Jungheinrich EZS 350 XL, EZS 330 XL Operating instruction

EZS 330/350 / XL |

04.06 - |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operating instructions |

|

|

|

|

G |

|||

|

|

|

|

|

|

|

||

50468397 |

|

|

|

|

|

|

|

|

04.06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Downloaded from www.Manualslib.com manuals search engine

Foreword

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide sufficient instruction for the safe operation of the industrial truck. The information is provided clearly and concisely. The chapters are arranged by letter. Each chapter starts with page 1. The page identification consists of a chapter letter and a page number.

For example: Page B 2 is the second page in chapter B.

The operating instructions detail different truck models. When operating and servicing the truck, make sure that the instructions apply to your truck model.

Safety instructions and important explanations are indicated by the following graphics:

F Used before safety instructions which must be observed to avoid danger to personnel.

M Used before notices which must be observed to avoid material damage.

Z Used before notices and explanations.

t Used to indicate standard equipment.

oUsed to indicate optional equipment.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the truck. No guarantee of particular features of the truck should therefore be inferred from the present operating instructions.

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - GERMANY Telephone: +49 (0) 40/6948-0 www.jungheinrich.com

0108.GB

Downloaded from www.Manualslib.com manuals search engine

0108.GB

Downloaded from www.Manualslib.com manuals search engine

Table of Contents

ACorrect use and application

BTruck Description

1 |

Application ........................................................................................... |

B 1 |

2 |

Assemblies ......................................................................................... |

B 2 |

2.1 |

EN norms ............................................................................................ |

B 3 |

2.2 |

Conditions of use ................................................................................ |

B 3 |

3 |

Standard Version Specifications ......................................................... |

B 4 |

3.1 |

Performance data for standard trucks ................................................. |

B 4 |

3.2 |

Dimensions ......................................................................................... |

B 4 |

4 |

Identification points and data plates .................................................... |

B 6 |

4.1 |

Truck data plate .................................................................................. |

B 7 |

C |

Transport and Commissioning |

|

1 |

Lifting by crane .................................................................................... |

C 1 |

2 |

Securing the truck during transport ..................................................... |

C 1 |

3 |

Using the truck for the first time .......................................................... |

C 2 |

4 |

Operating the truck without its own drive system ................................ |

C 3 |

D |

Battery Maintenance, Charging & Replacement |

|

1 |

Safety regulations for handling acid batteries ..................................... |

D 1 |

2 |

Battery types ....................................................................................... |

D 2 |

3 |

Exposing the battery ........................................................................... |

D 3 |

4 |

Charge the battery .............................................................................. |

D 4 |

5 |

Battery removal and installation .......................................................... |

D 5 |

0205.GB

I 1

Downloaded from www.Manualslib.com manuals search engine

E |

Operation |

|

1 |

Safety Regulations for the Operation of Forklift Trucks ...................... |

E 1 |

2 |

Controls and Displays ......................................................................... |

E 2 |

3 |

Starting up the truck ............................................................................ |

E 4 |

4 |

Industrial Truck Operation ................................................................... |

E 5 |

4.1 |

Safety regulations for truck operation ................................................. |

E 5 |

4.2 |

Travel, Steering, Braking ..................................................................... |

E 6 |

4.3 |

Pedestrian operation (o) .................................................................... |

E 9 |

4.4 |

Coupling Types ................................................................................... |

E 10 |

4.5 |

Travelling with trailers ......................................................................... |

E 11 |

4.6 |

Seat o (XL only) ................................................................................. |

E 12 |

4.7 |

Parking the truck securely ................................................................... |

E 12 |

5 |

Display instrument (CANDIS) (o) ....................................................... |

E 13 |

5.1 |

Operating hours display ...................................................................... |

E 13 |

5.2 |

Power up test ...................................................................................... |

E 14 |

6 |

Keypad (CANCODE) (o) .................................................................... |

E 15 |

6.1 |

Code Lock ........................................................................................... |

E 15 |

6.2 |

Travel programs .................................................................................. |

E 17 |

6.3 |

Parameters .......................................................................................... |

E 17 |

6.4 |

Parameter Settings ............................................................................. |

E 18 |

6.5 |

Travel parameters ............................................................................... |

E 22 |

7 |

Troubleshooting .................................................................................. |

E 27 |

F |

Industrial Truck Maintenance |

|

1 |

Operational safety and environmental protection ................................ |

F 1 |

2 |

Maintenance Safety Regulations ........................................................ |

F 1 |

3 |

Servicing and inspection ..................................................................... |

F 3 |

4 |

Maintenance checklist ......................................................................... |

F 4 |

5 |

Lubrication Schedule ........................................................................... |

F 6 |

5.1 |

Consumables ...................................................................................... |

F 7 |

6 |

Maintenance Instructions .................................................................... |

F 8 |

6.1 |

Preparing the truck for maintenance and repairs ................................ |

F 8 |

6.2 |

Tightening the wheel nuts ................................................................... |

F 8 |

6.3 |

Remove the front panel ....................................................................... |

F 9 |

6.4 |

Checking electrical fuses .................................................................... |

F 10 |

6.5 |

Recommissioning ................................................................................ |

F 11 |

7 |

Decommissioning the industrial truck .................................................. |

F 11 |

7.1 |

Prior to decommissioning: ................................................................... |

F 11 |

7.2 |

During decommissioning: .................................................................... |

F 11 |

7.3 |

Returning the truck to operation after decommissioning ..................... |

F 12 |

8Safety checks to be performed at regular intervals and following any unusual incidents (D: Accident prevention check according

|

to BGV D27 ......................................................................................... |

F 12 |

9 |

Final de-commissioning, disposal ....................................................... |

F 12 |

I 2

0205.GB

Downloaded from www.Manualslib.com manuals search engine

|

Appendix |

|

JH Traction Battery Operating Instructions |

Z |

These operating instructions apply only to Jungheinrich battery models. If using |

|

another brand, refer to the manufacturer's operating instructions. |

0506.GB

1

Downloaded from www.Manualslib.com manuals search engine

0506.GB

2

Downloaded from www.Manualslib.com manuals search engine

A |

Correct use and application |

Z |

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are |

supplied with the truck. The guidelines form part of these operating instructions and |

|

|

must be observed. National regulations apply in full. |

|

The truck described in the present operating instructions is an industrial truck |

|

designed for lifting and transporting loads. |

|

It must be applied, operated and serviced in accordance with the instructions |

|

contained in the present manual. Any other type of use is beyond the scope of |

|

application and can result in damage to personnel, the truck or property. In particular, |

|

avoid overloading the truck with loads that are too heavy. The data plate attached to |

|

the truck or the load diagram are binding for the maximum load capacity. The |

|

industrial truck must not be used in fire or explosion endangered areas, or areas |

|

threatened by corrosion or excessive dust. |

|

Proprietor responsibilities: For the purposes of the present operator manual the |

|

“proprietor” is defined as any natural or legal person who either uses the industrial |

|

truck himself, or on whose behalf it is used. In special cases (e.g. leasing or renting) |

|

the proprietor is considered the person who, in accordance with existing contractual |

|

agreements between the owner and user of the industrial truck, is charged with |

|

operational duties. |

|

The proprietor must ensure that the industrial truck is used only for the purpose it is |

|

intended for and that danger to life and limb of the user and third parties are excluded. |

|

Furthermore, accident prevention regulations, safety regulations and operating, |

|

servicing and repair guidelines must be followed. The proprietor must ensure that all |

|

truck users have read and understood this operator manual. |

M |

Failure to comply with the operator manual shall invalidate the warranty. The same |

applies if improper work is carried out on the truck by the customer or third parties |

|

|

without the permission of the manufacturer’s customer service department. |

|

Attaching accessories: The mounting or installation of additional equipment which |

|

affects or supplements the performance of the industrial truck requires the written |

|

permission of the manufacturer. In some cases, local authority approval shall be |

|

required. |

|

Approval of the local authorities however does not constitute the manufacturer’s |

|

approval. |

0406.GB

A 1

Downloaded from www.Manualslib.com manuals search engine

Downloaded from www.Manualslib.com manuals search engine

B Truck Description

1Application

The truck is a three-wheel electric tow truck with a driver’s platform, equipped with a Jet Pilot. It is designed for transporting goods on level surfaces in buildings.

The tow force is shown on the data plate.

0406.GB

B 1

Downloaded from www.Manualslib.com manuals search engine

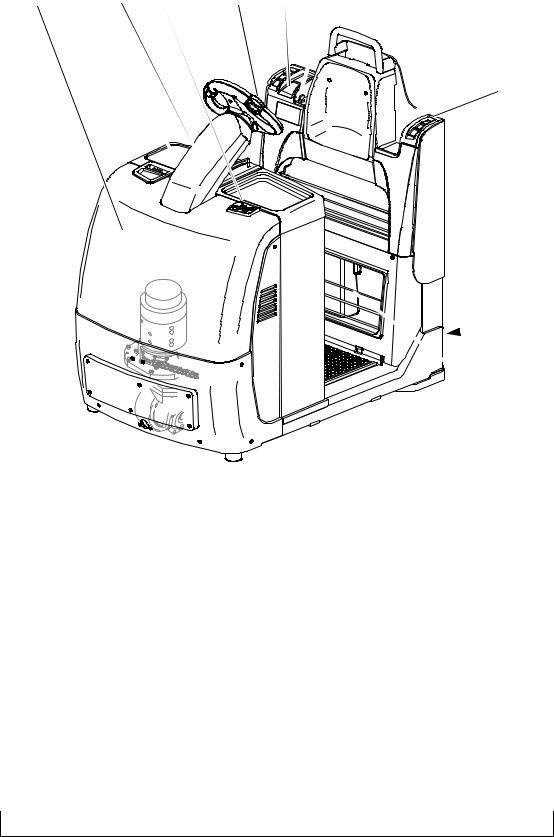

2 Assemblies

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8

9

9  10

10

11

11

12

13

Item |

|

Description |

Item |

|

Description |

1 |

t |

Front panel |

8 |

o |

Reverse “pedestrian |

|

|

|

|

|

operation” switch |

2 |

t |

Battery panel |

9 |

o |

Stop button |

3 |

t |

Jet Pilot |

10 |

o |

Forward “pedestrian / walk- |

|

|

|

|

|

along operation” button |

4 |

t |

Main switch / isolator |

11 |

o |

Trailer coupling |

|

|

(emergency disconnect) |

|

|

|

5 |

t |

Controller |

12 |

t |

Storage compartment |

6 |

o |

CANCODE |

13 |

t |

Drive wheel |

|

|

keypad |

|

|

|

7 |

t |

Key switch |

|

o |

Headlight (not shown) |

|

|

|

|

o |

Strobe (not shown) |

|

|

|

|

||

|

t = Standard equipment |

|

o = Optional Equipment |

||

0406.GB

B 2

Downloaded from www.Manualslib.com manuals search engine

2.1EN norms

|

Noise level: |

66 dB(A) |

|

|

|

in accordance with EN 12053 as harmonized |

with |

|

|

ISO 4871. |

|

Z |

The noise emission level is calculated in accordance with standard procedures and |

||

takes into account the noise level when travelling, lifting and when idle. The noise |

|||

|

level is measured at the driver’s ear. |

|

|

|

Vibration: |

0.94 m/s2 |

|

|

|

in accordance with EN 13059 |

|

Z |

The vibration |

acceleration acting on the body in the operating position |

is, in |

accordance with standard procedures, the linearly integrated, weighted acceleration |

|||

in the vertical direction. It is calculated when travelling over bumps at constant speed. Electromagnetic Compatibility (

|

The manufacturer confirms that equipment complies with |

|

tolerance levels for electromagnetic emissions and |

|

resistance as well as static electricity discharge testing in |

|

accordance with EN 12895 including the normative |

|

procedures contained therein. |

Z |

No changes to electric or electronic components or their arrangement may be made |

|

without the written agreement of the manufacturer. |

2.2Conditions of use

Ambient temperature

|

- during operation -10°C to 40 °C |

Z |

Special equipment and authorisation are required if the truck is to be constantly used |

|

in conditions of extreme temperature or air humidity fluctuations. |

0406.GB

B 3

Downloaded from www.Manualslib.com manuals search engine

3 |

Standard Version Specifications |

|

|

|

|

|

|

|

|

|

|||

Z |

Technical specification details in accordance with VDI 2198. Technical modifications |

||||||||||||

|

and additions reserved. |

|

|

|

|

|

|

|

|

|

|

|

|

3.1 |

Performance data for standard trucks |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Description |

EZS 330 |

EZS 350 |

|

EZS 330 XL |

EZS 350 XL |

|

|

|

|||

|

Q |

Tow capacity 1) |

3000 |

|

5000 |

|

3000 |

|

5000 |

|

kg |

|

|

|

F |

Rated tow force |

600 |

|

1000 |

|

600 |

|

1000 |

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

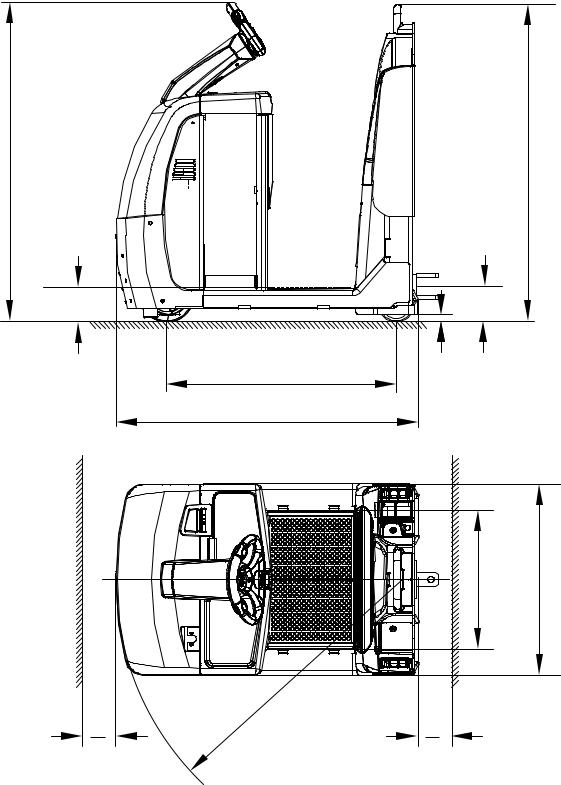

3.2 |

Dimensions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Description |

EZS 330 |

|

EZS 350 |

EZS 330 XL |

EZS 350 XL |

|

|

|

|

||

|

|

Net weight |

1066 |

|

1066 |

1201 |

1201 |

kg |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Axle load w.o. load |

514/552 |

|

514/552 |

635/566 |

635/566 |

kg |

|

|

|||

|

|

front/rear |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

h7 |

Height |

132 |

|

132 |

142 |

142 |

mm |

|

|

|||

|

h14 |

Tiller height in travel |

1342 |

|

1342 |

1387 |

1387 |

mm |

|

|

|||

|

|

position 2) |

|

|

|

|

|

|

|

|

|

|

|

|

h10 |

Coupling height |

158 |

|

158 |

158 |

158 |

mm |

|

|

|||

|

l1 |

Overall length3) |

1260 |

|

1260 |

1427 |

1427 |

mm |

|

|

|||

|

b1 |

Overall width |

810 |

|

810 |

810 |

810 |

mm |

|

|

|||

|

b11 |

Track width, rear |

490 |

|

490 |

490 |

490 |

mm |

|

|

|||

|

y |

Wheel base |

920 |

|

920 |

1087 |

1087 |

mm |

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||

|

m2 |

Centre wheelbase |

45 |

|

45 |

45 |

45 |

mm |

|

|

|||

|

|

ground clearance |

|

|

|

|

|

|

|

|

|

|

|

|

Wa |

Turning radius |

1160 |

|

1160 |

1320 |

1320 |

mm |

|

|

|||

|

|

Travel speed w / w.o. |

8,5/12,5 |

|

5,0/8,0 |

8,5/12,5 |

5,0/8,0 |

km/h |

|

|

|||

|

|

load |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tow force without |

600 |

|

1000 |

600 |

1000 |

|

N |

|

|

||

|

|

load s2 60 min |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. tow force |

3000 |

|

3500 |

3000 |

3500 |

|

N |

|

|

||

|

|

without load s2 5 min |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive motor, output at |

2.5 |

|

2.5 |

2.5 |

2.5 |

kW |

|

|

|||

|

|

s2 60 min |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Battery voltage, rated |

24/420 |

|

24/420 |

24/560 |

24/560 |

V/Ah |

|

|

|||

|

|

capacity k5 |

(450) |

|

(450) |

(600) |

(600) |

|

|||||

|

|

|

|

|

|

|

|||||||

|

|

Battery weight |

370 |

|

370 |

370/450 |

370/450 |

kg |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1)Level, rolling resistance 200N/t

2)JetPilot height

3)Total length excluding coupling, as different coupling versions are available

0406.GB

B 4

Downloaded from www.Manualslib.com manuals search engine

4) Rated tow force

h14  1335

1335

h7 |

m2 |

h10 |

|

y |

|

|

l1 |

|

|

|

b11 |

b1 |

a |

Wa |

a |

|

2 |

2 |

|

0406.GB

B 5

Downloaded from www.Manualslib.com manuals search engine

4 Identification points and data plates

XXXXXXXXX |

|

|

XXXXXXXXX |

|

|

XXXXXXXXX |

XXXXXXXXXXX |

XXXXXXXXXXXX |

XXXXXXXXX |

XXXXXXXXXXX |

XXXXXXXXXXXX |

XXXXXXXXX |

XXXXXXXXXX |

XXXXXXXXXXXXXX |

XXXXXXXXX |

XXXXXXXXXX |

XXXXXXXXXXXXXX |

XXXXXXXXX |

XXXXXXXXXX |

XXXXXXXXXXXXX |

XXXXXXXXX |

XXXXXXXXXX |

XXXXXXXXXXXXX |

XXXXXXXXX |

|

|

XXXXXXXXX |

|

|

XXXXXXXXX |

|

XXXXXXX |

XXXXXXXXX |

|

XXXXXXX |

14

15

16

|

1 |

11 |

9 |

0 |

|

|

|

|

8 |

2000 |

|

7 |

|

|

6 |

|

|

|

5 |

4 |

17

18

21

3

1

2

Item |

Description |

14 |

Truck data plate |

|

|

15 |

“Caution, pushbutton operation” warning |

|

|

16 |

Accident prevention inspection label (Donly) |

|

|

17 |

Warning: Risk of trapping when reversing |

|

|

18 |

Attachment point of hooks for transportation by crane (inside) |

|

“Read operating instructions” warning |

|

|

|

|

0406.GB

B 6

Downloaded from www.Manualslib.com manuals search engine

4.1Truck data plate

32 |

XXXXXXXXX |

|

|

|

|

|

|

|

|

|

|

|

XXXXXXXXX |

|

|

|

|

31 |

|

XXXXXXXXXXX |

|

XXXXXXXXXXXX |

19 |

30 |

|

XXXXXXXXXXX |

|

XXXXXXXXXXXX |

|

XXXXXXXXX |

XXXXXXXXXX |

|

XXXXXXXXXXXXXX |

20 |

|

29 |

|

XXXXXXXXXX |

|

XXXXXXXXXXXXXX |

|

|

|

|

|

||

|

XXXXXXXXXX |

|

XXXXXXXXXXXXX |

21 |

|

28 |

|

XXXXXXXXXX |

|

XXXXXXXXXXXXX |

|

XXXXXXXXX |

|

|

|

22 |

|

|

XXXXXXXXX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

XXXXXXX |

|

27 |

|

|

|

XXXXXXX |

23 |

|

|

|

|

||

|

|

26 |

25 |

24 |

|

|

Item |

Description |

|

|

|

|

|

|

19 |

Max. supporting force (kg) |

|

|

|

|

|

|

20 |

Net weight w.o. battery (kg) |

|

|

|

|

|

|

21 |

Min./max. battery weight (kg) |

|

|

|

|

|

|

22 |

Manufacturer |

|

|

|

|

|

|

23 |

Customer no. |

|

|

|

|

|

|

24 |

Year of manufacture |

|

|

|

|

|

|

25 |

Rated tow force 5 min. in N |

|

|

|

|

|

|

26 |

Output (kW) |

|

|

|

|

|

|

27 |

Order no. |

|

|

|

|

|

|

28 |

Battery: Voltage (V) |

|

|

|

|

|

|

29 |

Rated tow force 60 min. in N |

|

|

|

|

|

|

30 |

Serial no. |

|

|

|

|

|

|

31 |

Type |

|

|

|

|

|

|

32 |

Manufacturer’s logo |

|

Z |

|

|

|

|

|

|

|

For any queries relating to the truck or spare part orders, please state the truck serial |

|||

|

no. (22). |

||

0406.GB

B 7

Downloaded from www.Manualslib.com manuals search engine

0406.GB

B 8

Downloaded from www.Manualslib.com manuals search engine

C |

Transport and Commissioning |

||||||

1 |

Lifting by crane |

|

|

|

|||

|

Only |

use |

lifting |

gear |

with |

|

|

F sufficient capacity |

|

|

|

||||

|

(for transport weight see truck |

|

|||||

|

data plate). |

|

|

|

|

||

Z |

Lifting |

gear |

attachment points |

|

|||

are provided on the chassis (3) |

|

||||||

|

and the back wall (1) in case the |

|

|||||

|

truck is to be lifted or transported |

|

|||||

|

by crane. |

|

|

|

|

||

|

– Park the truck securely (see |

|

|||||

|

Chapter E). |

|

|

|

|||

|

– Open the front cover (2) and |

1 |

|||||

|

put |

it |

to one side (refer to |

||||

|

chapter F). |

|

|

|

3 |

||

|

|

|

|

|

|||

|

– Secure the lifting slings to the |

|

|||||

|

attachment points (1) and (3). |

|

|||||

M |

The |

lifting |

gear |

must |

be |

2 |

|

attached |

to |

the |

attachment |

|

|||

points in such a manner that it

cannot slip under any circumstances and cannot come into contact with any attachments when the truck is lifted.

2 Securing the truck during transport

The truck must be securely fastened when transported on a lorry or a trailer. The lorry / trailer must have fastening rings.

To fasten the truck pull the tensioning belt (5) over the truck (4) and attach it to the fastening rings.

Tighten the tensioning belt with |

4 5 |

6 |

the tensioner (6). |

|

|

Loading must be carried out by specially trained staff in accordance with recommendations contained in Guidelines VDI 2700 and VDI 2703. In each case correct measurements shall be determined and appropriate safety measures adopted.

0406.GB

C 1

Downloaded from www.Manualslib.com manuals search engine

3 |

Using the truck for the first time |

M |

Only operate the truck with battery current. Rectified AC current will damage the |

electronic components. Cables connected to the battery (trailing cables) must be less |

|

|

than 6 meters in length. |

|

To prepare the truck after delivery or after transport, proceed as follows: |

|

– Check the truck for completion and satisfactory condition of the equipment. |

|

– Install battery (where required). Do not damage battery cables (see Chapter D). |

|

– Charge the battery (see Chapter D). |

|

– Commission the truck in accordance with instructions (see Chapter E). |

Z |

When the truck is parked, the running surface of the tyres will flatten. The flattening |

|

will disappear after a short period of operation. |

0406.GB

C 2

Downloaded from www.Manualslib.com manuals search engine

4

F

F

0406.GB

Operating the truck without its own drive system

This operating mode is not permitted when negotiating inclines and gradients.

If the truck has to be moved after a failure has rendered it immobile, proceed as follows:

–Set the master switch to position “OFF”.

–Set the key switch to position “OFF” (“0”) and remove the key.

–Prevent the truck from rolling away.

–Open battery cover (refer to chapter D).

–Open the front cover (7) and put it to one side (see chapter F).

–Slacken the lock nuts (8) and tighten the screws (9).

The brake is now released and the truck can move.

On reaching your destination, ensure that the brake is restored to its initial state. The truck must never be parked with the brakes released.

–Loosen the screws (9) by approx. 5 mm and lock by tightening the lock nuts (8). The brake is now applied again.

–Refit the front cover (7).

9

8

7

C 3

Downloaded from www.Manualslib.com manuals search engine

0406.GB

C 4

Downloaded from www.Manualslib.com manuals search engine

D Battery Maintenance, Charging &

Replacement

1Safety regulations for handling acid batteries

Park the truck securely before carrying out any work on the batteries (see Chapter E).

Maintenance personnel: Batteries may only be charged, serviced or replaced by trained personnel. The present operator manual and the manufacturer’s instructions concerning batteries and charging stations must be observed when carrying out the work.

Fire protection: Smoking and naked flames must be avoided when working with batteries Wherever a truck is parked for charging there shall be no inflammable material or operating fluids capable of creating sparks within 2 metres around the truck. The area must be well ventilated. Fire protection equipment must be provided.

Battery maintenance: The battery cell covers must be kept dry and clean. The terminals and cable shoes must be clean, secure and have a light coating of dielectric grease. Batteries with non insulated terminals must be covered with a non slip insulation mat.

M

F

M

F

Battery Disposal: Batteries may only be disposed of in accordance with national environmental protection regulations or disposal laws. The manufacturer’s disposal instructions must be followed.

Before closing the battery cover make sure that the battery lead cannot be damaged.

Batteries contain an acid solution which is poisonous and corrosive. Therefore, always wear protective clothing and eye protection when carrying out work on batteries. Avoid all contact with battery acide.

Should however clothing, skin or eyes come in contact with acid the affected parts should be rinsed with plenty of clean water - where the skin or eyes are affected call a doctor immediately. Immediately neutralise any spilled battery acid.

Only batteries with a sealed battery container may be used.

The weight and dimensions of the battery have considerable affect on the operational safety of the truck. Battery equipment may only be replaced with the agreement of the manufacturer.

0406.GB

D 1

Downloaded from www.Manualslib.com manuals search engine

2Battery types

The truck will be equipped with different battery types, depending on the application. The following table shows which combinations can be included as standard:

|

LxWxH 798x212x784 mm; 370 kg |

|

|

|

|

|

|

|

24 V EPzS battery |

3 EPzS 420 Ah |

|

|

|

|

|

|

24 volt EPzS battery |

3 |

EPzS 450 Ah |

|

enhanced |

|

|

|

24 volt EPzV battery |

3 |

EPzV 360 Ah |

|

maintenance free |

|

|

|

24 volt PzW battery |

3 |

PzW 420 Ah |

|

wf 200 1) |

|

|

|

LxWxH 798x330x784 mm; 450 kg 2) |

|

|

|

24 V EPzS battery |

4 EPzS 560 Ah |

|

|

|

|

|

|

24 volt EPzS battery |

4 |

EPzS 620 Ah |

|

enhanced |

|

|

|

24 volt EPzV battery |

4 |

EPzV 480 Ah |

|

maintenance free |

|

|

|

24 volt PzW battery |

4 |

PzW 560 Ah |

|

wf 200 1) |

|

|

|

1) partially maintenance-free with electrolytic recirculation |

||

|

2) XL only |

|

|

|

The battery weight is indicated on the battery data plate. |

||

|

Depending on the type of battery used, it is also possible to use models with |

||

|

enhanced performance or maintenance-free batteries. |

||

M |

When replacing/installing the battery make sure the battery is securely located in the |

||

|

battery compartment of the truck. |

|

|

0406.GB

D 2

Downloaded from www.Manualslib.com manuals search engine

3 Exposing the battery

F Park the truck securely (see Chapter E).

– Pull lever (1) upward while at the same time setting the tiller vertical.

– Release the lever (1) again.

– Flip up the battery latch (3) and open the battery cover (2).

3 2 1

F All covers and connections must be restored to the normal operating condition before the truck can operate again.

0406.GB

D 3

Downloaded from www.Manualslib.com manuals search engine

4

F

Charge the battery

To charge the battery, the truck must be parked in a closed and properly ventilated room.

– Expose the battery (see Section 3).

M |

The battery connector (5) and the charging cable (4) of the battery charging station |

must only be connected or disconnected with the truck and the battery charger |

switched off. The main switch (7) must also only be pressed when the truck and the battery charger are switched off.

F When charging, the tops of the battery cells must be exposed to provide sufficient ventilation. Do not place any metal objects on the battery. Before charging, check all cables and plug connections for visible signs of damage.

All safety instructions given by the battery and battery charger manufacturers must be strictly observed.

–Pull out the battery plug (5) from the bracket (6).

–Remove any insulating mats from the battery.

–Connect the charging cable (4) of the battery charging station to the battery connector (5) and switch on the charger.

M Charge the battery in accordance with the battery and charging station manufacturers’ instructions.

4 |

5 |

6 |

7 |

0406.GB

D 4

Downloaded from www.Manualslib.com manuals search engine

5 |

Battery removal and installation |

|

The truck must be parked on level ground. To prevent short circuits, batteries with |

F exposed terminals or connectors must be covered with a rubber mat. Place the |

|

|

battery connector or the battery cable in such a way that they will not get caught on |

|

the truck when the battery is withdrawn. |

M |

When transporting batteries using a crane, ensure that the crane is of adequate |

capacity (the battery weight is indicated on the battery data plate on the battery |

|

container). The lifting gear must exert a vertical pull so that the battery container is not compressed. Attach the hooks to the attachment points (8) in such a way that the lifting gear, when slack, cannot collapse on the battery cells.

– Expose the battery (see Section 3).

– Pull out the battery plug (10) from the bracket.

– Flip back the battery locking mechanism (9).

– Using crane lifting gear, lift the battery (11) slowly and carefully out of the truck.

The battery can optionally be removed from the side. To do this, pull the battery out at the side onto the battery replacement trolley.

F F

Do not put your fingers between the truck frame and the battery.

Follow the operating instructions of the battery replacement trolley manufacturer!

Installation is in the reverse order of removal. When reinstalling the battery, note the required installation position and make sure the battery is connected correctly.

F Afterdamage.installing the battery check all cables and plug connections for visible signs of The battery must be securely fixed in the truck to avoid damage arising from accidental movement. After each replacement ensure that the battery is prevented from sliding, by flipping the battery locking mechanism (9) back into the recess.

The battery cover must be firmly closed.

9 10 11

8

0406.GB

D 5

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...