Page 1

STRALIS

EURO 6

BODYBUILDERS INSTRUCTIONS

H E A V Y R A N G E

ISSUE 2013

Page 2

IVECO S.p.A

Technical Application & Homologation

Strada delle Cascinette, 424/34

10156 Torino (TO) - Italy

www.iveco.com

Printed 603.95.513 – 1st ed. 06/2013

mages and text: IVECO S.p.A. 2013

I

All rights reserved.

Page 3

STRALIS Euro 6 ‒ GUIDELINES FOR TRANSFORMATION AND

GUIDELINES FOR TRANSFORMATION AND VERSIONS

UPDATE DATA

GUIDELINES FOR TRANSFORMATION AND VERSIONS

UPDATE DATA

Section Description Page Revision date

5

– Printed 603.95.513 – Base 06/2013

Page 4

- Printed 603.95.513 – Base 06/2013

Page 5

STRALIS Euro 6 ‒ GUIDELINES FOR TRANSFORMATION AND

GUIDELINES FOR TRANSFORMATION AND VERSIONS

6

INTRODUCTION

INTRODUCTION

This publication provides information, features and instructions for transformation and fitting of the vehicle; considering the type of

content, it is meant for qualities and specialised staff.

The Bodybuilder is manager of the project and its execution, and must assure compliance with what is set forth in this publication

and in the laws in forth.

Any modification, transformation or fitting not provided by this manual and not expressly authorised, will result in exemption of any liability by IVECO and in particular, if the vehicle is covered by a guarantee, the immediate dissolution of the same.

This criterion also applies with regard to single units and components, those described in this manual have

been submitted by IVECO to for deliberations, approvals and inspections and belong to normal production.

The use of any type of unit not recognised (such as PTO, tyres, horns, etc.) relieves IVECO from any liability.

IVECO is available to provide information on the implementation of the interventions and to provide instructions for any cases and

situations not covered in this publication.

Before performing any operation, it is necessary to:

● verify that you have the manuals for the vehicle model on which you are about to work;

● ensure that all the safety devices (goggles, helmet, gloves, shoes, etc.), as well as the equipment used for work, lifting and trans-

port, is available and working;

● ensure that the vehicle is placed in safe conditions.

At the end of the operation, the operational, efficiency and safety conditions set by IVECO must be restored. Contact the Service

network for vehicle calibration if necessary.

Data and information contained in this publication may be outdated as a result of changes adopted by IVECO, at any time, for technical or commercial reasons or due to the need to adapt the vehicle to new legal requirements.

In the event of discordance between the information herein and the actual vehicle, please contact the Product Manager operating

on the market before performing any interventions.

SYMBOLS - WARNINGS

Danger for persons

Failure to comply with these prescriptions can result in the risk of serious injury.

Risk of serious damage to the vehicle

Partial or complete non observance of these prescriptions can lead to serious damages to the vehicle and can sometimes result in the

guarantee being voided.

General danger

Includes the dangers of both above described signals.

Environmental protection

Indicates correct behaviour in order that vehicle use is as environmentally friendly as possible.

NOTE Indicates an additional explanation for a piece of information.

– Printed 603.95.513 – Base 06/2013

Page 6

- Printed 603.95.513 – Base 06/2013

Page 7

GENERAL INFORMATION 1

CHASSIS INTERVENTIONS 2

APPLICATIONS OF

SUPERSTRUCTURES 3

POWER TAKE-OFFS 4

INDEX OF SECTIONS

ELECTRONIC

SUB-SYSTEMS 5

SPECIAL INSTRUCTIONS

FOR SCR EXHAUST SYSTEM 6

- Printed 603.95.513 – Base 06/2013

Page 8

- Printed 603.95.513 – Base 06/2013

Page 9

SECTION 1

GENERAL

NFORMATION

I

- Printed 603.95.513 – Base 06/2013

Page 10

- Printed 603.95.513 – Base 06/2013

Page 11

STRALIS Euro 6 ‒ GENERAL INFORMATION

Index

1.1 SCOPE OF THE GUIDELINES . . . . . . . . . . . . . 5

1.2 TECHNICAL DOCUMENTATION AVAILABLE

ELECTRONICALLY . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 IVECO AUTHORISATION . . . . . . . . . . . . . . . 5

1.4 AUTHORISATION REQUEST . . . . . . . . . . . . . 6

1.5 RESPONSIBILITIES . . . . . . . . . . . . . . . . . . . . 6

1.6 LEGISLATIVE REQUIREMENTS . . . . . . . . . . . . 6

1.7 MULTI-STAGE APPROVAL - COLLABORATION

(only for EU countries, Switzerland and Turkey) . . . . . 6

GENERAL INFORMATION

Index

3

1.8 GUARANTEES . . . . . . . . . . . . . . . . . . . . . . 7

1.9 QUALITY SYSTEM MANAGEMENT . . . . . . . . . . 8

1.10 ACCIDENT PREVENTION . . . . . . . . . . . . . . 8

1.11 CHOICE OF MATERIALS TO USE: ECOLOGY

- RECYCLING . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.12 VEHICLE MANAGEMENT ON THE PART OF

BODYBUILDER . . . . . . . . . . . . . . . . . . . . . . . . . 9

Acceptance of chassis . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 9

Delivery of the vehicle to the final customer . . . . . 9

1.13 VEHICLE NAMES . . . . . . . . . . . . . . . . . . . 10

Commercial name . . . . . . . . . . . . . . . . . . . . . 10

1.14 TRADEMARKS AND SYMBOLS . . . . . . . . . . 11

1.15 DIMENSIONS AND GROUND . . . . . . . . . . 11

General information . . . . . . . . . . . . . . . . . . . . 11

Determination of the centre of gravity of the

superstructure and the payload . . . . . . . . . . . . . 11

Respect of the permitted masses . . . . . . . . . . . . 15

1.16 INSTRUCTIONS FOR PROPER

FUNCTIONING OF THE VEHICLE PARTS AND

ACCESSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . 16

1.17 CONVENTIONS . . . . . . . . . . . . . . . . . . . 17

– Printed 603.95.513 – Base 06/2013

Page 12

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

4

– Printed 603.95.513 – Base 06/2013

Page 13

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.1 SCOPE OF THE GUIDELINES

GENERAL INFORMATION

1.1 SCOPE OF THE GUIDELINES

The scope of this publication is to provide information, features and instructions for fitting and transformation of the original

IVECO vehicle in order to ensure its functionality, safety and reliability.

These Guidelines also aim to indicate to Bodybuilders:

● the quality level to be obtained;

● obligations regarding the safety of operations;

● obligations regarding the objective responsibility of the product.

It should be noted that the collaboration with IVECO is based on the assumption that the Bodybuilder uses the maximum of their

technical and organisational skills and that operations are technically and perfectly complete. As outlined below, the topic is extensive and we can only provide the rules and minimum precautions that can allow development of the technical initiative.

Faults or defects caused by total or partial failure to comply with these Guidelines are not covered by the guarantee on the chassis

or relative mechanical units.

5

1.2 TECHNICAL DOCUMENTATION AVAILABLE ELECTRONICALLY

On the website www.ibb.iveco.com the following technical documentation is available:

● Guidelines for transformation and fitting of vehicles;

● technical specifications;

● truck diagrams;

● tractor diagrams;

● chassis diagrams;

● other range-specific data.

Requests to access the site must be made exclusively at www.ibb.iveco.com.

1.3 IVECO AUTHORISATION

Modifications or fittings proved in these Guidelines and carried out in respect of the same do not require a specific authorisation.

On the other hand, IVECO authorisation is required to carry out:

● particular changes to the wheelbase;

● work on the braking system;

● modifications to the steering system:

● modifications to the stabiliser bars and suspensions;

● modifications to the cab, cab mounts, locking and tilting devices;

● modifications to intake, engine exhaust and SCR components;

● applications of retarders;

● power take-off applications;

● variations in tyre measurements;

● modifications to hook organisms (hooks, fifth wheels).

– Printed 603.95.513 – Base 06/2013

Page 14

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

6

1.4 AUTHORISATION REQUEST

1.4 AUTHORISATION REQUEST

Authorisation requests, when necessary, must be sent to the responsible IVECO Departments on the market.

The Bodybuilder must provide vehicle data (cab, wheelbase, overhang, chassis No.) and adequate documentation (drawings, calculations, technical report, etc.) showing the realisation, use and operating conditions of the vehicle. The drawings should evidence

everything that differs from these instructions.

The Bodybuilder will be responsible for obtaining final approval from the competent authority for completed operations.

1.5 RESPONSIBILITIES

The authorisations issued by IVECO are exclusively related to the technical/conceptual feasibility of the modification and/or fitting.

The Bodybuilder is therefore responsible for:

● the design;

● the choice of materials;

● the implementation;

● the compliance of the design and implementation to any specific indications provided by IVECO and the laws in force in the

countries where the vehicle is destined;

● effects on functionality, safety, reliability and, in general, good behaviour of the vehicle;

● the supply of spare parts for a minimum period of 10 years starting from the last fitting of an order and for all pieces and

components that are installed.

1.6 LEGISLATIVE REQUIREMENTS

The Bodybuilder must verify that the final product is compliant, without exception, to all applicable legal requirements, on the municipal/autonomous/national level of each State in which it is registered and/or will circulate (Highway code, Official Regulations, etc.)

and on the international level (European Union Directives, ONU/Geneva ECE Regulations, etc.). It is also necessary to comply with

all requirements for accident prevention, instructions for assistance, the environment, etc.

The regulations on accident prevention or the legal indications cited in these Guidelines may be considered the most important, but

are not meant in any way to replace or eliminate the obligation and responsibility of the Bodybuilder to stay properly informed.

For this reason, IVECO shall not be held liable for any consequences due to errors caused by insufficient knowledge or incorrect

interpretation of the legal provisions in force.

1.7 MULTI-STAGE APPROVAL - COLLABORATION (only for EU countries, Switzerland and Turkey)

Attachment XVII of Directive 2007/46/EC concerns Multi-stage approval.

This procedure requires that each manufacturer is responsible for the approval and compliance of the production of systems, components and "separate technical units" produced by the same or applied to the vehicle.

The manufacturer of the vehicle is defined as first-stage manufacturer, while the bodybuilder is defined as Second-stage manufacturer

or that of the next stage.

– Printed 603.95.513 – Base 06/2013

Page 15

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.8 GUARANTEES

7

1. IVECO

2. Dealer

191319

3. Bodybuilder

4. Customer

Figure 1

Based on this Directive, IVECO (main vehicle manufacturer) and a Bodybuilder intending to launch the multi-stage approval process

must sign a specific Collaboration Contract, called Technical Agreement, which sets out the content and reciprocal obligations in

detail.

Consequently:

1. IVECO has the responsibility of providing, in the agreed form, the approval documents (EC/ECE approvals) and the technical

information necessary for the proper implementation of the fitting and/or transformation (manuals, drawings, specifications);

2. the Bodybuilder has the following responsibilities:

■ the design and implementation of modifications to the basic vehicle received from IVECO,

■ reattainment of approvals of systems already approved in a previous stage when, due to changes on the basic vehicle the

approvals need to be updated,

■ compliance with national/international laws and in particular the laws of the destination country, for all changes made,

■ presentation of the changes made to a technical service, for evaluation,

■ appropriate documentation of the changes made, in order to give objective evidence of compliance to the aforemen-

tioned provisions of law (e.g. approval documents/test reports).

Before signing the Technical Agreement IVECO reserves the right to visit the Bodybuilder, in order to verify qualifications to carry

out the fittings and/or processing for which the above collaboration is requested.

The contents of the Technical Agreement can be evaluated in detail upon request to the Manager for relations with the Bodybuilder

for the single Market.

1.8 GUARANTEES

The guarantee that the work has been performed to standard must be given by the Bodybuilder who made the superstructure or

modifications to the chassis, in full compliance with the instructions in these Guidelines.

IVECO reserves the right to void the guarantee on the vehicle, if:

● unauthorised fittings or transformations have been carried out;

● a chassis not suitable for the fitting or intended use has been used;

● the standards, specifications and instructions, provided by IVECO for proper execution of the work, have not been respected;

● original spare parts or components made available by IVECO for specific operations have not been used;

● safety regulations have not been respected;

● the vehicle is used for purposes other than those for which it was designed.

– Printed 603.95.513 – Base 06/2013

Page 16

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

8

1.9 QUALITY SYSTEM MANAGEMENT

1.9 QUALITY SYSTEM MANAGEMENT

IVECO has always promoted the training and development of a Quality System for Bodybuilders.

This requirement is not only due to regulations on product liability, but also to the increasingly higher quality level demands, new

organizational forms in various sectors and the search for more advanced levels of efficiency.

IVECO therefore considers it appropriate for Bodybuilders to be equipped with:

● organizational charts for roles and responsibilities;

● quality objectives and indicators;

● design technical documentation;

● process documentation, including controls;

● plan for product improvement, also obtained through corrective actions;

● post-sales assistance;

● training and qualification of staff.

The availability of ISO 9001 certification, even though not required, is considered very important by IVECO.

1.10 ACCIDENT PREVENTION

Do not allow unauthorised staff to intervene or operate on the vehicle.

It is forbidden to use the vehicle with safety devices that have been tampered with or are damaged.

▶ Structures and devices installed on the vehicle must comply with the applicable regulations for

accident prevention, and with safety regulations required in the individual countries where the

vehicles will be used.

All precautions dictated by technical knowledge must be taken to avoid damage and functional defects.

Compliance with these requirements must be overseen by the builders of the structures and devices.

▶ Seats, coatings, gaskets, protective panels, etc., may pose a fire hazard when exposed to an in-

tense heat source. Remove them before working with welding and with flames.

1.11 CHOICE OF MATERIALS TO USE: ECOLOGY - RECYCLING

In the study and design phase, the choice of materials to be used by be made carefully, even from the ecological and recycling point

of view.

To this regard, please note that:

● it is forbidden to use materials that are harmful to health, or at least which may pose a risk, such as those containing asbestos,

lead, halogen additives, fluorocarbons, cadmium, mercury, hexavalent chromium, etc.;

● it is advisable to use materials whose processing produces limited waste quantities and allows easy recycling after first use;

● in synthetic materials of the composite type, it is advisable to use components that are compatible with each other, allowing

use with the possible addition of other recovery components. Prepare the required markings in accordance with the regulations in force;

● the batteries contain substances that are very dangerous for the environment. To replace the batteries it is possible to go to

the Service Network, equipped for disposal in accordance with the nature and the law.

▶ To comply with Directive 2000/53 EC (ELVs), IVECO prohibits the in-vehicle installation of com-

ponents that contain lead, mercury, cadmium and hexavalent chromium; exceptions are made

in cases allowed by Annex II of the above Directive.

– Printed 603.95.513 – Base 06/2013

Page 17

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.12 VEHICLE MANAGEMENT ON THE PART OF BODYBUILDER

1.12 VEHICLE MANAGEMENT ON THE PART OF BODYBUILDER

Acceptance of chassis

The Bodybuilder receiving a chassis/vehicle from IVECO or from a Dealer must perform a preliminary check, notifying of any missing accessories or damage attributable to the transporter.

Maintenance

To preserve the chassis/vehicle in its full efficiency, even while parking in the warehouse, maintenance operations may be necessary

within a predetermined time.

The expenses for carrying out these operations are borne by the owner of the vehicle in that moment (Bodybuilder, Dealer or

Customer).

▶ In case of long periods of vehicle inactivity, it is advisable to disconnect the negative pole of the

battery to maintain optimal charging status.

Delivery of the vehicle to the final customer

9

Before delivering the vehicle, the Bodybuilder must:

● calibrate its production (vehicle and/or equipment) and verify functionality and safety;

● carry out the controls set forth in the Pre-Delivery Inspection (PDI) list available in the IVECO network, for the items being

worked on (obviously the other items of the PDI will be the responsibility of the Dealer, such as the guarantee pamphlet);

● measure battery voltage with a digital multimeter (2 digit decimal), keeping in mind that:

1. optimal value is equal to 12.5 V,

2. between 12.1 V and 12.49 V the battery should be put under a slow charge,

3. with values less than 12.1 V the battery should be replaced.

Note

The batteries must be maintained at regular intervals (refer to IVECO Std 20-1812 and/or IVECO Std 20-1804) until delivery of

the vehicle to the Customer/Dealer to avoid problems of insufficient charging, short circuit or corrosion.

IVECO reserves the right to nullify the guarantee on the battery if the prescribed maintenance procedures are not respected.

● carry out a functional road test (in case of vehicle transformation). Any defects or problems should be notified to the IVECO

Assistance Service to verify conditions for inclusion in the PDI costs;

● prepare and deliver to the final Customer the necessary instructions for service and maintenance of the fitting and any added

units;

● report new data on special labels;

● provide confirmation that the operations carried out comply with the indications of the vehicle Manufacturer and legal re-

quirements;

● draw up a guarantee covering the changes made.

– Printed 603.95.513 – Base 06/2013

Page 18

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

10

1.13 VEHICLE NAMES

1.13 VEHICLE NAMES

The commercial names (an example follows) of IVECO vehicles do not coincide with approval names.

Commercial name

STRALIS HI-WAY 440 S 48 T/P

● STRALIS ‒ Vehicle name

● HI-WAY ‒ Cab type

HI-STREET Short cab

HI-ROAD Long cab

HI-WAY Hi-Way Cab

● 440 ‒ Total Ground - PTT Cab versions / PTC Tractors with semi-trailers (no./10 = weight in t)

190 4x2 trucks

260 Trucks 6x2 - 6x4

320 8x2x6 Cab vehicles

440 Tractors 4x2 - 6x2- 6x4

● S ‒ Stralis Range Code

● 48 ‒ Engine power (no. x 10 = power in HP)

● T ‒ Model

T Tractor 4x2

TX Tractor 6x2 C (added central axle)

TY Tractor 6x2 C (added rear axle)

TZ Tractor 6x4 (Tandem rear axle)

X Cab version 6x2 C - 8x2x6 C (added central axle)

Y Cab version 6x2 P - 8x2x6 P (added rear axle)

Z Cab 6x4 (tandem rear axle)

● / P ‒ Version

P 4x2 - 6x2 C - 6x4 with air suspension on rear axle - 6x2 P with 3rd liftable single-wheel rigid axle

PT Only 6x2 P with air suspension on rear axle and 3rd twin wheel lifting rigid axle

PS Only 6x2 P - 8x2x6 P with air suspension on rear axle and 3rd single wheel lifting rigid axle

FP 4x2 - 6x2 P - 6x2 C - 6x4 with front and rear air suspensions (ev. 3rd lifting rigid axle)

FS 6x2 P - 8x2x6 with front and rear air suspensions, 3rd single wheel lifting steering axle

TN Only 6x2 P with air suspension on rear axle and 3rd liftable rigid axle

CM Demountable Bodies

GV Large Volumes

D Timing system

HM Heavy Mission

LT Lowered tractor

CT Lowered cab

RR Rough Roads

HR Double reduction rear axle

SL Super Light

– Printed 603.95.513 – Base 06/2013

Page 19

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.14 TRADEMARKS AND SYMBOLS

1.14 TRADEMARKS AND SYMBOLS

Trademarks, symbols and names may not be altered or moved from their original placement, as the originality of the vehicle image

must be protected.

The application of transformation or fitting trademarks must be authorised. Their placement should not be in the immediate vicinity

of the IVECO trademark and symbols.

IVECO reserves the right to withdraw trademarks and symbols if the fitting or transformation present features that do not comply

with requirements; the Bodybuilder assumes full responsibility for the entire vehicle.

Instructions for additional units

For additional units, the Bodybuilder must provide all necessary maintenance instructions upon vehicle delivery.

All the units that make up the same order must be equipped with components of the same brand, model and quality.

1.15 DIMENSIONS AND GROUND

General information

The dimensions and masses of vehicles allowed on the axles are shown in the drawings, the technical descriptions and, more generally, on the documents on the official IVECO website. Defects refer to vehicles in their standard versions; the use of special equipment may lead to changes on the masses and their distribution on the axles.

11

Weighing of the chassis

It should be noted that variations are possible on the masses of the order of 5%.

For this reason, before carrying out the fitting, it is a good idea to determine the mass of the vehicle cab and its distribution on the

axles.

Vehicle adaptability

The vehicle adaptability limits for each model are mainly defined as:

● distribution of mass on the axles;

● width of mirrors adopted;

● rear under-run protection device position.

The positioning of lights and mirrors, normally set for widths of 2550 mm, is also suitable for special superstructures 2600 mm

wide (e.g. mini-vans).

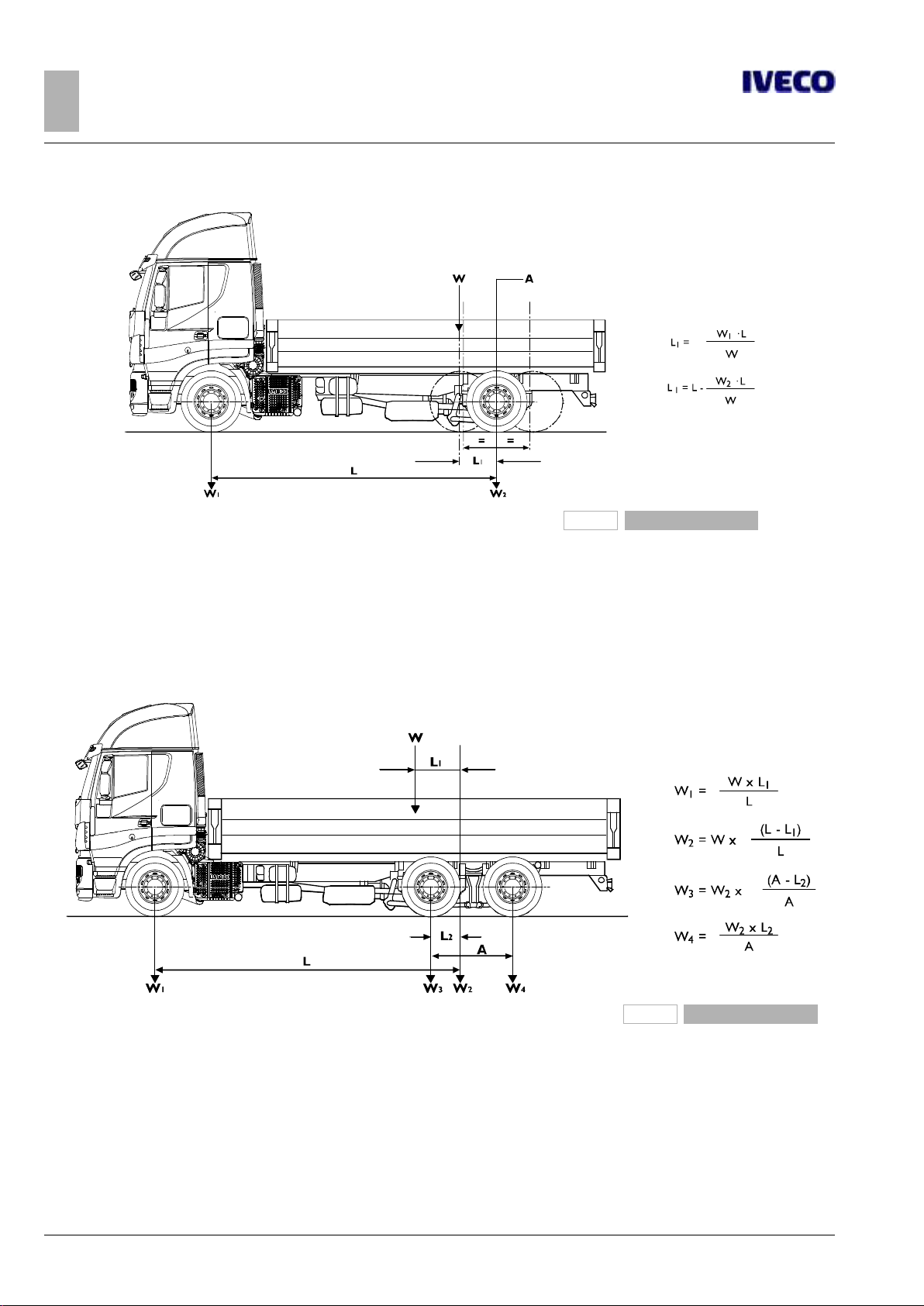

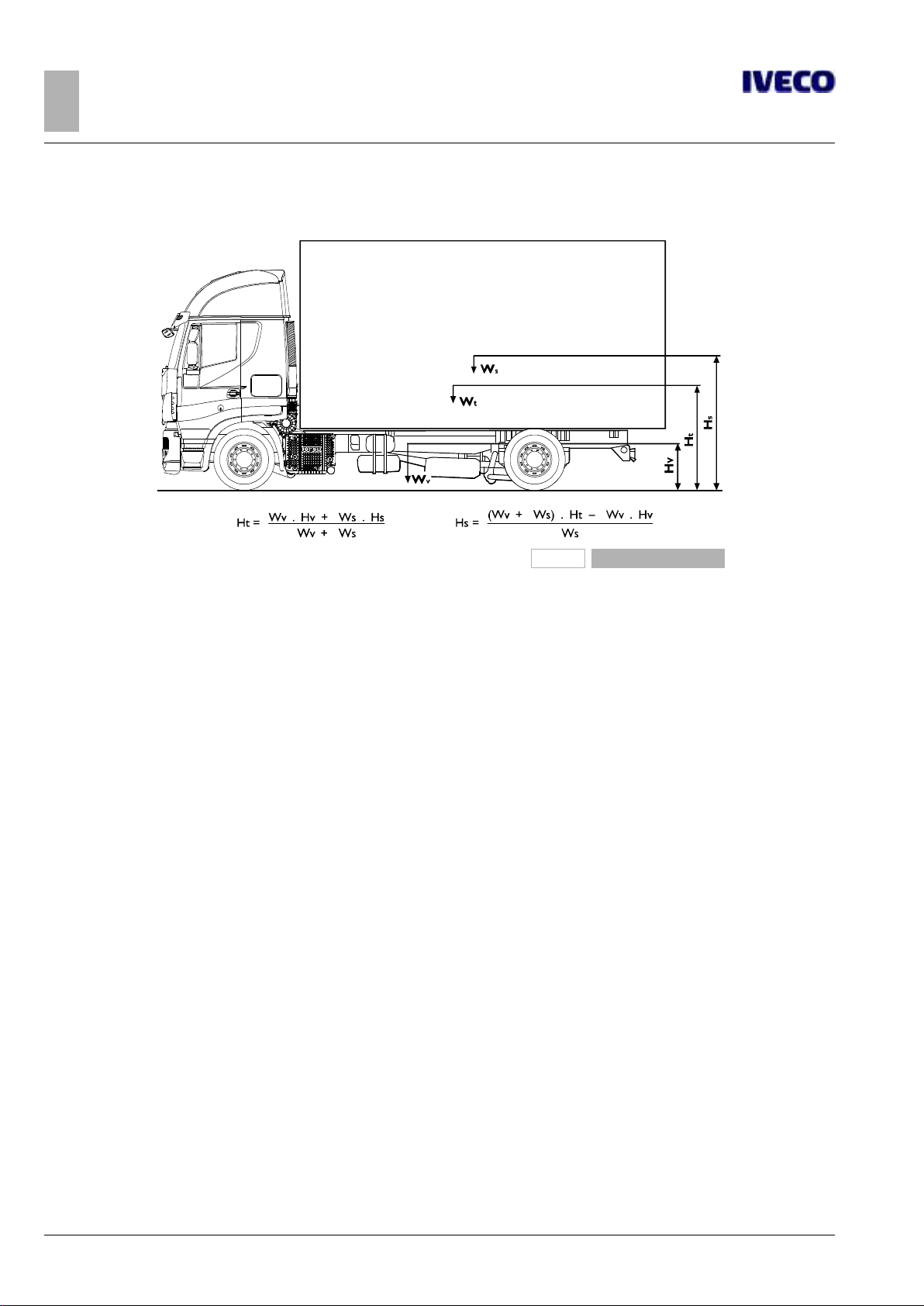

Determination of the centre of gravity of the superstructure and the payload

Positioning on the longitudinal plane

To determine the position of the centre of gravity of the superstructure and the payload, you can proceed according to the examples given below.

On the technical documentation for each model (cab version diagram), you can see the positions allowed by the vehicle in the

standard version. The masses and the positioning of the individual components of the vehicle are shown on the chassis and weight

allocation diagram.

– Printed 603.95.513 – Base 06/2013

Page 20

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

12

1.15 DIMENSIONS AND GROUND

192336

Figure 2

Example to determine the placement of the centre of gravity of the payload plus superstructure (Vehicle with 2 axles;

vehicles with 3 axles having equal loads on two rear axles)

A = Front wheel axle or tandem centre line

W = Payload plus superstructure

W1 = Measurement of payload on front axle

L1 = Distance of centre of gravity from the centre line of the

rear axle (or tandem centre line)

L = Actual wheelbase

W2 = Measurement of payload on rear axle (or tandem)

192337

Figure 3

Example to verify compliance with the permitted axle masses (vehicles with 3 or more axles, with a constant ratio of

weight distribution on the two rear axles, for which the "virtual" value of the wheelbase and the centre line between

the axles, due to the weight distribution, are defined by the manufacturer)

W = Payload plus superstructure

W1 = Measurement of payload on front axle

W2 = Measurement of payload on rear axles

W3 = Measurement of payload on first rear axle

W4 = Measurement of payload on second rear axle

L = Calculated wheelbase (virtual)

L1 = Distance of centre of gravity relative to the calculated

centre line

L2 = Calculated centre line (virtual)

A = Rear axles wheelbase

– Printed 603.95.513 – Base 06/2013

Page 21

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.15 DIMENSIONS AND GROUND

13

Note

For vehicles with three or more axes, with variable ratio of the distribution of the masses on the two rear axles depending on the

load, the "virtual" value of the wheelbase and the centre line between the axles must be determined for the respective load condition realized, using the instructions on the vehicle cab diagram.

This way, in particular version fittings (e.g. cranes on the rear overhang), the correct positioning can be determined for the centre of

gravity of the equipment and the payload, depending on the load carried (see Chapter 3.8).

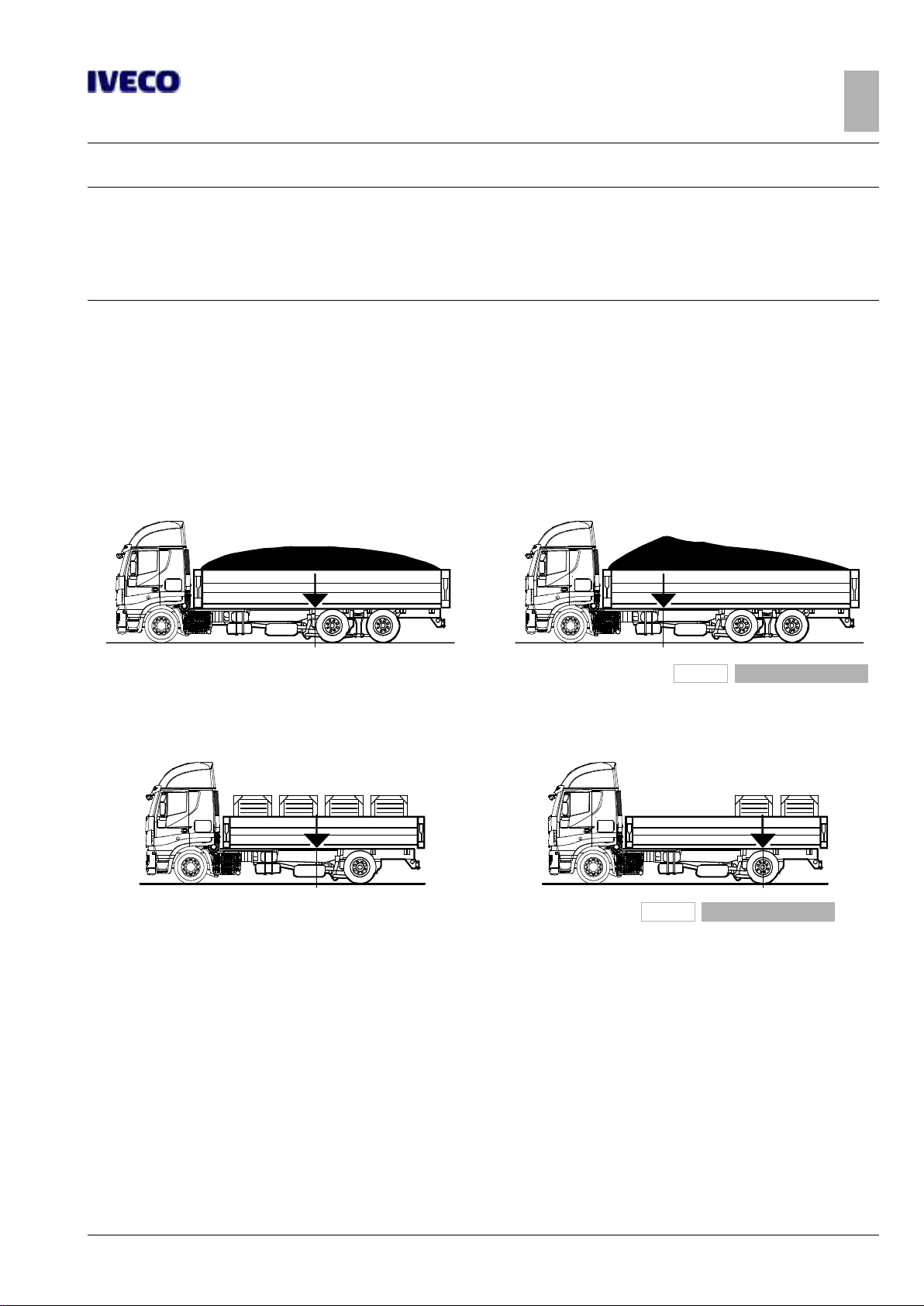

For the purposes of breakdown of the payload on the axes, it should be considered that this is evenly distributed, except in cases in

which the shape of the load surface leads to a different load distribution.

For equipment, the centre of gravity is obvious considered for its actual position.

In the realisation of the superstructure or containers, automatic loading and unloading of the goods transported must be provided

to avoid excessive variations of the distribution and/or excessive loads on the axles, providing information for users if necessary.

The Bodybuilder should also provide a suitable anchoring systems for the load on the superstructure, so that transport can occur in

maximum security.

192338

Figure 4

Even distribution of load Uneven distribution of load

192339

Figure 5

Even distribution of load Uneven distribution of load (attention to loads on axles

and minimum ratio)

Height of centre of gravity

For the cab version and no-load vehicle, the value of the height of the centre of gravity is shown on the specific technical documentation for each model (cab version diagram).

For the vehicle complete with super structure and full load, this height must comply with the maximum values allowed by national

or international standards, in particular, Directives ECE 13 on longitudinal stability and ECE 111 on lateral stability while driving.

The following cases should be distinguished:

1. fixed loads,

2. mobile loads;

3. loads that result in increased aerodynamic actions.

– Printed 603.95.513 – Base 06/2013

Page 22

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

14

1.15 DIMENSIONS AND GROUND

1. Fixed loads

192340

Figure 6

Control at full load

Hv = Cab vehicle centre of gravity height (cab version)

Hs = Payload centre of gravity height plus superstructure relat-

ive to ground

Ht = Complete full-load vehicle centre of gravity height

Wv = Cab version vehicle tare weight

Ws = Payload plus superstructure tare weight

Wt = Complete vehicle ground at full load

For any inspections with the vehicle set up without payload you can proceed similarly, assuming Ws is only the tare weight of the

superstructure (considering for Hv a value appropriate for the load and between the no-load cab version trim and the full-load

trim).

2. Mobile loads

In the versions where the load can be moved laterally while cornering (e.g.: suspended loads, liquid transport, animal transport,

etc..) high lateral dynamic forces may be generated which may jeopardise the stability of the vehicle.

With reference to the indications of ECE 111, special attention should therefore be paid:

● in defining the height of the fitted vehicle's centre of gravity and at full load;

● in assessing the dynamic forces and the lateral displacement of the centre of gravity;

● in considering (for liquids) the density;

● in prescribing the adoption of adequate precautions for driving.

Any cases where evaluation is difficult should be submitted to IVECO for approval.

– Printed 603.95.513 – Base 06/2013

Page 23

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.15 DIMENSIONS AND GROUND

3. Loads that result in increased aerodynamic actions

In fittings characterised by high vertical and surface development (e.g.: advertising panelling), the hight of the centre of thrust, determined in the case of cross-wind, must be evaluated very carefully.

▶ Even with the low centre of gravity, a vehicle fitting that has a high surface area may not provide

sufficient lateral stability and may be exposed to the danger of tilting.

Special attention must therefore be paid:

● in defining the height of the fitted vehicle's centre of gravity and at full load,

● in assessing the aerodynamic forces,

● in prescribing the adoption of adequate precautions for driving.

Any cases where evaluation is difficult should be submitted to IVECO for approval.

Adoption of stabiliser bars

The application of additional or reinforced stabiliser bars, where available, reinforcing the springs or rubber elastic elements (in

accordance with the procedure outlined in Section 2.7), may allow higher values of the centre of gravity of the payload, to be determined from time to time. The operation must be carried out after a careful evaluation of the features of the fitting, the wheelbase and the subdivision of lateral forces on the suspension, and should generally concern both the front and the rear. However,

it should be kept in mind that in many cases it is advisable to carry out the operation only on the rear axle; acting on the front axle

would give the driver an incorrect sensation of greater stability, making it actually harder to perceive the safety limit. Interventions

on the front axle can be made in the presence of concentrated loads behind the cab (e.g. cranes) or superstructures with high rigidity (e.g. vans).

15

Exceeding the limits

In the case of special transport with a high centre of gravity height (e.g., transport of machinery, indivisible loads, etc.), from a technical standpoint it is possible to exceed the values shown in the table, provided that the driving is adjusted appropriately (e.g. reduced speed, gradual variations of the trajectory of travel, etc.).

Respect of the permitted masses

All the limits shown on IVECO documentation must be respected. It is particularly important to evaluate the maximum ground on

the front axle in any load condition, in order to ensure the necessary steering features in all road surface conditions.

Special attention must therefore be paid to vehicles with concentrated load on the rear overhang (e.g.: cranes, tail lifts, central axle

trailers) and vehicles with a short wheelbase and high centre of gravity height (e.g. silo vehicles, concrete mixers).

In vehicles with an added lifting rear axle, it must be considered that, in the case of a lifted axle, the actual wheelbase is reduced

while the rear overhang increases, so it is advisable not to place the centre of gravity of the superstructure and the payload behind

the centre line of the engine axle. installation of the axle lifting system in the case of concentrated rear loads is also discouraged.

Note

In the positioning of the auxiliary bodies and superstructure, a proper load distribution in the transverse direction must be ensured.

A variation on the nominal load may be permitted for each wheel (50% load on the corresponding axle) of±4% (e.g.: load allowed

on the axle 10,000 kg; allowed for each wheel side from 4,800 to 5,200 kg) in compliance with what is permitted by the tyres,

without affecting the braking and driving stability characteristics of the vehicle.

Unless otherwise specified individual vehicles, the minimum valuesof the mass on the front axle must be:

–

20% of the actual mass of the vehicle, if the load is evenly distributed,

–

25% of the actual mass of the vehicle, if the load is concentrated on the rear overhang.

Actual mass is meant to include any vertical load resulting from the trailer.

– Printed 603.95.513 – Base 06/2013

Page 24

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

16

1.16 INSTRUCTIONS FOR PROPER FUNCTIONING OF THE VEHICLE PARTS AND ACCESSIBILITY

Variations on permitted masses

Special exemptions from the maximum permissible masses may be granted for specific uses, for which, however, there are precise

limits for use and reinforcements to be made to parts of the vehicle.

These exceptions, if they exceed the limits of the law, must be authorised by the Administrative Authority.

In the authorisation request, you must indicate:

● type of vehicle, wheelbase, chassis number, intended use;

● division of the tare weight on the axles (in fitted vehicles, e.g.: crane with flatbed), with the position of the payload centre of

gravity;

● any proposals for strengthening the parts of the vehicle.

The permitted reduction of mass on vehicles (derating), can lead to interventions on some parts, such as suspensions and brakes,

and may require a new calibration for the braking correction operation; in these cases the necessary indications may be provided.

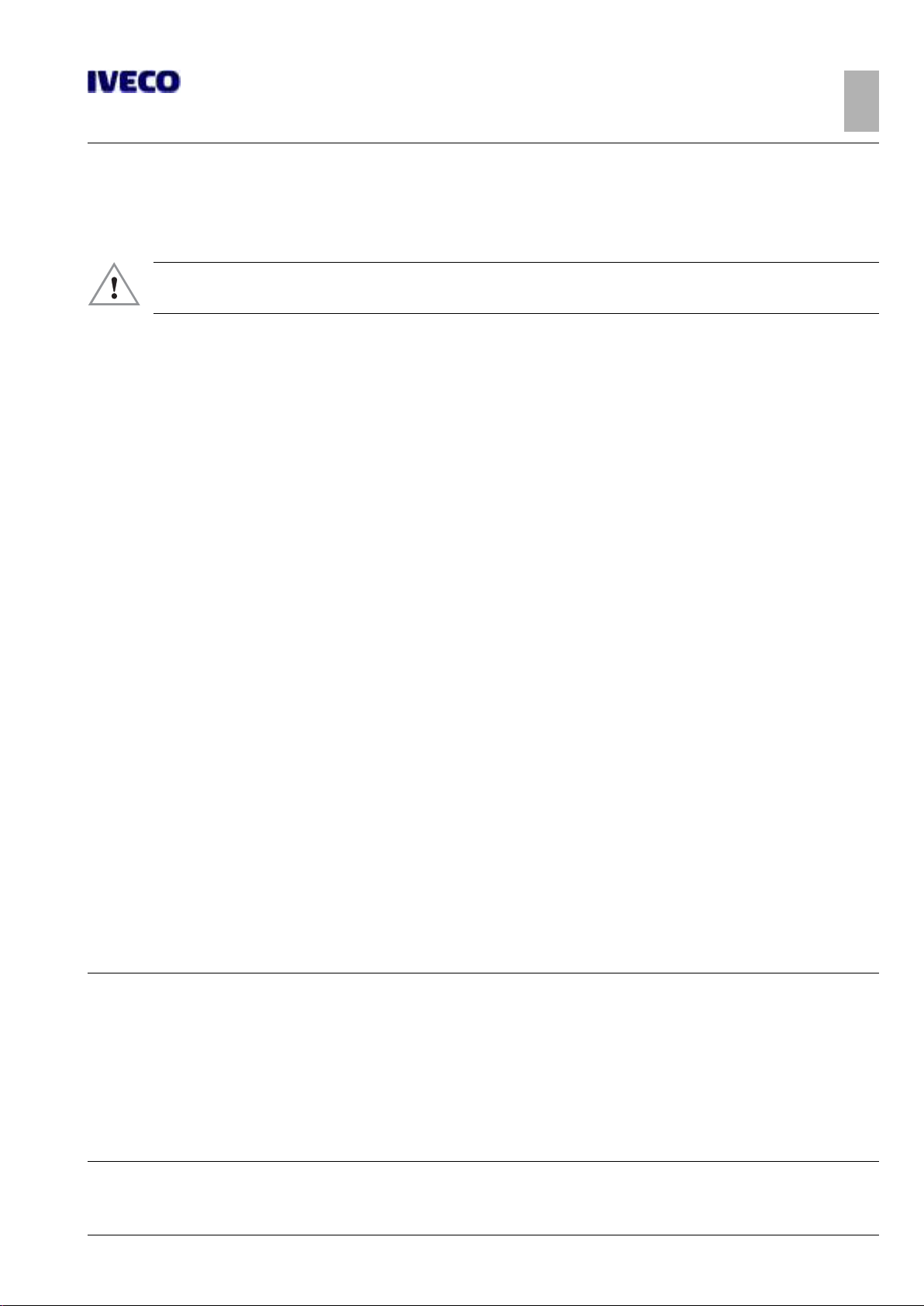

1.16 INSTRUCTIONS FOR PROPER FUNCTIONING OF THE VEHICLE PARTS AND ACCESSIBILITY

In carrying out the transformations and applying any type of equipment, there should be no alteration to what enables the proper

functioning of the vehicle units and parts under various working conditions.

For example:

● free access must be guaranteed to the places that need inspection, maintenance or periodic controls (e.g., battery replace-

ment, access to the air suspension compressor) and, in the case of enclosed superstructures, special compartments and doors

should be provided;

● freedom of cab tilting must be provided; in Figure 1-7, the quotas of maximum longitudinal dimension of the cab and radius of

rotation are indicated;

195914

Figure 7

– Printed 603.95.513 – Base 06/2013

Page 25

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

1.17 CONVENTIONS

17

Note

due to the new location of the air filter on the Stralis Hi-Way, the minimum distance between the centre line of the front axle and

the body of the trailer is increased by 20 mm, from 920 to 940 mm.

The minimum distances on the Euro 6 versions are therefore:

–

Stralis Hi-Way: 940 mm (+ 20 mm compared to the Euro 5 version);

–

Stralis Hi-Road: 900 mm (unchanged compared to the Euro 5 version);

–

Stralis Hi-Street: 445 mm (unchanged compared to the Euro 5 version).

● The possibility of disassembling the various groups for assistance operations must be maintained. Any servicing on the transmission/clutch or controls (e.g. suspension bars) must be carried out without removing important parts of the added structure;

● conditions should not be affected regarding cooling (radiator grille, radiator, air passages, cooling etc.), fuel supply (pump positioning, filters, pipe diameter, etc.) and engine air intake;

● panels for noise emission levels must not be altered or moved so as not to vary the approved sound emission limits. If there

are any openings (e.g. for the passage of the longitudinal sections of the chassis), they must be thoroughly closed, using fireproof materials and soundproofing materials, equivalent to the original materials used;

● adequate ventilation must be maintained for the brakes and battery casing (particularly in the execution of truck bodies);

● in the placement of fenders and wheel arches, free shaking of the rear wheels must be guaranteed, even under the conditions

of use with chains. It must also be guaranteed enough space for the lifting axle tyres. Some models include steering of the 3rd

axle in the raised position as well: respect the spaces necessary for this function (see Chapter 2.21);

● adjustment of the vehicle's headlamps must be checked once construction is completed, to correct any changes in their structure; for adjustment, proceed according to the instructions given in the "Use and Maintenance" manual;

● for any elements supplied loose (e.g. spare wheel, chocks), the Bodybuilder must position and fasten them in an accessible and

secure way, in compliance to any national regulations.

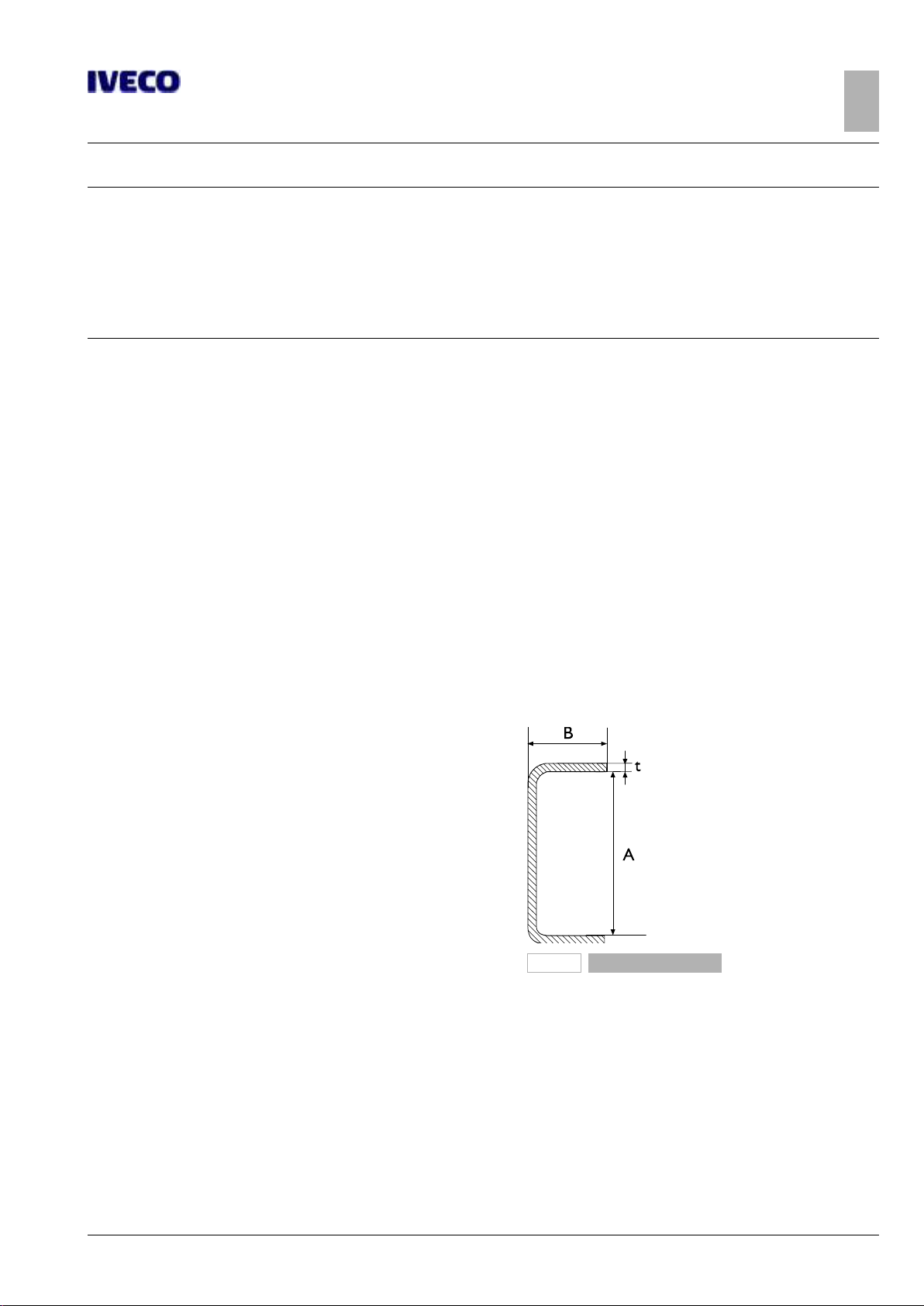

1.17 CONVENTIONS

In these Guidelines the following conventions are adopted:

● Wheelbase: distance between the centre lines of the first

steering axle and the first rear axle (engine or not).

● Rear overhang: distance between the centre line of the last

axle and the rear extremity of the chassis side members.

● Dimensions A, B and t of the chassis section: see the picture

on the side.

91473

Figure 8

– Printed 603.95.513 – Base 06/2013

Page 26

STRALIS Euro 6 ‒ GENERAL INFORMATION

GENERAL INFORMATION

18

– Printed 603.95.513 – Base 06/2013

Page 27

SECTION 2

CHASSIS

NTERVENTIONS

I

- Printed 603.95.513 – Base 06/2013

Page 28

- Printed 603.95.513 – Base 06/2013

Page 29

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

Index

3

Index

2.1 GENERAL CHASSIS MODIFICATION

STANDARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preventive measures . . . . . . . . . . . . . . . . . . . . 5

Characteristics of the material used in chassis

modifications . . . . . . . . . . . . . . . . . . . . . . . . . 6

Stresses on the chassis . . . . . . . . . . . . . . . . . . . 7

2.2 DRILLS ON THE CHASSIS . . . . . . . . . . . . . . . 7

Hole position and size . . . . . . . . . . . . . . . . . . . 7

Screws and nuts . . . . . . . . . . . . . . . . . . . . . . . 8

Welds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sealing holes by welding . . . . . . . . . . . . . . . . . 10

2.3 RUST AND PAINT PROTECTION . . . . . . . . . 10

Original vehicle parts . . . . . . . . . . . . . . . . . . . 11

Added or modified parts . . . . . . . . . . . . . . . . . 13

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 WHEELBASE MODIFICATION . . . . . . . . . . . 14

General information . . . . . . . . . . . . . . . . . . . . 14

Authorisation . . . . . . . . . . . . . . . . . . . . . . . . 14

Effects on steering . . . . . . . . . . . . . . . . . . . . . 15

Effects on braking . . . . . . . . . . . . . . . . . . . . . 15

Intervention procedure . . . . . . . . . . . . . . . . . . 16

Checking chassis stress . . . . . . . . . . . . . . . . . . 16

Cross members . . . . . . . . . . . . . . . . . . . . . . 16

Gearbox modifications . . . . . . . . . . . . . . . . . . 17

2.5 REAR OVERHANG MODIFICATION . . . . . . . 17

General information . . . . . . . . . . . . . . . . . . . . 17

Authorisation . . . . . . . . . . . . . . . . . . . . . . . . 17

Chassis Shortening . . . . . . . . . . . . . . . . . . . . 18

Elongation . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6 INSTALLING THE TOW HOOK . . . . . . . . . . 19

General information . . . . . . . . . . . . . . . . . . . . 19

Precautions for Installation . . . . . . . . . . . . . . . 19

Towing hooks for conventional trailers . . . . . . . . 20

Drawbar couplings for centre axle trailers . . . . . . 20

Rear crossbar in lowered position . . . . . . . . . . . 22

2.7 ASSEMBLING AN ADDITIONAL AXLE . . . . . . 33

General information . . . . . . . . . . . . . . . . . . . . 33

Reinforcements on the chassis . . . . . . . . . . . . . 33

Added axle . . . . . . . . . . . . . . . . . . . . . . . . . 34

Steering axles . . . . . . . . . . . . . . . . . . . . . . . . 35

Suspension . . . . . . . . . . . . . . . . . . . . . . . . . 35

Stabiliser bars . . . . . . . . . . . . . . . . . . . . . . . . 36

Attachments to the chassis . . . . . . . . . . . . . . . 36

Brake system . . . . . . . . . . . . . . . . . . . . . . . . 36

Lifting device . . . . . . . . . . . . . . . . . . . . . . . . 37

2.8 GEARBOX MODIFICATION . . . . . . . . . . . . 37

Lengths allowed . . . . . . . . . . . . . . . . . . . . . . 37

Positioning the sections . . . . . . . . . . . . . . . . . 40

2.9 MODIFYING THE ENGINE AIR INTAKE AND

EXHAUST SYSTEMS . . . . . . . . . . . . . . . . . . . . . 42

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Engine exhaust . . . . . . . . . . . . . . . . . . . . . . . 43

2.10 MODIFYING THE ENGINE COOLING

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.11 INSTALLING AN ADDITIONAL HEATING

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.12 INSTALLING AN AIR CONDITIONING

SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.13 WORK ON THE CAB . . . . . . . . . . . . . . . . 45

General information . . . . . . . . . . . . . . . . . . . . 45

Work on the roof . . . . . . . . . . . . . . . . . . . . . 46

2.14 CHANGING TYRE SIZE . . . . . . . . . . . . . . . 46

2.15 WORK ON THE BRAKING SYSTEM . . . . . . 47

General information . . . . . . . . . . . . . . . . . . . . 47

Brake pipes . . . . . . . . . . . . . . . . . . . . . . . . . 47

ABS electronic brake control devices . . . . . . . . . 50

Withdrawing air from the cooling system . . . . . . 50

2.16 ELECTRICAL SYSTEM: CURRENT

INTERVENTIONS AND DRAWS . . . . . . . . . . . . . 51

2.17 PART RELOCATION AND ANCHORAGE OF

ADDITIONAL UNITS AND EQUIPMENT . . . . . . . . 51

– Printed 603.95.513 – Base 06/2013

Page 30

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

4

Index

2.18 TRANSPORT OF HAZARDOUS MATERIALS

(ADR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.19 INSTALLING A RETARDER . . . . . . . . . . . . 54

2.20 MODIFYING THE UNDER-RUN

PROTECTION BAR . . . . . . . . . . . . . . . . . . . . . . 54

2.21 REAR MUD GUARDS AND WHEEL

ARCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.22 RAIN FLAP . . . . . . . . . . . . . . . . . . . . . . . 56

2.23 SIDE PROTECTIONS . . . . . . . . . . . . . . . . 56

2.24 WHEEL CHOCKS . . . . . . . . . . . . . . . . . . 58

– Printed 603.95.513 – Base 06/2013

Page 31

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.1 GENERAL CHASSIS MODIFICATION STANDARDS

CHASSIS INTERVENTIONS

2.1 GENERAL CHASSIS MODIFICATION STANDARDS

Keep in mind that:

● weldings on the supporting structures of the chassis are absolutely forbidden (except as prescribed in Para-

graph"Weldings" ( ➠ Page 8) and in Chapters 2.4 ( ➠ Page 14), and 2.5 ( ➠ Page 17));

● no holes may be drilled into the side members (with exception to what is stated in Paragraphs "Weldings"

( ➠ Page 8) and "Choosing the type of connection" ( ➠ Page 12));

● for cases where modifications to nailed unions are allowed, the nails may be replaced with flanged head screws or with hex

head screws classed 8.8 with the next higher class diameter and nuts fitted with an anti-unscrewing system. Screws larger than

M12 may not be used (maximum hole diameter of 15,5 mm), unless otherwise specified;

● for cases where unions that require screws are restored, the suitability of these screws must be checked before being reused, and they must be tightened to the appropriate torque;

▶ As regards remounting safety components, it is prohibited to re-use the same screws and tight-

ening must be done at the specified torque (contact the Service Network for the value).

5

● for cases involving remounting of safety components where nails are replaced by screws, the union must be checked again

after about 500 - 1000 km of travel.

Preventive measures

▶ When welding, drilling, milling and cutting near brake hoses and electrical wires, be sure to ad-

opt appropriate precautions for their protection; disconnect these parts if necessary (respect

the prescriptions in Chapters 2.15 and 5.5).

– Printed 603.95.513 – Base 06/2013

91444

Figure 1

Page 32

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

6

2.1 GENERAL CHASSIS MODIFICATION STANDARDS

Precautions for alternators and electric/electronic components

In order to avoid damage to the rectifier diode, the battery must never be disconnected (or the isolator switch opened) while the

engine is running.

In cases where the vehicle must be started by towing (strongly discouraged), make sure that the battery is charged and connected

so as to ensure minimum supply voltage to the engine ECU.

Recharge the battery only after disconnecting it from the vehicle circuit. In cases where the engine must be started-up with external charging equipment, be sure to avoid using the "start" function (if these devices feature this function) in order to avoid peak

currents that may damage electric and electronic components.

Start-up must be performed only via an external battery assembly, making sure that polarity is respected.

Earth connection

The original earth connections of the vehicle should never be altered; in cases where these connections must be moved or new

connections added, use the holes present on the chassis to the extent possible, taking care to:

● mechanically remove - either by filing and/or with a suitable chemical based solution - the paint on both the chassis and ter-

minal side, thus creating a contact surface free of indentations and edges;

● paint the area between the terminal and metal surface with a high conductivity paint (e.g. zinc coating Part Number IVECO

459622 from PPG);

● connect to earth within 5 minutes after application of the paint.

For ground connections at the signal level (e.g. sensors or devices with low absorption), absolutely never use standardised IVECO

M1 points (ground connection of the batteries), M2 or M8 (grounding the starter motor, depending on the position of the guide)

and connect the signal cable ground on points separate from the power cables and wires that serve as radio frequency screens.

Avoid earth connections between devices in a concatenated fashion for electronic equipment; install individual earth connections of

optimal length (favour the shortest routes).

Braking and electrical systems

For additional details on the braking and electrical systems see Chapters 2.15 ( ➠ Page 47) and 5.5 ( ➠ Page 30).

Characteristics of the material used in chassis modifications

For chassis modifications on the vehicle (all models and wheelbases) and for applications of reinforcements on the side members,

the material used must correspond to the original chassis material in terms of quality and thickness (see Tables 2.1 and 2.2).

If it is not possible to procure materials of the thickness indicated, materials having immediately higher standard thickness may be

employed.

Table 2.1 - Material to be used in chassis modifications

Name of steel

IVECO Fe E490

Germany QStE500TM

IVECO Fe 510D

Europe S355J2G3

Germany QSt52-3N

U.K. BS50D

(1)

Breaking strength

[N/mm2]

610 490 19%Europe S500MC

(1)

(1)

(1)

520 360 22%

Yield stress

[N/mm2]

A5 elongation

(1)

Alternatively, only by lengthening the rear overhang.

– Printed 603.95.513 – Base 06/2013

Page 33

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.2 DRILLS ON THE CHASSIS

Table 2.2 - Section dimension and chassis thickness

Model

STRALIS 190

STRALIS 260 X/P*, X/F* 289 x 80 x 6.7

STRALIS 260 Y/P*, Y/F* (-CM, -D)

STRALIS 260 Y/F*-GV 289 / 199 x 80 x 7.7

STRALIS 260 Z/*P-HM 289 x 80 x 7.7

STRALIS 320 X/*S, Y/*S 289 x 80 x 7.7

STRALIS 440 T/*P (-LT), TX/P 289 x 80 x 6.7

STRALIS 440 T/P (-HR, -RR), TY/P, TY/PT, TZ/P-HM 289 x 80 x 7.7

Wheelbase

[mm]

up to 6300 289 / 199 x 80 x 6.7

6700 289 x 80 x 6.7

up to 5100 289 / 199 x 80 x 6.7

5700 and on 289 x 80 x 7.7

Stresses on the chassis

Area of side member near wheelbase A x B x t

[mm]

(see Figure 6)

7

The following stress value in static conditions cannot be exceeded for any reason whatsoever:

static stress σ allowed on chassis: 150 N/mm

2

In any case, respect any more restrictive limits placed by national standards.

Welding causes material property deterioration; therefore, when checking stresses in thermally altered zones, a resistance reduction of 15% must be accounted for.

2.2 DRILLS ON THE CHASSIS

Installation of auxiliary equipment onto the chassis must be done using the factory drilled holes whenever possible.

▶ It is strictly forbidden to drill holes into the side member flaps, with exception to what is indic-

ated in Chapter 3.3 - Paragraph "Choosing the type of connection".

When new holes must be made for specific applications (installation of shelves, corner shelves, etc.), these must be drilled into the

upright rib of the side member and must be thoroughly de-burred and bored.

Hole position and size

The new holes must not be drilled into the areas subjected to greater stresses (such as spring supports) or where the side member

section varies.

Hole diameter must be suited to sheet metal thickness but cannot exceed 15 mm (unless otherwise stated). The distance of the

hole axle from the edge of the side member must never fall below 40 mm (for chassis with thickness of 7.7 mm) or 39 mm (for

chassis with thickness of 6.7 mm), likewise, the hole axes must not be at a distance of less than 45 mm from each other, or from

the axes of existing holes.

The holes must be offset as in Figure 2.2.

The original hole layout must be maintained when moving spring supports or crossbars.

– Printed 603.95.513 – Base 06/2013

Page 34

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

8

2.2 DRILLS ON THE CHASSIS

192342

(*)

valid with chassis thickness 7.7 mm, with chassis thickness 6.7 mm the measurement is equal to 39 mm.

Figure 2

Screws and nuts

We generally recommend the use of the same type and class of screws and nuts as those employed for similar anchorages on the

original vehicle (see Table 2.3).

Screws classed 8.8 and 10.9 must be well cleaned and, for applications using a screw with a diameter of ≤ 6 mm; we recommend

protection FeZnNi 7 IV.

Screw treatment allowed is Geomet or zinc coating. Geomet treated screws are discouraged when using them in welding operations.

Use flange headed screws and nuts if there is sufficient space.

Use nuts with an anti-unscrewing system and keep in mind that the tightening torque must be applied to the nut.

Welds

▶ When welding, drilling, milling and cutting near brake hoses and electrical wires, be sure to ad-

opt appropriate precautions for their protection; disconnect these parts if necessary (respect

the prescriptions in Chapters 2.15 and 5.5).

Welds are allowed:

● in side member unions for elongations or trimming;

● in the application of corner reinforcements in the area regarding side member modification, as hereafter specified (see Figure

2.3).

– Printed 603.95.513 – Base 06/2013

Page 35

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.2 DRILLS ON THE CHASSIS

9

91448

Figure 3

The following instructions must be respected when performing electric arc welding and in order to protect electrical components

and ECUs:

● before disconnecting the power cables ensure there are no active electric users;

● if an electric circuit breaker (main switch) is present, wait for it to complete the cycle;

● disconnect the negative pole from the battery;

● disconnect the positive pole of the battery without connecting it to earth; do NOT short-circuit the negative pole;

● disconnect all ECU connectors, proceed with caution and do not touch the ECU connector pins;

● disconnect the ECU from the vehicle for welds close to the ECU;

● connect the welder earth directly to the weld piece;

● protect the plastic pipes from heat and disconnect them if necessary;

● protect the surfaces of the leaf and air springs against any weld splashes when welds are performed nearby;

● avoid touching the spring leafs with the electrodes or pliers.

Weld operations

● Thoroughly remove paint and rust from the chassis where welds will be made, as well as all parts that will be covered by reinforcements.

● Cut the side members with a skewed or vertical cut. The side members must not be cut at the points where the chassis contour and width changes or where stress is greater (e.g. spring mounts). The cutting line must not go through the holes on the

side member (see Figure 2.4).

91446

Figure 4

● Make a 60 degree bevel cut on the internal part of the side member of the parts to join, for the entire length of the weld area

(see Figure 2.5).

– Printed 603.95.513 – Base 06/2013

Page 36

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

10

2.3 RUST AND PAINT PROTECTION

91447

Figure 5

● Arc weld the area with multiple steps and use base electrodes that are thoroughly dried.

Avoid power overloads; the welds must be free of marginal incisions and slag.

● Start from the opposite end and weld as in the previous item.

● Let the side members cool slowly and in a uniform fashion. No cooling with air jets, water or other means is allowed.

● Grind off the excess material.

● Mount steel corner reinforcements that have the same characteristics as the chassis; the minimum indicative sizes are shown in

Figure 2.3.

Reinforcement anchorage must regard only the vertical rib of the side member and can be realised with a weld bead, staples,

bolts or nails (even Huck nails).

Area and length of the weld bead, number and distribution of staples, number of nails of bolts must be adequate to transmit

the bending and shearing moments.

● Once work is complete, use anti-rust protection (see Paragraph"Added or Modified Parts" ( ➠ Page 13)).

Sealing holes by welding

If new holes are located near old holes (see Figure 2.2), these last can be welded shut.

Good results are obtained by:

● chamfering the outer edge of the hole;

● applying a copper plate on the inner edge of the side member to hold the welding material;

● welding the side member on both sides with elimination of all residual material.

Holes of 20 mm diameter can be sealed off by using chamfered washers welded on both sides.

2.3 RUST AND PAINT PROTECTION

Note

All components mounted on the chassis must be painted in compliance with IVECO Standard 18-1600 Colour IC444 RAL 7021 70/80 gloss.

– Printed 603.95.513 – Base 06/2013

Page 37

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.3 RUST AND PAINT PROTECTION

Original vehicle parts

The following tables show, respectively, the classes of coating and protection required for the original vehicle components, the

protections required for the parts not painted or in aluminium and treatments required for the painted parts.

Table 2.3 - Class of protection - IVECO Standard 18 - 1600 (Prospectus I)

Class Part requirements Examples of parts involved

Bodywork - Rear-view mirrors - Windscreen wipers -

A Parts in direct contact with atmospheric agents

B

B2

B1 Only for rear axles and front axles

C Parts in direct contact with atmospheric agents, not in clear view Engine and relative parts

D Parts not in direct contact with atmospheric agents

Parts in direct contact with atmospheric agents that mainly have

structural characteristics, in clear sight

Metallic structured sun visors - Metallic bumpers -

Cab hook lock - Door stop device -

Bodywork fastening elements (screws, bolts, nuts, washers), etc.

Frame and relative parts, including its fasteners

Parts below the radiator grille (class B)

External cab ramps

Pedals - Seat coverings - Fastening elements - etc.,

mounted inside the cab

11

Table 2.4 - Various parts and components not painted and in aluminium - IVECO Standard 18 - 1600

(Prospectus IV)

Classes

– –

yes

yes

Class B1

yes yes yes

Geomet

Zinc coating

Lega Zn-Ni

Aluminium

Type of protection

Stainless steel

(2)

(3)

(1)

GEO 321-8

GEO 500-8

GEO 321-8 PM

GEO 321-8 PML

GEO 321-8 PL

GEO 500-8 PL

GEO 321-5

GEO 500-5

GEO 321-5 PM

GEO 321-5 PML

GEO 321-5 PL

GEO 500-5 PL

Fe/Zn 12 II

Fe/Zn 7 IV

Fe/Zn 12 IV

Fe/Zn 7 IV LUB

Fe/Zn 7 IV S

Fe/Zn 12 IV S

Fe/Zn Ni 7 VII S

Fe/Zn Ni 7 IV

Anode oxidation 18-1148 yes

Painting See Table III yes

IVECO

standard

18-0506 – – – –

18-1101

18-1102

FIAT 9.57409 – yes yes yes

A B - B1 - B2 C D

yes –

–

wheel studs

– – yes yes

– – yes yes

– yes yes yes

– Printed 603.95.513 – Base 06/2013

Page 38

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

12

2.3 RUST AND PAINT PROTECTION

(1)

Coupling with other materials must not cause the "battery effect”.

(2)

Coatings free from chromium salts.

(3)

Coatings free of hexavalent chromium.

Table 2.5 - Painted parts - IVECO Standard 18 - 1600 (Prospectus III)

MECHANICAL SURFACE

CLEANING

(1)

PRE-TREATMENT

CATAPHORETIC PAINTING

RUST PREVENTER

ANTIROCK PRIMER

VARNISH

Cycle phase description

Sand/shot blasting –

Brushing

Sandpapering

Iron phosphating

(only for non-precoated ferrous materials)

Zinc phosphating

(**)

High thickness (30-40 μm)

Medium thickness (20-30 μm)

Acrylic finishing (>35 μm) – –

Bi-component (30-40 μm)

Single-component (30-40 μm)

Single (130 °C) or bicomponent (30-40 μm)

Single (130 °C) or bicomponent (30-40 μm)

Powders (40-110 μm)

Low temperature single-component (30-40 μm)

A B

(*)

yes

–

yes

(2)

yes

(3)

yes

–

(3)

yes

yes

(4)

yes

– – yes

Classes

(8)

(*)

yes

(*)

yes

(*)

yes

(6)

yes – yes

– yes –

(5)

B1

– yes

– yes

–

B2 C D

yes

(*)

(*)

(*)

(6)

yes

yes

yes

(6) (9)

yes

(9)

(*)

(*)

(*)

(*)

– – – – –

(*)

yes

–

– yes

(*)

yes

yes

yes

yes

yes

(*)

(*)

(*)

(6)

(*)

(*)

(7)

(1)

This operation must be performed when dealing with cutting burr, oxidation, weld slag, or laser-cut surfaces.

(2)

Two-layer bodywork cycle.

(3)

Three-layer bodywork cycle.

(4)

In alternative to single and bi-component paint only for particular bodywork (windscreen wipers, rear-view mirrors, etc.).

(5)

Only rear/front axles.

(6)

Excluding parts that cannot be immersed in pre-treatment baths or undergo painting because of compromised functionality (e.g.: mech-

anical parts).

(7)

Only if the colour is defined in a drawing according to I.C.

(8)

For fuel tanks in ferrous or pre-coated sheets.

(9)

Only parts to mount on the engine.

(*)

Alternative products and cycles for the same phase under the condition of comparability with the part to treat.

(**)

Specific phosphates must be used for zinc coated or aluminium sheets.

– Printed 603.95.513 – Base 06/2013

Page 39

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.3 RUST AND PAINT PROTECTION

Added or modified parts

All vehicle parts (body, chassis, equipment, etc.) that are add-ons or subjected to modifications must be protected against oxidation

and corrosion.

Areas free of protection on ferrous materials are not accepted.

Tables 2.6 and 2.7 indicate the minimal treatment that modified or added components must receive when it is not possible to have

protection that is similar to that of original components. Different treatment is allowed if it ensures similar oxidation and corrosion

protection.

Do not used powder varnish directly after degreasing has been performed.

Lightweight alloy, copper and brass parts must be protected.

Table 2.6 - Painted modified parts or add-ons

Cycle phase description

Mechanical surface cleaning

(including elimination of burrs/oxidation and cleaning of cut parts)

Pre-treatment Degreasing

Rust preventer

Varnish

Brushing/sandpapering/sand blasting

Bi-component (30-40 μm)

Bi-component (30-40 μm)

Class

A - B -D

(1)

(2)

(3)

13

(1)

Modifications on rear axles, from axles and engine (classes B1 and C) not allowed

(2)

Preferably epoxy

(3)

Preferably polyurethane

Table 2.7 - Unpainted or aluminium modified parts or add-ons

Type of protection

Stainless steel

Geomet –

Zinc coating

(1)

Free from hexavalent chromium

(1)

(1)

A - B

yes

– yes

Class

D

–

Precautions

On the vehicle

Appropriate precautions must be taken to protect parts on which paint could be harmful to the conservation and operation

thereof:

● hoses for pneumatic and hydraulic systems in rubber or plastic, with particular reference to the braking system;

● gaskets, rubber or plastic parts;

● drive shaft and PTO flanges;

● radiators;

● suspension, hydraulic/pneumatic cylinder stems;

● air vent valve (mechanical assembly, air tank, thermostarter preheat tanks, etc.)

● sediment bowl and fuel filter assembly;

● plates, codes.

If painting is required after wheels are removed, it is necessary to:

– Printed 603.95.513 – Base 06/2013

Page 40

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

14

2.4 WHEELBASE MODIFICATION

● Protect the wheel rim mounting surfaces on the hubs and the contact areas of the locking lugs/wheel studs;

● ensure adequate protection of brake discs.

The electronic components and modules must be removed.

Engines and their electric/electronic components

Appropriate precautions must be taken to protect:

● engine wiring and ground contacts;

● the sensor/actuator side connectors and wiring side;

● the sensors/actuators on the flywheel and on the flywheel rpm sensor mounting bracket;

● pipes (plastic and metal) of the fuel circuit;

● complete basic diesel filter;

● the ECU and its base;

● the entire internal part of the sound-proof cover (injectors, rails, pipes);

● the common rail pump and its control valve;

● the vehicle electric pump;

● tank containers;

● the front V-belts and relative pulleys;

● the power steering pump and relative pipes.

▶ When painting is complete and before oven drying (max. temperature 80 °C), the parts that risk

heat damage must either be removed or protected.

2.4 WHEELBASE MODIFICATION

General information

▶ Any wheelbase modifications that regard the electric circuits and/or relocation of the

electric/electronic components requires IVECO approval and must be carried out in compliance

with chapter 5.5 instructions.

Usually, wheelbase modification must be performed on the standard wheelbase that is closest to the target value.

If the dimensions of the superstructure are suitable, it is best to use wheelbases in standard production because this allows the use

of original drive shafts and pre-defined crossbar positions.

Nevertheless, IVECO must issue its authorisation for wheelbases below the minimum or maximum approved standard sizes on the

market.

Authorisation

Wheelbase modification is allowed without IVECO authorisation only when:

● the target wheelbase is listed in the catalogue for the type of vehicle being transformed;

● the structure (area of side members; number, type and position of the crossbars), the existing circuits and systems on the

series chassis corresponding to this length will be replicated.

When these conditions do not exist in combination at the same time, which ensure that the schematics of the transformed frame is

equal to that of the original, the modification must undergo approval.

The workshop that performs the transformation must provide sufficient guarantees in terms of technology and inspections (qualified personnel, appropriate operational processes, etc.).

– Printed 603.95.513 – Base 06/2013

Page 41

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.4 WHEELBASE MODIFICATION

For the 6x2, 6x4 and 8x2x6 versions, variation in the wheelbase is only allowed with specific approval from IVECO.

The operations must be performed in compliance with these directives, taking into account the suitable adjustments and adaptations, as well as all required precautions (e.g.: check on whether the ECUs must be reparameterised, exhaust pipes adjusted, respect of minimum tare on the rear axle, etc.) called for on the corresponding original wheelbases.

Effects on steering

Generally speaking, extending the wheelbase will have a negative effect on steering.

When required by standard, the maximum thresholds for cornering path, steering wheel force and relative time to negotiate

curves should not be exceeded (e.g.: ECE Regulation of EC Directive in force).

Table 2.8 lists the maximum wheelbase elongation values allowed for the vehicle with series steering, maximum load and tyres.

Longer wheelbases require approval and technical solutions must be adopted to improve steering, such as reduction of maximum

load on the front axle or the implementation of a caster trail with a restricted set of values.

The installation of an additional pump must also be authorised, while successive installations require the participation of the specialised Company.

Table 2.8 - Maximum allowable wheelbase elongation, depending on the load on the front axle and the

size of the tyres (Regulation ECE-R79/01 e EG/70/311)

Max load on front axle

Models

STRALIS 190 8000 6050 120 470

STRALIS 190 /FP-CM 8000

STRALIS 260 Y/P, Y/FP 8000 6050 120 470

STRALIS 260 Z/P -HM 8000 6050 120 470

STRALIS 260 Y/FP -CM 8000

STRALIS 260 Y/PS,

Y/FS

STRALIS 260 XP 7500 120 470

STRALIS 320 YP 7500 120 470

STRALIS 320 XP 7500 120 470

STRALIS 440 TX/P 7500 3140 120 470

(respect the load capacity of

the tyres) [kg]

7500

7500

8000

Max wheelbase value between the

steering axle and the engine axle

[mm]

5700

6700

4500

5100

5700

6050

5700

Caster trail

[mm]

120

120

120

Steering wheel

diameter [mm]

470

510

470

510

470

510

470

15

For the pneumatic fitting see Chapter 2.14 ( ➠ Page 46).

Effects on braking

Generally speaking, shortening the wheelbase will have a negative effect on braking.

Contact the IVECO Department - Homologation & Technical Application to find out at what conditions (brake cylinders, minimum

tare, theoretically admissible loads, tyres, height of centre of gravity) transformation can be allowed.

▶ Vehicles mounting an ASR system require settings to be updated.

– Printed 603.95.513 – Base 06/2013

Page 42

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

16

2.4 WHEELBASE MODIFICATION

Intervention procedure

Proceed as follows to obtain good results:

● position the vehicle so that the chassis is perfectly horizontal, use appropriate trestles;

● detach the drive shafts, braking system hoses, cables and all other equipment that may interfere with proper work execution;

● identify the reference points on the frame (e.g: guide holes, suspension supports);

● mark the reference points with a slight punch mark on the top flaps on both side members, after having verified that the con-

junction line is at a perfect right angle with the longitudinal axle of the vehicle;

● if moving the suspension supports, identify the new position using the previously determined references;

● make sure that the new measurements are identical on both the right and left sides; the diagonal check, for lengths of at least

1500 mm must not yield deviations of over 2 mm;

● make the new holes using as jig - if any other tools are unavailable - the supports and gusset plates of the crossbars;

●

secure the supports and crossbars using nails or screws; if using screws, bore the holes and use calibrated screws class 10.9

with anti-unscrewing nuts; if size allows, flanged head screws may be employed;

● if cutting the frame (to be carried out according to indications of the second item in "Welding Operations" - Paragraph "Welding" ( ➠ Page 8)) mark a second line of reference points so that the work area is set between the two lines (plan for a distance of at least 1500 mm upon work completed). Carry over the points relative to the cutting area between the two lines;

proceed as instructed in Paragraph "Welding" ( ➠ Page 8);

● before welding, check that the side members and any added parts are perfectly aligned and perform the check measurements on both sides and along the diagonal line, as previously indicated. Apply the reinforcements as in Paragraph "Welding"

( ➠ Page 8).

Additional information

● Protect the surfaces against oxidation as in Paragraph "Added or modified parts" ( ➠ Page 13).

● Restore the braking and electrical systems as according to Chapters 2.15 ( ➠ Page 47) and 5.5.

● Follow the instructions in Chapter 2.8 ( ➠ Page 37) for interventions on the transmission.

Checking chassis stress

With regard to wheelbase elongation, aside from local reinforcement in the joint area of the side members, the Bodybuilder must

also account for reinforcements - along the entire contour of the wheelbase - until achieving area strength modulus equal to

IVECO values for the same wheelbase or for the next admissible greater length. In alternative, for cases allowed by local standards,

larger counter-frame profiles can be adopted.

The Bodybuilder must make sure that the stress limits prescribed by national standards are respected. These stresses must not

be greater than those or the original wheelbase frame, assuming an evenly distributed load and considering the frame as a beam

positioned in place of the suspension supports.

When an elongation is performed starting from the longest original wheelbase, the reinforcements adopted must account for

wheelbase elongation, type of chassis produced and vehicle use.

Cross members

The need to apply one or more crossbars is subject to the amount of elongation, the positioning of the gearbox, the welding area,

the points of application of forces arising from the superstructure, and the conditions of use of the vehicle.

Any additional cross members must have the same characteristics of those already mounted on the frame (bending and torsion

strength, material quality, connection to side members, etc.). Figure 2.6 shows an example. In any case an additional crossbar must

be installed for elongations exceeding 600 mm.

The distance between the two cross members must generally be within 1000 ÷ 1200 mm.

The minimum distance between the cross members, especially for "heavy duty use" must not be less than 600 mm; this restriction

excluded "lightweight" cross member that acts as transmission and suspension supports.

– Printed 603.95.513 – Base 06/2013

Page 43

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

2.5 REAR OVERHANG MODIFICATION

17

91449

Figure 6

Gearbox modifications

See Chapter 2.8 ( ➠ Page 37) for checks of modifications allowed.

2.5 REAR OVERHANG MODIFICATION

General information

When modifying the rear overhang it is necessary to take note of the variations that this modification inflicts on distribution of

axle loads, in compliance with loads established by IVECO (see Chapter 1.15 ( ➠ Page 11)). Limits set by national law must also

be respected, as well as maximum distances from the rear structural edge and distance from ground, defined for towing hook and

under-run protection. The distance from the tip of the frame to the rear edge of the superstructure must, as a rule, not exceed

350 ÷ 400 mm.

If it is necessary to move the rear crossbar fixed using screws, it is necessary to maintain the same type of union as in the series

(number of screws, dimensions, strength class).

If a drawbar shall be attached, it is necessary to leave sufficient space (approx. 350 mm) between the rear crossbar and that

nearest, for any drawbar assembly/disassembly operations.

If all works are performed in a professional manner and according to the instructions contained herein, the original towing capacity

may remain the same.

In all cases, the parties performing the work shall be liable thereof.

Authorisation

Rear frame elongation as well as shortening to the smallest value for each model of the series do not require authorisation if performed in compliance with the instructions provided herein.

For vehicles destined to special uses, where load distribution is predefined and fixed, the rear overhand can be extended with values greater than 60% of the wheelbase, as long as the conditions stated in Chapter 1.15 ( ➠ Page 11), Directive CEE 97/27 and

their relative national laws are respected in terms of cornering path.

▶ If you need to adjust the length of the electrical circuits, see Chapter 5, "Special instructions for

electronic subsystems”.

– Printed 603.95.513 – Base 06/2013

Page 44

STRALIS Euro 6 ‒ CHASSIS INTERVENTIONS

CHASSIS INTERVENTIONS

18

2.5 REAR OVERHANG MODIFICATION

Chassis Shortening

The last crossbar must be moved forward when shortening the rear overhang of the frame.

When the rear crossbar is too close to another crossbar, this last can be eliminated if it plays no role in suspension support.

Elongation