KEYENCE SL-R11E User Manual

96M13269

Safety Control Unit

SL-R11E

Instruction Manual

NOTICE

Do not attempt to operate or service this machine

until you have read and understood the

instructions written in this manual.

Contents

Safety Precautions

1. Safety Headings ....................................................................................................................................iii

2. General Precautions .............................................................................................................................iii

3. Warning ..................................................................................................................................................iv

4. Circuit Design and Wiring .....................................................................................................................iv

5. Testing and Maintenance .......................................................................................................................v

6. About Standards and Regulations........................................................................................................v

7. Accessories ............................................................................................................................................ v

1 Specifications

Integration with the SL-C ...................................................................................................................... 1-1

1-1 Part Names .......................................................................................................................................... 1-2

1-2 Specifications ..................................................................................................................................... 1-3

1-3 External Dimensions Diagram .......................................................................................................... 1-3

1-4 Power Supply Precautions ................................................................................................................ 1-4

1-4-1 Power Units that Can Be Used as Power Supplies for SL-C Series and SL-R11E ..................... 1-4

1-4-2 Recommended Dedicated Power Supply Unit ............................................................................ 1-4

2 Functions

ENGLISH

English

2-1 Start Interlock ..................................................................................................................................... 2-1

2-2 Restart Interlock ................................................................................................................................. 2-1

2-3 E-STOP Input ...................................................................................................................................... 2-1

2-4 MPCE (Machine Primary Control Element) Monitor ........................................................................ 2-2

2-5 Main/Sub Setting ................................................................................................................................ 2-3

2-6 TEST Input .......................................................................................................................................... 2-3

2-7 Power OFF Input ................................................................................................................................. 2-3

2-8 OSSD Output ...................................................................................................................................... 2-3

2-9 AUX Output ......................................................................................................................................... 2-3

2-10 Status Indicators ................................................................................................................................ 2-3

2-11 Mode Switch Settings ........................................................................................................................ 2-5

2-12 Circuit Diagram (Signal Input Terminal) ........................................................................................... 2-7

2-13 Input/Output Terminal Circuit ............................................................................................................ 2-8

3 Mounting and Installation

3-1 Installation Location .......................................................................................................................... 3-1

3-2 Installation Using a DIN Rail .............................................................................................................. 3-1

3-3 Wall Mounting Using Screws ............................................................................................................ 3-3

3-4 Connection to the SL-U2 Recommended Dedicated Power Supply .............................................. 3-3

i

4 Wiring

4-1 Method for Connection to the SL-C Series ...................................................................................... 4-1

4-2 Method for Wiring to the Relay Output Terminal.............................................................................. 4-1

4-2-1 How to Replace the Relay Output Terminal Block....................................................................... 4-2

4-2-2 Wiring the Power OFF Input Terminals ........................................................................................ 4-3

4-3 Method for Wiring to Signal Input Terminals .................................................................................... 4-4

4-3-1 Wiring to Start/Restart Input Terminals ....................................................................................... 4-5

4-3-2 Wiring to E-STOP Input Terminals .............................................................................................. 4-6

4-3-3 Wiring to the MPCE Monitor Input Terminal ................................................................................ 4-7

4-3-4 Connecting to Main/Sub Select Input Terminal ........................................................................... 4-8

4-3-5 Wiring to the Test Input Terminal ................................................................................................. 4-9

4-4 About the Light Interference Prevention Connection ................................................................... 4-10

4-4-1 What is a Light Interference Prevention Connection? ............................................................... 4-10

4-4-2 Parts Required for Connection .................................................................................................. 4-10

4-4-3 Main/Sub Switching Input Setting ............................................................................................. 4-10

4-4-4 Wiring Connections ................................................................................................................... 4-10

5 Checklist

5-1 List of Pre-use Check Items .............................................................................................................. 5-1

5-1-1 First, Check the SL-R11E Installation Conditions ...................................................................... 5-1

5-1-2 Check the Wiring Before Turning on the Power .......................................................................... 5-1

5-1-3 Check Using an Operation Test While Machine is Stopped ....................................................... 5-1

6 Maintenance

6-1 Regular Inspections ........................................................................................................................... 6-1

6-1-1 Output Relay Inspection .............................................................................................................. 6-1

6-1-2 E-STOP Function Check ............................................................................................................. 6-1

7Troubleshooting

Troubleshooting .................................................................................................................................... 7-1

8Revision History

Revision History .................................................................................................................................. 8-1

ENGLISH

96M13269

ii

Safety Precautions

WARNING

CAUTION

This manual describes handling, operation, and precautionary information for the Safety Control Unit (SLR11E). Read this manual thoroughly before operating the SL-R11E in order to understand device features,

and keep this instruction manual readily available for reference.

1. Safety Headings

“OSSD” described in this manual indicates the output of the SL-R11E. When using the SL-R11E, the output

of the SL-C Series indicates the output that controls the “OSSD” of the SL-R11E, instead of the “OSSD” itself.

This instruction manual uses the following headings to display important safety information. Strict adherence

to the instructions next to these headings is required at all times.

Failure to follow the instructions may result in significant harm to machine operators, including death.

Failure to follow the instructions may result in failure to the machine to which the

SL-R11E is installed.

2. General Precautions

ENGLISH

English

•Verify that this device is operating normally in terms of functionality and performance before the start of

work and before the start of device operation.

• KEYENCE is unable to warrant the function or performance of the SL-R11E if it is used in a manner that

differs from the SL-R11E specifications contained in this instruction manual or if the SL-R11E is modified.

• When using the SL-R11E to protect machine operators from a hazardous zone or a hazard, or using it as

safety equipment for any purpose, always follow the applicable requirements, regulations, and laws

(collectively “regulations”) existing in the country or region where the SL-R11E is being used. For such

regulations, contact directly the regulatory agency responsible for occupational safety and health in your

country or region.

• Depending on the type of machine to which the SL-R11E is to be attached, there may be special safety

regulations related to the use, installation, maintenance, and operation of the device, and such safety

regulations must be followed. The responsible personnel must install the SL-R11E in strict compliance

with such safety regulations.

• The responsible personnel must train the assigned personnel for the correct use, installation, maintenance, and operation of the SL-R11E. “Machine operators” refers to personnel who have received appropriate training from the responsible personnel and are qualified to operate the device correctly.

• Machine operators must receive specialized training for the SL-R11E and must understand and follow the

safety regulations for the country or region in which they are using the SL-R11E.

• When the SL-R11E fails to operate properly, machine operators must immediately stop the use of the

device and report this fact to the responsible personnel.

• The SL-R11E is designed with the assumption that it would be properly installed in accordance with the

installation procedures described in this instruction manual and operated according to the instructions in

this instruction manual. Perform an appropriate installation of the SL-R11E after conducting a sufficient

risk assessment for the target machine.

• This device should be processed as an industrial waste product when being disposed.

iii

3. Warning

■ Operators

• In order for the SL-R11E to operate properly, the responsible personnel and machine operators must

follow all procedures described in this instruction manual.

• No person other than the responsible personnel and machine operators should be allowed to install or

test the SL-R11E.

• When performing electrical wiring, always follow electrical standards and regulations for the country or

region in which the SL-R11E is being used.

■ Usage environment

• Do not use the device in an environment (temperature, humidity, interfering light, etc.) that does not

conform to the specifications contained in this instruction manual.

• Do not use wireless devices such as cellular phones or transceivers in the vicinity of the SL-R11E.

• The SL-R11E is not designed to be explosion-proof. Never use it in the presence of flammable or

explosive gases or elements.

• Do not use the SL-R11E in the presence of substances, such as heavy smoke, particulate matter, or

corrosive chemical agents, that may induce deterioration in product quality.

■ Target machine

• The SL-R11E has not undergone the model certification examination in accordance with Article 44-2 of

the Japanese Industrial Safety and Health Law. The SL-R11E, therefore, cannot be used in Japan as a

“Safety Device for Press and Shearing machines” as established in Article 42 of that law.

• The machine on which the SL-R11E is to be installed must be susceptible to an emergency stop at all

operating points during its operation cycle. Do not use the SL-R11E for machines with irregular stop

times.

• Do not use the SL-R11E for power presses equipped with full-revolution clutches.

• Do not use the SL-R11E to control (stop forward motion, etc.) trains, cars and other transportation

vehicles, aircraft, equipment for use in space, medical devices, or nuclear power generation systems.

• The SL-R11E is designed to protect people or objects from entering a machine’s hazardous zone or

hazard. It cannot provide protection against objects or materials that are displaced from the machine's

hazardous zone or hazard, and so implement additional safety measures such as installing safeguards

when there is the possibility of such displacements.

■ Installation

• Install the SL-R11E inside an enclosure such as a control panel that offers a rating of at least IP54 in

accordance with the IEC 60529 standard.

• The SL-R11E is a special control unit for the Safety Light Curtain SL-C Series, so be sure to connect it

to the SL-C Series when using it.

4. Circuit Design and Wiring

• Always turn off the device power when performing electrical wiring.

•Follow electrical standards and regulations for the country or region in which the SL-R11E is being used

when performing the electrical wiring. Only qualified persons should perform wiring.

• Do not place any cables or electrical lines used in wiring the SL-R11E in the same duct as high-voltage

electrical or power lines or in parallel with such lines.

• Do not extend transmitter and receiver cables over a maximum distance of 30 meters (98.43 ft.).

• Install the mechanism used to reset the interlock (switches, etc.) in a position from which the condition of

the entire hazardous zone can be checked. Do not install the reset mechanism in a position where it can

be operated within the hazardous zone.

• The control outputs (OSSD) of the two systems provided in the SL-R11E must both be used to build a

safety system. Building a safety system with just one of these systems cannot stop the machine due to a

control output malfunction and can result in a serious accident, including serious injury or death to the

machine operator.

• The AUX output provided in the SL-R11E is not an output for the safety system, so it cannot be used by

connecting a control output (so called OSSD or MPCE) to stop the machine. If using the AUX by connecting an output to build a safety system and stop the machine, it could result in the serious injury or death of

the machine operator.

• When wiring the SL-R11E output terminal to the machine control circuit of a machine containing the SL-C,

check with the machine manufacturer to make sure the wiring is appropriate for the machine being used

to ensure that the machine can be stopped correctly. If the wiring is not done correctly for the machine, a

serious accident, such as serious injury or death to the machine operator could result.

• Connect the load (MPCE) between the control output (OSSD) and 0V. If it is erroneously connected

between the control output (OSSD) and +24V, the OSSD does not operate normally and the SL-C Series

turns ON when the beams are blocked. This is very dangerous.

ENGLISH

iv

5. Testing and Maintenance

• Always perform testing in accordance with the test procedures after maintenance, adjustment, or calibration of the target machine or the SL-R11E, and before the machine start-up.

• If the SL-C or SL-R11E does not operate properly when tested in accordance with the test procedures

established in this instruction manual, do not operate the machine.

•Periodically examine the machine to verify that all brakes, other stop mechanisms, and control devices

operate reliably and accurately in addition to checking for SL-C and SL-R11E.

• The responsible personnel must perform maintenance procedures as established in this instruction

manual at least once every six months to ensure safe device operation.

6. About Standards and Regulations

1) The SL-C and SL-R11E comply with the following UL (Underwriters Laboratories Inc.) Standards

and have received Canada-U.S.-Listing certification from UL.

• UL61496-1 (Type 4 ESPE - Electro-Sensitive Protective Equipment)

• UL61496-2 (Type 4 AOPD - Active Opto-Electronic Protective Device)

2) The SL-C and SL-R11E have not received the model certification examination in accordance with

Article 44-2 of the Japanese Industrial Safety and Health Law. Therefore, the SL-C Series and SLR11E cannot be used in Japan as a “Safety Devices for Presses and Shearing machines” as

established in Article 42 of that law.

ENGLISH

English

3) The SL-C Series and SL-R11E have been designed in consideration of the following standards and

regulations. For details regarding the following standards, contact the third-party certification

organization, such as UL.

<Corresponding standards>

• OSHA 29 CFR 1910.212

• OSHA 29 CFR 1910.217

• ANSI B11.1 - B.11.19

• “Guidelines for Comprehensive Safety Standards of Machinery”, July 31, 2007, number 0731001 issued

by, Ministry of Health, Labor, and Welfare in Japan.

7. Accessories

Confirm that the package includes the main unit (SL-R11E) and following accessories.

Instruction Manual (this manual) 1 copy

v

1 Specifications

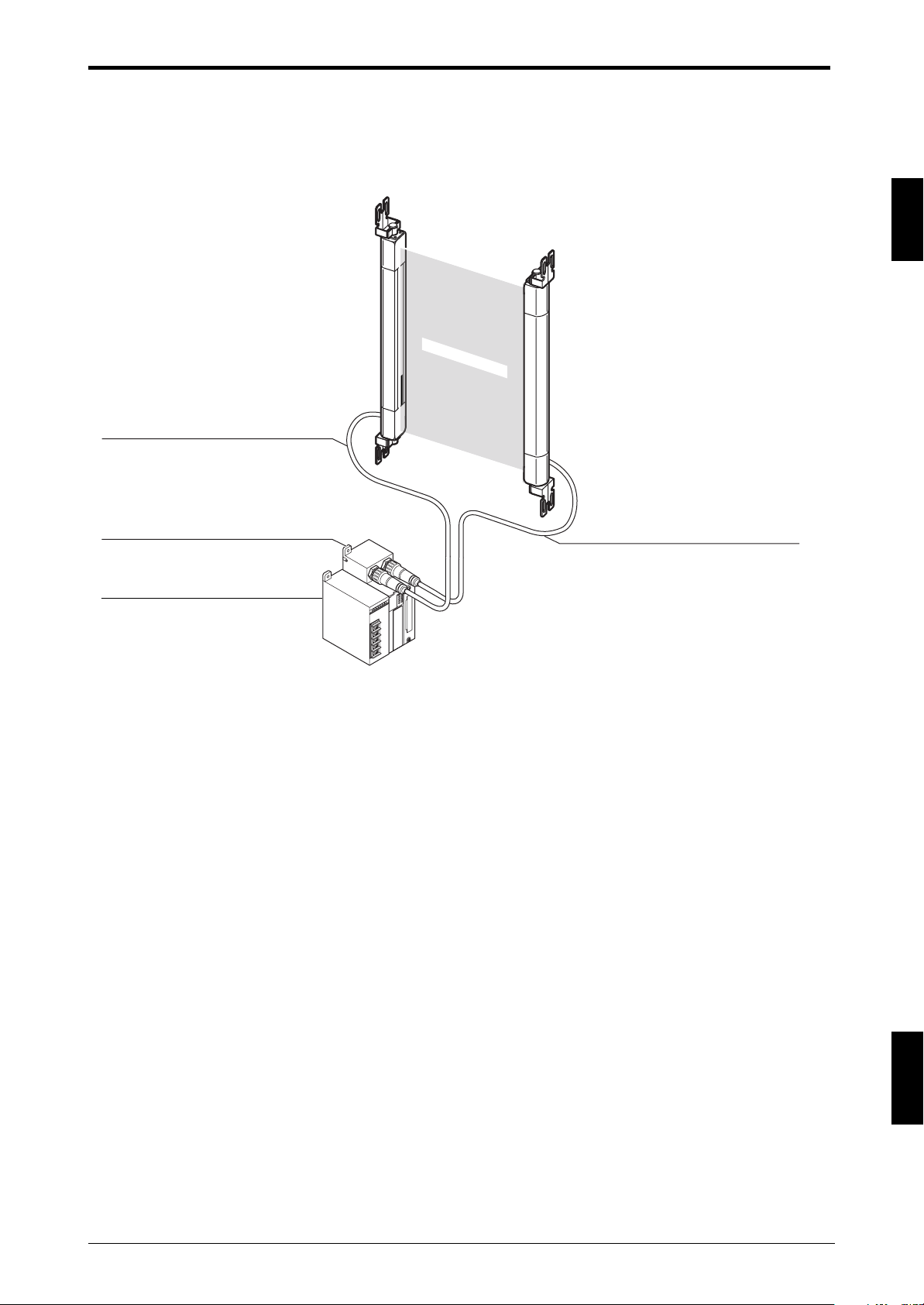

SL-U2 dedicated power supply unit

SL-R11E Safety Control Unit

SL-PC5P (5m (16.4 ft.)) cable for transmitter (gray)

* 10 m (32.81 ft.) SL-PC10P cable

SL-PC5P (5m (16.4 ft.)) cable for receiver (black)

* 10 m (32.81 ft.) SL-PC10P cable

Detection zone

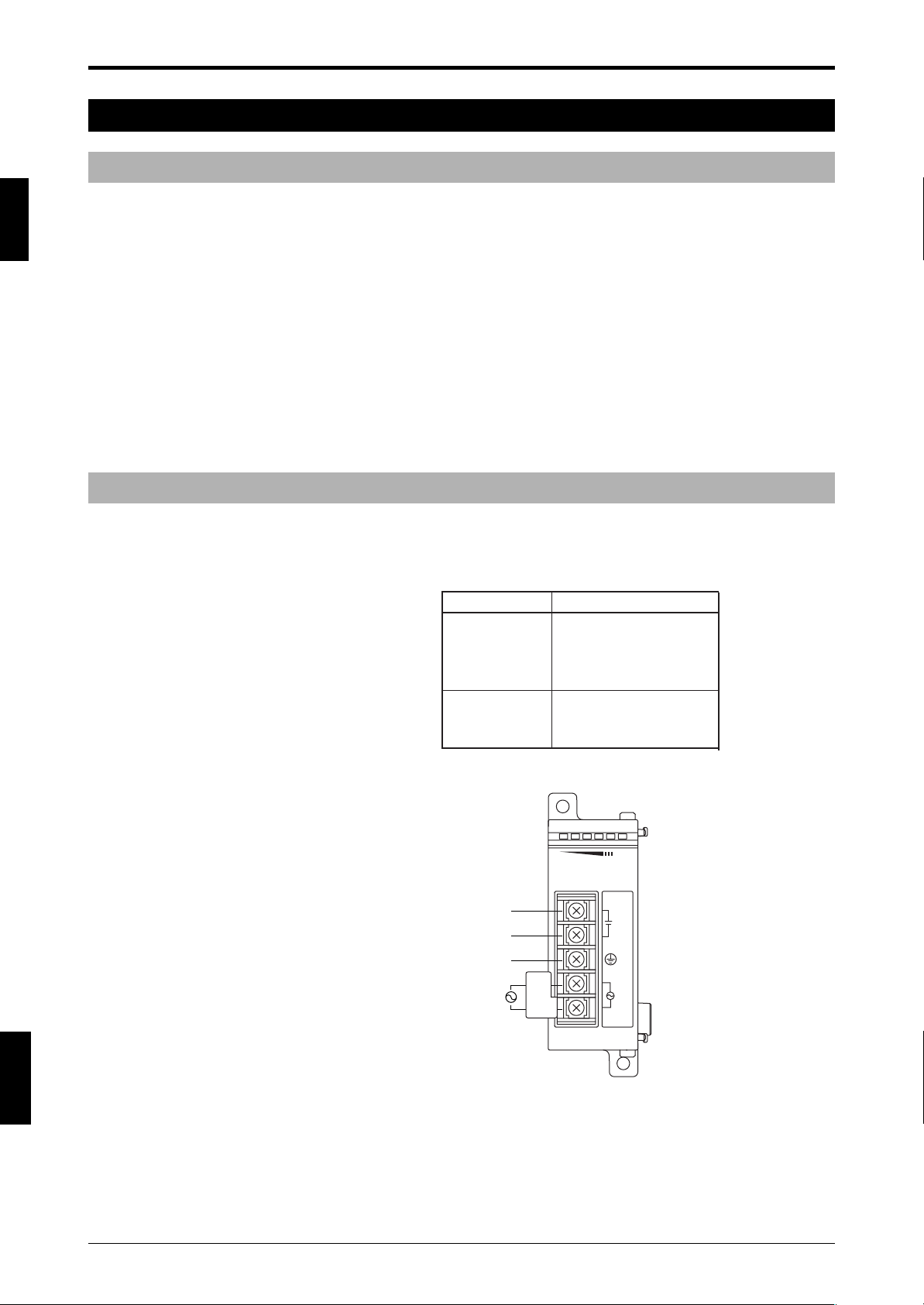

Integration with the SL-C

SL-C Series+ SL-R11E (Safety Control Unit) + SL-U2 (Dedicated power supply unit)

Chapter 1 Specifications

1

SL-U2: The UL certified, recommended dedicated power supply unit

* For connecting the SL-CHM Series, contact your nearest Sales Office.

ENGLISH

1-1

1

Front view

Side

Front view

Bottom

See Instruction Manual.

T R

Rear

See Instruction Manual.

T R T R

Hole for mounting screw

(for M4)

Hole for mounting screw (for M4)

SL-C Series connector,

"T" side

SL-C Series connector,

"R" side

Mode switch

cover fastener

SL-R12EX connector

*Covered by tape at

time of shipment.

SL-U2 connector

*Covered by tape at

time of shipment.

Mode switches

Signal input

terminal block

See Instruction Manual.

Input/output

terminal block

SL-U2,

SL-R12EX

mounting

holes

DIN rail

mating area

Din rail

lock pin

Connector for the

light interference

prevention connection

*Covered by tape at

time of shipment.

POWER

OSSD-ON

OSSD-OFF

INTERLOCK

LOCKOUT

RESTART

TEST

MPCE

E-STOP1

E-STOP2

POWER

OSSD-ON

OSSD-OFF

INTERLOCK

LOCKOUT

RESTART

TEST

MPCE

E-STOP1

E-STOP2

Chapter 1 Specifications

1-1 Part Names

This chapter gives the names of the SL-R11E parts.

ENGLISH

English

1-2

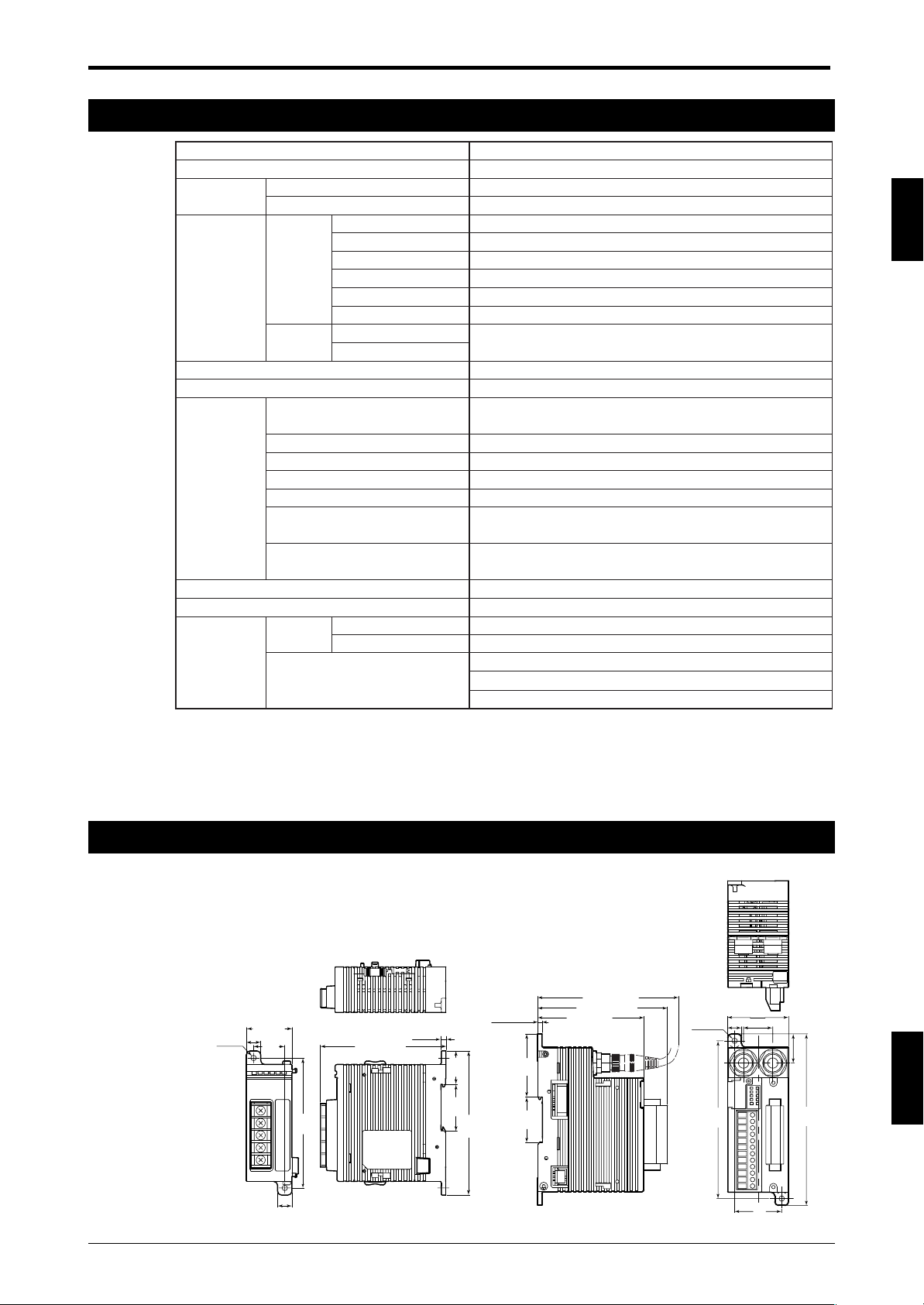

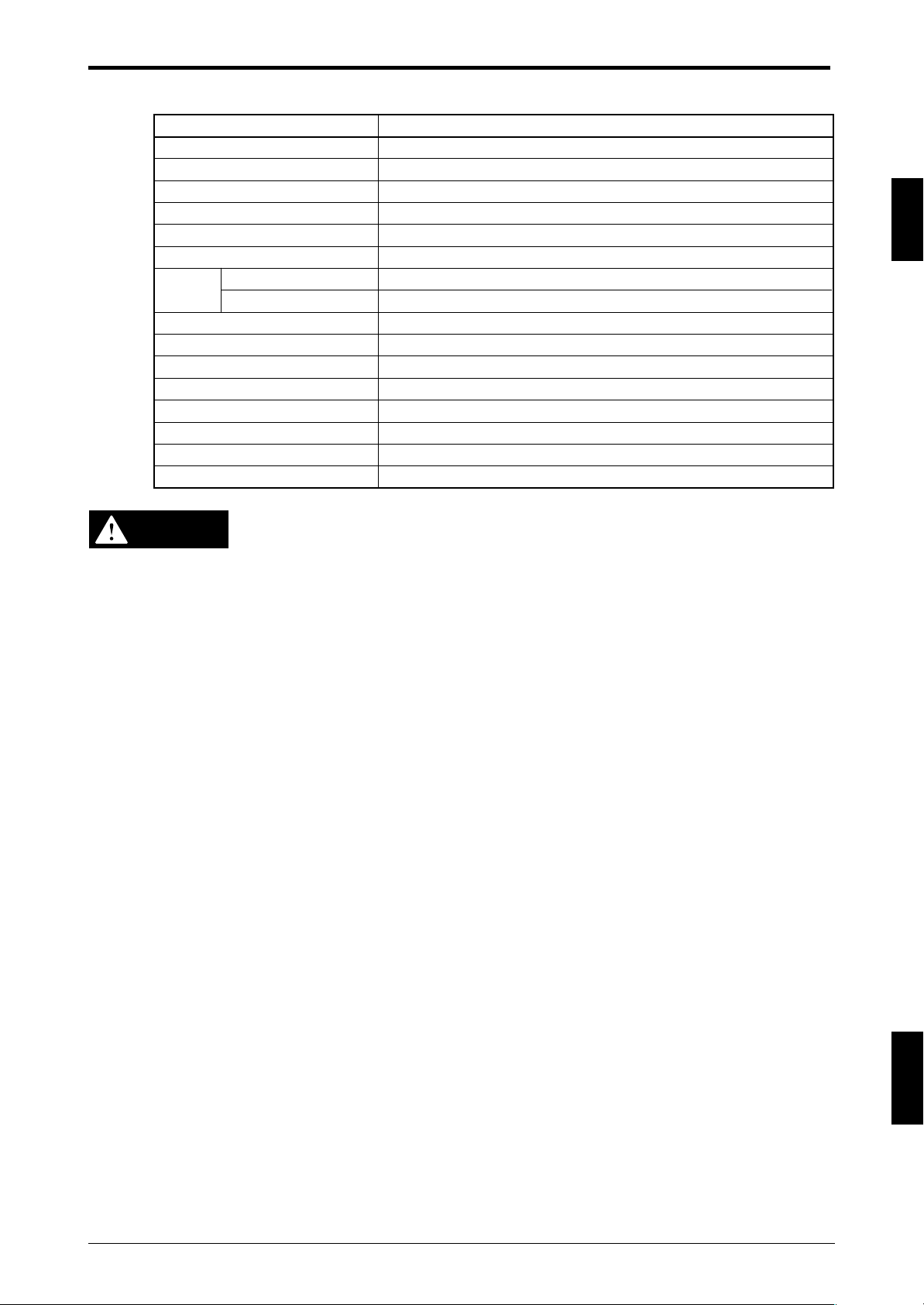

1-2 Specifications

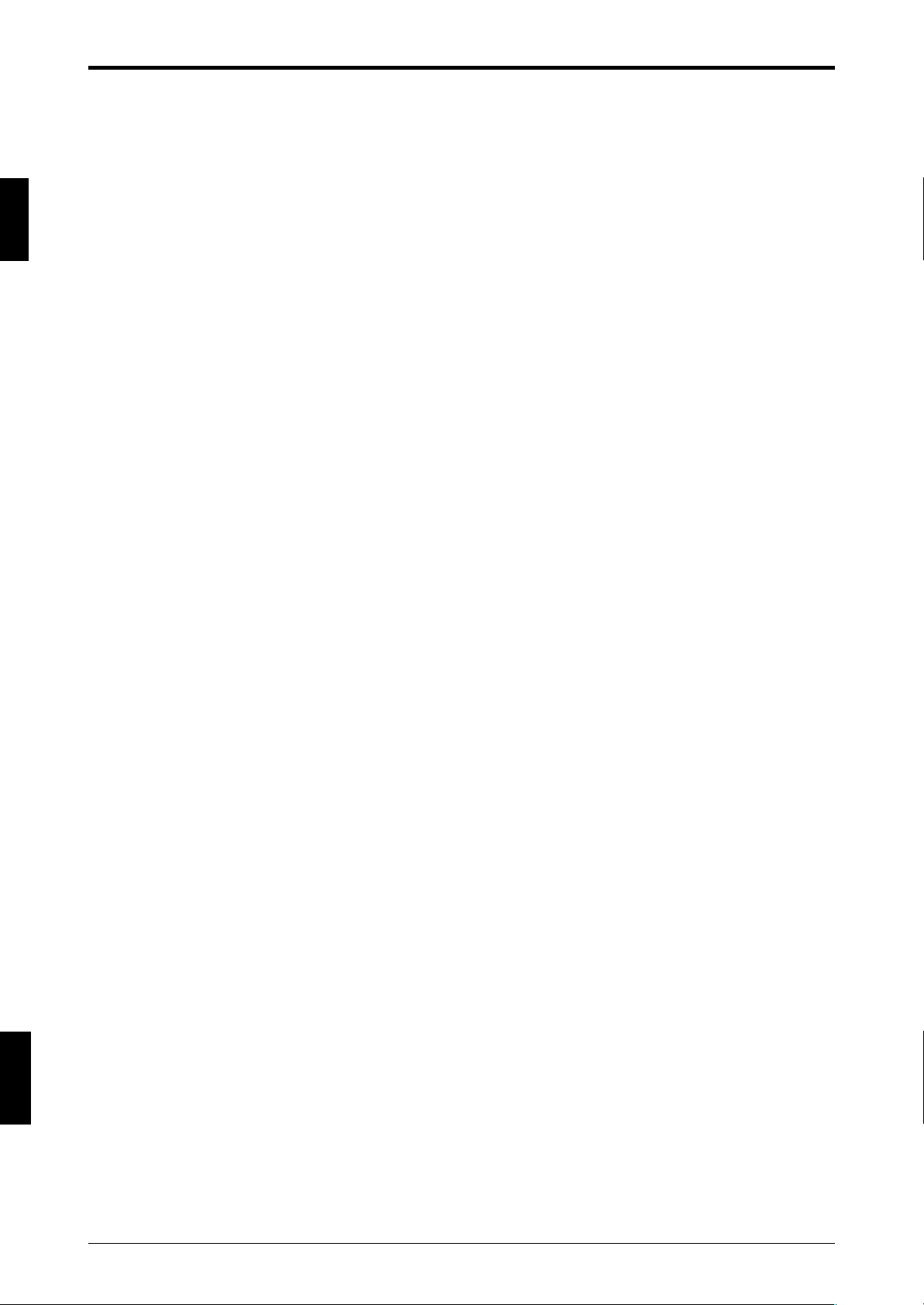

11

(0.43")

100

(3.94")

24

(0.94")

35 (1.38")

2-ø4.2

(96.6 (3.8"))

25.8

(1.02")

35.9

(1.41")

111

(4.37")

(ø0.17")

2-ø4.2

SL-U2 SL-R11E

3.5 (0.14")

(102.3 (4.03"))

3.5

(0.14")

(112 (4.41"))

49.8

(1.96")

35.9

(1.41")

83.8 (3.3")

11 (0.43")

(ø0.17")

11 (0.43")

48 (1.89")

23 (0.91")

23 (0.91")

135

(5.31")

124

(4.89")

37

(1.46")

Model

Safety Light Curtain

Rating

Power supply voltage

Current consumption

Output

OSSD1, 2

Output type

Maximum load current

Residual voltage (ON)

Leak current

Maximum load capacity

Load wiring resistance

AUX PNP

NPN

Response time OSSD1, 2, AUX

Response time during E-STOP input

Environmental

Protective structure

specifications

Ambient temperature

Storage ambient temperature

Relative humidity

Storage ambient humidity

Vibration

Shock

Material

Weight

Approved EMC EMS

standards

*

1

EMI

Safety

SL-R11E

SL-C Series

24V DC ±10% ripple (P-P) 10% max.

100mA max. (for SL-R11E only)

PNP open collector

500 mA

2V

100 μA max.

2.2 μ

F(with 100-Ω_load resistance)

10-Ω

_max.*2

24 VDC,5 mA max.,residual voltage:2V max.

20ms (including sensor response time)*

3

20ms

IP20 (IEC60529) (Install in control panels equal to or

greater than IP54)

-10 to +55 °C (No frost)

-10 to +60 °C (No frost)

35 to 85% RH (No condensation)

35 to 95% RH

10 to 55 Hz double amplitude width 0.7 mm, 20 sweeps

each for X, Y, Z directions

100 m/s

2

(Approx. 10G) 16ms pulse, in X, Y, Z directions

1,000 times each axis

Polycarbonate

350 g max.

UL61496-1

FCC Part 15B Class A

UL61496-1 (type 4 ESPE)

UL61496-2 (type 4 AOPD)

UL508

Chapter 1 Specifications

1

1Evaluated in combination with the SL-C Series

1-3 External Dimensions Diagram

*

2For the correct performance of the SL-R11E, limit the wiring resistance of the

*

3 The OFF → ON return time is 146 ms.

*

device connected to the OSSD to 10 Ω.

ENGLISH

1-3

Chapter 1 Specifications

Standard

EN60950-1

Safety EN50178

standard UL60950-1 (R/C)

UL508 (Listing)

EN55011 Class A

EMC standard EN61000-6-2

FCC Part 15B Class A

SL-U2

24V DC

100 to

240 V AC

+

–

PE (GND)*

SL-U2

OC

+

-

N

L

CAUTION

100-240V AC

ONLY

1-4 Power Supply Precautions

1

1-4-1

The power supply units that can be used as the power supply for SL-C Series and SL-R11E must completely

satisfy the following requirements in order to satisfy the requirements of UL61496-1 for the SL-C Series and

SL-R11E.

(a) Rated output voltage is 24V DC ±10%.

(b) The power supply to be used shall be a dedicated power supply for the SL-C Series and/or SL-R11E and

(c) The power supply output must satisfy the requirements for a Class 2 Circuit or Limited Voltage/Current

(d) The power supply must comply with the laws, regulations, and standards covering electrical safety,

(e) The output hold time is 20 ms min.

Power Units that Can Be Used as Power Supplies for SL-C Series and SL-R11E

shall not be used to supply power to other devices.

Circuit as prescribed by UL508. (This requirement applies only when the SL-C is to be used in North

America.)

electromagnetic compatibility (EMC), etc., for the country or region in which the SL-C Series and/or SLR11E will be used.

1-4-2 Recommended Dedicated Power Supply Unit

The SL-U2 is offered as the SL-C Series dedicated power supply. The SL-U2 is a power supply that

completely satisfies the above requirements.

<Approved standards>

ENGLISH

English

(*) The PE terminal is a protective conductor terminal that must be connected to a protective earthing

conductor in the building installation.

1-4

<Specification>

System

Switching type

Input power supply voltage

AC 100 to 240 V ±10 % (50/60 Hz)

Overvoltage category

Output voltage

DC 24 V ±10 %, Class 2

II

Ripple/noise

240 mVp-p or less

Output capacity

1.8 A

Ambient temperature

-10 °C to +55 °C (non-freezing)

Relative humidity

35 % to 85 % RH (non-condensing)

Pollution degree

2

Withstand voltage

AC 1,500 V, 1 min. (between all external terminals and case)

Insulation resistance

At least 50 MΩ (DC 500 V mega, between all external terminals and case)

Supply voltage interruption

10 ms or less

Power consumption

135VA

Weight (excluding dedicated brackets)

Approx. 240 g

Model

SL-U2

Environment

10 to 55 Hz, 0.7 mm (0.03") compound amplitude, 20 sweeps each in X, Y, and Z directions

100 m/s2, 1,000 iterations each in X, Y, and Z directions

Vibration resistance

Shock resistance

WARNING

Chapter 1 Specifications

1

For the power supply used for the SL-C Series and SL-R11E, always use a power

supply that can fully satisfy the above requirements or use recommended SL-U2

power supply. Otherwise, the UL61496-1 requirements may not be satisfied and the

SL-C Series and SL-R11E may not be recognized as a safety component.

ENGLISH

1-5

1

Chapter 1 Specifications

MEMO

ENGLISH

English

1-6

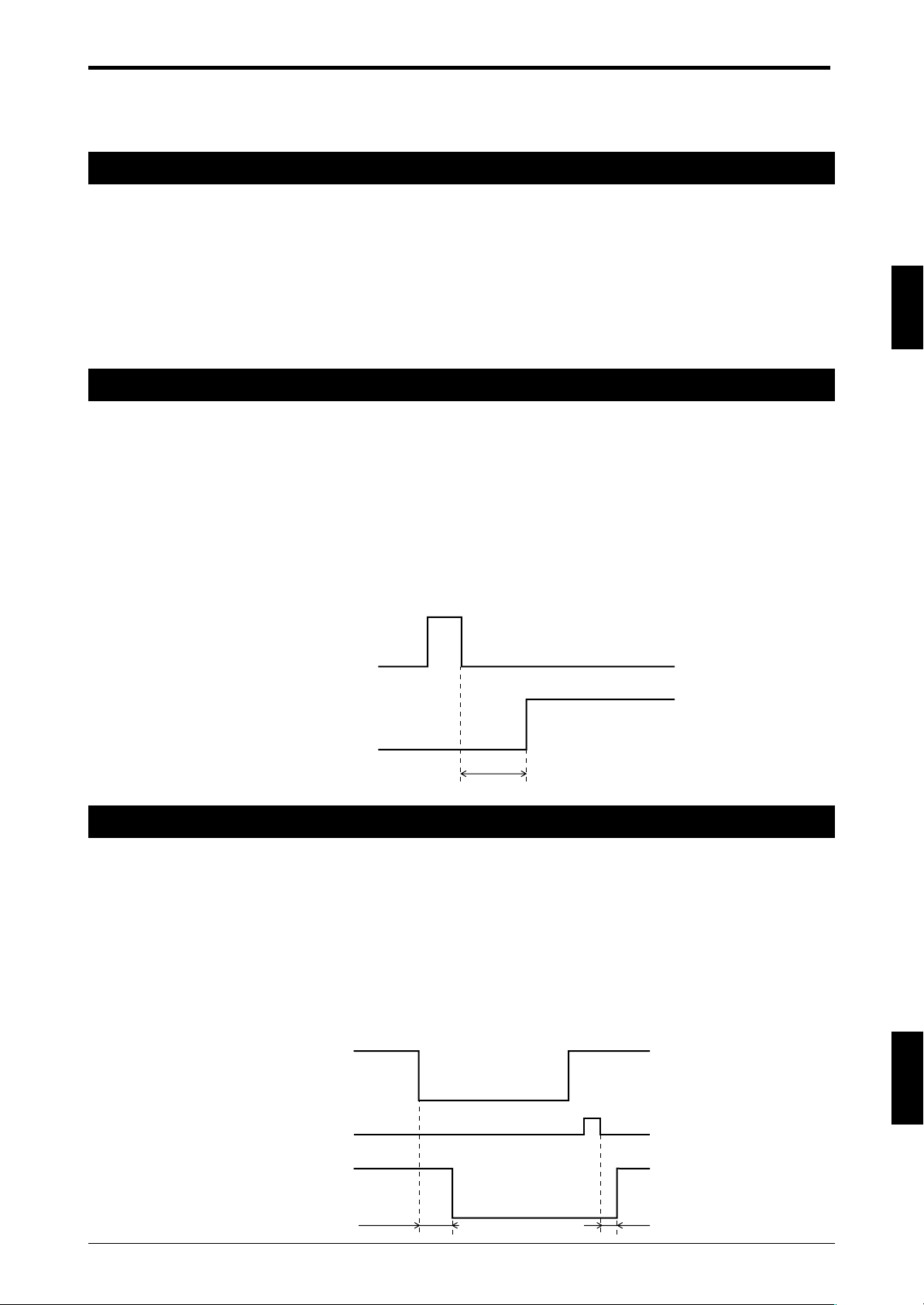

Chapter 2 Functions

ON

OFF

ON

OFF

Start/restart input

OSSD

35ms Max.

ON

OSSD

ON

OFF

OFF

20ms Max.

35ms Max.

Start/restart input

E-STOP input

2 Functions

2-1 Start Interlock

This function keeps the OSSD turned off when the power to the SL-R11E is turned on. At this time, the

OSSD will not turn on even when the SL-C Series connected to the SL-R11E is clear of any obstruction in

the detection zone. In order to cancel the start interlock status (in other words, to turn the OSSD ON to allow

the machine to start), the start/restart input must be input when there are no obstacles in the detection zone.

This will cause the OSSD to turn on, allowing the cancellation of the start interlock status.

Using this function prevents the machine from being automatically started when the power is turned on, or

when the start switch, etc., is pressed after safety has been confirmed.

➮

For details, See page 4-4 “4-3-1 Wiring to Start/Restart Input Terminals”.

2-2 Restart Interlock

The OSSD turns off when an obstacle interrupts the detection zone, and this function keeps the OSSD

turned off even after the obstacle is removed from the detection zone. In order to cancel the restart interlock

status (in other words, to turn the OSSD ON to allow the machine to restart), the start/restart input must be

input when there are no obstacles in the detection zone. This will cause the OSSD to turn on, allowing the

cancellation of the restart interlock status.

This function prevents the machine from automatically starting even when the obstacle detected by the SL-C

Series is removed from the detection zone, so after the safety check is completed, the machine can be

restarted by pressing the start switch, etc.

➮

For details, See page 4-4 “4-3-1 Wiring to Start/Restart Input Terminals”.

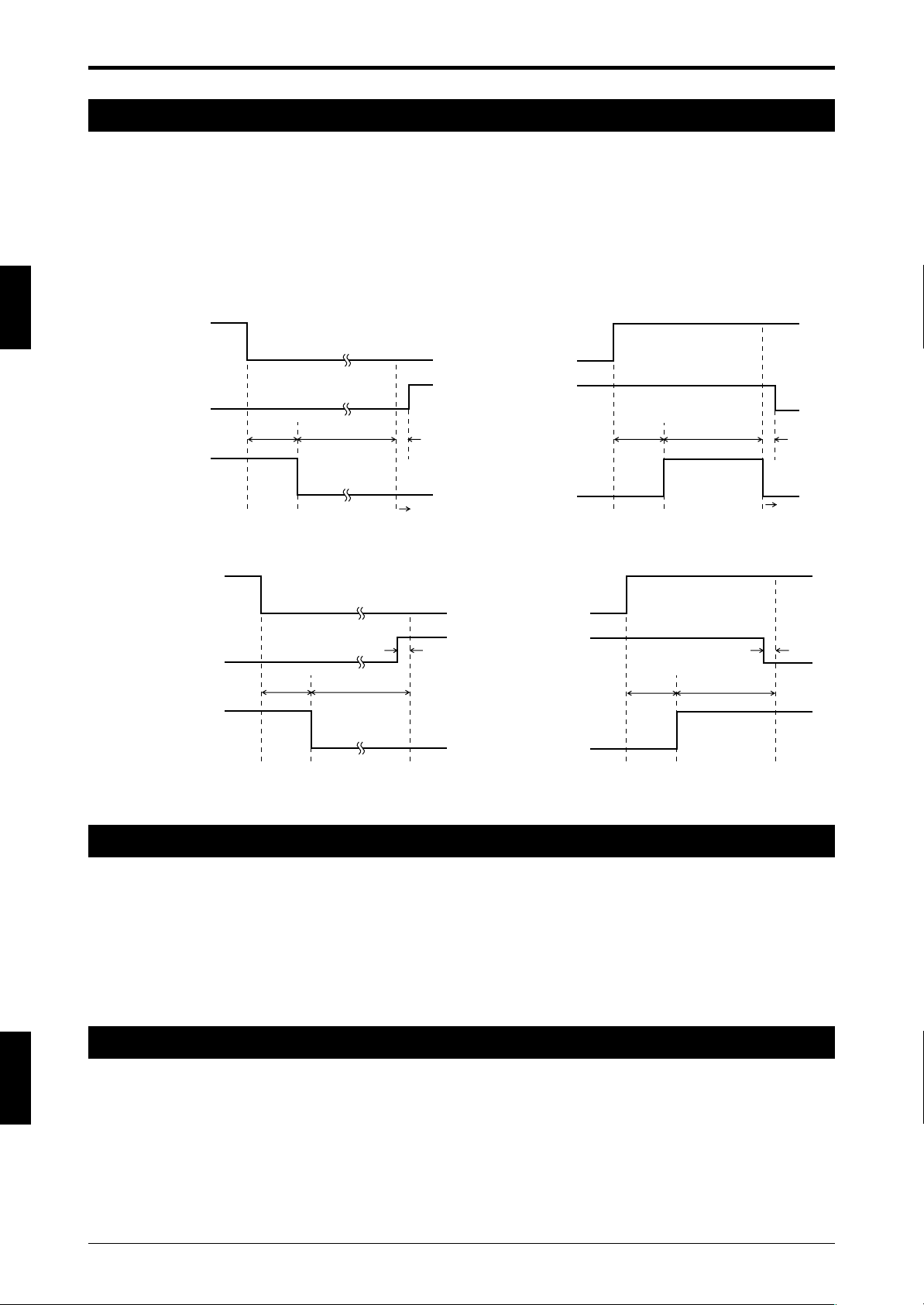

Start/restart input timing chart

2

2-3 E-STOP Input

E-STOP input refers to 2 normally closed signal inputs that are used to rapidly stop the machine when the

emergency stop switch or similar button is operated. The SL-R11E has a terminal (E-STOP1 and E-STOP2

input terminals) for receiving the input signal from the emergency stop switch (or similar button) operation, so

the machine can be emergency stopped via the SL-R11E. SL-R11E requires the start/restart input in order to

return to the normal operation from an emergency stop state. That is why the SL-R11E requires the start/

restart input to cancel the interlock state in addition to the manual restart of E-STOP signal input.

This function not only makes emergency stopping possible when danger is detected by the SL-C, but can

also cause the OSSD provided in the SL-R11E to be operated by E-STOP input from an emergency stop

switch, etc., so it can be used to make output systems uniform.

➮

For details, See page 4-5 “4-3-2 Wiring to E-STOP Input Terminals”.

2-1

ENGLISH

2

ON

OFF

ON

OFF

Clear

Blocked

OSSD

20ms Max. 292ms Max.

ON

OFF

ON

OFF

Clear

Blocked

OSSD

MPCE monitor

input

20ms Max. 292ms Max.

Lockout

condition

Lockout

condition

MPCE monitor

input

**

ON

OFF

ON

OFF

Clear

Blocked

OSSD

MPCE monitor

input

20ms Max. 292ms Max.

ON

OFF

ON

OFF

Clear

Blocked

OSSD

MPCE monitor

input

20ms Max. 292ms Max.

**

Chapter 2 Functions

2-4 MPCE (Machine Primary Control Element) Monitor

MPCE (Machine Primary Control Element) is the machine's main control element and is used between the

SL-R11E control output (OSSD) and the machine to directly control the machine start/stop. The MPCE uses

safety relays, contactors, and so on, and inputting the feedback signal from these to the MPCE monitor input

terminal provided in the SL-R11E makes it possible to monitor MPCE errors. When an MPCE error causes

the OSSD and MPCE operation not to be linked, the SL-R11E immediately turns off the OSSD, and the SL-C

Series and SL-R11E go to the lockout condition.

➮

For details, See page 4-7 “4-3-3 Wiring to MPCE Monitor Input Terminal”.

Timing chart when an error occurs

Timing chart when normal

* Depends on response time of machine’s MPCE

2-5 Main/Sub Setting

This is set when making a light interference prevention connection to the SL-C Series. Be sure to read about

the light interference prevention connection from the “Safety Light Curtain SL-C Series Instruction Manual.”

The light interference prevention connection function is enabled only when a maximum of 4 SL-R11Es are

connected via a light interference prevention cable and the maximum number of beam axes of the SL-C

Series connected to the SL-R11E is 192, only one SL-R11E must be set to the main mode, and all of the

other SL-R11E that are connected via light interference prevention cables must be set to the sub mode.

➮

For details, See page 4-7 “4-3-4 Connecting to Main/Sub Select Input Terminal”.

ENGLISH

English

2-6 TEST Input

The test input forcefully stops light beam transmission from the transmitter by using an external input.

The test input is used to see if the machine connected to the SL-C and SL-R11E can stop within the prescribed time when the OSSD turns off.

For example, when the test input is performed with the SL-C in the normal state (when OSSD output is on

when all beam axes are clear of any obstruction), the OSSD is forced off and only one bar LED of the SL-C

flashes red. (However, this excludes when the Fixed Blanking function is used.)

This test input cannot be used when the SL-R12EX is used and the Programmable Muting Bank function is

enabled. Therefore, the Programmable Muting Bank function must be canceled to enable test input.

2-2

Loading...

Loading...