Honda WMP20X Owner's Manual

INTRODUCTION

Congratulations on your selection of a Honda multi-purpose pump! We are certain you will be pleased with your purchase of one of the finest pumps on the market.

We want to help you get the best results from your new pump and to operate it safely. This manual contains the information on how to do that; please read it carefully.

We suggest you read the DISTRIBUTOR’S LIMITED WARRANTY (page 18) and EMISSION CONTROL SYSTEM WARRANTY

(page 19) to fully understand coverage and your responsibilities of ownership.

When your pump needs scheduled maintenance, keep in mind that an authorized Honda servicing dealer is specially trained in servicing Honda pumps and is supported by the parts and service divisions of American Honda. Your Honda dealer is dedicated to your satisfaction and will be pleased to answer your questions and concerns.

Keep this owner’s manual handy so that you can refer to it at any time. This owner’s manual is considered a permanent part of the pump and should remain with the pump if resold.

The information and specifications included in this publication were in effect at the time of approval for printing. American Honda Motor Co., Inc. reserves the right, however, to discontinue or change specifications or design at any time without notice and without incurring any obligation whatever. No part of this publication may be reproduced without written permission.

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided important safety messages in this manual and on the pump. This information alerts you to potential hazards that could hurt you or others. Please read these messages carefully.

Of course, it is not practical or possible to warn you about all the hazards associated with operating or maintaining a multi-purpose pump. You must use your own good judgment.

You will find important safety information in a variety of forms:

•Safety Labels – on the pump.

•Instructions – how to use this pump correctly and safely.

•Safety Messages – preceded by a safety alert A symbol and one of three signal words: DANGER, WARNING, or CAUTION. These signal words mean:

BDANGER

BWARNING

BCAUTION

You WILL be KILLED or SERIOUSLY HURT if you don't follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you don't follow instructions.

You CAN be HURT if you don't follow instructions.

Each message tells you what the hazard is, what can happen, and what you can do to avoid or reduce injury.

•Damage Prevention Messages – You will also see other important messages that are preceded by the word NOTICE. This word means:

|

|

|

|

Your pump or other property can be damaged |

||

|

|

NOTICE |

|

|||

|

|

|

if you don’t follow instructions. |

|

||

|

|

|

|

|

||

|

|

|||||

© 1996–2011 American Honda Motor Co., Inc.—All Rights Reserved |

||||||

31YE0628 |

|

POM31YE0628 |

||||

EM3 |

HPE.2011.05 |

|||||

00X31-YE0-6280 |

||||||

|

|

|

|

|

PRINTED IN U.S.A. |

|

OWNER’S MANUAL

WMP20X

BWARNING: B

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

CONTENTS

INTRODUCTION ............................... |

1 |

SAFETY MESSAGES........................ |

1 |

PUMP SAFETY ................................. |

2 |

IMPORTANT SAFETY INFORMATION ...... |

2 |

SAFETY LABEL LOCATIONS ....... |

2 |

ASSEMBLY ....................................... |

3 |

CONTROL LOCATIONS ................... |

4 |

BEFORE OPERATION...................... |

4 |

IS YOUR PUMP READY TO GO? .............. |

4 |

OPERATION...................................... |

5 |

SAFE OPERATING PRECAUTIONS.......... |

5 |

APPROVED LIQUIDS .................... |

6 |

PUMP PERFORMANCE ................ |

6 |

STARTING THE ENGINE .............. |

7 |

STOPPING THE ENGINE.............. |

7 |

SERVICING YOUR PUMP ................ |

8 |

MAINTENANCE SAFETY .............. |

8 |

MAINTENANCE SCHEDULE......... |

8 |

REFUELING................................... |

9 |

ENGINE OIL................................... |

9 |

AIR CLEANER ............................. |

10 |

SPARK PLUG .............................. |

11 |

SPARK ARRESTER |

|

(OPTIONAL EQUIPMENT) .......... |

11 |

TRANSPORTING ............................ |

12 |

BEFORE LOADING ..................... |

12 |

LOADING AND UNLOADING ...... |

12 |

STORAGE....................................... |

12 |

STORAGE PREPARATION......... |

12 |

PLACING IN STORAGE .............. |

13 |

REMOVAL FROM STORAGE ..... |

14 |

TAKING CARE OF UNEXPECTED |

|

PROBLEMS .................................... |

14 |

TECHNICAL INFORMATION .......... |

14 |

SERIAL NUMBER LOCATIONS .. |

14 |

CARBURETOR |

|

MODIFICATION FOR HIGH |

|

ALTITUDE OPERATION.............. |

15 |

EMISSION CONTROL SYSTEM . 15 |

|

AIR INDEX ................................... |

15 |

SPECIFICATIONS ....................... |

16 |

CONSUMER INFORMATION ......... |

17 |

REPLACEMENT PARTS, |

|

OPTIONAL EQUIPMENT, AND |

|

SERVICE ITEMS ......................... |

17 |

DEALER LOCATOR INFORMATION ....... |

17 |

CUSTOMER SERVICE |

|

INFORMATION ............................ |

17 |

DISTRIBUTOR'S LIMITED |

|

WARRANTY................................. |

18 |

EMISSION CONTROL SYSTEM |

|

WARRANTY................................. |

19 |

1

PUMP SAFETY

This chapter explains what you need to know to operate your pump safely.

IMPORTANT SAFETY INFORMATION

Most injuries or property damage can be prevented if you follow all instructions in this manual and on the pump. The most common hazards are discussed below, along with the best way to protect yourself and others.

Keep Shields in Place

Guards and shields are designed to protect you from being hurt by hot or moving parts. For your safety and the safety of others, keep all shields in place when the engine is running.

Wear Protective Clothing

Wearing protective clothing will reduce your risk of injury. Heavy-duty gloves protect your hands. While the sound level of the pump is well within safe limits, hearing protection will further protect your hearing.

Turn Engine Off When Not Pumping

If you need to leave the pump for any reason, always turn the engine OFF.

Operator Responsibility

It is the operator's responsibility to provide the necessary safeguards to protect people and property against chemical leakage. Refer to the handling instructions provided by the manufacturer of the chemical before operating the pump.

Know how to stop the pump quickly in case of emergency. Understand the use of all controls and connections.

Be sure that anyone who operates the pump receives proper instruction. Do not let children operate the pump. Keep children, pets, and bystanders away from the area of operation.

Pump Operation

Do not use for pumping liquids for human consumption.

Never pump flammable liquids such as gasoline or fuel oils. An explosion may result, causing serious injury.

Pump only those chemicals listed in the APPROVED LIQUIDS table on page 6 of this manual. Pumping chemicals that are not listed may result in damage to the pump or injury to the operator.

Operate the pump on a level surface. If the engine is tilted, fuel may spill.

Do not enclose the pump in any structure.

Fuel vapors are extremely flammable and may ignite after the engine has started. Make sure that any spilled fuel has been wiped up before starting the pump. Keep flammable materials away from the pump.

Refuel With Care

Gasoline is extremely flammable, and gasoline vapor can explode. Refuel outdoors, in a well-ventilated area, with the engine stopped and allowed to cool, and the pump on a level surface. Do not overfill the fuel tank. Never smoke near gasoline, and keep other flames and sparks away. Always store gasoline in an approved container. Make sure that any spilled fuel has been wiped up before starting the engine.

2

Hot Exhaust

The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Be careful not to touch the muffler while it is hot. Let the engine cool before transporting the pump or storing it indoors.

To prevent fire hazards, keep the pump at least 3 feet (1 meter) away from building walls and other equipment during operation. Do not place flammable objects close to the engine.

Carbon Monoxide Hazards

Exhaust contains poisonous carbon monoxide, a colorless and odorless gas. Breathing carbon monoxide can cause loss of consciousness and may lead to death.

If you run the pump in an area that is confined, or even partly enclosed, the air you breathe could contain a dangerous amount of exhaust gas.

Never run the engine inside a closed garage, house, or confined area.

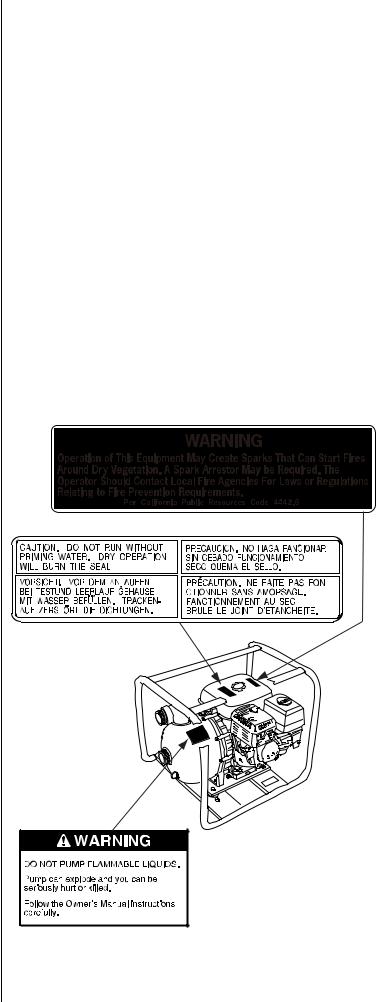

SAFETY LABEL LOCATIONS

The label shown here contains important safety information. Please read it carefully. This label is considered a permanent part of your pump. If the label comes off or becomes hard to read, contact your authorized Honda pump dealer for a replacement.

ASSEMBLY

After assembly and before operation, review the SAFE OPERATING PRECAUTIONS on page 5.

IMPORTANCE OF PROPER ASSEMBLY

Proper assembly is essential to operator safety and the reliability of the machine. Any error or oversight made by the person assembling and servicing a machine can result in faulty operation, damage to the machine, or injury to the operator.

B WARNING

Improper assembly can cause an unsafe condition that can lead to serious injury or death.

Follow the procedures and precautions in the assembly instructions carefully.

Some of the most important safety precautions are given below. However, we cannot warn you of every conceivable hazard that can arise in performing this assembly. Only you can decide whether or not you should perform a given task.

B WARNING

Failure to properly follow instructions and precautions can cause you to be seriously hurt or killed.

Follow the procedures and precautions in this manual carefully.

IMPORTANT SAFETY PRECAUTIONS

•Make sure you have a clear understanding of all basic shop safety practices and that you are wearing appropriate clothing and safety equipment.

•Read the instructions before you begin and be sure you have the tools and skills required to perform the tasks safely.

•Make sure the engine is off before you begin any maintenance or repairs. This will help eliminate several potential hazards:

•Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever you run the engine.

•Burns from hot parts. Let the engine and exhaust system cool before touching.

•Injury from moving parts. Do not run the engine unless the instruction tells you to do so. Even then, keep your hands, fingers, and clothing away from moving parts. Do not run the engine when any protective guard or shield is removed.

•To reduce the possibility of a fire or explosion, be careful when working around gasoline. Use only a nonflammable solvent, not gasoline, to clean parts. Keep all cigarettes, sparks, and flames away from all fuel-related parts.

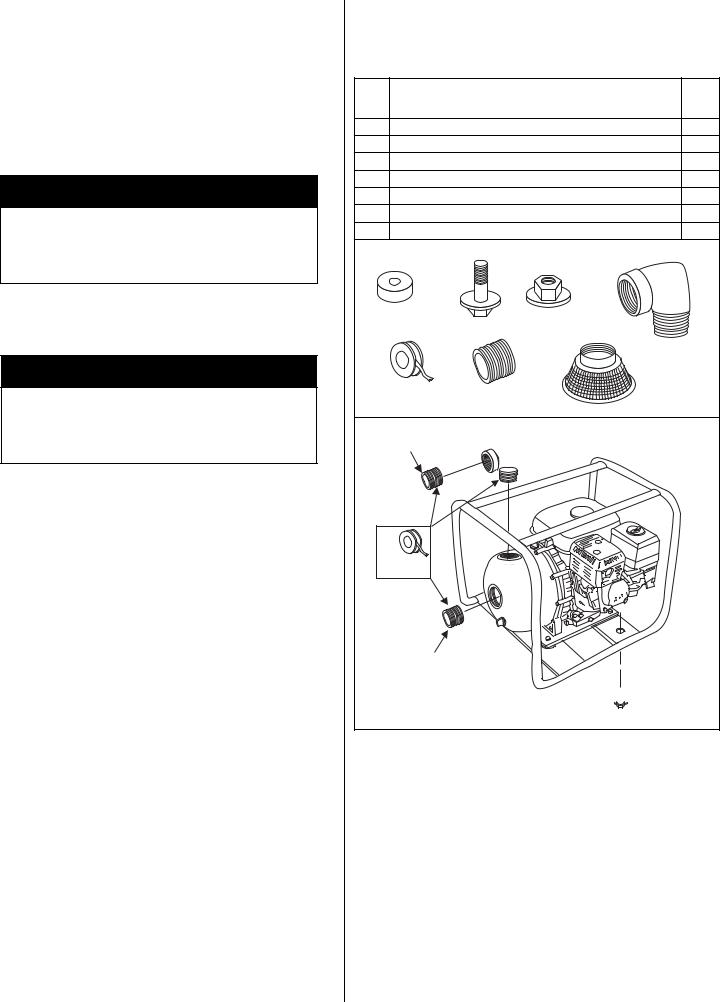

UNPACKING

Carefully remove the pump and loose parts from the carton and compare the loose parts with the inventory list.

Tools Required:

12 mm wrench Torque wrench

LOOSE PARTS

Check all loose parts against the following list. Contact your authorized Honda servicing dealer if any of the loose parts shown are not included with your pump.

Ref. |

|

Description |

Qty. |

No |

|

||

|

|

|

|

1 |

Rubber mount |

|

4 |

2 |

8 x 16 mm Flange bolt |

4 |

|

3 |

8 mm Locking nut |

|

4 |

4 |

Outlet elbow |

|

1 |

5 |

Thread tape |

|

1 |

6 |

Hose coupling |

|

2 |

7 |

Strainer |

|

1 |

1 |

2 |

3 |

4 |

5 6 7

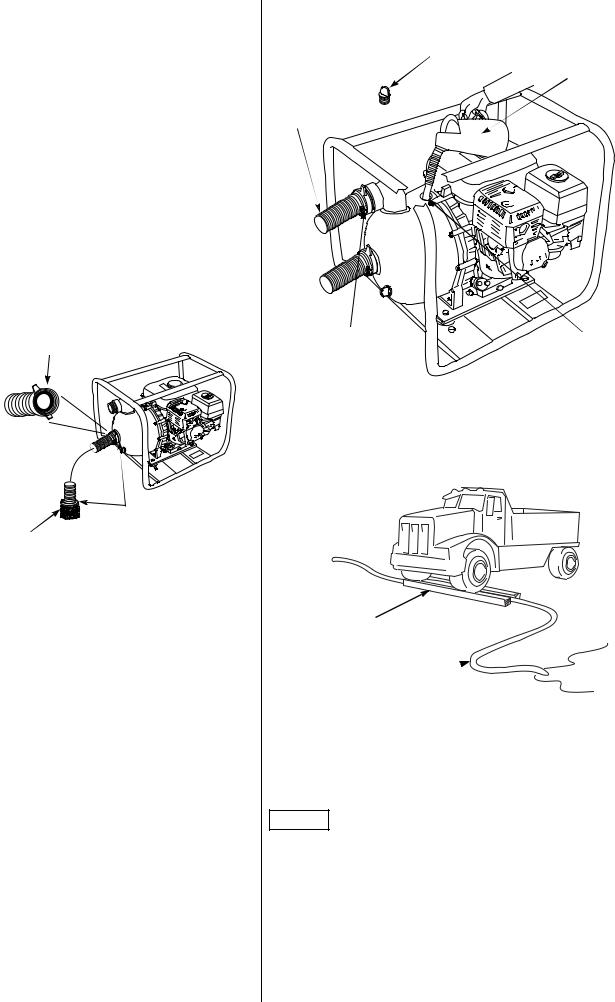

1.Install the four rubber mounts 1 on the pump using the 8 x 16 mm flange bolts 2 and 8 mm locking nuts 3. Tighten to 6 - 7 ft-lb.

2.Apply thread tape 5 to the outlet elbow 4 and then install it securely in the pump housing.

3.Apply thread tape to the two hose couplings 6 and securely install one in the suction port and the other in the outlet elbow 4.

3

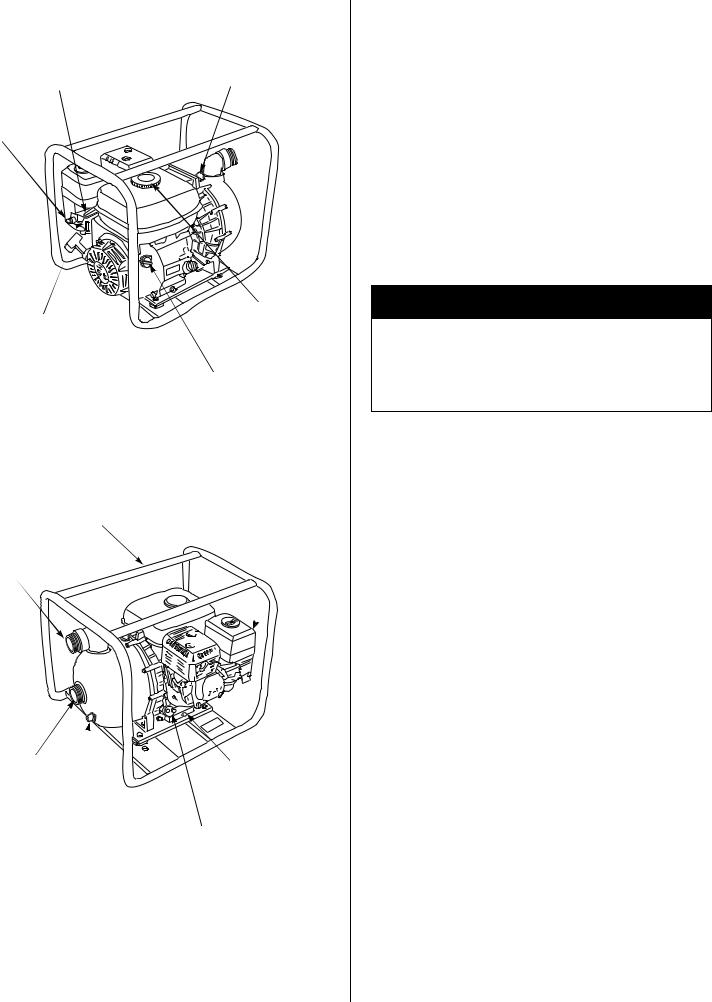

CONTROL LOCATIONS

THROTTLE |

PRIMING |

LEVER (p. 7) |

FILLER CAP (p. 5) |

CHOKE LEVER (p. 7)

FUEL  VALVE

VALVE

(p. 7)

(p. 7)

STARTER

GRIP

FRAME

DISCHARGE

PORT (p. 5)

FUEL FILLER

CAP (p. 9)

IGNITION SWITCH (p. 7)

AIR CLEANER (p. 10)

SUCTION PORT |

OIL DRAIN PLUG |

|

(p. 5) |

(p. 10) |

|

PUMP DRAIN |

OIL FILLER CAP/ |

|

DIPSTICK (p. 9) |

||

PLUG (p. 12) |

||

|

4

BEFORE OPERATION

Your safety is your responsibility. A little time spent in preparation will significantly reduce your risk of injury.

Read and understand this manual. Know what the controls do and how to operate them.

Familiarize yourself with the pump and its operation before you begin using it. Know how to quickly shut off the engine in case of an emergency.

Be familiar with any safety precautions that are needed to properly pump the chemicals that are listed on page 6.

IS YOUR PUMP READY TO GO?

For your safety, and to maximize the service life of your equipment, it is very important to take a few moments before you operate the pump to check its condition. Be sure to take care of any problem you find, or have your servicing dealer correct it, before you operate the pump.

B WARNING

Improperly maintaining this pump, or failing to correct a problem before operation, could cause a malfunction in which you could be seriously injured.

Always perform a pre-operation inspection before each operation, and correct any problem.

Before beginning your pre-operation checks, be sure the pump is on a level surface and the ignition switch is in the OFF position.

Check the General Condition of the Pump

•Look around and underneath the pump for signs of oil or gasoline leaks.

•Remove any dirt or debris, especially around the engine, muffler, and recoil starter.

•Look for signs of damage.

•Check that all nuts, bolts, screws, hose connectors, and clamps are tightened.

•Keep all shields and covers in place while operating the pump.

•Check the general condition of the hoses. Be sure the hoses are in serviceable condition before connecting them to the pump.

Check the Engine

•Check the oil level (page 9).

•Check the air cleaner (page 10).

•Check the fuel level (page 9). Starting with a full tank will help to eliminate or reduce operating interruptions for refueling.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the pump for the first time, please review

IMPORTANT SAFETY INFORMATION (page 2) and BEFORE OPERATION (page 4).

For your safety, do not start or operate the engine in an enclosed area, such as a garage. Your engine’s exhaust contains poisonous carbon monoxide gas, which can collect rapidly in an enclosed area and cause illness or death.

Suction Hose Connection

Use a commercially available hose, hose connector, and hose clamps. The suction hose must be reinforced with a non collapsible wall or wire braided construction to prevent suction hose collapse. Keep the pump as close to the liquid to be pumped as possible. Avoid bends and sharp turns. Pump performance is best when the pump is not far above the liquid level and the hose is kept straight. Self-priming time is also proportional to the suction hose length. Using a longer suction hose will increase the self-priming time.

Tighten the hose |

|

|

connector to the |

SEALING WASHER |

|

suction hose with a |

||

|

||

hose clamp to |

|

|

prevent air leakage |

|

|

and loss of suction. |

|

|

Verify that the |

|

|

connector sealing |

|

|

washer is installed |

|

|

and in good |

|

|

condition. A loosely |

|

|

connected suction |

|

|

hose will reduce |

HOSE CLAMP |

|

pump performance |

||

|

||

and self-priming |

STRAINER |

|

ability. |

||

|

The strainer provided with the pump should always be attached to the end of the suction hose with a hose clamp as shown.

The strainer will prevent debris from entering the pump, preventing clogging or damage to the pump. Clean the strainer of any debris.

Discharge Hose Connection

Use a commercially available hose, hose connector, and hose clamp. A short, large diameter hose will provide lower fluid friction and improve pump efficiency. A long or small diameter hose increases fluid friction and reduces pump output.

Tighten the hose clamp to prevent the hose from disconnecting under high pressure.

PRIMING FILLER CAP

PRIMING LIQUID

DISCHARGE

HOSE

HOSE CLAMP |

PRIMING FILLER |

|

HOLE |

If the discharge hose must run across a roadway, the hose should cross the roadway perpendicular to traffic flow. Also, heavy boards should be placed next to the hose so the motor vehicle weight does not shut off the discharge as vehicles cross over the hose.

BOARDS

DISCHARGE

HOSE

Driving over a discharge hose while the pump is running, or even possibly when the pump is stopped, may cause pump case failure.

Pump Priming

Remove the priming filler cap and completely fill the pump chamber with water before starting the engine. Replace the priming filler cap.

NOTICE

Operating the pump dry will destroy the pump seal.

•Ensure the pump chamber is full of liquid and the suction hose strainer is submerged in the liquid to be pumped.

•If the unit has been operated dry, stop the engine immediately and allow the pump to cool before adding priming liquid.

5

APPROVED LIQUIDS

The following is a list of chemicals that the multi-purpose pump is capable of pumping. The operator must verify that the liquid that is to be pumped is on these lists. After each use, drain the pump chamber into a suitable container and flush with fresh water.

DO NOT PUMP LIQUIDS FOR HUMAN CONSUMPTION.

B WARNING

Chemicals can cause burns or serious injury.

Wear protective clothing and eye protection when handling chemicals.

Follow the chemical manufacturer’s handling procedures.

NOTICE

Pumping liquids that are not listed may damage the pump.

Agricultural Chemicals

Aatrex |

Dual |

N-Serve 24 |

Amiben |

Eradicane |

Phosphoric Acid |

|

|

Solutions |

Ammonium |

Extrazine |

Poly-N |

Thiosulfate |

|

|

Banvel |

Larsban |

Ranger |

Basagran |

Lasso |

Round-up |

Bicep |

URAN Solutions |

Sutan |

Bladex |

Modown |

Treflan |

|

|

Vernam |

Industrial Chemicals

Acetic Acid, 20% |

Glycerine (Glycerol) |

Sodium Acetate |

Aluminum Sulfate |

Lactic Acid |

Sodium Bicarbonate |

Ammonium Nitrate |

Lead Acetate |

Sodium Bisulfate |

Ammonium Sulfate |

Magnesium Chloride |

Sodium Bisulfite |

Barium Sulfate |

Magnesium Nitrate |

Sodium Carbonate, |

|

|

10% |

Borax (Sodium Borate) |

Magnesium Sulfate |

Sodium Chlorate |

* Calcium Chloride |

Maleic Acid |

Sodium Chloride |

Citric Acid |

Nickel Chloride |

Sodium Nitrate |

Copper Sulfate |

Nickel Sulfate |

Sodium Silicate |

Detergents (General) |

Oleic Acid |

Sodium Sulfate |

Ethylene Glycol |

Phosphoric Acid, |

Stearic Acid |

|

0-80% |

|

Fatty Acids |

Potassium Carbonate |

Sulfuric Acid, 0-29% |

Ferric Nitrate |

Potassium Chloride |

Tartaric Acid |

Ferric Sulfate |

Potassium Nitrate |

Vinegar |

Ferrous Sulfate |

Potassium Sulfate |

Water (Clear) |

Formaldehyde, 40% |

Soaps (neutral) |

Water (Salt) |

|

|

Zinc Sulfate |

* Temperature does not exceed 80°F (26°C)

The temperature operating range of the pump is between 20 ~ 130°F (-7 ~ 54°C).

6

PUMP PERFORMANCE

The maximum pump discharge capacity is determined when pumping clear water at 0 ft (0 meters) total head and at sea level. As the total head (discharge head + suction head) increases, pump discharge capacity decreases (see figure below). If the pump is used at higher elevations, pump discharge capacity may also decrease. Other factors affecting pump discharge capacity are:

•The type of chemical being pumped

•The length and type of the suction and discharge hose used

Pump Performance (Maximum with clear water)

Total head |

105 ft (32 m) |

|

|

Suction head |

26 ft (8 m) |

|

|

Discharge capacity |

220 gal/min (833 l/min) |

|

|

Self-priming time |

65 sec at 16.4 ft (5 m) |

|

|

Pressure |

45 psi (310 kPa) |

|

|

DISCHARGE

HEAD

TOTAL

HEAD

SUCTION HEAD

Oil Alert® System

The Oil Alert system is designed to prevent engine damage caused by insufficient oil in the crankcase. Before the oil level in the crankcase can fall below a safe limit, the Oil Alert system will automatically shut down the engine (the ignition switch will remain in the ON position).

If the engine stops and will not restart, check the oil level (page 9) before troubleshooting in other areas.

Loading...

Loading...