Page 1

Operation and Safety Manual

®

Original Instructions - Keep this manual with the machine at all times.

TOUCAN 10E

TOUCAN 26E

AS

English - Operation and Safety Manual

31210088

May 11, 2010

Page 2

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

31210088 – JLG Lift – a

Page 4

FOREWORD

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

DECAL WILL HAVE AN ORANGE BACKGROUND.

RESULT IN SERIOUS INJURY OR DEATH. THIS

INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE A

YELLOW BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES

DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

b – JLG Lift – 31210088

Page 5

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED

JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETYRELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS

PRODUCT.

For:

• Accident Reporting

• Product Safety Publications

• Current Owner Updates

• Questions Regarding

Product Safety

FOREWORD

• Standards and Regulations

Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding Product Modifications

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE

OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,

INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE

UPDATED AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN

ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR

WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT.

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office

(See addresses on inside of manual cover)

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

31210088 – JLG Lift – c

Phone: 240-420-2661

Fax: 301-745-3713

E-mail: ProductSafety@JLG.com

Page 6

FOREWORD

Original Issue - July 10, 2008

Manual Revised - June 22, 2009

Manual Revised - May 11, 2010

REVISION LOG

d – JLG Lift – 31210088

Page 7

TABLE OF CONTENTS

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Operator Training and Knowledge . . . . . . . . . . 1-1

Workplace Inspection . . . . . . . . . . . . . . . . . . . . 1-2

Machine Inspection. . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trip and Fall Hazards . . . . . . . . . . . . . . . . . . . . 1-4

Electrocution Hazards. . . . . . . . . . . . . . . . . . . . 1-5

Tipping Hazards . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Crushing and Collision Hazards . . . . . . . . . . . . 1-8

1.4 TOWING, LIFTING, AND HAULING . . . . . . . . . . . 1-8

1.5 ADDITIONAL HAZARDS / SAFETY. . . . . . . . . . . . 1-9

SECTION - 2 - USER RESPONSIBILITIES, MACHINE

PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING. . . . . . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . 2-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Function Check. . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Tilt Sensor Check . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-2

Overload Sensor Check (If Equipped) . . . . . . 2-9

Slack/Broken Chain Sensors Check . . . . . . . 2-10

SECTION - 3 - MACHINE CONTROLS AND INDICATORS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 CONTROLS AND INDICATORS . . . . . . . . . . . . . . 3-2

Ground Control Station . . . . . . . . . . . . . . . . . . 3-2

Platform Manual Descent Valves. . . . . . . . . . . 3-6

Mast Manual Descent Valve . . . . . . . . . . . . . . 3-6

Jib Manual Descent Valve . . . . . . . . . . . . . . . . 3-7

Manual Swinging Operating Devices . . . . . . . 3-7

Platform Control Station . . . . . . . . . . . . . . . . . 3-8

3.3 DECAL INSTALLATION . . . . . . . . . . . . . . . . . . . . 3-14

SECTION - 4 - MACHINE OPERATION

4.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 OPERATING SPECIFICATIONS AND LIMITATIONS

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Grade and Side Slope . . . . . . . . . . . . . . . . . . . 4-3

4.3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 STEERING AND TRAVELLING (DRIVING) . . . . . . 4-5

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Travelling (driving) . . . . . . . . . . . . . . . . . . . . . . 4-6

Drive Orientation System (DOS) . . . . . . . . . . . 4-7

. . 4-1

31210088 – JLG Lift – 1

Page 8

TABLE OF CONTENTS

4.5 RAISING AND LOWERING THE PLATFORM . . . . 4-7

Raising and lowering the mast . . . . . . . . . . . . 4-8

Raising and lowering the jib . . . . . . . . . . . . . . 4-8

4.6 SWINGING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.7 EMERGENCY CONTROL . . . . . . . . . . . . . . . . . . . 4-9

4.8 ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Overload Warning Light/Alarm (If equipped) 4-10

Tilt Warning Light/Alarm . . . . . . . . . . . . . . . . 4-10

Slack Chain Warning Light/Alarm . . . . . . . . 4-11

Soft Touch Warning Light/Alarm (Option) . . 4-12

4.9 SHUT DOWN AND PARK . . . . . . . . . . . . . . . . . . 4-12

4.10 BATTERY CHARGING. . . . . . . . . . . . . . . . . . . . . 4-13

Battery Charger Fault Code. . . . . . . . . . . . . . 4-14

4.11 TIE-DOWN/LIFT LUGS . . . . . . . . . . . . . . . . . . . . 4-15

Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.12 TOWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Electric Brake Release. . . . . . . . . . . . . . . . . . 4-17

SECTION - 5 - EMERGENCY PROCEDURES

5.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . 5-1

5.3 EMERGENCY OPERATION. . . . . . . . . . . . . . . . . . 5-1

Operator Unable to Control Machine . . . . . . . 5-1

Platform or Jib Caught Overhead . . . . . . . . . . 5-2

5.4 PLATFORM MANUAL DESCENT. . . . . . . . . . . . . .5-2

5.5 EMERGENCY TOWING . . . . . . . . . . . . . . . . . . . . .5-2

SECTION - 6 - GENERAL SPECIFICATIONS & OPERATOR

MAINTENANCE

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Other Publications Available . . . . . . . . . . . . . . 6-1

6.2 OPERATING SPECIFICATIONS. . . . . . . . . . . . . . .6-2

6.3 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . .6-9

6.4 CHASSIS HOOD REMOVAL . . . . . . . . . . . . . . . .6-10

6.5 BATTERY MAINTENANCE. . . . . . . . . . . . . . . . . .6-10

Battery Maintenance and Safety Practices . . 6-10

Filling System Draining . . . . . . . . . . . . . . . . . 6-12

Battery Voltage and Electrolyte Specific Gravity

Filling System Maintenance . . . . . . . . . . . . . . 6-15

Use of a Battery in a Cold Environment. . . . . 6-15

Battery Not Working Continuously or Inactive

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Battery Troubleshooting. . . . . . . . . . . . . . . . . 6-16

6.6 OIL LEVEL/OIL FILTER . . . . . . . . . . . . . . . . . . . .6-17

Hydraulic Oil Check . . . . . . . . . . . . . . . . . . . . 6-17

Hydraulic Filter Replacement. . . . . . . . . . . . . 6-18

6.7 TIRES & WHEELS . . . . . . . . . . . . . . . . . . . . . . . .6-19

Tire Wear and Damage . . . . . . . . . . . . . . . . . 6-19

Wheel and Tire Replacement. . . . . . . . . . . . . 6-19

Wheel Installation . . . . . . . . . . . . . . . . . . . . . . 6-19

6-14

2 – JLG Lift – 31210088

Page 9

TABLE OF CONTENTS

6.8 LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Overload System Spring Washer (If Equipped)

Swing Bearing Race . . . . . . . . . . . . . . . . . . . . 6-22

Swing Bearing Teeth. . . . . . . . . . . . . . . . . . . . 6-23

Mast Profiles Races. . . . . . . . . . . . . . . . . . . . . 6-24

Lifting Chains . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.9 OVERLOAD SYSTEM VERIFICATION

(IF EQUIPPED) . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

6.10 TILT SENSOR VERIFICATION . . . . . . . . . . . . . . 6-27

6.11 SUPPLEMENTAL INFORMATION . . . . . . . . . . . 6-28

6.12 DIAGNOSTIC TROUBLE CODES (DTC) . . . . . . 6-28

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

6.13 DTC INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

6.14 DTC CHECK TABLES . . . . . . . . . . . . . . . . . . . . . 6-29

0-0 Help Comments . . . . . . . . . . . . . . . . . . . . 6-29

2-1 Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

2-2 Platform Controls . . . . . . . . . . . . . . . . . . . 6-31

2-3 Ground Controls . . . . . . . . . . . . . . . . . . . . 6-33

2-5 Function Prevented. . . . . . . . . . . . . . . . . . 6-35

3-1 Line Contactor Open Circuit . . . . . . . . . . . 6-37

3-2 Line Contactor Short Circuit . . . . . . . . . . . 6-37

3-3 Ground Output Driver . . . . . . . . . . . . . . . . 6-38

4-2 Thermal Limit . . . . . . . . . . . . . . . . . . . . . . 6-41

4-4 Battery Supply. . . . . . . . . . . . . . . . . . . . . . 6-43

4-6 Transmission and Drive System . . . . . . . . 6-45

6-6 Communication. . . . . . . . . . . . . . . . . . . . . 6-46

6-21

6-7 Accessory . . . . . . . . . . . . . . . . . . . . . . . . 6-46

7-7 Electric Motor. . . . . . . . . . . . . . . . . . . . . . 6-47

8-1 Tilt Sensor . . . . . . . . . . . . . . . . . . . . . . . . 6-48

8-2 Platform Load Sense . . . . . . . . . . . . . . . . 6-49

8-6 Steering/Axle . . . . . . . . . . . . . . . . . . . . . . 6-49

9-9 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . 6-50

SECTION - 7 - INSPECTION AND REPAIR LOG

31210088 – JLG Lift – 3

Page 10

TABLE OF CONTENTS

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Minimum Approach Distance (M.A.D.) . . . . . . . . . . 1-5

1-2 Beaufort Scale (For Reference Only) . . . . . . . . . . 1-10

2-1 Inspection and Maintenance Table. . . . . . . . . . . . . 2-3

3-1 T10E & T26E - Decal Installation. . . . . . . . . . . . . . 3-17

4-1 Battery Charger Fault Code . . . . . . . . . . . . . . . . . 4-14

6-1 Operating Specifications And Dimensions . . . . . . 6-2

6-2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-3 Tires Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-4 Drive Motors - Hydraulic Power Unit. . . . . . . . . . . . 6-6

6-5 Battery Specifications . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-6 Lubrication Specifications . . . . . . . . . . . . . . . . . . . . 6-7

6-7 Hydraulic Oil Specifications - Standard . . . . . . . . . 6-7

6-8 Hydraulic Oil Specifications - Optional . . . . . . . . . . 6-8

6-9 Wheel Torque Chart . . . . . . . . . . . . . . . . . . . . . . . 6-20

6-10 Recommended Viscosity Grade . . . . . . . . . . . . . . 6-25

7-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . . 7-1

4 – JLG Lift – 31210088

Page 11

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

2-1. Daily Walk-Around Inspection . . . . . . . . . . . . . . . . 2-5

2-2. Tilt Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-3. Overload Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-4. Slack/Broken Chain Sensors . . . . . . . . . . . . . . . . 2-10

3-1. Basic Nomenclature - Location of Machine Controls

3-2. Ground Control Station . . . . . . . . . . . . . . . . . . . . . 3-3

3-3. Mast Manual Descent Valve . . . . . . . . . . . . . . . . . . 3-6

3-4. Jib Manual Descent Valve . . . . . . . . . . . . . . . . . . . 3-7

3-5. Manual Swinging Operating Devices. . . . . . . . . . . 3-8

3-6. Platform Control Indicator Panel . . . . . . . . . . . . . 3-10

3-7. Decal Installation - Sheet 1. . . . . . . . . . . . . . . . . . 3-14

3-8. Decal Installation - Sheet 2. . . . . . . . . . . . . . . . . . 3-15

3-9. Decal Installation - Sheet 3. . . . . . . . . . . . . . . . . . 3-16

4-1. Position of Least BACKWARD stability. . . . . . . . . . 4-2

4-2. Position of Least FORWARD stability. . . . . . . . . . . 4-2

4-3. Grade and Side Slope . . . . . . . . . . . . . . . . . . . . . . 4-4

4-4. Steer/Drive Controls . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-5. Drive Orientation System (DOS) . . . . . . . . . . . . . . 4-7

4-6. Lift Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-7. Swing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-8. Emergency Controls. . . . . . . . . . . . . . . . . . . . . . . 4-10

4-9. Machine Tie-Down . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4-10. Lifting the Machine . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-11. Lifting the Machine Using a Fork Truck . . . . . . . . 4-16

. . 3-1

4-12. Electric Brake Release . . . . . . . . . . . . . . . . . . . . . 4-17

6-1. Range Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-2. Operator Maintenance & Lubrication Diagram . . . . 6-9

6-3. Chassis Hood Removal. . . . . . . . . . . . . . . . . . . . . 6-10

6-4. Level Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6-5. Adding Water to Batteries . . . . . . . . . . . . . . . . . . . 6-11

6-6. Filling System Draining . . . . . . . . . . . . . . . . . . . . . 6-12

6-7. Draining the Water . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6-8. Measuring Electrolyte Specific Gravity . . . . . . . . . 6-14

6-9. Hydraulic Oil Check . . . . . . . . . . . . . . . . . . . . . . . 6-17

6-10. Hydraulic Filter Replacement . . . . . . . . . . . . . . . . 6-18

6-11. Wheel Lug Nut Tightening Sequence. . . . . . . . . . 6-19

6-12. Overload System Spring Washer Lubrication . . . 6-21

6-13. Swing Bearing Race Lubrication. . . . . . . . . . . . . . 6-22

6-14. Swing Bearing Teeth lubrication. . . . . . . . . . . . . . 6-23

6-15. Mast Profiles Races Lubrication . . . . . . . . . . . . . . 6-24

6-16. Overload System Verification . . . . . . . . . . . . . . . . 6-26

6-17. Jacking Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

31210088 – JLG Lift – 5

Page 12

TABLE OF CONTENTS

NOTES:

6 – JLG Lift – 31210088

Page 13

SECTION 1 – SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper

and safe machine operation and maintenance. For proper

machine use, it is mandatory that a daily routine is established based on the content of this manual. A maintenance

program, using the information provided in this manual and

the Service and Maintenance Manual, must also be established by a qualified person and followed to ensure the

machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine

should not operate the machine until this manual has been

read, training is accomplished, and operation of the machine

has been completed under the supervision of an experienced and qualified operator.

If there are any questions with regard to safety, training,

inspection, maintenance, application, and operation, please

contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN

THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

1.2 PRE-OPERATION

Operator Training and Knowledge

• Read and understand this manual before operating the

machine.

• Do not operate this machine until complete training is performed by authorized persons.

• Only authorized and qualified personnel can operate the

machine.

• Read, understand, and obey all DANGERS, WARNINGS,

CAUTIONS, and operating instructions on the machine

and in this manual.

• Use the machine in a manner which is within the scope of

its intended application set by JLG.

31210088 – JLG Lift – 1-1

Page 14

SECTION 1 – SAFETY PRECAUTIONS

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine

as specified in this manual.

• Read, understand, and obey all applicable employer,

local, and governmental regulations as they pertain to

operation of the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all hazards in the work area prior to machine operation.

• Do not operate or raise the platform while on trucks, trailers, railway cars, floating vessels, scaffolds or other equipment unless approved in writing by JLG.

• Do not operate the machine in hazardous environments

unless approved for that purpose by JLG.

• Be sure that the ground conditions are able to support the

maximum load shown on the decals located on the

machine.

• This machine can be operated in temperatures of 0

o

F (-20o C to 40o C). Consult JLG for operation out-

104

side this range.

• This machine must be used in a sufficient ambient light.

o

F to

Machine Inspection

• Before machine operation, perform inspections and functional checks. Refer to Section 2 of this manual for

detailed instructions.

• Do not operate this machine until it has been serviced and

maintained according to requirements specified in the

Service and Maintenance Manual.

• Be sure the trigger control, platform enable button and all

other safety devices are operating properly. Modification

of these devices is a safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM

SHALL BE MADE ONLY WITH WRITTEN PERMISSION FROM THE MANUFACTURER.

• Do not operate any machine on which safety or instruction

placards or decals are missing or illegible.

• Avoid any buildup of debris on the platform floor. Keep

mud, oil, grease, and other slippery substances from footwear and platform floor.

1-2 – JLG Lift– 31210088

Page 15

SECTION 1 – SAFETY PRECAUTIONS

1.3 OPERATION

General

• Do not use the machine for any purpose other than positioning personnel, their tools and equipment.

• Never operate a machine that is not working properly. If a

malfunction occurs, shut down the machine.

• Never slam a control switch or lever through neutral to an

opposite direction. Always return switch to neutral and

stop before moving the switch to the next function. Operate controls with slow and even pressure.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing. Contact

JLG for approved material handling accessories.

• When two persons are in the platform, the operator shall

be responsible for all machine operations.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Supplies or tools which extend outside the platform are

prohibited unless approved by JLG.

• When driving, always position extending structure over

rear axle in line with the direction of travel. Remember, if

extending structure is over the front axle, steer and drive

functions will be reversed.

• Do not assist a stuck or disabled machine by pushing,

pulling, or by using extending structure functions. Only

pull the unit from the tie-down lugs on the chassis.

• Do not place extending structure or platform against any

structure to steady the platform or to support the structure.

• Stow extending structure and shut off all power before

leaving machine.

31210088 – JLG Lift – 1-3

Page 16

SECTION 1 – SAFETY PRECAUTIONS

Trip and Fall Hazards

During operation, occupants in the platform must wear a full

body harness with a lanyard attached to an authorized lanyard anchorage point. Attach only one (1) lanyard per lanyard anchorage point.

• Before operating the machine, make sure all gates are

closed and fastened in their proper position.

• Keep both feet firmly positioned on the platform floor at all

times. Never use ladders, boxes, steps, planks, or similar

items on platform to provide additional reach.

• Never use the extending structure to enter or leave the

platform.

• Use extreme caution when entering or leaving platform.

Be sure that the platform is fully lowered. Face the

machine, maintain “three point contact” with the machine,

using two hands and one foot or two feet and one hand

during entry and exit.

1-4 – JLG Lift– 31210088

Page 17

SECTION 1 – SAFETY PRECAUTIONS

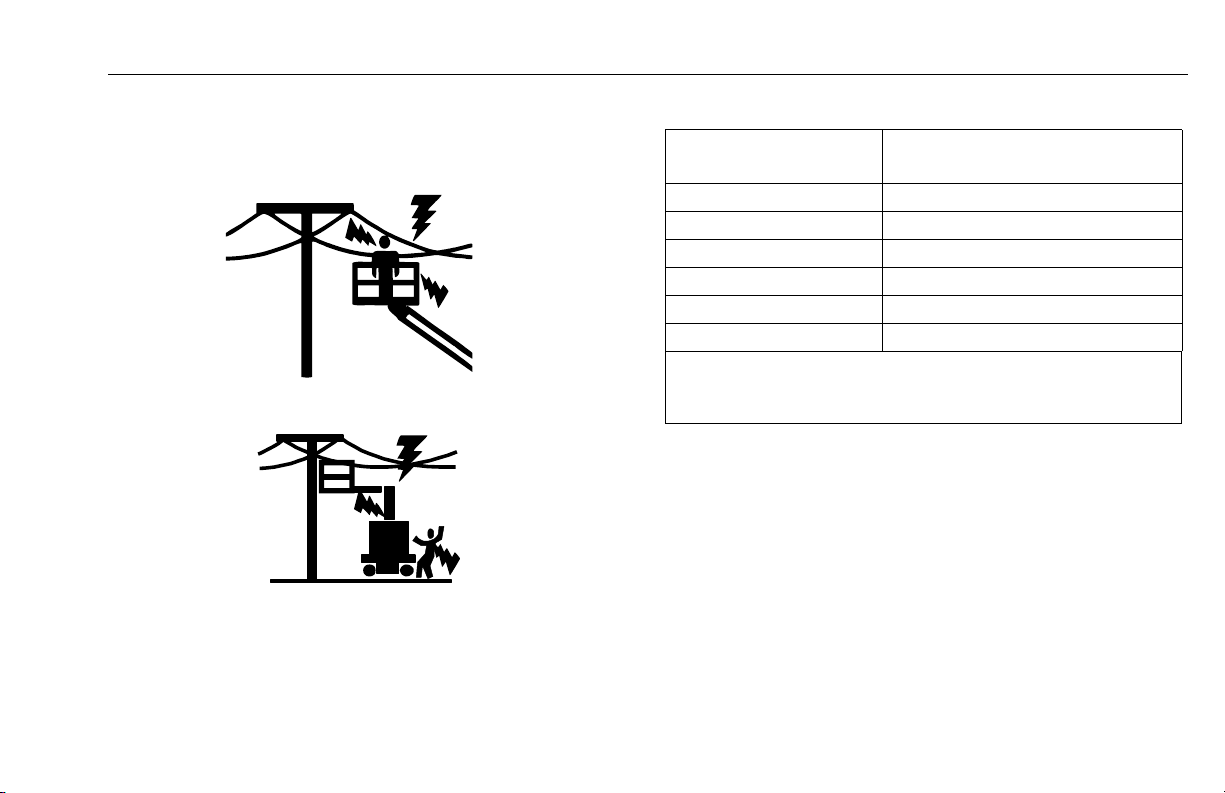

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in Table 1-1.

• Allow for machine movement and electrical line swaying.

Table 1-1. Minimum Approach Distance (M.A.D.)

Voltag e Ran ge

(Phase to Phase)

0 to 50 kV 3 (10)

Over 50 kV to 200 kV 5 (15)

Over 200kV to 350 kV 6 (20)

Over 350 kV to 500 KV 8 (25)

Over 500 kV to 750 kV 11 (35)

Over 750 kV to 1000 kV 14 (45)

NOTE: This requirement shall apply except where

employer, local or governmental regulations are

more stringent.

• Maintain a clearance of at least 3 m (10 ft.) between any

part of the machine and its occupants, their tools and their

equipment from any electrical line or apparatus carrying

up to 50 000 volts. A 0,3 m (1 ft.) additional clearance is

required for every additional 30 000 volts or less.

• The minimum approach distance may be reduced if insulating barriers are installed to prevent contact and the barriers are rated for the voltage of the line being guarded.

These barriers shall not be part of (or attached to) the

machine. The minimum approach distance shall be

reduced to a distance within the designed working dimen-

MINIMUM APPROACH DISTANCE

in Meters (Feet)

31210088 – JLG Lift – 1-5

Page 18

SECTION 1 – SAFETY PRECAUTIONS

sions of the insulating barrier. This determination shall be

made by a qualified person in accordance with employer,

local or governmental requirements for work practices

near energized equipment.

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED

ZONE (MAD). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE

ENERGIZED UNLESS KNOWN OTHERWISE.

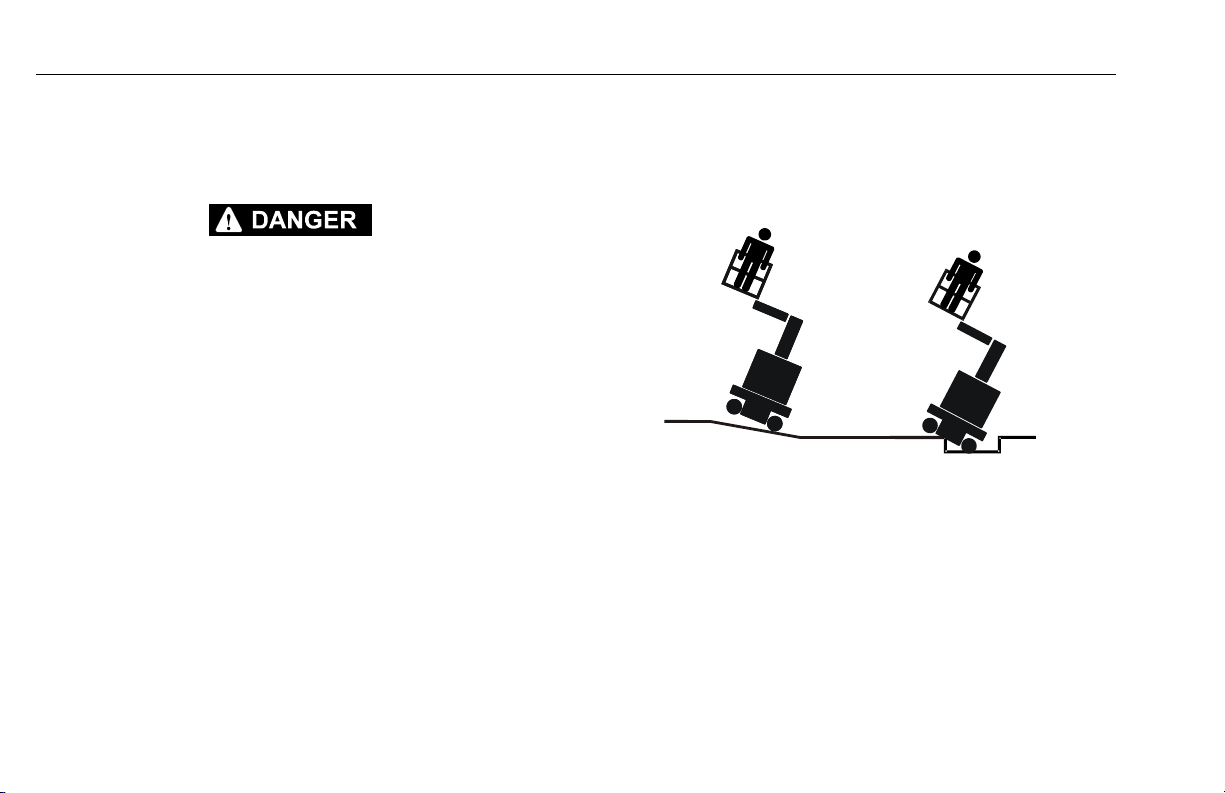

Tipping Hazards

• The user should be familiar with the surface before driving. Do not exceed the allowable sideslope and grade

while driving.

• Never exceed the maximum platform capacity. Distribute

loads evenly on platform floor.

• Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of the surfaces.

• Do not elevate platform or drive with platform elevated

while on a sloping, uneven, or soft surface.

1-6 – JLG Lift– 31210088

Page 19

SECTION 1 – SAFETY PRECAUTIONS

• Do not raise the platform or drive from an elevated position unless the machine is on firm, level and smooth surfaces.

• When travelling on grades (Refer to Section 4), the platform MUST be fully lowered. It is recommended to drive

up the grade in FORWARD gear and to REVERSE down

the slope.

• Keep the chassis of the machine at least 0,6 m (2 ft.) from

holes, bumps, drop-offs, obstructions, debris, concealed

holes, and other potential hazards on the floor/surface.

• Do not push or pull any object with the extending structure.

• Never attempt to use the machine as a crane. Do not tieoff machine to any adjacent structure.

• Do not operate the machine when wind conditions exceed

12.5 m/s (28 mph). Refer to Table 1-2, Beaufort Scale (For

Reference Only).

• Do not increase the surface area of the platform or the

load. Increase of the area exposed to the wind will

decrease stability.

• Do not increase the platform size with unauthorized deck

extensions or attachments.

• If extending structure assembly or platform is in a position

that one or more wheels are off the ground, all persons

must be removed before attempting to stabilize the

machine. Use cranes, forklift trucks, or other appropriate

equipment to stabilize machine.

31210088 – JLG Lift – 1-7

Page 20

SECTION 1 – SAFETY PRECAUTIONS

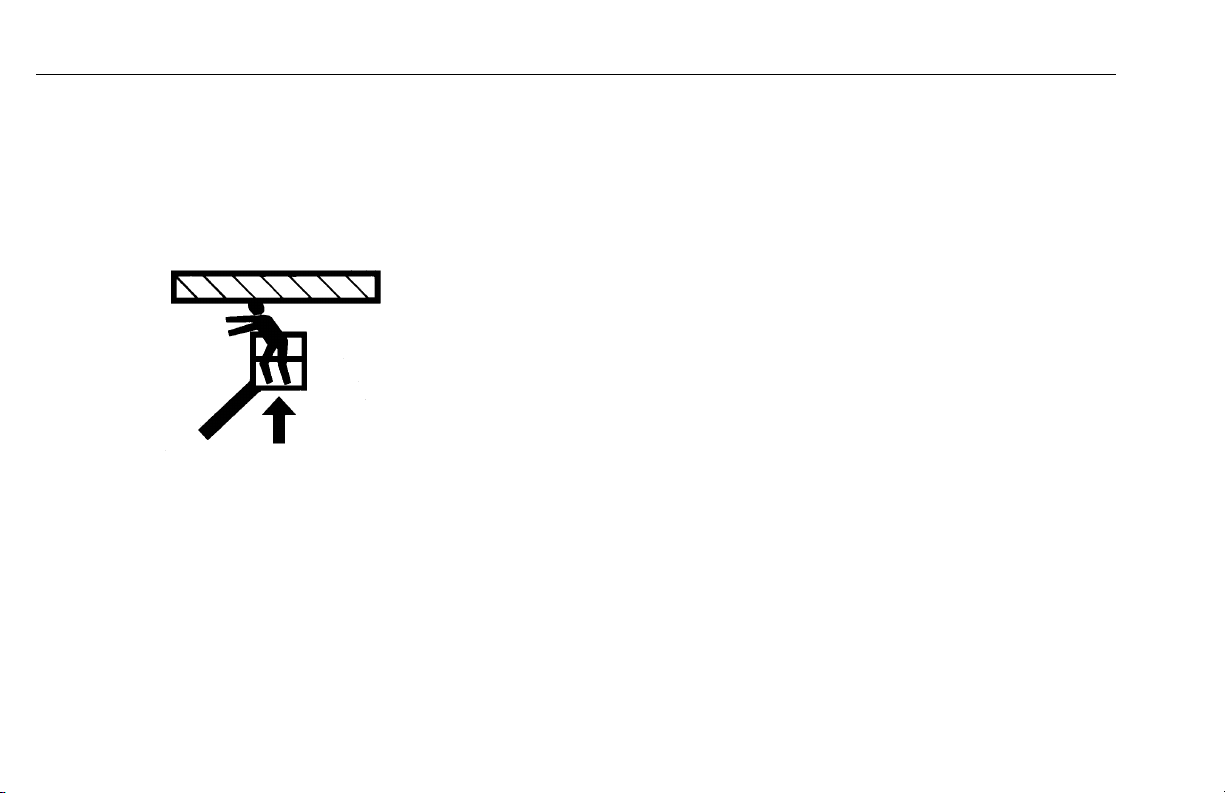

Crushing and Collision Hazards

• Approved head gear must be worn by all operating and

ground personnel.

• Check work area for clearances overhead, on sides, and

bottom of platform when lifting, swinging or lowering platform, and driving.

• During operation, keep all body parts inside platform railing.

• Always post a lookout when driving in areas where vision

is obstructed.

• Keep non-operating personnel at least 2m (6 ft.) away

from machine during all driving and swinging operations.

• Limit travel speed according to conditions of ground surface, congestion, visibility, slope, location of personnel,

and other factors which may cause hazard of collision or

injury to personnel.

• Be aware of stopping distances in all drive speeds. When

driving in high speed, slow down the machine using the

controller before stopping.

• Do not use high speed drive in restricted or close quarters

or when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and persons in the platform.

• Be sure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence. Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk under a raised

extending structure or platform. Position barricades on

floor if necessary.

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing, lifting, or

hauling.

• This machine should not be towed, except in the event of

emergency, malfunction, power failure, or loading/unloading. Refer to Emergency Towing Procedures Section of

this Manual for emergency towing procedures.

1-8 – JLG Lift– 31210088

Page 21

SECTION 1 – SAFETY PRECAUTIONS

• Ensure extending structure is in the stowed position prior

to towing, lifting or hauling. The platform and the tool tray

must be completely empty of tools.

• When lifting machine, lift only at designated areas of the

machine. Lift the unit with equipment of adequate capacity.

• Refer to the Machine Operation Section of this Manual for

lifting information.

1.5 ADDITIONAL HAZARDS / SAFETY

• Do not use machine as a ground for welding.

• When performing welding or metal cutting operations,

precautions must be taken to protect the chassis from

direct exposure to weld and metal cutting spatter.

• Battery fluid is highly corrosive. Avoid contact with skin

and clothing at all times.

• Charge batteries only in a well ventilated area.

31210088 – JLG Lift – 1-9

Page 22

SECTION 1 – SAFETY PRECAUTIONS

DO NOT OPERATE THE MACHINE WHEN WIND CONDITIONS EXCEED 28

MPH (12,5 M/S OR 45 KM/H).

Table 1-2. Beaufort Scale (For Reference Only)

Beaufort

Number

0 0 0-0.2 Calm Calm. Smoke rises vertically.

1 1-3 0.3-1.5 Light air Wind motion visible in smoke.

2 4-7 1.6-3.3 Light breeze Wind felt on exposed skin. Leaves rustle.

3 8-12 3.4-5.4 Gentle breeze Leaves and smaller twigs in constant motion.

4 13-18 5.5-7.9 Moderate breeze Dust and loose paper raised. Small branches begin to move.

5 19-24 8.0-10.7 Fresh breeze Smaller trees sway.

6 25-31 10.8-13.8 Strong breeze Large branches in motion. Whistling heard in overh ead wires.

7 32-38 13.9-17.1 Near Gale/Moderate Gale Whole trees in motion. Effort needed to walk against the wind.

8 39-46 17.2-20.7 Fresh Gale Twigs broken from trees. Cars veer on road.

9 47-54 20.8-24.4 Strong gale Light structure damage.

Wind Speed

mph m/s

Description Land Conditions

Umbrella use becomes difficult.

1-10 – JLG Lift– 31210088

Page 23

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is

necessary that it be operated and maintained only by trained

personnel.

Persons under the influence of drugs or alcohol or who are

subject to seizures, dizziness or loss of physical control must

not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and at

the ground, emergency controls and safety systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of the

machine to recognize a malfunction or potential malfunction.

6. The safest means to operate the machine where overhead obstructions, other moving equipment, and obstacles, depressions, holes or drop-offs exist.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified

person in an open area free of obstructions until the trainee

has developed the ability to safely control and operate the

machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of a

malfunction or other unsafe condition of either the machine

or the job site.

31210088 – JLG Lift – 2-1

Page 24

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The following table covers the periodic machine inspections

and maintenance recommended by JLG Industries, Inc.

Consult local regulations for further requirements for aerial

work platforms. The frequency of inspections and maintenance must be increased as necessary when the machine is

used in a harsh or hostile environment, if the machine is

used with increased frequency, or if the machine is used in a

severe manner.

JLG INDUSTRIES, INC. RECOGNIZES A FACTORY-TRAINED SERVICE

TECHNICIAN AS A PERSON WHO HAS SUCCESSFULLY COMPLETED

THE JLG SERVICE TRAINING SCHOOL FOR THE SPECIFIC JLG PRODUCT

MODEL.

2-2 – JLG Lift – 31210088

Page 25

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

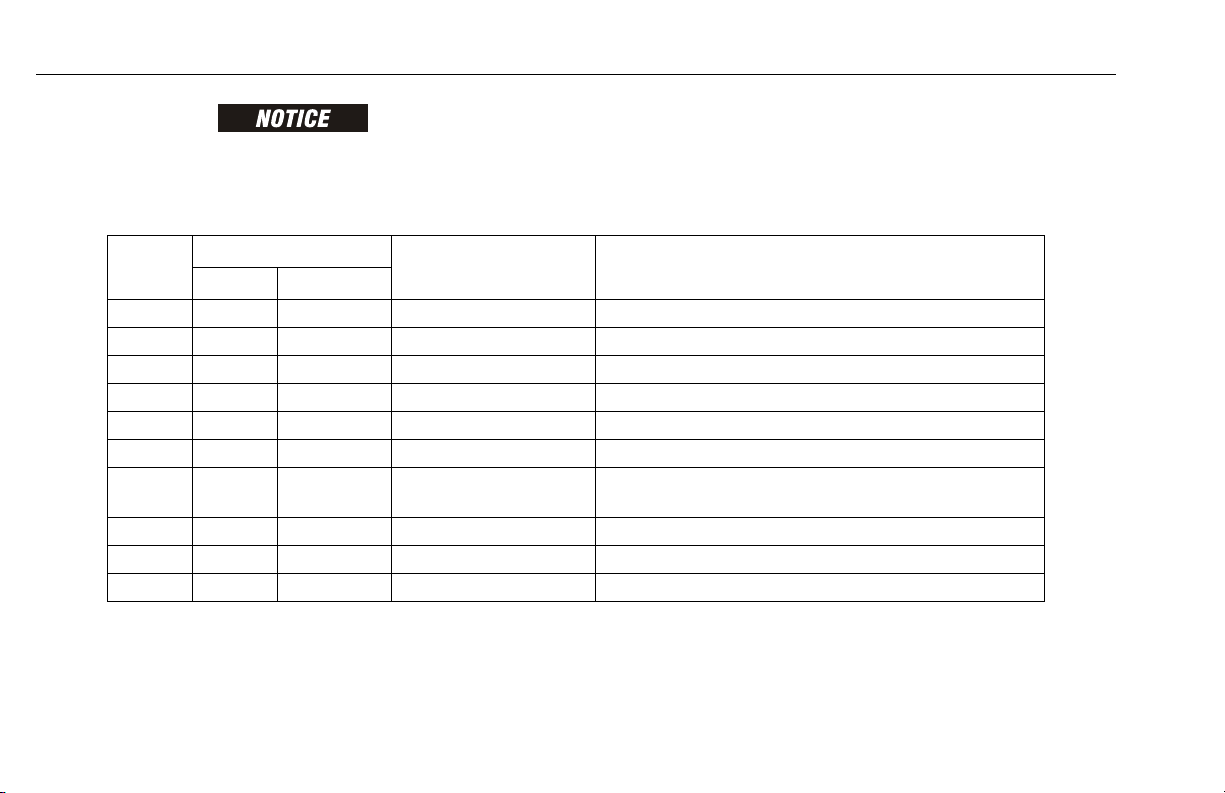

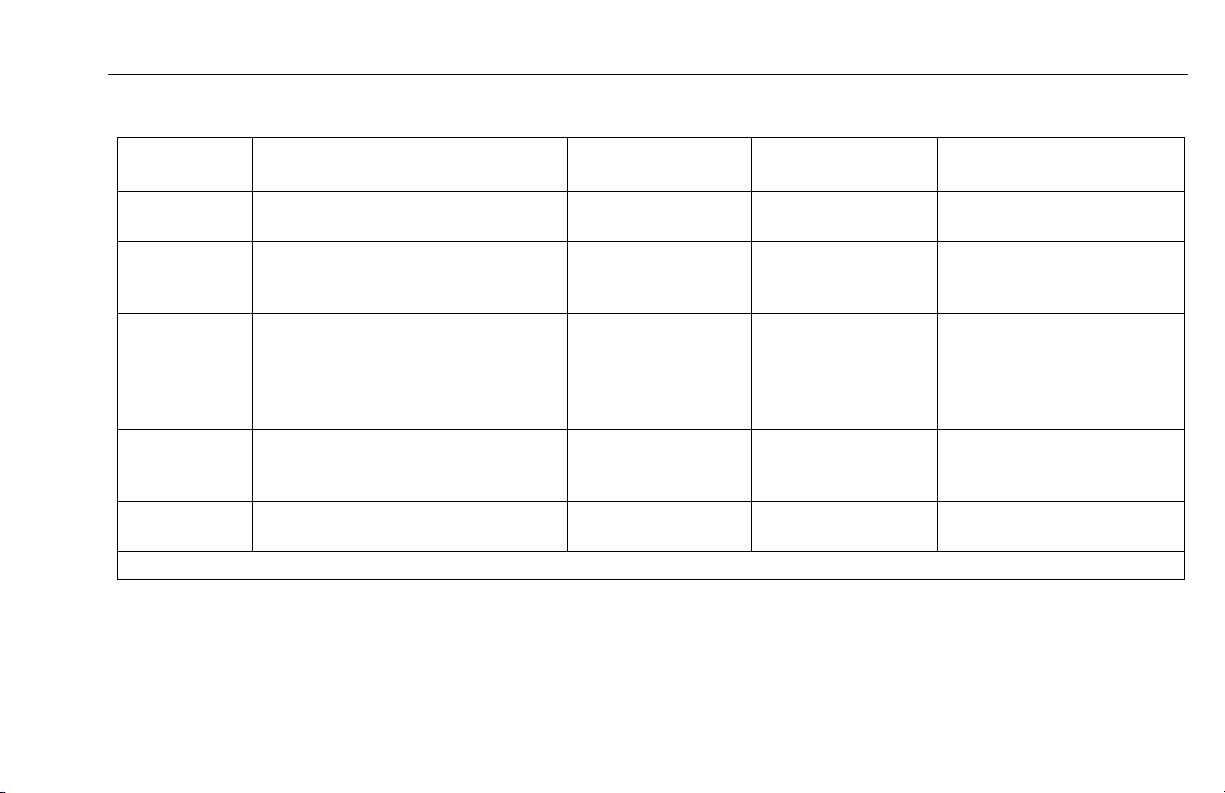

Table 2-1.Inspection and Maintenance Table

Type Frequency

Pre-Start Inspection

Pre-Delivery

Inspection

(See Note)

Freque nt Inspec tion

(See Note)

Annual Machine

Inspection

(See Note)

Preventative

Maintenance

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

Before using each day;

or whenever there’s an Operator change.

Before each sale, lease, or rental delivery. Owner, Dealer or User Qualified JLG Mechanic Service and Maintenance Manual

In service for 3 months or 150 hours, whichever comes first; or

Out of service for a period of more than 3

months; or

Purchased used.

Annually, no later than 13 months from the

date of prior inspection.

At intervals as specified in the Service and

Maintenance Manual.

Primary

Responsibility

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer or User Qualified JLG Mechanic Service and Maintenance Manual

Owner, Dealer or User Factory-Trained Service

Owner, Dealer or User Qualified JLG Mechanic Service and Maintenance Manual

Service

Qualification

Technician (Recommended)

Reference

and applicable JLG inspection form

and applicable JLG inspection form

Service and Maintenance Manual

and applicable JLG inspection form

31210088 – JLG Lift – 2-3

Page 26

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

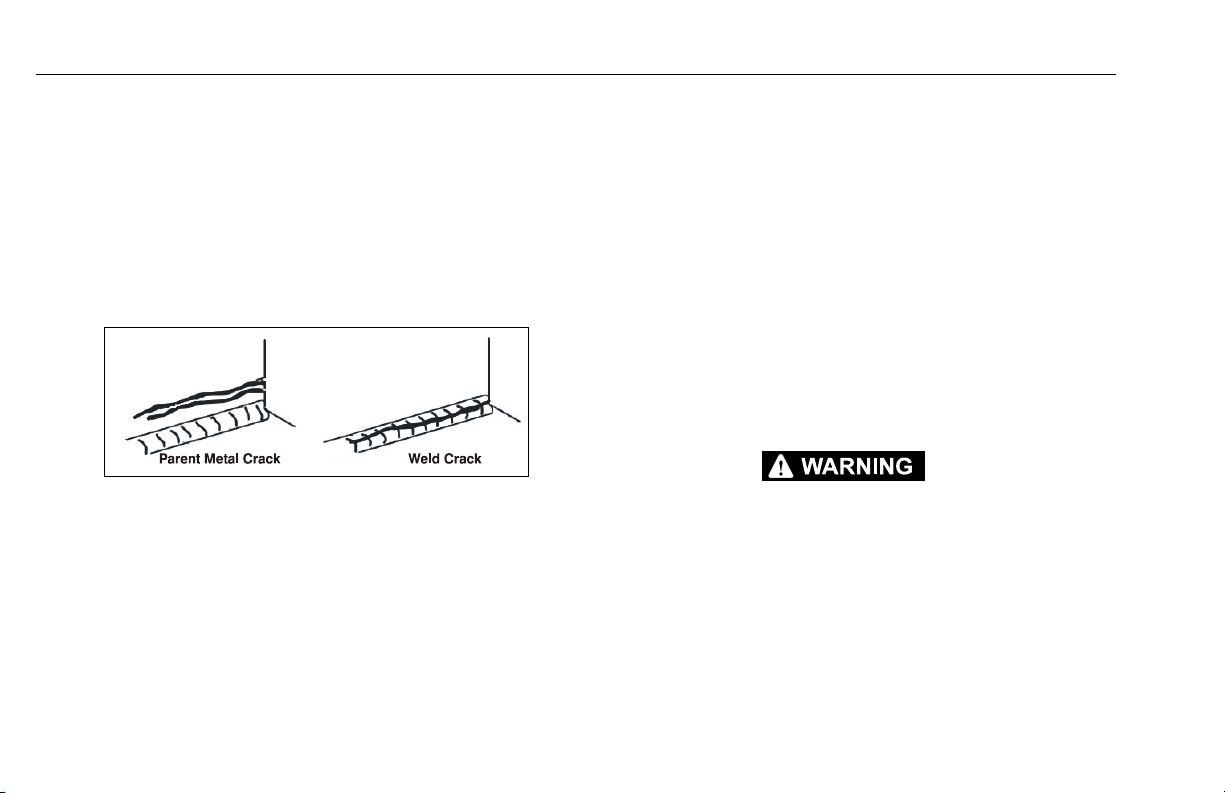

Pre-Start Inspection

The Pre-Start Inspection must include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil or battery fluid) or foreign objects. Report any leakage to the

proper maintenance personnel.

2. Structure – Inspect the machine structure for dents,

damage, weld or parent metal cracks or other discrepancies.

3. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards are

missing. Make sure all illegible and missing decals and

placards are cleaned or replaced.

4. Operation and Safety Manuals – Make sure a copy of

the Operator and Safety manual, AEM Safety manual

(ANSI markets only), and ANSI Manual of Responsibility

(ANSI markets only) is enclosed in the weather resistant

storage container.

5. “Walk-Around” Inspection – Refer to Figure 2-1.

6. Battery – Charge as required.

7. Hydraulic Oil – Check the hydraulic oil level in the reser-

voir. Ensure hydraulic oil is added as required.

8. Accessories/Attachments - Reference the Operator

and Safety Manual of each attachment or accessory

installed upon the machine for specific inspection, operation, and maintenance instructions.

9. Function Check – Once the “Walk-Around” Inspection

is complete, perform a functional check of all systems in

an area free of overhead and ground level obstructions.

Refer to Section 4 for more specific operating instructions.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF THE

MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE PROPER

MAINTENANCE PERSONNEL. DO NOT OPERATE THE MACHINE UNTIL IT

IS DECLARED SAFE FOR OPERATION.

2-4 – JLG Lift – 31210088

Page 27

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Figure 2-1. Daily Walk-Around Inspection

31210088 – JLG Lift – 2-5

Page 28

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

General

Begin the "Walk-Around Inspection" at Item 1, as noted on

the diagram. Continue checking each item in sequence for

the conditions listed in the following checklist.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS OFF.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN

CORRECTED.

INSPECTION NOTE: On all components, make sure there

are no loose or missing parts, that they are securely fastened,

and no visible damage, leaks or excessive wear exists in

addition to any other criteria mentioned.

1. Platform Assembly and Gate - Gate opens and closes

properly, manual in storage container. See inspection

note.

2. Platform & Ground Control Consoles - Placards

secure and legible, control levers and switches return to

neutral and emergency stop switches function properly.

3. Steering Assembly - See inspection note.

4. Wheel/Tire Assemblies - Properly secured, no missing

lug nuts. Inspect for worn tread, cuts, tears or other discrepancies. Inspect wheels for damage and corrosion.

See inspection note.

5. Hood Assemblies - See Inspection Note.

6. Hydraulic Cylinders- No visible damage, pivot pins and

hydraulic hoses undamaged, no leakage (hose connections - valve block).

7. Manual Descent - See Inspection Note.

8. Lifting Chains, Chain Yokes and Clevis Pins - Must be

installed and in good condition. Chains must be correctly tensioned and lubricated.

9. Hydraulic Pump/Motor Control Valves Installation/Oil

Level in Reservoir - Swing needle valve fully closed.

See Inspection Note.

10. Limit Switches - Mast limit switch(es), chain slack limit

switches and overload sensor (if equipped) are properly

installed and fastened. See inspection note.

2-6 – JLG Lift – 31210088

Page 29

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Function Check

Refer to Sections 3 & 4 for description and operation of machine

functions.

Control Stations

1. From the Ground Control Console with no load in the

platform:

a. Operate all functions to ensure proper operation.

b. While operating a mast lift-up movement, push in all

other function buttons. Mast lift-up movement

should continue and no other movement should

occur.

c. Ensure that all machine functions are disabled

when the emergency stop button is depressed.

d. Raise the mast about one meter (3 ft.), check if the

manual descent valve lowers the mast properly

(refer to Figure 3-3. for mast manual descent valve

location).

e. Raise the jib about half a meter (2 ft.), check if the

manual descent valve lowers the jib properly (Refer

to Figure 3-4).

2. From the Platform Control Console:

a. Ensure that the platform control console is firmly

secured.

b. Check that all guards protecting the switches are

securely in place.

c. Operate all functions including horn button to

ensure proper operation.

d. Ensure that all machine functions are disabled

when the emergency stop button is depressed.

e. Ensure all mast and jib functions stop when the

function enable button is released.

f. Ensure all drive functions stop when joystick trigger

is released.

g. With the mast elevated half a meter (2 ft.), on a

smooth, firm and level surface, drive the machine to

check if the high drive cutout speed-limit is

engaged. Drive speed will be reduced from a top

speed of 5.5 km/h to 0.75 km/h (3.40 mph to 0.45

mph) (Approx.).

h. Toucan 10E only: With the mast elevated 4.50 m

(14.8 ft.), on a smooth, firm and level surface, drive

the machine to check if the extra drive cutout

speed-limit is engaged. Drive speed will be reduced

to 0.40 km/h (0.25 mph) (Approx.).

31210088 – JLG Lift – 2-7

Page 30

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Figure 2-2. Tilt Sensor

i. Swing the superstructure either to the left or to the

right: when the jib is no longer over the rear axle,

the drive orientation system (DOS) indicator lights

up (Yellow).

Actuate a drive function: the drive function is disabled. The DOS indicator blinks, and the DOS override button must be used for the drive function to

operate.

j. With the machine in transport (stowed) position,

drive the machine on a grade, not to exceed the

rated gradeability and stop to ensure the brakes

hold.

Tilt Sensor Check

Check the tilt indicator light/alarm to ensure proper operation. Wedge a block (P/N: ST2741 - located in the manual

storage container) to activate the tilt sensor and keep it tilted.

The tilt sensor is located on the chassis behind the right rear

wheel. Refer to Figure 2-2.

1. From the platform console :

- Raise the mast by approximately 1m (3 ft.).

a. Confirm an audible alarm sounds.

b. Verify the tilt indicator (red) blinks.

c. Check that the following functions are affected :

- Drive function disabled.

- Mast/Jib lift-up and swinging movements can be

performed only in creep mode.

2-8 – JLG Lift – 31210088

Page 31

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

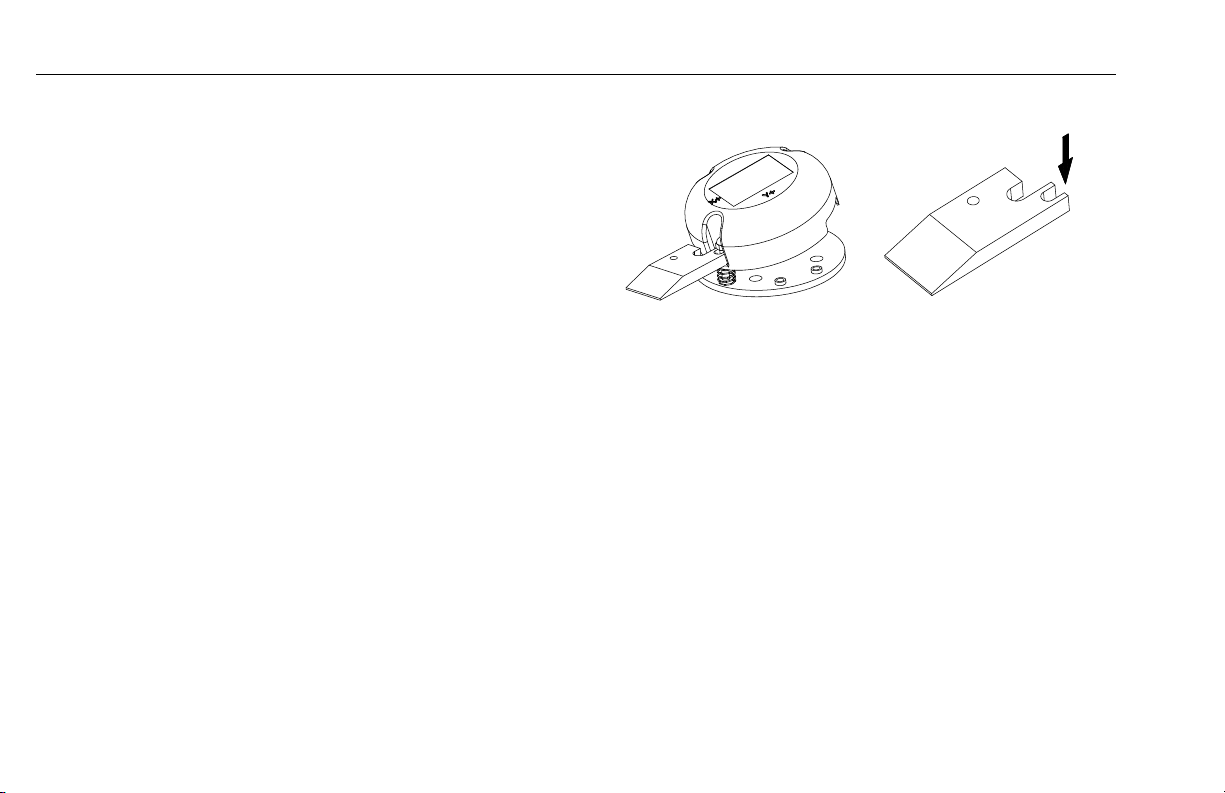

Figure 2-3. Overload Sensor

Overload Sensor Check (If Equipped)

Check the overload indicator light/alarm to ensure proper

operation. Wedge a block (P/N: ST2741 - located in the manual

storage container) to activate the overload sensor and keep it

activated. Refer to Figure 2-3.

1. From the Platform Control Console:

a. Confirm an audible alarm sounds.

b. Verify the overload indicator (Red) blinks.

c. Check that all functions are disabled.

2. From the Ground Control Panel:

a. Confirm an audible alarm sounds.

b. Verify the overload indicator (Red) blinks.

31210088 – JLG Lift – 2-9

Page 32

SECTION 2 – USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Figure 2-4. Slack/Broken Chain Sensors

Slack/Broken Chain Sensors Check

Check the slack/broken chain indicator light/alarm and interlock

to ensure proper operation. Refer to Figure 2-4. for chain sensors

location (Qty:3). Wedge a block (P/N: ST2741 - located in the

manual storage container) to activate a slack chain sensor and

keep it activated.

1. From the Platform Control Console:

a. Confirm an audible alarm sounds.

b. Verify the slack chain indicator (Red) lights up.

c. Check when the slack chain indicator warning is

activated, the following functions are disabled:

- Mast/Jib lower

- Swing

- Drive

2. From the Ground Control Panel:

a. Confirm an audible alarm sounds.

b. Check when the slack chain indicator warning is

activated, the following functions are disabled:

- Mast/Jib lower

- Swing

c. Repeat check for each chain sensor.

2-10 – JLG Lift – 31210088

Page 33

SECTION 3 – MACHINE CONTROLS AND INDICATORS

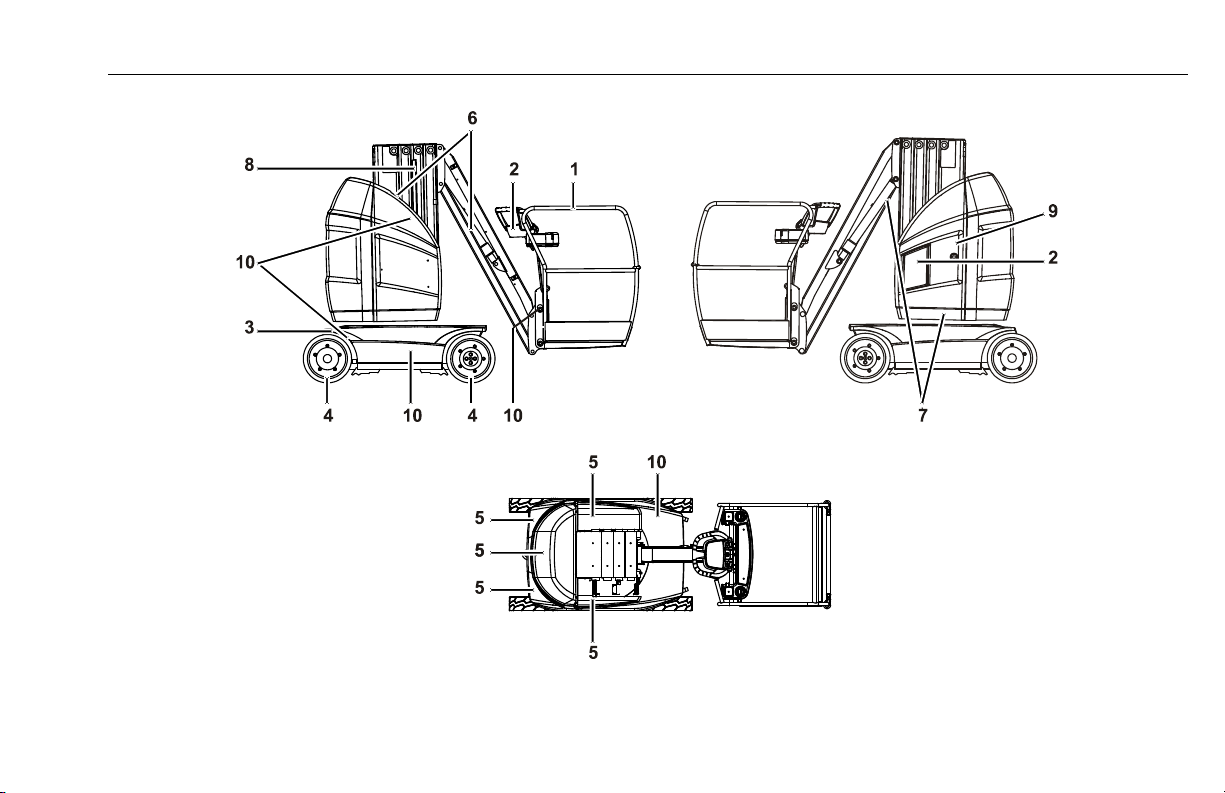

Figure 3-1. Basic Nomenclature - Location of Machine Controls

1- Driving wheels

2- Steering Wheels

3- Access door to Pump/Motor

Control valves

4- Counterweight

5- Jib

6- Ground Control Panel

7- Telescopic mast

8- Platform

9- Platform Control console

10- Manual Storage Container

11- Access door to battery/charger

12- Mast manual descent valve

13- Jib manual descent valve

14- Swinging motor release valve

15- Manual swinging operating device

SECTION 3. MACHINE CONTROLS AND INDICATORS

31210088 – JLG Lift – 3-1

Page 34

SECTION 3 – MACHINE CONTROLS AND INDICATORS

3.1 GENERAL

This section provides the necessary information needed to

understand controls and their functions.

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE

APPLICATION AND OPERATION. THE USER AND OPERATOR ARE

RESPONSIBLE FOR CONFORMING WITH GOOD SAFETY PRACTICES.

3.2 CONTROLS AND INDICATORS

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY CONTROL LEVERS OR TOGGLE SWITCHES CONTROLLING PLATFORM

MOVEMENT DO NOT RETURN TO THE OFF POSITION WHEN RELEASED.

Ground Control Station

DO NOT OPERATE FROM GROUND CONTROL STATION WITH PERSONNEL IN THE PLATFORM EXCEPT IN AN EMERGENCY.

WHEN THE MACHINE IS SHUT DOWN FOR OVERNIGHT PARKING OR

BATTERY CHARGING, THE PLATFORM/OFF/GROUND SELECTOR AND

THE EMERGENCY STOP SWITCHES MUST BE POSITIONED TO OFF TO

PREVENT DRAINING THE BATTERIES.

3-2 – JLG Lift – 31210088

Page 35

SECTION 3 – MACHINE CONTROLS AND INDICATORS

1- 5 Amp Circuit Breaker

2- Overload Warning Light (If equipped)

3- Multi-Display Indicator (MDI)

4- Platform/Off/Ground Selector Switch

5- Battery Charger Status Indicators (depending on equipment)

6- Emergency Stop Switch

7- Function Enable Button

8- Mast Lift/Lower Buttons

9- Jib Lift/Lower Buttons

10- Superstructure Swing Buttons

11- Brake Release Button

Figure 3-2. Ground Control Station

31210088 – JLG Lift – 3-3

Page 36

SECTION 3 – MACHINE CONTROLS AND INDICATORS

1. 5 Amp. Circuit Breaker - This circuit breaker protects

the control circuit in case of a short circuit or other malfunction.

2. Overload Warning Light (If equipped) - This lamp

(red), when blinking, indicates that the maximum rated

load in the platform is exceeded. The platform must be

safely unloaded until the alarm stops.

3. Multi-Display Indicator (MDI)

Hourmeter - The hourmeter symbol is lit when

the number of operated hours is displayed.

Speed reduction - Indicates that the maximum

drive speed is reduced when the platform is

out of transport position.

The wrench symbol is lit when a DTC (Diagnosis Troubleshooting Code) is displayed.

Five Digits Display

In normal operating condition, displays the

total amount of machine operation time accumulated.

In abnormal operating condition, displays a

DTC (Diagnosis Troubleshooting Code).

Alarm LED

Illuminates in abnormal operating condition

(when a DTC, other than 00xx DTC’s exists).

Battery Discharge Indicator (BDI).

This bar-graph is designed to let the operator

know the condition of the battery before starting to use the machine.

The last bar flashes when the level of charge is

less than 10%. The bar-graph is not displayed

when the batteries are completely discharged.

3-4 – JLG Lift – 31210088

Page 37

SECTION 3 – MACHINE CONTROLS AND INDICATORS

4. Platform/Off/Ground Selector Switch - A three-posi-

tion, key-operated power select switch supplies power

to the platform or ground controls and powers machine

down in the off position.

5. Battery Charger Status Indicators - This panel is

designed to give the operator an accurate reading on

the status of the battery charger. DEPENDING ON THE

CHARGER INSTALLED ON THE MACHINE THOSE

LIGHTS MAY NOT BE USED. REFER TO SECTION 4-10

OF THIS MANUAL FOR FURTHER INFORMATION.

GREEN- Charge complete

YELLOW- Charging in process

RED- Charging abnormal

6. Emergency Stop Switch - Depress the switch to stop

all functions of the machine. The switch must be turned

clockwise to restore the machine functions.

7. Function Enable Button - A membrane switch that must

be pushed in and held to enable the controls of the

ground control station.

8. Mast Lift/Lower Buttons - Membrane switches that provide raising or lowering of the mast (with the Function

Enable Switch (7) pushed in).

9. Jib Lift/Lower Buttons - Membrane switches that provide raising or lowering of the jib (with the Function

Enable Switch (7) pushed in).

10. Superstructure Swing Buttons - Membrane switches

that provide swinging of the superstructure to the right

or to the left (with the Function Enable Switch (7)

pushed in).

11. Brake Release Switch

DO NOT MANUALLY DISENGAGE THE BRAKES UNLESS THE MACHINE:

- IS IN TRANSPORT (STOWED) POSITION.

- IS ON A SMOOTH, FIRM AND LEVEL SURFACE.

- WHEELS CHOCKED OR MACHINE POSITIVELY CONNECTED TO TOW

VEHICLE.

The machine must be powered ON to Ground Control Mode

at the Platform/Off/Ground selector switch to operate the

brake release switch. Refer to section 4-12 of this manual for

further information.

31210088 – JLG Lift – 3-5

Page 38

SECTION 3 – MACHINE CONTROLS AND INDICATORS

Platform Manual Descent Valves

The platform manual descent valves are used in the event of

total power failure to lower the platform using gravity.

1. Push on the remote push bar (1) to lower the mast.

Release the bar when the platform is lowered to the

desired level.

2. To lower the jib once the mast is fully retracted, push in

the manual descent valve, override button (2). Release

the button when the platform is lowered to the desired

level.

KEEP BODY, HANDS AND ARMS OUT OF THE PATH OF THE MAST, THE

JIB AND THE PLATFORM WHILE LOWERING.

Mast Manual Descent Valve

- The mast manual descent valve remote push bar (1) (red)

located behind the access door to the pump/motor assembly.

Figure 3-3. Mast Manual Descent Valve

is

3-6 – JLG Lift – 31210088

Page 39

SECTION 3 – MACHINE CONTROLS AND INDICATORS

Jib Manual Descent Valve

- The jib manual descent button (2) is located on the jib cylinder valve.

Manual Swinging Operating Devices

The manual swinging operating devices are used in the event of

total power failure to manually swing the superstructure. Those

devices are composed of:

- a rotary valve (1) located on the pump/motor control valves

assembly to release the swinging motor (Refer to Figure 3-

5.).

- a pinion (2), located below the pump/motor control valves

compartment, that can be operated using, depending on

equipment, a square 1/2 inch ratchet wrench (a) or the folding lever (b).

Figure 3-4. Jib Manual Descent Valve

31210088 – JLG Lift – 3-7

Page 40

SECTION 3 – MACHINE CONTROLS AND INDICATORS

DO NOT RELEASE THE SWINGING MOTOR UNLESS THE MACHINE IS ON

A LEVEL SURFACE.

NEVER LEAVE THE MACHINE WITH A WRENCH ENGAGED ON THE PINION, WITH THE LEVER UNFOLDED OR WITH THE ROTARY VALVE

UNSCREWED.

Platform Control Station

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY CONTROL LEVERS OR SWITCHES CONTROLLING PLATFORM MOVEMENT

DO NOT RETURN TO THE OFF OR NEUTRAL POSITION WHEN

Figure 3-5. Manual Swinging Operating Devices

RELEASED.

1. Open the access door to the pump/motor assembly.

2. Fully unscrew the rotary valve.

3. Depending on equipment, engage a square 1/2 inch

ratchet wrench in the square hole on top of the pinion or

lift the folding lever. Push on top of the pinion to engage

it in the turntable bearing teeth. Turn the lever clockwise

to swing the structure to the right or turn the lever counter-clockwise to swing the structure to the left.

4. When finished swinging, depending on equipment,

remove the wrench from the pinion or fold back the lever

until it is latched. Fully screw in the rotaty valve.

3-8 – JLG Lift – 31210088

Page 41

SECTION 3 – MACHINE CONTROLS AND INDICATORS

1. Indicator Panel

2. Emergency Stop Switch

3. Trigger Switch

4. Drive/Swing Functions Controller

5. Steer Switch

6. Mast/Jib Function Enable Button

7. Mast Lift Up/Down Joystick Controller

8. Jib Lift Up/Down Joystick Controller

9. Drive Orientation System (DOS) Override Button

10. Horn Button

31210088 – JLG Lift – 3-9

Page 42

SECTION 3 – MACHINE CONTROLS AND INDICATORS

1. Indicator panel

NOTE: The indicator panel uses different shaped symbols to alert

the operator to different types of operational situations

that could arise. The definition of those symbols are

explained below.

Indicates a potentially hazardous situation,

which if not corrected, could result in serious

injury or death. This indicator will be red.

Indicates an abnormal operating condition,

which if not corrected, may result in machine

interruption or damage. This indicator will be

yellow.

Indicates important information regarding the

operating condition, i.e. procedures essential

for safe operation. This indicator will be green.

Figure 3-6. Platform Control Indicator Panel

a- Control Enable Indicator

b- Creep Speed Indicator

c- System Distress Indicator

d- Drive Orientation Indicator

e- Tilt Indicator Warning Light

f- Overload Indicator Warning Light (If equipped)

g- Slack Chain Indicator Warning Light

h- Battery Discharge Indicator (BDI)

i- Soft Touch Indicator (Optional)

3-10 – JLG Lift – 31210088

Page 43

SECTION 3 – MACHINE CONTROLS AND INDICATORS

Green

Green

Yellow

Yellow

Red

Red

Red

Yellow

a. When lit, indicates that the controls are enabled. If

a function is not actuated within seven seconds, or

a seven seconds lapse between ending one function and beginning the next function occurs, the

enable light will go out and the enable must be

released and activated again to enable the controls.

When blinking, indicates that the machine is in a

configuration where the current activated function

is not permitted.

b. Indicates that the high drive cutout limit-speed is

engaged (the mast is out of transport (stowed)

position).

c. This light indicates that the control system has

detected an abnormal condition. This lamp when

actuated is flashing a DTC (Diagnostic Troubleshooting Code). For an explanation of these codes

and items, the operator can or cannot correct, see

Section 6 Diagnostic Trouble Codes (DTC).

d. When the structure is swung beyond the rear tires

or further in either direction, the Drive Orientation

indicator will illuminate. This is a signal for the operator to verify that the drive control is being operated

in the proper direction (i.e. controls reversed situations).

e. Indicates that the chassis is out of level (refer to

machine specifications for max. allowable slope

angle). If the mast is out of the transport (stowed)

position and the chassis is out of level, an audible

alarm will sound.

f. (If equipped) - Indicates that the maximum rated

load in the platform is exceeded. In addition to the

warning indicator, an audible alarm sounds. The

platform must be unloaded until the alarm stops.

g. Indicates that a slack chain condition has been

detected. In addition to the warning indicator, an

audible alarm will sound as long as the chain slack

chain condition exists.

h. This set of lights indicates the charge level of the

battery.

i. (If equipped) - Indicates the Soft Touch frame is

against an obstacle. In addition to the warning indicator, an audible alarm sounds. Once illuminated,

only the reverse movement to the one that caused

the contact with the obstacle can be operated in

Creep mode.

31210088 – JLG Lift – 3-11

Page 44

SECTION 3 – MACHINE CONTROLS AND INDICATORS

2. Emergency Stop Switch - A two-position, red, emergency stop switch, when positioned to ON furnishes

operating power to the platform control station. In addition, the switch can be used to turn off power to the

function controls in the event of an emergency. Power is

turned off by depressing the switch and power is turned

on by turning the switch clockwise to pull it out.

3. Trigger Switch - This switch located at the front of the

controller acts as an enable and must be depressed

before operating the drive, steer and swinging functions.

When released, the function being operated will stop.

4. Drive/Swing Functions Controller - This dual axis joystick controls drive and swinging functions. The speed

of both functions is proportionally controlled by the distance of travel of the hand joystick.

Drive - Engage the trigger switch lever (3) with the joystick in neutral position then move the control handle

forward to drive the machine forward or move the control handle backward to drive the machine backward.

Swing - Engage the trigger switch lever (3) with the joystick in neutral position then toggle the control handle to

the left to swing the superstructure to the left or toggle

the control handle to the right to swing to the right.

5. Steer Switch - The thumb-operated steer switch on top

of the control handle activates the steer wheels in the

direction activated (right or left).

6. Mast/Jib Function Enable Button - This button is used

to enable mast and jib functions. It must be depressed

and held before actuating a mast or jib function. When

released, the function being operated will stop.

7. Mast Lift Up/Down Joystick Controller - This fingertip,

single axis, joystick controller operates Mast Lift Up and

Lift Down functions.

With the joystick controller in neutral position, push-in

and hold the Mast/Jib Function Enable Button (6), moving the joystick backward will raise the mast and moving

the joystick forward will lower the mast. The speed of the

movements is proportionally controlled by the distance

of travel of the joystick.

8. Jib Lift Up/Down Joystick Controller - This fingertip,

single axis, joystick controller operates Jib Lift Up and

Jib Lift Down functions.

With the joystick controller in neutral position, push-in

and hold the Mast/Jib Function Enable Button (6), moving the joystick backward will raise the jib and moving

the joystick forward will lower the jib. The speed of the

movements is proportionally controlled by the distance

of travel of the joystick.

3-12 – JLG Lift – 31210088

Page 45

SECTION 3 – MACHINE CONTROLS AND INDICATORS

9. Drive Orientation Override Button - When the jib is

swung beyond the rear tires or further in either direction,

the Drive Orientation indicator will illuminate. Before driving, locate the black/white orientation arrows on both

the chassis and the platform controls. Push and release

the override switch and within 3 seconds slowly move

the Drive/Steer control to actuate drive or steer. Move

the drive control toward the arrow matching the

intended direction of machine travel.

10. Horn - This button, when activated, permits the operator

to warn job site personnel when the machine is operating in the area.

31210088 – JLG Lift – 3-13

Page 46

SECTION 3 – MACHINE CONTROLS AND INDICATORS

3.3 DECAL INSTALLATION

Figure 3-7. Decal Installation - Sheet 1

3-14 – JLG Lift – 31210088

Page 47

SECTION 3 – MACHINE CONTROLS AND INDICATORS

Figure 3-8. Decal Installation - Sheet 2

31210088 – JLG Lift – 3-15

Page 48

SECTION 3 – MACHINE CONTROLS AND INDICATORS

Figure 3-9. Decal Installation - Sheet 3

3-16 – JLG Lift – 31210088

Page 49

SECTION 3 – MACHINE CONTROLS AND INDICATORS

Table 3-1. T10E & T26E - Decal Installation

Item # T10E

1701499 1701499 1701499 1701499 1701499

1

1701640 1701640 1701640 1701640 1701640

2

1703811 1703811 1703811 1703811 1703811

3

1703814 1703814 1703814 1703814 1703814

4

1704016 1704016 1704016 1704016 1704016

5

1704277 1704277 1704277 1704277 1704277

6

1705781 1705781 1705781 1705781 1705781

7

1705803 1703785 1703785 1703785 1704031

8

1706493 -- -- -- --

9

1706740 1706740 1706740 1706740 1706740

10

1706764 1704885 1704885 1704885 1704885

11

12

13

14

15

16

17

18

AU0149 AU0149 AU0149 AU0149 AU0149

AU1423 AU1423 AU1423 AU1423 AU1423

-- -- -- -- -AU1825 AU1825 AU1825 AU1825 AU1825

AU2095 AU2095 AU2095 AU2095 AU2095

AU2096 AU2096 AU2096 AU2096 AU2096

AU2097 AU2097 AU2097 AU2097 AU2097

T26E

ANSI

T26E

CSA

T26E

Spanish

T26E

Portuguese

Item # T10E

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

AU2098 AU2098 AU2098 AU2098 AU2098

AU2099 AU2099 AU2099 AU2099 AU2099

AU2100 AU2122 AU2122 AU2122 AU2122

AU2101 AU2101 AU2101 AU2101 AU2101

AU2102 AU2120 AU2120 AU2120 AU2148

AU2103 AU2118 AU2118 AU2118 AU2150

AU2104 AU2104 AU2104 AU2104 AU2104

AU2105 AU2105 AU2105 AU2105 AU2105

AU2106 AU2116 AU2116 AU2116 AU2116

AU2107 AU2119 AU2119 AU2119 AU2147

AU2108 AU2117 AU2117 AU2117 AU2149

AU2109 AU2121 AU2142

-- -- AU2140 AU2147 AU2152

-- -- 1705514 -- --

-- --

-- --

-- --

-- --

T26E

ANSI

T26E

CSA

AU2141 AU2148 AU2153

AU2143 AU2149 AU2154

AU2144 AU2150 AU2155

AU2145 1704031 1704023

T26E

Spanish

AU2146 AU2151

T26E

Portuguese

31210088 – JLG Lift – 3-17

Page 50

SECTION 3 – MACHINE CONTROLS AND INDICATORS

NOTES:

3-18 – JLG Lift – 31210088

Page 51

SECTION 4 – MACHINE OPERATION

SECTION 4. MACHINE OPERATION

4.1 DESCRIPTION

This machine is a self-propelled hydraulic lift equipped with a

work platform on the end of an elevating and rotating mast.

The primary operator control station is in the platform. From this

control station, the operator can drive and steer the machine in

both forward and reverse directions. The operator can raise or

lower the mast and the jib or swing the mast to the left or right.

Standard mast swing is 172.5 degree left and right of the

stowed position. The machine has a Ground Control Station

which will override the Platform Control Station. Ground Controls operate mast and jib lift and swing and are to be used in an

emergency to lower the platform to the ground should the operator in the platform be unable to do so. The Ground Control is

also to be used in Pre-Start Inspection.

4.2 OPERATING SPECIFICATIONS AND LIMITATIONS

Capacities

The mast and the jib can be raised above horizontal with or

without any load in the platform if:

1. Machine is positioned on a smooth, firm and level surface.

2. Load is within manufacturer’s rated design capacity.

3. All machine systems are functioning properly.

4. Machine is as originally equipped from JLG.

Stability

Machine stability is based on two (2) conditions which are called

FORWARD and BACKWARD stability. The machine’s position of

least FORWARD stability is shown in (See Figure 4-2.) and its

position of least BACKWARD stability is shown in (See Figure 4-

1.).

TO AVOID FORWARD OR BACKWARD TIPPING, DO NOT OVERLOAD

MACHINE OR OPERATE THE MACHINE ON AN OUT-OF-LEVEL SURFACE.

31210088 – JLG Lift – 4-1

Page 52

SECTION 4 – MACHINE OPERATION

Figure 4-1. Position of Least BACKWARD stability

Figure 4-2. Position of Least FORWARD stability

4-2 – JLG Lift – 31210088

Page 53

Grade and Side Slope

With the machine in transport mode, travelling is limited by two

factors: gradeability and side slope (Refer to Figure 4-3.).

Gradeability is the percent of grade of the incline the machine

can climb. Side slope is the angle of the surface the machine

can be driven across. Refer to Table 6-1.

With the mast out of transport (stowed) position, the machine

must not be operated on grade or side slopes greater than that

is specified in Table 6-1.

SECTION 4 – MACHINE OPERATION

31210088 – JLG Lift – 4-3

Page 54

SECTION 4 – MACHINE OPERATION

Figure 4-3. Grade and Side Slope

4-4 – JLG Lift – 31210088

Page 55

SECTION 4 – MACHINE OPERATION

4.3 OPERATION

1. At ground control station, position the key-select switch

to PLATFORM.

2. Position the emergency stop switch to the on (out) position by turning it clockwise.

3. At platform control station, position the emergency stop

switch to the on (out) position by turning it clockwise.

NOTE: If at any time during operation, the machine remains idle

for a period exceeding 2 hours, machine power will be

shut down. The emergency stop switch(es) must be recycled to start machine again.

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY CONTROL LEVERS OR SWITCHES CONTROLLING THE PLATFORM MOVEMENT DOES NOT RETURN TO THE OFF OR NEUTRAL POSITION WHEN

RELEASED.

IF THE PLATFORM DOES NOT STOP WHEN CONTROL LEVER OR THE

ENABLE BUTTON/TRIGGER SWITCH IS RELEASED, USE THE EMERGENCY STOP SWITCH TO STOP THE MACHINE.

4.4 STEERING AND TRAVELLING (DRIVING)

DO NOT DRIVE WITH MAST OUT OF TRANSPORT (STOWED) POSITION

EXCEPT ON A SMOOTH, FIRM AND LEVEL SURFACE FREE OF

OBSTRUCTIONS AND HOLES.

TO AVOID LOSS OF TRAVEL CONTROL OR "TIP OVER", DO NOT DRIVE

MACHINE ON GRADES OR SIDE SLOPES EXCEEDING THOSE SPECIFIED

IN SECTION 6.

USE EXTREME CAUTION WHEN DRIVING IN REVERSE AND AT ALL

TIMES WHEN THE PLATFORM IS ELEVATED.

BEFORE DRIVING, LOCATE THE BLACK/WHITE ORIENTATION ARROWS

ON BOTH THE CHASSIS AND THE PLATFORM CONTROLS. MOVE THE

DRIVE CONTROLS IN A DIRECTION MATCHING THE DIRECTIONAL

ARROW FOR THE INTENDED DIRECTION OF TRAVEL.

31210088 – JLG Lift – 4-5

Page 56

SECTION 4 – MACHINE OPERATION

Figure 4-4. Steer/Drive Controls

Steering

1.

Squeeze and hold the

2. Activate the thumb switch on top of the joystick to right

(2) for travelling right or to left (3) for travelling left.

When released, the thumb switch will return to the center-off position and the wheels will remain in the previously selected position. To return the wheels to the

straightened position, the switch must be activated in

the opposite direction until the wheels are centered.

trigger switch (1)

on front of the joystick.

Travelling (driving)

1. With all control levers in neutral position, squeeze and

hold the trigger switch (1) on front of the joystick.

2. Move the joystick forward (4) (within 7 seconds after the

trigger has been actuated) to drive forward or move the

joystick backward (5) to drive in reverse. The speed of

the movement is proportionally controlled by the distance of travel of the joystick.

3. Return the controller to its centered (neutral) position to

stop, then release the trigger.

IF THE TILT INDICATOR WARNING LIGHT/ALARM IS ACTIVATED WHILE

DRIVING WITH THE MAST RAISED, LOWER THE MAST COMPLETELY

AND DRIVE TO A SMOOTH, FIRM AND LEVEL SURFACE.

4-6 – JLG Lift – 31210088

Page 57

SECTION 4 – MACHINE OPERATION

Drive Orientation System (DOS)

When the structure is swung beyond the rear wheels or further

in either direction, the drive orientation indicator (1) will illuminate and drive will be disabled.

1. Push and release the override button (2), and within 3

seconds move the drive/steer controls to activate drive

or steer.

2. Before driving, locate the black/white directional arrows

on both the chassis and the platform controls (3). Move

the drive control joystick in a direction matching the

directional arrow, for the intended direction of travel.

4.5 RAISING AND LOWERING THE PLATFORM

DO NOT RAISE THE PLATFORM EXCEPT ON A SMOOTH, FIRM AND

LEVEL SURFACE FREE OF OBSTRUCTIONS AND HAZARDS.

ENSURE THE AREA BENEATH THE PLATFORM IS FREE FROM

PERSONNEL PRIOR TO LOWERING THE PLATFORM.

Figure 4-6. Lift Controls

Figure 4-5. Drive Orientation System (DOS)

31210088 – JLG Lift – 4-7

Page 58

SECTION 4 – MACHINE OPERATION

Raising and lowering the mast

1. With all control levers in neutral position, push in and

hold the green enable button (1) on the left hand side

of the console.

2. To raise the mast, move the mast controller backward

(2). The speed of the movement is proportionally con-

trolled by the distance of travel of the joystick.

3. Return the controller to its centered (neutral) position to

stop.

4. To lower the mast, move the mast controller forward

(3). The speed of the movement is proportionally con-

trolled by the distance of travel of the joystick.

5. Return the controller to its centered (neutral) position to

stop, then release the enable button.

Raising and lowering the jib

1. With all control levers in neutral position, push in and

hold the green enable button (1) on the left hand side

of the console.

2. To raise the jib, move the jib controller backward (4).

The speed of the movement is proportionally controlled

by the distance of travel of the joystick.

3. Return the controller to its centered (neutral) position to

stop.

4. To lower the jib, move the jib controller forward (5).

The speed of the movement is proportionally controlled

by the distance of travel of the joystick.

5. Return the controller to its centered (neutral) position to

stop, then release the enable button.

4-8 – JLG Lift – 31210088

Page 59

SECTION 4 – MACHINE OPERATION

1

2

3

4.6 SWINGING

DO NOT SWING THE SUPERSTRUCTURE EXCEPT ON A SMOOTH, FIRM

AND LEVEL SURFACE, FREE OF OBSTRUCTIONS AND HOLES.

WHEN SWINGING, MAKE SURE THERE IS AMPLE ROOM FOR THE JIB

TO CLEAR SURROUNDING WALLS, PARTITIONS AND EQUIPMENT.

Figure 4-7. Swing Control

1. With all control levers in neutral position, squeeze and

hold the trigger switch (1) on front of the joystick.

2. Move the joystick to the desired direction: right (2) or

left (3). The speed of the movement is proportionally

controlled by the distance of travel of the joystick.

3. Return the controller to its centered (neutral) position to

stop, then release the trigger.

4.7 EMERGENCY CONTROL

The machine has a Ground Control Station which will override

the Platform Control Station. Ground controls operate Lift and

Swing, and are to be used in an emergency to lower the platform to the ground, should the operator in the platform be

unable to do so.

DO NOT OPERATE FROM GROUND CONTROL STATION WITH

PERSONNEL IN THE PLATFORM EXCEPT IN AN EMERGENCY.

ENSURE THE AREA BENEATH THE PLATFORM IS FREE OF PERSONNEL

OR OBSTACLES PRIOR TO LOWERING.

31210088 – JLG Lift – 4-9

Page 60

SECTION 4 – MACHINE OPERATION

1. Position the key-select switch (1) to GROUND.

2. Push and hold the enable button (2).

3. Actuate the appropriate function button (3) until the

desired elevation or position of the platform is achieved.

4.8 ALARMS

Overload Warning Light/Alarm (If equipped)

When the maximum rated load in the platform is exceeded, RED

light indicators at both the ground and the platform control stations will blink and an audible alarm will sound. When the overload indicator warning is activated, all machine functions are

disabled. The platform must be safely unloaded until the alarm stops.

Tilt Warning Light/Alarm

When the chassis is out of level (Refer to Table 6-1), the RED

light indicator at platform control station will illuminate. If the

mast is out of transport (stowed) position, and the chassis is out

of level an audible alarm will sound.

IF THE WARNING LIGHT IS ILLUMINATED WHEN THE MAST IS RAISED,

LOWER THE MAST AND REPOSITION MACHINE SO THAT IT IS LEVEL

Figure 4-8. Emergency Controls

BEFORE ELEVATING THE MAST.

4-10 – JLG Lift – 31210088

Page 61

SECTION 4 – MACHINE OPERATION

When the tilt indicator warning is activated, the following functions are affected:

-The Drive function is disabled out of stowed position.

-Mast/Jib Lift and Swinging movements switch to Creep

mode.

When the tilt indicator warning is activated, control the machine

as follows:

1. Lower the mast.

2. Return the platform in line with the chassis.

3. Lower the Jib.

4. Drive the machine to a smooth, firm and level surface.

AVOID RAISING THE MAST, OPERATING THE JIB OR SWINGING WITH

THE MAST RAISED WHEN THE MACHINE IS OUT OF LEVEL. ALWAYS

LOWER THE MAST AS MUCH AS POSSIBLE BEFORE OPERATING THE

JIB OR SWINGING.

Slack Chain Warning Light/Alarm

When the system detects a slack chain condition, the RED light

indicator at platform control station will illuminate and an audible

alarm will sound.

Slack chain condition is generally caused by the platform or the

jib coming to rest on an obstacle while lowering.

When the slack chain indicator warning is activated, all machine

functions, except mast and jib raising movements are disabled.

Procedure to follow in case the slack chain indicator warning is

activated:

1. Raise the mast or the jib (generally the reverse movement to the one that caused the alarm to be activated).

This will re-tension the chain(s) and stop the alarm.

2. Examine surroundings to identify the cause.

3. Perform the movement which will clear the machine and

prevent contact with the obstacle.

IF THE EXAMINATION OF THE SURROUNDINGS DOES NOT REVEAL ANY

POSSIBLE OBSTACLE, DISCONTINUE OPERATION IMMEDIATELY.

DO NOT USE MANUAL DESCENT CONTROLS.

PLATFORM OCCUPANTS MUST BE RESCUED AND THE MAST MECHANISM SERVICED BY A QUALIFIED TECHNICIAN.

31210088 – JLG Lift – 4-11

Page 62

SECTION 4 – MACHINE OPERATION

Soft Touch Warning Light/Alarm (Option)

When the bumper under the work platform is against an obstacle, the YELLOW light indicator at platform control station will

illuminate and an audible alarm will sound. Only the reverse

movement to the one that caused the contact with the obstacle

can be controlled in the Creep mode.

NOTE: This feature is only operational when the machine is con-

trolled from the platform control station.

4.9 SHUT DOWN AND PARK

Shut down and park the machine as follows:

1. Drive the machine to a reasonably well-protected and

well-ventilated area.

2. Ensure the platform is fully lowered.

3.

Turn the platform/ground selector switch to off and remove

the key to disable the machine and prevent unauthorized

use.

4. At the ground control station, position the emergency

stop switch to the off (pushed in) position.

5. If necessary, cover the platform console, the instruction

placards, caution and warning decals so that they will be

protected from hostile environment.

6. If necessary, charge the battery.

4-12 – JLG Lift – 31210088

Page 63

SECTION 4 – MACHINE OPERATION

4.10 BATTERY CHARGING

NOTE: Be sure that the machine is parked in a well-ventilated

area before charging begins.

ONLY PLUG THE CHARGER INTO A PROPERLY INSTALLED AND

GROUNDED OUTLET. DO NOT USE GROUND ADAPTORS OR MODIFY