Jungheinrich DFG 670, DFG 680, DFG 690, DFG S80, DFG S90 User Manual

...

DFG/TFG 660-690

Operating instructions

51139143

02.11

02.11 -

G

DFG 660 DFG 670 DFG 680 DFG 690 DFG S80 DFG S90 TFG 660 TFG 670 TFG 680 TFG 690 TFG S80 TFG S90

Declaration of Conformity

Jungheinrich AG, Am Stadtrand 35, D-22047 Hamburg

Manufacturer or agent acting in the European Union

Type |

Option |

Serial no. |

Year of |

|

|

|

manufacture |

DFG 660

DFG 670

DFG 680

DFG 690

DFG S80

DFG S90

TFG 660

TFG 670

TFG 680

TFG 690

TFG S80

TFG S90

Additional information

On behalf of

Date

GEU Conformity Declaration

The undersigned hereby declare that the powered industrial truck described below in detail complies with the European Directives 2006/42/EC (Machinery Directive) and 2004/108/EEC (Electromagnetic Compatibility - EMC) including amendments as well as the legislative decree to incorporate the directives in national law. The signatories are in each case individually authorized to compile the technical documents.

02.11 EN

3

4

02.11 EN

02.11 EN

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide sufficient instruction for the safe operation of the industrial truck. The information is provided clearly and concisely. The chapters are arranged by letter and the pages are numbered continuously.

The operator manual details different industrial truck models. When operating and servicing the industrial truck, make sure that the particular section applies to your truck model.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the system. No guarantee of particular features of the truck should therefore be assumed from the present operating instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following graphics:

DANGER!

Indicates an extremely hazardous situation. Failure to comply with this instruction will result in severe irreparable injury and even death.

WARNING!

Indicates an extremely hazardous situation. Failure to comply with this instruction may result in severe irreparable injury and even death.

CAUTION!

Indicates a hazardous situation. Failure to comply with this instruction may result in slight to medium injury.

NOTE

Indicates a material hazard. Failure to comply with this instruction may result in material damage.

ZUsed before notices and explanations.

t Indicates standard equipment

oIndicates optional equipment

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

5

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - Germany

Tel: +49 (0) 40/6948-0

www.jungheinrich.com

02.11 EN

6

Table of Contents |

|

|

A |

Correct Use and Application .................................................... |

11 |

1 |

General.................................................................................................... |

11 |

2 |

Correct application................................................................................... |

11 |

3 |

Approved application conditions.............................................................. |

12 |

4 |

Proprietor responsibilities ........................................................................ |

13 |

5 |

Adding attachments and/or accessories.................................................. |

13 |

B |

Truck Description..................................................................... |

15 |

1 |

Application............................................................................................... |

15 |

1.1 |

Truck models and rated capacity............................................................. |

15 |

2 |

Assemblies and Functional Description................................................... |

16 |

2.1 |

Assembly Overview................................................................................. |

16 |

2.2 |

Functional Description............................................................................. |

17 |

3 |

Technical Specifications.......................................................................... |

19 |

3.1 |

Performance data.................................................................................... |

19 |

3.2 |

Dimensions.............................................................................................. |

23 |

3.3 |

Weights ................................................................................................... |

28 |

3.4 |

Mast versions .......................................................................................... |

29 |

3.5 |

Tyre type ................................................................................................. |

31 |

3.6 |

Engine Data............................................................................................. |

32 |

3.7 |

EN norms................................................................................................. |

33 |

3.8 |

Conditions of use..................................................................................... |

35 |

3.9 |

Electrical requirements............................................................................ |

35 |

4 |

Identification points and data plates ........................................................ |

36 |

4.1 |

Data plate ................................................................................................ |

38 |

4.2 |

Truck capacity plate................................................................................. |

39 |

4.3 |

Attachment capacity plate ....................................................................... |

40 |

4.4 |

Jack attachment point.............................................................................. |

40 |

5 |

Stability.................................................................................................... |

40 |

C |

Transport and Commissioning................................................. |

41 |

1 |

Transport ................................................................................................. |

41 |

2 |

Truck laden.............................................................................................. |

41 |

2.1 |

Centre of gravity of the truck ................................................................... |

41 |

2.2 |

Lifting the truck by crane ......................................................................... |

42 |

2.3 |

Loading with another industrial truck....................................................... |

42 |

3 |

Securing the truck during transport ......................................................... |

43 |

4 |

Using the Truck for the First Time ........................................................... |

44 |

02.11 EN

7

D |

Fuelling the Truck .................................................................... |

45 |

1 |

General.................................................................................................... |

45 |

1.1 |

Safety regulations for handling diesel fuel and LPG................................ |

45 |

1.2 |

LPG system relief valve........................................................................... |

47 |

2 |

Adding diesel........................................................................................... |

48 |

2.1 |

Fuelling.................................................................................................... |

48 |

2.2 |

Fuelling with fuel containers .................................................................... |

49 |

3 |

LPG containers........................................................................................ |

50 |

3.1 |

LPG bottles.............................................................................................. |

50 |

3.2 |

Liquid gas tank ........................................................................................ |

53 |

4 |

Fuel level indicator................................................................................... |

54 |

4.1 |

Display unit.............................................................................................. |

54 |

E |

Operation ................................................................................. |

55 |

1 |

Safety Regulations for the Operation of the Forklift Truck....................... |

55 |

2 |

Displays and Controls.............................................................................. |

57 |

2.1 |

Multi-task switch ...................................................................................... |

57 |

2.2 |

SOLO-PILOT........................................................................................... |

59 |

2.3 |

MULTI-PILOT .......................................................................................... |

60 |

2.4 |

Controls ................................................................................................... |

61 |

2.5 |

Multifunction display ................................................................................ |

63 |

2.6 |

Operation of the multifunction display ..................................................... |

68 |

3 |

Dashboard............................................................................................... |

78 |

3.1 |

Without air conditioning system............................................................... |

78 |

3.2 |

With air conditioning system.................................................................... |

78 |

3.3 |

With automatic air conditioning................................................................ |

79 |

4 |

Heater, fan, air conditioning system ........................................................ |

80 |

4.1 |

Heater...................................................................................................... |

80 |

4.2 |

Air conditioning system (o) ...................................................................... |

80 |

5 |

Preparing the Truck for Operation........................................................... |

84 |

5.1Checks and operations to be performed before starting daily operation. 84

5.2 |

Entry and exit .......................................................................................... |

86 |

5.3 |

Setting up the operator position............................................................... |

87 |

5.4 |

Seat Belt.................................................................................................. |

93 |

6 |

Industrial Truck Operation ....................................................................... |

94 |

6.1 |

Safety regulations for truck operation...................................................... |

94 |

6.2 |

Preparing the truck for operation............................................................. |

96 |

6.3 |

Operational Checks................................................................................. |

99 |

6.4 |

Parking the truck securely ....................................................................... |

100 |

6.5 |

Emergency Disconnect............................................................................ |

102 |

6.6 |

Travel ...................................................................................................... |

102 |

6.7 |

Steering ................................................................................................... |

104 |

6.8 |

Brakes ..................................................................................................... |

105 |

6.9 |

Adjusting the forks................................................................................... |

107 |

6.10 |

Replacing the forks.................................................................................. |

108 |

6.11 |

Lifting, transporting and depositing loads................................................ |

109 |

6.12 |

Operating the lift mechanism and integrated attachments ...................... |

111 |

6.13 |

Safety instructions for operating additional attachments......................... |

116 |

6.14 |

Operating additional attachments for the SOLO-PILOT.......................... |

119 |

02.11 EN

8

02.11 EN

6.15 |

Operating additional attachments for the Multi Pilot................................ |

120 |

6.16 |

Fitting additional attachments.................................................................. |

122 |

7 |

Towing trailers ......................................................................................... |

123 |

8 |

Optional equipment ................................................................................. |

125 |

8.1 |

Sliding windows....................................................................................... |

125 |

8.2 |

Emergency Exit ....................................................................................... |

126 |

8.3 |

Driver'S Seat Heater................................................................................ |

126 |

8.4 |

Adjusting the Multifunction Display.......................................................... |

127 |

8.5 |

Fire Extinguisher...................................................................................... |

127 |

8.6 |

Rockinger Coupling with Hand Lever ...................................................... |

128 |

9 |

Troubleshooting....................................................................................... |

129 |

9.1 |

Automatic Emergency Brake................................................................... |

129 |

9.2 |

Troubleshooting....................................................................................... |

131 |

9.3 |

Operating the truck without its own drive system .................................... |

132 |

F |

Industrial Truck Maintenance................................................... |

137 |

1 |

Operational Safety and Environmental Protection................................... |

137 |

2 |

Maintenance Safety Regulations............................................................. |

138 |

3 |

Servicing and Inspection ......................................................................... |

143 |

4 |

Maintenance checklist ............................................................................. |

144 |

4.1 |

Maintenance checklist DFG..................................................................... |

144 |

4.2 |

Maintenance checklist TFG..................................................................... |

147 |

4.3 |

DFG/TFG Options Maintenance Checklist .............................................. |

151 |

5 |

Lubricants and Lubrication Schedule ...................................................... |

156 |

5.1 |

Handling consumables safely.................................................................. |

156 |

5.2 |

Lubrication Schedule............................................................................... |

158 |

5.3 |

Consumables........................................................................................... |

160 |

5.4 |

Coolant specification ............................................................................... |

161 |

6 |

Maintenance and repairs......................................................................... |

162 |

6.1 |

Preparing the truck for maintenance and repairs .................................... |

162 |

6.2 |

Opening the Service Panel...................................................................... |

163 |

6.3 |

Tilting the Cab ......................................................................................... |

163 |

6.4 |

Checking the wheel attachments............................................................. |

167 |

6.5 |

Hydraulic system ..................................................................................... |

168 |

6.6 |

Engine maintenance................................................................................ |

171 |

6.7 |

Check the transmission oil level .............................................................. |

177 |

6.8 |

Performing Other Maintenance Work...................................................... |

177 |

6.9 |

Closing the Motor Compartment.............................................................. |

177 |

6.10 |

Checking electrical fuses......................................................................... |

178 |

6.11 |

Starter battery.......................................................................................... |

183 |

6.12 |

Exhaust system ....................................................................................... |

184 |

6.13 |

Seat belt maintenance............................................................................. |

189 |

6.14 |

Restoring the truck to service after maintenance and repairs ................. |

190 |

7 |

Decommissioning the industrial truck...................................................... |

191 |

7.1 |

Prior to decommissioning ........................................................................ |

192 |

7.2 |

During decommissioning ......................................................................... |

192 |

7.3 |

Restoring the truck to service after decommissioning............................. |

193 |

8 |

Safety tests to be performed at intervals and after unusual incidents..... |

194 |

9 |

Final de-commissioning, disposal............................................................ |

195 |

10 |

Human vibration measurement ............................................................... |

195 |

9

10

02.11 EN

A Correct Use and Application

1General

The industrial truck described in the present operating instructions is designed for lifting, lowering and transporting load units.

It must be used, operated and serviced in accordance with the present instructions. Any other type of use is beyond the scope of application and can result in damage to personnel, the industrial truck or property.

2Correct application

NOTE

The maximum load and load distance are indicated on the load chart and must not be exceeded.

The load must rest on the load handler or be lifted by an attachment approved by the manufacturer.

The load must rest on the back of the fork carriage and centrally between the forks.

–Lifting and lowering of loads.

–Transporting lowered loads over short distances.

–Do not travel with a raised load (>30 cm).

–Do not carry or lift passengers.

–Do push or pull load units.

–Occasional towing of trailer loads.

–When towing trailer loads the load must be secured on the trailer.

–The permissible trailer load must not be exceeded.

02.11 EN

11

3Approved application conditions

DANGER!

Do not exceed the permissible surface and spot load limits on the travel routes. At blind spots get a second person to assist.

The driver must ensure that the loading dock / ramp cannot move or come loose during loading / unloading.

–Operation in industrial and commercial environments.

–Permissible temperature range -20 to 40°C.

–Operation only on secure, level surfaces with sufficient capacity.

–Operation only on routes that are visible and approved by the proprietor.

–Negotiating inclines up to a maximum of 15 %.

–Do not negotiate inclines crosswise or at an angle. Transporting loads downhill.

–Operation in partially public traffic.

–The truck may only be operated in areas that are clean and free of oil and similar substances.

WARNING!

Extreme conditions

XSpecial equipment and authorisation are required if the truck is to be constantly used in extreme conditions, especially in dusty or corrosive atmospheres.

XThe truck is not authorised for use in areas at risk of explosion.

XIn adverse weather conditions (thunder, lightning) the industrial truck must not be operated outside or in endangered areas.

02.11 EN

12

4Proprietor responsibilities

For the purposes of the present operating instructions the “proprietor” is defined as any natural or legal person who either uses the industrial truck himself, or on whose behalf it is used. In special cases (e.g. leasing or renting) the proprietor is considered the person who, in accordance with existing contractual agreements between the owner and user of the industrial truck, is charged with operational duties.

The proprietor must ensure that the industrial truck is used only for the purpose for which it is intended and that there is no danger to life and limb of the user and third parties. Furthermore, accident prevention regulations, safety regulations and operating, servicing and repair guidelines must be followed. The proprietor must ensure that all users have read and understood these operating instructions.

NOTE

Failure to comply with the operating instructions shall invalidate the warranty. The same applies if improper work is carried out on the truck by the customer or third parties without the permission of the manufacturer.

5Adding attachments and/or accessories

Adding accessories

The mounting or installation of additional equipment which affects or enhances the performance of the forklift truck requires the written permission of the manufacturer. Local authority approval may also need to be obtained.

Local authority approval does not however constitute the manufacturer’s approval.

02.11 EN

13

14

02.11 EN

B Truck Description

1Application

The DFG/TFG 660-690 is a four-wheel IC engine sit-down forklift truck. The DFG series are diesel engine trucks, while the TFG series are fitted with a petrol engine for LPG operation.

The DFG/TFG 660-690 is a cantilever counterbalanced truck which can lift, transport and deposit loads using the load handler attached in front.

Closed bottom pallets can also be lifted.

The DFG/TFG 660-690 is equipped with a hydrodynamic drive.

1.1Truck models and rated capacity

The rated capacity depends on the model. The rated capacity can be derived from the model description.

DFG660

DFG Model name

6Series

60 Rated capacity x 100 kg

The rated capacity does not generally match the permissible capacity. The capacity can be found on the load chart attached to the rack.

02.11 EN

15

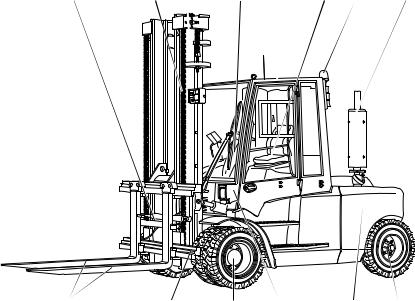

2Assemblies and Functional Description

2.1Assembly Overview

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

14 |

13 |

12 |

11 |

10 |

9 |

Item |

Description |

Item |

Description |

||

1 |

o |

Fork adjustment |

8 |

t |

Exhaust pipe |

2 |

t |

Load chains |

9 |

t |

Steer axle |

3 |

t |

Mast |

10 |

t |

Counterweight |

4 |

t |

Steering column |

11 |

t |

Illumination |

5 |

t |

Cab |

12 |

t |

Drive |

6 |

t |

Driver's seat |

13 |

t |

Fork carriage |

7 |

o |

Beacon |

14 |

t |

Fork tines |

|

t = |

Standard equipment |

|

o = |

Optional equipment |

02.11 EN

16

2.2Functional Description

Chassis and superstructure

A rigid chassis which protects the units and controls, provides the truck with maximum static safety. A wide opening cab (5) facilitates service and maintenance work. The hydraulic oil reservoir is integrated on the right-hand side and the fuel tank on the opposite side of the chassis. The vertical, free standing front exhaust pipe (8) is positioned much higher than is common. It prevents vibrations and sound saves from being transferred and exhaust gases from penetrating into the operator position.

Operator position

The operator position is articulating, which cushions vibrations and noise. Non-slip steps and a handle on the cab post ensure easy entry and exit. The driver is protected by the cab (5). To adapt the seat position, the driver can adjust the seat and steering head both vertically and horizontally. The accelerator pedal and brake pedal are of "automotive" design.

Steering

The steer cylinder of the hydrostatic steering is integrated in the steer axle (9) and is controlled by the power steering. The steer axle is fully floating in the chassis to ensure excellent grip even on non-level surfaces.

Wheels

All wheels are located within the truck geometry. A choice of pneumatic or superelastic tyres are available.

Diesel engine

Quiet-running, water-cooled diesel engines featuring high performance and low consumption with very clean fuel combustion under all operating conditions ensure soot values are below the limit of visibility. An additional particle filter (o) ensures very low exhaust levels.

LPG engine

Quiet running, water-cooled four-stroke engines featuring high performance and low consumption. Petrol engines with very low residual exhaust levels are used. An additional 3-way catalytic converter (o) ensures very low exhaust levels.

Electrical system

12 volt system with threephase alternator. A start block prevents malfunctions when the truck is powered up. For diesel engines, a rapid pre-heat system is installed; LPG motors have an electronic ignition system for rapid and trouble-free engine starting. The key switch is used to stop the engine.

02.11 EN

17

Drive system

A power shift gear with radiator and torque converter is directly flanged to the engine. This transfers the force to the drive axle (12).

The travel direction lever on the steering column, on the multi-task lever or on the pedal controller (o) controls forward/reverse travel and the neutral position.

Brakes

The brake pedal activates the laminated brakes hydraulically. The parking brake is switched on and off by pressing the parking brake button in the multifunction display. It acts mechanically on the brake disc of the cardan shaft.

Hydraulic System

All operations can be performed sensitively, proportionally and simultaneously. Hydraulic functions are controlled by a servo hydraulic controller. Control is possible via single lever (SOLO-PILOT) or multi-task lever (MULTI-PILOT).

Mast

Two or three-stage masts, optionally with free lift function; narrow mast sections ensure excellent visibility of the fork tines and attachments. Fork carriages and lift frames run on lubricating support rollers.

Attachments

The trucks can be optionally fitted with mechanical and hydraulic attachments.

02.11 EN

18

3Technical Specifications

All technical details refer to standard trucks.

Values indicated with *) may vary, depending on the types of equipment used (e.g. mast, cabin, tyres etc.).

ZTechnical data specified in accordance with VDI 2198. Technical modifications and additions reserved.

3.1Performance data

DFG 660-690

|

Description |

|

660 |

670 |

680 |

690 |

|

Q |

Capacity 1) |

|

6000 |

7000 |

8000 |

9000 |

kg |

C |

Load centre distance |

600 |

600 |

600 |

600 |

mm |

|

|

Travel speed* |

with / |

22.4/22.5 |

22.4/22.6 |

22.4/22.5 |

22.4/22.6 |

km/h |

|

without load |

||||||

|

|

|

|

|

|

||

|

Lift speed with / without |

0.50/0.60 |

0.40/0.60 |

0.40/0.60 |

0.40/0.60 |

m/s |

|

|

load |

|

|

|

|

|

|

|

Lowering speed with / |

0.60/0.36 |

0.60/0.36 |

0.60/0.36 |

0.60/0.36 |

m/s |

|

|

without load |

||||||

|

|

|

|

|

|

||

|

Gradeability 2) |

30.3/32.0 |

28.7/31.0 |

27.1/31.0 |

24.6/28.0 |

% |

|

|

with / without load |

||||||

|

|

|

|

|

|

||

|

Tow force |

49.5/49.5 |

49.5/49.5 |

49.5/49.5 |

49.5/49.5 |

kN |

|

|

with / without load |

||||||

|

|

|

|

|

|

||

|

Acceleration* |

with / |

6.0/5.0 |

6.0/5.0 |

6.0/5.0 |

7.0/6.0 |

s |

|

without load to 15 m |

||||||

|

|

|

|

|

|

||

|

Working pressure |

160 |

160 |

160 |

160 |

bar |

|

|

for attachments |

||||||

|

|

|

|

|

|

||

|

Oil volume |

|

80 |

80 |

80 |

80 |

l/min |

|

for attachments |

||||||

|

|

|

|

|

|

||

1)for vertical mast.

2)The values shown represent the maximum gradeability to overcome short differences in height and surface unevenness (surface edges). The truck must not operate on inclines of more than 15%.

02.11 EN

19

DFG S80-S90

|

Description |

|

S80 |

S90 |

|

Q |

Capacity 1) |

|

8000 |

9000 |

kg |

C |

Load centre distance |

900 |

900 |

mm |

|

|

Travel speed* |

with / |

22.3/22.6 |

22.3/22.6 |

km/h |

|

without load |

||||

|

|

|

|

||

|

Lift speed with / without |

0.40/0.60 |

0.40/0.60 |

m/s |

|

|

load |

|

|

|

|

|

Lowering speed with / |

0.60/0.36 |

0.60/0.36 |

m/s |

|

|

without load |

||||

|

|

|

|

||

|

Gradeability 2) |

21.5/25.0 |

20.9/24.0 |

% |

|

|

with / without load |

||||

|

|

|

|

||

|

Tow force |

49.5/49.5 |

52.9/52.9 |

kN |

|

|

with / without load |

||||

|

|

|

|

||

|

Acceleration* |

with / |

7.0/6.0 |

7.0/6.0 |

s |

|

without load to 15 m |

||||

|

|

|

|

||

|

Working pressure |

160 |

160 |

bar |

|

|

for attachments |

||||

|

|

|

|

||

|

Oil volume |

|

80 |

80 |

l/min |

|

for attachments |

||||

|

|

|

|

||

1)for vertical mast.

2)The values shown represent the maximum gradeability to overcome short differences in height and surface unevenness (surface edges). The truck must not operate on inclines of more than 15%.

02.11 EN

20

TFG 660-690

|

Description |

|

660 |

670 |

680 |

690 |

|

Q |

Capacity (1 |

|

6000 |

7000 |

8000 |

9000 |

kg |

C |

Load centre distance |

600 |

600 |

600 |

600 |

mm |

|

|

Travel speed* |

with / |

22.4/22.6 |

22.4/22.6 |

22.4/22.6 |

22.4/22.6 |

km/h |

|

without load |

||||||

|

|

|

|

|

|

||

|

Lift speed with / without |

0.40/0.48 |

0.40/0.48 |

0.40/0.48 |

0.40/0.48 |

m/s |

|

|

load |

|

|

|

|

|

|

|

Lowering speed with / |

0.60/0.48 |

0.60/0.36 |

0.60/0.36 |

0.60/0.36 |

m/s |

|

|

without load |

||||||

|

|

|

|

|

|

||

|

Gradeability (2 |

27.5/30.0 |

27.5/30.0 |

26.5/30.0 |

23.0/27.0 |

% |

|

|

with / without load |

||||||

|

|

|

|

|

|

||

|

Tow force |

45.6/45.6 |

45.6/45.6 |

45.6/45.6 |

45.6/45.6 |

kN |

|

|

with / without load |

||||||

|

|

|

|

|

|

||

|

Acceleration* |

with / |

6.0/5.0 |

6.0/5.0 |

6.0/5.0 |

7.0/6.0 |

s |

|

without load to 15 m |

||||||

|

|

|

|

|

|

||

|

Working pressure |

160 |

160 |

160 |

160 |

bar |

|

|

for attachments |

||||||

|

|

|

|

|

|

||

|

Oil volume |

|

80 |

80 |

80 |

80 |

l/min |

|

for attachments |

||||||

|

|

|

|

|

|

||

1)for vertical mast.

2)The values shown represent the maximum gradeability to overcome short differences in height and surface unevenness (surface edges). The truck must not operate on inclines of more than 15%.

02.11 EN

21

TFG S80-S90

|

Description |

|

S80 |

S90 |

|

Q |

Capacity |

|

8000 |

9000 |

kg |

C |

Load centre distance |

900 |

900 |

mm |

|

|

Travel speed* |

with / |

22.4/22.6 |

22.4/22.6 |

km/h |

|

without load |

||||

|

|

|

|

||

|

Lift speed with / without |

0.40/0.48 |

0.40/0.48 |

m/s |

|

|

load |

|

|

|

|

|

Lowering speed with / |

0.60/0.36 |

0.60/0.36 |

m/s |

|

|

without load |

||||

|

|

|

|

||

|

Gradeability* |

20.2/23.0 |

17.6/20.0 |

% |

|

|

with / without load |

||||

|

|

|

|

||

|

Tow force |

45.6/45.6 |

45.6/45.6 |

kN |

|

|

with / without load |

||||

|

|

|

|

||

|

Acceleration* |

with / |

7.0/6.0 |

7.0/6.0 |

s |

|

without load to 15 m |

||||

|

|

|

|

||

|

Working pressure |

160 |

160 |

bar |

|

|

for attachments |

||||

|

|

|

|

||

|

Oil volume |

|

80 |

80 |

l/min |

|

for attachments |

||||

|

|

|

|

||

1)for vertical mast.

2)The values shown represent the maximum gradeability to overcome short differences in height and surface unevenness (surface edges). The truck must not operate on inclines of more than 15%.

02.11 EN

22

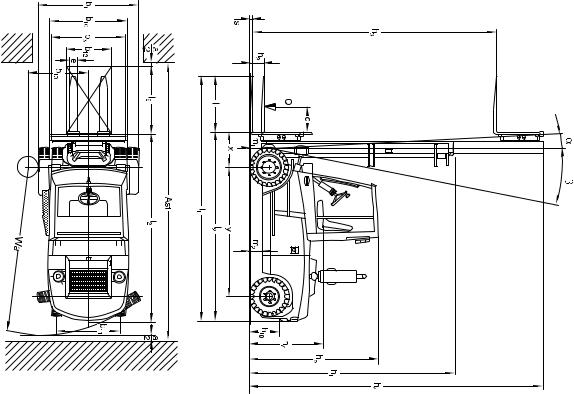

3.2Dimensions

DFG 660-690

|

Description |

660 |

670 |

680 |

690 |

|

a/2 |

Safety distance |

100 |

100 |

100 |

100 |

mm |

h1 |

Mast height retracted* |

2710 |

2710 |

3010 |

3160 |

mm |

h3 |

Lift* |

3600 |

3600 |

3600 |

3600 |

mm |

h4 |

Mast height extended* |

4510 |

4510 |

4810 |

4960 |

mm |

h6 |

Overhead guard |

2705 |

2705 |

2705 |

2705 |

mm |

|

height* |

|

|

|

|

|

h7 |

Seat height* |

1600 |

1600 |

1600 |

1600 |

mm |

h10 |

Coupling height |

500 |

500 |

500 |

500 |

mm |

Į |

Mast tilt, forward* |

6 |

6 |

6 |

6 |

° |

ȕ |

Mast tilt, back* |

9 |

9 |

9 |

9 |

° |

l1 |

Length, including |

4760 |

4770 |

4880 |

5035 |

mm |

|

forks* |

|

|

|

|

|

l2 |

Length, including fork |

3560 |

3570 |

3680 |

3835 |

mm |

|

shank* |

|

|

|

|

|

b1 |

Overall width* |

1820 |

1820 |

2002 |

2002 |

mm |

s/e/l |

Fork dimensions* |

50/150/ |

60/150/ |

60/150/ |

65/150/ |

mm |

|

|

1200 |

1200 |

1200 |

1200 |

|

m1 |

Floor clearance with |

250 |

250 |

250 |

250 |

mm |

|

load below mast* |

|

|

|

|

|

m2 |

Floor clearance centre |

250 |

250 |

250 |

250 |

mm |

|

wheel base* |

|

|

|

|

|

|

Fork carriage ISO |

4 A |

4 A |

4 A |

4 A |

mm |

|

2328 class / type A, B |

|

|

|

|

|

b3 |

Fork carriage width |

1800 |

1800 |

2000 |

2000 |

mm |

Ast |

Working aisle width for |

5320 |

5330 |

5440 |

5745 |

mm |

|

pallets 800 x 1200 |

|

|

|

|

|

|

longit. |

|

|

|

|

|

Ast |

Working aisle width for |

5120 |

5130 |

5240 |

5545 |

mm |

|

pallets 1000 x 1200 |

|

|

|

|

|

|

traverse |

|

|

|

|

|

Wa |

Turning radius |

3250 |

3250 |

3350 |

3650 |

mm |

b13 |

Smallest turning |

1270 |

1270 |

1320 |

1390 |

mm |

|

radius |

|

|

|

|

|

x |

Load distance* |

670 |

680 |

690 |

695 |

mm |

c |

Load centre of gravity |

600 |

600 |

600 |

600 |

mm |

y |

Wheel base |

2295 |

2295 |

2395 |

2545 |

mm |

*) The data listed in the table corresponds to the standard version.

02.11 EN

23

DFG S80-S90

|

Description |

S80 |

S90 |

|

a/2 |

Safety distance |

100 |

100 |

mm |

h1 |

Mast height retracted* |

3160 |

3310 |

mm |

h3 |

Lift* |

3600 |

3600 |

mm |

h4 |

Mast height extended* |

4960 |

5110 |

mm |

h6 |

Overhead guard |

2705 |

2705 |

mm |

|

height* |

|

|

|

h7 |

Seat height* |

1600 |

1600 |

mm |

h10 |

Coupling height |

500 |

500 |

mm |

Į |

Mast tilt, forward* |

6 |

6 |

° |

ȕ |

Mast tilt, back* |

9 |

9 |

° |

l1 |

Length, including |

5640 |

5840 |

mm |

|

forks* |

|

|

|

l2 |

Length, including fork |

3840 |

4040 |

mm |

|

shank* |

|

|

|

b1 |

Overall width* |

2150 |

2150 |

mm |

s/e/l |

Fork dimensions* |

70/180/ |

70/180/ |

mm |

|

|

1800 |

1800 |

|

m1 |

Floor clearance with |

250 |

250 |

mm |

|

load below mast* |

|

|

|

m2 |

Floor clearance centre |

250 |

250 |

mm |

|

wheel base* |

|

|

|

|

Fork carriage ISO |

4 A |

4 A |

mm |

|

2328 class / type A, B |

|

|

|

b3 |

Fork carriage width |

2100 |

2100 |

mm |

Ast |

Working aisle width for |

5745 |

5995 |

mm |

|

pallets 800 x 1200 |

|

|

|

|

longit. |

|

|

|

Ast |

Working aisle width for |

5545 |

5795 |

mm |

|

pallets 1000 x 1200 |

|

|

|

|

traverse |

|

|

|

Wa |

Turning radius |

3900 |

3900 |

mm |

b13 |

Smallest turning |

1490 |

1490 |

mm |

|

radius |

|

|

|

x |

Load distance* |

700 |

700 |

mm |

c |

Load centre of gravity |

900 |

900 |

mm |

y |

Wheel base |

2545 |

2745 |

mm |

*) The data listed in the table corresponds to the standard version.

TFG 660-690

|

Description |

660 |

670 |

680 |

690 |

|

a/2 |

Safety distance |

100 |

100 |

100 |

100 |

mm |

h1 |

Mast height retracted* |

2710 |

2710 |

3010 |

3160 |

mm |

02.11 EN

24

TFG 660-690

|

Description |

660 |

670 |

680 |

690 |

|

h3 |

Lift* |

3600 |

3600 |

3600 |

3600 |

mm |

h4 |

Mast height extended* |

4510 |

4510 |

4810 |

4960 |

mm |

h6 |

Overhead guard |

2705 |

2705 |

2705 |

2705 |

mm |

|

height* |

|

|

|

|

|

h7 |

Seat height* |

1600 |

1600 |

1600 |

1600 |

mm |

h10 |

Coupling height |

500 |

500 |

500 |

500 |

mm |

Į |

Mast tilt, forward* |

6 |

6 |

6 |

6 |

° |

ȕ |

Mast tilt, back* |

9 |

9 |

9 |

9 |

° |

l1 |

Length, including |

4860 |

4870 |

4980 |

5135 |

mm |

|

forks* |

|

|

|

|

|

l2 |

Length, including fork |

3660 |

3670 |

3780 |

3935 |

mm |

|

shank* |

|

|

|

|

|

b1 |

Overall width* |

1820 |

1820 |

2002 |

2002 |

mm |

s/e/l |

Fork dimensions* |

50/150/ |

60/150/ |

60/150/ |

65/150/ |

mm |

|

|

1200 |

1200 |

1200 |

1200 |

|

m1 |

Floor clearance with |

250 |

250 |

250 |

250 |

mm |

|

load below mast* |

|

|

|

|

|

m2 |

Floor clearance centre |

250 |

250 |

250 |

250 |

mm |

|

wheel base* |

|

|

|

|

|

|

Fork carriage ISO |

4 A |

4 A |

4 A |

4 A |

mm |

|

2328 class / type A, B |

|

|

|

|

|

b3 |

Fork carriage width |

1800 |

1800 |

2000 |

2000 |

mm |

Ast |

Working aisle width for |

5420 |

5430 |

5640 |

5895 |

mm |

|

pallets 800 x 1200 |

|

|

|

|

|

|

longit. |

|

|

|

|

|

Ast |

Working aisle width for |

5220 |

5230 |

5440 |

5695 |

mm |

|

pallets 1000 x 1200 |

|

|

|

|

|

|

traverse |

|

|

|

|

|

Wa |

Turning radius |

3350 |

3350 |

3550 |

3800 |

mm |

b13 |

Smallest turning |

1320 |

1320 |

1370 |

1440 |

mm |

|

radius |

|

|

|

|

|

x |

Load distance* |

670 |

680 |

690 |

695 |

mm |

c |

Load centre of gravity |

600 |

600 |

600 |

600 |

mm |

y |

Wheel base |

2395 |

2395 |

2495 |

2645 |

mm |

*) The data listed in the table corresponds to the standard version.

|

|

|

TFG S80-S90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Description |

S80 |

S90 |

|

|

|

a/2 |

Safety distance |

100 |

100 |

mm |

|

|

h1 |

Mast height retracted* |

3160 |

3310 |

mm |

EN |

h3 |

Lift* |

3600 |

3600 |

mm |

|

h4 |

Mast height extended* |

4960 |

5110 |

mm |

||

02.11 |

|

|

|

|

|

|

25

TFG S80-S90

|

Description |

S80 |

S90 |

|

h6 |

Overhead guard |

2705 |

2720 |

mm |

|

height* |

|

|

|

h7 |

Seat height* |

1600 |

1600 |

mm |

h10 |

Coupling height |

500 |

500 |

mm |

Į |

Mast tilt, forward* |

6 |

6 |

° |

ȕ |

Mast tilt, back* |

9 |

9 |

° |

l1 |

Length, including |

5740 |

5740 |

mm |

|

forks* |

|

|

|

l2 |

Length, including fork |

3940 |

3940 |

mm |

|

shank* |

|

|

|

b1 |

Overall width* |

2150 |

2150 |

mm |

s/e/l |

Fork dimensions* |

70/180/ |

70/180/ |

mm |

|

|

1800 |

1800 |

|

m1 |

Floor clearance with |

250 |

250 |

mm |

|

load below mast* |

|

|

|

m2 |

Floor clearance centre |

250 |

250 |

mm |

|

wheel base* |

|

|

|

|

Fork carriage ISO |

4 A |

4 A |

mm |

|

2328 class / type A, B |

|

|

|

b3 |

Fork carriage width |

2100 |

2100 |

mm |

Ast |

Working aisle width for |

5895 |

5895 |

mm |

|

pallets 800 x 1200 |

|

|

|

|

longit. |

|

|

|

Ast |

Working aisle width for |

5695 |

5695 |

mm |

|

pallets 1000 x 1200 |

|

|

|

|

traverse |

|

|

|

Wa |

Turning radius |

3800 |

3800 |

mm |

b13 |

Smallest turning |

1440 |

1440 |

mm |

|

radius |

|

|

|

x |

Load distance* |

700 |

700 |

mm |

c |

Load centre of gravity |

900 |

900 |

mm |

y |

Wheel base |

2645 |

2645 |

mm |

*) The data listed in the table corresponds to the standard version.

02.11 EN

26

02.11 EN

27

3.3Weights

ZAll dimensions in kg.

DFG 660-690

|

660 |

670 |

680 |

690 |

Net weight* |

10500 |

10800 |

11700 |

12500 |

Axle load w.o. load front / |

5500/5000 |

5500/5300 |

6000/5700 |

6000/6500 |

rear* |

|

|

|

|

Axle load with load front / |

14900/1600 |

16000/1800 |

17700/2000 |

19000/2500 |

rear* |

|

|

|

|

*) The data listed in the table corresponds to the standard version.

DFG S80-S90

|

S80 |

S90 |

Net weight* |

14400 |

15500 |

Axle load w.o. load front / |

7400/7000 |

8200/7300 |

rear* |

|

|

Axle load with load front / |

20400/2000 |

22500/2000 |

rear* |

|

|

*) The data listed in the table corresponds to the standard version.

TFG 660-690

|

660 |

670 |

680 |

690 |

Net weight* |

10970 |

10970 |

11900 |

13000 |

Axle load w.o. load front / |

5610/5360 |

5610/5360 |

5900/6000 |

6000/7000 |

rear* |

|

|

|

|

Axle load with load front / |

14810/2160 |

16350/1620 |

17900/2000 |

19500/2500 |

rear* |

|

|

|

|

*) The data listed in the table corresponds to the standard version.

TFG S80-S90

|

S80 |

S90 |

Net weight* |

14600 |

15000 |

Axle load w.o. load front / |

7000/7600 |

7200/7800 |

rear* |

|

|

Axle load with load front / |

20100/2500 |

22000/2000 |

rear* |

|

|

*) The data listed in the table corresponds to the standard version.

02.11 EN

28

3.4Mast versions

ZAll dimensions in mm

DFG/TFG 660-680

|

|

|

Mast table |

|

|

|

|

VDI3596 |

Lift h3 |

Free lift |

Retracted height h1 |

Extended height h4 |

|||

Description |

|

h2 |

|

|

|

|

|

|

|

|

660/670 |

|

680 |

660/670 |

680 |

|

3600 |

0 |

2710 |

|

3010 |

4510 |

4810 |

|

4000 |

0 |

2910 |

|

3210 |

4910 |

5210 |

|

4500 |

0 |

3160 |

|

3460 |

5410 |

5710 |

ZT |

5000 |

0 |

3410 |

|

3710 |

5910 |

6210 |

|

5500 |

0 |

3660 |

|

3960 |

6410 |

6710 |

|

6000 |

0 |

3910 |

|

4210 |

6910 |

7210 |

|

6500 |

0 |

4160 |

|

4460 |

7410 |

7710 |

|

3600 |

1800 |

2875 |

|

3025 |

4675 |

4825 |

|

4000 |

2000 |

3075 |

|

3225 |

5075 |

5225 |

|

4500 |

2250 |

3325 |

|

3475 |

5675 |

5725 |

ZZ |

5000 |

2500 |

3575 |

|

3725 |

6075 |

6225 |

|

5500 |

2750 |

3825 |

|

3975 |

6575 |

6725 |

|

6000 |

3000 |

4075 |

|

4225 |

7075 |

7225 |

|

6500 |

3300 |

4325 |

|

4475 |

7575 |

7725 |

|

4500 |

1500 |

- |

|

2735 |

- |

5736 |

|

5000 |

1667 |

2752 |

|

2902 |

6086 |

6236 |

|

5500 |

1833 |

2918 |

|

3068 |

6586 |

6736 |

DZ |

6000 |

2000 |

3085 |

|

3235 |

7086 |

7236 |

6500 |

2167 |

3252 |

|

3402 |

7586 |

7736 |

|

|

|

||||||

|

7000 |

2333 |

3418 |

|

3568 |

8086 |

8236 |

|

7500 |

2500 |

3585 |

|

3735 |

8586 |

8736 |

|

8000 |

2667 |

3752 |

|

3902 |

9086 |

9236 |

Special trucks are not included in this overview.

02.11 EN

29

DFG/TFG 690-S90

|

|

|

Mast table |

|

|

|

|

VDI3596 |

Lift h3 |

Free lift |

Retracted height h1 |

Extended height h4 |

|||

Description |

|

h2 |

|

|

|

|

|

|

|

|

690-S80 |

|

S90 |

690-S80 |

S90 |

|

3600 |

0 |

3160 |

|

3310 |

4960 |

5110 |

|

4000 |

0 |

3360 |

|

3510 |

5360 |

5510 |

|

4500 |

0 |

3610 |

|

3760 |

5860 |

6010 |

ZT |

|

|

|

|

|

|

|

5000 |

0 |

3860 |

|

4010 |

6360 |

6510 |

|

|

5500 |

0 |

4110 |

|

4260 |

6860 |

7010 |

|

6000 |

0 |

4360 |

|

4510 |

7360 |

7510 |

|

6500 |

0 |

4610 |

|

4760 |

7860 |

8010 |

|

3600 |

1800 |

3175 |

|

3325 |

4975 |

5125 |

|

4000 |

2000 |

3375 |

|

3525 |

5375 |

5525 |

|

4500 |

2250 |

3625 |

|

3775 |

5875 |

6025 |

ZZ |

|

|

|

|

|

|

|

5000 |

2500 |

3875 |

|

4025 |

6375 |

6525 |

|

|

5500 |

2750 |

4125 |

|

4275 |

6875 |

7025 |

|

6000 |

3000 |

4375 |

|

4525 |

7375 |

7525 |

|

6500 |

3300 |

4625 |

|

4775 |

7875 |

8025 |

|

4500 |

1500 |

2885 |

|

3035 |

5886 |

6036 |

|

5000 |

1667 |

3052 |

|

3202 |

6386 |

6536 |

|

5500 |

1833 |

3218 |

|

3368 |

6886 |

7036 |

DZ |

6000 |

2000 |

3385 |

|

3535 |

7386 |

7536 |

6500 |

2167 |

3552 |

|

3702 |

7886 |

8036 |

|

|

|

||||||

|

7000 |

2333 |

3718 |

|

3868 |

8386 |

8536 |

|

7500 |

2500 |

3885 |

|

4035 |

8886 |

9036 |

|

8000 |

2667 |

4052 |

|

4202 |

9386 |

9536 |

Special trucks are not included in this overview.

02.11 EN

30

3.5Tyre type

NOTE

When replacing tyres/rims fitted at the factory, always use original spare parts or tyres approved by the manufacturer. Otherwise the manufacturer's specification cannot be guaranteed.

If you have any queries please contact the manufacturer's customer service department.

DFG/TFG 660-690

|

Description |

|

DFG/TFG |

|

||

|

|

|

660 |

670 |

680 |

690 |

|

|

SE* |

355/65 - 15 |

355/65 - 15 |

8.25 - 15 |

8.25 - 15 |

Front |

|

Pneumatic* |

355/65 - 15 |

355/65 - 15 |

8.25 - 15 |

8.25 - 15 |

|

18 PR |

18 PR |

18 PR |

18 PR |

||

tyres |

|

|

||||

|

Tyre pressure bar |

10 |

10 |

10 |

10 |

|

|

|

|||||

|

|

Torque Nm |

450 |

450 |

450 |

450 |

|

|

SE* |

8.25 - 15 |

8.25 - 15 |

8.25 - 15 |

300 - 15 |

Rear |

|

Pneumatic* |

8.25 - 15 |

8.25 - 15 |

8.25 - 15 |

300 - 15 18 |

|

18 PR |

18 PR |

18 PR |

PR |

||

tyres |

|

|

||||

|

Tyre pressure bar |

10 |

10 |

10 |

10 |

|

|

|

|||||

|

|

Torque Nm |

290 |

290 |

290 |

450 |

DFG/TFG S80-S90

|

Description |

DFG/TFG |

||

|

|

|

S80 |

S90 |

|

|

SE* |

300 - 15 |

300 - 15 |

Front |

|

Pneumatic* |

300 - 15 |

300 - 15 |

|

18 PR |

18 PR |

||

tyres |

|

|

||

|

Tyre pressure bar |

10 |

10 |

|

|

|

|||

|

|

Torque Nm |

450 |

450 |

|

|

SE* |

300 - 15 |

300 - 15 |

|

|

Pneumatic* |

300 - 15 |

300 - 15 |

Rear |

|

18 PR |

18 PR |

|

|

|

|||

tyres |

|

Tyre pressure bar |

10 |

10 |

|

|

Torque Nm |

290 |

450 |

|

|

DFG 450 |

||

|

|

|

|

|

*) The models listed in the table correspond to the standard version. Other tyres can be used depending on the truck's equipment.

02.11 EN

31

Loading...

Loading...