JUKI DDL-9000B, SC-920 Instruction Manual

DDL-9000B Series

INSTRUCTION MANUAL

CONTENTS

SPECIFICATIONS................................................ |

1 |

|

1. |

INSTALLATION............................................. |

2 |

2. |

ADJUSTING THE HEIGHT OF THE KNEE |

|

|

LIFTER.......................................................... |

4 |

3. |

INSTALLING THE THREAD STAND............ |

4 |

4. |

LUBRICATION (DDL-9000B-S , -M )......... |

5 |

5. |

ATTACHING THE NEEDLE.......................... |

6 |

6. |

SETTING THE BOBBIN INTO THE BOB- |

|

|

BIN CASE......................................................... |

6 |

7.ADJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK

(DDL-9000B-S , -M ).................................. |

7 |

(1) How to confirm the amount of oil (oil splash- |

|

es).................................................................... |

7 |

(2)Sample showing the appropriate amount of oil.7

8.ADJUSTING THE AMOUNT OF OIL IN

|

THE HOOK (DDL-9000B-S , -M ).............. |

8 |

9. |

THREADING THE MACHINE HEAD............ |

9 |

10. |

THREAD TENSION....................................... |

9 |

|

(1) Adjusting the needle thread tension................. |

9 |

|

(2) Adjusting the bobbin thread tension ................ |

9 |

11. |

WINDING THE BOBBIN THREAD............. |

10 |

12. |

PRESSER FOOT PRESSURE.................... |

11 |

13. |

ADJUSTING THE STITCH LENGTH.......... |

11 |

14.ADJUSTING THE THREAD TAKE-UP SPRING AND THE THREAD TAKE-UP

STROKE........................................................... |

12 |

15. ADJUSTING THE NEEDLE STOP POSI- |

|

TION............................................................ |

13 |

(1) Stop position after thread trimming................ |

13 |

(2) Adjusting procedure of the needle up/down |

|

stop position................................................... |

13 |

16. PEDAL PRESSURE AND PEDAL |

|

|

STROKE...................................................... |

14 |

|

(1) |

Adjusting the pressure required to depress |

|

|

the front part of the pedal............................... |

14 |

(2) |

Adjusting the pressure required to depress |

|

|

the back part of the pedal .............................. |

14 |

(3) |

Adjusting the pedal stroke ............................. |

14 |

17. |

ADJUSTMENT OF THE PEDAL................. |

14 |

|

|

(1) |

Installing the connecting rod.......................... |

14 |

|

(2) |

Adjusting the pedal angle............................... |

14 |

18. |

PEDAL OPERATION................................... |

15 |

|

19. |

NEEDLE-TO-HOOK RELATIONSHIP......... |

16 |

|

20. |

ONE-TOUCH TYPE REVERSE FEED |

|

|

|

STITCHING MECHANISM.......................... |

17 |

|

21. |

ADJUSTING THE POSITION OF THE |

|

|

|

WIPER (DDL-9000B- -WB, -0B) ........... |

18 |

|

22. |

COUNTER KNIFE....................................... |

19 |

|

23. |

HEIGHT AND TILT OF THE FEED DOG.... |

20 |

|

|

(1) |

Standard value of the height of the feed dog. 20 |

|

|

(2) Adjusting the height and tilt of the feed dog... |

20 |

|

24. |

ADJUSTING THE FEED TIMING................ |

21 |

|

25. |

THREAD TENSION RELEASE RELEAS- |

|

|

|

ING MECHANISM....................................... |

21 |

|

26. |

MICRO-LIFTING MECHANISM OF THE |

|

|

|

PRESSER FOOT......................................... |

22 |

|

27. |

SEWING CONDENSED STITCHES........... |

23 |

|

28. |

FEED CONVERSION SPRING MECHA- |

|

|

|

NISM (DDL-9000B-S , -M )...................... |

23 |

|

29. |

CARE........................................................... |

24 |

|

|

(1) |

Confirmation of the amount of oil in the hook |

|

|

|

oil tank............................................................ |

24 |

|

(2) |

Cleaning ........................................................ |

24 |

30. |

APPLYING GREASE................................... |

25 |

|

|

(1) |

Sections to which grease is to be replen- |

|

|

|

ished............................................................... |

25 |

|

(2) |

Releasing procedure of the grease-up warn- |

|

|

|

ing for SC-920................................................ |

26 |

i

|

|

|

|

|

|

DDL-9000B- |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

S : |

Medium-weight materials |

|

|||||

|

S : |

Micro-quantity lubrication |

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

H : |

Heavy-weight materials |

|

|||||||||

|

M : |

Semi-dry |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A : |

Light weight materials |

|

||||

|

D : |

Dry |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

-SS |

|

|

-MS |

|

-DS |

|

|

|

|

|

-SH |

|

-MA*3 |

||

Max. sewing |

|

5,000sti/min |

|

4,000 sti/min |

|

|

|

4,500 sti/min |

5,000 sti/min |

||||||||||

speed |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Thread trimming |

|

|

|

|

|

|

500 sti/min (100 to 500 sti/min) |

|

|

|

|||||||||

speed |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Stitch length |

|

|

|

|

|

|

5 mm *1 |

|

|

|

|

|

|

|

4mm |

||||

Presser foot lift |

|

|

|

|

|

|

10 mm (standard) 15 mm (max.) |

|

|

|

|||||||||

(by knee lifter) |

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1738 Nm65 to 110 |

|

1738 Nm125 to 160 |

1738 SAN10 Nm60 to 75 |

|||||||||||

Needle *2 |

|

|

|

(DB×1 #9 to 18) |

|

|

|

|

(DB×1 #20 to 23) |

(DB×1 SF#8 to 11) |

|||||||||

|

|

134 Nm65 to 110 |

|

|

134 Nm125 to 160 |

134 Nm60 to 75 |

|||||||||||||

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

(DP×5 #9 to 18) |

|

|

|

|

(DP×5 #20 to 23) |

(DP×5 #8 to 11) |

|||||||

Lubricating oil |

|

JUKI NEW DEFRIX OIL No. 1 |

|

- |

|

|

|

|

|

|

JUKI NEW DEFRIX OIL No. 1 |

||||||||

|

or JUKI MACHINE OIL #7 |

|

|

|

|

|

|

|

|

or JUKI MACHINE OIL #7 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

SS, MS, MA ; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

'- Equivalent continuous emission sound pressure level (LpA) at the workstation: |

|||||||||||||||

|

|

|

|

A-weighted value of 77 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 |

|||||||||||||||

|

|

|

|

GR2 at 4,000 sti/min. |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

SH ; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

|

|

'- Equivalent continuous emission sound pressure level (LpA) at the workstation: |

||||||||||||||||

|

|

A-weighted value of 77 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 |

|||||||||||||||||

|

|

|

|

||||||||||||||||

|

|

|

|

GR2 at 4,000 sti/min. |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

DS ; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

'- Equivalent continuous emission sound pressure level (LpA) at the workstation: |

|||||||||||||||

|

|

|

|

A-weighted value of 79 dBA ; (Includes KpA = 2.5 dBA) ; according to ISO 10821- C.6.2 -ISO 11204 |

|||||||||||||||

|

|

|

|

GR2 at 4,000 sti/min. |

|

|

|

|

|

|

|

|

|

|

|

||||

•The sewing speed will vary depending on the sewing conditions. The sewing speed preset at the time of shipping is 4,000sti/ min. The thread trimming speed can be changed within the range of ( ). The thread trimming speed preset at the time of shipping is 420 sti/min.

*1 |

: |

When stitch length exceeds 4 mm or more, set the max. sewing speed to 4,000 sti/min or less for use. |

*2 |

: |

Needle used depends on the destination. |

*3 |

: |

MA type is for light-weight materials. In the case the sewing machine is used with its speed of stitch set at 4,000 sti/min or |

|

|

higher, the presser regulating spring and thread tension spring should be changed with S type ones. |

– 1 –

1. INSTALLATION

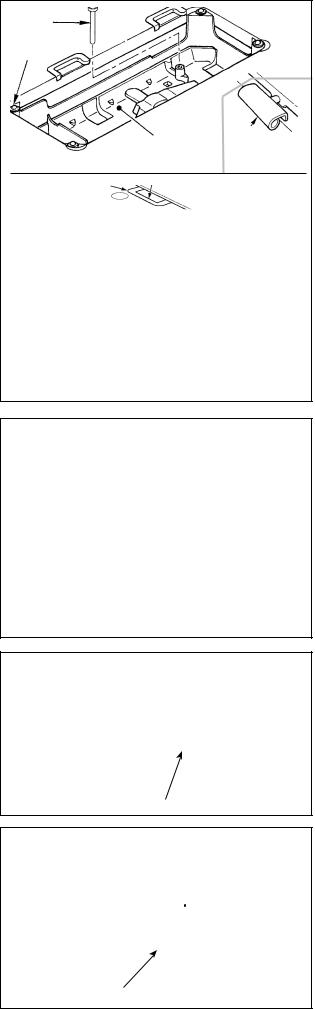

1)Carry the sewing machine with two persons as shown in the figure above.

(Caution) Do not hold the handwheel.

2)Do not put protruding articles such as the screwdriver and the like at the location where the sewing machine is placed.

|

|

|

|

|

|

|

23.5 mm |

19.5 mm |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

A |

B |

|

|

|

|

|

3)The under cover should rest on the four corners

of the machine table groove. Mount rubber hinge seat on the table and fix it on the table with a nail.

4)Fix two rubber seats on side A (operator’s side) using nails as illustrated above. Fix two cushion seats on side B (hinged side) using a

rubber-based adhesive. Then place under coveron the fixed seats.

5)Remove air vent cap attached to the machine bed.

(Caution)

1.If the sewing machine is operated without removing air vent cap , oil leakage from gear box portion C may occur.

2.Be sure to attach cap when transporting the machine head in the state that the machine head is removed from the machine table.

– 2 –

6)Fit knee lifter pressing rod . Fit hinge into the

opening in the machine bed, and fit the machine head to table rubber hinge before placing the machine head on cushions on the four corners.

7)Securely attach head support rod to the table

until it goes no further. Regarding the control panel , remove two side plate fixing screws , place the rubber packing , which is one of the accessories of the control panel , between the head section and control panel , then fix them together.

(Caution)

1.Do not use the screws supplied as accessories of control panel .

2.Be sure to mount the machine head support rod on the machine table so that its height from the table surface becomes 55 to 60 mm.

For the sewing machine provided with theAK device, be sure to mount the support rod on the table so that its height from the table surface becomes 38 to 43 mm.

8)Bundle cable clip band supplied as accessories of the machine head at the root of the cable.

2.0 to 3.5 mm

9)Check to be sure that the table and the safety switch arm are engaged with each other by 2.0 mm to 3.5 mm, with the sewing machine slightly tilted.

(Caution) If the engagement between the table and the safety switch arm is 2 mm or less, Error 302 may occur at the time of startup. Or, if the aforementioned engagement is 3.5 mm or more, safety switch arm may break.

10)If the engagement between the table and safety switch arm is outside the range of 2.0 mm and 3.5 mm, loosen safety switch mounting screw and tiltsafety switch in thedirection ofthe arrow to adjust the engagement of safety switch arm with the table.

– 3 –

2. ADJUSTING THE HEIGHT OF THE KNEE LIFTER

WARNING :

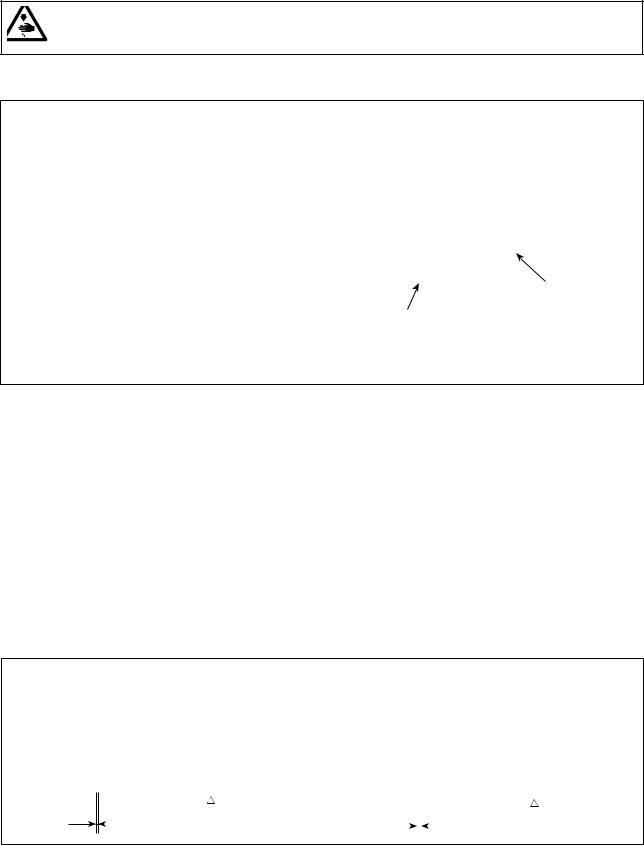

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

|

|

|

|

|

The standard height of the presser foot lifted using the |

|

|

|

|

|

|

|

|

|

|

|

knee lifter is 10 mm. |

|

|

|

|

|

You can adjust the presser foot lift up to 15 mm using |

|

|

|

|

|

knee lifter adjust screw . |

|

|

|

|

|

(Caution) |

|

|

|

|

|

1.Do not operate the sewing machine in the |

|

|

|

|

|

state that the presser foot is lifted by 10 |

|

|

|

|

|

mm or more since the needle bar comes |

|

|

|

|

in contact with the presser foot . |

|

|

|

|

|

|

|

|

|

|

|

|

2. Knee lifter initial position |

|

|

|

|

|

|

|

|

|

|

|

If the adjustment screw is over tightened, |

|

|

|

|

the sewing machine will operate in a state |

|

|

|

|

where the presser foot is lifted up, causing |

||

|

|

|

|

|

|

|

|

|

|

|

defective sewing or noise. |

|

|

|

|

|

|

3. INSTALLING THE THREAD STAND

1)Assemble the thread stand unit, and insert it in the hole in the machine table.

2)Tighten nut .

3)For ceiling wiring, pass the power cord through spool rest rod .

– 4 –

4. LUBRICATION (DDL-9000B-S , -M

, -M )

)

WARNING :

1.Do not connect the power plug until the lubrication has been completed so as to prevent accidents due to abrupt start of the sewing machine,

2.To prevent the occurrence of an inflammation or rash, immediately wash the related portions if oil adheres to your eyes or other parts of your body.

3.If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children cannot reach.

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

Upper |

||

|

|

|

|

|

|

|

engraved |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

marker line |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Upper |

|

|

|||

|

|

|

engraved |

|

|

|

||

|

|

|

marker line |

|

|

|

||

|

|

|

|

|

|

|

|

|

Fill the oil tank with oil for hook lubrication before operating the sewing machine.

1)Remove oil hole cap and fill the oil tank with JUKI NEW DEFRIX OIL No.1 (Part No. : MDFRX1600C0) or JUKI MACHINE OIL#7 (Part No. : MML007600CA) using the oiler supplied with the machine.

2)Fill the oil tank with the oil until the top end of oil amountindicatingrod comesbetweentheupper

engraved marker line A and the lower engraved marker B line of oil amount indicating window . If the oil is filled excessively, it will leak from the air vent hole in the oil tank or proper lubrication will be not performed. In addition, when the oil is vigorously filled, it may overflow from the oil hole. So, be careful.

3)When you operate the sewing machine, refill oil if the top end of oil amount indicating rod comes down to the lower engraved marker line of oil amount indicating window .

(Caution)

1.When you use a new sewing machine or a sewing machine after an extended period of disuse, use the sewing machine after performing break-in at 2,000 sti/min or less.

2.For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MDFRX1600C0) or JUKI MACHINE OIL #7 (Part No. : MML007600CA).

3.Be sure to lubricate clean oil.

4.Do not operate the machine with the oil hole cap removed. Never remove cap from the oil inlet in any case other than oiling. In addition, take care not to lose it.

– 5 –

5. ATTACHING THE NEEDLE

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the sewing machine.

|

|

|

Use the specified needle for the machine. Use the |

|

|

|

|

||

|

D |

B |

proper needle in accordance with the thickness of |

|

|

thread used and the kinds of the materials. |

|||

|

|

|

||

|

|

|

1) |

Turn the handwheel until the needle bar reaches |

|

C |

A |

|

the highest point of its stroke. |

|

|

2) |

Loosen screw , and hold needle with its |

|

|

|

|||

|

|

|

|

indented part A facing exactly to the right in di- |

|

|

|

rection B. |

|

|

|

|

|

|

|

|

|

3) |

Insert the needle fully into the hole in the needle |

|

|

|

|

bar in the direction of the arrow until the end of |

|

|

|

|

hole is reached. |

4)Securely tighten screw .

5)Check that long groove C of the needle is facing exactly to the left in direction D.

(Caution) When polyester filament thread is used, if the indented part of the needle is tilted toward operator's side, the loop of thread becomes unstable. As a result, hangnail of thread or thread breakage may occur. For the thread that such phenomenon is likely to occur, it is effective to attach the needle with its indented part slightly slanting on the rear side.

6. SETTING THE BOBBIN INTO THE BOBBIN CASE

|

|

1) |

Install the bobbin in the bobbin case so that the |

|

A |

||

|

|

thread wound direction is clockwise. |

|

|

|

2) |

Pass the thread through thread slit A, and pull |

|

|

|

the thread in direction C. By so doing, the thread |

|

|

|

will pass under the tension spring and come out |

|

|

|

from notch B. |

B |

|

3) |

Check that the bobbin rotates in the direction of |

|

|

|

the arrow when thread is pulled. |

|

C |

|

|

|

|

|

|

– 6 –

7.ADJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK (DDL-9000B-S , -M

, -M )

)

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked by turning the hook at a high speed.

(1)How to confirm the amount of oil (oil splashes)

Amount of oil (oil splashes) confirmation paper Position to confirm the amount of oil (oil splashes)

Approx. 25 mm

Approx. 70 mm

* Use any paper available regardless of the material.

Hook |

Hook driving shaft front bushing |

10mm-3 |

Bed |

|

|

|

Closely fit the |

|

paper against the |

|

wall surface of |

|

the bed. |

Oil splashes confirmation paper |

|

*Place the amount of oil (oil splashes) confirmation paper under the hook and keep it from the hook by 3 to 10 mm to confirm

the amount.

*When carrying out the procedure described below in 2), confirm the state that the needle thread from the thread take-up lever to the needle and the bobbin thread are removed, the presser foot is lifted and the slide plate is removed. At this time, take extreme caution not to allow your fingers to come in contact with the hook.

1)If the machine has not been sufficiently warmed up for operation, make the machine run idle for approximately three minutes. (Moderate intermittent operation)

2)Place the amount of oil (oil splashes) confirmation paper under the hook while the sewing machine is in operation.

3)Confirm that oil exists in the oil tank.

4)Confirmation of the amount of oil should be completed in five seconds. (Check the period of time with a watch.)

(2)Sample showing the appropriate amount of oil

Appropriate amount of oil (small) |

Appropriate amount of oil (large) |

Splashes of oil from the hook |

Splashes of oil from the hook |

• DDL-9000B-SS, -M : 0.5 to 1 mm |

|

|

• DDL-9000B-SS, -M : 1 to 1.5 mm |

|||

• DDL-9000B-SH : 1 to 3 mm |

|

|

• DDL-9000B-SH : 2 to 4 mm |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1)The state given in the figure above shows the appropriate amount of oil (oil splashes). It is necessary to finely adjust the amount of oil in accordance with the sewing processes. However, do not excessively increase/decrease the amount of oil in the hook. (If the amount of oil is too small, the hook will be seized (the hook will be hot). If the amount of oil is too much, the sewing product may be stained with oil.)

2)Check the oil amount (oil splashes) three times (on the three sheets of paper), and adjust so that it should not change.

–7 –

Loading...

Loading...