Owner's Manual

Includes Remote Control

Supplement

Outboard Motor

BF9.9A/15A

©1990 Honda Motor Co., Ltd. — All Rights Reserved

.

The engine exhaust from this product

contains chemicals known to the State

defects or other reproductive harm.

Thank you for purchasing a Honda Outboard Motor.

This manual describes the operation and maintenance of the Honda

Outboard Motor: BF9.9AJ15A

All information in this publication is based on the latest product

information available at the time of printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written

permission.

This manual should be considered a permanent part of the Outboard

Motor and it must stay with the Outboard motor if resold.

READ THIS OWNER’S MANUAL CAREFULLY. Pay special attention to

these symbols and any instructions that follow.

m

You WILL be KlLLED or SERIOUSLY HURT if you don’t

follow instructions.

m

You CAN be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

CAUTION:

pic?iEq

You CAN be HURT if you don’t follow instructions.

Your outboard motor or other property could be damaged if

you don’t follow instructions.

Honda Outboard Motors are designed to give safe and dependable

service if operated according to instructions. Operating this Outboard

Motor requires special effort on your part to ensure your safety and

the safety of others.

Careless operation or misuse may cause injury or property damage.

Read and understand this owner’s manual before operating the

Outboard Motor.

If a problem should arise, or if you have any .questions about your

Outboard Motor, see an authorized Honda Outboard Motor dealer.

Illustrations are mainly based on: BF15A LAS type

HONDA MOTOR CO., LTD. 1990, ALL RIGHTS RESERVED

1

CONTENTS

1. SAFETY

2. COMPONENT IDENTIFICATION

3. INSTALLATION

4. PRE-OPERATION CHECKS

5. STARTING THE ENGINE

6. OPERATION

0 High altitude operation

7. STOPPlNG,THE ENGINE

8. MAINTENANCE

9. TRANSPORTING/STORAGE

10. TROUBLESHOOTING

11. SPECIFICATIONS

12. WIRING DIAGRAM

13. OPTIONAL PARTS

14. WARRANTY SERVICE

..................................................................................................

.....................................................................................

.................................................................

....................................................................

........................................................................................

.................................................................

....................................................................

..................................................................................

..............................................................

.........................................................................

................................................................................

.............................................................................

...............................................................................

........................................................................

..........................................................

11

16

22

23

29

30

44

48

49

zi

54

3

5

7

2

1. SAFETY

I

Safety label locations

Read all safety instructions before using the Outboard Motor.

DANGER

IlAWFUL OS FATAL IF SIALLOVEO.

EL? OUT OF REACH OF CIIILOSEN.

IF SUAlLWEO.00 II01 IYOUCE

~CUtll16.CALl A PHYSICIAN

IUIEOIAYELY.

3

SAFETY INFORMATION

For your safety and the safety of others, pay special attention to these

precautions.

l Know how to stop the engine quickly in case of emergency.

Understand the use of all controls.

l Do not exceed the boat manufacturer’s power recommendation,

and be sure the outboard motor is properly mounted.

l Never permit anyone to operate the outboard motor without

proper instruction.

l Stop the engine immediately if anyone falls overboard.

l Do not run the motor while the boat is near anyone in the water.

l Attach the emergency stop switch lanyard securely to the operator.

l Before operating the outboard motor, familiarize yourself with all

laws and regulations relating to boating and the use of outboard

motors.

l Do not attempt to modify the outboard motor.

l Always wear a PERSONAL FLOTARON DEVlCE (PFD) when on

board.

l Exhaust contains poisonous carbon monoxide which can cause

unconsciousness and may lead to death. Never run the outboard in

a closed garage or confined area.

l Gasoline is.extremely flammable and is explosive under certain con-

ditions. Refuel in a well ventilated area with the engine stopped.

. Do not smoke or allow flames or sparks where the engine is

refueled or where gasoline is stored.

l Do not overfill the fuel tank. After refueling make sure that the fuel

tank cap is closed properly and securely.

l Be careful not to spill any fuel while refueling. Spilled fuel or fuel

vapor may ignite. lf any fuel is spilled make sure that the area is dry

before starting the engine.

l Do not remove any guards, labels, shields, covers or safety devices;

they are installed for your safety.

4

ENGINE COVER

WATER CHECK HOLE

ENGINE OIL DRAIN PLUG

2. COMPONENT IDENTIFICATION

STARTER GRIP

/

CY STOP SWlTCH

CLAMP SCREW

ANTI-VENWAlTlON PLATE

PRIMER BULB

FRAME SERIAL NUMBER

*Always list the serial number when

ordering parts.

THRO:::&

TILLER HANDLE

STERN BRACKET

Jz OIL LNEL DIPSTICK

ENGINE COVER LOCK LEifER

ADJUSTlNG ROD

GEAR OIL LEVEL PLUG

WATER INTAKE SCREEN

GEAR OIL DRAIN iLUG’

OIL PRESSURE INDICATOR UGHT

ENGINE STOP SWlTCH

CHOKE KNOB

WASHING BOLT

ANODE METAL

ZEllST AND DRAlNlNG

6

FUEL HOSE CONNECTORIMALE)

3. INSTALLATION

It is your responsibility to choose a boat suitable for the engine.

BF9.9A: 9.9 HP (7.4 kW)

BFlSA: 15 HP (11.2 kW1

N

Do not exceed the boat manufacturer’s power recommendatidn.

Damage and injury may result.

1. Installation position

Install at the stern, at the center

line of the boat.

2. Installation height

For proper ropeller depth and

engine coo ing, the boat and P

outboard motor transom height

must match. .

Three outboard motor transom

heights are available. Match

your boats transom height to the

outboard motor transom height

shown below.

MOTOR

EFM

STERN CEiTER

The anti-ventilation plate should

be O-50 mm (O-2 in) below the

bottom of the boat. With the

boat in the water, loaded and

motor off, the anti-ventilation

late should be about 100 mm

3.9 in) below the surface of the

P

water.

(J

Running the outboard motor

without sufficient cooling water

will damage the water pump

and overheat the engine.

mm

in)

7

3. Motor attachment

Attach the stern bracket to the

transom and tighten the clamp

screws.

[NoncEI

l Before operating the boat, check

the tightness of the clamp screws.

l Tie a rope through the hole in the

stern bracket and secure the

other end of the rope to the boat.

This will prevent accidental loss

of the motor.

SAFETY ROPE

NOTE:

To prevent the outboard motor from

falling accidentally, you may further

secure the stern bracket to the

transom board with commercially

available bolts, nuts and washers.

After attaching the stern bracket to

the transom board, be sure to apply

sealant (THREEBOND 1216 or equivalent) to the bolt holes.

This modification should be made

by your authorized Honda Outboard

Motor dealer.

,

a

STERN WASHER

WASHER TRANSOM BOARD

8

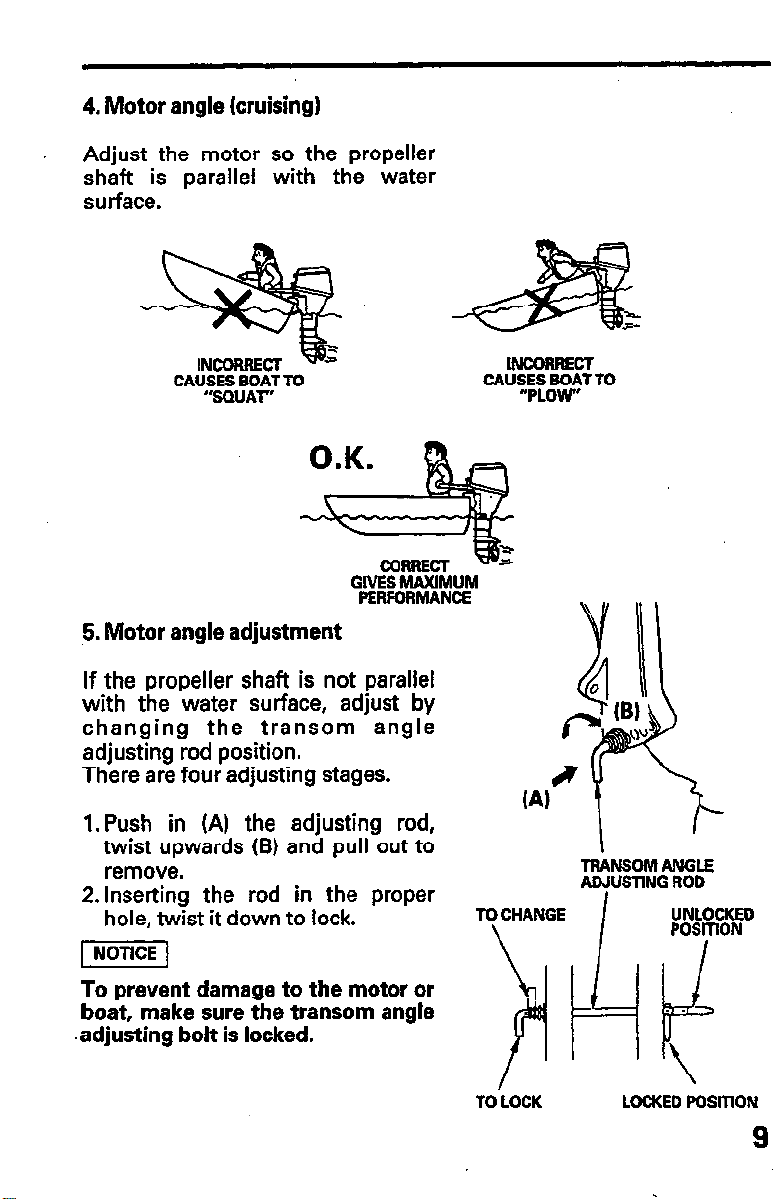

4. Motor angle (cruising)

Adjust the motor so the propeller

shaft is parallel with the water

surface.

CAUSES BOAT TO

“‘SQUAT”

GlVES MAXlMUM

PERFORMANCE

5. Motor angle adjustment

If the propeller shaft is not parallel

with the water surface, adjust by

changing the transom angle

adjusting rod position.

There are four adjusting stages.

1. Push in (A) the adjusting rod,

twist upwards (B) and pull out to

remove.

2. Inserting the rod in the proper

hole, twist it down to lock.

INCORRECT

CAU%fo~~T TO

TRANSOM ANGLE

ADJUSTlNG ROD

TO CHANGE UNLOCKED

pii5iq

To prevent damage to the motor or

boat, make sure the transom angle

.adjusting bolt is locked.

TO LOCK

LOCKED POSmON

9

6. Battery connections (for electric starter)

Use a 12V40AH battery.

Place the battery in a corrosion-resistant battery box and fix the

battery box securely to the hull.

Install the battery box in a location such that remains level while the

boat is cruising and is not exposed to spray or direct sunlight.

Connecting the battery cord

1. Connect the cable with the red terminal cover to the (+) side of the

battery.

2. Connect the cable with the black terminal cover to the (-1 side of the

battery.

(-)lERMINAL

l Be sure to connect the (+) side battery cable first. When

disconnecting the cables, disconnect the (- 1 side first then the (+ 1

side.

l Unless the cables are properly connected to the terminals, the

starter motor may fail to operate normally.

l Do not place the fuel tank near the battery.

1. Engine oil level

sevice

recommended,

engine

/iiGiq

l Engine oil is a major factor affecting engine performance and

life. Nondetergent and low quality oils are not

because they have inadequate lubricating properties.

l Running the engine with insufficient oil can cause serious

damage.

Use Honda 4-stroke oil, or an equiva-

lent high detergent, premium

quality motor oil certified to meet or

exceed U.S. automobile manufacturer’s requirements for Service

Classification SG, SF. Motor oils =~p

classified SG, SF will show this designation on the container.

SAE low/30 is recommended for general, all-temperature use. Other

viscosities shown in the chart may be used when the average

temperature in your area is within the indicated range.

1. Position the outboard motor vertically,and remove the engine cover

by pushing down the engine cover lock lever.

2. Remove the oil level dipstick and wipe with a clean rag.

3. Reinsert the dipstick all the way in, then pull it out and read the level.

If the oil level is down toward the lower level mark, fill to the upper

level mark.

Tighten the oil filler cap securely.

4. Install the engine cover and lock it securely by pulling up lock lever.

Oil capacity: 1 .l 8 (1.2 US qt , 1.0 Imp qt)

2. Fuel level

Fuel tank capacity: 12 8 (3.0 US gal, 2.6 Imp gal)

EL GAUGE

Check the fuel gauge and refill the tank to the SAFE FILL LEVEL mark if

necessary.

Gasoline is extremely flammable, and gasoline virpor can explode,

causing serious injury or death. Do not smoke or allow flames or

sparks in your working area. KEEP OUT OF REACH OF CHILDREN.

VENT KNOB

.

FUELC

Refilling

Remove the fuel tank from the boat for refilling. Turn the vent knob

counterclockwise to the open position and remove the fuel cap.

Refuel in a well-ventilated area. Fill the fuel tank up to the SAFE FILL

LEVEL mark only. Inspect the condition of the fuel cap gasket and

replace if necessary.

After refilling, install and tighten the fuel cap securely. Turn the vent

knob clockwise to the closed position. Return the fuel tank to the boat.

12

Fuel Recommendations

13

Use unleaded gasoline with a pump octane rating of 86 or higher.

This engine is desi ned to operate on unleaded gasoline. Unleaded

gasoline produces ewer engine and spark plug deposits and extends

9

. exhaust system life.

Never use stale or contaminated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

Occasionally

rapping noise while operating under heavy loads. T

ou may hear light “spark knock” or ”

Y

inging” (metallic

It

is IS no cause for

concern.

If spark knock or pin

normal load, than

persists, see an aut

ing occurs at a steady engine speed, under

13

e

rands of gasoline. If spark knock or pinging

1

orized Honda dealer.

Running the engine with persistent spark knock or pinging can cause

engine damage.

Running the engine with persistent spark knock or pinging is misuse,

and the Distributor’s Limited Warranty does not cover parts damaged

by misuse.

OXYGENATED FUELS

Some conventional asolines are being blended with alcohol or an

ether compound. T ese I! gasolines are collectively referred to as

oxygenated fuels. To meet clean air standards, some areas of the

United States and Canada use oxygenated fuels to help reduce

emissions.

If you use an oxygenated fuel, be sure it is unleaded and meets the

mmimum octane rating requirement.

Before using an oxygenated fuel, try to confirm the fuel’s contents.

Some states/provinces require this information to be posted on the

pump.

The following are the EPA approved percentages of oxygenates:

ETHANOL -

MTBE

(ethyl or grain alcohol) 10% by volume

You may use

by volume. 8

marketed under the name “Gas0

asoline containing up to 10% ethanol

asoline containin

ethanol may be

I!

01”.

(Methyl Tertiary Butyl Ether) 15% by volume

You may use gasohne containing up to 15% MTBE

by volume.

METHANOL -

(methyl or wood alcohol) 5% by volume

You may use gasoline containing up to 5%

methanol by volume, as long as it also contains

cosolvents and corrosion inhibitors to protect the

fuel system. Gasoline containing more than 5%

methanol by volume may cause starting and/or

performance problems. It may also damage metal,

rubber, and plastic parts of your fuel system.

If you notice any undesirable operating symptoms, try another service

station, or switch to another brand of gasoline.

Fuel system dama e or performance problems resulting from the use

of an oxygenate

CB

fuel containing more than the percentages of

oxygenates mentioned above are not covered under warranty.

14

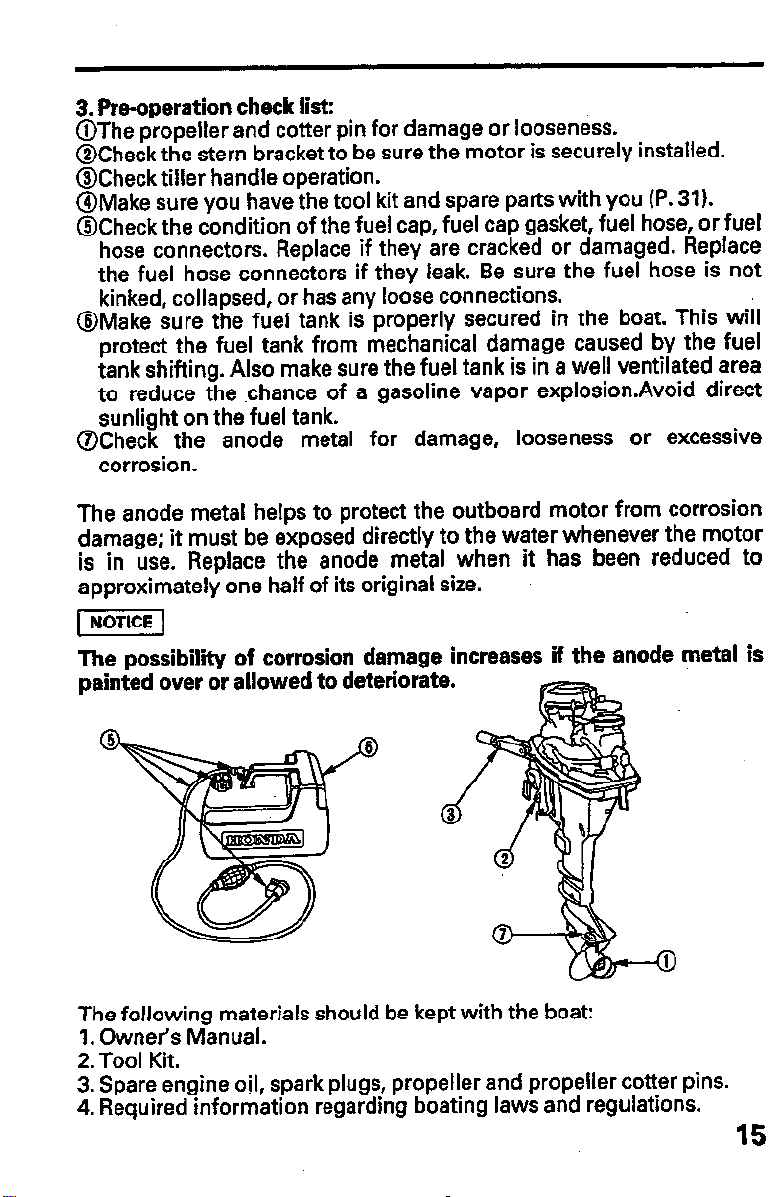

3. Pre-operation check list:

is

15

@The propeller and cotter pin for damage or looseness.

@Check the stern bracket to be sure the motor is securely installed.

@Check tiller handle operation.

@Make sure you have the tool kit and spare parts with you (P. 31).

@Check the condition of the fuel cap, fuel cap gasket, fuel hose, or fuel

hose connectors. Replace if they are cracked or damaged. Replace

the fuel hose connectors if they leak. Be sure the fuel hose is not

kinked, collapsed, or has any loose connections.

@Make sure the fuel tank is properly secured in the boat. This will

protect the fuel tank from mechanical damage caused by the fuel

tank shifting. Also make sure the fuel tank is in a well ventilated area

to reduce the .chance of a gasoline vapor explosion.Avoid direct

sunlight on the fuel tank.

@Check the anode metal for damage, looseness or excessive

corrosion.

The anode metal helps to protect the outboard motor from corrosion

damage; it must be exposed directly to the water whenever the motor

is in use. Replace the anode metal when it has been reduced to

approximately one half of its original size.

The possibility of corrosion damage increases if the anode

painted over or allowed to deteriorate.

The following materials should be kept with the boat:

1. Owner’s Manual.

2. Tool Kit.

3. Spare engine oil, spark plugs, propeller and propeller cotter pins.

4. Required information regarding boating laws and regulations.

metal

5. STARTING THE ENGINE

Fuel line connection

Check the fuel tank related components and fuel tank positioning

(refer step @ and @ on page 15 1.

Due to the fuel pump capacity, do not place the fuel tank more than 6

feet away from the motor or lower than 3 feet below the outboard end

fuel hose connector.

Be careful not to spill any fuel while refueling. Spilled fuel or fuel

vapor may ignite. lf any fuel is spilled make sure that the area is dry

before starting the engine.

1iConnect the fuel hose connectors to the outboard motor and fuel

tank as shown. The outboard end fuel hose connector must be

installed with the clip toward the outside or the fuel hose connector

O-ring seal can be damaged. Replace the fuel hose connectors if

they leak. Check to be sure that both connectors are securely

snapped in place.

(OUTBOARD END) (FUEL TANK END)

FUEL HOSE CONNECTOR

FUEL HOSE

CONNECTOR

If the outboard end fuel hose connector is installed in the reversed

direction, the fuel hose connector O-ring seal can be damaged.’ A

damaged O-ring seal can cause a fuel leak.

2. Open the fuel cap vent knob 2 to 3 turns.

3.Hold the primer bulb so that the outlet end is higher than the inlet,

and squeeze it until it feels firm, indicating that fuel has reached the

motor. Check for leaks.

NOTE:

Do not squeeze the primer bulb when the motor is running because

this could cause the carburetors to overflow.

PRIMER SU

16

Starting

cause

17

Exhaust contains poisonous carbon monoxide which can

unconsciousness and may lead to death. Never run the outboard in a

closed garage or confined area.

The anti-ventilation plate must be lowered into the water and be at

least 2 inches below the surface. Running the outboard motor out of

the water will damage the water pump and overheat the engine.

1. Engage the emergency stop switch clip located at one end of the

emergency stop switch lanyard with the engine stop switch. Attach

the other end of the emergency stop switch lanyard securely to the

operator.

If the operator does not attach the emergency stop switch lanyard,

and is thrown from his seat or out of the boat, the out-of-control boat

can seriously injure the operator, passengers, or bystanders. Always

r;frly attach the lanyard before starting the motor.

.

.

l The engine will not start unless the emergency stop switch clip is

engaged with the engine stop switch.

l A spare emergency stop switch

ENGINE STOP

clip is provided in the tool bag.

fPWAREEIE$GENCY STOP

2. Put the gearshift lever in NEUTRAL.

NEUTRAL

EARSHIFT LEVER

EMERGENCY STOP

SWlTCH LANYARD

3.Align the throttle grip START position with the mark on the tiller

handle.

THR0lTl.E GRIP

4. If the engine is “cold”, pull out the choke knob for starting and then

push it in gradually as the engine warms up.

CHOKE KNOB

5. Pull the starter rope slowly until a resistance is felt, then pull briskly.

piiEq

l Do not allow the starter grip to snap back against the engine.

Return it gently to prevent damage to the starter.

l Do not pull the starter grip while the engine is running, as that may

damage the starter.

STARER GRIP

18

6. Electric starter (Electric starter model only)

Put the outboard motor in NEUTRAL, then press the electric starter

button and start the engine.

ELECTRIC STARTER BUllON

-

l Do not use the starter motor for more than 5 seconds. lf the engine

fails to start, release the key, and wait at least 10 seconds before

operating the starter motor again.

l Do not press the electric starter button while the engine is running.

. This may damage the starting unit.

NOTE:

If the engine fails to start, check the emergency stop switch clip.

7.The oil pressure indicator light should be ON while the engine is

running. If the light goes off, stop the engine immediately, check the

engine oil level and inspect engine for oil leaks.

NOTE:

If the oil level is OK, but the light stays off while the engine is running,

take the motor to an authorized Honda Outboard dealer immediately.

OIL PRESSURE INMCATOR UGHT

19

8. After starting, be sure water is flowing out of the water check hole.

If water does not flow out, or if steam comes out, stop the engine.

Check to see if the screen in the cooling water inlet is obstructed. Do

not operate the engine until the problem has been corrected.

9. If the choke was used, push it in gradually as the engine warms up.

NOTE:

Before leaving the dock, check the operation of the emergency stop

switch.

20

Emergency stating

If the recoil starter is not working properly, the engine can be started

with the spare starter rope in the tool kit.

1. Remove the engine cover.

6MM BOLT6

2. Remove the recoil starter by removing the three 6 mm bolts.

3. Disconnect the neutral starter

cable.

4. Wind the spare rope clockwise

around the pulley, and then pull it

straight out to start the engine.

c 1

Keep clear of moving pa-.

5. Leave the recoil starter off and

reinstall engine cover.

Exposed moving parts can cause

injury. Use extreme care when

installing the engine cover. Do not

operate the outboard motor

Without the engine cover.

STARTER CABLE

STARTER ROPE

21

6. OPERATION

r

For the first 10 hours of operation, run the outboard motor at low

speed, and avoid abrupt operation of the throttle.

1. Gear shifting

Put the tilt lever in the RUN position to prevent the outboard motor

from tilting up, when operating in reverse (refer to page 25 1.

The gearshift lever has 3 positions : FORWARD, NEUTRAL, and

REVERSE. An indicator at the base of the gearshift lever aligns with

letters F, N, or R on the engine case to show the gear that has been

selected.

Turn the throttle grip to SHIFT to decrease engine speed before

moving the gearshift lever.

p?iEq

When operating in reverse, proceed with caution to avoid hitting any

underwater obstructions with the propeller.

NOTE:

The throttle mechanism is designed to limit throttle opening in

REVERSE and NEUTRAL. The throttle can be opened to FAST only in

FORWARD gear.

THROTILE GRIP

NEUTRAL

22

2. Steering

To turn to the right, swing the tiller handle to the left. To turn to the left,

swing the tiller handle to the right.

Boats equipped with a remote control steering wheel are controlled in

the same way as a car.

RIGHT TURN

LEFTTURN

Swing the tiller handle to the left.

Swing the tiller hendle to the right.

The steering friction should be adjusted so that stable boat operation

is maintained with a minimum of operator effort.

STEERING

FRICTION BOLT

23

3. Cruising

With the gearshift lever in the

forward position F, turn the throttle

grip toward FAST to increase speed.

For normal cruising, open the

throttle about 3/4.

To hold the throttle at a steady

setting, turn the throttle. friction

knob clockwise. To free the throttle

grip for manual speed control, turn

the friction knob counterclockwise.

NOTE:

This outboard motor is provided

with an over-rev limiter in order to

prevent a breakdown due to

excessive engine speed. Depending

upon the running condition of the

outboard motor (if the force applied

to the propeller is light, for example),

the limiter may operate, causing the

engine speed to become unstable,

thus preventing stable running. If

the engine speed becomes unstable

when the outboard motor is run

with the grip near the “fully open”

position, return the grip to the “low

speed”

side until the speed

becomes stable.

1NoTlCEJ

GEARSHIFT LEVER

THROTTLE GRIP

l Do not operate without the

engine cover. Exposed moving

parts could cause injury; water

may damage the engine.

l Confirm that the tilt lever is in the

“RUN” position (page 25 I.

l For best performance, passengers

and equipment should be

distributed evenly to balance the

boat.

24

Loading...

Loading...