Page 1

WATER TREATMENT

SOLUTIONS

REVERSE OSMOSIS SYSTEM

MODEL

RO-150

INSTRUCTION

MANUAL

701 S. RIDGE AVENUE - TROY, OHIO 45374-0001

F25054 (January 2004)

Page 2

TABLE OF CONTENTS

GENERAL ...............................................................................-3-

Unpacking............................................................................-3-

Included in RO-150 Filtration System .......................................................-3-

Required Tools ........................................................................-3-

Required Hardware ....................................................................-3-

INSTALLATION ...........................................................................-4-

Mounting Location Requirements ..........................................................-4-

Mounting the RO-150 ...................................................................-4-

Water Supply Requirements ..............................................................-5-

Plumbing Connections ..................................................................-5-

Push Type Fitting Connections ............................................................-6-

Water Supply Connection ................................................................-6-

Storage Tank Connection ................................................................-6-

Drain Connection ......................................................................-7-

Equipment Connection ..................................................................-7-

Sampling Line Connection ...............................................................-8-

Electrical Requirements .................................................................-8-

OPERATION .............................................................................-9-

System Start Up .......................................................................-9-

MAINTENANCE..........................................................................-10-

Component Location ..................................................................-10-

Testing Efficiency of RO Membrane.......................................................-10-

Releasing Water Pressure ..............................................................-11-

Restarting the System .................................................................-11-

Pre-Filter Replacement.................................................................-11-

RO Membrane Replacement ............................................................-11-

Post Neutralizing Filter Replacement......................................................-11-

RO-150 Flow Diagram .................................................................-12-

Component Function ..................................................................-13-

REPLACEMENT PARTS ...................................................................-14-

-2-

Page 3

Installation, Operation and Care of

RO-150 Reverse Osmosis System

SAVE THESE INSTRUCTIONS

GENERAL

The Hobart RO-150 filter system is designed for foodservice equipment where high quality water is essential. The

Hobart RO150 meets low water usage demands for steamers, combi-ovens, proofers, deck & rack ovens, and

misting systems. Ensure that the water demand of the equipment does not exceed six gallons per hour or a total

draw down of 13.5 gallons.

NOTE: The standard storage tank size is 20 gallon. Other sizes of storage tanks are available (up to 80 gallon).

NOTE: The RO-150 is intended only for water feeding the cooking equipment boiler or generator. A separate

condensate line not treated by the RO-150 must be installed on equipment if required.

Filter cartridge replacement is recommended at least every 4 - 6 months for moderate to low usage and 90 days

for high usage. The RO membrane should be replaced annually or when the removal of Total Dissolved Solids TDS becomes less than 80% efficient (determined by comparison testing of water supply and product water).

UNPACKING

This water filter system was inspected before leaving

the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of

the shipment. Immediately after unpacking, check for

possible shipping damage. If the water filter system

is found to be damaged, save the packaging material

and contact the carrier within 15 days of delivery.

INCLUDED IN RO-150 FILTRATION SYSTEM

• Reverse osmosis filtration system assembly

with supplied filters, cartridges and 24VAC

transformer.

• 20 Gallon storage tank (13 gallon capacity)*.

• 3/8" Push on ball valve

• 3/8" to 1/4" Push on tee

• 1/4" Ball valve

• 10' - 3/8" LLDPE John Guest tubing

• 10' - 1/4" LLDPE John Guest tubing

• 3/8" Plastic ferrules and stainless steel stiffening

inserts

• Filter wrench

* The RO-150 filtration system can be purchased

without a storage tank.

REQUIRED TOOLS

• Spirit Level

• PVC pipe cutter, razor blade tubing cutter or

sharp razor knife

• Electric drill

•Marker

• Air pressure gauge capable of measuring 10-60

psi.

REQUIRED HARDWARE

• Connection fitting to water supply with 3/8"

compression fitting

• Connection fitting to equipment with 3/8"

compression fitting

• Teflon tape

• Two 3/16" diameter mounting screws at least 11/4" in length.

• Appropriate wall anchor hardware for 3/16"

screws

-3-

Page 4

INSTALLATION

MOUNTING LOCATION REQUIREMENTS

CAUTION: Do not mount to equipment.

1. The filter system must be mounted on a sturdy

support structure or wall and must be level.

2. Allow a minimum of ten inches clearance

around the left and right sides and 14 inches

clearance from the bottom of the system for

routine maintenance and servicing.

3. Locate the RO filter system and storage tank

near the equipment it services.

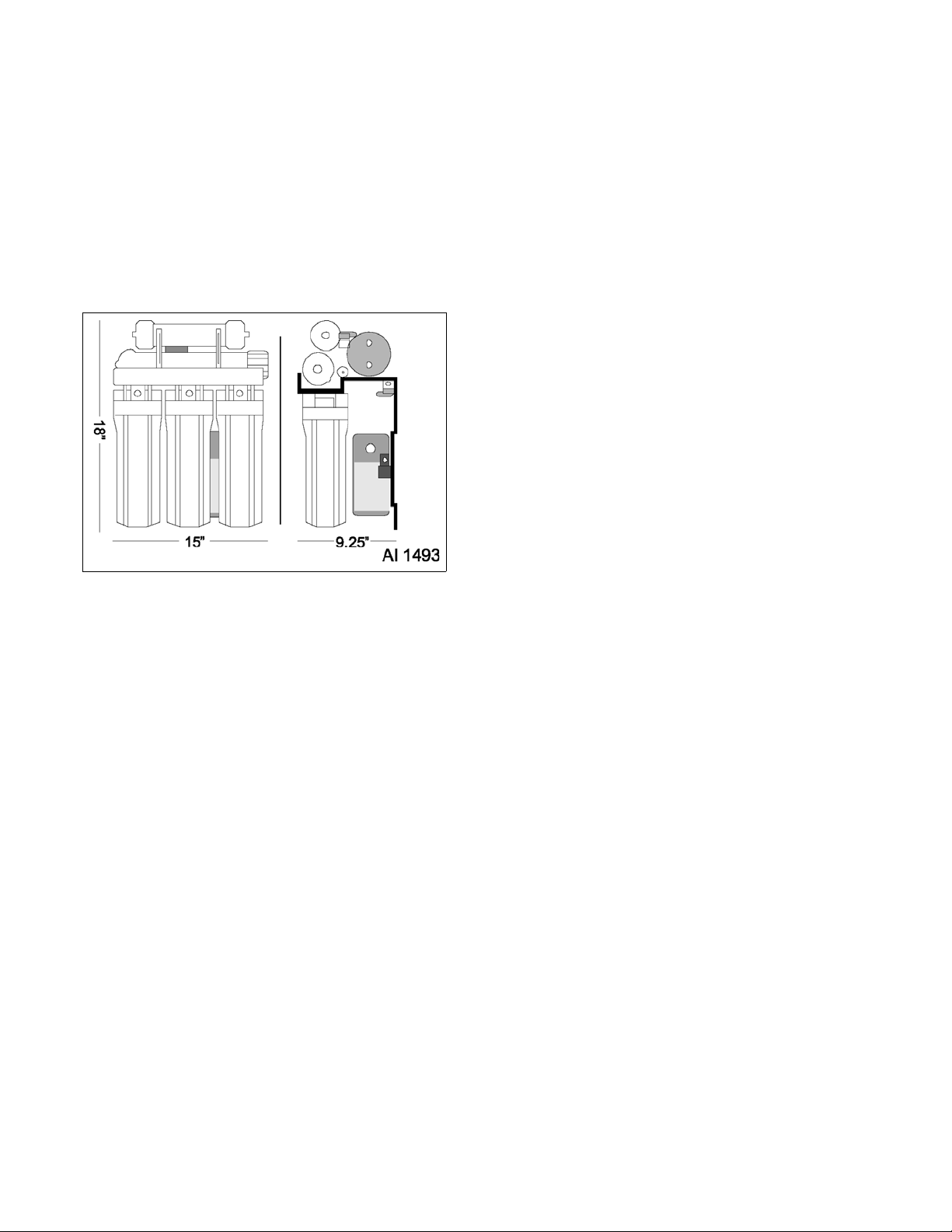

DIMENSIONS OF SYSTEM SHOWN

NOTE: The shorter the distance between the RO

filter system and the equipment, the lower the water

delivery line pressure drop.

4. Ensure there is an open drain nearby to drain

waste water produced by the RO system. Most

commonly this is the same drain used by the

equipment the RO filter system is servicing.

B. Level pre-filter head against mounting

structure.

C. Mark the two mounting hole locations.

2. Drill mounting holes to the required diameter

(depends on wall anchors being used).

3. Install two 3/16" mounting screws at least 1-1/4"

in length in the marked locations using the

appropriate wall anchors. Screw in the mounting

screws leaving a 1/8"-1/4" gap. Lift the pre-filter

head assembly and install over mounting

screws. Slide pre-filter head assembly into

place then securely tighten the mounting

screws.

CAUTION: Do not plug in the transformer at this

time.

4. Place the transformer in the space provided to

the right of the permeate pump.

5. Connect the transformer 24V output to the

wiring harness.

A. Route transformer output wiring under right

side of bracket and connect to plug located

on the left side of filter system near high

pressure switch.

6. Insert filter cartridge into the pre-filter housings.

A. Verify that the filter cartridge being installed

matches the labeling on the bracket.

B. For each pre-filter, ensure the O-ring is in

place on pre-filter housing and hand

tighten filter housing onto the pre-filter

head.

5. Make sure 120V electrical service is within six

feet of the RO mounting location.

6. Do not install the RO filter system where it will

be exposed to hot air or steam exhaust.

7. The filter system must be protected against

freezing. Failure to do so could result in

breakage of the filter housing and water

leakage.

MOUNTING THE RO-150

NOTE: The Hobart RO-150 can be mounted on a

wall or other stable surface that will support its wet

weight of 30 lbs. When mounted to a wall, the

mounting hardware used must be able support its full

weight and withstand the additional forces applied

during pre-filter replacement.

Wall Mounting

1. Remove the pre-filters from the filtration system.

A. Lift the pre-filter head assembly to the

desired location.

-4-

Page 5

WATER SUPPLY REQUIREMENTS

NOTE: Install the RO-150 in the cold water line only. Installation of the water filter system in a hot water line can

damage the filter housing. System performance varies with the incoming water supply temperature. Optimum

performance is achieved when water temperature is 70° F. For each 10° F drop in water temperature, a decrease

in water production of 10% will be observed. A larger storage tank may be required when the water temperature is

less than 55° F.

NOTE: The following are recommended inlet water supply parameters. Exceeding these parameters may

decrease system performance or result in more frequent filter changes. Most municipal water supplies will meet

these conditions with the exception of water hardness. In cases where water hardness exceeds the maximum

recommended levels, life of the RO membrane may be shortened. Proper system performance checks will

determine if the membrane needs replacement.

WATER PARAMETERS

Inlet Water Supply TDS < 2,000 ppm

Hardness < 10 grains (171 ppm)

Iron < 0.2 ppm

Manganese < 0.05 ppm

Turbidity < 5 NTU

pH 5 -10

Free Chlorine < 2 ppm

Hydrogen Sulfide None Allowable

Feed Water Temperature 40 - 100° F

Feed Water Pressure 20 - 125 psi

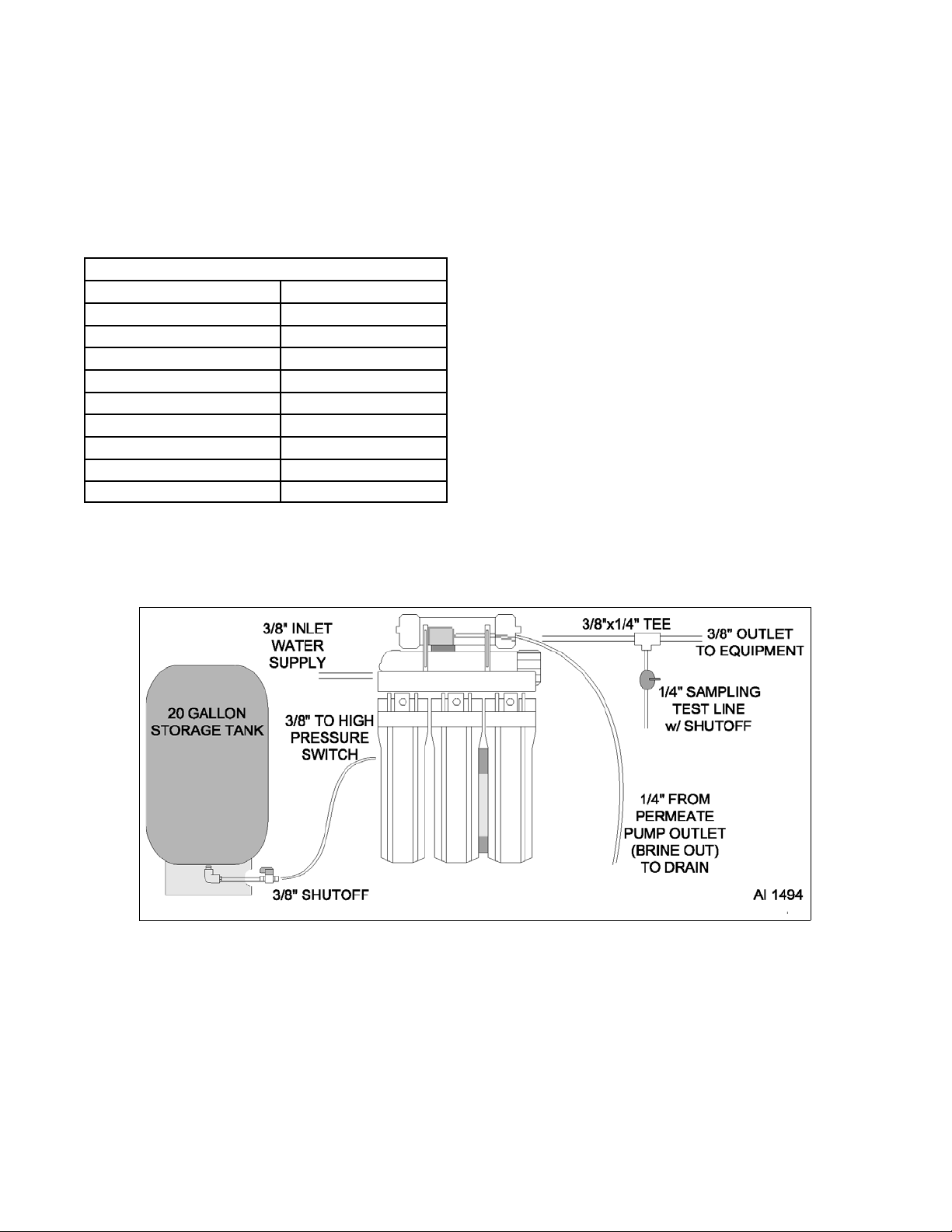

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY AND

PLUMBING CODES.

-5-

Page 6

PUSH TYPE FITTING CONNECTIONS

The Hobart RO-150 utilizes quick disconnect push fittings for the majority of connections. Quick disconnect push

fittings demand smooth, round, nick-free tubing and straight edges to form leak-free connections. Use either a

PVC pipe cutter, razor blade tubing cutter or sharp razor knife to ensure straight, clean cuts. Leaks at connections

are usually the result of deformed tubing. To correct a leak, release the water pressure, disconnect the tubing, cut

1/4" off the end of the tubing and reconnect.

Any tubing that is removed from the fitting frequently will eventually develop nicks or scratches that may lead to

leaks. In such cases, periodically trim the tubing as described above.

NOTE: Always release the water pressure before attempting to disconnect the tubing from the fitting.

To connect tubing, push tubing squarely into the opening as far as it will go. To release the tubing, push in on the

collette and pull out on the tubing.

WATER SUPPLY CONNECTION

TUBING / FITTING REQUIREMENTS

Due to the aggressive nature of high-purity RO product water, all tubing and fittings feeding the storage tank

and equipment should be plastic. Although the Post Neutralizing Filter corrects pH and the aggressive

tendencies of RO water, steps should be taken in avoiding the use of metallic connections and piping.

1. Ensure inlet water pressure is a minimum of 20

psi.

NOTE: Use the minimum amount of tubing to

connect the water supply to the system to cut down

on pressure drop.

NOTE: Inlet supply line should not exceed 20 feet in

length. Do not use a self-piercing saddle valve to tap

into the main feed water line.

NOTE: If using a brass compression fitting to

connect the plastic tubing, discard the brass ferrule

and use a plastic ferrule in its place. Use of a plastic

insert (stiffener) will increase strength of connection.

2. Run 3/8" poly tubing from the water supply to

the inlet connection tee on the left side of the

RO filter system located under the system

bracket and behind the sediment filter.

STORAGE TANK CONNECTION

NOTE: A 20 gallon storage tank pre-charged with air

between 12-15 psi is supplied with the Hobart RO-

150. This allows for a total draw down of

approximately 13 gallons RO water for on demand

use. If a larger draw down is required, larger storage

tanks are available upon request.

NOTE: A small air pump, such as that used for balls

or a bicycle tire, will work to charge the storage tank.

1. Verify the air pressure pre-charge of the empty

tank is within 12-15 psi.

A. Purge or add air as needed.

-6-

Page 7

2. Determine a location that is easily accessible for

storage tank shutoff valve placement.

A. Measure the distance from storage tank

connection point to desired shutoff valve

location.

B. Cut off appropriate length of 3/8" tubing.

C. Insert 3/8" tubing into the push fitting on

the tank adapter so that the tubing extends

through the hole at the base of the tank.

D. Connect the supplied 3/8" ball valve (tank

shut-off valve) to the other end of 3/8"

tubing.

3. Place the tank in a location away from traffic.

Ensure the selected area will support the weight

of the tank when full (140lbs).

4. Run 3/8" poly tubing from the tank shut-off valve

to the push connection at the bottom of the high

pressure switch mounted on the left side of the

RO filter system under the bracket and behind

the sediment filter.

NOTE: The drain line cannot be crimped or blocked.

2. Run tubing from brine outlet port to the drain

using the least amount of tubing as possible.

3. Provide an air gap between end of drain tubing

and drain.

4. Secure drain line in place using plastic ties.

NOTE: All local plumbing codes must be met when

installing drain line.

EQUIPMENT CONNECTION

1. Insert 3/8" tubing into the outlet connection tee

on the right side of the system. Run the

minimum amount of tubing required to the inlet

port of the equipment being fed.

DRAIN CONNECTION

1. Insert supplied 1/4" tubing into the brine outlet

port on the permeate pump.

NOTE: RO product water is only intended for misting

and the equipment boiler/generator. Do not connect

product water to the condensate line.

-7-

Page 8

SAMPLING LINE CONNECTION

NOTE: A product water sampling line must be installed on the feed line between the outlet connection tee of the

RO filtration system and the connected cooking equipment for water sampling purposes.

1. Determine a location in the feed line to install the Tee and sampling shut-off valve. The shut-off valve should

be easily accessible.

A. Install the 3/8" x 1/4" tee in the feed line after the outlet connection tee and before the connected cooking

equipment.

2. Connect the required amount of 1/4" tubing between 3/8" x 1/4" Tee and 1/4" shut-off valve.

3. Connect an additional length of 1/4" tubing to the output side of the shut-off valve for sample water collection.

4. Turn shut-off valve to the off position.

ELECTRICAL REQUIREMENTS

The RO-150 comes with a 110V/60Hz, 24V two amp transformer.

-8-

Page 9

OPERATION

SYSTEM START UP

Start-up conditions.

• Water supply is connected to system inlet Tee

(inlet ball valve closed).

• Storage tank is connected to high pressure

switch.

• Outlet is connected to equipment (outlet shutoff

valve closed).

• Sampling line (shut-off valve closed).

• Transformer output connected to the high

pressure switch (transformer not connected to

power source).

• Equipment being fed is turned off during start

up.

• Internal inlet valve on equipment is closed.

• Ensure that the bypass valve is closed.

1. Open the RO filter system inlet and storage tank

ball valves.

2. Open the water supply main valve and allow

water to enter the system.

3. Check the three pre-filter assemblies and

related connections for leaks.

A. If a leak is detected, release water

pressure from the system before

attempting repairs to the leaking

connection. Refer to RELEASING WATER

PRESSURE as outlined under

MAINTENANCE.

WARNING: ELECTRICAL CONNECTIONS MUST

COMPLY WITH THE APPLICABLE PORTIONS OF

THE NATIONAL ELECTRICAL CODE AND/OR

OTHER LOCAL CODES.

4. Connect transformer to the power source. This

will open the electronic solenoid valve and start

the booster pump.

B. Verify that the booster pump turns off

immediately and water stops flowing to the

drain.

NOTE: The system is now under full pressure.

7. Check all fittings for leaks.

NOTE: If a leak is detected, release water pressure

from the system before attempting repairs to the

leaking connection. Refer to RELEASING WATER

PRESSURE as outlined under MAINTENANCE.

8. After successful checks, open the storage tank

and outlet ball valves.

NOTE: The booster pump should switch back on and

the system should begin operating normally.

9. Allow system to run for approximately 15-20

minutes.

10. Open the outlet ball valve and sampling valve.

A. Collect approximately 1 gallon of water in a

container.

NOTE: This water will appear milky or cloudy as it

flushes out media fines from the post neutralizing

cartridge.

B. Close the sampling valve and discard

collected water.

NOTE: It will take approximately two hours for the

system to fill the storage tank with product water. If

water is needed for equipment operation prior to the

storage tank filling, close the outlet ball valve and

open the bypass ball valve. This will allow the flow of

untreated water to the equipment while the RO

system continues to fill the storage tank.

11. To use product water, ensure that the inlet,

outlet and storage tank ball valves are open and

the bypass and sampling valves are closed

before turning on the cooking equipment.

NOTE: Allow system to operate for a couple of

minutes allowing trapped air to be purged from the

system.

5. Check operation of the permeate pump. Once

air is purged from the system, water will pulse

out of the drain line for 2-3 seconds, then stop

for the same duration. During normal operation

water will pulse on and off continuously until

storage tank is filled.

6. Check high pressure switch and electronic

solenoid shut-off valve operation.

A. While the system is producing water, close

the outlet ball valve and the storage tank

ball valve.

-9-

Page 10

COMPONENT LOCATION

MAINTENANCE

TESTING EFFICIENCY OF RO MEMBRANE

NOTE: The RO membrane should be replaced annually or when the removal of Total Dissolved Solids - TDS

becomes less than 80% efficient. Contact your local Hobart Service office for TDS efficiency testing of your

Reverse Osmosis system.

NOTE: To determine grains of hardness delivered to equipment, divide the measured RO TDS by 17.1.

1. Ensure bypass valve is closed.

2. Measure inlet TDS before water enters RO filtration system.

3. Measure RO TDS through sampling line.

4. Determine efficiency percentage using the equation:

Efficiency Percentage =

Example: The inlet water to an RO filtration system is sampled and found to have TDS equal to 198 ppm. A

water sample is then taken from the output of the RO system and it measures a TDS of 17 ppm. Find the

efficiency percentage using the above equation and the gathered data.

Solution:

!

Efficiency

Percentage

198 ppm

=

17 ppm

x 100 =

198 ppm 198 ppm

Inlet TDS

181 ppm

!

RO TDS

Inlet TDS

x 100 = 0.914 x 100 = 91.4%

x 100

-10-

Page 11

RELEASING WATER PRESSURE

Prior to replacing any of the RO-150 filters or

repairing connections, water pressure must be

relieved from the system.

1. Unplug transformer from the electrical outlet.

2. Close the inlet and storage tank shut off valves.

2. Place a pan under pre-filter housing being

removed to catch water overflow.

3. Remove pre-filter housing from pre-filter head.

4. Remove the old cartridge and wipe out inside of

pre-filter housing.

5. Install a new cartridge into the pre-filter housing.

A. Make sure the bypass valve is closed.

3. Place sampling line in container and open

sampling shutoff valve to relieve pressure in the

system.

NOTE: Failure to relieve system water pressure

makes it very difficult to remove the pre-filter

housings or make repairs to connections.

RESTARTING THE SYSTEM

1. Close the storage tank valve.

A. Make sure bypass valve is closed.

2. Place sampling line into a container and open

sampling valve.

3. Open the 3/8" inlet and outlet ball valves. Open

water supply valve if necessary.

4. Connect transformer to power source.

NOTE: Inlet solenoid valve will not open unless

power is applied to the RO filtration system.

5. Allow system to operate several minutes to

purge trapped air from the system.

6. After air is purged from the system and while

the system is producing water, close the outlet

ball valve.

A. Verify that the booster pump turns off

immediately and water stops flowing to the

drain.

NOTE: The system is now under full pressure.

7. Check all fittings for leaks.

A. If a leak is detected, release water

pressure from the system before

attempting repairs. Refer to RELEASING

WATER PRESSURE as outlined under

MAINTENANCE.

8. After successful checks, close the sampling ball

valve and open the storage tank and outlet ball

valves.

PRE-FILTER REPLACEMENT

A filter wrench is provided to remove the pre-filter

housings. In most cases, the filter wrench is not

needed if the system pressure is relieved.

CAUTION: Do not apply excessive force on the

filter mounting hardware when removing or

replacing the pre-filter housings.

1. Follow procedure for RELEASING WATER

PRESSURE.

NOTE: Ensure new cartridges are positioned in the

correct order; carbon block-SS filter on the right,

carbon block filter in the middle and 5 micron

sediment filter on the left side.

6. Inspect filter housing O-rings. Replace O-ring if

damaged.

7. Reinstall pre-filter housing onto the pre-filter

head. Hand tighten. Use the wrench only to

remove pre-filter housings - DO NOT OVER

TIGHTEN.

8. Perform RESTARTING THE SYSTEM.

RO MEMBRANE REPLACEMENT

1. Follow procedure for RELEASING WATER

PRESSURE.

2. Disconnect the 1/4" line from the elbow fitting on

the inlet side of the membrane housing.

NOTE: The housing can be lifted away from the

mounting clips in order to get a firm grasp on the

housing and cap.

3. Unscrew the membrane housing cap.

4. Remove the used RO membrane from the

housing by threading a plastic tie through the

hole on top of the membrane post and pulling it

out.

CAUTION: Do not touch the new RO membrane.

5. Cut the bottom of the plastic bag containing the

RO membrane and insert membrane by

pushing it into the housing until it stops. Handle

the membrane only by the plastic bag.

6. Insert the new RO membrane into the housing.

7. Replace the membrane cap and reconnect the

1/4" tubing to the inlet fitting.

8. Perform RESTARTING THE SYSTEM.

POST NEUTRALIZING FILTER REPLACEMENT

1. Follow procedure for RELEASING WATER

PRESSURE.

2. Loosen both Jaco nuts on the inlet and outlet of

the post filter.

3. Pull away nuts and tubing from post filter.

4. Remove used post filter by pulling it out of the

mounting clips.

5. Snap in new post filter and reconnect inlet and

outlet tubing.

6. Perform RESTARTING THE SYSTEM.

-11-

Page 12

RO-150 FLOW DIAGRAM

-12-

Page 13

COMPONENT FUNCTION

Inlet Connection Tee ............ Splits water supply into two paths. One path goes to the beginning of the

RO system, the other goes to the bypass ball valve.

Inlet Ball Valve ................. Controls inlet water to the RO system. Valve is to be either fully open or

closed. Valve is open during normal operation.

Outlet Ball Valve................ Controls outlet RO product water feeding connected equipment. Valve is

to be either fully open or closed. Valve is open during normal operation.

Sampling Ball Valve ............. 1/4" valve that allows sampling water feeding equipment for testing

purposes. Valve is closed during normal operation.

Bypass Ball Valve............... This valve is placed in the untreated water supply line parallel with the

filtration system and is used to bypass the filtration system when servicing

or maintaining the RO system.

Storage Tank Ball Valve .......... Used to shut the product water off at the storage tank when servicing the

system.

Check Valve ................... One-way check valve allows water to flow in one direction. Three check

valves are incorporated into the system, one prevents untreated water

from entering the product water storage tank, another prevents RO

product water loss through the inlet water supply and the third is

connected to the RO housing product water output.

Solenoid Valve ................. Controls water flow into the RO membrane. The solenoid closes when the

storage tank is full and whenever power is removed from the system.

High Pressure Switch ............ Connected in the line that feeds product water to the storage tank, the

high pressure switch shuts down the booster pump and solenoid once the

storage tank is full.

Product Water Storage Tank ...... Twenty gallon storage tank charged with 12-15 psi air pressure when

empty. Stores approximately 13 gallons of RO product water for ondemand use.

Drain Flow Controller ............ Controls (slows) the rate reject water flows to the drain causing pressure

to build on inlet side of RO membrane. The pressure rise increases RO

product water quality and quantity.

Permeate Pump ................ Pump that directs permeate (product) water to the storage tank or

equipment. Also pumps reject water to an unrestricted drain.

Booster Pump.................. Boosts the water pressure after inlet water passes through the sediment

filter. Increased pressure produces higher product water quantities.

5 Micron Filter.................. Sediment filter. Inlet water first enters this filter for fine particle filtration

then enters into the booster pump.

Carbon Block Filter .............. Middle filter. Removes majority of chlorine from water supply. Chlorine will

damage the RO membrane if it is not removed.

Carbon Block-SS Filter ........... Second carbon filter. Removes remaining chlorine and contains the

ScaleStick product to reduce minerals and extend RO membrane life.

RO Membrane ................. The reverse osmosis membrane allows only water to pass thru the

membrane and rejects 95-98% dissolved solids. As water flows thru the

membrane, it splits into two streams, the permeate (product) water stream

and the reject water stream.

Neutralizing Cartridge............ Mounted in the filtration after the storage tank. The cartridge contains

crushed limestone to add some mineral content (between 10-20mg/l) back

into the RO product water stream and adjusts the pH of the water close to

neutral (7.0 pH).

-13-

Page 14

REPLACEMENT PARTS

-14-

Page 15

INDEX # PART NO. NAME OF PART AMT.

1 01-234506-17400 Elbow 1 NPT x 1 Slip ............................................................................... 1

2 01-234506-16200 Reducer 1 Slip x 1/2 NPT ........................................................................... 1

3 01-234501-58800 Adapter 1/2 NPT x 3/8 Push-In .......................................................................1

4 01-234501-25000 Ball Valve (3/8) .................................................................................... 1

5 01-234501-29800 Check Valve (3/8) ................................................................................. 1

6 01-234506-00200 Clip - Membrane (2 In.) ............................................................................. 2

7 01-234503-27000 Switch - High Pressure ............................................................................. 1

8 01-234501-54600 Tee 3/8 x 3/8 x 1/4 (Push-In) .........................................................................1

9 01-234501-29800 Check Valve (3/8) ................................................................................. 1

10 01-234501-52200 Elbow 1/4 NPT x 3/8 Jaco ........................................................................... 1

11 01-234301-98500 Cartridge - Neutralizing ............................................................................. 1

12 01-234501-54900 Adapter 1/8 NPT x 1/4 Tube (W/Check Valve) ........................................................... 1

13 01-234503-21000 Pump - Permeate (W/Clip) ........................................................................... 1

14 01-234501-53400 Elbow 1/4 Push-In x 1/4 Plug-In ...................................................................... 2

15 01-234503-23400 Controller - Drain Flow .............................................................................. 1

16 01-234501-55200 Elbow 1/8 NPT x 1/4 Push-In ......................................................................... 1

17 01-234506-00500 Clip - Post Filt er (2 x 2) ............................................................................. 2

18 01-234219-01200 Housing - Membrane Cap (Incls. Item 18) ............................................................... 1

19 01-234502-01400 O-Ring (Membrane Housing Cap) ..................................................................... 1

20 01-234301-98800 Membrane - Reverse Osmosis (100 GPD) .............................................................. 1

21 01-234502-01100 O-Ring (Membrane Housing) ......................................................................... 1

22 01-234219-01200 Housing - Membrane (Incls. Item 22) .................................................................... 1

23 01-234501-55200 Elbow 1/8 NPT x 1/4 Push-In ......................................................................... 1

24 01-234506-93100 Mach. Screw 10-24 x 3/4 Philips Pan Hd ............................................................... 12

25 01-234501-52200 Elbow 1/4 NPT x 3/8 Jaco ........................................................................... 1

26 01-234501-25000 Ball Valve (3/8) .................................................................................... 1

27 01-234501-53100 Tee 3/8 x 3/8 x 3/8 (Push-In) ......................................................................... 1

28 - Mach. Screw 10-24 x 1 1/4 Philips Pan Hd .............................................................. 4

29 01-234501-54300 Elbow 3/8 Push-In x 3/8 Plug-In ...................................................................... 1

30 01-234501-54600 Tee 3/8 x 3/8 x 1/4 (Push-In) ......................................................................... 1

31 01-234501-42000 Ferulle - Delrin .................................................................................... 1

32 01-234501-42200 Stainless Insert ...................................................................................1

33 01-234501-25300 Ball Valve (1/4) .................................................................................... 1

34 01-234501-55200 Elbow 1/8 NPT x 1/4 Push-In ......................................................................... 1

35 01-234503-41600 Valve - Electronic Shutoff............................................................................ 1

36 01-234501-55200 Elbow 1/8 NPT x 1/4 Push-In ......................................................................... 1

37 01-234501-50100 Adapter 1/4 NPT x 1/4 Tube ......................................................................... 1

38 01-234401-02200 Head - Filter ...................................................................................... 1

39 01-234402-00400 Housing - Filter (10 In.) ............................................................................. 1

40 01-234402-01900 Housing - Filter (20 In.) ............................................................................. 1

41 01-234502-00100 O-Ring (Filter Head) ............................................................................... 1

42 01-234301-97400 Filter - Carbon Block W/ScaleStick Insert (10 In.) ......................................................... 1

43 01-234301-98300 Filter - Carbon Block W/ScaleStick Insert (20 In.) ......................................................... 1

44 01-234501-51000 Elbow 1/4 NPT x 1/4 Push-In ......................................................................... 1

45 - Lock Nut 10-24 Hex (Plastic) ......................................................................... 4

46 - Washer..........................................................................................4

47 01-234503-20100 Pump - Booster ................................................................................... 1

48 01-234501-51300 Elbow 1/4 NPT x 3/8 Push-In1 ........................................................................ 1

49 01-234402-00400 Housing - Filter (10 In.) ............................................................................. 1

50 01-234402-01900 Housing - Filter (20 In.) ............................................................................. 1

51 01-234502-00100 O-Ring (Filter Head) ............................................................................... 1

52 01-234301-97200 Filter - Carbon Block (10 In.) ......................................................................... 1

53 01-234301-98100 Filter - Carbon Block (20 In.)

54 01-234501-51000 Elbow 1/4 NPT x 1/4 Push-In ......................................................................... 1

55 01-234401-02200 Head - Filter ...................................................................................... 1

56 01-234501-51300 Elbow 1/4 NPT x 3/8 Push-In ......................................................................... 1

57 01-234501-25000 Ball Valve (3/8) .................................................................................... 1

58 01-234402-00400 Housing - Filter (10 In.) ............................................................................. 1

59 01-234402-01900 Housing - Filter (20 In.) ............................................................................. 1

60 01-234502-00100 O-Ring (Filter Head) ............................................................................... 1

61 01-234301-95100 Filter - Sediment (5 Micron)(10 In.) .................................................................... 1

62 01-234301-96300 Filter - Sediment (5 Micron)(20 In.) .................................................................... 1

63 01-234501-51300 Elbow 1/4 NPT x 3/8 Push-In ......................................................................... 1

64 01-234401-02200 Head - Filter ...................................................................................... 1

65 01-234501-54300 Elbow 3/8 Push-In x 3/8 Plug-In ...................................................................... 1

66 01-234501-25000 Ball Valve (3/8) .................................................................................... 1

67 01-234501-53100 Tee 3/8 x 3/8 x 3/8 (Push-In) ......................................................................... 1

68 01-234501-42000 Ferulle - Delrin .................................................................................... 1

69 01-234501-42200 Stainless Insert ...................................................................................1

70 01-234504-92000 Tank (20 Gallon) ..................................................................................1

71 - Screw #12 x 3/4 Philip Pan Hd ....................................................................... 2

01-234503-25200 Transformer ...................................................................................... 1

00-913033-00002 Tubing 1/4 (50 Ft.) .................................................................................AR

00-913034-00002 Tubing 3/8 (50 Ft.) .................................................................................AR

01-234509-00600 Wrench - Filter .................................................................................... 1

01-234301-40000 RO150 W/20 Gallon Storage Tank .................................................................... 1

01-234301-40500 RO150 W/O Storage Tank........................................................................... 1

01-234507-08100 Bracket - Mounting ................................................................................. 1

......................................................................... 1

-15-

Page 16

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE POSSIBLE REMEDY

Booster pump doesn't

operate.

Booster pump runs

continuously.

No RO product water

output to equipment.

Low RO product water

output to equipment.

1. Storage tank ball valve closed.

2. No power at electrical outlet.

3. Transformer malfunction.

4. Booster pump malfunction.

5. High pressure switch malfunction.

1. Sampling shutoff valve or

equipment valve malfunction.

2. Check Valve on product water

outlet of RO membrane housing

malfunction.

3. High pressure switch malfunction.

1. No power at electrical outlet.

2. Inlet shutoff or output valve(s)

closed.

3. Clogged pre-filter(s).

4. Transformer malfunction.

5. Electronic shutoff valve

malfunction.

1. Clogged filter(s).

2. Low inlet water pressure.

3. Mineral scaling on RO

membrane.

4. Permeate pump malfunction.

1. Open ball valve.

2. Restore power at outlet.

3-5. Contact your local Hobart Service office.

1. Close valve(s).

2-3. Contact your local Hobart Service office.

1. Restore power at outlet.

2-5. Contact your local Hobart Service office.

1. Replace filter(s).

2-4. Contact your local Hobart Service office.

Low RO product water

yield. (Draw down less

than 13 gallon when

full)

Equipment water level

probes not operating

properly.

Metallic plumbing on

equipment shows

signs of corrosion.

Brine water flows

continuously through

drain. (Booster pump

is not operating.)

1. Storage tank air pressure not

correct.

2. Low inlet water pressure.

3. Clogged filter(s).

4. Mineral scaling on RO

membrane.

5. Permeate pump malfunction.

1. Product water mineral content too

low.

2. Bypass valve set incorrectly.

3. Cooking equipment probe

malfunction.

1. Product water mineral content too

low. 1. Contact your local Hobart Service office.

1. Check Valve on product water

outlet of RO membrane housing

malfunction.

2. Permeate pump malfunction.

1-5. Contact your local Hobart Service office.

1. Contact your local Hobart Service office.

2. Ensure bypass valve is closed.

3. Check cooking equipment instruction

manual for possible solution.

1-2. Contact your local Hobart Service office.

-16-

Loading...

Loading...