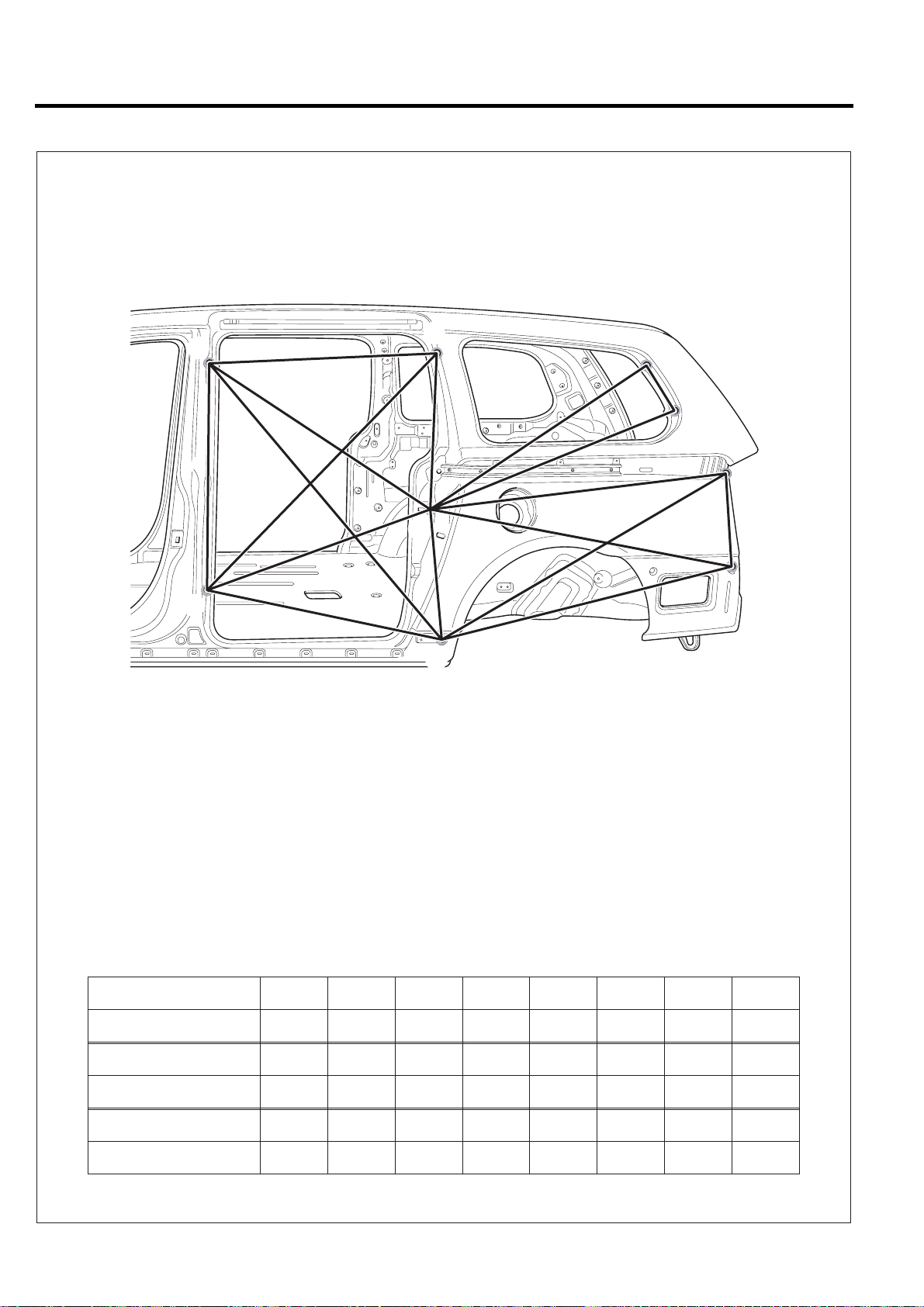

SIDE BODY (REAR)

A

B

C

F

G

H

D

K

E

BVQBD6300

* These dimensions indicated in this figure are actual-measurement dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

A-B

913.6

D-E

535.3

F-G

231.0

A-C

959.7

D-F

1151.5

A-D

1077

D-G

1153.1

A-E

1479.8

D-H

1327.6

B-C

1377.8

D-K

1353.2

B-D

968

E-H

1432

B-E

1000

E-K

1303.1

C-D

658.9

H-K

398.4

Page 29

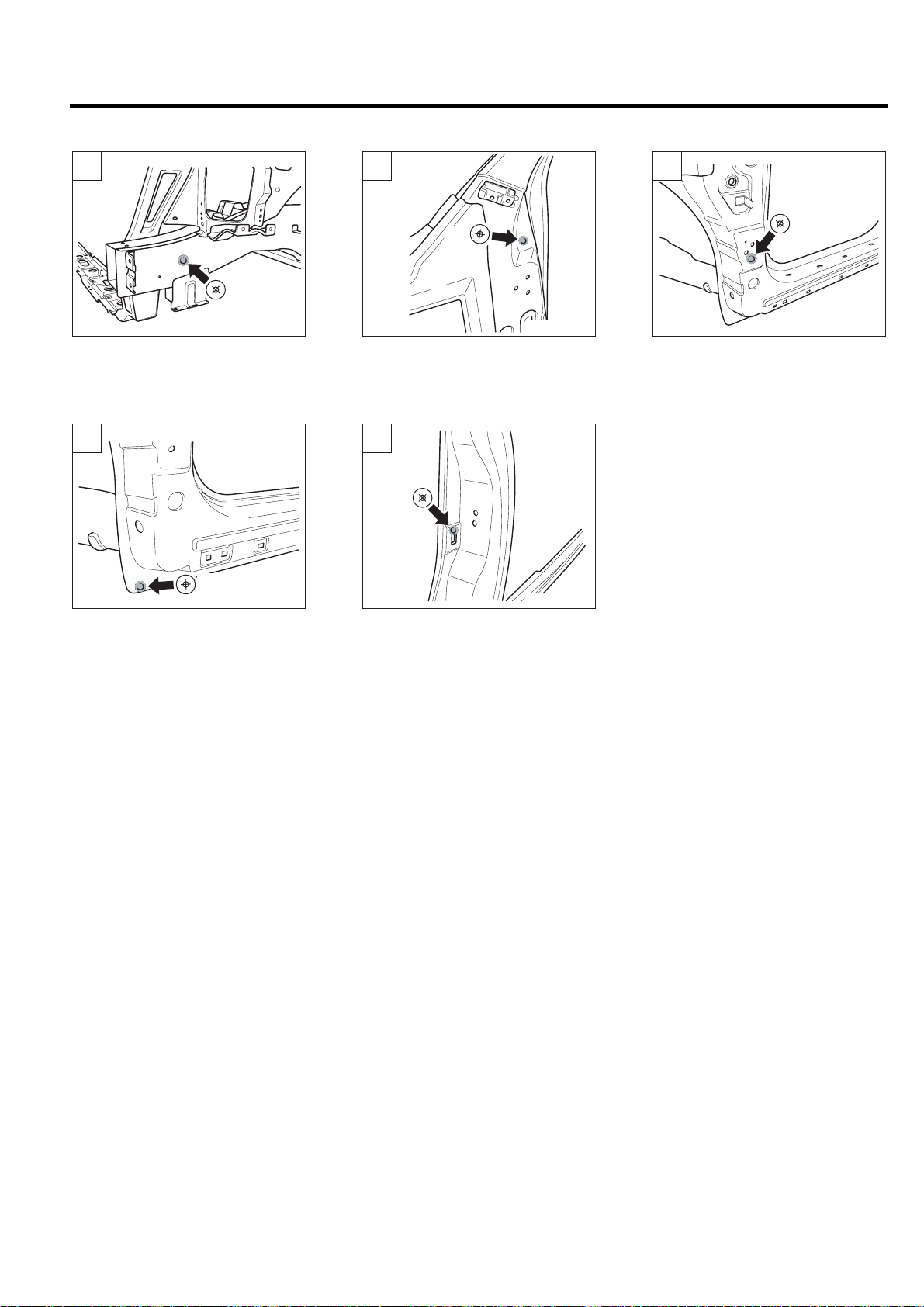

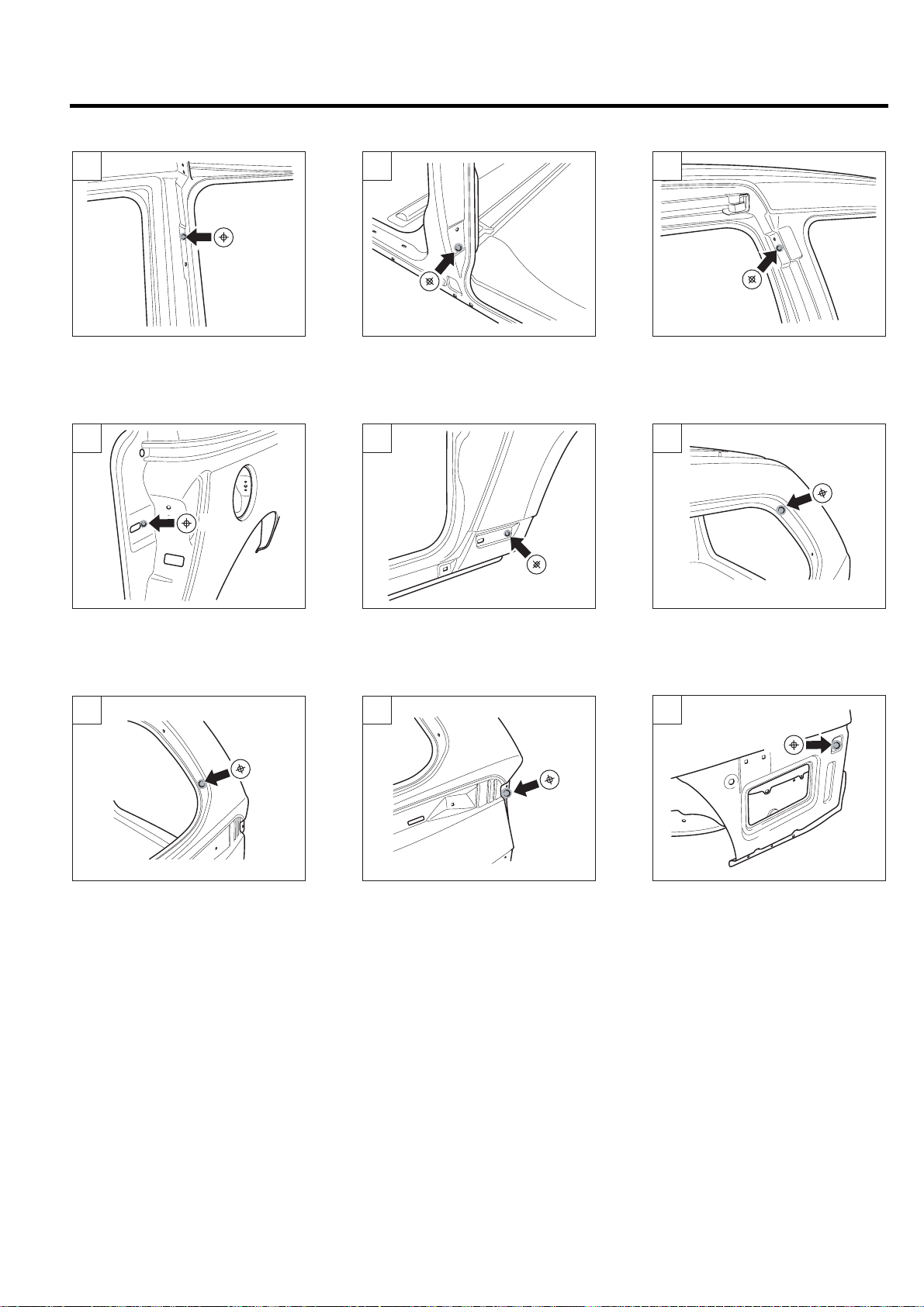

BODY DIMENSIONS BD-9

A

A

BVQBD6301

Rear door stopper mounting hole

(ø10)

D

D

BVQBD6304

B

B

BVQBD6302

Rear door stopper mounting hole

(ø10)

E

E

BVQBD6305

C

C

BVQBD6303

Qurter glass guide mounting hole

(S6.2X8)

F

F

BVQBD6306

Rear door switch mounting hole

(ø8)

G

G

BVQBD6307

Qurter glass stopper mounting

hole (ø8.5)

Side garnish mounting hole

(R9X12)

H

H

BVQBD6308

Center rail cover mounting hole

(ø10)

Qurter glass stopper mounting

hole (ø8.5)

K

K

BVQBD6309

Rear bumper mounting hole (ø11)

Page 30

BD-10 BODY DIMENSIONS

INTERIOR A

C'

B'

A'

B

C

F'

D'

A

E'

D

E

F

H'

K'

G'

M'

G

N'

H

P'

K

M

N

P

BVQBD6400

* These dimensions indicated in this figure are actual-measurement dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

A-A'

1315.9

K-K'

1639.5

B-B'

1525.9

M-M'

1106.0

C-C'

1550.0

N-N'

1293.0

D-D'

1279.7

P-P'

1317.1

E-E' F-F' G-G' H-H'

1572.0 1569.2 1291.2 1593.3

Page 31

BODY DIMENSIONS BD-11

A

A,A'

BVQBD6401

A pillar trim mounting hole (ø8.5)

D

D,D'

BVQBD6404

B

B,B'

BVQBD6402

Curtain airbag mounting hole

E

E,E'

BVQBD6405

C

C,C'

BVQBD6403

A pillar trim mounting hole (ø8.5)

(ø6.6)

F

F,F'

BVQBD6406

B pillar trim mounting hole (ø6.6)

G

G,G'

BVQBD6407

C pillar trim mounting hole (ø9)

M

M,M'

Paint stay mounting hole (ø11)

H

H,H'

Power sliding door module

mounting hole (ø9)

BVQBD6408

N

Seat belt mounting hole (ø12.4)

K

K,K'

BVQBD6409

Tooling hole (ø12)

P

BVQBD6410

D pillar trim mounting hole (ø8.5)

N

N'

BVQBD6411

Net hook mounting hole (ø9)

P,P'

BVQBD6412

Wire harness earth mounting

hole (ø9)

Page 32

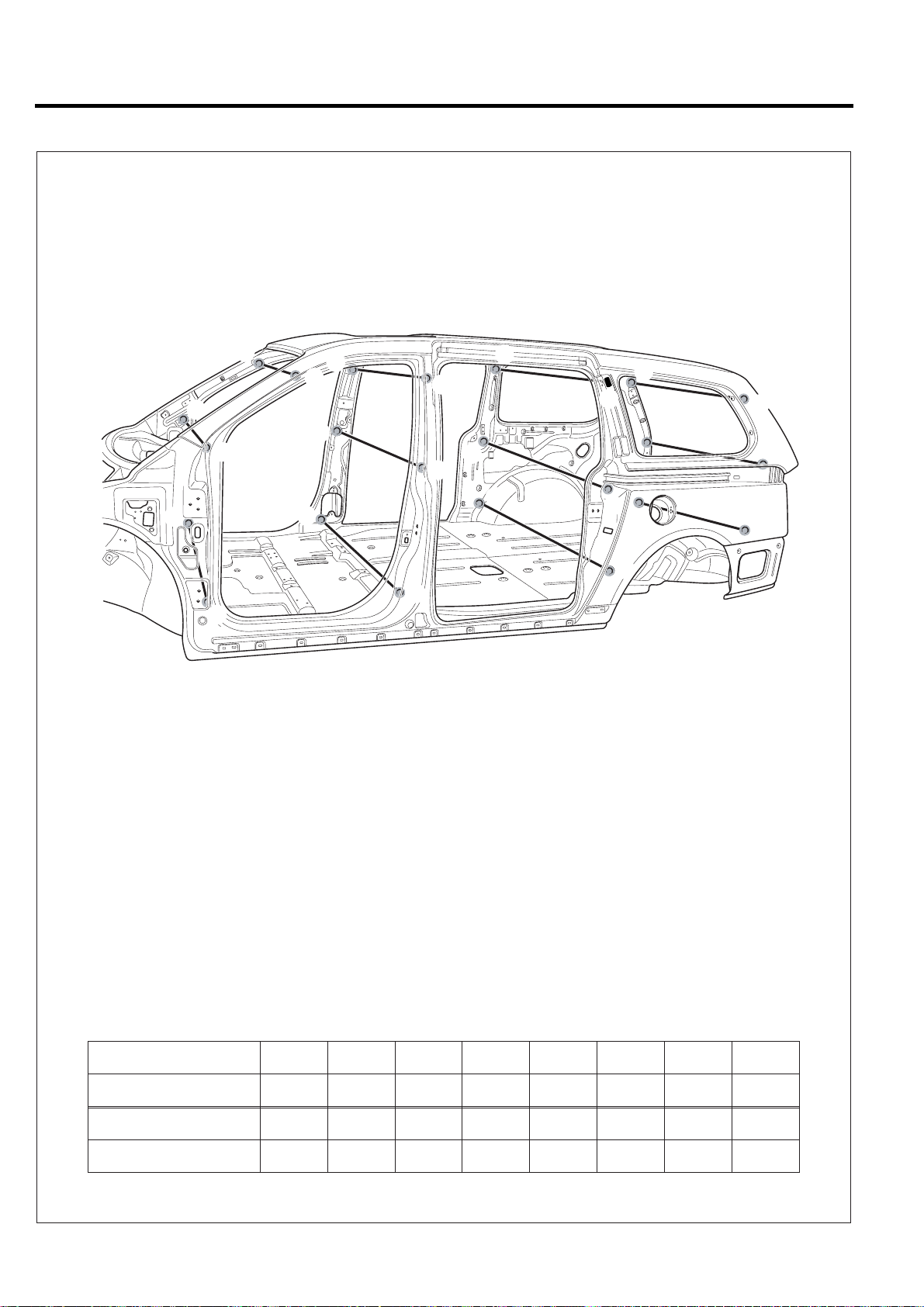

BD-12 BODY DIMENSIONS

INTERIOR B

C'

B'

B

A'

C

F'

D'

A

E'

M'

M

D

E

F

H'

K'

G'

G

H

K

BVQBD6500

* These dimensions indicated in this figure are actual-measurement dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

M-A'

1482.6

M-K'

1555.2

M'-H

1632.0

M-B'

1539.7

M'-A

1482.6

M'-K

1511.7

M-C'

1350.8

M'-B

1539.7

M-D'

1417.6

M'-C

1350.8

M-E'

1207.5

M'-D

1417.6

M-F'

1010.6

M'-E

1207.5

M-G'

1807.2

M'-F

1010.6

M-H'

1649.3

M'-G

1807.2

Page 33

BODY DIMENSIONS BD-13

A

A,A'

BVQBD6401

A pillar trim mounting hole (ø8.5)

D

D,D'

BVQBD6404

B

B,B'

BVQBD6402

Curtain airbag mounting hole

E

E,E'

BVQBD6405

C

C,C'

BVQBD6403

A pillar trim mounting hole (ø8.5)

(ø6.6)

F

F,F'

BVQBD6406

B pillar trim mounting hole (ø6.6)

G

G,G'

BVQBD6407

C pillar trim mounting hole (ø9)

M

M'

Paint stay mounting hole (ø11)

H

H,H'

Power sliding door module

mounting hole (ø9)

BVQBD6408

Seat belt mounting hole (ø12.4)

K

K,K'

BVQBD6409

Tooling hole (ø12)

M

BVQBD6501

Seat mounting hole (ø14)

Page 34

BD-14 BODY DIMENSIONS

INTERIOR C

D'

E'

F'

* These dimensions indicated in this figure are actual-measurement dimensions.

D

G '

H

E

K

Q'

Q

F

G

M'

N'

H'

P'

K'

M

N

P

BVQBD6600

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

Q-D'

1695.2

Q-P'

1641.4

Q'-N

1737.0

Q-E'

1579.8

Q'-D

1695.2

Q'-P

1637.9

Q-F'

1507.8

Q'-E

1579.8

Q-G'

1412.2

Q'-F

1507.8

Q-H'

1210.9

Q'-G

1412.2

Q-K'

1087.3

Q'-H

1192.4

Q-M'

1720.1

Q'-K

1084.7

Q-N'

1737.0

Q'-M

1720.1

Page 35

BODY DIMENSIONS BD-15

D

D,D'

BVQBD6404

B pillar trim mounting hole (ø6.6)

G

G,G'

BVQBD6407

E

E,E'

BVQBD6405

Paint stay mounting hole (ø11)

H

H,H'

BVQBD6408

F

F,F'

BVQBD6406

Seat belt mounting hole (ø12.4)

K

K,K'

BVQBD6409

C pillar trim mounting hole (ø9)

M

M,M'

BVQBD6410

D pillar trim mounting hole (ø8.5)

Q

Power sliding door module

mounting hole (ø9)

N

N

N'

BVQBD6411

Net hook mounting hole (ø9)

Tooling hole (ø12)

P

P,P'

BVQBD6412

Wire harness earth mounting

hole (ø9)

Q'

Q

BVQBD6601

Tooling hole (ø20)

Page 36

BD-16 BODY DIMENSIONS

REAR BOD Y

A

B

C

E E'

D

A'

B'

C'

D'

* These dimensions indicated in this figure are actual-measurement dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

A-A'

820.0

C-B'

1391.0

B-B'

1174.7

C-D'

1565.1

BVQBD6700

C-C' D-D' E-E' B-E B-C' B-E'

1394.0 1464.0 976.0 994.4 1391.0 1461.3

Page 37

BODY DIMENSIONS BD-17

A

A,A'

BVQBD6701

Tail gate hinge mounting hole

D

D,D'

BVQBD6704

(ø12)

B

B,B'

BVQBD6702

Gas lift mounting hole (ø9)

E

E,E'

BVQBD6705

C

C,C'

BVQBD6703

Rear clamp mounting hole

(R8.5X8.5)

Rear bumper mounting hole (ø14)

Package trim mounting hole

(ø8.5)

Page 38

BD-18 BODY DIMENSIONS

UNDER BODY ( PROJECTED DIMENSIONS )

A

A'

B

B'

C

C'

E

E'

D

D'

F'

K

F

G

G'

H

H'

M

M'

N

N'

K'

R

Q

P

P'

Q'

R'

S

S'

0

AB C ED F G H

* These dimensions indicated in this figure are projected dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

A-A'

1095

K-K'

1325

O-B

-61.3

O-M

13.5

C-E

329.5

N-P

B-B'

1095

M-M'

959

O-C

78.1

O-N

-54.3

E-D

55

P-Q

C-C'

1048

N-N'

1097.5

O-D

-117.5

O-P

18

D-F

366.5

Q-R

D-D'

696

P-P'

840

O-E

-87.6

O-Q

81.5

F-G

972

R-S

KMNPQRS

BVQBD6800

E-E'

878

Q-Q'

1060

O-F

-85.8

O-R

26

G-H

415

F-F'

924.8

R-R'

1338

O-G

-31(LH)/-14(RH)

O-S

39.2

H-K

85

G-G'

1050

S-S'

1338

O-H

-15(LH)/0(RH)

A-B

138

K-M

605

H-H'

1066

O-A

-33.5

O-K

-1.4

B-C

631

M-N

164.5

Length(mm)

56

344.5

15

350

Page 39

BODY DIMENSIONS BD-19

A

A

BVQBD6801

Front stay mounting hole (ø13)

D

D

BVQBD6803

B

B

BVQBD6801A

Sub frame front mounting hole

(ø16)

E

E

BVQBD6803A

C

C

BVQBD6802

Brake pipe mounting hole (ø7)

F

F

BVQBD6804

Rear stay mounting hole (ø12)

G

G

BVQBD6805

Tooling hole (S22X20)

M

M

Sub frame rear mounting hole

(ø18)

H

H

BVQBD6806

Tooling hole (ø20)

N

N

Tooling hole (ø13)

K

K

BVQBD6806A

Traling arm mounting front hole

(ø14)

P

BVQBD6807

Sub frame mounting hole (ø18)

BVQBD6807A

Rear bumper stopper mounting

hole (ø11)

P

BVQBD6807B

Brake pipe bolt mounting hole

(ø16)

Page 40

BD-20 BODY DIMENSIONS

Q

Q

BVQBD6808

Tooling hole (S15X17)

R

R

BVQBD6808A

Tooling hole (S20X22)

S

S

BVQBD6809

Tooling hole (ø10)

Page 41

BODY DIMENSIONS BD-21

UNDER BOD Y ( A CTU AL-MEASUREMENT DIMENSIONS )

A

A'

C

C'

D'

R

D

F

F'

G

G'

H

H'

M

M'

R'

S

S'

BVQBD6900

* These dimensions indicated in this figure are actual-measurement dimensions.

Point symbol

Length(mm)

Point symbol

Length(mm)

Point symbol

Length(mm)

A-A'

1095

D'-H

2006.8

H-S'

2017.6

A-C'

1325.2

F-G'

1386.6

M-R'

1286.7

A'-D

1518.8

F'-H

1709.4

M'-S

1478

C-D'

1048.2

F'-M

2282.7

R-S'

1383.1

C'-F

1251.1

G-H'

1136.5

S-S'

1338

C'-G

2020.4

G'-M

1494

D-F'

973.1

H'-R

1749.1

D-G'

1650.5

H-M'

1225.3

Page 42

BD-22 BODY DIMENSIONS

A

A

BVQBD6801

Front stay mounting hole (ø13)

F

F

BVQBD6804

C

C

BVQBD6802

Brake pipe mounting hole (ø7)

G

G

BVQBD6805

D

D

BVQBD6803

Rear stay mounting hole (ø12)

H

H

BVQBD6806

Tooling hole (ø13)

M

M

BVQBD6807

Sub frame mounting hole (ø18)

Tooling hole (S22X20)

R

R

BVQBD6808A

Tooling hole (S20X22)

Tooling hole (ø20)

S

S

BVQBD6809

Tooling hole (ø10)

Page 43

BODY DIMENSIONS BD-23

Page 44

Body Panel Repair

Procedure

REPLACING BODY PANELS

CODES FOR REMOVING AND

INSTALLING BODY PANELS...........................BP - 2

NOTES WHEN WELDING BODY

REMOVING SPOT WELDED AREA ................BP - 3

INSTALLING A NEW BODY FRAME................BP - 5

DETERMINING A WELDING METHOD...........BP - 5

SPOT WELDING ..............................................BP - 5

CARBON ARC WELDING ...............................BP - 6

REPLACING BODY PANEL

REMOVAL...................................................BP - 7

PREPARATION FOR INSTALLATION ........BP - 9

INSTALLATION ...........................................BP - 10

RADIATOR SUPPORT PANEL

ASSEMBLY.......................................................BP - 12

REMOVAL ........................................................BP - 12

INSTALLATION.................................................BP - 14

COWL SIDE OUTER PANEL

REMOVAL ........................................................BP - 15

INSTALLATION.................................................BP - 16

FENDER APRON INNER LOWER PANEL

REMOVAL ........................................................BP - 17

INSTALLATION.................................................BP - 18

QUARTER PANEL

REMOVAL ........................................................BP - 35

INSTALLATION.................................................BP - 37

REAR FLOOR SIDE MEMBER

REMOVAL ........................................................BP - 38

INSTALLATION.................................................BP - 40

REAR COMBINATION LAMP HOUSING

PANEL

RREMOVAL......................................................BP - 42

INSTALLATION.................................................BP - 43

BACK PANEL

REMOVAL ........................................................BP - 44

INSTALLATION.................................................BP - 45

BP

FENDER APRON INNER UPPER PANEL

REMOVAL ........................................................BP - 19

INSTALLATION.................................................BP - 20

FRONT SIDE MEMBER...............................BP - 21

REMOVAL ........................................................BP - 22

INSTALLATION.................................................BP - 23

FRONT PILLAR

REMOVAL ........................................................BP - 25

INSTALLATION.................................................BP - 28

CENTER PILLAR

REMOVAL ........................................................BP - 31

INSTALLATION.................................................BP - 33

Page 45

BP-2 BODY PANEL REPAIR PROCEDURE

REPLACING BOD Y PANELS

CODES FOR REMOVING AND INSTALLING BODY PANELS

0.8~1.2 in.

(20~30 mm)

0.8~1.2 in.

(20~30 mm)

Rough cutting location

Location for cut and assembly

BVQBP6001

Page 46

BODY PANEL REPAIR PROCEDURE BP-3

NOTES WHEN WELDING BOD Y

REMOVING SPOT WELDED AREA

Most body parts are spot welded. In order to remov e the damaged area, it is best to remov e the spot welded area from the

body frame using a spot cutter or candle type edge drill bit.

Do not use a drill bit with a tapered edge. Center punch middle of spot weld to insure the entire spot weld will be removed.

1. Spot cutter 1. Drill(candle type edge) 1. Drill(taper edge)

2. 2. 2.

3. 3. 3.

Correct

Correct

Not correct

BVQBP6002

Page 47

BP-4 BODY PANEL REPAIR PROCEDURE

Center punch the middle(nugget) of the spot weld. Otherwise,

This part will not be cut. This part will be cut.

Spot welded area can be removed from the body frame. Spot welded area cannot be removed from the body

frame.

BVQBP6003

Page 48

BODY PANEL REPAIR PROCEDURE BP-5

INSTALLING A NEW BODY FRAME

The efficiency of the transmission and load distribution are determined by many complicated factors such as thickness of

plate, shape and size of a cross section, damage of parts, variance of joints, welding method, and/or welding locations.

Therefore, a new part should be fitted to the body frame using the proper procedures to avoid reducing the strength of the

body.

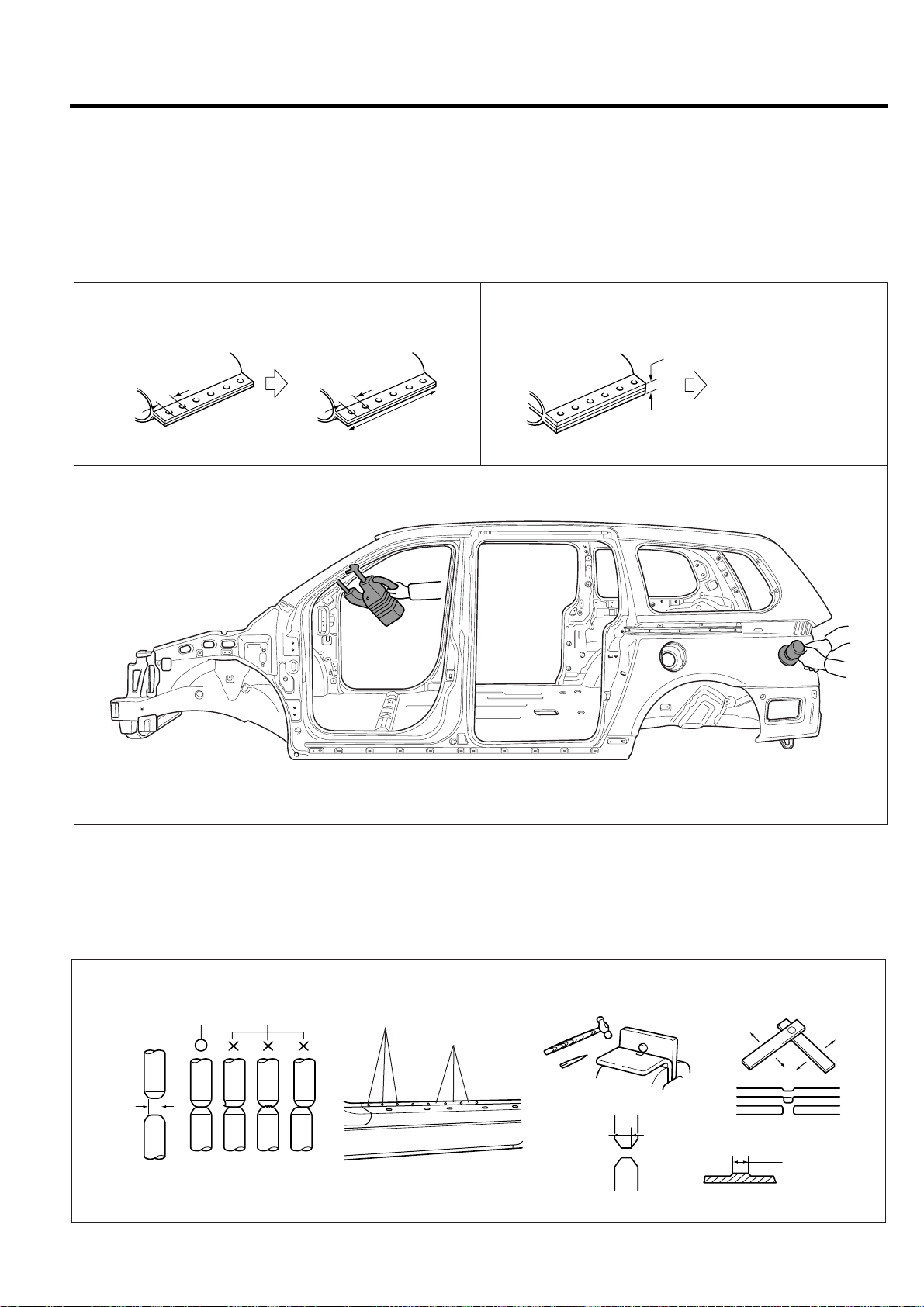

DETERMINING A WELDING METHOD

It is extremely important that appropriate welding methods, which don't reduce the original strength and durability of the body

be used when making repairs, Try to use either spot welding or carbon arc(plug) welding, Do not braze any body components

other than the ones brazed at the factory. Do not use an o xy-acetylene torch f or welding.

Welding Symbol Details

Spot welding

Carbon arc welding

(Plug welding)

Oxygen-acetylene welding

The most reliable welding method

(provides high efficiency and quality of assembled part.)

Use when spot welding cannot be done or spot welding is not necessary.

Not used

SPOT WELDING

1. Commercial spot welding machines do not perform as

well as the machines used in the manufacturing

process. When spot welding, increase the number of

spot welds by 30% (1.3 times the original number of

welds).

BVQBP6004

2. When spot welding, weld in the middle of the joint.

Good

BVQBP6006

BVQBP6005

• Spot welding on the edge of the joint will reduce welding

strength.

No good

BVQBP6007

Page 49

BP-6 BODY PANEL REPAIR PROCEDURE

CARBON ARC WELDING

In areas where spot welding is not suitable, do plug welding

using a carbon are welding machine.

1. Clamp the parts to be welded together tightly . Do not

exceed 1 mm of space between parts. A tolerance

greater than 1 mm will reduce the strength of the

welded area.

1mm

Maximum

tolerance

BVQBP6008

b) Do not weld on the edge of the flange joint.

No good

BVQBP6009

2. Weld in the middle of the flange joint.

a) Drill a hole 5~6 mm on one side of the flange only,

and weld within the hole.

Good

BVQBP6006

Page 50

BODY PANEL REPAIR PROCEDURE BP-7

REPLACING BODY PANEL

REMOVAL

1. Body measurement

a) Before removing, measure the damaged area

according to the dimensions supplied in Body

Dimension, section 31. If deformation is present,

use a frame straightener to adjust.

b) When removing a panel, apply clamps to prevent

damage of each part, and support the lower end

of the frame to prevent deformation during the

procedure.

Tracking gauge

3. Cutting rough area for replacement part

Cutting should be done according to the following steps

to make removal easy:

a) Use care when cutting an area close to a pipe or

wiring harness.

b) Cut an area leaving 30~50 mm of tolerance.

BVQBP6012

4. Removing paint from an area to be spot welded

Using a torch and wire brush, remove paint completely

before beginning welding.

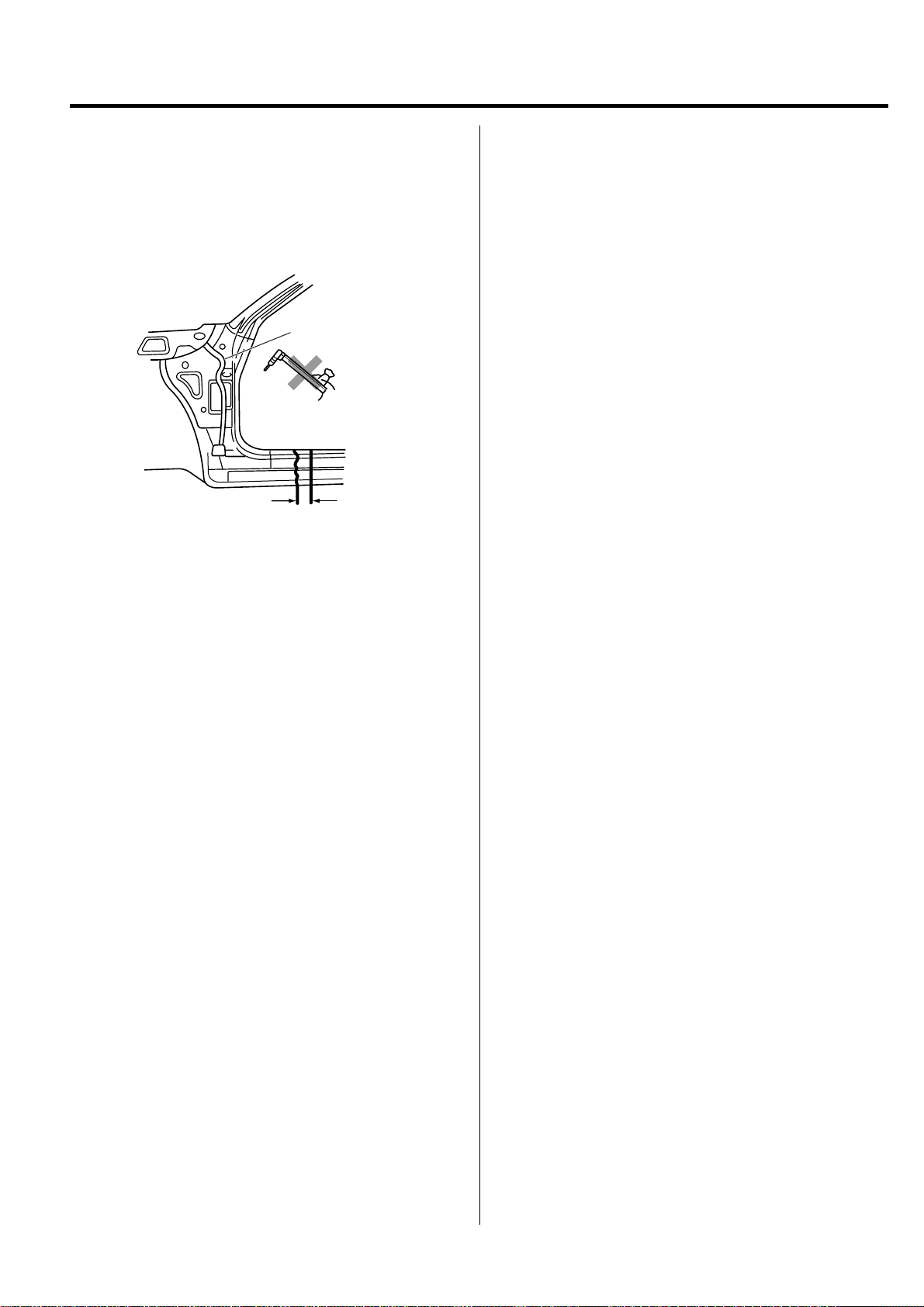

2. Cut and welding point selection

Cutting, if necessary, should not be done in a

reinforcement area. Select an area which will result in

the least amount of deformation after welding.

Cut area

Reinforcement

Reinforcement

BVQBP6010

BVQBP6013

BVQBP6011

Page 51

BP-8 BODY PANEL REPAIR PROCEDURE

5 . Determine a cutting method

a) Cutting a spot welded area

Make a hole in the middle of spot welded area

with a punch, remove welded area using a spot

cutter and remove using a chisel.

BVQBP6014

b) Removing brazed area

Remove using a torch and wire brush, and chisel.

c) Removing arc welded area

Remove plug welded area using a disk grinder

and chisel.

BVQBP6015

BVQBP6016

Page 52

BODY PANEL REPAIR PROCEDURE BP-9

E

PREPARATION FOR INSTALLATION

1. Spot weld finish

Use a disk grinder or similar tool to finish spot weld

mark, Do not grind more than is necessary to smooth

surface.

2. Panel preparation

Repair any bent or uneven areas with a hammer to

improve the installation process.

BVQBP6017

4 . Preparation for spot welding

Remove paint on spot welded area and on the area

overlapped by the new part using a belt sander or similar

tool.

BVQBP6020

5. Drilling a hole for plug welding

If the thickness of the part to be welded is less than 3

mm, drill a 5~6 mm diameter hole. If the thickness of

the part to be welded is greater than 3 mm, drill a hole

using a 7 mm diameter drill.

3. Cutting a rough area for a new part

When rough cutting an area for a new part, leave a

tolerance of 30~50 mm.

NOT

Do not spot weld where thickness is greater than

3 mm.

BVQBP6018

BVQBP6021

BVQBP6019

Page 53

BP-10 BODY PANEL REPAIR PROCEDURE

E

INSTALLATION

1. Checking welding and fitting in advance

a) When installing a new part, measure the

dimensions of each part according to the body

dimensions given in Section 31, and set part to

the reference dimensions.

b) Prior to final welding, check the fit of all related

parts.

BVQBP6022

2. Selecting number of welding points

Spot welding : Multiply the original number of

factory welds by 1.3 times

Plug welding : Same number as original number

of factory welds

NOT

• Plug welding should be done using a carbon arc

welding machine.

• Brazing should be done only on areas that were

originally brazed at the factory .

Initial welding

pitch:50 mm

Spot welding:initial number of welds x1.3

Welding points-same number as original number of factory welds.

3mm

3mm

Welding after repair

pitch:35 mm

Plug welding-used when

spot welding is not

feasible or material is

thicker than 3 mm

BVQBP6024

BVQBP6023

3. Caution when spot welding

a) Do a test welding on a piece of material of the

same type and thickness as the part to be welded

and proceed if test weld is good.

b) Before spot welding, check if welding debris, oil

or paint is present on the area where surfaces

meet.

Clean or sand as necessary .

Using a test piece

Nugget

diameter:

4/5 of tip

Center

diameter

Using a hammer

and a chisel

3 mm

BVQBP6025

Page 54

BODY PANEL REPAIR PROCEDURE BP-11

E

c) The tip of the spot welding machine should be

maintained to a minimum tolerance of 3 mm. Also

let area cool after 5 or 6 welds to minimize problems

caused by excessive heat.

3mm(0.2 in)

4 . Cutting and welding an removed area

T o align a roof panel and a center pillar together f or butt

welding, temporarily fasten a steel flange to the roof

panel and then apply the new center pillar panel.

Remove the flange when final welding is done.

b) Finish areas that have been brazed by applying

body filler then smooth the area with a flexible file

and sander.

BVQBP6029

BVQBP6026

6. Applying anti-rust agent and body sealer

After coating the surface with anti-rust agent, apply

body sealer where necessary.

NOT

Apply body sealer before assembly.

5. Finishing after welding

a) Grind any areas that were plug welded or butt

welded using a disk grinder. Grind carefully to avoid

removing too much material. This degrades the

strength of the weld.

BVQBP6027

BVQBP6028

BVQBP6030

7. Anti-rust treatment

Apply anti-rust agent to inside of doors and sills by

spraying through access holes provided.

BVQBP6031

Page 55

BP-12 BODY PANEL REPAIR PROCEDURE

E

E

RADIATOR SUPPORT PANEL

ASSEMBLY

NOT

Before repairing, remove Engine and Suspension

Components.

Refer to the body dimension charts and measure the vehicle

to determine straightening and alignment requirements. The

body must be returned to its original dimension before you

begin the repair procedure.

REMOVAL

1. Drill out all the spotwelds to separate radiator support

panel from front side member(10 points) and fender

apron upper outer panel(10 points).

NOT

When spotwelded portions are not apparent, remove

paint with a rotary wire brush

BVQBP6033

BVQBP6032

BVQBP6034

BVQBP6035

Page 56

BODY PANEL REPAIR PROCEDURE BP-13

2 . Drill out all the spotwelds to separate radiator support

panel from front side member(7 points).

BVQBP6036

3. Using a belt sander, remov e the front side member by

drilling out the spotwelds(4points).

5. Before welding the radiator support panel, apply the

epoxy primer to the interior of the radiator support panel

BVQBP6039

4. Clean MIG welds with a disc grinder.

BVQBP6037

BVQBP6038

Page 57

BP-14 BODY PANEL REPAIR PROCEDURE

E

INSTALLATION

1. Drill 6mm holes in the new radiator support panel for

MIG plug welding.

2. Remove paint from both sides of all portions that are to

be welded such as peripheries of MIG plug weld holes.

BVQBP6040

3. T emporarily install new parts in place.

4. Measure each measurement point (Refer to the BODY

DIMENSIONS) and correct the installation position

6 . Clean MIG welds with a disc grinder.

NOT

• Be careful not to grind welded portions too much.

• The internal parts will be stronger if the weld traces

are not ground.

BVQBP6043

7. After welding the radiator support panel, apply the

epoxy primer and anti-corrosion to the radiator support

panel

5. MIG plug weld all holes.

BVQBP6041

BVQBP6042

BVQBP6044

Page 58

BODY PANEL REPAIR PROCEDURE BP-15

COWL SIDE OUTER PANEL

REMOVAL

1. Drill out all spotwelds to separate cowl side outer panel

from cowl assembly and fender apron inner panel(33

points).

BVQBP6045

2. Using a disc grinder, remove the co wl side outer panel

by drilling out the MIG lap welds.(5 points)

4. Before welding the cowl side outer panel, apply the

epoxy primer to the interior of the cowl side outer panel.

BVQBP6048

3. Clean MIG welds with a disc grinder.

BVQBP6046

BVQBP6047

Page 59

BP-16 BODY PANEL REPAIR PROCEDURE

E

INSTALLATION

1. Drill 6mm holes in the new cowl side outer panel for

MIG plug welding.

2. Remove paint from both sides of all portion that are to

be welded such as peripheries of MIG plug weld holes.

BVQBP6049

3. T emporarily install new parts in place.

4. MIG plug weld all holes.

5 . Clean MIG welds with a disc grinder .

NOT

Be careful not to grid welded portion too much.

The internal parts will be stronger if the weld traces are

not ground.

BVQBP6051

6. After welding the cowl side outer panel, apply the epoxy

primer and anti corrosion to the cowl side outer panel.

BVQBP6052

BVQBP6050

Page 60

BODY PANEL REPAIR PROCEDURE BP-17

FENDER APRON INNER LOWER PANEL

REMOVAL

1. Drill out all the spotwelds to separate fender apron inner

lower panel from fender apron inner upper panel, shock

absorber housing panel and front side member.

BVQBP6053

2 . Clean MIG welds with a disc grinder .

BVQBP6055

3. Before welding the fender apron inner lower panel, apply

the epoxy primer to the interior of the fender apron inner

lower panel.

BVQBP6054

BVQBP6056

Page 61

BP-18 BODY PANEL REPAIR PROCEDURE

E

INSTALLATION

1. Drill 6mm holes in the new fender apron inner lower

panel for MIG plug welding.

2. Remove paint from both sides of all portion that are to

be welded such as peripheries of MIG plug weld holes.

BVQBP6058

3. T emporarily install new parts in place.

5 . Clean MIG welds with a disc grinder .

NOT

Be careful not to grid welded portion too much.

The internal parts will be stronger if the weld traces are

not ground.

BVQBP6061

6. After welding the fender apron inner lower panel, apply

the epoxy primer and anti corrosion to the cowl side

outer panel

4. MIG plug weld all holes.

7. Prepare the exterior surfaces for priming using wax

and grease remover .

8. Apply metal conditioner and water rinse.

9. Apply conversion coating and water rinse.

10. Apply the two-part epoxy primer

BVQBP6059

BVQBP6062

BVQBP6060

Page 62

BODY PANEL REPAIR PROCEDURE BP-19

FENDER APRON INNER UPPER PANEL

REMOVAL

1. Measure and mark the vertical cut lines on fender outer

mounting hole edge.

LH

65 mm

BVQBP6063

RH

70 mm

3 . Prepare all surfaces to be welded.

4. Clean MIG with a disc sander.

BVQBP6066

5. Apply the epoxy primer to interior of the fender apron

inner upper panel.

BVQBP6064

2 . Cut through the fender apron inner upper panel cutline.

BVQBP6065

BVQBP6067

Page 63

BP-20 BODY PANEL REPAIR PROCEDURE

E

INSTALLATION

1. T emporarily Fit and clamp the fender inner upper panel

in place.

2. Measure each measurement point(refer to the BODY

DIMENSIONS) and correct the installation position.

BVQBP6068

3. MIG butt weld all seams.

5 . Clean MIG welds with a disc grinder.

NOT

Be careful not to grid welded portion too much.

The internal parts will be stronger if the weld traces are

not ground.

BVQBP6071

6. Apply the epoxy primer and anti-corrosion to the fender

apron inner upper panel.

BVQBP6069

4. After welding the fender apron inner upper panel,

measure each measurement point(refer to the BODY

DIMENSIONS) and correct the installation position.

7. Prepare the exterior surfaces for priming using wax

and grease remover .

8. Apply metal conditioner and water rinse.

9. Apply conversion coating and water rinse.

10. Apply the two-part epoxy primer.

BVQBP6072

BVQBP6070

Page 64

BODY PANEL REPAIR PROCEDURE BP-21

FRONT SIDE MEMBER

LH

RH

35 mm

260 mm

80 mm

MIG plug welding

MIG butt welding

50 mm

BVQBP6073

Page 65

BP-22 BODY PANEL REPAIR PROCEDURE

E

E

REMOVAL

NOT

This procedure is to be used only for repair of minor damage

to the front side member and when it is impossible to

straighten the damaged side member.

The following procedure illustrates a repair for the front left

side member.

The procedure may also be applied to the front left side

member.

1. Measure and mark the vertical cut lines on front side

member inner tooling hole outer side.

3 . Drill out all the spotwelds to separate fender apron inner

panel from front side member.

NOT

• When spotwelded portions are not apparent,

remove paint with a rotary wire brush.

• In order to perform cutting and separation of

spotwelded points use a spot weld cutter which is

larger than the size of the nugget to make a hole

only in the panels to be replaced.

BVQBP6074

2. Drill out the spotwelds to separate front side member

from engine mounting bracket.(6points)

BVQBP6075

BVQBP6076

BVQBP6077

Page 66

BODY PANEL REPAIR PROCEDURE BP-23

E

3. Cut through the front side member inner and outer at

cutlines.

NOT

Take care not to cut through front side member inner

reinforcement.

BVQBP6078

4. Prepare all surfaces to be welded

INSTALLATION

1. Transcribe the front side member inner and outer cut

line to the new front side member, cut to length and

chamfer butt end to improve weld surface.

2. Drill 8mm holes in new front side member for MIG plug

welding.

BVQBP6080

3. Fit and clamp the front side member inner and outer in

place.

BVQBP6079

4. MIG plug weld all holes and MIG butt weld all seams.

5. Measure each measurement point (Refer to the BODY

DIMENSIONS) and correct the installation position.

BVQBP6081

Page 67

BP-24 BODY PANEL REPAIR PROCEDURE

6 . Clean and prepare all welds, remove all residue.

7. MIG plug weld all holes.

BVQBP6082

8. Clean MIG welds with a disc grinder.

10. Apply the two-part epoxy primer to the interior of the

front side member.

BVQBP6085

11 . Apply an anti-corrosion agent as required

(Refer to the CORROSION PROTECTION).

12. Prepare the exterior surfaces for priming using wax

and grease remover .

13. Apply metal conditioner and water rinse.

BVQBP6083

9. MIG plug weld engine mounting bracket from front side

member.

14. Apply conversion coating and water rinse.

15. Apply the two-part epoxy primer.

16. Apply the correct seam sealer to all joints carefully

(Refer to the BOD Y SEALING LOCATIONS).

17. Reprime over the seam sealer to complete the repair.

BVQBP6084

Page 68

BODY PANEL REPAIR PROCEDURE BP-25

E

FRONT PILLAR

REMOVAL

1. Measure and mark the each cut line on the front outer

pillar at 130mm from the roof panel end line as indicated

in the illustration.

130mm

50mm

50mm

BVQBP6086

2. Measure and mark the cut line on front side sill outer

panel as shown in the illustration.

3. To remove the front pillar, grind away and drill out all

welds and cut all laser welds attaching the cowl side

upper outer panel as shown in the illustration.

NOT

If it is possible that the cowl side upper outer panel is

reusable, be careful not to damage it while removing.

BVQBP6088

4. Drill out all welds attaching the front pillar to cowl cross

member bracket.

100mm

5. Remove spotwelds attaching cowl cross member

bracket to remo ve side inner pillar .

BVQBP6087

BVQBP6089

Page 69

BP-26 BODY PANEL REPAIR PROCEDURE

E

6 . Before cutting front pillar, be sure to support roof panel.

BVQBP6090

7. Cut through the front pillar outer at cutline.

9. Before cutting the front side sill outer panel, make a

rough cut the side sill outer panel only .

NOT

When cutting the front side sill outer panel, be careful

not to cut side outer reinforcement.

BVQBP6093

10. Drill out all the spotwelds to separate side outer panel

from side inner panel (82points).

BVQBP6091

8. Cut the front pillar through each cut line, taking care

not to damage the other panel as illustration.

Roof side outer

reinforcement

Front pillar

outer panel

Front pillar outer lower

Side inner panel

reinforcement

BVQBP6092

BVQBP6094

11. Cut the side outer reinforcement as shown in the

illustration.

BVQBP6095

Page 70

BODY PANEL REPAIR PROCEDURE BP-27

E

12. Cut the side sill inner panel ver tical cutting line and

remove the front pillar .

BVQBP6093

13. Straighten all flanges as necessary , prepare all surfaces

to be welded.

15. Apply the two-part epo xy primer to the interior of the

front side member

BVQBP6099

14. Clean all welds with a disc grinder.

NOT

• Be careful not to grind welded portions too much.

• The internal parts will be stronger if the weld traces

are not ground.

BVQBP6097

BVQBP6098

Page 71

BP-28 BODY PANEL REPAIR PROCEDURE

INSTALLATION

1. Transcribe the cut line to the new side inner panel, cut

to length and chamfer butt end to improve weld surface.

BVQBP6100

2. Transcribe the cut line to the new side outer

reinforcement and new front pillar , adding 30mm overlap

to end and cut to length.

3. Drill 8mm holes along outer panel flanges in production

location for attachment to other panels.

4. Transcribe the cutline to the ne w side inner panel, adding

30mm overlap to end and cut to length.

5. Drill 8mm holes in the side inner panel for MIG plug

welding.

6. Fit and clamp the new side inner panel in place for

welding.

7. MIG plug weld all holes and MIG butt weld the seams.

BVQBP6102

8. T emporarily install front pillar outer panel in place.

BVQBP6101

9. Measure and each measurement point (Refer to the

BODY DIMENSIONS) and correct the installation

position.

10. If necessary , make temporary welds, and then chec k

to confirm that the closing and fit for windshield glass,

door and fender are correct.

BVQBP6103

Page 72

BODY PANEL REPAIR PROCEDURE BP-29

E

11 . MIG butt weld front pillar outer panel and side sill outer

reinforcement seams.

12. Reattach the cut away front pillar outer panel section,

then MIG butt weld.

Front pillar outer

panel section

100mm

BVQBP6104

13. MIG plug weld all holes and MIG butt weld all seams in

the side outer panel.

14. Clean and prepare all welds, remove all residue.

15. Apply body filler to joints and sand as needed.

17 . Clean all welds with a disc grinder.

NOT

• Be careful not to grind welded portions too much.

• The internal parts will be stronger if the weld traces

are not ground.

BVQBP6106

18. Before welding the cowl side upper outer panel, apply

the two-part epoxy primer and anti-corrosion agent to

the interior of the cowl side upper outer panel.

16. Apply the two-part epoxy primer to the interior of the

front pillar.

BVQBP6105

BVQBP6107

Page 73

BP-30 BODY PANEL REPAIR PROCEDURE

19. Install the cowl side upper outer panel in place.

20. MIG plug weld all holes.

21. Clean and prepare all welds, remove all residue.

BVQBP6108

22. Apply an anti-corrosion agent to the welded parts and

inside of front pillar (Refer to the CORROSION

PROTECTION).

27. Apply the correct seam sealer to all joints carefully

(Refer to the BOD Y SEALING LOCATIONS).

28. Reprime over the seam sealer to complete the repair.

BVQBP6110

23. Prepare exterior surfaces for priming, using wax and

grease remover .

24. Apply metal conditioner and water rinse.

25. Apply conversion coating and water rinse.

26. Apply the two-part epoxy primer.

BVQBP6109

Page 74

BODY PANEL REPAIR PROCEDURE BP-31

E

CENTER PILLAR

REMOVAL

1. Measure and mark the horizontal cutting line on center

pillar outer panel as indicated in the illustration.

150mm

50mm

50mm

BVQBP6111

2. Measure and mark the vertical cutline on side sill outer

panel 80mm from the front door step trim mounting

hole.

4 . Drill out all spotwelds and cut all laser welds attaching

the center outer pillar to the body to remove center

outer pillar.

BVQBP6114

5. Cut through center outer pillar and side sill outer panel

at cutlines.

NOT

When cutting side sill outer panel take care not to cut

through mating flanges or side outer reinforcement.

100mm

80mm

BVQBP6112

3. Before cutting center pillar , be sure to support roof panel.

BVQBP6113

BVQBP6115

6. After cutting side outer panel (center pillar outer & side

sill), cut the center pillar outer reinforcement and center

pillar inner panel.

BVQBP6116

Page 75

BP-32 BODY PANEL REPAIR PROCEDURE

E

7 . Remov e the center pillar.

NOT

When cutting center inner pillar, be careful not to cut

front seat belt mounting upper bracket.

Center pillar

Side outer

reinforcement

8. Determine if the side outer reinforcement is damaged

and needs to be replaced. If replacing is necessary,

mark out the damaged portion of the reinforcement.

Cut at cutlines and remove damaged portion.

outer panel

Side inner panel

BVQBP6117

9. Straighten all flanges as necessary .

10. Prepare all surfaces to be welded.

BVQBP6118

Page 76

BODY PANEL REPAIR PROCEDURE BP-33

INSTALLATION

1. In order to install center inner pillar drill out all spotwelds

attaching the roof side outer rail to center inner pillar to

separate them.

BVQBP6119

2. Transcribe the center outer pillar cutlines to the new

center outer pillar, adding 50mm o verlap at center lower

pillar ends.

3. Cut and chamfer butt end to improve weld surface.

6 . Clean MIG welds with a disc grinder.

BVQBP6122

7. Apply the epoxy primer to the side inner reinforcement.

4. Drill 6mm holes in overlap area and along outer panel

flanges.

BVQBP6120

5. MIG butt weld all seams in center inner pillar and sill

side outer reinforcement as shown in the illustration.

BVQBP6123

8. T emporarily install new center outer panel in place .

9. Screw center pillar in place.

10. Measure and each measurement point (Refer to the

BODY DIMENSIONS) and correct the installation

position.