Page 1

B 80 W Bp

Register and win!

www.kaercher.com

59643610 03/13

Page 2

2

Page 3

Page 4

Page 5

http://www.kaercher.com/dealersearch

Page 6

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent owners.

Contents

Safety instructions . . . . . . . EN . . 1

Function . . . . . . . . . . . . . . . EN . . 1

Proper use . . . . . . . . . . . . . EN . . 1

Environmental protection . . EN . . 1

Warranty . . . . . . . . . . . . . . . EN . . 1

Operating and Functional Ele-

ments . . . . . . . . . . . . . . . . . EN . . 2

Before Startup. . . . . . . . . . . EN . . 3

Operation . . . . . . . . . . . . . . EN . . 4

Shutting Down the Appliance EN . . 5

Grey Intelligent Key . . . . . . EN . . 5

Transport. . . . . . . . . . . . . . . EN . . 6

Storage . . . . . . . . . . . . . . . . EN . . 6

Maintenance and care . . . . EN . . 6

Frost protection. . . . . . . . . . EN . . 8

Faults . . . . . . . . . . . . . . . . . EN . . 9

Accessories . . . . . . . . . . . . EN . 10

Technical specifications . . . EN . 11

EC Declaration of Conformity EN . 11

Spare parts . . . . . . . . . . . . . EN . 11

Safety instructions

Before using the appliance for the first time,

read and observe these operating instructions and the accompanying brochure:

Safety information for brush cleaning units

and spray-extraction units, No. 5.956-251.

The appliance must only be operated on

surfaces that do not exceed the max. permitted incline (see "Technical Specifications").

The appliance may only be operated

when the hood and all lids are closed.

Remove the Intelligent Key (emergency

stop) to take all functions out of operation immediately.

Safety Devices

Safety devices serve to protect the user

and must not be rendered in operational or

their functions bypassed.

Driving lever

If the drive lever is released, the travel drive

and the brush drive shuts off.

Symbols in the operating

instructions

Danger

Immediate danger that can cause severe

injury or even death.

몇 Warning

Possible hazardous situation that could

lead to severe injury or even death.

Caution

Possible hazardous situation that could

lead to mild injury to persons or damage to

property.

Function

The scrubber vacuum is used for wet

cleaning or polishing of level floors.

– You can adjust the machine to suit the

cleaning task by modifying the settings

for water quantity, contact pressure of

the brushes, detergent quantity and

driving speed.

– The appliance is equipped with a fresh

water and a wastewater reservoir (80 litres each). These allow an effective

cleaning with a long usage life.

– Depending on the selected cleaning

head, the working width of the B 80 is

between 650 mm and 750 mm.

– This appliance is equipped with a travel

drive, drive motor and brush drive that

are driven by four batteries.

– The charger is already installed. Batter-

ies can be selected according to the

configuration (see Chapter "Recommended batteries“)

Note

The appliance can be equipped with various accessories depending on the cleaning

task.

Please request our catalogue or visit us on

the Internet at:

www.kaercher.com

Proper use

Use this appliance only as directed in these

operating instructions.

– The appliance may only be used for the

cleaning of hard surfaces that are not

sensitive to moisture and polishing operations.

– The appliance is not suited for the

cleaning of frozen grounds (e.g. in cold

stores).

– The appliance may only be equipped

with original accessories and spare

parts.

– The appliance is not suited for the use

in potentially explosive environments.

– The machine should not be used to

suck in inflammable gases, undiluted

acids or solvents.

This includes petrol, thinning agents or

hot oil that can form an explosive mixture when it comes in contact with

sucked air. Do not use acetone, undiluted acids and solvents as they are aggressive towards the materials from

which the appliance is made.

– The machine has been approved for

use on surfaces with max. gradients as

listed under "Technical Specifications".

Environmental protection

The packaging materials are recyclable. Please do not throw

packaging in the domestic

waste but pass it on for recycling.

Old units contain valuable recyclable materials. Batteries, oil

and similar substances may not

be released into the environment. Therefore please dispose

of old units through suitable collection systems.

Notes about the ingredients (REACH)

You will find current information about the

ingredients at:

www.kaercher.com/REACH

Warranty

The warranty terms published by our competent sales company are applicable in

each country. We will repair potential failures of your accessory within the warranty

period free of charge, provided that such

failure is caused by faulty material or defects in fabrication. In the event of a warranty claim please contact your dealer or the

nearest authorized Customer Service center. Please submit the proof of purchase.

6 EN

- 1

Page 7

Operating and Functional Elements

1 Parking brake

2 Rotary handle to incline the vacuum bar

3 Height adjustment of suction bar

4 Wing nuts for fastening the vacuum bar

5 Suction hose

6 Vacuum bar *

7 Connecting cable for charger

8 Storage compartment for mains cable

9 Driving lever

10 Operator console

11 Storage surface for cleaning set "Home

base box“

12 Cover dirt water reservoir

13 Holding rail for home base

14 Recessed grip

15 Cleaning head (illustration is symbolic) *

Brush rollers (BR model) Disk brushes

(BD model) *

16 Waste container (only BR)

17 Battery pole fuse

18 Battery *

19 Automatic fill of fresh water reservoir

(option)

20 Fresh water level display

21 Fresh water tank

22 Lock of the fresh water reservoir with fil-

ter

23 Homebase - accessories holder *

24 Coarse dirt sieve

25 Drain hose for wastewater with dosing

unit

Illustration of scrubbing vacuum

26 Push handle

27 Lock of wastewater reservoir

28 Flexible lock of rinsing system (option)

29 Wastewater reservoir rinsing system

(option)

30 Float

31 Fluff filter

32 Dirt water reservoir

33 Suction hose for detergent (only DOSE

model)

34 Detergent bottle (only DOSE model)

35 Fresh water reservoir filler neck

* not included in the delivery

Colour coding

– The operating elements for the cleaning

process are yellow.

– The controls for the maintenance and

service are light gray.

Operator console

3

1

1 Rotating button for drive speed

2 Intelligent Key

yellow - operator

grey - supervisor

3 Display

4 Program selection switch

5 Info button

6 Water quantity regulator

2

4

5

6

- 2

7EN

Page 8

Program selection switch

4

3

2

1

1 OFF

Device is switched off

2 Transport mode

Driving to the Place of Use.

3 Eco mode

Wet clean the floor (with reduced brush

speed) and vacuum up wastewater

(with reduced suction).

4 Normal mode

Wet clean the floor and vacuum up dirt

water.

5 Increased brush contact pressure

Wet clean the floor (with increased

brush contact pressure) and vacuum up

dirt water.

6 Intense mode

Wet clean the floor and allow the detergent to react.

7 Vacuum mode

Suck in the dirt fleet.

8 Polishing mode

Polishing the floor without the application of liquid.

5

6

8

Before Startup

Installing the Brushes

BD model

The disc brush must be installed before the

initial operation (see "Maintenance work").

BR model

The brushes are mounted.

Install batteries

Install the batteries (see "Care and Maintenance/Install and connect batteries").

7

Setting the charging marker line

Prior to the initial startup, following a service reset or when switching to another battery type, you must adjust the charging

marker line.

Use the Grey Intelligent Key.

Setting the charging marker line (see

Chapter "Grey Intelligent Key/Setting

the charging marker line“.

Using batteries made by other manufacturers

We recommend using our batteries as described in chapter "Care and Maintenance/

Recommended batteries".

Note

While using other batteries (for e.g. batteries from other manufacturers) the total discharge protection level must be reset by

the Kärcher after sales service according to

the respective battery.

Charging battery

Note

The appliance is equipped with a safety

mechanism to prevent total discharge, i.e.

when the permissible minimum capacity is

reached, the brush motor and the turbine

are switched off.

Drive the machine directly to the charg-

ing station; avoid any steep gradients in

the process.

Danger

Risk of injury on account of electric shock.

The mains voltage must correspond with

the type plate on the appliance.

Use the charger only in dry rooms with sufficient ventilation!

Charging process

Average charging time is approx. 10 -15

hours.

The built-in charger has electronic controls

and is suitable for all recommended batteries; it automatically switches off the charging process.

The built-in battery is shown on the display

during the charging process. If this is not

the case, the charging marker line must be

selected (see "Setting the charging marker

line").

The appliance must not be used during the

charging process.

Initial charge tips

With the initial charge, the control will not

yet be able to detect which battery type has

been installed. Keep charging the batteries

until the display shows a full charge (batteries may still not be completely charged).

The next charging process will have an accurate display and charge power and the

batteries will be fully charged.

Use the appliance until the deep discharge

protection switches off the brush motor and

the turbine after the initial charge of the battery. This procedure is necessary to adjust

the battery indicator. Only then the correct

battery status is displayed.

Insert the plug of the connecting cable

into the socket. The charging process

will start.

Note: The selected battery will be dis-

played during charging.

Charge until the display shows a full

charge.

Low maintenance batteries (wet batteries)

몇 Warning

Danger of causticization!

– Adding water to the battery in its dis-

charged state can cause the acid to

leak.

– Use safety glasses while handling bat-

tery acid and follow the safety instruc-

tions to avoid personal injury or damage

to clothes.

– Should the acid spray on to the skin or

clothes, rinse immediately with lots of

water.

Caution

Risk of damage!

– Use only distilled or desalinated water

(EN 50272-T3) for filling the battery.

– Do not add any substances (so-called

performance improving agents), else

warranty claims will not be entertained.

– Replace batteries only with batteries of

the same type. Otherwise, the charging

guideline must be readjusted by cus-

tomer service.

8 EN

- 3

Page 9

Installing the Vacuum Bar

Insert the vacuum bar into the vacuum

bar suspension in such a manner that

the profiled sheet is positioned above

the suspension.

Tighten the wing nuts.

Insert the suction hose.

Check if the height adjustment is

mounted on the inside of the vacuum

bar.

When the height adjustment is mounted

on the outside, the vacuum bar gets

caught at the bottom of the appliance.

Unloading

Danger

Risk of injury. Pull the Intelligent Key to take

all functions out of operation immediately.

Insert batteries and connect (see "Be-

fore Start-up").

Place long lateral boards of the packag-

ing as a ramp next to the pallet.

Fix the ramp on the pallet with nails.

Place short boards as a support under-

neath the ramp.

Remove the wooden bars in front of the

wheels.

Plug in the Intelligent Key.

Turn the program selection switch to

transport mode.

Press the driving lever and slowly move

the machine down from the ramp.

Remove the Intelligent Key.

Operation

Danger

In dangerous situations, release the drive

lever.

Parking brake

Loosen the parking brake; for that press

the pedal downward and move it to the

left. Then let the pedal go upward.

Activate immobilising brake. Press the

pedal downwards and move it to the

right to lock it.

Driving

Note

The machine is designed in such a way that

the brush head protrudes on the right. This

helps in working in a proper way even close

to the edges.

Plug in the Intelligent Key.

Preselect the speed on the drive speed

rotary knob.

Turn the programme selection switch to

transport mode.

Release parking brake.

Drive the machine.

Forwards:

Press the driving lever to the front.

Backward:

Press the driving lever to the rear.

Note

The machine moves only when the driving

lever is moved by 15°.

Stop the machine: Release driving lever.

Filling in detergents

Fresh water

Open the lock of the fresh water reser-

voir.

Fill fresh water (maximum 60 °C) until

the lower edge of the filling nozzle.

Close the lock of the fresh water reservoir.

With automatic fill of fresh water reservoir (option)

Connect the hose to the automatic fill-

ing system and open the water supply

(max. 60 °C, max. 5 bars).

Monitor the appliance - the automatic

filling system will interrupt the water

supply when the tank is full.

Shut off the water supply and discon-

nect the hose from the appliance.

Detergent

몇 Warning

Risk of damage. Only use the recommended detergents. With respect to different detergents the operator bears the increased

risk regarding the operational safety and

danger of accident.

Only use detergents that are free from solvents, hydrochloric acid and hydrofluoric

acid.

Follow the safety instructions for using detergents.

Note

Do not use highly foaming detergents.

Recommended detergents:

Application Detergent

Routine cleaning of all water resistant floors

Routine cleaning of glossy

surfaces (e.g. granite)

Routine cleaning and basic

cleaning of industrial floors

Routine cleaning and basic

cleaning of fine stoneware

tiles

Routine cleaning of tiles in

sanitary areas

Cleaning and disinfection in

sanitary areas

Removal of coating from all

alkali-resistant floors (e.g.

PVC)

Removal of coating from linoleum floors

Appliance with dosing equipment DOSE

(option)

Detergent is added to the fresh water on

the way to the cleaning head with the help

of a dosaging device.

Note

The metering device can be used to add

3% of detergent at maximum. In case of a

higher dose the detergent must be poured

into the fresh water tank.

Place the detergent bottle into the hold-

er.

Close the bottle lid.

Insert the suction hose of the dosaging

equipment into the bottle.

Note

If the fresh water tank is empty, then the

function of adding detergent gets deactivated. The cleaning head continues to work

without the addition of any liquid. Detergent

addition is also stopped when the detergent

can is empty.

Models without dosing equipment

Add the detergent to the fresh water

reservoir.

RM 746

RM 780

RM 755 es

RM 69 ASF

RM 753

RM 751

RM 732

RM 752

RM 754

Setting the water quantity

Adjust the water quantity using the reg-

ulating button according to the dirt on

the floor covering.

Note

Carry out the initial cleaning attempts with

little quantities of water. Increase water

quantity step-by-step until the desired

cleaning result is achieved.

The detergent pump of the dosing equipment does not start working until a minimum water volume is present.

- 4

9EN

Page 10

Setting the Vacuum Bar

Oblique position

To improve the vacuuming result on tiled

floors the vacuum bar can be turned to an

oblique position of up to 5°.

Loosen the wing nuts.

Turn the vacuum bar.

Tighten the wing screws.

Inclination

If the vacuum result is unsatisfactory the inclination of the straight vacuum bar can be

modified.

Adjust the rotary handle to incline the

suction bar.

Setting the parameters

With yellow Intelligent Key

Parameters for the different cleaning programmes are preset in the appliance.

Depending on the authorisation of the yellow Intelligent Key, individual parameters

can be changed.

The modification of the parameters is only

valid until another cleaning programme is

selected via the programme selection

switch.

If you wish to permanently change the parameters, you must use a grey Intelligent

Key. This adjustment procedure is described in the section "Grey Intelligent

Key“.

Note:

Almost all displayed text regarding parameter adjustment is self-explanatory. The

only exception is the parameter FACT:

– Fine Clean: Lower brush speed for re-

moving the grey film on fine stone

floors.

– Whisper Clean: Medium brush speed

for regular cleaning with reduced noise

level.

– Power Clean: High brush speed for pol-

ishing, crystallising and sweeping.

Turn the program selection switch to

the desired cleaning program.

Turn the info button until the desired pa-

rameter is displayed.

Press Info button - the set value blinks.

Set the desired value by turning the info

button.

Confirm the changed setting by press-

ing the Info button or wait till the set value is automatically accepted after 10

seconds.

Cleaning

Caution

Risk of damage to the floor covering. Do

not operate the appliance on the spot.

Turn the program selection switch to

the desired cleaning program.

Lower the cleaning head

The appliance controls the lowering

and raising of the cleaning head automatically, depending on the selected

programme mode. The brush motor

also runs and stops automatically.

Note

The brush motor comes to a halt when the

machine stops and when there is overload.

Lower the vacuum bar

The appliance controls the lowering

and raising of the suction bar automatically, depending on the selected programme mode.

Note

For cleaning tiled floors, set the straight

vacuum bar in such a way that cleaning is

done at right angles to the joints.

The inclined position and the inclination of

the vacuum bar can be adjusted to achieve

better suction results (see "Setting the Vacuum Bar").

If the wastewater reservoir is full, the

floater will close the suction opening and

the suction turbine will run at a higher

speed. If this is the case, shut the vacuum

off and drive to empty the wastewater reservoir.

Shutting Down the Appliance

Close the regulatory button for setting

the water quantity.

Release driving lever.

Set the program selection switch to suc-

tion or vacuuming.

Briefly drive forward and suck of the re-

maining water.

Remove the Intelligent Key.

Charge battery, if required.

Drain off dirt water

몇 Warning

Please observe the local provisions regarding the wastewater treatment.

Take the water discharge hose from the

support and lower above a suited collection device.

Crush or bend the dosing equipment.

Open the lid of the dosing equipment.

Drain off the dirt water - regulate the

water quantity by pressing or bending.

Rinse the wastewater reservoir with

clean water or with the rinsing system

for the wastewater reservoir (option).

Drain off clean water

Loosen the lid for emptying the fresh

water - do not remove it fully. Drain wa-

ter.

To rinse the fresh water reservoir, re-

move the cover completely and remove

the fresh water filter.

Grey Intelligent Key

Plug in the Intelligent Key.

Select the desired function by turning

the Info button.

The different functions are described in the

following.

Key menu >>

In this menu item, the authorisations for the

yellow Intelligent Keys are released.

Press the info button while "Key menu

>>“ is displayed.

Remove the grey Intelligent Key and in-

sert the yellow Intelligent Key to be pro-

grammed.

Select the desired menu item to be

modified by turning the Info button.

Press Info button.

Adjust the menu item by turning the Info

button.

Confirm the setting by pressing the

menu item.

Select the next menu item to be modi-

fied by turning the Info button.

To save the authorisations, retrieve the

menu "Save settings" by turning the info

button and pressing it.

To exit, retrieve the menu "Exit menu"

by turning the info button and pressing

it.

Cleaning App >>

Parameters that are adjusted with the grey

Intelligent Key, are kept until another setting is selected.

Turn the program selection switch to

the desired cleaning program.

Turn the info button until "Cleaning App

>>“ is displayed.

Press the info button - the first adjusta-

ble parameter is displayed.

Press Info button - the set value blinks.

Set the desired value by turning the info

button.

10 EN

- 5

Page 11

Confirm the changed setting by press-

ing the Info button or wait till the set value is automatically accepted after 10

seconds.

Select the next parameter by turning

the Info button.

After all desired parameters have been

modified, turn the info button until "Exit

menu" is displayed.

Press the info button - you will exit the

menu.

Setting the language

Press Info button - the set value blinks.

Set the desired language by turning the

info button.

Confirm the changed setting by press-

ing the Info button or wait till the set value is automatically accepted after 10

seconds.

Brush trailing

Adjust the trailing time of the brushes.

Same adjustment as "Set language".

Setting the charging marker line

Turn the info button until the function

"Battery menu" is displayed.

Press the info button - select the charg-

ing marker line according to the built-in

batteries.

Note: Setting the charging marker line

should be discussed with Kärcher customer service. This applies especially if

the battery is not listed in the menu.

Confirm the changed setting by press-

ing the Info button or wait till the set value is automatically accepted after 10

seconds.

LOAD DEFAULT

Recreate the basic settings.

Transport

Danger

Risk of injury! When loading or unloading

the machine, it may only be operated on

gradients of max. incline (see "Technical

Specifications"). Drive slowly.

Caution

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

Remove the brush to avoid damage to

the brushes.

When transporting in vehicles, secure

the appliance according to the guidelines from slipping and tipping over.

Storage

Caution

Risk of injury and damage! Note the weight

of the appliance in case of storage.

This appliance must only be stored in interior rooms.

Maintenance and care

Danger

Risk of injury! Before working on the appliance, remove the Intelligent Key and the

mains plug of the charger.

Drain and dispose of the dirt water and

the residual fresh water.

Maintenance schedule

Maintenance intervals

Perform the maintenance task shown

on the display.

Vacuum bar

Clean the filter

Water filter

Clean the filter

Suction lips

opinion

Turbine

Clean filter

Brush

Clean or replace

Press the Info Button, the display will be

reset. The display will be shown again

at certain predefined time intervals.

After each operation

Caution

Risk of damage. Do not wash down the appliance with water and do not use aggressive detergents.

Drain off dirt water.

Rinse the wastewater reservoir with

clean water or with the rinsing system

for the wastewater reservoir (option).

Remove the coarse dirt sieve from the

wastewater reservoir and clean it.

Clean the outside of the appliance with

a damp cloth which has been soaked in

mild detergent.

Check the fluff filter, clean if required.

Only BR model: Remove bulk waste

container and empty it.

Only BR model: Clean water distributor

channel (see section „Maintenance

work“).

Clean the vacuum lips and the wiping

lips, check for wear and replace if required.

Check the brushes for wear, replace if

required.

Press the lock of the wastewater reser-

voir in and close the cover of the wastewater reservoir so that a gap remains

open to facilitate drying.

Monthly

Check battery poles for oxidation, brush

off if necessary. Ensure that the con-

nection cable sits firmly.

Clean the seals between dirt water res-

ervoir and cover and check for tight-

ness, replace if required.

Check the acid density of the cells if the

batteries are not maintenance-free bat-

teries.

Clean the brush tunnel (only BR model).

Yearly

Have the prescribed inspection carried

out by the customer service.

Maintenance Works

Wastewater reservoir rinsing system

(option)

Take the dirt water discharge hose from

the support and lower above a suited

collection device.

Open the lid of the dosing equipment.

Open the cover of the wastewater res-

ervoir.

Pull the flexible lock off of the rinsing

system.

Connect the water hose to the rinsing

system.

Close the cover of the wastewater res-

ervoir until it rests on the flexible lock.

Open the water supply and rinse the

wastewater reservoir for about 30 sec-

onds.

Repeat the rinsing process 2 to 3 times.

Shut off the water supply and discon-

nect the hose from the appliance.

- 6

11EN

Page 12

Replace or turn vacuum lips

1 Wear indicator

2 Vacuum lip

The vacuum lips must be replaced or reversed if they are worn down to the wear indicator.

Remove the vacuum bar.

Unscrew the star grips.

Insert a new brush roller.

Reassemble the bearing lid in the re-

verse sequence.

Repeat process on the opposite side.

Replacing the disk brushes

Press the pedal for changing the brush-

es downward beyond its resistance.

1 Spring element

2 Push handle

Insert the push bow into the cleaning

head intake.

Push the spring elements down and

lock them into place.

1 Excenter lever

2 Locking pin

Remove the plastic parts.

Remove the vacuum lips.

Insert new or reversed vacuum lips.

Insert the plastic parts.

Screw in and tighten the star grips.

Clean water distribution channel

Remove the rubber strip and clean the

channel with a cloth. After cleaning, replace the rubber strip evenly.

Replacing the brush rollers

Loosen the lock of the wiper flap.

Push the bearing lid down and remove.

Pull out the brush rollers.

Note: The brush rollers must be replaced when the bristle length has

reached 10 mm.

Pull the disc brush out of the side below

the cleaning head.

Hold the new disc brush under the

cleaning head, push upward and lock.

Install cleaning head

Push the appliance forward about 2 m

so that the steering rollers point toward

the rear.

1 Spring element

2 Locking pin

3 Terminal strip cover

4 Lock of safety pin

5 Excenter lever

Remove the terminal strip cover.

Place the cleaning head halfway in front

of the appliance.

Connect the mains supply cable of the

cleaning head to the appliance.

Attach the terminal strip cover.

Connect the hose couplers on the

cleaning head to the hose on the appliance.

Open the excenter lever of the slideable

intake on the lift arm.

Lower the lift arm of the appliance

(use only the grey Intelligent Key); pro-

ceed as follows:

Rotate the info button to the menu

"Manual control" and then press it.

Rotate the info button and select the

menu "Brush head".

Press the info button - lift arm will lower,

press info button again to stop it.

Press the cleaning head all the way

against the push handle.

Note: The less play the cleaning head

has after being installed, the less vibra-

tion will occur during cleaning.

Move the intake and insert the safety

pin and lock it into place.

Close the excenter lever.

Select the installed cleaning head (R

or D)

in the menu (use only the grey In-

telligence Key).

Dismantling the cleaning head

The removal will take place in the opposite

order of the installation.

Caution

When the cleaning head is removed, the

stability of the appliance can be compromised; ensure a safe stance.

Possibly support the rear to prevent tipping.

12 EN

- 7

Page 13

Batteries

Please observe the following warning notes

when handling batteries:

Observe the directions on the battery, in the instructions for use and

in the vehicle operating instructions

Wear eye protection

Keep children away from acid and

batteries

Danger of explosion

Fire, sparks, naked flames and

smoking must be strictly avoided

Danger of chemical burns

First aid

Warning note

Disposal

Insert batteries and connect

Caution

When the batteries are installed and removed, the stability of the appliance can be

compromised; ensure a safe stance.

Push the appliance forward about 2 m

so that the steering rollers point toward

the rear.

Hold the wastewater reservoir by the

handle recess and swivel the reservoir

upwards toward the side.

Insert all four batteries into the trough.

The 240 Ah batteries are seated flush in

the battery intake, no holding blocks are

required.

For the 170 Ah and 180 Ah batteries, 2

holding blocks must be installed in the

front and one in the right rear on the

floor. In addition to that, a foam strip is

inserted on the rear left.

몇 Warning

Pay attention to correct poles.

Removing the batteries

Caution

Risk of damage due to tipping appliance;

remove batteries only if the appliance is

equipped with a cleaning head.

Remove the Intelligent Key.

Push the appliance forward about 2 m

so that the steering rollers point toward

the rear.

Hold the wastewater reservoir by the

handle recess and swivel the reservoir

upwards toward the side.

Clamp off the minus pole of the battery.

Clamp off the remaining cables from the

battery.

Remove the support blocks.

Remove the batteries.

Caution

When the batteries are installed and removed, the stability of the appliance can be

compromised; ensure a safe stance.

Dispose of the used batteries according

to the local provisions.

Maintenance contract

To ensure a reliable operation of the appliance maintenance contracts can be concluded with the competent Kärcher sales

office.

Do not throw the battery into the

regular waste

Danger

Danger of explosion. Do not put tools or

similar on the battery, i.e. on the terminal

poles and cell connectors.

Risk of injury. Ensure that wounds never

come into contact with lead. Always clean

your hands after having worked with batteries.

Recommended batteries, B 80

Order No. Description

6.654-119.0

6.654-124.0

6.654-242.0

6.654-086.0

** Appliance requires 4 batteries

1)

Complete set (24 V/240 Ah) incl. connect-

ing cable, order no. 4.035-393.0

2)

Complete set (24 V/180 Ah) incl. connect-

ing cable, order no. 4.035-387.0

3)

Complete set (24 V/170 Ah) incl. connect-

ing cable, order no. 4.035-388.0

4)

Complete set (24 V/180 Ah) incl. connect-

ing cable, order no. 4.035-440.0

1)

240 Ah - maintenance-free

2)

180 Ah - maintenance-free

3)

170 Ah - maintenance-free

4)

180 Ah, - low maintenance

6 V**

6 V**

6 V**

6 V**

1 Connecting cable of battery (-)

2 Connecting cable of battery (+)

3 short connecting cable

4 long connecting cable

Connect the batteries as shown, use

the included connecting cables for this.

Connect the connection cable to the

free battery poles (+) and (-).

Note: The red connecting cable has an

increased protective layer. In order for

the tank not to touch when close, the

connecting cable must be connected as

shown in the illustration.

Tilt the wastewater tank down.

몇 Warning

Charge the battery before commissioning

the machine.

Frost protection

In case of danger of frost:

Empty the fresh and dirt water reser-

voirs.

Store the appliance in a frost-protected

room.

- 8

13EN

Page 14

Faults

Danger

Risk of injury! Before working on the appliance, remove the Intelligent Key and the

mains plug of the charger.

Drain and dispose of the dirt water and

the residual fresh water.

Faults with display

Display Remedy

ERR_I_BÜRSTE_049 Check if foreign matters block the brushes; remove foreign matter if required.

ERR_I_TURB_050 Check suction turbine for contamination and clean it if necessary.

ERR_U_BATT_001 Check battery; charge it if required.

If the display shows different error messages or if the error cannot be remediated:

Remove the Intelligent Key.

Wait for 10 seconds.

Plug in the Intelligent Key.

If the fault recurs, call customer service.

Faults without display on the console

Fault Remedy

Machine does not move Stand-by. Turn the appliance off and reinsert the Intelligent Key.

Turn the program selection switch to the desired programme.

Release parking brake.

Check battery; charge it if required.

Make sure that all battery terminals are connected.

Insufficient water

quantity

Do not add detergents Increase the water volume to activate the dosing pump.

Insufficient vacuum

performance

Insufficient cleaning

result

Vibrations during

cleaning

Brushes do not turn Check if foreign matters block the brushes; remove foreign matter if required.

In case of faults that cannot be remedied using the table below please contact the customer service.

Check fresh water level, refill tank if necessary.

Increase the water volume on the regulating knob for water volume.

Unscrew the lock of the fresh water reservoir. Remove and clean the fresh water filter. Insert the filter and screw

in the lock.

Remove the water distribution strip from the cleaning head and clean water canal (only R cleaning head).

Check hoses for blockages; clean if required.

Check the detergent level

Clean the seals between dirt water reservoir and cover and check for tightness, replace if required.

Wastewater reservoir is full; shut off the appliance and empty the wastewater reservoir

Clean the fluff filter.

Clean the vacuum lips on the vacuum bar, replace if required

Check suction hose for blockages; clean if required.

Check the suction hose for tightness; replace if required.

Check if the cover on the dirt water discharge hose is closed

Check the setting of the vacuum bar.

Check the brushes for wear, replace if required.

Cleaning head has play, open the excenter lever and press the cleaning head all the way against the push handle, close the excenter lever.

You might need to use softer brushes.

If over-current switch in the electronics system has been triggered, turn programme selection switch to "OFF".

Afterwards, set it back to the desired programme.

14 EN

- 9

Page 15

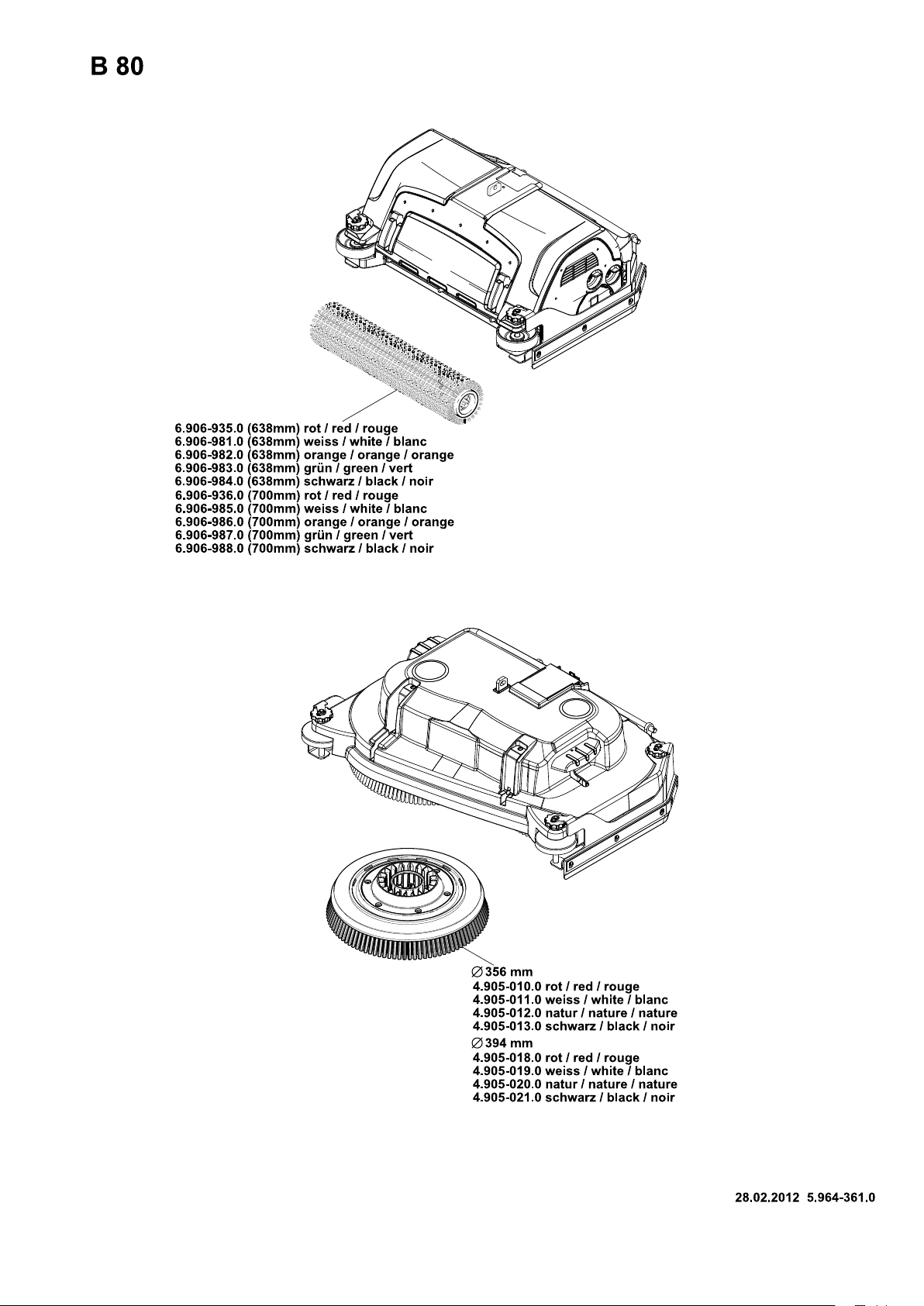

Accessories

BR appliance B 80 (brush roller accessories)

Description Part no.:

Working

width 650

mm

Brush roller, red (medium, standard) 6.906-935.0 6.906-936.0 Also for regular cleaning of heavily dirtied

Brush roller, white (soft) 6.906-981.0 6.906-985.0 For polishing and cleaning sensitive floors. 1 2

Brush roller, orange (high/ low) 6.906-982.0 6.906-986.0 For scrubbing structured floors (safety tiles,

Brush roller, green (hard) 6.906-983.0 6.906-987.0 For thoroughly cleaning heavily dirtied floors

Brush roller, black (very hard) 6.906-984.0 6.906-988.0 1 2

Pad roller shaft 4.762-433.0 4.762-434.0 For intake of roller pads. 1 2

Roller pad, yellow (soft) 6.369-454.0 6.369-454.0 For polishing floors. 20 96; 106

Roller pad, red (medium) 6.369-456.0 6.369-456.0 For cleaning slightly dirtied floors. 20 96; 106

Roller pad, green (hard) 6.369-455.0 6.369-455.0 For cleaning normal to heavily dirtied floors. 20 96; 106

Part no.:

Working

width 750

mm

Description

floors.

etc.).

and for removing the coating (for e.g. of wax,

acrylate).

Packaging unit

Appliance requires

12

12

12

BD appliances B 80 (disc roller accessories)

Description Part no.:

Working

width 650

mm

Part no.:

Working

width 750

mm

Description

Disk brush, natural (white) 4.905-012.0 4.905-020.0 For polishing floors. 1 2

Disk brush, white 4.905-011.0 4.905-019.0 For polishing and cleaning sensitive floors. 1 2

Disk brush, red (medium, standard) 4.905-010.0 4.905-018.0 For cleaning slightly dirtied or sensitive floors. 1 2

Disk brush, black (hard) 4.905-013.0 4.905-021.0 For cleaning heavily dirtied floors. 1 2

Driver plate pad 4.762-446.0 4.762-447.0 For intake of pads. 1 2

Packaging unit

BR/BD appliances B 80 (vacuum bar accessories)

Description Part no.:

Working width

850 mm

Rubber lip, blue 6.273-214.0 6.273-213.0 Standard pair 1 pair

Rubber lip, transparent, grooved 6.273-207.0 6.273-208.0 oil-resistant pair 1 pair

Rubber lip, transparent 6.273-229.0 6.273-205.0 Non-scarring pair 1 pair

Rubber lip, transparent 6.273-290.0 6.273-291.0 For difficult floors pair 1 pair

Vacuum bar, straight 4.777-401.0 4.777-402.0 Standard 1 1

Vacuum bar, bent 4.777-411.0 4.777-412.0 Standard 1 1

Part no.:

Working width

940 mm

Description Pack-

aging

unit

Appliance requires

Appliance requires

- 10

15EN

Page 16

Technical specifications

BR appliance

B 80

BD appliance

B 80

R 65 R 75 D 65 D 75

Power

Nominal voltage V 24

Battery capacity Ah (5h) 170, 180, 240

Average power consumption W 2200

Drive motor output (rated output) W 350

Suction engine output W 580

Brush engine output W 2 x 600

Vacuuming

Vacuum power, air volume (max.) l/s 25

Vacuuming power, negative pressure (max.) mbar / kPa 167 / 16,7

Cleaning brushes

Brush speed 1/min 400 - 1550 180

Dimensions and weights

Theoretical surface cleaning performance m²/h 3900 4500 3900 4500

Max. working range incline % 2

Fresh/dirt water reservoir volume l 80/80

Max. water temperature °C 60

max. water pressure MPa (bar) 0,5 (5)

Net weight (transport weight) kg 280 (with 240 Ah batteries)

Total weight (ready to operate) kg 360 (with 240 Ah batteries)

Values determined as per EN 60335-2-72

Total oscillation value m/s

Uncertainty K m/s

Sound pressure level L

Uncertainty K

pA

Sound power level L

pA

+ Uncertainty K

WA

WA

2

2

0,1

0,1

dB(A) 69

dB(A) 2

dB(A) 83

Subject to technical modifications!

EC Declaration of Conformity

We hereby declare that the machine described below complies with the relevant

basic safety and health requirements of the

EU Directives, both in its basic design and

construction as well as in the version put

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

Product: Floor cleaner

Type: B 80 W Bp

Relevant EU Directives

2006/42/EC (+2009/127/EC)

2004/108/EC

Applied harmonized standards

EN 55014–1: 2006+A1: 2009+A2: 2011

EN 55014–2: 1997+A1: 2001+A2: 2008

EN 60335–1

EN 60335–2–29: 2004+A2: 2010

EN 60335–2–72

EN 61000–3–2: 2006+A1: 2009+A2: 2009

EN 61000–3–3: 2008

EN 62233: 2008

Applied national standards

-

CEO

Head of Approbation

Authorised Documentation Representative

S. Reiser

Alfred Kärcher GmbH Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Phone: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2011/05/01

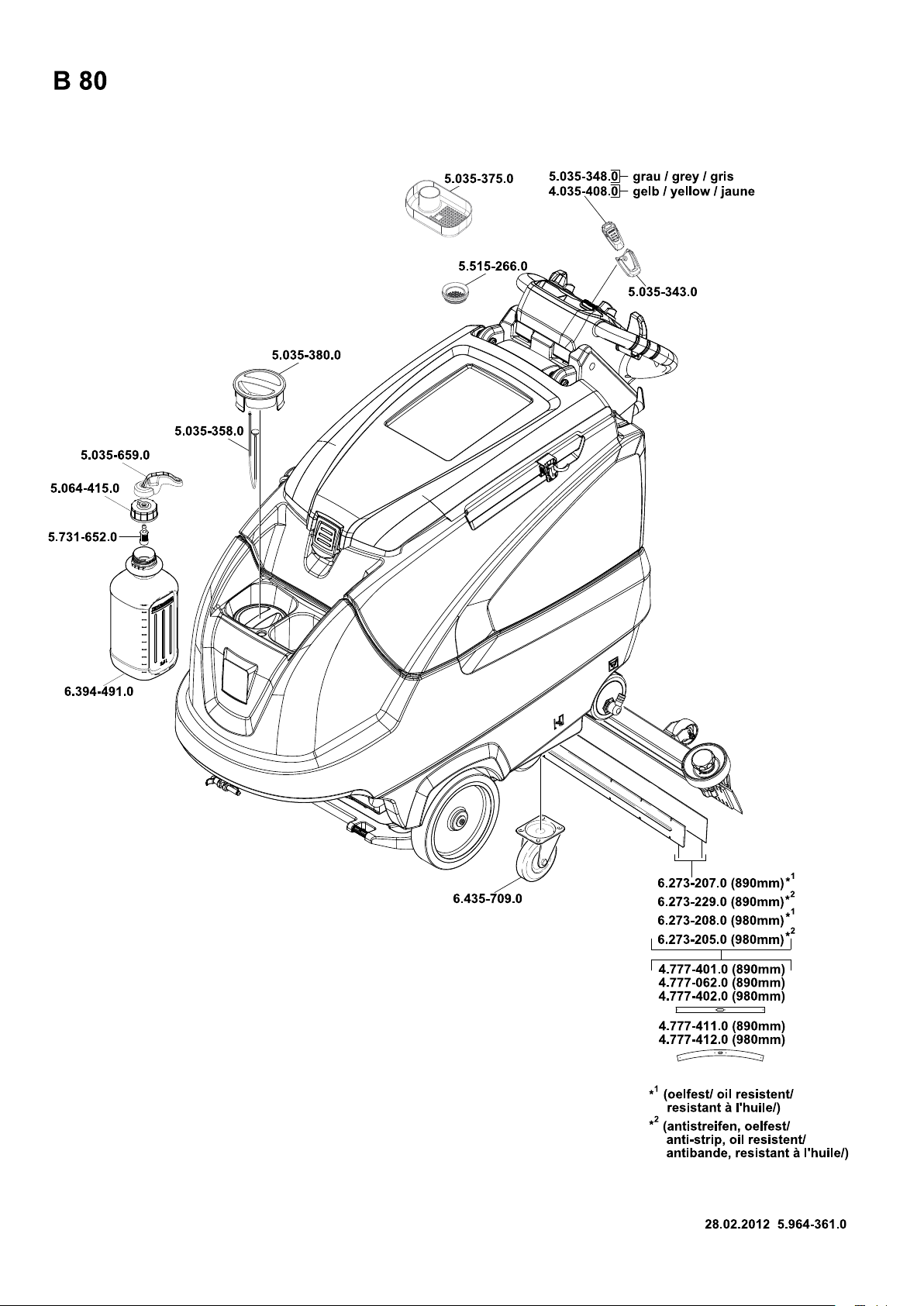

Spare parts

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original

accessories and original spare parts

ensures that the appliance can be operated safely and trouble free.

– At the end of the operating instructions

you will find a selected list of spare

parts that are often required.

– For additional information about spare

parts, please go to the Service section

at www.kaercher.com.

The undersigned act on behalf and under

the power of attorney of the company management.

16 EN

- 11

Loading...

Loading...