Honeywell C7110A Manual

C7110A

ROOM AIR QUALITY SENSOR

SPECIFICATION DATA & INSTALLATION INSTRUCTIONS

GENERAL

The C7110A Room Air Quality Sensor is suitable for measuring air quality in rooms, offices, and production bays.

This mixed gas sensor can be used to control ventilation plants. It detects unpleasant odors, tobacco smoke, and vapors emitted by such materials as furniture, carpets, paint, glue, etc. As proven in practice, this device detects those substances typically present in air having a poor quality, some of which may otherwise go undetected by room occupants, themselves. This sensor has proven itself in numerous applications over many years.

FEATURES

•Measurement of a variety of air quality factors

•Output signal: 0...10 Vdc (adjusted using potentiometer)

•Adjustable output offset

•Easy installation and wiring connection

SPECIFICATION

Supply voltage |

15...30 Vdc / 24 Vac (+/-10%) |

Power consumption |

< 1 W |

Output signal |

0...10 Vdc (increases as air |

|

quality worsens); adjustable |

|

using potentiometer |

Max. load at output |

5 kOhm |

Weight /Dimensions |

approx. 125 g / see page 3 |

Electrical connection |

Screw terminal block for |

Air Quality Sensor |

conductors up to 1.5 mm² |

|

|

Sensitivity/Linearity |

see Fig. 1 on page 2 |

Dynamic behavior |

see Fig. 6 on page 4 |

Ambient Limits |

-30...+60 °C (-22...+140 °F) |

Transport/storage temp. |

|

Operating temperature |

0...+50 °C (+32...+122 °F) |

Humidity |

5...95%rh, non-condensing |

Safety |

|

Protection class |

II as per EN60730-1 |

Protection standard |

IP30 as per EN60529 |

Flame retardant |

V0 as per UL94 Plastic ABS |

NOTE: The mixed gas sensor does not measure or indicate the concentration of individual gases, and thus cannot be used for the monitoring or control of specific substances.

Models

Order Number |

Description |

Output |

C7110A1005 |

Room Air Quality Sensor |

0...10Vdc |

|

|

|

® U.S. Registered Trademark |

EN0B-0295GE51 R0409 |

Copyright © 2009 Honeywell Inc. • All rights reserved |

|

C7110A ROOM AIR QUALITY SENSOR

FUNCTION

The electrical conductivity of a heated tin-dioxide semiconductor sensor varies in proportion to the number of molecules of the reducing agents. This leads to a voltage at the measuring element which is amplified to an output voltage of 0 to 10 Vdc.

The following particles and gases can be detected: cigarette smoke, hydrogen, carbon monoxide, ethanol, ammonia, etc.

In contrast to CO2 sensors, which selectively measure the concentration of only one type of gas, a mixed gas sensor is a broadband detector, i.e. the sensor signal does not indicate the type of gas or its concentration in ppm (parts per million). The complex and constantly changing composition of room air makes it necessary to perform broadband air quality measurement.

1 |

|

|

|

|

air |

methane |

|

|

|

/ R |

ammonia |

|

|

|

0.1 |

|

|

|

|

Rgas |

acetic acid |

|

|

|

CO |

|

|

||

|

ethanol |

|

|

|

|

hydrogen |

|

ppm |

|

0.01 |

|

|

||

10 |

100 |

1000 |

||

1 |

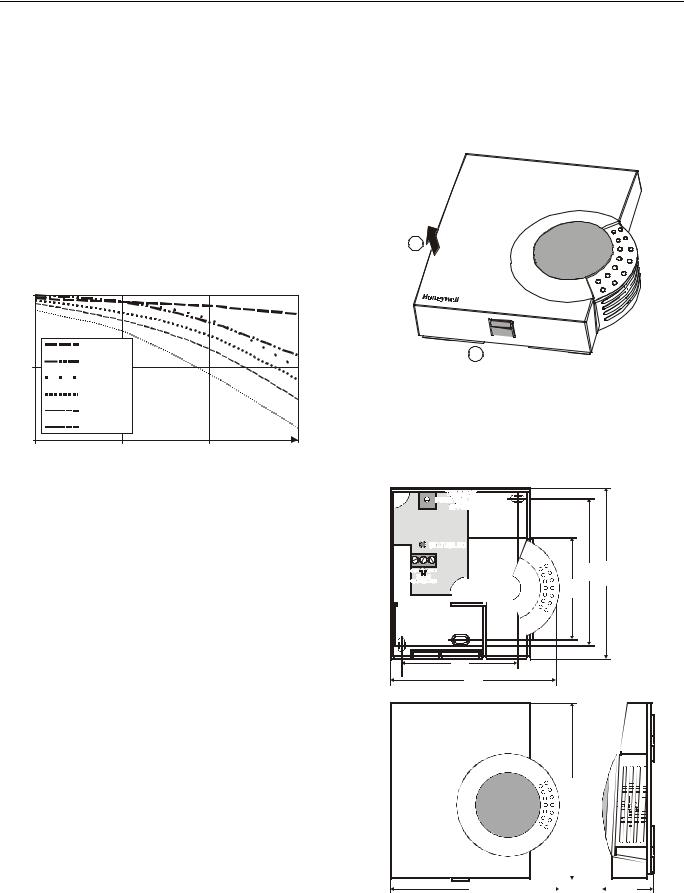

Fig. 1 Sensor sensitivity with different gases

INSTALLATION

Wiring

All wiring must comply with local electrical codes and ordinances or as specified on installation wiring diagrams.

Wall module wiring can be sized from 16 to 22 AWG (1.5 to 0.34 mm2), depending on the application. The maximum length of wire from a device to a wall module is 1000 ft (305 m). Twisted pair wire is recommended for wire runs longer than 100 ft (30.5 m).

Keep wiring at least one ft (305 mm) away from large inductive loads such as motors, line starters, lighting ballast, and large power distribution panels.

Run wall module wiring separately from 50 Vac or greater power wiring.

Positioning

To avoid falsifying the measuring results, the device should be installed at sites at which typical air quality prevails.

Direct exposure to sunlight and drafts should be avoided.

If the device is mounted on a standard flush box, the end of the installation tube in the flush box must be sealed so to avoid any draft in the tube falsifying the measuring result.

Maintain a mounting clearance of approx. 4 in. (10 cm) to the right-hand side of the module in order to allow free airflow to the air quality sensor.

Mounting

1.The cover of the air quality sensor is fixed by a tab on the underside of the unit; to disassemble the cover and the sub-base, see Fig. 2.

LIFT

2

1  PRESS

PRESS

Fig. 2 Cover disassembly

2.a) Mount the sensor onto the wall outlet box, or

b)bore wall holes as specified in Fig. 3 and mount the wall module with appropriate screws.

60 |

86 |

100 |

68 |

|

|

97 |

|

|

104

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

99 |

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|||||||

Fig. 3 Dimensions and mounting holes (mm)

EN0B-0295GE51 R0409 |

2 |

Loading...

Loading...