Page 1

HP LaserJet 5000, 5000 N

English

and 5000 GN Printers

Service Manual

Page 2

HP LaserJet 5000, 5000 N, and

5000 GN Printers

Service Manual _____________

Page 3

© Copyright Hewlett-Packard

Company 1998

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except

as allowed under the cop yright

laws.

Publication number

C4110-91033

First Edition

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

Trademark Credits

PostScript

™

is a trademark of

Adobe Systems Incorporated

which may be registered in

certain jurisdictions.

™

CompuServe

is a U.S.

trademark of CompuServe, Inc.

®

Windows

is a U.S. registered

trademarks of Microsoft

Corporation.

™

TrueType

is a U.S. trademark

of Apple Computer, Inc.

NERGY STAR

E

®

is a U.S.

registered service mark of the

U.S. EPA.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 4

Contents

1 Printer Description

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Printer Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Model and Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Site Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Supported Types of Paper . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Guidelines for Using Paper. . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Transparencies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Vellum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Envelopes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Card Stock and Heavy Paper . . . . . . . . . . . . . . . . . . . . . . .1-20

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Laser Safety Statement . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

Canadian DOC Regulations . . . . . . . . . . . . . . . . . . . . . . . . 1-22

FCC Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Laser Statement for Finland . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Toner Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

Environmental Product Stewardship. . . . . . . . . . . . . . . . . . 1-26

EN

2 Service Approach

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Service Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Parts and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Helpful Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Phone Numbers for Ordering . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Exchange Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Toner Cartridge Information . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Contents

1

Page 5

3 Printer Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Using the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Control Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Control Panel Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Control Panel Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Settings and Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Control Panel Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Paper Handling Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Print Quality Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Printing Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

I/O Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

EIO Menu (Networked Printers) . . . . . . . . . . . . . . . . . . . . . 3-27

Resets Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Setting the Page Count, Maintenance Count,

and Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Cold Reset Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Clear Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Testing the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Resetting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

MS-DOS System Configuration . . . . . . . . . . . . . . . . . . . . . 3-37

Parallel DOS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Serial MS-DOS Commands . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Printer I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Parallel Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Serial Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

2 Contents

4 Printer Maintenance

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Cleaning the Printer and Accessories. . . . . . . . . . . . . . . . . . . . . 4-2

Cleaning Spilled Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Preventative Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Reset Maintenance Count . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Expected Life of Components. . . . . . . . . . . . . . . . . . . . . . . . 4-5

EN

Page 6

5 Functional Information

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Printer Subsystems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Power Supply System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

AC/DC Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Overcurrent Overvoltage Protection . . . . . . . . . . . . . . . . . . .5-5

High Voltage Power Distribution. . . . . . . . . . . . . . . . . . . . . . 5-6

Toner Cartridge Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

DC Controller System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Laser and Scanner Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Paper Motion Monitoring and Control. . . . . . . . . . . . . . . . . . 5-9

Solenoids, Sensors, Clutches, and Switches . . . . . . . . . . . . 5-9

Engine Test Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Formatter System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

PowerSave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Resolution Enhancement technology (REt) . . . . . . . . . . . . 5-13

EconoMode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Printer Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Random Access Memory (RAM) . . . . . . . . . . . . . . . . . . . .5-15

DIMM Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Memory Enhancement technology (MEt) . . . . . . . . . . . . . . 5-16

Page Protect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

PJL Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

PML. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Image Formation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Toner Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Photosensitive Drum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Writing the Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Developing the Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Transferring the Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Image Fusing/Variable Fusing Temperature. . . . . . . . . . . . 5-27

Paper Feed System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Clutches and Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Printing from Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-31

Printing from Tray 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

Printing from the Optional 500-sheet and

250-sheet Trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

Paper Jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

Paper Jam in the Duplexer . . . . . . . . . . . . . . . . . . . . . . . . .5-44

Basic Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

EN

Contents

3

Page 7

6 Removing and Replacing Parts

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

User Installable Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Removal and Replacement Strategy. . . . . . . . . . . . . . . . . . . . . . 6-7

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Removing Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Rear Door / Rear Output Bin. . . . . . . . . . . . . . . . . . . . . . . . 6-10

Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Control Panel Overlay and Control Panel. . . . . . . . . . . . . . 6-15

Toner Cartridge Door Assembly . . . . . . . . . . . . . . . . . . . . .6-17

Front Cover and Tray 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Front Cover Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Face Down Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Left and Right Side Covers. . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Tray 1 Inner Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Right and Left Corner Covers. . . . . . . . . . . . . . . . . . . . . . . 6-26

Removing Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Transfer Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Fuser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Paper Handling PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Main Gear Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Pickup Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Tray 1 Pickup Solenoid. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-39

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

Formatter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

Tray 1 Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-42

Tray 2 Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-43

Paper Feed Roller Assembly . . . . . . . . . . . . . . . . . . . . . . . 6-44

DC Controller Board and Power Supply . . . . . . . . . . . . . . .6-47

Paper Feed Belt Assembly . . . . . . . . . . . . . . . . . . . . . . . . .6-51

Tray 1 Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-53

Tray 2 Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-55

Tray 1 Lift Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-57

Tray 1 Separation Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-58

Paper Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

Paper Path Detect Sensor . . . . . . . . . . . . . . . . . . . . . . . . . 6-60

Face Down Bin Full Sensor . . . . . . . . . . . . . . . . . . . . . . . .6-61

Power Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63

Registration Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-64

Upper Delivery Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 6-66

Delivery Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . .6-68

Laser Scanner Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 6-70

Main Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-71

Toner Cartridge Guides . . . . . . . . . . . . . . . . . . . . . . . . . . .6-72

Power Inlet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-73

4 Contents

EN

Page 8

Optional 500-sheet Tray Disassembly . . . . . . . . . . . . . . . . . . .6-74

Tray Indicator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .6-76

Left Front Corner Cover Installation . . . . . . . . . . . . . . . . . . 6-77

Paper Size Spring Assembly . . . . . . . . . . . . . . . . . . . . . . .6-78

D-roller and Feed Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-79

Gear Assembly and PCA . . . . . . . . . . . . . . . . . . . . . . . . . . 6-81

Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-82

Separation Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-83

7 Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Troubleshooting Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Troubleshooting Process Flow . . . . . . . . . . . . . . . . . . . . . . . 7-4

Troubleshooting the Printing System . . . . . . . . . . . . . . . . . . . . .7-6

Preliminary Operating Checks . . . . . . . . . . . . . . . . . . . . . . . 7-6

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Printer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

General Paper Path Troubleshooting . . . . . . . . . . . . . . . . .7-41

Information Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Interface Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 7-77

Reference Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-80

Locations of Components. . . . . . . . . . . . . . . . . . . . . . . . . . 7-80

Sensors and Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-88

DC Controller PCA Inputs and Outputs . . . . . . . . . . . . . .7-107

EN

8 Parts and Diagrams

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

How To Use the Parts Lists and Diagrams . . . . . . . . . . . . . . . . .8-2

Accessories and Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Common Hardware and Replacement Cables . . . . . . . . . . .8-6

Illustrations and Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Alphabetical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-39

Numerical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

Index

Contents

5

Page 9

6 Contents

EN

Page 10

1

Printer Description

Overview

This chapter discusses the following:

Printer Features

●

Identification

●

Site Requirements

●

Paper Specifications

●

Safety Information

●

EN

Overview

1-1

Page 11

Printer Features

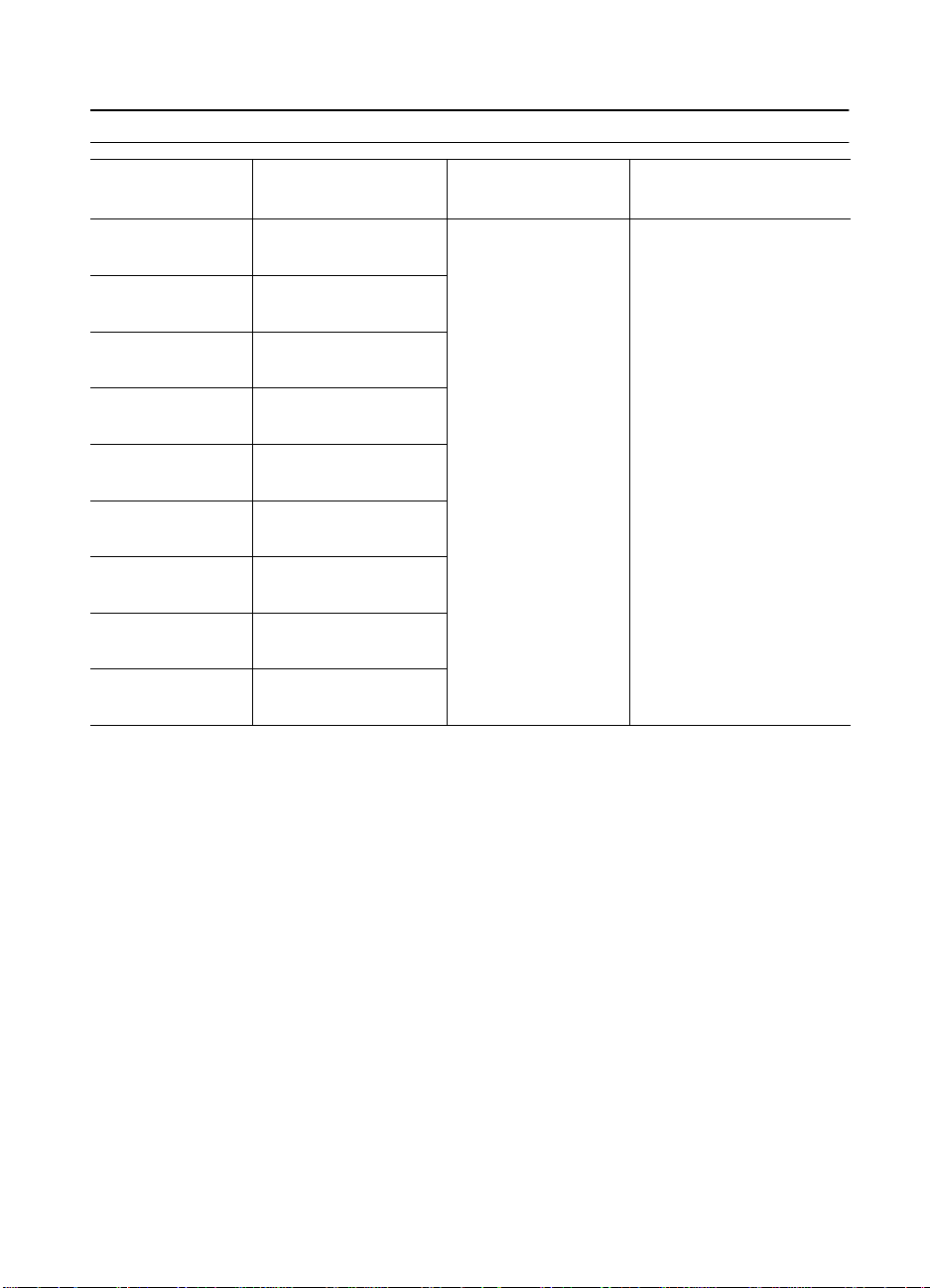

Table 1-1. Printer Features

Speed 17 pages per minute (ppm), A4 paper or 16 ppm, letter paper

100 MHz RISC microprocessor

First Page Out = 13 sec.

Resolution

Typefaces

Memory Options HP LaserJet 5000: 4 MB RAM standard

Expansion Slots 3 100-pin DIMM slots

Interface Bidirectional IEEE 1284 compliant parallel interface

300 dpi with PCL5e/PostScript

600 dpi with PCL5e/PS

HP FastRes 1200 (PCL6 only)

HP ProRes 1200 (PCL6, PS)

110 Scalable TrueType

and PCL accessible)

HP LaserJet 5000 N: 8 MB RAM standard

HP LaserJet 5000 GN: 12 MB RAM standard

Optional Memory:

2, 4, 8, 16 MB EDO DIMMs

32 MB SDRAM DIMM

2 enhanced I/O (EIO) slots

RS-232 9-pin serial

Paper Handling Connector (PHC)

TM

TM

Level 2 emulation (PS)

(80 built-in, 30 via FontSmart, all PS

Optional Networking 10Base-T and 10Base-2

10/100Base-TX

Token Ring

LocalTalk

Mass Storage Options 2 and 4 MB Flash DIMMs

1-2 Printer Description

EN

Page 12

Table 1-1. Printer Features (continued)

Paper Trays 100-sheet Tray 1

Size: 3 by 5 in (76 by127 mm) to 12.28 by 18.5 in

(312 by 470 mm)

Optional 250-sheet Tray 2 supports

Size: 5.8 by 8.2 in (149 by 210 mm) to 11 by 17 in (279 by 432)

Optional Universal 500-sheet Tray supports standard and custom

sizes from 5.8 by 8.2 in (149 by 210 mm) to 11 by 17 in

(279 by 432)

Paper Path Straight through from Tray 1 to rear output bin

Or to top output bin

Output Capacity 250-sheet top output bin

50-sheet rear output bin

Paper Handling Options Duplexer, optional 250-sheet and 500-sheet universal tray

assembly

EN

Printer Features

1-3

Page 13

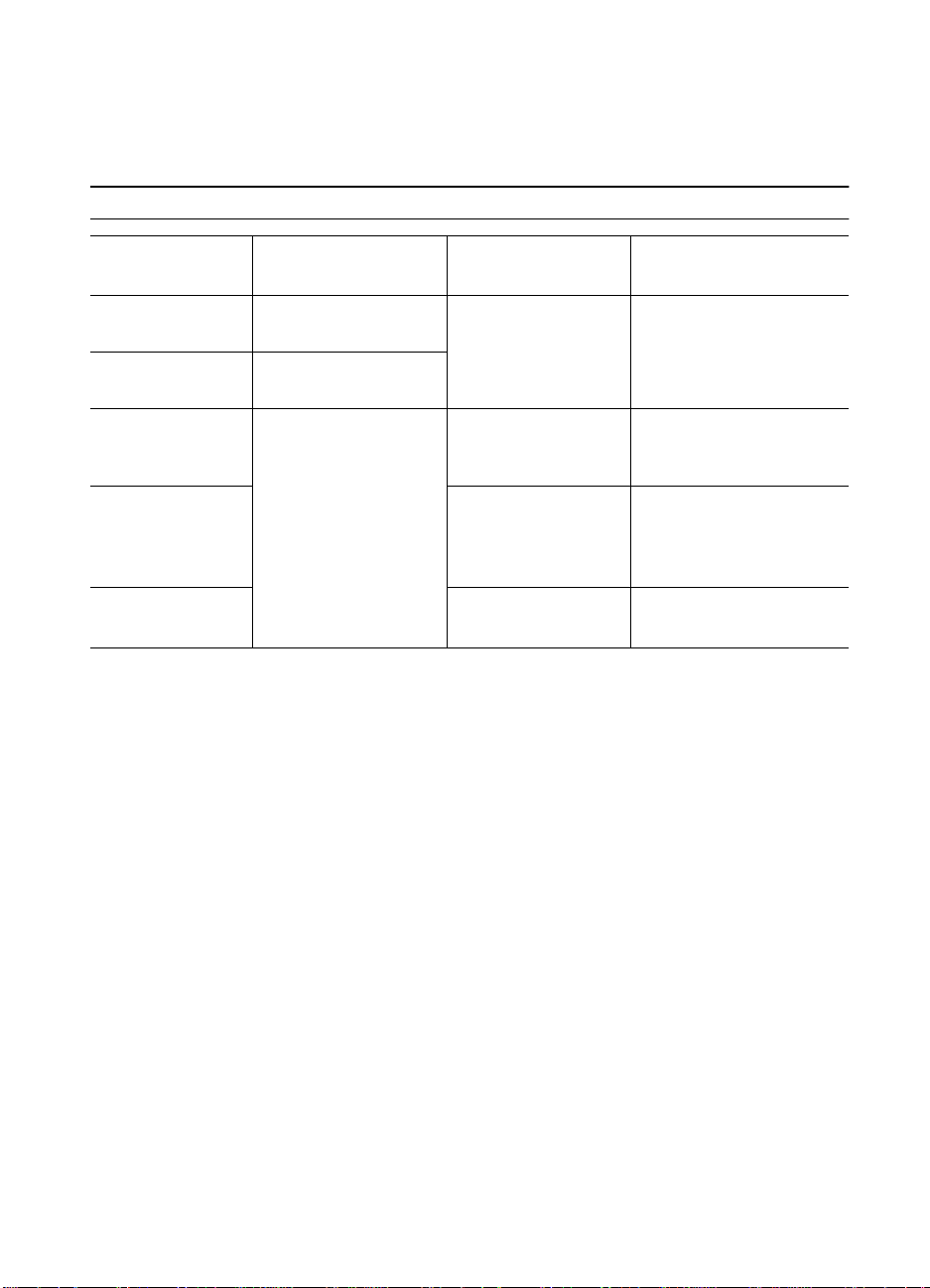

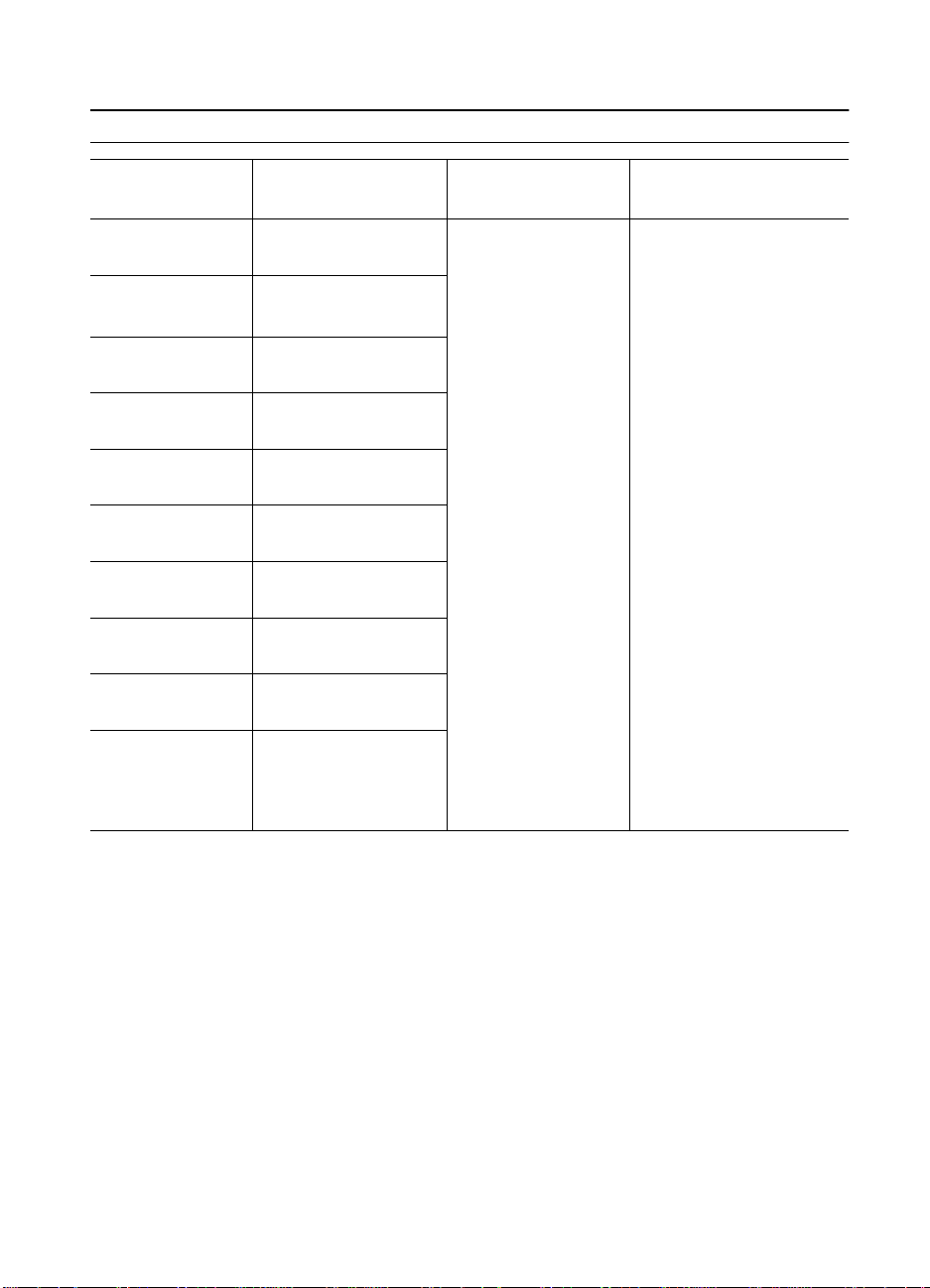

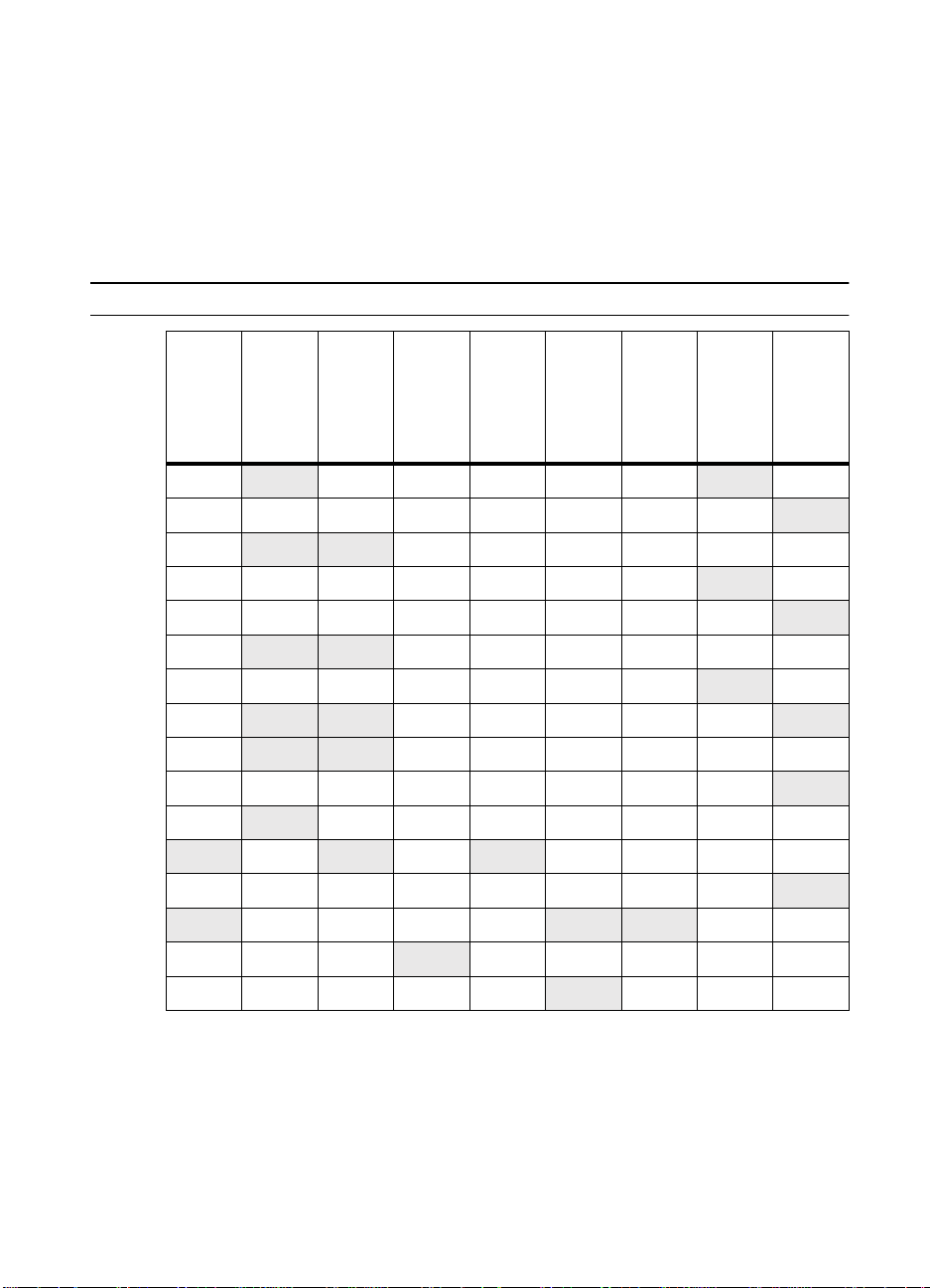

Table 1-2. Comparison of HP LaserJet 5000 Series Printers

HP LaserJet

5000

Ethernet 10-T/

10-2

Max. # input bins 444

Standard RAM 4 MB internal 8 MB

250-sheet Tray 1 standard

500-sheet

Universal Tray

1.4 GB EIO Drive optional optional standard

Duplexer optional optional optional

Envelope feeder not available not available not available

optional standard standard

1 optional

optional standard standard

HP LaserJet

5000 N

1

1 standard

1 optional

HP LaserJet

5000 GN

1

12 MB

1 standard

1 optional

LocalTalk optional standard standard

1. 4 MB internal, with remainder in DIMM

1-4 Printer Description

EN

Page 14

Identification

Model and Serial Numbers

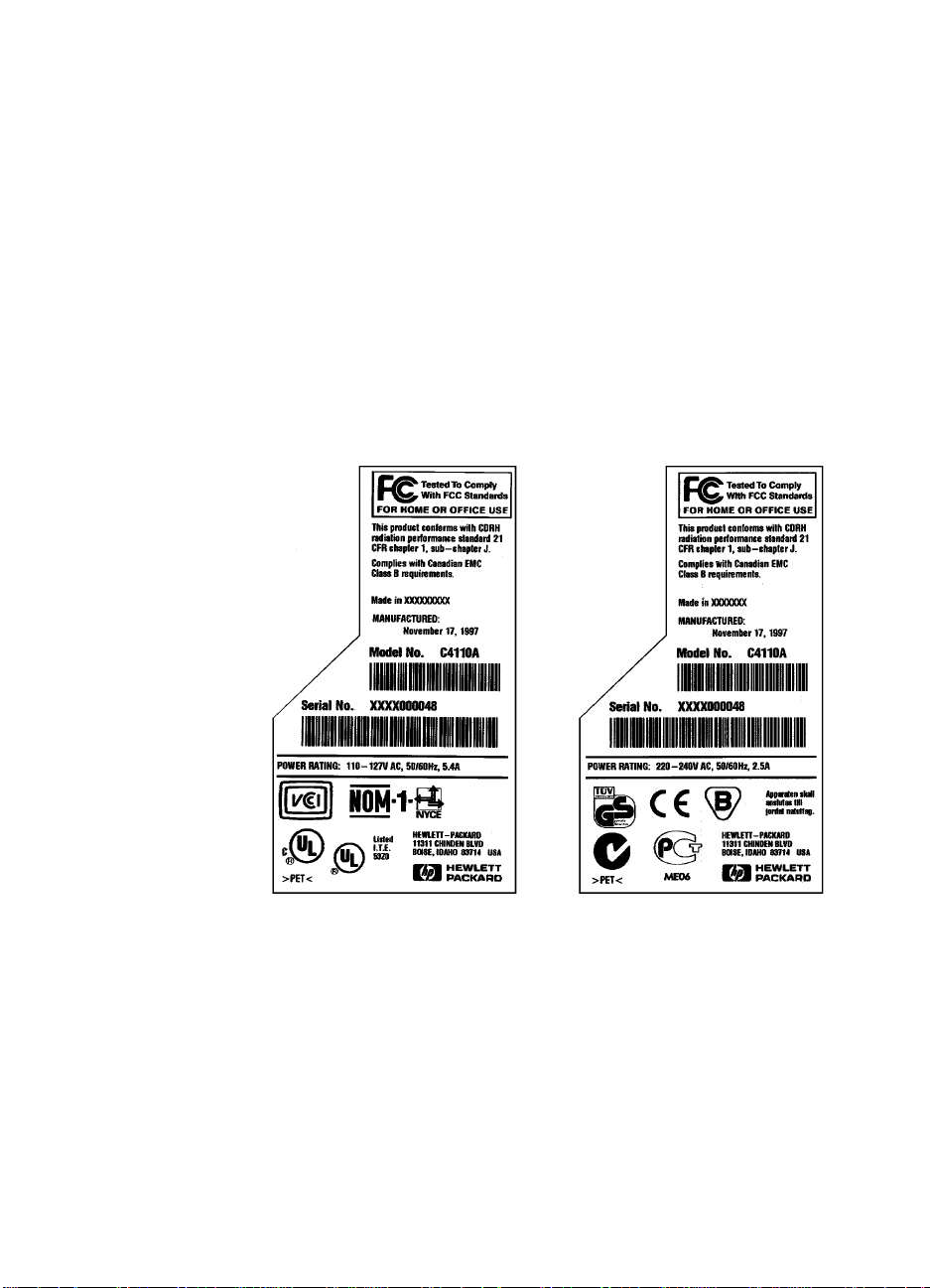

The model number and serial numbers are listed on identification

labels located on the rear left side of the printer. The serial number is

alphanumeric, such as USB0000146 for the HP LaserJet 5000 N

printer.

The serial number contains information about the Country of Origin,

the Revision Level, the Production Code, and Production Number of

the printer.

The rear labels also contain power rating and regulatory information

as shown in Figure 1-1.

Figure 1-1

EN

Sample Labels

Identification

1-5

Page 15

Site Requirements

The following environmental specifications must be maintained to

ensure the proper operation of the printer. Consider the following

points before installing the printer:

●

Install in a well-ventilated, dust-free area.

●

Install on a hard, flat and continuous surface, with all four printer

feet level. Do not install on carpet or other soft surfaces.

●

Ensure adequate power is supplied. Printer power requirements

are listed in Table 1-3.

●

Install where temperature and humidity is stable, aw a y from water

sources, humidifiers, air conditioners, refrigerators, or other major

appliances.

●

Install away from direct sunlight, open flames, or ammonia fumes.

If the printer is placed near a window, make sure the window has

a curtain or blind to block any direct sunlight.

●

Install with enough space around the printer for proper access

and ventilation.

●

Install printer away from the direct flow of exhaust from air

ventilation systems.

Table 1-3. Electrical Specifications

Volts Frequency Amps Watts (typical)

100-127 VAC±10% 50/60 Hz ±3Hz 11 amps printing = 365

standby = 40

PowerSave On = 27 (EPA

NERGY STAR

E

220-240 VAC±10% 50/60 Hz ±3Hz 5 amps printing = 355

standby = 40

PowerSave On = 22 (EPA

NERGY STAR

E

®)

®)

1-6 Printer Description

EN

Page 16

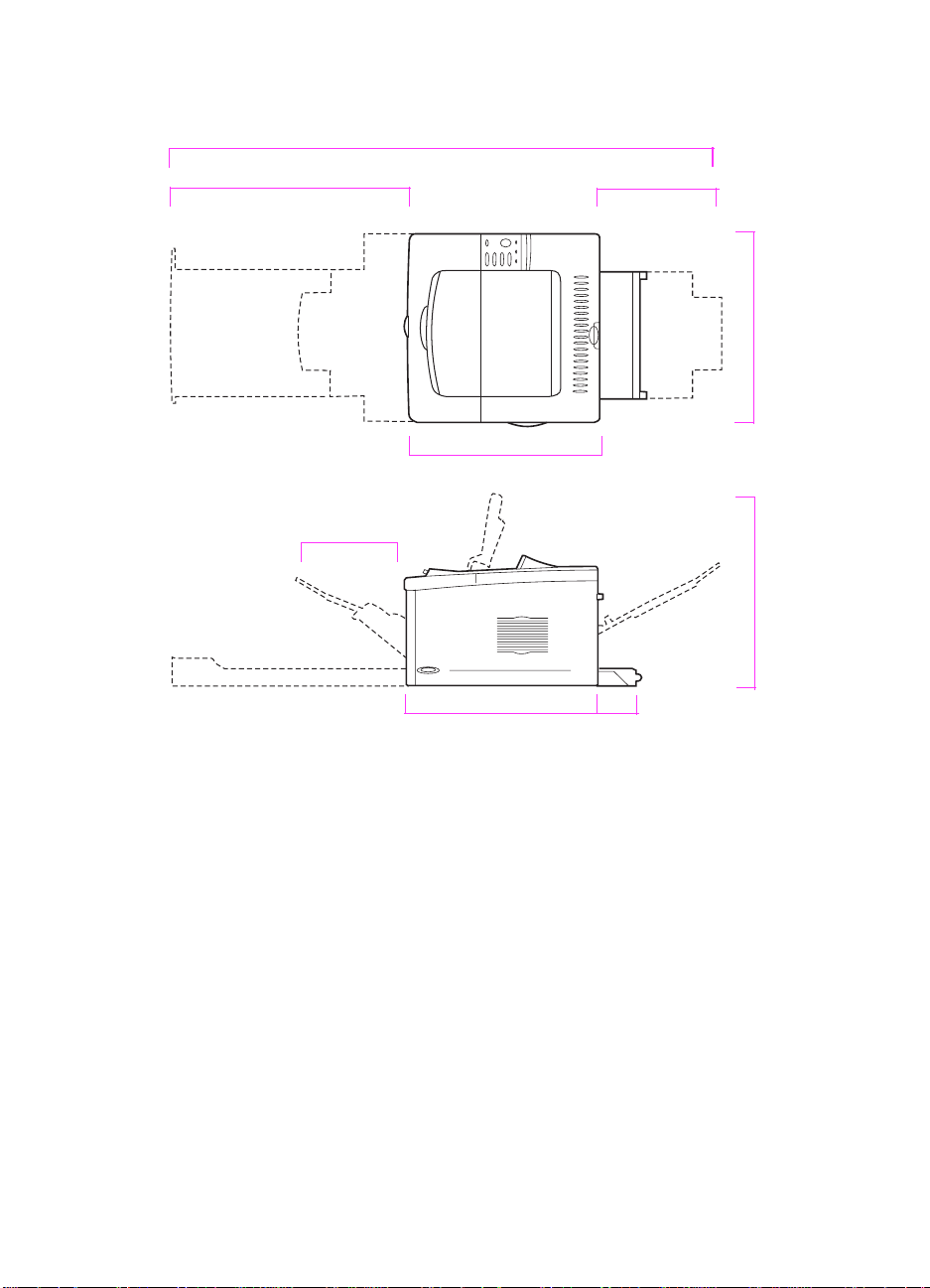

Space Requirements

55 in (139.8 cm)

18.5 in (47.0 cm)

10.6 in (27.0 cm)

11.9 in (30.3 cm)24.6 in (62.5 cm)

18.7 in (47.5 cm) 18.6 in (47.3 cm)

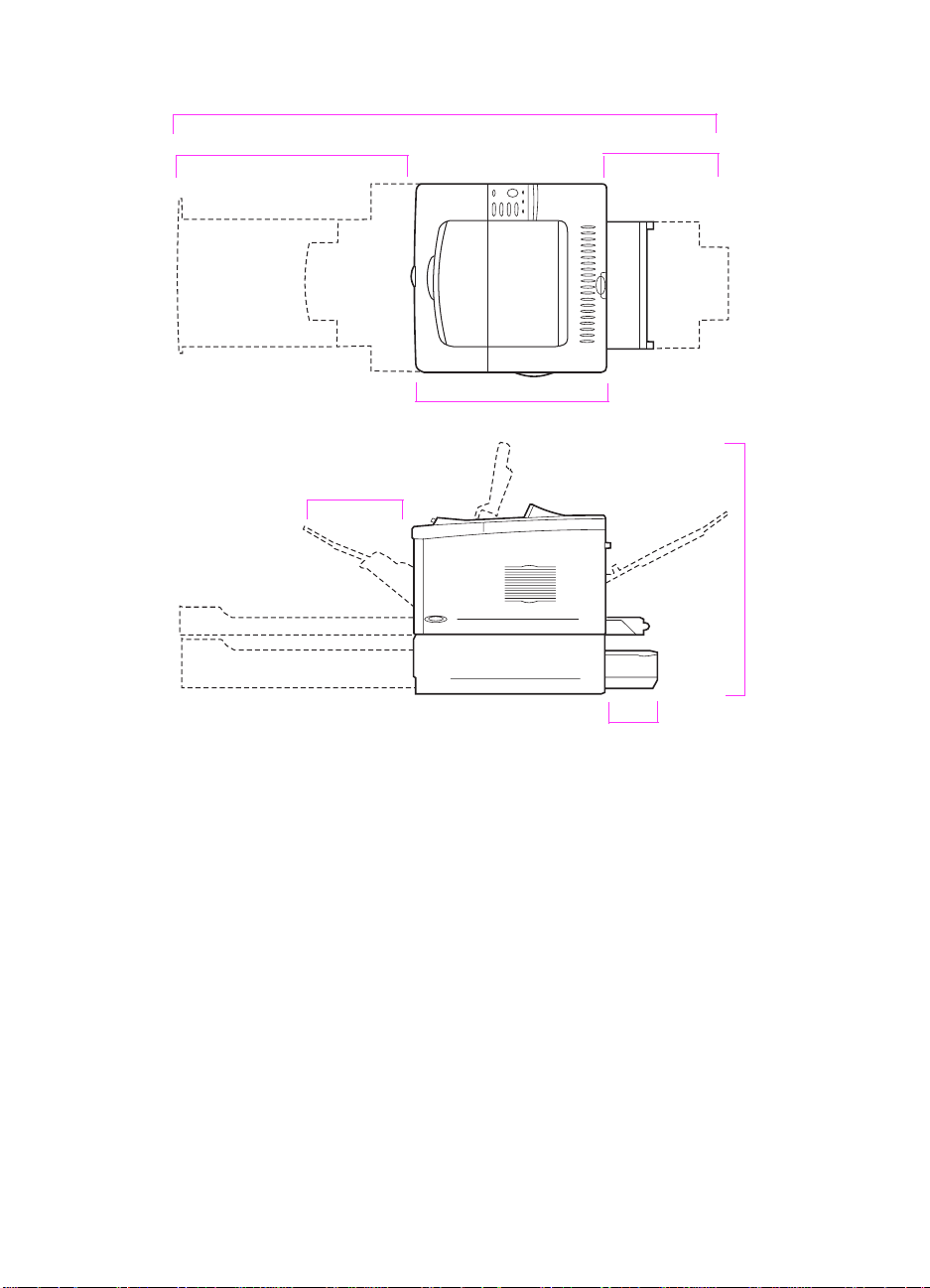

Figure 1-2

EN

18.5 in (47.0 cm)

Printer Dimensions, HP LaserJet 5000

4.3 in (11.0 cm)

Site Requirements

1-7

Page 17

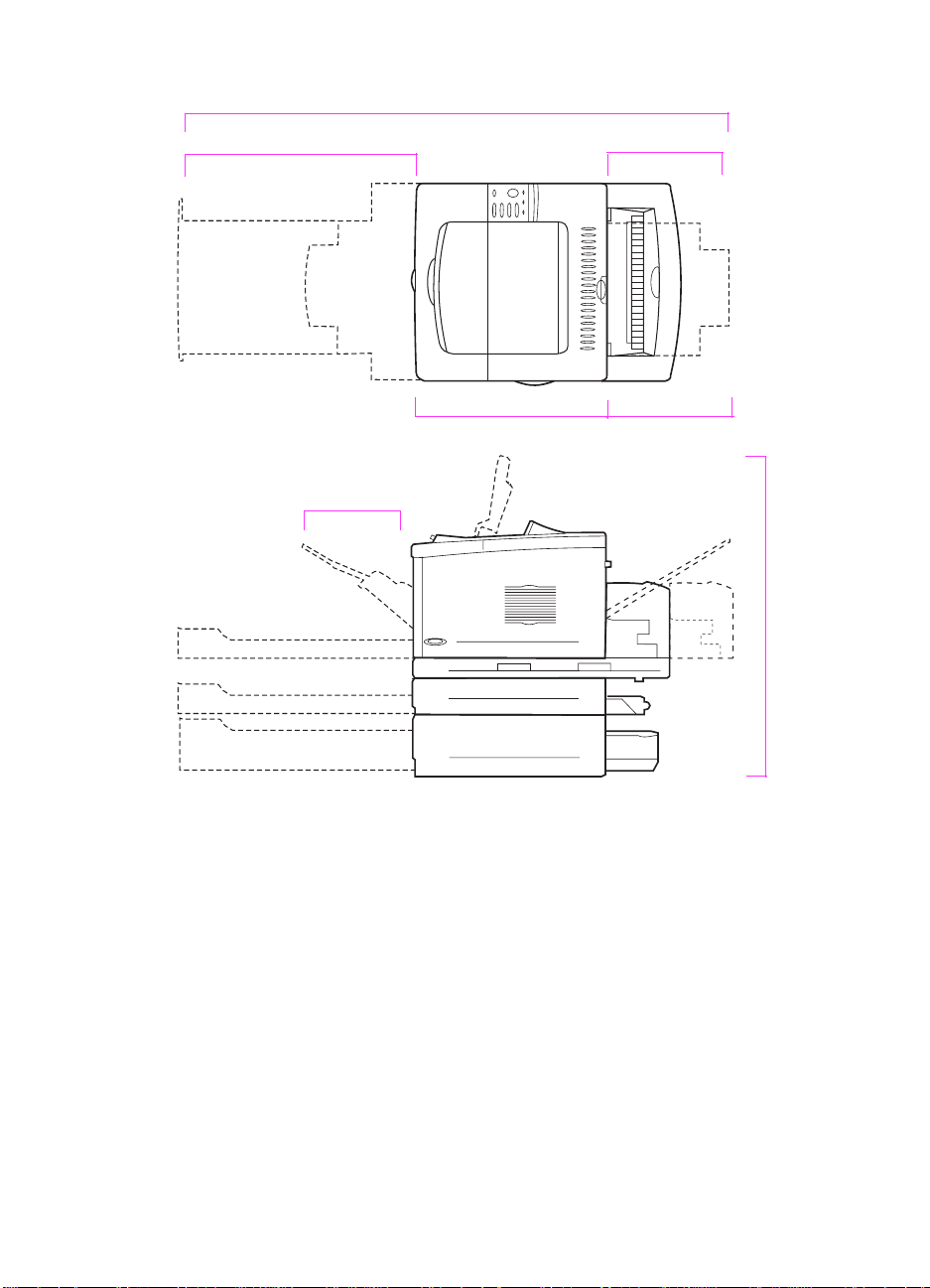

55 in (139.8 cm)

24.6 in (62.5 cm)

10.6 in (27.0 cm)

11.9 in (30.3 cm)

18.5 in (47.0 cm)

24.4 in (62.0 cm)

6.1 in (15.5 cm)

Figure 1-3 Printer Dimensions, HP LaserJet 5000 N/5000 GN

1-8 Printer Description

EN

Page 18

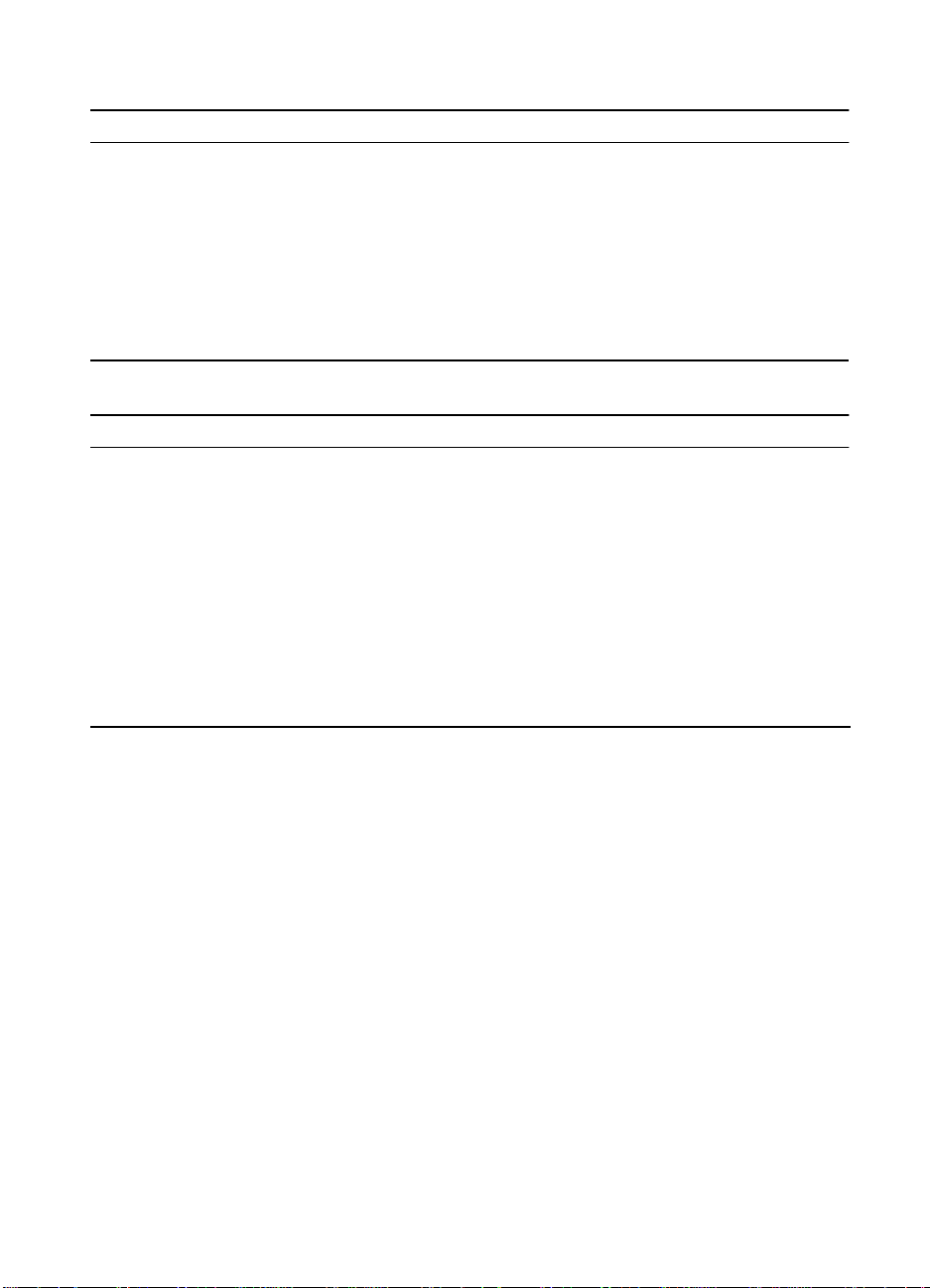

55 in (139.8 cm)

24.6 in (62.5 cm)

10.6 in (27.0 cm)

18.5 in (47.0 cm)

11.9 in (30.3 cm)

6.5 in (16.6 cm)

29.7 in (75.5 cm)

Figure 1-4

EN

Printer Dimensions, HP LaserJet 5000 with Accessories

Printer Weight (without toner cartridge)

HP LaserJet 5000 printer: 50 lb (23 kg)

●

HP LaserJet 5000 N/5000 GN printers: 75 lb (34 kg)

●

HP LaserJet 5000 N/5000 GN printers with duplexer and optional

●

250-sheet feeder: 114 lb (52 kg)

Site Requirements

1-9

Page 19

Environmental Requirements

Table 1-4. Printer and Toner Cartridge Environmental Conditions

Item Operating Storage

Temperature

Relative Humidity 20-80% RH (with no

°

50-91

F (10-32° C)

condensation)

Table 1-5. Acoustic Emissions (Per ISO 9296)

Printer State Sound Power

Printing, 16 pages per

minute (ppm)

Printing, 8 ppm L

PowerSave L

L

= 6.6 bels (A)

wad

= 6.3 bels (A)

wad

= 4.4 bels (A)

wad

-4 to 140°F (-20 to 60°C)

10% TO 95% RH

1-10 Printer Description

EN

Page 20

Paper Specifications

The following tables show paper specifications for the printer.

Table 1-6. Paper Specifications, Tray 1

Supported

Dimensions

1

Weight Capacity

2

Paper

Minimum Size

(custom)

Maximum Size

(custom)

Transparencies

Labels Thickness:

Envelopes 20 to 28 lb

3 by 5 in

(76 by 127 mm)

12.28 by 18.5 in

(312 by 470 mm)

Same as minimum

and maximum paper

sizes listed above.

16 to 53 lb

(60 to 199 g/m

Thickness:

0.0039 in to 0.0045 in

(0.099 to 0.114 mm)

0.005 in to 0.007 in

(0.127 mm to

0.178 mm)

(75 to 105 g/m

2

)

2

)

100 sheets of 20 lb

(75 g m2) paper

75 transparencies

50 labels

10 envelopes

1. The printer supports a wide range of paper sizes. Check the printer software

for supported sizes. To print custom-size paper see the User’s Guide.

2. Capacity may vary depending on paper weight and thickness, and environmental conditions.

EN

Paper Specifications

1-11

Page 21

Table 1-7. Paper Specifications, Tray 2 or Optional 250-sheet Tray

Supported

Dimensions

Paper

Letter 8.5 by 11 in

(216 by 279 mm)

A4 8.3 by 11.7 in

(210 by 297 mm)

Executive 7.3 by 10.5 in

(191 by 267 mm)

Legal 8.5 by 14 in

(216 by 356 mm)

B5 (JIS) 7.2 by 10 in

(182 by 257 mm)

A5 5.8 by 8.2 in

(148 by 210 mm)

11 x 17 11 by 17 in

(279 by 432 mm)

A3 11.7 by 16.5 in

(297 by 420 mm)

B4 (JIS) 10.1 by 14.3 in

(257 by 364 mm)

1

Weight Capacity

16 to 28 lb

(60 to 105 g/m

2

)

50-100 transparencies

2

250 sheets of 20 lb

(75 g/m

2

) paper

1. The printer supports a wide range of media sizes. Check the printer software

for supported sizes.

2. Capacity may vary depending on media weight and thickness, and environmental conditions.

1-12 Printer Description

EN

Page 22

Table 1-8. Paper Specifications, Optional 500-sheet Tray

Supported

Dimensions

Paper

Letter

Letter-R

A4

A4-R

Executive 7.3 by 10.5 in

Legal 8.5 by 14 in

B5 (JIS) 7.2 by 10 in

A5 5.8 by 8.2 in

11 by 17 11 by 17 in

A3 11.7 by 16.5 in

B4 (JIS) 10.1 by 14.3 in

Custom

3

3

4

8.5 by 11 in

(216 by 279 mm)

8.3 by 11.7 in

(210 by 297 mm)

(191 by 267 mm)

(216 by 356 mm)

(182 by 257 mm)

(148 by 210 mm)

(279 by 432 mm)

(297 by 420 mm)

(257 by 364 mm)

5.8 by 8.2 to

11.7 by 17 in

(148 by 210 to

297 by 432 mm)

1

Weight Capacity

16 to 28 lb

(60 to 105 g/m

2

)

50-100 transparencies

2

500 sheets of 20 lb

(75 g/m

2

) paper

1. The printer supports a wide range of media sizes. Check the printer software

for supported sizes.

2. Capacity may vary depending on media weight and thickness, and environmental conditions.

3. To print rotated paper see the User’s Guide.

4. To print custom-size paper see the User’s Guide.

EN

Paper Specifications

1-13

Page 23

Table 1-9. Paper Specifications, Optional Duplex Printing Accessory (Duplexer)

Dimensions

1

Weight

Minimum 5.8 by 8.3 inches

(148 by 210 mm)

Maximum 11.7 by 17 inches

16 to 28 lb

(60 to 105 g/m

2

)

(297 by 432 mm)

1. The printer supports a wide range of media sizes. Check the printer software

for supported sizes.

Supported Types of Paper

The printer supports the following types of paper:

●

plain

●

letterhead

●

prepunched

●

bond

●

color

●

rough

●

preprinted

●

transparency

●

labels

●

recycled

●

card stock

●

user-defined (5 types)

●

vellum

1-14 Printer Description

EN

Page 24

Guidelines for Using Paper

For best results, use con ventional 20 lb (75 g/m2) paper. Make sure

the paper is of good quality and free of cuts, nicks, tears, spots , loose

particles, dust, wrinkles, voids, and curled or bent edges.

Some paper causes print quality problems, jamming, or damage to

the printer.

For more specific information, see “Image Defects” on page 7-50.

Table 1-10. Guidelines for Using Paper

Symptom Problem with Paper Solution

Poor print quality or toner

adhesion.

Problems with feeding.

Dropouts, jamming, curl. Stored improperly . Store paper flat in its moisture-

Increased gray background

shading.

Excessive curl.

Problems with feeding.

Jamming, damage to printer. Cutouts or perforations. Do not use paper with cutouts

Problems with feeding. Ragged edges. Use quality paper.

Too moist, too rough, too

smooth, or embossed; faulty

paper lot.

Too heavy. Use lighter paper.

Too moist, wrong grain

direction or short-grain

construction.

Try another kind of paper,

between 100-250 Sheffield, 46% moisture content.

proof wrapping.

Open the rear output bin.

Open the rear output bin.

Use long-grain paper.

Set

PAPER REFORMING=ON

FUSER MODE=LOW

Set

or perforations.

.

.

EN

Paper Specifications

1-15

Page 25

Note Do not use letterhead paper that is printed with low-temperature inks,

such as those used in some types of thermography.

Do not use raised letterhead.

The printer uses heat and pressure to fuse toner to the paper. Make

sure that any colored paper or preprinted forms use inks that are

compatible with the printer’s temperature (392° F or 200° C for

0.1 second).

1-16 Printer Description

EN

Page 26

Paper Weight Equivalence Table

Use this table to determine approximate equivalent points in weight

specifications other than U.S. bond w eight. For e xample, to determine

the equivalent of 20 lb U.S. bond weight paper in U.S. cover weight,

locate the bond weight (in row 3, second column) and scan across the

row to the cover w eight (in the fourth column). The equivalent is 28 lb.

Shaded areas indicate a standard weight for that grade.

Table 1-11. Paper Weight Equivalence

U.S.

Post

Card1

thick-

ness

(mm)

U.S.

Bond

Weight

(lb)

U.S.

Text/

Book

Weight

(lb)

U.S.

Cover

Weight

(lb)

U.S.

Bristol

Weight

(lb)

U.S.

Index

Weight

(lb)

U.S. Tag

Weight

(lb)

Europe

Metric

Weight

(g/m2)

Japan

Metric

Weight

(g/m2)

1 16 41 22 27 33 37 60 60

2 17432429353964

3

4 215430364449

20 50 28 34 42 46 75 75

80 80

5 22563138465181

6

7 276837455561

8

9

24 60 33 41 50 55 90 90

100 100

28 70 39 49 58 65 105 105

32 80 44 55 67 74 120 120

10 34 86 47 58 71 79 128

11

12

.18 39 100 55 67 82 91 148 148

36 90 50 62 75 83 135 135

13 .19 42 107 58 72 87 97 157

64

81

128

157

14

15 .23 47 119

16 53 134 74 90

.20 43 110 60 74 90 100 163 163

65 80 97 108 176 176

110 122 199 199

1. U.S. Post Card measurements are approximate. Use for reference only.

EN

Paper Specifications

1-17

Page 27

Labels

CAUTION To avoid damaging the printer, use only labels recommended for use

in laser printers.

If you have problems printing labels, use T ray 1 and open the rear output

bin.

Never print on the same sheet of labels more than once.

Label Construction

When selecting labels, consider the quality of each component:

●

Adhesives: The adhesive material should be stable at 392° F

(200° C), the printer’s maximum temperature.

●

Arrangement: Only use labels with no exposed backing between

them. Labels can peel off of sheets that have spaces between the

labels, causing serious jams.

●

Curl: Prior to printing, labels must lie flat with no more than 0.5 in

(13 mm) of curl in any direction.

●

Condition: Do not use labels with wrinkles, bubbles, or other

indications of separation.

Transparencies

Transparencies used in the printer must be able to withstand 392° F

(200° C), the printer’s maximum temperature. For best results, close

the rear output bin to print transparencies to the top output bin.

CAUTION T o a void damaging the printer , use only transparencies recommended

for use in laser printers.

If you have problems printing transparencies, use Tray 1.

Vellum

Vellum is special lightweight paper similar to parchment. Print vellum

from Tray 1 only, and open the rear output bin. Do not print on both

sides of vellum.

Vellum used in the printer must be able to withstand 392° F (200° C),

the printer’s maximum temperature.

1-18 Printer Description

EN

Page 28

Envelopes

Envelope Construction

Envelope construction is critical. Envelope fold lines can vary

considerably, not only between manufacturers, but also within a box

from the same manufacturer. Successful printing on envelopes

depends upon the quality of the envelopes. When selecting

envelopes, consider the following components:

●

Weight:

28 lb (105 g/m

●

Construction:

The weight of the envelope paper should not exceed

2

), or jamming may result.

Prior to printing, envelopes should lie flat with less

than 0.25 in (6 mm) curl, and should not contain air. (Envelopes

that trap air may cause problems.)

●

Condition:

Make sure envelopes are not wrinkled, nicked, or

otherwise damaged.

●

Sizes in Tray 1:

From 3 by 5 in (76 by 127 mm) to 12.28 by 18.5

in (312 by 470 mm).

Always print envelopes from Tray 1. To prevent envelopes from

wrinkling or jamming, open the rear output bin.

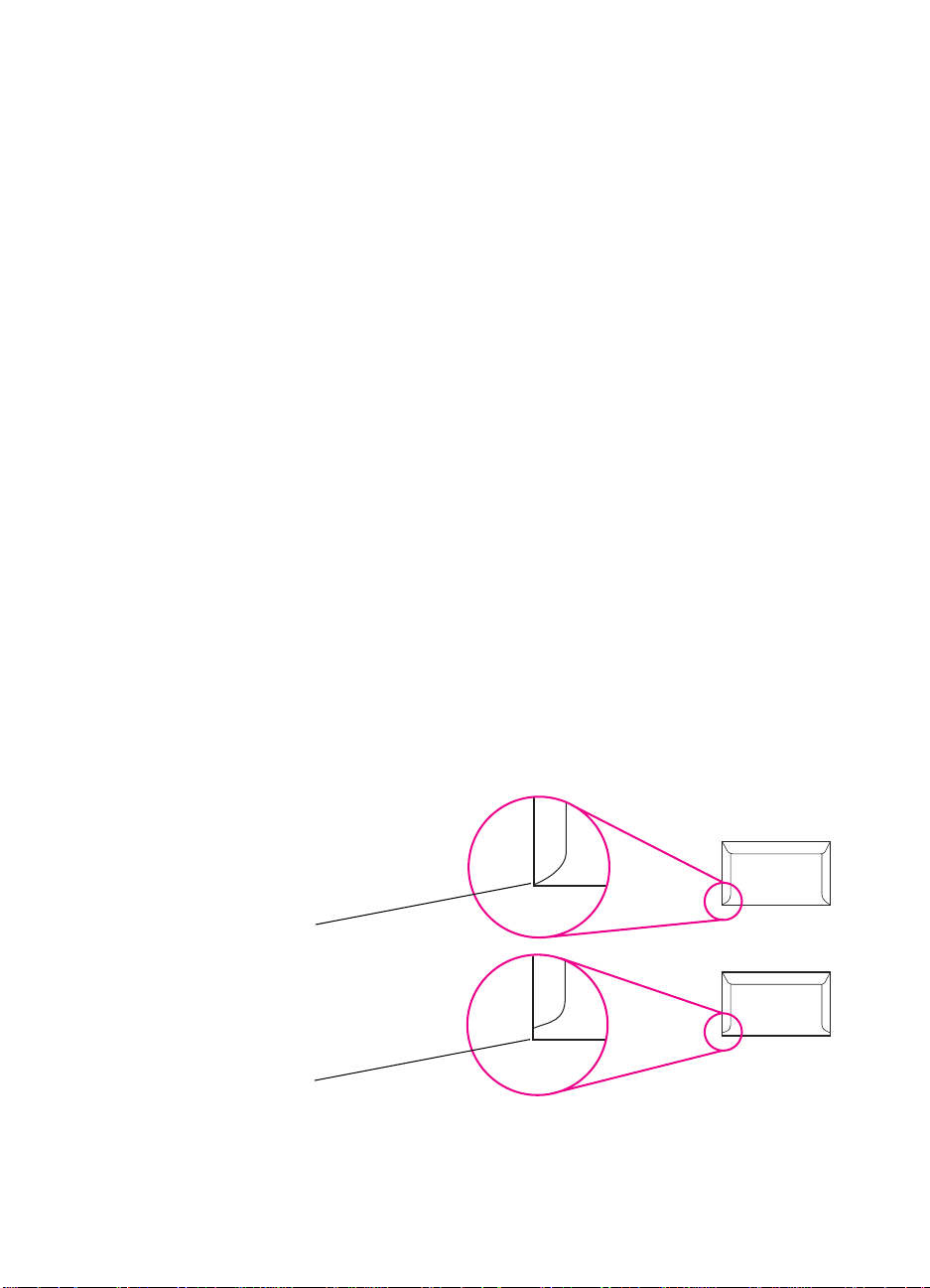

Envelopes with Double-Side-Seams

Double-side-seam construction has vertical seams at both ends of

the envelope rather than diagonal seams. This style may be more

likely to wrinkle. Be sure the seam extends all the wa y to the corner of

the envelope as illustrated below.

Figure 1-5

EN

Acceptable

Unacceptable

Envelopes with Double-Side-Seams

Paper Specifications

1-19

Page 29

Envelopes with Adhesive Strips or Flaps

Envelopes with a peel-off adhesive strip or with more than one flap

that folds over to seal must use adhesives compatible with the heat

and pressure in the printer. The extra flaps and strips might cause

wrinkling, creasing, or jams.

Envelope Margins

The following table gives typical address margins for a Commercial

#10 or DL envelope.

Table 1-12. Envelope Margins

Type of Address Top Margin Left Margin

Return Address 0.6 in (15 mm) 0.6 in (15 mm)

Delivery Address 2 in (51 mm) 3.5 in (89 mm)

Note For the best print quality , position margins no closer than 0.6 in (15 mm)

from the edges of the envelope.

Envelope Storage

Proper storage of envelopes helps contribute to good print quality.

Envelopes should be stored flat. If air is trapped in an envelope,

creating an air bubble, the envelope may wrinkle during printing.

Card Stock and Heavy Paper

Many types of card stock can be printed from Tray 1, including index

cards and postcards. Some card stock performs better than others

because its construction is better suited for feeding through a laser

printer.

For optimum printer performance, do not use paper hea vier than 53 lb

(199 g/m

too heavy might cause misfeeds , stacking problems , paper jams, poor

toner fusing, poor print quality, or excessive mechanical wear.

Note Printing on heavier paper may be possible if the tray is not filled to

capacity, and paper with a smoothness rating of 100-180 Sheffield is

used.

1-20 Printer Description

2

) in Tray 1 or 28 lb (105 g/m2) in other trays. Paper that is

EN

Page 30

Card Stock Construction

2

●

Smoothness:

36-53 lb (135-199 g/m

smoothness rating of 100-180 Sheffield. 16-36 lb (60-135 g/m

card stock should have a smoothness r ating of 100-250 Sheffield.

●

Construction:

Card stock should lie flat with less than 0.2 in

(5 mm) of curl.

●

Condition:

Make sure card stock is not wrinkled, nicked, or

otherwise damaged.

●

Use only card stock within the following size ranges:

Sizes:

• minimum: 3 by 5 in (76 by 127 mm)

• maximum: 12.28 by 18.5 in (312 by 470 mm)

) card stock should have a

2

)

Note

Before loading card stock in Tray 1, make sure it is regular in shape

and not damaged. Also, make sure the cards are not stuck together.

Card Stock Guidelines

If cards curl or jam, try printing from Tray 1 and opening the rear

●

output bin.

Set margins at least 0.08 in (2 mm) away from the edges of the

●

paper.

EN

Paper Specifications

1-21

Page 31

Safety Information

Laser Safety Statement

The Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration has implemented regulations for laser

products manufactured since August 1, 1976. Compliance is

mandatory for products marketed in the United States. The printer is

certified as a “Class 1” laser product under the U.S. Department of

Health and Human Services (DHHS) Radiation Performance

Standard according to the Radiation Control for Health and Safety Act

of 1968. Since radiation emitted inside the printer is completely

confined within protective housings and external covers, the laser

beam cannot escape during any phase of normal user operation.

WARNING! Using controls, making adjustments, or performing procedures other

than those specified in this service manual may result in exposure to

hazardous radiation.

Canadian DOC Regulations

Complies with Canadian EMC Class B requirements.

<<Conforme á la classe B des normes canadiennes de compatibilité

électromagnétiques. << CEM>>.>>

1-22 Printer Description

EN

Page 32

FCC Regulations

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy. If this

equipment is not installed and used in accordance with the

instructions, it may cause harmful interference to radio

communications. Howe ver, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

●

Increase separation between equipment and receiver.

●

Connect equipment to an outlet on a circuit different from that to

●

which the receiver is located.

Consult your dealer or an experienced radio/TV technician.

●

Note

Any changes or modifications to the printer that are not expressly

approved by HP could void the user’s authority to operate this

equipment.

Use of a shielded interface cable is required to comply with the Class B

limits of Part 15 of FCC rules.

EN

Safety Information

1-23

Page 33

Laser statement for Finland

Luokan 1 laserlaite

Klass 1 Laser Apparat

HP LaserJet 5000, 5000 N, 5000 GN -laserkirjoitin on käyttäjän

kannalta turvallinen luokan 1 laserlaite. Normaalissa käytössä

kirjoittimen suojakotelointi estää lasersäteen pääsyn laitteen

ulkopuolelle. Laitteen turvallisuusluokka on määritetty standardin EN

60825-1 (1994) mukaisesti.

Varoitus!

Laitteen käyttäminen muulla kuin käyttöohjeessa mainitulla tavalla

saattaa altistaa käyttäjän turvallisuusluokan 1 ylittävälle

näkymättömälle lasersäteilylle.

Varning!

Om apparaten används på annat sätt än i bruksanvisning

specificerats, kan användaren utsättas för osynlig laserstrålning, som

överskrider gränsen för laserklass 1.

HUOLTO

HP LaserJet 5000, 5000 N, 5000 GN -kirjoittimen sisällä ei ole

käyttäjän huollettavissa olevia kohteita. Laitteen saa avata ja huoltaa

ainoastaan sen huoltamiseen koulutettu henkilö. Tällaiseksi

huoltotoimenpiteeksi ei katsota väriainekasetin vaihtamista,

paperiradan puhdistusta tai muita käyttäjän käsikirjassa lueteltuja,

käyttäjän tehtäväksi tarkoitettuja ylläpitotoimia, jotka voidaan

suorittaa ilman erikoistyökaluja.

Varo!

Mikäli kirjoittimen suojakotelo avataan, olet alttiina näkymättömälle

lasersäteilylle laitteen ollessa toiminnassa. Älä katso säteeseen.

1-24 Printer Description

EN

Page 34

V arning!

Om laserprinterns skyddshölje öppnas då apparaten är i funktion,

utsättas användaren för osynlig laserstrålning. Betrakta ej strålen.

Tiedot laitteessa käytettävän laserdiodin säteilyominaisuuksista:

Aallonpituus 775-795 nm

Teho 5 mW

Luokan 3B laser

Material Safety Data Sheet

The Toner Cartridge/Drum MSDS can be obtained by calling the U.S.

HP FIRST (Fax Information Retrieval Support Technology) at (1)

(800) 231-9300. Use Index number 7 for a listing of the Toner

Cartridge/Drum Material/Chemical Safety Data Sheets. Non-U.S.

customers should refer to the support section of the User’s Guide for

appropriate phone numbers and information.

EN

Safety Information

1-25

Page 35

Environmental Product Stewardship

Protecting the Environment

Hewlett-Packard Company is committed to providing quality products

in an environmentally-sound manner. The printer has been designed

to minimize impacts on the environment.

The printer design eliminates:

Ozone

Production

Energy

Consumption

The printer does not use high-voltage corona wires in the

electrophotographic process and therefore generates no

appreciable ozone gas (O3). Instead, this printer uses charging

rollers in the toner cartridge and in the print engine.

This HP LaserJet printer design reduces:

Energy usage drops to as little as 21 W while in low-power

(Po werSave) mode. Not only does this save natural resources, but

it also saves money without affecting the high performance of this

printer. This product qualifies for the E

and Japan). E

NERGYSTAR

is a voluntary program established to

NERGYSTAR

encourage the dev elopment of energy-efficient office products.

E

NERGYSTAR

is a U.S. registered service mark of the U.S. EPA.

As an E

NERGYSTAR

partner, Hewlett-Packard

Company has determined that this product

meets E

efficiency

NERGYSTAR

.

Guidelines for energy

Program (U.S.

1-26 Printer Description

EN

Page 36

2

Service Approach

Overview

This chapter discusses the following:

Service Approach

●

Parts and Supplies

●

Warranty Statement

●

EN

Overview

2-1

Page 37

Service Approach

Repair of the printer normally begins with use of the printer’s internal

diagnostics in conjunction with the troubleshooting procedures in

Chapter 7. Once a faulty part is located, repair is generally

accomplished by assembly level replacement of Field Replaceable

Units (FRUs). Some mechanical assemblies may be repaired at the

subassembly lev el. PCA component replacement is not supported by

Hewlett-Packard.

2-2 Service Approach

EN

Page 38

Parts and Supplies

Ordering Information

Field replaceable and accessory part numbers are found in Chapter 8

of this manual. Replacement parts may be ordered from HP’s Support

Materials Organization (SMO) or Support Materials Europe (SME).

Use only accessories specifically designed for this printer.

Accessories can be ordered from an authorized service or support

provider. See page 2-5 and page 8-4 for more information.

EN

Parts and Supplies

2-3

Page 39

Helpful Documentation

Table 2-1 lists part numbers to order documentation.

Table 2-1. Helpful Documentation

Item Description or Use Part Number

HP LaserJet Printer Family

Paper Specification Guide

PCL 5/PJL Technical

Reference Documentation

Package

HP LaserJet 5000, 5000 N,

and 5000 GN Printers User’s

Guide

HP LaserJet 5000, 5000 N,

and 5000 GN Printers Getting

Started Guide

HP LaserJet 5000, 5000 N,

and 5000 GN Printers Quick

Reference Guide

User’s Documentation

Bundle, HP LaserJet 5000,

5000 N, and 5000 GN

A guide to using paper and

other print media with

HP LaserJet printers.

A guide to using printer

commands with HP LaserJet

printers.

An additional copy of the

user’s guide.

An additional copy of the

getting started guide.

An additional copy of the quick

reference guide.

An additional copy of the

user’s guide, the getting

started guide, and the quick

reference guide.

5021-8909

5021-0330

C4110-90901 (English)

C4110-90926 (English)

C4110-90976 (English)

C4110-99001 (English)

2-4 Service Approach

EN

Page 40

Phone Numbers for Ordering

SMO (Support Materials Organization)

●

1-800-227-8164 (U.S. only)

SME (Support Materials Europe)

●

(49 7031) 142253

Exchange Program

HP offers remanufactured assemblies for some parts. These are

identified in Chapter 8 and can be ordered through Support Materials

Organization (SMO), or Support Materials Europe (SME).

Consumables

Paper and Toner Cartridges can be ordered directly from HewlettPackard. See Chapter 8 for ordering information.

Technical Assistance

HP ASAP (Automated Support Access Program) provides free

technical support information 24 hours a day, 7 days a week. The

ASAP system includes HP AUDIO-TIPS and HP FIRST, both

explained below . The ASAP service 1-800-333-1917 (U .S.) requires a

touchtone phone.

EN

To order additional printer drivers for software applications, call HP’s

Distribution Center (HPD) 1-970-339-7009.

HP AUDIO-TIPS

HP AUDIO-TIPS is an interactive voice response system providing

prerecorded answers to the questions asked most frequently by

HP LaserJet printer users. Helpful “System Maps” to the HP AUDIOTIPS recordings are available by fax through HP FIRST.

Parts and Supplies

2-5

Page 41

HP FIRST

HP FIRST (Fax Information Retrieval Support Technology) is a

phone-in fax service that provides technical information for

HP LaserJet users as well as service personnel. Receiving a fax

requires a group 3 facsimile machine or fax card. Service related

information includes:

●

Service notes (HP Authorized dealers)

●

Application notes

●

Product Data Sheets

●

Material Safety Data Sheets (MSDS)

●

Typeface and accessory information

●

Printer support software information

●

Toner information

●

Driver request form and Software Matrix

HP FIRST, U.S.

Call the HP ASAP system (1-800-333-1917) and follow the voice

prompts to enter HP FIRST.

HP FIRST, Europe

Call HP FIRST at one of the following numbers:

U.K., 0800-96-02-71

Belgium (Dutch), 078-111906

Switzerland (German), 155-1527

Netherlands, 06-0222420

Germany, 0130-810061

Austria, 0660-8128

For English service outside the above countries,

call (31) 20-681-5792.

HP CompuServe Forum

CompuServe™ members can download a variety of support

materials including product data sheets, software application notes,

and printer drivers for many popular software applications. Members

may also post and reply to questions in an interactive format. To

access the HP Forum, type GO HP at any prompt. For more

information, or to join CompuServe, call 1-800-524-3388.

2-6 Service Approach

EN

Page 42

North American Response Center (NARC)

The North American Response Center (NARC) is available to assist

service technicians. The NARC can be reached at 1-800-544-9976.

Other Areas

Outside of North America and Europe, contact your local HP sales

office for assistance in obtaining technical support.

EN

Parts and Supplies

2-7

Page 43

Toner Cartridge Information

The Toner Cartridge is designed to simplify replacement of the major

“consumable” parts. The Toner Cartridge contains the printing

mechanism and a supply of toner.

At 5% page coverage, a Toner Cartridge will print approximately

10,000 pages. Howe v er, a T oner Cartridge should print more pages if

regularly printing pages with less coverage, such as short memos.

The cartridge may print fewer pages if routinely printing dense print.

Note For best results, always use a Toner Cartridge before the expiration

date stamped on the Toner Cartridge’s box.

Refilled Toner Cartridges

While Hewlett-Packard does not prohibit the use of refilled Toner

Cartridges during the warranty period or while the printer is under a

maintenance contract, it is not recommended for the following

reasons:

●

Repairs resulting from the use of refilled Toner Cartridges are not

covered under Hewlett-Packard warranty or maintenance

contracts.

●

Hewlett-Packard has no control or process to ensure that a

refilled Toner Cartridge functions at the high level of reliability of a

new HP LaserJet Toner Cartridge. Hewlett-Packard also cannot

predict what the long term reliability effect on the printer is from

using different toner formulations found in refilled cartridges.

●

The print quality of HP LaserJet Toner Cartridges influences the

customer’s perception of the printer. Hewlett-Packard has no

control over the actual print quality of a refilled Toner Cartridge.

Recycling Toner Cartridges

In order to reduce waste, Hewlett-Packard offers a recycling program

for used Toner Cartridges. Cartridge components that do not wear out

are recycled. Plastics and other materials are recycled. HP pays the

shipping costs from the user to the recycling plant. To join this

recycling effort, follow the instructions inside the Toner Cartridge’s

box.

2-8 Service Approach

EN

Page 44

Warranty Statement

This warranty gives specific legal rights. There may also be other

rights which vary from area to area. Refer to the User’s Guide for

further warranty information, or see the warranty card included with

the printer.

EN

Warranty Statement

2-9

Page 45

2-10 Service Approach

EN

Page 46

3

Printer Operation

Overview

This chapter discusses the following:

Using the Control Panel

●

Control Panel Menus

●

Service Mode

●

Testing the Printer

●

Resetting the Printer

●

System Configuration

●

Printer I/O Configuration

●

EN

Overview

3-1

Page 47

Using the Control Panel

Ready Data Attention

Go

Cancel

Job

Menu

Item

- Value +

Select

2-line

display

READY

Control Panel Layout

The printer’s Control Panel consists of the following:

Figure 3-1 Control Panel Layout

Control Panel Lights

Table 3-1. Control Panel Lights

Light Indication

Ready The printer is ready to print.

Data The printer is processing information.

Attention Action is required. See the Control Panel display.

3-2 Printer Operation

EN

Page 48

Control Panel Keys

Table 3-2. Control Panel Keys

Key Function

●

[Go]

Places the printer either online or offline.

●

Prints any data residing in the printer’s buffer.

●

Allows the printer to resume printing after being offline.

●

Clears most printer messages and places the printer online.

●

Allows the printer to continue printing with an error message

such as

PAPER SIZE

●

Confirms a manual feed request if Tray 1 is loaded and

TRAY 1 MODE=CASSETTE

Handling Menu in the printer’s Control Panel.

●

Overrides a manual feed request from Tray 1 by selecting

paper from the next available tray.

●

Exits the Control Panel menus. (To save a selected Control

Panel setting, first press

TRAY x LOAD [TY PE] [SIZE] or UNEXPECTED

.

has been set from the Paper

[Select]

.)

[Cancel Job]

[Menu]

[Item]

[- Value +]

[Select]

Cancels the print job that the printer is processing. The time it

takes to cancel depends on the size of the print job. (Press it only

once.)

Cycles through the Control Panel menus. Press the right end of

the button to move forward or the left end of the button to move

backward.

Cycles through the selected menu’s items. Press the right end of

the button to move forward or the left end of the button to move

backward.

Cycles through the selected menu item’s values. Press

move forward or

●

Saves the selected value f or that item. An asterisk (*) appears

next to the selection, indicating that it is the new default.

Default settings remain when the printer is switched off or

reset (unless you reset all factory defaults from the Resets

Menu).

●

Prints one of the printer information pages from the Control

Panel.

[-]

to move backward.

[+]

to

EN

Using the Control Panel

3-3

Page 49

Settings and Defaults

The printer makes most printing decisions based on either temporary

settings or permanent defaults.

Note Settings sent from software applications override printer defaults.

Table 3-3. Settings and Defaults

Setting or Default Explanation

Temporary Setting A value set for the current print job by the software application.

For example, a request from the software to print three copies

instead of the Control Panel default value of one copy is a

temporary setting. The printer continues to use the temporary

setting until it receives another software request or until it is reset.

Control Panel Default A value set at the Control Panel when you select a menu item. An

asterisk appears, indicating the default setting. The printer retains

this default when it is turned off.

Factory Default The value set for each menu item at the factory. Factory defaults

are listed in the item column in the menu tables starting on page

3-6.

Setting the Display Language

1 Press and hold [Select] while turning on the printer. Hold [Select]

until SELECT LA NGUAGE appears.

2 Release [Select]. INITIALIZING appears briefly. Wait for

LANGUAGE=ENGLISH to appear.

3 Press [- Value +] repeatedly until the desired language appears.

4 Press [Select] to save your choice. An asterisk (*) will appear

beside the selected language.

5 Press [Go] to exit menu.

3-4 Printer Operation

EN

Page 50

Control Panel Menus

Press [Menu] for access to all Control Panel menus. When additional

trays or other accessories are installed in the printer, ne w menu items

automatically appear.

To change a Control Panel setting:

Press [Menu] until the desired menu appears.

1

Press [Item] until the desired item appears.

2

Press [- Value +] until the desired setting appears.

3

Press [Select] to save the selection. An asterisk (*) appears next

4

to the selection in the display, indicating that it is now the default.

Press [Go] to exit the menu.

5

Note

Settings in the printer driver and software application override Control

Panel settings. (Software application settings override printer driver

settings.)

If you cannot access a menu or item, it is either not an option for the

printer, or the customer’ s network administrator has locked the function.

(The Control Panel reads ACCESS DENIE D MENUS LOCKE D.) See the

customer’s network administrator.

To print a Control Panel menu map:

To see the current settings for all of the menus and items available in

the Control Panel, print a Control Panel menu map.

Press [Menu] until INFORMATION MENU appears.

1

Press [Item] until PRINT MENU MA P appears.

2

Press [Select] to print the menu map.

3

EN

Control Panel Menus

3-5

Page 51

Information Menu

This menu contains printer information pages that give details about

the printer and its configuration. To print an information page, scroll to

the desired page and press [Select].

Table 3-4. Information Menu

Item Explanation

PRINT

MENU MAP

PRINT CONFIGURA TION

PRINT

PCL FONT LIST

PRINT

PS FONT LIST

PRINT

FILE DIR ECTORY

PRINT

EVENT LOG

The menu map shows the layout and current settings of the

Control Panel menu items.

The Configuration Page shows the printer’s current configuration.

If an HP JetDirect print server card is installed (HP LaserJet

5000 N/5000 GN printers), a JetDirect Configuration Page will

print out as well.

The PCL font list shows all the PCL fonts currently a v ailable to the

printer.

The PS font list shows all the PS fonts currently available to the

printer.

This item appears only when a mass storage device (such as an

optional flash DIMM or hard disk) containing a recognized file

system is installed in the printer. The file directory shows

information for all installed mass storage devices.

The event log lists printer events or errors.

SHOW

EVENT LOG

PRINT

PAPER PATH TEST

3-6 Printer Operation

This item allows you to view the most recent printer e v ents on the

Control Panel display. Press

log entries.

The paper path test can be used to verify that the paper path is

working properly, or to troubleshoot problems with a type of

paper.

Choose the input tray, output bin, duplexer (if available), and

number of copies.

[-V alue+]

to scroll through the event

EN

Page 52

Paper Handling Menu

When paper handling settings are correctly configured through the

Control Panel, you can print by choosing the type and size of paper

from the printer driver or software application.

Some items in this menu (such as duplex and manual feed) can be

accessed from a software application, or from the printer driver (if the

appropriate driver is installed). Printer driver and software application

settings override Control Panel settings.

Table 3-5. Paper Handling Menu

Item Values Explanation

TRAY 1 MODE=

FIRST

TRAY 1 SIZE=

LETTER

TRAY 1 TYPE=

PLAIN

TRAY 2 TYPE=

PLAIN

FIRST

CASSETTE

For supported paper types

see page 1-14.

For supported paper types

see page 1-14.

For supported paper types

see page 1-14.

Determine how the printer will use

Tray 1.

FIRST

: If paper is loaded in Tray 1,

the printer will pull paper from that

tray first.

CASSETTE

assigned to Tray 1 using the

TRAY 1 SIZE

in this menu when

MODE=CA SSETTE

Tray 1 to be used as a reserved tray.

This item appears only when

MODE=

correspond with the paper size

currently loaded in Tray 1.

This item appears only when

MODE=

correspond with the paper type

currently loaded in Tray 1.

Set the value to correspond with the

paper type currently loaded in Tray 2.

:

A paper size must be

option (the next item

TRAY 1

). This allows

CASSETTE

CASSETTE

. Set the value to

. Set the value to

TRAY 1

TRAY 1

TRAY 3 TYPE=

PLAIN

EN

For supported paper types

see page 1-14.

This item appears only when a third

paper tray is installed. Set the value

to correspond with the paper type

currently loaded in Tray 3.

Control Panel Menus

3-7

Page 53

Table 3-5. Paper Handling Menu (continued)

Item Values Explanation

TRAY 4 TYPE=

PLAIN

For supported paper types

see page 1-14.

MANUAL FEED=OFF OFF

ON

DUPLEX=OFF OFF

ON

BINDING=

LONG EDGE

LONG EDGE

SHORT EDGE

This item appears only when a fourth

paper tray is installed. Set the value

to correspond with the paper type

currently loaded in Tray 4.

Feed the paper manually from Tray 1,

rather than automatically from a tray.

MANUAL FEED=ON

When

is empty, the printer goes offline

when it receives a print job and

displays

SIZE]

This item appears only when an

optional duplexer is installed. Set the

value to

(duplex) or

(simplex) of a sheet of paper.

This item appears only when an

optional duplexer is installed and the

duplex option is on. Choose the

binding edge when duplexing

(printing on both sides of paper).

MANUALLY FEED [PAPER

.

to print on both sides

ON

to print on one side

OFF

and Tray 1

OVERRIDE A4 WITH

LETTER=NO

3-8 Printer Operation

NO

YES

Choose

paper when an A4 job is sent, but no

A4 size paper is loaded in the printer

(or to print on A4 size paper when a

letter job is sent, but no letter paper

is loaded in the printer).

to print on letter size

YES

EN

Page 54

Table 3-5. Paper Handling Menu (continued)

Item Values Explanation

CONFIGURE FUSE R MODE

MENU=NO

[TYPE ]=

NORMAL

NO

YES

NORMAL

LOW

HIGH

VELLU M

Configure the fuser mode associated

with each paper type. (This is only

necessary if you are experiencing

problems printing on certain paper

types.)

:

The fuser mode menu items are

NO

not accessible.

:

Additional items appear (see

YES

below).

Note

To see the default fuser mode for

each paper type, select

back to the Information Menu, and

print a menu map (page 3-6).

This item appears only when

YES

, scroll

CONFIGURE FUSE R MODE

MENU=YES

to

NORMAL

. Most paper types are set

by default.

ROUGH=HIGH

VELLUM=VE LLUM

For a complete list of supported paper

types, see page 1-14.

EN

Control Panel Menus

3-9

Page 55

Print Quality Menu

Some items in this menu can be accessed from a software

application, or from the printer driver (if the appropriate driver is

installed). Printer driver and software application settings override

Control Panel settings.

Table 3-6. Print Quality Menu

Item Values Explanation

RESOLUTION=

FASTRES 1200

300

600

FASTRE S 1200

PRORE S 1200

Select the resolution from the

following values:

:

300

Produces draft print

quality at the printer’s

maximum speed (16 ppm).

300 dpi (dots per inch) is

recommended for some

bitmapped fonts and graphics,

and for compatibility with the

HP LaserJet III family of

printers.

:

600

Produces high print

quality at the printer’s

maximum speed (16 ppm).

FASTRE S 1200

optimum print quality

(comparable to 1200 dpi) at

the printer’s maximum speed

(16 ppm).

PRORE S 1200

optimum print quality (true

1200 dpi) at half the printer’s

maximum speed (8 ppm).

When the resolution is

changed, any downloaded

resources (such as fonts or

macros) will need to be

downloaded again, unless

they are stored on an optional

hard disk or flash DIMM.

:

Produces

:

Produces

Note

It is best to change the

resolution from the printer

driver or software application.

(Driver and software settings

override Control Panel

settings.)

3-10 Printer Operation

EN

Page 56

Table 3-6. Print Quality Menu (continued)

Item Values Explanation

RET=ME DIUM OFF

LIGHT

MEDIUM

DARK

ECONOMODE =OFF OFF

ON

Use the printer’s Resolution

Enhancement technology

(REt) setting to produce print

with smooth angles, curves,

and edges.

REt does not affect print

quality when the print

resolution is set to

ProRes 1200. All other print

resolutions, including

FastRes 1200, benefit from

REt.

Note

It is best to change the REt

setting from the printer driver

or software application. (Driver

and software settings override

Control Panel settings.)

Turn EconoMode on (to save

toner) or off (for high quality).

EconoMode creates draftquality printing by reducing the

amount of toner on the printed

page by up to 50%.

Caution

HP does not recommend fulltime use of EconoMode. (If

EconoMode is used full-time, it

is possible that the toner

supply will outlast the

mechanical parts in the Toner

Cartridge.)

Note

It is best to turn EconoMode

on or off from the printer driver

or software application. (Driver

and software settings override

Control Panel settings.)

EN

Control Panel Menus

3-11

Page 57

Table 3-6. Print Quality Menu (continued)

Item Values Explanation

TONER D ENSITY=3 1

CREA TE CLEANING PAGE

2

3

4

5

No value to select.

Lighten or darken the print on

the page by changing the

toner density setting. The

settings range from 1 (light) to

5 (dark), but the default setting

of 3 usually produces the best

results.

Use a lower toner density

setting to save toner.

Note

It is best to change the toner

density from the printer driver

or software application. (Driver

and software settings override

Control Panel settings.)

[Select]

Press

cleaning page (for cleaning

excess toner from the paper

path).

In order for the cleaning page

to work properly, print the

page on copier grade paper

(not bond or rough paper).

Follow the instructions on the

cleaning page.

to print a

PROCESS CLEANING PAGE

3-12 Printer Operation

No value to select. This item appears only after a

cleaning page has been

generated (as described

above).

[Select]

Press

cleaning page.

to process the

EN

Page 58

Printing Menu

Some items in this menu can be accessed from a software

application, or from the printer driver (if the appropriate driver is

installed). Printer driver and software application settings override

Control Panel settings.

Table 3-7. Printing Menu

Item Values Explanation

COPIES=1 1 to 999

PAPER=

LETTER

(110 V printers)

and

For supported paper sizes

see page 1-11.

ENVELOPE =

COM10

(110 V printers)

Set the default number of

copies by selecting any

number from 1 to 999. Press

[-Value+]

setting by increments of 1, or

hold down

by increments of 10.

once to change the

[-Value+]

to scroll

Note

It is best to set the number of

copies from the printer driver

or software application. (Driver

and software settings override

Control Panel settings.)

Set the default image size for

paper and envelopes. (The

item name will change from

paper to envelope as you

scroll through the available

sizes.)

Note

The defaults indicated here

are for 110 V printers. The

default paper size for 220 V

A4

printers is

envelope size for 220 V

printers is

. The default

DL

.

CONFIGURE CUSTOM

PAPER =NO

EN

NO

YES

NO:

The custom paper menu

items are not accessible.

YES:

The custom paper menu

items appear (see the next

item).

Control Panel Menus

3-13

Page 59

Table 3-7. Printing Menu (continued)

Item Values Explanation

UNIT OF MEASURE=INCHES

(110 V printers)

or

MILLIMETERS

(220 V printers)

X DIMENSION=

12.28 INCHES

(110 V printers)

or

312 MILLIMETERS

(220 V printers)

Y DIME NSION=

18.50 INCHES

(110 V printers)

or

470 MILLIMETERS

(220 V printers)

ORIENTA TION=

PORTRAIT

INCHES

MILLIMETERS

3.00 to 12.28 INCHES

(110 V printers)

or

76 to 312 MILLIMETER S

(220 V printers)

5.00 to 18.50 INCHES

(110 V printers)

or

127 to 470 MILLIMETERS

(220 V printers)

PORTRAIT

LANDSCAPE

This item appears only when

CONFIGURE CUSTOM

PAPER =YES

measurement for the custom

paper size.

This item appears only when

. Select the unit of

CONFIGURE CUSTOM

PAPER =YES

dimension to be fed into the

printer (short edge).

This item appears only when

. Select the

CONFIGURE CUSTOM

PAPER =YES

dimension (long edge).

Determine the default

orientation of print on the

page.

. Select the other

Note

It is best to set the page

orientation from the printer

driver or software application.

(Driver and software settings

override Control Panel

settings.)

FORM=60 LINES

(110 V printers)

or

64 LINES

(220 V printers)

3-14 Printer Operation

5 to 128

Sets vertical spacing from 5 to

128 lines for default paper

size. Press

change the setting by

increments of 1, or hold down

[-Value+]

increments of 10.

[-Value+]

to scroll by

once to

EN

Page 60

Table 3-7. Printing Menu (continued)

Item Values Explanation

PCL FONT

SOURCE=INTE RNAL

PCL FONT

NUMBER=0

PCL FONT

PITCH= 10.00

PCL SYMBOL

SET=PC-8

INTERNAL

SOFT

SLOT 1, 2, or 3

0 to 999

0.44 to 99.99

PC-8

many others

INTERNAL

SOFT:

SLOT 1, 2

in one of the three DIMM slots.

The printer assigns a number

to each font and lists them on

the PCL Font List. The font

number appears in the Font #

column of the printout.

This item might not appear,

depending on the font

selected. Press

once to change the setting by

increments of .01 for pitch, or

hold down

by increments of 1.

Select any one of several

available symbol sets from the

printer’s control panel. A

symbol set is a unique grouping

of all the characters in a font.

PC-8 or PC-850 is

recommended for line draw

characters. Order the

PJL Technical Reference

Documentation Package

symbol set charts or for more

information see the user’s

guide.

: Internal fonts.

Permanent soft fonts.

, or 3: Fonts stored

[-Value+]

[-Value+]

to scroll

PCL 5/

for

EN

Control Panel Menus

3-15

Page 61

Table 3-7. Printing Menu (continued)

Item Values Explanation

COURIER=REGULAR REGULAR

DARK

WIDE A4=NO NO

YES

APPEND CR TO LF=

NO

NO

YES

Select the version of Courier

font to use:

REGULA R

font available on the

HP LaserJet 4 series printers.

DARK

available on the HP LaserJet III

series printers.

Both fonts are not available at

the same time.

The Wide A4 setting changes

the number of characters that

can be printed on a single line

of A4 paper.

NO

characters can be printed on

one line.

YES

characters can be printed on

one line.

Select

carriage return to each line feed

encountered in backwardcompatible PCL jobs (pure text,

no job control). Some

environments, such as UNIX,

indicate a new line using only

the line feed control code. This

option allows the user to

append the required carriage

return to each line feed.

: The internal Courier

: The internal Courier font

:

Up to 78 10-pitch

:

Up to 80 10-pitch

YES

to append a

PRINT PS ERRORS=OFF OFF

ON

3-16 Printer Operation

Select ON to print the PS error

page when PS errors occur.

EN

Page 62

Configuration Menu

Items in this menu affect the printer’s behavior. Configure the printer

according to your printing needs.

Table 3-8. Configuration Menu

Item Values Explanation

POWERSAVE=

30 MINUTES

PERSONALITY=

AUTO

OFF

15 MINUTES

30 MINUTES

1 HOUR

2 HOURS

3 HOURS

AUTO

PCL

PS

Set the printer to enter PowerSave after it