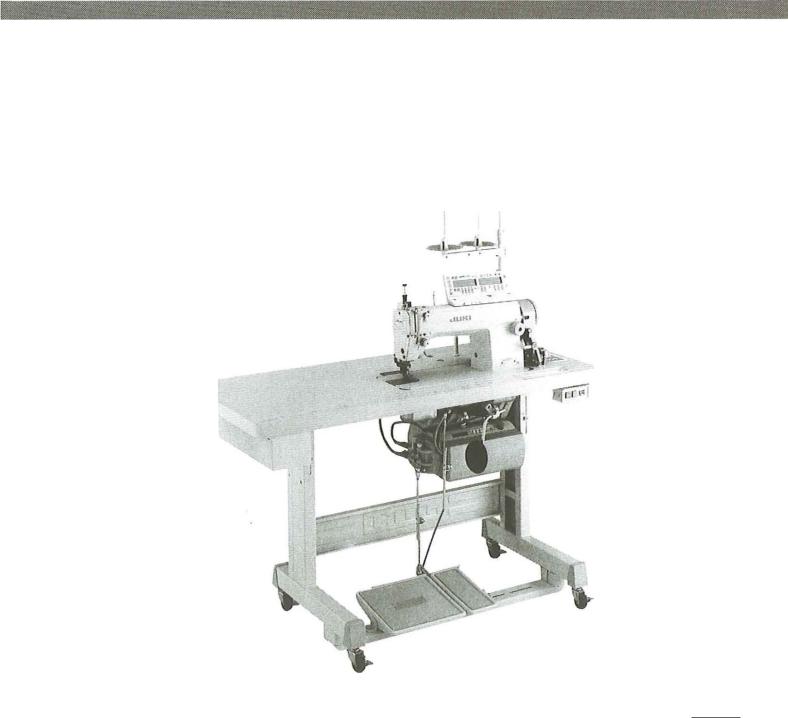

Juki DLU-5490N, DLU-5490N-7 Manual

a.lUKI®

1-NEEDLE,BOTTOM & VARIABLE TOP FEED LOCKSTITCH MACHINE

DLU-5490N

1-NEEDLE,BOTTOM & VARIABLE TOP FEED LOCKSTITCH MACHINE WITH AN AUTOMATIC THREAD TRIMMER

DLU-5490N 7

ENGINEER'S MANUAL

No. 1-45

1995.4

Preface

This Engineer's Manual mainly consists of three sections; "Standard adjustment", "How to adjust", and "Results of improper adjustment". All technical personnel who are responsible for the maintenance and repair of the DLU-5490N and DLU-5490N-7 should carefully read especially "Standard adjustment".Please read this manual carefully before using the units

in order to get the most out of them and to enjoy using them for a long time.

CAUTION

1.K~ep your hands away from the needle \'>'hen the powN switch is tumed ON or while the machine is opuatmg.

2.Do not put your lingen into the 1hnad take-up co•er v.hile the mil<:hine is operating

3.Be sure to tur~ the powtr switch OFF befora tihing the m•chine had or rema•lng the Vbelt

4.Ourin9 operation, be cardul not tO allow your or any other per!on's head or lunds to_ come close to tha handwhul, V belt, bobbin winder or mator. Al1o, do

not pl~ce anything dose to them. Doing so mly Ia dangerous. .

5.II your "'•chine is pro>ided with a belt covor, finger g\Jard or any <>Iller prot~to,, do not operate your machine with any of them removed.

BEFORE OPERATION

• Don't run the machine before filling the oil reservoir.

•After setting up your machine, make sure that it runs in the correct direction; lower the needle by turning the handwheel and watch the handwheel's revolution by momentarily switching the power "on" (correct rotational direction of the handwheel: counterclockwise when viewed from the handwheel's end).

Run the newly installed machine at a speed of 4,000 s.p.m. or lower for the one month.

Confirm the ratings of your power source by the machine plate stuck on the motor (power voltage, phase etc.)

Do not wipe the surface of the machine head with lacquer thinner.

From the Library of Superior Sewing Machine & Supply LLC

CONTENTS

1. SPECIFICATIONS ................................ |

|

|

|

|

•................. |

|

|

•...... |

|

||

2. APPLICATIONS . . . . . . . . . . . . . . . . . |

. . . |

. . . • . |

. . . . |

. . |

. . . . . . . |

. . . . |

. . . • . . . . |

. . . . . . . . |

2 |

||

3. STANDARD ADJUSTMENT . . . . . . . . . |

. . |

• . • . • • |

. . . . |

• . |

. . • . . . . |

• . . . |

. . . . . . . . . |

. . . . • . • |

3 |

||

|

( 1) |

Height of the needle bar ........ |

: ...... |

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

||||||

|

(2) |

Timing between the needle and the hook, . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

||||||||

|

(3) |

Height of the feed dog . . . . . . . . . . |

. . . |

. . . . . |

. . . . . |

. |

. . . . . . . |

. . . . . |

. . . . . • . . |

. . . . . . . |

3 |

|

(4) |

Feed .timing . . . . . . . . . . . . . . . . |

. . . |

. . . . . |

. . . . . |

. |

. . . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

3 |

|

(5) |

Tilt of the feed dog ........................... |

|

|

|

|

, ....................... , . |

5 |

|||

|

(6) |

Walking foot pressure and presser foot pressure . |

. . . . . |

. |

. . . . . . |

. . . . . . |

. . . . . . . . |

. . . . . . . |

5 |

||

|

(7) |

Relationship between the walking foot graduation plate |

. . . . • . . . . |

• . • . . |

. . . . . . . . |

. . . . . . . |

7 |

||||

|

(8) |

Top feed vertical timing ................................. |

|

|

|

|

|

·. . |

. . . . . . . . |

. . . . . . . |

7 |

|

(9) |

Top feed horizontal timing . . . . . . . |

. . . |

. . . . . |

. . . . . |

. |

. . . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

9 |

|

(10) |

Longitudinal position of the walking foot |

. . . . . |

. . . . . |

. |

. . . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

9 |

|

|

(11) |

Normal and reverse feed pitches ...... |

|

, ................. , . . . . . . . . . . . . . . . . . . . |

11 |

||||||

|

( 12) |

Position of the reverse feed solenoid ..................................... |

|

|

|

|

|

|

|

, . . . . |

11 |

|

(13) |

Position of the wiper . . . . . . . . . . . |

. . . |

. . . . . |

. . . . . |

. |

. . . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

13 |

|

(14) |

Position of the PF-6 partial shirring stopper .......... |

|

|

, ............... , .. , ...... , |

13 |

|||||

4. DISASSEMBLING AND REASSEMBLING PROCEDURES ........................... |

|

|

|

|

,,. |

15 |

|||||

|

(1) Disassembling and reassembling the face and top feed components...................... |

|

|

15 |

|||||||

|

(2} |

Disassembling and reassembling the top feed drive mechanism ......... |

|

, . . . . . . . . . . . . . . . |

19 |

||||||

5. HOW TO REMOVE PLAY........... |

. . . |

. . . . . |

. . . . . |

. |

. . . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

24 |

||

|

( 1) How to remove play from the walking foot rock shaft . . |

. |

. . . . . . |

. . . . . . |

. . . . . . . . |

. . . . . . . |

24 |

||||

|

(2) |

How to remove play from the walking foot adjusting link .................. |

|

|

, •..... |

, . . |

24 |

||||

|

(3) |

How to remove play from the reverse feed control lever . |

. |

. . . . . . |

. . . . . . |

. . . . . . . . |

. . . . . . . |

25 |

|||

|

(4) |

How to remove play from the reverse feed control lever shaft ........ |

, . . . . . . . . . . . . . . . . |

25 |

|||||||

6. HOW TO ADJUST THE TOP FEED DRIVE MECHANISM .......... |

|

|

, .... , ..... , ... , .. ,.. |

26 |

|||||||

|

(1) |

Trajectory of walking foot .....•.. |

·............ |

|

|

•............ |

|

|

, ...•. . . . |

. . . . . . . |

26 |

|

(2) |

Position of the roller . . . . . . . . . . . |

. . . |

. . . . . |

. . . . . |

. |

. . . . . . . |

• . . . . |

. . . . . . . . |

. . . . . . . |

27 |

7. REPLACING THE MOVING KNIFE ............ |

|

|

, .......................... , .... , |

28 |

|||||||

8. INSTALLING AND ADJUSTING THE PARTIAL SHIRRING DEVICE (PF·6)..... |

, . . . . . . . . . . . • |

29 |

|||||||||

|

( 1) |

Description of the PF·6partial shirring device . . |

. . . . . |

. . |

. . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

29 |

||

|

(2) |

Installing the stand other than JUKI Z·typestand |

. . . . . |

. |

. . . . . . |

. . . . • . |

. . . . . . . . |

• . • . . . . |

29 |

||

|

(3) |

PF·6pedal components ................. |

|

|

•............. |

|

|

, . . . . . . . . . . . . . . . . . . |

30 · |

||

9. TROUBLES AND CORRECTIVE MEASURES .•... |

•....... |

|

•..•............... |

|

|

:. . . . . |

31 |

||||

10. |

HOW TO USE GAUGES ......................... |

|

|

|

|

, .................... , . . . . . |

35 |

||||

11. |

PARTS LIST . . . . . . . . . . . . . . . . . . . |

. . . |

. . . . . |

. . . . . |

. . |

. . . . . . |

. . . . . |

. . . . . . . . |

. . . . . . . |

37 |

|

12. TABLE DIMENSIONS . . . . . . . . . . . . . . . |

. . . |

. . . . . . |

. . . . . . |

. . |

. . . . . . |

. . . . . . |

. . . . . . . . . |

• . . . . . . . |

38 |

||

From the Library of Superior Sewing Machine & Supply LLC

1. SPECIFICATIONS

|

|

|

|

|

|

Model |

DLU-5490N |

|

|||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

DLU-5490N-7(-7-0B, -7-WO, -7-WB) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

I |

Sewing speed |

4,000spm (normal speed), 4,500spm (max. speed) |

|

||||||||

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stitch length |

o- 5mm (0- 0.197") |

|

|||||||

|

2 |

|

|||||||||||

|

|

|

|

Needle bar stroke |

|

|

|

|

|||||

|

3 |

30.7mm (1.209") |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Top feed amout |

0- 8mm (0.315") (depends on gauges used) |

|

|||||||||

|

5 |

|

Needle (standard) |

DBX I #II |

|

||||||||

|

|

|

|||||||||||

|

|

|

|||||||||||

|

6 |

|

Presser foot pressure |

4- 5kg (at the standard height of presser spring regulator) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

Lift of walking foot |

3mm (0.118") for the standard version (BB) |

|

||||||||

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

Lift of presser foot |

|

|

|

|

||||||

|

|

|

|

|

|

||||||||

|

|

|

|

(by knee lifter) |

Standard: IOmm (0.394"), Max: 13mm (0.512"} |

|

|||||||

|

|

|

|

(by hand lifter) |

4.5- 5 .5mm (0.177"- 0.217") |

|

|||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

Gauges (Walking foot, |

DLU-491 Replacement gauges may be used. (standard: BB) |

|

||||||||

|

|

|

|

feed dog, throat plate) |

DLU-490 Replacement gauges may be used. (Some of them may not be used.) |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

Height of feed dog |

0.7- 0.8mm (0.028"- O.o31") |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

II |

Feed system |

Commonly known as "swing" system |

|

|||||||||

|

12 |

|

|

Thread take-up |

Link type |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

Thread take-up stroke |

Standard: 107mm (4.213"), Max. 112mm (4.409")- Min. 105mm (4.134") |

|

|||||||

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

Lubrication |

Fully automatic |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

Oil return system |

By plunger pump |

|

|||||||

|

16 |

|

|

Lubricating oil |

. |

|

|

|

|||||

|

|

|

New Defrix Oil No. I |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17 |

|

|

Wiper |

Provided on 5490N-7-WB |

|

|||||||

|

18 |

|

|

Automatic reverse |

Provided on 5490N-7-0B and 5490N-7WB |

|

|||||||

|

|

|

|

stitching device |

|

||||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

AC servomotor (applicable only to a version with automatic thread trimmer) |

|

||||

|

19 |

|

|

Motor |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

Motor output |

Rated output: 400W, Max. output: 550W (applicable only to a version with |

|

|||||||

|

|

|

|

|

|

|

|

|

|

automatic thread trimmer) |

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

Power supply |

3-phase or single-phase (applicable only to a version with automatic thread trimmer) |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||

|

22 |

|

|

Solenoid drive power |

DC-3!V (applicable only to a version with automatic thread trimmer) |

|

|||||||

|

|

|

|

supply |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||

|

23 |

|

|

Max. sewing speed limit |

200spmmax. sewing speed (applicable only to a version with automatic |

|

|||||||

|

|

|

|

|

|

|

|

|

|

thread trimmer) |

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

24 |

|

|

Needle up/down stop |

The machine usually stops with its needle down. By using this switch, the |

|

|||||||

|

|

|

|

switch |

machine can be stopped with its needle up. |

|

|||||||

|

25 |

|

|

Auto-lifer |

Available as an option (applicable only to a version with automatic thread |

|

|||||||

|

|

|

|

|

|

|

|

|

|

trimmer) |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From the Library of Superior-Sewing] - Machine & Supply LLC

2.APPLICATIONS

*Extensively used for light· to medium-weight general fabrics in men's suits, ladies' wear, working wear, students' uniforms, etc. The standard threads used with the models are cotton or synthetic fiber threads of #80 to #30.

Needle |

Needle system |

Thread count |

Material |

Application |

|

|||

|

|

|

|

|

|

|

|

|

|

|

# 9 |

#80 |

|

Georgette, T/C broadcloth |

Light-weight mate.rials |

|

|

|

|

|

|

|

|

|

|

|

|

|

#II |

#60 |

|

Wool, general broad cloth |

Medium-weight materials |

||

|

|

|

|

|

|

|

|

|

DBx I |

#16 |

#50 |

|

Drill, cotton gaberdine |

General fabrics |

-- |

||

#14 |

|

|

||||||

|

|

#18 |

#50-#30 |

|

Overcoating, denim |

Heavy-weight materials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From the Library of Superior -Sewing2 - Machine & Supply LLC

3. STANDARD ADJUSTMENT

STANDARD ADJUSTMENT

(1)Height of the needle bar

With the needle bar in its lowest position, align the bottom end of the bushing with the appropriate marker line on the needle bar according to the type of needle used.

~®

I ~o

€l

(For a DB needle)

Align the bottom end of needle bar bushing ~ with marker line fi.) on needle bar f) .

(For aDA needle)

Align the bottom end of needle bar bushing ~ with marker line @ on needle bar f) .

(2)Timing between the needle and the hook

When the bottom end of the lower bushing of the ascending needle bar aligns with marker line (@ or ®) on the needle bar, adjust so that hook point 0 meets the center of needle 0 . At this time, a clearance of0.04 (0.002") to O.lmm (0.004") should be provided between the needle and the hook point.

(3)Height of the feed dog

When the feed dog is in its highest position,

the top edge of the feed dog is 0.7 to 0.8mm

(0.028" to 0,031" ) above the throat plate surface.

0.7-0.8mm (0.028'"-0.031 ")

=~~

Throat plate

(4) Feed timing

Needle |

When the front 1st or 2nd tooth of the feed dog is flush with the |

||

|

|

|

throat plate surface, the upper end of the eyelet of the descending |

|

|

|

needle should be flush with the throat plate surface. |

I/777/J |

|

|

V/Z//1//, Throat plate |

Feed dog |

|

||

From the Library of Superior-Sewing3- Machine & Supply LLC

HOW TO ADJUST |

RESULTS OF IMPROPER |

|

ADJUSTMENT |

||

|

||

|

|

|

o Loosen the needle bar clamp screw to perform adjustment. |

o Changing the needle bar height |

|

|

disturbs the feed and hook timings. |

|

|

So, avoid altering the needle bar |

|

|

height unless the type of needle has |

|

|

been changed. |

0 |

Loosen the three hook setscrews to perform adjustment. |

0 |

|

If the clearance between the needle |

|||||

|

|

(A version without the automatic thread trimmer has two |

|

|

|

and hook blade point is too large, stitch |

|||

|

|

setscrews.) |

|

|

|

skipping or thread breakage may |

|||

|

|

|

|

|

|

|

|

frequently occur. |

|

|

|

|

|

|

|

o If the clearance between the needle |

|||

|

|

|

|

|

|

|

|

and hook blade point is too small, the |

|

|

|

|

|

|

|

|

|

needle may scratch the hook blade point. |

|

|

|

|

|

|

|

o If the hook timing is advanced, |

|||

|

|

|

|

|

|

|

|

tighter stitches will be produced, |

|

|

|

|

|

|

|

|

|

but stitch skipping may often |

|

|

|

|

|

|

|

|

|

occur. |

|

|

|

|

|

|

|

o A delayed hook timing is effective |

|||

|

|

|

|

|

|

|

|

for preventing balloon stitches and |

|

|

|

|

|

|

|

|

|

stitch skipping. |

|

|

|

|

|

|

|

o For a version without the auto· |

|||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

rna tic thread trimmer, use the |

|

|

|

|

|

|

|

|

|

lowest marker line to make adjust- |

|

|

|

|

|

|

|

|

|

rnent. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

Loosen screw f) , and move driving forked crank 0 to make |

|

o |

If the feed dog is too high, the |

||||

|

|

adjustment. |

|

|

|

needle may sway and possible bend |

|||

|

(The distance betwce> the top and bottom ends of a tooth of th) |

|

|

|

or break. |

||||

|

|

standard feed dog (81613-450-AOO) is about 0.8mm (0.031"). |

|

|

|

On the contrary, if the feed dog is |

|||

|

|

So, this may be used for easier adjustment. |

|

|

|

too low, insufficient feed power |

|||

|

|

|

|

|

|

|

|

may result, often causing stitch |

|

|

|

|

|

|

|

|

|

jam. |

|

|

|

|

|

|

|

|

|

Increasing the feed dog height adds |

|

|

|

|

|

|

|

|

|

to feed power, but at the same |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

time, chances of puckering may |

|

|

|

|

|

|

|

|

|

also increase. |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

Loosen the two setscrews of the feed eccentric cam. |

|

o |

If the feed dog descending timing |

||||

|

|

|

|

|

|

|

|

is advanced, chances of thread |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

splitting, balloon stitches |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

will be reducect;ho~ever, |

|

|

|

|

|

|

|

|

|

stitches will be loose. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From the Library of Superior -Sewing4- Machine & Supply LLC

STANDARD ADJUSTMENT

(5)Tilt of the feed dog

The standard tilt of the feed dog is obtained by aligning the marker dot on the feed bar shaft with point A of the feed rocker.

Front up |

Standard |

Front down |

A |

|

|

|

_,_fvvvv,__:_=·.A•,--_:_f"""""JL__i._---'i~£!.:_j..L Throat plate

1

[Note] The tilt of the feed dog of the DLU-5490N cannot be adjusted.

(6) Walking foot pressure and presser foot pressure

|

|

|

|

|

|

|

|

A |

|

B |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type of gauge |

Height of presser spring |

|

Height of adjusting |

||||||||||||||

|

|

|

|

|

|

|

regulator |

|

knob |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BA, BB, BC |

43 |

|

|

|

50 |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

L |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

M |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

N |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

p |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

s |

43 |

|

|

|

50 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Standard adjustments)

I

R

Adjusting nut

[Note I] The suitable pressures ofthewalking foot and presser foot vary, depending on the type of material. So, properly adjust the pressures for each type of material.

[Note 2] Distance B represents the height of the walldng foot adjusting screw when the walldng foot adjusting knob is depressed until its top end is engaged with the pin of the walking foot adjusting screw. If you do not have a scale etc., take the position where the white marker line on the presser spring regulating nut is aligned with the snap ring (colored in silver) as a reference for distance B. If the walking foot adjusting screw is excessively tightened, the durability ofthe

slot in the presser bar base may be impaired. So be careful.

From the Library of Superior-Sewing5- Machine & Supply LLC

HOW TO ADJUST |

RESULTS OF IMPROPER |

||

ADJUSTMENT |

|||

|

|

||

|

|

|

|

|

|

|

|

Loosen the setscrew of the feed bar shaft, and tum the feed bar |

0 Setting the feed dog with its front |

||

shaft to perform adjustment. |

up is effective for preventing |

||

|

|

puckering. Setting it with its front |

|

|

|

down reduces chances of fiber |

|

|

|

breakage when sewing knit. |

|

|

0 |

A : Turn the presser spring regulator clockwise to iilcrease the |

o The standard adjustments depend |

||

|

|

pressure, or counterclockwise to decrease it. |

|

on the type of material. |

|

|

0 |

B : Bring the presser foot down. With the presser foot sole in |

|

|

|

|

|

contact with the throat plate surface, push the walking foot |

|

The pressures of the walking foot |

|

|

|

adjusting knob down, and turn the walking foot adjusting |

|

and presser foot are closely related |

|

|

|

screw clockwise to increase the walking foot pressure, |

|

to the shirring capability of the |

|

|

|

or counterclockwise to decrease it. |

|

machine. |

|

|

|

|

|

When· the walking foot pressure is |

|

|

|

|

|

kept constant, the shirring capa- |

|

|

|

|

|

bility is enhanced as the presser |

|

|

|

|

|||

|

|

|

|

foot pressure' is-decreased. |

|

|

|

|

|

When the presser foot pressure is |

|

|

|

|

|

kept constant, the shirring capa- |

|

|

|

|

|||

|

|

|

|

bility is enhanced as the walking |

|

|

|

|

|||

|

|

|

|

foot pressure is increased. |

|

|

|

|

|

If the presser foot pressure is too |

|

|

|

|

|

low, however, the feed power will |

|

|

|

|

|

be decreased, leading to stitch jam. |

|

|

|

|

|

If the walking foot pressure is too |

|

|

|

|

|

high, the walking foot may scratch |

|

|

|

|

|

the material. |

|

|

|

|

|

|

|

|

|

|

|

As the sewing speed is increased, |

|

|

|

|

|

the feed power reduces. So, in- |

|

|

|

|

|

crease the presser foot pressure |

|

|

|

|

|

when sewing at high speed. |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

From the Library of Superior Sewing-6- Machine & Supply LLC

STANDARD ADJUSTMENT

(7)Relationship between the walking foot graduation plate and indicator

With the partial shirring stopper indicator set at "8" on the walking foot graduation plate, when the top feed adjusting knob is turned clockwise to set the indicator at the'maximum value, the top feed indicator should align with "8" on the walking foot graduation plate.

Partial shirring dial

Stopper indicator

Top feed indicator

Dial

(8) Top feed vertical timing

With. the dial set at "3" and the top feed indicator |

0 |

at "3", turn the handwheel by hand in the normal direction. The moment the presser foot sole touches the throat plate surface, the top feed dogs should start to go up.

Screw

Driving

roller

From the Library of Superior-Sewing7- Machine & Supply LLC

HOW TO ADJUST |

RESULTS OF IMPROPER |

|

ADJUSTMENT |

||

|

||

|

|

|

0 With the indicator set at the maximum value, loosen the screw, |

0 If the relationship between the |

|

at the rear of the machine arm. Move the plate to align the |

walking foot graduation plate |

|

indicator with "8" on the plate. Retighten the screw. |

and the indicator is not correct, |

|

|

it is difficult to know a proper to |

|

|

feed amount. |

o Remove the side cover from the back of the sewing machine, and |

|

o If the walking foot and feed dog |

|

loosen the screw. |

|

start to go up before the presser |

|

Tum the handwheel until the presser foot sole touches the throat |

|

foot comes in contact with the |

|

plate surface. Lightly press the driving roller of the walking foot |

|

throat plate, shirring amount will |

|

|

|||

driving arm (front) in direction A, and securely tighten the screw |

|

decrease. If they start to go up |

|

of the walking foot driving arm. |

|

after the presser foot comes in |

|

After adjustment, check the walking foot dog for proper motion. |

|

contact with the throat plate |

|

[Precaution] |

|

surface, the upper cloth will be |

|

The top feed vertical timing is factory-adjusted to the standard |

|

pushed back, resulting in decreased |

|

|

|||

timing. The timing may be somewhat disturbed when |

|

shirring amount. |

|

(I) |

the bottom feed timing has been changed, |

|

In the former case, the presser bar |

(2) |

the lift of the bottom feed dog has been changed, or |

|

may bind with consequent reduced |

|

|||

(3) |

a gauge has been changed. |

|

feed power. |

Avoid adjusting the top feed vertical timing as much as possible. |

|

|

|

|

|

|

|

From the Library of Superior Sewing-8- Machine & Supply LLC

STANDARD ADJUSTMENT

Max. lift A of each type of walking foot is as shown below. If the max. lift is significantly different from the following values, recheck the adjustment.

BABC types |

Approx. 3mm (0.118") |

|||||||

E |

|

types |

||||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

D |

|

types |

Approx. 1.6mm (0.063") |

|||||

|

|

|

|

|

|

|

|

|

J |

|

|

|

|

|

|

|

|

M |

|

types |

Approx. 2.7mm (0.106") |

|||||

p |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

s |

|

types |

Approx. 2.4mm (0.094") |

|||||

|

|

|

|

|

|

|

|

|

(9) Top feed horizontal timing

|

|

|

o With the needle bar in its highest |

|

|

|

|

||

Cam screw No.2 |

position, the cam screw No.2 |

|||

|

|

|

|

should be slightly below the main |

|

|

|

|

shaft axis. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The cam screw No.2 reaches the |

|

|

|

|

main shaft axis when the color |

|

|

|

|

boundary line of the descending |

|

|

|

|

needle bar aligns with the bottom |

|

|

|

|

end of the needle bar lower |

|

|

|

)mziiiif.:=-Aiigned |

bushing when the handwheel is |

|

|

|

turned in the nonnal direction. |

|

0

( 10) Longitudinal position of the walking foot

With the top feed amount set at the maximum (8 mm (0.315")), a clearance of Ll mm (0.043") should be provided between the front end of the slot in the walking foot mount and the roller.

Roller

Feed rocker shaft crank

(lower)

Feed rocker bar

From the Library of Superior-Sewing9- Machine & Supply LLC

HOW TO ADJUST |

RESULTS OF IMPROPER |

|

ADJUSTMENT |

||

|

||

|

|

|

|

o If the walking foot goes up too |

|

|

high, the needle bar may hit the |

|

|

walking foot when the presser foot |

|

|

rides over an overlapping section. |

|

|

Also, the path of the walking foot |

|

|

will be as shown in Fig. I, which |

|

|

means reduced walking foot feed |

|

|

power. |

|

|

If the walking foot does not go up |

|

|

high enough, its path will be as |

|

|

shown in Fig. 2. As a result, the |

|

|

walking foot may damage or push |

|

|

back the material. |

|

|

|

|

(Fig, 1) |

(Fig. 2) |

|

|

|

|

||

o Loosen the screw No.2 first, and then the screw No. l. With |

o |

If the horizontal feed timing of the |

|||

the screwdriver applied to the screw, slowly turn the hand wheel |

|

walking foot is earlier than the |

|||

with care taken not to cause the cam to move. Loosely tighten |

|

bottom feed, the walking foot pulls |

|||

the screw No.2 to adjust the top feed horizontal timing. After |

|

the upper cloth back before the |

|||

adjustment, securely tighten the screws. |

|

|

feed dog completes its feed motion, |

||

|

|

often causing scratches on the |

|||

|

|

|

|

||

|

|

|

|

material or poor shirring. On the |

|

|

|

|

|

contrary, if the timing is too late, |

|

|

|

|

|

the walking foot fails to feed the |

|

|

|

|

|

upper cloth when the feed dog |

|

|

|

|

|

feeds the material, often causing |

|

|

|

|

|

scratches on the materiaL |

|

|

|

|

|

(Fig. I) |

The horizontal feed |

|

|

|

|

|

timing of the walking foot |

|

(Fig, 1) |

(Fig, 2) |

|

|

will be delayed. |

|

|

|

|

(Fig. 2) |

The horizontal feed |

|

|

|

|

|

timing of the walking foot |

|

|

|

|

|

will be advanced. |

|

|

|

|

||

o Turn the top feed adjusting knob to set the top feed amount at |

o |

If the longitudinal position of the |

|||

the maximum ("8" on the top feed scale). Turn the handwheel |

|

walking foot is inaccurate, the top |

|||

until the horizontal feed bar reaches its front end position (shown |

|

feed components may interfere |

|||

in the direction of the arrow), then loosen the screw of the' |

|

with each other. After adjustment, |

|||

feed rocker shaft crank (lower) to release the feed rocker bar. |

|

set the top feed amount at the |

|||

Move the feed rocker bar forward or backward to adjust the |

|

maximum, and check the |

|||

clearance between the slot in the walking foot mount and the |

|

components for any contact |

|||

roller to 1.1 mm (0.043"). |

|

|

between them. |

||

After adjustment, tighten the screw. |

|

|

|

|

|

From the Library of Superior -Sewing10- Machine & Supply LLC

Loading...

Loading...