KEYENCE SL-CHS User Manual

96M13267

SafetyLightCurtain

SL-CHS Series

InstructionManual

NOTICE

Do not attempt to operate or service this light

curtain or product until you have read and

understood the instructions written in this

manual.

Contents

Safety Precautions

1. Safety Headings ........................................................................................................................................iii

2. General Precautions .................................................................................................................................iii

3. Warning ......................................................................................................................................................iv

4. Circuit Design and Wiring .........................................................................................................................v

5. Testing and Maintenance ..........................................................................................................................v

6. About Standards and Regulations ..........................................................................................................vi

7. Package Contents .................................................................................................................................... vii

1 Overview and Specifications

1-1 Component Names and Units ........................................................................................................... 1-1

1-1-1 Main System and Cables ............................................................................................................ 1-1

1-2 Mounting Brackets and Cables ......................................................................................................... 1-2

1-2-1 Mounting Brackets ...................................................................................................................... 1-2

1-2-2 Cables ......................................................................................................................................... 1-3

1-3 Specifications ..................................................................................................................................... 1-4

1-4 Dimensional Drawings ....................................................................................................................... 1-6

1-5 Functions ........................................................................................................................................... 1-11

1-5-1 Status Indicator .......................................................................................................................... 1-11

1-5-2 Lockout Status Bar LED Indicator ............................................................................................. 1-12

1-5-3 Test Input .................................................................................................................................. 1-13

1-5-4 NPN and PNP Outputs ............................................................................................................. 1-13

1-5-5 Series Connection .................................................................................................................... 1-13

1-5-4 Light Interference Prevention Connection ................................................................................ 1-13

ENGLISH

English

2 Installation and Assembly

2-1 Detection Zone and Installation ........................................................................................................ 2-1

2-1-1 Mounting Direction and Position ................................................................................................ 2-3

2-2 Safety Distances ................................................................................................................................. 2-5

2-2-1 EN999 (ISO13855) ..................................................................................................................... 2-6

2-2-2 ANSI B11.19-2003 ...................................................................................................................... 2-7

2-3 Mounting Procedure........................................................................................................................... 2-8

2-3-1 Connecting Cable Installation ..................................................................................................... 2-8

2-3-2 Fixing the Mounting Brackets...................................................................................................... 2-8

2-3-3 Protection Bar Installation ......................................................................................................... 2-11

2-3-4 Installation Distance from Glossy Surfaces .............................................................................. 2-13

2-3-5 Light Interference Prevention Method ....................................................................................... 2-14

i

3 Wiring

3-1 Wiring Methods .................................................................................................................................. 3-1

3-2 Power Requirements .......................................................................................................................... 3-1

3-3 When Only the SL-CHS is Used ........................................................................................................ 3-3

3-4 For SL-PC Cable (main unit plug - M12 connector)......................................................................... 3-4

3-5 Series Connection .............................................................................................................................. 3-4

3-6 Connection for Light Interference Prevention (Parallel Connection) ............................................ 3-5

3-7 Series Connection and Light Interference Prevention Connection (Parallel Connection) .......... 3-6

3-8 I/O Circuits .......................................................................................................................................... 3-7

3-9 Beam Axis Adjustment ...................................................................................................................... 3-8

4 Checklist

4-1 Post-Installation Itemized Checklist ................................................................................................. 4-1

4-2 Maintenance ........................................................................................................................................ 4-3

4-2-1 Inspection Prior to Daily Operation ............................................................................................. 4-3

4-2-2 Regular Inspection ...................................................................................................................... 4-5

5Troubleshooting

Troubleshooting .................................................................................................................................... 5-1

6Revision history

Revision History

96M13267

ENGLISH

ii

Safety Precautions

This instruction manual describes handling, operation, and precautionary information for the Safety Light

Curtain (“SL-CHS”).

Read this instruction manual thoroughly before operating the SL-CHS in order to understand the device

features, and keep this instruction manual readily available for reference.

1. Safety Headings

This instruction manual uses the following headings to display important safety information. Strict adherence

to the instructions next to these heading is required at all times.

ENGLISH

English

DANGER

WARNING

CAUTION

Important:

Note:

Tips

➮

Reference:

Failure to follow the instructions may lead to death or serious injury.

Failure to follow the instructions may result in significant harm to machine operators, including death.

Failure to follow the instructions may result in damage to the SL-CHS, or to the

machine on which it is installed.

Provides important precautions and restrictions for proper operation.

Provides additional information for proper operation.

Provides useful information for proper operation.

Provides reference pages.

2. General Precautions

•Verify that this device is operating normally in terms of functionality and performance before the start of

work and before the start of device operation.

• KEYENCE is unable to warrant the function or performance of the SL-CHS if it is used in a manner that

differs from the SL-CHS specifications contained in this instruction manual or if the SL-CHS is modified.

• When using the SL-CHS to protect machine operators from a hazardous zone or a hazard, or using it as

safety equipment for any purpose, always follow the applicable requirements, regulations, and laws

(collectively “regulations”) existing in the country or region where the SL-CHS is being used. For such

regulations, contact directly the regulatory agency responsible for occupational safety and health in your

country or region.

• Depending on the type of machine to which the SL-CHS is to be attached, there may be special safety

regulations related to the use, installation, maintenance, and operation of the device, and such safety

regulations must be followed. The responsible personnel must install the SL-CHS in strict compliance with

such safety regulations.

• The responsible personnel must train the assigned personnel for the correct use, installation, maintenance, and operation of the SL-CHS. “Machine operators” refers to personnel who have received appropriate training from the responsible personnel and are qualified to operate the device correctly.

• Machine operators must receive specialized training for the SL-CHS and must understand and follow the

safety regulations for the country or region in which they are using the SL-CHS.

• When the SL-CHS fails to operate properly, machine operators must immediately stop the use of the

device and report this fact to the responsible personnel.

• The SL-CHS is designed with the assumption that it would be properly installed in accordance with the

installation procedures described in this instruction manual and operated according to the instructions in

this instruction manual. Perform an appropriate installation of the SL-CHS after conducting a sufficient

risk assessment for the target machine.

• This device should be processed as an industrial waste product when being disposed.

iii

3. Warning

■ Operators

• In order for the SL-CHS to operate properly, the responsible personnel and machine operators must

follow all procedures described in this instruction manual.

• No person other than the responsible personnel and machine operators should be allowed to install or

test the SL-CHS.

• When performing electrical wiring, always follow electrical standards and regulations for the country or

region in which the SL-CHS is being used.

■ Usage environment

• Do not use the device in an environment (temperature, humidity, interfering light, etc.) that does not

conform to the specifications contained in this instruction manual.

• Do not use wireless devices such as cellular phones or transceivers in the vicinity of the SL-CHS.

• The SL-CHS is not designed to be explosion-proof. Never use it in the presence of flammable or

explosive gases or elements.

• Do not use the SL-CHS in the presence of substances, such as heavy smoke, particulate matter, or

corrosive chemical agents, that may induce deterioration in product quality.

• Install the SL-CHS in such a way so that no direct or indirect light from inverter-type fluorescent lights

(rapid-start type lights, high-frequency operation type lights, etc.) shine on the device.

■ Target machine

• The SL-CHS has not undergone the model certification examination in accordance with Article 44-2 of

the Japanese Industrial Safety and Health Law. The SL-CHS, therefore, cannot be used in Japan as a

“Safety Device for Press and Shearing machines” as established in Article 42 of that law.

• The machine on which the SL-CHS is to be installed must be susceptible to an emergency stop at all

operating points during its operation cycle. Do not use the SL-CHS for machines with irregular stop

times.

• Do not use the SL-CHS for power presses equipped with full-revolution clutches.

• Do not use the SL-CHS to control (stop forward motion, etc.) trains, cars and other transportation

vehicles, aircraft, equipment for use in space, medical devices, or nuclear power generation systems.

• The SL-CHS is designed to protect people or objects from entering a machine's hazardous zone or

hazard. It cannot provide protection against objects or materials that are displaced from the machine's

hazardous zone or hazard, and so implement additional safety measures such as installing safeguards

when there is the possibility of such displacements.

iv

ENGLISH

■ Installation

• The SL-CHS must be installed only after securing the minimum safety distance between the SL-CHS

and the hazardous zone or hazard as established by the applicable regulations of the country or region

in which the SL-CHS is being used.

• Choose locations for the installation of SL-CHS transmitters and receivers so that they are not subject

to the effects of light reflected from glossy surfaces in the area.

• Use the same models (same beam axis) for transmitter/receiver pairs.

• The SL-CHS must be installed in such a way that machine operators cannot reach the hazardous zones

or hazards of the machine without passing through the detection zone of the SL-CHS series. Strictly

avoid installations which allow machine operators to access the area between the SL-CHS and the

machine, or where machine operators can approach the machine's hazardous zones, without passing

through of the SL-CHS Series detection zone.

• Always perform tests after installing the SL-CHS in accordance with the test procedures established in

this instruction manual, verifying that the test pieces are detected in all of the detection zones.

• When the Intelligent Extension Unit (SL-R12EX) is used to enable the fixed blanking function, additional

safety measures must be implemented for the zone in which that function is enabled so that it is impossible to reach the hazardous zone or hazards of the machine by passing through that zone.

• When the Intelligent Extension Unit (SL-R12EX) is used to enable the floating blanking function, the

minimum safety distance will be affected due to the fact that the function has a negative effect on the

detection capability. Therefore, in such cases, calculate the minimum safety distance using the new

value for detection capability with the floating blanking function enabled and apply the result for the SLCHS installation.

• When the Intelligent Extension Unit (SL-R12EX) is used to enable the floating blanking function, confirm

that the actual number of beam axes with which the floating blanking function is active matches the

number of beam axes specified in the floating blanking function setting.

• When the Blanking Blind Protection Unit (SL-CHS08SB/SL-CHS16SB) is used to install the SL-CHS, a

test must be carried out according to the procedures described in this instruction manual to confirm that

the test piece can be detected in all detection zones including the detection zone that can be detected

by the Blanking Blind Protection Unit.

• Securely tighten mounting brackets and cord (cable) connectors used in the installation of the SL-CHS

in accordance with the torque values established in this instruction manual.

ENGLISH

English

4. Circuit Design and Wiring

• Always turn off the device power when performing electrical wiring.

• Follow electrical standards and regulations for the country or region in which the SL-CHS is being used

when performing the electrical wiring. Only qualified persons should perform wiring.

• Do not place any cables or electrical lines used in wiring the SL-CHS in the same duct as high-voltage

electrical or power lines or in parallel with such lines.

• Do not extend transmitter and receiver cables over a maximum distance of 30 meters (98.43 ft.).

• Install the mechanism used to reset the interlock (switches, etc.) in a position from which the condition of

the entire hazardous zone can be checked. Do not install the reset mechanism in a position where it can

be operated within the hazardous zone.

• The control outputs (OSSD for SL-CHS Series or FSD for SL-R11) of the two systems provided in the SLCHS must both be used to build a safety system. Building a safety system with just one of these systems

cannot stop the machine due to a control output malfunction and can result in a serious accident, including serious injury or death to the machine operator.

5. Testing and Maintenance

• Always perform testing in accordance with the test procedures after maintenance, adjustment, or calibration of the target machine or the SL-CHS, and before the machine start-up.

• If the SL-CHS does not operate properly when tested in accordance with the test procedures established

in this instruction manual, do not operate the machine.

• Periodically examine the machine to verify that all brakes, other stop mechanisms, and control devices

operate reliably and accurately in addition to checking the SL-CHS.

• The responsible personnel must perform maintenance procedures as established in this instruction

manual at least once every six months to ensure safe device operation.

v

6. About Standards and Regulations

1) The SL-CHS Series and SL-R11(E) comply with the following UL (Underwriters Laboratories Inc.)

Standards and have received Canada-U.S.-Listing certification from UL.

• UL61496-1 (Type 4 ESPE - Electro-Sensitive Protective Equipment)

• UL61496-2 (Type 4 AOPD - Active Opto-Electronic Protective Device)

2) The SL-CHS Series and SL-R11(E) have not received the model certification examination in

accordance with Article 44-2 of the Japanese Industrial Safety and Health Law. Therefore, the SLCHS Series and SL-R11(E) cannot be used in Japan as a “Safety Devices for Presses and Shearing

machines” as established in Article 42 of that law.

3) The SL-CHS Series and SL-R11(E) have been designed in consideration of the following standards

and regulations. For details regarding the following standards, contact the third-party certification

organization, such as UL.

<Corresponding standards>

• OSHA 29 CFR 1910.212

• OSHA 29 CFR 1910.217

• ANSI B11.1 - B.11.19

• “Guidelines for Comprehensive Safety Standards of Machinery”, July 31, 2007, number 0731001 issued

by, Ministry of Health, Labor, and Welfare in Japan.

vi

ENGLISH

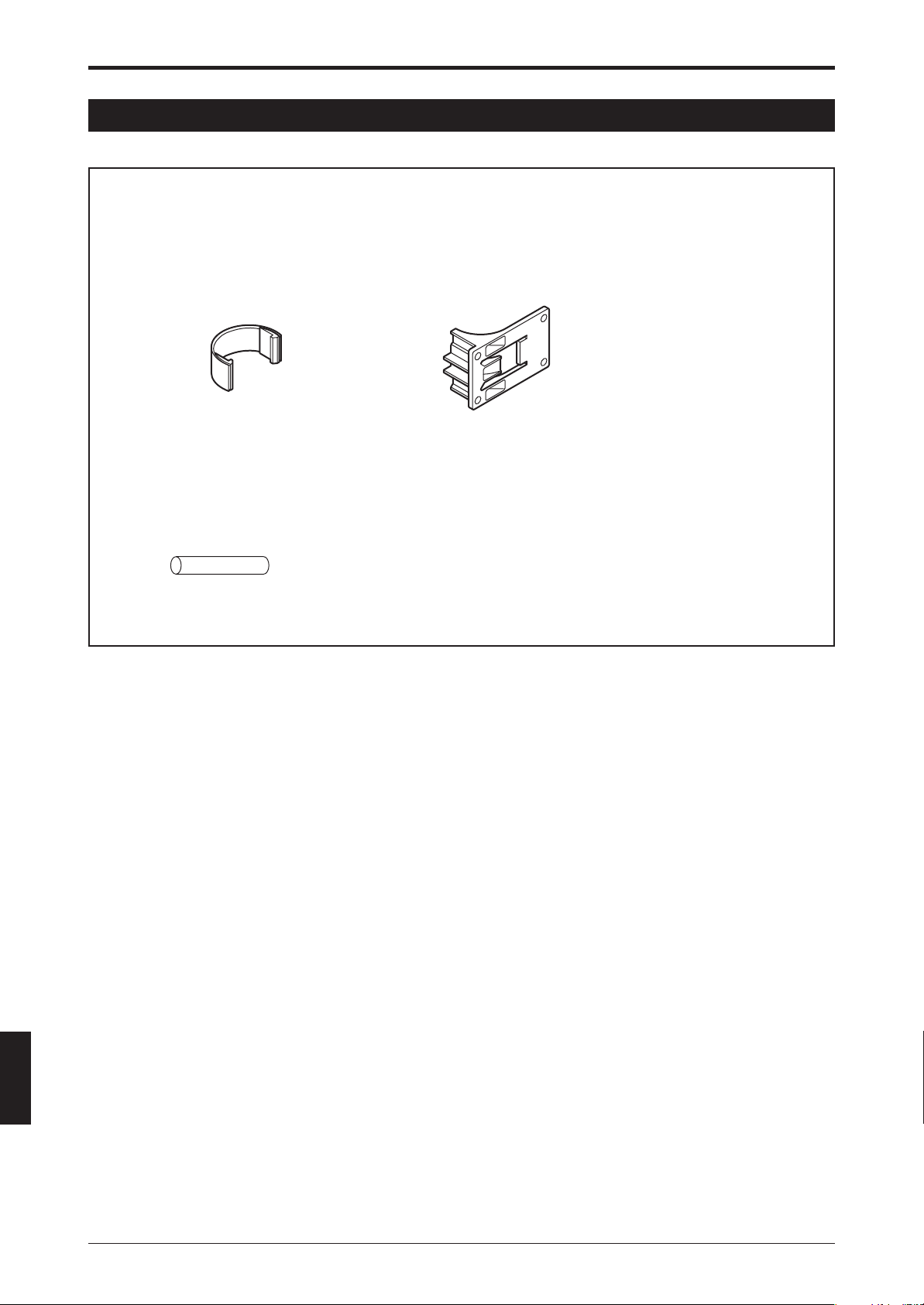

7. Package Contents

Confirm that the package includes the main unit and the following accessories.

■ Accessories

• Intermediate support bracket for installation

*Two pieces of supports are supplied with models SL-C36HS through SL-C48HS. Four pieces of

supports are supplied with models SL-C52HS through SL-C64HS.

Intermediate support bracket A Intermediate support bracket B

*Two connectors are also available grouped as a set (OP-42373).

* It is not possible to install the SL-CHS only by using the intermediate support brackets that come with

models SL-C36HS through SL-C64HS. Use optional mounting brackets along with Intermediate

support brackets.

• One test piece (Diameter, 25 mm (0.98") for SL-CHS)

ENGLISH

English

• Instruction manual (this document) 1 copy

vii

Chapter 1 Overview and Specifications

1 Overview and Specifications

1-1 Component Names and Units

This section describes each part of the SL-CHS Series and optional units.

For component locations and appearances, ➮

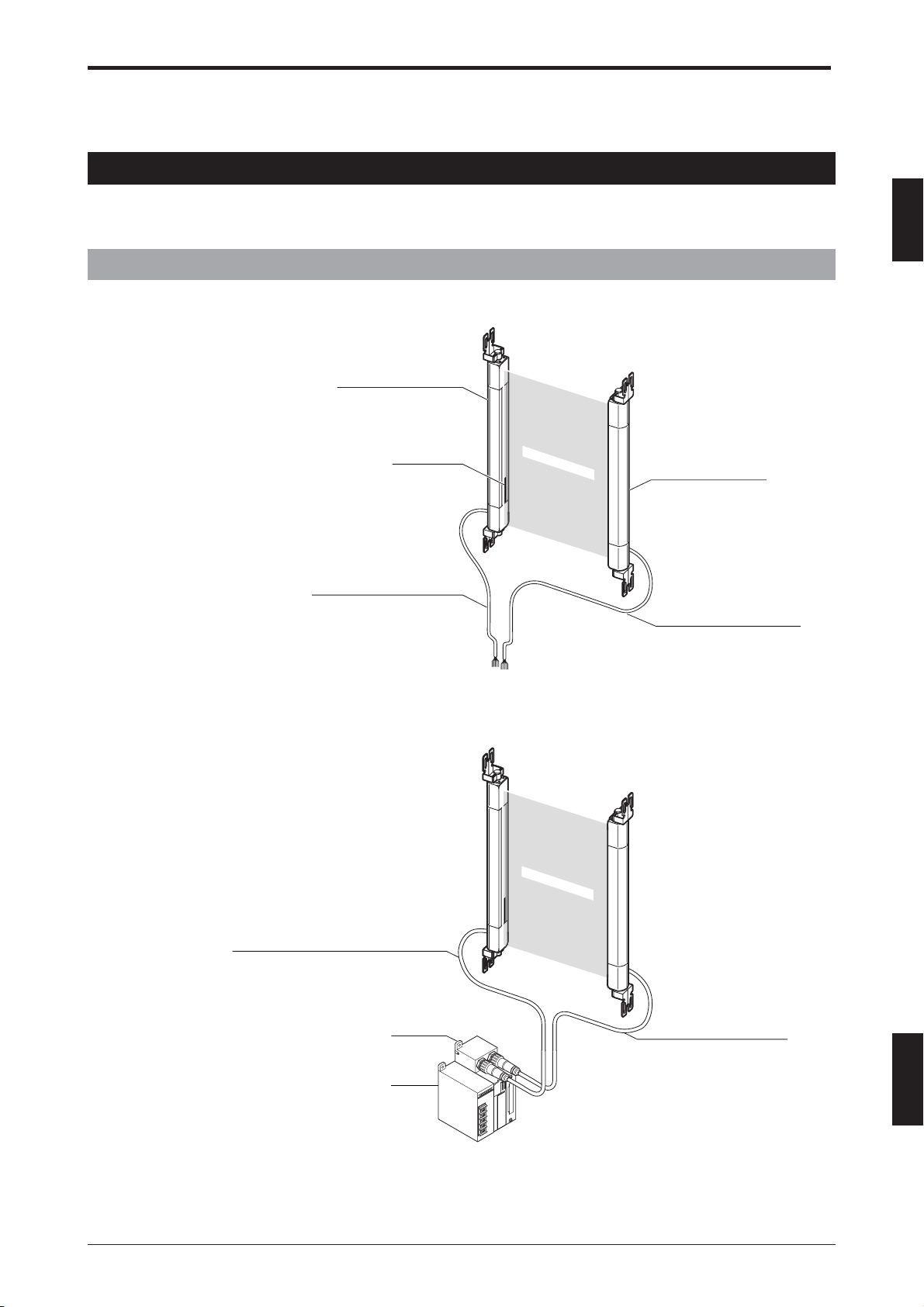

1-1-1 Main System and Cables

When using the SL-CHS stand-alone

see the “1-4 Dimensional Drawings” (page 1-7).

1

T: Transmitter

SL-CHS Series Transmitter

R: Receiver

Status indicator

(on both sides)

SL-P7N/P (7 m (22.97 ft.)) cable

for transmitter (gray)

Detection zone

SL-CHS Series Receiver

SL-P7N/P (7 m (22.97 ft.)) cable

for receiver (black)

When combining the SL-CHS with a controller

SL-CHS Series + SL-U2 (Dedicated power supply unit) + SL-R11 (Intelligent safety relay unit)

Detection zone

SL-PC5P (5 m (16.4 ft.)) cable for transmitter (gray)

* 10 m(32.81

ft.

) SL-PC10P cable

SL-R11

SL-U2

SL-PC5P (5 m(16.4 ft.)) cable

for receiver (black)

* 10 m(32.81

ft.

) SL-PC10P cable

SL-U2: The UL certified or recommended dedicated power supply unit

SL-R11:The safety relay is built-in. This is connected to the SL-CHS by a special connector.

ENGLISH

1-1

Chapter 1 Overview and Specifications

1-2 Mounting Brackets and Cables

This section offers an explanation of safety light curtain mounting brackets and cables. Mounting brackets

and cables are optional equipment for the SL-CHS.

1

1-2-1 Mounting Brackets

Normal mounting bracket A Normal mounting bracket B Normal mounting bracket C

OP-42347 (1 set of 2 brackets) OP-42348 (1 set of 2 brackets) OP-42349 (1 set of 2 brackets)

Includes 6 M3 screws (R=7). Includes 6 M3 screws (R=7). Includes 6 M3 screws (R=7).

Thin type mounting bracket E-to-E mounting bracket L-shaped mounting bracket

OP-51698 OP-42370 (1 set of 2 brackets) OP-42371 (1 set of 2 brackets)

ENGLISH

English

Includes 3 M3 screws Includes 6 M3 flathead screws

(R=7). (small head) (R=5).

Protection bar

SL-C Series Model

SL-C08HS

SL-C12HS

SL-C16HS

SL-C20HS

SL-C24HS

SL-C28HS

SL-C32HS

SL-C36HS

SL-C40HS

SL-C44HS

SL-C48HS

SL-C52HS

SL-C56HS

SL-C60HS

SL-C64HS

* The protection bar cannot be used combined with

the thin type mounting bracket (OP-51698).

Applicable Model

of protection bar

to SL-C Series

OP-42350

OP-42351

OP-42352

OP-42353

OP-42354

OP-42355

OP-42356

OP-42357

OP-42358

OP-42359

OP-42360

OP-42361

OP-42362

OP-42363

OP-42364

1-2

1-2-2 Cables

SL-CHS plug - bare wires SL-P7N (NPN Type 7 m (22.97 ft.))

SL-P15N (NPN Type 15 m (49.21 ft.))

SL-P7P (PNP Type 7 m (22.97 ft.))

ø6

34

(1.34")

SL-CHS plug - M12 connector SL-PC5N (NPN 5 m (16.4 ft.))

SL-PC5P (PNP 5 m (16.4 ft.))

SL-PC10P (PNP 10 m (32.81 ft.))

(Transmitter/receiver set)

Chapter 1 Overview and Specifications

1

ø6

(Transmitter/receiver set)

47

M12 connector - M12 connector SL-CHSC10NT (NPN 10 m (32.81 ft.) Transmitter),

SL-CHSC10NR (NPN 10 m (32.81 ft.) Receiver),

SL-CHSC10PT (PNP 10 m (32.81 ft.) Transmitter),

SL-CHSC10PR (PNP 10 m (32.81 ft.) Receiver)

41.5

ø14

ø6

M12 connector-bare wires SL-CHS5N (NPN 5 m (16.4 ft.))

SL-CHS5P (PNP 5 m (16.4 ft.))

(Transmitter/receiver set)

ø6

ø14

Series connection cable SL-S0 (0.08 m (3.14"))

SL-S1 (0.15 m (5.91"))

SL-S2 (0.5 m (1.64 ft.))

SL-S3 (3 m (9.84 ft.))

SL-S4 (1 m (3.28 ft.))

SL-S10 (10 m (32.79 ft.))

(Transmitter/receiver set)

ø6

ENGLISH

1-3

1

Chapter 1 Overview and Specifications

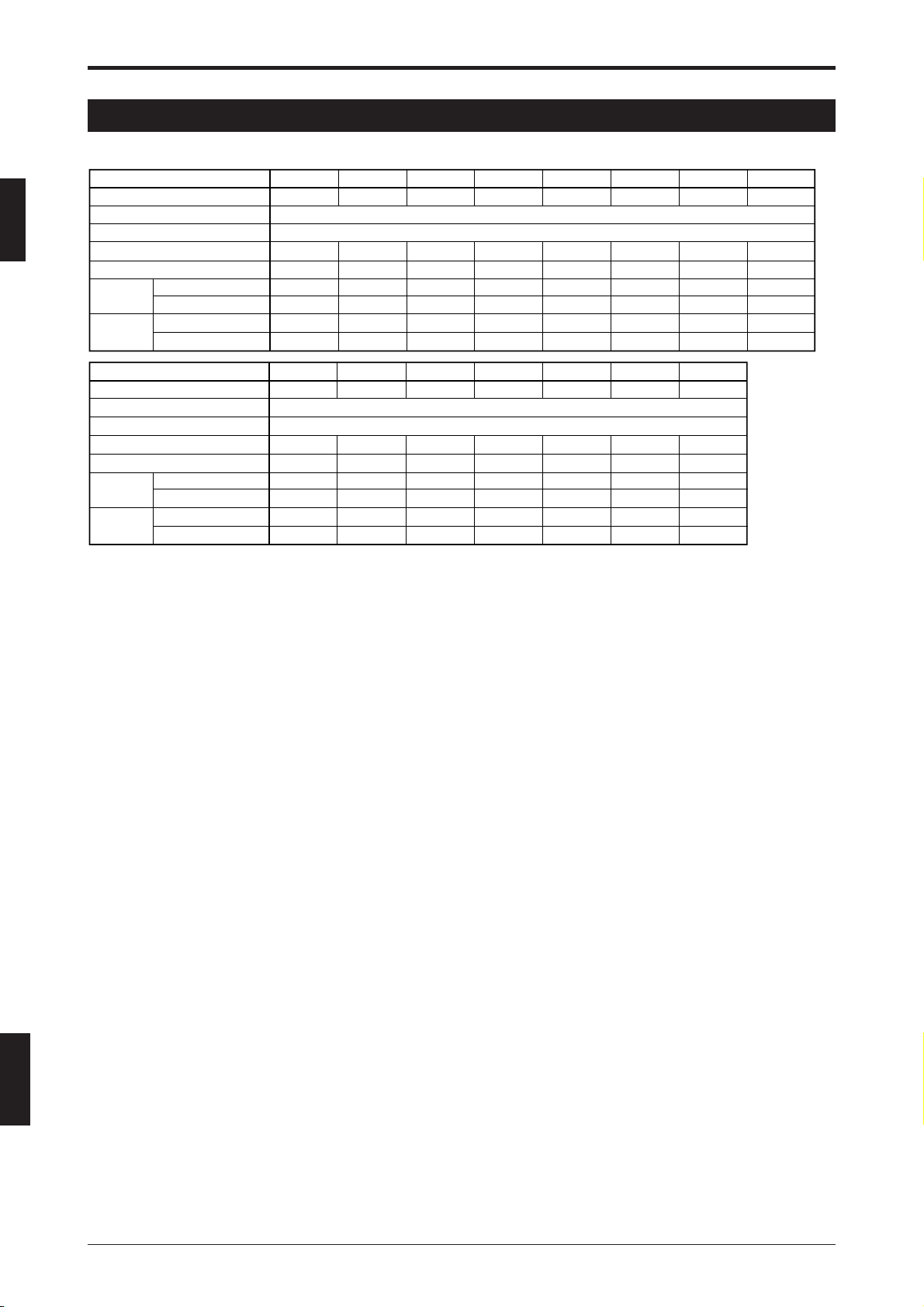

1-3 Specifications

Specifications (Detection capability of 25 mm (0.98") diameter type)

Model

No. of beam axes

Detection capability

Beam Axis Pitch/Lens Diameter

Detection zone

Protection zone

Current

consumption

Weight

Transmitter

Receiver

Transmitter

Receiver

SL-C08HS

140 mm (5.51")

185 mm (7.28")

55 mA

67 mA

Approx. 165 g

Approx. 180 g

SL-C12HS

8

220 mm (8.66")

265 mm (10.43")

Approx. 210 g

Approx. 230 g

SL-C16HS

12

ø25 mm (0.98") (when the blanking function is not used)

300 mm (11.81")

345 mm (13.58")

58 mA

69 mA

61 mA

71 mA

Approx. 255 g

Approx. 280 g

SL-C20HS

16

20 mm (0.79") / ø5 mm (0.19")

380 mm (14.96")

425 mm (16.73")

62 mA

73 mA

Approx. 300 g

Approx. 330 g

SL-C24HS

20

460 mm (18.11")

505 mm (19.88")

68 mA

76 mA

Approx. 345 g

Approx. 380 g

24

SL-C28HS

540 mm (21.26")

585 mm (23.03")

71 mA

78 mA

Approx. 390 g

Approx. 430 g

SL-C32HS

28

620 mm (24.41")

665 mm (26.18")

74 mA

81 mA

Approx. 435 g

Approx. 480 g

32

SL-C36HS

36

700 mm (27.56")

745mm (29.33")

77 mA

83 mA

Approx. 480 g

Approx. 530 g

Model

No. of beam axes

Detection capability

Beam Axis Pitch/Lens Diameter

Detection zone

Protection zone

Current

consumption

Weight

Transmitter

Receiver

Transmitter

Receiver

SL-C40HS

780 mm (30.71")

825 mm (32.48")

81 mA

86 mA

Approx. 525 g

Approx. 575 g

SL-C44HS

40

ø25 mm (0.98") (when the blanking function is not used)

860 mm (33.86")

905 mm (35.63")

84 mA

88 mA

Approx. 570 g

Approx. 625 g

44

SL-C48HS

20 mm (0.79") / ø5 mm (0.19")

940mm (37.01")

985 mm (38.78")

87 mA

90 mA

Approx. 615 g

Approx. 675 g

SL-C52HS

48

1020 mm (40.16")

1065 mm (41.92")

Approx. 660 g

Approx. 725 g

52

91 mA

93 mA

SL-C56HS

1100 mm (43.31")

1145 mm (45.08")

94 mA

95 mA

Approx. 705 g

Approx. 775 g

SL-C60HS

56

1180 mm (46.46")

1225 mm (48.23")

Approx. 750 g

Approx. 825 g

60

97 mA

97 mA

SL-C64HS

64

1260 mm (49.61")

1305 mm (51.38")

100 mA

100 mA

Approx. 860 g

Approx. 945 g

ENGLISH

English

1-4

Chapter 1 Overview and Specifications

Common specifications

Model

SL-C**HS Operating distance

Effective Aperture Angle

Max. ±2.5° (When operating distance is 3 m (9.84 ft.) or more)

Response time

Light source

Operation form

Rating

Power voltage

Output type

Turns on when light is received from all light beams (except when the blanking function is used)

24V DC ±10% (Ripple P-P 10% or less)

2 outputs each for PNP and NPN, Can be changed using the connector cable

Max. load current

OSSD

Output

OFF-state voltage

Leakage current

Max. capacitive load

2.5 V (with a cable length of 7 m (22.97 ft.))

0.47 µF (with a load resistance of 100 Ω)

Load wiring resistance

Protective structure

Environmental

specifications

Ambient temperature

Storage ambient temperature

Relative humidity

Storage ambient humidity

Ambient light

Vibration

Shock

35 % to 85 %RH (No condensation)

White incandescent lamp: 5,000rx or less Sunlight: 20,000rx or less

10 to 55 Hz, 0.7 mm compound amplitude, 20 sweeps each in X, Y, and Z directions

100 m/s2 (Approx. 10G) 16ms pulse, in X, Y, Z directions 1,000 times each axis

Main unit case

Material

Upper case/Lower case

Overlay

EMC

Approved

standards

*1 OFF ➝ ON return time is 125 ms.

*2 Note the derating illustrated in the graph to the right when using PNP output.

*3 Includes when the SL-CHS Series power supply is OFF or when there is a disconnection in the power

supply line.

*4 In order to guarantee the proper operation of the SL-CHS safety circuit, the wiring resistance

(excluding dedicated cable wiring resistance) of the cabling connected to the hardware to which the

OSSD output and OSSD input are connected must be 2.5 Ω or less. For NPN output type cable, do not

let wiring resistance exceed a maximum of 1.0 Ω when the cable length is 15 m (49.21 ft.) or greater

and the load current is 200 mA or higher.

Safety

EMS

EMI

SL-CHS Series

0.3 to 9 m

1

15 ms*

Infrared LED (850 nm)

300 mA*

2

Max. 100 µA*

Max. 2.5 Ω*

4

IP65 (IEC60529)

-10°C to 55°C (No frost)

-10°C to 60°C (No frost)

35 % to 95 %

Aluminum

Zinc die-cast

Polycarbonate

UL61496-1

FCC Part15 Class A

UL61496-1 (

UL61496-2 (

type

type

UL508

4 ESPE)

4 AOPD)

3

(mA)

300

200

100

0

10 20 30 40 50 (°C)

1

1-5

ENGLISH

Chapter 1 Overview and Specifications

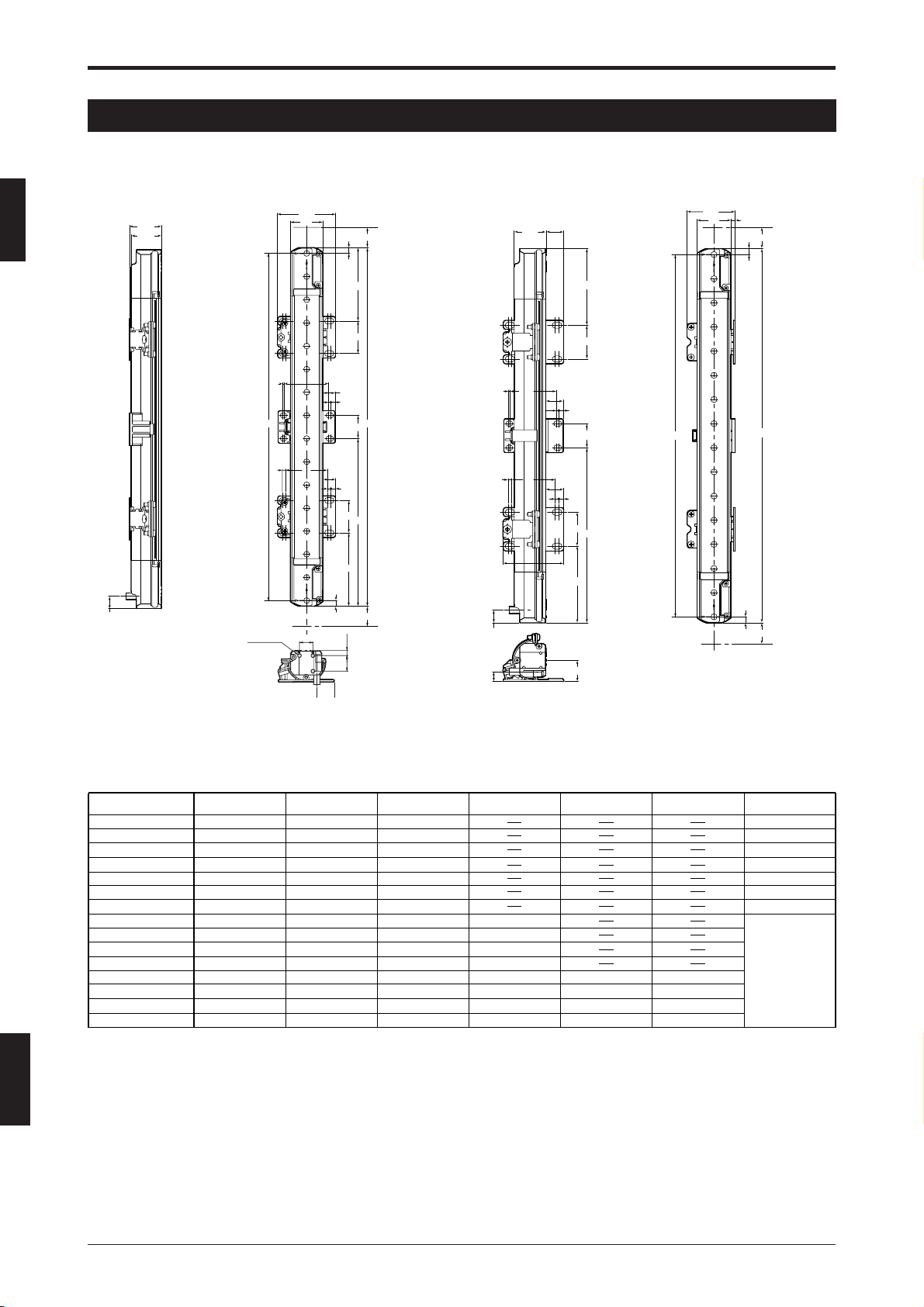

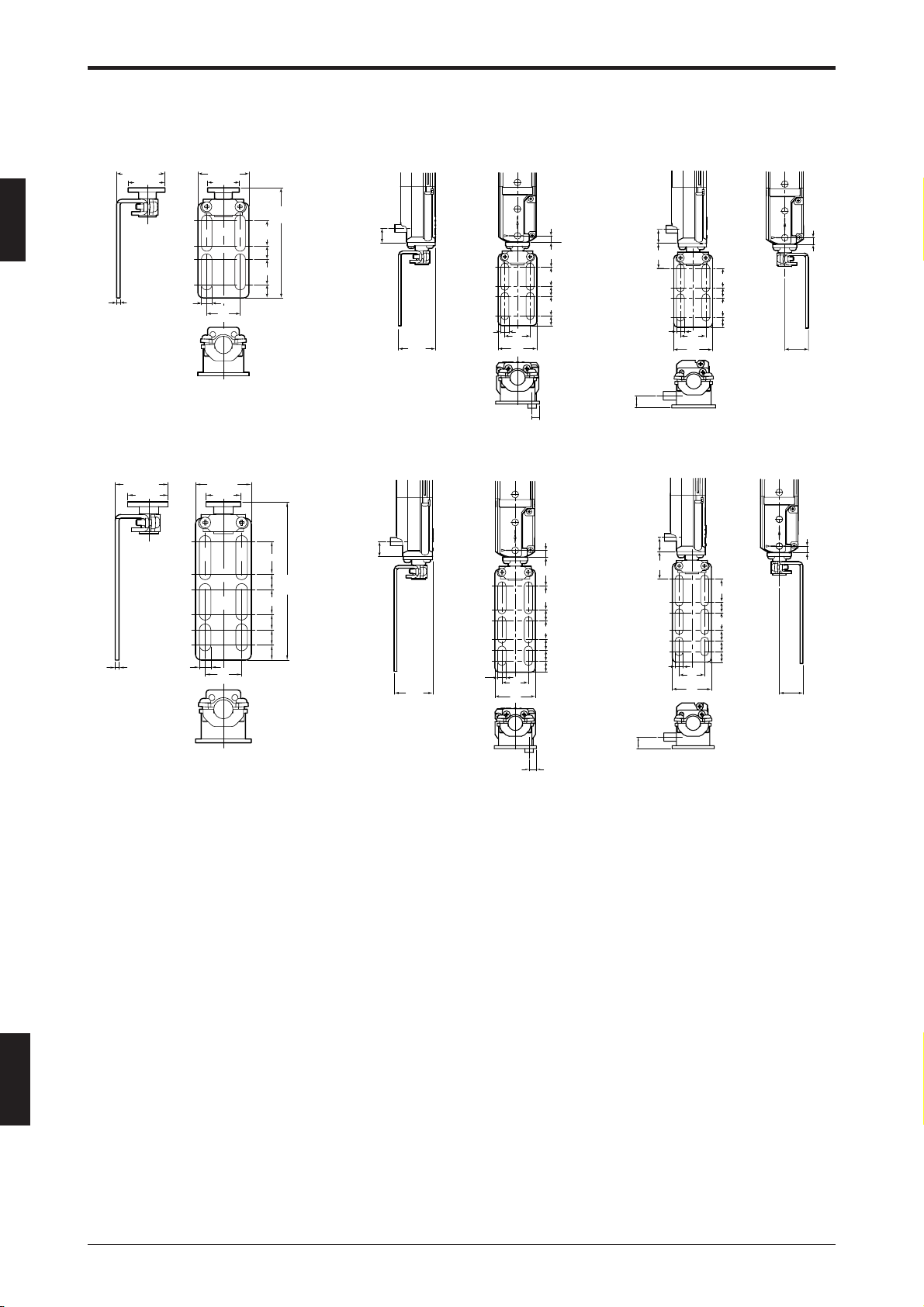

1-4 Dimensional Drawings

1

With the E-to-E mounting bracket (OP-42370) installed

50.4

28

17.5

5

D

28

38.5

1

B

3

10.5

2

3.5

A

20

36

11

3

4

28

C

D

5

17.5

4.5

12

14

15.5

1

3

10.6

8

10.6

27.9

26.4

3-M3

Depth:4.5

38.5

26.4

36

14.5

2

50.4

14.6

3

(

Unit: mm

39.7

3.5

28

17.5

5

D

28

3.5

20

15

4

28

C

D

17.5

B

A

5

17.5

)

ENGLISH

English

Dimensions by model

Model

SL-C08HS

SL-C12HS

SL-C16HS

SL-C20HS

SL-C24HS

SL-C28HS

SL-C32HS

SL-C36HS

SL-C40HS

SL-C44HS

SL-C48HS

SL-C52HS

SL-C56HS

SL-C60HS

SL-C64HS

* If using the normal mounting brackets A, B, C, or the L-shaped mounting bracket for installing the model that has the sensor length 710 mm (27.95") or more, use of two intermediate support

brackets is required. For such installation, attach intermediate support brackets at dimensional positions C1 and C2. For other installations, attach one intermediate support bracket at dimensional

position C.

No. of beam axes

8

12

16

20

24

28

32

36

40

44

48

52

56

60

64

Sensor length A

150 (5.91")

230 (9.06")

310 (12.20")

390 (15.35")

470 (18.50")

550 (21.65")

630 (24.80")

710 (27.95")

790 (31.10")

870 (34.25")

950 (37.40")

1030 (40.55")

1110 (43.70")

1190 (46.85")

1270 (50.00")

Detection zone B

140 (5.51")

220 (6.66")

300 (11.81")

380 (14.96")

460 (18.11")

540 (21.56")

620 (24.41")

700 (27.56")

780 (30.71")

860 (33.86")

940 (37.01")

1020 (40.16")

1100 (43.31")

1180 (46.46")

1260 (49.61")

Intermediate support

bracket position C*

345±80 (13.58"±3.15")

385±80 (15.16"±3.15")

425±80 (16.73"±3.15")

465±80 (18.31"±3.15")

505±80 (19.88"±3.15")

545±80 (21.46"±3.15")

585±80 (23.03"±3.15")

625±80 (24.61"±3.15")

Intermediate support

bracket position C1*

333±80 (13.11"±3.15")

360±80 (14.17"±3.15")

387±80 (15.24"±3.15")

413±80 (16.26"±3.15")

Intermediate support

bracket position C2*

677±80 (26.65"±3.15")

730±80 (28.74"±3.15")

783±80 (30.83"±3.15")

837±80 (32.95"±3.15")

D

43 (1.69")

43 to 63 (1.69" to 2.48")

43 to 89 (1.69" to 3.50")

43 to 116 (1.69" to 4.57")

43 to 143 (1.69" to 5.63")

43 to 169 (1.69" to 6.65")

43 to 196 (1.69" to 7.72")

43 to 197 (1.69" to 7.76")

1-6

Chapter 1 Overview and Specifications

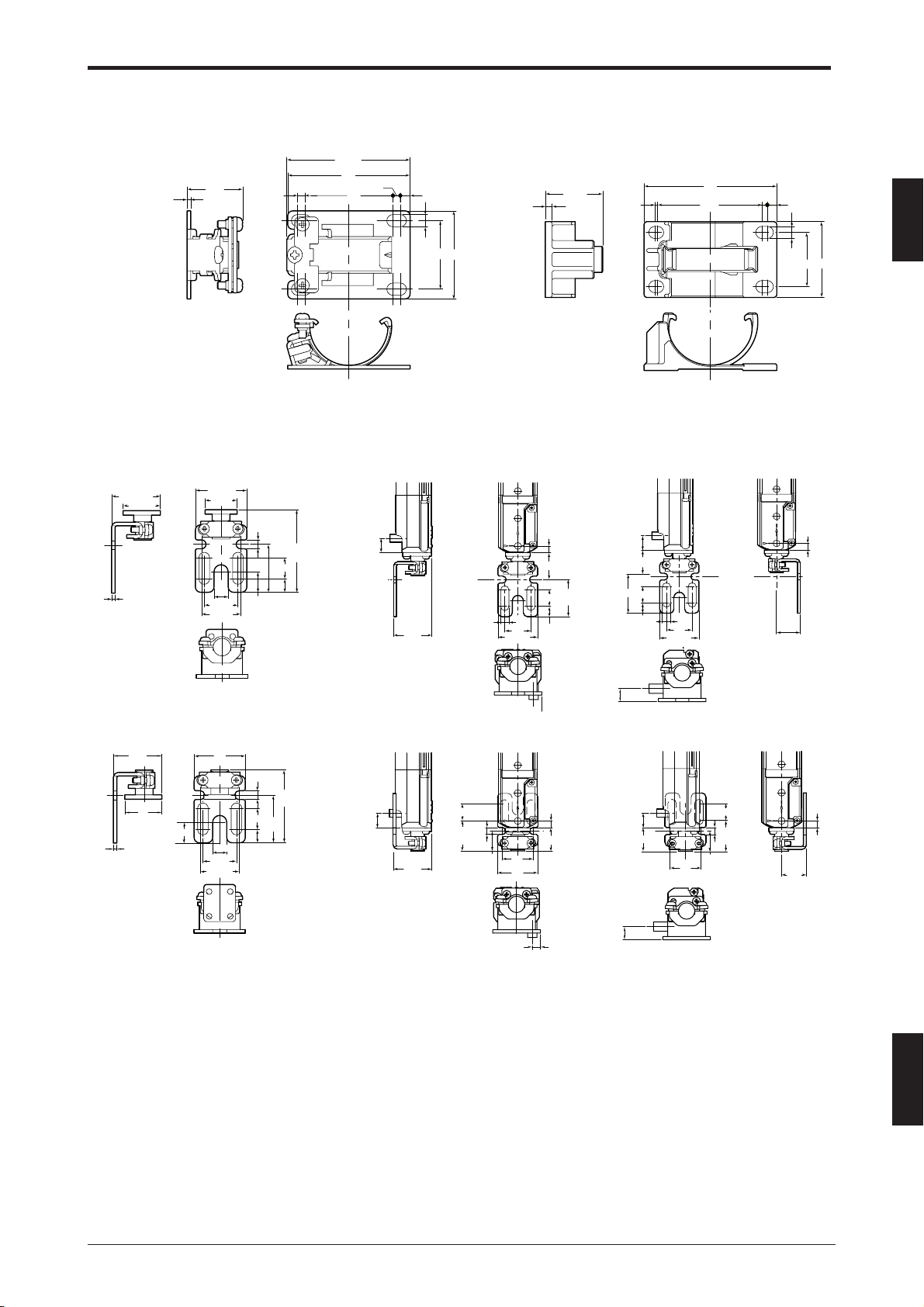

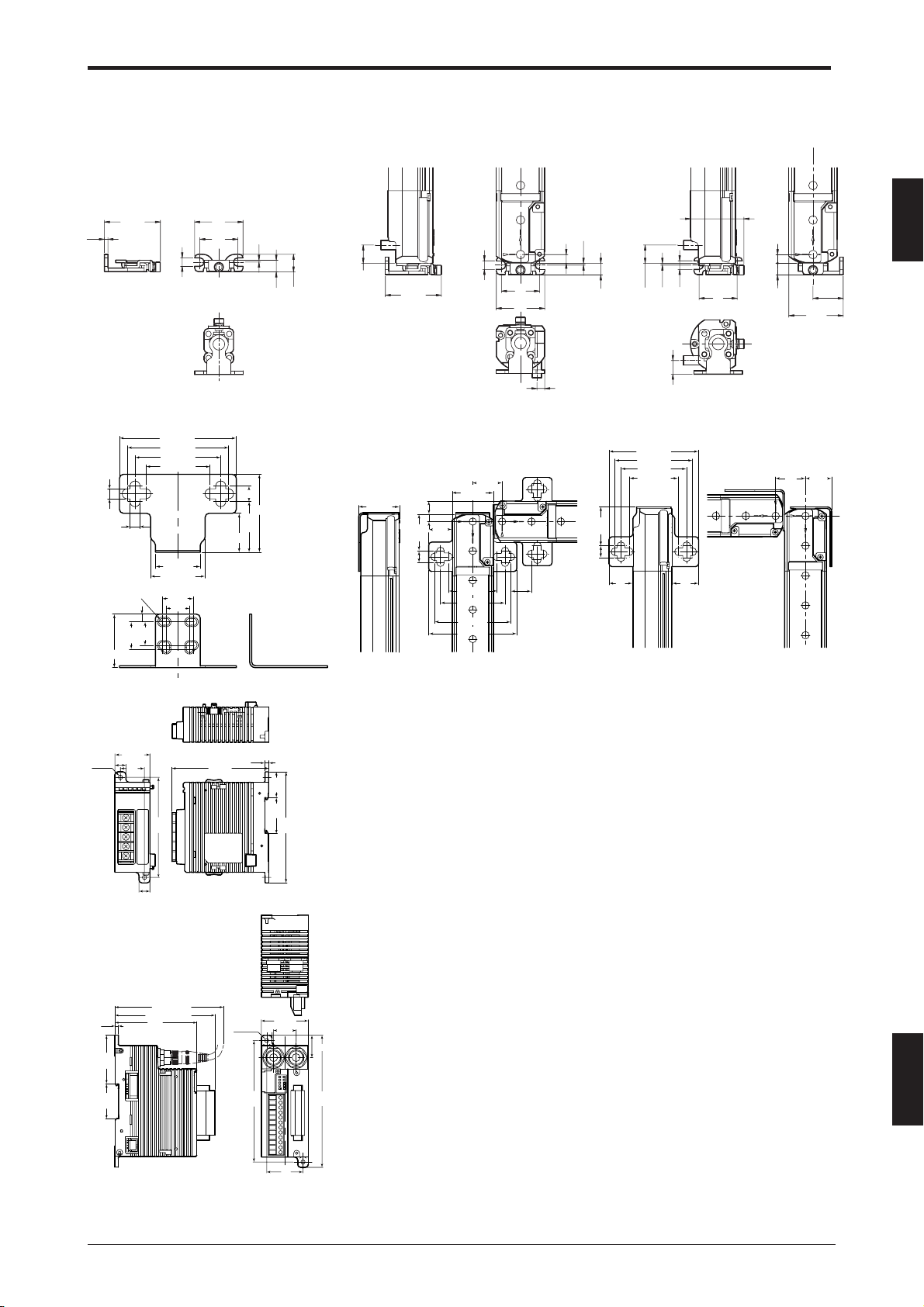

E-to-E mounting bracket

(

OP-42370

)

(24)

1.5

3 36

Normal mounting bracket A,

outward-facing (OP-42347)

(

)

29

27.5

(

)

1.08"

(

)

0.83"

21

(

)

0.08"

2

1.14"

(

)

18

0.71"

(

)

0.2"

5

(46.5)

(

27

(

)

12

1.06"

(

)

(

0.31"

8

(

0.75"

19

(

0.87"

22

0.47"

)

7.5

(

)

0.3"

11.5

)

(

)

0.45"

)

1.83"

(50.4)

50

Intermediate support brackets (OP-42373

3

4

5

28

36

(21.2)

2.5

1

38.5

49

2

4.5

)

3.5

1

28

20

With Normal mounting bracket A installed

(

)

0.42"

(

1.06"

(

0.77"

10.6

(19.5)

)

(

)

0.47"

27

)

12

(

)

7.5

0.3"

6

(

)

0.75"

(

)

0.24"

19

(

)

1.14"

29

(

0.69"

17.5

(

)

0.2"

5

)

(

)

0.42"

)

10.6

(

27.9

1.1"

(

)

6

0.24"

)

29

19

(

1.14"

(

0.75"

(

)

0.2"

5

(19.5)

(

)

0.77"

(

)

0.47"

27

12

(

)

1.06"

7.5

)

(

)

0.3"

)

Normal mounting bracket A,

inward-facing (OP-42347)

27.5

(

)(

1.08"

21

(

)

0.83"

(

0.45"

(

)

0.08"

2

)

11.5

29

)

1.14"

(

)

0.2"

5

(41.3)

(

1.63"

)

12 (0.47"

27

(

)

1.06"

7.5

(

)(

)

0.31"

0.3"

8

(

)

19

0.75"

(

)

22

0.87"

8

(

)

5

(

)

0.2"

0.31"

With Normal mounting bracket A installed

)

10.6

(

)

0.42"

27.9

(

)

1.1"

(

)(

0.47"

(21.8)

(

0.86"

12

5

(

)

0.2"

)

(14.3)

(

)

0.56"

(

22

0.87"

29

(

1.14"

5

(

16.5

)

)

(

)

5

0.2"

(

(

)

0.2"

)(

0.65"

(

0.31"

0.42"

0.65"

)

)

10.6

)

16.5

22

(

)

0.87"

8

5(0.2")

(21.8(0.86"))

(14.3)

(

0.56"

)

12

0.47"

)

(

)

0.86"

(

17.5

0.69"

(

)

0.2"

5

)

ENGLISH

1-7

Chapter 1 Overview and Specifications

1

Normal mounting bracket B (OP-42348)

(

1.08"

27.5

(

21

0.83"

(

2

0.08")(0.24"

)

)

(

)

29

1.14"

(

)

18

0.71"

(62.5)

(

)

2.46"

14.5

(

)

0.57"

(

)

7.5

0.3"

)

14.5 (0.57"

(

)

7.5

(

0.75"

0.3"

)

)

6

19

Normal mounting bracket C (OP-42349)

(

)

1.08"

27.5

(

21

0.83"

(

2

0.08")(0.24"

)

(

)

29

1.14"

(

)

18

0.71"

(

)

0.67"

17

(82.3)

(

)

8

0.31"

(

)

3.24"

(

)

0.51"

13

(

)

8

0.31"

(

)

8

0.31"

(

)

7.8

)

6

19

(

0.75"

0.31"

)

With Normal mounting bracket B installed

(

10.6

0.42"

)

(

)

6

0.24"

19

(

0.75"

27.9

(

)

1.1"

29

(

1.14"

(

)

0.2"

5

(18.5)

(

)

0.72"

(

)

0.57"

14.5

(

)

0.3"

7.5

(

)

0.57"

14.5

(

)

0.3"

7.5

)

)

(

)

5

0.2"

With Normal mounting bracket C installed

(

0.42"

10.6

)

(

)

0.24"

6

27.9

(

1.1"

)

(

19

0.75"

29

(

1.14"

(

)

0.2"

5

(

)

(20.5)

0.81"

(

)

17

0.67"

(

)

0.31"

8

(

)

0.51"

13

(

)

0.31"

8

(

)

0.31"

8

(

)

7.8

0.31"

)

)

(

0.31"

(

0.42"

(

0.42"

(

)

(

0.72"

0.81"

)

10.6

)

(18.5)

(

)

0.57"

14.5

(

)

0.3"

7.5

(

)

14.5

0.57"

(

)

0.3"

(

(

0.75"

0.75"

7.5

19

)

29

(

)

1.14"

(

)

17

0.67"

(

)

8

0.31"

13

(

)

0.51"

(

)

8

0.31"

(

)

8

0.31"

(

)

7.8

0.31"

19

)

29

(

)

1.14"

(

)

0.24"

6

8

)

10.6

)

(20.5)

(

)

0.24"

6

17.5

(

0.69"

(

17.5

0.69"

(

)

0.2"

5

)

(

)

5

0.2"

)

ENGLISH

English

(

)

0.31"

8

(

)

0.2"

5

1-8

Chapter 1 Overview and Specifications

Thin type mounting backet (OP-51698)

(32.4)

2

*When installing the normal

mounting bracket on the

machine, use the M4

screws shorter than 3.8

(0.15") mm.

28

1.1

22

5

(6.8)

(10.2)

L-shaped mounting bracket

(OP-42371)

60(2.36")

52(2.05")

4(0.16")

(0.55")

14

R1.8

(0.07")

12

(0.47")

44(1.73")

30(1.18")

23(0.91")

28(1.1")

16

(0.63")

12

(0.47")

20(0.79")

t=1.0

8(0.31")

26

(1.02")

40(1.57")

5.2

(0.2")

5.2

(0.2")

27.5 (1.08")

With thin mounting bracket installed

1.1

5

22

28

5

(6.8)

10.6

5

(32.4)

With the L-shaped mounting bracket installed

20

(0.79")

28

5(0.2")

16

(0.63")

(1.1")

30(1.18")

44(1.73")

52(2.05")

60(2.36")

14

(0.55")

(1.02")

8(0.31")

26

28

(1.1")

9(0.35")

25

(0.98")

8

(0.31")

16

(0.63")

10.6

60(2.36")

52(2.05")

44(1.73")

30(1.18")

(30.9)

1

5

5

1.1

8

18

(0.71")

22

(6.8)

20

(0.79")

31.5

17.5

(0.69")

17.5

SL-U2

35

2(0.08")

(1.38")

-ø4.2

11(0.43")

(0.67")

24

(0.94")

11(0.43")

SL-R11(E)

3.5

(0.14")

49.8

(1.96")

(1.41")

35.9

(102.3)(4.03")

83.8

(3.3")

100

(3.94")

(112)(4.41")

(96.6)

(3.8")

(0.14")

2(0.08")

-ø4.2

(0.67")

124

(4.88")

3.5

25.8

(1.02")

35.9

(1.41")

111

(4.37")

48

(1.89")

23

(0.91")

23(0.91")

135

(5.31")

ENGLISH

37

(1.46")

1-9

Loading...

Loading...