Page 1

96M13270

IntelligentExtensionUnit

SL-R12EX

InstructionManual

NOTICE

Do not attempt to operate or service this machine

until you have read and understand the

instructions written in this manual.

Page 2

Contents

Safety Precautions

1. Safety Headings .........................................................................................................................................iii

2. General Precautions .................................................................................................................................. iii

3. Warning .......................................................................................................................................................iv

4. Circuit Design and Wiring ........................................................................................................................... v

5. Testing and Maintenance ............................................................................................................................ v

6. About Standards and Regulations ........................................................................................................... vi

7. Accessories ................................................................................................................................................vi

1 Specifications

1-1 Part Names .......................................................................................................................................... 1-2

1-2 Specifications ..................................................................................................................................... 1-3

1-3 External Dimensions Diagram .......................................................................................................... 1-5

1-4 Power Supply Precautions ................................................................................................................ 1-6

1-4-1 Power Units that Can Be Used as Power Supplies for SL-C Series and SL-R11/SL-R12EX ..... 1-6

1-4-2 Recommended Dedicated Power Supply Unit ............................................................................ 1-6

2 Functions

2-1 Foreword ............................................................................................................................................. 2-1

2-2 Floating blanking function................................................................................................................. 2-1

2-2-1 Floating blanking for 1 beam axis ............................................................................................... 2-1

2-2-2 Floating blanking for 2 beam axes .............................................................................................. 2-2

2-2-3 Floating blanking for 3 beam axes .............................................................................................. 2-2

2-3 Fixed blanking function ..................................................................................................................... 2-2

2-4 Blanking blind protection function ................................................................................................... 2-3

2-5 Muting function .................................................................................................................................. 2-3

2-5-1 Muting function ........................................................................................................................... 2-3

2-5-2 Two-input muting ......................................................................................................................... 2-8

2-5-3 Four-input muting ........................................................................................................................ 2-9

2-5-4 Two-input programmable muting function ................................................................................. 2-12

2-5-5 Four-input programmable muting function ................................................................................ 2-14

2-6 Use of function combinations ......................................................................................................... 2-17

2-7 Status monitor .................................................................................................................................. 2-18

3 Mounting and Installation

3-1 Installation Location .......................................................................................................................... 3-1

3-2 Installation Using a DIN Rail .............................................................................................................. 3-1

3-3 Wall Mounting Using Screws ............................................................................................................ 3-3

3-4 Connection to the SL-U2 and the SL-R11 Recommended Dedicated Power Supply ................... 3-3

ENGLISH

English

i

Page 3

4 Wiring and setting

4-1 When not using the unit's blanking and muting features............................................................... 4-1

4-1-1 Setting procedure ....................................................................................................................... 4-1

4-2 Floating blanking function................................................................................................................. 4-2

4-2-1 Setting procedure ....................................................................................................................... 4-2

4-3 Fixed blanking function ..................................................................................................................... 4-3

4-3-1 Setting procedure ....................................................................................................................... 4-3

4-4 Blanking blind protection function ................................................................................................... 4-4

4-4-1 Blanking blind protection unit ...................................................................................................... 4-4

4-4-2 Installing the blanking blind protection (BBP) unit and the SL-C Series ..................................... 4-5

4-4-3 Obstacle restrictions .................................................................................................................. 4-7

4-4-4 Connecting the blanking blind protection (BBP) unit and the SLR-12EX.................................... 4-8

4-4-5 Setting procedure ....................................................................................................................... 4-8

4-5 Muting function ................................................................................................................................ 4-10

4-5-1 Muting devices .......................................................................................................................... 4-10

4-5-2 Muting lamps ............................................................................................................................ 4-12

4-5-3 Setting procedure for two-input muting function ....................................................................... 4-15

4-5-4 Setting procedure for four-input muting function ....................................................................... 4-16

4-5-5 Bank switching input devices .................................................................................................... 4-17

4-5-6 Setting procedure for two-input programmable muting function ............................................... 4-18

4-5-7 Setting procedure for four-input programmable muting bank function ...................................... 4-19

4-6 Combinations of functions .............................................................................................................. 4-21

4-6-1 Combination between the Floating blanking function and the Fixed blanking function ............ 4-21

4-6-2

Combination between the Floating blanking function and the Blanking blind protection function ...

4-6-3 Combination between the Floating blanking function and the Muting function ......................... 4-22

4-6-4 Combination between the Fixed blanking function and the Muting function ............................. 4-22

4-6-5 Combination between the Fixed blanking function and the Programmable muting function .... 4-22

4-6-6 Combination between the Blanking blind protection function and the Muting function ............. 4-23

4-6-7

Combination between the Blanking blind protection function and the Programmable muting function ...

4-6-8

Combination between the Floating blanking function, the Fixed blanking function, and the Muting function ...

4-6-9

Combining the Floating blanking function, the Blanking blind protection function, and the Muting function ...

4-7 Status monitor .................................................................................................................................. 4-25

4-7-1 The UNIT indicator .................................................................................................................... 4-25

4-7-2 The BEAM indicator .................................................................................................................. 4-26

4-7-3 Other indicators ........................................................................................................................ 4-27

4-8 Status Display (SL-R12D) ................................................................................................................ 4-28

4-8-1 Indicators on SL-R12D ............................................................................................................. 4-28

4-8-2 Installing the SL-R12D onto a panel ......................................................................................... 4-29

4-8-3 Connection method ................................................................................................................... 4-30

4-21

4-23

4-24

4-24

5 Checklist

5-1 List of Pre-use check Items ............................................................................................................... 5-1

5-1-1 Checking the SL-R12EX installation conditions .......................................................................... 5-1

5-1-2 Checking wiring .......................................................................................................................... 5-1

5-2 List of maintenance check items ...................................................................................................... 5-2

6 Troubleshooting

Troubleshooting .................................................................................................................................... 6-1

7 Revision History

Revision History .................................................................................................................................. 7-1

96M13270

ENGLISH

ii

Page 4

Safety Precautions

This manual describes handling, operation, and precautionary information for the Intelligent Extension Unit

(SL-R12EX). Read this manual thoroughly before operating the SL-R12EX in order to understand device

features, and keep this instruction manual readily available for reference.

1. Safety Headings

This instruction manual uses the following headings to display important safety information. Strict adherence

to the instructions next to these headings is required at all times.

DANGER

WARNING

CAUTION

Important:

Note:

Tips

➮

Reference:

WARNING

Failure to follow the instructions may lead to death or serious injury.

Failure to follow the instructions may result in significant harm to machine operators, including death.

Failure to follow the instructions may result in failure to the SL-R12EX, or to the

machine to which it is installed.

Provides important precautions and restrictions for proper operation.

Provides additional information for proper operation.

Provides useful information for proper operation.

Provides reference pages.

The SL-R12EX is a special controller unit for the Safety Light Curtain SL-C Series

and the Intelligent Safety Relay Unit SL-R11.

Therefore, be sure to refer to and strictly observe the precautions and warnings

written in the SL-C Series and/or SL-R11 Instruction Manual.

2. General Precautions

ENGLISH

English

•Verify that this device is operating normally in terms of functionality and performance before the start of

work and before the start of device operation.

• KEYENCE is unable to warrant the function or performance of the SL-R12EX if it is used in a manner that

differs from the SL-R12EX specifications contained in this instruction manual or if the SL-R12EX is modified.

• When using the SL-R12EX to protect machine operators from a hazardous zone or a hazard, or using it

as safety equipment for any purpose, always follow the applicable requirements, regulations, and laws

(collectively “regulations”) existing in the country or region where the SL-R12EX is being used. For such

regulations, contact directly the regulatory agency responsible for occupational safety and health in your

country or region.

• Depending on the type of machine to which the SL-R12EX is to be attached, there may be special safety

regulations related to the use, installation, maintenance, and operation of the device, and such safety

regulations must be followed. The responsible personnel must install the SL-R12EX in strict compliance

with such safety regulations.

• The responsible personnel must train the assigned personnel for the correct use, installation, maintenance, and operation of the SL-R12EX. “Machine operators” refers to personnel who have received

appropriate training from the responsible personnel and are qualified to operate the device correctly.

• Machine operators must receive specialized training for the SL-R12EX and must understand and follow

the safety regulations for the country or region in which they are using the SL-R12EX.

• When the SL-R12EX fails to operate properly, machine operators must immediately stop the use of the

device and report this fact to the responsible personnel.

• The SL-R12EX is designed with the assumption that it would be properly installed in accordance with the

installation procedures described in this instruction manual and operated according to the instructions in

this instruction manual. Perform an appropriate installation of the SL-R12EX after conducting a sufficient

risk assessment for the target machine.

• This device should be processed as an industrial waste product when being disposed.

iii

Page 5

3. Warning

■ Operators

• In order for the SL-R12EX to operate properly, the responsible personnel and machine operators must

follow all procedures described in this instruction manual.

• No person other than the responsible personnel and machine operators should be allowed to install or

test the SL-R12EX.

• When performing electrical wiring, always follow electrical standards and regulations for the country or

region in which the SL-R12EX is being used.

■ Usage environment

• Do not use the device in an environment (temperature, humidity, interfering light, etc.) that does not

conform to the specifications contained in this instruction manual.

• Do not use wireless devices such as cellular phones or transceivers in the vicinity of the SL-R12EX.

• The SL-R12EX is not designed to be explosion-proof. Never use it in the presence of flammable or

explosive gases or elements.

• Do not use the SL-R12EX in the presence of substances, such as heavy smoke, particulate matter, or

corrosive chemical agents, that may induce deterioration in product quality.

■ Target machine

• The SL-R12EX has not undergone the model certification examination in accordance with Article 44-2

of the Japanese Industrial Safety and Health Law. The SL-R12EX, therefore, cannot be used in Japan

as a “Safety Device for Press and Shearing machines” as established in Article 42 of that law.

• The machine on which the SL-R12EX is to be installed must be susceptible to an emergency stop at all

operating points during its operation cycle. Do not use the SL-R12EX for machines with irregular stop

times.

• Do not use the SL-R12EX for power presses equipped with full-revolution clutches.

• Do not use the SL-R12EX to control (stop forward motion, etc.) trains, cars and other transportation

vehicles, aircraft, equipment for use in space, medical devices, or nuclear power generation systems.

• The SL-R11 is designed to protect people or objects from entering a machine’s hazardous zone or

hazard. It cannot provide protection against objects or materials that are displaced from the machine's

hazardous zone or hazard, and so implement additional safety measures such as installing safeguards

when there is the possibility of such displacements.

■ Installation

• Install the SL-R12EX inside an enclosure such as a control panel that offers a rating of at least IP54 in

accordance with the IEC 60529 standard.

• The SL-R12EX is a special controller unit for the Safety Light Curtain SL-C Series and the Intelligent

Safety Relay Unit SL-R11, so be sure to connect it to the SL-C Series and SL-R11 when using it.

• The SL-C**L Series with the detection capability of ø45 mm (1.77") cannot be used in combination with

the SL-R12EX.

■ Function

• When floating blanking function is carried out, the SL-C series cannot keep the original detection

capability. The detection capability of the SL-C**F Series varies among ø14 mm (0.55"), ø24 mm

(0.94"), ø34 mm (1.33"), and ø44 mm (1.73") according to the exact settings used. The detection

capability of the SL-C**H Series varies among ø25 mm (0.98"), ø45 mm (1.77"), ø65 mm (2.56"), and

ø85 mm (3.35") according to the exact settings used. Therefore you must accurately calculate the new

safety distance and install the SL-C Series at the minimum safety distance separately from the

hazardous zone or hazards.

• When fixed blanking function is carried out, it may create a hazardous zone allowing human approach

between the obstacle and the SL-C Series against which the SL-C Series provides no protection. Be

sure to install additional safety protective equipment.

• Enabling the blanking blind protection function does not necessarily remove all hazardous zones

allowing human approach. Depending on the target machine, installation of the blanking blind protection

unit may result in the creation of one or more hazardous zones allowing human approach. Be sure to

read “4-4 Blanking blind protection function” (➮4-4) in this manual before installing or using this unit.

This function can only be used in the SL-C**H Series with the detection capability of ø25 mm (0.98").

• The muting function deactivates the light curtain's safety functions while the light curtain detects the

input signal from one or more muting devices (sensors, switches, etc.). The muting devices (sensors,

switches, etc.) that are used to carry out the muting function as well as the method to install them must

satisfy all the conditions described in this instruction manual as well as the applicable requirements

imposed by all laws, regulations, standards, and ordinances in effect in the country and region where

the SL-R12EX is to be used. Failure to follow this warning results in significant harm to machine operators, including serious injury or death.

ENGLISH

iv

Page 6

• The following conditions must be considered before installing muting devices (sensors, switches, etc.) to

carry out the muting function.

1. The muting function of the light curtain is only permitted during the nonhazardous portion of the

machine cycle.

2. Muting devices must not get active and the light curtain (SL-C Series) must not go to the muting state

even if a person inadvertently approaches the light curtain's detection zone.

• Setting the muting function and muting device configuration must be restricted to an extremely limited

number of the responsible personnel.

• Any personnel other than the responsible personnel must not easily change the position at which the

muting devices are installed. When the muting devices are moved, the procedure must require the

use of specialized tools and must be performed under the responsibility of the responsible personnel.

• Customers who carry out the muting function bear sole responsibility for complying with the requirements imposed on that function. KEYENCE makes no guarantee regarding damage arising from installation, orientation, usage, or maintenance not in accordance with what is described in this instruction

manual, or from the failure to follow all applicable legal regulations in effect in the country and region in

which the SL-R12EX is used.

• The muting lamp or the SL-R12D must be installed prior to carrying out the muting function on the SL-C

Series. The muting lamp or the SL-R12D must be installed at the location where it can always be clearly

and easily visible for the machine operators or the responsible personnel in case of normal machine

operation, setting or alignment for muting or maintenance, etc.

• If it is necessary to install 2 or more muting lamps in order to satisfy the above requirements, the muting

lamps must be installed so that they are connected in series to the LAMP terminal on the SL-R12EX

terminal block. The SL-R12D cannot be used with the other muting lamps simultaneously. Therefore,

the other muting lamps must be installed instead of using the SL-R12D.

ENGLISH

English

4. Circuit Design and Wiring

• Always turn off the device power when performing electrical wiring.

• Follow electrical standards and regulations for the country or region in which the SL-R12EX is being used

when performing the electrical wiring. Only qualified persons should perform wiring.

• Do not place any cables or electrical lines used in wiring the SL-R12EX in the same duct as high-voltage

electrical or power lines or in parallel with such lines.

• The length of the cables from the blanking blind protection unit (SL-C08SB/SL-C16SB) transmitter and

receiver to the SL-R12EX must not exceed 30 m (98.43 ft.).

5. Testing and Maintenance

• Always perform testing in accordance with the test procedures after maintenance, adjustment, or calibration of the target machine or the SL-R12EX, and before the machine start-up.

• If the SL-C, SL-R11 or SL-R12EX does not operate properly when tested in accordance with the test

procedures established in this instruction manual, do not operate the machine.

• Periodically examine the machine to verify that all brakes, other stop mechanisms, and control devices

operate reliably and accurately in addition to checking for SL-C, SL-R11 and SL-R12EX.

• The responsible personnel must perform maintenance procedures as established in this instruction

manual at least once every six months to ensure safe device operation.

v

Page 7

6. About Standards and Regulations

1) The SL-C Series and SL-R11/SL-R12EX comply with the following UL (Underwriters Laboratories

Inc.) Standards and have received Canada-U.S.-Listing certification from UL.

• UL61496-1 (Type 4 ESPE - Electro-Sensitive Protective Equipment)

• UL61496-2 (Type 4 AOPD - Active Opto-Electronic Protective Device)

2) The SL-C Series and SL-R11/SL-R12EX have not received the model certification examination in

accordance with Article 44-2 of the Japanese Industrial Safety and Health Law. As a result, the SLC Series and SL-R11/SL-R12EX cannot be used in Japan as a “Safety Devices for Presses and

Shearing machines” as established in Article 42 of that law.

3) The SL-C Series and SL-R11/SL-R12EX have been designed in consideration of the following

standards and regulations. For details regarding the following standards, contact the third-party

certification organization, such as UL.

<Corresponding standards>

• OSHA 29 CFR 1910.212

• OSHA 29 CFR 1910.217

• ANSI B11.1 - B.11.19

• “Guidelines for Comprehensive Safety Standards of Machinery”, July 31, 2007, number 0731001 issued

by, Ministry of Health, Labor, and Welfare in Japan.

7. Accessories

Confirm that the package includes the main unit (SL-R12EX) and following accessories.

Instruction Manual (this manual) 1 copy

ENGLISH

vi

Page 8

ENGLISH

English

vii

Page 9

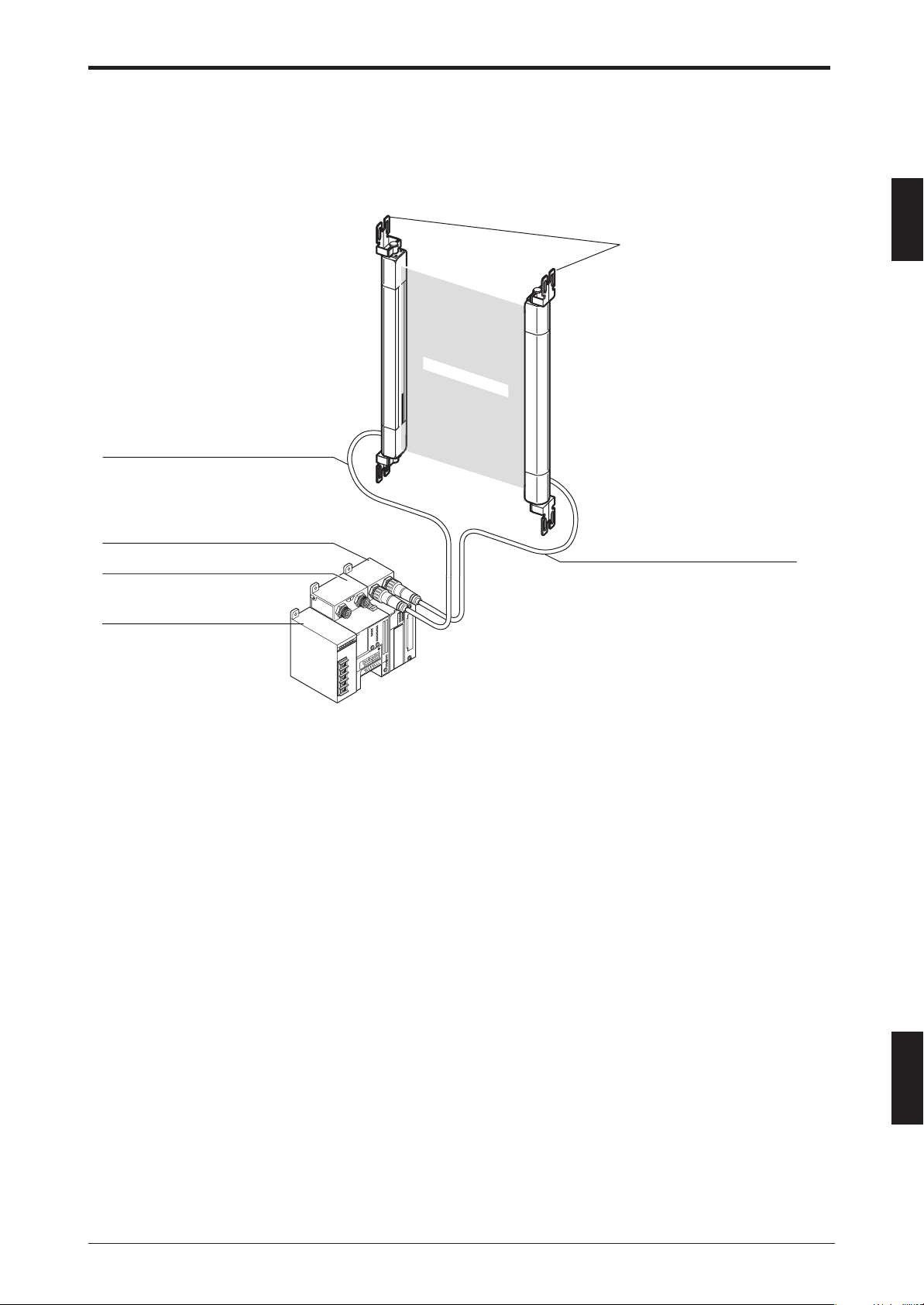

Chapter 1 Specifications

1 Specifications

Composition

SL-C Series+ SL-R11 (Intelligent Safety Relay Unit) + SL-R12EX (Intelligent Extension Unit) + SL-U2

(Dedicated power supply unit)

SL-PC5P (5m (16.4 ft.)) cable for transmitter (gray)

* 10 m (32.81 ft.) SL-PC10P cable

SL-R11 intelligent safety relay unit

SL-R12EX intelligent extension unit

SL-U2 dedicated power supply unit

SL-C Series

1

Detection zone

SL-PC5P (5m (16.4 ft.)) cable for receiver (black)

* 10 m (32.81 ft.) SL-PC10P cable

T R

SL-U2: The UL certified, recommended dedicated power supply unit

* The SL-C**L Series with the detection capability of ø45 mm (1.77") cannot be used in combination with

the SL-R12EX.

ENGLISH

1-1

Page 10

1

Chapter 1 Specifications

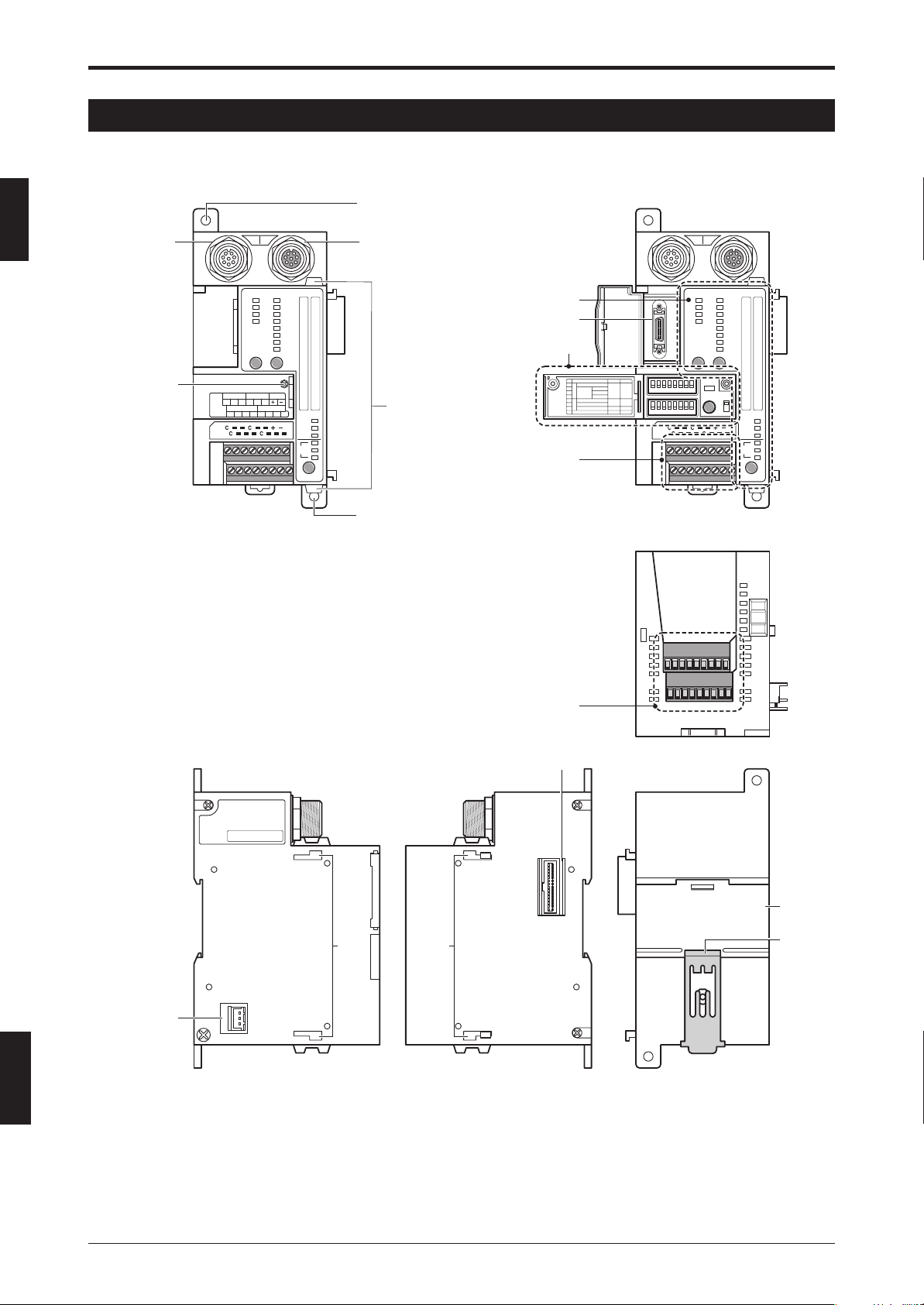

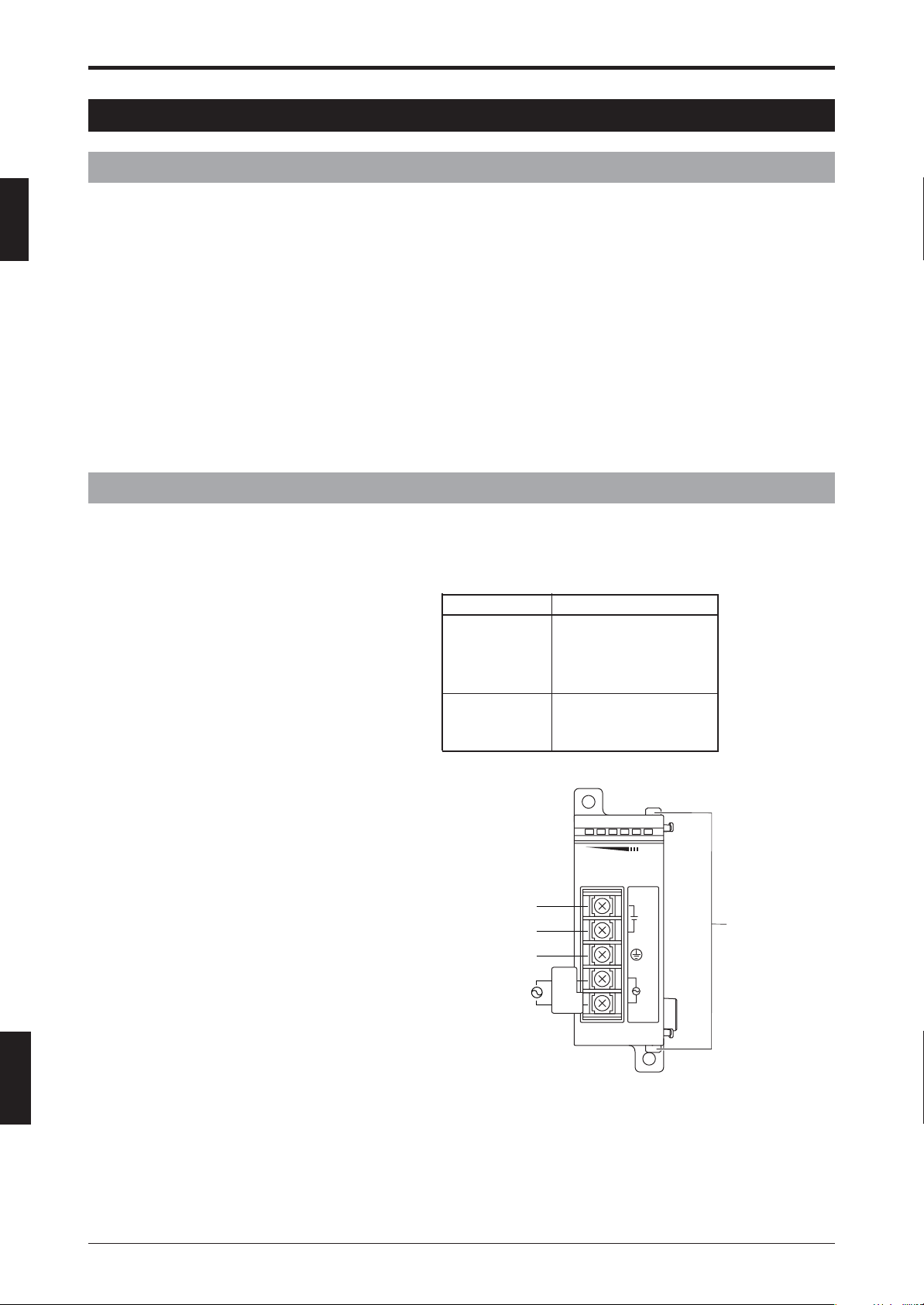

1-1 Part Names

This chapter gives the names of the SL-R12EX parts.

Front view

Hole for mounting screw

(for M4)

12345678

MUTE A

C A1 A2

PMB A

12345678

C A1 A2 A3

T R

UNIT BEAM

4

3

2

1

TEACHING

MUTE B

SET/TEACH

C B1 B2

PMB B

C B1 B2 B3

Blanking blind protection

unit connector (receiver)

CLEAR/

MODE

BLOCKED

STATUS

113-128

16

16

97-112

15

15

81-96

14

14

65-80

13

13

49-64

12

12

33-48

11

11

17-32

10

10

1-16

9

9

8

8

7

7

6

6

5

5

4

4

3

3

LAMP

2

2

PROG.

1

1

RUN

BLANKING

FIXED

FLOATING

B.B.P

1

P.M.

2

BANK

3

Connection hooks

Blanking blind

protection unit

connector

(transmitter)

Function switch

cover screw

Status monitor

SL-R12D status

display connector

Function switches

Input terminal

No. FUNTION UP DOWN

1

Fixed

1beam

2

Enable Disable

2beams

Floating

3

3beams

4

Mute

5

Enable Disable

Programmable

6

Mute Blanking

Inputs

4in 2in

7

MODE SWITCH

Blanking Blind Protect

8

W W/O

Front view

12345678

12345678

T R

UNIT BEAM

4

3

2

1

TEACHING

SET/TEACH

PROG.

RUN

113-128

97-112

81-96

65-80

49-64

33-48

17-32

1-16

CLEAR/

BLOCKED

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

BLANKING

FIXED

FLOATING

B.B.P

P.M.

BANK

MODE

STATUS

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

KEYENCE CORPORATION

SL-R12EX

For use with SL-R11 only.

RATED CURRENT 110 mA

TYPE OF ESPE TYPE 4

MADE IN JAPAN

No.

Hole for mounting screw

(for M4)

Side

SL-U2

mounting

holes

SL-R11

mounting

holes

Input terminal

SL-R11 connector

Bottom

Rear

DIN rail

mating area

Din rail

lock pin

ENGLISH

English

SL-U2 connector

*Covered by tape at

time of shipment.

1-2

Page 11

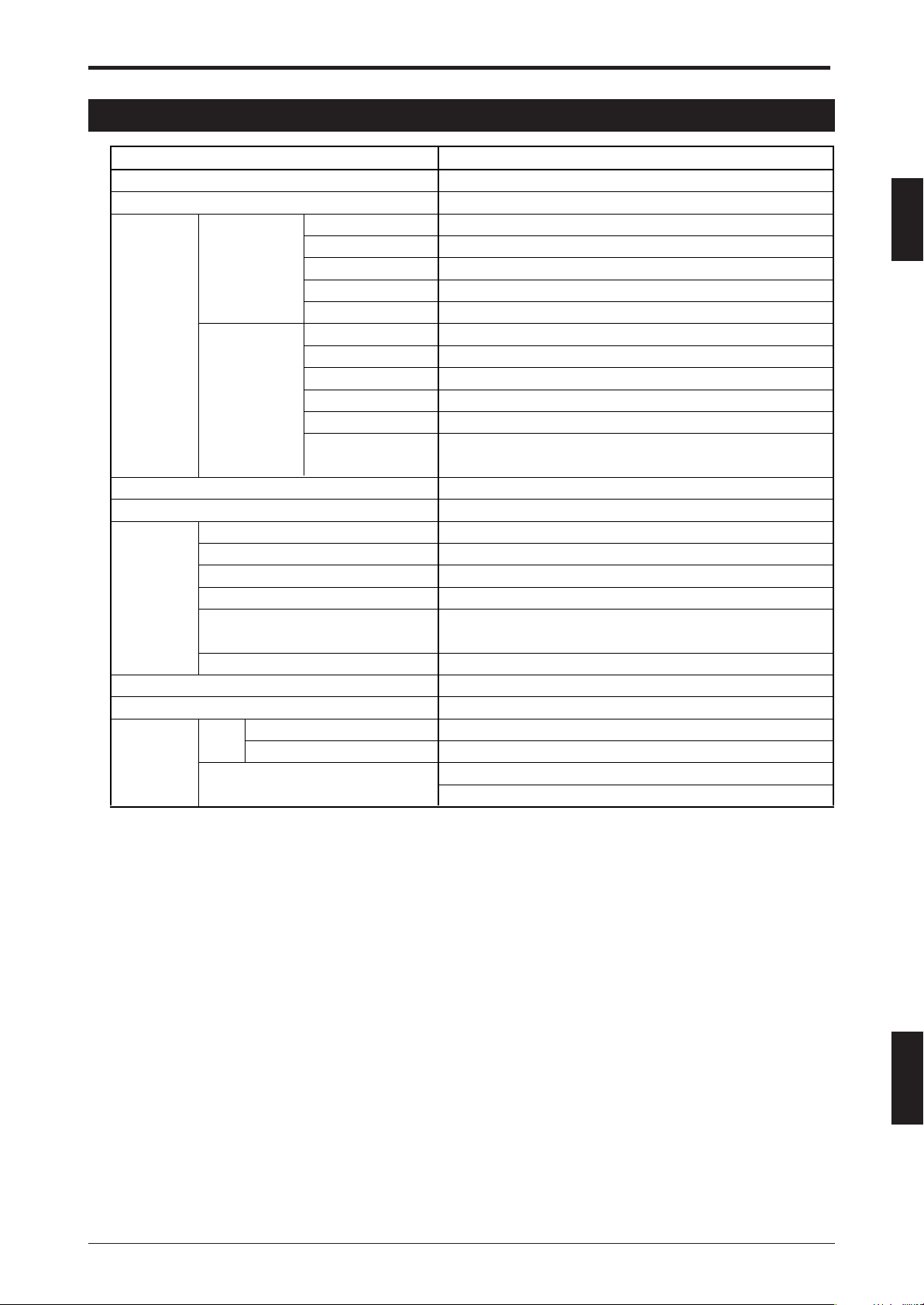

1-2 Specifications

Chapter 1 Specifications

Model

Power supply

Current consumption

Muting

device inputs

Inputs

Bank

switching

inputs

Muting lamp output

Protective structure

Ambient temperature

Storage ambient temperature

Environmental

specifications

Material

Weight

Approved

standards

Relative humidity

Storage ambient humidity

Vibration

Shock

EMC

Safety

EMS

EMI

Max. input voltage

Input rating

Min. ON voltage

Min. OFF current

Common wiring

Max. input voltage

Input rating

Min. ON voltage

Min. OFF current

Common wiring

Permissible timing

lag between 2 inputs

SL-R12EX

Supplied from SL-U2

Max. 110 mA (24 V DC, including SL-R12D)

26.4 V DC

24 V DC, 2.3 mA

19 V

0.5 mA

A1 and A2 are common; B1 and B2 are common.

26.4 V DC

24 V DC, 1.6 mA

19 V

0.5 mA

A1, A2, and A3 are common; B1, B2, and B3 are common.

Max. 200 ms

24 V DC, 15 to 300 mA

IP20 (IEC60529) Must be installed inside a control panel with at least an IP54 rating.

-10 to +55 °C (No frost)

-10 to +60 °C (No frost)

35 to 85% RH (No condensation)

35 to 95% RH

10 to 55 Hz, 0.7 mm (0.03") compound amplitude, 20 sweeps

each in X, Y, and Z directions

100 m/s2 (Approx. 10G) 16 ms pulse, in X, Y, Z directions 1,000 times each axis

Polycarbonate

Approx. 300 g

UL61496-1

FCC Part15B Class A

UL61496-1 (type 4 ESPE)

UL508

1

1-3

ENGLISH

Page 12

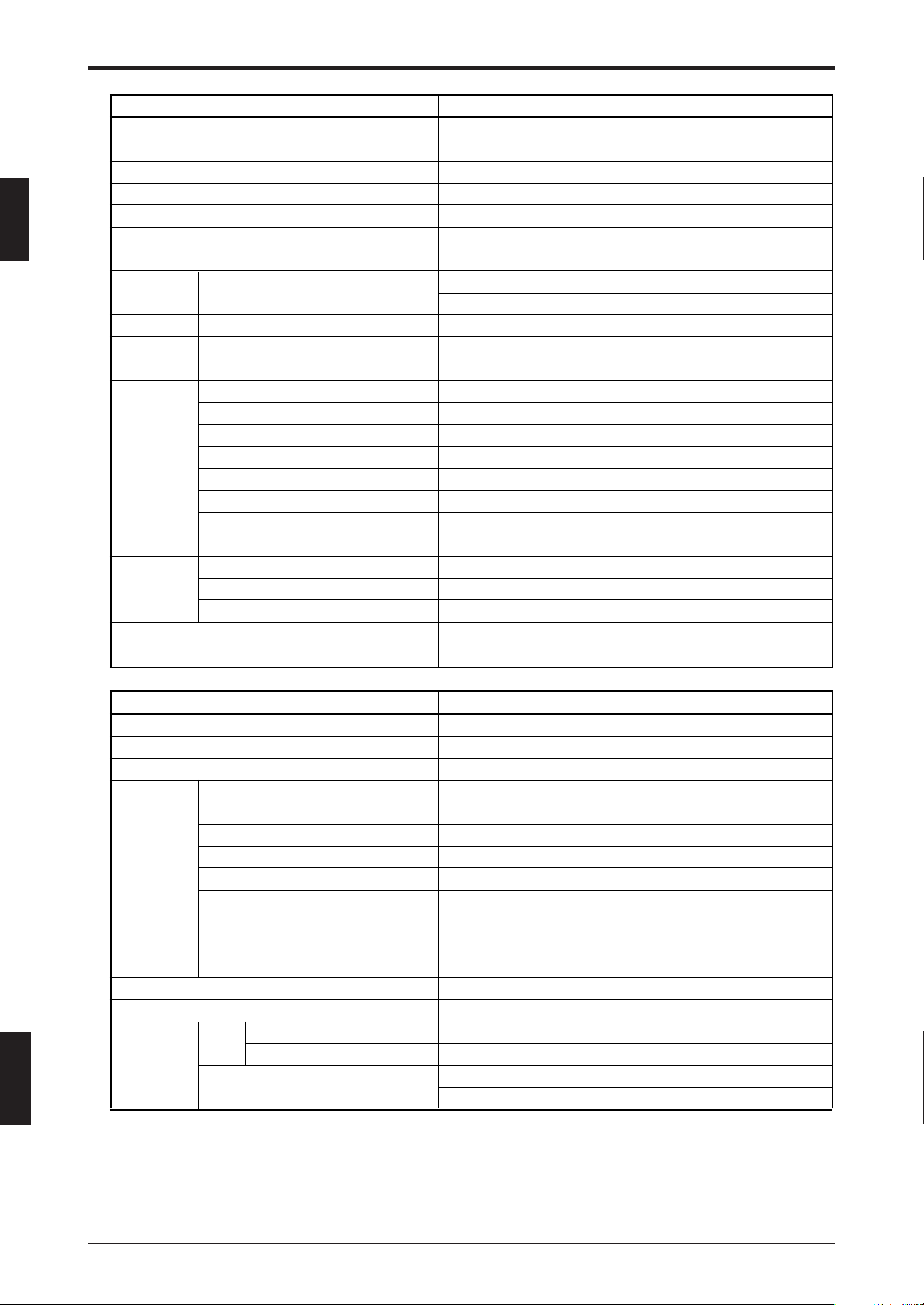

Chapter 1 Specifications

1

Model

Detection zone

Beam axis interval

Operating distance

Detection capability

Effective Aperture Angle

Response time

Power supply

Current consumption

Light source

Operation form

Protective structure

Ambient temperature

Storage ambient temperature

Environmental

specifications

Material

Weight

Relative humidity

Storage ambient humidity

Ambient light

Vibration

Shock

Main unit case

Upper case/Lower case

Overlay

SL-C08SB, SL-C16SB

Depends on sensors used.

Beam axis interval: 20 mm (0.79"), Lens diameter: 5.0 mm (0.2")

0.3 to 9 m (0.98 to 29.53 ft.) *Limited by operating distance of sensors used.

ø 25mm (0.98")

Max. ±2.5° (When operating distance is at least 3 m (9.84 ft.))

24 ms (including sensor and SL-R11 response speed)

Supplied from SL-R12EX

Transmitter: Max. 50 mA (24 V DC)

Receiver: Max. 50 mA (24 V DC)

Infrared LED (850 nm)

Turns on when light is received from all light beams (except when

the blanking function is used)

IP65 (IEC60529)

-10 to +55 °C (No frost)

-10 to +60 °C (No frost)

35 to 85% RH (No condensation)

35 to 95% RH

White incandescent lamp: 5,000rx or less Sunlight: 20,000rx or less

10 to 55 Hz, 0.7 mm (0.03") compound amplitude, 20 sweeps each in X, Y, and Z directions

100 m/s2 (Approx. 10G) 16ms pulse, in X, Y, Z directions 1,000 times each axis

Aluminum

Zinc die-cast

Polycarbonate

SL-C08SB: Transmitter approx. 165 g, Receiver approx. 180 g

SL-C16SB: Transmitter approx. 255 g, Receiver approx. 280 g

ENGLISH

English

Model

Power supply

MUTE lamp brightness Min.

Area

Protective structure

Ambient temperature

Environmental

specifications

Material

Weight

Approved

standards

Storage ambient temperature

Relative humidity

Storage ambient humidity

Vibration

Shock

EMC

Safety

EMS

EMI

SL-R12D

Supplied from SL-R12EX

Min. 200 cd/m

2

3 cm

IP65 (IEC60529) Applies to display only when mounted so device

is embedded in a panel.

-10 to +55 °C (No frost)

-10 to +60 °C (No frost)

35 to 85% RH (No condensation)

35 to 95% RH

10 to 55 Hz, 0.7 mm (0.03") compound amplitude, 20 sweeps

each in X, Y, and Z directions

100 m/s2 (Approx. 10G) 16ms pulse, in X, Y, Z directions 1,000 times each axis

Polycarbonate

Approx. 60 g (excluding cables)

UL61496-1

FCC Part15B Class A

UL61496-1

UL508

2

1-4

Page 13

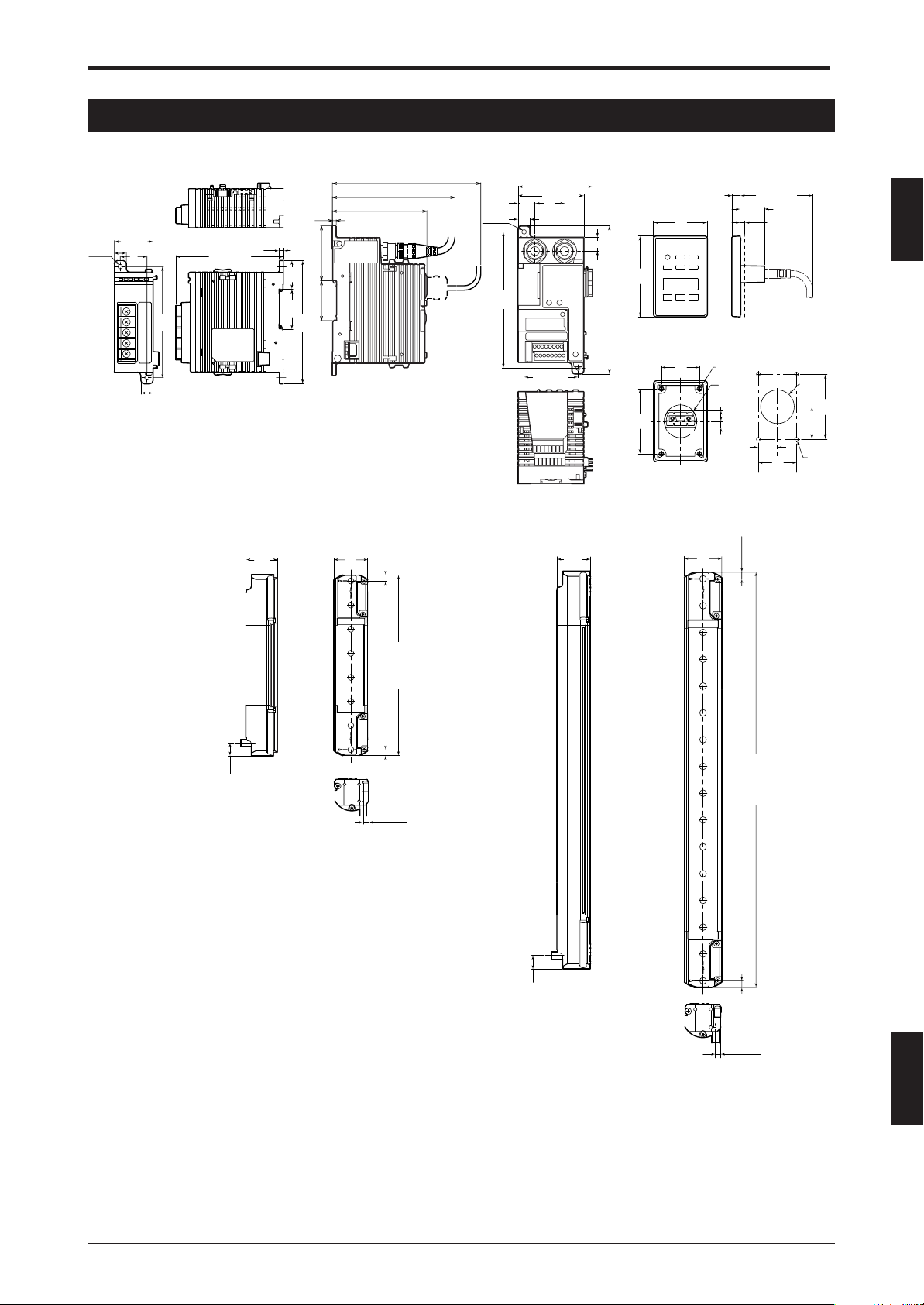

1-3 External Dimensions Diagram

Chapter 1 Specifications

SL-U2

11 (0.43")

2-ø4.2

35 (1.38")

24

(0.94")

(0.43")

11

100

(3.94")

(96.6 (3.8"))

SL-C08SB

(0.14")

26.4

(1.04")

SL-R12EX

3.5

3.5

25.8

(1.02")

35.9 49.8

35.9

(1.41")

111

(4.37")

85.5

(112)

(135)

2-ø4.2

(4.88")

124

15.4

(0.61")

68 (2.68")

60 (2.36")

27

(1.06")

11 (0.43")

49 (1.93")

12.5 (0.49")

135

(5.31")

SL-R12D

72

(2.83")

Bottom

58

(2.28")

48

(1.89")

34

(1.34")

(0.3")

(65 (2.56"))

7.5

21.7

(0.85")

Panel cut dimensions

4-M3

depth 5

ø29.2

(1.15")

9.6 (0.38")

5.6 (0.22")

17

(0.67)

(1.34")

Panel

thickness

1 to 5 mm

(0.04 to 0.2")

34

ø30

(1.18")

29

(1.14")

4-ø3.4

+1

0

58

(2.28")

1

SL-C16SB

28

(1.1")

5.5 (0.22")5.5 (0.22")

26.4

(1.04")

28

(1.1")

5.5 (0.22")5.5 (0.22")

10.8 (0.43")

151 (5.94")

311 (1.02 ft.)

4.5 (0.81")

10.8 (0.43")

ENGLISH

4.5 (0.18")

1-5

Page 14

Chapter 1 Specifications

1-4 Power Supply Precautions

1

1-4-1

The power supply units that can be used as the power supply for SL-C Series, SL-R11 and SL-R12EX must

completely satisfy the following requirements in order to satisfy the requirements of UL61496-1 for the SL-C

Series, SL-R11, and SL-R12EX.

(a) Rated output voltage is 24V DC ±10%.

(b) The power supply to be used shall be a dedicated power supply for the SL-C Series, SL-R11 and/or SL-

(c) The power supply output must satisfy the requirements for a Class 2 Circuit or Limited Voltage/Current

(d) The power supply must comply with the laws, regulations, and standards covering electrical safety,

(e) The output hold time is 20 ms min.

Power Units that Can Be Used as Power Supplies for SL-C Series and SL-R11/SL-R12EX

R12EX and shall not be used to supply power to other devices.

Circuit as prescribed by UL508. (This requirement applies only when the SL-C Series, SL-R11 and/or SLR12EX is to be used in North America.)

electromagnetic compatibility (EMC), etc., for the country or region in which the SL-C Series, SL-R11 and/

or SL-R12EX will be used.

1-4-2 Recommended Dedicated Power Supply Unit

The SL-U2 is offered as the SL-C Series, SL-R11 and SL-R12EX dedicated power supply. The SL-U2 is a

power supply that completely satisfies the above requirements.

<Approved standards>

Standard No.

EN60950

Safety EN50178

standard UL60950 (R/C)

UL508 (Listing)

EN55011 Class A

EMC standard EN61000-6-2

FCC Part 15B Class A

ENGLISH

English

SL-U2

SL-U2

OC

+

24V DC

PE (GND)*

240 V AC

(*) The PE terminal is a protective conductor terminal that must be connected to a protective earthing

conductor in the building.

100 to

–

100-240V AC

CAUTION

ONLY

+

Connection hooks

-

L

N

1-6

Page 15

<Specification>

Chapter 1 Specifications

Model

System

Input power supply voltage

Overvoltage category

Output voltage

Ripple/noise

Output capacity

Environment

Pollution degree

Withstand voltage

Vibration resistance

Shock resistance

Insulation resistance

Power consumption 135VA

Supply voltage interruption 10 ms or less

Weight (excluding dedicated brackets)

WARNING

Ambient temperature

Relative humidity

For the power supply used for the SL-C Series, SL-R11 and SL-R12EX, always

use a power supply that can fully satisfy the above requirements or use recommended SL-U2 power supply. Otherwise, the UL61496-1 requirements may not be

satisfied and the SL-C Series, SL-R11 and SL-R12EX may not be recognized as a

safety component.

Switching type

100 V AC to 240 V AC ±10 % (50/60 Hz)

2

24 V DC ±10 %, Class 2

240 mVp-p or less

1.8 A

-10 °C to +55 °C (non-freezing)

35 % to 85 % RH (non-condensing)

2

1,500 V AC, 1 min. (between all external terminals and case)

10 to 55 Hz, 0.7 mm (0.03") compound amplitude, 20 sweeps each in X, Y, and Z directions

100 m/s2, 1,000 iterations each in X, Y, and Z directions

At least 50 MW (500 V DC mega, between all external terminals and case)

Approx. 240 g

SL-U2

1

1-7

ENGLISH

Page 16

1

Chapter 1 Specifications

MEMO

ENGLISH

English

1-8

Page 17

Chapter 2 Functions

2 Functions

2-1 Foreword

This section describes the functions that are provided by the SL-R12EX. These functions allow you to

configure various settings related to the detection performance of the SL-R11 and SL-C Series devices that

are connected to the SL-R12EX and can be set for individual SL-C Series beam axes. For this reason,

references throughout this text to “detection capability” and “beam axes” should be understood to refer to the

detection capability and beam axes of the SL-C Series.

2-2 Floating blanking function

When this function is carried out, the SL-C series cannot keep the original

WARNING

detection capability. The detection capability of the SL-C**F Series varies among

ø14 mm (0.55"), ø24 mm (0.94"), ø34 mm (1.33"), and ø44 mm (1.73") according

to the exact settings used. The detection capability of the SL-C**H Series varies

among ø25 mm (0.98"), ø45 mm (1.77"), ø65 mm (2.56"), and ø85 mm (3.35")

according to the exact settings used. Therefore you must accurately calculate the

new safety distance and install the SLC Series at the minimum safety distance

separately from the hazardous zone or hazards. When installing the SL-C Series

onto/into a machine, always follow the instructions in the SL-C Series Instruction

Manual. Failure to follow this warning may result in significant harm to machine

operators, including serious injury or death.

2

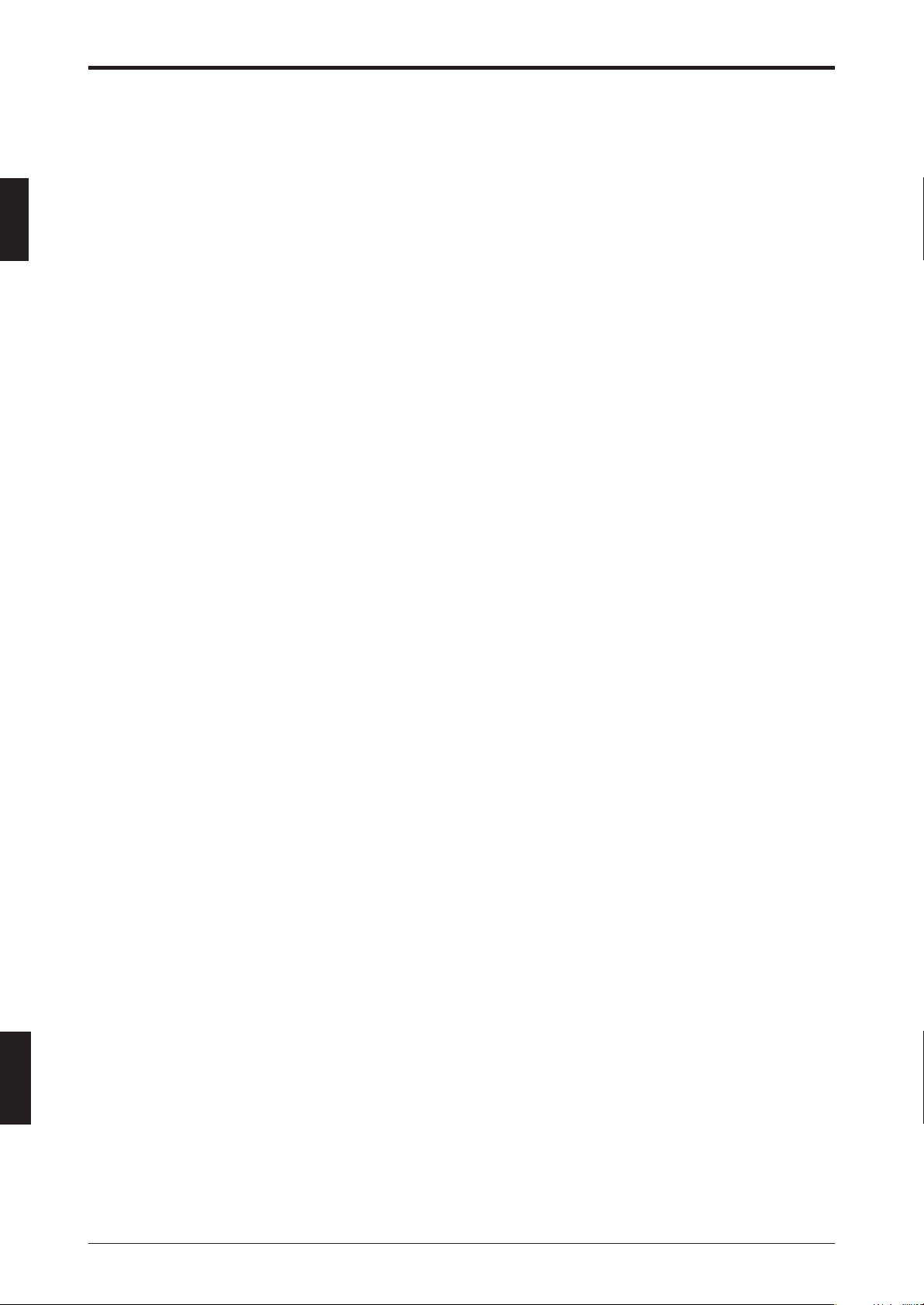

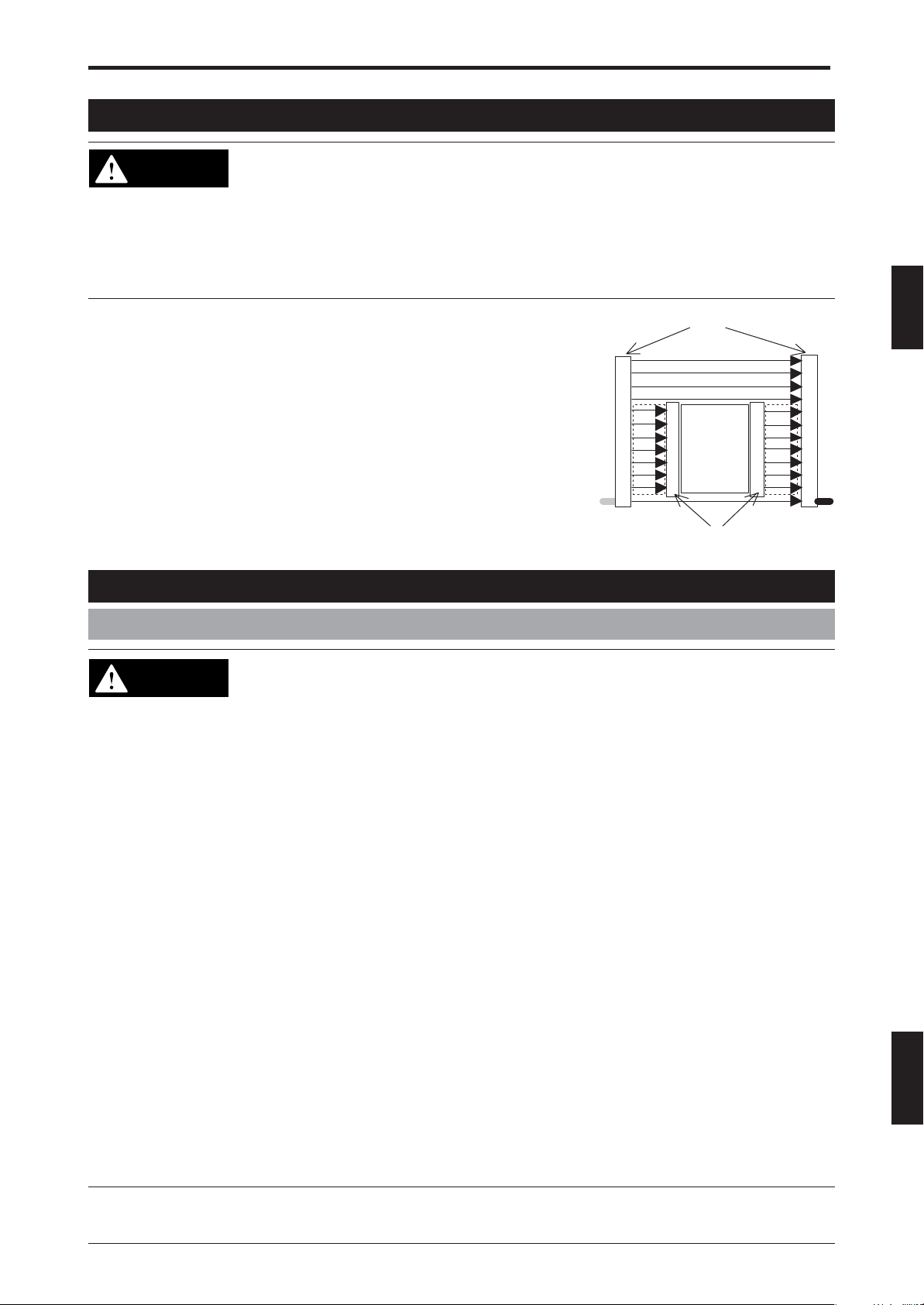

Normally, the FSD turns OFF-state when an obstacle blocks even a

single SL-C Series beam axis. When this function is enabled, the FSD

keeps ON-state in the event that only a preset number (between 1 and

3) of beam axes are blocked. Only when the number of beam axes

blocked by the objects exceeds that preset number, the FSD turns

OFF-state.

In order to carry out this function, the SL-C Series need not be a single

transmitter/receiver pair. This function can be set for all beam axes on

all SL-C Series units connected in series. (See the right diagram.)

See “4-2 Floating blanking function” (➮4-2) for more information about

how to set or configure this function.

This function can be configured in one of three ways, as indicated

below.

<Example configuration>

: Zone where floating blanking

function is active

Connected

in series

2-2-1 Floating blanking for 1 beam axis

The FSD keeps ON-state when only 1 beam axis is blocked, and turns OFF-state when 2 or more beam

axes are blocked. Note that for the SL-C**F Series the detection capability is ø24 mm (0.94"), and for the SLC**H Series the detection capability is ø45 mm (1.77").

ENGLISH

●: Object blocking beam axis

FSD keeps ON-state

●: Object blocking beam axis

FSD is OFF-state

●: Object blocking beam axis

FSD is OFF-state

2-1

Page 18

2

Chapter 2 Functions

2-2-2 Floating blanking for 2 beam axes

The FSD keeps ON-state when 1 or 2 beam axes are blocked, and turns OFF-state when 3 or more beam

axes are blocked. Note that for the SL-C**F Series the detection capability is ø34 mm (1.33"), and for the SLC**H Series the detection capability is ø65 mm (2.56").

2-2-3 Floating blanking for 3 beam axes

The FSD keeps ON-state when 1, 2, or 3 beam axes are blocked, and turns OFF-state when 4 or more

beam axes are blocked. Note that for the SL-C**F Series the detection capability is ø44 mm (1.73"), and for

the SL-C**H Series the detection capability is ø85 mm (3.35").

2-3 Fixed blanking function

ENGLISH

English

WARNING

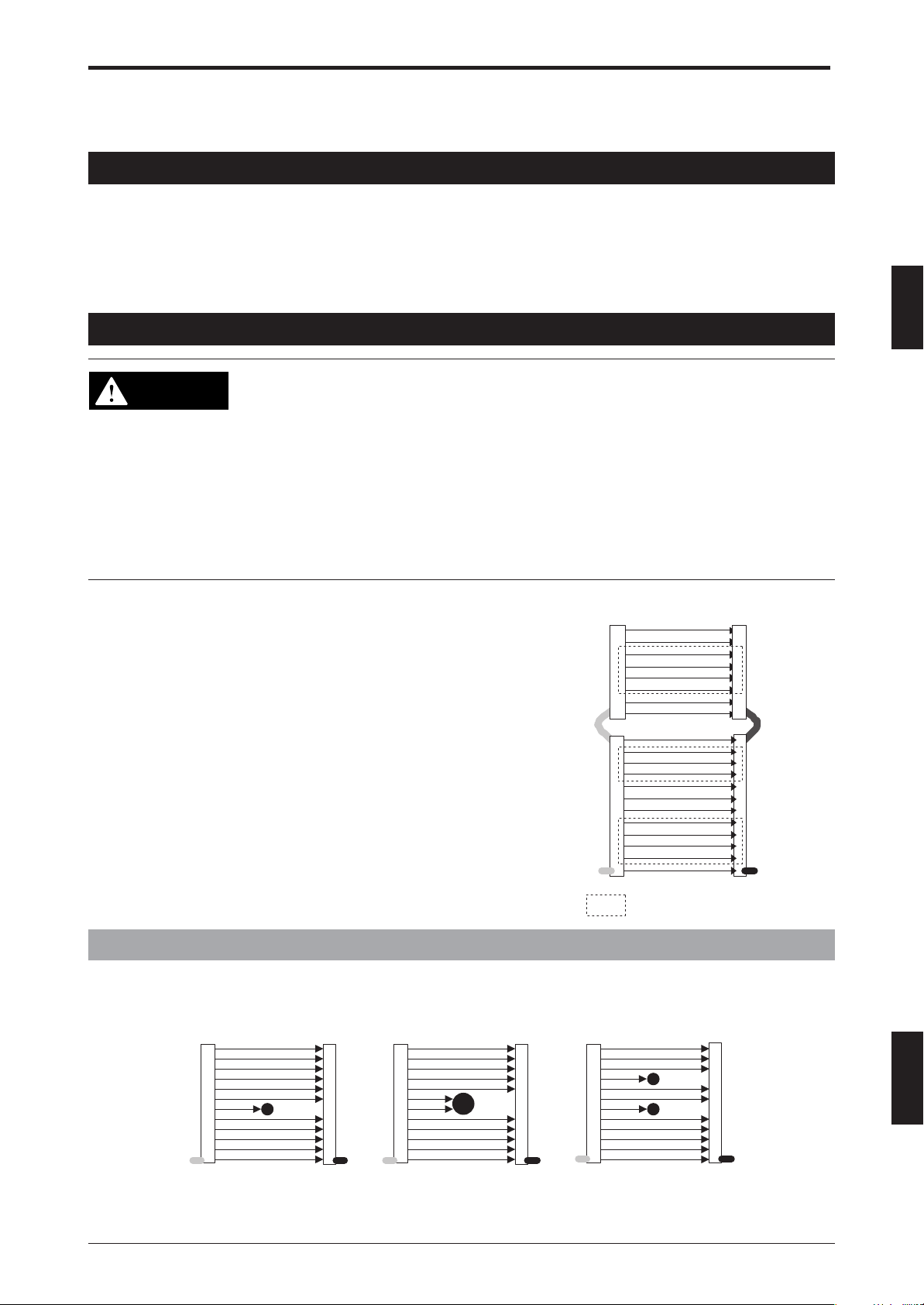

Normally, the FSD keeps the ON-state only when all beam axes are

clear of any obstruction (that is, when there are no obstacles present

in the detection zone). The Fixed blanking function is enabled only for

the beam axes in the zone initially specified by the user and allows the

FSD to keep ON-state when an obstacle blocks the beam axes in that

zone.

For example, if an obstacle blocks the beam axes of the SL-C Series,

the FSD turns OFF-state (see the right diagram.) In contrast, if the

light curtain is configured to enable fixed blanking, the FSD keeps ONstate when an obstacle blocks these pre-set beams. It allows the

target machine to continue the normal operation. Conversely, if the

obstacle is removed from the detection zone while this function is

carried out, the FSD turns OFF-state and it causes the machine stop.

Note that enabling this function may create hazardous zones, allowing

human approach against which the SL-C Series provides no protection. It is required to install additional safety protective equipment like

a cover designed to prevent human approach.

In order to carry out this function, the SL-C Series need not be a

single transmitter/receiver pair The function can be configured to be

operational for all beam axes on all SL-C Series units connected in

series. (See the right diagram.)

See “4-3 Fixed blanking function” (➮4-3) for more information about

how to set or configure this function.

When this function is carried out, it may

create a hazardous zone allowing human

approach between the obstacle and the SL-C

Series against which the SL-C Series provides no protection. (See the right diagram.)

Be sure to install additional safety protective

equipment, such as a safe guard, for this

zone. When installing the SL-C Series into/

onto a machine, always follow the instructions

in the SL-C Series Instruction Manual. Failure

to follow this warning may result in significant

harm to machine operators, including serious

injury or death.

Obstacle

: Hazardous zone allowing

human approach

<Example configuration>

Obstacle

Obstacle

Obstacle

: Zone where fixed blanking

function is active

Connected

in series

2-2

Page 19

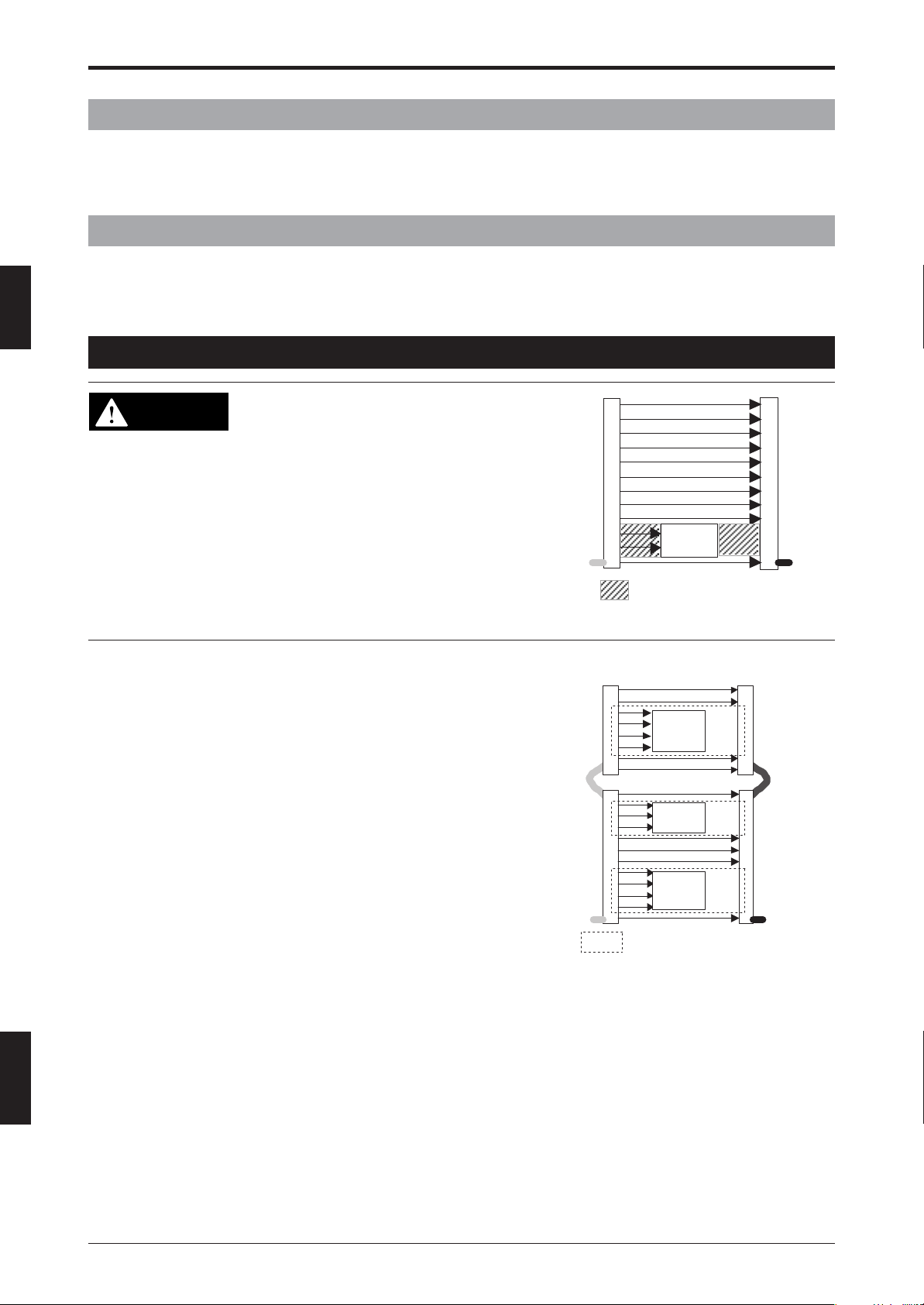

2-4 Blanking blind protection function

Chapter 2 Functions

WARNING

This function is an advanced improvement of the fixed blanking function.

It can be used to eliminate the hazardous zone allowing human approach

that arises when the conventional fixed blanking function is enabled.

(Subject to the above warning.)

A blanking blind protection unit (SL-C08SB or SL-C16SB) is required in

order to enable this function. As shown in the right diagram, the blanking

blind protection unit is placed on either side of the obstacle so that the SL-C

Series transmitter faces the blanking blind protection unit's receiver, and the

blanking blind protection unit's transmitter faces the SL-C Series receiver,

with all beam axes aligned. This configuration may eliminate the hazardous zones allowing human approach that are created by the obstacle.

Be sure to read “4-4 Blanking blind protection function” (➮4-4) carefully

for more information about how to set and install this unit before use.

Enabling the blanking blind protection function does not necessarily remove all

hazardous zones allowing human approach. Depending on the target machine,

installation of the blanking blind protection unit may result in the creation of one or

more hazardous zones allowing human approach. Be sure to read “4-4 Blanking

blind protection function” (➮4-4) in this manual before installing or using this unit.

When installing the SL-C Series into/onto a machine, always follow the instructions

in the SL-C Series Instruction Manual. Failure to follow this warning may result in

significant harm to machine operators, including serious injury or death.

2-5 Muting function

SL-C Series

Obstacle

Blanking blind protection unit

2

2-5-1 Muting function

• The muting function deactivates the light curtain's safety functions while the light

DANGER

curtain detects the input signal from two or more muting devices (sensors,

switches, etc.). The muting devices (sensors, switches, etc.) that are used to carry

out the muting function as well as the method to install them must satisfy all

conditions described in this instruction manual as well as the applicable requirements imposed by all laws, regulations, standards, and ordinances in effect in the

country and region where the SL-R12EX is to be used. Failure to follow this

warning results in significant harm to machine operators, including serious injury

or death.

• The following conditions must be considered before installing muting devices

(sensors, switches, etc.) to carry out the muting function.

1. The muting function of the light curtain is only permitted during the nonhazard-

ous portion of the machine cycle.

2. Muting devices must not get active and the light curtain (SL-C Series) must

not go to the muting state even if a person inadvertently approaches the light

curtain's detection zone.

These are minimum requirements. Always follow the regulations in effect in the

country and region where the SL-R12EX is used.

In addition, you must take note of the following information if you carry out the

muting function.

• Muting of the light curtain shall be accomplished in such a manner that no

single component failure shall prevent the normal stop command and shall

prevent subsequent machine cycles until the failure is corrected. (ANSI B11.19)

• Setting the muting function and muting device configuration must be restricted

to an extremely limited number of the responsible personnel.

• Any personnel other than the responsible personnel must not easily change

the position at which the muting devices are installed. When the muting devices are moved, the procedure must require the use of specialized tools and

must be performed under the responsibility of the responsible personnel.

ENGLISH

2-3

Page 20

Chapter 2 Functions

The muting function supported by the SL-C Series can be classified into two types.

I)A muting function where the safety functions of all beam axes, including those on SL-C Series units

connected in series, are disabled when the signals from the muting devices are ON (active).

II)A muting function (called as the programmable muting function) where the safety functions of pre-defined

beam axes are disabled when the signals from the muting devices are ON (active).

For all beam axes for which either of the functions described in I and II is enabled, the FSD keeps ON-state

even when those beam axes are blocked by the detection capability.

Both of the functions described in I and II above support either 2 or 4 input signals from the muting devices,

comprising the 4 types of muting function described below.

2

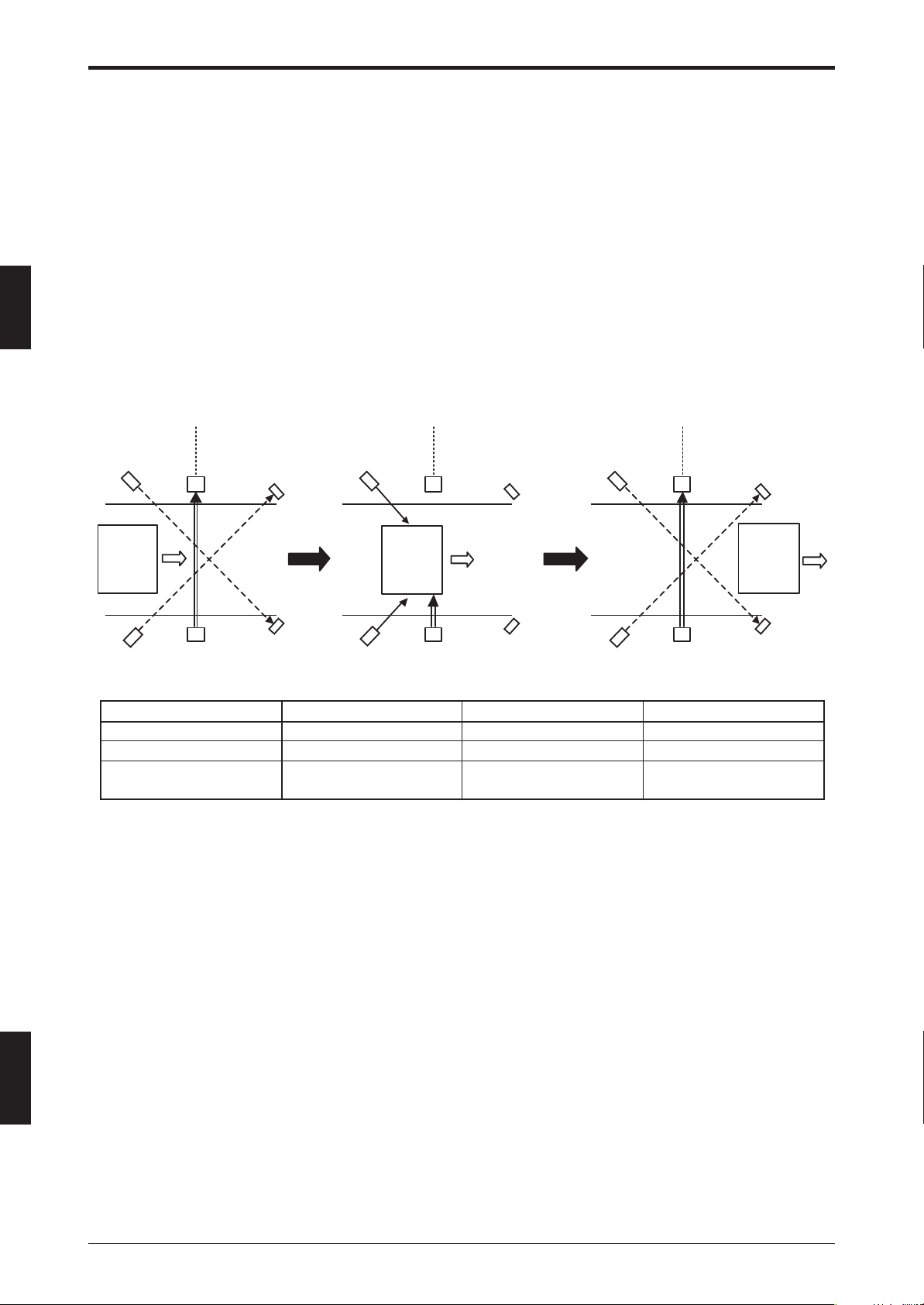

Examples of 2-input muting

See the pages starting with “2-5-2 Two-input muting” (➮2-8) for detailed time charts of this function.

1. Using 2 retro-reflective photoelectric sensors (Keyence model PZ-M61, etc.) as muting devices

(1) (2) (3)

Safe zone Hazardous zone

Sensor A1

Workpiece

Sensor A2

SL-C Series

Sensor A1 OFF ON OFF

Sensor A2 OFF ON OFF

SL-C Series state

Safe zone Hazardous zone

Reflector

Reflector

Sensor A1 Sensor A1

Workpiece

Sensor A2

SL-C Series

Reflector

Reflector

(1) (2) (3)

Safety functions enabled Safety functions disabled Safety functions enabled

(Normal operation) (Muting function enabled) (Normal operation)

Safe zone Hazardous zone

Sensor A2

SL-C Series

Reflector

Workpiece

Reflector

ENGLISH

English

* In the example described above, 2 muting devices are installed so that the location where their beam

axes intersect falls within the hazardous zone. This prevents the muting function from being active even if

a person inadvertently passes the point where the beams intersect.

2-4

Page 21

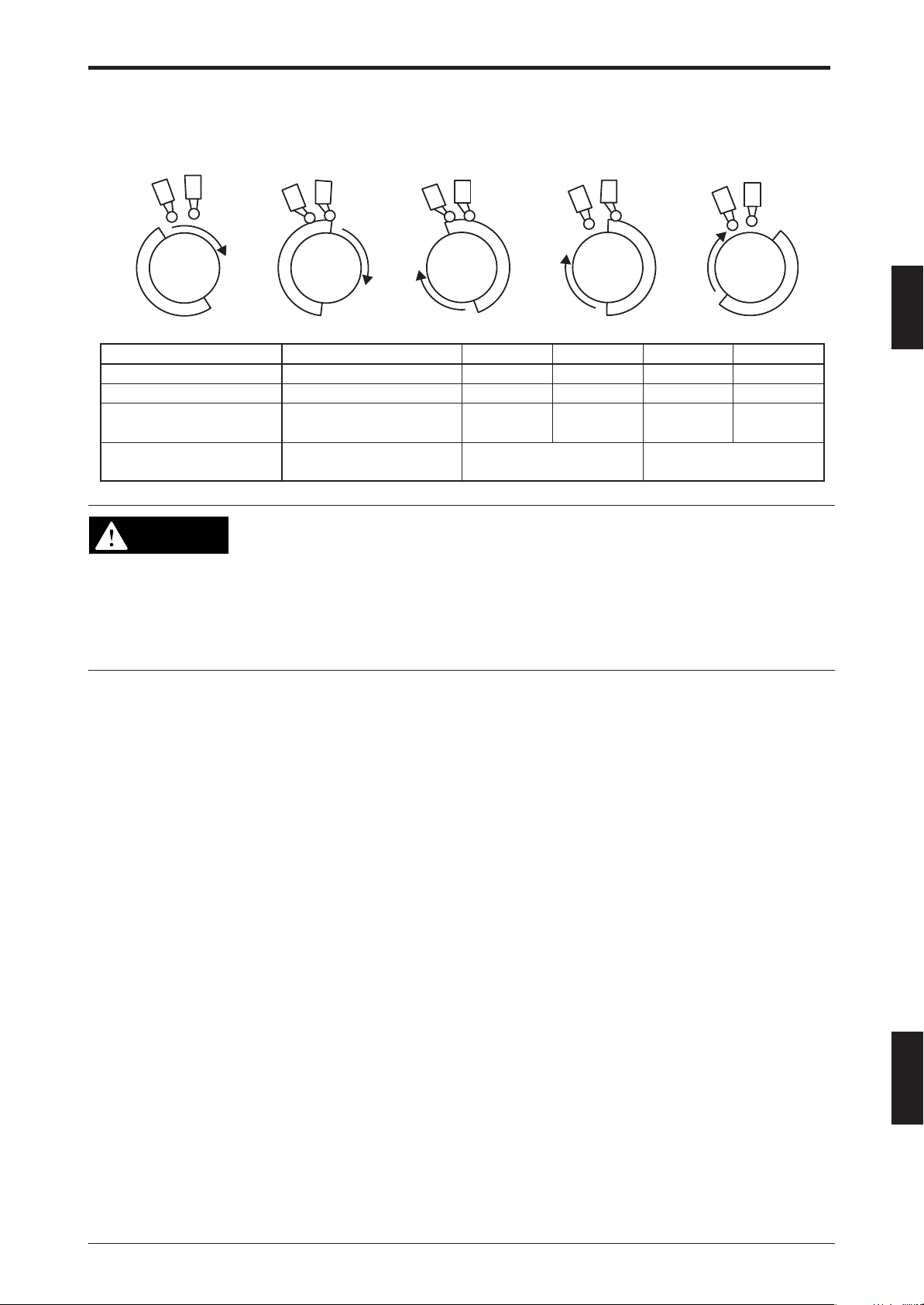

2. Using 2 cam switches as muting devices for a mechanical presses, etc.

(1) (2) (3) (4) (5)

Switch A1

SL-C Series state

Switch A2

Cam

Sensor A1 OFF ON ON OFF OFF

Sensor A2 OFF ON ON ON OFF

Machine state Bottom dead center Rising

A2

A1

(1) (2) (3) (4) (5)

Safety functions enabled Safety functions disabled Safety functions enabled

(Normal operation) (Muting function enabled) (Normal operation)

A1

A2

A2

A1

Top dead Starting to

center fall

Chapter 2 Functions

A2

A1

Falling

2

WARNING

The SL-R12EX has not received the model certification examination in accordance

with Article 44-2 of the Japanese Industrial Safety and Health Law. As a result, the

SL-R12EX cannot be used in Japan as a “Safety Device for Presses and Shearing

machines” as established in Article 42 of that law.

When using the SL-C Series, including SL-R11 and SL-R12EX with mechanical

press equipment in the United States, check the regulations stipulated in

OSHA1910.217 and ANSI B11.1, B11.2, and B11.3, and be sure to follow those

regulations in both the installation and use.

2-5

ENGLISH

Page 22

Chapter 2 Functions

Examples of 4-input muting

See the pages starting with “2-5-3 Four-input muting” (➮2-9) for detailed time charts of this function.

1. Using 4 thrubeam photoelectric sensors (KEYENCE model PZ-M51, etc.) as muting devices

2

(1) (2)

Sensor A1

Workpiece

(3) (4)

Safe zone Hazardous zone

Sensor A2

SL-C Series

Safe zone Hazardous zone

A2

Sensor

Sensor A1

Workpiece

Sensor B1

Sensor B2

Sensor B1

Sensor B2

Sensor

Workpiece

Sensor A1

Sensor

Sensor B2

B 1

Sensor

Safe zone Hazardous zone

A 2

Sensor

A1

SL-C Series

Safe zone Hazardous zone

Sensor A2

Sensor B1

Workpiece

B 2

ENGLISH

English

SL-C Series

(5) (6)

Sensor A1

Safe zone Hazardous zone

Sensor A2

Sensor B1

Sensor B2

Workpiece

SL-C Series

Sensor A2

Sensor A1

SL-C Series

Safe zone Hazardous zone

Sensor B1

Sensor B2

Workpiece

SL-C Series

2-6

Page 23

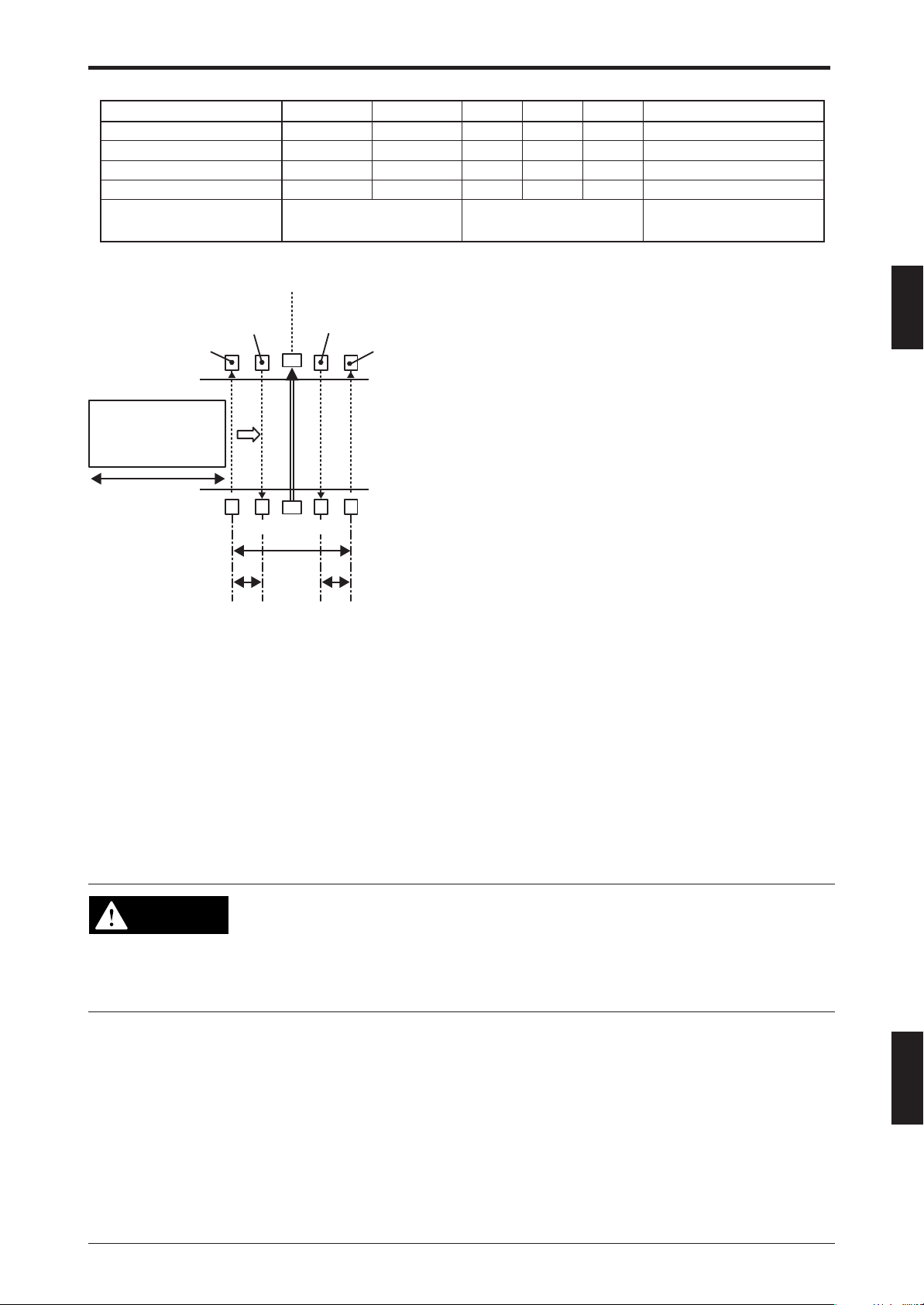

State (1) (2) (3) (4) (5) (6)

Sensor A1 OFF ON ON ON OFF OFF

Sensor A2 OFF OFF ON ON OFF OFF

Sensor B1 OFF OFF OFF ON ON OFF

Sensor B2 OFF OFF OFF ON ON ON

SL-C Series state

* Muting device location in the above examples

(Normal operation) (Muting function enabled) (Normal operation)

Safety functions enabled Safety functions disabled Safety functions enabled

Chapter 2 Functions

Safe zone Hazardous zone

Sensor A2

Sensor A1

Workpiece

L

See “4-5 Muting function” (➮4-10) for information about how to set or configure these functions.

In order to carry out this function, you must install muting devices (sensors, switches, etc.) and a muting

lamp (SL-R12D is recommended). See “4-5-1 Muting devices” (➮4-10) for information about muting device

requirements and “4-5-2 Muting lamps” (➮4-12) for information about muting lamp requirements.

The information presented up to this point is intended as an example of typical requirements. The satisfaction of these requirements must not be understood as being equivalent to the satisfaction of all regulations

imposed on the muting function (including methods of installation and use) being used by the customer.

Therefore, KEYENCE does not guarantee the validity and/or accuracy for use, installation and orientation

methods of the muting devices that the customers made. Accordingly, customers intending to carry out the

muting function must check the all applicable regulations in effect in the country and region where the SLR12EX is used.

S

SL-C Series

D2 D3

Sensor B1

Sensor B2

D1

As indicated in the diagram to the left, L represents the

workpiece length, while S indicates the speed of the

workpiece as it approaches the light curtain's detection

zone.

When installing the muting devices, the following conditions must be fully satisfied.

D1: The distance between A1 and B2

D2: The distance between A1 and A2

D3: The distance between B1 and B2.

L: The length of the workpiece

S: The speed of the workpiece

(1) D1 < L

(2) D2 < S X 3 (seconds)

(3) D3 < S X 3 (seconds)

2

WARNING

Customers who carry out the muting function bear sole responsibility for complying

with the requirements imposed on that function. KEYENCE makes no guarantee

regarding damage arising from installation, orientation, usage, or maintenance not

in accordance with what is described in this instruction manual, or from the failure

to follow all applicable regulations in effect in the country and region in which the

SL-R12EX is used.

ENGLISH

2-7

Page 24

2

Chapter 2 Functions

2-5-2 Two-input muting

The light curtain (SL-C Series) goes to the muting state when it detects the input signals from 2 muting

devices, and the FSD keeps ON-state no matter which beam axes of SL-C Series are blocked.

The following time chart shows the muting function performance when two sensors are used as the muting

devices.

ON

Sensor A1

Sensor A2

Muting function

Beam reception

FSD

OFF

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

24 ms

Less than 3 sec.

20 ms

150 ms

5 ms

(1) (2) (3)

Time chart explanation

(1) The muting function does not get active when both sensors A1 and A2 are OFF, or when only one of them

is ON. In other words, the light curtain (SL-C Series) keeps normal operation. (The muting function is

OFF.)

(2) The muting function gets active once both sensors A1 and A2 turn ON, and then, the muting lamp turns

ON.

(3) Once either sensor A1 or A2 turns OFF, the muting function is to be inactive. Therefore, the light curtain’s

(SL-C Series) muting state is canceled. The muting lamp turns OFF, and the light curtain (SL-C Series)

returns to normal operation.

Important: * The SL-C Series muting function is designed so that it cannot be active while FSD is OFF-

state. As a result, the SL-C Series does not go to the muting state when any beam axes are

being blocked or when the restart interlock is enabled, even if the signals from the 2 muting

devices turn ON.

* When the SL-R11 receives an E-STOP input signal, the FSD always turns to OFF-state and

the light curtain (SL-C Series) automatically goes to the restart interlock state, even if it has

been in the muting state. When the E-STOP input signal is canceled and the restart input

turns ON, the light curtain (SL-C Series) returns to normal operation, rather than resuming

the set muting state. As a result, in order to return the light curtain (SL-C Series) to the

muting state again, you must temporarily cancel the input signals from the muting devices

that have been activated and resend the input signals from them to the SL-R12EX.

* The SL-C Series cannot go to the muting state after 1 muting device turns OFF, even if both

devices then turn back ON again. Both muting devices must turn OFF to get the muting

function active again.

ENGLISH

English

2-8

Page 25

Chapter 2 Functions

2-5-3 Four-input muting

The light curtain (SL-C Series) goes to the muting state when it received input signals from 4 muting devices,

and the FSD keeps ON-state no matter which beam axes of the SL-C Series is blocked.

The following time chart shows the muting function performance when four sensors are used as muting

devices.

Forward direction

Sensor A1

Sensor A2

Sensor B1

Sensor B2

Muting function

Beam reception

FSD

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

24 ms

Less than 3 sec.

Less than 3 sec.

20 ms

150 ms

(1) (2) (3)

5 ms

2

Time chart explanation

(1) The muting function does not get active when the signals from the muting devices are all OFF. In other

words, the light curtain (SL-C Series) keeps normal operation. (The muting function is OFF)

(2) The muting function gets active once the signal from sensor A1 turns ON at first and the signal from

sensor A2 turns ON sequentially. At this time, the muting lamp turns ON. Further, the signal from sensor

B1 turns ON, and finally, the signal from sensor B2 turns ON. As long as the light curtain (SL-C Series)

receives the signals from the muting devices in this sequence, it keeps muting function.

(3) If the signal from sensor A1 turns OFF, A2 turns OFF and then B1 also turns OFF sequentially after the

signals from all the sensors turn ON, the muting function cannot keep active. Therefore, the light curtain's

(SL-C Series) muting state is canceled. The muting lamp turns OFF, and the light curtain (SL-C Series)

returns to normal operation.

ENGLISH

2-9

Page 26

Chapter 2 Functions

The following time chart shows muting function performance when it gets active in the reverse sequence

from above. This time chart also assumes sensor is used as muting devices.

Reverse direction

Sensor A1

ON

OFF

2

Sensor A2

Sensor B1

Sensor B2

Muting function

Beam reception

FSD

Time chart explanation

(1) The muting function does not get active when the signals from the muting devices are all OFF. In other

words, the light curtain (SL-C Series) keeps normal operation. (The muting function is OFF)

(2) The muting function gets active once the signal from sensor B2 turns ON at first and the signal from

sensor B1 turns ON sequentially. At this time, the muting lamp turns ON. Further, the signal from sensor

A2 turns ON, and finally, the signal from sensor A1 turns ON. As long as the light curtain (SL-C Series)

receives the signals from the muting devices in this sequence, it keeps the muting function.

(3) If the signal from sensor B2 turns OFF, B1 turns OFF and then A2 also turns OFF sequentially after the

signals from all the sensors turn ON. The muting function cannot keep active. Therefore, the light curtain's

(SL-C Series) muting state is canceled. The muting lamp turns OFF, and the light curtain (SL-C Series)

returns to normal operation.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

24 ms

Less than 3 sec.

Less than 3 sec.

20 ms

150 ms

(1) (2) (3)

5 ms

ENGLISH

English

2-10

Page 27

Chapter 2 Functions

Important: * In the event that the signals from the muting devices turn ON or OFF in a different sequence

from what is indicated in the above 2 time charts (for either the forward and reverse directions) – for example, signal input from sensor A1 is followed by signal input from sensor B1,

etc. – the light curtain (SL-C Series) goes to the lockout condition, and the FSD turns OFFstate.

* The SL-C Series muting function is designed so that it cannot be active while FSD is in the

OFF-state. As a result, the SL-C Series does not go to the muting state when any beam

axes are being blocked or when the restart interlock is enabled, even if the signals from the 4

muting devices turn ON in the correct sequence indicated above.

* When the SL-R11 receives an E-STOP input signal, the FSD always turns OFF-state and

the light curtain (SL-C Series) automatically goes to the restart interlock state, even if it has

been in the muting state. When the E-STOP input signals are canceled and the restart input

turns ON, the light curtain (SL-C Series) returns to normal operation, rather than resuming

the set muting state. As a result, in order to return the light curtain (SL-C Series) to the

muting state again, you must temporarily cancel the input signals from the muting devices

that have been activated and resend the input signals from them to the SL-R12EX.

* In the event that a change of the signal from one of the muting devices (ON or OFF) is not

followed by a change of the signal from the next muting device in less than 5 minutes, the

light curtain (SL-C Series) goes to the lockout condition, and the FSD turns OFF-state. (See

the below time chart for reference.)

2

Example

Sensor A1

Sensor A2

Sensor B1

Sensor B2

Muting function

Beam reception

FSD

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

Lockout

More than 5 min.

2-11

ENGLISH

Page 28

2

Chapter 2 Functions

2-5-4 Two-input programmable muting function

Only the preset beam axes are muted if the memory bank switching input turns ON while the signals from

muting devices are ON. The FSD keeps ON-state even if the muted beam axes are blocked. On the other

hand, the FSD turns to the OFF-state if beam axes other than the muted ones are blocked, since those

beam axes keep normal operation.

The information about the preset beam axes for muting is stored in 3 memory banks, and you can switch

among those banks using inputs from an external source. Although the following time chart shows only 1

bank switching input signal in order for the customer’s easy understanding of this function, actually 2 (double) signals are required for 1 bank switching input (Duplication). See “4-5-5 Bank switching input devices”

(➮4-17) for more information.

The following time chart shows programmable muting bank function performance when 2 sensors are used

as muting devices.

ON

Sensor A1

Sensor A2

Bank switching inputs

OFF

ON

OFF

ON

OFF

Less than 3 sec.

ENGLISH

English

Muting function

Muting lamp

Beam reception

FSD

Time chart explanation

(1) The muting function does not get active when both sensors A1 and A2 are OFF, or when only one of them

is ON. In other words, the light curtain (SL-C Series) keeps normal operation. (The muting function is

OFF.)

(2) The muting lamp turns ON when both sensors A1 and A2 turn ON. At this time, if any one of the 3 bank

switching inputs has already been ON, the preset beam axes in the bank go to the muting state. Even if

muted beam axes are blocked, the FSD keeps ON-state.

If 2 or more bank switching inputs have already been ON prior to the inputs from 2 muting devices, then

all preset beam axes in these banks go to the muting state.

(3) If all of the bank switching inputs turn OFF when both sensors A1 and A2 keep ON, the muting function is

canceled, and the light curtain (SL-C Series) returns to normal operation. At this time, the muting lamp

does not turn OFF. (The muting lamp turns OFF when at least either sensors A1 or A2 turns OFF.)

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

24 ms

5 ms

20 ms

150 ms

(1) (2) (3)

20 ms

2-12

Page 29

Chapter 2 Functions

Important:*The SL-C Series muting function is designed so that it cannot be active while FSD is in the

OFF-state. As a result, the SL-C Series does not go to the muting state when any beam axes

are being blocked or when the restart interlock is enabled, even if the signals from the 2

muting devices turn ON.

* Bank switching input requires 2 (double) channels of signal input. As a result, if one of the

channels is ON while the other is OFF for 200 ms or more, the light curtain (SL-C Series)

goes to the lockout condition.

* At least 1 of the bank switching inputs must be ON prior to the signal input from the second

muting device (in the example above, the input signal from sensor A2). Therefore, in order to

switch among the 3 banks, you must turn the bank switching input ON when the SL-R12EX

detects no signals from the muting devices, or when it only detects the signal from the first

muting device (in the example above, the input signal from sensor A1).

* If additional bank switching input is made while a muted beam axis is blocked, the FSD turns

to OFF- state.

* When the SL-R11 receives an E-STOP input signal, the FSD always turns OFF-state and

the light curtain (SL-C Series) automatically goes to the restart interlock state, even if it has

been in the muting state. When the E-STOP input signal is canceled and the restart input

turns ON, the light curtain (SL-C Series) returns to normal operation, rather than resuming

the set muting state. As a result, in order to return the light curtain (SL-C Series) to the

muting state again, you must temporarily cancel the input signals from the muting devices

that have been activated and resend the input signals from them to the SL-R12EX.

* If there is no bank switching input to the SL-R12EX while the signals from the muting devices

are ON, the programmable muting bank function does not get active and the light curtain

(SL-C Series) keeps normal operation. However, the muting lamp turns ON if there is signal

input from the muting devices.

* The SL-C Series cannot go to the muting state after 1 muting device turns OFF, even if both

devices then turn back ON again. Both muting devices must turn OFF to get muting function

active again.

2

2-13

ENGLISH

Page 30

2

Chapter 2 Functions

2-5-5 Four-input programmable muting function

Only preset beam axes can be in a muting state if the memory bank switching input turns ON while the

signals from the muting devices are ON. The FSD keeps ON-state even if the muted beam axes are blocked.

On the other hand, the FSD turns OFF-state if beam axes other than the muted ones are blocked, since

those beam axes keep normal operation.

The information about the preset beam axes for muting is stored in 3 memory banks, and you can switch

among these banks using inputs from the external sources. Although the following time chart shows only 1

bank switching input signal in order for customer’s easy understanding for this function, actually 2 (double)

signals are required for 1 bank switching input (Duplication). See “4-5-5 Bank switching input devices” (➮4-

17) for more information.

The following time chart shows programmable muting bank function performance when 4 sensors are used

as muting devices.

Forward direction

ON

Sensor A1

Sensor A2

Sensor B1

OFF

ON

OFF

ON

OFF

Less than 3 sec.

ENGLISH

English

Sensor B2

Bank switching inputs

Muting function

Muting lamp

Beam reception

FSD

Time chart explanation

(1) The muting function does not get active when both sensors A1 and A2 are OFF, or when only one of them

is ON. In other words, the light curtain (SL-C Series) keeps normal operation. (The muting function is

OFF.)

(2) The muting function is enabled once the signal from sensor A1 turns ON at first and the signal from

sensor A2 turns ON sequentially. At this time, the muting lamp turns ON. If any one of the 3 bank switching inputs has already been ON, the preset beam axes in the bank go to the muting state. Even if muted

beam axes are blocked, the FSD keeps ON-state.

If 2 or more bank switching inputs have already been ON prior to the inputs from 2 muting devices, the all

preset beam axes in these banks go to the muting state.

(3) The signal from sensor B1 turns ON, and then, the signal from sensor B2 should turn ON. As long as the

SL-R12EX detects the signals from the muting devices in this sequence, it keeps the muting function as

in (2) above.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

24 ms

Less than 3 sec.

20 ms

150 ms

(1) (2) (3) (4) (5)

5 ms

20 ms

2-14

Page 31

Chapter 2 Functions

(4) Even if the signal from sensor A1 turns OFF and then A2 also turns OFF sequentially after the signals

from all the sensors turn ON, it keeps the muting function as in (2) above as long as the SL-R12EX

detects the signals from the muting devices in this sequence and the signals from sensors B1 and B2 still

keep ON. Even if muted beam axes are blocked, the FSD keeps ON-state.

(5) When the signal from sensor B1 turns OFF, the muting function is canceled, and the light curtain (SL-C

Series) returns to normal operation. At this time, the muting lamp turns OFF. Alternatively, if all bank

switching inputs turn OFF, even as the signal from sensor B1 keeps ON, the muting function is canceled,

and the light curtain (SL-C Series) returns to normal operation. At this time, the muting lamp does not turn

OFF. (The muting lamp turns OFF when sensor B1 turns OFF in correct sequence.)

Reverse direction

ON

Sensor A1

Sensor A2

Sensor B1

OFF

ON

OFF

Less than 3 sec.

ON

OFF

2

Sensor B2

Bank switching input

Muting function

Muting lamp

Beam reception

FSD

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Clear

Blocked

ON

OFF

24 ms

Less than 3 sec.

5 ms

20 ms

150 ms

(1) (2) (3) (4) (5)

20 ms

Time chart explanation

(1) The muting function does not get active when both sensors B2 and B1 are OFF, or when only one of them

is ON. In other words, the light curtain (SL-C Series) keeps normal operation. (The muting function is OFF.)

(2) The muting function is enabled once the signal from sensor B2 turns ON at first and the signal from

sensor B1 turns ON sequentially. At this time, the muting lamp turns ON. If any one of the 3 bank switching inputs has already been ON, the preset beam axes in the bank go to the muting state. Even if muted

beam axes are blocked, the FSD keeps ON-state.

If 2 or more bank switching inputs have already been ON prior to the inputs from 2 muting devices, then

all preset beam axes in these banks go to the muting state.

(3) The signal from sensor A2 turns ON, and then, the signal from sensor A1 turns ON. As long as the SL-

R12EX detects the signals from the muting devices in this sequence, it keeps the muting function as in (2)

above.

(4) Even if the signal from sensor B2 turns OFF and then B1 also turns OFF sequentially after the signals

from all the sensors turn ON, it keeps the muting function as in (2) above as long as the SL-R12EX

detects the signals from the muting devices in this sequence and the signals from sensors A2 and A1 still

keep ON. Even if the muted beam axes are blocked, the FSD keeps ON-state.

(5) When the signal from sensor A2 turns OFF, the muting function is canceled, and the light curtain (SL-C

Series) returns to normal operation. At this time, the muting lamp turns OFF. Alternatively, if all bank

switching inputs turn OFF, even as the signal from sensor A2 keeps ON, the muting function is canceled,

and the light curtain (SL-C Series) returns to normal operation. At this time, the muting lamp does not turn

OFF. (The muting lamp turns OFF when sensor A2 turns OFF in correct sequence.)

ENGLISH

2-15

Page 32

2

Chapter 2 Functions

Important: * In the event that the signals from the muting devices turn ON or OFF in a different sequence

from what is indicated in the previous 2 time charts (for either the forward and reverse

directions) – the light curtain (SL-C Series) goes to the lockout condition, and the FSD turns

OFF-state. For example, a signal input from sensor A1 is followed by a signal input from

sensor B1, etc.

* One of the bank switching inputs must be ON prior to the signal input from the second

muting device. (For the forward direction sequence, input from sensor A2; for the reverse

direction sequence, input from sensor B1). Therefore, in order to switch among the 3 banks,

you must switch the bank switching input when the SL-R12EX receives no signals from the

muting devices, or when it only receives the signal from the first muting device. (For the

forward direction sequence, input from sensor A1; for the reverse direction sequence, input

from sensor B2).

* The SL-C Series muting function is designed so that it cannot be active while FSD is OFF-

state. As a result, the SL-C Series does not go to the muting state when any beam axes are

being blocked or when the restart interlock is enabled, even if the signals from the 4 muting

devices turn ON in the correct sequence indicated above.

* If there is no bank switching input to the SL-R12EX while the signals from the muting devices

are ON, the programmable muting bank function does not get active and the light curtain

(SL-C Series) keeps normal operation. However, the muting lamp turns ON if there is signal

input from the muting devices.

* If additional bank switching input is made while a muted beam axis is blocked, the FSD turns

OFF-state.

* Bank switching input requires 2 (double) channels of signal input. As a result, if 1 of the

channels is ON while the other is OFF, the light curtain (SL-C Series) goes to the lockout

condition.

* When the SL-R11 receives an E-STOP input signal, the FSD always turns OFF-state and

the light curtain (SL-C Series) automatically goes to the restart interlock state, even if it has

been in muting state. When the E-STOP input signal is canceled and the restart input turns

ON, the light curtain (SL-C Series) returns to normal operation, rather than resuming the set

muting state. As a result, in order to return the light curtain (SL-C Series) to the muting state

again, you must temporarily cancel the signal input from the muting devices that have been

activated and resend the input signals from them to SL-R12EX.