Page 1

HP Large-Format Printers

DesignJets 500, 510 and 800 Series

Service Manual

Page 2

For HP Internal Use Only

©Copyright Hewlett-Packard

Company 2000

This document contains

proprietary information that is

protected by copyright. All rights

are reserved. No part of this

document may be photocopied,

reproduced, or translated to

another language without the

prior written consent of HewlettPackard Company.

First Edition, August 2000

Second Edition, November 2001

Third Edition, August 2008

Fourth Edition, January 2013

Warranty

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warranty of any kind with

regard to this material,

including, but not limited to,

the implied warranties of

merchantability and fitness for

a particular purpose.

Hewlett-Packard shall not be

liable for errors contained herein

or for incidental or consequential

damages in connection with the

furnishing, performance, or use

of this material.

WARNING

The procedures described in this

manual are to be performed by

HP-qualified service personnel

only.

Electrical Shock Hazard

Serious shock hazard leading to

death or injury may result if you

do not take the following

precautions:

- Ensure that the ac power outlet

(mains) has a protective earth

(ground) terminal.

- Disconnect the Printer from the

power source prior to performing

any maintenance.

- Prevent water or any other

liquids from running onto

electrical components or circuits,

or through openings in the

enclosure.

Electrostatic Discharge

Refer to the beginning of Chapter

8 of this manual, for precautions

you should take to prevent

damage to the Printer circuits

from electrostatic discharge.

WARNING

The Warning symbol calls

attention to a procedure, practice,

or the like, which, if not correctly

performed or adhered to, could

result in personal injury. Do not

proceed beyond a Warning

symbol until the indicated

conditions are fully understood

and met.

CAUTION

The Caution symbol calls

attention to an operating

procedure, practice, or the like,

which, if not correctly performed

or adhered to, could result in

damage to or destruction of part

or all of the product. Do not

proceed beyond a Caution

symbol until the indicated

conditions are fully understood

and met.

Technical Marketing,

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

Safety Symbols

General definitions of safety

symbols are given immediately

after the table of contents.

Page 3

1

DesignJets 500, 510 and 800 SeriesHP Large-Format Printers

Service Manual

Page 4

Using this Manual

Purpose

This Service Manual contains information necessary to test,

calibrate and service:

HP DesignJet 500 Printer - 24” Model (P/N C7769B)

HP DesignJet 500 Printer - 42” Model (P/N C7770B)

HP DesignJet 500PS Printer - 24” Model (P/N C7769C)

HP DesignJet 500PS Printer - 42” Model (P/N C7770C)

HP DesignJet 500Plus – 24” Model (P/N C7769F)

HP DesignJet 500Plus – 42” Model (P/N C7770F)

HP DesignJet 500Mono – 24” Model (P/N C7769E)

HP DesignJet 500Mono – 42” Model (P/N C7770E)

HP Designjet 510 – 24” Model (P/N CH336A)

HP Designjet 510 – 42” Model (P/N CH337A)

HP Designjet 510ps – 24” Model (P/N CJ996A)

HP Designjet 510ps – 42” Model (P/N CJ997A)

HP DesignJet 800 Printer - 24” Model (P/N C7779B)

HP DesignJet 800 Printer - 42” Model (P/N C7780B)

HP DesignJet 800PS Printer - 24” Model (P/N C7779C)

HP DesignJet 800PS Printer - 42” Model (P/N C7780C)

For information about using these printers, refer to the

corresponding User and Quick Reference Guides.

Readership

The procedures described in this Service Manual are to be

performed by HP Certified Service Personnel only.

Part Numbers

Part Numbers for Printer options, accessories and service parts are

2

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 5

located in Chapter 7.

Conventions

A small arrow is used to indicate other parts of the Service

Manual where you can find information related to the topic you are

consulting.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

3

Page 6

Table of Contents

Table of Contents 1

Troubleshooting 1-1

Introduction 1-2

Troubleshooting System Error Codes 1-2

Solving Print Quality Problems 1-3

Cover Sensors are not Working 1-3

The Line Sensor has Problems Detecting Media 1-3

Troubleshooting Paper-Axis Shutdowns 1-4

Problems with the Vacuum Fan 1-5

Vacuum suction much lower at high altitudes 1-5

HP-GL/2 color differences in different HP DesignJet Printers 1-6

Banding at variable extreme environmental conditions 1-6

The Priming Procedure Fails 1-7

Using the Power Switch LED to Troubleshoot 1-10

Using the Boot-Up Sequence to Troubleshoot 1-12

Using the Formatter/Accessory Card LEDs to Troubleshoot 1-14

System Error Codes 2-1

Introduction 2-2

Continuable and Non-Continuable Error Codes 2-2

System Error Codes - Explanation 2-2

Error Log Utility 2-5

Accessing the Error Log Utility 2-5

Ink Supplies Troubleshooting 3-1

What are the Ink Supplies? 3-2

Ink Cartridges 3-2

Printheads 3-3

Identifying the Components 3-3

General Information About the Ink Supplies 3-4

Some General Precautions When Handling the Ink Supplies 3-5

When Should You Replace the Ink Cartridges? 3-6

When Should You Replace the Printheads? 3-7

Obtaining Ink Cartridge Information 3-9

4

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 7

Table of Contents

Obtaining Printhead Information 3-10

Ink Cartridge Status Messages 3-12

Ink Cartridge Status While Replacing 3-12

Printhead Status Messages 3-13

Printhead History Utility 3-14

Accessing the Printhead History Utility 3-14

Is the Printer Causing Repetitive Printhead Problems? 3-16

Is the User Replacing the Printheads too Early? 3-18

Troubleshooting Repetitive Ink Cartridge Messages 3-20

Troubleshooting Repetitive Printhead Error Messages 3-21

Printhead Error Codes 3-22

Summary of Solving Ink Supplies Problems 3-23

Service Tests and Utilities 4-1

Introduction 4-2

Phone Support 4-2

Diagnostics - Self Test 4-2

Service Tests (Diagnostics) 4-3

Entering the Service Tests Menu 4-4

Ink Supply Station 4-6

Carriage Movement 4-8

Paper Advance Test 4-10

Service Utilities 4-13

Entering the Service Utilities Menu 4-14

EEROM Setup 4-16

Turn Drive Roller 4-21

Unlock Carriage 4-22

Prime Tubes 4-23

Change Cutter 4-24

Change Ink Tubes 4-25

Printer Information 4-26

Service Calibrations 5-1

Entering the Service Calibrations Menu 5-3

Printhead Alignment (includes PPS Calibration) 5-5

Color Calibration 5-7

Advance Calibration 5-9

Factory Advance Calibration 5-11

HP DesignJets 500, 510 and 800 Series Printers Service Manual

5

Page 8

Table of Contents

Print Quality 6-1

Print Quality 6-2

Print Quality Troubleshooting Checklist 6-2

How to Use the Troubleshooting Procedure 6-4

What is the Troubleshooting Procedure? 6-4

Considerations for Using the Troubleshooting Procedure. 6-4

Performing the Troubleshooting Procedure 6-4

Troubleshooting Procedure Flowchart 6-7

No Printing Defects Found Using the Troubleshooting Procedure 6-8

Solving Color Accuracy problems 6-9

Color Consistency problems 6-9

Long Term Color Bleeding (Glossy Papers) 6-9

Media 6-10

There are Smears or Scratching on the Printed Media 6-10

Parts and Diagrams 7-1

Printer Support 7-2

Right Hand Cover 7-4

Left Hand Cover 7-6

Top Cover and Deflectors 7-8

Rollfeed Module 7-10

Back Platen Assembly 7-12

Electronics Module 7-14

Power Supply 7-16

Cutter Assemblies 7-18

Ink Delivery System 7-20

Service Station and Spittoon 7-22

Service Station Holder 7-24

Pinch-Wheel Assemblies 7-26

Scan-Axis Motor 7-28

Drive Roller Encoder Sensor 7-30

Print Platen Assembly 7-32

Carriage Assembly 7-34

Vacuum Fan 7-36

Interconnect Cable 7-38

Paper-Axis Motor 7-40

Drive Roller 7-42

Miscellaneous Items 7-44

6

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 9

Removal and Installation 8-1

Introduction 8-2

Safety Precautions 8-2

Electrostatic Discharge (ESD) Precautions 8-3

Required Tools 8-3

Screw Types 8-4

Left Hand Cover 8-5

Right Hand Cover 8-7

Front Panel 8-9

Window and Top Cover 8-10

Media Deflectors 8-11

Left End Roll-Feed 8-13

Right End Roll-Feed 8-15

Back Platen 8-17

Media Sensor 8-19

Formatter 8-20

LAN Card 8-21

Spittoon 8-23

Electronics Module 8-24

Power Supply 8-27

Scan-Axis Motor Assembly 8-29

Cutter Assembly 8-32

Left Encoder Holder 8-33

Cutter Bushing 8-35

Cutter Guide Bracket 8-36

Drive Roller Encoder Sensor 8-38

Trailing Cable 8-40

Ink Supply Station 8-48

Interconnect PCA 8-50

Service Station and Aerosol Fan 8-52

Cutter Guide 8-55

Print Platen 8-56

Service Station Holder 8-57

Interconnect Cable 8-59

Ink Supply Tubes 8-60

Vacuum Fan 8-64

Pinch-Arm 8-66

Pinch-Arm Mechanism 8-67

Pinch-Arm Lever 8-69

Table of Contents

HP DesignJets 500, 510 and 800 Series Printers Service Manual

7

Page 10

Table of Contents

Pinch-Arm Sensor 8-71

Fork Idler, Tensioner and Idler Pulley 8-74

Encoder Strip 8-76

Carriage Assembly (Including Belt) 8-78

Paper-Axis Motor 8-84

Drive Roller 8-86

Gear Assemblies 8-92

Preventive Maintenance 9-1

Moisture on the Printer 9-2

Noisy Carriage Bushing 9-2

Belt Swelling 9-2

Cleaning the Printer 9-2

General Cleaning 9-2

Cleaning the Drive Roller/Print Platen 9-3

Scheduled Maintenance 9-3

Level of Printer Usage 9-3

Scan-Axis Maintenance 9-4

Functional Overview 10-1

Introduction 10-2

SKU Overview 10-2

Electrical System 10-3

Introduction 10-3

Hardware Description 10-3

Power Supply Unit (PSU) 10-5

Front Panel 10-6

Ink Delivery System (IDS) 10-7

Ink Supply Station (ISS) 10-7

Tubes Assembly 10-9

Service Station 10-10

Glossary

Index

8

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 11

Troubleshooting 1

Introduction 1-2

Troubleshooting System Error Codes 1-3

Performing a Service Test on a Failed Assembly 1-3

Performing the Necessary Service Calibrations 1-3

Solving Print Quality Problems 1-4

The Printer does not Power ON 1-4

Cover Sensors are not Working 1-4

The Line Sensor has Problems Detecting Media 1-4

Troubleshooting Paper-Axis Shutdowns 1-5

Problems with the Vacuum Fan 1-6

Vacuum suction much lower at high altitudes 1-6

HP-GL/2 color differences in different HP DesignJet Printers 1-7

Banding at variable extreme environmental conditions 1-7

The Priming Procedure Fails 1-8

Using the Power Switch LED to Troubleshoot 1-11

Using the Boot-Up Sequence to Troubleshoot 1-13

How to Detect Problems Related to the Encoder Disk 1-17

1

HP DesignJets 500, 510 and 800 Series Printers Service Manual

1-1

Page 12

Troubleshooting

Menu

Back

Enter

Cancel

Form Feed

and cut

Guide to Troubleshooting the Printer

Introduction

This chapter will guide you through the relevant steps to take when

troubleshooting the printer.

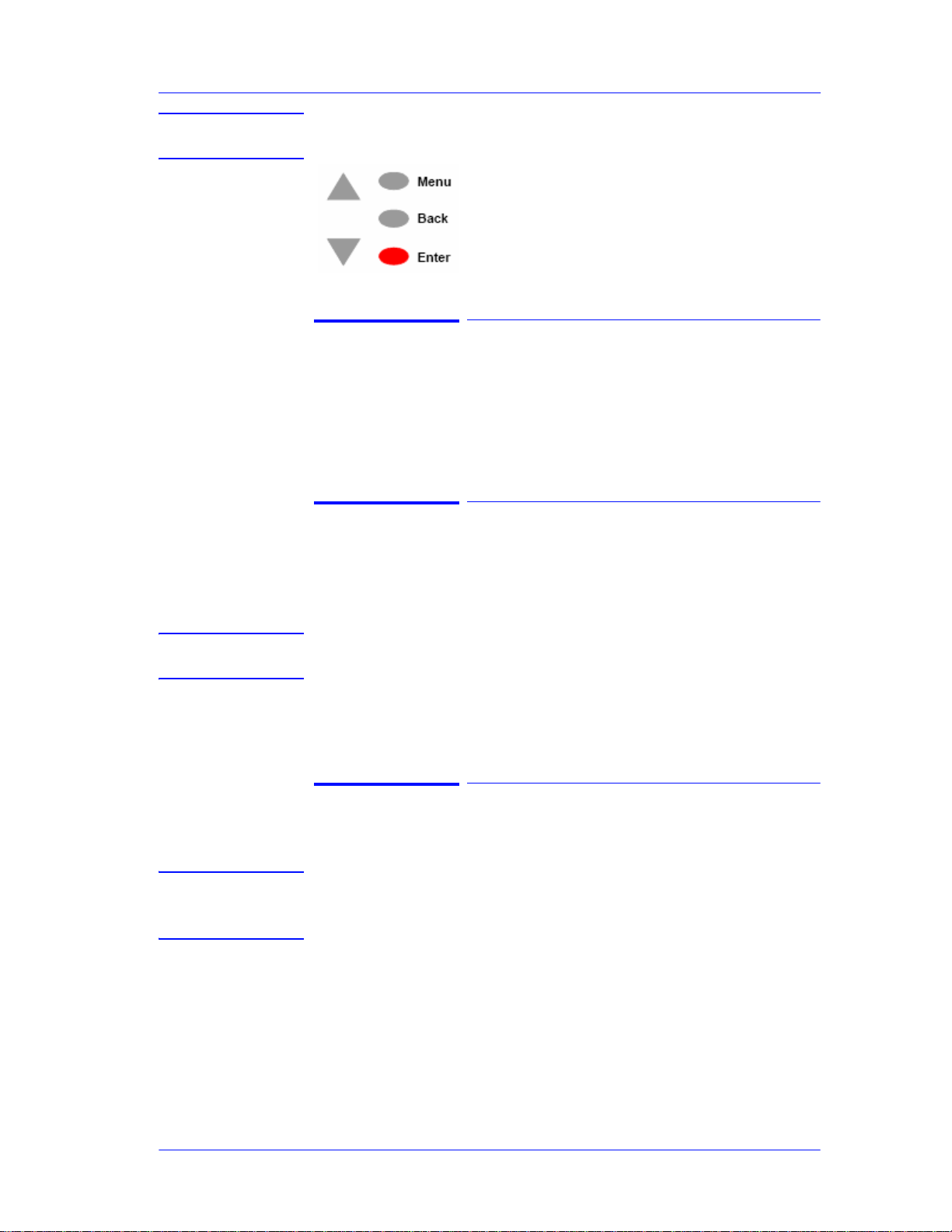

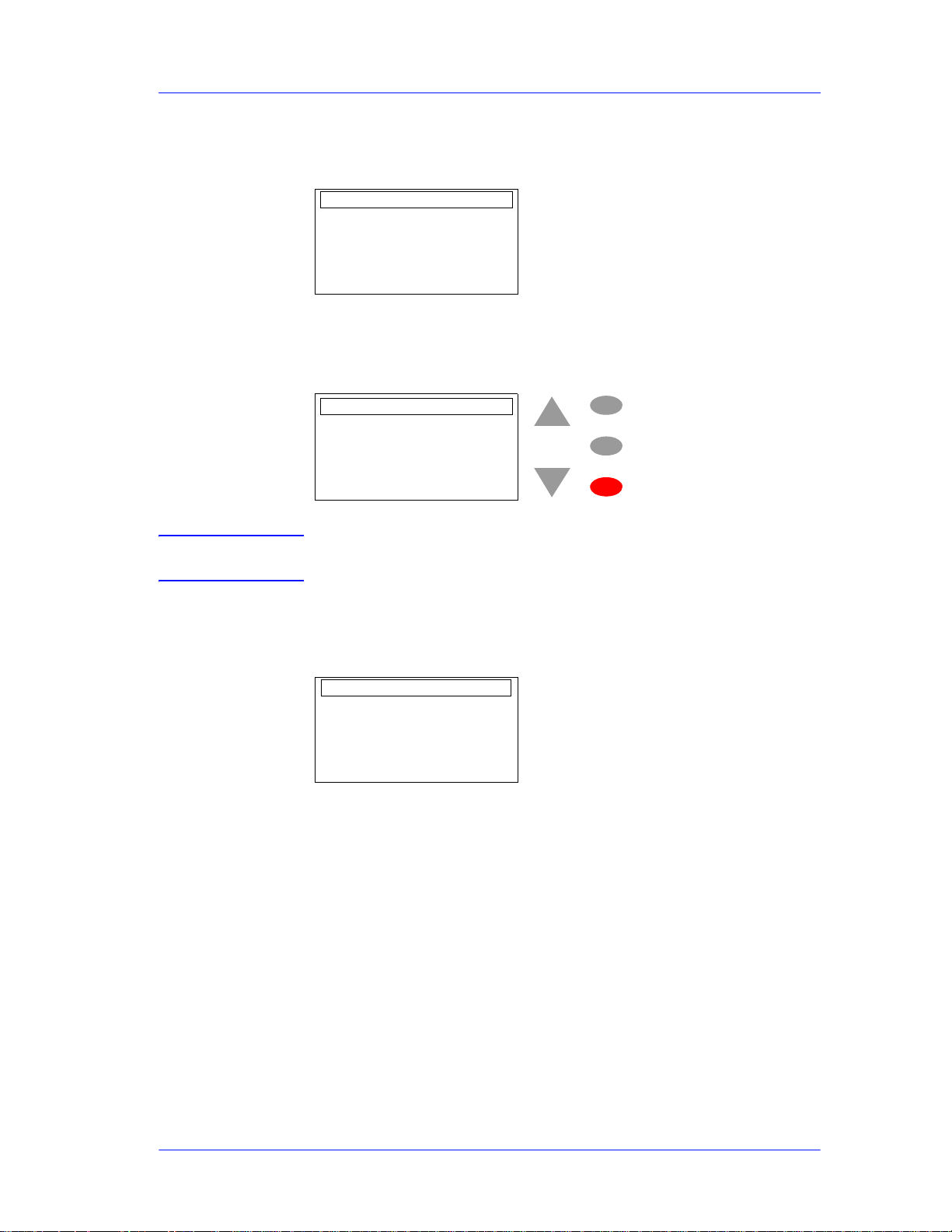

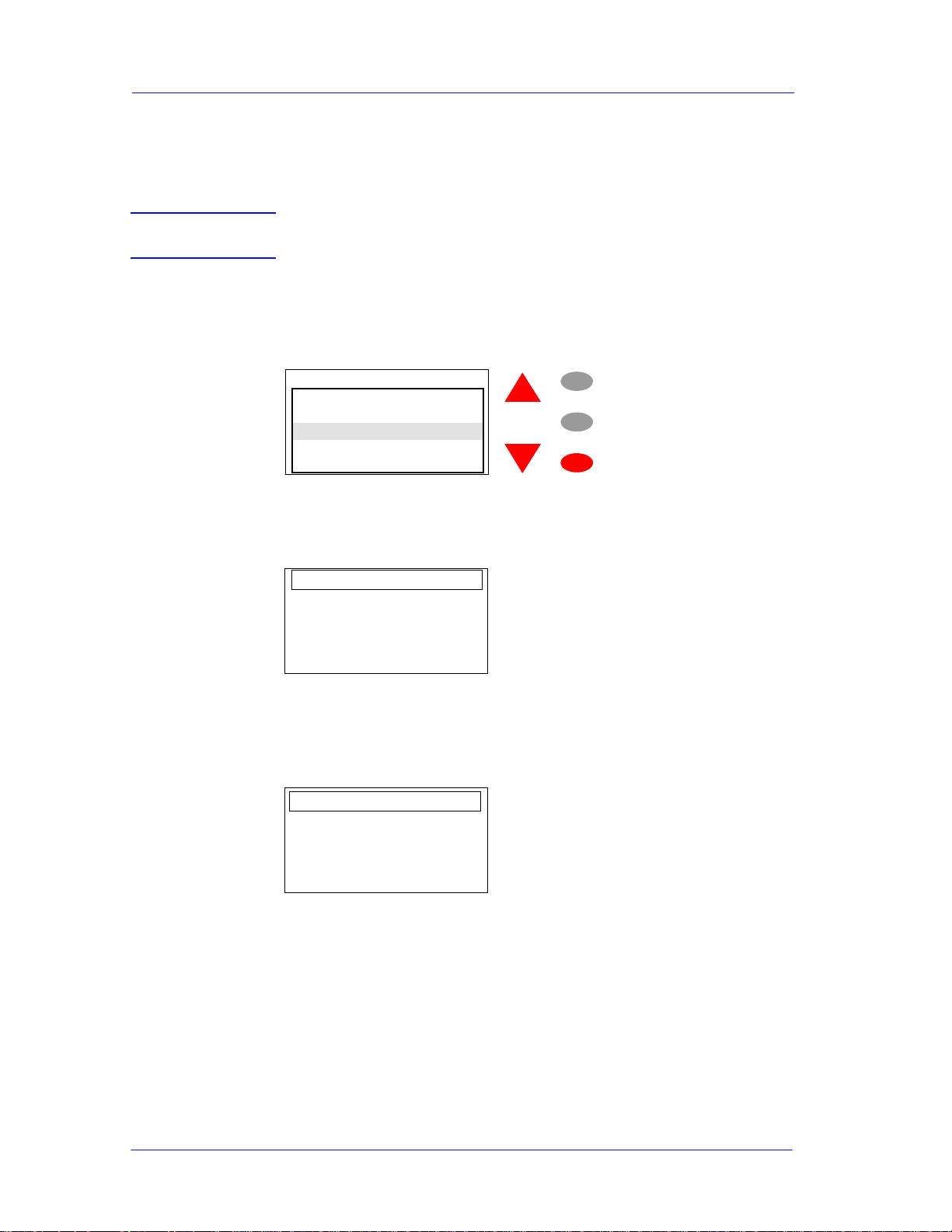

Front Panel Difference for the HP DesignJet 500, 510 and 800 Series Printers

Front Panel for the HP DesignJet 500 and 800 Series

Front Panel for the HP DesignJet 510 Series

1-2

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 13

Troubleshooting

NOTE The layout shown below will be used to refer to both types of

front panels

Troubleshooting System Error Codes

Chapter 2 - System Error Codes contains a list of system error

codes and their respective descriptions and recommended corrective

actions. Only try one recommended action at a time and check if the

error code has disappeared.

Performing a Service Test on a Failed Assembly

If possible, always perform a Service Test on the component/

assembly that you are about to replace, just to make sure that is the

component/assembly that has failed.

NOTE If the test on that component/assembly passes, you should NOT

replace it.

For information on the Service Tests and how to use them see

Chapter 4 - Service Tests and Utilities.

Performing the Necessary Service Calibrations

Is the printer calibrated correctly after replacing a component?

NOTE Remember that certain Calibrations are required even if an

Assembly has been disassembled to gain access to another

Assembly or Component.

For information on the Service Calibrations and how to use them

see Chapter 5 - Service Calibrations.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

1-3

Page 14

Troubleshooting

Solving Print Quality Problems

The Printer contains an internal Troubleshooting procedure which

helps you to diagnose and resolve the possible source of any Image

Quality or Line Quality defects. If Print Quality is poor before the

minimum life expectancy of the Printhead has been reached, the

Troubleshooting procedure should be performed which will

determine whether the Printhead needs replacing or not after

performing various levels of recovery actions.

For information on solving Print Quality problems see Chapter 6 -

Print Quality.

The Printer does not Power ON

1 Check that the power cord is connected correctly to the Printer and

to the Power Socket.

2 Check that the Front-Panel Cable is correctly connected to the

Interconnect PCA. Also make sure that the Front-Panel cable is not

damaged.

3 Check that the Interconnect Cable is properly connected at the both

ends of the Printer.

Cover Sensors are not Working

1 Check if the faulty sensor is installed correctly.

2 Check if the cable for the faulty sensor is connected correctly.

3 Replace the faulty Sensor (or the assembly that contains the Sensor).

The Line Sensor has Problems Detecting Media

1 Check the type of media that is being used since the Line Sensor

may have problems detecting transparent media or some types of

Non-HP media. Try loading white HP media in to the Printer and

check if the Line Sensor detects it.

2 Excessive ink deposits on the Print Platen surface can fool the

sensor by reflecting the light. Clean the Print Platen.

1-4

3 The Line Sensor is damaged or faulty. Replace the Carriage

Assembly Page 8-78.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 15

Troubleshooting

Troubleshooting Paper-Axis Shutdowns

A Paper-Axis shutdown can happen when the Printer detects that

the Drive Roller is not moving but at the same time power is being

supplied to the Paper-Axis Motor (which should be turning the

Drive Roller).

The reasons for the Paper-Axis shutdown, and their solutions, are

explained as follows:

1 The Paper-Axis Motor does not respond to the electrical simulation.

It is possible to determine whether the Paper-Axis is faulty by

performing the Paper Advance Test (Refer to Page 4-11). The

Printer will move the Motor backwards and forwards and

measure directly from the Motor Encoder whether the Paper-Axis

Motor responded to the force. If the Paper-Axis Motor did not

respond, the solution would be to replace the Paper-Axis Motor

Page 8-84.

2 The Transmission Gears, which transmit the moveme nt to the Drive

Roller, are not turning. This problem could be caused either by

blockage of the gears (caused by an obstacle) or by one of the gears

being damaged. To solve the problem, try the following:

Remove the Back Platen Page 8-67 and check if there are any

obstacles blocking the Gears. Remove the obstacles if necessary.

Remove the Back Platen Page 8-67 and check if the

Transmission Gears are damaged. If the Gears are damaged,

replace the Gear Assemblies Page 8-92.

3 The Drive Roller cannot move because of an obstacle or because it

is damaged. To solve the problem, try the following:

Remove the Back Platen Page 8-67 and check if there are any

obstacles blocking the Drive Roller. Remove the obstacles if

necessary.

Remove the Back Platen Page 8-67 and check if the Drive

Roller is damaged. If the Drive Roller is damaged, replace the

Drive Roller Page 8-86.

4 The Drive Roller Encoder Sensor is faulty

It is possible to determine whether the Encoder Sensor is faulty

by loading a sheet of paper from the front of the Printer. If the

Drive Roller is working, the sheet will be loaded correctly, and

the Printer will detect that media has been loaded (using the

Media Sensor). Therefore the problem must be the Encoder

Sensor and the solution would be to replace the Encoder Sensor

Page 8-38.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

1-5

Page 16

Troubleshooting

Problems with the Vacuum Fan

If you have problems loading either Roll or Sheet Media, then there

could be a problem with the Vacuum Fan. T o verify if there really is

a problem with the Vacuum Fan, try the following:

1 With the Printer ON, open the Window of the Printer and place a

sheet of HP High Gloss Photo Paper (must be D-Size), aligned with

the blue lines on the Center Platen. If the Vacuum Fan holds the

sheet in place, and then loads it correctly, then the Vacuum Fan

functions correctly. If the Vacuum Fan does not hold the sheet in

place (no suction), then try the following:

Check that the holes in the Center Platen are NOT blocked.

Check that the Vacuum Fan is installed correctly.

Replace the Vacuum Fan Page 8-64.

2 If the Vacuum Fan held the sheet in place, but couldn’t correctly

load it, then there could be a problem with the Drive Roller. In this

case, replace the Drive Roller Page 8-86.

Vacuum suction much lower at high altitudes

Sometimes, at high altitudes, the vacuum force holding down the

media will be lower, therefore the media will not be held in place

properly causing:

Ink Smearing on the Media.

Printhead crashes against the Media.

Cut Sheet loading problems (high probability).

Roll Media loading problems (low probability).

The solution to this would be to change the Vacuum force by

changing the Altitude setting. This can be done via the front panel

Set-up Menu / Altitude.

1-6

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 17

Troubleshooting

HP-GL/2 color differences in different HP DesignJet Printers

Color differences between one image printed on the HP DesignJet

500/510/800 Series and the rest of the DesignJet platforms are due

to the different chemistry of the 500/510/800 series inks compared

with the rest of the inks for other printers. This color variability

among different HP DesignJet Series Printers has always been

present. To solve the problem, try the following:

Perform the color calibration from the driver at the time of

printing. However, that calibration is not very accurate but it may

help in the most severe cases.

Some applications have color controls for the user to modify the

image in order to obtain the desired colors.

Printing with PostScript reduces the problem significantly.

Avoid very long exposures to extreme environmental conditions

after printing with glossy media (more than 12 hours at 80%

humidity may result in severe changes in color).

Banding at variable extreme environmental conditions

Since the Accuracy Calibration has been done at normal

environmental conditions, printing in extreme environmental

conditions will cause banding because the advance of the Drive

Roller does not correspond to the same conditions that the

calibration was done in. To solve the problem, try the following:

Perform the Accuracy Calibration in the new environmental

conditions (Refer to the User’s Guide).

HP DesignJets 500, 510 and 800 Series Printers Service Manual

1-7

Page 18

Troubleshooting

The Priming Procedure Fails

When the customer first receives the Printer, it is supplied with a set

of four Start-up Printheads pre-installed in the Printhead Carriage.

These Start-up Printheads are used for the priming of the tubes in

the Ink Delivery System.

When the Printer is powered ON for the first time, the Printer will

automatically perform the priming process. Without the priming

process, the customer will NOT be able to use the Printer.

The initial startup assumes that the Start-up Printheads are installed,

but the Printer cannot detect them because the Printer can only

detect normal Printheads. If normal Printheads are installed during

the initial startup, the Printer will request the User to remove them

and check if they really have been removed. It will then request the

User to install the Start-up Printheads.

Also the Printer will request the User to install the Ink Cartridges if

they have not been installed already . If the Ink Cartridges contain less

than 20cc of ink (the Ink Cartridges are encoded with the quantity of

ink remaining) they will be rejected. Normally with a new Printer this

should not be a problem since the Printer comes with Ink Cartridges

that are full, but there maybe cases when the Ink Supply Tubes need

to be replaced, in which case half empty Ink Cartridges may be used.

Once the Printer assumes that the

Start-up

Printheads and Ink Cartridges

with enough ink are installed, the priming process will begin.

If the priming process is completed successfully, the Printer will

directly proceed to the Printhead replacement procedure in order to

replace the used Start-up Printheads with normal Printheads.

Once the priming process has started, it can fail due to 2 different

problems:

The Ink Supply Tubes were not completely empty - This is the

most common cause especially if the Printer has been powered

ON and OFF several times with the Ink Cartridges installed since

the initialization process performs at least one pumping cycle.

The Printer detects that one or more of the tubes cannot be

detected as filled with ink - The most likely cause for this

problem is Ink Cartridges with a faulty valve.

Even if the priming process fails, the Printer will try to verify

whether the priming process has been completed by moving the

Carriage to the access position and you will see the following

1-8

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 19

Troubleshooting

Unable to prepare

ink system.

Open window to check

SETUP printheads

1. Lift printhead cover

Menu

Back

Enter

2. Check if there is ink

inside printhead windows

3. Press ENTER to continue

Check for ink

Menu

Back

Enter

Are all printhead windows

filled with ink?

ALL with some ink

NOT all with ink

message on the Front Panel:

Open the Window and you will see the following message on the

Front Panel:

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Open the Carriage Cover and check if there is ink inside the Start-up

Printheads. On the Front Panel you will see the following question

and you will need to select the answer depending on whether the

Start-up Printheads were filled with ink or not:

If there is ink in all of the Start-up printheads, the Printer considers

that the priming procedure has been completed successfully and will

proceed to the Printhead replacement process.

If you select NOT all with ink the Printer will react differently

depending on the source of the problem:

1-9

Page 20

Troubleshooting

NOTE If you need to reseat the Start-up Printheads, make sure you re-

insert them in the same color slot in the Carriage.

The Printer will request you to reseat the Start-up Printheads (or

in the case of missing Start-up Printheads you should install them

or order new ones) and then retry the priming process (if the

priming process fails 3 times because of the same problem, it will

display a System Error). In this situation, the problem could be

the following:

1 The Start-up Printheads were not installed co rrectly or they are

missing (one or all of them).

2 The Start-up Printheads do not work properly and do not allow

air to flow (one or all of them).

3 The Ink Supply Station fails to pressurize the Ink Cartridges.

To check this, perform the Ink Supply Station test Page 4-6.

4 The Ink Supply Tubes are blocked, preventing the ink from

flowing correctly.

If a System Error is displayed, try the following:

1 The Ink Cartridge valve is broken so the Ink Cartridge should

be replaced.

2 The Start-up Printhead is not working properly and allows ink

to flow outside.

3 The Ink Supply Tube is leaking.

NOTE The last 2 cases will be more obvious because there will be a lot

of ink in the Printer (around 20 cc of ink). Remove the Ink

Cartridges and release the Tubes Bracket from the Ink Supply

Station and check if there is ink in this area.

For more information on this problem, refer to System Error 93:10

on Page 2-19.

1-10

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 21

Troubleshooting

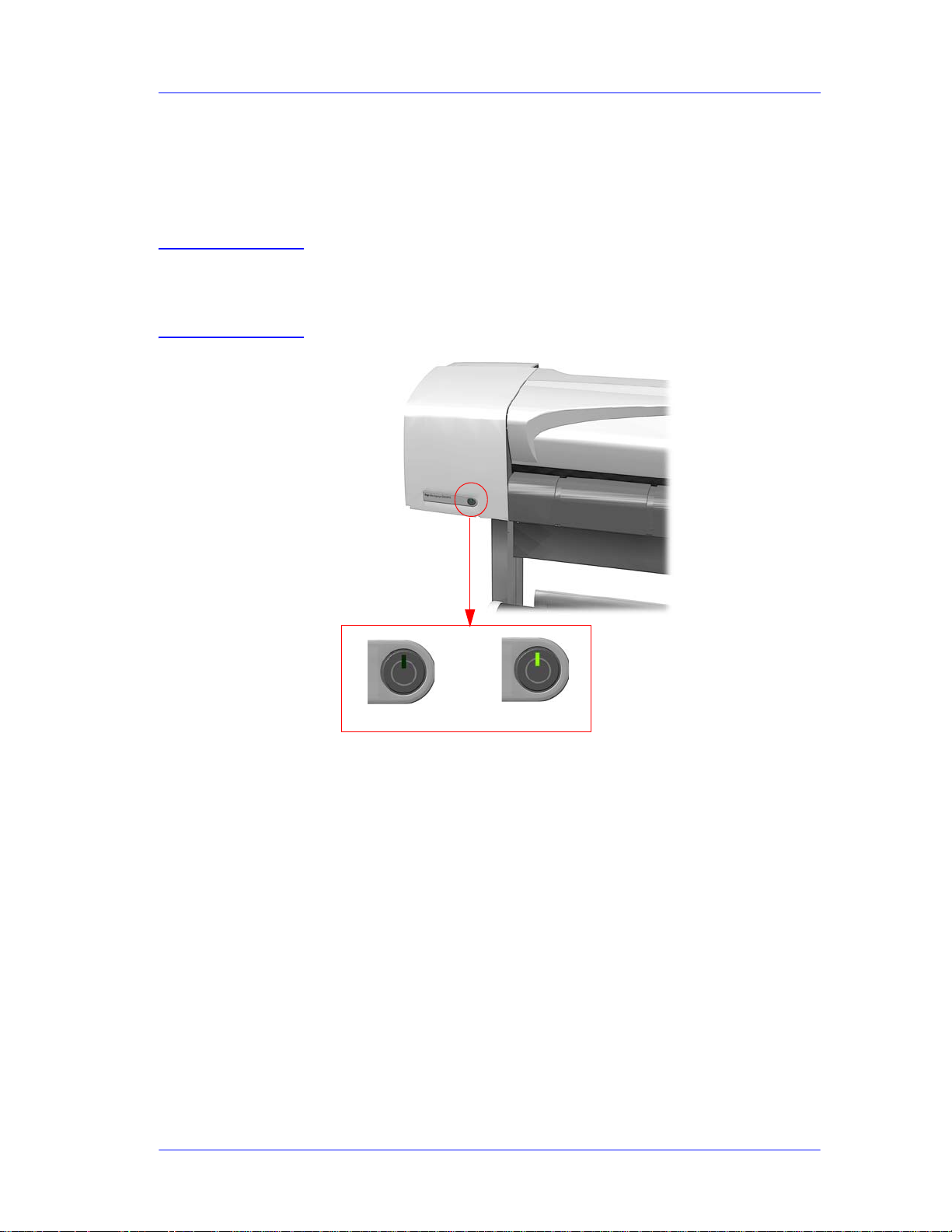

LED OFF

LED ON

Using the Power Switch LED to Troubleshoot

In certain circumstances the LED located in the power switch

(located on the left hand side of the Printer) can help to troubleshoot

the Printer. The LED can be OFF, ON or flashing and using different

combinations can indicate different problems.

NOTE You should only use the LED to troubleshoot when the Printer

does not Power up completely. The LED may flash in other

circumstances which are completely normal and this does not

mean that there is a problem with the Printer.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

1 Check that power cord is connected correctly to the Printer and to

2 Replace the Power Supply Unit Page 8-27.

LED is OFF - This indicates that the Power Supply Unit is

completely dead. Try the following:

the Power Socket. Also make sure that you firmly press the Power

Switch to the ON position.

LED is ON (all the time) - This indicates that the Main PCA is

completely dead. Replace the Electronics Module Page 8-24.

LED is Flashing continuously

- A problem has been detected with the

previous firmware upgrade. Try resending the firmware upgrade file.

LED Flashes twice every few seconds - The Printer cannot detect

1-11

Page 22

Troubleshooting

the Interconnect Cable. Try the following:

1 Check that the Interconnect Cable is connected correctly to the

Electronics Module and to the Interconnect PCA.

2

If the Interconnect cable is connected correctly and the LED continues

to flash twice then replace the Interconnect Cable Page

8-59

.

LED Flashes 3 times every few seconds - The Printer cannot

detect the Front Panel. Try the following:

1 Check that the Front Panel is connected correctly to the Interconnect

PCA.

2 Check that the Interconnect Cable is properly connected at the both

ends of the Printer.

3 If the Front Panel is connected correctly and the LED continues to

flash 3 times then replace the Front Panel Page 8-9.

4 R

eplace the Interconnect Cable Page

5

Replace the Electronics Module Page

8-59

8-24

.

.

LED Flashes 4 times every few seconds

- This indicates that the

Main PCA has failed. Replace the Electronics Module Page

LED Flashes 5 times every few seconds

- This indicates that the

Main PCA has failed. Replace the Electronics Module Page

8-24

8-24

.

.

1-12

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 23

Troubleshooting

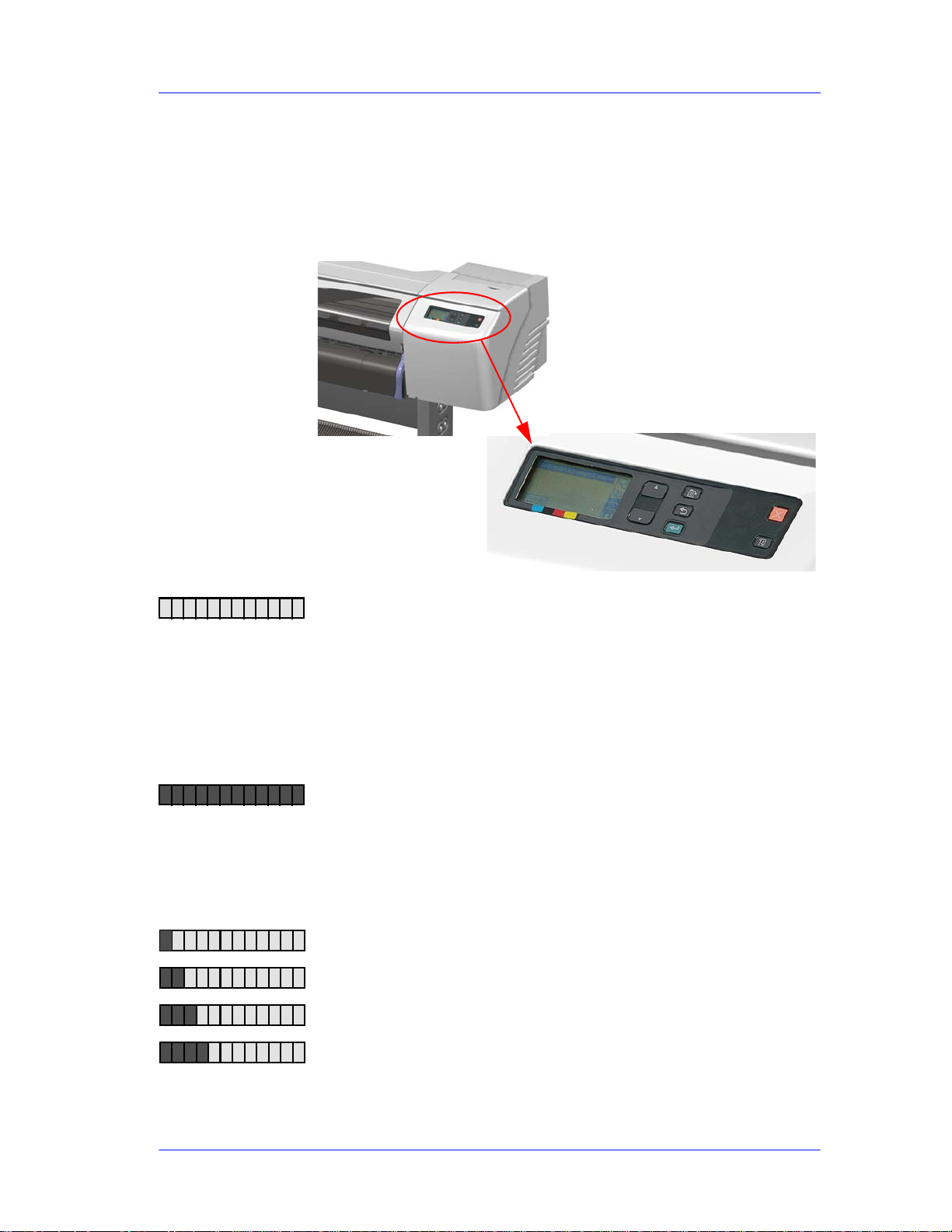

Using the Boot-Up Sequence to Troubleshoot

When you Power On the Printer, the Printer performs the Boot-Up

sequence which initializes the major components of the Printer. If

for some reason the Boot-Up sequence fails because a component

has failed to initialize, the following explanations will help you to

locate the failing component:

During the first phase of the Boot-up sequence (all the squares turn

grey) the Printer is initializing the Operating System. If for some

reason this sequence fails, try the following:

1 Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the initialization sequence is successful.

2 If the initialization sequence fails again, replace the Electronics

Module Page 8-24.

During the second phase of the Boot-up sequence (all the squares

turn black) the Printer is initializing various components (too

numerous to mention). In normal circumstances, if a component fails

during this sequence a System Error will appear and you should refer

to Chapter 2 -

System Error Codes

. The following information

explains what is being initialized as each square turns black:

Initializing various components of the Main PCA.

Initializing various components of the Main PCA.

Initializing a portion of the Firmware.

Initializing various components of the Main PCA.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

1-13

Page 24

Troubleshooting

Initializing various components of the Main PCA.

Initializing a portion of the Firmware.

Initializing the I/O.

Initializing the User Interface (Front Panel menus).

Initializing a portion of the Firmware.

Initializing the Formatter.

Initializing the communication between Main PCA and Formatter.

End of initialization sequence.

Entering Service Menu at Power Up - Only for Onsite Repair

If the Printer fails to initialize completely because of a System Error

and you need to use the Service Menu (Service Tests and Utilities),

the Printer can be powered up in Service Mode by pressing the Up

and Enter keys while switching the Printer ON. This will give you

access to some of the Service Tests and Utilities without having to

complete the System Initialization (if you perform some of the tests,

they will need to initialize the relevant part of the System).

1-14

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 25

Troubleshooting

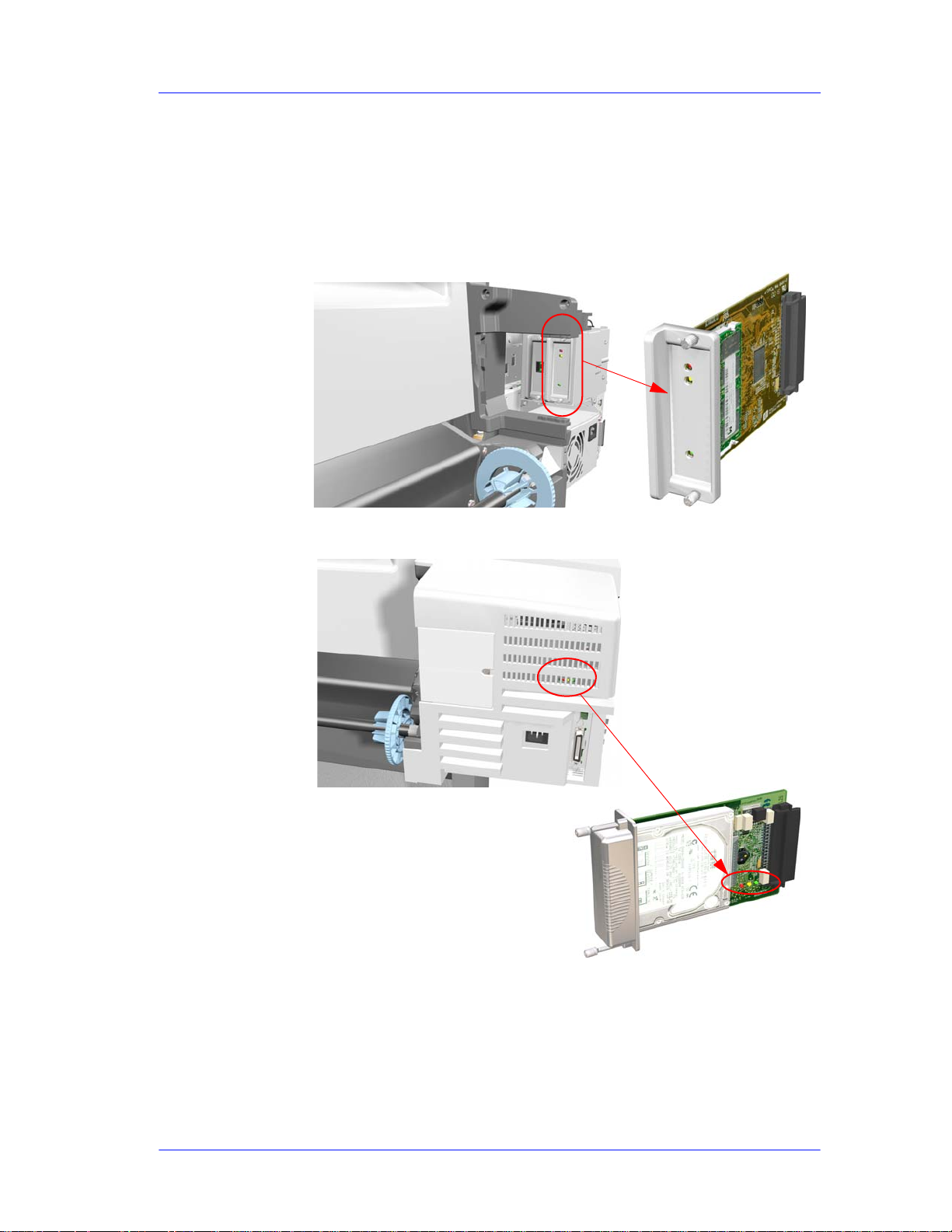

LED’s on the HP-GL/2

The LED’s on the Formatter

can be seen without having to

remove the Left Hand Cover.

LED’s on the Formatter

Accessory Card

Using the Formatter/Accessory Card LEDs to Troubleshoot

In certain circumstances the LEDs located in the Formatter or HPGL/2 Accessory Card can help to highlight certain failures. There

are 3 LEDs, Red, Yellow and Green and using different

combinations can indicate different problems.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

The yellow LED (normally flashing) indicates that the Formatter/

Accessory Card is alive. If it stops flashing, it means that the

Formatter/Accessory Card has failed and should be replaced.

The green LED indicates that there is power being supplied to the

1-15

Page 26

Troubleshooting

Formatter/Accessory Card. If the green LED is NOT lit and the

LED in the Power Switch is ON, then it could mean that the

Formatter/Accessory Card is badly connected or that the Printer if

switched OFF . If after reseating the Formatter/Accessory Card, the

problem persists, try the following:

1 Switch the Printer OFF and remove the Formatter/Accessory Card

BUT leaving the LAN Card installed (if available). Switch the

Printer ON. If the Printer powers up correctly and the LAN Card

works properly , then try step 2. If the LAN Card doesn’ t work, then

try step 3.

2 Switch the Printer OFF and remove the LAN Card from the current

slot and install the Formatter/Accessory Card in the same slot (that

was previously used by the LAN Card). Switch the Printer ON and

check if the green LED in the Formatter/Accessory Card is lit. If the

green LED is NOT lit, it means that the Formatter/Accessory Card

is faulty and should be replaced.

If the green LED is lit, then switch the Printer OFF and install the

LAN Card in the vacant slot. Switch ON the Printer and check if the

LAN Card works properly. If the LAN Card does NOT work, then

there is a problem with the Electronics Module and should be

replaced Page 8-24.

3 Switch the Printer OFF and remove the LAN Card. Switch ON the

Printer and check if it initializes completely . If it initializes correctly

without any problems, then the problem could be with the

Electronics Module and should be replaced Page 8-24.

4 If the Printer does not even start to power up (i.e. nothing seen on

the Front Panel and the LED in the Power Switch is NOT flashing)

without the LAN Card nor the Formatter/Accessory Card, but the

power switch LED is ON (all the time) the problem could be with

the Electronics Module or the Power Supply Unit.

The red LED will flash a few times when the Printer is started up

but if it stays lit (all the time) or flashes continuously, then this

indicates that the Formatter/Accessory Card is faulty and should

be replaced.

HP Designjet 510 Series printers will only include “HPGL/2

Accessory Card (Processor Card)” installed in the Left Slot of the

Electronics Module.

1-16

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 27

Troubleshooting

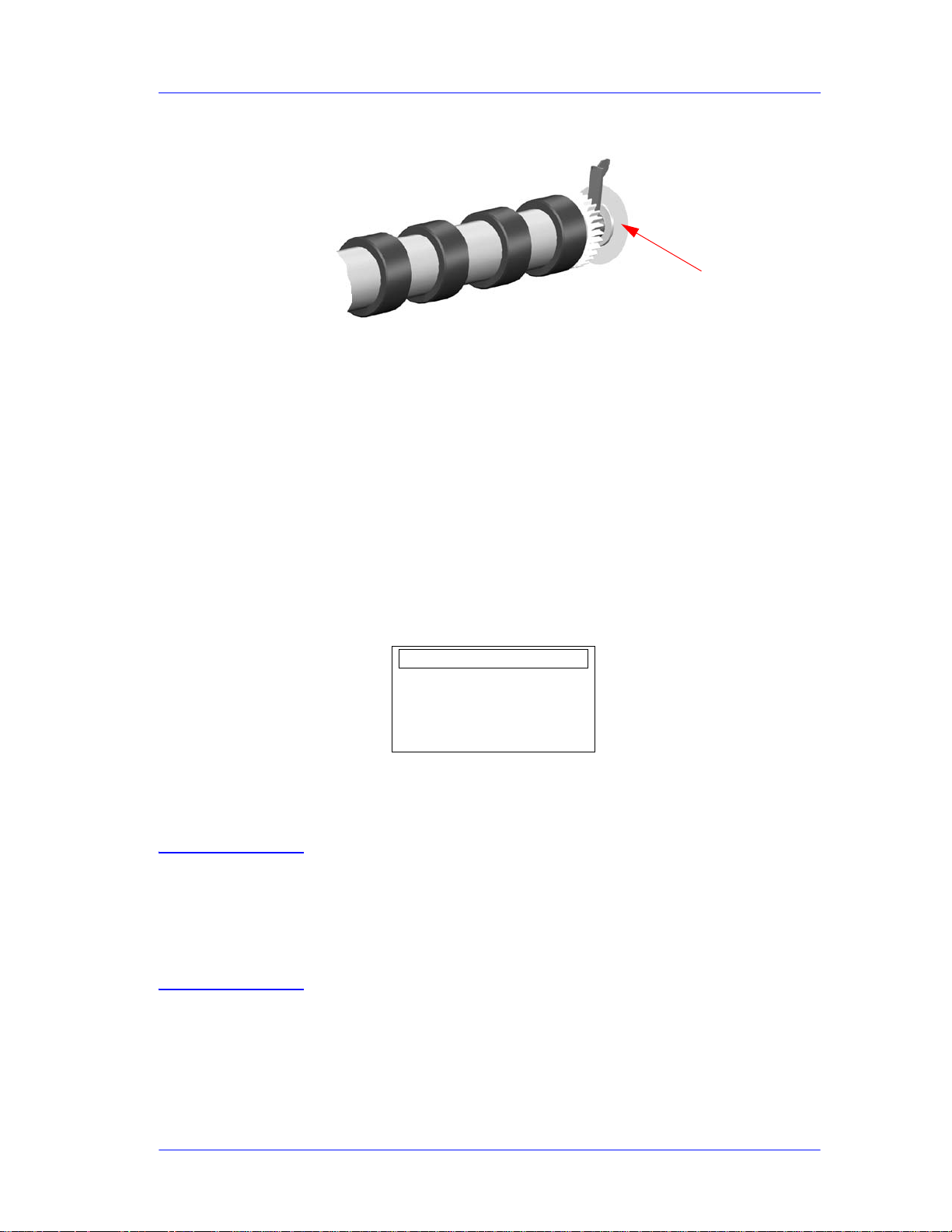

Encoder Disk

Paper Advance test

System error 56:10

Roller encoder sensor

failed

How to Detect Problems Related to the Encoder Disk

The following information will help you detect any problems

related to the Encoder Disk:

Horizontal and periodic white lines, all of them with the same

width depending on the failure mode. This is a clear indication

that the Encoder Disk is damaged.

System Error 56:10 - This means that you have to replace the

Drive Roller Encoder Sensor Page 8-38. But, if the problem

persists, replace the Encoder Disk Assembly.

System Error 81:01 - This means a Paper-Axis shutdown. If this

error code appeared but was NOT caused by a paper jam, then

perform the Paper Advance Test Page

Advance Test fails during the third test, the Front Panel will

display the following message:

4-11

. If the Paper

NOTE In order to remove the Encoder Disk, you must first remove t he Driv e

HP DesignJets 500, 510 and 800 Series Printers Service Manual

In this case, you should replace the Drive Roller Encoder Sensor

Page 8-38. But, if the problem persists, replace the Encoder Disk

Assembly.

Roller

Be very careful when assembling the Axle Spring because you could

damage the Encoder Disk.

Check that no air bubbles are trapped between the Encoder Disk and the

hub once it is installed.

Page 8-86.

1-17

Page 28

Troubleshooting

1-18

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 29

System Error Codes 2

System Error Codes 1

Introduction 2-2

Continuable and Non-Continuable Error Codes 2-2

System Error Codes - Explanation 2-2

Accessing the Error Log Utility 2-5

01:10 2-7

01:11 2-7

01:12 2-7

01:13 2-8

02:10 2-8

02:13 2-8

03:10 2-9

04:11 2-9

05:10 Warning (Only applicable to HP DesignJet 800 Series) 2-9

05:11 2-10

08:11 2-10

11:11 2-10

11:13 2-10

12:11 2-11

21:10 2-11

21:11 2-11

22:10 2-11

41:10 2-12

41:13 2-12

42:10 2-12

43:10 2-12

43:11 2-12

56:10 2-13

56:13 2-13

61:04 2-13

61:05 2-14

64:04 2-14

71:04 2-15

71:06 2-15

72:04 2-16

73:04 2-16

79:04 2-17

81:01 2-17

81:11 2-17

85:10 2-18

86:01 2-18

86:11 2-18

86:13 2-19

87:13 2-19

93:10 2-19

2

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-1

Page 30

System Error Codes

Introduction

System error codes are hexa-decimal based numbers generally

caused by internal system errors. The following pages contain a list

of system error codes and their respective descriptions and

recommended corrective actions. Only try one recommended action

at a time and check if the error code has disappeared.

Continuable and Non-Continuable Error Codes

Some of the Error Codes are continuable, which means you can

press Enter on the front-panel and continue working with the

Printer. Non-Continuable Error Codes do not allow you to continue

working with the Printer, in this case power the Printer OFF and ON

again and see if the System Error disappears. If the Error Code

reappears, then the Printer requires an on-site visit in order to

resolve the problem.

NOTE Even though the customer can continue working with a

Continuable Error Code, an on-site visit should still be planned

to troubleshoot the problem.

System Error Codes - Explanation

System Error Codes consist of 4 digits which explain which

component/system is failing and what action should be taken to

resolve the problem.

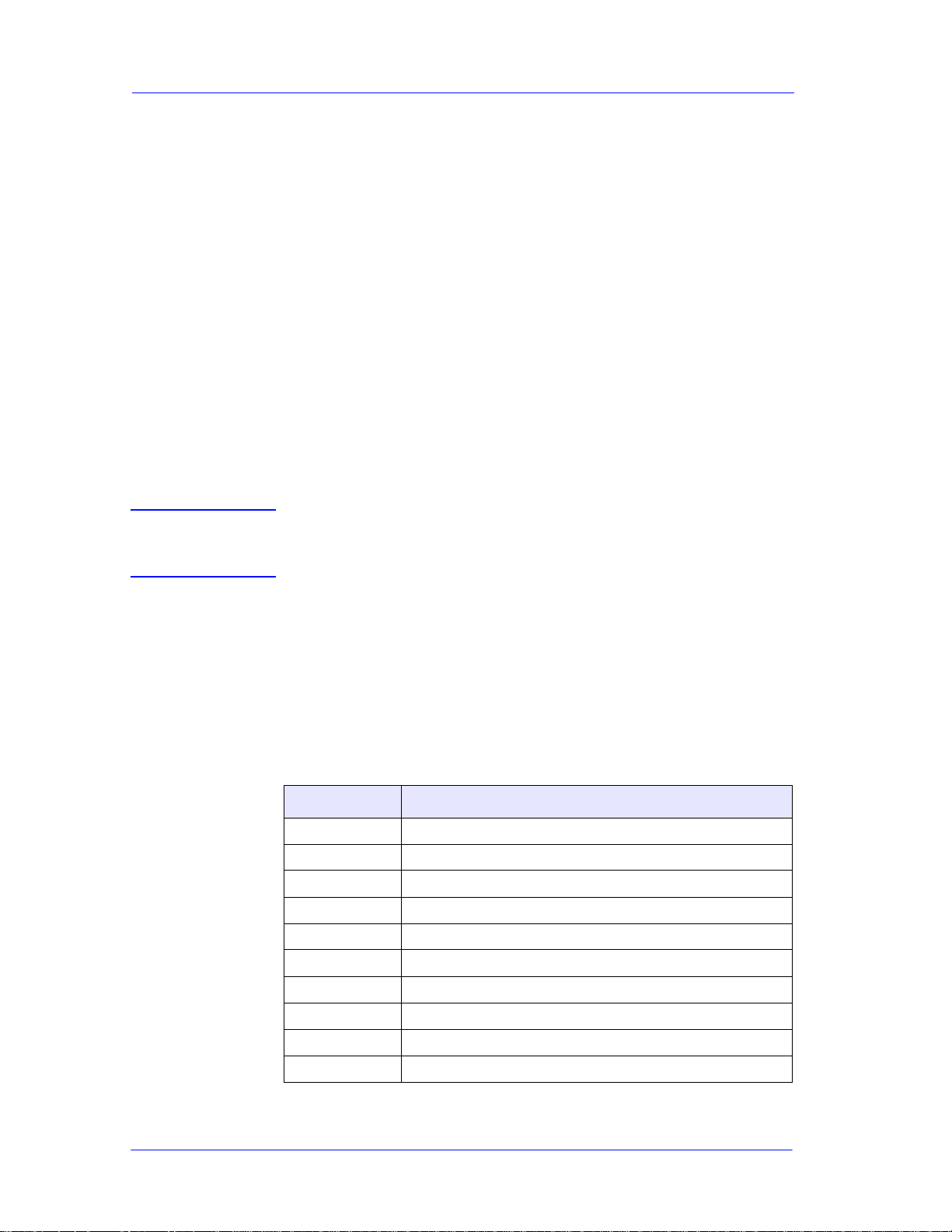

The following table explains the

Code Component/System

01 Main PCA/Electronics Module

02 Carriage/Carriage PCA

03 Power Supply Unit

04 Network Card

05 Formatter

06 Hard Disk Drive

first

2 digits of the System Error Code:

2-2

07 Interconnect PCA

08 Front Panel

11 Trailing Cable

12 Carriage Flex Circuit

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 31

System Error Codes

Code Component/System

17 Interconnect Cable

21 Service Station

22 Ink Supply Station

23 Pressure System (APS)

24 Ink Delivery System

25 Spittoon

31 Cutter

32 Take-up Reel

33 Sheet Feeder

34 Dryer/Blower

41 Paper-Axis Motor

42 Scan-Axis Motor

43 Vacuum Fan

51 Window Sensor

52 Drop Detector

53 Media Sensor

54 Pinch-Arm Sensor

55 Line Sensor

56 Drive Roller Encoder Sensor

57 Ink Leak Detector

58 Color Sensor

59 Media Type Sensor

61 Language Interpreting

62 Input/Output through Parallel Port

63 Input/Output through Network Card

64 Input/Output through USB Port

65 Input/Output

71 Memory Management

72 Generic Firmware

73 Servo

79 Assertion

81 Media Advance

82 Media Cut

83 Single-Sheet Feeding

84 Roll Feeding

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-3

Page 32

System Error Codes

Code Component/System

85 Media-Axis Encoder Reading

86 Carriage Movement

87 Scan-Axis Encoder Reading

91 Printhead Firing

92 Servicing

93 Ink Pumping

The following table explains the

last

2 digits of the System Error Code:

Code Recovery Action Response

00 Replace

01

02

03 Power OFF

04 Upgrade System Firmware

Reseat/Reconnect/Clean/Adjust (manually)

Calibrate/Adjust (using Automatic Process)

Possible for

customer to

perform

action

05 Upgrade Driver

06 Add Accessory

07 Escalate

08 Send Plot Again

09 Wrong Part Installed

10 Replace

11

12

13 Power OFF

14 Upgrade System Firmware

Reseat/Reconnect/Clean/Adjust (manually)

Calibrate/Adjust (using Automatic Process)

On-Site

visit

required

15 Upgrade Driver

16 Add Accessory

2-4

17 Escalate

18 Send Plot Again

19 Wrong Part Installed

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 33

System Error Codes

Menu

Back

Enter

Press ENTER for

Set-up menu

Set-up menu

Menu

Back

Enter

Set-up menu

Expansion cards

I/O set-up

front panel

Altitude = 0-1000 m.

Log

Error Log Utility

The Error Log utility contains a record of the last 10 system error

codes the Printer has experienced. The purpose of this information

is to:

Determine whether the Printer is experiencing repetitive failures.

Determine whether the previous problems are causing the current

failure in the printer.

Determine whether there are additional symptoms to the current

system error code.

The information that is stored for each error code is:

The reported System error code.

The code line in the Firmware where the error was triggered.

The date when the error code was triggered.

Accessing the Error Log Utility

1 Press the ↑ or ↓ key until the front panel displays the Setup Menu and

then press Enter

.

2 Press the ↑ or ↓ key until the front panel highlights Log. Press the

Enter key.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-5

Page 34

System Error Codes

Menu

Back

Enter

Log

Printheads

Errors

Menu

Back

Enter

Error log

Select for more info:

1 Error 21:10

2 Error 01:11

3 Error 21:11

4 Error 43:10

Error log

Error code: 21:10

linefeed.c, 217

Date: 20-Sep-01

3 Press the ↑ or ↓ key until the front panel highlights Errors. Press

4 Press the ↑ or ↓ key until the front panel highlights the error code

5 The front panel displays information on the selected item.

the Enter key.

that you want to see information on. Press the Enter key .

NOTE To view information on another Error Code, press BACK and

the front panel will return to the previous screen

2-6

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 35

System Error: 01:10

System Error Codes

Problem

Description:

Electronics Module failure. The possible cause could be:

1. The Electronics Module is of the wrong type (a 16 MB

Electronics Module will not work in a 24" Model).

2. Reading, writing or initializing the EEROM failed.

3. One of the ASIC’s was not found within the Serial Bus that

connects the Electronics Module to the Carriage Assembly.

4. One of the ASIC’ s did not respond to the Serial Bus that connects

the Electronics Module to the Carriage Assembly.

5. The Electronics Module is requesting a move to the Service

Station while the previous move is still being completed.

6. The Electronics Module Cooling Fan has reached its current

limit.

Corrective Action: Replace the Electronics Module Page 8-24.

System Error: 01:11 Problem

Description:

The Electronics Module Cooling Fan badly connected.

Corrective Action: Reconnect the Cooling Fan (located on top of the Electronics

Module). If the Cooling Fan continues to fail, check that the

connector pins in the Electronics Module are NOT bent.

System Error: 01:12 Problem

Description:

Corrective Action: Configure the EEROM correctly using the EEROM setup utility

The EEROM is not configured correctly (the product number may

be missing).

Page 4-17.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-7

Page 36

System Error Codes

System Error: 01:13 Problem

Description:

Electronics Module failure. The possible cause could be:

1. One of the ASIC’ s in the Electronics Module is reporting that it is

too hot.

2. The interruptions from the Scan-Axis servo or from the PaperAxis servo are not coming as regularly as they are expected or

are coming too late.

Corrective Action: Try the following:

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code continues, replace the Electronics Module

Page 8-24.

System Error: 02:10 Problem

Description:

Carriage failure. The possible cause could be:

1. The Carriage PCA is not compatible with the rest of the Printer.

2. The Carriage ASIC has problems initializing.

3. The +2.5V reference voltage generated in the Carriage PCA is

out of range.

4. One of the Carriage ASIC’s cannot be found within the Serial

Bus that connects the Electronics Module to the Carriage.

5. One of the Carriage ASIC’ s did not r espond to the Serial Bus that

connects the Electronics Module to the Carriage Assembly.

Corrective Action: Replace the Carriage Assembly Page 8-78.

System Error: 02:13 Problem

Description:

Corrective Action: Try the following:

Carriage failure. The possible cause could be:

1. One of the ASIC’s in the Carriage is reporting that it is too hot.

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code continues, replace the Carriage Assembly

Page 8-78.

2-8

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 37

System Error: 03:10

System Error Codes

Problem

Description:

Corrective Action: Replace the Power Supply Unit Page 8-27.

System Error: 04:11 Problem

Description:

Corrective Action: Power OFF the Printer and reconnect the LAN Card.

System Error: 05:09 Error (Only applicable to HP DesignJet 500 and 510

Power Supply failure.

LAN Card not detected.

Series)

Problem

Description:

Corrective Action: Power OFF the Printer and remove the Formatter and install the HP-

Formatter installed instead of HP-GL/2 Accessory Card.

GL/2 Accessory Card Page 8-20.

NOTE: If this Error Code appears on a DesignJet 800 Series Printer,

then the model number configured in the Printer is incorrect (the

Printer thinks it’s a DesignJet 500 Series Printer). In this case

reconfigure the model number Page 4-17.

System Error: 05:10 Warning (Only applicable to HP DesignJet 800 Series) Problem

Description:

Corrective Action: Power OFF the Printer and reseat the Formatter.

System Error: 05:10 Error (Only applicable to HP DesignJet 800 Series) Problem

Description:

Corrective Action: Power OFF the Printer and replace the Formatter Page 8-20.

Formatter not detected.

Formatter failure.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-9

Page 38

System Error Codes

System Error: 05:10 Error (Only applicable to HP DesignJet 500 and 510

Series)

Problem

Description:

Corrective Action: Power OFF the Printer and replace the HP-GL/2 Accessory Card

HP-GL/2 Accessory Card failure.

Page 8-20.

System Error: 05:11 Problem

Description:

Corrective Action: Power OFF the Printer and reconnect the Formatter.

System Error: 08:11 Problem

Description:

Corrective Action: Reconnect the Front Panel.

System Error: 11:11 Problem

Description:

Formatter not detected.

Front Panel cannot be detected.

Trailing Cable badly connected.

Corrective Action: Reconnect the Trailing Cable correctly.

System Error: 11:13 Problem

Description:

Corrective Action: Try the following:

Problem with setting the voltage of the Printheads.

Check that the Trailing Cable is connected correctly at both ends.

Replace the Trailing Cable Page 8-40.

Replace the Carriage Assembly Page 8-78.

2-10

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 39

System Error: 12:11

System Error Codes

Problem

Description:

Corrective Action: Try the following:

A short detected in the Carriage Assembly.

Remove ALL the Printheads and clean the flex contacts on the

Printheads and in the Carriage Assembly.

Replace ALL the Printheads.

Replace the Carriage Assembly Page 8-78.

System Error: 21:10 Problem

Description:

Service Station failure. The possible cause could be:

1. The steps counted by the Service Station motor are not consistent

with the expected length of the current movement.

2. The Aerosol Fan has reached its maximum current limit.

3. The Service Station motor has shutdown because of blockage.

Corrective Action: Replace the Service Station/Aerosol Fan Assembly Page 8-52.

System Error: 21:11 Problem

Description:

Corrective Action: Try the following:

System Error: 22:10 Problem

Description:

Service Station cannot be detected or the Service Station is badly

adjusted.

Reconnect the Service Station Assembly.

Reposition the Service Station trip lever.

Ink Supply Station failure. The possible cause could be:

1. Reading, writing or initializing the backup EEROM failed.

2. One of the out-of-ink sensors (located in the Ink Supply Station)

is not reporting what it should during the initializing process

while depressurizing.

Corrective Action: Replace the Ink Supply Station Page 8-48.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-11

Page 40

System Error Codes

System Error: 41:10 Problem

Description:

Corrective Action: Replace the Paper-Axis Motor Page 8-84.

System Error: 41:13 Problem

Description:

Corrective Action: Try the following:

Paper-Axis Motor failure.

Error in the Paper-Axis Motor Encoder quadrature.

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code continues, replace the Paper-Axis Motor

Page 8-84.

System Error: 42:10 Problem

Description:

Corrective Action: Replace the Scan-Axis Motor Page 8-29.

Scan-Axis Motor failure.

System Error: 43:10 Problem

Description:

Corrective Action: Replace the Vacuum Fan Page 8-64.

System Error: 43:11 Problem

Description:

Corrective Action: Reconnect the Vacuum Fan.

Vacuum Fan failure.

Vacuum Fan not detected.

2-12

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 41

System Error: 56:10

System Error Codes

Problem

Description:

Corrective Action: Try the following:

System Error: 56:13 Problem

Description:

Corrective Action: Try the following:

Drive Roller Encoder Sensor error.

Replace the Drive Roller Encoder Sensor Page 8-38.

If the problem persists, replace the Encoder Disk Assembly.

Error in the Drive Roller Encoder Sensor quadrature.

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code continues, replace the Drive Roller Encoder

Sensor Page 8-38.

System Error: 61:04 Problem

Description:

Firmware Error.

Corrective Action: Try the following:

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem, or if new

Firmware release was not available, then contact the HP

Response Center (or directly to the Division) supplying the

following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information

4-27

Page

).

2-5

).

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-13

Page 42

System Error Codes

System Error: 61:05 Problem

Description:

Error Processing Job. This Error Code only appears in HP DesignJets

800 Series, or in the HP DesignJet 500 and 510 Series

GL/2 card installed, when processing either a PostScript or HP-GL/2

file.

Corrective Action: Try the following:

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and resend the file that you were trying to print.

If the Error Code reappears after resending the file, then try

generating the file again and try to print again.

If the file that is causing this error is PostScript, check if it is

Binary. If the file is Binary, use AppleTalk to send the file to the

Printer. If AppleTalk is not being used to send the Binary file to

the Printer, then change the PostScript settings to Binary through

the Front Panel (Set-up menu / PS settings / Encoding / Binary).

If the Error Code continues to reappear, check for a new release

of the Driver.

System Error: 64:04

with

an HP-

Problem

Description:

Corrective Action: Try the following:

Firmware Error (USB Port).

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem, or if new

Firmware release was not available, then contact the HP

Response Center (or directly to the Division) supplying the

following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility

Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information Page

4-27

).

2-5

).

2-14

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 43

System Error: 71:04

System Error Codes

Problem

Description:

Corrective Action: Try the following:

Problem allocating Memory. This Error Code only appears in HP

DesignJets 800 Series, or in the HP DesignJet 500 and 510 Series

with

an HP-GL/2 card installed.

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem, or if new

Firmware release was not available, then contact the HP

Response Center (or directly to the Division) supplying the

following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information Page

4-27

).

2-5

).

System Error: 71:06 Problem

Description:

Out of Memory problem. This Error Code only appears in HP

DesignJets 800 Series, or in the HP DesignJet 500 and 510 Series

with an HP-GL/2 card installed, when processing either a PostScript

or HP-GL/2 file.

Corrective Action: Try the following:

Look on your computer screen for error messages; some drivers

allow you to choose a different printing mode and attempt to send

the file again. If necessary, select Send Job as a Bitmap in the

driver’s Troubleshooting menu (Services tab). This may slow

down print speed.

If the problem persists, you can install extra memory on the HP-

GL/2 Accessory Card in your printer.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-15

Page 44

System Error Codes

System Error: 72:04 Problem

Description:

Corrective Action: Try the following:

Problem in the Scan-Axis (Firmware Error).

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem, or if new

Firmware release was not available, then contact the HP

Response Center (or directly to the Division) supplying the

following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information Page

System Error: 73:04

4-27

).

2-5

).

Problem

Description:

Corrective Action: Try the following:

Servo Error .

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem then

replace the Electronics Module Page 8-24.

If the problem continues, contact the HP Response Center (or

directly to the Division) supplying the following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information

4-27

Page

).

2-5

).

2-16

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 45

System Error: 79:04

System Error Codes

Problem

Description:

Corrective Action: Try the following:

Firmware Error.

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem, or if new

Firmware release was not available, then contact the HP

Response Center (or directly to the Division) supplying the

following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information Page

System Error: 81:01

4-27

).

2-5

).

Problem

Description:

Corrective Action: If this error code appeared but was NOT caused by a paper jam, then

Paper-Axis shutdown.

try the following:

Perform the Paper Advance Test

If the problem persists, replace the Encoder Disk Assembly.

System Error: 81:11 Problem

Description:

Corrective Action: Refer to Error Code 81:01.

Paper-Axis shutdown (during the Paper Advance test).

Page

4-11

.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-17

Page 46

System Error Codes

System Error: 85:10 Problem

Description:

Corrective Action: Try the following:

Paper-Axis Encoder error. The Drive Roller Encoder Sensor cannot

find the zero position of the Encoder Disk.

Replace the Drive Roller Encoder Sensor Page 8-38.

If the Error Code continues, replace the Drive Roller Page 8-

86.

System Error: 86:01 Problem

Description:

Corrective Action: If this error code appeared but was NOT caused by a paper jam, then

Carriage-Axis shutdown.

try the following:

T oo mu ch friction in the Slider Rod. Enter the Printer Information

utility ( Page

4-27

) and check the Scan-Axis usage. If the

percentage is close to 100%, then lubricate the Slider Rod.

The Carriage is bumping into the Service Station. If the carriage

is stuck at the right hand side of the Printer and cannot be moved

out to the center of the Print Platen it is because the Service

Station cannot uncap the Printheads. In this case replace the

Service Station/Aerosol Fan Assembly Page 8-52.

Perform the Carriage Movement test Page 4-8.

System Error: 86:11 Problem

Description:

Corrective Action: Refer to Error Code 86:01.

2-18

Carriage-Axis shutdown (during the Carriage Movement test).

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 47

System Error: 86:13

System Error Codes

Problem

Description:

Corrective Action: Try the following:

Carriage-Axis shutdown (Firmware Error).

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code reappears, check for a new Firmware release.

If the new Firmware release does not solve the problem, or if new

Firmware release was

(or directly to the Division) supplying the following information:

– Model and Serial Number of the Printer.

– Firmware release of the Printer (use the Printer Information

utility

Page

– The complete Error Code information, including the linefeed

where the error occurred (use the Error Log utility to obtain this

information Page

System Error: 87:13 Problem

Description:

Unable to read the Carriage Encoder Sensor.

4-27

not

available, contact the HP Response Center

).

2-5

).

Corrective Action: Try the following:

Switch the Printer Off and wait a few minutes. Switch the Printer

On again and check if the Error Code has disappeared.

If the Error Code continues, replace the Carriage Assembly

Page 8-78 or the Encoder Strip Page 8-76.

System Error: 93:10 Problem

Description:

Corrective Action: Try the following:

Ink System startup failed (also see Page 1-8 for more information).

Check for a leak in the Printer. If a leak is evident (there is ink on

Printer components), replace the Ink Supply Tubes Page 8-60.

Perform the Prime Tubes utility (Refer to Page 4-24) and check

how long it takes to complete the procedure. If it takes too long to

complete the procedure and there is no leak in the Printer, then

replace the Ink Cartridges. If it takes a short time to complete the

procedure, then replace the Ink Supply Tubes Page 8-60.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

2-19

Page 48

System Error Codes

2-20

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 49

Ink Supplies Troubleshooting

What are the Ink Supplies? 3-2

Ink Cartridges 3-2

Printheads 3-3

Identifying the Components 3-3

General Information About the Ink Supplies 3-4

Some General Precautions When Handling the Ink Supplies 3-5

When Should You Replace the Ink Cartridges? 3-6

When Should You Replace the Printheads? 3-7

Obtaining Ink Cartridge Information 3-9

Obtaining Printhead Information 3-10

Ink Cartridge Status Messages 3-13

Ink Cartridge Status While Replacing 3-13

Printhead Status Messages 3-14

Printhead History Utility 3-15

Accessing the Printhead History Utility 3-15

Is the Printer Causing Repetitive Printhead Problems? 3-17

Is the User Replacing the Printheads too Early? 3-19

Troubleshooting Repetitive Ink Cartridge Messages 3-21

Troubleshooting Repetitive Printhead Error Messages 3-22

Printhead Error Codes 3-23

Summary of Solving Ink Supplies Problems 3-24

3

3

HP DesignJets 500, 510 and 800 Series Printers Service Manual

3-1

Page 50

Ink Supplies Troubleshooting

Printhead Ink Cartridge

69cc

What are the Ink Supplies?

For each of the four ink colors used in the Printer, there are two

separate components: the Printhead and the Ink Cartridge. Both

components are coded with an HP selection number to identify the

correct replacement supplies.

Ink Cartridges

The Ink Cartridges for the HP DesignJet 500, 510 and 800 Series

Printers require no maintenance or cleaning. As long as each Ink

Cartridge is inserted correctly into its slot, the ink will flow to the

Printheads.

The Ink Cartridges are number coded as follows:

HP No.10 for the Black Ink Cartridge (for the HP DesignJet 500

and 800 Series Printers only).

HP No.82 for the Black Ink Cartridge (for the HP DesignJet 510

Series Printers only).

HP No.82 for the Cyan, Magenta and Yellow Ink Cartridges.

NOTE It is also possible to use HP No.11 Ink Cartridges for the Cyan,

Magenta and Yellow colors. The HP No.11 Ink Cartridges

contain 33cc of ink.

The front panel displays the status of the Ink Cartridge. With the

front panel, detailed information can be checked on the Ink

Cartridges, see page Page 3-9, Obtaining Ink Cartridge Information.

3-2

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 51

Ink Supplies Troubleshooting

Printheads

The Printheads are extremely durable and do not need to be replaced

every time an Ink Cartridge is replaced. They are independent of the

Ink Cartridges and will continue giving excellent image quality

results even if the Ink Cartridges are low on ink. In order to know

when to replace a Printhead, see page Page 3-7, When Should You

Replace the Printheads?

The Printheads are number coded HP No.11 for ALL colors.

If you notice a decline in print quality such as lines or dots missing

from text / graphics, go to page Page 6-4, Performing the

Troubleshooting Procedure.

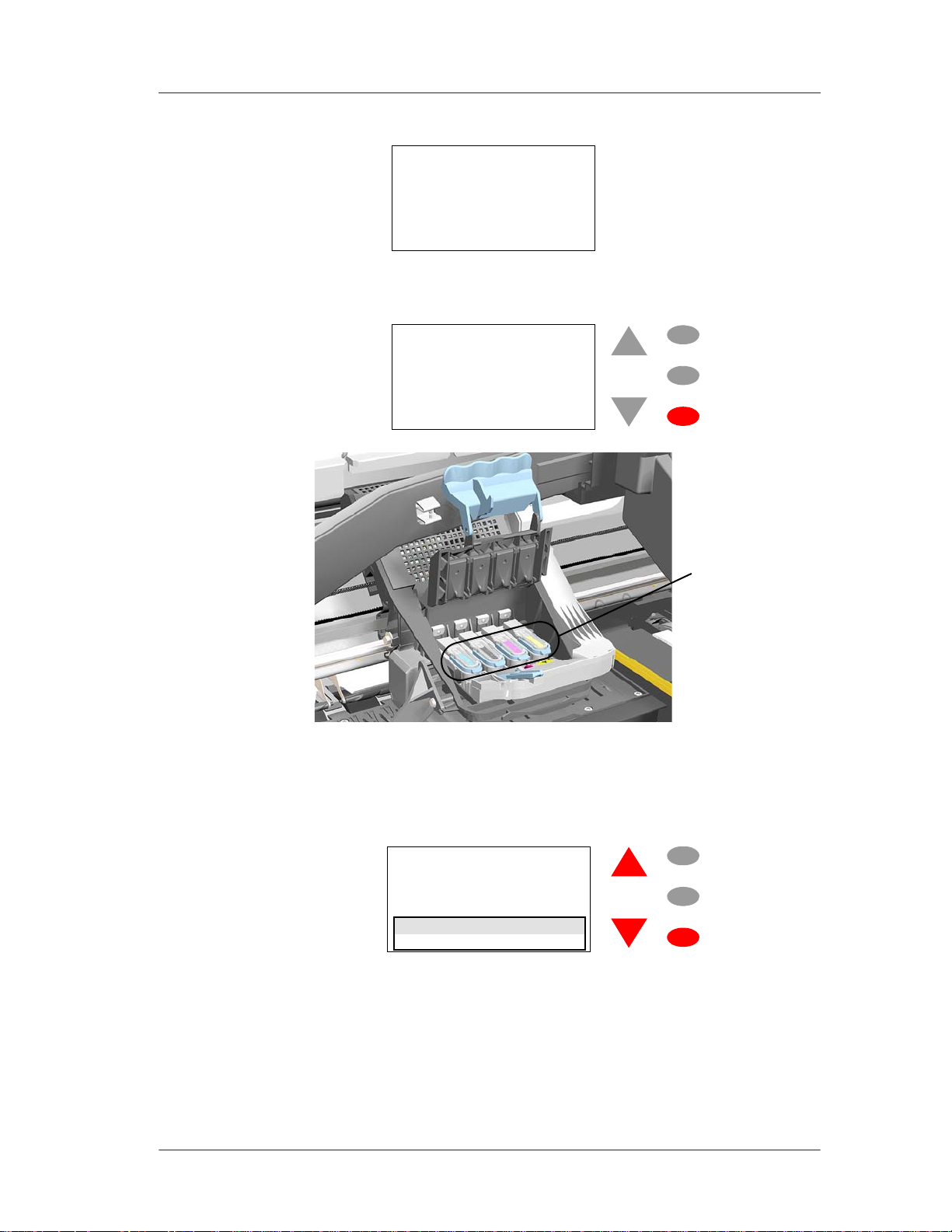

Identifying the Components

The following illustration will help you identify the components of

the ink supplies.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

3-3

Page 52

Ink Supplies Troubleshooting

General Information About the Ink Supplies

For optimum results from the printer and modular ink delivery system always follow these guidelines when handling the ink supplies:

Always install the Ink Cartridges and Printheads before the

expiration date, which is on the packaging.

Install Ink Cartridges and Printheads in their color-coded slots.

Follow the instructions on the front panel of the Printer during

installation.

Avoid unnecessary removal of the Ink Cartridges and Printheads.

When turning off the Printer always use the power Off button

located on the left hand side of the Printer. The Printheads are

then stored correctly which prevents them from drying out.

The Ink Cartridges should never be removed while the Printer is

printing. They should only be removed when the Printer is ready

for you to replace them. The front panel will guide you through

the removal and installation procedure. See page Page 3-6, When

Should You Replace the Ink Cartridges?

3-4

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 53

CAUTION

C6074297a

Do not touch, wipe or attempt

This can damage the printhead.

to clean the printhead nozzles.

Do not touch the Electrical Contacts

Ink Supplies Troubleshooting

Some General Precautions When Handling the Ink Supplies

Do not touch, wipe or attempt to clean the Printh ead nozzles. This can

damage the Printhead.

Handle the Ink Supplies with care. In particular the Printhead,

which is a high precision device, must be handled very carefully.

Do not touch the Printhead nozzles.

Do not touch the Electrical contacts on the Printhead.

Do not put the Printhead down on the nozzles.

Do not be rough when handling the Printheads. Always set them

down gently.

Do not drop the Printheads.

Proper handling will assure optimum performance throughout the

Printhead life.

Do not touch the end of the Ink Cartridge which is inserted into

the Printer as there may be a small amount of ink on the

connection.

Avoid storing partially used Ink Cartridges on their ends.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

3-5

Page 54

Ink Supplies Troubleshooting

When Should You Replace the Ink Cartridges?

When to change the Ink Cartridges is mostly determined by you

with guidance from the front panel. In conjunction with the

messages displayed in the front panel and the message explanations

in this chapter, you will be able to choose for yourself when is the

right time to change the Ink Cartridges.

The printer will also display the ink level and will tell you when the

Ink Cartridge is almost empty. This means you have constantly

updated information about the Ink Cartridges.

There are 3 circumstances when you need to replace the Ink

Cartridges which are explained as follows:

Ink Cartridge Error message. When this message appears, the

Ink Cartridge has experienced a problem and should be replaced.

If this message appears repetitively, refer to Page 3-21,

Troubleshooting Repetitive Ink Cartridge Messages.

Out of Ink message. When this message appears, the Ink

Cartridge is out of ink and should be replaced. If this message

appears repetitively, refer to Page 3-21, Troubleshooting

Repetitive Ink Cartridge Messages.

Expiration message. When this message appears, the Printer is

warning you that the Ink Cartridge is close to the expiration date.

Once the expiration date has been reached, the Printer will stop

working and you will need to install a new Ink Cartridge in order

to proceed. If this message appears repetitively, refer to Page 321, Troubleshooting Repetitive Ink Cartridge Messages.

3-6

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 55

Ink Supplies Troubleshooting

When Should You Replace the Printheads?

In a normal situation, the Printhead should ONLY ever be replaced

when advised by the Printer. If Print Quality is poor, the first step

should ALWAYS be to perform the Troubleshooting procedure

(Refer to Page 6-4) which will determine whether the Printhead

needs replacing or not after performing various levels of recovery

actions.

The minimum life expectancy of the Printhead is anticipated to be

530cc for the Black Printhead and 200cc for the Color Printheads,

provided that the Printhead is used under normal operating

conditions (using HP Ink Cartridges only) and its “install before

date” has not lapsed. However results vary depending on the print

quality setting being used.

There are 3 circumstances when you need to replace the Printheads

which are explained as follows:

Printhead Error message. When this message appears, the

Printer has determined that one of the Printheads has experienced

a problem and should be replaced. If this message appears

repetitively, refer to Page 3-22, Troubleshooting Repetitive

Printhead Error Messages.

Printhead Error (unknown) message. When this message

appears, one of the Printheads has experienced a problem but the

Printer does not know which one it is.

In order to identify and replace the failing Printhead, try the following:

1 Select replace Printheads from the front panel.

2 Open the Carriage cover and remove ALL the Printheads.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

3-7

Page 56

Ink Supplies Troubleshooting

3 Reinsert the Cyan Printhead only and close the Carriage cover and

the Window.

4 Check the front panel - if the status of the Cyan Printhead is X or ?

then the conclusion is that the Cyan Printhead is faulty and must be

replaced. If the status of the Cyan Printhead is OK the conclusion is

that the Cyan Printhead is working correctly. Repeat the process

from step 1 for the other Printheads to identify which one is failing.

Printhead Warning message. When this message appears

(normally appears when you check the status of the Printheads by

selecting the Ink Menu), the Printer has determined that one of

the Printheads has worn out and should be replaced.

The Printer normally determines this when:

1 The Printhead Alignment fails due to a faulty Printhead and the

Printer tries to recover the Printhead (upto 3 times) but is not

successful after the 4th attempt at the Printhead Alignment (or if the

recovery process or the Printhead Alignments are cancelled).

2 The Troubleshooting process is performed but the Printer cannot

recover the failing Printhead even after performing the maximum

recovery action.

NOTE The user can continue using the Printer even with the Printhead

Warning message but will not get the maximum Print Quality

that the Printer is designed to provide, unless he replaces the

worn out Printhead.

3-8

HP DesignJets 500, 510 and 800 Series Printers Service Manual

Page 57

Ink Supplies Troubleshooting

Menu

Back

Enter

Ink cartridges

Ink menu

Menu

Back

Enter

Ink Menu

Information

Color calibration

Troubleshooting

Align printheads

Replace printheads

Menu

Back

Enter

Information

Ink cartridges

Printheads

Menu

Back

Enter

Select ink cartridge

Ink levels

Cyan ink cartridge

Magenta ink cartridge

Yellow ink cartridge

Black ink cartridge

Obtaining Ink Cartridge Information

1 To get information on the Ink Cartridges press the ↑ or ↓ key until

the front panel displays the Ink Menu. Press the Enter key.

2 Press the ↑ or ↓ key until the front panel highlights Information.

Press the Enter key.

3 Press the ↑ or ↓ key until the front panel highlights Ink cartridges.

Press the Enter key.

4 Press the ↑ or ↓ key until the front panel highlights the color that

you want to see information on. Press the Enter key.

HP DesignJets 500, 510 and 800 Series Printers Service Manual

3-9

Page 58

Ink Supplies Troubleshooting

Menu

Back

Enter

Black cartridge info

Status: inserted

Expiration date:

15-Aug-2002

Serial number:

Model: HP Black No. 10 (500

06-02-1232651

and 800 series) HP Black

No. 82 (510 Series)

Menu

Back

Enter

Ink cartridges

Ink menu

Menu

Back

Enter

Ink Menu