Jungheinrich EFG 535, EFG 545, EFG 540, EFG 550 User Manual [de]

EFG 535 - 550 |

10.09 - |

|

|

|

|

|

|

|

Operating instructions |

G |

|

51151559 |

|

|

09.12 |

EFG 535 |

|

|

EFG 540 |

|

EFG 545

EFG 550

Declaration of Conformity

Jungheinrich AG, Am Stadtrand 35, D-22047 Hamburg

Manufacturer or agent acting in the European Union

Type |

Option |

Serial no. |

Year of |

|

|

|

manufacture |

EFG 535

EFG 540

EFG 545

EFG 550

Additional information

On behalf of

Date

GEU Conformity Declaration

The undersigned hereby declare that the powered industrial truck described below in detail complies with the European Directives 2006/42/EC (Machinery Directive) and 2004/108/EEC (Electromagnetic Compatibility - EMC) including amendments as well as the legislative decree to incorporate the directives in national law. The signatories are in each case individually authorized to compile the technical documents.

09.12 EN

3

4

09.12 EN

09.12 EN

Foreword

Notes on the operating instructions

The present ORIGINAL OPERATING INSTRUCTIONS are designed to provide sufficient instruction for the safe operation of the industrial truck. The information is provided clearly and concisely. The chapters are arranged by letter and the pages are numbered continuously.

The operator manual details different industrial truck models. When operating and servicing the industrial truck, make sure that the particular section applies to your truck model.

Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the system. No guarantee of particular features of the truck should therefore be assumed from the present operating instructions.

Safety notices and text mark-ups

Safety instructions and important explanations are indicated by the following graphics:

DANGER!

Indicates an extremely hazardous situation. Failure to comply with this instruction will result in severe irreparable injury and even death.

WARNING!

Indicates an extremely hazardous situation. Failure to comply with this instruction may result in severe irreparable injury and even death.

CAUTION!

Indicates a hazardous situation. Failure to comply with this instruction may result in slight to medium injury.

NOTE

Indicates a material hazard. Failure to comply with this instruction may result in material damage.

Z Used before notices and explanations.

t Indicates standard equipment o Indicates optional equipment

Copyright

Copyright of these operating instructions remains with JUNGHEINRICH AG.

5

Jungheinrich Aktiengesellschaft

Am Stadtrand 35

22047 Hamburg - Germany

Tel: +49 (0) 40/6948-0

www.jungheinrich.com

09.12 EN

6

Contents |

|

|

A |

Correct Use and Application ................................................... |

11 |

1 |

General.................................................................................................... |

11 |

2 |

Correct application................................................................................... |

11 |

3 |

Approved application conditions.............................................................. |

12 |

4 |

Proprietor responsibilities ........................................................................ |

13 |

5 |

Adding attachments and/or accessories.................................................. |

13 |

B |

Truck Description .................................................................... |

15 |

1 |

Application ............................................................................................... |

15 |

1.1 |

Truck models and rated capacity............................................................. |

15 |

2 |

Assemblies and Functional Description................................................... |

16 |

2.1 |

Assembly Overview ................................................................................. |

16 |

2.2 |

Functional Description ............................................................................. |

17 |

3 |

Technical Specifications .......................................................................... |

19 |

3.1 |

Performance data .................................................................................... |

19 |

3.2 |

Dimensions.............................................................................................. |

21 |

3.3 |

Weights.................................................................................................... |

23 |

3.4 |

Mast versions .......................................................................................... |

25 |

3.5 |

Tyre type.................................................................................................. |

27 |

3.6 |

Engine Data............................................................................................. |

27 |

3.7 |

EN norms................................................................................................. |

28 |

3.8 |

Conditions of use..................................................................................... |

29 |

3.9 |

Electrical requirements ............................................................................ |

29 |

4 |

Identification points and data plates ........................................................ |

30 |

4.1 |

Indication Points ...................................................................................... |

30 |

4.2 |

Data plate ................................................................................................ |

32 |

4.3 |

Truck capacity plate................................................................................. |

33 |

4.4 |

Attachment capacity plate ....................................................................... |

34 |

5 |

Stability .................................................................................................... |

34 |

C |

Transport and Commissioning ................................................ |

35 |

1 |

Transport ................................................................................................. |

35 |

2 |

Truck laden.............................................................................................. |

35 |

2.1 |

Centre of gravity of the truck ................................................................... |

35 |

2.2 |

Lifting the truck by crane ......................................................................... |

36 |

2.3 |

Loading with another industrial truck ....................................................... |

37 |

3 |

Securing the truck during transport ......................................................... |

38 |

4 |

Using the Truck for the First Time ........................................................... |

39 |

09.12 EN

7

D |

Battery - Servicing, Recharging, Replacement ....................... |

41 |

1 |

Safety Regulations Governing the Handling of Lead-Acid Batteries ....... |

41 |

1.1 |

General notes on handling batteries........................................................ |

43 |

2 |

Battery types............................................................................................ |

44 |

3 |

Exposing the battery................................................................................ |

45 |

4 |

Charging the battery ................................................................................ |

46 |

4.1 |

Charging the battery with a stationary charger........................................ |

46 |

4.2 |

Charging the battery with a charger socket (o) ...................................... |

47 |

5 |

Battery removal and installation .............................................................. |

48 |

6 |

Closing the battery cover......................................................................... |

49 |

E |

Operation ................................................................................ |

51 |

1 |

Safety Regulations for the Operation of the Forklift Truck....................... |

51 |

2 |

Displays and Controls.............................................................................. |

53 |

2.1 |

Control panel with display unit................................................................. |

56 |

2.2 |

Side compartment control panel switch (o) ............................................ |

58 |

2.3 |

Instrument panel switches (o) ................................................................ |

58 |

2.4 |

Display..................................................................................................... |

59 |

3 |

Starting up the truck ................................................................................ |

61 |

3.1Checks and operations to be performed before starting daily operation . 61

3.2 |

Entry and exit........................................................................................... |

63 |

3.3 |

Trucks with reduced headroom X (o) ..................................................... |

63 |

3.4 |

Setting up the operator position............................................................... |

64 |

3.5 |

Seat Belt .................................................................................................. |

68 |

4 |

Industrial Truck Operation ....................................................................... |

69 |

4.1 |

Safety regulations for truck operation...................................................... |

69 |

4.2 |

Preparing the truck for operation ............................................................. |

71 |

4.3 |

Setting the time........................................................................................ |

72 |

4.4 |

Parking the truck securely ....................................................................... |

73 |

4.5 |

Emergency Disconnect............................................................................ |

74 |

4.6 |

Travel....................................................................................................... |

75 |

4.7 |

Steering ................................................................................................... |

76 |

4.8 |

Brakes ..................................................................................................... |

77 |

4.9 |

Adjusting the forks ................................................................................... |

79 |

4.10 |

Replacing the forks.................................................................................. |

80 |

4.11 |

Lifting, transporting and depositing loads ................................................ |

81 |

4.12 |

Operating the lift mechanism and integrated attachments ...................... |

83 |

4.13 |

Safety instructions for operating additional attachments ......................... |

90 |

4.14 |

Operating additional attachments for the SOLO-PILOT .......................... |

94 |

4.15 |

Operating additional attachments for the Multi Pilot ................................ |

96 |

4.16 |

Fitting additional attachments.................................................................. |

98 |

5 |

Towing trailers ......................................................................................... |

100 |

6 |

Optional equipment ................................................................................. |

102 |

6.1 |

CanCode keypad..................................................................................... |

102 |

6.2 |

Assistance systems ................................................................................. |

106 |

6.3 |

Steel cab.................................................................................................. |

108 |

6.4 |

Sliding windows ....................................................................................... |

108 |

6.5 |

Automatic / mechanical folding gate........................................................ |

109 |

6.6 |

BODYGUARD ......................................................................................... |

110 |

09.12 EN

8

6.7 |

Panel door ............................................................................................... |

110 |

6.8 |

Operator position extension..................................................................... |

111 |

6.9 |

Adjusting the driver’s seat ....................................................................... |

111 |

6.10 |

Heating .................................................................................................... |

112 |

6.11 |

Removable load backrest ........................................................................ |

113 |

6.12 |

Lift cutout override ................................................................................... |

113 |

6.13 |

Fire extinguisher ...................................................................................... |

114 |

6.14 |

Tilt angle display...................................................................................... |

114 |

6.15 |

Rockinger coupling with hand lever or remote control............................. |

115 |

6.16 |

Camera system ....................................................................................... |

116 |

6.17 |

Control layout “N” .................................................................................... |

117 |

7 |

Troubleshooting....................................................................................... |

118 |

7.1 |

Troubleshooting....................................................................................... |

118 |

7.2 |

Operating the truck without its own drive system .................................... |

121 |

7.3 |

Emergency lowering ................................................................................ |

123 |

F |

Industrial Truck Maintenance .................................................. |

125 |

1 |

Operational Safety and Environmental Protection................................... |

125 |

2 |

Maintenance Safety Regulations............................................................. |

126 |

3 |

Servicing and Inspection ......................................................................... |

131 |

4 |

Maintenance checklist ............................................................................. |

132 |

4.1 |

Owner ...................................................................................................... |

132 |

4.2 |

Customer Service .................................................................................... |

135 |

5 |

Lubricants and Lubrication Schedule ...................................................... |

144 |

5.1 |

Handling consumables safely.................................................................. |

144 |

5.2 |

Lubrication Schedule ............................................................................... |

146 |

5.3 |

Consumables........................................................................................... |

147 |

6 |

Maintenance and repairs ......................................................................... |

149 |

6.1 |

Preparing the truck for maintenance and repairs .................................... |

149 |

6.2 |

Opening the rear panel............................................................................ |

149 |

6.3 |

Checking the wheel attachments............................................................. |

150 |

6.4 |

Replacing wheels .................................................................................... |

151 |

6.5 |

Hydraulic system ..................................................................................... |

153 |

6.6 |

Replacing the hydraulic oil filter............................................................... |

155 |

6.7 |

Replacing the ventilation/discharge filter ................................................. |

155 |

6.8 |

Check the gear oil level ........................................................................... |

156 |

6.9 |

Replacing the suction filter of the engine fan........................................... |

157 |

6.10 |

Heating .................................................................................................... |

158 |

6.11 |

Adding window washer system fluid........................................................ |

158 |

6.12 |

Checking electrical fuses......................................................................... |

159 |

6.13 |

Seat belt maintenance............................................................................. |

161 |

6.14 |

Restoring the truck to service after maintenance and repairs ................. |

162 |

7 |

Decommissioning the industrial truck ...................................................... |

163 |

7.1 |

Prior to decommissioning ........................................................................ |

164 |

7.2 |

During decommissioning ......................................................................... |

164 |

7.3 |

Restoring the truck to service after decommissioning ............................. |

165 |

8 |

Safety tests to be performed at intervals and after unusual incidents ..... |

166 |

9 |

Final de-commissioning, disposal............................................................ |

167 |

10 |

Human vibration measurement ............................................................... |

167 |

09.12 EN

9

10

09.12 EN

|

Appendix |

|

JH Traction Battery Operating Instructions |

Z |

These operating instructions apply only to Jungheinrich battery models. If using |

another brand, refer to the manufacturer's operating instructions. |

0506.GB

1

2

0506.GB

A Correct Use and Application

1 General

The industrial truck described in the present operating instructions is designed for lifting, lowering and transporting load units.

It must be used, operated and serviced in accordance with the present instructions. Any other type of use is beyond the scope of application and can result in damage to personnel, the industrial truck or property.

2 Correct application

NOTE

The maximum load and load distance are indicated on the load chart and must not be exceeded.

The load must rest on the load handler or be lifted by an attachment approved by the manufacturer.

The load must rest on the back of the fork carriage and centrally between the forks.

–Lifting and lowering loads.

–Transporting lowered loads over short distances.

–Do not travel with a raised load (>30 cm).

–Do not carry or lift passengers.

–Do push or pull load units.

–Occasional towing of trailer loads.

–When towing trailer loads the load must be secured on the trailer.

–The permissible trailer load must not be exceeded.

09.12 EN

11

3 Approved application conditions

DANGER!

Do not exceed the permissible surface and spot load limits on the travel routes. At blind spots get a second person to assist.

The driver must ensure that the loading dock / ramp cannot move or come loose during loading / unloading.

–Operation in industrial and commercial environments.

–Permissible temperature range -20°C to +40°C.

–Operation only on secure, level surfaces with sufficient capacity.

–Operation only on routes that are visible and approved by the proprietor.

–Negotiating inclines up to a maximum of 15 %.

–Do not negotiate inclines crosswise or at an angle. Transporting loads downhill.

–Operation in partially public traffic.

WARNING!

Extreme conditions

XSpecial equipment and authorisation are required if the truck is to be constantly used in extreme conditions, especially in dusty or corrosive atmospheres.

XThe truck is not authorised for use in areas at risk of explosion.

XIn adverse weather conditions (thunder, lightning) the industrial truck must not be operated outside or in endangered areas.

09.12 EN

12

4 Proprietor responsibilities

For the purposes of the present operating instructions the “proprietor” is defined as any natural or legal person who either uses the industrial truck himself, or on whose behalf it is used. In special cases (e.g. leasing or renting) the proprietor is considered the person who, in accordance with existing contractual agreements between the owner and user of the industrial truck, is charged with operational duties.

The proprietor must ensure that the industrial truck is used only for the purpose for which it is intended and that there is no danger to life and limb of the user and third parties. Furthermore, accident prevention regulations, safety regulations and operating, servicing and repair guidelines must be followed. The proprietor must ensure that all users have read and understood these operating instructions.

NOTE

Failure to comply with the operating instructions shall invalidate the warranty. The same applies if improper work is carried out on the truck by the customer or third parties without the permission of the manufacturer.

5 Adding attachments and/or accessories

Adding accessories

The mounting or installation of additional equipment which affects or enhances the performance of the forklift truck requires the written permission of the manufacturer. Local authority approval may also need to be obtained.

Local authority approval does not however constitute the manufacturer’s approval.

09.12 EN

13

14

09.12 EN

B Truck Description

1 Application

The EFG 535 - 550 is a four-wheel electric sit-down forklift truck. It is a cantilever counterbalanced truck which can lift, transport and deposit loads using the load handler attached in front.

Closed bottom pallets can also be lifted.

1.1Truck models and rated capacity

The rated capacity depends on the model. The rated capacity can be derived from the model description.

EFG 535

EFG Model name 5 Series

35 Rated capacity x 100 kg

The rated capacity does not generally match the permissible capacity. The capacity can be found on the load chart attached to the rack.

09.12 EN

15

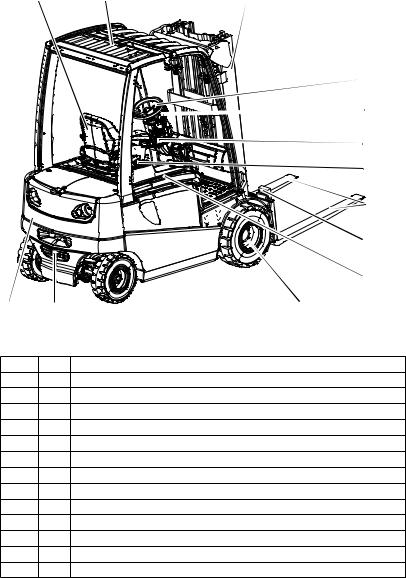

2 Assemblies and Functional Description

2.1Assembly Overview

1 |

2 |

3 |

|

|

|

4 |

|

|

|

5 |

|

|

|

6 |

|

|

|

7 |

|

|

|

8 |

|

|

|

9 |

|

|

|

10 |

13 |

12 |

|

11 |

Item |

t |

Description |

|

1 |

Driver's seat |

|

|

2 |

t |

Overhead guard |

|

3 |

t |

Mast |

|

4 |

t |

Steering wheel |

|

5 |

t |

Control / display unit |

|

6 |

t |

Lift mechanism control |

|

7 |

t |

Emergency Disconnect switch |

|

8 |

t |

Fork tines |

|

9 |

t |

Fork carriage |

|

10 |

t |

Battery cover |

|

11 |

t |

Drive |

|

12 |

t |

Trailer coupling |

EN |

13 |

t |

Counterweight |

|

|

|

|

09.12 |

16

2.2Functional Description

Chassis

The chassis, in conjunction with the counterweight, forms the supporting base structure of the truck. It is used to support the main components.

Operator position and overhead guard

The overhead guard (2) comes in a range of models and protects the driver from falling objects and other external

influences. All the controls are ergonomically arranged. The steering column and driver's seat can be adjusted individually.

The controls and warnings on the control and display unit (5) enable the system to be monitored during operation, thereby ensuring a very high level of safety.

Steering

The steer cylinder of the hydrostatic steering is integrated in the steer axle (12) and is controlled by the power steering. The steer axle is fully floating in the chassis to ensure excellent grip even on non-level surfaces.

Wheels

There is a choice of super elastic or fully rubber tyres as well as optional pneumatic tyres.

Drive system and brakes

The front drive provides maximum traction to the drive wheels at all times. The hydraulic oil bath multi-plate brakes form the operating brake and are practically maintenance-free. The transmission encapsulation allows the truck to be used even in hostile environments. The drive motor also decelerates to a halt. This minimizes energy consumption.

The parking brake applies approx. 15 seconds when the truck comes to a halt or 1 to 15 seconds (adjustable) after the driver’s seat has been vacated.

The parking brake is automatically released again when the accelerator pedal is pressed.

09.12 EN

17

Hydraulic system

A multi-pilot valve allows for sensitive operation of the functions via the controls. A speed-controlled hydraulic pump ensures a proportionate and efficient supply to the hydraulic functions.

Mast

Two or three-stage masts, optionally with free lift function; narrow mast sections ensure excellent visibility of the forks and attachments. Fork carriage and mast run on permanently lubricated and hence maintenance-free support rollers.

Attachments

The trucks can be optionally fitted with mechanical and hydraulic attachments.

09.12 EN

18

3 Technical Specifications

All technical details refer to standard trucks.

Values indicated with *) may vary, depending on the types of equipment used (e.g. mast, cabin, tyres etc.).

Z Technical data specified in accordance with VDI 2198. Technical modifications and additions reserved.

3.1Performance data

EFG 535-540

|

Description |

|

EFG |

|

|

535 |

540 |

|

|

|

|

|

||

Q |

Rated capacity |

3500 |

4000 |

kg |

(where C = 500 mm)1) |

||||

C |

Load centre of gravity |

500 |

500 |

mm |

|

Travel speed |

16 / 17 |

15 / 17 |

km/h |

|

w / w.o. load *) |

|||

|

|

|

|

|

|

Lift speed |

0,38 / 0,50 |

0,35 / 0,47 |

m/s |

|

w / w.o. load |

|||

|

|

|

|

|

|

Lowering speed |

0,58 / 0,55 |

0,55 / 0,50 |

m/s |

|

w / w.o. load |

|||

|

|

|

|

|

|

Gradeability (30 min) |

8,5 / 14,5 |

8 / 13,5 |

% |

|

with / without load *) |

|||

|

|

|

|

|

|

Max. gradeability 2) (5 min) |

15,5 / 25 |

14 / 23,5 |

% |

|

with / without load |

|||

|

|

|

|

|

|

Acceleration (10 m) |

4,8 / 4,2 |

5,0 / 4,4 |

s |

|

with / without load *) |

|||

|

|

|

|

|

|

Max. operating pressure |

200 |

200 |

bar |

|

Oil flow for attachments |

30 |

30 |

l/min |

1)for vertical mast.

2)The values shown represent the maximum gradeability to overcome short differences in height and surface unevenness (surface edges). The truck must not operate on inclines of more than 15%.

09.12 EN

19

EFG 545-550

|

Description |

|

EFG |

|

|

|

545 |

550 |

|

||

|

|

|

|||

Q |

Rated capacity |

4500 |

4990 |

kg |

|

(where C = 500 mm)1) |

|||||

C |

Load centre of gravity |

500 |

500 |

mm |

|

|

Travel speed |

15 / 16,5 |

15 |

/ 16 |

km/h |

|

w / w.o. load *) |

||||

|

|

|

|

|

|

|

Lift speed |

0,33 / 0,45 |

0,31 |

/ 0,45 |

m/s |

|

w / w.o. load |

||||

|

|

|

|

|

|

|

Lowering speed |

0,55 / 0,50 |

0,55 |

/ 0,50 |

m/s |

|

w / w.o. load |

||||

|

|

|

|

|

|

|

Gradeability (30 min) |

7 / 12 |

6,5 / 12 |

% |

|

|

with / without load *) |

||||

|

|

|

|

|

|

|

Max. gradeability 2) (5 min) |

12,5 / 21,5 |

12 |

/ 21 |

% |

|

with / without load |

||||

|

|

|

|

|

|

|

Acceleration (10 m) |

5,5 / 4,8 |

5,8 |

/ 5,2 |

s |

|

with / without load *) |

||||

|

|

|

|

|

|

|

Max. operating pressure |

200 |

200 |

bar |

|

|

Oil flow for attachments |

30 |

30 |

l/min |

|

1)for vertical mast.

2)The values shown represent the maximum gradeability to overcome short differences in height and surface unevenness (surface edges). The truck must not operate on inclines of more than 15%.

09.12 EN

20

3.2Dimensions

EFG 535-540

|

Description |

|

EFG |

|

|

535 |

540 |

|

|

|

|

|

||

a/2 |

Safety distance |

100 |

100 |

mm |

h1 |

Mast height retracted* |

2228 |

2405 |

mm |

h2 |

Free lift* |

150 |

150 |

mm |

h3 |

Lift* |

3100 |

3000 |

mm |

h4 |

Mast height extended* |

3883 |

3830 |

mm |

h6 |

Overhead guard height* |

2320 |

2320 |

mm |

h7 |

Seat height* |

1165 |

1165 |

mm |

h10 |

Coupling height |

390/500 |

390/500 |

mm |

Į |

Mast tilt, fwd. |

6 |

6 |

° |

ȕ |

Mast tilt, back |

8 |

8 |

° |

L1 |

Length including forks* |

3975 |

3980 |

mm |

L2 |

Headlength* |

2830 |

2830 |

mm |

b1 |

Overall width* |

1340 |

1340 |

mm |

b3 |

Fork width* |

1120 |

1260 |

mm |

m1 |

Ground clearance with load below |

120 |

120 |

mm |

mast |

||||

m2 |

Ground clearance centre wheelbase |

160 |

160 |

mm |

Ast |

Working aisle width |

4180 |

4360 |

mm |

800 x 1200 longitudinal pallets |

||||

Ast |

Working aisle width |

3980 |

4160 |

mm |

1000 x 1200 traverse pallets |

||||

Wa |

Turning radius |

2300 |

2450 |

mm |

x |

Load distance |

510 * |

510 * |

mm |

y |

Wheelbase |

1855 |

2000 |

mm |

09.12 EN

21

22

09.12 EN

EFG 545-550

|

Description |

|

EFG |

|

|

545 |

550 |

|

|

|

|

|

||

a/2 |

Safety distance |

100 |

100 |

mm |

h1 |

Mast height retracted* |

2405 |

2405 |

mm |

h2 |

Free lift* |

150 |

150 |

mm |

h3 |

Lift* |

3000 |

3000 |

mm |

h4 |

Mast height extended* |

3830 |

3830 |

mm |

h6 |

Overhead guard height* |

2320 |

2320 |

mm |

h7 |

Seat height* |

1165 |

1165 |

mm |

h10 |

Coupling height |

390/500 |

390/500 |

mm |

Į |

Mast tilt, fwd. |

6 |

6 |

° |

ȕ |

Mast tilt, back |

8 |

8 |

° |

L1 |

Length including forks* |

3980 |

3980 |

mm |

L2 |

Headlength* |

2830 |

2830 |

mm |

b1 |

Overall width* |

1340 |

1340 |

mm |

b3 |

Fork width* |

1120 |

1260 |

mm |

m1 |

Ground clearance with load below |

120 |

120 |

mm |

mast |

||||

m2 |

Ground clearance centre wheelbase |

160 |

160 |

mm |

Ast |

Working aisle width |

4360 |

4360 |

mm |

800 x 1200 longitudinal pallets |

||||

Ast |

Working aisle width |

4160 |

4160 |

mm |

|

1000 x 1200 traverse pallets |

|

|

|

Wa |

Turning radius |

2450 |

2450 |

mm |

x |

Load distance |

510 * |

510 * |

mm |

y |

Wheelbase |

2000 |

2000 |

mm |

3.3Weights

Z All dimensions in kg.

|

EFG 535-550 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Description |

|

|

EFG |

|

|

|

|

535 |

540 |

|

545 |

550 |

|

Net weight |

5800 |

6600 |

|

6950 |

7300 |

|

(including battery) |

|

||||

|

|

|

|

|

|

|

|

Front axle load (without lifting |

3000 |

3700 |

|

3700 |

3700 |

|

load) |

|

||||

|

|

|

|

|

|

|

|

Front axle load (with lifting |

8350 |

9700 |

|

10400 |

11200 |

|

load) |

|

||||

EN |

|

|

|

|

|

|

Rear axle load (without lifting |

2800 |

2900 |

|

3250 |

3600 |

|

09.12 |

|

|||||

load) |

|

|||||

|

|

|

|

|

||

|

|

|

|

|

|

|

23

EFG 535-550

Description |

|

|

EFG |

|

|

|

535 |

540 |

|

545 |

550 |

Rear axle load (with lifting |

950 |

900 |

|

1050 |

1100 |

load) |

|

||||

|

|

|

|

|

|

09.12 EN

24

3.4Mast versions

Z All dimensions in mm

EFG 535-540 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

VDI 3596 |

Lift h3 |

Free lift h2 |

Height |

Height |

||||

Description |

|

|

|

mast |

mast |

|||

|

|

|

|

retracted h1 |

extended h4 |

|||

|

|

EFG 535 |

EFG 540 |

EFG 535 |

EFG 540 |

EFG 535 |

EFG 540 |

|

|

2750 |

|

|

|

2280 |

|

3580 |

|

|

3000 |

|

|

|

2405 |

|

3830 |

|

|

3100 |

|

|

2228 |

|

3883 |

|

|

|

3500 |

|

|

2428 |

2655 |

4283 |

4330 |

|

ZT |

4000 |

150 |

2678 |

2905 |

4783 |

4830 |

||

4500 |

2978 |

3155 |

5283 |

5330 |

||||

|

|

|

||||||

|

5000 |

|

|

3228 |

3405 |

5783 |

5830 |

|

|

5500 |

|

|

|

3655 |

|

6330 |

|

|

6000 |

|

|

|

3905 |

|

6830 |

|

|

6500 |

|

|

|

4155 |

|

7330 |

|

|

2700 |

|

1376 |

|

2080 |

|

3404 |

|

|

2950 |

|

1501 |

|

2205 |

|

3654 |

|

|

3450 |

|

1751 |

|

2455 |

|

4154 |

|

ZZ |

3950 |

|

2001 |

|

2705 |

|

4654 |

|

|

4450 |

|

2251 |

|

2955 |

|

5154 |

|

|

4950 |

|

2501 |

|

3205 |

|

5654 |

|

|

5450 |

|

2751 |

|

3455 |

|

6154 |

|

|

3800 |

|

1376 |

|

2080 |

|

5405 |

|

|

4175 |

|

1501 |

|

2205 |

|

4879 |

|

|

4700 |

1430 |

|

2193 |

|

5463 |

|

|

|

4925 |

|

1751 |

|

2405 |

|

5629 |

|

|

5000 |

1530 |

|

2293 |

|

5763 |

|

|

DZ |

5300 |

|

1871 |

|

2580 |

|

6004 |

|

5500 |

1730 |

|

2493 |

|

6263 |

|

||

|

|

|

|

|||||

|

5675 |

|

2001 |

|

2705 |

|

6379 |

|

|

6000 |

1930 |

|

2693 |

|

6763 |

|

|

|

6425 |

|

2251 |

|

2955 |

|

7159 |

|

|

6500 |

2130 |

|

2893 |

|

7263 |

|

|

|

7175 |

|

2521 |

|

3205 |

|

7879 |

|

Special trucks are not included in this overview.

09.12 EN

25

EFG 545-550 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

VDI 3596 |

Lift h3 |

Free lift h2 |

Height |

Height |

||||

Description |

|

|

|

|

mast |

mast |

||

|

|

|

|

|

retracted h1 |

extended h4 |

||

|

|

EFG 545 |

EFG 550 |

EFG 545 |

EFG 550 |

EFG 545 |

EFG 550 |

|

|

2750 |

|

|

|

2280 |

2280 |

3580 |

3580 |

|

3000 |

|

|

|

2405 |

2405 |

3830 |

3830 |

|

3500 |

|

|

|

2655 |

2655 |

4330 |

4330 |

|

4000 |

|

|

|

2905 |

2905 |

4830 |

4830 |

ZT |

|

|

150 |

|

|

|

|

|

4500 |

|

3155 |

3155 |

5330 |

5330 |

|||

|

5000 |

|

|

|

3405 |

3405 |

5830 |

5830 |

|

5500 |

|

|

|

3655 |

3655 |

6330 |

6330 |

|

6000 |

|

|

|

3905 |

3905 |

6830 |

6830 |

|

6500 |

|

|

|

4155 |

4155 |

7330 |

7330 |

|

2700 |

1376 |

|

1227 |

2080 |

2080 |

3404 |

3553 |

|

2950 |

1501 |

|

1352 |

2205 |

2205 |

3654 |

3803 |

|

3450 |

1751 |

|

1602 |

2455 |

2455 |

4154 |

4303 |

ZZ |

|

|

|

|

|

|

|

|

3950 |

2001 |

|

1852 |

2705 |

2705 |

4654 |

4803 |

|

|

4450 |

2251 |

|

2102 |

2955 |

2955 |

5154 |

5303 |

|

4950 |

2501 |

|

2352 |

3205 |

3205 |

5654 |

5803 |

|

5450 |

2751 |

|

2602 |

3455 |

3455 |

6154 |

6303 |

|

3800 |

1376 |

|

1227 |

2080 |

2080 |

5405 |

4653 |

|

4175 |

1501 |

|

1352 |

2205 |

2205 |

4879 |

5023 |

|

4925 |

1751 |

|

1602 |

2405 |

2405 |

5629 |

5773 |

DZ |

|

|

|

|

|

|

|

|

5300 |

1871 |

|

1727 |

2580 |

2580 |

6004 |

6153 |

|

|

5675 |

2001 |

|

1852 |

2705 |

2705 |

6379 |

6523 |

|

6425 |

2251 |

|

2102 |

2955 |

2955 |

7159 |

7273 |

|

7175 |

2521 |

|

2352 |

3205 |

3205 |

7879 |

8023 |

Special trucks are not included in this overview.

09.12 EN

26

3.5Tyre type

NOTE

When replacing tyres/rims fitted at the factory, always use original spare parts or tyres approved by the manufacturer. Otherwise the manufacturer's specification cannot be guaranteed.

If you have any queries please contact the manufacturer's customer service department.

EFG 535-550

|

Description |

EFG 535-545 |

EFG 550 |

|

|

SE *) |

|

250 / 70 R15 |

28 x 12.5 - 15 |

|

Full rubber*) |

28 x 10 x 22 |

28 x 12 x 22 |

|

Front tyres |

Pneumatic*) |

250 / 70 R15 |

- |

|

|

Tyre pressure bar |

10 |

- |

|

|

Torque |

(Nm) |

430 |

|

|

SE *) |

|

21 x 8 - 9 |

|

|

Full rubber*) |

21 x 7 - 15 ǩ" |

||

Rear tyres |

Pneumatic*) |

250 / 70 R15 |

21 x 8 - 9 |

|

|

Tyre pressure bar |

10 |

10 |

|

|

Torque |

(Nm) |

220 |

220 |

*) The models listed in the table correspond to the standard version. Other tyres can be used depending on the truck's equipment.

3.6Engine Data

Description |

EFG535-550 |

Drive motor |

18 kW |

Lift motor |

23,5 kW |

09.12 EN

27

3.7EN norms

Noise emission level

Ð 75 dB(A)

*+/- 3 dB(A) depending on the truck's equipment

in accordance with 12053 as harmonised with ISO 4871.

Z The noise emission level is calculated in accordance with standard procedures and takes into account the noise level when travelling, lifting and when idle. The noise level is measured at the level of the driver's ear.

Vibration

Ð 0,64 m/s ²

in accordance with EN 13059.

Z The vibration acceleration acting on the body in the operating position is, in accordance with standard procedures, the linearly integrated, weighted acceleration in the vertical direction. It is calculated when travelling over thresholds at constant speed (standard truck version). These recordings were taken on a single occasion and must not be confused with the human vibrations of the "2002/ 44/EC/Vibrations" operator directive. The manufacturer offers a special service to measure these human vibrations, (see "Human vibration measurement" on page 167).

Electromagnetic compatibility (EMC)

The manufacturer confirms that the truck adheres to the limits for electromagnetic emissions and resistance as well as the static electricity discharge test in accordance with EN 12895 as well as the standardised instructions contained therein.

Z No changes to electric or electronic components or their arrangement may be made without the written agreement of the manufacturer.

WARNING!

Medical equipment can be damaged by non-ionised radiation

Electrical equipment on the truck emitting non-ionised radiation (e.g. wireless data transmission) can affect operators' medical equipment (pacemakers, hearing aids etc.) and result in malfunctions. Consult with a doctor or the medical equipment manufacturer to clarify whether it can be used near the industrial truck.

09.12 EN

28

3.8Conditions of use

Ambient temperature

– operating at -20°C to +40°C

Z Special equipment and authorisation are required if the truck is to be constantly used in conditions of extreme temperature or air humidity fluctuations.

3.9Electrical requirements

The manufacturer certifies compliance with the requirements for the design and manufacture of electrical equipment, according to EN 1175 "Industrial Truck Safety - Electrical Requirements", provided the truck is used according to its purpose.

09.12 EN

29

Loading...

Loading...