IVECO STRALIS AS EURO 4, STRALIS AS EURO 5, STRALIS AT EURO 4, STRALIS AT EURO 5, STRALIS AD EURO 4 Instruction Manual

...Page 1

STRALIS AS/AT/AD EURO 4/5

BODYBUILDERS INSTRUCTIONS

HEAVY RANGE

EDITION 2008

Page 2

Publication Edited by:

Technical Application

Strada delle Cascinette, 424/34

10156 Turin - Italy

Publication Nr. 603.93.721 - 2

Printed in Italy - 01/08

nd

Edition

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

Page 3

STRALIS AS/AT/AD EURO 4/5

Bodybuilders instructions

nd

Print 603.93.721 - 2

edition

Base - January 2008

UPDATE DATA

Section Description Page Revision date

2 Frame Paragraph 2.16 moved to chapter 5 January 2008

3 Structures 3-34: paragraph added 3.5.4.3 January 2008

4 Power take-off Full overhaul chapters 4.6 and 4.7 January 2008

4 Power take-off 4-17: Control unit added

Expansion Module (EM) (*)

5 Electronic subsystems 5-4: Cab Module (CM)

integrated in the Body Computer (BC) (*)

5 Electronic subsystems 5-8,5-9: connectors ST14A e ST14B January 2008

5 Electronic subsystems 5-40: note added to paragraph 5.4.8 January 2008

6 Exhaust systems with SCR Chapters 6.6 and 6.7 added.

Full overhaul chapter 6.5

January 2008

January 2008

January 2008

(*) Specific parts only for OBD1 Phase 2.

NOTE

The eighth digit of the PIC (Product Identification Code) indicates STEP 2 of the vehicle:

3-4-C-B StralisAS

3-4-C StralisAT/AD

Update data

Print 603.93.721 Base - January 2008

Page 4

Update data

Base - January 2008 Print 603.93.721

Page 5

Foreword

This manual contains instructions and data for fitting body structures/ancillaries and Vehicle modifications and is intended for

skilled and qualified personnel.

The bodybuilder is responsible for the design and fitting and any modifications necessary for the installation. The bodybuilder must

ensure full compliance with the requirements set out in this manual and with national and international regulations (Construction

and Use, and EEC Standards) in force.

Before starting any work make sure you are working form the latest Iveco Bodybuilders Instruction manual for the model. Make sure

that all safety equipment e.g. eye protection, hard hat, shoe, gloves etc are used. Check that all mechanical equipment e.g. lifts and

handling gear is in good working order and is used. Finally work on the vehicle in good conditions and ensure maximum safety at

all times.

Any change, modification or installations not covered by this manual and not expressly authorized in writing by IVECO will relieve

the latter of any responsibility and make, in particular, the vehicle warranty null and void.

For installations / modifications and general information not covered by this manual contact Iveco.

On completion ofthe installation e.g. body, crane, wheelbasemodification the vehicle andsystems must be checkedto ensure vehicle

operation and safety is as designed by Iveco and has not been compromised. If a vehicle system needs to beset up i.e. engine control

for PTO installation then contact your local Iveco Service Department.

IVECO shafl not be responsible for any change, modification or fittings concerning the vehicle.

Due to continuing vehicle improvementsand changes in regulations which cover or affectthe vehicle, the information in this publica-

tion may not always be up to date.

If the bodybuilder has any queries regarding the information contained in this manual regarding the vehicle that is to be worked on

he should contact Iveco thbiveco@iveco.com before starting.

Symbols - Warnings

Danger to people:

failure to fully comply with these precautions can i nvolve serious danger for personal safety.

Danger of serious damage to the vehicle

Partial or complete non observance of these precautions can cause serious damage to the vehicle and invalidate the

Iveco warranty.

Warning / Precaution:

!

failure to fully comply with these precautions can result in serious danger to personal safety and damage to the vehicle

with the loss of the vehicle warranty.

This indicates the correct use of materials in order to make the vehicle as environmentally friendly as possible.

Indicates additional information.NOTE

Foreword

Print 603.93.721 Base - January 2008

Page 6

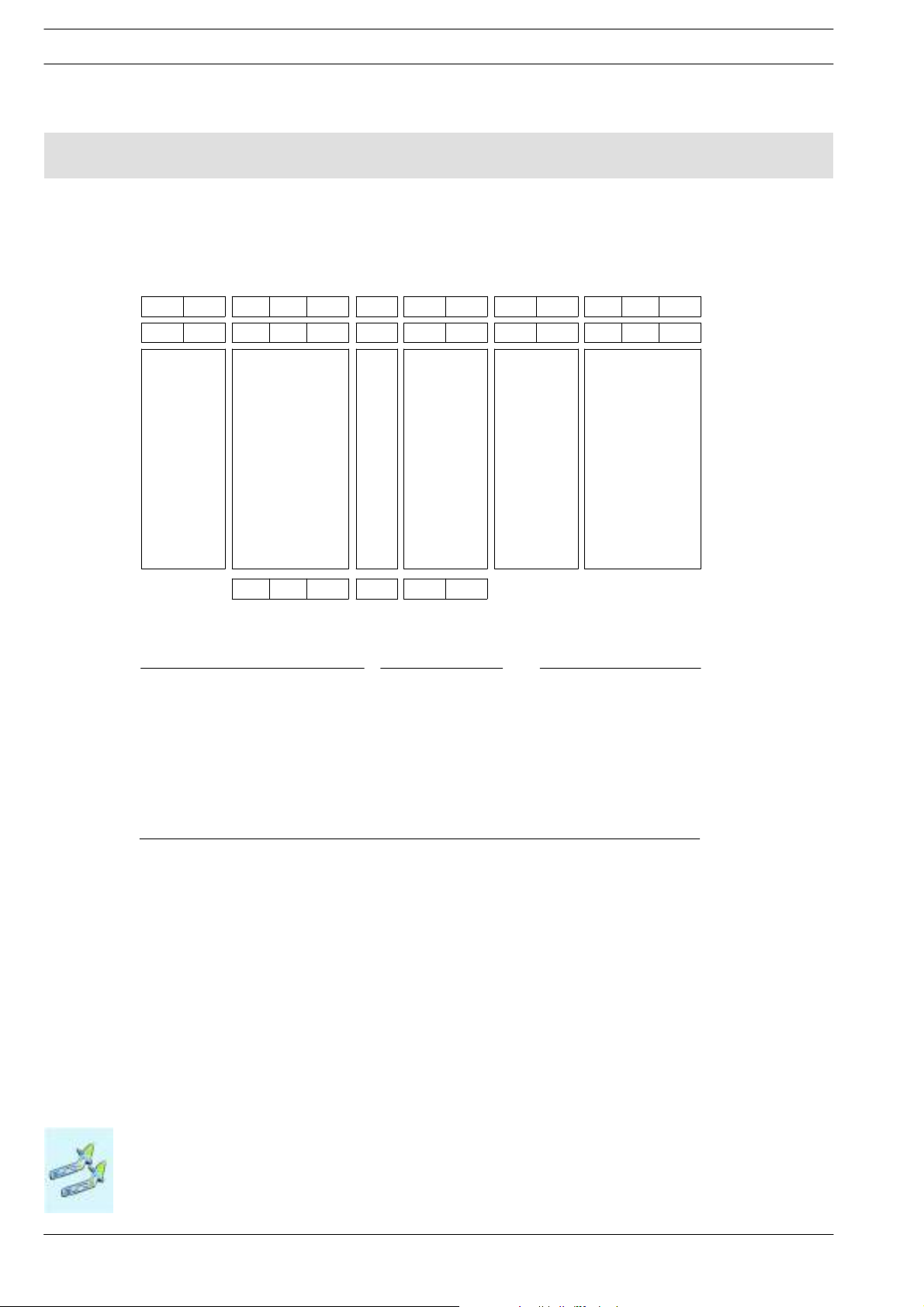

Page header and footer interpretation

Vehicle type

Section title

Section number -

page number

Print

number

Foreword

Base - January 2008 Print 603.93.721

Chapter title

Basic edition -

month year

Page 7

INDEX OF SECTION

Section

General specifications

Chassis modifications 2

Building & Mounting the structures 3

Power Take-offs 4

Special instructions for electronic subsystems 5

Special instructions for -SCR- exhaust system 6

1

Index of section

Print 603.93.721 Base - January 2008

Page 8

Index of section

Base - January 2008 Print 603.93.721

Page 9

STRALIS AS/AT/AD Euro 4/5

Index

GENERAL SPECIFICATIONS

SECTION 1

General specifications

Page

1.1 Aim of bodybuilders instructions 1-3

1.2 IVECO “no objection” for changes and fittings 1-3

1.3 Liabilities 1-4

1.4 Guarantees 1-4

1.5 Request for a “no objection” 1-4

1.6 IVECO technical documents available by means of computer 1-5

1.7 Trademarks and Logos 1-5

1.8 Legal Provisions 1-5

1-1

1.9 Prevention of accidents 1-6

1.10 Choice of material to use: Ecology - Recycling 1-6

1.11 Vehicle delivery 1-7

1.12 Vehicles Identification 1-8

1.13 Dimensions and weights 1-9

1.13.1 General Specifications 1-9

1.13.2 Determining the Centre of Gravity of the Body and Payload 1-9

1.13.3 Observing the Permitted Weights 1-13

1.14 Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance 1-14

1.15 Quality System management 1-15

1.16 Vehicle maintenance 1-15

1.17 Conventions 1-16

Index

Print 603.93.721 Base- January 2008

Page 10

1-2

GENERAL SPECIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Index

Base - January 2008 Print 603.93.721

Page 11

STRALIS AS/AT/AD Euro 4/5

Aim ofbod ybuilde rs instr uctions

GENERAL SPECIFICATIONS

1-3

1.1 Aim of bodybuilders instructions

The purposeof this publication isto provide data,specifications and instructions forthe bodybuilding andconversion of anoriginal

IVECO vehicle to ensure th e function ality, safety and reliability of the vehicle and its components.

1.2 IVECO “no objection” for changes and fittings

Changes must be carried out in accordance with the requirements set out in the following guidelines.

The following may becarried out only with IVECO’sauthorisation after submitting acopy (two forEnglish Market) ofthe documentation required for technical evaluation of the proposed change (drawings, calculations, technical report etc.):

- wheelbase modifications, where the new wheelbase does not fall within the minimumand maximum wheelbase available within

theIVECOrangeforthesamevehicle;

- work carried out on the braking system;

- work carried out on the suspension system;

- steering wheel modifications;

- changes to the stabiliser bars and suspensions;

- changes to the cab, cab supports, locking and tipping devices;

- changes to the intake systems, engine exhaust and SCR components;

- engine cooling system modifications;

- power unit and driving component modifications;

- work carried out on front and rear axles;

- fitting additional axles;

- fitting decelerator brakes;

- fitting power take-offs;

- changing the tyre dimensions;

- coupling device (hooks, fifth wheels) modifications;

- electric/electronic unit modifications.

The other modifications of fittings covered by the following standards and made in compliance with the same do not require specific

authorisation fromIVECO. Anymodification orfitting not coveredby these standards shall,on the contrary, beauthorized by IVECO

in advance

.

Aim of bodybuilders instructions

Print 603.93.721 Base- January 2008

Page 12

1-4

GENERAL SPECIFICATIONS

Liabilities

S

TRALIS AS/AT/AD Euro 4/5

1.3 Liabilities

The authorizations issu ed by IVECO concern solely the technical/conceptual feasibility of the modification and/or fitting to be

made on a genuine IVECO vehicle.

The bodybuilder is responsible for the:

- project of the modification or fitting;

- choice and features of the products used;

- workmanship of the modification or fitting;

- compliance of the project and its implementation with all the instruction s provided by IVECO;

- compliance of the project and its implementation with all the current regulations in the country where the vehicle is registered;

- the operation, safety and reliability and in general the effective performance of the vehicle and also the effects that the changes

and the conversion may have on the performance and specific ations of the vehicle.

1.4 Guarantees

The bodybuilder/chassis converter who has built the body or who has modified the chassis must guarantee that the work was

undertaken in a professional manner in full compliance with the specifications contained in this manual. IVECO reserves the right

to declare void its own warranties for the vehicles where:

- these specifications have not been adhered to or where unauthorised equipment was installed, or unauthorised modifications

were carried out;

- an unsuitable vehicle/model has been used for the required conversion or application;

- the specifications, standards or instructions issued by the Manufacturer for the flawless execution of th e operations have not

been followed;

- original spare parts or components which IVECO has made available for specific conversions were not used.

Maintaining the functionality of vehicle components.

The effective operation of vehicle components, all component safety and running conditions, com-

pliance with national and international regulations (e.g. EC Directives) and accident prevention standards must be guaranteed in all permitted conversions and applications.

All our vehicles are covered by a warranty as laid down in the specific documents.

The bodybuilder must carry out operations at least in an equivalent manner.

1.5 Request for a “no objection”

The requests for approval orsupport to carry out work or make modifications or fittingsshall be forwarded to the IVECO marketing offices in charge.

To obtain the approval,t h e body builder shall provide adequate documents that illustrate the anticipated implementation, utilization

and c on ditions of use on the vehicle. The drawings shall highlight any item differing from the instructions contained in this manual.

The body builder shall submit the modification and/or fitting to the competent authorities for approval.

Liabilities

Base - January 2008 Print 603.93.721

Page 13

STRALIS AS/AT/AD Euro 4/5

IVECO techni cal documents avail able by means of computer

GENERAL SPECIFICATIONS

1-5

1.6 IVECO technical documents available by means of computer

The following technical documents are available on the Internet at www.thbiveco.com:

- bodybuilder instruction manuals;

- specification sheets;

- chassis cab diagrams in .dwg and tiff formats;

- chassis diagrams in tiff formats;

- other specifications concerning the vehicle range.

1.7 Trademarks and Logos

Trademarks, nameplates anddenominations must not be modified or displaced in relation to the original design. The appearance

of the vehicle must not be changed or modified.

The application of t rademarks tied to the transformation or trim levels must be authorised by IVECO. They must not be applied

near to the IVECO tradenames or logos.

IVECO reserves the right to withdraw the tradenames and logos if the fitting or conversion fails to conform with requirements. The

bodybuilder accepts all responsibility for the entire vehicle.

Instruction for added assemblies

Whereassembliesare added,the bodybuilder must providethe necessary service andmaintenance instructionswhen the vehicle

is delivered.

1.8 Legal Provisions

On completing the vehicle, the bodybuilder/chassis converter must check the work (modifications, body + equipment etc.) to

ensure that the legal provisions required in the country of registration are observed (e.g. weights, dimensions, braking, noise,

emissions etc.). Information regarding thesematters may be obtained from the competent Authoritiesor the IVECO AreaNetwork.

The vehicles manufacturedat our plant(except some versions forExtra-Europeancountries) complywith the EC directives.Converted vehicles must also comply with these directives.The only permissibleexception is granted where local type approval differs from

EC homologation.

IVECO technical documents available by means of computer

Print 603.93.721 Base- January 2008

Page 14

1-6

GENERAL SPECIFICATIONS

Preventi onof accid ents

S

TRALIS AS/AT/AD Euro 4/5

1.9 Prevention of accidents

The structures and devices fitted to the vehicles must comply with the current regulations concerning

the prevention of accidents and safety regulations in force in the countries where the vehicle is to be

used.

All the precautions dictated by technical awareness must be adopted to prevent malfunction and functional defects.

Compliance with th ese regulations will be the responsibility of the manufacturers of the structures and devices.

Components such as seats, coverings, linings, protective panels etc. may present a potential fire hazard

if they are exposed to an intense heat source.

!

They should be removed before working with welding equipment and flames.

1.10 Choice of material to use: Ecology - Recycling

Increasingly greater at tention should be paid, at t he study and design stage, to th e choice of materials to be used.

This is especially the caseas regards the aspects connected withecology and recycling in the light ofdomestic and international

regulations that are constantly being developed in the sector.

In this connection:

- everyonemust be aware ofthe prohibitionson using harmful orpotentially hazardous materials,such as onescontaining asbestos,

lead, halogen additives, fluoroc a rbons, cadmium, mercury, hexavalent chrome, etc.

- Use materials whose processing produces limited waste and that permit easy recycling after th eir first use.

- With composite synthetic materials, use components that are compatible with each other, envisaging also their possible utilization with t he addition of other salvaged components. Affix the markings required in compliance with the current regulations.

In order to comply with EC directive 2000/53 (ELVs), IVECO S.p.A. prohibits fitting parts containing

lead, mercury, cadmium and hexavalent chrome to vehicles (except for the departures referred to in

Attachment II of the above directive).

Prevention of accidents

Base - January 2008 Print 603.93.721

Page 15

STRALIS AS/AT/AD Euro 4/5

Vehicledelivery

GENERAL SPECIFICATIONS

1-7

1.11 Vehicle delivery

Prior to delivering the vehicle, the body builder shall:

- verify that the work has been made correctly;

- perform vehicle and/or equipment set-up;

- check the operation and safety of the vehicle and/or equipment;

- prepare and deliverthe necessary instructions for service and maintenance of the fitting and any additionalunits to the end customer;

- write the new data down on the special tags;

- confirm that the work carried out complies with the indications provided by the vehicle manufacturer and with all legal requirements;

- carry out the checks included in the ”IVECO Pre-Delivery inspection” list (available from the IVECO network) with regard to

the items affected by the work done;

- provide a guarantee for the modifications made;

- in the event that the connections originally provided with screws have been mounted and restored, the same screws must not

be used. In such an instance, and in the event that rivets have been replaced with screws, you must again check the tightness

of the connection after travelling approximately 500-1000 km, to ensure it is to the correct torque.

- measure the battery voltage. Ensure there is a minimum charge of 12.5 V. If the voltage reading is between 12.1 and 12.49 V,

recharge the battery (slow charge). If the voltage is less than 12.1 V, the battery must be scrapped and replaced with a new one.

Vehicle delivery

Print 603.93.721 Base- January 2008

Page 16

1-8

GENERAL SPECIFICATIONS

Vehicl es ide ntificati on

S

TRALIS AS/AT/AD Euro 4/5

1.12 Vehicles identification

The commercial designation of IVECO vehicles is not the same as the type approval (homologation) designation. Two types

of commercial designation are shown below w ith the meaning of th e codes used:

Cab

Range

CAB VERSIONS

TRACTOR

AS 260 /PSS24

AS 440 /PS54XT

AS

AD

AT

EXTERNAL NAMEPLATE ON

VEHICLE

CAB RANGE

AS = Active Space

AT = Active Time

AD = Active Day

SUSPENSION

/TN = 6x2P, mechanics with third fixed axle to twinned wheels

/P = 4x2, 6x4, 6x2P, air suspension at rear. 6x2P with single wheels fixed third axle

/PT = Only for 6x2P, air suspension at rear with twin wheels fixed third axle

/PS = Only for 6x2P, air suspension at rear with single wheels third axle, controlled steering

/FP = 4x2, 6x4, 6x2P, full air

/FS = Only for 6x2P full air with single wheels third axle, controlled steering

Model Power Version Suspension

Y

PTT-Cab versions

(n˚/10 → hung in ton)

PTC-Tractors

(with semitrailers)

(n˚/10 → hung in ton)

STRALIS Engine power

(n˚ x10→ HP)

VERSION

T=Tractor

X = 6x2C

Y = 6x2P

(Z= 6x4)

T

X

Y

Z

MISSION

GV = Bulky Goods

transport

CM = Mobile Boxes

LT = Low Tractor

RR = Rough Roads

HM = Heavy Mission

D = Delivery

CT = With Transporter

HR = Hub Reduction

/TN

/P

/PT

/PS

/FP

/FS

Vehicles identification

Base - January 2008 Print 603.93.721

Page 17

STRALIS AS/AT/AD Euro 4/5

Dimensionsand weights

GENERAL SPECIFICATIONS

1-9

1.13 Dimensions and weights

1.13.1 General Specifications

The dimensions and maximum permissible weight on the axles are indicated on drawings, on technical specifications and, in

greater details, on the official documentation issued by IVECO.

The kerb weights refer to vehicles with standard equipment. Special equipment may involve considerable modification to the weight

and its distribution on the axles.

Lights and rear-view mirrors positioning on our vehicles is designed for w idths of 2,550 mm. This dimension may also be applied

to special body versions with a width of 2,600 mm (e.g. refrigerator vans).

Weighing the Chassis

As a result of production factors there may be a variation in weight of approx. 5%.

It is, therefore, advisable to determine the weight of the vehicle with its c ab before fitting the body and equipment and establishing

their distribution o n th e axles.

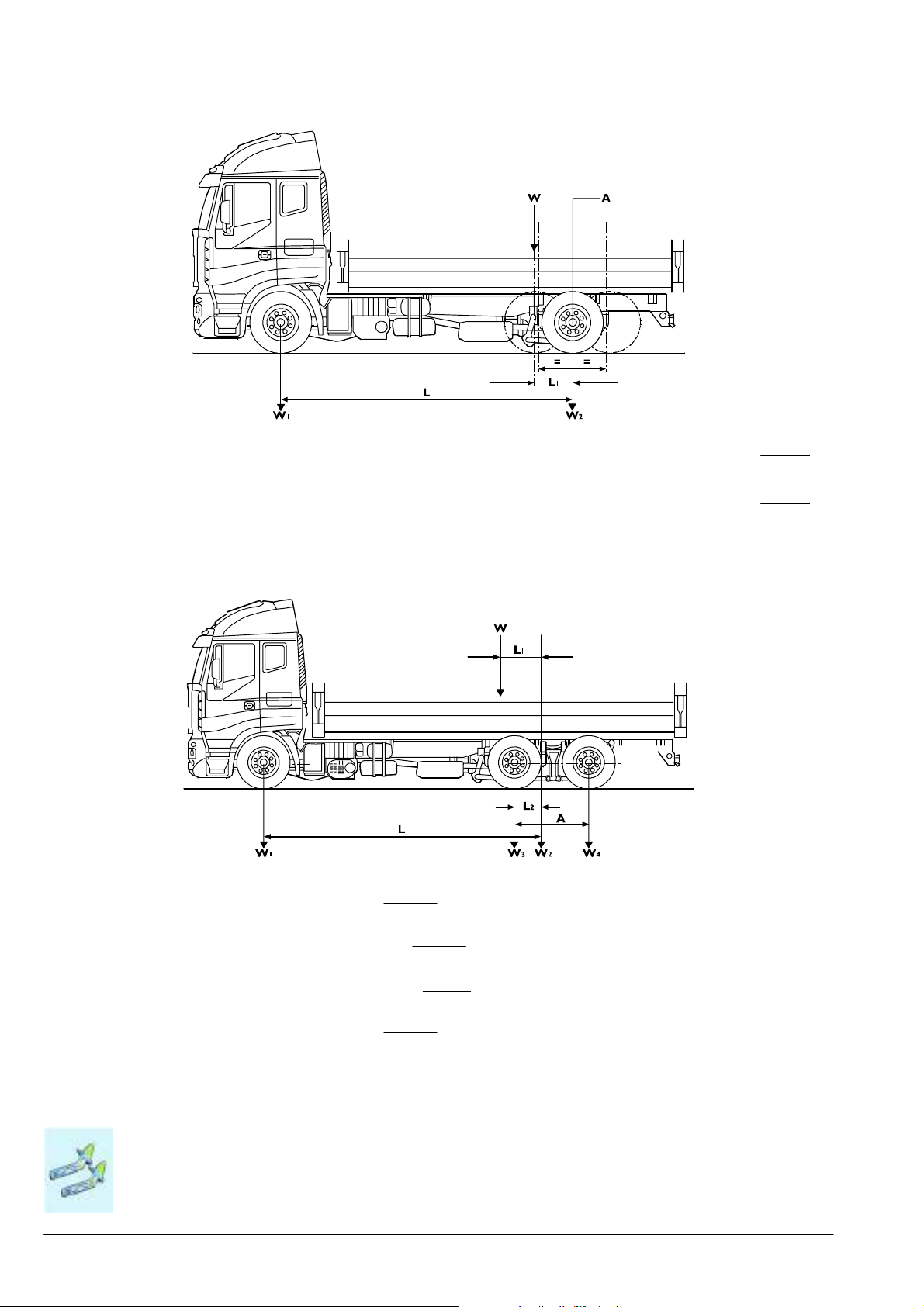

1.13.2 Determining the Centre of Gravity of the Body and Payload

Positioning on longitudinal plane

To establishthe location of the centreof gravity of the body and payloadthe following examples belowmay be used asguidelines.

The technical documentation specific to each model (chassis cabdrawing) give the positions permitted with thevehicle in itsstandard

form. The weight and positioning of the single components of the vehicle are given in the chassis and weight distribution diagram.

Dimensions and weights

Print 603.93.721 Base- January 2008

Page 18

1-10

GENERAL SPECIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Figure 1.1 Vehicles with 2 axles; vehicles with 3 axles with an equal load on the two

rear axles

A = Rear axle or tandem mid axle

W = Payload + body

= Share of payload on front axle

W

1

= Shareof payload on rear axle (ortandem)

W

2

Figure 1.2

Example to determine the position of the centre of gravity of the payload plus body

= Distance of centre of gravity from

L

1

centre-line of rear axle

(or tandem centre-line)

L = Actual wheelbase

Vehicles with 3 or more axles with a constant mass distribution ratio on

the two rear axles. For these vehicles the ”ideal” values of the wheelbase

and centreline between the axles, resulting from mass distribution, is determined by the Manufacturer.

L1=

respectively L1=L-

W1⋅ L

W

W2⋅ L

W

Example to verify compliance of admitted weight on the axles

W = Payload + body

= Share of payload on front axle

W

1

W

= Share of payload on rear axles

2

= Share of payload on first rear axle

W

3

W

= Share of payload on second rear axle

4

= Distance of centre of gravity relative

L

1

calculated centreline

L = Calculated wheelbase (ideal)

L

= Calculated centreline (ideal)

2

A = Distance between rear axles

W

W

W

W

=

1

=Wx

2

3=W2

=

4

WxL

L

x

W2xL

A

1

(L - L1)

L

(A - L2)

A

2

Attention:

On vehicles with three or more axles, with a variable mass distribution

ratio o n the two re a r a xles depending on the lo a d , t he ”i d e a l” values of

wheelbase and centreline between the axles will have to be calc ula ted

on the basis of the information given in the chassis cab diagram, or in the

specific documentation specially prepared by IVECO. In this way, for

special versions (e.g . cranes on rear overhang) it will be possible todetermine the co r r e ct positioning of the cent r e of gravi t y of the equipment

and payload on the basis of the actual load (see point 5.4 in section 5).

Dimensions and weights

Base - January 2008 Print 603.93.721

Page 19

STRALIS AS/AT/AD Euro 4/5

GENERAL SPECIFICATIONS

1-11

In order to apportion the payload on the axles, it must be uniformly distributed except when the shape of the loading surface itself

entails a different distribution of the load.

As for equipment, the actual location of the centre of gravity is used.

When building bodies or containers, loading and unloading systems for the transported goods must be devised which preclude ex-

cessive variations in the distribution of the load and/or excessive loads on the axles, also giving the relevant instructions to t he users.

The bodybuilder willalso need to installsu itable payload securing systemson the body sothat transport can be madewith the utmost

safety.

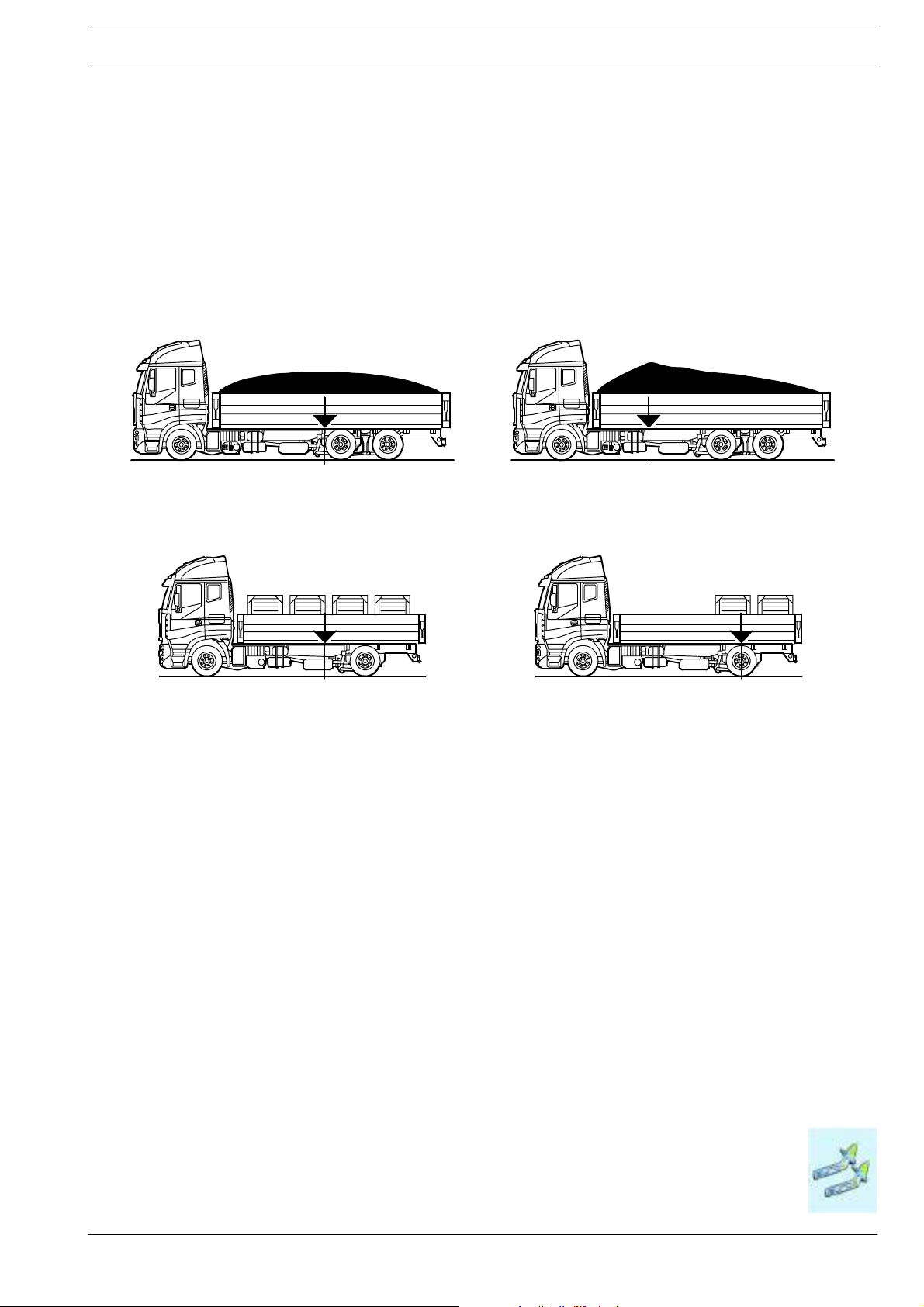

Figure 1.3

Uniform distribution of the load Non-uniform distribution of the load due to the

Uniform distribution of the load Non-uniform distribution of th e load (beware of load on axles

lack of rear overhang

and minimum ratio)

Dimensions and weights

Print 603.93.721 Base- January 2008

Page 20

1-12

GENERAL SPECIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Height of the Centre of Gravity

The height of the centre of gravity of the chassis cab is given in the technical documentation specific to each model (chassis

drawing).

For testing the vehicle complete with superstructure, the bodybuilder must check that the height of the centre of gravity of the

equipment including the payload, or of the entire vehicle when fully loaded, falls within the maximum permitted values.

These limits are defined in compliance with the national or international regulations (e.g. as amended by the current EC braking

Directive) or requested by the Manufacturer to ensure good handling of the vehicle (e.g. transverse stability of the moving vehicle).

In order toc omply with the current ECDirective, IVECO providesinformation forthe various models (wheelbaseand specific body)

on computer, regarding:

- height of centre of gravity of chassis cab (e.g. chassis cab diagram, braking data);

- maximum height of centre of gravity of complete vehicle at full load (e.g. national type-approval document);

- braking capacity of each single axle (e.g. braking data).

Figure 1.4

Verification with full load:

Wv . Hv + Ws . Hs

Ht =

Wv = Chassis cab vehicle kerb weight

Hv = Height of centre of gravity of chassis cab vehicle (laden condition)

Ws = Body and payload

Hs = Height of centre of gravity of body and payload in relation to ground

Wt = Vehicle weight when fully loaded

Ht = Height of centre of gravity of vehicle fully laden to gvw

Wv + Ws

(Wv + Ws) . Ht − Wv . Hv

Hs =

Ws

To check the vehicle with its body but no payload, use above formula but for Ws use only the body kerb weight (The position for

Hv will depend on the load and deflection of the suspension).

The height of the centre of gravity indicated in Tabella 2.6 represents values which are not to be exceeded for each given equipment

level. These values have been calculated only in terms of the transverse stability of the vehicle and are applicable to a mid wheelbase.

Any other possible restrictive specification, e.g. braking regulation , shou ld be taken into consideration.

The values given in Tabella 2.6 refer to the superstructure with fixed payload. In versions where the payload tends to move on side

(e.g. suspended loads, fluid loads etc.) especially when turning, higher dynamic stress is generated which makes the vehicle less stable.

This must be taken int o consideration when providing vehicle operating instructions or for possible reduction in the height of the

centre of gravity.

Dimensions and weights

Base - January 2008 Print 603.93.721

Page 21

STRALIS AS/AT/AD Euro 4/5

GENERAL SPECIFICATIONS

1-13

Using Stabiliser Bars

Supplementary stabilising or anti-roll bars, where available, spring reinforcements or the application of rubber components (in

compliance with point 2.7) may increase the height of the centre of gravity of the payload which must be defined as each occasion

arises. The modification must be carried out after careful consideration has been given to the specifications of the version, to the

wheelbase and to the distribution of the cross-stresses act in g on the suspension both at the front and at the rear of the vehicle.

It must be borne in mind that it is often advisable to modify the rear axle only since a modified front axle would give th e driver a

false sense of stability making it more difficult to perceive the safety limits. Modification to the front axle may be made where the

load is positioned behind the cab (e.g. crane) or where the superstructures are very rigid (e.g. van conversion).

Exceeding the Limits

When transportinggoods with anexceptionally highcentre of gravity(e.g. machinery,indivisiblecargo etc.) froma technical point

of view it is possible to exceed the values indicated in the table provided that the steering system of the vehicle is suitably adapted

to this condition (e.g. reduced speed, gradual changes on the steering wheel, etc.).

1.13.3 Observing the Permitted Weights

All limitsindicated in our documentation must be adhered to. The load of the front axle is of particular importance undervarying

load conditions, in order to ensure the correct steering characteristics on road surfaces of all types.

Particular attention must th erefore be paid to vehicles with a weigh t which is concentrated on the rear overhang (e.g. cranes, tail-lifts,

centre axle trailers) and to vehicles with a short wheelbase and a high centre of gravity (e.g. silo vehicles, cement mixers).

When positioning the body and equipment, the loads must be correctly distributed transversally. For each wheel a variation in th e

rated load (1/2 of the axial load) of 4% is permitted (e.g. admitted load on axle: 10,000 kg load admitted on each wheel: 4,800 to

5,200 kg) provided that the tyres permit it, without impairing braking or driving stability.

For vehicles with an added rear lift axle it must be remembered that, with the axle in the raised position, the effective wheelbase

is reduced, whereas the rear overhang is increased. It is therefore advisable that the centre of gravity of the body and payload is

located in front of the centre line of the driving axle. In addition to this it is not advisableto equipa vehicle which has its load concentrated at the rear, with a lifting device.

Apart from different specifications for specific individual vehicles, the following may be taken to be the minimum values for the front

axle:

- 20% of the total vehicle weight with uniformly distributed loads

- 25% of the total vehicle weight for loads that are concentrated on the rear overhang.

The rear overhang of the body must be built in strict observance of the permitted axle loads, the limitations in length, the positioning

of the tow hook and of the underride guard stipulated by the relevant regulations and legal requirements.

Variations in the Permissible weight

Special exceptions to the maximum permissible weight may be granted for particular applications for which, however, precise

limitations regarding th e use will be imposed in addition to possible vehicle reinforcements.

Such exemptions, if they exceed the limits imposed by law, must be authorised by the Administrative Authority.

A reduction in admissible vehicle load (downrating) may require modifications on some parts, such as the suspension. In these cir-

cumstances, the necessary information may be supplied.

The request for authorisation must include:

- Vehicle type, wheelbase, identification number, designated use.

- Weight distribution on the axles (e.g. vehicles equipped with crane and body) including positions of the centre of gravity of th e

payload.

- Proposals concerning the reinforcement of the vehicle components where necessary.

Dimensions and weights

Print 603.93.721 Base- January 2008

Page 22

1-14

GENERAL SPECIFICATIONS

Instructionsforthe CorrectFunctioningofthe Partsof the Vehicle andAccessibilityforMaintenance

S

TRALIS AS/AT/AD Euro 4/5

1.14 Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

As a rule, when modifying or installing any type of equipment, nothing must be altered which prevents the correct fu n ctioning

of assemblies and parts of the vehicle under all operational conditions.

For example:

- Ready access to all parts requiring inspection or maintenance and periodic servicing must be provided. In the case of closed body

types suitable opening doors must be provided.

- For tilting cabs, adequate space permitting tilting must be assured. In the case of structures which involve the space above the

driver’s cab, adequate space for the passage of intake air must be guaranteed (see 1.5).

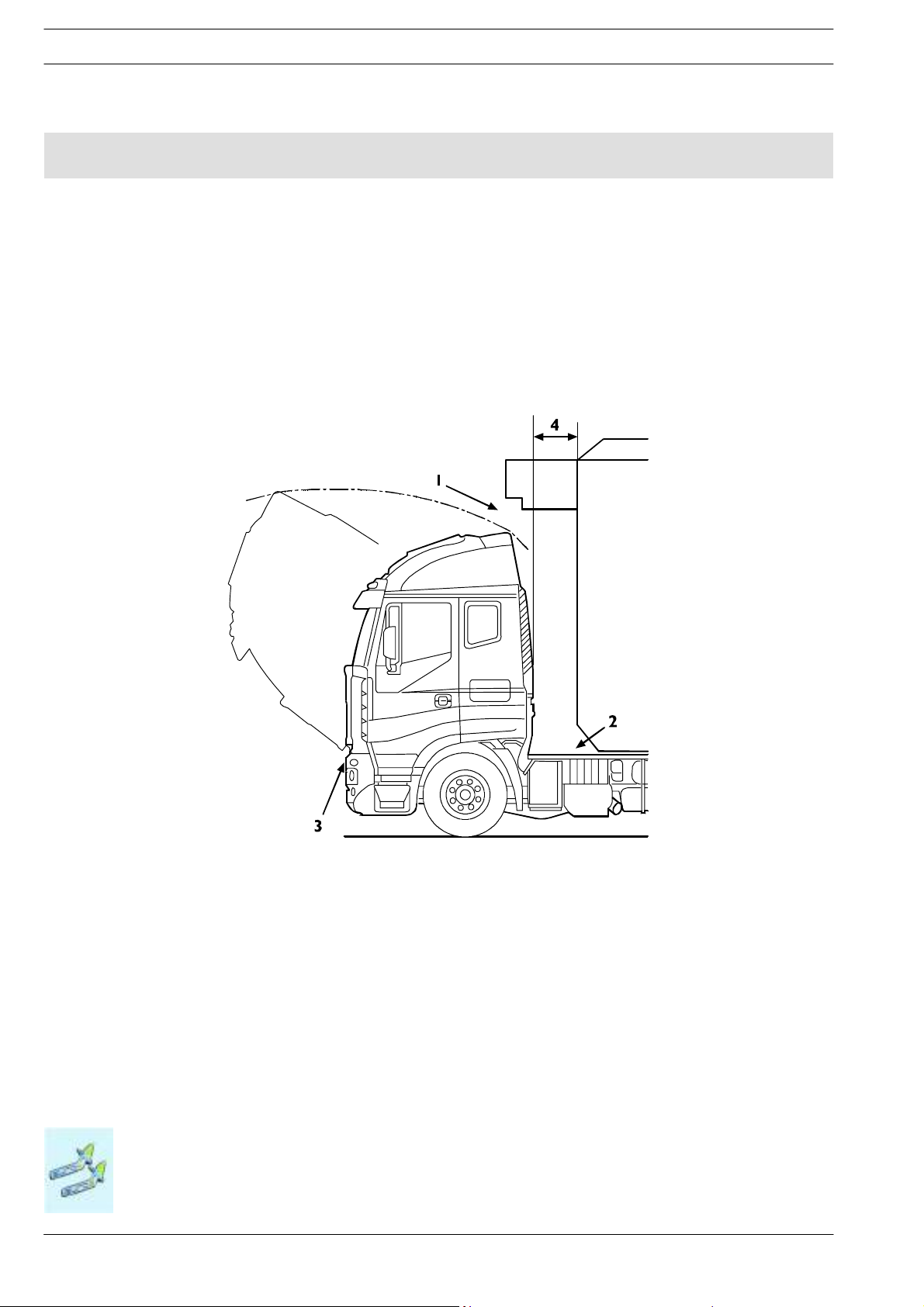

Figure 1.5

1. Retain adequate room for tilting the driver’s cab - 2. Retain thefreespaceabovethegearbox(fortractorswithsemitrailers

consider the movement between tractor and semitrailer) - 3. Cab pivot point - 4. Min. distance to be met

- Service access to chassis/driveline components must be retained. For instance repairing the gearbox or clutch must be possible

without necessitating the removal of major components of the added structure.

- The cooling system (radiator cowling, radiator, air passages, cooling circuit etc.), fuel supply (pump position, filters, pipe diameter,

etc.) and the engine air intake must not be altered.

- The anti-noise panels must not be altered or moved in order to prevent changes in the approved noise levels of the vehicle.

Should it be necessary to make openings (e.g. for the longitudinal runner of the body to pass through) these must be properly

closed off u sin g material with inflammability and sou ndproofing c haracteristics equivalent to those used originally.

Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

Base - January 2008 Print 603.93.721

Page 23

STRALIS AS/AT/AD Euro 4/5

GENERAL SPECIFICATIONS

- Adequate ventilation of the brakes and battery case (especially in the case of box bodies) must be guaranteed.

1-15

- The positioning of the mud-guards and wheel-arches must allow free movement of the rear wheels even when chains are being

used. Sufficient space must also be ensured with lifting axles. Some of our models have 3

rd

axle steering which also steers in

the raised position; and it is necessary to leave space for this function (see point 2.20).

- When the vehicle has been set up, for safety reasons, headlight attitude must be checked and adjusted as necessary. Perform

the adjustment according to the instructions provided in the user and maintenance manual.

- In the c ase of parts which are supplied loose (e.g. spare wheel, chocks) it will be the responsibility of the bodybuilder to position

and secure them in an accessible and safe manner in compliance with possible national regulations.

1.15 Quality System management

For some time IVECO has been promoting Quality System development and trainin g for bodybuilders.

This is arequirement duen ot only to compliance with domestic andinternation al regulations on productliability, but alsothe growing

demand for increasingly higher quality levels. The creation of new forms of organization in the various sectors and the quest for

increasingly more advanced levels of efficiency.

IVECO believes it essential for bodybuilders to be equipped and organ ised where the following are defined and available:

- organization charts for functions and responsibilities.

- Quality System.

- quality goals.

- technical design documentation.

- process and control phases with relevant resources.

- product improvement plan, obtained also with corrective actions.

- after sales service.

- staff training.

- manufacturer liability documentation.

1.16 Vehicle maintenance

In addition t o making the necessary checks on the body/structure in keeping with customary working procedures, the bodybuil-

der shall perform the checks specified in th e “IVECO pre-delivery inspection” list, whic h can be obtained from the IVECO network,

for the aspects affected by the modifications performed.

Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

Print 603.93.721 Base- January 2008

Page 24

1-16

GENERAL SPECIFICATIONS

Convention

S

TRALIS AS/AT/AD Euro 4/5

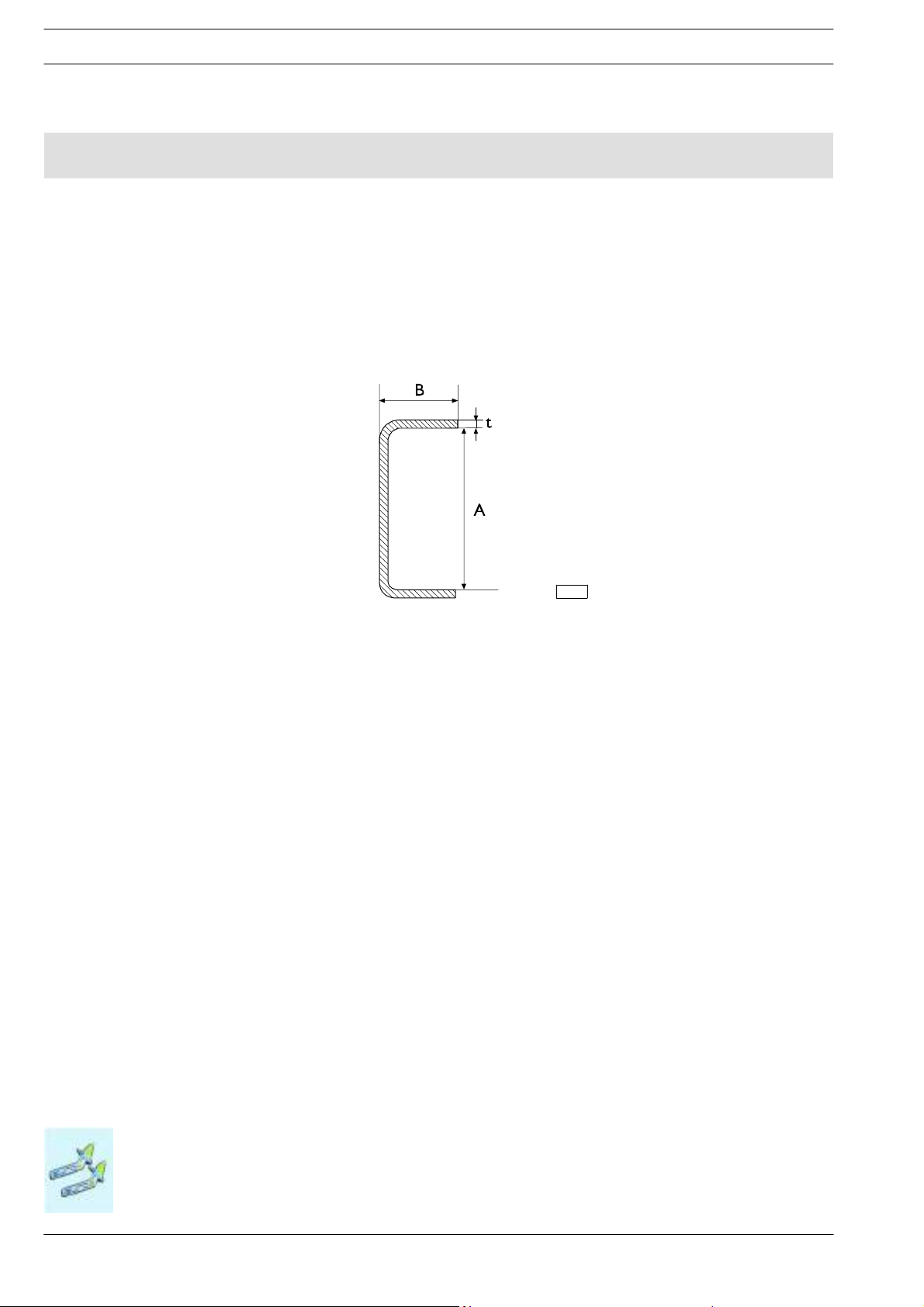

1.17 Conventions

In these bodybuilders instructions, the wheelbase is taken as the distance between the centreline of the first steering axle and

the centreline of the first rear axle (driven ornon-driven). This definition differs fromthe definition of wheelbase inthe CE Directives.

The rear overhang is taken as the distance between centreline of the lastaxle and the rear end ofthe chassisrunner. For dimensions

A, B and t of the frame and subframe section please refer to the figure below.

Figure 1.6

91473

Convention

Base - January 2008 Print 603.93.721

Page 25

STRALIS AS/AT/AD Euro 4/5

Index

CHASSIS MODIFICATIONS

SECTION 2

Chassis modifications

2.1 General instruct ions for chassis modifications 2-5

2.1.1 Specific Precautions 2-5

2.2 Painting and Rust Protection 2-7

2.2.1 Original components 2-7

2.2.2 Added or modified painted parts 2-9

2.2.3 Precautions 2-10

2.2.4 Max indicative height of center of gravity of payload in relation to transverse stability 2-11

2.3 Drilling t he Chassis 2-12

2-1

Page

2.3.1 Screws and nuts 2-12

2.3.2 Characteristics of the material to be u sed when modifying the chassis 2-13

2.3.3 Stresses on the chassis 2-14

2.3.4 Welding the Chassis 2-15

2.3.5 Closing of existing holes 2-17

2.4 Modifying the Wheelbase 2-18

2.4.1 General Specifications 2-18

2.4.2 Authorisation 2-18

2.4.3 Effects on the steering 2-18

2.4.4 Effects on braking 2-19

2.4.5 Recommended procedure 2-19

2.4.6 Chassis Stress Level 2-20

2.4.7 Cross Members 2-20

2.4.8 Changes to transmissions 2-20

2.5 Modifying the Rear Overhang 2-21

2.5.1 General Specifications 2-21

2.5.2 Reducing the Overhang 2-21

2.5.3 Increasing the Overhang 2-21

2.6 Installing a Towing Device 2-23

Index

Print 603.93.721 Base- January 2008

Page 26

2-2

CHASSIS MODIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Page

2.6.1 General Specifications 2-23

2.6.2 Traditional towing hooks 2-24

2.6.3 Towhook for mid-axled trailers 2-25

2.6.4 Lowered Rear Cross Member 2-27

2.6.4.1 Centre axle trailers: towing cross member in lowered and forward positions (sh o rt coupling) 2-35

2.6.4.2 Reinforcement of Standard Rear Cross Member 2-35

2.6.4.3 Tow hooks for Centre Axle Trailers 2-37

2.6.4.4 Remarks about the Payload 2-37

2.6.4.5 Increasing the Towable weight 2-38

2.7 Installing a Supplementary Axle 2-38

2.7.1 General Specifications 2-38

2.7.2 Chassis Frame Reinforcement 2-38

2.7.3 Installing a Rear Supplementary Axle 2-40

2.7.4 Steering Axles 2-41

2.7.5 Components and Suspension 2-41

2.7.6 Stabilisers 2-41

2.7.7 Connection to the Chassis Frame 2-41

2.7.8 Braking system for additional axle 2-42

2.7.9 Raise Device 2-42

2.7.10 Modifying the suspension 2-45

2.8 Modifying the Drive Line 2-43

2.8.1 Permitted lengths 2-44

2.8.2 Determining Driveshaft Positions 2-46

2.9 Modifications of t he Engine Air Intake and Exhaust Syatem 2-49

2.9.1 Intake 2-49

2.9.2 Engine exhaust 2-49

2.10 Modification of the Engine Cooling System 2-50

2.11 Installation of a Supplementary Heating System 2-51

2.12 Installing an Air-Conditioning System 2-52

Index

Base - January 2008 Print 603.93.721

Page 27

STRALIS AS/AT/AD Euro 4/5

CHASSIS MODIFICATIONS

2-3

Page

2.13 Cab Modifications 2-53

2.13.1 General Specifications 2-53

2.13.2 Roof Panel Modifications 2-53

2.14 Changing the Size of the Tyres 2-54

2.15 Modifications to the Braking System 2-56

2.15.1 General Specifications 2-56

2.15.2 Brake Pipes 2-56

2.15.3 Electronic braking system control devices 2-61

2.15.4 Taking air from the system 2-61

2.16 Electrical System: Modifications and Drawing-Off Power 2-62

2.17 Repositioning Parts and Mounting Auxiliary Assemblies and Equipment 2-62

2.18 Transporting hazardous goods ADR 2-65

2.19 Retarder installation 2-67

2.20 Modifications to the Rear Underrun 2-68

2.21 Rear Mudguards and Wheel Boxes 2-69

2.22 Mudflaps 2-70

2.23 Side Guards 2.71

2.24 Chocks 2-73

Index

Print 603.93.721 Base- January 2008

Page 28

2-4

CHASSIS MODIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Index

Base - January 2008 Print 603.93.721

Page 29

STRALIS AS/AT/AD Euro 4/5

2222.2

General i nstructi ons for chassis modi fications

CHASSIS MODIFICATIONS

2-5

2.1 General instructions for chassis modifications

Particular attention must be given to the following points:

- Welding to the bearing structures of the chassis is explicitly prohibited (with the exception of the items described at points

2.3.4, 2.4 e 2.5).

- Holes in the flanges of the side members are not permitted (except for the items described at point 3.4).

- Where riveted connections exist and can be modified as explained below, these can be replaced by flanged-head screws and

nuts of min. class 8.8 or by hex screws of the next greater diameter and self locking nuts. Screws greater than M14 must not

be used (max. diameter of hole 15 mm) unless otherwise specified.

- In cases where the original joints were detached and rejoined with bolts it is forbidden to reuse the same bolts. In this event

and when rivets are replaced with bolts, the bolt torque must be c hecked after the vehicle has been driven approximately 500

÷ 1.000 kms.

2.1.1 Specific Precautions

!

Figure 2.1

During welding, drilling, grinding and cutting operations near brake system pipes, and electrical cables, adopt the appropriate precautions for their protection. Remove them altogether

if necessary (observe the requirements set out under points 2.15.2 and 5.5).

91444

General instructions for chassis modifications

Print 603.93.721 Base- January 2008

Page 30

2-6

CHASSIS MODIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

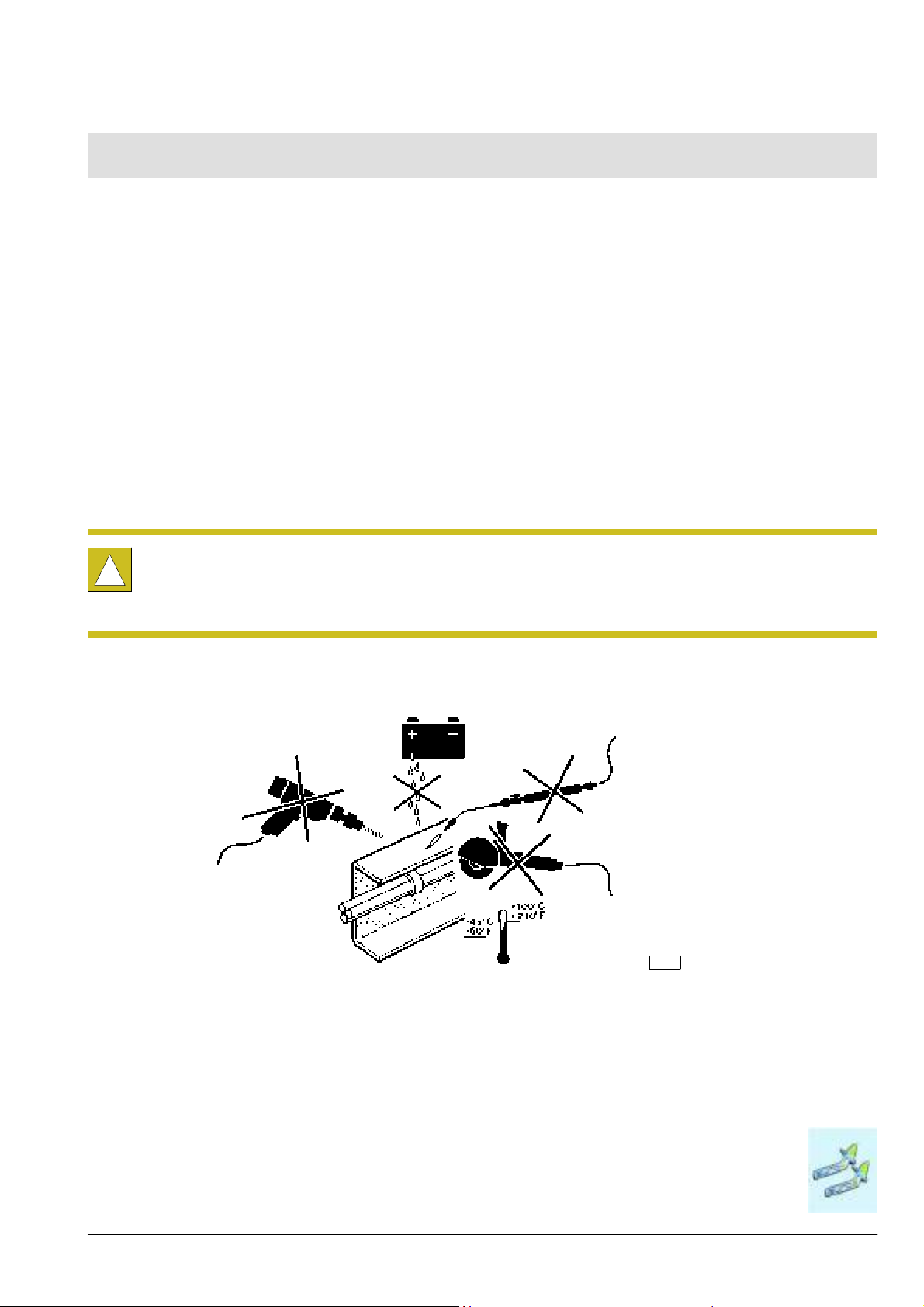

Take precautions concerning the alternator and the electrical/electronic components

In order to avoid damaging the diode rectifier, never disconnect the batteries (or open the isolator) when the engine is running.

If the vehicle has to be tow started make certain that the batteries are connected. Should it be necessary to charge the batteries,

disconnect them from the vehicle circuit.

In order to run the engine with external means and in order to avoid current peaks which might damage the electric/electronic

components, do not use the ”start” function in conjunction with external charge devices if such devices are equipped with this

function. Starting will have to be carried out only with the external battery trolley ensuring correct polarity.

Earth connections

As a general rule the original earth connections of the vehicle must not be changed. If it is necessary to move these connections

or to implement further earth points use the existing holes on the chassis as far as possible and:

- Remove, mechanically , and/or with an appropriate chemical product, the paint on the chassis side andon the terminal side creat-

ing a resting plane free from indentations or ridges.

- Apply appropriate high conductivity paint between the cable terminal and the metal surface (e.g. galvanizin g paint IVECO Part

number 459622 by PPG).

- Connect the earth cables within 5 minutes from the application of the paint.

Do not use the IVECO standardised M1 (battery earth connection) M2, M8 (earth connection for started motor depending on the

driving position) points for the earth connections for control switches (e.g. sensor or low absorption devices).

With regard to theelectronic devices, avoid linking earth connections between the devices; only use single wireearths with optimised

lengths (as short as possible).

Electric wiring

Stralis vehicles are equipped with an innovative electronic system called MUX. Before performing any

operation on the electrical system, read section 5 “Special instructions for electronic subsystems”.

!

For further information regar ding the braking and electronic system, refer to point 2.15 and 5.5.

List of technical guidelines and standards for correct installation of electrical cables in vehicle electron ic systems

Power cables (+ direct type) must be fed on their own into corrugated piping (of appropriate diameter) and not together with other

smaller cables (signal and negative cables); they must be spaced a minimum distance of 100 mm apart (reference value = 150 mm)

from high heat sources (engine turbine, exhaust manifold, etc., ...). and a distance of at least 50 mm must be maintained from chemical

agent containers (batteries, etc.).

This rule also applies to the area around moving parts.

Cables that run through perforated or angled panels must be protected by screw-on adaptors for cables (in addition to the corru-

gated pipe).

The corrugated pipe must wrap fully around the entire cable and must be secured with a heat-shrink sleeve or using adhesive tape

to the plastic terminal caps. Collars securing the corrugated pipe cut along their length must not deform the pipe, otherwise the

cables could be laid bare or come into contact with the sharp corners of the corrugated pipe.

All connection terminals (+) of the above cables and also their terminals must be covered with plastic caps waterproof version, at

all points exposed to atmospheric ingress or where water builds up.

The fastening of the terminal on the clamps (including the earth clamps) must be protected against accidental loosening. For this

reason, it is necessary to apply an appropriate tightening torque if possible. In the case of multiple terminal connections, these must

be in a star configuration (but this connection method should be avoided if possible).

The relevant cable route must be supported by fastenings and collars spaced close together to prevent hanging cables. After repair,

outfitting or conversion work, restore the wiring harness to its original condition.

When connecting the frame andthe tipper cab, check the wiring with the cab raised and tipped to detect and correct any abrasions

or tautness of the cables.

General instructions for chassis modifications

Base - January 2008 Print 603.93.721

Page 31

STRALIS AS/AT/AD Euro 4/5

tlyst

ructuralcharacter

ist

i

directlyvisibl

M

l

Typeof

p

(

)

(

)

y

A

lumini

Paintin gand R ust Protecti on

CHASSIS MODIFICATIONS

2-7

2.2 Painting and Rust Protection

2.2.1 Original components

Table 2.1shows the protection and painting classes required for original vehicle components. Table 2.2 shows classes forunpain-

ted or aluminium parts and Table 2.3 shows classes for painted parts.

Table 2.1 - Protection classes as for STD 18 - 1600 (Schedule I)

Class Features of the part Examplesofthetypeofpart

A Parts in direct contact with atmospheric agents Cab, rear view mirrors, cab fixing components

B

B1

C

Parts in direct contact with atmospheric agents with

mos

cs,

e

Parts in direct contact with atmospheric agents, not

directly visible

D Parts not in direct contact with atmospheric agents Pedals, seat frames, fixing components, internal cab pillars

Chassis and related parts, including fixing. Components

and parts under the hood

Rear and front axles

Engine and related parts

ateria

Stainless

steel

chemical coating

Ferrous

Zinc treatment

Anodizing yes yes yes yes

um

Painting yes - - -

(*) Hexavalent chromium-free

(1) I.S. 18-1101

(2) I.S. 18-1102

Table 2.2 - Various unpainted and/or aluminium parts and components

rotection

A B-B1 C D

Class

- yes - - -

FE/ZN 12 III

FE/ZN 12 IV (*)

DAC 500/8/PL

GEO 321/8/PL (*)

GEO 321/8/PM (*)

-

-

DAC 320/5

GEO 321/5 (*)

(1)

GEO 500/5 (*)

(1)

-

-

-

(2)

FE/ZN 12 V

FE/ZN 12 IV S (*)

-

-

yes

yes

-

-

-

yes yes

yes yes

- -

- -

-

-

-

Painting and Rust Protection

Print 603.93.721 Base- January 2008

Page 32

2-8

D

i

pti

p

h

g

(

g

Mechanicalsurfacecleaning(including

g

P

r

Anti-r

CHASSIS MODIFICATIONS

Table 2.3 - Painted parts as for STD 18 - 1600 (Schedule III)

S

TRALIS AS/AT/AD Euro 4/5

escr

Mechanical surface cleanin

on ofthecycle

includin

the removal of burrs / rust and cleaning

of modified parts)

ase

A B(5) B1 C D

Sand blasting - yes • - ye s • yes •

Brushing yes •

Sanding

Classes

Degreasing - - - yes • yes •

e-treatment

Phosphate degreasing

Phosphating of the heavy iron yes •

Phosphating of the zinc yes

High thickness (30-40 μm) yes (1) yes (4)•- yes (6)•yes •

Cataphoretic treatment

Low thickness (15-25 μm) yes (2)

Acrylic to finish (>35 μm) -

ust

Chip-resistant base

Bicomponent (30-40 μm) - yes (7) Monocomponent (30-40 μm) - yes

Mono (130 °C) or bicomponent (30-40

yes (2) - - - -

μm)

Mono (130 °C) or bicomponent (30-40

yes yes • - yes • yes •

μm)

Paint

Powders (50-60 μm) yes (3) yes

Monocomponentatlowtemperature

- - yes

(30-40 μm)

(1) = Cycle for two-coat preparation.

(2) = Cycle for three-coat preparation.

(3) = Alternative to the mono or bicomponent paint, only for cab parts (windscreen wipers, rear view mirrors, etc.)

(4) = Excluding parts that cannot beimmersed in pre-treatmentand paint baths, due to their geometry (air tanks), their large size (castings) or where this would

compromise their functionality (mechanical parts).

(5) = For ferrous steel or pre-coated fuel tanks, refer to Table 2.2.

(6) = Only parts fitted on the engine.

(7) = Parts that cannot be treated cataphoretically (4).

• = Alternative products and cycles for the same class, as long as they are compatible with the part being treated.

NOTE

All components installed on chassis must be painted as per Sta Iveco 18-1600 Colour IC444RAL 7021

brightness 70/80 gloss.

Painting and Rust Protection

Base - January 2008 Print 603.93.721

Page 33

STRALIS AS/AT/AD Euro 4/5

D

i

pti

p

h

Mechanicalsur

f

g(includ

ingther

f

bur

rs/

rust

g

r

ts)Brushing/sanding/sandblastin

g

M

l

Typeof

p

y

Fer

r

A

lumini

CHASSIS MODIFICATIONS

2-9

2.2.2 Added or modified painted parts

All parts of the vehicle (cab, chassis, bodywork, etc.) which are added or subjected to modification must be protected from rust

and corrosion.

There must be no unprotected areas on ferrous materials.

Table 2.4 (painted) and Table 2.5 (unpainted) show the minimum treatments required for modified or added components when

it is not possible to provide the same protection as that used on IVECO original components. Different treatments are allowed

on condition that the same level of protection against rust and corrosion is guaranteed.

Never use powder enamels directly after degreasing.

Parts in light alloy, brass and copper must not be protected.

Table 2.4 - Added or modified painted parts

escr

ace cleanin

and cleaningof modifiedpa

on ofthecycle

ase

emovalo

A-B-D(1)

Brushing/sanding/sand blastin

Pre-treatment Degreasing

Anti-rust Bicomponent (30-40μm) (2)

Paint Bicomponent (30-40μm) (3)

Class

(1) = Modifications to rear axles, front axles and engine (Classes B1 and C) are not allowed.

(2) = Preferably epoxy.

(3) = Preferably polyurethane.

Table 2.5 - Added or modified unpainted and/or aluminium parts

Class

ateria

rotection

A-B(1) D

Stainless steel

es

ous

chemical coating

Zinc treatment - yes

Anodizing yes yes

um

(1) = Modifications to rear axles, front axles and engine (Classes B1 and C) are not allowed.

Painting - -

-

-

Painting and Rust Protection

Print 603.93.721 Base- January 2008

Page 34

2-10

CHASSIS MODIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

2.2.3 Precautions

Suitable precautions must be taken to protect those parts whose preservation and operation could be damaged by paints such

as:

- rubber or plastic pipes for the air and hydraulic installations;

- gaskets, parts in rubber or plastic;

- flanges of the transmission shafts or power take-offs;

-radiators;

- shock absorber and hydraulic or air cylinder rods;

- drainage and bleeder valves (mechanical components, air tanks, cold starting heater plug pre-heating tanks etc.);

- fuel sediment filter;

- nameplates and logos.

With particular regard to the engine and its electric and electronic components, adequate precautions must be taken to protect:

- on the whole engine and vehicle wiring, including earth contacts;

- on all connectors on sensor/actuator side and wiring side;

- on all sensors/actuators, on flywheel, on flywheel rev sensor bracket;

- on the whole diesel fuel system pipes (plastic and metallic);

- on complete diesel fuel filter base;

- on control unit and control unit base;

- on the whole soundproofing cover inner side (injectors, rail, pipes);

- on common rail pump including regulator;

- on vehicle electric pump;

- on tank;

- on front belt circuit and relevant pulleys;

- on power steering pump and relevant piping;

- ECU’s fitted on the vehicle.

If the wheels are removed, protect the contact surfaces on the hubs, avoid increasing the thickness and especially avoid the build-up

of paint on the connecting flanges of the wheel disks and contact points of the fixing nuts.

Ensure that the disc brakes are adequately protected.

The electronic components and modules must be removed.

When the painting operation is to be completed by oven drying (max. temp. 80ºC), all parts which may

be damaged by exposure to heat, must be removed.

!

Painting and Rust Protection

Base - January 2008 Print 603.93.721

Page 35

STRALIS AS/AT/AD Euro 4/5

(

theground(mm)

CHASSIS MODIFICATIONS

2-11

2.2.4 Max indicative height of center of gravity of payload in relation to transverse stability

1)

Table 2.6

Base equipment

Max indicative height of center of gravity

includingbody or equipment)in relation to

Models

with anti roll bars

Front Rear

1 2 1 2

AS/AD/AT 190 x x 2720

AS/AD/AT 190/P x x 2750

AS/AD/AT 260 Y/TN x x 2740

AS/AD/AT 260 Y/P, Y/PS x x x 2720

AS/AD/AT 260Z/P x x x 2830

AS/AD/AT 260/P x x x 2720

Notes:

1) = Values refer to the transverse stability of the vehicle, to hold present eventual other limitations takes from the national and international regulations in

force (es. braking)

x = with standard anti-roll bar

- = without anti-roll bar

SW = to request roll bar

Painting and Rust Protection

Print 603.93.721 Base- January 2008

Page 36

2-12

CHASSIS MODIFICATIONS

DrillingtheChassis

S

TRALIS AS/AT/AD Euro 4/5

2.3 Drilling the Chassis

When it is necessary to mount assemblies or auxiliary units on the chassis, as a general rule,the existing holes made at the factory

should be used.

Under no circumstances should the flanges of the supporting member of the vehicle be drilled unless in compliance with

the indications given in point 3.3.1.

In those cases (installation of shelves, brackets etc.) where it is necessary to drill new holes, they must be drilled on the vertical

web of the side member and must be carefully deburred and reamed.

Position and Size

The new holes must not be made in areas of high stress (such as supports for springs) and at variance with the cross-section

ofthesidemember.

The diameter of the holes must be proportional to the thickness of the steel. Under no circumstances must this exceed 15 mm

unless otherwise specified. The distance from the centre of the hole to the edges of the side member must not be below 40 mm.

The centres of the holes must never be located at a distance of less than 45 mm from each other or in relation to the existing holes.

The holes must be staggered as shown in Figure 2.2. When moving spring support or crossmembers, the same drilling arrangement

must be u sed always maintain the original boring.

Figure 2.2

91445

2.3.1 Screws and nuts

In general, use connectors of the same type and class as those for similar fixings on the original vehicle (Table 2.7).

As a general rule, materials of class 8.8 are recommended. Class 8.8 and 10.9 screws must have been hardened and tempered. For

applications of diameter

in Table 2.2. A Dacromet finish is not recommended if the screws are to be subjected to welding. If space allows, use screws and

nuts with flanged heads. Use self-locking nuts. Nuts must be tightened using a torque wrench set to the correct torque setting for

the fixing.

± 6mm, stainless steel parts are recommended. Approved finishes are Dacromet and zinc coating, as detailed

Drilling the Chassis

Base - January 2008 Print 603.93.721

Page 37

STRALIS AS/AT/AD Euro 4/5

52036022%

Table 2.7 - Classes of resistance for screws

CHASSIS MODIFICATIONS

2-13

Class of resistance Usage

Tensile strength

(N/mm

2

)

Yield point

(N/mm

2

)

4 (1) Non-load bearing screws 400 320

5.8 (1) Low resistance screws 500 400

Medium resistance screws

8.8

(cross members, cleat plates,

800 640

brackets)

High resistance screws

10.9

(spring supports, anti-roll bars

1000 900

and shock absorbers)

(*) Do not use

2.3.2 Characteristics of the material to be used when modifying the chassis

When modifying the chassis of the vehicle, and in applications which reinforce the side members dire ctly, the material used must

correspond in quality (Table 2.8) and thickness (Table 2.9) to that of the original chassis.

Should it not be possible to source materials of the thickness indicated, the next greater thickness may be used (e.g. 1 mm instead

of 6.1 mm).

Table 2.8 - Material to be used to modify the chassis

Steel name

Tensile strength

(N/mm

2

)

Yield point

(N/mm

2

)

IVECO FeE490

Europe S500MC 610 490 19%

Germany QStE500TM

Alternatively, just for rear overhang extension.

IVECO Fe510D

Europe S355J2G3

Germany QSt52-3N

UK BS50D

A5 elongation

Drilling the Chassis

Print 603.93.721 Base- January 2008

Page 38

2-14

CHASSIS MODIFICATIONS

Table 2.9 - Chassis section dimension and thickness

S

TRALIS AS/AT/AD Euro 4/5

Model Wheelbase (mm)

AxBxt longitudinal pitch

section(See Figure 1.6)

AD/AT/AS 190 Up to 6300 289/199x80x6,7

AS260/FP/FS Up to 5100+1395 289/199x80x6,7

AS260 S/PT Only 5700, 6050 289x80x7.7

AS260 (6X4) 4500 289x80x7.7

IVECO recommends the following chassis extension pieces, available from theSpare PartDivision are used for chassis extensions.

2.3.3 Stresses on the chassis

Do not exceed the following stres s values under static conditions:

Table 2.10

Range Permitted static stress on the chassis (N/mm2) σ amm.

On road Off -road use

Stralis 150 100

When required by national regulations, the bodybuilder must check that the stress limits are not exceeded.

Welding activity will cause a deterioration in the characteristics of the material. There f o re , when checking the stresses in thermicall y -

modifie d zones, consider a reduction of app r ox. 15% of the resistance characteristi cs.

Drilling the Chassis

Base - January 2008 Print 603.93.721

Page 39

STRALIS AS/AT/AD Euro 4/5

CHASSIS MODIFICATIONS

2-15

2.3.4 Welding the Chassis

Welding operations must only be carried out by specialist, trained personnel, using suitable equipment

and in a perfectly workmanlike manner. Any intervention on the system not carried out as per instruc-

!

tions provided by IVECO or carried out by unskilled staff, might severely damage the on-board systems, thus adversely affecting vehicle operation safety and efficiency and causing damages not covered

by warranty.

Welding is permitted:

- When joining the sidemembers to extend or shorten the wheelbase or rear overhang.

- For the application of reinforcing L section flitch on a side member that is to be modified as detailed below (v. Figure 2.3).

Figure 2.3

When arc welding, the instructions below must be followed in order to protect electric units and ECUs:

- before disconnecting power cables, check to ensure all electrical items are switched off;

- where an electric switch is installed (battery isolation switch) wait for cycle end;

- disconnect negative power pole;

- disconnect positive power pole without connecting it to ground and DO NOT short circuit it with negative pole;

- disconnect ECUs connectors, carefully and do not touch ECU connector pins;

- when welding within the electronic control devices, disconnect them from the vehicle;

- connect welding machine ground directly to the part to be welded;

- protect plastic pipes against heat sources and remove, if nec essary;

- if welding near leaf springs or air springs protect against welding spatters;

- avoid electrode or gun contact with spring leaves;

91448

Drilling the Chassis

Print 603.93.721 Base- January 2008

Page 40

2-16

CHASSIS MODIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Operations for welding preparation

As part of the procedure it will be necessary to remove the paint and deoxidise the parts of the chassis that are affected by the

welding operation as well as those partswhich may have to becovered by possible reinforcements. When work has been completed

the modified part must be protected with adequate rustproofing (see point 2.2.2).

a) Cut the side members with a diagonal or vertical cut. (We recommend that the diagonal cut be used particularlyfor the section

between the wheelbase) Cuts are not permitted in areas in which the profile of the side member as well as the chassis width

change or in those where there is a high concentration of stresses (e.g. spring brackets). The cuts must not be made through

the holes present in the side member (see Figure 2.4).

Figure 2.4

YES

YES

91446

b) On the inner side of the side member give the parts that are to be joined a V-sh aped chamfer of 60° along the entire length

to be welded (see Figure 2.5).

c) Arc weld in stretches using carefully dried basic electrodes. The recommended electrodes are:

For S 500 MC (FeE490: QStE 500TM)

Diameter of the electrode is 2.5 mm, current intensity approx. 90A (max. 40A for each millimetre of diameter of the electrode).

Using MIG-MAG welding use a welding rod with th e same characteristics as the material to be welded (diameter 1 to 1.2 mm).

Recommended welding rod: DIN 8559 - SG3 M2 5243

gas DIN 32526-M21 or DIN EN 439

If FeE490 is used at very low temperatures, we recommend:

PrEN 440 G7 AWS A 5.28 - ER 80S - Ni 1

gas DIN EN439-M21

Avoid current overloading. Welding must be free from marginal cuts and waste material.

d) Repeat the operation on the reverse side by welding as detailed in point c).

e) Allow th e side members to cool slowly and uniformly. Cooling by air, water or other means is not permitted.

f) Remove excess material resulting from the welding operations by grinding.

Drilling the Chassis

Base - January 2008 Print 603.93.721

Page 41

STRALIS AS/AT/AD Euro 4/5

CHASSIS MODIFICATIONS

2-17

Figure 2.5

91447

g) On the inner side reinforcing L-section flitches should be applied. These should be made of steel and have the same characteris-

tics as the steel used for the chassis. The minimum dimensions are given in Figure 2.3.

The reinforcements may only be fixed to the vertical web of the side member using welding beads, plug welds, bolts or rivets

(Huck rivets may also be used).

The cross-section and the length of the weld bead, the number and distribution of the plug welds, bolts or rivets must be adequate to transmit the bending and shearing moment of the section.

2.3.5 Closing of existing holes

If, when making new holes, the existing holes are found to be too close (see Figure 2.2) these may be closed up by welding. To

ensure the success of this operation the outer edge of the hole should be chamfered and copper plate used for the inner part.

For holes with a diameter of over 20 mm, chamfered plugs may be used, welded on both sides.

Drilling the Chassis

Print 603.93.721 Base- January 2008

Page 42

2-18

CHASSIS MODIFICATIONS

ModifyingtheWheelbase

S

TRALIS AS/AT/AD Euro 4/5

2.4 Modifying the Wheelbase

2.4.1 General Specifications

Any change to the wheelbase affecting the electrical circuits and/or entailing a relocation of the electrical/electronic components must be approved and performed according to the instructions provided

!

in chapter 5.

As a rule, for each vehicle, modification to the wheelbase must be carried out on the standard wheelbase above or closer to

the new wheelbase required.

The measurements given in th e written authorisations will apply in all cases particularly for extensions made to the longest stan dard

wheelbase.

Frame cutting must be performed according to the indications given at point 2.3.4. Whenever permitted by the body size, wheelbases

should bemade equal to those planned inour production. This enables theoriginal transmission shafts and previously definedcrossmember positions to be used.

When extending a wheelbase beyond the production longest planned, the vehicle used must have the longest production wheelbase

to ensure the correct thickness side members are used. Particular care must betaken to comply with thelimits set by national regulations particularly with regard to t he limits for overall dimensions (where specified). Use only material shown at point 2.3.2.

2.4.2 Authorisation

The alteration of the wheelbase for the 4x2 versions is permitted without specific approval by IVECO in the following cases:

- If the wheelbase is to be lengthened and the new value is still within the standard range of length with the same side member

section. These sizes are given in the specific technical documentation or in Table 2.8 and Table 2.9.

- If the wheelbase is to be shortened without falling below the standard minimum values established for each model.

Provided the chassis converter gives sufficient guarantees from the technological and control point of view (qualified personnel,

adequate operating processes, etc.).

For the 6x2 and 6x4 versions the wheelbase may only be modified following specific approval by IVECO.

Conversion must be carried out performed in compliance with these instructionsby making the necessarychanges and adjustments

and taking the appropriate precautions (e.g., determining whether ECU parameters need updating, rearranging the exhaust pipes,

ensuring compliance with specific load limits on the rear axle, etc.), by taking into due account the requirements specified for the

original wheelbase lengths.

2.4.3 Effects on the steering

Generally, lengthening the wheelbase has a negative effect on the steering.

Whenever national regulations require it, the limits on the overall dimensions must be observed as well as the limits concerning

the effort applied on the steering wheel and the relevant operation times (e.g. ECE - R 79/01 standard or current EC Directive).

Tables 2.11 contain, the wheelbase extension limits for the various models, with series drive, at max load admissible on front axle

and with tires admissible on vehicle.

Should vehicles withlonger wheelbase beneeded, forspecial applications, itwill be necessary to fitvarious devices aimedat improving

the steering characteristics such as a reduction in th e maximum permitted load on the fron t axle or the installation of wheels and

tyres with shorter kingpin offset values (Table 2.17).

The fitting of an additional pump and a dual circuit power steering unit, if not immediately available, will require authorisation and

must only be installed by an authorised workshop.

Modifying the Wheelbase

Base - January 2008 Print 603.93.721

Page 43

STRALIS AS/AT/AD Euro 4/5

CHASSIS MODIFICATIONS

2-19

2.4.4 Effect on braking

Generall y, shortening the wheelbase has a negative effect on braking characteristics.

Table 2.11 gives the wheelbase alteration limits. Ask an authorised IVECO dealer for the conditions (brake cylinder, minimum tare

settings see section, technically permitte d masses, tyres, height of centre of gravity) under which these values are permissibl e .

Table 2.11 - Maximum permitted wheelbase lengthening depending on the load on the front axle and tyre dimensions

(ECE - R79/01 regulation and EG/70/311)

Max wheelbase value

between 1st steering

axle and 1st driving

axle (mm)

Kingpin offset

(mm)

Steering wheel

dia. (mm)

Models

AS/AD/AT 190

Max. load on front axle

(observe tyre carrying

capacity)

8000 6050 120 470

(without CM)

AS/AD/AT 190/FP-CM 8000

8000

AS/AD/AT 260 Y/P, Y/FP

8000 6050 120 470

5700

6700

120

120

470

510

(without CM)

AS/AD/AT 260 Z/P - HM 8000 6050 120 470

AS/AD/AT 260 Y/FP -CM 8000

8000

AS/AD/AT 260 Y/PS, Y/FS

7500

7500

(with CM)

8000

4500

5100

5700

6050

5700

120

120

120

120

120

470

510

470

510

470

AS/AD/AT 440TX/P (E5) 7500/7500 3140 120 470

AS/AD/AT 260XP 7500/7500 3140 120 470

FortyretypeseeTable2.17.

2.4.5 Recommended procedure

To ensure the success of the conversion proceed as follows:

- Arrange the vehicle so that the chassis is perfectly level, using the appropriate stands.

- Disconnect the propeller shafts, the braking system pipes, the wiring harness and any equipment that might prevent the work

being carried out correctly.

- Identify the reference points on the chassis (e.g. pilot holes, suspension supports).

- Mark the reference points with a light lineof punch markson the top flangeon both side membersafter ensuringthat their joining

line is perfectly at right-angles to the longitudinal axis of the vehicle.

- When re-positioning the spring hanger brackets, identify the new position using the reference marks made previously.

Check that the new measurements are identical between the left and right sides. Differences no greater than 2 mm should

emerge from diagonal checking of the lengths less than 1,500 mm.

Unless another tool is available, make new holes by using the supports and gussets of th e cross members as a template.

Fix the supports and cross members with rivets or bolts. If using bolts, fix the supports by reaming the holes and using class 10.9

calibrated bolts with nuts equippedwith a device that preventsthem from working loose.When space permitsit use flanged-head

screws and nuts.

- If cutting the chassis, make a second line of reference points so that the area affected by the modification is included between

these and the previous points (in any event ensure a distance of not less than 1500 mm. measured when the work has been

completed). Inside these two reference lines make points to mark out the area of the cut then proceed as indicated in point

2.3.4.

Before welding, ensure that the side members, including any added portion, are perfectly aligned and take measurements on

both sides and diagonally to check, as previously described. Fit the reinforcements as instructed at point 2.3.4.

Modifying the Wheelbase

Print 603.93.721 Base- January 2008

Page 44

2-20

CHASSIS MODIFICATIONS

S

TRALIS AS/AT/AD Euro 4/5

Further indications

- Protect the surfaces from oxidation as described in point 2.2.2.

- Restore the electrical and braking systems as described in points 2.15 and 5.5.

- For changes to the drive line follow the instructions given in point 2.8.

2.4.6 Chassis Stress Level

When lengthening a wheelbase, in addition to local reinforcement on the side member joint, the bodybuilder must provide sufficient reinforcements to achieve the section moduli of the side member section no lower than that designed by IVECO for the same

wheelbase or for next size up. Alternatively, when permitted by local regulations, larger subframe sections can be used.

The body builder shall verify that such stress is not greater than the one of the chassis with the original wheelbase, by assuming an

evenly distributed load and the chassis being considered as a beam resting on the suspension supports. In any case, more restrictive

limits (if an y) set by the national standards shall be complied with.

When extending out from the longest original wheelbase the reinforcements must depend on the length of the extension, the type

of body built and the use to which the vehicle is to be put.

2.4.7 Cross Members

The necessity of applying one or more additional cross members depends on the length of the extension, the location of the

transmission shaft support, the welding area, the introduction points of the forces produced by the body and the condition under

which the vehicle is to be used .

Any supplementary cross membersmust have the samefeatures as those already existing (flexural strength, torsional strength, quality

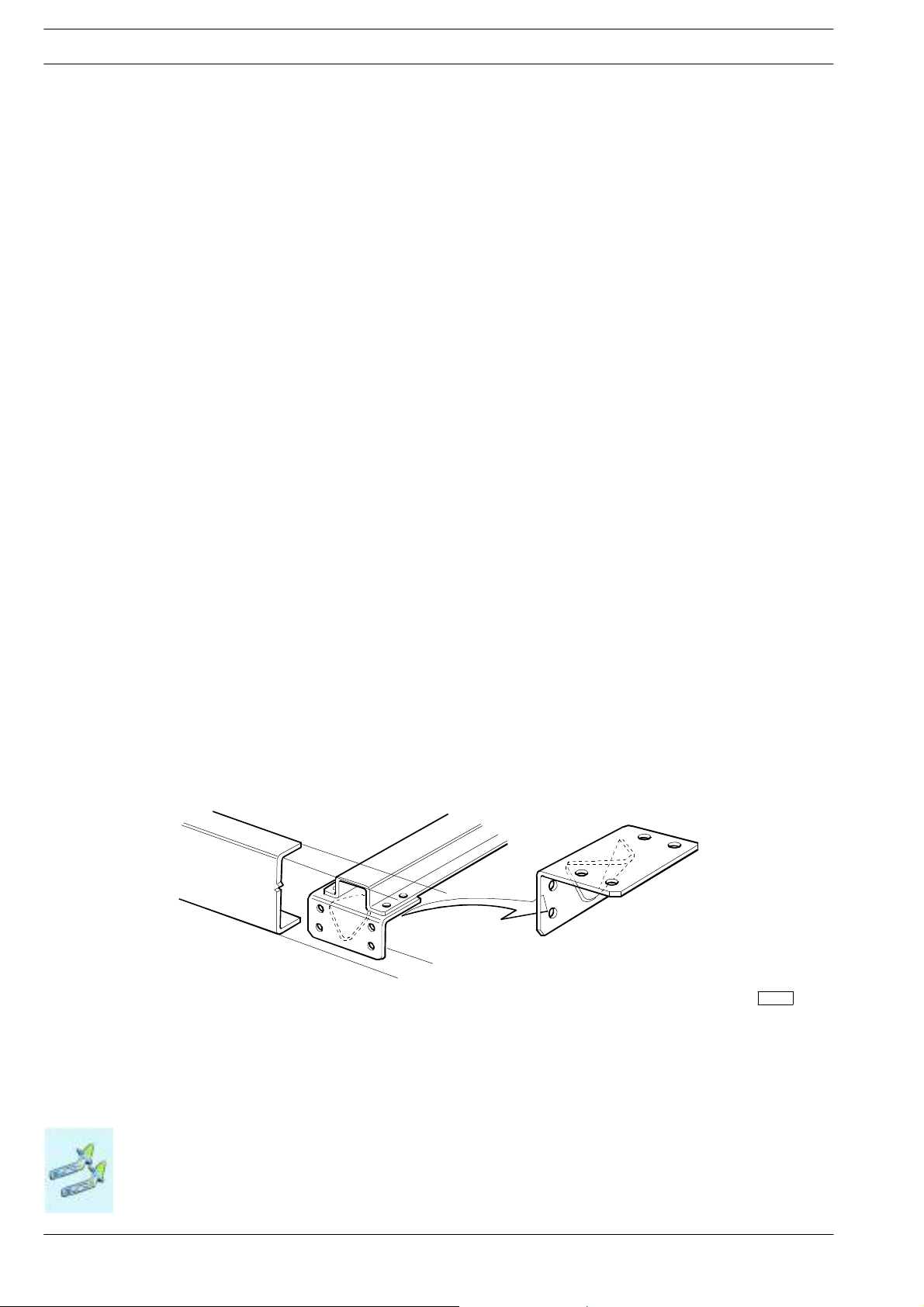

of thematerial, connection to the side members,etc). In Figure 2.6 shows anexample of the application. A crossmember is mandatory for any extension over 600 mm.

As a general rule the distance between the two cross members must not be greater than 1000 to 1200 mm.

The minimum distance between two cross members must not be less than 600 mm, particularly for heavy-duty and off-road use;

this limit does no t apply to the ”lightweight” transmission support cross member.

Figure 2.6

91449

2.4.8 Changes to transmissions

See chapter 2.8 for admissible c hanges.

Modifying the Wheelbase

Base - January 2008 Print 603.93.721

Page 45

STRALIS AS/AT/AD Euro 4/5

ModifyingtheR earOverhang

CHASSIS MODIFICATIONS

2-21

2.5 Modifying the Rear Overhang

2.5.1 General Specifications

In modifying the rear overhang it must be borne in mind that such modification entails changes in the distribution of the payload

on the axles relative to the loads established by IVECO (see point 1.13). The limitations established by national laws must also be

respected as well as t he maximum distance from the rear edge of the body and the ground clearance prescribed for the tow hook

and the underrun bar.The distance fromthe extremity of thec hassis to the rear edge of the body must not, as a general rule,exceed

350 to 400 mm.

Should the bolted rear cross member be re-positioned, the same standard type of connections shou ld be maintained (i.e. number

of screws, dimensions, class of resistance).

When re-positioning rear cross members fastened by rivets, these can be replaced by flanged nuts and bolts with same diameter

or by class 8.8 hexagonal-headed screws with the next largest diameter. Use self-locking nuts (do not use bolts with a diameter

larger than M14).

When the installation of a tow hook is planned an adequate distance (approximately 350 mm) must be left from the rear cross

member to the next nearest cross member for mounting and removing the tow hook wherever necessary.

If the modifications are carried out competently and in compliance with the specifications contained in this manual, the towable