Jamo E-650, E-670, E-6-CEN, E-6-SUB, E-6-SUR Brochure

...

E6 Series

2005 / 2006

®

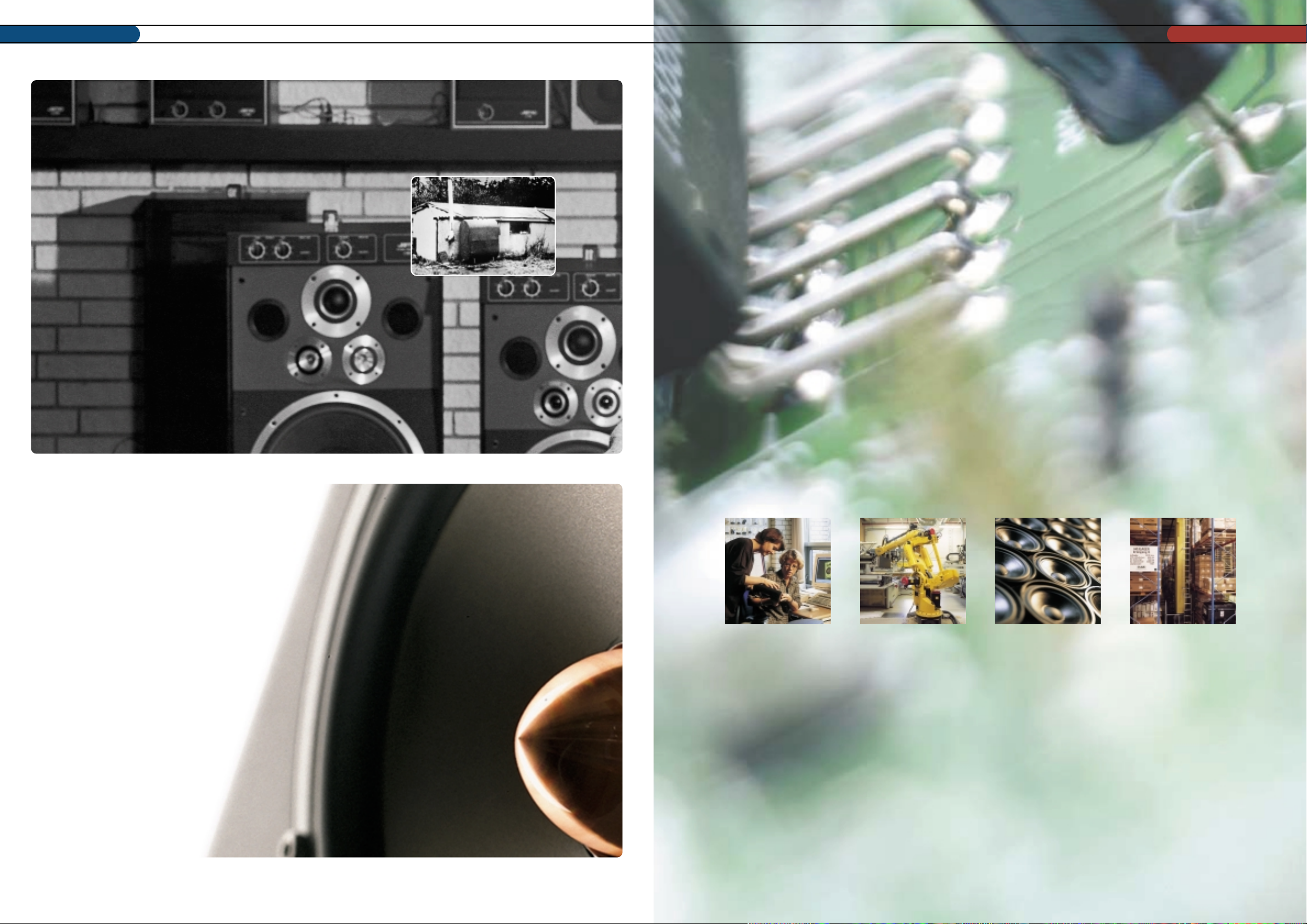

The story of Jamo begins in the Danish fishing village of Glyngøre.The year

is 1966, and Preben Jacobsen, a carpenter, decides to start building loud-

speakers in his little henhouse. He has a passion for good craftsmanship

and fine sound,and produces superbly designed loudspeakers with the

aid of the latest acoustic technologies. However, he is somewhat less

talented at selling so his brother-inlaw, Julius Mortensen, enters the

picture in 1968, bringing with him his export experience, gained in

the fishing industry.Jacobsen and Mortensen: Jamo.The stage is set

for an adventure to begin.

OUR HISTORY

In the years since then, Jacobsen's little henhouse has grown

to become a 30,000 m2/ 300,000 sq.ft state-of-the-art factory

while Jamo is now Europe's biggest manufacturer of loudspeakers. At the same time, customer demands have

become more individual and challenging.Which is lucky for

us because developing new solutions is a daily source of

inspiration in our work. Much has changed, but the soul

and the driving force behind Jamo is still the same:

we want to develop and build products that make a

difference to people’s lives, that connect on an

emotional level.

A chain is only as strong as its weakest link.

That’s why designing loudspeakers is not just a

question of selecting the best possible components

and materials, but also ensuring that they provide

the best solution when combined.

OUR PRODUCTION

The first step in the construction process is to set up an

advanced 3D computer model to provide a foundation for

both further design work and the programming of the

computer-controlled part of the production process. The

actual production environment brings together some of the

world’s most advanced robot machines and a team of vastly

experienced carpenters who take great pride in their craftsman-

ship. It is no coincidence that Jamo’s headquarters lies in a region

that is home to a large part of Denmark’s world renowned furniture

production industry. For Jamo, production and quality control are

simply two sides of the same coin all the way from the control of raw

materials to the painstaking final inspection of every single finished

loudspeaker. That’s your guarantee that the sound, finish, accessories,

packaging – in short, every aspect of a Jamo product – will totally match

your expectations.

What is good sound? There’s no simple answer to that

question because good sound is a highly subjective

experience. Not only do we respect that fact – we

consciously base our work upon it. This is clearly

expressed in the promise that lies at the foundation of our

work and our success: Jamo will create sound solutions

that make a difference to the individual. This promise is

built into all Jamo’s products. You can hear it in our

unrivalled sound quality. And you can see it in the stylish

finish that characterises every single detail.

OUR PROMISE

Jamo’s products are based on the Danish design tradition of

simplicity and functionality. We care about the complete

solution, not just the sound. In this catalogue, we hope you

will notice both the details and the harmonious integrity

that characterises Jamo products. They have been carefully

developed, designed and manufactured to provide you with

a unique experience. Or in other words: Jamo will make a

difference to you.

Product development

This is based on market

feedback, to ensure that

we have a good sense of

our customers’ wishes and

requirements. Jamo’s

innovative acoustic,

electronic and mechanical

engineers are responsible

for product development –

but the development

process is never concluded

until our experienced

panel of listeners has

approved the new product.

Construction

Everything is first modelled

in 3D computer software,

to make it easier to check

that the various

components, wooden

elements, etc., fit together.

This also means that

design optimisation is

possible at a much earlier

stage of the development

process. Such advanced 3D

applications, however, are

no replacement for our

experienced model

carpenters, who then

produce a perfect, full size

prototype.

Quality control

This begins with entry

point checking, during

which all of the raw

materials are subjected to

test sampling. Similarly,

samples of all production

components are tested

during the production

process.Then comes a final

inspection of every

product before it leaves

the factory. Moreover,

products are selected

every week from the

finished goods warehouse

and subjected to an

additional 100% quality

check of their sound,

finish, packaging,

accessories etc.

Warehouse

This is fully automated and

based on the latest

technology.Everything is

controlled by bar codes

and computers – right

from the time that the

orders are keyed into the

system until they are

delivered directly from

Glyngøre to outlets all over

Europe. For overseas

deliveries, Jamo makes use

of its finished goods

warehouses in Chicago

and Shanghai.

2 3

Loading...

Loading...