Page 1

Operation & Safety

An Oshkosh Corporation Company

Manual

Original Instructions

Keep this manual with machine at all times.

Model

G6-42A

S/N 0160003986 & After

31200149

Revised

August 8, 2011

Page 2

CALIFORNIA PROPOSITION 65

BATTERY WARNING

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemical known to the

State of California

to cause cancer and

reproductive harm.

WASH HANDS

AFTER HANDLING!

CALIFORNIA PROPOSITION 65

EXHAUST WARNING

Diesel Engine exhaust and

some of its constituents

are known to the State of

California to cause cancer,

birth defects and other

reproductive harm.

Page 3

Revision Log

Revision Log

April 28, 2006 - A - Original Issue of Manual

January 14, 2009 - B - Revised manual.

January 5, 2010 - C - Revised covers and pages b, 1-5 , 1- 6, 2-1 , 3-7, 3-13 , 4-1, 4-2 ,

4-3, 4-5, 4-7, 4-10, 5-3, 5-4, 5-5, 5-18, 5-19, 5-20, 5-22, 5-24, 5-26, 5-28, 5-30 thru

5-34, 5-36, 5-38, 5-39, 5-40, 5-42, 7-2, 7-3, 7-5, 7-16, 7-21, 9-1 & 9-2.

December 21, 2010 - D - Revised pages 7-14, 9-3 & 9-5.

March 31, 2011 - E - Revised pages 1-9, 2-3, 2-6 thru 2-11, 2-13, 2-15, 3-1 thru 3-5,

3-7 thru 3-15, 3-18, 4-1 thru 4-4, 4-10, 4-11, 5-5, 5-19, 5-20, 5-22, 5-24, 5-25, 5-26,

5-30, 5-32, 5-34, 5-36, 5-38, 5-42, 6-1, 7-1 thru 7-15, 7-19 thru 7-23, 9-1 & 9-2.

August 8, 2011 - F - Revised pages 2-6 & 2-9.

REVISION LOG

a31200149

Page 4

Read This First

Read This First

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and

lessees with the precautions and operating procedures essential for the safe and

proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to

make specification changes without prior notification. Contact JLG Industries, Inc.

for updated information.

Operator Qualifications

The operator of the machine must not operate the machine until this manual has

been read, training is accomplished and operation of the machine has been

completed under the supervision of an experienced and qualified operator.

Operation within the U.S.A. requires training per OSHA 1910.178.

Operators of this equipment must possess a valid, applicable driver’s license, be in

good physical and mental condition, have normal reflexes and reaction time, good

vision and depth perception and normal hearing. Operator must not be using

medication which could impair abilities nor be under the influence of alcohol or any

other intoxicant during the work shift.

In addition, the operator must read, understand and comply with instructions

contained in the following material furnished with the telehandler:

• This Operation & Safety Manual

• Telehandler Safety Manual (ANSI only)

• All instructional decals and plates

• Any optional equipmen t instr uctions furnished

The operator must also read, understand and comply with all applicable Employer,

Industry and Governmental rules, standards and regulations.

Modifications

Any modification to this machine must be approved by JLG.

b 31200149

Page 5

Read This First

This product must comply with all safety related bulletins. Contact JLG Industries,

Inc. or the local authorized JLG representative for information regarding safetyrelated bulletins which may have been issued for this product.

JLG Industries, Inc. sends safety related bulletins to the owner of record of this

machine. Contact JLG Industries, Inc. to ensure that the current owner records are

updated and accurate.

JLG Industries, Inc. must be notified immediately in all instances where JLG

products have been involved in an accident involving bodily injury or death of

personnel or when damage has occurred to personal property or the JLG product.

FOR:

• Accident Reporting and Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Applications and Safety

• Standards and Regulations Compliance Information

• Questions Regarding Product Modifications

CONTACT:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office

(Addresses on back cover)

In USA

Toll Free: 1-877-JLG-SAFE (1-877-554-7233)

Outside USA

Phone: +1-717-485-6591

E-mail

ProductSafety@JLG.com

c31200149

Page 6

Read This First

Other Publications Available

Service Manual......................................... ................................. ...... ..........31200151

Illustrated Parts Manual....................................... ...... ................................9147 400 1

Note: The following standards may be referenced in this manual:

ANSI is compliant to ANSI/ITSDF B56.6

AUS is compliant to AS 1418.19

CE is compliant to EN1459

Refer to the machine Serial Number Plate to identify the applicable compliance

standard.

d 31200149

Page 7

Table of Contents

TABLE OF CONTENTS

Revision Log

Read This First

Operator Qualifications......................................................b

Modifications......................................................................b

Other Publications Available..............................................d

Table of Contents

Section 1 - General Safety Practices

1.1 Hazard Classification System..............................................1-1

Safety Alert System and Safety Signal Words................1-1

1.2 General Precautions............................................................1-1

1.3 Operation Safety..................................................................1-2

Electrical Hazards...........................................................1-2

Tip Over Hazard..............................................................1-3

Travel Hazard ............................................. ...... ....... ...... .1-6

Load Falling Hazard........................................................1-7

Lifting Personnel .............................................................1-8

Driving Hazards on Slopes .............................................1-9

Pinch Points and Crush Hazards..................................1-10

Fall Hazard....................................................................1-12

Chemical Hazards.........................................................1-13

Table of Contents

Section 2 - Pre-Operation and Inspection

2.1 Pre-Operation Check and Inspection...................................2-1

2.2 Safety Decals.......................................................................2-3

ANSI................................................................................2-3

ISO (S/N 0160040169 & After, If Equipped) ............ ...... .2-9

2.3 Walk-Around Inspection.....................................................2-12

2.4 Warm-Up and Operational Checks....................................2-14

Warm-Up Check ...........................................................2-14

Operational Check ........................................................2-14

2.5 Operator Cab.....................................................................2-15

2.6 Windows ............................................................................2-16

Cab Door Window (if equipped)....................................2-16

Section 3 - Controls and Indicators

3.1 General................................................................................3-1

3.2 Controls ...............................................................................3-2

Dash Controls and Indicators..........................................3-4

Ignition ............................................................................3-6

Park Brake ......................................................................3-7

Parking Procedure ..........................................................3-7

i31200149

Page 8

Table of Contents

Transmission Control Lever............................................ 3-8

Boom Joystick .............................................................. 3-10

Frame Level and Attachment Tilt (if equipped)

Joystick......................................................................... 3-11

Auxiliary Hydraulic Joystick (if equipped) ..................... 3-12

Right Hand Panel (S/N 0160040678 & After)...............3-14

Heater and Air Conditioning Controls

(Before S/N 0160040678, if equipped)......................... 3-15

Accessory Control Lever (if equipped) ......................... 3-16

3.3 Steer Modes...................................................................... 3-18

Steer Mode Change ..................................................... 3-18

3.4 Operator Seat.................................................................... 3-19

Adjustments.................................................................. 3-19

Seat Belt....................................................................... 3-21

3.5 Boom Angle and Extension Indicators .............................. 3-22

Section 4 - Operation

4.1 Engine................................................................................. 4-1

Starting the Engine......................................................... 4-1

Cold Weather Starting Aids............................................ 4-2

Extreme Cold Weather Starting (if equipped)................. 4-3

Battery Boosted Starting................................................. 4-4

Normal Engine Operation.............. ....... ...... ....... ...... ....... 4-5

Shut-Down Procedure .................................................... 4-5

4.2 Operating with a Non-Suspended Load .............................. 4-6

Lift Load Safely............................................................... 4-6

Picking Up a Load ................... ...... ....... ...... ....... ...... ....... 4- 6

Transporting a Load ................ ...... ................................. 4-7

Leveling Procedure......................................................... 4-7

Placing a Load................................................................ 4-8

Disengaging a Load........................................................ 4-8

4.3 Operating with a Suspended Load...................................... 4-9

Lift Load Safely............................................................... 4-9

Picking Up a Suspended Load....................................... 4- 9

Transporting a Suspended Load ............................. ..... 4 -10

Leveling Procedure....................................................... 4-10

Placing a Suspended Load........................................... 4-11

Disengaging a Suspended Load .................................. 4-11

4.4 Loading and Securing for Transport.................................. 4-12

Tiedown........................................................................ 4-12

Lifting............................................................................ 4-13

ii 31200149

Page 9

Section 5 - Attachments

5.1 Approved Attachments ........................................................5-1

5.2 Unapproved Attachments ....................................................5-2

5.3 JLG Supplied Attachments ..................................................5-3

Before S/N 0160037722 .................................................5-3

S/N 0160037722 & After.................................................5-5

5.4 Telehandler/Atta chmen t/For k Capacity..... ....... ...... ....... ...... .5-6

5.5 Use of the Capacity Chart....................................................5-7

Capacity Indicator Locations...........................................5-7

Sample Capacity Chart ...................................................5-8

Example........................................................................5-12

5.6 Attachment Installation ......................................................5-13

Hydraulic Operated Attachment....................................5-16

5.7 Adjusting/Moving Forks......................................................5-17

5.8 Attachment Operation........................................................5-18

Carriage with Forks.......................................................5-19

Side Tilt Carriage ..........................................................5-20

Swing Carriage .............................................................5-22

Dual Fork Positioning Carriage.....................................5-24

Mast Carriage ............................................. ...... ....... .....5 -2 6

Mast Carriage with Swing and Side Shift

(Before S/N 0160037722) .............................................5-28

Mast Carriage with Side Tilt

(S/N 0160037722 & After).............................................5-30

Fork Mounted Hook ......................................................5-32

Truss Boom...................................................................5-34

Bucket...........................................................................5-36

Grapple Bucket .............................................................5-38

Personnel Work Platform - Quick Switch Mounted

(Before S/N 0160037722) .............................................5-40

Personnel Work Platform - Fork Mounted.....................5-42

Boom Head-Mounted Winch

(Before S/N 0160037722) .............................................5-44

Table of Contents

Section 6 - Emergency Procedures

6.1 Towing a Disabled Product..................................................6-1

Moving Short Distances.......... ....... ...... ....... ....................6-1

Moving Longer Distances ................................. ....... .......6-1

6.2 Emergency Lowering of Boom.............................................6-2

6.3 Emergency Exit from Enclosed Cab....................................6-2

iii31200149

Page 10

Table of Contents

Section 7 - Lubrication and Maintenance

7.1 Introduction.......................................................................... 7-1

Clothing and Safety Gear ............................................... 7-1

7.2 General Maintenance Instructions....................................... 7-2

7.3 Service and Maintenance Schedule.................................... 7-3

10, 1st 50 & 50 Hour Maintenance Schedule................. 7-3

1st 250, 250 & 500 Hour Maintenance Schedule........... 7-4

1000, 1500 & 2000 Hour Maintenance Schedule........... 7-5

7.4 Lubrication Schedules......................................................... 7-6

50 Hour Lubrication Schedule........................................ 7-6

250 Hour Lubrication Schedule...................................... 7-7

1000 Hour Lubrication Schedule.................................... 7-8

7.5 Operator Maintenance Instructions ................................... 7-10

Fuel System.................................................................. 7-10

Air Intake System ......................................................... 7-12

Engine Oil..................................................................... 7-14

Hydraulic Oil................................................................. 7-15

Tires.............................................................................. 7-16

Transmission Oil........................................................... 7-19

Hydraulic Return Filter (Before S/N 0160040678)........ 7-20

Engine Cooling System ................................................ 7-21

Battery.......................................................................... 7-23

Windshield Washer System (if equipped)..................... 7-24

Section 8 - Additional Checks

Section 9 - Specifications

9.1 Product Specificatio ns............................................ ...... ....... 9- 1

Capacities....................................................................... 9-1

Tires................................................................................ 9-3

Performance................................................................... 9-4

Dimensions..................................................................... 9-5

Index

Inspection, Maintenance and Repair Log

iv 31200149

Page 11

Section 1 - General Safety Practices

DANGER

OW0010

WARNING

OW0021

CAUTION

OW0031

SECTION 1 - GENERAL SAFETY PRACTICES

1.1 HAZARD CLASSIFICATION SYSTEM Safety Alert System and Safety Signal Words

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentiality hazardous situation which, if not avoided, may

result in minor or moderate injury.

1.2 GENERAL PRECAUTIONS

WARNING

Before operation, read and understand this manual. Failure to comply with the

safety precautions lis ted in thi s m anu al c oul d res ult in ma ch ine dam age , prop erty

damage, personal injury or death.

1-131200149

Page 12

Section 1 - General Safety Practices

OW0040

10 FT

(3 M)

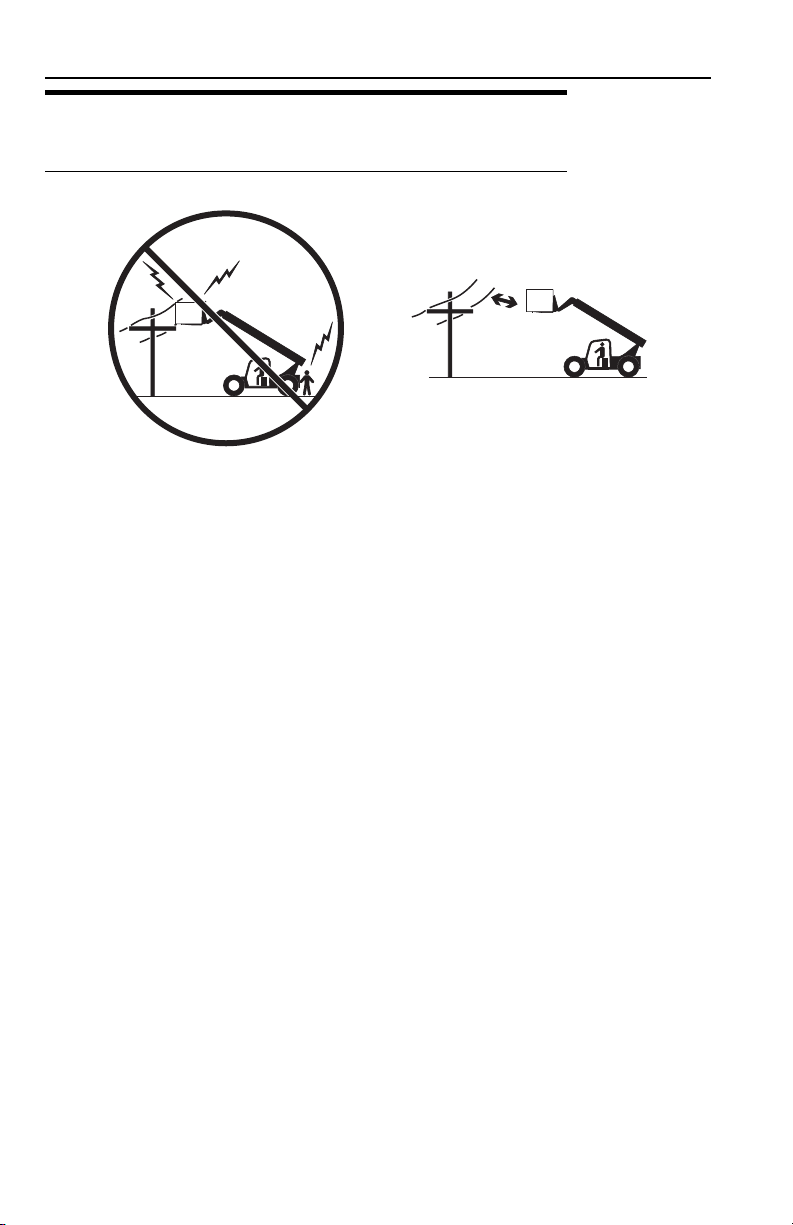

1.3 OPERATION SAFETY Electrical Hazards

• This machine is not insulated and does not provide protection from contact or

being near electrical current.

• NEVER operate the telehandler in an area where overhead power lines,

overhead or underground cables, or other power sources may exist without

ensuring the appropriate power or utility company de-energizes the lines.

• Always check for power lines before raising the boom.

• Follow employer, local and governmental regulations for clearance from

powerlines.

1-2 31200149

Page 13

Section 1 - General Safety Practices

OW0050

OW0080

OW0100

4 FT

(1,2 M)

Tip Over Hazard

General

• For additional load requirements, refer to the appropriate capacity chart.

• Never use an attachment without the appropriate JLG approved capacity chart

installed on the telehandler.

• Understand how to properly use the capacity charts located in cab.

• DO NOT exceed rated lift capacity.

• Be sure that the ground conditions are able to support the machine.

• DO NOT rai se boom unles s frame is lev el (0 degrees ), unless othe rwise not ed on

capacity chart.

• DO NOT level machine with boom/attachment above 4 ft (1,2 m).

(AUS - DO NOT level machine with load more than 11.8 in (300 mm) above

ground surface.)

1-331200149

Page 14

Section 1 - General Safety Practices

OH2291

OH20911

OH2221

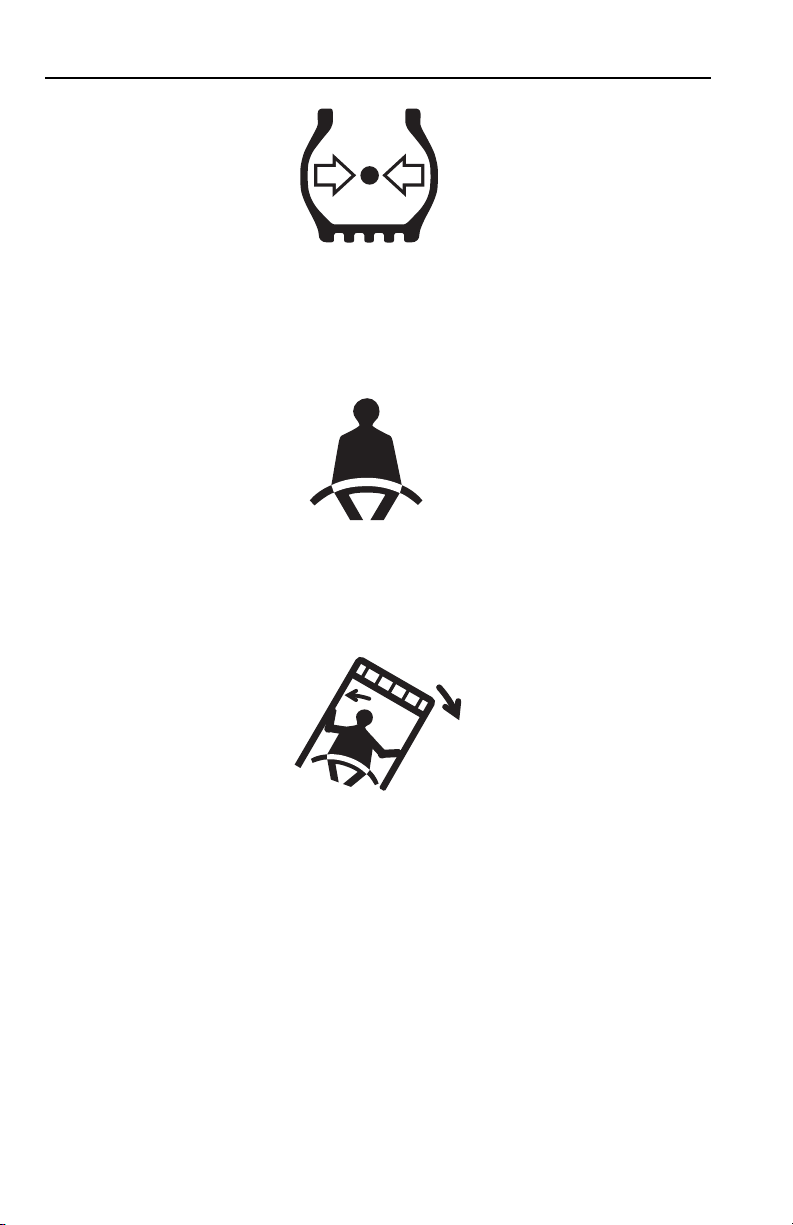

• MAINTAIN proper tire pressure at all times. If proper tire pressures are not

maintained, this machine cou ld tip ov er.

• Refer to manufacturer’s specifications for proper fill ratio and pressure

requirements for tires equipped with ballast.

• Always wear the seat belt.

• Keep head, arms, han ds, le gs and al l ot her bo dy part s inside op erator’s ca b at al l

times.

If the telehandler starts to tip over:

• DO NOT JUMP

• BRACE YOURSELF and STAY WITH THE MACHINE

• KEEP YOUR SEAT BELT FASTENED

•HOLD ON FIRMLY

• LEAN AWAY FROM THE POINT OF IMPACT

1-4 31200149

Page 15

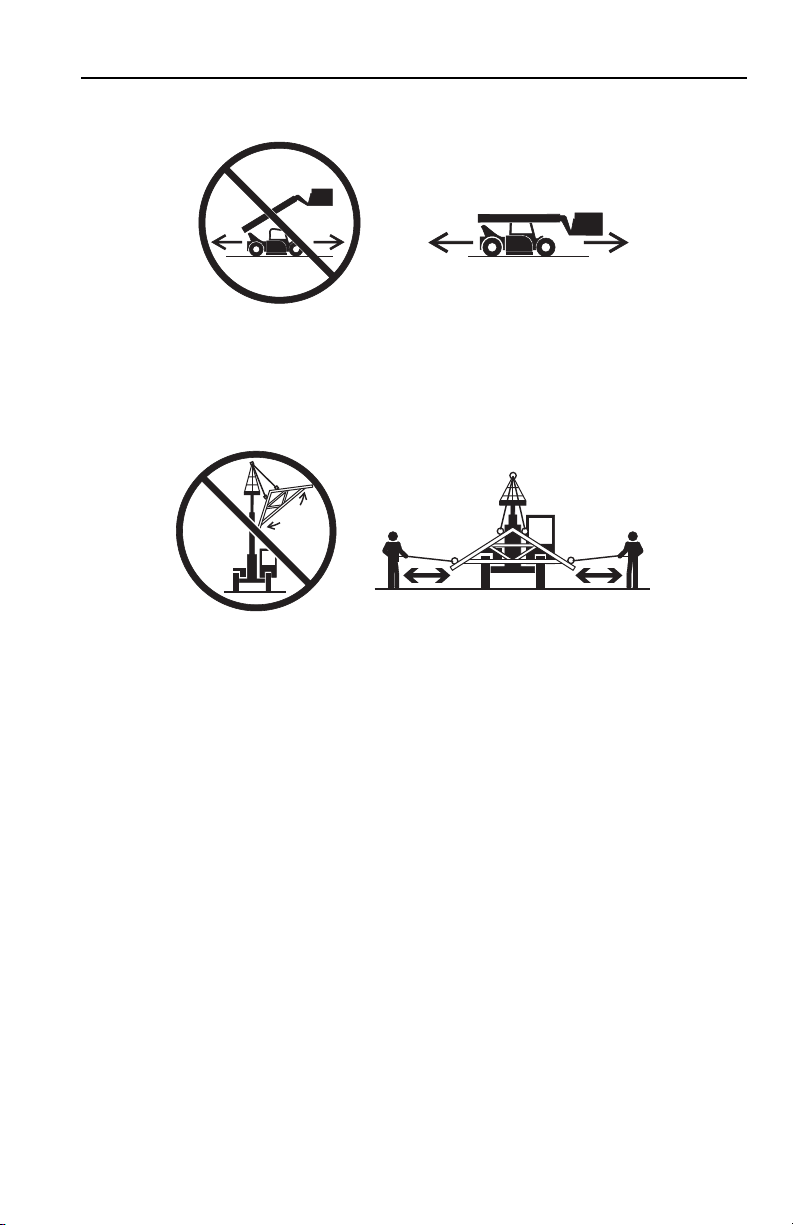

Non-Suspended Load

OW0060

OW0150

• DO NOT drive with boom raised.

Suspended Load

Section 1 - General Safety Practices

• Tether suspended loads to restrict movement.

• Weight of all rigging (slings, etc.) must be included as part of load.

• Beware of wind. Wind can cause a suspended load to swing and cause

dangerous side loads - even with tag lines.

• DO NOT a ttemp t to us e teleh andle r frame-l eveling to com pens ate for load sw ing.

• Keep heavy part of load closest to attachment.

• Never drag the load; lift vertically.

When driving with a suspended load:

• Start, travel, turn and stop slowly to prevent load from swinging.

• DO NOT extend boom.

• DO NOT raise the load more than 11.8 in (300 mm) above ground surfac e or

the boom more than 45°.

• DO NOT exceed walking speed.

1-531200149

Page 16

Section 1 - General Safety Practices

OAL2030

2-Wheel Front Steer 4-Wheel Circle Steer 4-Wheel Crab Steer

Tr avel Hazard

• Steering characteristics differ between steer modes. Identify the steer mode

settings of the telehandler being operated.

• DO NOT change steer modes while traveling. Steer modes must be changed

while telehandler is stationary.

• Visually verify proper wheel alignment after each steer mode change.

• Ensure that adequate clearance is provided for both rear tail swing and front fork

swing.

• Look out for and avoid other personnel, machinery and vehicles in the area. Use

a spotter if you DO NOT have a clear view.

• Before moving be sure of a clear path and sound horn.

• When driving, retract boom and keep boom/attachment as low as possible while

maintaining visibility of mirrors and maximum visibility of path of travel.

• Always look in the direction of travel.

• Always check boom clearances carefully before driving underneath overhead

obstructions. Position attachment/load to clear obstacles.

• When driving in high speed, use only front wheel steer (if steering modes are

selectable).

1-6 31200149

Page 17

Section 1 - General Safety Practices

OW0130

Load Falling Hazard

• Never suspend load from forks or other parts of carriage.

• DO NOT burn or drill holes in fork(s).

• Forks must be centered under load and spaced apart as far as possible.

1-731200149

Page 18

Section 1 - General Safety Practices

OW0170

OW0190

Lifting Personnel

• When lifting personnel, USE ONLY a JLG approved personnel work platform,

with proper capacity chart displayed in the cab.

• DO NOT drive machine from cab when personnel are in platform.

1-8 31200149

Page 19

Section 1 - General Safety Practices

OW0200

Driving Hazards on Slopes

To maintain sufficient traction and braking capabilities, travel on slopes as follows:

• When unloaded, drive with forks pointed downhill.

• When loaded, drive with the forks pointed uphill.

• For additional travel requirements, refer to the appropriate capacity chart.

• To avoid overspeeding the engine and drivetrain when driving down slopes,

downshift to a lower gear and use the service brake as necessary to maintain a

slow speed. DO NOT shift into neutral and coast downhill.

• Avoid excessively steep slopes or unstable surfaces. To avoid tip over DO NOT

drive across excessively steep slopes under any circumstances.

• Avoid turning on a slope. Never engage “inching” or shift to “Neutral” when going

downhill.

• DO NOT park on a slope.

1-931200149

Page 20

Section 1 - General Safety Practices

OW0210

OW0220

OW0230

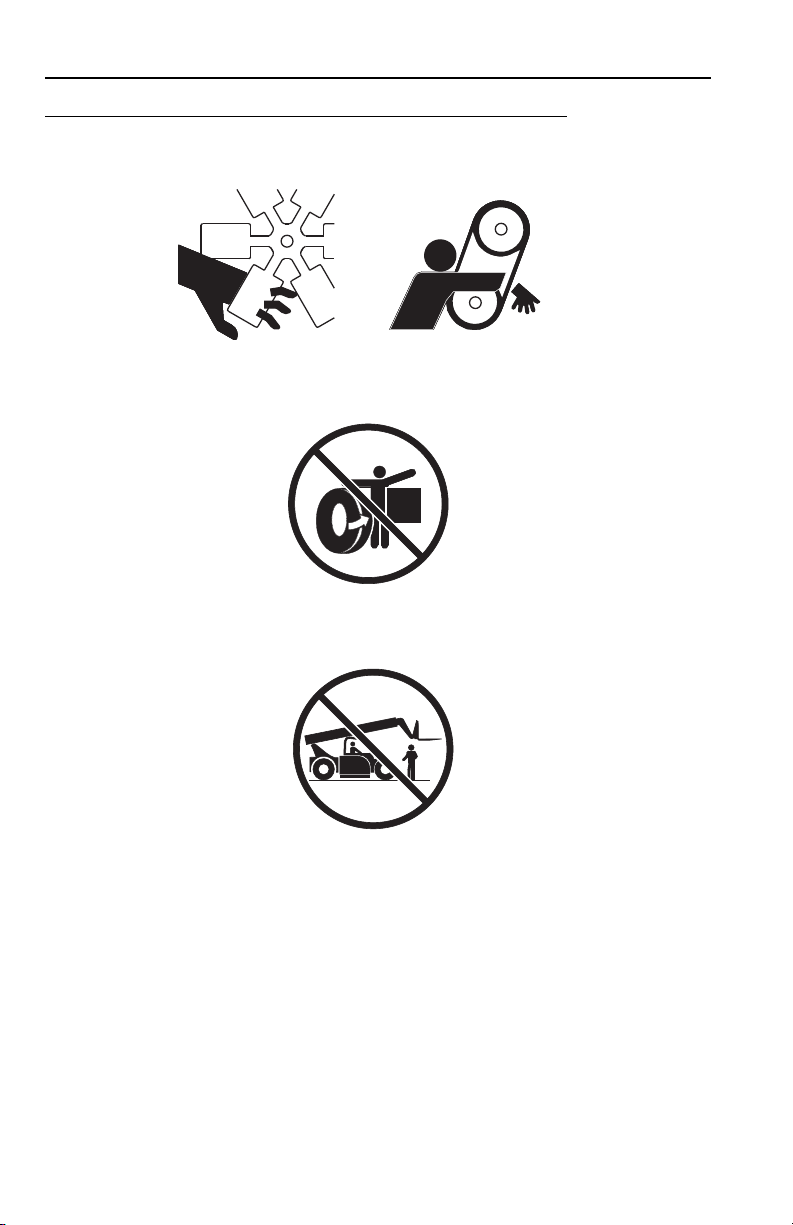

Pinch Points and Crush Hazards

Stay clear of pinch points and rotating parts on the telehandler.

• Stay clear of moving parts while engine is running.

• Keep clear of steering tires and frame or other objects.

• Keep clear from under boom.

1-10 31200149

Page 21

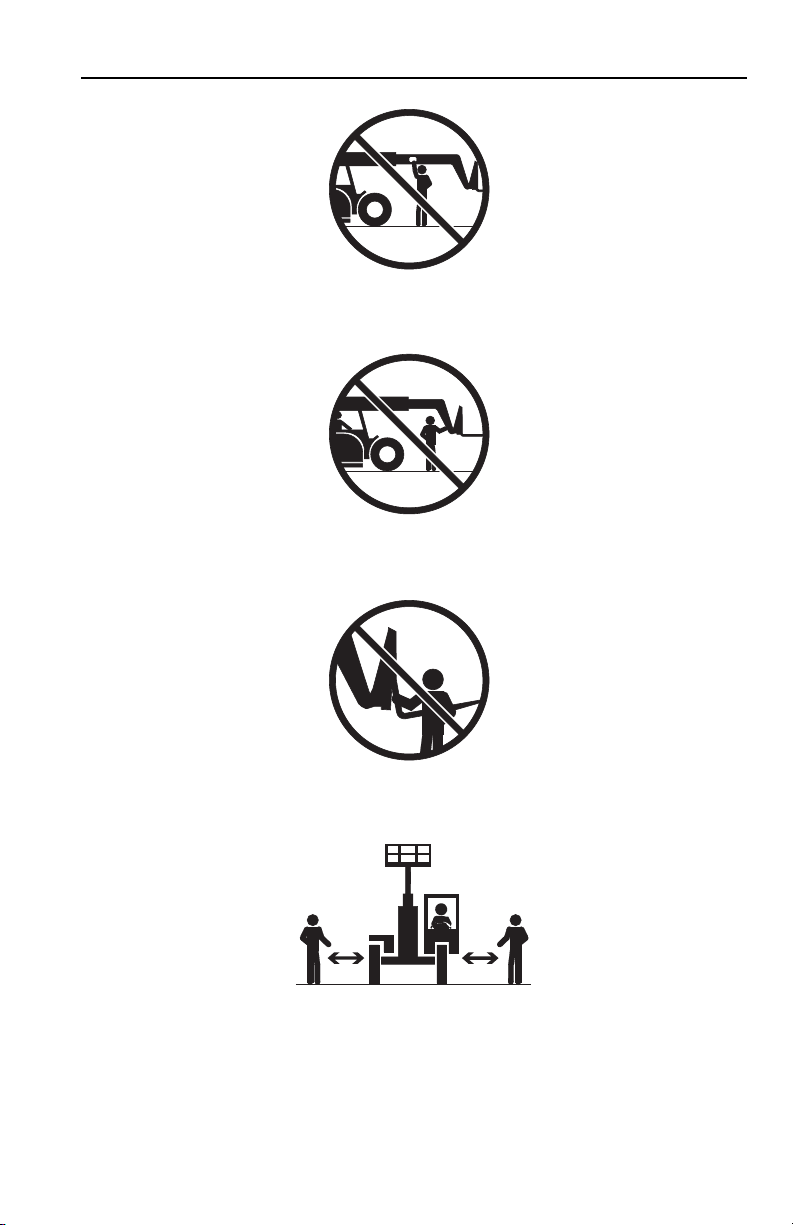

Section 1 - General Safety Practices

OW0240

OW0250

OW0260

OW0960

• Keep clear of boom holes.

• Keep arms and hands clear of attachment tilt cylinder.

• Keep hands and fingers clear of carriage and forks.

• Keep others away while operating.

1-1131200149

Page 22

Section 1 - General Safety Practices

OW0280

OW0290

Fall Hazard

• Enter using the proper hand holds and steps provided. Always maintain 3-point

contact when mounting or dismounting. Never grab control levers or steering

wheel when mounting or dismounting the machine.

• DO NOT get o f f th e m ac hi ne until the shutdown procedure on pa ge4-5 has been

performed.

• DO NOT carry riders. Riders could fall off machine causing death or serious

injury.

1-12 31200149

Page 23

Section 1 - General Safety Practices

OW0300

OW0950

Chemical Hazards

Exhaust Fumes

• DO NOT operate machine in an enclosed area without proper ventil ation.

• DO NOT operate the machine in hazardous environments unless approved for

that purpose by JLG and site owner. Sparks from the electrical system and the

engine exhaust can cause an explosion.

• If spark arrestors are required, ensure they are in place and in good working

order.

Flammable Fuel

• DO NOT fill the fuel tank or service the fuel system near an open flame, sparks

or smoking materials. Engine fuel is flammable and can cause a fire and/or

explosion.

Hydraulic Fluid

• DO NOT attempt to repair or tighten any hydra ulic hoses or fittin gs while t he

engine is running or when the hydraulic system is under pressure.

• Stop engine and relieve trapped pressure. Fluid in the hydraulic system is under

enough pressure that it can penetrate the skin.

• DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to

search for leaks. Wear gloves to protect hands from spraying fluid.

1-1331200149

Page 24

Section 1 - General Safety Practices

This Page Intentionally Left Blank

1-14 31200149

Page 25

Section 2 - Pre-Operation and Inspection

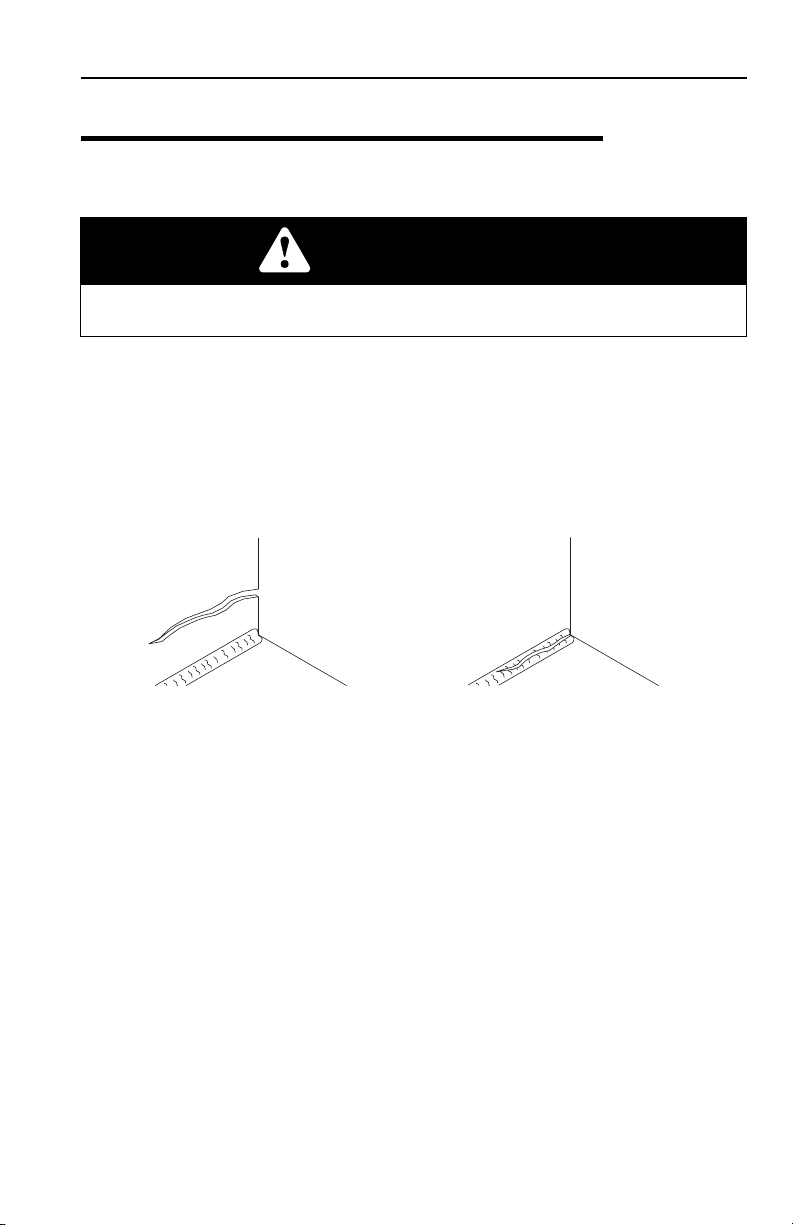

OAH1000

PARENT METAL CRACK WELD CRACK

SECTION 2 - PRE-OPERATION AND INSPECTION

2.1 PRE-OPERATION CHECK AND INSPECTION

Note: Complete all required maintenance before operating unit.

WARNING

FALL HAZARD. Use extreme caution when checking items beyond your normal

reach. Use an approved ladder.

The pre-operation check and inspection, performed at beginning of each work shift

or at each change of operator, should include the following:

1. Cleanliness - Check all surfaces for leaka ge (oil, fuel or battery fluid) or fo reign

objects. Report any leakage to the proper maintenance personnel.

2. Structure - Inspect the machine structure for dents, damage, weld or parent

metal cracks or other discrepancies.

3. Safety Decals - Ensure all safety decals are legible and in place. Clean or

replace as required. See page 2-3 for details.

4. Operation and Safety Manuals - Operation & Safety Manual and AEM Safety

Manual (ANSI only) are located in cab manual holder.

5. Walk-Around Inspection - See page2-12 for details.

6. Fluid Levels - Check fluids, includi ng fuel, hydr aulic o il, eng ine oil , transm ission

fluid and coolant. When adding fluids, refer to Section 7 - Lubrication and

Maintenance and Section 9 - Specifications to determine proper type and

intervals. Before removing filler caps or fill plugs, wipe all dirt and grease away

from the ports. If dirt enters these ports, it can severely reduce component life.

7. Attachments/Accessories - Ensure correct capa cit y cha rts are ins tal led on

the telehandler. If provided, reference the Operation & Safety Manual of each

attachment or accessory installed for specific inspection, operation and

maintenance instructions.

2-131200149

Page 26

Section 2 - Pre-Operation and Inspection

8. Oper ational Check - Once the walk-around inspection is complete, perform a

warm-up and operational check (see page 2-14) of all systems in an area free

of overhead and ground level obstructions. See Section 3 - Controls and

Indicators for more specific operating instructions.

WARNING

If telehandler does not operate properly, immediately bring machine to a stop,

lower boom and attachm ent to grou nd and st op th e engine . Deter mine c ause an d

correct before continued use.

2-2 31200149

Page 27

Section 2 - Pre-Operation and Inspection

OY0951

1705881

91143283

9114-3283

NO RIDERS PERMITTED ON HANDLER.

OPERATOR ONLY IN MACHINE

WHILE RUNNING.

RIDERS COULD FALL OFF MACHINE

CAUSING SERIOUS INJURY OR DEATH.

91143286

9114-3286

DIESEL FUEL IS FLAMMABLE

EXTINGUISH ALL OPEN FLAME AND

SMOKING MATERIALS WHEN REFUELING

INJURY OR DEATH COULD RESULT

FROM FIRE.

91083492

91143282

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

91143282

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

DO NOT use Ether or

other high energy

starting aids.

Engine equipped with

Pre-heating system.

ENGINE EXPLOSION

could result in death

or serious injury.

1706300C

1706300

(PERKINS ENGINE

ONLY )

9151-3201 REV. (-)

91513201

(IF EQUIPPED WITH

TILT ON JOYSTICK)

90553027

9055-3027 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED PERSONNEL WORK PLATFORM.

DO NOT DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

WHEN PERSONNEL ARE IN PLATFORM REMAIN SEATED IN CAB WITH PERSONNEL

IN DIRECT LINE OF SIGHT.

OPERATE CONTROLS LIGHTLY AND CAUTIOUSLY WHEN LIFTING PERSONNEL.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL BEFORE LIFTING PERSONNEL.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

80603022

8060-3022

AVOID HIGH VOLTAGE LINES.

IT IS UNLAWFUL TO PLACE

ANY PART OF THIS MACHINE

OR LOAD WITHIN 10 FEET

OF HIGH VOLTAGE LINES

UP TO 50,000 VOLTS.

DEATH OR INJURY MAY

RESULT FROM CONTACTING

ELECTRIC LINES.

90553028

8. ON INCLINES, TRAVEL WITH LOAD UP-GRADE.

9. DO NOT USE BOOM AS WALKWAY.

10. USE TWO HANDS WHEN CLIMBING ON MACHINE.

1. ONLY TRAINED AND AUTHORIZED PERSONNEL MAY

OPERATE THIS MACHINE.

2. BEFORE OPERATING, READ AND UNDERSTAND ALL CAPACITY

CHARTS, OPERATOR MANUALS AND SAFETY MANUALS. IF

MANUALS ARE NOT AVAILABLE, CONSULT AN AUTHORIZED

JLG DEALER. UNDERSTAND ALL CONTROLS IN CAB AND

CHECK FOR PROPER OPERATION. CLEAR LOOSE OBJECTS

OFF MACHINE AND SOUND HORN BEFORE STARTING ENGINE.

3. OPERATOR MUST BE SEATED WITH SEAT BELT FASTENED.

ASSURE FORWARD/REVERSE LEVER IS IN NEUTRAL,PARK

BRAKE APPLIED AND ALL HYDRAULIC CONTROLS ARE IN

NEUTRAL BEFORE IGNITION SWITCH IS TURNED ON.

4. DO NOT OPERATE MACHINE WITHOUT PROPER CAPACITY

CHART IN PLACE.

5. BEFORE MOVING, BE SURE OF A CLEAR PATH AND SOUND

HORN. WATCH FOR PEDESTRIANS AND OBSTRUCTIONS.

CHECK OVERHEAD AND SIDE CLEARANCES. ALWAYS LOOK

IN DIRECTION OF TRAVEL.

6. START, TURN, AND BRAKE SMOOTHLY. REDUCE TRAVEL

SPEEDS FOR TURNS, SLIPPERY, OR UNEVEN SURFACES.

AVOID RUNNING OVER LOOSE OBJECTS OR HOLES IN THE

ROADWAY SURFACE.

7. WHEN TRAVELING WITH LOAD, FULLY RETRACT BOOM AND

PLACE FORKS IN CARRY POSITION (APPROX.12" ABOVE

GROUND). TILT CARRIAGE BACK SLIGHTLY TO CRADLE

LOAD. USE EXTREME CAUTION WHEN TURNING.

11. USE ONLY A JLG MANUFACTURED PERSONNEL WORK

PLATFORM FOR LIFTING PERSONNEL. NO RIDERS ON MACHINE,

FORKS, LOAD, OR OTHER LIFTING ATTACHMENTS AT ANY

TIME. DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN THE CAB. DO NOT

DRIVE MACHINE WITH PERSONNEL IN PLATFORM.

12. KEEP OTHERS AWAY FROM MACHINE WHILE OPERATING.

DO NOT STAND UNDER BOOM OR LOAD.

13. USE EXTREME CARE WHEN HANDLING LONG, HIGH, OR

WIDE LOADS. DO NOT HANDLE UNSTABLE OR LOOSELY

STACKED LOADS.

14. FORKS TO BE CENTERED UNDER LOAD AND SPACED APART

AS FAR AS POSSIBLE.

15. BEFORE ADJUSTING OR SERVICING, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, REST BOOM ON

GROUND OR SUPPORT, SET PARKING BRAKE, SHUT OFF

ENGINE AND CHOCK WHEELS.

16. BEFORE LEAVING MACHINE UNATTENDED, PLACE

FORWARD/REVERSE LEVER IN NEUTRAL, LOWER BOOM,

SET PARKING BRAKE,AND SHUT-OFF ENGINE. CHOCK

WHEELS IF MACHINE MUST PARK ON AN INCLINE.

17. LEVEL MACHINE BEFORE LIFTING ANY LOAD ABOVE 4

FEET. (IF EQUIPPED WITH FRAME LEVELING).

18. OPERATOR PROTECTION (SUCH AS HARD HATS, SAFETY

GLASSES, AND/OR HEARING PROTECTION) SHOULD BE

WORN WHEN JOB CONDITIONS WARRANT. ALWAYS USE

SEAT BELT.

19. IMPROPER USE OF MACHINE COULD RESULT IN MACHINE

TIPPING OVER. IF MACHINE STARTS TO TIP OVER, DO

NOT LEAVE OPERATORS SEAT. LEAN AWAY FROM TIP &

BRACE YOURSELF.

20. KEEP MIRROR(S) CLEAN AND PROPERLY ADJUSTED.

OBJECTS IN MIRROR ARE CLOSER THAN THEY APPEAR.

9055-3028 REV C

FOR SAFE OPERATION OF MACHINE AND TO MINIMIZE RISK OF

SERIOUS INJURY, READ AND OBSERVE THE FOLLOWING:

91323030

9132-3030

NEVER OPERATE MACHINE WITHOUT

CONSULTING PROPER CAPACITY CHART FOR THE

CARRIAGE/FORK COMBINATION BEING USED.

91503102

9150-3102 REV. -

91473217

Diesel Engine

SERVICE INTERVALS

LUBRICATION AND MAINTENANCE

MATERIAL HANDLER

9147-3217 REV(-)

Use this chart in conjunction with the "Lubrication & Maintenance" and "Recommended

Lubricants & Capacities" sections of the Owner/Operator Manual.

Service intervals may need to be more frequent than those shown depending upon

application severity. Consult your JLG dealer for recommendations.

It is recommended that engine oil and filter, transmission lubricant and filter,

transfer case lubricant and axle lubricant be changed after first 100 hours on

new, or rebuilt units.

LUBRICANT TYPE

OR

SPECIFICATION

Air Cleaner Element

Fuel Filter

Engine Oil Filter

Engine Oil

Coolant

Diesel Fuel

YEARLY

OR

1500 HRS

6 MO.

OR

1000 HRS

3 MO.

OR

500 HRS

EVERY 5

WKS OR

250 HRS

WEEKLY

OR

50 HRS

DAILY

OR

10 HRS

Transmission

Lubricant

Filter

Transfer Case

Lubricant

Center Section

Axle Lubricant

Planetary Hubs

Filter

Lubricant

Hydraulic System

Breather/Filter

Grease Fittings

Axles (6 Pts. Ea.)

Boom Head Pivot (2 Pts.)

Boom Pivot (2 Pts.)

Extend Chain Sheave (1 Pt.)

Drive Shafts (1 Pt. Ea.)

Cylinder Pins(13 Pts.)

Quick Switch Pin (1 Pt.)

Retract Chain Sheave (1 Pt.)

Boom

Front Bottom Bearing Pads

All Other Bearing Pads

Extend/Retract Chains

Options And Attachments

Stabilizer Cylinder (3 Pts.)

Attachment Pivots And Pins

Tires

13.00-24 12 Ply

13.00R24 Radial

15.5-25 12 Ply

Lug Nut Torque

Torque

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Check

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Grease

Change

Change

Change

Change

Change

Change

Change

Change

Change

Change

Change

Change

SAE 15W-40 CH/CI Oil

Ethylene Glycol

No. 2 Diesel Fuel

Mobil 424

Mobil 424

Mobil 424

Mobil 424

Mobil 424

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

Mystik Tetrimoly

See Manual

65 PSI (448 kPa)

70 PSI (483 kPa)

58 PSI (400 kPa)

350-400 Lb-Ft (475-540 Nm)

Fill

91343016

9134-3016

TURBOCHARGER DAMAGE CAN RESULT

FROM QUICK START-UP & SHUTDOWN.

FOR LONGER TURBOCHARGER LIFE

AND TO MINIMIZE TURBOCHARGER

DAMAGE, IDLE ENGINE AT LEAST

3-5 MINUTES AFTER START-UP

AND BEFORE SHUTDOWN.

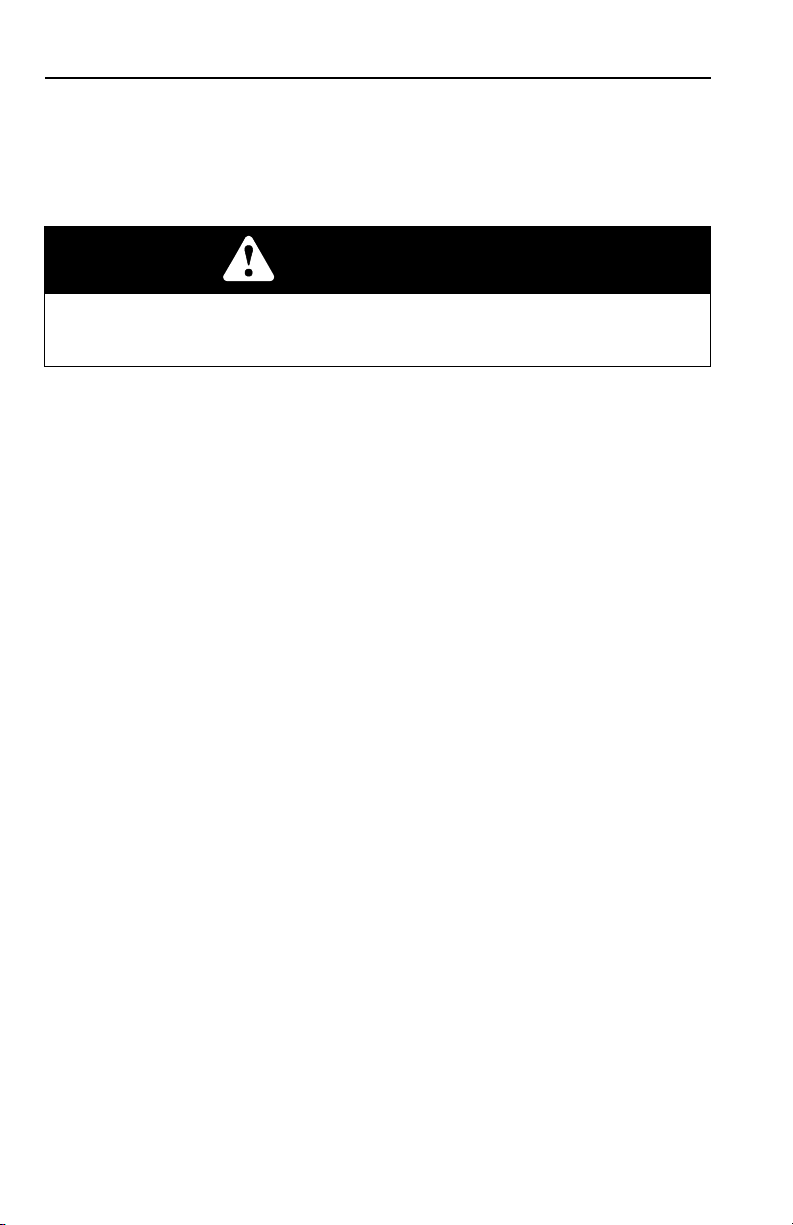

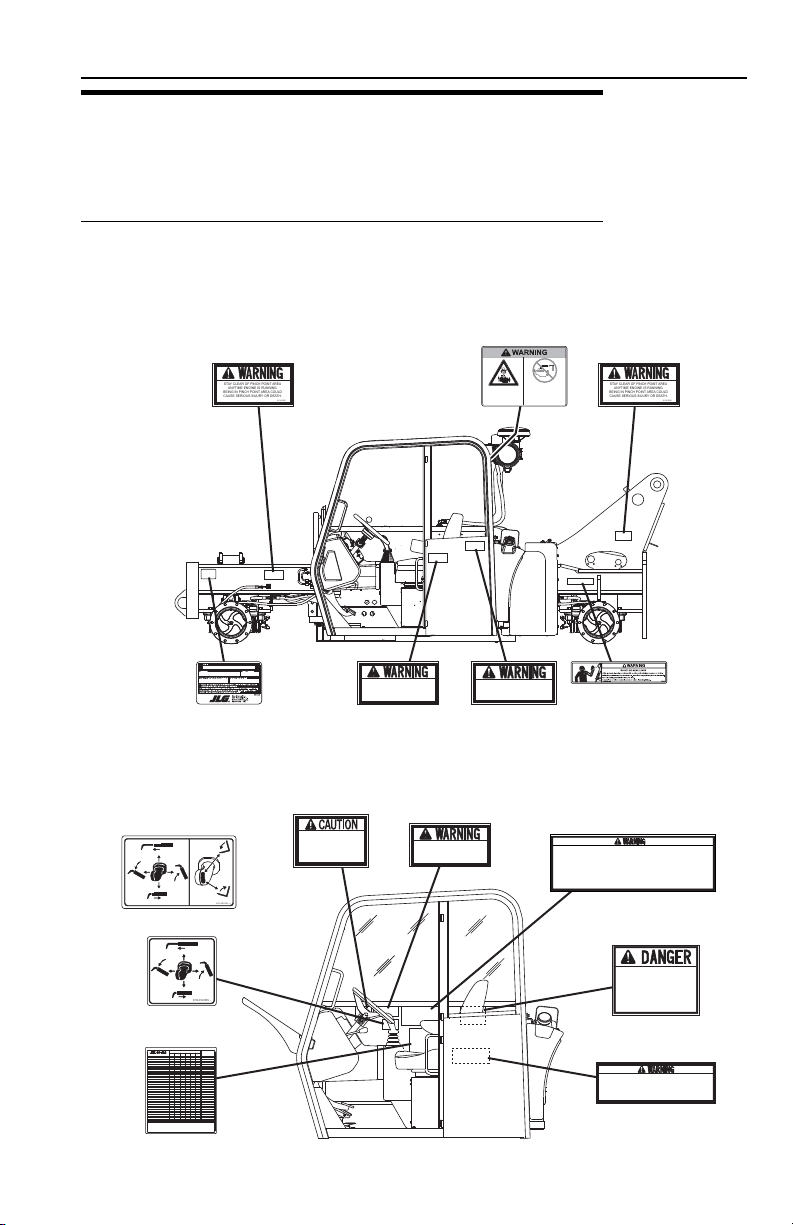

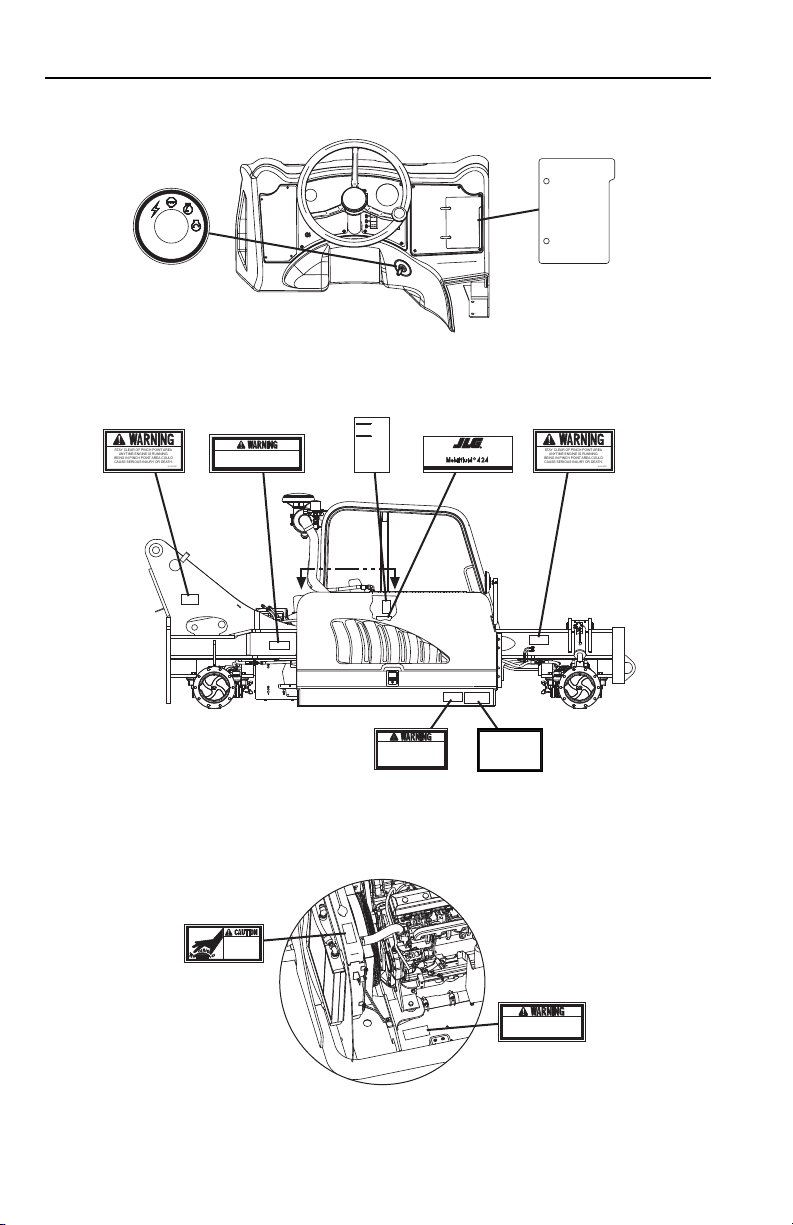

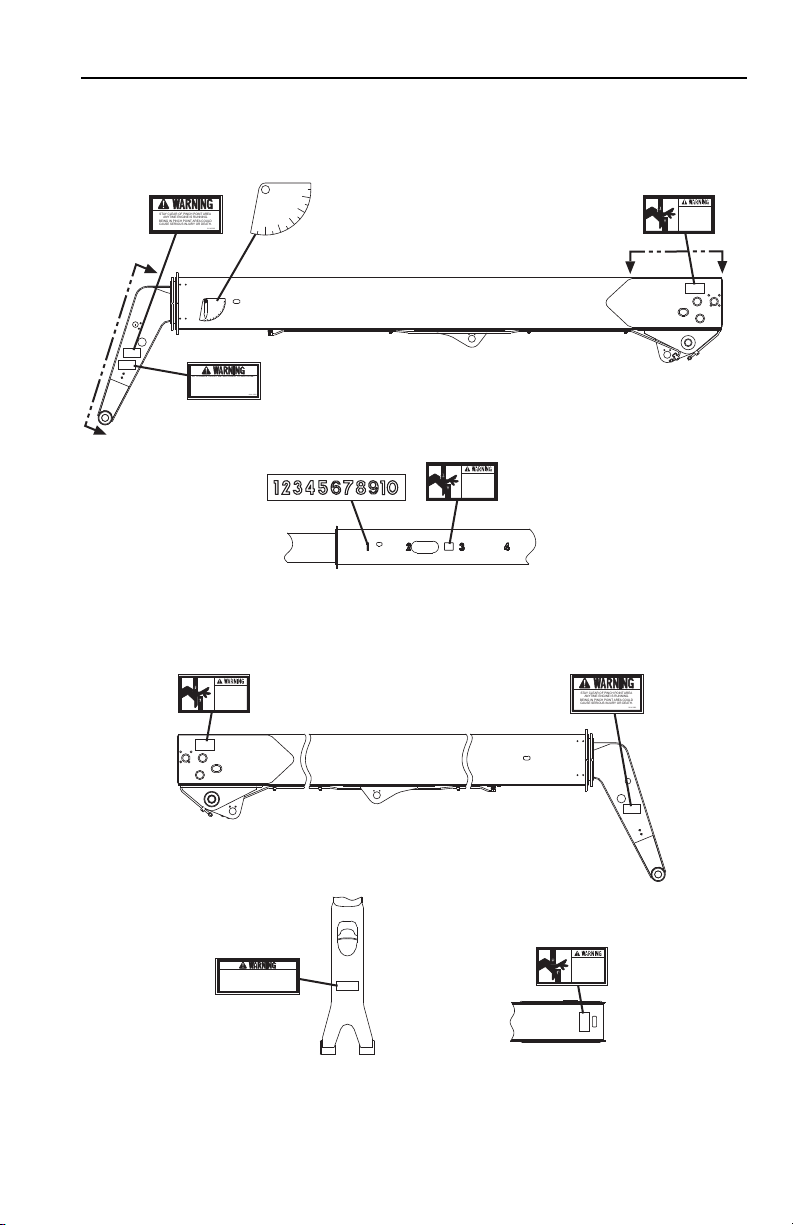

2.2 SAFETY DECALS

Ensure all DANGER, WARNING, CAUTION and instructional decals and proper

capacity charts are legible and in place. Clean and replace as required.

ANSI

Before S/N 0160040169

2-331200149

Page 28

Section 2 - Pre-Operation and Inspection

OY0961

91413061

91413061

80603026

8060-3026

COOLING SYSTEM

IS PRESSURIZED.

REMOVE CAP SLOWLY.

HOT FLUID CAN

CAUSE BURNS.

91143281

9114-3281

STAY CLEAR OF MOVING PARTS

WHILE ENGINE IS RUNNING.

MOVING PARTS CAN CAUSE

SERIOUS INJURY.

91143282

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

91143280

(BEFORE

S/N 0160027200)

9114-3280

EXHAUST SYSTEMS CAN BE HOT.

KEEP AWAY FROM EXHAUST SYSTEM WHEN HOT.

HOT EXHAUST COMPONENTS CAN CAUSE

SEVERE BURNS.

91403569

ADD

FULL

9140-3569

CHECK OIL LEVEL WITH

HANDLER LEVEL AND ALL

CYLINDERS RETRACTED.

2.5 GALLON BETWEEN

ADD AND FULL MARKS

HYDRAULIC

OIL LEVEL

91143282

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

9114-3284

LEAD ACID BATTERIES PRODUCE FLAMMABLE AND

EXPLOSIVE GASES

WHEN CHECKING, TESTING, USING

BOOSTER BATTERY OR CHARGING BATTERIES:

* DO NOT USE SMOKING MATERIALS NEAR BATTERIES

* KEEP FLAMES AND SPARKS AWAY FROM BATTERIES

* WEAR SAFETY GLASSES

* ASSURE BATTERY IS NOT FROZEN AND ELECTROLYTE

IS AT PROPER LEVEL IN EACH CELL

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY OR DAMAGE TO THE

ELECTRICAL SYSTEM

91143284

91143285

9114-3285

WHEN JUMP STARTING MATERIAL HANDLER

* NEVER ALLOW VEHICLES TO TOUCH

* CONNECT THE POSITIVE (+) JUMPER CABLE TO

POSITIVE (+) POST OF DISCHARGED BATTERY

* CONNECT OPPOSITE END OF POSITIVE (+) JUMPER

CABLE TO POSITIVE (+) POST OF BOOSTER BATTERY

* CONNECT THE NEGATIVE (-) JUMPER CABLE TO

NEGATIVE (-) POST ON BOOSTER BATTERY

* CONNECT OPPOSITE END OF NEGATIVE (-) JUMPER

CABLE TO GROUND POINT ON MACHINE AWAY FROM

DISCHARGED BATTERY

* FOLLOW STANDARD STARTING PROCEDURES

* REMOVE CABLES IN REVERSE ORDER AFTER MACHINE

HAS STARTED

JUMP STARTING INSTRUCTIONS

91143288

R

HYDRAULIC SYSTEM

FILL WITH TRACTOR HYDRAULIC FLUID

For Mobil Product Information, Call 1-800-662-4525.

or equivalent.

9114-3288

VIEW OF CAB DASH

CAPACITY CHARTS

VIEW A-A

AA

2-4 31200149

Page 29

Section 2 - Pre-Operation and Inspection

OY1251

80603037

8060-3037-A

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

-10

°

0°

10°

20°

3

0

°

4

0

°

5

0

°

6

0

°

70°

80°

80603037

8060-3037-A

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

-10

0

10

20

30

40

50

60

7

0

8

0

4105262

91143282

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

91143290

9114-3290

ATTCHMENT MUST BE SECURED TO MACHINE.

CHECK TO ASSURE QUICK SWITCH PLUNGER

PIN IS FULLY ENGAGED AND LOCKED AFTER

ATTACHMENT CHANGE.

IF PLUNGER PIN IS NOT FULLY ENGAGED

AND LOCKED ATTACHMENT MAY FALL OFF

CAUSING SERIOUS INJURY OR DEATH.

80603037

8060-3037-A

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

91553072

80603037

8060-3037-A

PINCH POINT

KEEP OUT

REACHING INTO BOOM

HOLES AND OTHER PINCH

POINTS CAN CAUSE

SERIOUS INJURY

OR DEATH.

91143282

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

90553026

9055-3026 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED

PERSONNEL WORK PLATFORM.

ALL PERSONNEL IN PLATFORM MUST WEAR A FULL BODY HARNESS WITH

LANYARD ATTACHED TO A DESIGNATED ANCHORAGE POINT.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL

BEFORE OCCUPYING PERSONNEL WORK PLATFORM.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

VIEW B-B

C

VIEW C-C

B

C

B

2-531200149

Page 30

Section 2 - Pre-Operation and Inspection

OY2091

1705881

1706768

(ENCLOSED CAB)

DO NOT use Ether or

other high energy

starting aids.

Engine equipped with

Pre-heating system.

ENGINE EXPLOSION

could result in death

or serious injury.

1706300C

1706300

(PERKINS ENGINE

BEFORE S/N 0160040678)

1706768

(OPEN CAB)

1701640

(S/N 0160040678

& AFTER)

1701640

91163028

91163028REV.B

F

N

R

1706304A

RUN-OVER

HAZARD

couldcause

deathor

serious

injury.

1706304

1706767A

1706767

1706851A

1706851

Fasten

seat

belt.

1706303A

Operatormust be trained and

mustread and understand

allcapacity charts, operator

andsafety manuals.

1706303

1001130802

1001130920

A

B

1001118911 B

IF EQUIPPED

1000

B

2

B

2

B

2

B

2

2

B

B

2

4

2

A

2

A

2

A

2

A

2

A

A

A

A

A

2

2

2

2

2

A

1001130782

S/N 0160040678 & AFTER

91473217

BEFORE S/N 0160040678

1001114982

A

B

1001118911 B

IF EQUIPPED

1000

B

2

B

2

B

2

B

2

2

B

B

2

4

2

A

2

A

2

A

2

A

2

A

A

A

A

A

2

2

2

2

2

A

CAPACITY

CHARTS

1001131745A

1001131745

(IF EQUIPPED WITH

TILT ON JOYSTICK)

1001109459

1001109459C

1001108847

(IF EQUIPPED WITH

RH SWAY)

91413061

91413061

1001108836

(IF EQUIPPED WITH

RH TILT/SWAY)

1001108836B

A

A

S/N 0160040169 & After, If Equipped

2-6 31200149

Page 31

Section 2 - Pre-Operation and Inspection

OY2100

1706850A

CRUSHING HAZARD

Keepothers

awaywhile

operating.

Loweringboom or falling load could

causedeath or serious injury.

WARNING

1706850

1706306A

1706306

1706299A

CONTACTING

POWERLINES

willresult in death

orserious injury.

1706299

4109801

4109801

1706296

4109801

4109801

91563220

9156-3220 REV A

4100181

4100181

1706301A

1706301

91563220

9156-3220 REV A

4100181

4100181

DO NOT use Ether or

other high energy

starting aids.

Engine equipped with

Pre-heating system.

ENGINE EXPLOSION

could result in death

or serious injury.

1706300C

1706300

1001109053

2.5 GPM

9.5 lpm

MAX

1001109053 REV A

1706301A

1706301

VIEW A-A

VIEW B-BVIEW C-C

VIEW D-D

B

B

CC

D

D

S/N 0160040169 THRU 0160040677

B

B

CC

D

D

S/N 0160040678 & AFTER

2-731200149

Page 32

Section 2 - Pre-Operation and Inspection

OY2110

1706302

-1

0

°

0°

10°

20°

3

0

°

4

0

°

5

0

°

6

0

°

70°

80°

1706302

-10

0

10

20

30

40

50

60

7

0

8

0

4105262

1706298A

1706298

1706302

1706302

91553072

1706302

VIEW E-E

FF

E

E

VIEW F-F

2-8 31200149

Page 33

Section 2 - Pre-Operation and Inspection

OY2121

91163028

91163028REV.B

F

N

R

1001130802

1001130920

A

B

1001118911 B

IF EQUIPPED

1000

B

2

B

2

B

2

B

2

2

B

B

2

4

2

A

2

A

2

A

2

A

2

A

A

A

A

A

2

2

2

2

2

A

1001130782

S/N 0160040678 & AFTER

91473217

BEFORE S/N 0160040678

1001114982

A

B

1001118911 B

IF EQUIPPED

1000

B

2

B

2

B

2

B

2

2

B

B

2

4

2

A

2

A

2

A

2

A

2

A

A

A

A

A

2

2

2

2

2

A

CAPACITY

CHARTS

1001131745A

1001131745

(IF EQUIPPED WITH

TILT ON JOYSTICK)

1001109459

1001109459C

1001108847

(IF EQUIPPED WITH

RH SWAY)

91413061

91413061

1001108836

(IF EQUIPPED WITH

RH TILT/SWAY)

1001108836B

1706283

1706287

1706289

1706293

1705881

1001092878

(ENCLOSED CAB)

1701640

(S/N 0160040678

& AFTER)

1701640

1706098

(PERKINS ENGINE

BEFORE S/N 0160040678)

1706098B

1001092878

(OPEN CAB)

A

A

ISO (S/N 0160040169 & After, If Equipped)

2-931200149

Page 34

Section 2 - Pre-Operation and Inspection

OY2130

4109801

4109801

4109801

4109801

1706281

91563220

9156-3220 REV A

4100181

4100181

1706285

91563220

9156-3220 REV A

4100181

4100181

1001109053

2.5 GPM

9.5 lpm

MAX

1001109053 REV A

1706098

1706098B

1706285

1706288

1706284

1001092877

VIEW A-A

VIEW B-BVIEW C-C

VIEW D-D

B

B

CC

D

D

S/N 0160040169 THRU 0160040677

B

B

CC

D

D

S/N 0160040678 & AFTER

2-10 31200149

Page 35

Section 2 - Pre-Operation and Inspection

OY2140

1706282

1706292

1706292

1706292

91553072

1706292

-1

0

°

0°

10°

20°

3

0

°

4

0

°

5

0

°

6

0

°

70°

80°

-10

0

10

20

30

40

50

60

7

0

8

0

4105262

1706292

VIEW E-E

FF

E

E

VIEW F-F

2-1131200149

Page 36

Section 2 - Pre-Operation and Inspection

OY0182

3

1

5

6

8

9

11

12

4

13

14

2

15

4

10

7

2.3 WALK-AROUND INSPECTION

Begin your walk-around inspection at item 1, as noted below. Continue to your right

(counterclockwise when viewed from top) checking each item in sequence.

INSPECTION NOTE: On all components, make sure there are no loose or missing

parts, that they are securely fastened and no visible leaks or excessive wear exists

in addition to any other criteria mentioned. Inspect all structural members including

attachment for cracks, excessive corrosion and other damage.

1. Boom Sections and Lift, Tilt, Extend/Retra ct, Compensating (Slave) Cylin ders

• Check front, top, side and rear wear pads for presence of grease.

• Pivot pins secure; hydraulic hoses undamaged, not leaking.

2. Front Axle

hydraulic hoses undamaged, not leaking.

3. Wheel/Tire Assembly - Properly inflated and secured; no loose or missing lug

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

4. Mirrors

- Steer cylinders undamaged, not leaking; pivot pins secure;

- Clean and undamaged.

2-12 31200149

-

Page 37

Section 2 - Pre-Operation and Inspection

5. Cab and Electrical -

• General appearance; no visible damage.

• Frame level indicator and window glass undamaged and clean.

• Gauges, switches, joysticks, foot controls and horn operational.

• Emerg ency escape hammer in place (enclosed cab only).

• Check seat belt for damage, replace belt if frayed or cut webbing, damaged

buckles or loose mounting hardware.

6. Air Cleaner

check for clogged condition. Replace element as required.

7. Main Control Valve

(Before S/N 0160040678) - Air cleaner element condition indicato r,

- See Inspection Note.

8. Wheel/Tire Assembly

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

9. Stabilizer Cylinder

leaking.

10. Rear Axle - Steer cylinders undamaged, not leaking; pivot pins secure;

hydraulic hoses undamaged, not leaking.

11. Wheel/Tire Assembly

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

12. Engine Compartm ent

• Air Cleaner (S/N 0160040678 & After) - Air cleaner element condition

indicator, check for clogged condition. Replace element as required.

• Drive belts, check condition and replace as required.

• Engine mounts - See inspection note.

• Battery cables tight, no visible damage or corrosion.

• Engine cover properly secured.

13. Wheel/Tire Assembly

nuts. Inspect for worn tread, cuts, tears or other discrepancies.

14. Frame Level Cylinder

15. Attachment - Properly installed, see See “Attachment Installation” on

page 5-13.

- Properly inflated and secured; no loose or missing lug

(if equipped) - Pins secure ; hydr aulic hos es und amage d, not

- Properly inflated and secured; no loose or missing lug

-

- Properly inflated and secured; no loose or missing lug

- Pins secure; hydraulic hoses undamaged, not leaking.

2-1331200149

Page 38

Section 2 - Pre-Operation and Inspection

2.4 WARM-UP AND OPERATIONAL CHECKS Warm-Up Check

During warm-up period, check:

1. Heater, defroster and windshield wiper (if equipped).

2. Check all lighting systems (if equipped) for proper operation.

3. Voltmeter should show 13.5 to 14 volts.

4. Adjust mirror(s) for maximum visibility.

WARNING

CUT/CRUSH/BURN HAZARD. Keep engine cover clo sed while engine is running

except when checking transmission oil level and hydraulic filter condition

indicator.

Operational Check

When engine warms, perform an operational check:

1. Service brake and parking brake operation.

2. Forward and reverse travel.

3. Each gear.

4. Steering in both directions with engine at low idle (steering lock to lock will not

be reached). Check in each steering mode.

5. Horn and back-up alarm. Must be audib le from ins ide operato rs cab with en gine

running.

6. All joystick functions - operate smoothly and correctly.

7. Perform any additional checks described in Section 8.

8. Hydraulic filter condition indicator.

2-14 31200149

Page 39

Section 2 - Pre-Operation and Inspection

2.5 OPERATOR CAB

The telehandler is equipped with an open or enclosed ROPS/FOPS cab.

WARNING

Never operate telehandler unless the overhead guard, cab structure and right

side glass or screen are in goo d condition. Any modification to this machine mus t

be approved by JLG to assure compliance with ROPS/FOPS certification for this

cab/machine configuration. If the overhead guard or cab structure is damaged,

the CAB CANNOT BE REPAIRED. It must be REPLACED.

2-1531200149

Page 40

Section 2 - Pre-Operation and Inspection

OAL0011

1

2

3

4

2.6 WINDOWS

Keep all windows and mirrors clean and unobstructed.

Cab Door Window (if equipped)

• Cab doo r (1) must be closed during operation.

• During operation the cab door window (2) must either be latched open or closed.

• Open the cab door window and secure it in the latch (3).

• Press latch release button inside the cab or pull on lever (4) outside the cab to

unlatch the window.

2-16 31200149

Page 41

Section 3 - Controls and Indicators

SECTION 3 - CONTROLS AND INDICATORS

3.1 GENERAL

This section provides the necessary information needed to understand control

functions.

Note: The manufacturer has no direct control over machine application and

operation. The user and operator are responsible for conforming with good safety

practices.

NOTICE

EQUIPMENT DAMAGE. When a red light illuminates (except park brake),

immediately bring machine to a stop, lower boom and attachment to ground and

stop the engine. Determine cause and correct before continued use.

3-131200149

Page 42

Section 3 - Controls and Indicators

OY2160

5

9

10

11

12

1

2

3

4

6

7

8

3.2 CONTROLS

Before S/N 0160040678

1. Transmission Control Lever: See page 3-8.

2. Instrument Panel

3. Steering Wheel

machine in the corresponding direction. Three steering modes are available.

See “Steer Modes” on page 3-18.

4. Frame Level Indicato

condition of the telehandler.

5. Accessory Control Lever

6. Boom Joystick

7. Frame Level and Attachment Tilt (if equipped) Joystick

8. Heater and Air Conditioning Controls

9. Accelerator Pedal

speed.

10. Service Brake Pedal

speed.

11. Ignition Switch

12. Auxiliary Hydraulic Joystick

3-2 31200149

: See page 3-4.

: Turning the steering wheel to the left or right steers the

r: Enables the operator to determine the left to right level

(if equipped): See page 3-16.

: See page 3-10.

: Pressing down the pedal increases engine and hydraulic

: The further the pedal is depressed, the slower the travel

: Key activated. See page 3-6.

(if equipped): See page3-12.

: See page 3-11.

(if equipped): See page 3-15.

Page 43

S/N 0160040678 & After

OY2150

8

5

1

4

2

3

6

7

9

10

11

12

Section 3 - Controls and Indicators

1. Transmission Control Lever

2. Instrument Panel

3. Steering Wheel

: See page 3-4.

: Turning the steering wheel to the left or right steers the

: See page 3-8.

machine in the corresponding direction. Three steering modes are available.

See “Steer Modes” on page 3-18.

4. Frame Level Indicator

condition of the telehandler.

5. Accessory Control Lever (if equipped): See page 3-16.

6. Right Hand Panel

7. Boom Joystick

8. Frame Level and Attachment Tilt (if equipped) Joystick

9. Accelerator Pedal

: Enables the operator to determine the left to right level

: See page 3-14.

: See page 3-10.

: See page 3-11.

: Pressing down the pedal increases engine and hydraulic

speed.

10. Service Brake Pedal: The further the pedal is depressed, the slower the travel

speed.

11. Ignition Switch: Key activated. See page 3-6.

12. Auxiliary Hydraulic Joystick

: See page 3-12.

3-331200149

Page 44

Section 3 - Controls and Indicators

OY0084

145

6712

3

8131011

R

N

F

145

6712

2 3

891011

BEFORE S/N 0160031634

S/N 0160031634 THRU

0160040677

Dash Controls and Indicators

Before S/N 0160040678

1. Hourmeter

: Indicates total time of engine operation in hours and tenths of

hours.

2. Boom Work Light Switch

3. Beacon Light Switch

4. Park Brake Switch

5. 4-in-1 Gauge

:

(Before S/N 0160031634, if equipped): On/Off switch.

(if equipped): On/Off switch.

: See page 3-7 for details.

a. Engine Coolant Temperature Gauge

b. Engine Oil Pressure Gauge

c. Fuel Gauge

d. Voltmeter indicates alternator output and battery condition.

6. Horn Button

7. Steer Select Switch

: Depress button to sound horn.

: Three positions: 4-wheel circle steer, 4-wheel crab steer

and 2-wheel steer. See page 3-18 for details.

8. Work Light Switch

9. Driving Lights Switch

10. Windshield Wiper Control

(if equipped): On/Off switch.

(Before S/N 0160031634, if equipped): On/Off switch.

(if equipped): Two speed rotary switch. Depress to

activate washer fluid. Return to first position to turn off wiper.

11. Engine Pre-Heat Switch

(Perkins Only): Depress to engag e engin e pre- heat. At

temperatures below 32°F (0°C), do not start until engine is preheated.

Auxiliary Electrics Sw itches (John Deere, if equipped): Enables functions of

attachments that require auxiliary electrics. See Section 5- Attachments for

approved attachments and control instructions.

12. Transmission Temperature Light

too high. Bring machine to a stop, lower boom and attachment to ground. Idle

machine until the transmission temperature light goe s o ut, the n s hut off engine.

Determine cause and correct before continued use.

13. Hazard Light Switch

(S/N 0160031634 thru 0160040677, if equipped): On/Off

: Illuminates when transmission temperature is

switch.

3-4 31200149

Page 45

Section 3 - Controls and Indicators

OAL2430

12 3

678

4 5

S/N 0160040678 & After

1. Transmission Temperature Light: Illuminates when transmission temperature is

too high. Bring machine to a stop, lower boom and attachment to ground. Idle

machine until the transmission temperature light goe s o ut, the n s hut off engine.

Determine cause and correct before continued use.

2. Engine Pre-Heat Indicator Light

position. Light goes out when start temperature is reached. Do not start until

light goes out.

3. Steer Select Switch

: Three positions: 4-wheel circle steer, 4-wheel crab steer

and 2-wheel steer. See page 3-18 for details.

4. Park Brake Switch

5. Horn Button

: See page 3-7 for details.

: Depress button to sound horn.

6. Auxiliary Electrics Switches

require auxiliary electrics. See Section 5 - Attachments for approved

attachments and control instructions.

7. Warning and Check Engine Lights

engine fault and/or parameter that is outside of acceptable range. Engine may

derate.

8. 3-in-1 Gauge and Display

a. Engine Coolant Temperature Gauge

b. Engine Oil Pressure Gauge

c. Fuel Gauge

d. Display - Displays engine operating hours, battery voltage and engine rpm.

Engine fault codes displayed when detected. See Service Manual for

details.

: Illuminates with ignition key in the “RUN”

(if equipped): Enab les funct ions of a ttachments that

: Any combination of i llum ination indic ate s an

:

3-531200149

Page 46

Section 3 - Controls and Indicators

N

F

R

ACC

RUN

START

OFF

OY0052

Ignition

• In "ACC" or "RUN" position, voltage is available for all electrical functions.

• Full clockwise rotation to "START" engages starter motor.

• Counter-clockwise rotation to "OFF" stops engine and removes voltage from all

electrical functions.

3-6 31200149

Page 47

Section 3 - Controls and Indicators

OY0123

R

N

F

1

2

BEFORE S/N 0160040678 S/N 0160040678 & AFTER

Park Brake

Park brake switch controls the application and release of the park brake. Indicator

light on switch illuminates to indicate brake is applied.

• With the engine running and the park brake switch in "OFF" position (1), park

brakes are disengaged.

• With switch in "O N" position (2), park brake is engaged and transmission will not

engage forward or reverse.

WARNING

MACHINE ROLL-AWAY HAZARD. Always move park brake switch to "ON"

position, lower boom to ground and stop engine before leaving cab.

WARNING

CRUSH HAZARD. Turning eng ine of f applies t he park brak e. Applyin g park brak e

or turning engine off while traveling will cause unit to stop abruptly and could

cause load loss. Either may be used in an emergency situation.

Parking Procedure

1. Using service brake, stop telehandler in an appropriate parking area.

2. Follow “Shut-Down Procedure” on page 4-5.

3-731200149

Page 48

Section 3 - Controls and Indicators

OY0034

N

F

R

1

N

F

R

Transmission Control Lever

Direction of Travel Selection

Transmission control lever (1) engages forward or revers e travel.

• Lift and push lever forward for forward travel; lift and pull lever rearward for

reverse tr avel. Move lever to centered position for neutral.

• Forward or reverse travel can be selected while in any gear.

• When traveling in reverse, the back-up alarm will automatically sound.

• Drive in reverse and turn only at slow rates of speed.

• Do not increase engine spee d with the transmi ssion in forw ard or reverse and th e

service brake depressed in an attempt to get quicker hydraulic performances.

This could cause unexpected machine movement.

WARNING

TIP OVER/CRUSH HAZARD. Bring telehandler to a complete stop before

shifting transmission control lever. A sudden change in direction of travel could

reduce stability and/or cause load to shift or fall.

3-8 31200149

Page 49

Section 3 - Controls and Indicators

OY0043

1st

2nd

3rd

4th

2

N

F

R

OY0551

ND

R

N

F

N

F

R

2

3

4

Gear Selection

Gear selection is located on the twist grip handle (2) of transmission control lever.

• Twist hand grip to select gear.

• Select the appropriate gear for the task being performed. Use a lower gear

when transporting a load. Use a higher gear only when driving unloaded for

longer distances.

• Slow down prior to downshifting. Do not downshift more than one gear at a

time.

Neutral Lock Lever (Before S/N 0160040678)

• To lock transmission control lever in the neutral position, place transmission

• To unlock, move neutral lock lever to position “D” (4).

control lever in neutral position and move neutral lock lever (2) to position “N” (3).

3-931200149

Page 50

Section 3 - Controls and Indicators

OAL0792

1

2

TILT SPEED

CONTROL

3

3

IF EQUIPPED

(S/N 0160040678 & AFTER)

(BEFORE S/N 0160040678)

Boom Joystick

The boom joystick (1) controls the boom and attachment tilt (if equipped) functions.

Boom Functions

• Move the joystick back to lift boom; move joystick forward to lower boom; move

joystick right to extend boom; move joystick left to retract boom.

• The speed of boom functions depends upon the amount of joystick travel in

corresponding direction. Increasing engine speed will also increase function

speed.

• For two simultaneous boo m fu nc tion s, move the joystick be tween quadrants. For

example; moving the joystick forward and to the left w ill lower and retract boom

simultaneously.

Attachment Tilt Function (if equipped)

Tilt control is ac tuated by the switch (2).

• Depress the left side of the switch to tilt up; depress the right side of switch to tilt

down.

• Use knob (3) to regulate the speed of the tilt. Rotate knob counter-clockwise to

increase speed; rotate knob clockwise to decrease speed.

WARNING

TIP OVER/CRUSH HAZARD. Rapid, jerky operation of controls will cause rapid,

jerky movement of the load. Such movements could cause th e load to shift or fall

or could cause the machine to tip over.

3-10 31200149

Page 51

Section 3 - Controls and Indicators

OY2180

4

Frame Level and Attachment Tilt (if equipped) Joystick

The rear joystick (4) controls the left to right frame level and attachment tilt (if

equipped) functions.

Frame Level

• Move the joystick left to rotate frame left, move the joystick right to rotate frame

right.

• A level indicator is located above the front cab window to permit operator to

determine whether the telehandler frame is level.

WARNING

TIP OVER HAZARD. Always move boom as low as possible while allowing for

best visibility of right hand mirror before leveling frame. Attempting to level

machine with boom raised could cause it to tip over.

Attachment Tilt Function

• Move the joystick forward to tilt down, move the joystick back to tilt up.

WARNING

TIP OVER/CRUSH HAZARD. Rapid, jerky operation of controls will cause rapid,

jerky movement of the load. Such movements could cause th e load to shift or fall

or could cause the machine to tip over.

3-1131200149

Page 52

Section 3 - Controls and Indicators

1

OY0154

Auxiliary Hydraulic Joystick (if equipped)

• Auxiliary hydraulic joystick (1) controls function of attachments that require

hydraulic supply for operation. See Section 5 - Attachments for approved

attachments and control instructions.

3-12 31200149

Page 53

Section 3 - Controls and Indicators

This Page Intentionally Left Blank

3-1331200149

Page 54

Section 3 - Controls and Indicators

OAL0542

2

1

1

2

10

11

6

5

4

12

13

9

2

3

8

7

Right Hand Panel (S/N 0160040678 & After)

Heater and Air Conditioning Controls (if equipped)

1. Air Vent: Two individually adjustable round vents.

2. Air Louver

3. Defroster Fan: Two speed fan. Press fan switch down for slow speed; press

switch up for fast speed. Return switch to middle position to turn off.

4. Temperature Control Switch: Adjustable rotary switch.

5. Fan Speed: Four-position rotary switch.

6. Air Conditioning Switch

7. Air Louver

8. Recirculation Vent

operating air conditioning.

Other Controls (if equipped)

9. Work Light Switch

10. Beacon Light Switch

11. Hazard Light Switch: On/Off switch.

12. Windshield Wiper and Washer Switch

activate washer. Return to first position to turn off wiper.

13. Attachment Tilt Speed Switch

: Three individually adjustable air louvers.

: On/Off switch.

: Two individually adjustable air louvers.

: Open louvers when operating heat. Close louvers when

: On/Off switch.

: On/Off switch.

: Two speed rotar y switc h. Depre ss to

: See page 3-10.

3-14 31200149

Page 55

Section 3 - Controls and Indicators

OAL0801

4

5

6

2

1

1

2

2

3

8

7

Heater and Air Conditioning Controls (Before S/N 0160040678, if equipped)

1. Air Vent: Two individually adjustable round vents.

2. Air Louver

3. Defroster Fan

switch up for fast speed. Return switch to middle position to turn off.

4. Temperature Control Switch

5. Fan Speed

6. Air Conditioning Switch: On/Off switch.

7. Air Louver

8. Recirculation Vent

heat. Close louvers when operating air conditioning.

: Three individually adjustable air louvers.

: Two speed fan. Press fan switch down for slow speed; press

: Adjustable rotary switch

: Four-position rotary switch.

(S/N 0160038331 & After): Two individually adjustable air louvers.

(S/N 0160038331 & After): Open louvers when operating

3-1531200149

Page 56

Section 3 - Controls and Indicators

OY0761

R

N

F

R

N

F

2

3

4

1

Accessory Control Lever (if equipped)

Before S/N 0160031634

The accessory control lever (1) operates the turn signals, hi/low beams and hazard

lights.

Tu rn Signal

• Push the lever (2) forward to activate the left turn signal.

• Pull the lever back to activate the right turn signal.

• The lever must be manually returned to the center position to deactivate either

turn signal. The lever will not cancel automatically after a turn.

High/Low Beam

• With driving lights on, depress button (3) to switch between low and high beam.

Hazard Lights

• Depress button (4) to activate hazard lights.

3-16 31200149

Page 57

Section 3 - Controls and Indicators

OY1790

6

7

11

9

10

8

5

S/N 0160031634 & After

The accessory control lever (5) operates the turn signals, parking lights and

headlights.

Tu rn Signal

• Push the lever forward (6) to activate the left turn signal.

• Pull the lever back (7) to activate the right turn signal.

• The lever must be manually returned to the center position to deactivate either

turn signal. The lever will not cancel auto ma tic all y afte r a turn.

Parking Lights and Headlights

• Turn the twist grip (8) of the lever counterclockwise to the first position (9) to turn

on the parking lights.

• Turn the twist grip to the second position (10) to turn on the headlights.

• Raise/lower the lever to switch between low beam and high beam.

• Turn the twist grip clockwise to the OFF position (11) to turn all lights off.

3-1731200149

Page 58

Section 3 - Controls and Indicators

OAL2030

2-Wheel Front Steer 4-Wheel Circle Steer 4-Wheel Crab Steer

OAL2790

1 2 3

R

N

F

BEFORE S/N 0160040678

S/N 0160040678 & AFTER

OAM2400

4 5

3.3 STEER MODES

Three steer modes are available for operator use.

Note: 2-Wheel Front Steer mode is required for travel on public roads.

Steer Mode Change

1. Bring machine to a stop using service brake w hile either ci rcle st eer mode (1) or

crab steer mo de (3) is selected.

2. Turn the steering wheel until the left rear wheel (4) is ali gned with the side of the

machine.

3. Select front steer mode (2).

4. Turn the steering wheel until the left front wheel (5) is aligned with the side of

the machine.

5. Wheels are now aligned. Select desired steer mode.

3-18 31200149

Page 59

Section 3 - Controls and Indicators

OY1800

1

2

3.4 OPERATOR SEAT Adjustments

Prior to starting engine adjust seat for position and comfort.

Before S/N 0160015458

1. Fore/Aft

2. Seat Belt

seat belt is available.

: Pull up on handle to move seat fore and aft.

: Always fasten seat belt during operation. If required, a 3 in (76 mm)

3-1931200149

Page 60

Section 3 - Controls and Indicators

1

2

3

4

OW0480

S/N 0160015458 & After

Prior to starting engine adjust seat for position and comfort as follows:

1. Suspension

: Use knob to adjust suspension to the appropriate setting. Turn

clockwise to increase stiffness. Turn counterclockwise to reduce sti f fn es s.

2. Fore/Aft

3. Arm Rest

: Pull up on handle to move seat fore and aft.

: Arm rest can be moved up or down for comfort.

4. Seat Belt: Always fasten seat belt during operation. If required, a 3 in (76 mm)

seat belt is available.

3-20 31200149

Page 61

Section 3 - Controls and Indicators

OH20912

Seat Belt

Fasten seat belt as follows:

1. Grasp both free ends of the belt making certain that belt webbing is not twisted

or entangled.

2. With back straight in the seat, couple the retractable end (male end) of the belt

into the receptacle (buckle) end of the belt.

3. With belt buckle positioned as low on the body as possible, pull the retractable

end of the belt away from the buckle until it is tight across the lap.

4. To release belt latch, depress red button on the buckle and pull free end from

buckle.

3-2131200149

Page 62

Section 3 - Controls and Indicators

OX0541

2

1

-1

0

°

0°

1

0

°

20

°

30°

40°

50°

60°

70°

8

0

°

3.5 BOOM ANGLE AND EXTENSION INDICATORS

• The boom angle indicator (1) is located on the left side of the boom. Use this

indicator to determine the boom angle when using the capacity chart (see “Use

of the Capacity Chart” on page 5-7).

• The boom extension indicators (2) are located on the left side of the boom. Use

these indicators to de termin e boom exte nsion when us ing th e cap acity chart (see

“Use of the Capacity Chart” on page 5-7).

3-22 31200149

Page 63

Section 4 - Operation

SECTION 4 - OPERATION

4.1 ENGINE Starting the Engine

This machine can be operated under normal conditions in temperatures of 0°F to

104°F (-20°C to 40°C). Consult JLG for operation outside this range or under

abnormal conditions.

If equipped for extreme cold weather, -40°F to 0°F (-40°C to -20°C), see page 4-3

for starting procedure.

1. Make sure all controls are in “Neutral” and all electrical components (lights,

heater, defroster, etc.) are turned off. Set parking brake.

2. (Before S/N 0160040678) If equipped with Perk ins eng ine and the te mperature

is below 32° F (0° C), turn the ignition switch to “RUN”. Depress and hold

engine pre-heat switch for approx im atel y 10 secon ds.

(S/N 0160040678 & After) Turn the ignition switch to “RUN” position and wait

until engine pre-heat indicator light goes out.

3. Turn ignition switch to “START” to engage starting motor. Release key

immediately when engine starts. If engine fails to start within 20 seconds,