Jungheinrich EKX-513, EKX-515 User Manual

Highly flexible model with modular construction and intelligent truck Management system

80 V 3-phase AC technology giving powerful torque and high productivity

Low cost operation through two-fold energy reclamation and effective energy management

Ergonomic workplace with electrically adjustable operators console

EKX 513–515

Electric order picker / tri-lateral stacker (1250 –1500 kg)

The EKX 513 / 515 high rack stackers stand for high performance in the narrow aisle warehouse. They set new standards with regards to flexibility, low cost operation and ergonomics.

Flexibility through modular construction: this model has over 5 million possible configurations providing flexibility from the start. The advantage is adaptability to any warehousing and logistics operation. An intelligent truck management with our in house electronic controller, and CAN-Bus system keeps the options open for a wide range of

requirements with a large number of additional safety features.

Excellent performance and energy efficiency: the important factors for fast throughput and outstanding cost efficiency. This is precisely what is provided by Jungheinrich’s 3-phase AC technology with higher performance and low energy usage. The advantage: full utilisation over two shifts in normal operation without battery change.

This high efficiency is available to the EKX operator with effortless ease. The cab pro-

vides a generous workplace with excellent visibility. At the centre of the operators cab is the electronically adjustable operators cab:

■Informative colour display. Important operating data is easily and legibly laid out.

■All parameters and programmes can be set individually.

■Softkeys to control functions and menus.

■Travel and hydraulics control via thumb operation.

■Two-handed operation for high safety and operating comfort. Sensors register the operator’s touch and pass this information on to the onboard computer.

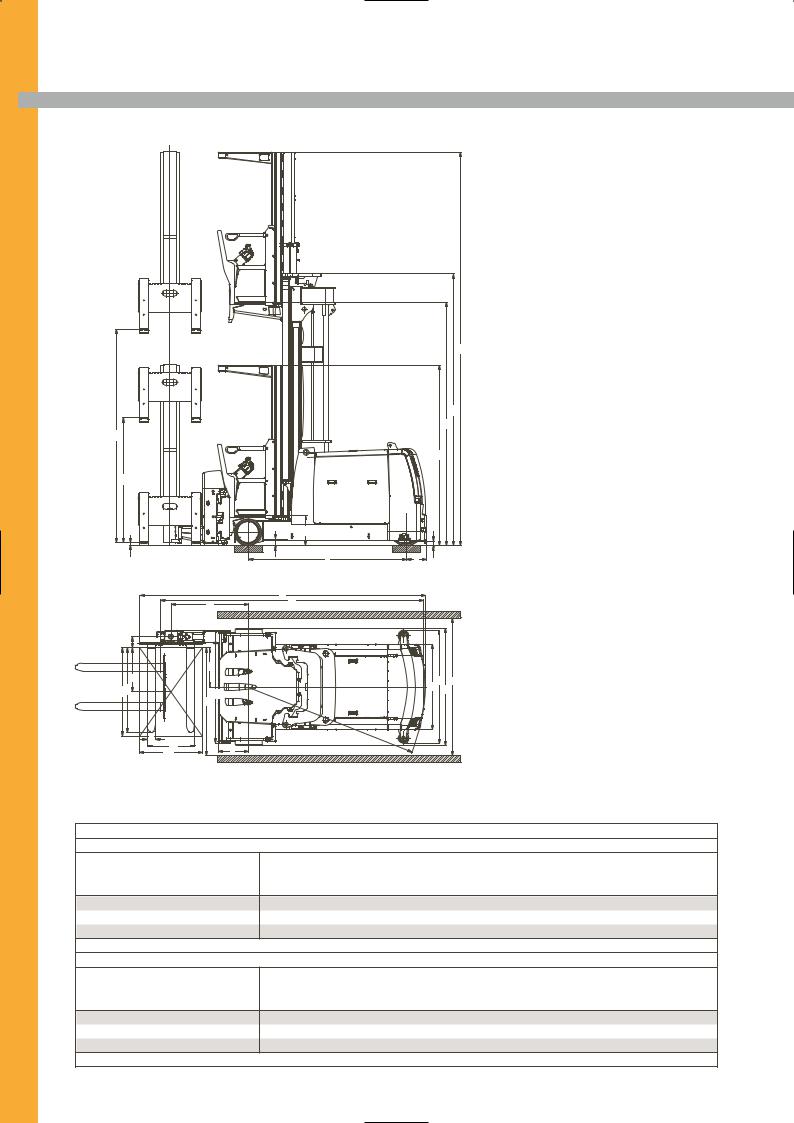

EKX 513–515

h3

h9

s |

|

|

l8 |

r |

|

|

b8 |

c |

|

l6 l |

b14 |

|

b7 |

e |

|

b5 |

x |

b12 |

Pallet size |

Stacking-in depth |

1200 x 800 |

1200 |

1200 x 1200 |

1200 |

800 x 1200 |

800 |

|

|

* The practical transfer aisle width is a reference value.

Pallet size |

Stacking-in depth |

1200 x 800 |

1200 |

1200 x 1200 |

1200 |

800 x 1200 |

800 |

|

|

h4

h1

h12

h6

|

h7 |

|

m 1 |

y |

m2 |

|

z |

|

l1 l2 |

|

|

b6 Ast b1 b2

Wa

Standard values for working aisle widths (mm)

with rail guidance

Ast |

|

Ast3 / VDI |

|

Ast3 / VDI |

Ast3 / VDI |

Ast3* |

theoretical |

|

theoretical |

|

theoretical |

theoretical |

practical |

|

|

EKX 513 |

|

EKX 515k |

EKX 515 |

|

1640 |

|

3608 |

|

3708 |

4004 |

+ 500 |

1640 |

|

3967 |

|

4067 |

4363 |

+ 500 |

1440 |

|

3971 |

|

4071 |

4367 |

+ 500 |

|

with inductive guidance |

|

|

|

||

Ast |

|

Ast3 / VDI |

|

Ast3 / VDI |

Ast3 / VDI |

Ast3* |

theoretical |

|

theoretical |

|

theoretical |

theoretical |

practical |

|

|

EKX 513 |

|

EKX 515k |

EKX 515 |

|

1720 |

|

3834 |

|

3934 |

4230 |

+ 1000 |

1720 |

|

4221 |

|

4321 |

4617 |

+ 1000 |

1490 |

|

4034 |

|

4134 |

4430 |

+ 1000 |

|

|

|

|

|

|

|

* The practical transfer aisle width is a reference value.

Loading...

Loading...