Page 1

DesignJet 1050C/1055CMHP Large-Format Printers

Service Manual

Page 2

For HP Internal U s e Onl y

©Copyright Hewlett-Packard

Compa n y 1999

This document contains

proprietary information that is

protected by copyright. All rights

are reserved. No part of this

document may be photocopied,

reproduced, or translated to

another language with out th e

prior written con sen t of He wle ttPackard Company.

First Edition, March 1999

Warranty

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warrant y of any kind with

regard to this material,

including, but not limited to,

the implied warranties of

merchantabilit y and fitness f or

a particular purpose.

Hewlett- Packard shall not be

liable for errors contained herein

or for incidental or cons equential

damages in connection with the

furnishing, performance, or use

of this material.

WARNING

The procedu r es des cribed in this

manual are to be performed by

HP-qualified service per s onnel

only.

Electrical Shock Hazard

Serious shock hazard leading to

death or injury may result if you

do not take t he following

precautions:

- Ensure that th e ac pow er outlet

(mains) has a protective earth

(ground) terminal.

- Disconnect the Printer from the

power source prior to performing

any maintenance.

- Prevent water or any other

liquids from running onto

electrical components or ci rcuits,

or through openings in the

enclosure.

Electrostatic Discharge

Refer to the beginning of Chapter

8 of this manual, for precautions

you should take to prevent

damage to the Printer circuits

from electrost atic discharge.

WARNING

The Warning symbol calls

attention to a procedure, practice,

or the like, which, if not correctly

performed or adhered to, could

result in personal in jur y. Do not

proceed beyond a Warning

symbol until the in di cated

conditions are fully understood

and met.

CAUTION

The Caution symbol calls

attention to an oper atin g

procedure, practice, or the like,

which, if not correctly performed

or adhered to, could result in

damage to or destruction of part

or all of t h e pr o duct. Do not

proceed beyond a Caution

symbol until the in di cated

conditions are fully understood

and met.

Technical Marketing,

Barcelona Division,

Hewlett-Packard Espa nola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

Safety S ymbols

General definitions of safety

symbols are given immediatel y

after the tabl e of contents.

Page 3

1

DesignJet 1050C/1055CMHP Large-Format Printers

Service Manual

Page 4

Using this Manual

Purpose

This Service Manual contains information necessary to test,

calibrate and service:

n

HP DesignJet 1050C Printer (Model C6074A)

n

HP DesignJet 1055CM Printer (Model C6075A)

For information about using these printers, refer to the

corresponding User and Quick Reference Guides.

Readership

The procedures described in this Service Manual are to be

performed by HP Certified service personnel only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are

located in Chapter 7.

Conventions

A small arrow ⇒ is used to indicate other parts of the Service

Manual where you can find information related to the topic you are

consulting.

2

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 5

Table of Contents 1

Troubleshooting 1-1

Introduction 1-2

Troubleshooting System Error Codes 1-2

Performing a Service Test on a Failed Assembly 1-3

Performing the Necessary Service Calibrations 1-3

Solving Image Quality Problems 1-3

Front-Panel LEDs Flash Briefly at Power ON & Nothing Else Happens 1-4

The Printer does not Power ON 1-5

ALL the Front-Panel LEDs are Lit but Nothing Else Happens 1-5

One of the Print Quality LEDs on the Front Panel is Lit (and nothing

else) and the "SELF TEST..." Message Remains on the Front P anel 1-5

The Printer Continuously Rejects Printheads 1-6

Cover Sensors are not Working 1-6

The Line Sensor has Problems Detecting Media 1-6

Troubleshooting Media Jams/Printhead Crashes 1-7

Troubleshooting Shutdowns 1-7

Problems with the Vacuum Fan 1-9

Vacuum suction much lower at high altitudes 1-9

Bin marks on prints done on HP High Gloss media 1-9

Printhead Crashes/Smears on High Density Prints Using Coated Media 1-10

Color changes when stacking prints done on HP High Gloss Media 1-10

HP-GL/2 color differences in different HP DesignJet Printers 1-1 1

Scratches on prints done on NTP, Vellum and HP High Gloss media 1-11

Banding at variable extreme environmental conditions 1-12

Banding due to Ink Cartridge replacement while printing 1-12

Long term bleed and hue shift on HP High Gloss media 1-12

Lower imag e gloss directly after printing on HP H igh Gloss Photo Pape r 1-13

34" Rice Paper not supported 1-13

Cut Sheet rice paper loading failure 1-13

Worm marks on HP Coated media with light area fills 1-13

Solving Media-Handling Problems 1-14

How to Navigate through the Front-Panel Menu 1-15

Service Configuration Print 1-19

Table of Contents

HP DesignJets 1050C and 1055CM Printers Service Manual

3

Page 6

Table of Contents

System Error Codes 2-1

Introduction 2-2

Continuable and Non-Continuable Error Codes 2-2

System Error Codes During Initialization 2-18

HP No.80 Ink Supplies Troubleshoo ting 3-1

What are HP No.80 Supplies? 3-2

Ink Cartridges 3-2

Printheads and Printhead Cleaners 3-2

Identifying the Components 3-3

General Information About HP No.80 Supplies 3-4

Some General Precautions When Handling HP No.80 Supplies 3-5

Priming the Ink System 3-6

When Should You Replace the HP No.80 Supplies? 3-6

The Front Panel Display 3-7

Obtaining Ink Cartridge Information 3-8

Obtaining Printhead Information 3-9

Ink Cartridge Status Messages 3-11

Ink Cartridge Status While Printing 3-11

Ink Cartridge Status While Replacing 3-12

Printhead Status Messages While Printing 3-13

Printhead Status Messages While Replacing 3-15

Summary of Solving HP No.80 Supplies Problems 3-17

Carriage Interconnect Wiper 3-18

4

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 7

Service Tests and Utilities 4-1

Service Tests (Diagnostics) 4-3

Entering the Service Te sts Menu 4-4

1. Electronic Systems 4-5

2. EIO Card 4-10

3. Hard Disk Drive 4-12

4. Ink Pressure System 4-14

5. Scan Axis 4-17

6. Paper Axis 4-20

7. Drop Detector 4-22

Service Utilities 4-25

Entering the Service Utilities Menu 4-26

1. Tubes Purge 4-28

2. Release Info 4-32

3. Set Asian PS Fonts 4-33

4. Printer Model T ype 4-35

5. Overdrive Cleaning 4-37

6. EEROM Utilities 4-38

7. Printhead Check 4-41

8. Mon. Mode Baud Sel. 4-42

Table of Contents

Service Calibrations 5-1

Service Calibrations 5-2

Entering the Service Calibrations Menu 5-4

1. Accuracy Calibration 5-6

2. Line Sensor 5-9

3. Service Station 5-11

4. Roller Mark Position 5-13

5. Pen to Paper Spacing 5-15

6. Color to Color calibration 5-16

7. Calibrations Backup 5-19

8. Pen Alignment 5-22

Carriage Height Calibration 5-24

HP DesignJets 1050C and 1055CM Printers Service Manual

5

Page 8

Table of Contents

Print Quality 6-1

Print Quality Troubleshooting Checklist 6-2

Print Modes 6-3

How to Use the Print Quality Test 6-4

What is the Print Quality Test? 6-4

Considerations for Printing the Print Quality Test. 6-4

Printing the Print Quality Test 6-4

Nozzle Print Test 6-6

How to fix the Nozzle Defects 6-7

Color Alignment Print Test 6-7

Solving the Color Alignment Problem 6-8

Overall Print Quality Test in BEST mode 6-9

What is Banding? 6-9

Solving the Banding Problem 6-10

Aligning the Printheads 6-12

Service Accuracy Calibration 6-12

Troubleshooting Print Quality Problems 6-13

Problems with Stepped Lines 6-13

Problems with printing lines 6-14

Problems with Color-to-Color Alignment 6-15

Problems with Horizontal Lines (Banding) 6-17

No Printing Defects Found in the Print Quality Test 6-21

Solving Color Accuracy problems 6-22

Color Consistency problems 6-22

Long T e rm Color Bleeding (Glossy Papers) 6-22

Color Accuracy Configuration 6-23

Media 6-24

There are Smears or Scratching on the Printed Media 6-24

6

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 9

Parts and Diagrams 7-1

Printer Support 7-2

Rear Covers 7-4

Electronics Module 7-6

Right Hand Cover 7-8

Left Hand Cover and Window 7-10

Right Hand Assemblies 7-12

ISS and APS Assembly 7-14

Clutch Assembly 7-16

Carriage Assembly 7-18

Scan-Axis Assemblies 7-20

Drive Roller and ARSS Miscellaneous Parts 7-22

Paper Path Assemblies 7-24

Pinch Assembly 7-26

Drive Roller Assemblies 7-28

Center Guide and Media Sensor 7-30

Tubes Guide Assemblies 7-32

Ordering Accessories 7-34

Table of Contents

Removal and Installation 8-1

Introduction 8-2

Safety Precautions 8-2

Electrostatic Discharge (ESD) Precautions 8-3

Required Tools 8-3

Right Hand Cover 8-4

Front Panel Assembly 8-6

Right Hand Trim and Window Switch 8-7

Service Station Assembly 8-8

Drop Detector Assembly 8-10

Vacuum Fan 8-11

Paper-axis Motor Assembly 8-12

Left Hand Cover 8-13

Left Hand Trim Assembly 8-18

Ink Supply Station Assembly (ISS) 8-19

Air Pressurization System (APS) 8-20

Clutch Assembly and left hand miscellaneous parts 8-21

Tail Deflectors and Rear Platen 8-23

Left and Right Rear Covers 8-24

HP DesignJets 1050C and 1055CM Printers Service Manual

7

Page 10

Table of Contents

Electronics Module 8-25

Media Sensor 8-29

Window 8-30

Top Cover 8-31

Back Cover 8-32

Scan-axis Motor Assembly 8-33

Encoder Strip 8-34

Tensioner 8-37

Trailing Cable 8-39

Cutter Assembly 8-42

Carriage Assembly and Belt 8-44

Tubes System Assembly 8-53

Ink Leak Detector Assembly 8-60

Front Platen Assembly 8-62

Platen Assembly 8-63

Paper Entry Assembly 8-64

Roller Guide 8-66

Media Holder Strip 8-69

Drive Roller 8-70

Center Guide 8-71

Pinch-Wheel Assembly and Cam 8-73

Preventive Maintenance 9-1

Moisture on the Printer 9-2

Noisy Carriage Bushing 9-2

Belt Swelling 9-2

Cleaning the Printer 9-2

General Cleaning 9-2

Cleaning the Overdrive 9-3

Scheduled Maintenance 9-3

Level of Printer Usage 9-3

Scan-axis Maintenance 9-4

8

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 11

Funct ional Overv iew 10-1

Introduction 10-2

HP DesignJet 1050C Printer 10-2

HP DesignJet 1055CM printer 10-2

Electrical System 10-2

Power Supply Unit (PSU) 10-3

Soft Power-Off Switch 10-4

Front Panel 10-4

Ink Delivery System (IDS) 10-5

Ink Supply Station (ISS) 10-5

Tubes System 10-6

Air Pressurization System (APS) 10-7

Ink Level Sense (ILS) 10-7

Leak Detect System (LDS) 10-8

Service Station 10-9

Print Head Cleaner (PHC) 10-9

Printer Specifications 10-12

Printable Area 10-16

Interface Specifications 10-17

Regulatory Notices 10-18

To Obtain a Material Safety Data Sheet (MSDS) 10-18

Sound 10-18

Electro-Magnetic Compatibility (E MC) 10-18

VCCI Class A and Class B (Japan) 10-21

Declaration of Conformity 10-22

www.designjet-online.hp.com 10-23

Table of Contents

Glossary

Index

HP DesignJets 1050C and 1055CM Printers Service Manual

9

Page 12

Table of Contents

10

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 13

Tr oubleshooting 1

Introduction 1-2

Troubleshooting System Error Codes 1-2

Performing a Service Test on a Failed Assembly 1-3

Performing the Necessary Service Calibrations 1-3

Solving Image Quality Problems 1-3

Front-Panel LEDs Flash Briefly at Power ON & Nothing Else Happens 1-4

The Printer does not Power ON 1-5

ALL the Front-Panel LEDs are Lit but Nothing Else Happens 1-5

One of the Print Quality LEDs on the Front Panel is Lit (and nothing else) and

the "SELF TEST..." Message Remains on the Front Panel 1-5

The Printer Continuously Rejects Printheads 1-6

Cover Sensors are not Working 1-6

The Line Sensor has Problems Detecting Media 1-6

Troubleshooting Media Jams/Printhead Crashes 1-7

Troubleshooting Shutdowns 1-7

Problems with the Va cuum Fan 1-9

Vacuum suction much lower at high altitudes 1-9

Bin marks on prints done on HP High Gloss media 1-9

Printhead Crashes/Smears on High Density Prints Using Coated Media 1-10

Color changes when stacking prints done on HP High Gloss Media 1-10

HP-GL/2 color differences in different HP DesignJet Printers 1-11

Scratches on prints done on NTP, Vellum and HP High Gloss media 1-11

Banding at variable extreme environmental conditions 1-12

Banding due to Ink Cartridge replacement while printing 1-12

Long term bleed and hue shift on HP High Gloss media 1-12

Lower image g lo ss dire c tly after prin ting on HP High Glos s P hot o Pa per 1-13

Cut Sheet rice paper loading failure 1-13

34" Rice Paper not supported 1-13

Worm marks on HP Coated media with light area fills 1-13

Solving Media-Handling Problems 1-14

How to Navigate through the Front-Panel Menu 1-15

Service Configuration Print 1-19

1

HP DesignJets 1050C and 1055CM Printers Service Manual

1-1

Page 14

Troubleshooting

Guide to Troublesho oti ng the Printer

Introduction

This chapter will guide you through the relevant steps to take when

troubleshooting the printer.

Troubleshooting System Error Codes

Chapter 2 - System Error Codes contains a list of system error

codes and their respective descriptions and recommended corrective

actions. Only try one recommended action at a time and check if the

error code has disappeared.

If you have an error code which is not documented in this Service

Manual or you have an error which you cannot resolve, then report

the error to the HP Response Center or the nearest HP Support

Office. When reporting the error , have the following information

ready:

n

Model and Serial Number of the printer.

n

Which firmware revision the printer is using (See Note below).

Check firmware in Utilities / Statistics / Code rev.

n

The complete error number (See Note below).

n

The Service Configuration Print ⇒ Page 1-19

n

The Current configuration sheet.

n

Which software application the customer is using (name, version,

etc. ) .

NOTE When reporting the System Error Code, make sure that you

supply the full Error Code (including the last 8 numbers where

applicable) and the firmware version. Without thi s information,

HP Support Personnel cannot help you.

1-2

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 15

Troubleshooting

Performing a Service Test on a Failed Assembly

If possible, always perform a Service Test on the component/

assembly that you are about to replace, just to make sure that is the

component/assembly that has failed.

NOTE If the test on that component/assembly passes, you should NOT

replace it.

For information on the Service Tests and how to use them see

Chapter 4 - Service T es ts and Utilities.

Performing the Necessary Service Calibrations

Is the printer calibrated correctly after replacing a component?

Refer to the table on Page 5-2 to determine when a calibration is

required.

NOTE Remember that certain Calibrations are required even if an

Assembly has been disassembled to gain access to another

Assembly or Component.

For information on the Service Calibrations and how to use them

see Chapter 5 - Service Calibrations.

Solving Image Qua lity P roblems

Whenever an Image Quality problem appears, it is advisable to print

the Image Quality Print to help diagnose the problem. The Image

Quality Print will help you differentiate between possible printhead

errors and other problems such as incorrect front-panel selection,

driver or RIP configuration or mechanical problems. For

information on solving Image Quality problems see Chapter 6 -

Print Quality.

HP DesignJets 1050C and 1055CM Printers Service Manual

1-3

Page 16

Troubleshooting

Front-Panel LEDs Flash Briefly at Power ON &

Nothing Else Happen s

The Power Supply detects a Short and shuts down the Power.

1 The Hard Disk Drive or the Network Card could be faulty.

Troubleshoot the problem as follows:

a If the Printer has a Hard Disk Drive and/or a Network card

installed, switch the Printer OFF from the back of the Print er , and

remove them both.

b Switch the Printer ON again.

c If the Printer functions correctly now, switch the Printer OFF

again and reinstall the Network Card correctly, making sure that

the two installation screws are completely tightened.

NOTE If the Printer DOES NOT function correctly with the Hard Disk

Drive and the Network Card removed, then you must replace the

Electronics Module.

d Switch the Printer ON again

e If the Printer functions correctly with the Network C ard installe d,

switch the Printer OFF again.

NOTE If the Printer DOES NOT function correctly with the Network

Card installed, then you must replace it.

f Reinstall the Hard Disk Drive corr ect ly, making sure that the two

installation screws are completely tightened.

g Switch the Printer ON again

h Check if the Printer f uncti ons cor rec tly with the Hard Disk Drive

installed.

NOTE If the Printer DOES NOT function correctly with the Hard Disk

Drive installed, then you must replace it.

2 Make sure that none of the cables connected to the Electronics

Module have been pinched between the cover and the sideplate.

1-4

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 17

Troubleshooting

The Printer does not Power ON

1 Check that the power cord is connected correctly to the Printer and

to the Power Socket.

2 Check that the Firmware DIMM is installed correctly in the correc t

slot (the first slot from the right) at the back of the Printer.

3 Check that the Power Switch on the BACK of the Printer is in the

ON position.

4 Check that the Front-Panel Cable is correctly connected to the

Electronics Module. Also make sure that the Front-Panel cable is

not damaged.

ALL the Front-Panel LEDs are Lit but Nothing Else

Happens

The Firmware DIMM is NOT correctly installed.

1 Power OFF the Printer from the back and disconnect the power

cord. Reseat the Firmwar e DIMM (the firs t slot from the right)

making sure that it is installed correctly.

One of the Print Quality LEDs on th e Front Panel is

Lit (and nothing else) and the "SELF TEST..."

Message Remains on the Front Panel

One of the DRAM DIMMs is NOT correctly installed or Faulty.

1 Power OFF the Printer from the back and disconnect the power

cord. Reseat both Firmware DIMMs (the first two slots from the

left) making sure that they are installed correctly. If reseating the

DRAM DIMMs does not solve the problem, replace them instead.

HP DesignJets 1050C and 1055CM Printers Service Manual

1-5

Page 18

Troubleshooting

The Printer Continuously Rejects Printhead s

1 Clean the flex contacts on the Printhead and in the Carriage

Assembly using the Carriage Interconnect Wiper (R e fer to Chapter

3) and try again.

2 If ALL the Printheads are rejected (the status message on the Front

Panel does NOT show "OK" for all the Print heads) then perf orm the

Electronic Systems Test ⇒ Page 4-5.

Cover Sensors are not Working

1 Check if the faulty sensor is installed correctly.

2 Check if the cable for the faulty sensor is connected correctly .

3 Replace the faulty Sensor.

The Line Sensor has Problems Detecting Media

1 Check the type of media that is being used since the Line sensor

may have problems detecting transparent media or some types of

Non-HP media. Try loading white HP media in to the Printer and

check if the Line sensor detects it.

2 Excessive ink deposits on the Platen surface can fool the sensor by

reflecting the light. Clean the Platen.

3 The Line Sensor is not calibrated correctly. Perform the Line Sensor

calibration ⇒ Page 5-9.

4 The Line Sensor is damaged or faulty. Replace the Carriage

Assembly ⇒ Page 8-44.

1-6

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 19

Troubleshooting

Troubleshooting Media Jams/Printhead Crashes

NOTE If using HP Coated Media when problem occurred, please also

refer to Page 1-10, Printhead Crashes/Smears on High Density

Prints Using Coated Media.

The failure modes "media jam" and "head crash" are grouped

together because in many cases a media jam causes the media to lift

up into the carriage path and cause a head crash, thus causing many

media jam failures to be reported as head crashes.

1 Did the media jam occur when loading media?

n

If the client has had media jams, it is common for pieces of media

to get stuck in the media path. Clear the media path.

NOTE When clearing a media jam, sometimes media is stuc k in the

paper path. To clear this, you must lift the media load handles

and insert thicker media into the paper path to pus h out the

media that is still stuck there.

2 Is the customer using non-HP media?

n

The use of non-HP media can easily be the cause of media jams

and head crashes (especially head crashes because HP media is

specially formulated to avoid cockle, one of the primary causes

of head crashes). If the media is not HP approved, advise the

customer to use HP media and check to see if the problem is now

solved .

3 The Carriage is at the incorrect height in relation to the Center

Platen. Adjust the carriage to the correct height ⇒ Page 5-24 and try

to load the media again.

4 Check that the Vacuum Fan works correctly - Refer to Page 1-9,

Problems with the Vacuum Fan.

Troubleshooting Shutdowns

If a shutdown occurs, you will get the message "Switch Power Off"

followed by:

n

Check Printhead Cleaner Path.

n

Check Paper Path.

n

Check Printhead Path (followed by (1), (2) or (3)).

A shutdown in each path will require different steps to resolve the

HP DesignJets 1050C and 1055CM Printers Service Manual

1-7

Page 20

Troubleshooting

problem as explained as follows.

WARNING In each case, make sure that you power OFF the printer before

attempting any procedures to resolve the problem.

Printhead Cleaner Path

1 Open the right door of the printer and check for any visible

obstacles restricting the movement of the Service Station. Manually

move the Service Station, checking for smooth and free movement.

Paper Path

1 Open the Window and check for any visible obstacles restricting the

movement of the Drive Roller. If there is a wrinkled mass of media

inside the paper path, lift the Pinch wheels (using the Media Load

Handles) and clear the obstruction. If you cannot reach the media,

remove the Electronics Module (⇒ Page 8-25) and the Roller Guide

(⇒ Page 8-66) from the Rear of the Printer to gain better access.

2 If this shutdown happens at the end of a Roll of Media, it could be

because the media is stuck firmly to the Roll. Lift the Pinch wheels

(using the Media Load Handles) and pull the media clear.

3 Replace media spindle if broken.

4 Replace the Paper-Axis Motor ⇒ Page 8-12.

Printhead Path

When a shutdown occurs in the Printhead path, you will get the

message "Switch Power Off / Check Printhead Path (*). The (*)

will be a number, which will give an indication on where the f a ilure

occurred:

PWM Shutdown (1) and Energy Shutdown (3)

1 Clean Slider Rods and Apply Oil along the complete axis of the

Slider Rods. After applying the Oil, perform the Scan-Axis Te st ⇒

Page 4-17 and ch eck that the valu es are within the given limits.

2 Replace the Scan-Axis Motor ⇒ Page 8-33.

Velocity Shutdown (2)

1 Open the Window and check for any visible obstacles restricting the

movement of the Carriage Assembly. Try and move the Carriage

Assembly manually , checking for smooth and free movement.

1-8

2 Check that the Encoder Strip is clean. If necessary, clean Encoder

Strip using a damp cloth.

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 21

Troubleshooting

Problems wi th the Vacu um Fan

If you have problems loading either Roll or Sheet Media, then there

could be a problem with the Vacuum Fan. T o ver ify i f ther e really is

a problem with the Vacuum Fan, try the following:

1 With the Printer ON, open the Window of the Printer and place a

sheet of HP High Gloss Photo Paper (must be D-Size), aligned with

the blue lines on the Center Platen. If the Vacuum Fan holds the

sheet in place, and then loads it correctly, then the Vacuum Fan

functions correctly. If the Vacuum Fan does not hold the sheet in

place (no suction), then try the following:

n

Check that the holes in the Center Platen are NOT blocked.

n

Check that the Vacuum Fan is installed correctly.

n

Replace the Vacuum Fan ⇒ Page 8-11.

2 If the Vacuum Fan held the sheet in place, but couldn’t correctly

load it, then there could be a problem with the Overdrive. In this

case, replace the Platen Assembly ⇒ Page 8-63.

Vacuum suction much lower at high altitudes

At altitudes above 3,000 meters, the vacuum force holding down the

media will be lower, therefore the media will not be held in place

properly causing:

n

Ink Smearing on the Media.

n

Printhead crashes against the Media.

n

Cut Sheet loading problems (high probability).

n

Roll Media loading problems (low probability).

PRINTER LIMITATION - NO SOLUTION AVAILABLE.

Bin marks on prints done on HP High Gloss media

Prints done on HP High Gloss media are sensitive to scratches when

they fall into the media bin. To solve the problem, try the following:

n

Advise the customer to install the Media Bin cover, that was

included with the Printer, to avoid this problem.

n

If possible, advise the customer to hold the prints and prevent

them from falling in to the bin.

HP DesignJets 1050C and 1055CM Printers Service Manual

1-9

Page 22

Troubleshooting

Printhead Cra s hes/Smears on Hig h D e nsity Pr ints

Using Coated Media

High density prints can cause cockle mainly on HP Coated Media.

This causes two main problems:

1. Cockling in the borders - Because the printer places too much ink on

the Coated Media, the borders of the print become raised, causing

the Printhead to crash against the media. To solve the problem, try

the following:

n

Check in the Front Panel if Ink Limiting is ON or OFF. If Ink

Limiting is OFF, turn it ON.

n

Change the paper margins to 15mm, either in the Front Panel or

in the Driver. If the customer is printing PostScript images, send

them a PPD file containing the extended margins of 15mm.

2. Cockling within the print - If the P rinter places too much ink within

the print, the media starts to ripple, causing the Printhead to smear

against the media. To solve the problem, try the following:

n

Check in the Front Panel if Ink Limiting is ON or OFF. If Ink

Limiting is OFF, turn it ON.

n

Never use HP Coated Media for High Density prints. As a

substitute use HP Heavy Coated Media.

Color changes whe n s tacking prints done on HP High

Gloss Media

Color differences can be seen between the covered and uncovered

part of a print done on HP High Gloss Media. This is because the

part of the print exposed to the air is always lighter than the covered

one. The ink on the covered part of the print cannot evaporate

therefore the ink continues to diffuse creating larger ink dots. To

solve the problem, try the following:

n

Allow the print to absolute drying completion before stacking.

Depending on the ink percentage, this can take from 10 minutes

up to 3 hours.

n

Creating dryer environmental conditions helps reduce the

problem. To find the environmental conditions, print the Service

Configuration Print (Printer Setup Menu / Utilities / Test prints /

Service config)

1-10

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 23

Troubleshooting

HP-GL/2 color differences in different HP DesignJet

Printers

Color differences between one image printed on the HP DesignJet

1000 Series and the rest of the DesignJet platforms are due to the

different chemistry of the 1000 series inks compared with the rest of

the inks for other printers. This color variability among different HP

DesignJet Series Printers has been always present. To solve the

problem, try the following:

n

Perform the color calibration from the driver at the time of

printing. However, that calibration is not very accurate but it may

help in the most severe cases.

n

Some applications have color controls for the user to modify the

image in order to obtain the desired colors.

n

Printing with PostScript reduces the problem significantly.

n

A void very long exposures to extreme environmental conditions

after printing with glossy media (more than 12 hours at 80%

humidity may result in severe changes in color).

Scratches on prints done on NTP , Vellum and HP High

Gloss media

Normally at the end of a roll, the curl on the media is high and the

printed area can touch the media load handles or the media roll,

transferring ink to the "still-not-printed" media or damaging the

actual print. This problem mainly affects Natural Tracing Paper

(NTP), Vellum and HP High Gloss Media. To solve the problem, try

the following:

n

Increase the Dry Time using the Front Panel (Refer to the User’s

Guide - Chapter 3 Work ing with Paper).

n

Install a new roll of media.

HP DesignJets 1050C and 1055CM Printers Service Manual

1-11

Page 24

Troubleshooting

Banding at variable extreme environmental conditions

Since the Accuracy Calibration has been done at normal

environmental conditions, printing in extreme environmental

conditions will cause banding because the advance of the Drive

Roller does not correspond to the same conditions that the

calibration was done in. To solve the problem, try the following:

n

Perform the Accuracy Calibration in the new environmental

conditions (Refer to the User’s Guide - Chapter 8 Reconfiguring

your Printer).

Banding due to Ink Cartridge replacement while

printing

A user has removed the Ink Cartridge while the printer was printing,

which has caused the printer to stop. If the user does not replace the

Ink Cartridge immediately, when the printer starts to print again, a

band will appear in the position where the printing restarted. This is

because the wet ink interacts with the dried ink on the media

causing the band to appear. To solve the problem, try the following:

n

Do NOT remove the Ink Cartridge while the Printer is Printing.

Only replace/remove Ink Cartridges in between Prints.

n

If the Ink Cartridge was replaced due to the "Empty" status on the

Front Panel, then advise the customer to replace the Ink Cartridge

when the "Very Low" status is showing on the Front Panel.

Long term bleed and hue shift on HP High Glos s

media

Under high humidity conditions (approx. >65%) the water trapped

in the air can easily be absorbed by the highly hydrophilic media

coating polymers. That allows the dye to migrate through the

coating and causes bleeding. This problem is especially noticeable

with the colors that require Magenta. To solve the problem, try the

following:

n

Reduce the level of humidity (<65%) that the Printer is working

in. T o find the humidity level, print the Service Configuration

Print (Printer Setup Menu / Utili tie s / Test prints / Service config).

1-12

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 25

Troubleshooting

Lower image gloss directly after printing on HP High

Gloss Photo Paper

Lower gloss appearance of the print when the media is drying which

gradually disappears to get the final gloss level (between 10 and 60

minutes depending on the ink density). Try the following:

n

W a it at least 60 minutes to achieve the high gloss appearance.

34" Rice Paper not supported

Roll length is 34" (Non-standard) and the pinch wheels can’t control

edge of media causing ink smears and Printhead crashes in middle

of prints with or without area fills.

PRINTER LIMITATION - NO SOLUTION AVAILABLE.

Cut Sheet rice paper loading failure

Thin rice paper is sucked into the Center Platen grooves and Linear

Blade Ridge. This implies that the friction between the Center

Platen and the rice paper becomes higher than between the

Overdrive wheels and the paper. This effect make it almost

impossible to load the rice paper correctly because the Vacuum is

too high.

PRINTER LIMITATION - NO SOLUTION AVAILABLE.

Worm marks on HP Coated media with light area fills

Light bands (S-shaped) in Paper axis direction where light area fills

are printed, causing unacceptable Image Quality defect.

n

Print the Service Configuration Print (⇒ Page 1-19) and check if

the level of Humidity is very low (below 30%). Increasing

humidity may help in reducing the severity of the problem.

NOTE The media is causing the problem and NOT the Printer. Do not

attempt to try an d re pla c e Pri nte r part s to solv e this pr o blem.

HP DesignJets 1050C and 1055CM Printers Service Manual

1-13

Page 26

Troubleshooting

Solving Media-Handling Problems

The Front Panel Keeps Indicating that Media Is Misa ligned or

Incorrectly Positioned

Roll media

n

The roll may be loaded the wrong way. The paper should load

over the roll toward you.

n

The paper may be loaded at an angle. The right-hand edge must

be parallel to the white line on the paper entry roller.

WARNING Ensure that the paper is wrapped tightly on the roll. This is a

very important step to remember b ecau s e i f this i s not do ne, t h e

media may be loaded at an angle, causing the media to be

rejected.

n

Perform the manual alignment procedure (Refer to the User’s

Guide).

n

Check that the paper is correctly loaded onto the spindle.

Sheet media

n

It must be loaded with the right-hand edge against the blue

perforated line on the printer.

n

The media may be crumpled or warped or may have irregular

edges.

n

If you are using hand-cut media, the edges may not form a rightangle or they may be rough. Do not use hand-cut media. Use only

purchased sheet media.

n

If the media you are trying to load is very slippery, hold the

media with both hands, and gently push the media into the printer

until it buckles upwards in the middle, this will help the printer to

load it.

n

If the overdrive is covered in dust, it will have problems picking

up the sheet media during the load process. Clean the Overdrive

using the Overdrive Cleaning Service Utility ⇒ Page 4-37.

1-14

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 27

Troubleshooting

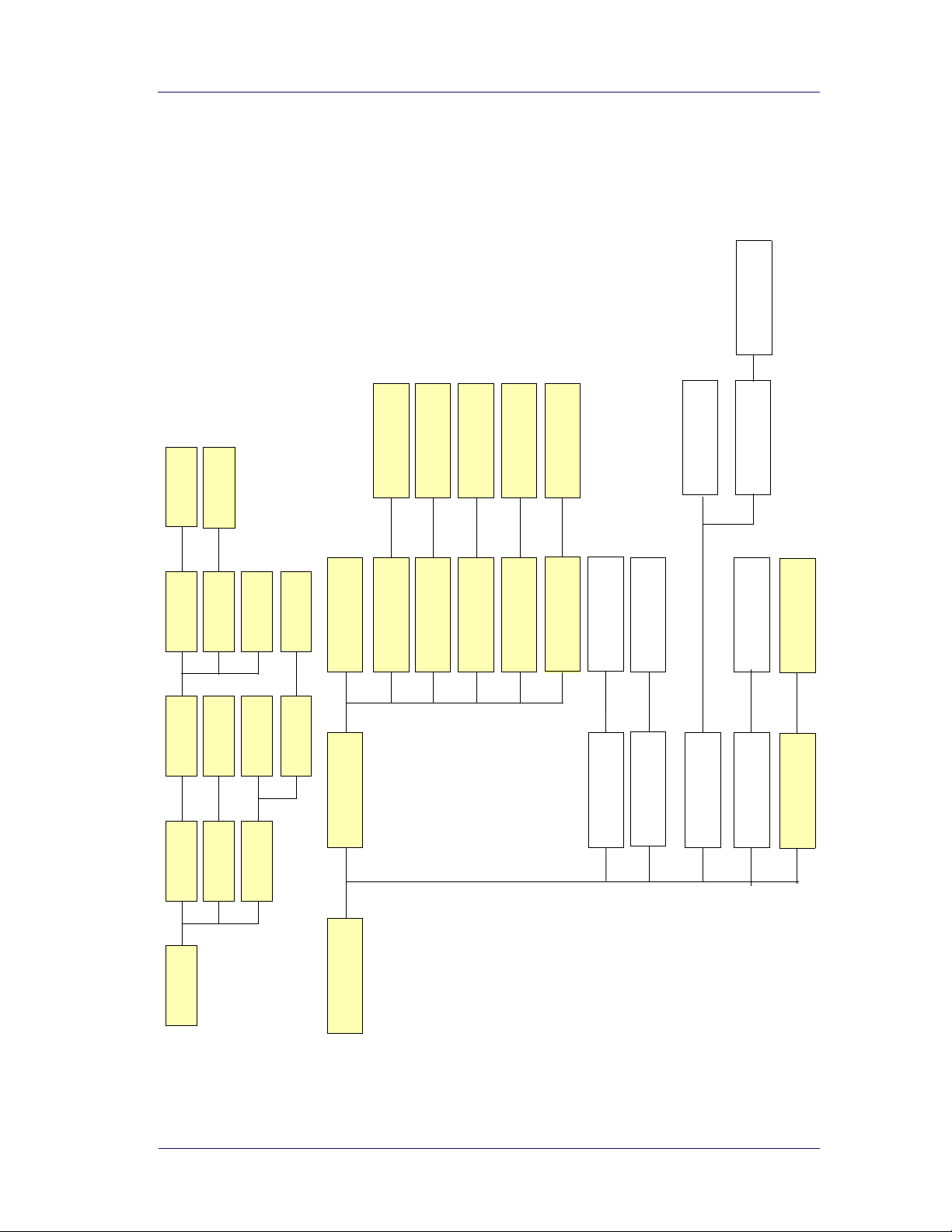

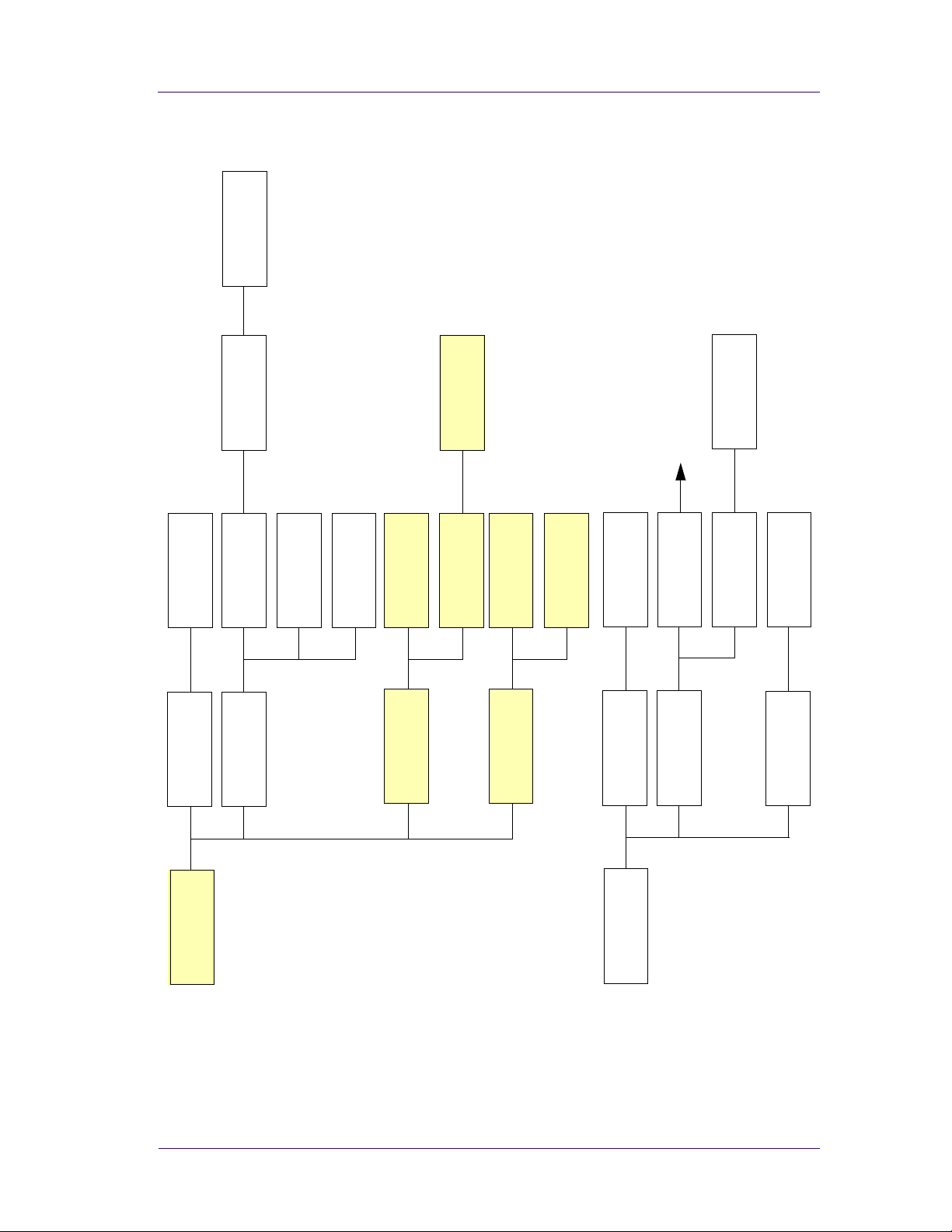

How to Navigate through the Front-Panel Menu

30...5

Statistics

Best ARCH,

Over A2, Over A1

99 ... 1, 0

Width, Length

ARCH A ... E1

Best ANSI,

Best JIS B,

JIS B4 ... B1

Best ISO A,

ANSI A ... E

ISO A4 ... A0

Automatic

Manual

@@

Copies

Statistics

Delete page

Move to top,

99 ... 2, 1 min

Oversize

JIS

ARCH

Inked Area, Software etc

O. K.

Off

On, Off

In orde r, Opt imal

Size

Nest

Queue

Queuing Management

ISO

ANSI

0 ... 270

TOYO,

Rotate

On, Off

On, Off

Normal, Extended

SWOP, Native

Margins

Nest Spacing

On, Off

Fit to Page

100% ... 419%

Mirroring

PostScript Scale

Page Format

Queuing & Nesting

HP DesignJets 1050C and 1055CM Printers Service Manual

1-15

Page 28

Troubleshooting

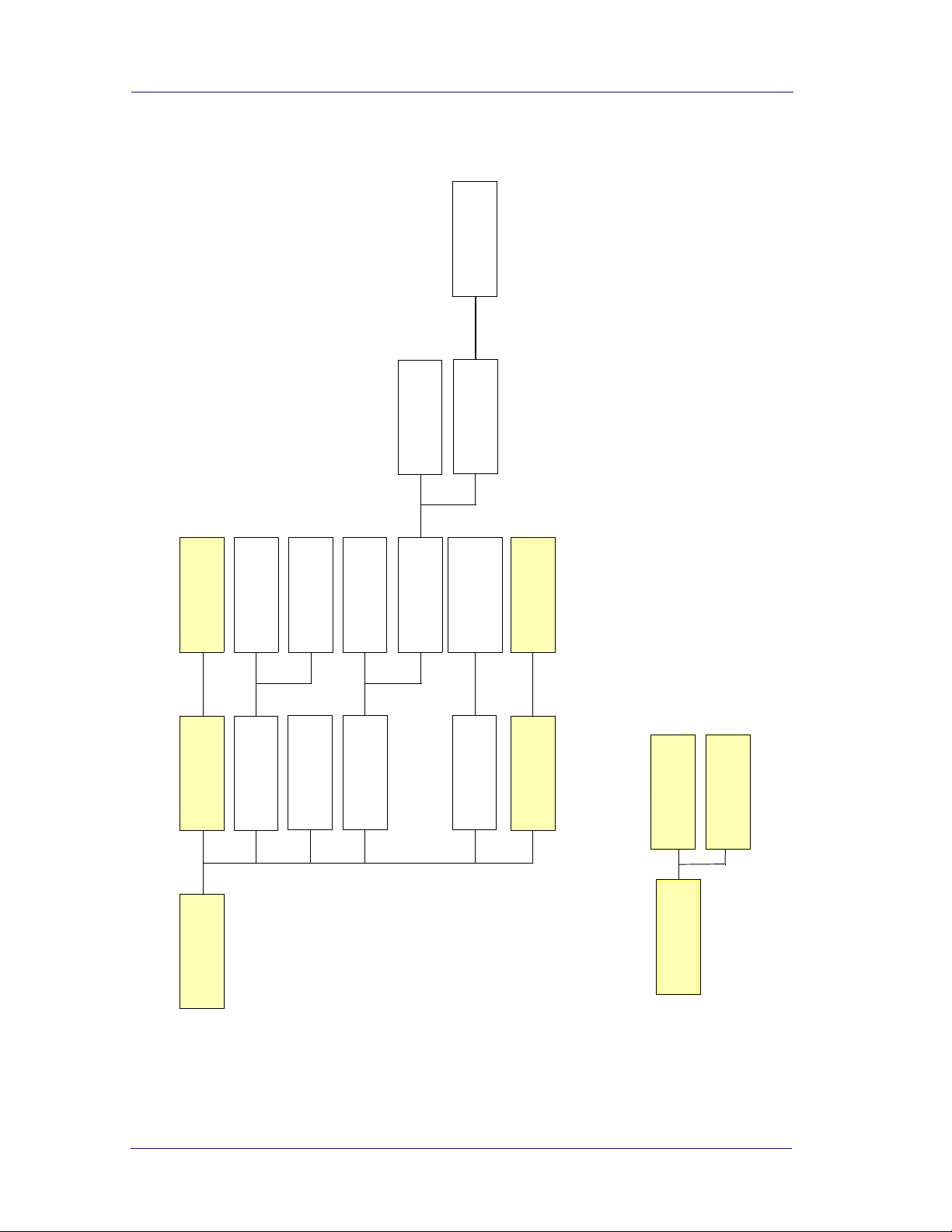

255 ... 1, 0

0.13 mm - 12.0 mm

Width

Color

Pen Number 0 ... 15

Pen Number 0 ... 15

@

@

Off, On

TOYO, EuroScale

SWOP, Native

Off, On

Palette A,

Software, Factory,

Pale tte A, P alette B

Palette

Factory

Palette B

@

Merging

Define palette

@

Color Calib.,

Ink Emulation

Ink Limit ing

@

HP-GL/2 S ettin gs

Image Quality

1-16

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 29

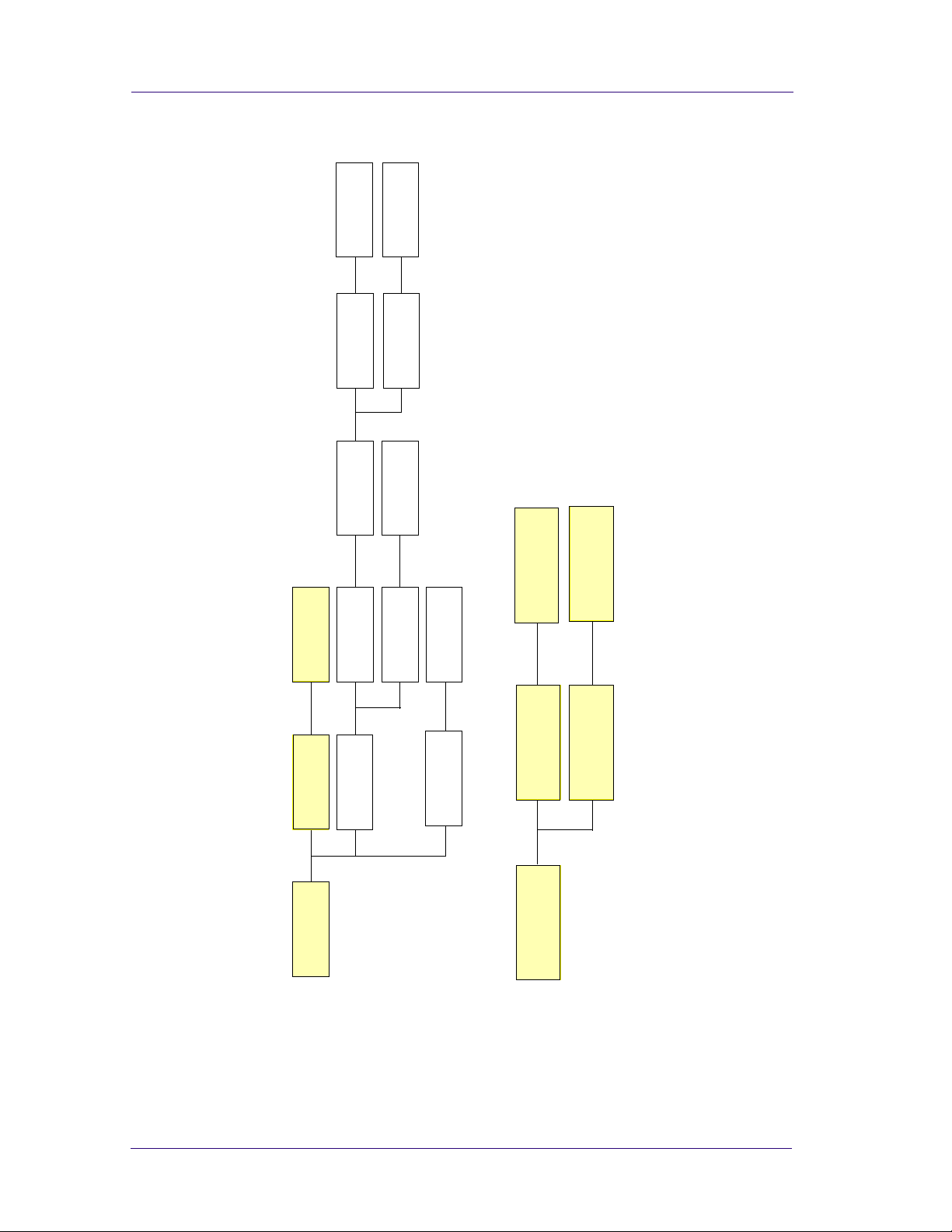

Troubleshooting

Normal, Special

Terminator

@

On, Off

7586, HP-GL/2

Cutter

Lang

HP-GL/2,

CALS/G4

Automatic

PostScript,

None

Automatic,

Drying time

255 ... 2, 1 min

JetDirect Menu

Manual

Optimized

Page Accuracy

Maximum

HW Address

DNS Name,

Appletalk, IP Address

Network ID

Configuration

Network Ca r d

Reset Card

See the Setup Guide

Advanced

0.5 min ... 30 mi n

I/O Timeout

Device Setup

HP DesignJets 1050C and 1055CM Printers Service Manual

I/O Setup

1-17

Page 30

Troubleshooting

Create pattern,

Measure pattern

Restore Factory

@

Up, Down

Display contrast

RAM present,

Hard disk, Code Rev

Statistics

PostScript Font Rev

PostScript Code Rev,

Palette, Menu,

Samples

Default menu,

Recover printheads,

Off, On

Printhead alignment

Off, On

Calibration

Display data

Palette, Menu,

Samples

Accuracy

Recalibrate

Short, Full

Print Quality

Usage Report,

Service Config,

HP-GL/ 2 Config,

@

enu,

Test prints

Menu mo de

alette, M

P

onts

F

ples

cript

am

S

ostS

P

1-18

os

em

D

Demos

Utilities

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 31

Troubleshooting

Servi c e C onfigu r a tion Pr int

The Service Configuration Print is a useful tool for troubleshooting

the Printer. The Service Configuration Print contains the following

information about the Printer:

n

General Configuration

n

Printhead Info.

n

Cartridge In fo.

n

Operating Conditions.

n

Calibrations.

n

Maintenance.

n

IIO Configuration.

How to Print the Service Configuration Print

1 Load media (Roll media or at least an A4 Sheet) into the Printer.

2 Once the message "Ready" is displayed on the front-panel, scroll to

the "Printer Setup Options" icon and press the Enter key.

Ready

Ink

CYAN

MAGENTA

YELLOW

BLACK

Printer Setup Options

3 Once inside the "Printer Setup Options" menu, use the Arrow keys

to scroll to the "Utilities" menu display and press the Enter key.

Top

Printer setup options

Pen settings ...

Device setup ...

Utilitie s ...

Demos ...

Imag e qu a lity ...

Back

↑

↓

Enter

Press Enter

4 Once inside the "Utilities" menu, use the Arrow keys to scroll to the

"Test Prints" menu display and press the Enter key.

Top

Utilitie s

Display Contrast ...

Contrast .. .

Recover Printheads ...

Calibr at io ns ...

Test Pr ints ...

Back

↑

↓

Enter

Press Enter

HP DesignJets 1050C and 1055CM Printers Service Manual

1-19

Page 32

Troubleshooting

5 Use the Arrow keys to scroll to "Service Config." and press the

Enter key to print the Service Configuration Print.

Top

Test Pr ints

HP-GL/2 config

Service config

Usage report

Print Quality

Back

↑

↓

Enter

Press Enter

How to Use the Service Configuration Print

The Service Configuration Print is divided into 7 different areas

where you can find information to troubleshoot the Printer .

n

General Configuration - In this area you can find information

regarding the general configuration of the Printer, for example,

the firmware version, amount of memory installed or the capacity

of the Hard Disk Drive.

n

Printhead Info - In this area you can find all the information

regarding the Printheads, for example, the part number, the

manufacturing date or the number of times a certain Printhead

has been inserted in the carriage. This information is useful for

troubleshooting Printhead problems and even knowing if the

Printheads have been used with Non-HP Cartridges.

n

Cartridge In f o - In this area you can find all the information

regarding the Cartridges, for example, the part number, the

manufacturing date or the ink level. This area also shows you if

the customer is using Non-HP Cartridges.

n

Operating Conditions - In this area you can find the level of

humidity and the temperature that the Printer is working in.

n

Calibrations - In this area you can find information on certain

calibrations that have been performed on the Printer. It will also

tell you if a required calibration was performed or not.

n

Maintenance - In this area you can find information relating to

maintenance, for example, the number times the Printer ha s been

powered ON, the number of Carriage cycles or the last System

Error Code that was triggered.

n

IIO Configuration - I n this area you can find information on the

configuration of the JetDirect Card.

1-20

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 33

Sample of the Service Configuration Print

Troubleshooting

HP DesignJets 1050C and 1055CM Printers Service Manual

1-21

Page 34

Troubleshooting

1-22

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 35

System Err or Codes 2

System Err or Codes 1

System Error Codes 2-2

0000D8 XXXXXXXX (Non-Continuable) 2-3

01002D (Non-Continuable) 2-3

010020 (Non-Continuable) 2-3

010021 (Non-Continuable) 2-4

010023 (Non-Continuable) 2-4

010040 2-5

010041 2-5

010042 2-6

010050 XXXXXXXX (Non-Continuable) 2-6

01009X (Continuable) 2-7

02xxxx (Non-Continuable) 2-7

04Cxxx 2-8

048xxx 2-8

060301 2-9

060305 0000000X 2-9

060309 2-10

06030A (Continuable) 2-10

06030B 2-11

070100 XXXXXXXX (Non-Continuable) 2-11

080001 (Non-Continuable) 2-12

09xxxx (Non-Continuable) 2-12

0A0000 2-13

0A0010 2-13

0A0020 2-14

0A0030 2-14

0A0040 2-14

0A0050 (Non-Continuable) 2-15

0A0060 (Non-Continuable) 2-15

0A0070 (Continuable) 2-16

0C0030 2-16

0C0032 (Continuable) 2-17

0C1000 2-17

0C1001 2-17

System Error Codes During Initialization 2-18

2

HP DesignJets 1050C and 1055CM Printers Service Manual

2-1

Page 36

System Error Codes

System Error Codes

Introduction

System error codes are hexa-decimal based numbers generally

caused by internal system errors. The following pages contain a list

of system error codes and their respective descriptions and

recommended corrective actions. Only try one recommended action

at a time and check if the error code has disappeared.

If you have an error code which is not documented in this Service

Manua l or you have an er ror which you cannot res olve, then report

the error to the HP Resp onse Cente r or the nearest HP S upport Of fice.

When reporting the er ror, have the follow ing information ready :

n

Model and Serial Number of the printer.

n

Which firmware revision the printer is using (See Note below).

Check firmware in Utilities / Statistics / Code rev.

n

The complete error number (See Note below).

n

The Service Configuration Print ⇒ Page 1-19.

The Current configuration sheet.

n

n

Which software application the customer is using (name, version, etc.).

NOTE When reporting the System Error Code, make sure that you

supply the full Error Code (including the last 8 numbers where

applicable) and the firmware version. Without this information,

HP Support Personnel cannot help you.

Continuable and Non-Continuable E rror Codes

Some of the Error Codes are continuable, which means you can

press Enter on the front-panel and continue working with the

Printer. Non-Continuable Error Codes do not allow you to continue

working with the Printer, in this case power the Printer OFF and ON

again and see if the System Error disappears. If the Error Code

reappears, then the Printer requires an on-site visit in order to

resolve the problem.

NOTE Even though the customer can continue working with a

Continuable Error Code, an on-site visit should still be planned

to troubleshoot the problem.

2-2

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 37

System Error: 0000D8 XXXXXXXX (Non-Continuable)

System Error Codes

Problem

Description:

Corrective Acti on: Refer to System Error Code 070100.

System Error: 01002D (Non-Continuable)

Problem

Description:

Corrective Acti on: Perform the Electronic Systems Test ⇒ Page 4-5.

System Error: 010020 (Non-Continuable)

Problem

Description:

Corrective Acti on: Try the following:

External Li b rary Error.

The Main PCA cannot communicate with the Carriage.

Firmware DIMM Test failure.

n

Switch the Power OFF from the back of the Printer and

disconnect the Power cord. Reseat the Firmware DIMM,

reconnect the power cord and power On the Printer.

n

If the Error Code appears again, switch the Power OFF from the

back of the Printer, disconnect the power cord and Replace the

Firmware DIMM. Reconnect the power cord and power On the

Printer and check if the Error Code has been resolved.

n

If the System Error continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-3

Page 38

System Error Codes

System Error: 010021 (Non-Continuable)

Problem

Description:

Corrective Acti on: Try the following:

Memory DRAM DIMM Test failure.

n

Switch the Power OFF from the back of the Printer and

disconnect the Power cord. Reseat the DRAM DIMMs (Memory

Modules), reconnect the power cord and power On the Printer.

n

If the Error Code appears again, switch the Power OFF,

disconnect the power cord and Replace the Flash DIMMs

(Memory Modules). Reconnect the power cord and power On the

Printer and check if the Error Code has been resolved.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 010023 (Non-Continuable)

Problem

Description:

Corrective Acti on: Try the following:

EEROM Test failure.

n

Clear the EEROM ( ⇒ Page 4-38) and turn the Printer OFF and

ON again from the back of the Printer. If after clearing the

EEROM, the Error Code disappears, make sure you perform the

Calibrations Backup ⇒ Page 5-19.

NOTE Make sure that you select "Electronics Module Replaced" when

performing the Calibrations Backup.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

2-4

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 39

System Error: 010040

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

Error in Paper-axis Encoder quadrature.

n

Check that the Paper-Axis Motor cable is NOT broken or

damaged.

n

Check that the Paper-Axis Motor cable is correctly connected.

n

Replace the Paper-Axis Motor ⇒ Page 8-12.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 010041

Problem

Description:

Error in Scan-axis Encoder quadrature.

Corrective Acti on: Try the following:

n

Check that the Encoder Strip is NOT broken or damaged.

n

Replace the Encoder Strip ⇒ Page 8-34.

n

Replace the Carriage Assembly ⇒ Page 8-44.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-5

Page 40

System Error Codes

System Error: 010042

Problem

Description:

Corrective Acti on: Try the following:

Error in Service Station-axis Encoder quadrature.

n

Check that the Service Station Encoder-Cable is NOT broken or

damaged.

n

Check that the Service Station Encoder-Cable is correctly

connected.

n

Replace the Service Station ⇒ Page 8-8.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 010050 XXXXXXXX (Non-Continuable)

Problem

Description:

PostScript Processing Error.

Corrective Acti on: Power the Printer OFF and ON again to see if the System Error

disappears. Try sending the print again.

If the Error Code reappears after sending the print again, then report

the error to the HP response Center or the nearest HP Support

Office, stating the following information.

n

Model and Serial Number of the printer.

n

Which firmware revision the printer is using (See Note below).

Check firmware in Utilities / Statistics / Code rev.

n

The complete error number (See Note below).

n

The Service Configuration Print ⇒ Page 1-19.

The Current configuration sheet.

n

n

Which software application the customer is using (name, version, etc.).

NOTE When reporting the System Error Code, make sure that you

supply the full Error Code (including the last 8 numbers where

applicable) and the firmware version. Without this information,

HP Support Personnel cannot help you.

2-6

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 41

System Error: 01009X (Continuable)

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

Error in Paper-axis Motor Enc oder

n

Check that the Paper-Axis Motor cable is NOT broken or

damaged.

n

Check that the Paper-Axis Motor cable is correctly connected.

n

Replace the Paper-Axis Motor ⇒ Page 8-12.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 02xxxx (Non-Continuable)

Problem

Description:

PostScript/Firmware Err or.

Corrective Acti on: Power the Printer OFF and ON again to see if the System Error

disappears.

If the Error Code reappears, then report the error to the HP response

Center or the nearest HP Support Office, stating the following

information.

n

Model and Serial Number of the printer.

n

Which firmware revision the printer is using (See Note below).

Check firmware in Utilities / Statistics / Code rev.

n

The complete error number (See Note below).

n

The Service Configuration Print ⇒ Page 1-19.

The Current configuration sheet.

n

n

Which software application the customer is using (name, version, etc.).

NOTE When reporting the System Error Code, make sure that you

supply the full Error Code (including the last 8 numbers where

applicable) and the firmware version. Without this information,

HP Support Personnel cannot help you.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-7

Page 42

System Error Codes

System Error: 04Cxxx

Problem

Description:

Corrective Acti on: Try the following:

EIO Accessories (EIO Card/Hard Disk Drive) Error.

n

Press ENTER and switch the printer OFF. Remove the Hard Disk

Drive (if installed) and make sure that the EIO card is installed

correctly by pushing it firmly inwards and checking that the two

installation screws are completely tightened. Switch the printer

ON again. If this error code continues to appear then replace the

EIO card.

n

If this Error Code disappeared after removing the Hard Disk

Drive, then switch the Printer OFF and reinstall the Hard Disk

Drive, making sure that the two installation screws are

completely tightened. Switch the Printer ON again. If this Error

Code reappears, then the Hard Disk Drive could be faulty.

Replace the Hard Disk Drive.

n

If this system error continues to appear after replacing the EIO

card or the Hard Disk Drive, then r e place the E lectronics M odule

⇒ Page 8-25.

System Error: 048xxx

Problem

Description:

The EIO card is from a third party vendor and may not be fully

compliant with the IIO Protocol specification 2.0 OR the EIO Card

firmware is not updated.

Corrective Acti on: Try the following:

n

Check with the third party vendor. If the EIO card is not

compliant with the IIO Protocol specification 2.0 then you must

install a new EIO card which is compliant.

n

Update the EIO Card firmware.

2-8

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 43

System Error: 060301

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

One of the Printheads has an Internal Electrical Problem.

n

Remove all the Printheads and clean the flex contacts on the

Printheads and in the Carriage Assembly (Refer to Chapter 2).

n

Perform the Electronic Systems Test ⇒ Page 4-5.

n

Make sure that the T railing Cable is connected correctly.

n

Replace the Trailing Cable ⇒ Page 8-39.

n

Replace the Carriage Assembly ⇒ Page 8-44.

n

If the error code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 060305 0000000X

Problem

Description:

Thermal Shutdown error (one of the Printheads has gone above the

maximum T e mperature).

Error Data:

00000000

00000001

00000002

00000003

Corrective Acti on: Try the following:

n

Replace the failing Printhead.

n

If the problem remains after replacing the failing Printhead then

Í

Cyan Printhead Failed.

Í

Magenta Printhead Failed.

Í

Yellow Printhead Failed.

Í

Black Printhead Failed.

check if the customer is using a 3rd Party RIP. If a 3rd Party RIP

is being used, check the Print Settings in the RIP or try printing

one of the Internal Demo Prints to see if the problem is solved

without the RIP.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-9

Page 44

System Error Codes

System Error: 060309

Problem

Description:

Corrective Acti on: Try the following:

Problem with setting the Voltage of the Printheads.

n

Remove ALL the Printheads and clean the flex contacts on the

Printheads and in the Carriage Assembly (Refer to Chapter 2).

n

Perform the Electronic Systems Test ⇒ Page 4-5.

n

Replace ALL the Printheads.

n

Replace the Trailing Cable ⇒ Page 8-39.

n

Replace the Carriage Assembly ⇒ Page 8-44.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 06030A (Continuable)

Problem

Description:

Corrective Acti on: Try the following:

Error in finding the Mark Encoder.

n

Clean the Mark Encoder if necessary (use the Overdrive Cleaning

Utility to position the Mark Encoder ⇒ Page 4-37).

n

Clean the Line Sensor (located on the Carriage Assembly).

n

Perform the Line Sensor Calibration ⇒ Page 5-9.

n

Perform the Mark Encoder Calibration ⇒ Page 5-13.

n

Replace the Trailing Cable ⇒ Page 8-39.

n

Replace the Carriage Assembly ⇒ Page 8-44.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

2-10

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 45

System Error: 06030B

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

The Ambient Temperature measured is out of the normal range.

n

Make sure that the Ambient temperature is within the allowed

range (between 0 and 55 Degrees Centigrade).

n

Replace the Electronics Module ⇒ Page 8-25.

System Error: 070100 XXXXXXXX (Non-Continuable)

Problem

Description:

Corrective Acti on: Power the Printer OFF and ON again to see if the System Error

Firmware Er ror.

disappears.

If the Error Code reappears, then report the error to the HP response

Center or the nearest HP Support Office, stating the following

information.

n

Model and Serial Number of the printer.

n

Which firmware revision the printer is using (See Note below).

Check firmware in Utilities / Statistics / Code rev.

n

The complete error number (See Note below).

n

The Service Configuration Print ⇒ Page 1-19.

The Current configuration sheet.

n

n

Which software application the customer is using (name, version, etc.).

NOTE When reporting the System Error Code, make sure that you

supply the full Error Code (including the last 8 numbers where

applicable) and the firmware version. Without this information,

HP Support Personnel cannot help you.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-11

Page 46

System Error Codes

System Error: 080001 (Non-Continuable)

Problem

Description:

Corrective Acti on: Refer to System Error Code 070100.

System Error: 09xxxx (Non-Continuable)

Problem

Description:

Corrective Acti on: Try the following:

PostScript Error.

EIO Accessories (EIO Card/Hard Disk Drive) Error.

n

Swit ch the P rin t er OF F a nd O N a ga in an d w a it fo r t he in it ia liza ti o n.

n

If the Error code continues to appear, switch the Printer OFF.

Remove the EIO Card (if installed) and make sure that the Hard

Disk Drive is installed correctly by pushing it firmly inwards and

checking that the two installation screws are completely

tightened. Switch the Printer ON again. If the error codes 09Axxx

or 09Bxxx appear then replace the Hard Disk Drive.

n

If the Error Code disappeared after removing the EIO Card, then

switch the Printer OFF and reinstall the EIO Card, making sure

that the two installation screws are completely tightened. Switch

the Printer ON again. If the Error Code reappears, then the EIO

Card could be faulty. Replace the EIO Card.

n

If Error Code 09Cxxx appears after initialization, then replace the

Electronics Module ⇒ Page 8-25.

n

Once the Error Code has been solved, print an Internal Demo

Print to make sure that the Hard Disk Drive is functioning

correctly. If the Error Code reappears, then use the above

information to troubleshoot the problem.

2-12

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 47

System Error: 0A0000

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

The Air Pressure is below the minimum requirement.

n

Check all the cables of the APS and make sure they are correctly

connected and are NOT damaged.

n

Check all the tubes of the APS and Tubes System and make sure

they are correctly connected and are NOT pinched or damaged.

n

Check that the Air Tube from the APS is correctly connected to

the Tubes System.

n

Faulty APS Sensor, APS Valve or APS Pump. Replace the

complete APS ⇒ Page 8-20.

n

Replace ONE Ink Cartridge at a time, checking if the error code

disappears.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 0A0010

Problem

Description:

Corrective Acti on: Try the following:

Problem in Pressurizing the Air System.

n

Replace ONE Ink Cartridge at a time, checking if the error code

disappears.

n

Check all the cables of the APS and make sure they are correctly

connected and are NOT damaged.

n

Check all the tubes of the APS and Tubes System and make sure

they are correctly connected and are NOT pinched or damaged.

n

Faulty APS Sensor, APS Valve or APS Pump. Replace the

complete APS ⇒ Page 8-20.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-13

Page 48

System Error Codes

System Error: 0A0020

Problem

Description:

Corrective Acti on: Try the following:

Error in Calibrating the APS Sensor.

n

Check all the cables of the APS and make sure they are correctly

connected and are NOT damaged.

n

Check all the tubes of the APS and Tubes System and make sure

they are correctly connected and are NOT pinched or damaged.

n

Faulty APS Sensor or APS Valve. Replace the complete APS ⇒

Page 8-20.

System Error: 0A0030

Problem

Description:

Corrective Acti on: Try the following:

Problem in Depressurizing Air System.

n

Check the APS for any signs of Ink. Also inspect ALL Ink

Cartridges for any signs of leaking (the bottom valve of the Ink

Cartridge will contain ink).

n

If there is Ink Leakage, replace ALL Ink Cartridges, the APS ( ⇒

Page 8-20) and the Tubes System ( ⇒ Page 8-53).

System Error: 0A0040

Problem

Description:

Corrective Acti on: Try the following:

Ink Tubes Initialization Failure Due to Low Air Pressure.

n

Check all the cables of the APS and make sure they are correctly

connected and are NOT damaged.

n

Check all the tubes of the APS and Tubes System and make sure

they are correctly connected and are NOT pinched or damaged.

n

Replace ONE Ink Cartridge at a time, checking if the error code

disappears.

n

Faulty APS Sensor or APS Pump. Replace the complete APS ⇒

Page 8-20.

2-14

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 49

System Error: 0A0050 (Non-Continuable)

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

The Printer has detected a leak in the Tubes System before the life

of the System.

n

The leak detector could have been triggered due to condensation

in the Printer . Power OFF the Printer and allow the Printer to dry

for 15 minutes. Power ON the Printer and check if the error code

has disappeared.

n

If the Error Code reappears, replace the complete Tubes System

(SRK) ⇒ Page 8-53.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 0A0060 (Non-Continuable)

Problem

Description:

Corrective Acti on: Try the following:

The Printer has detected a leak in the Tubes System after the life of

the System.

n

The leak detector could have been triggered due to condensation

in the Printer . Power OFF the Printer and allow the Printer to dry

for 15 minutes. Power ON the Printer and check if the error code

has disappeared.

n

If the error code reappears, replace the complete Tubes System

(SRK) ⇒ Page 8-53.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-15

Page 50

System Error Codes

System Error: 0A0070 (Continuable)

Problem

Description:

Corrective Acti on: Try the following:

NOTE Make sure that you s elect "Tubes Replaced" when performing

The Backup EEROM contents stored in the Tubes System are not

consistent with the ones required by the firmware.

n

Perform the Calibrations Backup ⇒ Page 5-19.

the Calibrations Backup.

System Error: 0C0030

Problem

Description:

Corrective Acti on: Try the following:

Bad Drop Detector.

n

Check that the Drop Detector Cable is NOT broken or damaged.

n

Check that the Drop Detector cable is correctly connected to the

Service Station Cable.

n

Remove the Drop Detector and make sure that there are no

obstacles inside which are blocking the sensor.

n

Replace the Drop Detector Assembly ⇒ Page 8-10.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

2-16

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 51

System Error: 0C0032 (Continuable)

System Error Codes

Problem

Description:

Corrective Acti on: Try the following:

Drop Detector not Calibrated for all Printheads.

n

Perform the Service Station Calibration ⇒ Page 5-11.

n

Replace the Drop Detector Assembly ⇒ Page 8-10.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 0C1000

Problem

Description:

Corrective Acti on: Try the following:

Primer not Calibrated.

n

Perform the Service Station Calibration ⇒ Page 5-11.

n

Make sure that the Primer Arm is not damaged. If the Primer

Arm is damaged, replace the Service Station ⇒ Page 8-8.

n

Replace the Electronics Module ⇒ Page 8-25.

System Error: 0C1001

Problem

Description:

Corrective Acti on: Try the following:

Primer Shutdown Error.

n

Check that the Primer Stepper-Motor Cable is NOT broken or

damaged and that the Primer arm moves freely from side to side.

n

Replace the Service Station ⇒ Page 8-8.

n

If the Error Code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-17

Page 52

System Error Codes

System Error Codes During Initialization

The following System Error Codes will only appear during the

Initialization process when you power ON the Printer.

System Error: 0B0000

Problem

Description:

Corrective Acti on: Try the following:

Bad Ambient Temperature measured.

n

Make sure that the Ambient temperature is within the allowed

range (between 0 and 55 Degrees Centigrade).

n

Replace the Electronics Module ⇒ Page 8-25.

System Error: 0B0001

Problem

Description:

Corrective Acti on: Replace the Electronics Module ⇒ Page 8-25.

System Error: 0B0002

Problem

Description:

Corrective Acti on: Try the following:

Bad Humidity read.

Bad IDS pressure re a d.

n

Check that the cable from the Ink Supply Station (ISS) PCA to

the Ink Supply Station is correctly connected.

n

Check that the Air Pressurization System Sensor Cable is

correctly connected and is NOT damaged.

n

Check all the tubes of the APS and make sure they are NOT

pinched or damaged.

n

Faulty APS Sensor. Replace the complete APS ⇒ Page 8-20.

n

If the error code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

2-18

HP DesignJets 1050C and 1055CM Printers Service Manual

Page 53

System Error: 0B0003

System Error Codes

Problem

Description:

Corrective Acti on: Replace the Electronics Module ⇒ Page 8-25.

System Error: 0B0004

Problem

Description:

Corrective Acti on: Try the following:

ADC0 Internal channels check Failure.

Unable to detect Pump.

n

Check that the cable from the Ink Supply Station (ISS) PCA to

the Ink Supply Station is correctly connected.

n

Faulty APS Pump. Replace the complete APS ⇒ Page 8-20 .

n

If the error code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

System Error: 0B0005

Problem

Description:

Corrective Acti on: Try the following:

Unable to detect Valve.

n

Check that the cable from the Ink Supply Station (ISS) PCA to

the Ink Supply Station is correctly connected.

n

Faulty APS Valve. Replace the complete APS ⇒ Page 8- 20.

n

If the error code continues, replace the Electronics Module ⇒

Page 8-25.

WARNING Only replace one component at a time and check if the error has

gone before replacing another component. Using this procedure

you will be able to determine exactly which component failed.

HP DesignJets 1050C and 1055CM Printers Service Manual

2-19

Page 54

System Error Codes

System Error: 0B0006

Problem

Description:

Corrective Acti on: Turn the Printer OFF and disconnect the trailing cable. Check that

The Trailing Cable has been incorrectly connected OR the fuse in

the Electronics Module has been burned.

the ends of the Trailing Cable are flat and are not damaged or bent.

Reconnect the Trailing Cable correctly, making sure it is pushed in

firmly (Refer to the instructions on Page 8-39). Power ON the

Printer and check if the Error Code disappears. If the Error Code

continues, replace the Electronics Module (Refer to the instructions

on Page 8-25), making sure you take care when you reconnect the

Trailing Cable.

WARNING PLEASE TAKE CARE WHEN CONNECTING THE

TRAILING CABLE TO THE ELECTRONICS MODULE.

INCORRECT INSTALLATION WILL BURN THE FUSE IN

THE ELECTRONICS MODULE, CAUSI NG THE COMPLETE

REPLACEM ENT OF THE ELEC TRO NICS MODUL E.

System Error: 0B0007

Problem

Description:

Unable to detect Vacuum Fan.

Corrective Acti on: Try the following:

n

Make sure that the Vacuum Fan is connected correctly to the

Electronics Module.

n

Turn the Printer OFF and disconnect the V acuum Fan from the

Electr onics Module. Connect a

New

Vacuum Fan to the

Electronics Module and power ON the Printer. If the

Fan functions correctly without any Error Codes then remove the