Jungheinrich ETMV 214, ETM V 216, ETM V220 Operator Manual

|

|

ETM/V 214/216/220 |

05.99- |

|

|

|

|

|

|

|

|

|

|

|

|

|

Operating instructions |

G |

|

|

|

|

|

|

|

|

50048184 |

|

|

|

|

03.06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Important notes on transporting and mounting load lifting devices to reach trucks

Transport

Depending on the overall height of the lifting mast and the local conditions transport can be performed in three different ways

–Standing, with the lifting mast mounted (for trucks with low overall height)

–Standing, with martially mounted lifting mast tilted towards the overhead guard (for trucks with medium overall height). Hydraulic line for the lifting function is interrupted.

–Standing, with the lifting mast dismounted (for trucks with large overall height)

|

Safety Instructions for Assembly and Commissioning |

f |

The assembly of the truck on site, commissioning the truck and instructing the driver |

|

must be carried out by personnel trained and authorised by the manufacturer |

|

Connect the hydraulic lines to the basic machine / mast interface and commission the |

|

truck only after having installed the mast as per the instructions. |

<![endif]>0903.GB

1

<![endif]>2

0903.GB

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide sufficient instruction for the safe operation of the industrial truck. The information is provided clearly and concisely. The chapters are arranged by letter. Each chapter starts with page 1. The page identification consists of a chapter letter and a page number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following graphics:

f Usedpersonnel.before safety instructions which must be observed to avoid danger to

m

AUsed before notices and explanations.

t Used to indicate standard equipment.

oUsed to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the truck. No guarantee of particular features of the truck should therefore be inferred from the present operating instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY Telephone: +49 (0) 40/6948-0 www.jungheinrich.com

<![endif]>0108.GB

0108.GB

Table of contents

ACorrect use and application of the truck

BDescription of the truck

1 |

Application ........................................................................................... |

B |

1 |

2 |

Assembly description and functional description ............................... |

B |

2 |

2.1 |

Truck ................................................................................................... |

B |

3 |

2.2 |

Load lifting system .............................................................................. |

B |

5 |

3 |

Technical data - Standard version ...................................................... |

B |

6 |

3.1 |

Output data ......................................................................................... |

B |

6 |

3.2 |

Dimensions ......................................................................................... |

B |

6 |

3.3 |

Standard hoist frame versions ETM/V 214/216 .................................. |

B |

8 |

3.4 |

Standard hoist frame versions ETM/V 220 ......................................... |

B |

8 |

3.5 |

EN standards ...................................................................................... |

B |

9 |

3.6 |

Operation conditions ........................................................................... |

B |

9 |

4 |

Location of instruction labels and identification plates ....................... |

B |

10 |

4.1 |

Truck identification plate ..................................................................... |

B |

11 |

4.2 |

Load diagram / capacity / load centre / lifting height ........................... |

B |

11 |

4.3 |

Load diagram, capacity / load centre / fork ......................................... |

B |

12 |

4.4 |

Load diagram, capacity / lateral traversing device .............................. |

B |

12 |

4.5 |

Pick-up points for lifting jack ................................................................ |

B |

12 |

4.6 |

Information sign: Observe the operating instructions! ......................... |

B |

12 |

C |

Transportation and commissioning |

|

|

1 |

Loading and unloading of trucks by crane .......................................... |

C 1 |

|

2 |

Commissioning .................................................................................... |

C 2 |

|

3 |

Parking brake transport restraint ......................................................... |

C 2 |

|

D |

Battery - servicing, recharging, replacement |

|

|

1 |

Safety regulations governing the handling of lead-acid batteries ........ |

D |

1 |

2 |

Battery type ......................................................................................... |

D |

1 |

3 |

Exposing the battery ........................................................................... |

D |

2 |

3.1 |

Bypassing the drive current interruption .............................................. |

D 2 |

|

3.2 |

Battery trolley emergency unlocking system ....................................... |

D 3 |

|

4 |

Charging the battery ............................................................................ |

D |

3 |

5 |

Removing and installing the battery .................................................... |

D 4 |

|

6 |

Battery discharge indicator, |

|

|

|

battery discharge monitor and hour meter .......................................... |

D 5 |

|

<![endif]>0903.GB

I 1

E |

Operation |

|

1 |

Safety regulations governing the operation of the truck ...................... |

E 1 |

2 |

Description of the operating controls and indicators ........................... |

E 2 |

3 |

Start-up of truck ................................................................................... |

E 6 |

3.1 |

How to use the safety belt o ............................................................... |

E 7 |

3.2 |

Emergency stop device ....................................................................... |

E 9 |

4 |

Truck operation ................................................................................... |

E 10 |

4.1 |

Safety regulations applicable when operating the truck ...................... |

E 10 |

4.2 |

Driving, steering, braking .................................................................... |

E 11 |

4.3 |

Adjusting the fork tines ........................................................................ |

E 13 |

4.4 |

Picking up and setting down loads ...................................................... |

E 13 |

4.5 |

Picking up, lifting and transporting of loads ......................................... |

E 16 |

4.6 |

Operating an attachment ..................................................................... |

E 17 |

4.7 |

Rendering vehicle safe when parking ................................................. |

E 17 |

5 |

Information and service display (LISA) ............................................... |

E 18 |

5.1 |

LED warning lamps ............................................................................. |

E 19 |

5.2 |

Key assignment ................................................................................... |

E 19 |

5.3 |

Displays ............................................................................................... |

E 20 |

5.4 |

Changing truck parameters ................................................................. |

E 21 |

6 |

Fault locating operations ..................................................................... |

E 22 |

7 |

Mechanical stand-by steering system |

|

|

(emergency steering operation) .......................................................... |

E 23 |

8 |

Auxiliary electrical system ................................................................... |

E 25 |

8.1 |

Seat heating ........................................................................................ |

E 25 |

8.2 |

Floodlight ............................................................................................ |

E 25 |

8.3 |

360° warning light ............................................................................... |

E 26 |

8.4 |

Flash lamp ........................................................................................... |

E 26 |

8.5 |

Override button (ESA / Electrical lifting limitation) ............................... |

E 27 |

9 |

Single-lever operation o ..................................................................... |

E 28 |

9.1 |

Driving, steering, braking o ................................................................ |

E 28 |

9.2 |

Picking up and setting down loads o .................................................. |

E 30 |

9.3 |

Picking up, lifting and transporting of loads o .................................... |

E 32 |

9.4 |

Operating an attachment o ................................................................ |

E 33 |

<![endif]>0903.GB

I 2

F |

Maintenance of the fork-lift truck |

|

1 |

Operational safety and environmental protection ................................. |

F 1 |

2 |

Safety regulations applicable to truck maintenance ............................. |

F 1 |

3 |

Servicing and inspection ...................................................................... |

F 3 |

4 |

Maintenance Check - list ETM/V 214-220 ........................................... |

F 4 |

5 |

Lubrication Schedule ETMV 214-220 .................................................. |

F 6 |

5.1 |

Fuels, coolants and lubricants .............................................................. |

F 7 |

5.2 |

Reservoir filling level ETM/V 214/216 .................................................. |

F 8 |

5.3 |

Reservoir filling level ETM/V 220 ......................................................... |

F 8 |

6 |

Instructions for the servicing operations ............................................... |

F 9 |

6.1Preparing the truck for the performance of servicing and

|

maintenance operations ....................................................................... |

F 9 |

6.2 |

Safety belt maintenance o .................................................................. |

F 9 |

6.3 |

Opening the arm rest ........................................................................... |

F 10 |

6.4 |

Opening the hood (Direct current motor) ............................................. |

F 10 |

6.5 |

Opening the hood (Three-phase current) o ........................................ |

F 11 |

6.6 |

Opening the battery doors and the seat hood ...................................... |

F 11 |

6.7 |

Checking the hydraulic oil level ............................................................ |

F 12 |

6.8 |

Pressure filter for regenerative lowering .............................................. |

F 12 |

6.9 |

Checking the electric fuses (Direct current motor) ............................... |

F 13 |

6.10 |

Checking the electric fuses (Three-phase current) o .......................... |

F 14 |

6.11 |

Recommissioning the truck .................................................................. |

F 15 |

7 |

Decommissioning the truck .................................................................. |

F 15 |

7.1 |

Operations to be performed prior to decommissioning ........................ |

F 15 |

7.2 |

Measures to be taken during decommissioning ................................... |

F 15 |

7.3 |

Recommissioning the truck .................................................................. |

F 16 |

8Safety checks to be performed at regular intervals and following any untoward incidents (D: Accident prevention check

according to BGV D27) ........................................................................ |

F 16 |

<![endif]>0903.GB

I 3

<![endif]>0903.GB

I 4

A Correct use and application of the truck

A The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are included in the scope of delivery for this truck. The guidelines are part of these operating instructions and must always be heeded. National regulations are fully applica-

|

ble. |

|

The fork lift truck described in these operating instructions is a truck that is suitable |

|

for lifting and transporting loads. |

|

It must be used, operated and maintained according to the information in these ope- |

|

rating instructions. Any other uses are outside the design envelope and can lead to |

|

injury to persons or damage to equipment and property. Above all, overloading |

|

caused by excessively heavy or unbalanced loads must be avoided. The max. admis- |

|

sible load to be picked up is indicated on the identification plate or load diagram label |

|

shown on the truck. The fork lift truck must not be operated in spaces subject to fire |

|

or explosion hazards, or in spaces where corrosive or very dusty atmospheres pre- |

|

vail. |

|

Duties of the user: A “user” within the meaning of these operating instructions is de- |

|

fined as any natural or legal person who either uses the fork lift truck himself, or on |

|

whose behalf it is used. In special cases (e.g. leasing or renting), the user is conside- |

|

red the person, who, in accordance with existing contractual agreements between the |

|

owner and the user of the fork lift truck, is charged with the observance of the opera- |

|

ting duties. |

|

The user must ensure that the truck is not abused and only used within its design li- |

|

mits and that all danger to life and limb of the operator, or third parties, is avoided. In |

|

addition to this, it must be ensured that the relevant accident prevention regulations |

|

and other safety-related provisions, as well as the operating, servicing and mainte- |

|

nance guidelines, are observed. The user must also ensure that all persons operating |

|

the truck have read and understood these operating instructions. |

m |

If these operating instructions are not observed the warranty becomes void. The |

same applies if improper works are carried out at the device by the customer and/or |

|

|

third parties without permission of our Customer Service. |

|

Mounting of attachments: The mounting or installation of any attachments which |

|

will interfere with, or supplement, the functions of the truck is permitted only after writ- |

|

ten approval by the manufacturer has been obtained. If necessary, the approval of |

|

local authorities has to be obtained. |

|

Any approval obtained from local authorities does not, however, make the approval |

|

by the manufacturer unnecessary. |

<![endif]>0600.GB

A 1

<![endif]>0600.GB

A 2

B Description of the truck

1Application

The ETM/V 214-220 is an electrically driven three-wheel truck incorporating a traversing mast and a lateral seat. It is intended for the lifting and transportation of goods on level ground. It can pick up pallets of open ground support, pallets provided with lateral boards arranged outside or inside the range of the load-bearing wheels, or trolleys. Loads can be stacked in and out and transported across greater distances.

Its capacity is shown on the identification label.

Type |

Capacity |

Load centre distance |

ETM/V 214 |

1400 kg |

600 mm |

ETM/V 216 |

1600 kg |

600 mm |

ETM/V 220 |

2000 kg |

600 mm |

<![endif]>0903.GB

B 1

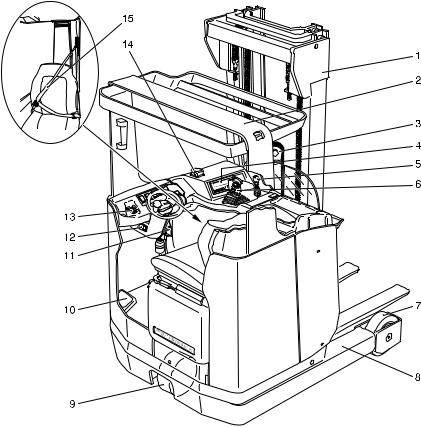

2 Assembly description and functional description

Item |

|

Designation |

Item |

|

Designation |

|

|

|

|

|

|

|

|

1 |

t |

Clear-view lifting mast |

9 |

t |

Drive wheel |

|

2 |

t |

Overhead guard |

10 |

t |

Foot switch |

|

3 |

t |

Free-lift cylinder |

11 |

t |

Battery trolley unlocking system |

|

4 |

t |

Information and |

12 |

t |

Parking brake |

|

|

|

service display (LISA) |

|

|

|

|

5 |

o |

Auxiliary hydraulics (ZH2) |

13 |

t |

Key switch |

|

6 |

t |

Multi-pilot stick |

14 |

t |

Master switch (emergency stop) |

|

7 |

t |

Load-bearing wheels |

15 |

o |

Safety belt |

|

8 |

t |

Wheel arm |

|

|

|

|

|

|

|

|

|

|

|

t |

= |

Standard equipment |

o |

= |

Optional equipment |

<![if ! IE]> <![endif]>0903.GB |

|

|

|

|

|

|

B 2

2.1Truck

Safety installations: The enclosed truck contour featuring rounded edges ensures safe handling of the ETM/V 214-220 truck. The driver is protected by the overhead guard (2). The drive wheel (9) and the load-bearing wheels (7) are enclosed by a sturdy collision guard.

The master switch (14) ensures instant cut-out of all electrical functions in an emergency. Six red LED warning lights in the information and service display (4) indicate the following states:

–Direction of motion Forward(V), „Drive direction“

–Parking brake applied

–Direction of motion Backward (R), „Load direction“

–Lack of brake liquid

–Center position of lateral traversing device (option)

–Battery locking

In case of malfunctions within the hydraulic system, line break safety devices limit the speed at which the load is lowered.

Indicating instruments: Information and service display (LISA) (4) with large indications in LCD-technology. Hour meter and battery discharge indicator with lifting movement cut-out function.

Drive system: The complete drive unit is screwed into the vehicle chassis. A rigidly mounted 5.4 kW shunt motor, or an optional 6 kW rotary current generator, runs the driving wheel (9) via a front bevel-wheel gear mechanism.

The electronic drive current control system provides variable speed to the drive motor, thus allowing smooth starting without jerks, vigorous accelerating and electronically controlled regenerative braking.

The rate of energy regeneration can be set with the LISA system.

Brake system: Two independent brake systems act on the drive wheel. The service brake is designed as a hydraulic drum brake with asbestos-free brake linings and is applied by means of the foot pedal. The parking brake (12) acts mechanically as an electromagnetic brake on the drum brake by pulling a rope.

The brake fluid level is monitored by the LISA system. A warning light shows when the parking brake is applied.

Malfunctions in the steering system and in the parking brake system (release of emergency stop) are indicated in the LISA diplay.

Steering system: Chain-operated steering using a steering gear and, as standard, electric steering. The pivoted drive unit can be swivelled by 90° to both sides.

Driver position: The driver’s place is ergonomically designed and equipped with a large foot space. In order to obtain an ergonomic seating position, the driver can adjust the driver’s seat and the steering column horizontally and vertically.

Accelerator and brake pedals are arranged as found in normal vehicles.

<![if ! IE]><![endif]>0903.GB

B 3

Item |

|

Designation |

Item |

|

Designation |

|

|

|

|

|

|

|

|

1 |

t |

Clear-view lifting mast |

9 |

t |

Drive wheel |

|

2 |

t |

Overhead guard |

10 |

t |

Foot switch |

|

3 |

t |

Free-lift cylinder |

11 |

t |

Battery trolley unlocking system |

|

4 |

t |

Information and |

12 |

t |

Parking brake |

|

|

|

service display (LISA) |

|

|

|

|

5 |

o |

Auxiliary hydraulics (ZH2) |

13 |

t |

Key switch |

|

6 |

t |

Multi-pilot stick |

14 |

t |

Master switch (emergency stop) |

|

7 |

t |

Load-bearing wheels |

15 |

o |

Safety beltt |

|

8 |

t |

Wheel arm |

|

|

|

|

|

|

|

|

|

|

|

t |

= |

Standard equipment |

o |

= |

Optional equipment |

<![if ! IE]> <![endif]>0903.GB |

|

|

|

|

|

|

B 4

Operating controls and indicators: The operating controls and indicators are clearly laid out and arranged at the driver position.

The logically structured multi-pilot stick (6) allows single-handed operation of the drive direction, lifting/ lowering, forward/backward traversing of mast, mast inclination, traversing to the left/right (in lateral traversing operation - auxiliary hydraulics ZH1) and horn functions.

The information and service display (LISA) (4) combines a battery discharge indicator and a working hour meter. The battery discharge indicator is designed as a discharge monitor and will interrupt the lifting function when the battery is depleted to prevent battery exhaustion.

As an option, an auxiliary hydraulic system ZH2 can be operated via the control lever

(5).

Hydraulic system: Pump unit with a remotely ventilated series-wound motor and a noiseless precision jetting pump integrated in the oil reservoir. The system is controlled via the multi-pilot stick (6) and the optional auxiliary hydraulics (5).

Instead of the multi-pilot, an optional control via individual levers is possible (see chapter E).

Electric system: 48 V two-wire system.

As a standard feature, the truck is equipped with an electronic drive and lifting control system. The electronic drive control system variably controls the travelling speed and allows counter-current braking when switching the direction of travel.

The information and service display (LISA) (4) allows a adjustment of the driving and lifting parameters according to the current requirements. Warning indications, operating error indications and service functions are also shown on the LISA.

(For possible drive batteries, see chapter D.)

2.2Load lifting system

Mast holder: The mast holder is borne by supporting rollers. The protracting and retracting movements are carried out directly by a simply telescoping traversing cylinder. The guide rails for the mast holder are screwed onto the wheel arms (8).

Hoist frame: The trucks are equipped with tiltable, telescoping free-vision hoist frames (1) supported by the mast holder. Adjustable lateral rollers and guide pieces absorb the lateral pressure acting on the fork carrier when transporting unbalanced loads. The mounting of the fork to the fork carrier permits adjustments to be made to the tines. In the case of the double-lift triplex mast (DZ), the initial lifting sequence of the load carriage (free lift), which does not change the total height, is effected by a short free-lift cylinder (3) arranged off-centre. In the case of the telescopic mast (ZT), the free-lift sequence is limited to 80 mm due to the construction of the truck.

Attachments: Mechanical and hydraulic attachments are available as optional equipment.

<![if ! IE]><![endif]>0903.GB

B 5

3 Technical data - Standard version

A Technical data to VDI 2198.

Technical data are subject to alteration and extension in scope.

3.1Output data

|

Designation |

ETM/V 214 |

ETM/V 216 |

ETM/V 220 |

|

Q |

Capacity (at C = 600 mm) |

1400 |

1600 |

2000 |

kg |

C |

Load centre distance |

600 |

600 |

600 |

mm |

|

Travelling speed |

10,8/11 |

10,3/10,6 |

10,1/ 10,6 |

km/h |

|

with / without load |

||||

|

|

|

|

|

|

|

Lifting speed |

0,35/0,55 |

0,34/0,54 |

0,28/0,43 |

m/s |

|

with / without load |

(±10%) |

|||

|

|

|

|

||

|

Lowering speed |

0,50/0,50 |

0,50/0,50 |

0,50/0,50 |

m/s |

|

with / without load |

(±15%) |

|||

|

|

|

|

||

|

Traversing speed |

0,2 |

0,2 |

0,12 d) |

m/s |

|

with / without load |

||||

|

|

|

|

|

|

|

Climbing ability |

9/13 |

8/12 |

7/11 |

% |

|

with / without load |

||||

|

|

|

|

|

|

|

Max. climbing ability (max. 5 min) |

10/15 |

10/15 |

10/15 |

% |

|

with / without load |

||||

|

|

|

|

|

d)h3 ≥ 6201 - 8000 mm = 0,10 m/s h3 ≥ 8001 mm = 0,08 m/s

3.2Dimensions

|

|

|

|

|

|

|

|

Designation |

|

ETM/V 214 |

ETM/V216 |

ETM/V220d) |

|

|

|

|

(ZT/DZ) |

(ZT/DZ) |

(ZT/DZ) |

|

|

|

|

|

|

|

|

s |

Height of lowered fork |

|

40 |

40 |

50 |

mm |

h6 |

Height above overhead guard |

e) |

2075/2190 |

2075/2190 |

2075/2190 |

mm |

l |

Total length |

a) |

1957/1985 |

1957/1985 |

2034/2060 |

mm |

1 |

|

|

|

|

|

|

l4 |

Traversing distance |

b) |

616/594 |

666/644 |

690/664 |

mm |

|

||||||

l7 |

Length across wheel arms |

|

1752 |

1802 |

1903 |

mm |

b1 |

Total width |

|

1120/1238 |

1120/1238 |

1126/1244 |

mm |

b2 |

Total width |

|

1106/1186 |

1106/1186 |

1106/1186 |

mm |

Wa |

Turning radius |

|

1617/1629 |

1663/1675 |

1745/1753 |

mm |

Ast |

Working aisle |

|

2617/2639 |

2617/2639 |

2669/2695 |

mm |

width 800 x 1200 pallets, lengthwisec) |

||||||

Ast |

Working aisle |

|

2417/2439 |

2417/2439 |

2469/2495 |

mm |

|

width1000 x 1200 pallets, crosswise c) |

|

|

|

|

|

|

Dead weight : |

|

Refer to |

truck identification plate |

||

a) Length of fork: 800 mm; 560 Ah battery: +90 mm; 700 Ah battery: +162 mm b) 560 Ah battery: -90 mm; 700 Ah battery: +162 mm

c) ± 5 mm; 560 Ah battery: +90 mm; 700 Ah battery: +162 mm d) 700 Ah battery: a( +162 mm, b) -162 mm, c) +162 mm e)Overall height h1 ≤ 2500: 2075 mm

Overall height h1 ≥ 2200: 2400 mm, 420/560 Ah battery: 2075mm 700 Ah battery: 2190 mm

Overall height h1 >2400 mm = 2190 mm

<![endif]>0903.GB

B 6

.

|

|

|

h4 |

h6 |

l4 |

c |

h3 |

h1 |

|||

|

|

|

h2 |

|

|

Q |

|

|

|

s |

h2 |

|

l7 |

|

|

|

l1 |

|

|

Wa

Wa

b2 |

b1 |

Ast

<![if ! IE]><![endif]>0903.GB

B 7

3.3Standard hoist frame versions ETM/V 214/216

|

Designation |

Telescopic |

Double lift |

Double lift triplex mast |

|

|

|

mast (ZT) |

triplex mast (DZ) |

(DZ), reinforced |

|

|

|

|

|

|

|

h1 |

Total height |

1950 - 3100 |

1950 - 2700 |

2700 - 3950 |

mm |

h2 |

Free lift |

80 |

1306 - 2056 |

2056 - 3306 |

mm |

h3 |

Lift |

2900 - 5200 |

4250 - 6500 |

6500 - 10250 |

mm |

h4 |

Max. height |

3544 - 5844 |

4894 - 7144 |

7144 - 18094 |

mm |

3.4Standard hoist frame versions ETM/V 220

|

|

Designation |

Telescopic |

Double lift |

Double lift triplex |

|

|

|

|

||||

|

|

|

|

mast (ZT) |

triplex mast (DZ |

mast (DZ) |

|

|

|

|

|||

|

|

|

|

|

|

|

reinforced |

|

|

|

|

||

h1 |

Total height |

2050 - 2700 |

2050 - 3440 |

2050 - 3440 |

|

|

mm |

||||||

h2 |

Free lift |

100 |

1320 - 2710 |

1320 - 2710 |

|

|

mm |

||||||

h3 |

Lift |

2900 - 4200 |

4250 - 8420 |

4250 - 8420 |

|

|

mm |

||||||

h4 |

Max. height |

3591 - 4891 |

4996 - 9166 |

4996 - 9166 |

|

|

mm |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

h4 |

h6 |

l4 |

c |

h3 |

h1 |

|||

|

|

|

h2 |

|

|

Q |

|

|

|

s |

h2 |

|

l7 |

|

|

|

l1 |

|

|

<![endif]>0903.GB

B 8

3.5EN standards Continuous sound level:

70 dB(A)

according to EN 12053 as stipulated in ISO 4871.

A The continues sound level is an average value determined according to the standard’s guidelines and takes into consideration the sound level when driving, lifting and in idle mode. The sound level is measured at the driver’s ear.

Vibration: |

0.40 m/s2 |

|

according to document N47E of CEN/TC 150/WG8. |

A The vibration acceleration applied to the operator’s body is measured according the standard’s guidelines as a linearly integrated, weighted acceleration in vertical direction. The acceleration is measured when driving across bumps at steady speed.

Electromagnetic compatibility (EMC)

The following limit values are observed according to the product standards “Electromagnetic Compatibility of Industrial Trucks (9/95)“:

-interference emission (EN 50081-1)

-interference immunity (EN 50082-2)

-electrostatic discharge (EN 61000-4-2).

A Electrical or electronic components and their arrangement may only be modified after written approval by the manufacturer has been obtained.

3.6Operation conditions Environmental temperature

– in operation –25°C to 40°C

A If the truck is operated continuously below 0°C, it is recommended to fill the hydraulic system with frost resisting oil as approved by the manufacturer.

For applications in cold stores resp. in areas with extreme temperature or humidity changes the truck has to be specially equipped and approved.

<![if ! IE]><![endif]>0903.GB

B 9

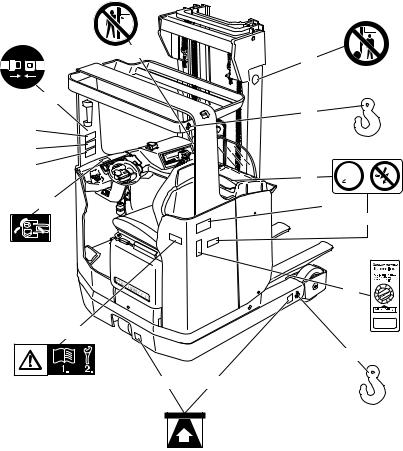

4 Location of instruction labels and identification plates

27 |

|

|

16 |

|

|

26.1 |

|

|

17 |

|

|

26 |

|

|

25 |

|

|

24 |

mV |

|

18 |

||

1,5 V |

||

23 |

19 |

|

|

||

|

18 |

20

22

17

21 21

0 |

1 |

11 |

21 |

|

|

1 |

|

9 |

|

96 |

|

8 |

|

19 |

2 |

7 |

|

3 |

|

|

6 |

5 |

4 |

Ihr Kundendienst-Partner

Item |

Designation |

|

|

16 |

Prohibitive sign “Keep away from under the load lifting device” |

|

|

17 |

Pick-up points for crane transportation |

|

|

18 |

Warning sign "Low voltage electronics" |

|

|

19 |

Truck identification plate |

|

|

20 |

Plaque confirming accident prevention checks (only D) |

|

|

21 |

Pick-up points for lifting jack |

|

|

22 |

Attention: Observe the operating instructions |

|

|

23 |

Drive direction when locking the steering wheel |

|

|

24 |

Load diagram, capacity / lateral traversing device |

|

|

25 |

Load diagram, capacity / load centre / fork |

|

|

26 |

Load diagram, capacity / load centre / lifting height |

|

|

26.1 |

Sign: Put on safety belt |

<![if ! IE]> <![endif]>0903.GB |

|

27 |

Prohibitive sign “Do not reach through the hoist frame” |

||

|

B 10

4.1Truck identification plate

28 |

39 |

29 |

38 |

30 |

37 |

31 |

36 |

32 |

35 |

|

34 |

|

33 |

Item |

Designation |

Item |

Designation |

28 |

Type |

34 |

Manufacturer |

29 |

Serial No. |

35 |

Min./max. battery weight in kg |

30 |

Rated capacity in kg |

36 |

Drive power in kW |

31 |

Battery: Voltage V |

37 |

Load centre distance in mm |

32 |

Empty weight without battery in kg |

38 |

Year of manufacture |

33 |

Manufacturer logo |

39 |

Option |

A In event of queries relating to the truck or spare part orders, please state the serial no. (29) of the truck.

4.2Load diagram / capacity / load centre / lifting height

The load diagram (26) shows the capacity of the truck in Q kg with the hoist frame in vertical position. The diagram indicates the maximum capacity at a standard load centre* C (in mm) and at the desired lifting height H (in mm) in the form of a table.

*) Apart from the height of the load, the standard load centre also includes the width of the load.

Example showing the determination of the max. capacity:

At a load centre C of 600 mm and a max. lifting height H of 3600 mm, the max. capacity Qkg is 1105 kg.

<![if ! IE]><![endif]>0903.GB

B 11

4.3Load diagram, capacity / load centre / fork

The load diagram (25) shows the capa-

city Q of the fork in kg. A diagram shows the max. capacity at different load centres (C in mm).

4.4Load diagram, capacity / lateral traversing device

The load diagram (24) shows the reduced capacity Q in kg with the lateral traversing device extended.

4.5Pick-up points for lifting jack

For lifting and jacking up the truck. (see chapter F)

4.6Information sign: Observe the operating instructions!

The notes contained in the operating instructions regarding the commissioning (see chapter C) and the mechanical stand-by steering system (see chapter E) must always be observed!

<![if ! IE]><![endif]>0903.GB

B 12

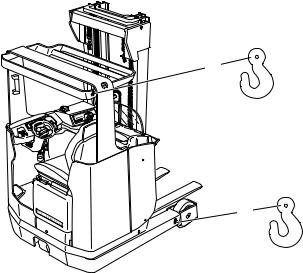

C |

Transportation and commissioning |

1 |

Loading and unloading of trucks by crane |

m |

Ensure that the lifting gear is of adequate capacity (Transportation weight = net |

|

weight + battery weight; see truck identification plate) |

|

– To load the truck with lifting gear, lay the loop of the rope around the strut of the |

|

overhead guard (1). Two lifting points (2) are provided on the wheel arms. |

|

– Park the truck and render it safe (see chapter E). |

|

– Use chocks to prevent the truck from moving! |

m |

The lifting gear must be secured to the lifting points in such a way that it does not |

|

come into contact with any attachments when the truck is lifted. |

1

2

|

Moving the truck without battery |

f |

The transport restraint prevents the parking brake from being applied. In this state, |

|

the truck is not braked! |

–Press the brake pedal. Use the service brake to prevent the truck from moving!

–Remove the safety chocks.

–Release the service brake.

A The truck can now be pulled or pushed.

<![if ! IE]><![endif]>0599.GB

C 1

2 |

Commissioning |

m |

The truck must only be operated on battery current. Rectified alternate current will da- |

mage the electronics. Cables connected to the battery (towing cable) must be less |

|

|

than 6 meters in length. |

|

To prepare the truck for work following delivery or transportation, the following ope- |

|

rations must be performed: |

|

– If necessary, install the battery. Do not damage the battery cable. |

|

– Charge the battery. (see chapter D) |

|

– Remove the transport restraint of the parking brake, if required. |

|

(see chapter C) |

|

– Commission the truck as prescribed. (see chapter E) |

A When supplied without battery, the truck can only be steered using the mechanical |

||

|

spare steering system (see chapter E). |

|

3 |

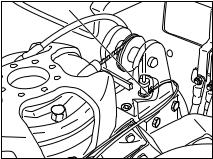

Parking brake transport restraint |

|

|

Before commissioning the truck, the transport restraint must be removed. This device |

|

f is used to lock the magnet actuating the parking brake so that the the truck is not bra- |

||

|

ked when no power is available. |

|

|

The transport restraint is applied if the truck is delivered with an uncharged battery. |

|

|

The transport restraint consists of a retaining ring (3) attached to a red cable tie which |

|

|

visibly protrudes from the seat hood. The retaining ring is inserted at the tie rod of the |

|

|

magnet. This prevents the magnet from moving. |

|

|

Removing the transport restraint: |

|

|

– Connect the charged battery. |

3 |

|

– Open the seat hood. |

|

|

|

|

|

(see chapter F) |

|

|

– Remove the retaining ring (3) with the |

|

|

cable tie from the tie rod. |

|

m |

The second retaining ring inserted at the |

|

tie rod must not be removed during com- |

|

|

|

missioning! |

|

|

– Close and lock the seat hood. |

|

|

– Switch on the master switch and the |

|

|

key switch. |

|

A The truck is now ready for operation.

<![if ! IE]><![endif]>0599.GB

C 2

Loading...

Loading...