Page 1

Easy

3 Step

Guide

Selecting Your First

Vision System

With many different camera, lighting, and controller options, this

guide is designed to help you determine which is the best vision

system for your inspection.

Page 2

Vision system configuration

First, we'll introduce the overall composition of a vision system. Broadly speaking, a vision system is composed of a "controller"

which processes the images, and a "camera" that captures the object for detection. Their human equivalents would be the

"brain" and "eyes." The "lens," which is attached to the camera, is used to gather light on the image receiving elements, and

"lighting," which is used to appropriately adjust the brightness of the object for detection, are both important components of a

vision system.

Controller

Selection flow

The "camera," "lens," and "lighting" form

the basis for any vision system. To carry

out optimal inspections, proper selection

of these components is essential. In this

document, we will provide some of the

key points to selecting these 3

components.

STEP 1

STEP 2

STEP 3

Camera + Lens + Lighting

Selecting a camera

Selecting a lens

Selecting lighting

2

Page 3

STEP 1

Selecting a camera

Verify the "minimum detection size" needed to find the object for detection

1

The "minimum detection size" refers to the smallest feature that a vision system will be able to detect with stability. Understand the size of the features

(defects, foreign particles, text/barcodes) that need to be detected, and understand what kind of capabilities the camera must have to find them.

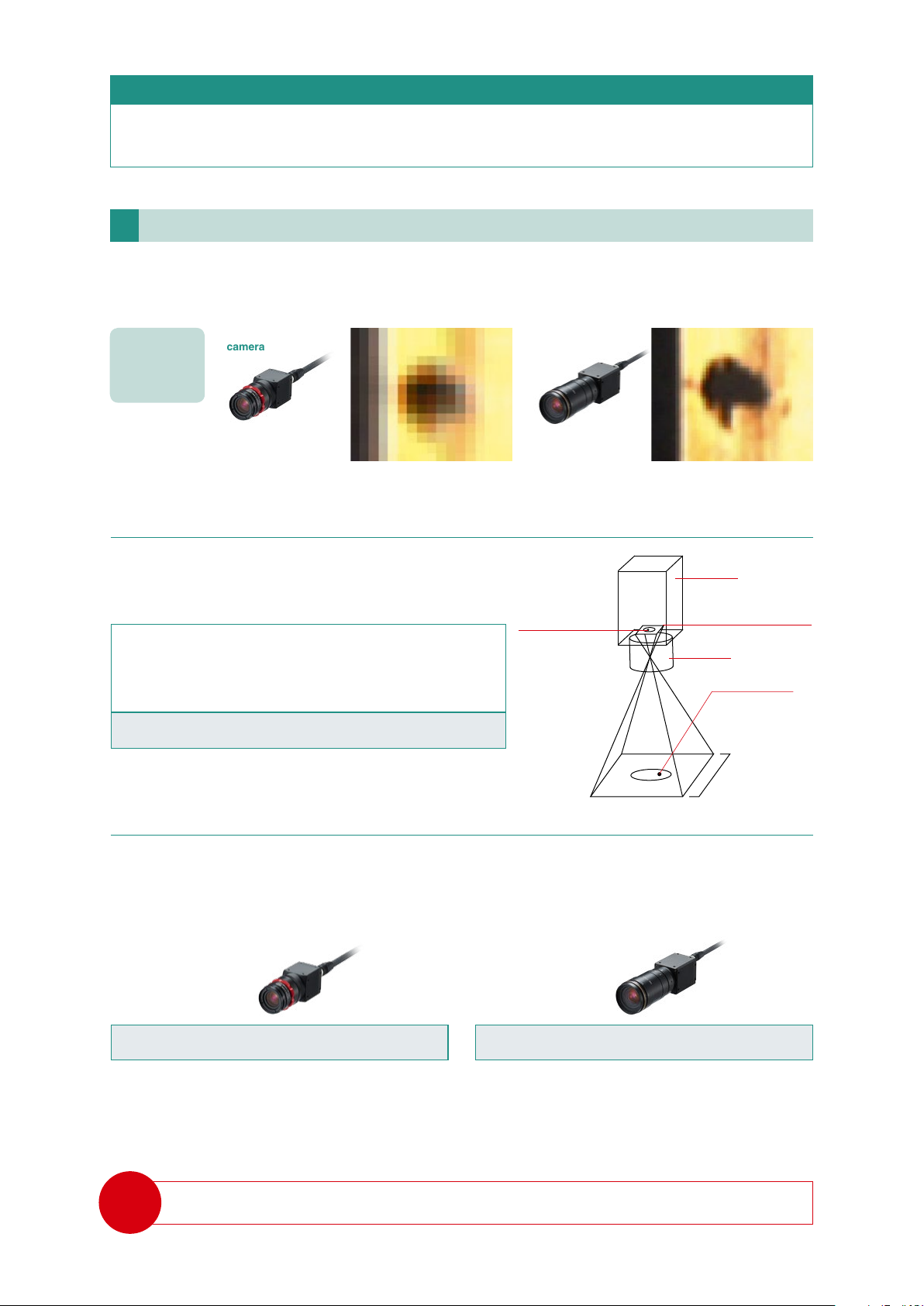

0.31 megapixel

Differences in

camera capabilities

(number of pixels)

camera

Foreign particles are

blurry and hard to detect

Calculate the minimum detection size

Next, we'll introduce an example of the calculation to decide the minimum detection

size the system will be capable of processing. Minimum detection size is calculated

from approximate values for the following elements.

= Number of pixels in the camera's capture range (Y axis) (Pixels)

A

= Field of view (Y-axis) (mm or inches)

B

= Minimum detection pixel size for image sensor elements (Pixels)

C

Minimum detection size =

B ÷ A × C

2 megapixel

camera

Foreign particle

detection capability

C = Minimum detection

pixel size

Camera

A = Image sensor size (Y)

Lens

Foreign particles

B = Field of view (Y)

For example:

Let's think about the minimum detection size when (B) is set to 30 mm.

We'll compare a standard type 0.31 megapixel camera (Y = 480 pixels) and a high pixel-count type

2 megapixel camera (Y = 1200 pixels) for (A). The minimum detectable pixel size, (C), would generally be "4 × 4 pixels."

* The target minimum detectable pixel size changes depending on the object for detection and the inspection environment.

Minimum detection size when

using 0.31 megapixel camera

Minimum detection size = 30 ÷ 480 × 4 = 0.25 mm Minimum detection size = 30 ÷ 1200 × 4 = 0.1 mm

If the goal of the inspection is "to detect ø0.1 mm debris within a 30 mm vision field,"

then it is necessary to select a camera with 2 megapixels or higher.

Check

POINT

What is the size of the object that needs to be detected?

Minimum detection size when

using 2 megapixel camera

3

Page 4

Select the optimal camera based on the "minimum detection size"

2

In general, as the number of pixels increases, increasingly smaller objects can be detected, but costs also increase.

It is important to select a camera that meets the "minimum detection size" requirement and is appropriate for the inspection. There are more than

20 types of cameras in the KEYENCE lineup. Beyond the number of pixels, choices such as monochrome or colour, compact or standard size and

so forth allow for selection of the optimal model for the application.

High precisionLow cost

Check

POINT

21 megapixels

5 megapixels

2 megapixels

0.47 megapixel

0.31 megapixel

What camera specifications are necessary?

Capture range

5104 × 4092 pixels

Capture range

2432 × 2040 pixels

Capture range

1600 × 1200 pixels

Capture range

784 × 596 pixels

Capture range

640 × 480 pixels

Colour

Monochrome

Colour

Monochrome

Colour

Monochrome

Compact model available

Colour

Monochrome

Colour

Monochrome

Compact model available

KEYENCE Technology

The power of a 21 megapixel camera

This camera can capture high resolution images with a valid pixel count of 21 megapixels (5104 × 4092 pixels). It can detect minute

defects and inspect small components on large work pieces.

140mm

0.31 megapixel camera

120mm

4

5 megapixel camera 21 megapixel camera

It is possible to

check fine details of

the inspection target.

Page 5

Confirm the time needed for inspection

3

When performing image inspection, it is necessary to think about processing speed. The latest vision systems are capable of ultra-high speed

processing, and depending on what is to be inspected, they can perform 100 inspections in just one second. However, because the image

processing time can vary greatly based on the camera's resolution, the contents to be processed, and the number of processing items, it is

important to confirm the vision system's processing speed and the inspection line's takt time.

Image processing flow

Trigger Input

PLC PLCPCSensors,

Image Capture

Image Processing

Judgment Output

Image sensor processing time Converted to inspection takt time

other

Capture and

Transmission

Image processing

controller

The camera captures an image, then sends the image data to the controller.

The captured image is processed. Depending on the inspection items, the presence or absence of foreign

particles, dimensions, position, quantity, etc. can be inspected.

A judgment result of whether or not the product is defective is output.

Capture and transmission time: several ms to several dozen ms

Image processing: several ms to several hundred ms

Image

Processing

Judgment

Output

Control

Several hundred objects/minute to

several thousand objects/minute

The relationship between camera resolution (number of pixels) and processing time

As the number of pixels the camera can capture increases, resolution capability

increases, but processing time becomes longer. An example of detection of

black dots in a container using 0.31 megapixel, 2 megapixel and 5 megapixel

cameras is shown below. When the binarised number of pixels of the same field

of view is compared between each of the cameras, it is easy to see that there is

a large difference in the number of inspection pixels, and that as the number of

pixels increases, more detailed detection is possible. As a result, we see that the

processing time becomes longer the higher the pixel count is.

* The numbers below are representative examples of processing time and number of pixels, with

processing time using the fastest trigger interval.

0.31 megapixel camera 2 megapixel camera 5 megapixel camera

pixels

3

23

pixels

pixels

55

2432 × 2040

1600 × 1200

640 × 480

Check

POINT

7 ms 32 ms 64 ms

What is the inspection takt time? (How long does image processing take?)

5

Page 6

STEP 2

Selecting a lens

Determine a field of view (image capture range) that will include the work piece size and any variations in the conveyor system

1

Determine the scope or range that will be captured by the camera, taking into account the size of the work pieces and the variation in positioning on

the line when transporting work pieces.

Field of view (image capture range)

Deviation amount

Maximum target

size

Check

POINT

2

The lens focal distance which can capture the target field of view for inspection as determined above is called the working distance (WD). In other words,

what position can the camera be installed in? Determine in advance the possible installation locations based on the facilities, equipment and

environment.

What is the maximum size of the inspection target? / Is there any misalignment in the process?

Determine the installation distance to maintain the required viewing angle (working distance)

The focusing distance (working distance) differs according to the lens. If the field of view for inspection and the WD are known in advance, then it

is possible to choose the most appropriate lens.

Check

POINT

6

What is the installation distance between the camera (lens) and the inspection target? /

Are there physical limitations on the installation environment?

Page 7

Select the optimal lens using the lens chart

3

There are many models of lenses, even within the same series.

A lens can be selected by checking the target field of view and WD on the lens chart.

* CA-LHE series

Example: When installing a CA-LHE series lens with a 21 megapixel camera

The graph (lens chart) below shows a simplified relationship among each lens's focal length, WD, and field of view for the specified camera.

The intersections of the target WD and field of view lines can be used to select the proper focal length.

CA-H2100C

CA-H2100M

series

CA-LHE

attached

Y visual field (mm)

1000

100

10

1

CA-LHE25

CA-LHE12

CA-LHE16

CA-LHE35

CA-LHE50

0.5

1.5

0.5

1.0

1.5

10

5

5

5

10

20

A lens chart is prepared for each lens/

100010010 10000

WD (mm)

camera. These are available in the

catalogue or on the website.

Check

POINT

What lenses are compatible with the desired camera? /

Are there problems with the installation distance?

7

Page 8

STEP 3

Selecting lighting

Select the optimal "method of lighting" to match the inspection contents

1

Lighting is essential to image inspection and helps optimise image capture. The

lighting method is selected based on the inspection target's properties (damage/

shape), whether the surface is flat or curved, whether there is unevenness, and so on.

Lighting method can be divided into 3 major types.

1

Specular reflection type

System in which light specularly reflected from the target is received by the lens.

Effective for targets which reflect easily, such as the surface of metal or glass plates.

2

Diffuse reflection type

System in which light specularly reflected from the target is avoided, and uniform light

is received by the lens. Effective for targets such as glossy surfaces or transparent

films in which glare can occur easily.

Incident

light

Target

Diffuse

reflected light

Absorption

Diffuse

transmitted light

Specular

reflection

Diffuse

reflection

Specular

reflection

Transmitted

light

3

Transparent type (backlight)

System in which the target is illuminated from behind, and the silhouette is detected

using the transmitted light. Effective when reflected light does not provide sharp

contrast, or for detecting complicated profiles.

Select the optimal "lighting colour"

2

Backlight

Method to use complementary colour of the inspection target

In the colour wheel shown to the right, the colours which face each other are called "complementary

colours." For example, the complementary colour for orange is blue. If the inspection target is orange, when

it is illuminated with its complementary colour blue, it is possible to obtain a monochrome image of the

inspection target with crisp contrast.

Detection using complementary colour

Sealing tape is applied. In order to detect presence or absence,

use red and blue lighting separately, then compare the difference in contrast.

Colour image Red LED used Blue LED used

Low grayscale

contrast between

red and

background

Anything red

(blue's

complementary

colour) becomes

darker, and stable

detection is

possible

Yellow

Orange

Green

Blue

Purple

Red

8

Page 9

Ultilise different wavelengths of lighting to achieve the desired image

When using LED lighting to achieve good contrast, it is possible to reflect the differences in dispersion rate by wavelength into the light and

shadow (intensity) differences on the capture screen. The dispersion rate for short wavelength colours like blue is high, while the longer

wavelength colours, such as red, do not disperse easily and have a higher transmission ratio.

Non-visible light Non-visible light

Visible light

Ultraviolet

light

~ 380 780 ~

Because the dispersion rate is high for short wavelength blue colours, diffuse

reflection occurs, and flaws "pop out," making blue an appropriate colour for

detecting minute flaws. Conversely, when trying to avoid the influence of

hairline scratches and so forth on metallic surfaces, a red colour is

appropriate. The longer wavelength and lower dispersion rate of red cause

specular reflection, and flaws are not noticeable.

Check

POINT

3

In addition to the light method and colour, the lighting type (format) can be chosen based on contents to be inspected, background and surrounding

environment. KEYENCE also handles a wide variety of image processing LEDs, and can provide the optimal capture conditions.

What is the optimal lighting method? / What is the optimal lighting colour?

Select the optimal "form" from a wide product lineup

Detection of scratches on the surface of

black steel plate

610 ~ 780590 ~ 610570 ~ 590500 ~ 570460 ~ 500430 ~ 460380 ~ 430

Infrared

RedYellowIndigoPurple GreenBlue Orange

light

(Unit: nm)

Detection of scratches in transparent

material

Coaxial type

CA-DX

There's a wide variety of inspection circumstances. An example is shown below.

Example of specular reflection detection

Example of transparent detection

Check

POINT

What about installation space for lighting? / What form can be installed?

Low angle type

CA-DL

Determination of lighting

based on target and

inspection contents

Determination of lighting

based on target and

inspection contents

Direct ring type

CA-DR

Reflection of lighting on glass surface

1

Want to clarify the difference between glass and background

2

Lighting perpendicular to the target is best

3

Possible to retain space above the target

4

Coaxial lighting is the best choice

The target is metallic and uneven, specular reflection is not even

1

Target edges can be highlighted when transmitted light is used

2

Installation of lighting behind the target is possible

3

Surface lighting (backlight) is the best choice

Backlight type

CA-DS

Dome type

CA-DD

Bar type

CA-DB

9

Page 10

KEYENCE Technology

Perfect when selecting lighting is a challenge!

Multi-spectrum lighting provides unparalleled all-in-one performance

8 colour LEDs, along with the 3 capture modes "Multi-spectrum mode," "LumiTraxTM mode," and "normal lighting mode," are combined to

provide unparalleled performance for colour, shape, gloss and multi-product environments.

Multi-spectrum mode

Inspection of Various Types of

Plastic Caps

Colour camera

The imaging element receives white

light reflected from the target through a

colour filter. This data is then used to

create a colour image.

❚ Conventional Colour Camera

Although some differences are noticeable,

the extracted colours are largely the same.

Multi-spectrum image

capture

❚ Multi-Spectrum Mode

Differences in colour are clearly defined.

Colour analysis is performed for every

pixel based on eight grayscale images

taken at different wavelengths.

UV

B

RRRRGGG

GGGGBBB

G

AM

R

B

IR

W

LumiTraxTM mode Normal lighting mode

G

FR

10

Detect changes in height with

directional lighting

❚ Conventional camera ❚ 1st image capture

Surface conditions interfere with

extraction.

Stamped Character Inspection on

Metal Casting

❚ LumiTraxTM mode

Extraction of only shape (irregularity)

information regardless of surface

conditions.

Lighting conditions can be

optimised for each target

depending on the colour conditions

Illumination using a red LED capable of

clearly viewing the pattern is performed

for alignment shift correction.

Red LED

Printing Appearance

Inspection

A red ink defect appears on a printing

with a blue background.

❚ 2nd image capture

To erase the printed pattern for defect

inspection, illumination using the same

blue colour as the background is performed.

Blue LED

Page 11

Customer focused support system

Please consult with KEYENCE when selecting a vision system.

At KEYENCE, our specialised vision system sales engineers use their knowledge and experience to help you select the optimal models. KEYENCE uses

a direct sales system instead of distribution to be

Customer KEYENCE

Loan a test unit free of charge

able to consult directly with customers to understand their circumstances and concerns.

We want to do "such and

such" an inspection...

Leave it to us!

Direct consultation!

At KEYENCE, we provide highly detailed technical sales support for product selection. We also provide test units free of charge*, which allows you

to confirm solution compatibility with your application prior to purchase.

*Not applicable for some units.

Customer KEYENCE

Can thoroughly

test in advance

Test unit

Support when problems occur & same-day shipping of replacement unit

KEYENCE is able to provide unparalleled after-sales support and service because of the direct sales model. In the event of a problem, product

specialists provide a quick solution. Our contracted partner companies provide first-class support as necessary. Same-day shipment of

replacement units* minimises losses due to equipment problems.

* Not applicable for some units.

Customer

Solid support even

when problems occur

after purchase

Response to problems

KEYENCE

Replacement unit

11

Page 12

IP Rated lensing and lighting options for

dust-proof and drip-proof environments

CA-DBWxP Series

IP67-compliant ring lighting/bar lighting available.

Can be used safely even in environments with dust or liquid droplets present.

CA-LHxP Series

IP64-compliant lens for use in FA locations with dust and vibration.

Screws have been eliminated, so there are no worries about losing focus.

Please visit:

GLOBAL NETWORK

AUSTRIA

BELGIUM

BRAZIL

CANADA

CHINA

The information in this publication is based on KEYENCE’s internal research/evaluation at the time of release and is subject to change without notice.

Company and product names mentioned in this catalogue are either trademarks or registered trademarks of their respective companies. Unauthorised reproduction of this catalogue is strictly prohibited.

Copyright © 2019 KEYENCE CORPORATION. All rights reserved.

CONTAC T YOUR NEARE ST OFF ICE FO R RELE ASE STATUS

CZECH REPUBLIC

FRANCE

GERMANY

HONG KONG

HUNGARY

INDIA

INDONESIA

ITALY

JAPAN

KOREA

www.keyence.com

MALAYSIA

MEXICO

NETHERLANDS

PHILIPPINES

POLAND

ROMANIA

SINGAPORE

SLOVAKIA

SLOVENIA

SWITZERLAND

SAFET Y INFORMATION

Please read the instruction manual carefully in

order to safely operate any KEYENCE product.

TAIWAN

THAILAND

UK & IRELAND

USA

VIETNAM

CVEasySelectionGuide-WW-TG-GB 1119-2

WW11-1039

600V73

Loading...

Loading...