JUKI DDL-9000C-F Instruction Manual

DDL-9000C-F

INSTRUCTION MANUAL

CONTENTS

1. SPECIFICATIONS............................................................................................................ |

1 |

|

1-1. |

Specifications of the sewing machine head...................................................................... |

1 |

1-2. |

Specifications of the control box....................................................................................... |

1 |

2. SET UP............................................................................................................................. |

2 |

|

2-1. |

Drawing of table................................................................................................................... |

2 |

2-2. |

Cautions when setting up the sewing machine................................................................ |

3 |

2-2-1. How to carry the sewing machine............................................................................................. |

3 |

|

2-2-2. Caution when placing the sewing machine............................................................................. |

3 |

|

2-3. |

Installation............................................................................................................................ |

3 |

2-4. |

Installing the thread stand.................................................................................................. |

4 |

2-5. |

Installing the electrical box................................................................................................. |

5 |

2-6. |

Connecting the power switch cable................................................................................... |

5 |

2-6-1. Installing the power switch........................................................................................................ |

5 |

|

2-6-2. Connecting the power source cord.......................................................................................... |

6 |

|

2-6-3. Installing the reactor box........................................................................................................... |

7 |

|

2-7. |

Connecting the cords.......................................................................................................... |

8 |

2-8. |

Handling the cords............................................................................................................... |

9 |

2-9. Attaching the connecting rod............................................................................................. |

9 |

|

2-10. Adjustment of the pedal.................................................................................................... |

10 |

|

2-10-1. Installing the connecting rod................................................................................................ |

10 |

|

2-10-2. Adjusting the pedal angle...................................................................................................... |

10 |

|

2-11. Pedal operation.................................................................................................................. |

10 |

|

2-12. |

Lubrication.......................................................................................................................... |

11 |

2-13. |

How to use the operation panel (Basic explanation)...................................................... |

12 |

2-13-1. Selection of the language (operation to be done at first)................................................... |

12 |

|

2-13-2. Names and functions of the panel keys............................................................................... |

14 |

|

2-13-3. Basic operation....................................................................................................................... |

15 |

|

3. PREPARATION BEFORE SEWING............................................................................... |

16 |

|

3-1. Attaching the needle.......................................................................................................... |

16 |

|

3-2. |

Removing/fitting the bobbin case.................................................................................... |

16 |

3-3. |

Winding the bobbin thread................................................................................................ |

17 |

3-4. |

Threading the machine head............................................................................................ |

19 |

3-5. |

Thread tension................................................................................................................... |

20 |

3-5-1. Adjusting the thread tension No. 1 tension........................................................................... |

20 |

|

3-5-2. Adjusting the needle thread tension (Active tension)........................................................... |

20 |

|

3-5-3. Adjusting the bobbin thread tension...................................................................................... |

20 |

|

3-6. |

Presser foot (Active presser device)................................................................................ |

21 |

3-6-1. Presser foot pressure.............................................................................................................. |

21 |

|

3-6-2. Micro-lifter function.................................................................................................................. |

21 |

|

3-6-3. Changing the initial value of presser foot pressure.............................................................. |

22 |

|

3-6-4. Manual lifter.............................................................................................................................. |

22 |

|

3-7. Adjusting the stitch length................................................................................................ |

23 |

|

3-8. |

Changing the sewing speed.............................................................................................. |

23 |

3-9. |

LED hand light.................................................................................................................... |

24 |

3-10. |

Reverse feed stitching....................................................................................................... |

24 |

3-11. Custom switch.................................................................................................................... |

25 |

|

i

3-12. Adjusting the amount of oil (oil splashes) in the hook................................................... |

26 |

3-12-1. Adjusting the amount of oil in the hook............................................................................... |

26 |

3-12-2. How to confirm the amount of oil (oil splashes)................................................................. |

27 |

3-12-3. Sample showing the appropriate amount of oil.................................................................. |

27 |

3-13. Adjusting the thread take-up spring and the thread take-up stroke............................. |

28 |

4. HOW TO USE THE OPERATION PANEL...................................................................... |

29 |

4-1. Explanation of the sewing screen (when selecting a sewing pattern).......................... |

29 |

4-2. Sewing patterns................................................................................................................. |

33 |

4-2-1. Sewing pattern configuration.................................................................................................. |

33 |

4-2-2. List of sewing patterns............................................................................................................ |

34 |

4-2-3. Reverse feed stitching (at start) pattern................................................................................. |

36 |

4-2-4. Double reverse-feed stitch...................................................................................................... |

41 |

4-2-5. Editing the sewing patterns..................................................................................................... |

42 |

4-2-6. List of pattern functions.......................................................................................................... |

44 |

4-2-7. Reverse feed stitching (at end) pattern.................................................................................. |

47 |

4-2-8. Teaching function..................................................................................................................... |

48 |

4-2-9. One-touch utility changeover function................................................................................... |

50 |

4-2-10. Registration of a new sewing pattern................................................................................... |

51 |

4-2-11. Copying a pattern................................................................................................................... |

53 |

4-2-12. Narrow-down function........................................................................................................... |

54 |

4-3. Counter function................................................................................................................ |

56 |

4-3-1. Displaying the sewing screen under the counter display mode.......................................... |

56 |

4-3-2. Types of the counter................................................................................................................ |

56 |

4-3-3. How to set the counter............................................................................................................. |

57 |

4-3-4. How to reset the count-completion state............................................................................... |

60 |

4-4. Simplified chart of panel displays.................................................................................... |

61 |

4-5. List of memory switch data............................................................................................... |

62 |

4-6. List of errors....................................................................................................................... |

67 |

4-7. Memory switch data........................................................................................................... |

71 |

5. MAIN NEW FUNCTIONS................................................................................................ |

73 |

5-1. Shorter-thread remaining thread trimming...................................................................... |

73 |

5-2. Adjusting the feed dog height........................................................................................... |

76 |

5-3. Operating timing of the feed............................................................................................. |

77 |

5-4. Changing the feed locus................................................................................................... |

78 |

6. CARE.............................................................................................................................. |

79 |

6-1. Maintenance mode............................................................................................................. |

79 |

6-2. Confirmation of the amount of oil in the hook oil tank................................................... |

79 |

6-3. Cleaning.............................................................................................................................. |

80 |

6-4. Applying grease................................................................................................................. |

80 |

6-5. Applying grease to the needle bar lower bushing and the presser bar bushing......... |

81 |

6-6. Replacing the fuse............................................................................................................. |

82 |

7. ADJUSTMENT OF THE MACHINE HEAD (APPLICATION)......................................... |

83 |

7-1. Needle-to-hook relationship.............................................................................................. |

83 |

7-2. Adjusting the needle thread presser device.................................................................... |

84 |

7-3. Adjusting the thread trimmer............................................................................................ |

87 |

7-3-1. For checking of the thread trimming cam timing.................................................................. |

87 |

7-3-2. Adjustment of the thread trimming cam timing..................................................................... |

87 |

7-3-3. Checking of the knife unit........................................................................................................ |

88 |

ii

7-3-4. Adjustment of the knife unit...................................................................................... |

89 |

7-3-5. Adjustment of thread trimming speed.................................................................................... |

90 |

7-4. Adjustment of the picker................................................................................................... |

91 |

7-4-1. Checking the standard adjustment......................................................................................... |

91 |

7-4-2. Standard adjustment................................................................................................................ |

91 |

7-4-3. Standard adjustment (Adjustment at the tip position).......................................................... |

91 |

7-5. Active-presser multi-layered section detection function............................................... |

92 |

7-5-1. Multi-layered section detection function................................................................................ |

92 |

7-5-2. Multi-layered-section detection number of stitches setting function................................. |

94 |

7-6. Grease shortage alarm...................................................................................................... |

95 |

7-6-1. Regarding the grease shortage alarm.................................................................................... |

95 |

7-6-2. E221 Grease-shortage error.................................................................................................... |

95 |

7-6-3. Regarding K118 error resetting procedure............................................................................ |

96 |

8. HOW TO USE THE OPERATION PANEL (APPLICATION).......................................... |

97 |

8-1. Management of sewing patterns...................................................................................... |

97 |

8-1-1. Creation of a new pattern........................................................................................................ |

97 |

8-1-2. Copying a pattern..................................................................................................................... |

99 |

8-1-3. Deleting a pattern................................................................................................................... |

100 |

8-2. Setting up the polygonal-shape stitching...................................................................... |

101 |

8-2-1. Editing a polygonal-shape stitching pattern........................................................................ |

101 |

8-2-2. Creating a new polygonal-shape stitching pattern............................................................. |

103 |

8-2-3. Setting the step from which polygonal-shape stitching is started.................................... |

103 |

8-3. Cycle pattern.................................................................................................................... |

104 |

8-3-1. Selecting the cycle pattern.................................................................................................... |

104 |

8-3-2. Editing cycle sewing data ..................................................................................................... |

105 |

8-3-3. Creating a new cycle pattern................................................................................................. |

106 |

8-3-4. Setting the step from which cycle sewing pattern is started............................................. |

108 |

8-4. Custom pitch.................................................................................................................... |

109 |

8-4-1. Selecting a custom pitch....................................................................................................... |

109 |

8-4-2. Creating a new custom pitch................................................................................................. |

111 |

8-4-3. Custom pitch edit function.................................................................................................... |

114 |

8-4-4. Copying/deleting a custom pitch.......................................................................................... |

115 |

8-5. Condensation custom pattern........................................................................................ |

116 |

8-5-1. Selecting the condensation custom..................................................................................... |

116 |

8-5-2. Creating a new condensation custom.................................................................................. |

116 |

8-5-3. Condensation custom edit function..................................................................................... |

119 |

8-5-4. Copying/deleting a condensation custom........................................................................... |

120 |

8-6. Simple lock of the screen................................................................................................ |

121 |

8-7. Version information......................................................................................................... |

121 |

8-8. Adjustment of brightness of the LED panel.................................................................. |

122 |

8-9. Information....................................................................................................................... |

123 |

8-9-1. Data communication.............................................................................................................. |

123 |

8-9-2. USB.......................................................................................................................................... |

126 |

8-9-3. Production management....................................................................................................... |

128 |

8-9-4. NFC.......................................................................................................................................... |

131 |

8-10. Key customization......................................................................................................... |

132 |

8-10-1. Assignable data.................................................................................................................... |

132 |

8-10-2. How to assign a function to a key....................................................................................... |

133 |

iii

1. SPECIFICATIONS

1-1. Specifications of the sewing machine head

|

|

DDL-9000C-F |

- |

|

|

B |

|||||||

|

Face plate portion lubricating method |

|

|

|

|

|

|

|

|

|

|

||

|

M |

Semi-dry |

|

|

|

|

|

|

|

|

|

|

|

|

S |

Micro-quantity lubrication |

|

|

|

|

|

|

|

|

|

|

|

|

Seam specification |

|

|

|

|

|

|

|

|

|

|

||

|

S |

Medium-weight materials |

|

|

|

|

|

|

|

|

|

|

|

|

H |

Heavy-weight materials |

|

|

|

|

|

|

|

|

|

|

|

|

Needle thread nipper specification |

|

|

|

|

|

|

|

|

|

|

||

|

N |

With |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

Without |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DDL-9000C-FMS |

|

|

|

|

|

|

|

|

|

DDL-9000C-FSH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. sewing speed |

Stitch length 0 to 4.00 : 5,000 sti/min |

|

|

|

Stitch length 0 to 4.00 : 4,500 sti/min |

||||||||

(standard locus) |

Stitch length 4.05 to 5.00 : 4,000 sti/min |

|

|

Stitch length 4.05 to 5.00 : 4,000 sti/min |

|||||||||

Stitch length |

|

|

|

|

|

|

5 mm |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Presser foot pressure control |

|

|

Electronic control |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Needle *1 |

1738 Nm65 to 110 (DB×1 #9 to 18) |

|

|

1738 Nm125 to 160 (DB×1 #20 to 23) |

|||||||||

134 Nm65 to 110 (DP×5 #9 to 18) |

|

|

|

134 Nm125 to 160 (DP×5 #20 to 23) |

|||||||||

|

|

|

|

|

|||||||||

Lubricating oil |

JUKI NEW DEFRIX OIL No. 1 or JUKI CORPORATION GENUINE OIL 7 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

|

|

AC servo motor |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Horizontal feed control |

|

|

Electronic control |

||||||||||

Vertical feed control |

|

|

Electronic control |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sewing pattern |

99 patterns (For the polygonal shape sewing, as |

||||||||||

|

|

|

|

many as 10 patterns can be registered.) |

|||||||||

Number of patterns |

Cycle sewing pattern |

9 patterns |

|

|

|||||||||

|

|

Custom-pitch pattern |

20 patterns |

|

|

||||||||

|

|

Condensation custom pattern |

9 patterns |

|

|

||||||||

|

|

FMS ; |

|

|

|

|

|

|

|

|

|

|

|

|

|

- Equivalent continuous emission sound pressure level (LpA) at the workstation: |

|||||||||||

|

|

A-weighted value of 81.5 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- |

|||||||||||

Noise |

C.6.2 -ISO 11204 GR2 at 5,000 sti/min. |

|

|

||||||||||

FSH ; |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

-Equivalent continuous emission sound pressure level (LpA) at the workstation: A-weighted value of 77.5 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 GR2 at 4,500 sti/min.

•The sewing speed will vary depending on the sewing conditions. The sewing speed preset at the time of shipping is 4,000 sti/min.

*1 : Needle used depends on the destination.

1-2. Specifications of the control box

Supply |

Single phase |

3-phase |

Single phase |

Single phase |

voltage |

100 to 120V |

200 to 240V |

220 to 240V |

220 to 240V CE |

Frequency |

50Hz/60Hz |

50Hz/60Hz |

50Hz/60Hz |

50Hz/60Hz |

|

|

|

|

|

Operating |

Temperature : 0 to 35˚C |

Temperature : 0 to 35˚C |

Temperature : 0 to 35˚C |

Temperature : 0 to 35˚C |

environment |

Humidity : 90% or less |

Humidity : 90% or less |

Humidity : 90% or less |

Humidity : 90% or less |

Input |

520VA |

520VA |

520VA |

350VA |

|

|

|

|

|

– 1 –

2. SET UP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

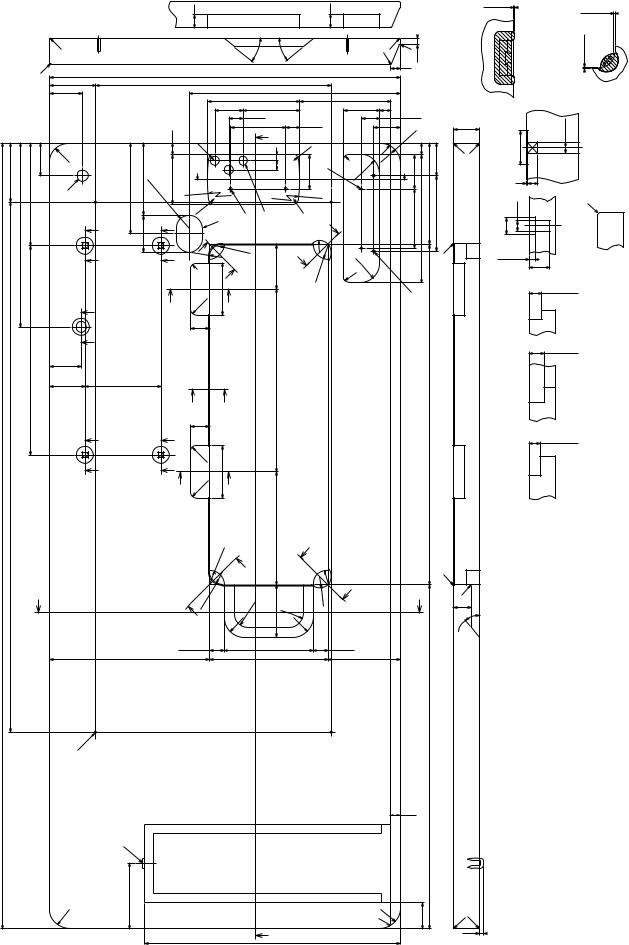

2-1. Drawing of table |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

+0.5 0 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

10 |

|

for |

|

|

-Y |

for |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-X drawing |

5.1±0 |

drawing |

|

|

|

|||||||

|

|

|

|

|

|

|

SS- |

|

20 |

|

|

|

|

|

|

|

|

+0.521 |

|

|

|

R2 |

|

|

|

cushion |

reference |

|

|

cushion |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rubber |

|

|

Rubber reference |

5.2±0.1 |

|

||||||

|

U - U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

installing X - X |

|

|

Y |

installing Y - Y 1.2±0.5 |

|

|

||

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

40° |

40° |

|

|

|

|

|

|

R2 |

|

|

X |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

535 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70 |

|

|

|

|

|

|

360 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

322 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

141 |

|

|

|

|

139 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

43 |

|

5.86 |

|

|

|

55 |

5 |

17 |

|

|

|

|

|

locations) |

|

|

8.5 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

|

|

|

|

R8 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.21 |

|

R8 |

|

|

|

|

|

R6 |

5.27 |

|

R2R2 |

V(1:1) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

84 |

5.21 |

|

|

|

40 |

R30 |

|

|

|

40 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

V |

26 |

|

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

R8 |

|

|

|

|

|

9 |

|

F |

|

|

|

|

52.5 |

|

50 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

S |

|

|

|

|

|

14 |

52 |

R27 |

|

|

|

|

|

(4 |

|

|

|

|

|

|

||||||

|

|

|

R30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

90 281 |

156.5 |

|

C |

|

138.5 |

56 110.5 |

|

|

|

|

|

E D |

|

|

|

|

|

90 |

195 |

154.6 |

115 |

|

Q-Q 26 |

16 |

|

IT-T |

|

|

||||||

|

V |

V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

75 |

|

.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

|

|

|

|

|

1 |

8 |

|

|

|

|

|

|

|

|

|

|

|

2×R20 |

R242 |

|

|

|

|

|

|

R242.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

R8 |

G |

|

|

|

R8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V |

|

|

V |

|

|

|

|

|

|

|

68.5±0.5 |

|

|

|

|

|

|

|

|

|

|

C1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

R20 |

|

|

5.R22 |

|

|

|

5 |

5 |

|

|

|

|

|

|

|

5±1.9 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R22 |

. |

R8 |

R27 |

|

|

|

|

|

|

|

|

32±1 |

|

|

|

||

|

|

|

|

|

|

|

|

|

R01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

locations)(2 |

|

|

|

|

|

|

|||

|

320 |

|

|

|

|

X |

|

R10 |

|

80 X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.5±0.19 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z-Z |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

279±1 |

|

|

|

|

|

|

|

|

|

520 |

|

|

locations)(2 |

|

|

5.5±0.23 |

|

|

|

|

|

|

48 |

|

|

|

|

|

T |

|

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

54 |

|

116 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y- |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

810 |

|

|

|

V |

|

|

V V X |

|

|

80 X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

locations)( |

|

|

|

|

|

|

||

|

|

|

V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.5±0.17 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

R10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X-X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

set-up.) |

|

|

1200 |

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

172.5 |

Y |

5 |

|

|

|

|

|

|

|

W-W |

|

set-up.) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

R22 |

. |

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R22 |

|

|

|

|

|

|

|

|

|

of |

|

|

|

of |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

|

80 |

|

|

R18 |

Y |

|

|

|

|

U |

C1 |

|

time |

|

|

|

time |

|

||

|

|

|

|

|

|

|

|

R20 |

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

R20 |

|

|

|

|

|

|

|

|

|

|

|

27 |

theatholea side)reverse |

|

|

theatholea |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

Z |

|

|

R30 |

|

|

R20 |

|

|

|

|

|

|

|

|

|

40° |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R03 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.(225) |

|

|

|

136 |

|

|

|

5.22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

(244) |

|

|

|

|

|

|

|

-1 |

|

|

|

|

110 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

0 |

181 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 525.4 |

|

|

20(Drill (on the |

|

10depth2×ø3.5, |

10(Drill |

only)side(hingeC2.5toC1.5 |

|||

|

|

|

A |

|

100 |

|

|

|

|

|

|

|

|

W |

|

|

|

|

|

|

|

|

|

|

|

surface,bottomtheon4×ø3.4depth stopperdrawerofpositionInstalling holedrilledø17 holedrilledø133× 10depth2×ø3.5, |

holeThrough surface,bottomtheon2×ø3.4depth |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

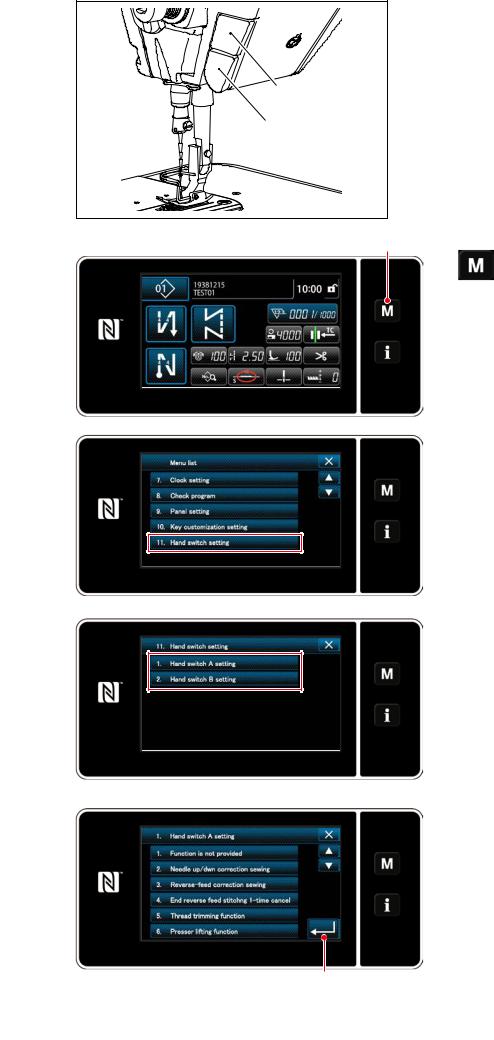

|

|

|

|

|

|

|

|

|

|

|

R30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R30 |

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R6 |

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

A B C D E F G H I |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

390 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 2 – |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

2-2. Cautions when setting up the sewing machine

Thank you very much for the purchase of JUKI Industrial Sewing Machine this time. Make sure of items 2-1 through 2-12 before operating to use this sewing machine with ease.

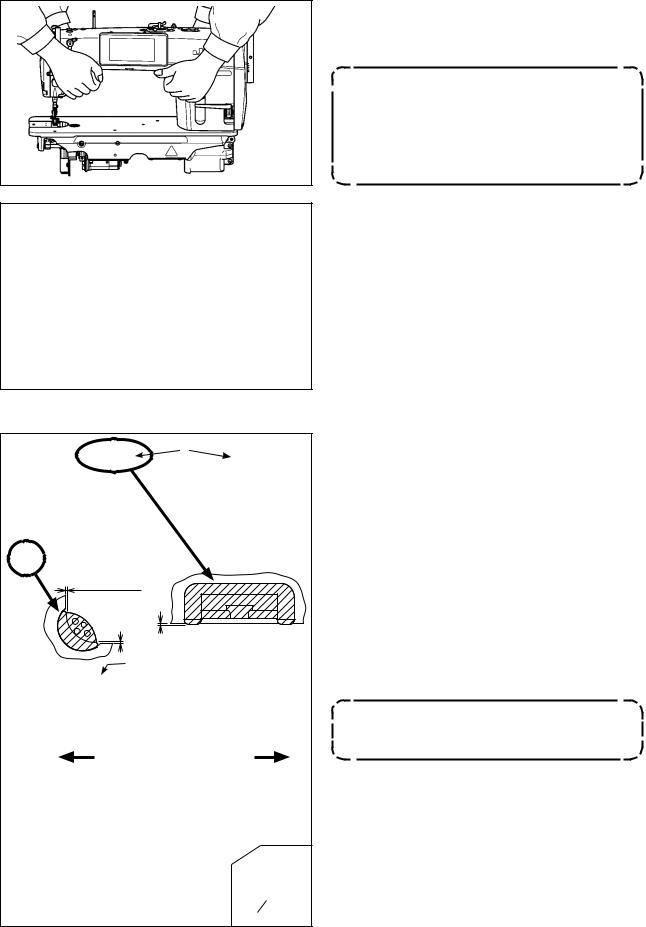

2-2-1. How to carry the sewing machine

Carry the sewing machine while holding the machine arm with two persons as shown in the figure.

1. Never hold the handwheel since it rotates.

2. Be sure to handle the sewing machine with two persons or more since the sewing machine weighs 40.5 kg or more.

2-2-2. Caution when placing the sewing machine

Place the sewing machine on a horizontal and plane place when placing it and do not place any protruding thing such as a screwdriver or the like.

2-3. Installation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.2 ± 0.5 mm |

|

|

|

1 ± 0.5 mm |

|

|

1.2 ± 0.5 mm |

|

23.5 mm |

|

19.5 mm |

|

||

|

|

|

|

|

|

|

A |

B |

|

|

|

|

|

|

|

|

|

1)The under cover should rest on the four cor-

ners of the machine table groove. Mount rubber hinge seat on the table and fix it on the table with a nail.

2)Fix two rubber seats on side A (operator’s side) using nails as illustrated above. Fix two cushion seats on side B (hinged side) using a

rubber-based adhesive. Then place under cover

on the fixed seats.

3)Fit hinge into the opening in the machine bed,

and fit the machine head to table rubber hinge seat before placing the machine head on cushions on the four corners.

Do not hold the handwheel.

– 3 –

4) Securely attach head support rod to the table until it goes no further.

Be sure to mount the machine head

support rod on the machine table so

that its height from the table surface

becomes 63 to 68 mm. For the sewing

machine provided with the AK device,

be sure to mount the support rod on

the table so that its height from the table surface becomes 33 to 38 mm.

5) Bundle cable clip band supplied as accessories

of the machine head at the root of the cable.

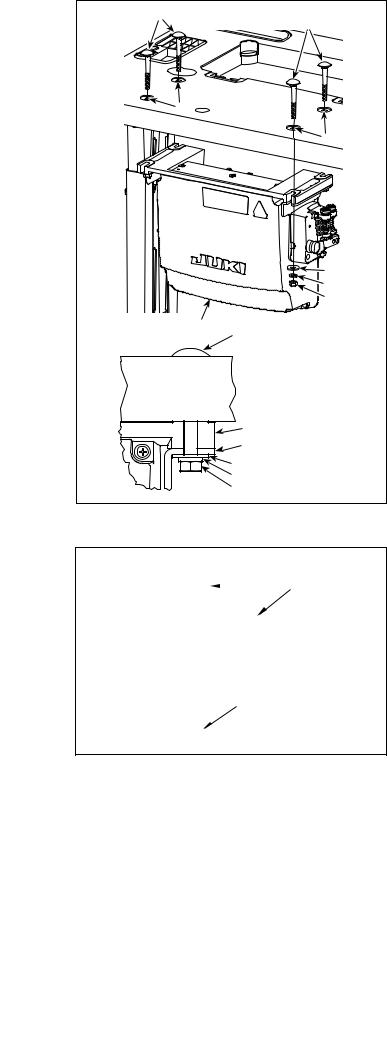

2-4. Installing the thread stand

1)Assemble the thread stand unit, and insert it in the hole in the machine table.

2)Tighten nut .

3)For ceiling wiring, pass the power cord through spool rest rod .

– 4 –

2-5. Installing the electrical box

|

|

|

|

|

|

|

a |

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frame |

|

|

Pedal sensor |

|

|

|

|

|

|

|

|

|

Install control box on the table using four holes a in the table. Secure the control box with four bolts, four plain washers , four spring washers and four hexagonal nuts supplied with the control box.

At this time, insert the nut and washer supplied with the unit as accessories as shown in the figure so that the control box is securely fixed.

2-6. Connecting the power switch cable

2-6-1. Installing the power switch

Fix power switch under the machine table with wood screws .

Fix the cable with staples supplied with the machine as accessories in accordance with the forms of use.

– 5 –

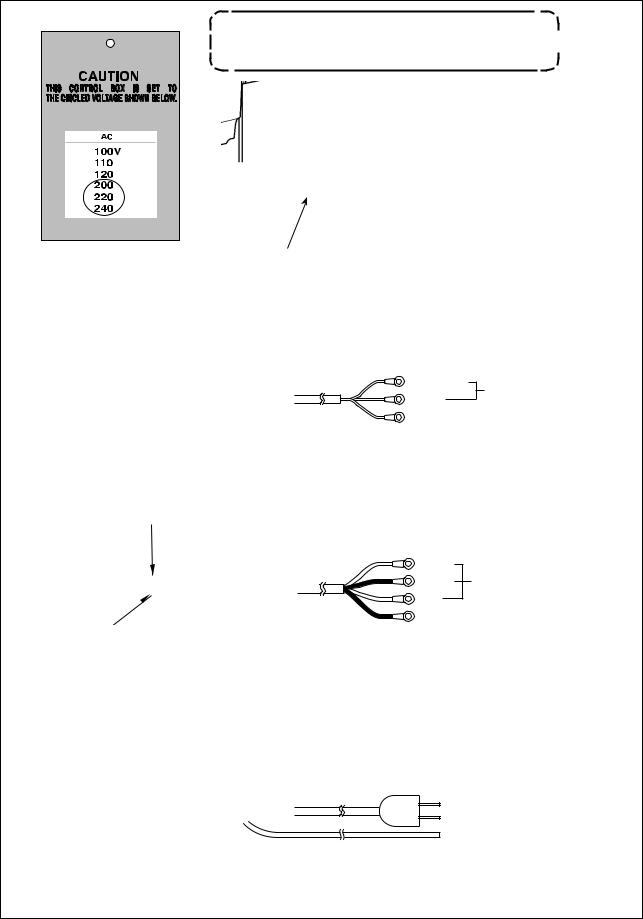

2-6-2. Connecting the power source cord

Voltage specifications at the time of delivery from the factory are indicated on the voltage indication seal. Connect the cord in accordance with the specifications.

Power indication tag

Never use under the wrong voltage and phase.

(For example : In the case of 200V) |

Rating plate |

|

• Connecting single phase 220 to 240V

Brown |

Brown |

|

|

Table |

|

|

|

Control box |

Green/Yellow |

Light blue |

AC220 to 240V |

Green/Yellow |

|

Brown |

|

|

Green/Yellow — GND |

||

|

|

||

|

Power switch |

|

|

Light blue Light blue |

|

|

|

• Connecting 3-phase 200 to 240V

|

White |

White |

|

|

Table |

|

|

|

|

|

|

Green/Yellow |

White |

|

Control box |

|

Black |

AC200 to 240V |

|

Green/Yellow |

|

|

Red |

|

Black |

Black |

|

Green/Yellow — GND |

|

Red |

|

|

||

Red |

|

|

|

|

Power switch

• Connecting single phase 100 to 120V

Brown Brown

Table

Green/Yellow

Control box

Green/Yellow

|

|

|

Light blue |

|

Power switch |

Light blue |

||

– 6 –

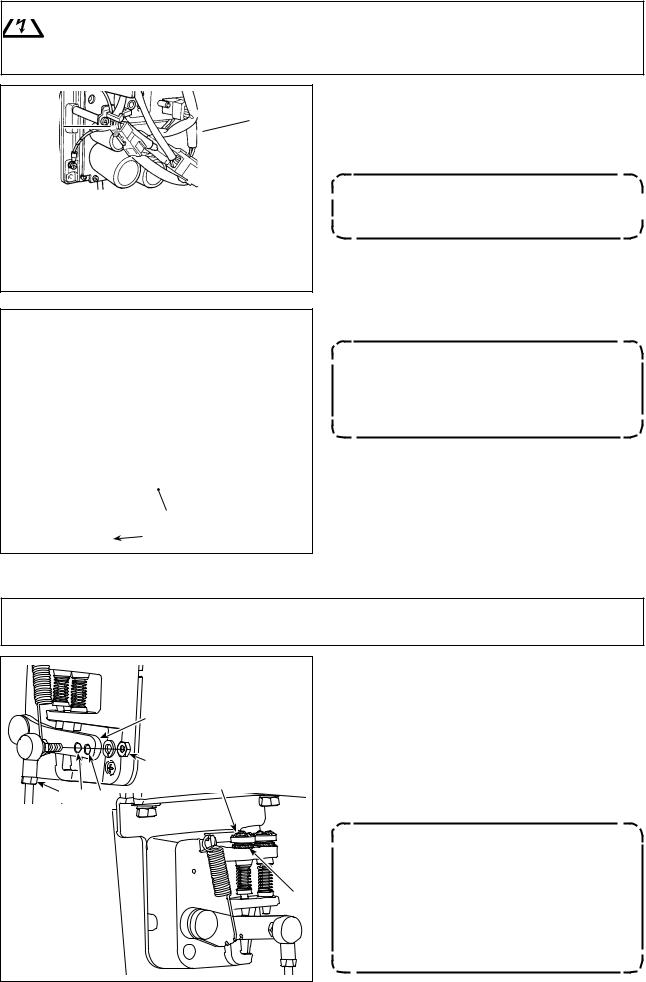

2-6-3. Installing the reactor box

* For the EU-type models, install the reactor box that is supplied with the sewing machine.

|

|

|

|

|

1) Connect the terminals of power cord of the |

|

|

SC-950(951) to reactor-box PCB asm. and |

|||

|

|

|

|||

|

|

|

|

|

to reactor box mounting plate . |

|

|

|

|

A |

Connect brown wire A to the first connector |

|

|

|

|

and blue wire B to the third connector respec- |

|

|

|

|

|

|

|

|

|

|

|

C |

tively from the top of terminal block on the |

|

|

|

|

B |

reactor box PCB asm. using screws. Connect |

|

|

|

|

|

green/yellow wire C to reactor box mounting |

|

|

|

|

|

plate with earth setscrew . |

|

|

|

|

|

2) Attach cable clip to the power cord of SC- |

|

|

|

|

|

950(951). Attach the power cord together with |

|

|

|

|

|

the cable clip to reactor box mounting plate |

|

|

|

with cable clip setscrew . |

||

|

|

|

|

||

|

|

|

|

|

3) Attach cord bushes to input/output cables |

|

|

|

|

and of the reactor box. Attach both bush- |

|

|

|

|

|

|

es in the same manner. |

|

|

|

|

|

|

|

|

|

|

4) Attach reactor box cover to reactor box |

|

|

|

|

|

|

|

|

|

|

|

|

mounting plate with four reactor-box cover |

|

|

|

|

|

setscrews . |

|

|

|

|

At this time, fix cord bushes attached to |

|

|

|

|

|

|

input/output cables and in the concave |

|

|

|

|

|

section on reactor box cover to eliminate a |

|

|

|

|

gap between reactor box and cover . |

|

|

|

|

|

||

|

|

|

|

5) Install reactor box on the table stand with |

|

|

|

|

|

|

|

|

|

|

|

|

four accessory wood screws at the position |

|

|

|

|

|

that is approximately 200 mm away from the |

|

|

|

|

|

front end of table stand. |

|

|

|

|

|

Adjust the installing position according to the |

|

|

|

|

|

size of table stand so that the reactor box does |

|

|

|

|

|

not protrude from the edge of table stand. |

|

|

|

|

|

6) Fix input/output cables and of reactor |

|

|

|

|

|

box on the table stand using accessory cord |

|

|

|

|

|

staple . |

Undersurface of table |

Operator's side |

|

At this time, take care not to cross the input- |

||

|

|

|

and output-cables. |

||

|

|

|

|

|

|

|

Power box |

|

mm |

|

|

|

|

200 |

|

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SC-950(951) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

– 7 – |

|

2-7. Connecting the cords

DANGER :

1.To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

2.To prevent accidents caused by unaccustomed work or electric shock, request the electric expert or engineer of our dealers when adjusting the electrical components.

1)Loosen four setscrews of control box cover . Remove control box cover .

2)Connect the cords to the respective connectors on CTL PWB, PWR PWB. (Fig. 1)

|

|

|

|

|

Securely fix the cords to be connected |

||

|

|

|

|

|

to CN20, CN21 and CN22 with cable |

||

|

|

|

|

|

clamp . |

|

|

|

|

|

|

|

Check the connector markers of |

||

|

|

|

|

|

CN21 and CN22 to prevent improper |

||

|

|

|

|

|

connection. |

|

|

|

|

|

3) Fix the ground wire on position A of the control |

||||

|

|

box with a screw. (Fig. 2) |

|||||

|

|

|

|

|

|

||

|

|

|

|

9P |

White |

|

|

|

|

|

CN30 |

|

|

||

|

|

|

CN32 |

40P |

Gray |

|

|

|

|

CTL PWB |

CN36 |

4P |

White |

|

|

|

|

CN37 |

4P |

White |

|

|

|

|

|

|

CN38 |

15P |

White |

|

|

|

|

|

CN63 |

2P |

Black |

|

|

|

|

|

|

|

|||

|

|

|

CN20 |

4P |

White |

|

|

|

|

PWR PWB |

CN21 |

6P |

White |

|

|

|

|

|

CN22 |

6P |

White |

|

|

|

|

|

|

|

|

|

|

|

|

CN37 |

CN30 |

CN38 |

CN63 |

||

A

Fig. 2

CN32

CN21 |

CN22 |

CN20 |

CN36 |

Fig. 1

– 8 –

2-8. Handling the cords

DANGER :

1.To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

2.To prevent accidents caused by unaccustomed work or electric shock, request the electric expert or engineer of our dealers when adjusting the electrical components.

1)Bring the cords under the table into the control box.

2) Put the cord brought into the control box through

2) Put the cord brought into the control box through

cord exit plate and fix cable clip band .

Arrange the cord so that it is not tensed or hitched even when the machine head  is tilted. (See A section.)

is tilted. (See A section.)

A

3) Install control box cover with four setscrews .

For the purpose of preventing the cord breakage, take care not to allow the cords to be caught between the control box and control box cover when attaching the latter.

2-9. Attaching the connecting rod

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the following work after turning the power off and a lapse of 5 minutes or more.

|

|

|

|

B A |

|

|

|

|

|

1)Fix connecting rod to installing hole B of pedal lever with nut .

2)Installing connecting rod to installing hole A will lengthen the pedal depressing stroke, and the pedal operation at a medium speed will be easier.

3)The pressure increases as you turn reverse depressing regulator screw in, and decreases as you turn the screw out.

1.If the screw is excessively loosened, the spring will come off. Loosen the screw to such an extent that the top of the screw can be observed from the case.

2.Whenever you have adjusted the

screw, be sure to secure the screw by tightening metal nut to prevent the screw from loosening.

– 9 –

2-10. Adjustment of the pedal

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

|

|

2-10-1. Installing the connecting rod |

|

|

|

1) |

Move pedal to the right or left as illustrated by the |

|

|

|

arrows so that motor control lever and connecting rod |

|

|

|

are straightened. |

|

|

2-10-2. Adjusting the pedal angle |

|

|

|||

|

|

1) |

The pedal tilt can be freely adjusted by changing the |

|

|

length of the connecting rod . |

|

|

|

|

|

|

|

2) |

Loosen adjust screw , and adjust the length of connect- |

|

|

|

ing rod . |

2-11. Pedal operation

A

B

C

D

E

The pedal is operated in the following four steps :

1)The machine runs at low sewing speed when you lightly depress the front part of the pedal. B

2)The machine runs at high sewing speed when you further depress the front part of the pedal. A (If the automatic reverse feed stitching has been preset, the machine runs at high speed after it completes reverse feed stitching.)

3)The machine stops (with its needle up or down) when you reset the pedal to its original position. C

4)The machine trims threads when you fully depress the back part of the pedal. E

*When the auto-lifer (AK device) is used, one more operating switch is provided between the sewing machine stop switch and thread trimming switch.

The presser foot goes up when you lightly depress the back part of the pedal D, and if you further depress the back part, the thread trimmer is actuated.

When starting sewing from the state that the presser foot has been lifted with the Auto-lifter and you depress the back part of the pedal, the presser foot only comes down.

•If you reset the pedal to its neutral position during the automatic reverse feed stitching at seam start, the machine stops after it completes the reverse feed stitching.

•The machine will perform normal thread trimming even if you depress the back part of the pedal immediately following high or low speed sewing.

•The machine will completely perform thread trimming even if you reset the pedal to its neutral position immediately after the machine started thread trimming action.

– 10 –

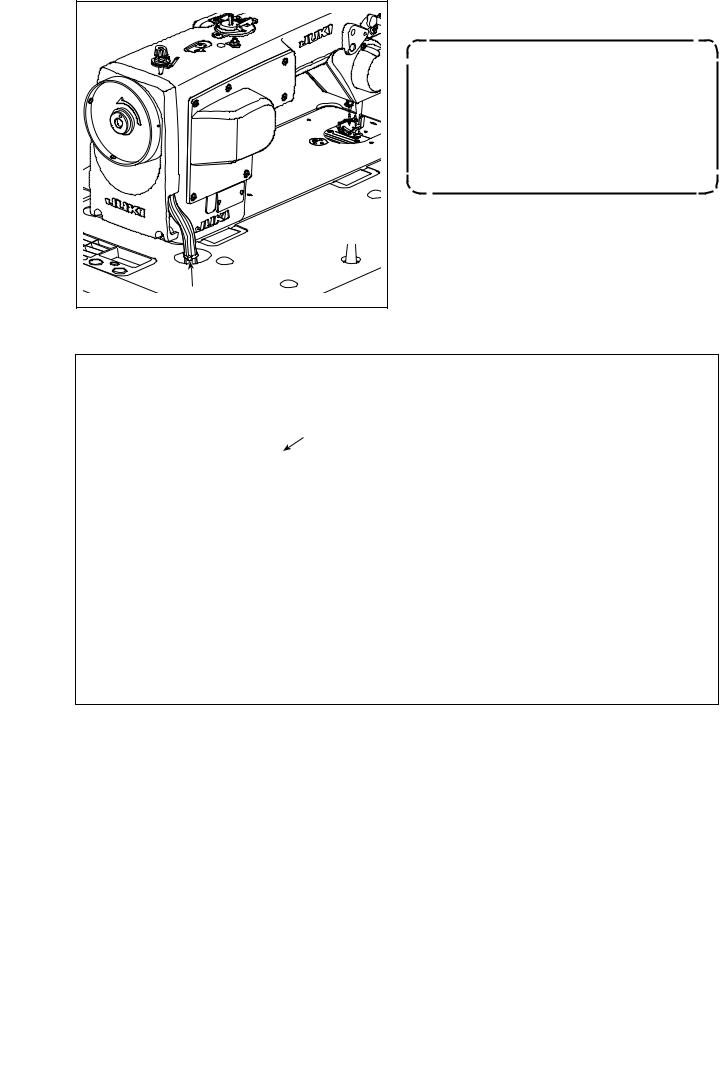

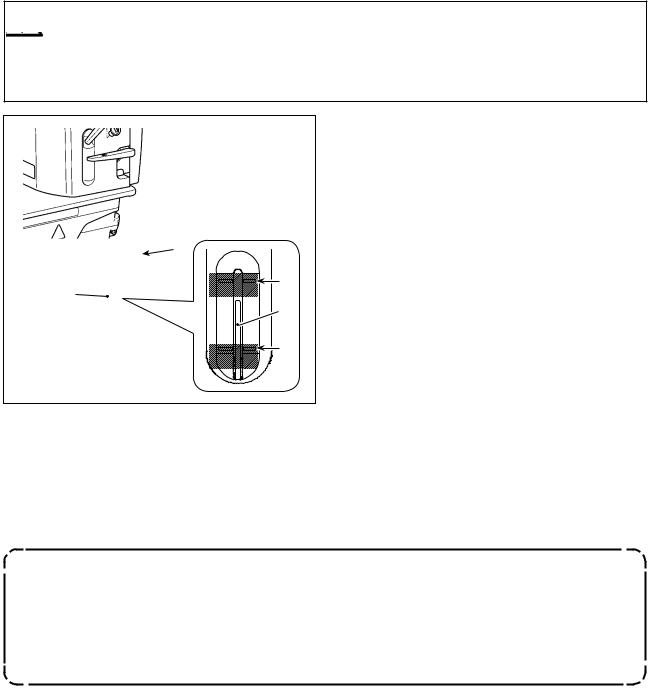

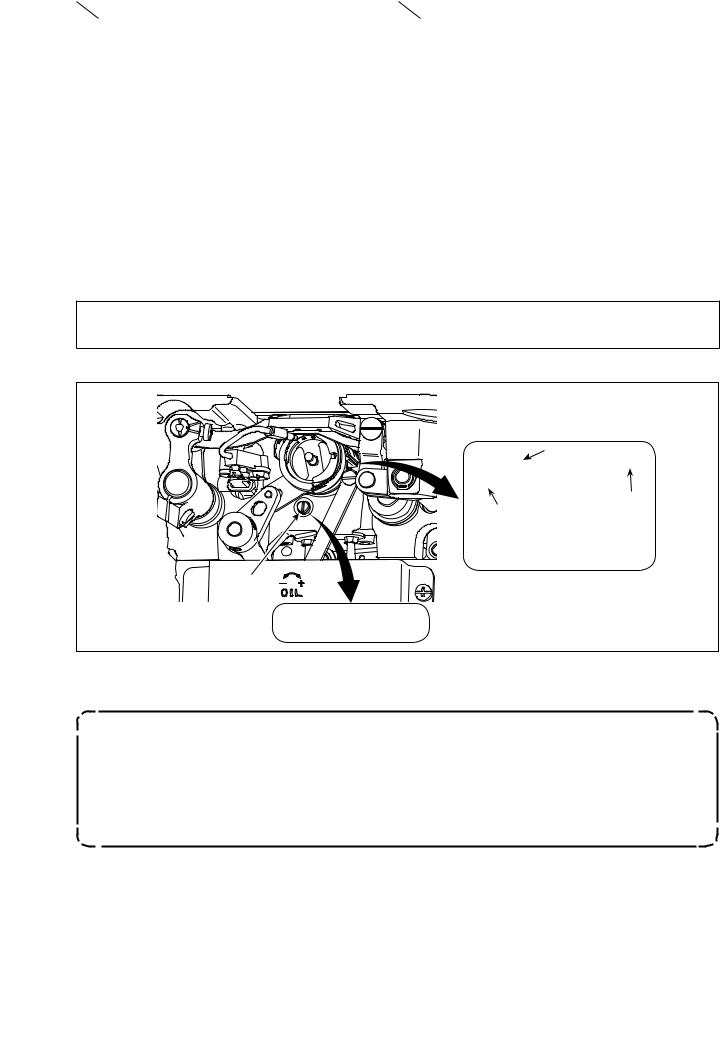

2-12. Lubrication

WARNING :

1.Do not connect the power plug until the lubrication has been completed so as to prevent accidents due to abrupt start of the sewing machine,

2.To prevent the occurrence of an inflammation or rash, immediately wash the related portions if oil adheres to your eyes or other parts of your body.

3.If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children cannot reach.

|

|

Fill the oil tank with oil for hook lubrication before |

|

|

|

operating the sewing machine. |

|

|

|

1) Remove oil hole cap and fill the oil tank with |

|

|

|

JUKI NEW DEFRIX OIL No.1 (part number : MD- |

|

|

|

FRX1600C0) or JUKI CORPORATION GENUINE |

|

|

|

OIL 7 (part number : 40102087) using the oiler |

|

|

|

supplied with the machine. |

|

|

|

2) Fill the oil tank with the oil until the top end of |

|

|

A |

oil amount indicating rod comes between the |

|

|

upper engraved marker line A and the lower |

||

|

|||

|

engraved marker line B of oil amount indicating |

||

|

|

||

|

B |

window . |

|

|

If the oil is filled excessively, it will leak from the |

||

|

|

||

|

|

air vent hole in the oil tank or proper lubrication |

|

|

|

will be not performed. In addition, when the oil is |

|

|

|

vigorously filled, it may overflow from the oil hole. |

|

|

|

So, be careful. |

|

|

|

3) When you operate the sewing machine, refill oil if |

|

|

|

the top end of oil amount indicating rod comes |

|

|

|

down to the lower engraved marker line B of oil |

|

|

|

amount indicating window . |

1.When you use a new sewing machine or a sewing machine after an extended period of disuse, use the sewing machine after performing break-in at 2,000 sti/min or less.

2.For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (part number : MDFRX1600C0) or JUKI CORPORATION GENUINE OIL 7 (part number : 40102087).

3.Be sure to lubricate clean oil.

4.Do not operate the machine with the oil hole cap removed. Never remove cap from the oil inlet in any case other than oiling. In addition, take care not to lose it.

– 11 –

2-13. How to use the operation panel (Basic explanation)

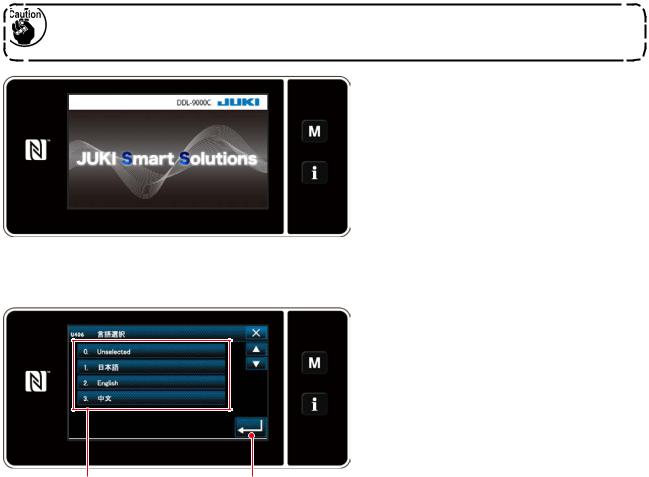

2-13-1. Selection of the language (operation to be done at first)

Select the language to be displayed on the operation panel when you turn ON the power to your sewing machine for the first time after the purchase. Note that, if you turn the power OFF without selecting the language, the language selection screen will be displayed every time you turn ON the power to the sewing machine.

Turning ON the power switch

Be aware that the needle bar moves automatically. The needle bar can also be set so that it does not move automatically. Refer to "4-5. List of memory switch data" p. 62 for details.

Firstly, the welcome screen is displayed on the panel. Then, the language selection screen is displayed.

<Welcome screen>

Selecting the language

Select the language you want to use and press corresponding language button .

Then, press  .

.

This determines the language to be displayed on the panel.

|

|

<Language selection screen>

The language to be displayed on the operation panel can be changed using the memory switch U406. Refer to "4-5. List of memory switch data" p. 62 for details.

– 12 –

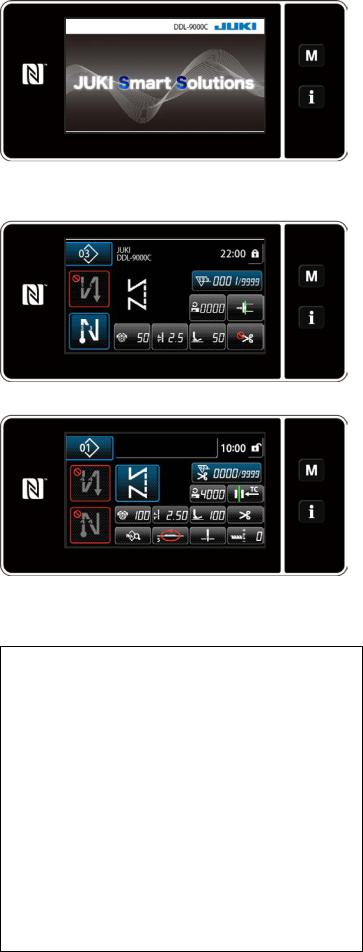

Setting the clock

1. Press  .

.

The "mode screen" is displayed. 2. Select the "7. Clock setting".

The "clock setting screen" is displayed.

<Mode screen>

<Clock setting screen>

Retrieval of the origin

<Origin retrieval screen>

3.Enter year/month/day/hour/minute/sec-

ond with  .

.

The time entered is displayed in 24-hour notation.

4.Press  to confirm the clock setting. Then, the current screen returns to the previous screen.

to confirm the clock setting. Then, the current screen returns to the previous screen.

Press to bring the origin retrieval needle bar to its upper position.

*In the case "U090 Initial operation upper position stop function" is set to "1", the screen shown on the left is not displayed, but the needle bar automatically goes up to its upper position.

– 13 –

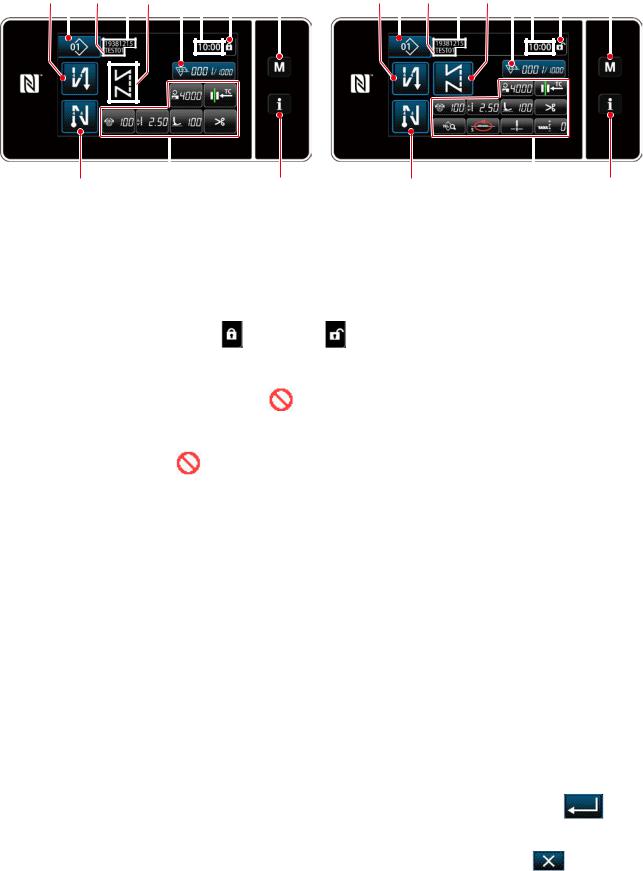

2-13-2. Names and functions of the panel keys

*Changeover between the operator mode and the maintenance personnel mode is carried out by pressing  and

and  simultaneously.

simultaneously.

|

|

<Operator mode> |

<Maintenance personnel mode> |

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

Switch/display |

|

|

|

|

|

Description |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Mode key |

|

|

|

This switch is used for displaying the menu screen. |

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

Information key |

|

|

|

This switch is used for displaying the information screen. |

|

|

|

||

|

|

|

|

|

|

|

||||

|

Sewing pattern No. button |

|

This switch is used for displaying the number of the sewing pattern. |

|

||||||

|

|

|

|

|

|

|

|

|||

|

Simplified screen lock |

|

|

|

This button is used for displaying the simplified lock status of the screen on it. |

|

||||

|

button |

|

|

|

Locked: |

Unlocked: |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

Sewing-start re- |

|

|

|

This switch is used for changing the ON/OFF status of the reverse feed stitching at the |

|||||

|

verse-feed stitch button |

|

|

|

beginning of sewing. When reverse feed stitching at the beginning of sewing is placed |

|||||

|

|

|

|

|

in the OFF state, |

|

mark is displayed at the upper left of the button. |

|

||

|

|

|

|

|

|

|

||||

|

Sewing-end re- |

|

|

|

This switch is used for changing the ON/OFF status of reverse feed stitching at the end |

|||||

|

verse-feed stitch button |

|

|

|

of sewing. When reverse feed stitching at the end of sewing is placed in the OFF state, |

|||||

|

|

|

|

|

mark is displayed at the upper left of the button. |

|

|

|

||

|

|

|

|

|

|

|

||||

|

Part number |

|

|

|

In the case the part number/process display is selected with U404, the part number is |

|||||

|

|

|

|

|

displayed. In the case the comment display is selected, the comment is displayed. |

|||||

|

|

|

|

|

|

|

||||

|

Process/comment |

|

|

|

In the case the part number/process display is selected with U404, the process is dis- |

|||||

|

|

|

|

|

played. In the case the comment display is selected, the comment is displayed. |

|

||||

|

|

|

|

|

|

|

|

|||

|

Clock display |

|

|

|

The time set on the sewing machine is displayed in this field in 24-hour system. |

|

||||

|

|

|

|

|

|

|

|

|

||

|

Sewing pattern display |

|

|

|

The selected sewing pattern is displayed in this field. |

|

|

|

||

|

|

|

|

|

|

|

||||

|

Customization button 1 |

|

|

|

A selected function can be allocated to and registered with this button. Initially, the |

|||||

|

|

|

|

|

sewing counter has been factory-allocate and -registered. |

|

|

|

||

|

|

|

|

|

|

|

||||

|

Customization buttons 2 |

|

A selected function can be allocated to and registered with this button. |

|

||||||

|

- 7 |

|

|

|

|

|

|

|

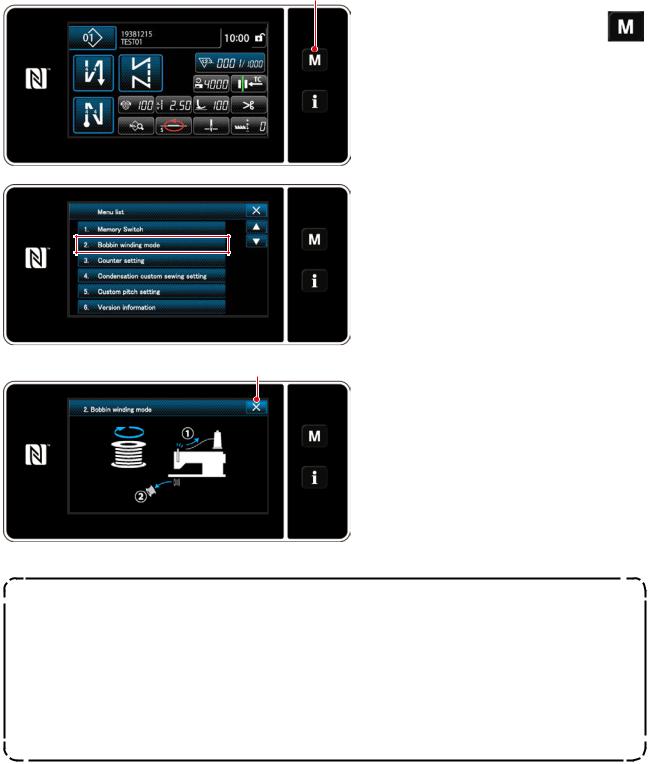

|