Page 1

Model MMV

TM 10794A-24/2

OM0651

SERVICE MANUAL

8990440

PCN 500 107941 00

Printed in U.S.A. 12/04

Page 2

Page 3

EFFECTIVITY PAGE

December 17, 2004 - B - Replaced all branding with JLG.

8990440 MMV i

Page 4

EFFECTIVITY PAGE

MMV 8990440-ii

Page 5

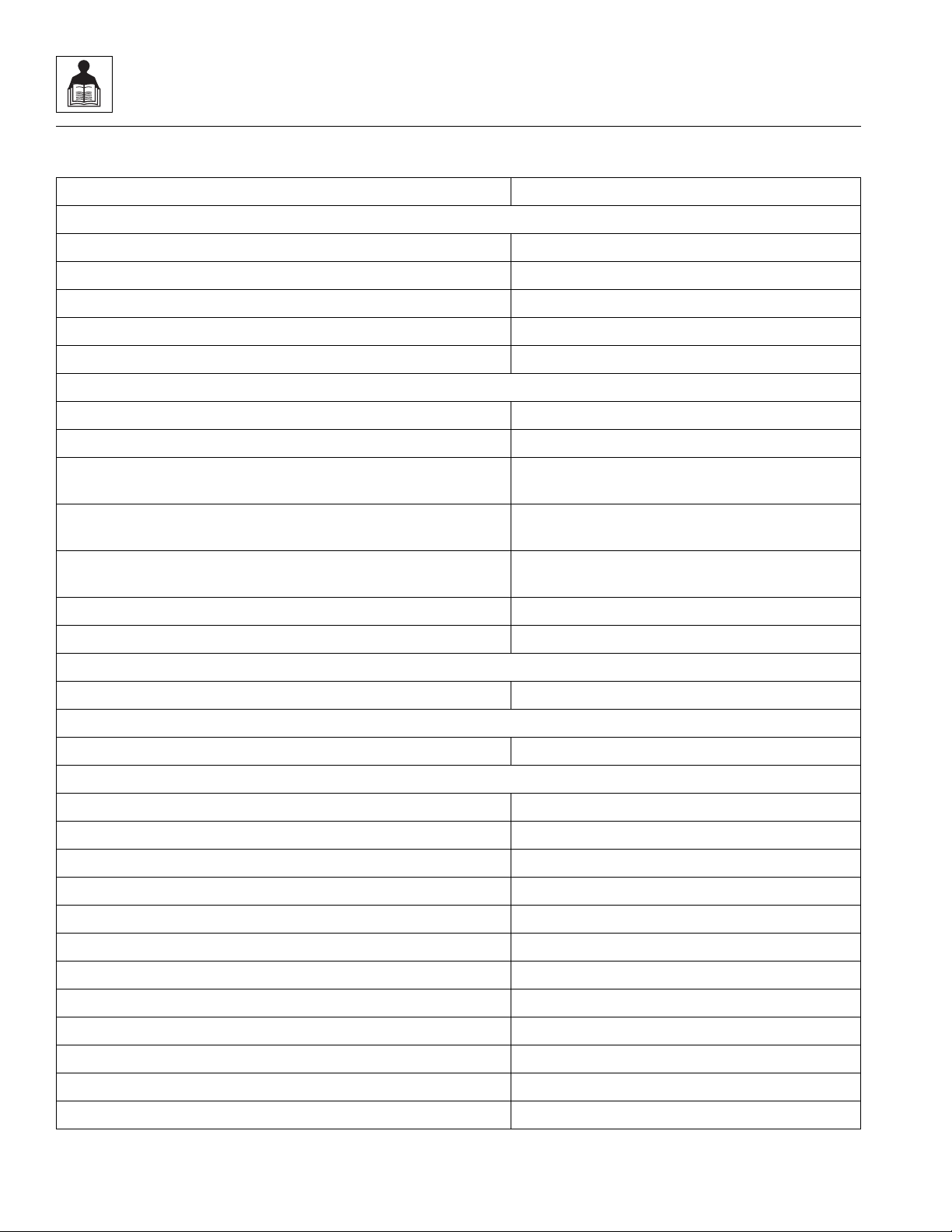

SECTION CONTENTS

Section Subject Page

Section 1

Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.2 Owners/Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3 Training Mechanics as Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.5 Accident Prevention Tag Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.6 Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.7 Emergency Exit Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.8 Hazard/Emergency Information Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

Section 2

General Information, Specifications and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1 MMV Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.4 Metric Conversion Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8

2.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.6 Fluids, Lubricants and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.20

2.7 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.8 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.9 Hoses and Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.10 Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.11 Pressure Testing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.12 After Service Startup and Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.13 Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.14 Emergency Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.77

2.15 Parking Brake/Transmission De-Clutch Test Procedures . . . . . . . . . . . . . . . . . . . . . . . 2.81

Section 3

Cab, Covers and Mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

3.1 Operator’s Cab and Covers Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . 4.2

3.2 Operator’s Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

3.3 Operator’s Seat and Seat Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.24

3.4 Cab Heater/Air Conditioning Blower Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.26

3.5 Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.30

3.6 Mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.43

3.7 Access Panels, Covers and Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.44

Section 4

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

4.1 Boom System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

4.2 Boom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

4.3 Boom Assembly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

4.4 Quick Attach Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.44

4.5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.46

Model MMV Rev. 12/17

.

i

Page 6

Section Subject Page

Section 5

Axles, Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1 Axle and Wheel Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

5.2 Axle Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

5.3 Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.17

Section 6

Transfer Case and Drive Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.1 Transfer Case and Drive Shaft Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . 6.2

6.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3

6.3 Transfer Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.3

6.4 Drive Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7

6.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.14

Section 7

Transmission: ZF 4 WG-98 TS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1

7.1 Transmission Assembly Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2

7.2 Transmission Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3

7.3 Transmission Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3

7.4 Transmission Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3

7.5 Transmission Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.6 Transmission Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.7 Transmission Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5

7.8 Towing a Disabled Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.18

7.9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.19

Section 8

Engine: Cummins 4BTA 3.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.2

8.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.4

8.3 Engine Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6

8.4 Specifications and Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6

8.5 Standard Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6

8.6 Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.7

8.7 Engine Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.18

8.8 Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.18

8.9 Engine Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.25

8.10 Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.26

8.11 Engine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.45

8.12 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.46

Section 9

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.1

9.1 Hydraulic Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.3

9.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4

9.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.5

9.4 Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.5

9.5 Hoses, Tube Lines, Fittings, Etc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.6

9.6 Hydraulic Pressure Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.7

9.7 Hydraulic System Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.10

9.8 Hydraulic Circuits and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.13

9.9 Steer Indexing Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.85

9.10 Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.86

ii

Model MMV Rev. 12/17

Page 7

Section Subject Page

9.11 Hydraulic System Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.87

9.12 Valves and Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.98

9.13 Accumulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.136

9.14 Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.142

Section 10

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1

10.1 Electrical Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4

10.2 Service Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.8

10.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.8

10.4 Effective Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.8

10.5 Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.9

10.6 Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.10

10.7 Electrical System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.16

10.8 Transmission Gear Selection Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.72

10.9 Dash Panel Warning Indicator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.80

10.10 Engine Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.88

10.11 Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.91

10.12 Electrical System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.108

10.13 Switches and Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.134

Section 11

Stabil-TRAK™ System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.1

11.1 Stabil-TRAK™ System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.2

11.2 Stabil-TRAK™ Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3

11.3 Stabil-TRAK™ Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.4

11.4 Stabil-TRAK™ Circuit Operation and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 11.6

11.5 Stabil-TRAK™ System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.28

Section 12

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.1

Accident Prevention Tags

Model MMV Rev. 12/17

iii

Page 8

Section Subject Page

iv

Model MMV Rev. 12/17

Page 9

Section 1

Safety Practices

Contents

PARAGRAPH TITLE PAGE

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.2 Owners/Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3 Training Mechanics as Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4.1 Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4.2 Hazard Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.5 Accident Prevention Tag Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.6 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6.1 Personal Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6.2 Equipment Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

1.6.3 General Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.6.4 Operational Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.7 Emergency Exit Rear Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.6

1.8 Hazard/Emergency Information Signs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

Model MMV Rev. 12/04

1.1

Page 10

Safety Practices

1.1 INTRODUCTION

JLG (hereafter, JLG) products meet all applicable indus-

try safety standards. JLG actively promotes safe practices in the use and maintenance of its products through

training programs, instructional manuals and the pro-active efforts of all employees involved in engineering, design, manufacture, marketing and service.

This manual is designed to provide service technicians

with complete information on the maintenance and repair

of the Sky Trak MMV Telescopic Material Handler.

Particular effort has been made to produce a manual to

serve as a reference handbook for the experienced service technician, but also provide essential step-by-step

procedures for the professional development of the less

experienced person. Remember, even the best manual in

the world is no substitute for an appropriate education,

skill development that comes through experience alone,

safety, wise and judicious discernment, and ultimately,

proper performance of service procedures.

This service manual provides general directions for accomplishing service and repair procedures with tested,

effective techniques. Following the procedures in this

manual will help assure safety and equipment reliability.

Read, understand and follow the information in this manual, and obey all locally approved safety practices, procedures, rules, codes, regulations and laws. Prior to

performing any maintenance on the vehicle, consider all

factors, circumstances and conditions which can have an

effect upon the safety of personnel and equipment, and

take appropriate action to ensure the safety of all

involved.

These instructions cannot cover all details or variations in

the equipment, procedures or processes described, nor

provide directions for meeting every possible contingency

during operation, maintenance or testing. When additional information is desired to satisfy a situation not covered

sufficiently, consult the local JLG Authorized Service

Center (ASC) or the JLG Service Department at 1-877554-5438 or 1-717-485-5161.

Many factors contribute to unsafe conditions; carelessness, fatigue, overload, inattentiveness, unfamiliarity,

even drugs and alcohol, among others. Although equipment damage can usually be repaired in a brief period of

time, death and irreparable injury are permanent. For optimal safety, encourage everyone to think, and to act,

safely.

Appropriate service methods and proper repair procedures are essential for the safety of the individual doing

the work, for the safety of the operator, and for the safe,

reliable operation of the vehicle.

Provisions for supplementary information are made by

JLG in the form of Service Bulletins, Service Campaigns,

Service Training Schools, the JLG web site, other

literature, and through updates to the manual itself.

Comments and suggestions for improvement are

welcome and encouraged.

All information, illustrations and specifications contained

in this manual are based on the latest product information

available at the time of publication approval. JLG re-

serves the right to make changes and improvements to

its products, and to discontinue the manufacture of any

product, at its discretion at any time without public notice

or obligation.

1.2 OWNERS/OPERATORS MANUAL

The vehicle must be driven and operated as a consequence of, or when performing, service, maintenance

and test procedures. The service technician must, therefore, thoroughly read, understand and follow the Sky Trak

MMV Telescopic Material Handler Owners/Operators

Manual.

An Owners/Operators and EMI Safety Manuals are supplied with each vehicle and must be kept in the pocket (1)

located in the lower door in the cab.

In the event that the Owners/Operators or Safety Manuals are missing, consult the local JLG Authorized Service

Center (ASC) or the JLG Service Department before proceeding.

1.2

Model MMV Rev. 12/04

Page 11

1

MM2240

1.3 TRAINING MECHANICS AS

OPERATORS

Because it is necessary to move the vehicle to service or

maintain the vehicle, it is necessary that all mechanics

are OSHA trained and certified as operators. A

mechanic trained in the proper operation of the vehicle

can better determine whether all the functions are

operating correctly.

Safety Practices

1.4 SAFETY INFORMATION

The following information provides general safety instructions, including examples of hazard statements with signal words, notification of hazards, methods to help avoid

hazards and the consequences of failing to follow the

safety information. To avoid possible death or injury,

carefully read and follow all safety messages. Fully understand the potential causes of death or injury.

In the event of an accident, know where to obtain medical

assistance, use a first-aid kit and fire extinguisher/fire

suppression system. Keep emergency telephone numbers (fire department, ambulance, rescue squad/paramedics, police department, etc.) nearby. If working alone,

check with another person routinely to help ensure personal safety.

The information in this manual does not replace any other

safety rules or proper judgment. Governmental

authorities and employers also have their own sets of

rules, codes, regulations and laws. Before starting work

at a worksite, check with the supervisor or safety

coordinator and ask about the safety policy. Learn the

safety requirements in effect before operating,

maintaining, servicing or testing the vehicle. Safety

depends on following safety requirements.

1.4.1 Safety Alert Symbol

The exclamation mark within a triangle is the Safety Alert

Symbol.

At the time of original purchase, the purchaser of this

vehicle was instructed by the seller on its proper use.

When this vehicle is to be serviced or maintained by

someone other than the purchaser, make certain that the

mechanic is trained, in accordance with the OSHA

regulations listed in the NOTICE below, and reads and

understands the Sky Trak MMV Telescopic Material

Handler Owners/Operators Manual before

operating or

maintaining the vehicle.

NOTICE: Under OSHA rules, it is the responsibility of the

employer to provide operator training. Successful completion and certification of Safety Training for Rough Terrain Forklifts is required. Operator Training Kits are

available by calling Ken Cook Company at

(414) 466-6060. An order form for these kits is available

through our website, http://www.jlg.com.

In addition, make sure that the mechanic has completed

a walk-around inspection of the vehicle, is familiar with

all decals and/or decal plates on the vehicle, and has

demonstrated the correct use of all controls.

Model MMV Rev. 12/04

OP0330

This symbol means “Attention! Become Alert! Your

Safety Is Involved!” The symbol is used to attract attention to safety hazards found on the vehicle safety decals

and/or decal plates throughout this manual.

1.3

Page 12

Safety Practices

1.4.2 Hazard Statements

Signal words and messages are used in conjunction with

the safety alert symbol to create hazard statements.

These hazard statements convey important information

about safety.

Four types of hazard statements are used in this manual.

Each statement indicates the existence and degree of relative risk of the hazard described within the statement

that follows the signal word.

Explanations of the types of hazard statements are as

follows:

DANGER:

The signal word “DANGER” indicates an imminently

hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING:

The signal word “WARNING” indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION:

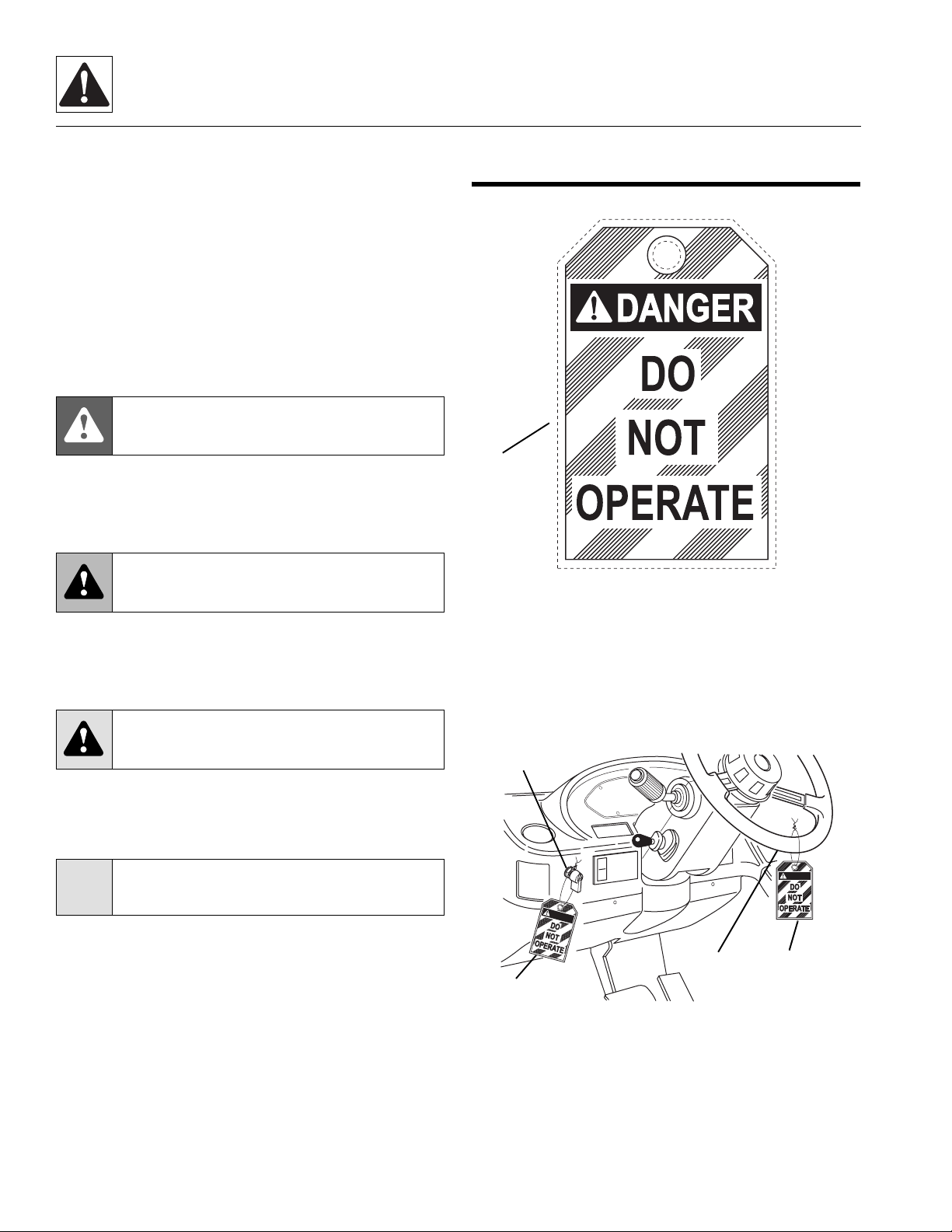

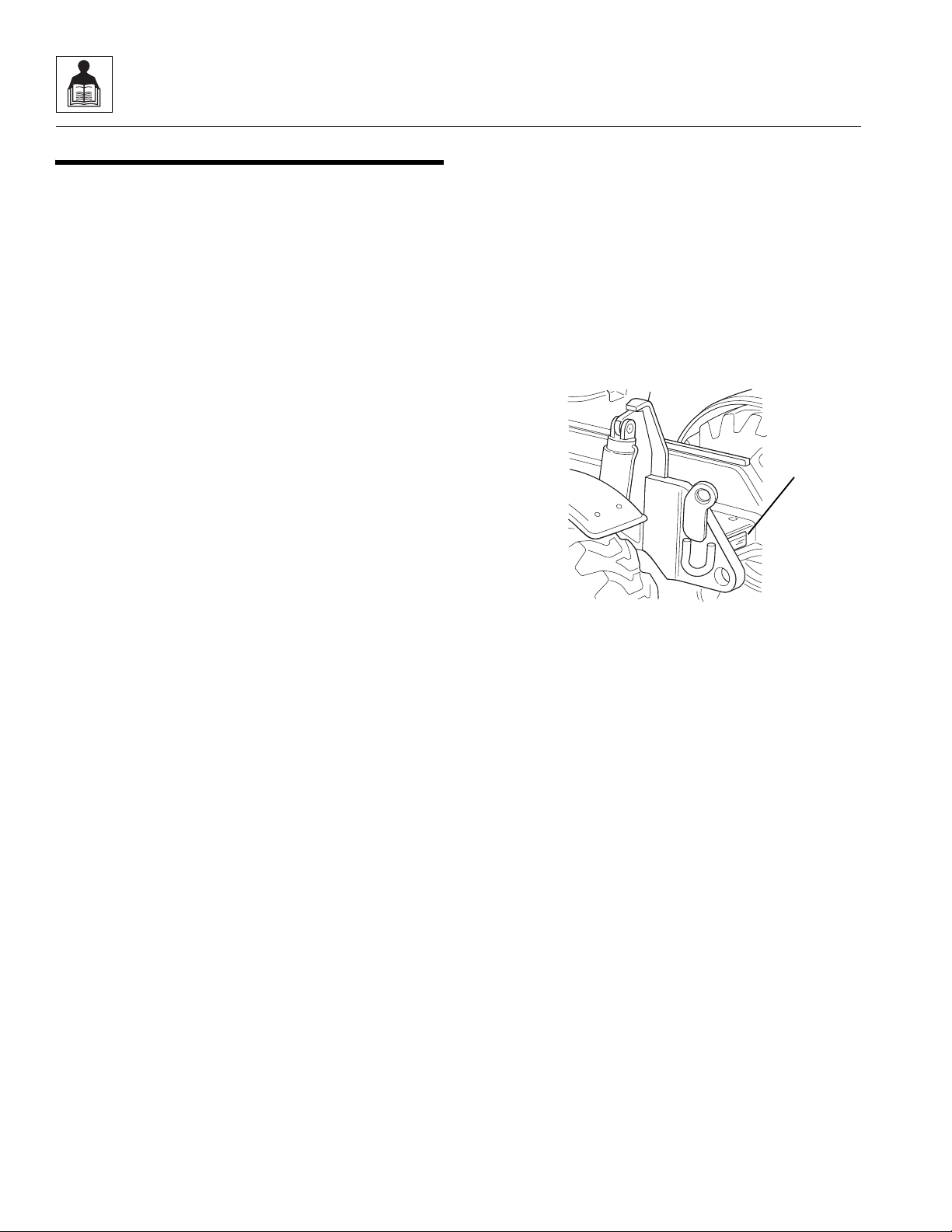

1.5 ACCIDENT PREVENTION

TAG U SAGE

1

MC0690

Before beginning any maintenance or service, place an

Accident Prevention Tag (1) on both the ignition switch

(2) and steering wheel (3), stating that the vehicle should

not be operated. Actual Accident Prevention Tags, that

can be punched out and used, are included as the last

page in this manual. Retain these Accident Prevention

Tags for reuse at a later date.

The signal word “CAUTION” indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury.

CAUTION:

The signal word “CAUTION,” used without the safety

alert symbol, indicates a potentially hazardous situation

which, if not avoided, could result in property damage.

For safe maintenance of the vehicle, read, understand

and follow all DANGER, WARNING and CAUTION

information.

1.4

2

DANGER

D

A

N

G

E

R

3

1

1

OM1510

Model MMV Rev. 12/04

Page 13

Safety Practices

1.6 SAFETY INSTRUCTIONS

Following are general safety statements to consider

before

Additional statements related to specific tasks and procedures are located throughout this manual and are listed

prior to any work instructions to provide safety information before the hazard occurs.

For all safety messages, carefully read, understand and

follow the instructions

1.6.1 Personal Hazards

HAIR and CLOTHING: DO NOT wear loose clothing or

jewelry. Tie up or restrain hair. Wear the correct safety

equipment for the job (including but not limited to: hard

hat; safety shoes; safety glasses, goggles, or face shield;

heavy gloves; hearing protection; reflective clothing; wetweather gear; respirator or filter mask).

E

tection when chiseling, grinding, sanding, welding, painting, repairing hydraulic systems, or checking, testing or

charging the battery.

B

tion when grinding or painting.

H

tion in a high-noise area.

F

inforced toe caps and slip-resistant soles.

L

least one assistant or a suitable sling and hoist.

performing maintenance procedures on a vehicle.

before

YE PROTECTION: Always wear appropriate eye pro-

REATHING PROTECTION: Wear respiratory protec-

EARING PROTECTION: Always wear hearing protec-

OOT PROTECTION: Wear protective footwear with re-

IFTING: NEVER lift a heavy object without the help of at

proceeding.

1.6.2 Equipment Hazards

OWNERS/OPERATORS MANUAL: Before operating

the vehicle, carefully read, understand and follow the

Owners/Operators Manual.

O

PERATIONAL PROTECTION: Before operating the vehicle or returning it for operational use, check that the operator’s protective structure is intact, undamaged,

unmodified and secure.

L

IFTING OF EQUIPMENT: Before using any lifting equipment (chains, slings, brackets, hooks, etc.), verify that it

is of the proper capacity, in good working condition and

properly attached.

NEVER stand or otherwise become positioned under a

suspended load or under raised equipment. The load or

equipment could fall or tip.

DO NOT use a hoist or jack to support raised equipment.

A hoist or jack failure can allow the equipment to fall or tip.

Always support equipment with proper capacity blocks or

stands that are properly rated for the load.

C

OMPRESSED AIR: Before and during the use of compressed air, wear eye protection and advise other personnel in the work area that compressed air is about to be

used.

H

AND TOOLS: Always use the proper tool for the job;

keep tools clean and in good working order, and use special service tools only as recommended.

Model MMV Rev. 12/04

1.5

Page 14

Safety Practices

1.6.3 General Hazards

SOLVENTS: Only use approved solvents, and solvents

that are known to be safe for use.

OUSEKEEPING: Keep the work area and operator’s

H

cab clean and remove all hazards (debris, oil, tools, etc.).

F

IRST AID: Immediately clean, dress and report all injuries (cuts, abrasions, burns, etc.), no matter how minor.

Know the location of a first-aid kit, and know how to

use it.

C

LEANLINESS: Wear eye protection, and clean all components with a high-pressure or steam cleaner before attempting service.

When removing hydraulic components, plug hose ends

and connections to prevent excess leakage and contamination. Place a suitable catch basin beneath the vehicle

to capture fluid run-off.

1.6.4 Operational Hazards

OPERATIONAL CONSIDERATIONS: Before operating

the vehicle, carefully read, understand and follow the

Owners/Operators Manual.

E

NGINE: Stop the engine before performing any service.

ANGEROUS START: Place Accident Prevention Tags

D

on both the ignition switch and steering wheel before attempting to perform any service or maintenance. Disconnect battery leads. Place a warning sign on vehicles that

are dangerous to start, if leaving the vehicle unattended.

V

ENTILATION: Avoid prolonged engine operation in en-

closed areas without adequate ventilation.

R

ADIATOR CAP: Always wear steam-resistant, heatprotective gloves when opening the radiator cap. Cover

cap with a clean, thick cloth and turn slowly to the first

stop to relieve pressure.

SOFT SURFACES AND SLOPES

vehicle that is parked on a soft surface or slope (inclined

ground or hill). The vehicle must be on a hard, level

surface with the wheels blocked when performing any

service. Obtain assistance, block all wheels, and add

supports if necessary before beginning any work.

S

UPPORTS AND STRAPS: Install safe, stable supports,

slings or straps, beneath or around a component or structural member before beginning any work.

: NEVER work on a

F

LUID PRESSURE: Before loosening any hydraulic or

diesel fuel component, hose or tube, turn engine OFF.

Wear heavy, protective gloves and eye protection.

NEVER check for leaks using any part of your body; use

a piece of cardboard or wood instead. If injured, seek

medical attention immediately. Diesel fuel leaking under

pressure can explode. Hydraulic fluid and diesel fuel

leaking under pressure can penetrate the skin, causing

infection, gangrene, and other serious personal injury.

Relieve all pressure before disconnecting any component, part, line or hose. Slowly loosen parts and allow release of residual pressure before removing any part or

component. Before starting engine or applying pressure,

use components, parts, hoses and pipes that are in good

condition, connected properly, and tightened to the proper torque. Capture fluid in an appropriate container and

dispose of it in accordance with prevailing environmental

regulations.

P

RESSURE TESTING: When conducting any test, only

use test equipment that is correctly calibrated and in good

condition. Use the correct equipment in the proper manner, and make changes or repairs as indicated by the test

procedures to achieve the desired results.

L

EAVING VEHICLE: Lower the attachment to the ground

before leaving the vehicle.

T

IRE PRESSURE: Always keep tires inflated to the proper pressure to help prevent dangerous travel and loadhandling situations. DO NOT over-inflate tires.

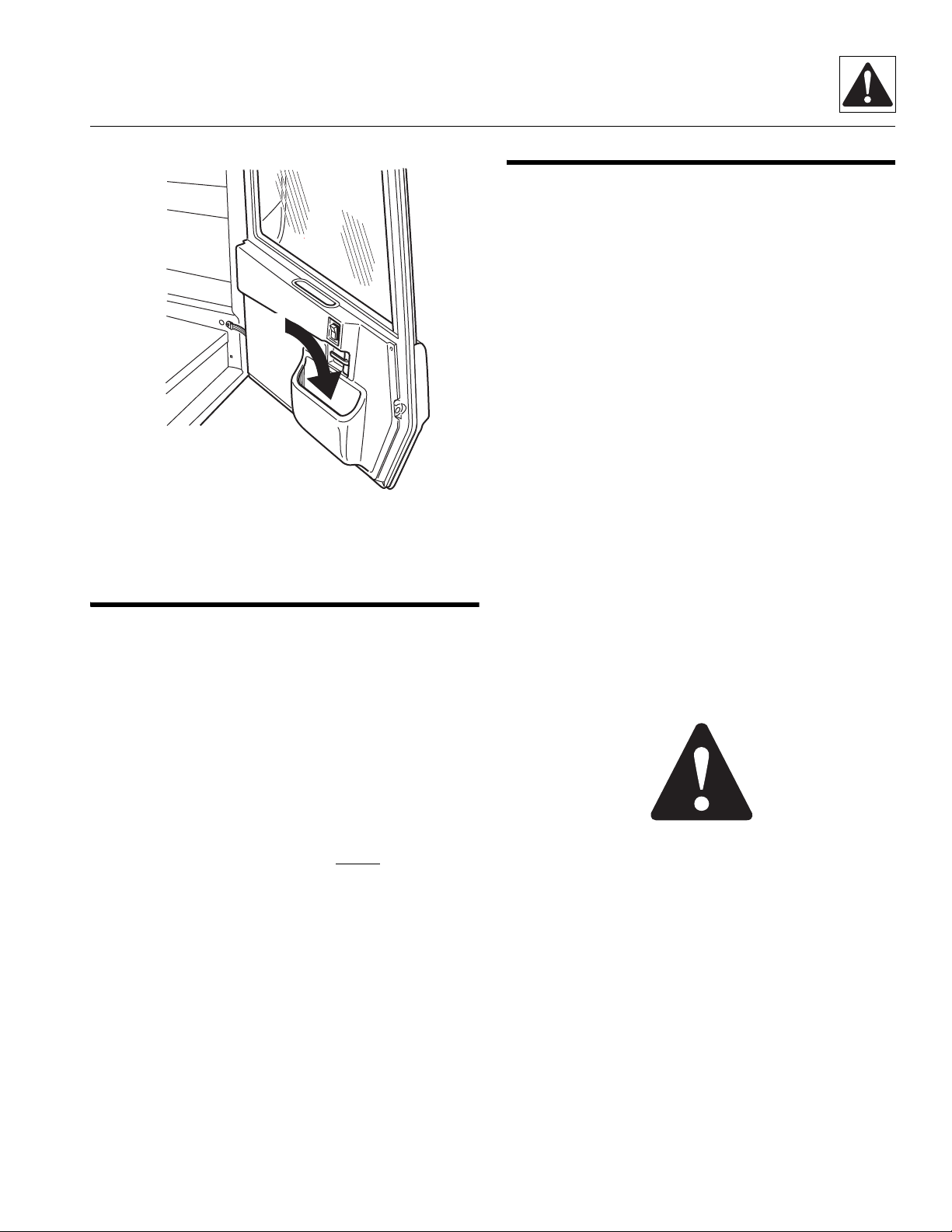

1.7 EMERGENCY EXIT REAR WINDOW

The rear window in the enclosed cab can be used as an

emergency exit by removing the latch pins (1) located on

the two window latches (2). Once the latch pins have

been removed, the window (3) can be swung open.

1

.

2

.

3

.

4

1

0

9

7

9

1

1

3

2

OT08902

1.6

Model MMV Rev. 12/04

Page 15

Safety Practices

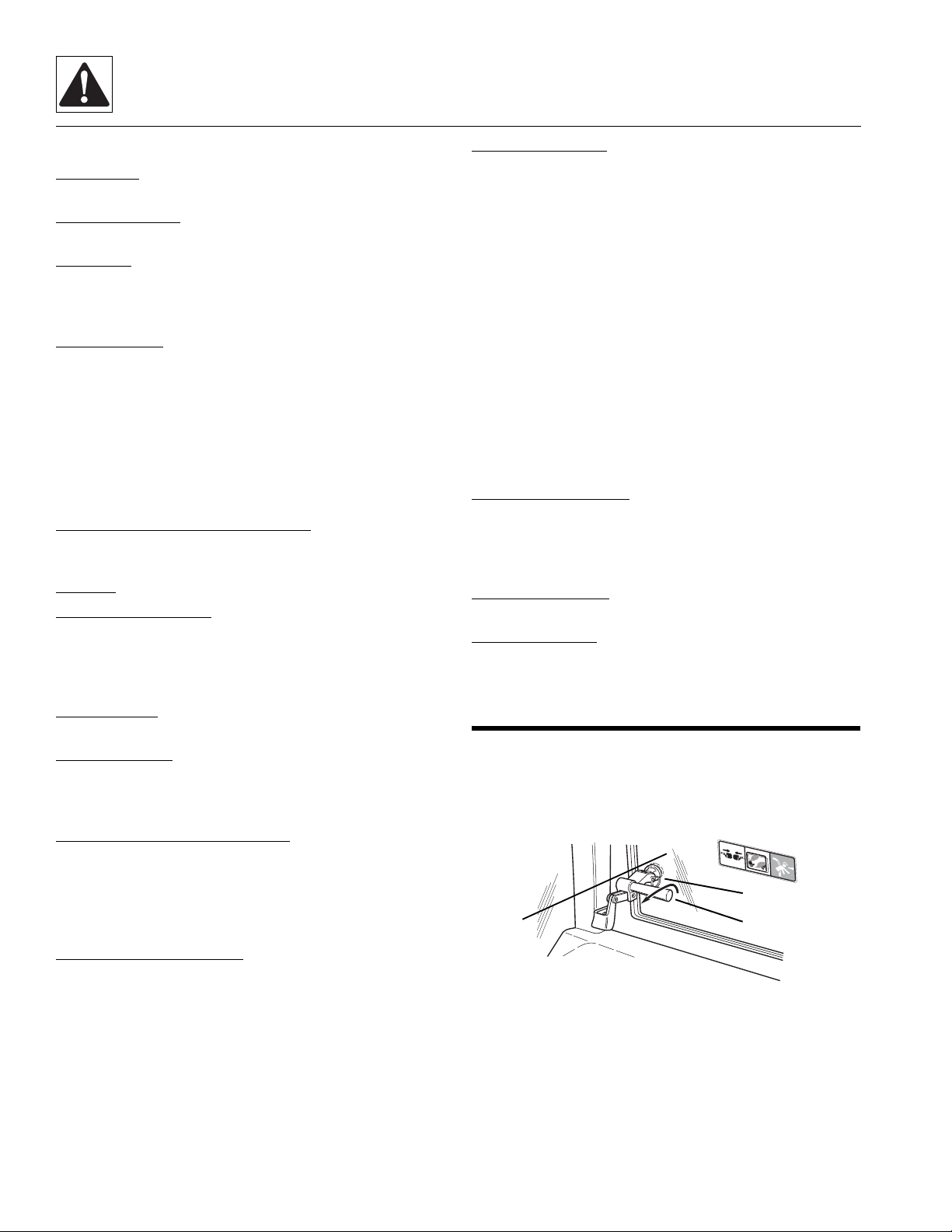

1.8 HAZARD/EMERGENCY

INFORMATION SIGNS

Locations of vehicle hazard and other emergency information signs are shown below. As part of routine maintenance, check that ALL hazard and emergency

information signs on the vehicle are present and readable. Keep all signs clean.

CONTACTING

ELECTRIC

POWER LINES

can result in

electrocution.

6

9

5

WARNING

VEHICLE

ROLLAWAY

can cause

death or

serious

injury.

WARNING

DANGER

ALWAYS

engage

parking

brake

before

dismounting.

NEVER operate

vehicle within

10 feet (3m) of

electric power

lines.

AVOID CRUSHING

if vehicle tips.

Jumping can

result in death or

serious injury.

DANGER

DO NOT JUMP.

Brace yourself.

Stay in cab.

Keep seat belt on.

VEHICLE

TIPOVER

can result

in death or

serious injury.

DANGER

DO NOT raise

DO NOT

boom while

travel

on a slope

with the

unless load

boom

is level.

raised.

SAFETY INSTRUCTIONS

1. Read operators manual

before operating.

2. Fasten seat belt.

MAINTAIN

proper tire

pressure at

all times.

8

10

3. Allow no riders.

4. Use an approved work

platform to lift or lower

personnel.

7

If a replacement sign is needed, refer to the Owners/Operators Manual and parts catalog for the latest parts numbers and ordering information. Or, contact JLG Inc.

directly at:

Domestic: 1-877-554-5438

or

International: 1-717-485-5161

MOVING PARTS can cut.

11

Keep clear of fan and belts

while engine is running.

MOVING PARTS can entangle.

14

2.

1.

12

15

3.

4109791

Allow no riders.

A

4

4. No Riders WARNING

5. Vehicle Rollaway WARNING

6. Electrocution DANGER

7. Load Chart Booklet

8. Tipover DANGER - Operating

9. Do Not Jump DANGER

OT05602

13

10. Safety Instructions

11. Moving Parts WARNING

12. Explosive Gases WARNING

13. Carrying Personnel WARNING

14. Boom Angle Indicator

15. Emergency Exit (Enclosed Cab Only)

B

Note: Many of these hazard related signs are available free of charge by

calling JLG Inc. at 1-717-485-5161(Domestic) or 1-877-554-5438(International).

OM11412

Model MMV Rev. 12/04

1.7

Page 16

Safety Practices

This Page Intentionally Left Blank

1.8

Model MMV Rev. 12/04

Page 17

Section 2

General Information, Specifications and Maintenance

Contents

PARAGRAPH TITLE PAGE

2.1 MMV Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

2.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.2.1 Service Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.2.2 The Owners/Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.2.3 Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . 2.6

2.2.4 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

2.3 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.3.1 Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.3.2 Bolts and Nuts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.3.3 Straight Thread O-ring Fitting (Non-Adjustable) . . . . . . . . . . . . . . . . . . . . 2.7

2.3.4 Straight Thread O-ring Fitting (Adjustable) . . . . . . . . . . . . . . . . . . . . . . . . 2.7

2.3.5 Flat-Face O-ring Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8

2.4 Metric Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.8

2.4.1 Approximate American to Metric Conversions . . . . . . . . . . . . . . . . . . . . . 2.8

2.4.2 Approximate Metric to American Conversions . . . . . . . . . . . . . . . . . . . . . 2.9

2.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.5.1 Vehicle Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.10

2.5.2 Vehicle Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

2.5.3 Attachment Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

2.5.4 Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.12

2.5.5 Hydraulic Cylinder Performance Specifications . . . . . . . . . . . . . . . . . . . . 2.13

2.5.6 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.14

2.5.7 Engine Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.15

2.5.8 Fluid and Lubricant Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.16

2.5.9 Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.17

2.5.10 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.18

2.5.11 Miscellaneous Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.18

2.5.12 Tamper Proofing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.19

2.5.13 Fork Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.19

Model MMV Rev. 12/04

2.1

Page 18

General Information, Specifications and Maintenance

2.6 Fluids, Lubricants and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.20

2.6.1 Axles (Differential Housings) and Transfer Case. . . . . . . . . . . . . . . . . . . . 2.20

2.6.2 Wheel Ends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.20

2.6.3 Lubrication Points (Grease Fittings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.21

2.6.4 Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.21

2.6.5 Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.21

2.6.6 Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

2.6.7 Air Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

2.6.8 Drive Shaft Splines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.22

2.6.9 General Anti-Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.6.10 Carriage Fork Shafts and Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.6.11 Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.6.12 Thread Locking Compound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.23

2.7 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.8 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.9 Hoses and Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.9.1 Hose and Tube Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.9.2 Hose and Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.24

2.10 Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.10.1 Bearing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.10.2 Bearing Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.10.3 Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.11 Pressure Testing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.12 After Service Startup and Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.12.1 After Service Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.25

2.12.2 After Electrical/Electronic Component Service . . . . . . . . . . . . . . . . . . . . . 2.26

2.12.3 After Hydraulic Component Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.12.4 After Brake System Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.12.5 After Fuel System Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.12.6 After Transmission Service or Replacement . . . . . . . . . . . . . . . . . . . . . . . 2.26

2.12.7 After Tire and Wheel Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.12.8 After Engine Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.12.9 After Boom Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.12.10 After Axle Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.27

2.2

Model MMV Rev. 12/04

Page 19

General Information, Specifications and Maintenance

2.13 Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.13.1 Maintenance Schedule and Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.28

2.13.2 Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.30

2.13.3 Closed Cab Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.32

2.13.4 Engine Cooling System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.33

2.13.5 Engine Oil and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.35

2.13.6 Engine Oil Sample Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.37

2.13.7 Engine Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.37

2.13.8 Engine Fan Belt & Air Conditioner Compressor Belt. . . . . . . . . . . . . . . . . 2.40

2.13.9 Hydraulic System Oil and Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.41

2.13.10 Transmission Oil and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.43

2.13.11 Axle Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.45

2.13.12 Brake Disc Wear Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.46

2.13.13 Wheel End Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.48

2.13.14 Transfer Case Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.49

2.13.15 Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.50

2.13.16 Emergency Tire Inflation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.50

2.13.17 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.54

2.13.18 Fuse and Relay Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.56

2.13.19 Boom Wear Pad Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.60

2.13.20 Boom Chain Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.61

2.13.21 Boom Chain Tension & Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.64

2.13.22 Chain Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.67

2.13.23 Short Term Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.68

2.13.24 Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.68

2.13.25 Counterweight Removal and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . 2.70

2.13.26 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.72

2.14 Emergency Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.77

2.14.1 Towing a Disabled Vehicle Short Distances . . . . . . . . . . . . . . . . . . . . . . . 2.77

2.14.2 Towing a Disabled Vehicle Long Distances . . . . . . . . . . . . . . . . . . . . . . . . 2.78

2.14.3 Boom Lowering and Retracting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.80

2.15 Parking Brake/Transmission De-Clutch Test Procedures . . . . . . . . . . . . . . . . . . 2.81

Model MMV Rev. 12/04

2.3

Page 20

General Information, Specifications and Maintenance

This Page Intentionally Left Blank

2.4

Model MMV Rev. 12/04

Page 21

General Information, Specifications and Maintenance

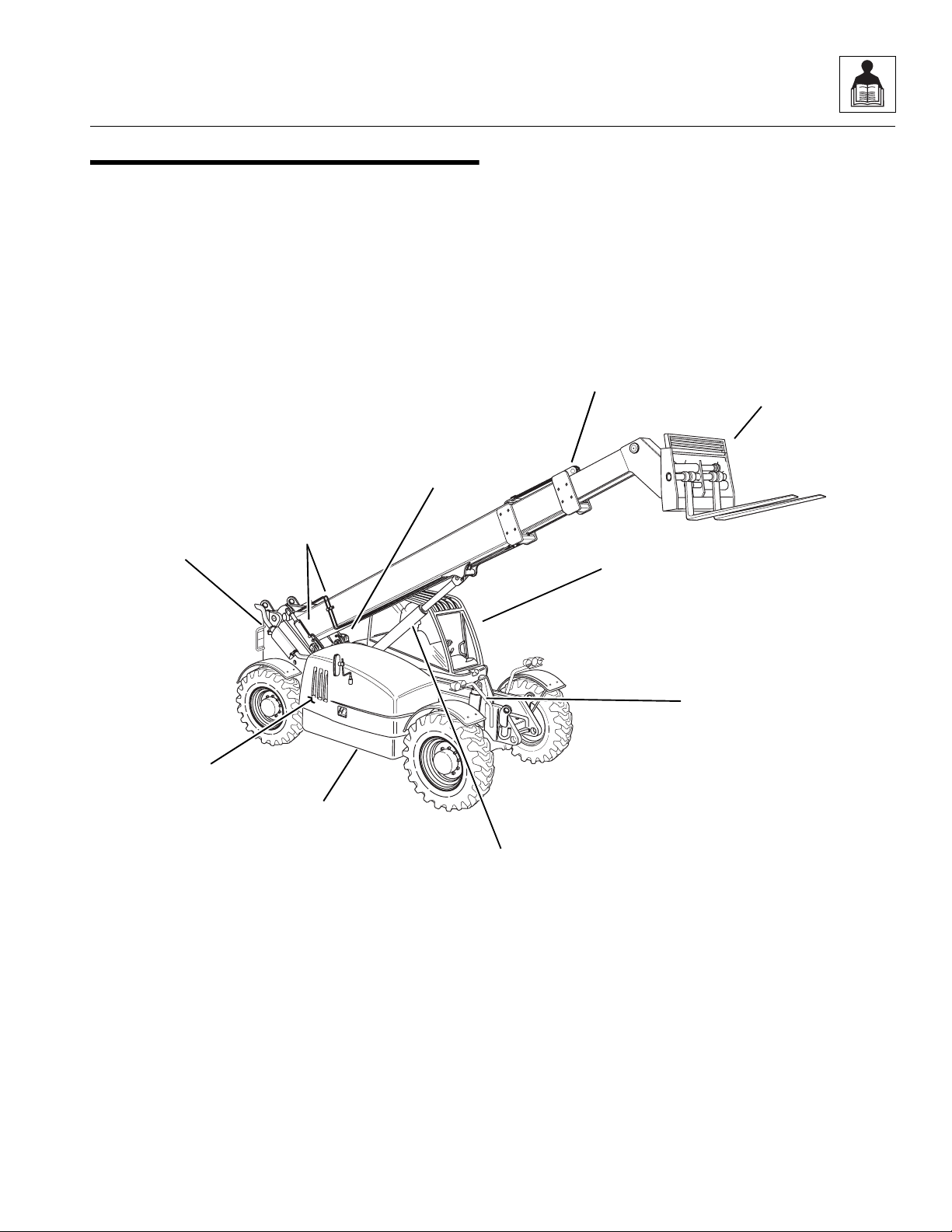

2.1 MMV COMPONENT TERMINOLOGY

To understand the safety, operation and maintenance

information presented in this manual, it is necessary that

the operator/mechanic be familiar with the name and

location of the major assemblies on this vehicle. The

following illustration identifies the components that are

referred to throughout this manual.

Stabilizer

Cylinder

Slave

Cylinders (2)

Rear Door

(Not Visible)

(1 Not Visible)

Boom

Assembly

Operator’s

Protective

Structure

Carriage

Assembly

Engine

Compartment

Frame Sway

Cylinder

Hydraulic

Oil Tank

Lift/Lower

Cylinder

MM1731

Model MMV Rev. 12/04

2.5

Page 22

General Information, Specifications and Maintenance

2.2 INTRODUCTION

2.2.1 Service Methods

Appropriate service methods and proper repair procedures are essential for safe, reliable operation of this vehicle and the safety of the individual doing the work. This

Service Manual provides general direction for accomplishing service and repair work with tested, effective

techniques. Following them will assure reliability.

There are many variations in procedures, techniques,

tools, and parts for servicing vehicles, as well as work

skills. This Manual cannot possibly anticipate all such

variations and provide advice or cautions for each one.

Accordingly, anyone who intends to depart from the instructions in this Manual must first consider personal

safety and then vehicle integrity.

IMPORTANT: JLG recommends the use of environmentally sound waste storage and disposal practices.

NEVER drain fluids on the ground or into a sewer or

catch basin. Use suitable collection containers, then

store and/or dispose of waste products in an approved

and safe manner. Check and obey all Federal, State and/

or Local regulations regarding waste storage, disposal

and recycling.

2.2.3 Replacement Parts and Warranty

Information

For reference when ordering replacement parts or making

service inquiries about the vehicle, the vehicle serial

number is required to help assure the provision of correct

parts and information. Before ordering parts or initiating

service inquiries, make note of the serial number.

The vehicle serial number plate (1) is located on the front

of the main frame.

1

2.2.2 The Owners/Operators Manual

The Owners/Operators Manual provides information you

need to properly operate and maintain this vehicle.

IMPORTANT: Before you operate this vehicle, read the

manual completely and carefully, so that you will understand the safety instructions and the operation of the

controls and safety equipment. You must comply with all

Danger, Warning, and Caution notices. They are for your

benefit.

All references to the right side, left side, front, and rear

are given from the operator’s seat looking in a forward

direction.

OM1370

IMPORTANT: The replacement of any part on this vehicle with any other than a JLG authorized replacement

part can adversely affect the performance, durability, or

safety of the vehicle, and will void the warranty. JLG disclaims liability for any claims or damages, whether

regarding property damage, personal injury or death

arising out of the use of unauthorized replacement parts.

A warranty registration form must be filled out by the JLG

Authorized Service Center (ASC), signed by the

purchaser, and returned to JLG when the vehicle is sold

and/or put into use.

Registration activates the warranty period and helps to

assure that warranty claims are promptly processed. To

guarantee full warranty service, verify that the distributor

has returned the business reply card of the warranty registration form to JLG.

2.2.4 Disclaimer

JLG reserves the right to make changes to and to add im-

provements upon its product at any time, without public

notice or obligation. JLG also reserves the right to discontinue manufacturing any product at its discretion at

any time.

2.6

Model MMV Rev. 12/04

Page 23

General Information, Specifications and Maintenance

2.3 TORQUES

2.3.1 Fasteners

All fasteners (nuts, bolts, washers, etc.) are equal to SAE

Grade 5 (PC8.8) and are plated, unless otherwise specified.

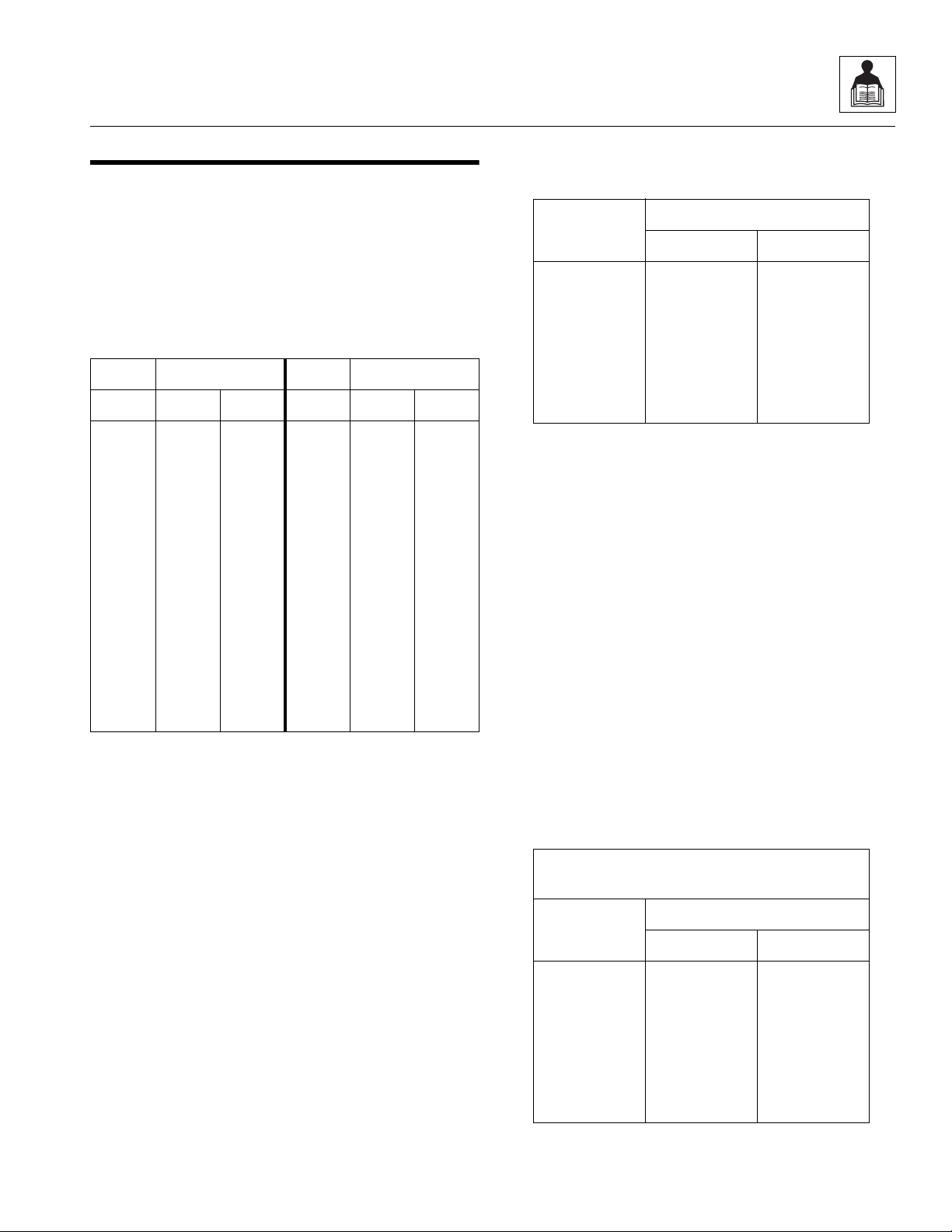

2.3.2 Bolts and Nuts

Unless otherwise specified, the following values apply for

Grade 5 (PC8.8) nuts and bolts:

Size Torque Size Torque

Inch lb/ft Nm mm Nm lb/ft

1/4 9 12 6.0 10 7

5/16 17 24 8.0 25 18

3/8 31 42 10.0 50 37

7/16 50 68 -- -- --

1/2 75 102 12.0 80 59

9/16 110 150 14.0 130 95

5/8 150 203 16.0 200 146

3/4 250 340 20.0 360 263

7/8 380 515 22.0 510 372

1.0 585 793 24.0 650 475

2.3.3 Straight Thread O-ring Fitting

(Non-Adjustable)

When the vehicle leaves the factory, it is equipped only

with straight thread o-ring fittings. Customer-added accessories may differ; therefore, consult the manufacturer’s product literature for information.

1. Verify that both threads and sealing surfaces are

free of burrs, nicks, scratches, and any foreign

material.

2. Lubricate the new o-ring with a light coating of

hydraulic oil.

3. Tighten fitting to the proper torque according to the

following chart:

SAE

Size

4

6

8

10

12

16

20

24

15-17

34-36

58-62

100-110

134-146

202-218

248-272

303-327

Torque

lb/ft Nm

20-23

46-49

79-84

136-149

181-198

274-296

336-369

411-443

2.3.4 Straight Thread O-ring Fitting

(Adjustable)

When the vehicle leaves the factory, it is equipped only

with straight thread o-ring fittings. Customer-added accessories may differ; therefore, consult the manufacturer’s product literature for information.

1. Verify that both mating parts are free of burrs, nicks,

scratches, and any foreign material.

2. Lubricate the new o-ring with a light coat of hydraulic

oil.

3. Back off the locknut as far as possible.

4. Screw the fitting into the port by hand until the backup washer contacts the face of the port and is

pushed all the way towards the locknut.

5. To position the fitting, unscrew by the required

amount, but not more than one full turn.

6. Hold the fitting in the desired position and tighten to

the proper torque according to the following chart:

Adjustable Straight-Thread O-ring

Fitting Torque Chart

SAE

Size

4

6

8

10

12

16

20

24

15-17

34-36

58-62

100-110

134-146

202-218

248-272

303-327

Torque

lb/ft Nm

20-23

46-49

79-84

136-149

181-198

274-296

336-369

411-443

Model MMV Rev. 12/04

2.7

Page 24

General Information, Specifications and Maintenance

2.3.5 Flat-Face O-ring Fittings

When the vehicle leaves the factory, it is equipped only

with straight thread o-ring fittings. Customer-added

accessories may differ; therefore, consult the manufacturer’s product literature for information.

Improper assembly of this type of joint will result in a leaking

joint. Under tightening will result in the joint loosening during normal use. Foreign material on either sealing surfaces

will cause damage to one or both mating parts when the

joint is tightened, resulting in a leaking joint. The absence

of the fitting o-ring will cause the joint to leak.

1. Verify that both threads and sealing surfaces are

free of burrs, nicks, scratches, and any foreign

material.

2. Inspect the male fitting for the presence of the o-ring

seal. Replace the o-ring if missing or damaged.

3. Place the flat surface of the female connector in full

contact with the o-ring in the male connector.

4. Finger tighten the nut onto the fitting.

5. Hold the fitting in the desired position, for hoses and

swivel fittings, use a second wrench to keep the

female connector from moving during tightening.

Tighten to the proper torque according to the

following chart:

SAE

Size

4

6

8

10

12

16

20

24

19-36

28-54

42-80

65-126

100-180

130-240

150-280

175-330

Torque

lb/ft Nm

26-49

38-73

57-108

88-171

136-244

176-325

203-380

237-447

2.4 METRIC CONVERSION FACTORS

2.4.1 Approximate American to Metric

Conversions

When this is known Multiply by To Find

TORQUE (moment of force)

Pound/feet (lb/ft) 1.356 Newton meters (Nm)

Pound/inches (lb/in) 0.113 Newton meters (Nm)

POWER

Horsepower (hp) 745.7 Watts

SPEED (velocity)

Miles per hour (mph) 1.609 Kilometers per hour

(km/hr; kph)

LENGTH (distance)

Inches (in) 25.4 Millimeters (mm)

Inches (in) 2.5 Centimeters (cm)

Feet (ft) 30.5 Centimeters (cm)

Feet (ft) 0.305 Meters (m)

Yards (yd) 0.9 Meters (m)

Miles (mi) 1.6 Kilometers (km)

AREA

2

Square inches (in

Square feet (ft

Square yards (yd

Square miles (mi

Acres 0.4 Hectares (ha)

MASS (weight)

Ounces (oz) 28.3 Grams (g)

Pounds (lb) 0.4536 Kilograms (kg)

Short tons (2000 lb) 0.9 Metric ton (t)

) 6.5 Square centimeters (cm2)

2

) 0.09 Square meters (m2)

2

) 0.8 Square meters (m2)

2

) 2.6 Square kilometers (km2)

2.8

Model MMV Rev. 12/04

Page 25

General Information, Specifications and Maintenance

VOLUME

Teaspoons (tsp) 5 Milliliters (ml)

Tablespoons (Tbsp) 15 Milliliters (ml)

3

Cubic inches (in

) 16 Milliliters (ml)

Fluid ounces (fl oz) 30 Milliliters (ml)

Cups (c) 0.24 Liters

Pints (pt) 0.47 Liters

Quarts (qt) 0.95 Liters

Gallons (gal) 3.8 Liters

3

Cubic feet (ft

Cubic yards (yd

) 0.03 Cubic meters (m3)

3

) 0.76 Cubic meters (m3)

AIR PRESSURE

Pounds per

square inch (psi) 6.895 Kilopascals (kPa)

HYDRAULIC PRESSURE

Pounds per

square inch (psi) 0.069 Bar

TEMPERATURE (exact)

To determine degrees Celsius (° C), subtract 32, then

multiply by 0.56; (° F -32) x 0.56 = ° C.

2.4.2 Approximate Metric to American

Conversions

When this is known Multiply by To Find

TORQUE (moment of force)

Newton meters (Nm) 0,738 Pounds/feet (lb/ft)

Newton meters (Nm) 8,85 Pounds/inches (lb/in)

POWER

Watts 0,0013 Horsepower (hp)

SPEED (velocity)

Kilometers per

hour (km/hr; kph) 0,621 Miles per hour (mph)

LENGTH (distance)

Millimeters (mm) 0,0394 Inches (in)

Centimeters (cm) 0,394 Inches (in)

Meters (m) 3,281 Feet (ft)

Meters (m) 1,1 Yards (yd)

Kilometers (km) 0,621 Miles (mi)

AREA

Square centimeters

2

) 0,4 Square inches (in2)

(cm

Square meters (m

2

) 1,1 Square yards (yd2)

Square kilometers

2

(km

) 0,6 Square miles (mi2)

2

Hectares (10000 m

)2,5 Acres

MASS (weight)

Grams (g) 0,035 Ounces (oz)

Kilograms (kg) 2,2 Pounds (lb)

Metric ton

(1000 kg) (t) 1,1 Short tons

VOLUME

Milliliters (ml) 0,03 Fluid ounces (fl oz)

3

Milliliters (ml) 0,06 Cubic inches (in

)

Liters 2,1 Pints (pt)

Liters 1,06 Quarts (qt)

Liters 0,26 Gallons (gal)

3

Cubic meters (m

Cubic meters (m

) 35 Cubic feet (ft3)

3

) 1,3 Cubic yards (yd3)

AIR PRESSURE

Kilopascals (kPa) 0,145 Pounds per square

inch (psi)

HYDRAULIC PRESSURE

Bar 14,5 Pounds per square

inch (psi)

TEMPERATURE (exact)

To determine degrees Fahrenheit (° F), multiply degrees

Celsius (° C) by 1.8, then add 32; (° C x 1.8) + 32 = ° F.

Model MMV Rev. 12/04

2.9

Page 26

General Information, Specifications and Maintenance

2.5 SPECIFICATIONS

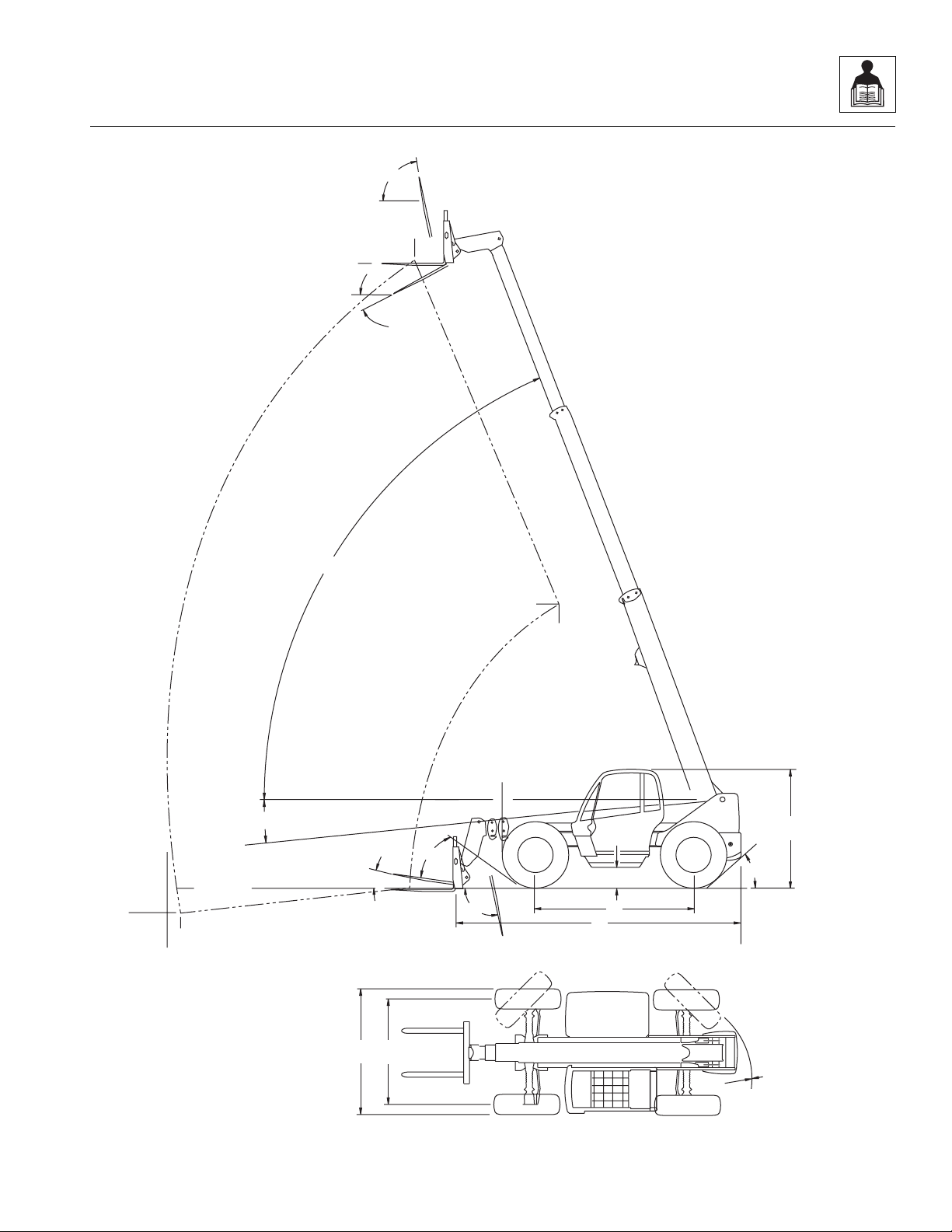

2.5.1 Vehicle Dimensions

With 15.50-25 Radial Tires

Description Specifications

(A) Length (without Forks) 248" (6.299 mm)

(B) Width 101" (2.565 mm)

(C) Height (Boom Lowered) 93" (2.362 mm)

(D) Wheelbase 131" (3.327 mm)

(E) Tread Center 84" (2.134 mm)

(F) Ground Clearance

(at the bottom of the hydraulic reservoir drain plug)

(G) Turning Radius, Curb to Curb 32.5' (9,91 m)

(H) Turning Radius, Clearance 45.5' (13,9 m)

(I) Maximum Lift Height, Boom Extended 42' 4" (12,9 m)

(J) Maximum Lift Height, Boom Retracted 20' 3" (6,2 m)

(K) Maximum Below Grade Depth, Boom Extended 1' 8" (0,5 m)

(L) Maximum Reach, from Front of Front Tires 30' (9,1 m)

(M) Maximum Reach at Maximum Lift Angle, Boom Extended 6' 2" (1,9 m)

(N) Maximum Reach at Maximum Lift Angle, Boom Retracted -2' 8" (-0,8 m)

(O) Maximum Reach at Minimum Lift Angle, Boom Extended 29' (8,8 m)

(P) Maximum Boom Lift Angle 70.0°

(Q) Minimum Boom Lift Angle -2.9°

(R) Percentage of Slope of Approach >45°

(S) Percentage of Slope of Departure >45°

Fork Tilt Angle:

(T) At Maximum Boom Angle - UP 84.0°

15.1" (383 mm)

(U) At Maximum Boom Angle - DOWN -23.4°

(V) At Minimum Boom Angle - UP 12.2°

(W) At Minimum Boom Angle - DOWN -30.3°

Frame Sway Angle (Not Shown):

Right 10.0°

Left 10.0°

2.10

Model MMV Rev. 12/04

Page 27

General Information, Specifications and Maintenance

T

M

I

U

P

J

N

0.0

Q

V

R

F

K

W

D

A

C

S

O

L

Model MMV Rev. 12/04

EB

G & H

MM2230

2.11

Page 28

General Information, Specifications and Maintenance

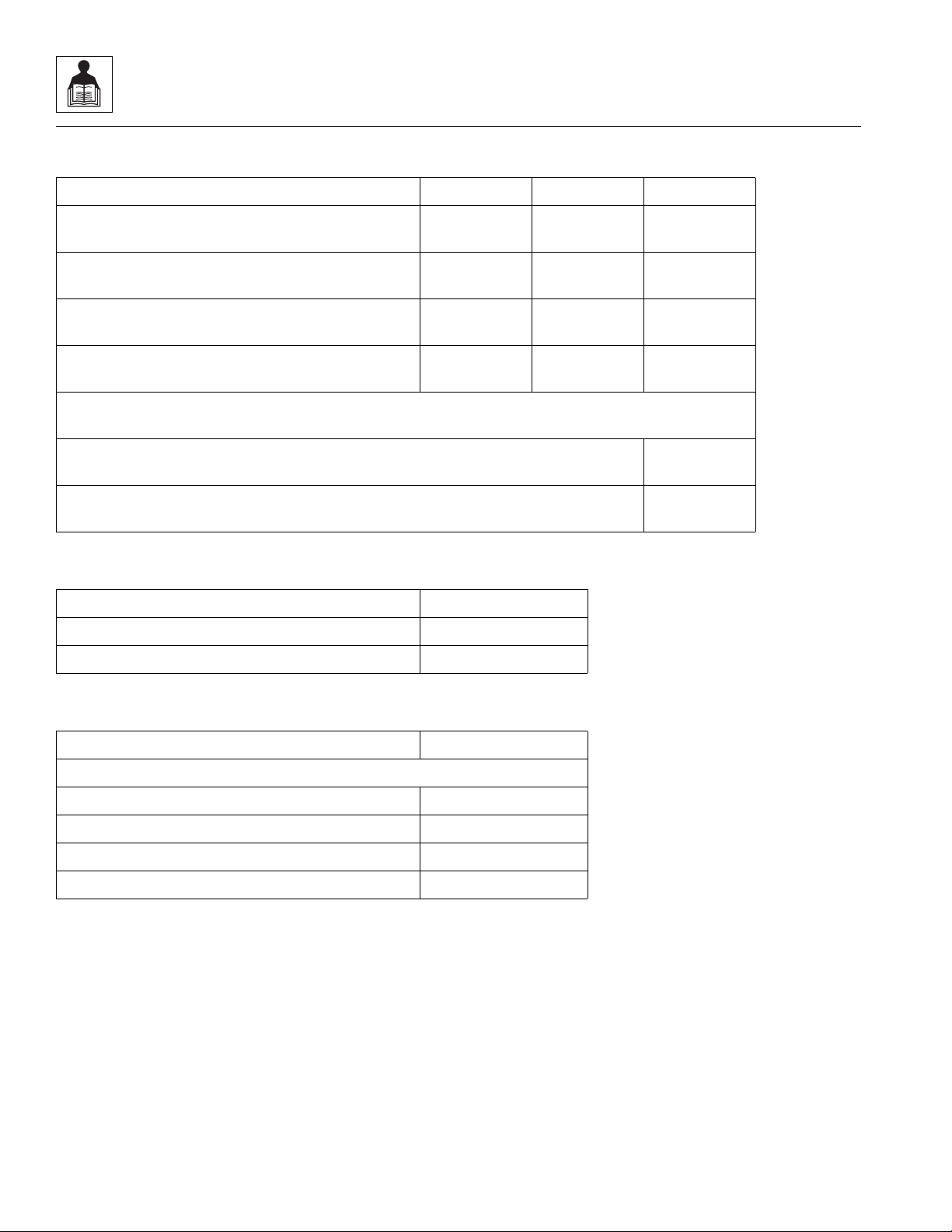

2.5.2 Vehicle Weights

Vehicle Configuration Front Axle Rear Axle Total

Without Carriage 9,250 lbs

(4.196 Kg)

With 11K Carriage 11,200 lbs

(5.080 Kg)

With 7K Carriage 12,900 lbs

(5.851 Kg)

With Both Carriages 14,800 lbs

(6.713 Kg)

Working Weight (Vehicle working weight is figured with one of the configurations listed above,

25%-full fuel tank, and radial tires [no hydrofill]):

Operating Load 7K Carriage 7,000 lbs

Operating Load 11K Carriage 11,000 lbs

17,650 lbs

(8.006 Kg)

16,900 lbs

(7.666 Kg)

16,400 lbs

(7.439 Kg)

15,700 lbs

(7.122 Kg)

26,900 lbs

(12.202 Kg)

28,100 lbs

(12.746 Kg)

29,300 lbs

(13.290 Kg)

30,500 lbs

(13.835 Kg)

(3.175 Kg)

(4.989 Kg)

2.5.3 Attachment Weights

Description Weight

7K Carriage 2,300 lb (1.043 kg)

11K Carriage 1,300 lb (590 kg)

2.5.4 Performance Specifications

Description Speed

Travel Speed (Radial Tires, No Load):

First Gear 3.5 mph (5,6 km/hr)

Second Gear 5.7 mph (9,2 km/hr)

Third Gear 13.5 mph (21,7 km/hr)

Fourth Gear 19.4 mph (31,2 km/hr)

2.12

Model MMV Rev. 12/04

Page 29

General Information, Specifications and Maintenance

2.5.5 Hydraulic Cylinder Performance Specifications

Note: Vehicle with no load, engine at full throttle, hydraulic oil warm (80° F [27° C] minimum), engine at operating

temperature

.

Function Approximate Times,

in Seconds

7K Carriage

Boom Extend 17.00 17.00

Boom Retract 23.60 23.60

Boom Lift Retracted 17.50 17.50

Boom Lower Retracted 19.80 19.80

Attachment Tilt - UP 7.60 7.60

Attachment Tilt - DOWN 7.30 7.30

Frame Sway Left to Right with Boom Down *12.00 to 15.50 *12.00 to 15.50

Frame Sway Left to Right with Boom Above 40°

and Emergency Brake Engaged

Frame Sway Right to Left with Boom Down *12.00 to 15.50 *12.00 to 15.50

Frame Sway Right to Left with Boom Above 40°

and Emergency Brake Engaged

Fork Side Shift

Left Cylinder, Right to Left 13.00 13.30

Left Cylinder, Left to Right 22.00 11.40

*17.50 to 33.40 *17.50 to 33.40

*21.50 to 43.00 *21.50 to 43.00

Approximate Times,

in Seconds

11K Carriage

Right Cylinder, Right to Left 13.00 13.30

Right Cylinder, Left to Right 22.00 11.40

* All times listed are approximate MAXIMUM times except where noted. Noted times are given

as a minimum to maximum range.

Model MMV Rev. 12/04

2.13

Page 30

General Information, Specifications and Maintenance

2.5.6 Electrical System

Description Specifications

Battery:

Type, Rating 12 VDC, Negative (-) Ground, Maintenance Free

Quantity 2

Reserve Capacity 1225 Cold Cranking amps @ 0° F (-18° C)

Group/Series HASP-FT

Alternator 24V/70 amps

Fuses - Standard Blade Style:

Switch Lamps, Service Brake, Hourmeter 2 amps

LMI System 3 amps

Fuel Shut-off Solenoid (FSOS), Transmission Gear,

5 amps

Transmission Direction, Steer Mode, Parking Brake

Joystick Logic Panel, Horn, Front Wiper/Washer, Top Wiper/

7.5 amps

Washer, Rear Wiper, Left Fork Shift, Right Fork Shift

Front Dash Display Panel, Ignition Pre-heat, Air Conditioner

15 amps

Condenser Fan Motor

Heater, Normal Lights, Blackout Lights 25 amps

Main, Power Window 30 amps

Fuses -

Battery Equalizer 125 amps

Circuit Breaker

Ignition Switch 12 volt/ 50 amp

Relays:

Neutral Engage Relay 12 volt

Work Light Power Relay 24 volt

High Beam Power Relay 24 volt

Brake Light Relay 12 volt

Light Power Relay 12 volt

Blackout Ignition Relay 12 volt

Normal Lights Ignition Relay 12 volt

Reverse Signal Relay 12 volt

Door Window Relay 12 volt

Closed Cab Accessory Power Relay 12 volt

Fuel Shut Off Solenoid Relay 12 volt

Air Conditioner Condenser Fan 12 volt

2.14

Model MMV Rev. 12/04

Page 31

General Information, Specifications and Maintenance

2.5.7 Engine Performance Specifications

Note: Engine manufacturer's maximum “high idle” setting is lockwired and sealed. DO NOT disturb this setting.

Description Specifications

Engine Make/Model Cummins Turbo/4BTA3.9

Displacement 239 in

Horsepower 116 HP @ 2500 rpm

Number of Cylinders 4

Engine High Idle with No Load 2750 ±100

Engine Low Idle 1050 ±50 rpm

Fuel Delivery Fuel Injection

Air Cleaner Dry Type, Replaceable Primary and

Peak Torque 407 lb/ft @ 1500 rpm

Average Fuel Consumption, Depending on Load/Duty 2.67 gal/hr (2,22 Imp gal/hr, or 10,1 l/hr)

3

(3.9 liters)

Safety Elements

Model MMV Rev. 12/04

2.15

Page 32

General Information, Specifications and Maintenance

2.5.8 Fluid and Lubricant Capacities

Fluid & Lubricant Description Specifications

Engine Crankcase Oil:

Capacity with Filter Change 13.3 qt (12,6 liters)

Filter Capacity 1.3 qt (1,2 liters)

Oil Type

(Refer to

Fuel Tank:

Total Capacity 35.5 gal (134 liters)

Usable Capacity 33.5 gal (127 liters)

Type of Fuel Above 32° F (0° C) Standard No. 2 Diesel. (Refer to

Type of Fuel Below 32° F (0° C) 50/50 Mix of #1 and #2 Diesel Fuels. (Refer to

Alternate Fuel JP-5, JP-8 and Jet A-1

Cooling System:

Capacity w/o Heater

(including 1.5 qt [1,4 liters]

for overflow bottle)

Overflow Bottle Capacity 3.0 qt (2,8 liters)

Type of Fluid 50/50-mix of ethylene glycol and water. (Refer to

Transmission:

Capacity w/Filter Change 12 qt (11,4 liters)

Section 2.6.5, Engine

Above 23° F (-5° C) use SAE 15W40 Diesel Engine Oil.

.)

23° F (-5° C) to -25° F (-32° C) use 5W30

Below -25° F (-32° C) use 0W30

Oil Meeting MIL-PRF-2104G Specifications is Also acceptable

Section 2.6.5, Engine

Section 2.6.5, Engine

12.5 qt (11,8 liters)

.)

.)

Section 2.6.5, Engine

.)

Filter Capacity 1 qt (1 liter)

Typ e o f O i l

(Refer to

sion

Transfer Case:

Capacity 1.5 qt (1,4 liters)

Typ e o f O i l

(Refer to

Section 2.6.6, Transmis-

.)

Section 2.6.1, Axles (Differential Housings) and Transfer

Case

.)

Axle (Differential Housing):

Capacity 10.5 qt (10,0 liters)

Typ e o f O i l

(Refer to

Section 2.6.1, Axles (Differential Housings) and Transfer

Case

.)

2.16

Above 125° F (50° C) Use MIL-PRF-2104G Grade 15W40

14° F (-10° C) to 125° F (50° C) use MIL-PRF-2104G Grade 10W30 (Universal

Tractor Fluid)

Below 14° F (-10° C) use DEXRON lll (Automatic Transmission Fluid)

Above 100° F (38° C) use MIL-PRF-2104G Grade 15W40

Below 100° F (38° C) use MIL-PRF-2104G Grade 10W30 (Universal Tractor

Fluid)

Above 100° F (38° C) use MIL-PRF-2104G Grade 15W40

Below 100° F (38° C) use MIL-PRF-2104G Grade 10W30 (Universal Tractor

Fluid)

Model MMV Rev. 12/04

Page 33

General Information, Specifications and Maintenance

Fluid & Lubricant Description Specifications

Axle (Wheel Ends):

Capacity 1.3 qt (41.6 fl oz, or 1,2 liters)

Type of Oil

(Refer to

Section 2.6.1, Axles (Differential Housings) and Transfer

Case

.)

Hydraulic System:

System Capacity 41.3 gal (156 liters)

Reservoir Capacity 28.5 gal (108 liters)

Type of Oil

(Refer to

System

Section 2.6.4, Hydraulic

.)

Above 100° F (38° C) use MIL-PRF-2104G Grade 15W40

Below 100° F (38° C) use MIL-PRF-2104G Grade 10W30 (Universal Tractor

Fluid)

14° F (-10° C) & Above use MIL-PRF-2104G Grade 10 Hydraulic Oil

125° F (50° C) & Below use DEXRON lll (Automatic Transmission Fluid)

2.5.9 Hydraulic System

Description Specifications

Valve Relief Settings:

Main System Relief 3500 ±100 psi (241 ±6,9 bar)

Port Relief Boom - Hoist/Lower/Extend/Retract 3200 ±100 psi (220,6 ±6,9 bar)

Port Relief Fork Tilt (Both Sides) 3500 ±100 psi (241 ±6,9 bar)

Stabilizer Cylinder 75-150 psi (5,2-10,3 bar)

Power Steering Relief 2500 ±100 psi (172,3 ±7 bar)

Standby Pressure 200 ±50 psi (13,8 ±3,4 bar)

Pilot Pressure 550 ±100 psi (37,9 ±7 bar)

Parking Brake Relief 650 ±50 psi (44.8 ±3,4 bar)

Model MMV Rev. 12/04

2.17

Page 34

General Information, Specifications and Maintenance

2.5.10 Tires

Description Specifications

Tire Size 15.5R25, L-2, (2 Star Minimum) Radial

Wheel Lug Nut Torque 430-470 lb/ft (583-637 Nm)

Air Pressure 87 psi (600 kPa)

Tire Footprint Area (area is established under max. tip load):

Vehicle with 7K Carriage with No Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Vehicle with 7K Carriage with Rated Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Vehicle with 11K Carriage with No Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Vehicle with 11K Carriage with Rated Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Maximum Ground Pressure

(maximum ground pressure at tip =

(machine weight + load) / (2 x footprint area):

126 in

183 in

129 in

209 in

2

(810 cm2)

2

(1.180 cm2)

2

(835 cm2)

2

(1.350 cm2)

Vehicle with 7K Carriage with No Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Vehicle with 7K Carriage with Rated Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Vehicle with 11K Carriage with No Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

Vehicle with 11K Carriage with Rated Load

(15.5R25, L-2, 2 Star tires at specified air pressure):

2.5.11 Miscellaneous Specifications

Description Specifications

Steering Wheel:

Maximum Number of Turns, Lock to Lock 4.25 turns

Minimum Number of Turns, Lock to Lock 3.75 turns

156 psi (1.070 kPa)

174 psi (1.200 kPa)

152 psi (1.050 kPa)

185 psi (1.275 kPa)

2.18

Model MMV Rev. 12/04

Page 35

2.5.12 Tamper Proofing

General Information, Specifications and Maintenance

A tamper-proof means is in place on the following

adjustable components prior to machine shipment. This

can either be tamper-proof paint, or a steel tamper-proof

cap. DO NOT attempt to defeat, by-pass or alter any

tamper-proof device.

• Main Valve Port Relief Valves [5]

• Fork Cylinder Counterbalance Valves [2]

• Secondary Function Manifold Valves [2]

• Unloader Valve [2]

• Main System Relief Valve [1]

2.5.13 Fork Ratings

All approved forks for this vehicle are marked with a

maximum load capacity rating. This rating (1) is stamped

on the right edge of the fork just below the fork pivot

shaft (2). The rating is listed in U.S. pounds and based

upon a 24" (610 mm) load center (3) (11K carriage) or

48" (1219 mm) load center (3) (7K carriage). This rating

specifies the maximum load capacity that the individual

fork can safely carry at the maximum specified load

center.

Since forks are always used in multiples, the total rating

of any combination of forks will be the sum of their rated

capacity. All forks should be used in matched pairs.

WARNING: DO NOT exceed the

total rated capacity of the specific pair of forks

being used. Forks can break causing loss of

load and possible death or serious personal

injury to the operator or personnel in the area.

If the total rated capacity of the forks exceeds

the capacity of the vehicle, the vehicle capacity

should not be exceeded.

The maximum load capacity for this vehicle is 7,000

pounds (3.175 Kg) for the 7K carriage or 11,000 pounds

(4.989 Kg) for the 11K carriage. The matched pair or set

of forks used on this vehicle should have total load

ratings which equal or exceed these weights. When the

load rating of the vehicle differs from the load capacity of

the forks, the lower value becomes the overall load

capacity.

Model MMV Rev. 12/04

3

1

2

OM0941

2.19

Page 36

General Information, Specifications and Maintenance

2.6 FLUIDS, LUBRICANTS AND

CAPACITIES

2.6.1 Axles (Differential Housings) and

Transfer Case

a. Axle and Transfer Case Lubricants

Recommended Oil/Temperature Range

MIL-PRF-2104G Grade 15W40

MIL-PRF-2104G Grade 10W30

(Universal Tractor Fluid*)

100° F (38° C)

*John Deere (JDM J20C Hy-Gard)

*Ford/New Holland ESN-M2C134-D (Hydraulic Oil 134)

*Massey Ferguson M-1141 (Permatran lll)

*Chevron 1000 THF

In general, use a oil that meets the following specifications:

Nominal viscosity at 104° F (40° C)....................... 55 cSt

Minimum viscosity at 212° F (100° C) .................. 9.1 cSt

Pour point (Maximum) .............................. -32° F (-36° C)

Flash point (Minimum) ............................ 392° F (200° C)

Minimum viscosity index ............................................ 135

b. Axle and Transfer Case Capacities

Axles (differential housings) .............. 10.5 qt (10,0 liters)

Transfer case......................................... 1.5 qt (1,4 liters)

OM1680

2.6.2 Wheel Ends

a. Wheel-End Lubricants

Recommended Oil/Temperature Range

MIL-PRF-2104G Grade 15W40

MIL-PRF-2104G Grade 10W30

(Universal Tractor Fluid*)

100° F (38° C)

*John Deere (JDM J20C Hy-Gard)

*Ford/New Holland ESN-M2C134-D (Hydraulic Oil 134)

*Massey Ferguson M-1141 (Permatran lll)

*Chevron 1000 THF

In general, use a oil that meets the following specifications:

Nominal viscosity at 104° F (40° C) ...................... 55 cSt

Minimum viscosity at 212° F (10° C) .................... 9.1 cSt

Pour point (Maximum).............................. -32° F (-36° C)

Flash point (Minimum).............................392° F (200° C)

Minimum viscosity index ............................................135

DO NOT add additional friction modifier to factory-filled

wheel ends. All wheel ends are factory-filled by the manufacturer with oil. If a wheel end is drained for service, it

should be refilled with the gear oils listed.

Note: DO NOT use synthetic oil without the express

written consent of the manufacturer.

b. Wheel-End Capacity

Wheel ends .......................1.3 qt (41.6 fl oz, or 1,2 liters)

OM1680

2.20

Model MMV Rev. 12/04

Page 37

General Information, Specifications and Maintenance

2.6.3 Lubrication Points (Grease Fittings)

Lubricants

When lubricating any component via the grease fittings,

use multi-purpose lithium-based grease with EP additives

that meets NLGI Grade 2 specifications. Products known

to meet these requirements include:

• AMOCO AMOLITH EP2

• ARCO LITHOLINE EP2

• BENZ MOLY-SERVICE EP2

• CHEVRON DUROLITH EP2

•CITGO H EP2

• GULF GULFCROWN EP2

• MOBILE MOBILUX EP2

• SHELL ALVANIA EP2

• SUN PRESTIGE 742EP

• TEXACO MULTIFAX EP2

Note: Refer to Section 2.13.1, Maintenance Schedule

and Checklist for lubrication intervals and grease fitting

locations.

2.6.4 Hydraulic System

a. Hydraulic Fluids

Recommended Oil/Temperature Range

MIL-PRF-2104G Grade 10

(Automatic Transmission Fluid)