Page 1

May 1998 Edition

HP LaserJet Family

Quick Reference

Service Guide

Volume II

Page 2

Page 3

HP LaserJet Family

Quick Reference

Service Guide

Volume II

Page 4

© Copyright Hewlett-Packard

Company, 1998

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except

as allowed under the copyright

laws.

Publication number

5021-8942

First edition, May 1998

Warranty

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warranty of any kind with respect

to this information. HEWLETTPACKARD SPECIFICALLY

DISCLAIMS THE IMPLIED

WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or other

damage alleged in connection

with the furnishing or use of this

information.

Trademark credits

MS-DOS® is a U.S. registered

trademark of Microsoft Corporation.

UNIX is a registered trademark in the

United States and other countries,

licensed exclusively through X/Open

Company Limited.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Contents

1 Control panel messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Error listings, descriptions, and recommended actions

2 Service mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

How to access Service mode and related functions

3 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DC voltages, test points, and tools

4 Input/Output (I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Printer interface and cabling information

5 Media specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Supported sizes and specifications for paper and special media

6 Toner cartridge information. . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Cartridge weights, capacities, and potential service issues

7 Printer options and replaceable parts. . . . . . . . . . . . . . . . . . 101

Support matrix and part numbers for accessories

8 Printer parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Selected high-usage replacement parts

9 Image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Image defect samples, suspect causes, and remedies

10 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Main wiring schematics

11 Services and support/resources and training . . . . . . . . . . . 173

How and where to get training, support, and materials

12 Hewlett-Packard LaserJet Companion . . . . . . . . . . . . . . . . . 179

HP LaserJet information and specifications

A Acronyms and abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . 183

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

EN

iii

Page 6

Ordering other manuals

The HP LaserJet Quick Reference Service Guide

support for newer monochrome printers (see the following page for a

complete list of supported printers). It has been created to help the

HP LaserJet service engineer quickly troubleshoot common printer

problems.

For older monochrome printers, see the

Service Guide,

LJ 6L, LJ 5Si Mopier, LJ 5Si, LJ 5Si MX, LJ 5L, LJ 6P, LJ 6MP, LJ 5P,

LJ 5MP, LJ 5, LJ 5M, LJ 5N, LJ 4V, LJ 4MV, LJ 4P, LJ 4MP, LJ 4L,

LJ 4ML, LJ 4+, LJ 4M+, LJ4, LJ 4M, LJ 4Si, LJ 4Si MX, LJ IIISi, LJ IIIP,

LJ IIP+, LJ IIP, LJ IIID, LJ III, LJ IID, LJ II, LJ 2686D, LJ 2686A.

While the quick reference guides are intended to provide all the

information the service engineer will need for on-site repair of HP

products, they are not intended to replace the service manual for any

HP LaserJet product. For detailed information about the HP LaserJet

products described in this guide, see the user guide or service manual

for that product.

Service manuals for HP LaserJet products are available from

Hewlett-Packard. The phone number for the Service Parts Order

Desk is:

Volume I. It provides support for the following printers:

HP LaserJet Quick Reference

, Volume II, provides

(800) 227-8164 (U.S. only)

If you are located outside of the U.S., contact your local HP Sales and

Service office.

iv

EN

Page 7

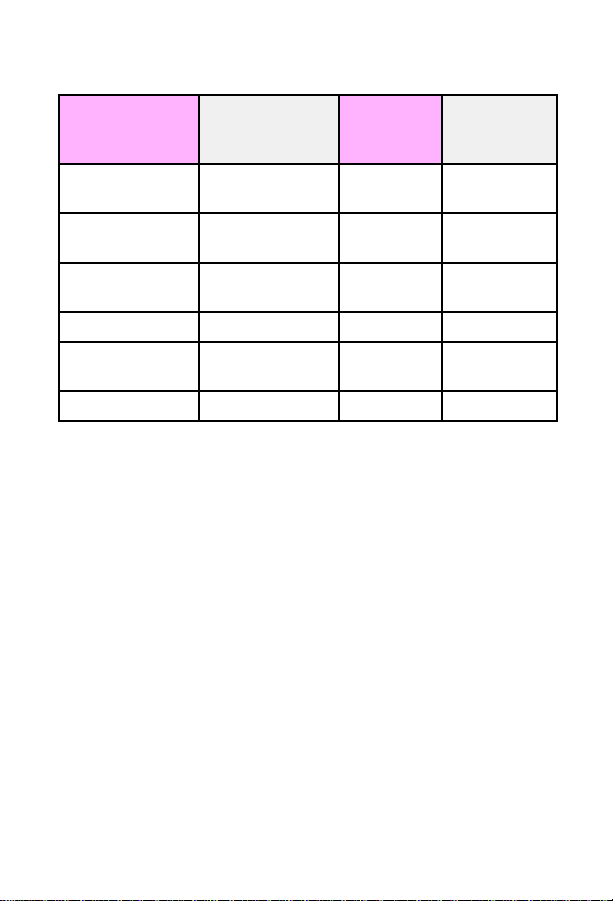

Supported products

Reference name

used in this

guide

LJ 4000/4000T

4000N/4000TN

LJ Companion LJ C3989A/

LJ 5000/5000N/

5000GN

LJ 3100 C3948A 6K C3948-90958

LJ8000/8000N/

8000DN

LJ Mopier 240 C4228A 130K C4085-91017

Model number

C4118A/C4119A/

C4120A/C4121A

C3979A/C4106A

C4110A/C4111A/

C4112A

C4085A/C4086A/

C4087A

Maximum

pages per

month

65K C4118-99024

N/A HP Central

65K C4110-91033

130K C4085-91017

Service

Manual part

number

Repair Only

Note

This guide will be updated on a regular basis as the service needs

change, as new products are introduced, and as information becomes

available.

EN

v

Page 8

vi

EN

Page 9

Control panel

1

messages

Overview

This chapter provides a list of printer control panel messages.

Alphabetical messages are listed first, followed by numerical messages.

Control panel messages that are self-explanatory are not included. If

you need more detailed information, see the service manual for the

printer.

EN

Chapter 1 –

7

Page 10

Alphabetical messages

(number) is a group, group not allowed

• Enter a different one-touch key or an unassigned speed-dial code.

Access denied, menus locked

• Ask the network administrator to unlock the function.

Already in group

• While programming a group-dial code, a fax number has been

added that is already in the group.

– Add the next fax number to the group.

Bad duplexer connection

• Re-install the duplexer.

• If the message persists, make sure that the duplexer is connected

and that the connector is not damaged.

• Replace the duplexer.

Bad opt tray connection

• Re-install the optional tray.

• Make sure that the optional tray is connected and that the connector

is not damaged.

• Replace the optional tray.

8 – Control panel messages

EN

Page 11

Blacklisted (France only)

• The attempted fax number has received a voice answer or no

answer, was busy on the first dial and redials, or was busy with

redials pending.

– Unplug the power cord for the fax machine from the power strip

or outlet, and then plug it back in.

Busy

• Check the fax number and try resending the fax. If the message

appears again, try sending to another fax machine or try again later.

1

Cancel group edit,

• Back space was pressed while in a group-dial code in the Group

Dial Setup level of the menu.

1

2

3

Press

Press

(Press

Press

to return to the group-dial code and continue editing.

[Start]

[Enter/Menu]

[Enter/Menu]

[Stop/Clear]

ENTER

to go to the Group Dial Setup level of the menu.

again to choose a different group-dial code.)

to exit the Menu settings.

Check finisher device

• Check to see if paper is jammed in the external paper-handling

finishing device.

Check finisher device

to confirm

alternates with

alternates with

Clear jam

Finisher align

error

• Check to see if an alignment error has occurred in the external

paper-handling finishing device.

EN

Chapter 1 –

9

Page 12

Check input device

alternates with

Paper path open,

please close it

• Check the doors and trays.

• Check the tabs and sensor levers in the tray for proper operation.

– Replace any defective tabs or sensors.

• Replace the printed-circuit assembly (PCA) controller in the feeder.

Check output device

alternates with

Close output

delivery path

• Make sure the paper path is closed between the printer and the

external paper-handling output device.

Chosen language not available

1 Print the job using a driver for a different printer language, or add the

requested language to the printer (if available).

2 Press [Go] to continue.

Clear document from scanner

• Check to see if the document is jammed or if multiple sheets of the

document were loaded.

• Check the special media lever. It should be to the left for regular-

weight items or to the right for thick items. Thick items must be fed

one at a time.

• Check the control panel configuration for outgoing faxes, including

the “send long pages” setting.

10 – Control panel messages

EN

Page 13

Close top cover

• Check SW101 for proper operation. Verify that the wires are

connected.

• If necessary, replace SW101.

– If the new switch does not solve the error, the wiring or the

engine controller board may be defective.

Communication error

Try resending the fax.

1

If the call fails again, check that the telephone cord is securely

2

connected. Then check for a dial tone on the phone line by pressing

[Manual Dial]

Wait; try resending the fax later.

3

.

Note

For additional details, see the

.

Manual

HP LaserJet 3100 Product Service

Configuration err # (number 1-4)

• An error was detected in the static random-access memory (SRAM).

– Unplug the power cord from the power source, wait 10 seconds,

and replug the power cord.

• If the error persists, replace the formatter.

Config. stuck addr

1

• In Service mode only, SRAM stuck address test.

– Unplug the power cord from the power source, wait 10 seconds,

and replug the power cord.

• If the error persists, replace the formatter.

EN

Chapter 1 –

11

Page 14

Config. tied addr.

• In Service mode only, SRAM tied address test.

– Unplug the power cord from the power source, wait 10 seconds,

and replug the power cord.

• If the error persists, replace the formatter.

[Date] [Time]

• The battery has failed. You can continue to use the HP LaserJet

3100 product without replacing the battery, but if you re-enter the

Menu settings and then turn off the power, the settings are erased

again.

Decoding error # (number 1-3)

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If the error persists, replace the formatter.

Disk device failure

• Reseat the enhanced input/output (EIO) disk or replace the old disk

device with a new disk.

Disk file operation failed

• Check the filename and directory name.

• Reattempt the operation.

Disk file system is full

• Delete the files from the EIO disk and then try again, or add a Flash

dual inline memory module (DIMM).

• Download or delete files from the HP JetAdmin software, and

download or delete fonts from the HP FontSmart software.

12 – Control panel messages

EN

Page 15

Disk is write protected

• Use the HP JetAdmin software to disable the write protection.

Documents were lost, START to continue

1

Press

1

Check the fax log status column for the “Fax Document was Lost”

2

message.

Resend the associated outgoing faxes. Ask the sender to resend

3

incoming faxes.

. A report is printed.

[Start]

Duplex error, check duplexer

• Check the duplexer for a paper jam.

• Reseat the duplex assembly, and check the connection.

• Replace the Duplex unit.

EIO x disk initializing

• Stand by until the EIO disk is done initializing.

EIO x disk spinning up

• Stand by until the disk accessory card is done initializing.

EIO disk x non-functional

• Replace the EIO disk.

Encoding error

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If the error persists, replace the formatter

.

EN

Chapter 1 –

13

Page 16

Envelope feeder load

1 Load the requested envelope type and size into the en v elope feeder.

2 Make sure that the envelope size and type are set correctly on the

Paper-Handling menu in the printer control panel.

3 Press [Go] if the envelope is already loaded in the feeder.

4 Press [-Value+] to scroll through the available types and sizes.

Errors likely in pages: (page range)

• Resend the fax or ask the sender to resend the fax to you.

Fax document was lost

• If you set up faxes to be sent at a future time or to be polled, print a

fax log to identify which faxes were lost. Then re-enter the faxes.

• Fax es that were received to memory (instead of printing) have been

lost. Ask the sender to resend the fax.

Fax memory error # (number 1-5)

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If you set up faxes to be sent at a future time or to be polled, print a

fax log to identify which fax es may ha ve been lost. Then, re-enter the

faxes.

• Fax es that were received to memory (instead of printing) have been

lost. Ask the sender to resend the fax.

• If the error persists, replace the formatter.

Flash device failure

• Remove the Flash DIMM and replace it with a new one.

14 – Control panel messages

EN

Page 17

Flash file operation failed

• Check the filename and directory name.

• Reattempt the operation.

Flash file system is full

• Delete files from the Flash DIMM or add another DIMM.

• Download or delete files from the HP JetAdmin software, and

download or delete fonts from the HP FontSmart software.

Flash is write protected

• Use the HP JetAdmin software to disable the write protection.

Group is empty, use ONE-TOUCH/SPEED DIAL

Begin adding fax numbers to the group-dial code by pressing the

1

one-touch key for each number or by pressing

Enter the speed-dial code for the fax number.

2

3

Press

[Enter/Menu]

.

[Speed Dial]

.

Initializing

• Reseat the DIMM(s).

1

EN

Chapter 1 –

15

Page 18

Input device condition xx.yy

1st x = Device number in chain.

2nd x = Device type (3 types):

1 = Input

2 = Output

3 = Stapler/stacker unit

yy = Device specific error.

• See the documentation that came with the paper-handling device.

Input limit reached

• The maximum number of fax numbers that can be added to an

ad-hoc group is 100. Resend the fax, but only to 100 or fewer fax

numbers.

Install front duplex cover

• Re-insert the duplexer’s front cover.

Install tray x

• Re-insert the specified tray.

• Check for damaged tabs in the tray.

• Check for damaged switches in the printer.

• Replace the PCA controller in the feeder.

Invalid date or time

• Re-enter the date and time.

16 – Control panel messages

EN

Page 19

Keypad test failed

• Run the keypad test again.

• If the error persists, try each of the following in the order given:

– Check the cabling.

– Replace the control panel.

– Replace the formatter.

1

Loading program <number>

alternates with

Do not

power off

• Wait for the program to load.

Long page? START to continue

• Press

seconds, the message disappears and the document scanner stops

scanning because it thinks the page has jammed.

• If sending a fax or copying a document longer than 991 mm (39 in),

the control panel configuration can also be set to “Send long pages.”

This ensures that long pages feed without having to monitor the

task. Press

to continue scanning. If

[Start]

before the document scanner shuts off.

[Start]

is not pressed within 3

[Start]

Manually feed [type] [size]

Load the requested paper into Tray 1.

1

2

3

4

Press

Press

Press

if the appropriate paper is already loaded in Tray 1.

[Go]

[-Value+]

[Select]

to scroll through the available types and sizes.

to accept the alternate type or size.

Memory full - send unscanned pages

• Reload the unscanned pages and re-send them to finish the fax job.

• Scan the unscanned pages to the computer and fax them from the

computer.

EN

Chapter 1 –

17

Page 20

Memory full - stored data lost

• Add more memory to the printer or simplify the print job.

Memory is full

• This message should clear automatically when the next task starts

(for example, when you start a copy or receive a fax).

Memory settings changed

• Try changing the memory settings for I/O Buffering and Resource

Saving (although default settings are usually best).

• Install additional memory in the printer.

Memory shortage job cleared

• Press [Go] to continue.

• On the printer control panel, change the setting for resource saving,

or add more memory to the printer.

Memory shortage page simplified

• Press [Go] to continue.

• Add more memory to the printer.

Modem error # (number 1-3)

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If the error persists, try each of the following in the order given:

– Check the cabling.

– Replace the LIU.

– Replace the formatter.

18 – Control panel messages

EN

Page 21

No answer

• Check the fax number and try resending the fax. If the message

appears again, try sending to another fax machine or try again later.

No dial tone

• Check that the telephone cord is securely connected.

• Check for a dial tone on the phone line by pressing

• If necessary, check the wall outlet by plugging in a phone and

attempting to place a call.

[Manual Dial]

.

No fax in (number) tries

• Check the fax number and try resending the fax. If the message

appears again, try sending to another fax machine or try again later.

No fax pages in memory to reprint

• Wait for a fax. As soon as a fax is in the memory, the fax will reprint.

No memory for report, erase/print document

• Print all faxes that have been received in memory.

• If you have several faxes set up to be sent at a future time or to be

polled, use job status to clear them.

No modem installed

1

• There is a problem with the line interface unit (LIU).

– Unplug the power cord from the power source, wait 10 seconds,

and replug in the power cord.

• If the problem persists, replace the LIU.

• If the problem persists, replace the formatter.

EN

Chapter 1 –

19

Page 22

No room in fax log

• The fax log was unable to print because of an error, such as out-of-

paper.

– Load paper in the paper input bin so the HP LaserJet 3100

product can print the log.

Not enough memory

• T ry resending the job . If the error persists, try reducing the amount of

activity on the HP LaserJet product. Cancel jobs in memory before

resending the job.

Out of memory -- switching to ONE COPY

• The HP LaserJet product continues to copy, but only one copy is

output.

– Divide the copy job into smaller sections and then try copying

again.

– If you are collating the job, turn the collation feature off, make

only one copy of the document at a time, or see the user guide

for instructions about using the Document Assistant.

Output bin full

alternates with

Clear paper from [bin

name]

1 Remove the media from the face-down tray.

2 Check PS1401 on the sensor PCA.

3 Make sure the sensor flag moves freely.

20 – Control panel messages

EN

Page 23

Paper bin is empty, please add paper

Load paper.

1

If paper is already loaded, remove it.

2

Check for, remove, and discard any jammed sheets.

3

Reload the paper.

4

Password must be 4 digits

• Re-enter a four-digit password.

Paused (memory full)

• Reduce activity on the HP LaserJet product, or wait for other jobs to

finish so memory will be freed.

• If faxes are set up to be polled or sent at a future time, y ou ma y want

to cancel these jobs to free memory.

Perform printer maintenance

Reset the maintenance page count only after a maintenance kit has

been installed. Resetting the maintenance page count causes

PRINTER MAINTENANCE

series), 200,000 (LJ 4000 series), or 350,000 (LJ 8000) pages have

printed.

Hold down the

1

Turn the printer on.

2

Wait until

3

both keys.

RESET MAINTENANCE COUNT

to appear after another 150,000 (LJ 5000

[Item-]

and

[Value-]

keys.

appears, and then release

PERFORM

1

EN

Chapter 1 –

21

Page 24

PC print timed out

• Let the “print jobs retry” continue for 5 minutes. If the HP LaserJet

3100 product still does not print, resend the print job.

Phone number error

• The maximum number of characters that can be entered is 40. If you

have a number longer than 40 characters, break the number into

smaller chunks.

1 Enter the first part of the number, and press [Redial/Pause] as the

last character in the first number.

2 Enter the second part of the number as if it were a second number

going to a group. When the product dials, it will treat both numbers

as if they are one.

Polling-in error

• Make sure that the sender’s fax machine is ready to be polled, and

check the fax number. Then set up to poll again.

Printer comm error^1

• Check that the parallel cable is securely connected between the

HP LaserJet 3100 product and the computer.

• If the problem persists, unplug the power cord from the power

source for 5 seconds, and then replug it.

• If the problems persists, replace the formatter.

Printer cover open or no cartridge

• Verify that the printer door is closed.

• Check the toner cartridge for proper installation.

22 – Control panel messages

EN

Page 25

Printer fixing error, replace fixing unit

• There is an error with the print engine.

• Check the cabling to the heating element.

• If the problem persists, replace the heating element.

• If the problem persists, replace the ECU.

Printer is busy

• No action is needed. If you already started another job, the job will

be completed when the HP LaserJet product becomes available.

Printer laser error, call for service

• Open and reclose the printer door.

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If the problem persists, replace the laser scanner assembly.

Printer motor error, call for service

• A problem has occurred with the print engine.

– Unplug the power cord from the power source, wait 10 seconds,

and replug the power cord.

– If the problem persists, replace the motor.

– If the problem persists, replace the ECU.

1

Printer paper jam, check paper path

• Check the input areas, the output areas, and the interior for the jam,

and then clear the jam. The job should continue to print. If it does

not, try reprinting the job.

EN

Chapter 1 –

23

Page 26

Printer signal error

• Open and reclose the printer door.

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If the problem persists, replace the laser scanner assembly.

Processing job from Tray x

• Check the tray selected and the type settings . If the printer does not

respond after you press the control panel keys, turn the printer off,

and then turn the printer on to clear the message.

• If paper is loaded when the printer is in Power Save mode, it might

not be recognized. Open and close the affected source when the

printer is in Ready mode.

RAM disk device failure

• Turn the printer off and on to clear the message.

• If the message persists, install a new RAM disk.

RAM disk file operation failed

• Check the filename and directory name.

• Reattempt the operation.

24 – Control panel messages

EN

Page 27

RAM disk file system is full

• Delete files and then try again, or turn the printer off and then turn

the printer on to delete all files on the device. (Use HP JetAdmin

software, HP FontSmart software, or another software utility to

delete files.)

• If the message persists, increase the size of the RAM disk.

– Change the RAM disk size from the Configuration menu in the

printer control panel.

RAM disk is write protected

• Use HP JetAdmin software to disable the write protection.

Received error

• Ask the sender to resend the fax.

Redial failed

• Try resending the fax. If the fax still fails to transmit, call the recipient

to check that the fax machine is on and working and to verify the fax

number.

Remote fax was busy

• Try resending the fax. If the fax still fails to transmit, call the recipient

to check that the fax machine is on is on and working and to verify

the fax number.

1

Scan reference error

• Recalibrate the document scanner.

• If the problem persists, replace the CIS.

EN

Chapter 1 –

25

Page 28

Scanner error #1

• An error has occurred within the SRAM.

• Press and hold down the [Stop/Clear] key for 7 seconds to reset the

product.

• If the error persists, unplug the power cord from its power source for

10 seconds, and then replug it.

• If the error persists, replace the CIS.

• If the error persists, replace the formatter.

Scanner isn’t available

• The document scanner mechanism is in use.

– Wait until the document scanner has finished the current job

before sending the next job.

Scanner jam - reload

• Pull open the document release door and then remove the jammed

document.

Speed dial (number) is not assigned

• Choose a speed-dial code that has already been assigned a fax

number.

System error

• Unplug the power cord from the power source, wait 10 seconds , and

replug the power cord.

• If the message is still displayed, replace the formatter.

26 – Control panel messages

EN

Page 29

There are no documents in memory

• No action is required. There are no faxes to retrieve.

Tray x empty

1

• Load the empty tray (

• Inspect the tray for damaged tabs.

• Check the sensor-arm flags for damage. Be sure the flags can mov e

freely .

• Replace any defective sensors.

) to clear the message.

x

Tray x lifting

• Verify that the media can be pulled from another tray.

• Replace the paper input unit.

Tray x load

Load the requested paper into the specified tray (

1

trays are correctly adjusted for size.

Press

2

Press

3

Press

4

Inspect the switches in the tray.

5

Remove the tray, and then turn the printer on. Push the switches by

6

hand to see if the switches register.

to print from the next available tray.

[Go]

[-Value+]

[Select]

to scroll through the available types and sizes.

to accept the alternate type or size.

). Ensure that the

x

EN

Chapter 1 –

27

Page 30

Unrecognized format

• When printing, the incorrect printer driver was selected or an error

occurred on the parallel interface.

1 After selecting the Print command in the software application you

are using, select the HP LaserJet 3100 as the printer.

2 Reprint the job.

Unsuccessful call

• Check the fax number and try resending the fax.

• If the message appears again, try sending to another fax machine or

try again later.

Unsupported size in tray [yy]

• Load a supported paper size in the tray.

Use [type] [size] instead?

1 Press [-Value+] to scroll through the available types and sizes.

2 Press [Select] to accept the alternate type or size.

28 – Control panel messages

EN

Page 31

Numerical messages

XX.YY printer error, press GO to continue

Press

on the printer control panel to clear the error message.

[Go]

13 Paper jam

• Remove the jammed paper from the specified location. Check the

entire paper path for other pieces of paper.

• Open and close the top cover to clear the message.

• Check sensors and flags in the paper path for proper operation.

13.1 Paper delay jam at paper feed area

13.2 Paper stopped jam at paper feed area

• Ensure that the paper trays are loaded properly so that paper can

feed from the trays.

• Check the input area for obstructions such as paper in the paper

path or damage to the registration assembly.

• Verify that the transfer roller is positioned correctly.

• Check PS 102 and PS 103 (4000 series) and PS 402 and PS 403

(5000 series) for proper operation.

– Replace any defective sensors or flags.

1

EN

Chapter 1 –

29

Page 32

13.5 Paper delay jam at fuser

13.6 Paper stopped jam at fuser

• Check the transfer roller and small media belt to ensure that the

roller and belt are operating and can feed the paper.

• Check the paper path for obstructions at the transfer roller, toner

cartridge, paper feed guide, and fuser.

• Check PS 501 and PS 106 (4000 series), PS 1307 (5000 series), or

PS 1403 (8000 series) for proper operation. Replace any defective

sensors or flags.

13.9 Check left door

• Inspect the path between the fuser and delivery assemblies.

• Check the diverter assembly.

13.10 Paper delay jam at paper reversing area/

duplexer

• Check the duplexer and the rear area of the printer for obstructions

or damage.

• In the duplexer, check PS 701 and PS 703 for proper operation.

• Replace the duplexer if a sensor is defective.

13.11 Paper jam

• Check the entire paper path.

• Reseat the duplexer.

• Try the Paper Path Test.

• Replace the duplexer.

30 – Control panel messages

EN

Page 33

13.11 Paper jam in input device

Open the vertical transfer unit (VTU) and remove the media.

1

Verify that the entry or exit sensor can move freely.

2

If the problem persists, open the VTU and override its Open Door

3

sensor, perform a Paper Path test from the 2,000-sheet Input Tray

(or 2x500-sheet Input Tray), and make sure the feed rollers are

advancing the paper.

– If the rollers do not rotate, verify the connections at the main

drive assembly, pickup assembly, controller PCA, and power

supply. If the rollers still do not rotate or do not drop down,

replace the pickup assembly.

– If the rollers rotate and drop down without advancing the paper,

replace the feed rollers using the maintenance kit.

– If the problem persists, replace the VTU.

13.12 Paper jam

• Check the paper path between the fuser and duplex assembly.

• Reseat the duplexer.

• Replace the duplexer.

13.13 Paper jam

• Check the entire paper path.

• Remove the duplex assembly and look for paper in the side of the

assembly.

– Retest.

• Replace the duplexer.

1

EN

Chapter 1 –

31

Page 34

13.20 Paper jam

• Check the paper path for obstructions.

• Check that all assemblies are seated and all doors are closed.

• Check all sensors and flags in the paper path.

13.21 Door open jam

• Check that all assemblies are seated and all doors are closed.

• Check all sensors and flags in the paper path.

13.22 Paper jam in output device

• Open the flipper jam access door and remove the media.

• Make sure the sensor flag moves freely.

• Make sure that the flipper shaft is in place.

• If the problem persists, replace the flipper assembly.

• If the problem persists, replace the mailbox controller PCA.

20 Insufficient memory

alternates with

Press GO to

continue

• Press [Go] to print the transferred data (some data might be lost);

then simplify the print job or install additional memory.

32 – Control panel messages

EN

Page 35

21 Page too complex

• Press

• To print the job without losing data, select Page Protect=on from the

Configuration menu in the printer control panel and then print the

job. Afterward, return to Page Protect=auto. Do not leave Page

Protect=on; doing so could degrade performance.

• If this message appears often, simplify the print job or install

additional memory.

to print the transferred data. (Some data could be lost).

[Go]

1

22 EIO x buffer overflow

alternates with

Press GO to

continue (too much data sent to EIO card)

• Press

to clear the message. (Data will be lost.)

[Go]

22 Parallel I/O buffer overflow

(too much data sent to parallel port)

• Check for a loose cable connection. Use a high-quality IEEE-1284

cable.

• Press

22 Serial I/O buffer overflow

to clear the error message. (Data will be lost.)

[Go]

alternates with

Press GO

to continue (too much data sent to the serial port)

• Verify that the correct option for serial pacing is selected on the I/O

menu.

• Print a Menu Map and verify that the serial pacing item (from the

I/O Menu on the printer control panel) matches the setting on the

computer.

• Press

to clear the error message. (Data will be lost.)

[Go]

EN

Chapter 1 –

33

Page 36

40 Bad serial transmission (data transfer error)

• Verify cable connections.

• Verify that the printer serial configuration is set the same as the

computer.

– Access the serial baud rate setting from the I/O Menu on the

printer control panel.

• Press [Go] to clear the error message and continue printing.

40 EIO x bad transmission (connection between

printer and EIO card broken)

x = Description

1 = EIO slot 1

2 = EIO slot 2

• Turn the printer off and reseat the card.

• Press [Go] to clear the error message and continue printing.

41.3 Unexpected paper size

• Verify that all trays are adjusted correctly for size. (The printer

attempts to print the job until size settings are correct.)

• If you are trying to print from Tray 1, make sure that the paper-size

setting in the printer control panel is configured correctly.

• If you are trying to print from the optional 500-sheet tray, be sure to

set the paper-size dial to match the paper size loaded in the tray.

• Press [Go]. The page containing the error is automatically reprinted.

(Or, press [Cancel Job] to clear the job from the printer’s memory.)

34 – Control panel messages

EN

Page 37

41.x Printer error

alternates with

Press GO to

continue

• A temporary printing error occurred.

x = Description

1 = Unknown misprint error

2 = Beam detect error

4 = No VSYNC error

5 = Media feed error

9 = Noise VSREQ error

• Press

the error persists, try the following procedures:

– Reseat the connections to the laser scanner and the engine

– Replace the laser scanner.

– Replace the engine controller board.

. The page containing the error reprints automatically. If

[Go]

controller board.

50.x Fuser error

x = Description

1 = Low fuser temperature

2 = Fuser warm-up service

3 = High fuser temperature

4 = Faulty fuser

5 = Inconsistent fuser

Turn the printer off, wait 20 minutes, and then turn the printer on.

1

If the message persists, reseat the fuser.

2

If the message persists, replace the fuser.

3

1

EN

Chapter 1 –

35

Page 38

51.x Printer error (loss of beam detect)

x = Description

1 = Beam detect error

2 = Laser error

• Press [Go]. The page containing the error reprints automatically.

• Turn the printer off and then on.

• Reseat the cables.

• Replace the laser scanner.

52.x Printer error (the laser scanner speed is

incorrect)

x = Description

1 = Scanner startup error

2 = Scanner rotation error

• Press [Go]. The page containing the error reprints automatically.

• Turn the printer off and then on.

• Reseat the cables.

• Replace the laser scanner.

53.xy.zz Printer memory error with an accessory

The DIMM that caused the error will not be used.

x = DIMM type

0 = read only memory (ROM)

1 = random access memory (RAM)

y = Device location

0 = Internal memory (ROM or RAM)

1 to 3 = DIMM slots 1, 2, or 3

zz = Error number

36 – Control panel messages

EN

Page 39

0 = Unsupported memory

1 = Unrecognized memory

2 = Unsupported memory size

3 = Failed RAM test

4 = Exceeded maximum RAM size

5 = Exceeded maximum ROM size

6 = Invalid DIMM speed

7 = DIMM reporting information incorrectly

8 = DIMM RAM parity error

9 = ROM needs to be mapped to an unsupported address

10 = DIMM address conflict

11 = PDC XROM out of bounds

12 = Unable to make a temporary mapping

• Turn the printer off, and reseat or replace the specified DIMM.

• Try the DIMM in another slot.

• Replace the DIMM that caused the error.

1

55 Printer error

alternates with

Press GO to continue

(internal communications problem)

• Press

• Check the power at the site.

• Replace the formatter PCA.

• Replace the DC controller.

• Replace the engine controller board.

EN

. The page containing the error reprints automatically.

[Go]

Chapter 1 –

37

Page 40

56.x Printer error

alternates with

Cycle Power to

continue

x = Description

1 = Illegal input

2 = Illegal output

• Press [Go]. The page containing the error reprints automatically.

• Turn the printer off and on.

• Check the printer’s configuration.

57.x Printer Error

x = Description

4 = Printer fan

7 = Duplex fan

• Check the fan’s connector and verify that the fan is not blocked.

• Replace the fan.

59.x Printer error

x = Description

0 = Motor error

1 = Motor startup error

2 = Motor rotation error

• Turn the printer off and then on.

• Make sure that the fuser or toner cartridge is not hindering gear

movement in the drive train.

• Verify that the cable in the main motor is seated properly.

• If the error persists, replace the motor.

38 – Control panel messages

EN

Page 41

62.x Printer error (printer memory)

x = Location of problem

0 = Internal memory

1 to 3 = DIMM slots 1, 2, or 3

• Reseat or replace the specified DIMM.

64.x Printer error (scan buffer)

• Turn the printer off and then on.

• If the message persists, replace the formatter.

66 Error (external paper-handling device)

First x = Device number in chain

Second x = Device type (3 types):

1 = Input

2 = Output

3 = Stapler/stacker unit

yy = Device-specific error

• Press

• Turn the printer off and then on.

• Check all of the cables.

• Reseat the external paper-handling device.

to clear the message.

[Go]

1

EN

Chapter 1 –

39

Page 42

66.11 Input device failure

• Verify that the lifting plate lifts up freely by hand.

• Verify that the paper size plates are installed correctly and are not

bent.

• Check the pickup roller for proper installation.

• Check the pickup assembly and replace if necessary.

• Replace Tray 4.

66.xx.yy Input device failure

alternates with

Check

cables and cycle power

• Check for an error in an external paper-handling device.

1st x = Device number in chain

2nd x = Device type (3 types):

1 = Input

2 = Output

3 = Stapler/stacker unit

yy = Device specific error

• Press [Go] to clear the message.

• Turn the printer off, and then turn the printer on.

• Reseat the external paper-handling device.

68 NVRAM full check settings

• Print a configuration page and check the printer settings to

determine which values have changed.

• Hold down [Cancel Job] while turning the printer on.

40 – Control panel messages

EN

Page 43

69.x Printer error

x = Description

0 = The duplex mechanism has failed.

1 = The duplex side adjust has failed.

• Turn the printer off, and then turn the printer on.

• Reseat the duplexer.

79.xxxx Error (printing)

The printer detected an error. The numbers (xxxx) indicate the specific

type of error.

• Turn the printer off and then on.

• Try printing a job from a different software application. If the job

prints, go back to the first application and try printing a different file.

(If the message appears only with a certain software application or

print job, the customer should contact the software vendor for

assistance.)

If the message persists, try the following procedures:

• Turn the printer off and then on.

• Reseat or replace the interface cable and power cycle the printer.

• Remove the DIMMs one at a time and power cycle the printer.

• If possible, use the parallel interface.

• With the EIO cards removed from the printer, perform a cold reset.

• If the error persists, replace the formatter.

1

EN

Chapter 1 –

41

Page 44

8x.yyyy critical error (EIO accessory)

• The EIO accessory in slot x has encountered a critical error as

specified by yyyy.

x = Description

1 = EIO slot 1 -The printer detected an error with the EIO card.

2 = EIO slot 2 -The printer detected an error with the EIO card.

6 = EIO slot 1 -The EIO card detected an error.

The EIO card may be defective.

7 = EIO slot 2 -The EIO card detected an error.

The EIO card may be defective.

• Turn the printer off, and then turn the printer on.

• Reseat or replace the EIO board.

42 – Control panel messages

EN

Page 45

2

Overview

Service mode allows service personnel to verify and manipulate

internal printer settings and to access the diagnostic feature. Service

mode should be used only by authorized service personnel.

Service mode

EN

Chapter 2 –

43

Page 46

Service mode tasks

You can perform the following tasks while in Service mode.

• Verify the page count.

• Set the page count.

• Set the maintenance count.

• Verify and set the serial number.

• Set the cold reset default. This sets the factory default paper size to

either Letter or A4.

• Turn the diagnostic function on or off (for software developer’s use

only).

• Clear the event log.

• Use the extended Service mode.

• Reset softswitches.

• Perform a firmware download.

• Recalibrate the document scanner.

• Set the interval at which the PERFORM PRINTER MAINTENANCE

message appears on the control panel.

44 – Service mode

EN

Page 47

Accessing Service mode

4000, 5000, and 8000 series only

Use the following procedure to access Service mode.

Turn the printer off.

1

Press

2

printer on. Hold the keys down until all lights are illuminated. (If the

control panel reads

soon.)

Press the right side of the

3

SERVICE MODE

To exit Service mode, press

4

[Select]

and

[Cancel Job]

INITIALIZING

appears.

simultaneously while turning the

, the keys were released too

key, and then press

[Menu]

.

[Go]

[Select]

.

Accessing Service mode

3100 only

Use the following procedure to access Service mode.

Press

1

2

See the display for further instructions. Notes about some of the menu

choices are provided in the Extended service menu tree on page 52.

[Backspace#**]

Use the

service menu (see the Extended service menu tree, page 52) and

press

and

[<]

[Enter/Menu]

to access the extended service menu.

keys to select the choices given in the extended

[>]

.

2

EN

Chapter 2 –

45

Page 48

Setting the page count

4000, 5000, and 8000 series only

The page count is stored in the printer’s non-volatile memory. If it is

necessary to replace the formatter PCA, the page count should be set

to the current value to reflect the age of the print engine. Use the

following procedure to set the page count.

1 Before replacing the formatter PCA, print a Configuration Page to

verify the current page count and serial number of the printer, if

possible. Use the information on the Configuration P age to reset the

page count and serial number for the new formatter PCA.

Note

Press the right side of the [Menu] and [Item] buttons to increase the

value (+). Press the left side of the [Menu] and [Item] buttons to

decrease the value (-).

2 Press [Menu+] to display SERVICE MENU.

3 Press [Item+] to advance to the PAGES=XXXXXX display. XXXXXX

represents the page count currently stored in the non-volatile

memory. The underlined character denotes the position of the

cursor.

4 Press [Select] to advance the cursor one digit to the right. If the last

digit is currently selected, the cursor will move to the first digit when

you press the [Select] key.

5 Press [Value+/-] to scroll the digit until the correct value is displayed

for the underlined digit. (Pressing [Value+] when 9 is the value of the

currently selected digit changes the value of the digit to 0).

6 Press [Select] to enter numeric changes to the current digit and to

advance the cursor one digit to the right.

7 Press [Go] to exit the Service Menu.

46 – Service mode

EN

Page 49

Setting the maintenance count

4000 and 5000 series only

The maintenance count should be reset only after a maintenance kit

has been installed. Resetting the maintenance count resets the

maintenance counter so that the message

MAINTENANCE

(4000 series), or 350,000 (8000 series) pages are printed.

displays after another 150,000 (5000 series), 200,000

Note

MAINTENANCE COUNT

interval for when the next printer service is due for the printer. The

maintenance count is set initially at the factory . Editing this number is

similar to editing the

Hold down the

1

Turn the printer on.

2

Wait until

3

keys.

RESET MAINTENANCE COUNT

in the Service mode Menu sets the page count

item.

PAGES

and

[Item-]

[Value-]

PERFORM PRINTER

keys.

displays and then release both

2

EN

Chapter 2 –

47

Page 50

Setting the serial number

4000 and 5000 series only

Re-enter the serial number whenever you replace a formatter.

1 Press [Menu] to display the SERVICE MENU.

2 Press [Item+] three times. SERIAL NUMBER=XXXXXX displays. XXXXXX

represents the page count currently stored in the printer’s nonvolatile memory. The underlined character denotes the position of

the cursor.

3 Press [Select] to advance the cursor one digit to the right. If the last

digit is currently selected, the cursor wraps around the first digit

when you press the [Select] key.

4 Press [Value+/-] to scroll the digit until the correct value is displayed

for the underlined digit. (Pressing [Value+] when 9 is the value of the

currently selected digit will change the value of the digit to 0).

5 Press [Select] to enter numeric changes to the current digit and to

advance the cursor one digit to the right.

6 Press [Go] to exit the Service Menu.

48 – Service mode

EN

Page 51

Setting the page count, maintenance

count, and serial number

8000 series only

The page count, maintenance count, and printer serial numbers are

stored in non-volatile memory .

printed by the printer;

preventive maintenance should be performed (every 350,000 images);

and

cover).

If it is necessary to replace the formatter PCA, these numbers should

be set to the current values to accurately reflect the age of the print

engine. The printer service manual provides the procedure for setting

these values.

Before removing the old formatter PCA, print a configuration page to

verify the current values, if possible.

is the printer serial number (also located on the printer back

S.N.

MAINTCOUNT

PAGECOUNT

Note

If it is not possible to print a configuration page, try to verify the values

before replacing the formatter PCA by following steps 1 through 5,

below.

After verifying the page count, maintenance count, and printer serial

number from the old formatter PCA, replace it with the new PCA.

Enter Service mode. See “Service mode” in the printer service

1

manual for instructions.

When

2

3

4

5

SERVICE MODE

Service Menu.

Press

Maintenance Interval = Serial Number =

Enter the appropriate values for each item.

Press

to display

[Items]

to exit Service mode.

[Go]

is displayed, press

Pages = Maintenance count =

is the total number of images

is the page count when the next

to access the

[Menu]

.

2

EN

Chapter 2 –

49

Page 52

Setting the default paper size used in

a cold reset

4000, 5000, and 8000 series only

Cold reset clears all data from the printer memory and sets all defaults

back to the factory setting.

The default paper size is stored in NVRAM. Whenev er the printer is cold

reset, the default paper size is restored. The default paper size is set to

the factory setting. Possible values are COLD RESET PAPER=LETTER and

COLD RESET PAPER=A4. When replacing the formatter in countries that

use the A4 paper size (in place of the letter- size paper), set the cold

reset paper size to A4.

To customize the cold reset paper size:

1 Enter the Service mode. See “Service Mode in the printer service

manual for instructions.

2 Press [Menu] to display SERVICE MENU.

3 Press [Item+] until COLD RESET PAPER=LETTER* or A4 displays.

4 Press [Item+] to toggle between

5 Press [Select] to activate your choice.

6 Press [Go] to exit the Service Menu.

LETTER

and A4.

50 – Service mode

EN

Page 53

Diagnostics

4000, 5000, and 8000 series only

The diagnostics menu item enables or disables the use of the firmware

diagnostic features. These features are accessible when

DIAGNOSTICS=ON

the printer is in the

displays. To access the diagnostic features, verify that

state and press

READY

[Select]

.

Note

This procedure is for software developers only.

Clear event log

Select this item to clear the internal event log.

Extended service menu

3100 only

Use the extended service menu to run various self-tests and to change

softswitch settings, such as the country code softswitch setting.

The following page shows the layout of the extended service menu

settings in a hierarchical diagram.

2

EN

Chapter 2 –

51

Page 54

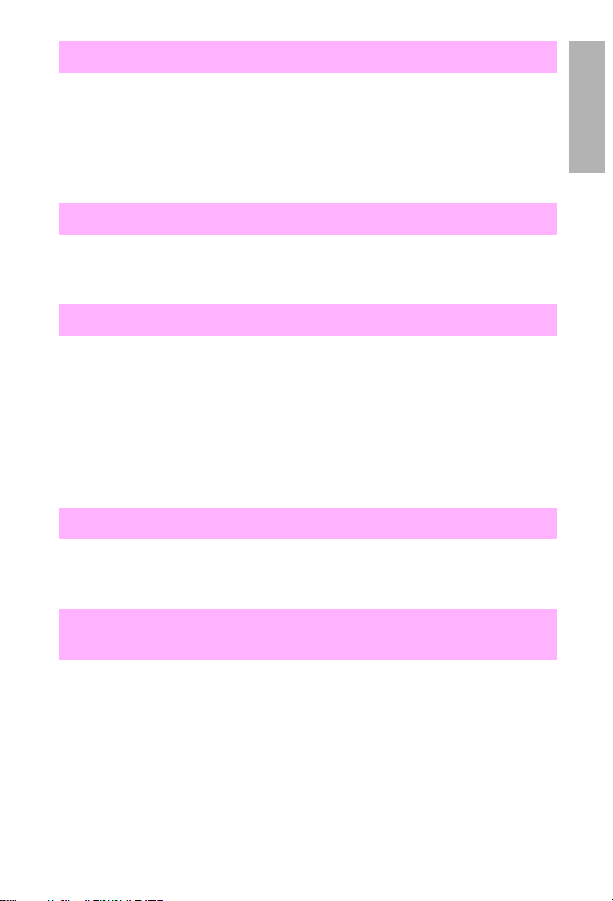

Extended service menu tree

Reports

Memory/softswitch

Control panel

Scanner

Self test

Modem/PTT

Help

T.30 protocol trace

SRAM dump

Scanner plots

Log debug report

Task stacks

Translations

Printer fonts

Softswitches

Clear memory

Check documents

Edit SRAM

SRAM dump

Firmware version

Keypad test

LCD test

Control panel test

Sensor states

Speaker test

All LCD characters

Scanner plots

Scanner LED

ADF feed test

ADF motor test

Do TWAIN scan

White ref summary

Burn-in

Individual diagnostics

System reset

Modem tone

Modem modulation

Modem type

Help

prints a menu

report for the product.

See “To change the

country code

softswitch” on the

following pages.

Various tests under

Control panel

assist in

troubleshooting the

product.

Scanner LED

contact image sensor

light bar test.

ADF feed test

document feeder pickup

rollers once.

ADF motor test

the document scanner

motor.

Burn-in

after running the

following tests:

Program test,

Configuration test #1,

Fax memory test #2,

Modem test #2, Scanner

test #1, Scanner LED.

can

is the

runs the

runs

prints a report

52 – Service mode

EN

Page 55

Self-test in extended service mode

3100 only

If you perform a self-test from the extended Service Menu, the printed

report will also show the firmware revision number and details.

Note

Print the internal reports before performing extended service mode

tests. The reports contain a record of all settings and can assist you

in restoring the product to its settings.

The table below lists the tests that are performed during a self-test and

the actions to take when tests fail.

Extended service mode self-test failures

Test If the test fails, take these actions:

Configuration test #1

Fax memory test #1

Program test #1

Configuration test #2

Configuration test #3

Configuration test #4

Fax memory test #2

Fax memory test #3

Fax memory test #4

Fax memory test #5

Modem 1 test #1

Modem 1 test #2

Modem 1 test #3

Replace the formatter.

Cycle power by unplugging the power cord

1

from the power source, waiting 10 seconds,

and replugging the power cord.

If the test fails again, clear all memory (see

2

the extended service menu tree, page 52).

If the test fails again, replace the formatter.

3

2

EN

Chapter 2 –

53

Page 56

Extended service mode self-test failures

Test If the test fails, take these actions:

1

Modem 1 dial tone

detect

Scanner test #1

Make sure that the telephone cable is

plugged into the correct connector on the

product and that the telephone line is

operational (use a telephone to test the line).

2

If the test fails again, check the configuration

settings in the control panel.

3

If the test fails again, replace the LIU.

This test fails under normal conditions if the

document scanner is busy. If the document scanner

is not busy:

1

Cycle power by unplugging the power cord

from the power source, waiting 10 seconds,

and replugging in the power cord.

2

If the test fails again, clear all memory (see

the extended service menu tree).

3

If the test fails again, replace the formatter.

54 – Service mode

EN

Page 57

Other tests in extended service mode

3100 only

The following charts shows tests that can be performed in extended

service mode and provides a brief explanation of each test:

Extended service mode tests

Test Explanation

Keypad test

LCD test

Control panel test

Sensor states

All LCD characters

Scanner plots

Scanner LED

ADF feed test

ADF motor test

Individual

diagnostics

Modem tone

Modem modulation

Tests that all keys are functioning (by pressing the

keys in sequence)

Tests the control panel display

Tests the control panel lights

Shows current detector activation levels. Detector 1

and detector 2 are paper-size detectors. The control

panel display shows the percentage of time each

detector is activated

Scrolls through the full list of control panel display

characters

Tests and recalibrates the document scanner

After selecting this menu item, lift the document

release door and verify that all of the LEDs in the

contact image sensor are lit.

Runs the document scanner pickup rollers once

Runs the document scanner motor

Run individual tests from the self-test sequence (see

the extended service mode self-test failures table).

Generates tones with various frequencies from

300 Hz to 2425 Hz

Generates various fax identification signals

2

EN

Chapter 2 –

55

Page 58

Reports in extended service mode

3100 only

The following chart shows reports that can be printed from extended

service mode and provides a brief explanation of each report.

Extended service mode reports

Report Explanation

T.30 protocol trace

SRAM dump

Scanner plots

Log debug report

Task stacks

Translations

Printer fonts

Firmware version

(under “memory/

softswitch”)

White reference

summary (under

“scanner”)

Prints a report of the G3 protocol transmissions and

receptions

Prints SRAM address values in an address range

you select

Prints the calibration page

Prints detailed fax and memory address information.

Fax information includes job number , start time used,

fax ID, transmission type, pages, communication

mode, and status.

Prints address locations of various tasks

Prints text strings used in the display, beginning with

the number you select. These text strings are printed

in the language currently in use by the product.

Compare the numbers in this report to the numbers

in an English report to translate non-English

messages on the display.

Prints all characters of fonts available in memory

Shows firmware revision information on the control

panel display

Displays average, minimum, and maximum white

reference values

56 – Service mode

EN

Page 59

Clear memory in extended service mode

3100 only

CAUTION

Clearing memory clears all parameters, which can render the product

illegal or inoperable. Print the internal reports before clearing memory

in extended service mode. The reports contain a record of all settings

and can assist you in restoring the product to its settings.

To perform a system reset, use extended service mode to choose

Memory/softswitch

and

keys to select the memory you want to clear:

[>]

•

Documents (and log)

all log information.

•

Phonebook

•

Configuration

report to their defaults.

•

Softswitches

•

Counters

printed. These page counts are printed at the end of the

configuration report.

•

Everything

includes white reference curve, total page count, and serial number.

, and then choose

deletes all documents stored in memory and

deletes all numbers stored in the phonebook.

resets all menu settings printed in the configuration

resets all softswitches to their defaults.

resets all page counts except the total number of pages

deletes and resets all of the above. Information retained

Clear memory

. Use the

[<]

2

EN

Chapter 2 –

57

Page 60

Softswitches

3100 only

Note

Reset the country code softswitch whenever the formatter board is

replaced or otherwise removed from the product, or when

softswitches are reset to defaults.

Extended service mode allows you to change softswitches on the 3100

product. A softswitch is a set of eight bits. See the software service

manual for a complete list of softswitches.

To change the country code softswitch

1 Press [Backspace], [#], [*], and [*], in sequence, to access the

extended service menu.

2 Press [<]or [>] until Memory/Softswitches appears below Service

on the control panel.

3 Press [Enter/Menu].

4 If Softswitches does not appear below Memory/Softswitches on

the control panel, press [<] or [>] until it appears.

5 Press [Enter/Menu].

6 Use the keypad to enter 101 (the “country code” softswitch).

7 Press [Enter/Menu].

8 Use the keypad to enter the sequence that corresponds to the

country in which the product is used. (See the list on the following

page.)

58 – Service mode

EN

Page 61

Country code softswitch sequences

Australia 00001011 (0B hex)

Denmark 00001100 (0C hex)

Finland 00001000 (08 hex)

France 00000111 (07 hex)

Germany 00000110 (06 hex)

Ireland 00000010 (02 hex)

Netherlands 00001101 (0D hex)

Norway 00000101 (05 hex)

Sweden 00000100 (04 hex)

United Kingdom 00000001 (01 hex)

United States 00000000 (00 hex)

Canada 00101001 (29 hex)

9

10

Press

Press

[Enter/Menu]

[Stop/Clear]

to complete the softswitch change.

.

The product will exit extended service mode within a few minutes.

Firmware download

3100 only

Newer versions of the firmware for the HP LaserJet 3100 product can

be downloaded to the product.

To perform a firmware download

®

Restart the computer in MS-DOS

1

window).

Press down and hold

2

Cycle power by unplugging the power cord from the power source,

3

[Stop/Clear]

and then replugging in the power cord.

Type the following, substituting the current version of the firmware

4

for

XXX

:

Copy /b leonXXX.rom lpt1:

mode (do not use an MS-DOS

while performing step 3.

2

EN

Chapter 2 –

59

Page 62

Recalibrating the document scanner

3100 only

Recalibrate the document scanner if you notice that copies, items

scanned to the computer, or faxes you send have black or white lines

running through them.

To recalibrate the document scanner

1 Clean the HP LaserJet 3100 product before recalibrating it. (See

“Cleaning the HP LaserJet 3100 product” in the product service

manual.)

2 On the control panel, press

3 Press [<] once to display Service and press

4 Use the [<] and [>] keys to select Scan Correction and press

[Enter/Menu]

5 Insert a blank, bright white piece of letter-sized paper into the

document feeder tray.

The HP LaserJet 3100 product pulls the piece of paper through and

then prints a recalibration test page. Discard this page. The

recalibration procedure is complete.

.

[Enter/Menu]

.

[Enter/Menu]

.

60 – Service mode

EN

Page 63

3

Overview

This chapter details the distribution of AC and DC power.

Power supply

EN

Chapter 3 –

61

Page 64

Distribution of AC and DC power for the

LaserJet 4000 series

AC power is supplied to the low-voltage power supply circuit in the

engine controller board when the power switch (SW 101) is turned on.

The low-voltage power supply circuit supplies +24 V DC and +3.3 V DC

to the printer. DC power drives the following items:

+24 VDC

• main motor

• scanner motor

• fan

• high-voltage power supply

+3.3 VDC

• sensors

• ICs on the engine controller board

• EIO accessories

62 – Power supply

EN

Page 65

Low-voltage power supply circuit (4000 series)

3

EN

Chapter 3 –

63

Page 66

Distribution of AC and DC power for the

LaserJet 5000 series

The AC line voltage fo r the LaserJet 5000 printer is applied through the

main switch (SW 101) and supplied to the low-voltage power supply

circuit through the fuse (FU1). The low-voltage power supply divides the

AC voltage to +24 VDC, +5 VDC and +3.4 VDC and supplies them to

the DC controller PCA. This circuit generates a zero-cross signal

(ZEROX) and supplies it to the DC controller PCA.

DC power is supplied as follows:

+3.4 VDC

• ICs on the DC controller PCA and the BD PCA

+5 VDC

• laser driver PCA

• sensors

+24 VDC

• high-voltage power supply PCA to drive the main motor

• exhaust fan

• scanner motor

• clutches

• solenoids

64 – Power supply

EN

Page 67

Low-voltage power supply circuit (5000 series)

3

EN

Chapter 3 –

65

Page 68

Distribution of AC and DC power for the

HP LaserJet 3100

The AC, DC, and high-voltage power supply circuits are all contained

within the ECU.

The AC power circuitry supplies AC voltage whene v er the po wer cord is

connected to the AC power source. AC voltage is distributed to the DC

power supply circuitry and to the AC driver circuitry. The AC driver

circuitry controls AC voltage to the heating element in the fusing

assembly.

The DC power distribution circuitry distributes +5 V DC and +12 V DC

as follows:

+5 V DC

• formatter

• photosensors

• DC controller circuitry

• laser/beam detect circuitry

+12 V DC

• motor

• scanner motor

• solenoid

+12VA DC

• high-voltage power supply

66 – Power supply

EN

Page 69

Distribution of AC and DC power for the HP

LaserJet 8000 series

The AC and DC power supply circuits are contained in the low-voltage

power supply (LVPS). The high voltages required for image formation

are generated by the high-voltage power supply (HVPS). The lowvoltage power supply and distribution system are illustrated below.

3

Low-voltage power supply circuit (8000 series)

EN

Chapter 3 –

67

Page 70

Protection Systems

Problems on the load side, such as short-circuits, can cause an

excessive flow of current from the DC power supplies or can generate

abnormal voltage. When this happens, the excess-current and excessvoltage protection systems automatically shut off output voltage to

protect the power supplies.

If the protection systems are activated and the power supply circuit

does not output DC voltage, turn the printer off, correct the problem in

the faulty load, and then turn the printer on again.

68 – Power supply

EN

Page 71

4

Overview

This chapter provides information on cabling and the printer interface.

Input/Output (I/O)

EN

Chapter 4 –

69

Page 72

Bidirectional parallel interface

The formatter PCA receives incoming data through its bidirectional

interface (IEEE 1284).

The bidirectional parallel interface (IEEE-1284 compliant) is compatible

with Centronics parallel interfaces. To take advantage of its enhanced

capabilities, such as bidirectional communication, the following must be

provided:

• Software application support for these features.

• An IEEE-1284 compliant parallel cable with the correct pin

configuration (see Table 4-1).

4000, 5000, and 8000 only

The user may configure the HIGH SPEED item in the Control Panel menu.

The default setting, YES, allows the I/O to run at the higher speeds

supported by most newer computers. When set to NO, the parallel

interface runs at the slower mode that is compatible for older

computers. The user may also configure the ADVANCED FUNCTIONS item.

The default setting, ON, allows f or two-wa y parallel communications . The

OFF mode disables this advanced functionality.

70 – Input/Output (I/O)

EN

Page 73

Pin configurations

Signal Name Printer Pin # Parallel Port

Pin #

nSTROBE 1 1

DATA 1 2 2

DATA 2 3 3

DATA 3 4 4

DATA 4 5 5

DATA 5 6 6

DATA 6 7 7

DATA 7 8 8

DATA 8 9 9

nACKNLG 10 10

BUSY 11 11

CALL (PE) 12 12

SELECT 13 13

nAUTOFd 14 14

On VDC (GND) 19 THRU 30 18 THRU 25

nFAULT 32 15

nSelIn 36 17

4

EN

Chapter 4 –

71

Page 74

IEEE-1284 compliant parallel cables

HP helped develop the IEEE-1284 standard and is one of the first

companies to introduce products that are compliant with it. HP offers

four IEEE-1284 compliant parallel cables. Each is described below.

Part number Length Connector type

C2950A 2 meters

(7 feet)

C2951A 3 meters

(10 feet)

C2945A 2 meters

(7 feet)

C2946A 3 meters

(10 feet)

C2947A 10 meters

(33 feet)

Host A to printer B (large) connector

Host A to printer B (large) connector

Host A to printer C (small) connector

Host A to printer C (small) connector

Host A to printer C (small) connector

Maximum I/O Cable Lengths

Serial RS-232C

RS-422A

Parallel (non-IEEE-1284)

Parallel (IEEE-1284) with “B”

type connector

Parallel (IEEE-1284) with “C”

type connector

72 – Input/Output (I/O)

15 meters (50 feet)

610 meters (2000 feet)

3 meters (10 feet)

3 meters (10 feet)

10 meters (33 feet)

EN

Page 75

Attaching the printer cables

The printer’s parallel port can have one or both of the following

connectors:

B-type parallel (large)

C-type parallel (small)

B-type

C-type

Printer interface connections

RS-232-C/RS-422-A serial interface

For this information, see the wiring diagram for common serial

input/output cables in the printer service manual.

4

EN

Chapter 4 –

73

Page 76

Configuring the computer interface

To configure the computer interface, see the

Reference Service Guide

, Volume I.

HP LaserJet Family Quick

74 – Input/Output (I/O)

EN

Page 77

LocalTalk I/O*

The printer implements AppleTalk networking protocol through

LocalTalk hardware. The LocalTalk network cable (HP part

number 92215N) is connected through the EIO card.

Expanded I/O*

The optional expanded I/O card can be installed in the slots provided on

the Formatter PCA. The expanded I/O card provides automatic

I/O switching between multiple computers or networks connected to

the printer. The network version printers include the HP JetDirect

Multi-protocol Network Card with Ethernet/10Base-T and 10Base-2,

and LocalTalk.

Flash*

Flash is provided in optional 2 and 4 megabyte (MB) flash memory

DIMMs for storage of forms, fonts, and signatures.

Disk*

The optional EIO-based hard disk is used for creating multiple original

prints (mopies) and for storing forms, fonts, and signatures.

*This feature does not apply to the HP LaserJet 3100.

EN

Chapter 4 –

4

75

Page 78

76 – Input/Output (I/O)

EN

Page 79

5

Media specifications

Overview

Use media that meet the specifications listed on the following pages. By

doing so, you will minimize the incidents of paper jams, prevent

premature wear to the printer, and reduce repair costs. Hewlett-P ac kard

recommends testing print media before buying it in large quantities.

Note

For complete paper specifications for all HP LaserJet printers, see the

HP LaserJet Family Paper Specification Guide

.

EN

Chapter 5 –

77

Page 80

Paper sizes

Metric System

Size Metric Dimensions U.S. Dimensions

A0 841 x 1189 mm 33.1 x 46.8 in

A3 297 x 420 mm 11.7 x 16.5 in

A4 210 x 297 mm 8.3 x 11.7 in

A5 148 x 210 mm 5.8 x 8.3. in

B4 (ISO) 250 x 353 mm 9.8 x 13.9 in

B5 (ISO) 176 x 250 mm 6.9 x 9.8 in

Imperial (U.S.) System

Size U.S. Dimensions Metric Dimensions

Ledger 11 x 17 in 279 x 432 mm

Legal 8.5 x 14 in 216 x 356 mm

Letter 8.5 x 11 in 216 x 279 mm

Executive 7.3 x 10.5 in 191 x 267 mm

Custom 5.8 x 8.2 in to

JIS B4** 10.1 x 14.3 in 257 x 364 mm

JIS B5** 7.2 x 10 in 182 x 257 mm

J Postcard* 3.9 x 5.8 in 100 x 148 mm

J Double Postcard* 5.8 x 7.9 in 148 x 200 mm

* J - Japanese

** JIS Japanese Industry Standard

8.5 x 14 in

149 x 210 mm to

216 x 356 mm

78 – Media specifications

EN

Page 81

Paper specifications

Category Specifications

Acid content 5.5 pH to 8.0 pH

Basis weight:

4000 series Tray 1

4000/4000 N Tray 2

4000 T/4000 TN Tray 2

and Tray 3

4000 series optional

500-sheet tray

4000 series Duplexer

5000 series:

Tray 1

Tray 2 or optional

250-sheet Tray

Optional 500-sheet Tray

Duplexer

3100:

Paper input bin

Single-sheet input slot

Document feeder tray

8000 series:

Standard output bin

Left output bin

Optional 2000-sheet

input tray

Duplexer

Optional envelope feeder:

4000 series

8000 series

60 to 199 g/m

60 to 105 g/m

60 to 105 g/m

60 to 105 g/m

60 to 105 g/m

60 to 105 g/m

60 to 105 g/m

the front output slot)

60 to 105 g/m

the front output slot)

44 to 105 g/m

the special media lever)

60 to 105 g/m

75 to 105 g/m

60 to 90 g/m

Caliper 3.0 to 7.0 mils (0.094-0.18 mm)

Curl in ream Flat within 5 mm (0.2 in)

Condition of cut edge Cut with sharp blades with no visible fray

Fusing compatibility Must not scorch, melt, offset, or release

hazardous emissions when heated to 205°C

(400°F) for 0.1 second

Grain Long grain

Moisture content 4% to 6% by weight

Smoothness 100-250 Sheffield

2

(16 to 53 lbs)

2

(16 to 28 lbs)

2

(16 to 28 lbs)

2

(16 to 28 lbs)

2

(16 to 28 lbs)

2

(16 to 28 lbs)

2

(16 to 28 lbs) (up to 42 lbs using

2

(16 to 28 lbs) (up to 42 lbs using

2

(12 to 28 lbs) (up to 67 lbs using

2

(16 to 28 lbs)

2

(20 to 28 lbs)

2

(16 to 24 lbs)

5

EN

Chapter 5 –

79

Page 82

Paper weight equivalences