Page 1

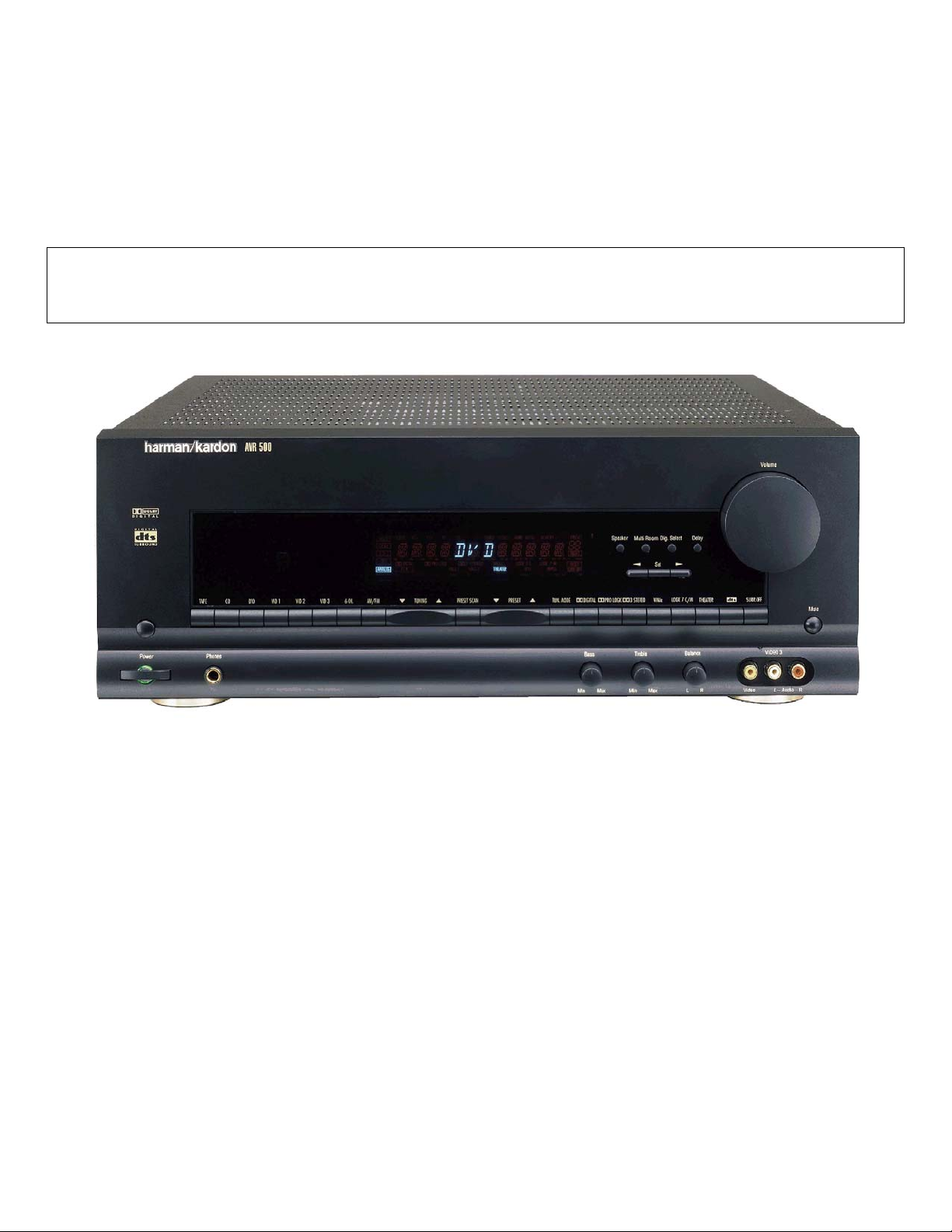

harman/kardon

AVR500

A/V DOLBY DIGITAL RECEIVER

SERVICE MANUAL

CONTENTS

SPECIFICATIONS ………………………………..…2

ESD WARNINGS…………………………………… 4

LEAKAGE TEST……………………………………. 5

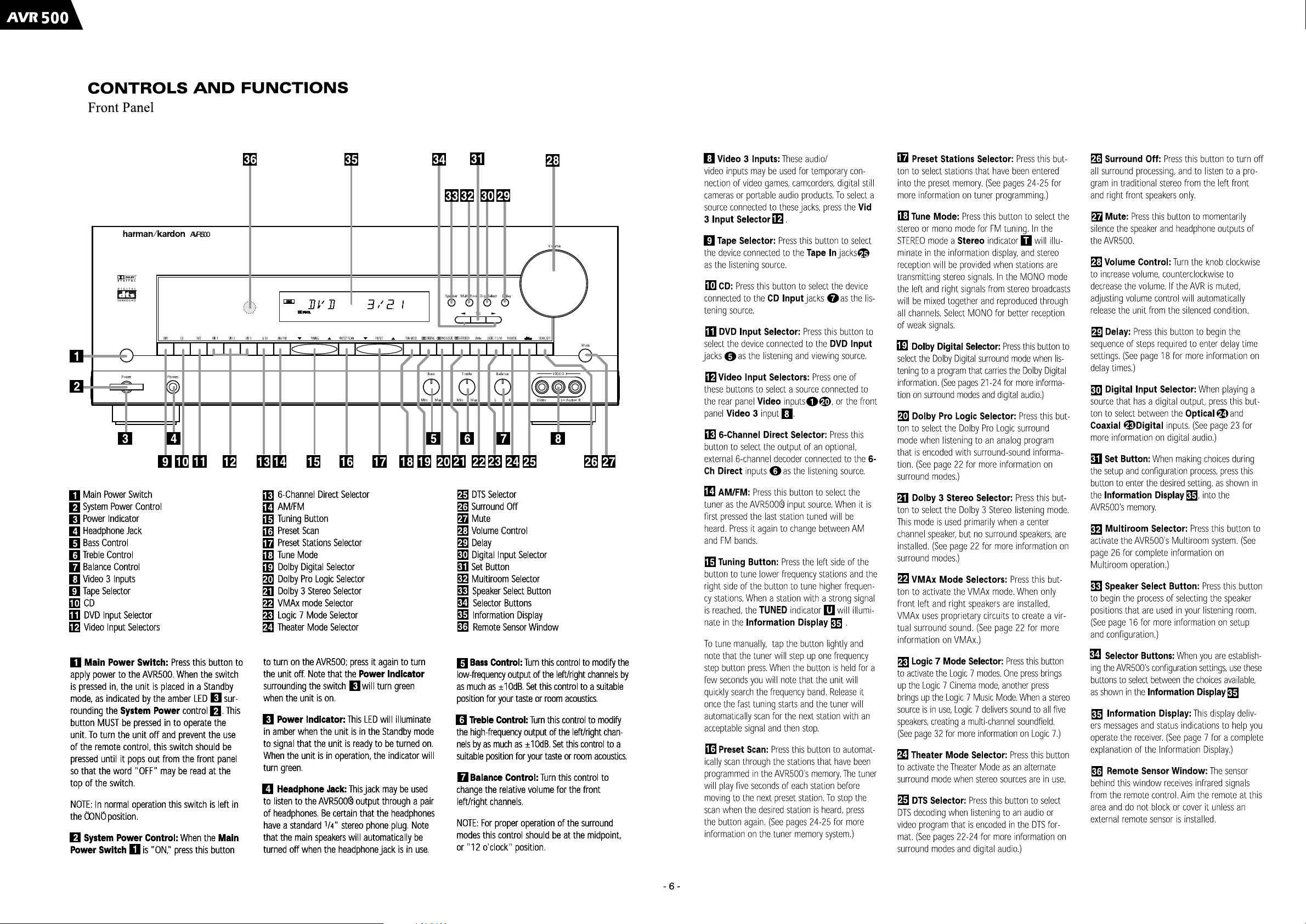

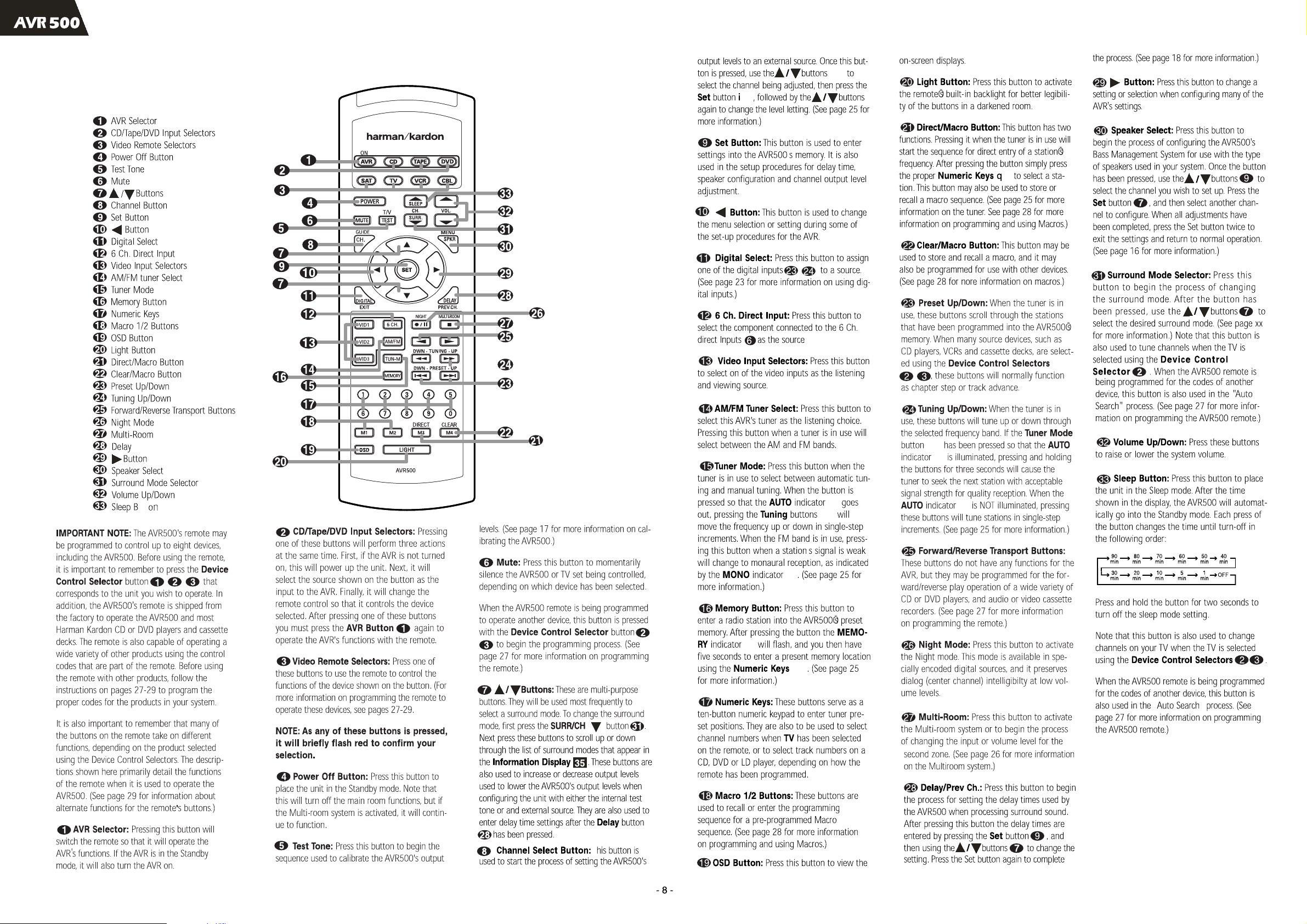

CONTROLS AND FUNCTIONS……………………6

SERVICE PROCEDURE………………………….. .9

TEST EQUIPMENT REQUIRED……………… …9

ALIGNMENT PROCEDURES………………………9

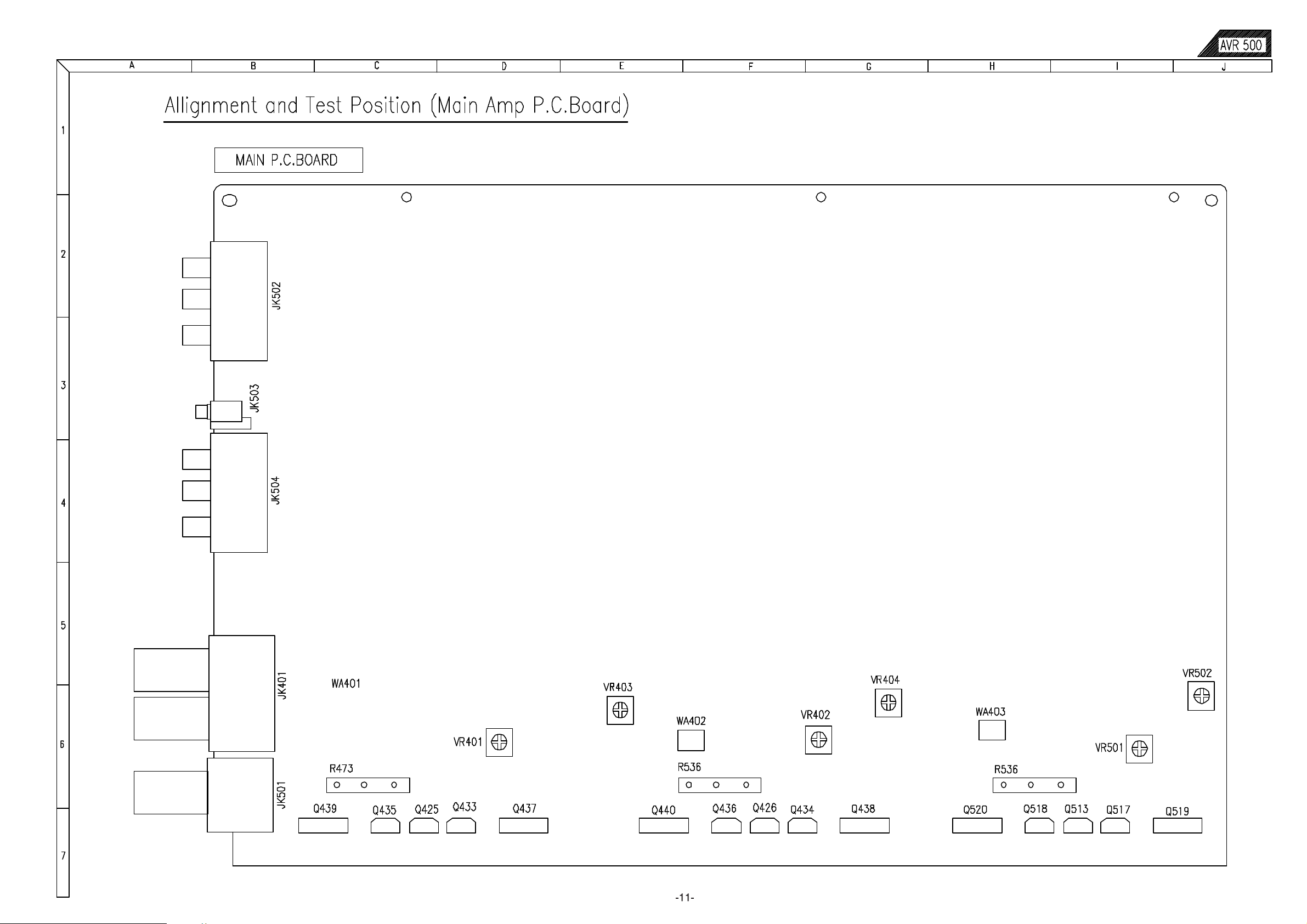

ALIGNMENT AND TEST POINTS……………….. 11

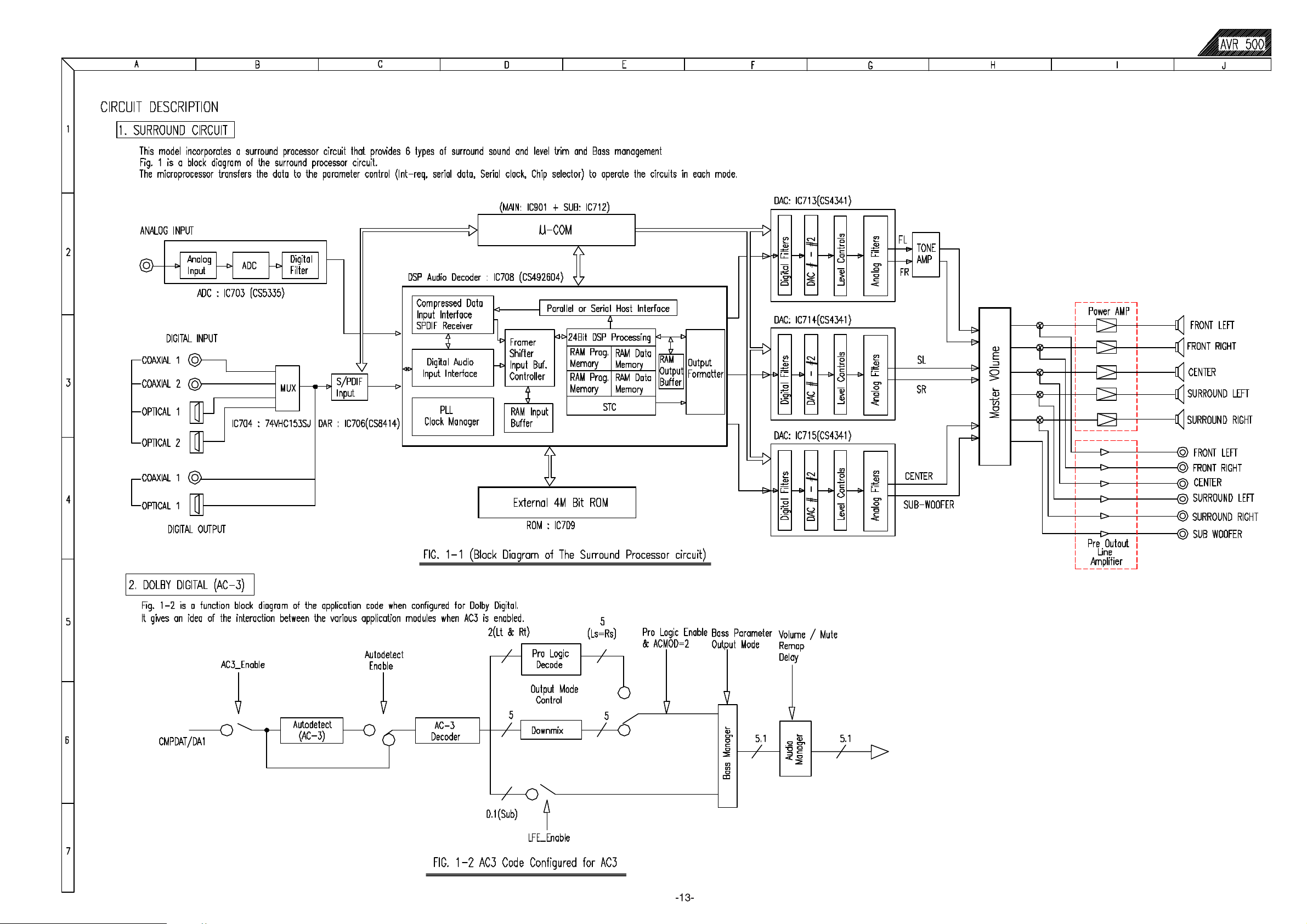

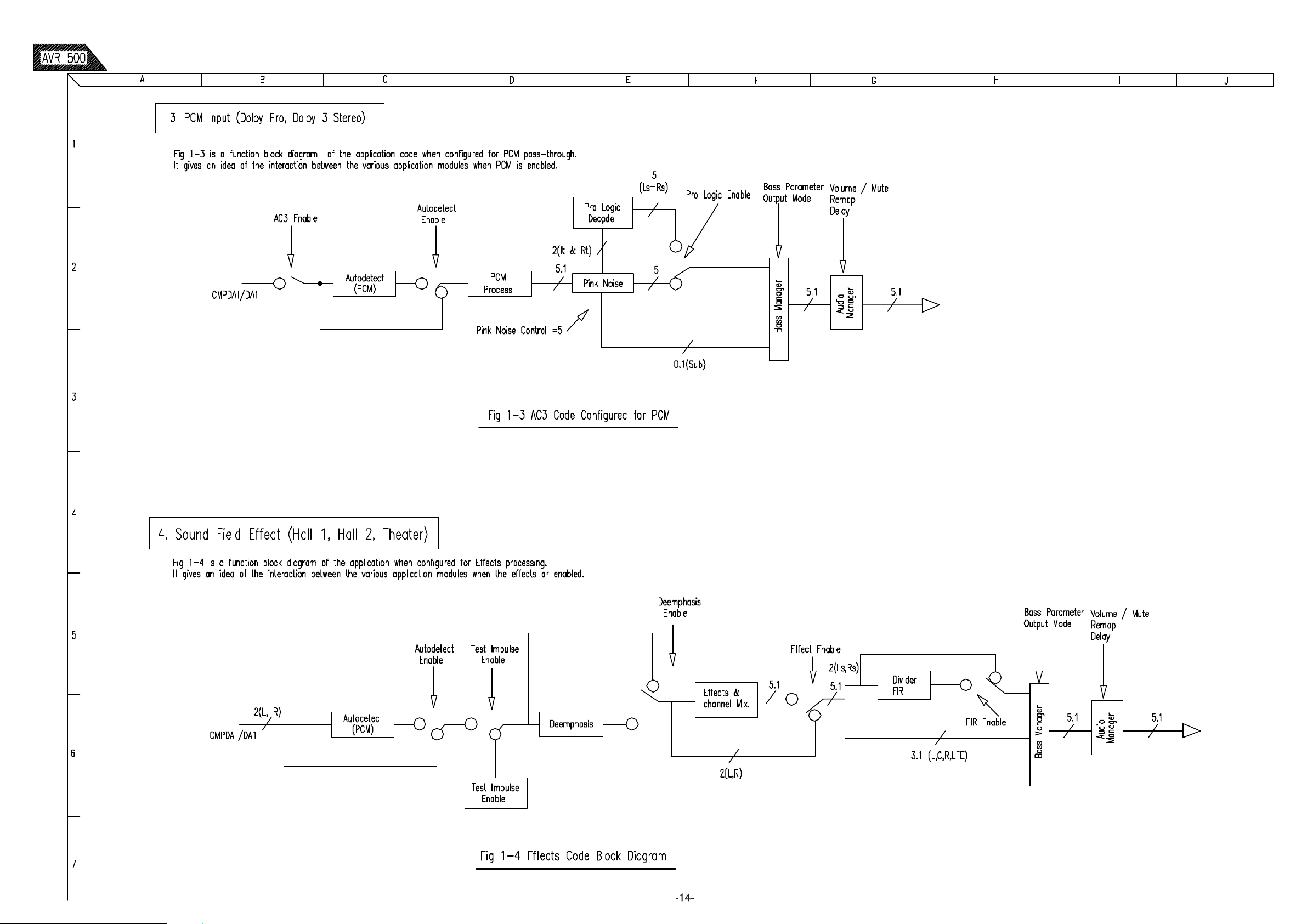

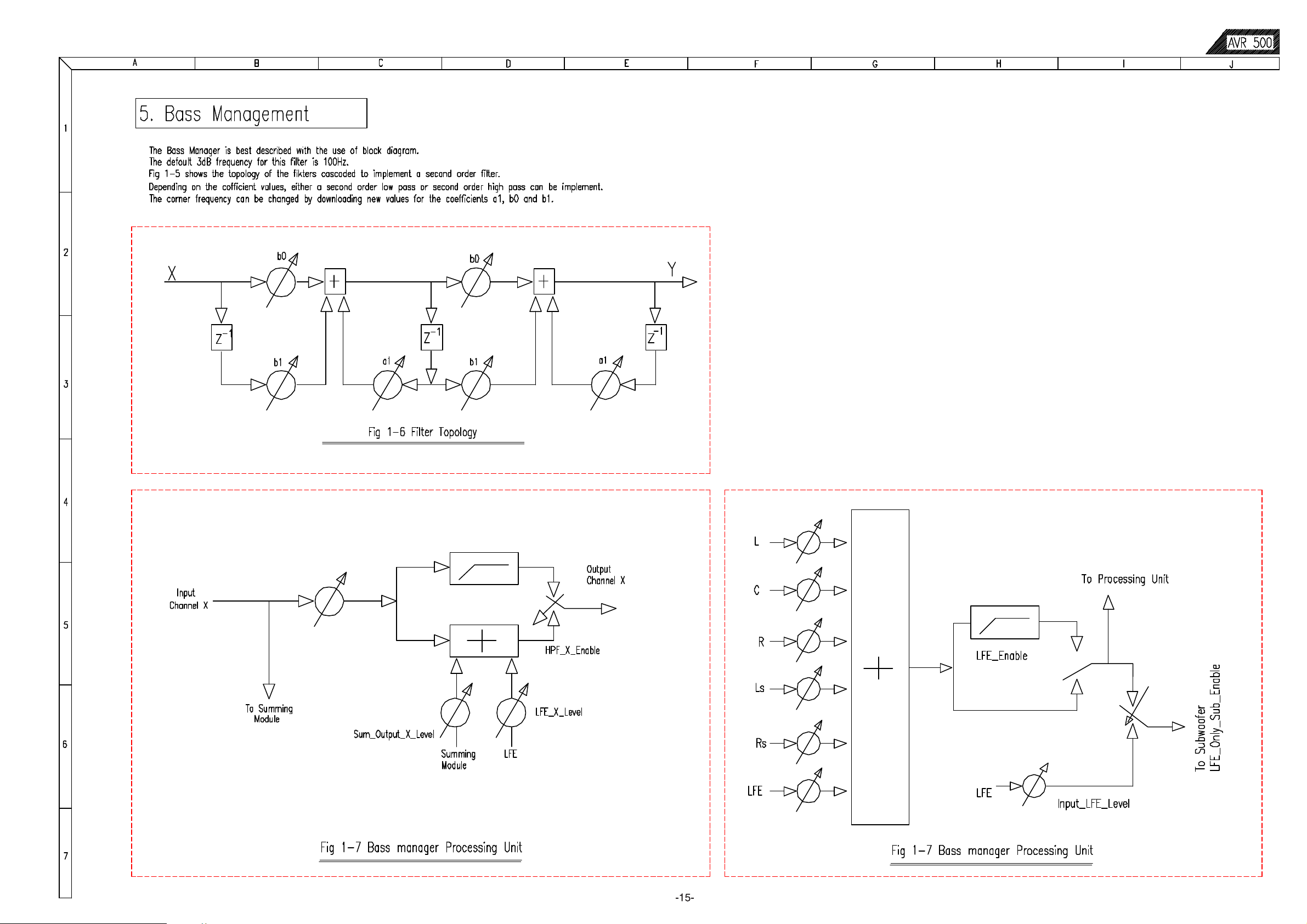

CIRCUIT DESCRIPTION…………………………..13

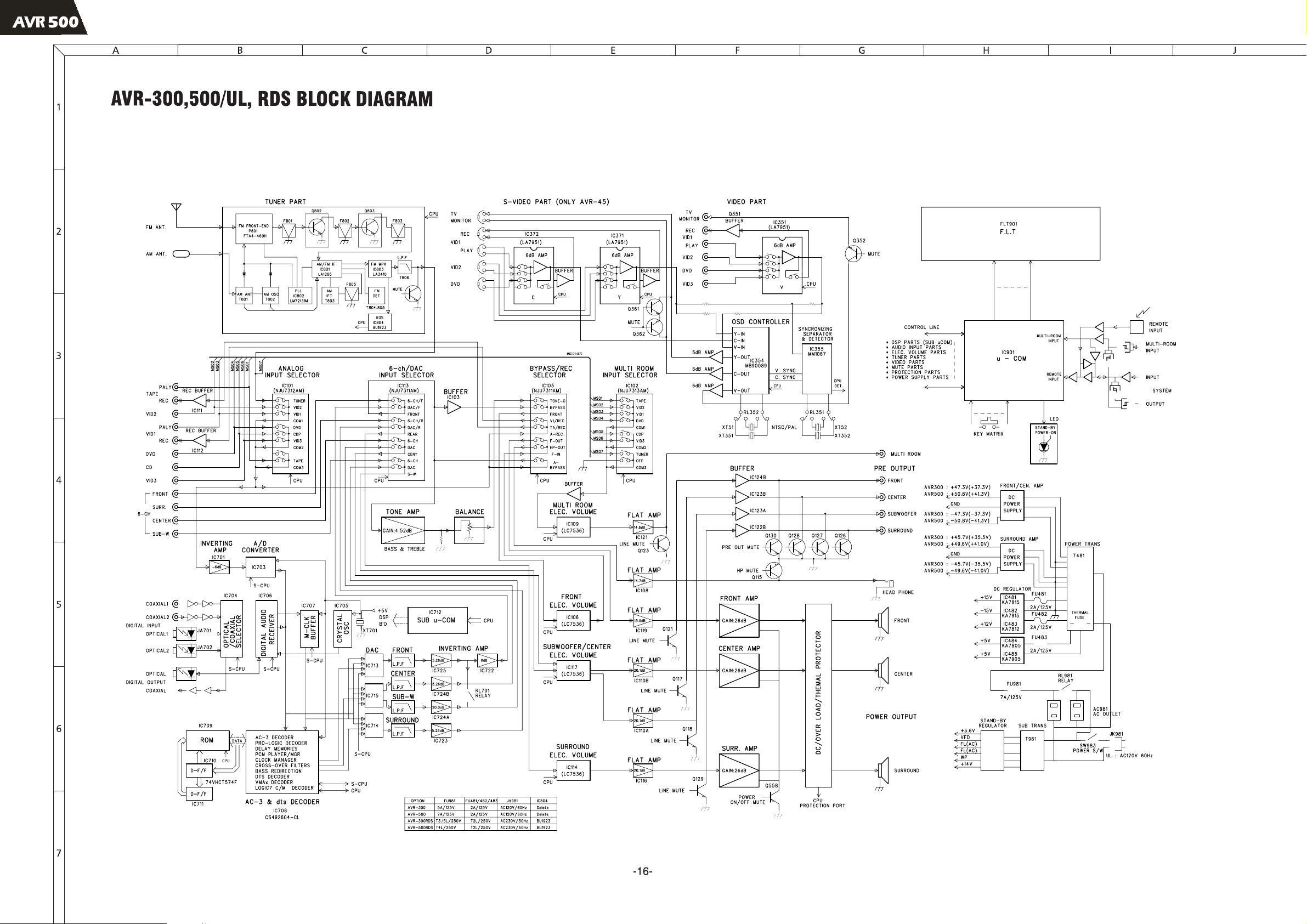

BLOCK DIAGRAM ………………………………….16

BULLETIN HK2000-02……………..………..……..17

BULLETIN HK2000-04………………...….………..19

BULLETIN HK2000-05………………...….………..21

harman/kardon, Inc.

250 Crossways Park Dr.

Woodbury, New York 11797 Rev1 – 11/2003

DISASSEMBLY PROCEDURES ………… .……23

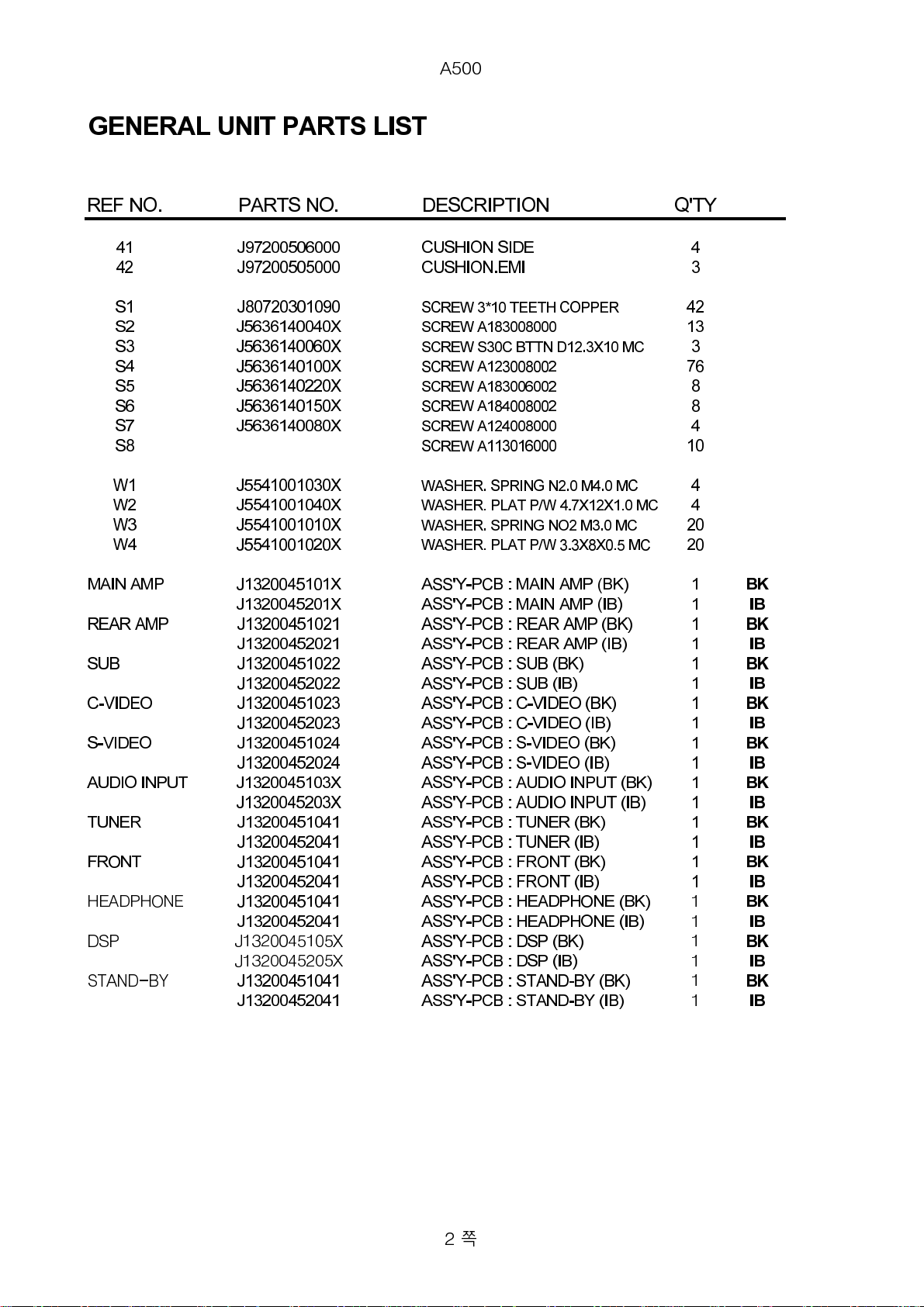

GENERAL UNIT PARTS LIST …………………..24

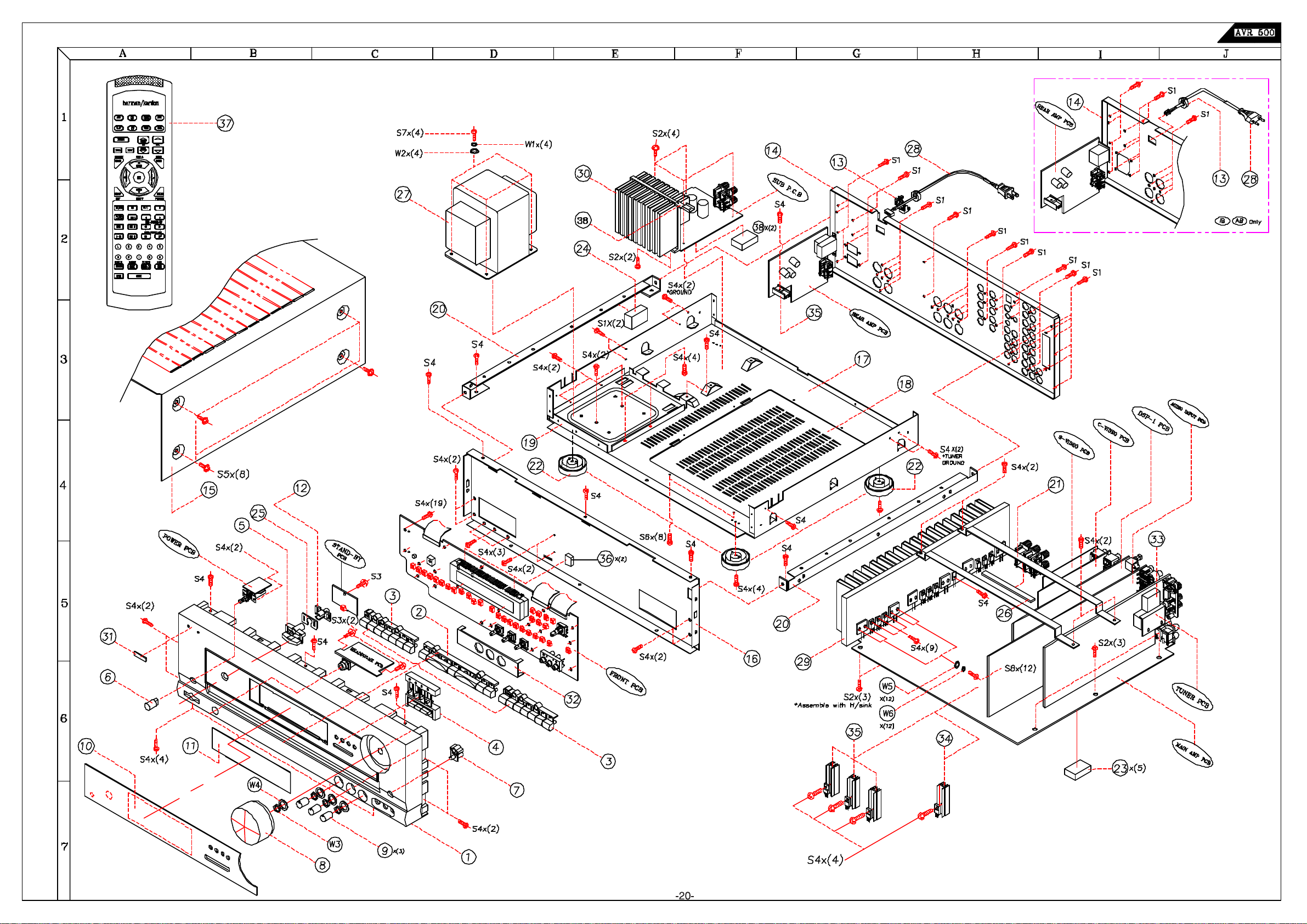

GENERAL UNIT EXPLODED VIEW………..….. 26

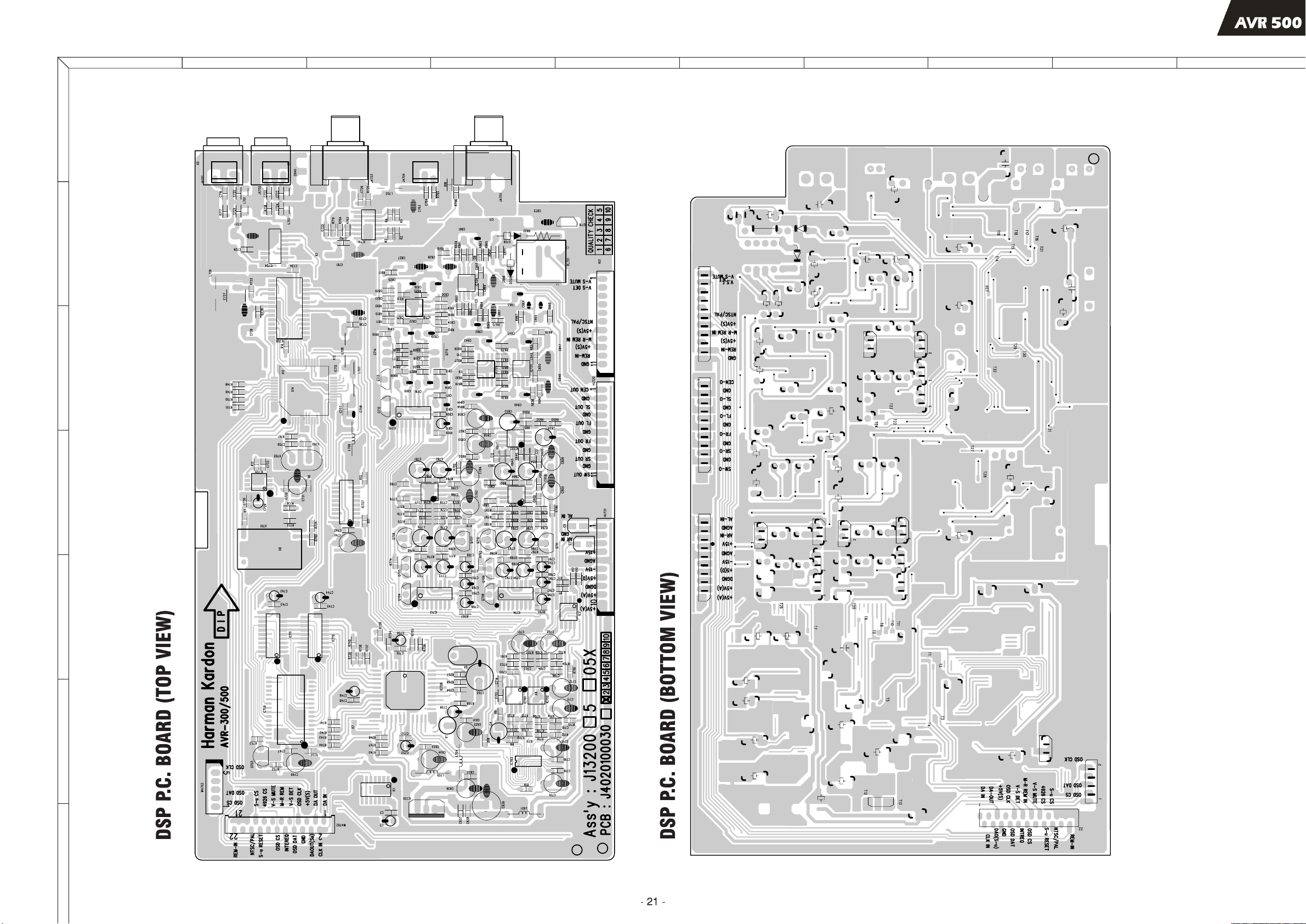

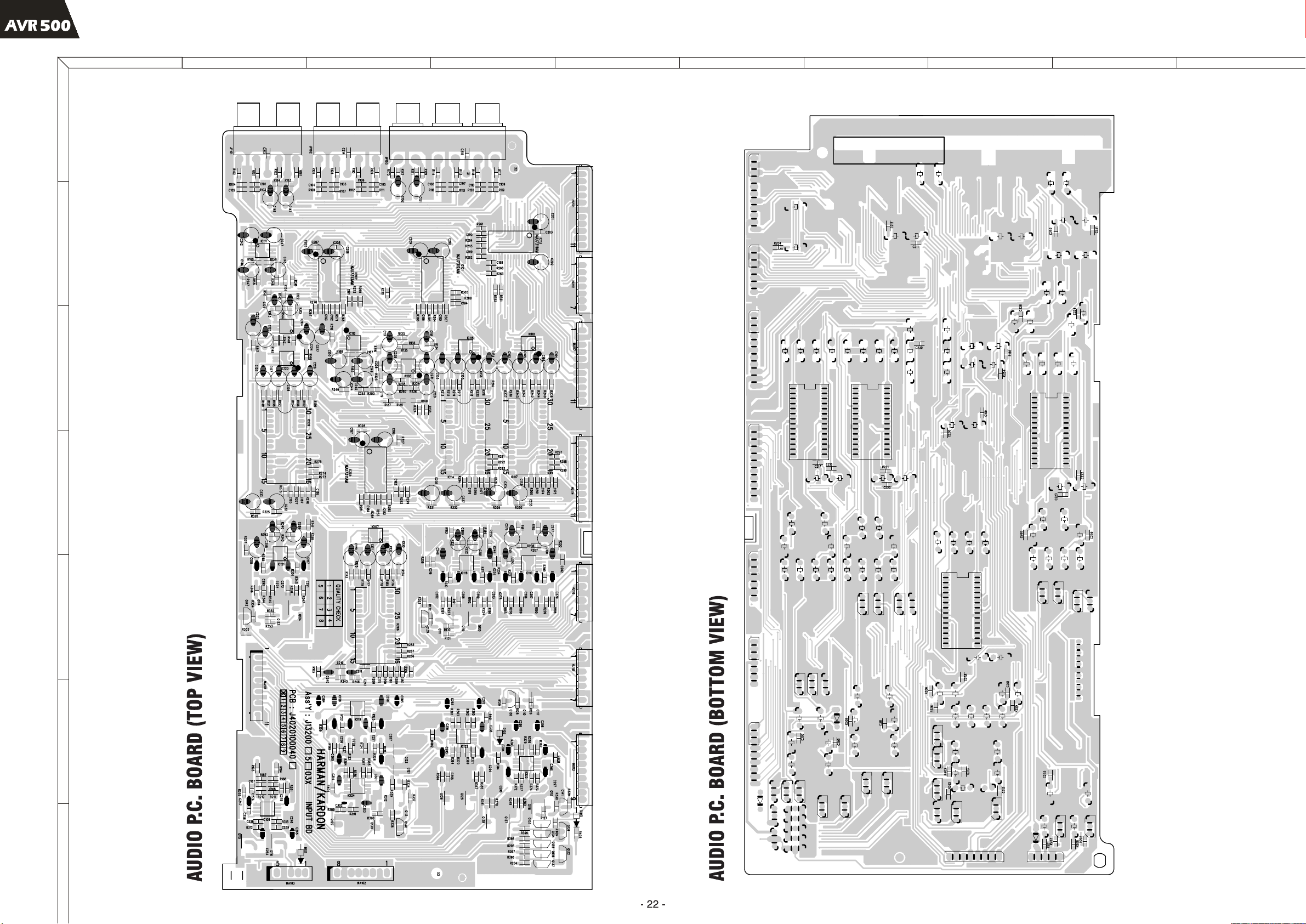

PC . BOARDS …………………………………..…27

ELECTRICAL PARTS LIST ………………….…..32

IC BLOCK DIAGRAMS …………………….….….55

CPU PIN CONFIGURATION……………….…….75

FLT PIN CONFIGURATION………………….…. 76

SCHEMATIC DIAGRAMS ……………..…….…..83

PIN CONNECTION DIAGRAM …………….……92

WIRING DIAGRAM ………………………….……93

PACKING MATERIAL AND PARTS LIST………94

Page 2

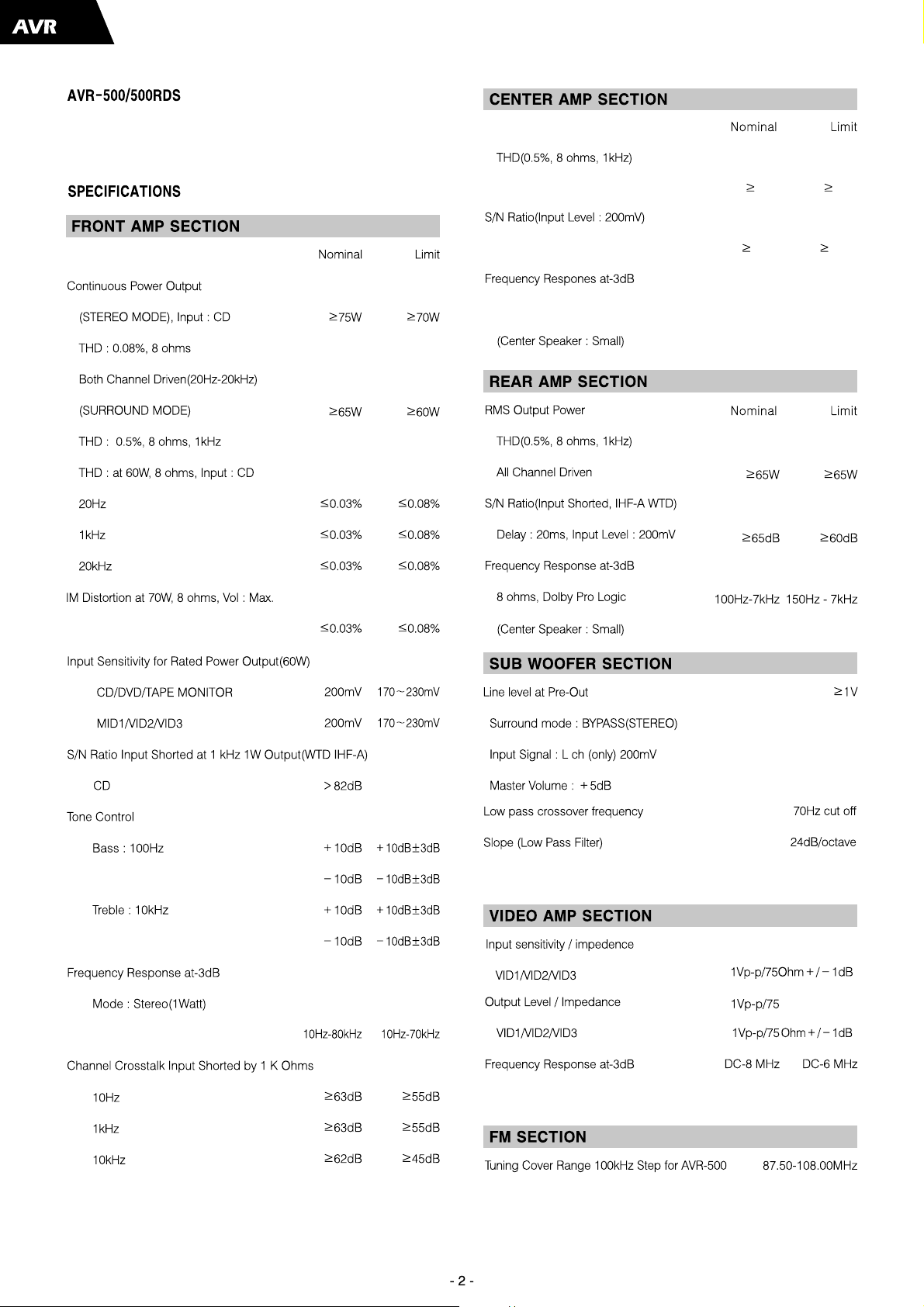

500

RMS Output Power

All Channel Driven

Input Shorted, IHF-A WTD

8 ohms, Dolby Pro Logic

65W 65W

65dB 60dB

100Hz-20kHz 150Hz-20kHz

Page 3

500

Page 4

500

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field effect transistors and

semiconductor "chip" components.

The following techniques should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to

prevent electrostatic charge build-up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can generate electrical charges

sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical change sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most replacement

ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material.)

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material to the

chassis or circuit assembly into which the device will be installed.

CAUTION :

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together

or your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ES devices.

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

Each precaution in this manual should be followed during servicing.

Components identified with the IEC symbol in the parts list are special significance to safety. When replacing a component identified with

, use only the replacement parts designated, or parts with the same ratings or resistance, wattage, or voltage that are designated in the

parts list in this manual. Leakage-current or resistance measurements must be made to determine that exposed parts are acceptably

insulated from the supply circuit before retuming the product to the customer.

-4-

Page 5

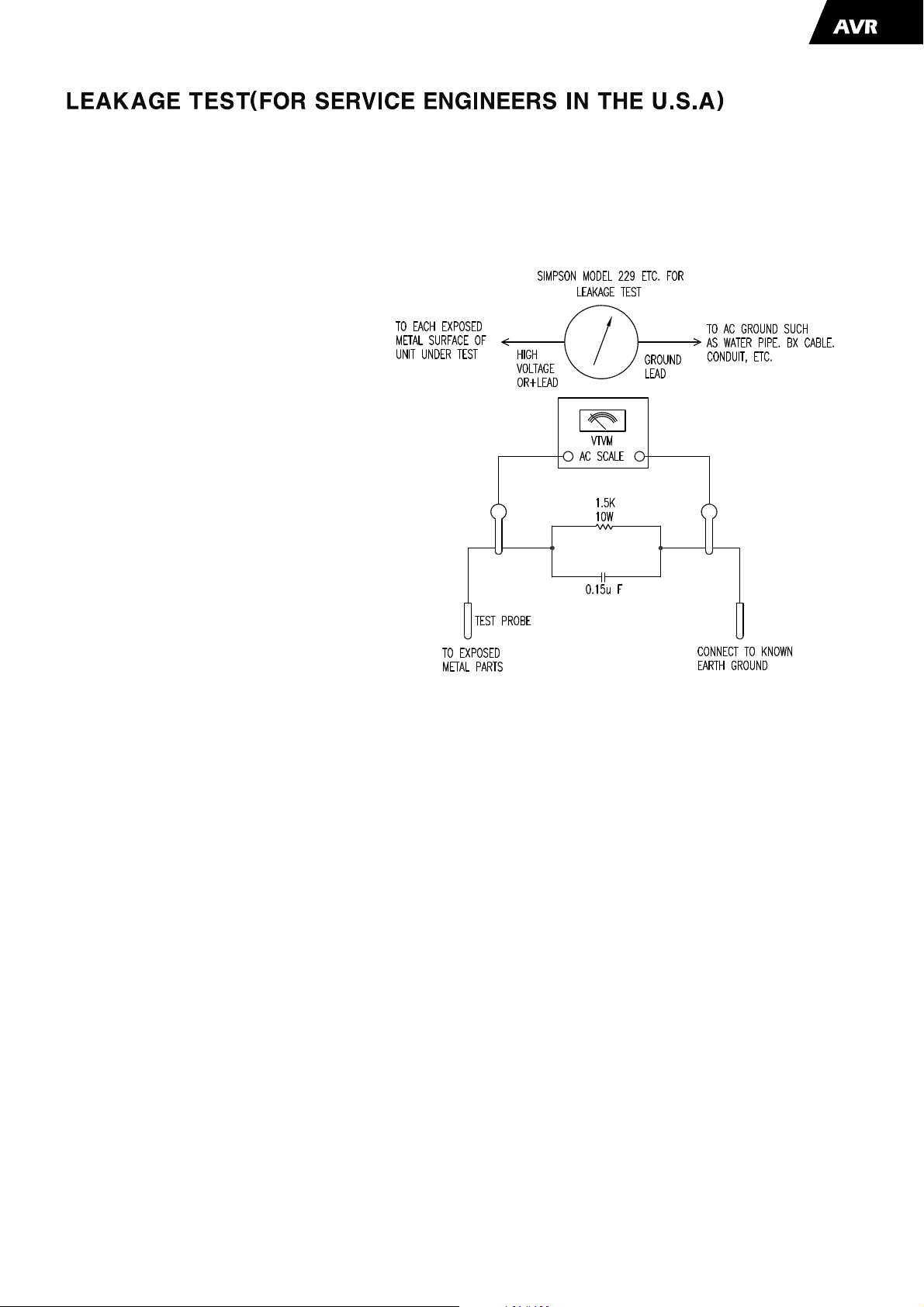

Before returning the unit to the user, perform the following safety checks :

1. lnspect all lead dress to make certain that

leads are not pinched or that hardware is not

lodged between the chassis and other metal

parts in the unit.

2. Be sure that any protective devices such as

nonmetallic control knobs, insulating fish-

papers, cabinet backs, adjustment and

500

compartment covers or shields, isolation

resistor-capacity networks, mechanical

insulators, etc. Which were removed for the

servicing are properly re-installed.

3. Be sure that no shock hazard exists ; check for leakage

current using Simpson Model 229 Leakage Tester, standard

equipment item No. 21641, RCA Model WT540A or use

alternate method as follows : Plug the power cord directly

Into a 120 volt AC receptacle (do not use an Isolation

Transformer for this test). Using two clip leads, connect a

1500 ohms, 10watt Resistor paralleled by a 0.15uF capacitor, in series with all exposed metal cabinet parts and a known earth ground, such

as a water pipe or conduit. Use a VTVM or VOM with 1000 ohms per volt, or higher sensitivity to measure the AC voltage drop across the

resistor. (See diagram) Move the resistor connection to each exposed metal part having a return path to the chassis (antenna, metal, be

performed with the 0.35 volt RMS or more is excessive and indicates a potential shock hazard which must be corrected before returning the

unit to the owner.

-5-

Page 6

Page 7

LR

SLEEP TUNED

STEREO

AUTOMONO PRESET

SURR. OFF

MUTE

PCM THEATER

LOGIC 7 C LOGIC 7 MVMAx3

-

STEREOPRO LOGICDIGITAL

COAX

OPT

12

ANALOG

NIGHT

MULTI

MEMORY

A

B

C

D

EG

N

O

K

M

L

X

WTUSRQ PV

F

H

I

J

A Coax Source

B Digital Source Input Number

C Optical Source

D Analog Source Indicator

E PCM Indicator

F Dolby Digital Indicator

G Analog Dolby Surround Mode Indicators

H VMAx Mode Indicator

I Theater Mode Indicator

J Logic 7 Mode Indicators

K DTS Mode Indicator

L Surround Off

M Multiroom System Indicator

N Night Mode Indicator

O Preset Number

P Preset Indicator

Q Memory

R Auto

S Mono Indicator

T Stereo Indicator

U Tuned Indicator

V Main Information Display

W Sleep Indicator

X Mute

A Coax Source:This indicator illuminates

when a digital source is in use via a connection

to the Coaxial Digital inputs e.

B Digital Source Input Number:These

indicators tell you which of the two digital

inputs is selected.This indicator works in cojunction with the Coax Source A and Optical

Source C indicators to show which form of

digital signal is in use.

C Optical Source:This indicator illuminates

when a digital source is in use via a connection

to the Optical Digital input d.

D Analog Source Indictor: This indicator

illuminates when an analog input source is in use.

E PCM Indicator:This indicator illuminates

to show that a standard PCM (S/P-DIF) digital

audio signal is being decoded by the digital-toanalog converter.

F Dolby Digital Indicator:This indicator

illuminates when a Dolby Digital source is

being played.

G Analog Dolby Surround Mode

Indicators:These indicators illuminate when

one of the analog (matrix) Dolby Surround

modes is in use.

H VMAx Mode Indicator: This indicator illu-

minates to show that the VMAx mode is in use.

I Theater Mode Indicator: This indicator illu-

minates to show that the Theater mode is in use.

J Logic 7 Mode Indicators:These indica-

tors illuminate when the Logic 7 mode is in

use.LOGIC 7C appears for the Cinema ver-

sion of Logic 7, LOGIC 7M appears for the

Music version of Logic 7.

K DTS Mode Indicator:This indicator illumi-

nates when a DTS-encoded source is playing.

L Surround Off:This indicator illuminates

when the surround processing has been disabled by pressing the Surround Off button

Ù.When this indicator is lit, the AVR 500 will

play traditional stereo sound using the front-left

and front-right speakers only.

M Multiroom System Indicator:This indica-

tor illuminates when the multiroom system is in

operation.(See page 26 for more information

on the multiroom system.)

N Night Mode Indicator:This indicator

lights when the AVR 500 is in the Night mode,

which preserves the dynamic range of digital

program material at low volume levels.

O Preset Number:This two-digit display

indicates the station preset number that is

currently in use,or that is being entered.

P Preset Indicator:This indicator illuminates

when a station previously entered into the preset

memory is tuned.The number that appears below

the indicator is the preset station’s memory.

Q Memory:This indicator flashes when

entering presetsand other information into the

tuner’smemory.

R Auto: This indicator illuminates when the

Auto mode is in use for FM tuning.

S Mono Indicator:This indicator illuminates

when the tuner has been placed in the monaural

mode by pressing the Tune Mode button *.

Set the tuner for mono listening to reduce noise

and improve the quality of distant stereo signals.

T Stereo Indicator:This indicator illuminates

when an FM station is being tuned in stereo.

U Tuned Indicator:This indicator illuminates

when a station is being received with sufficient signal strength to provide acceptable listening quality.

V Main Information Display:This display

shows messages relating to the status,input

source,surround mode,tuner,volume level or

other aspects of unit’s operation.

W Sleep Indicator:This indicator is illumi-

nated when the Sleep function is in use.The

number that appears above the indicator is

the number of minutes remaining before the

AVR 500 will return to the Standby mode.

X Mute:This indicator illuminates to remind

you that the AVR 500’s output has been

silenced by pressing the Mute button ıf.

Press the Mute button again to return to the

previously selected output level.

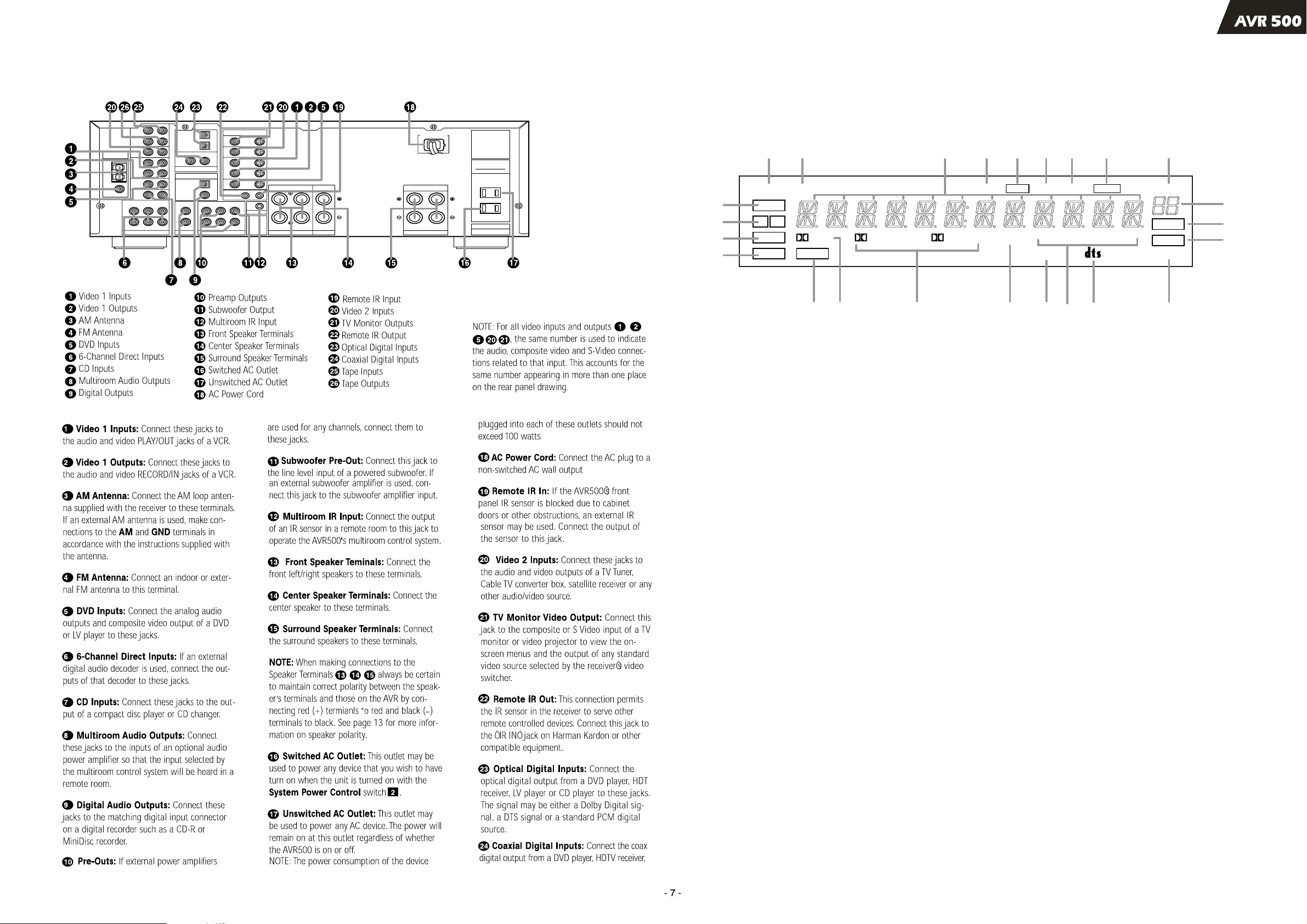

IN

TAPE

OUT

VIDEO

2

ANTENNA

IN

VIDEO

AM

1

OUT

GND

DVD

FM

(75½)

CD

SL

SR FRSUB WOOFER

6 CH. DIRECT MULTI OUT PRE OUT

FLCENTER

DIGITAL INPUT

OPTICAL

2

OPTICAL

1

COAXIAL 2 COAXIAL 1

DIGITAL INPUT

DIGITAL OUTPUT

OPTICAL

1

COAXIAL

1

ML

MR

VIDEO

TV

MONITOR

OUT

VIDEO 2

IN

VIDEO 1

VIDEO 1

OUT

DVD

OUT IN

REMOTE

CONTROL

SL

SUB WOOFERFL

MULTI IN

SR CENTERFR

RIGHT

SPEAKERS 8 Ohms SPEAKER 8 Ohm

FRONT

CENTER

LEFT CENTER

AC ~ 120V 60 Hz

SURROUND

RIGHT

SPEAKERS 8 Ohms

LEFT

MODEL NO. AVR 500

HARMAN KARDON

NORTHRIDGE

CALIFORNIA, USA

AC OUTLETS

(120V.60Hz)

TOTAL 150W or 1.5A MAX

UNSWITCHED

TOTAL 100W or 1A MAX.

SWITCHED

TOTAL 150W or 0.5A MAX.

SERIAL NO.

Page 8

Page 9

500

SERVICE PROCEDURE

1. All Clear

This service program can clear all memorized operations and functions.

When the POWER ON, press the "AM/FM" button while pressing the "PRO LOGIC"button.

After this, Preset memory will be set to these frequencies.

FM

AM

VERSION

120

230RDS

VERSION

120

230RDS

P1

87.5

87.50

P9

520

522

P2

88.0

88.00

P10

600

594

P3

90.0

90.00

P11

610

999

2. VFD segment illumination & text

This set do not have VFD segment check function because lack of u-com memory size

So For your checking VFD states according to each function

Please refer to owners manual process.

TEST EQUIPMENT REQUIRED

1) AM/FM Signal generator

2) Digital Multimeter

3) Distortion lever meter

P4

95.0

95.00

P12

1000

1395

P5

98.0

98.00

P13

1400

1611

P6

99.0

99.00

P14

1500

P7

106.0

106.00

P15

1710

P8

108.0

108.00

4. FM STEREO Separation Adjustment

Input Signal Source

step

1

2

Connection

Signal generator

output to FM

antenna

terminal.(750hm)

Signal

Frequency

98MHz

4. AM OSC Adujstment

Input Signal Source

step

1

Connection

Signal Generator

output to transmission

loop antenna

(standard required loop)

Signal

Frequency

522kHz

(230,230RDS)

520kHz(120)

Source Signal Output Level and

Modulation

same specification as

distortion adjustment.

Input only L channel

same specification as

distortion adjustment.

Input only R channel

Source Signal Output Level and

Modulation

5mV/m(74dBu)

MOD.30%

FM STEREO

FM STEREO

400Hz

Reception

Frequency

98MHz

(P5)

98MHz

(P5)

Reception

Frequency

522kHz

(230,230RDS)

520kHz

(120)

(P9)

Adjustment

Point

VR803

VR803

Adjustment

Point

T802

Adjustment

Value

Output level

at TAPE-OUT

channel R

Output level

at TAPE-OUT

channel R

Adjustment

Value

1.1V 1.2V

Minimum

Minimum

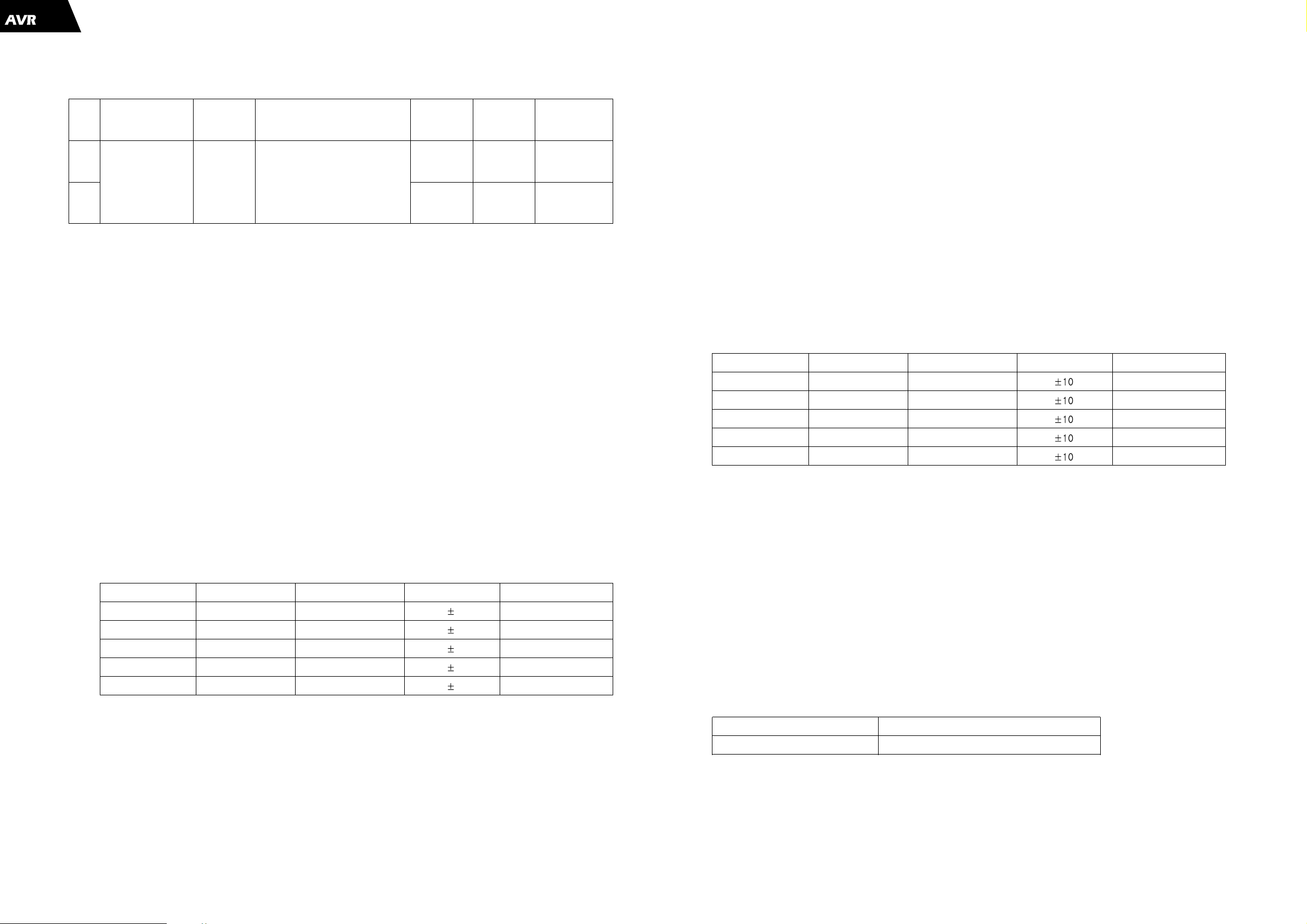

ALIGNMENT PROCEDURES

1. FM MONO. Distortion adjustment

Input Signal Source

step

1

2

Connection

Signal generator

output to FM

antenna

terminal.(750hm)

Signal

Frequency

98MHz

Source Signal Output Level and

Modulation

1000uV/m (60dBu)

MONO 1kHz/

Dev. 75kHz

2. FM MUTING LEVEL ADJUSTMENT

Turn variable resistor VR801 and stop at position "TUNED" is not shown (not indicated), then again turn the variable resistor VR801 to the

opposite revolution and stop at a position "TUNED" is shown.

Input Signal Source

step

1

2

Connection

Signal generator

output to FM

antenna

terminal.(750hm)

Signal

Frequency

98MHz

Source Signal Output Level and

Modulation

10uV/m (20dBu)

MONO 1kHz/

Dev. 75kHz

Reception

Frequency

98MHz

(P5)

Reception

Frequency

98MHz

(P5)

AUTO

SCAN

Adjustment

Point

T804

T805

Adjustment

Point

VR801

Only confirm

Adjustment

Value

0mV 0.5mV

(R831)

Distortion

level

Minimum

TAPE-OUT

Adjustment

indicate on VFD

indicate on VFD

at

Value

"TUNED"

"TUNED"

5. AM-Tracking Adjustment (MW)

Input Signal Source

step

1

2

Connection

Signal Generator

output to transmission

loop antenna

(standard required loop)

Frequency

(230,230RDS)

600kHz(120)

(230,230RDS)

1400kHz(120)

6. AM IF Adjustment

Input Signal Source

step

1

Connection

Signal Generator

output to transmission

loop antenna

(standard required loop)

Frequency

(230,230RDS)

1000kHz(120)

Signal

594kHz

1395kHz

Signal

999kHz

Source Signal Output Level and

Modulation

5mV/m(74dBu)

400Hz

MOD.30%

Source Signal Output Level and

Modulation

5mV/m(74dBu)

400Hz

MOD.30%

Reception

Frequency

594kHz

(230,230RDS)

600kHz(120)

Reception

Frequency

999kHz

(230,230RDS)

1000kHz

(120)

Adjustment

Point

T801

CT801

Adjustment

Point

T803

Adjustment

Value

Output level(L or R)

Minimum

TAPE-OUT

Output level(L or R)

Minimum

TAPE-OUT

Adjustment

Output level(L or R)

Maximum

TAPE-OUT

Output level(L or R)

Maximum

TAPE-OUT

at

at

Value

at

at

-9-

Page 10

500

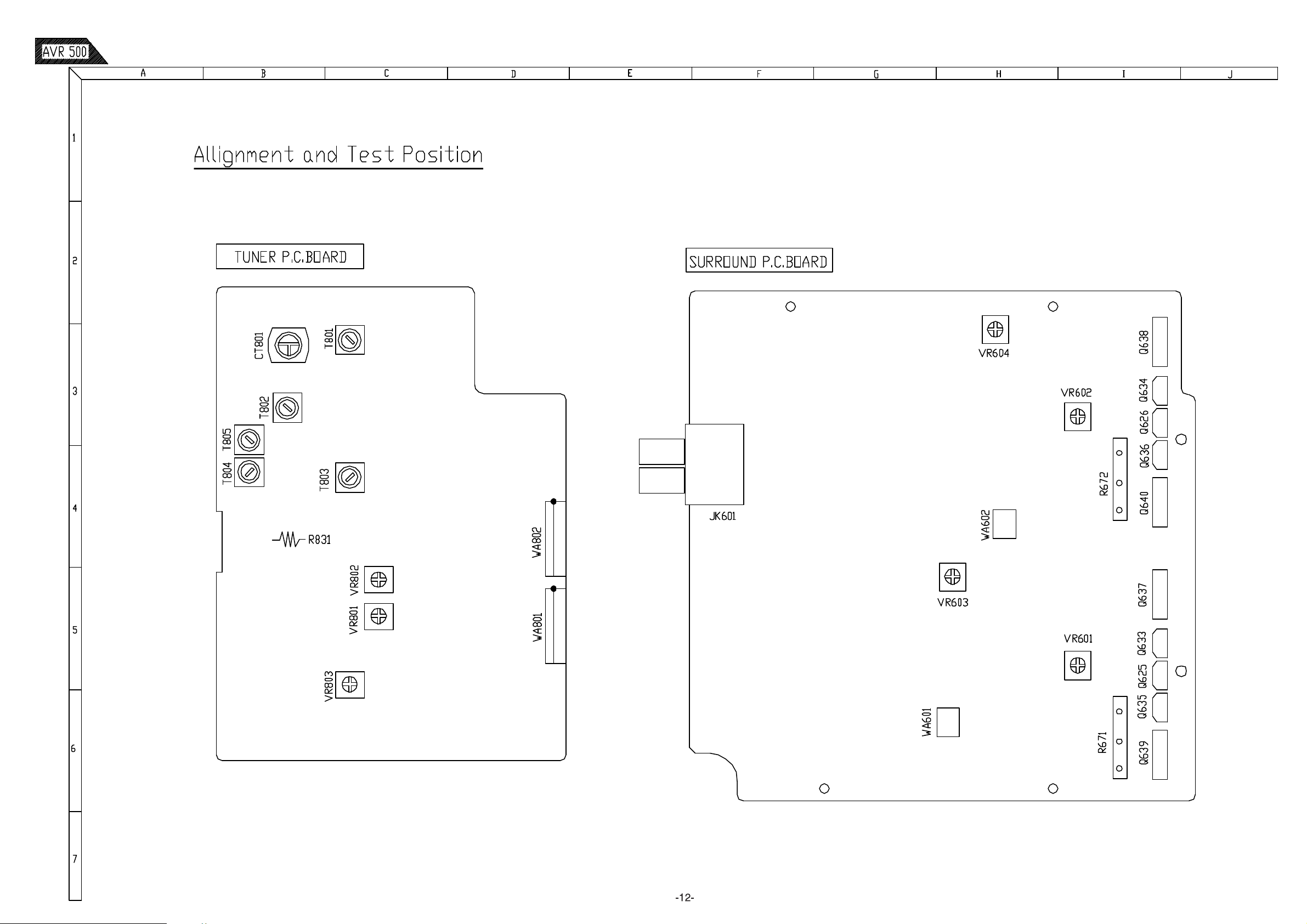

7. AM auto stop Adjustment

9. Main Amp DC OFFSET VOLTAGE Adjustment

Input Signal Source

step

1

2

Connection

Signal Generator

output to transmission

loop antenna

(standard required loop)

Signal

Frequency

999kHz

(230,230RDS)

1000kHz

(120)

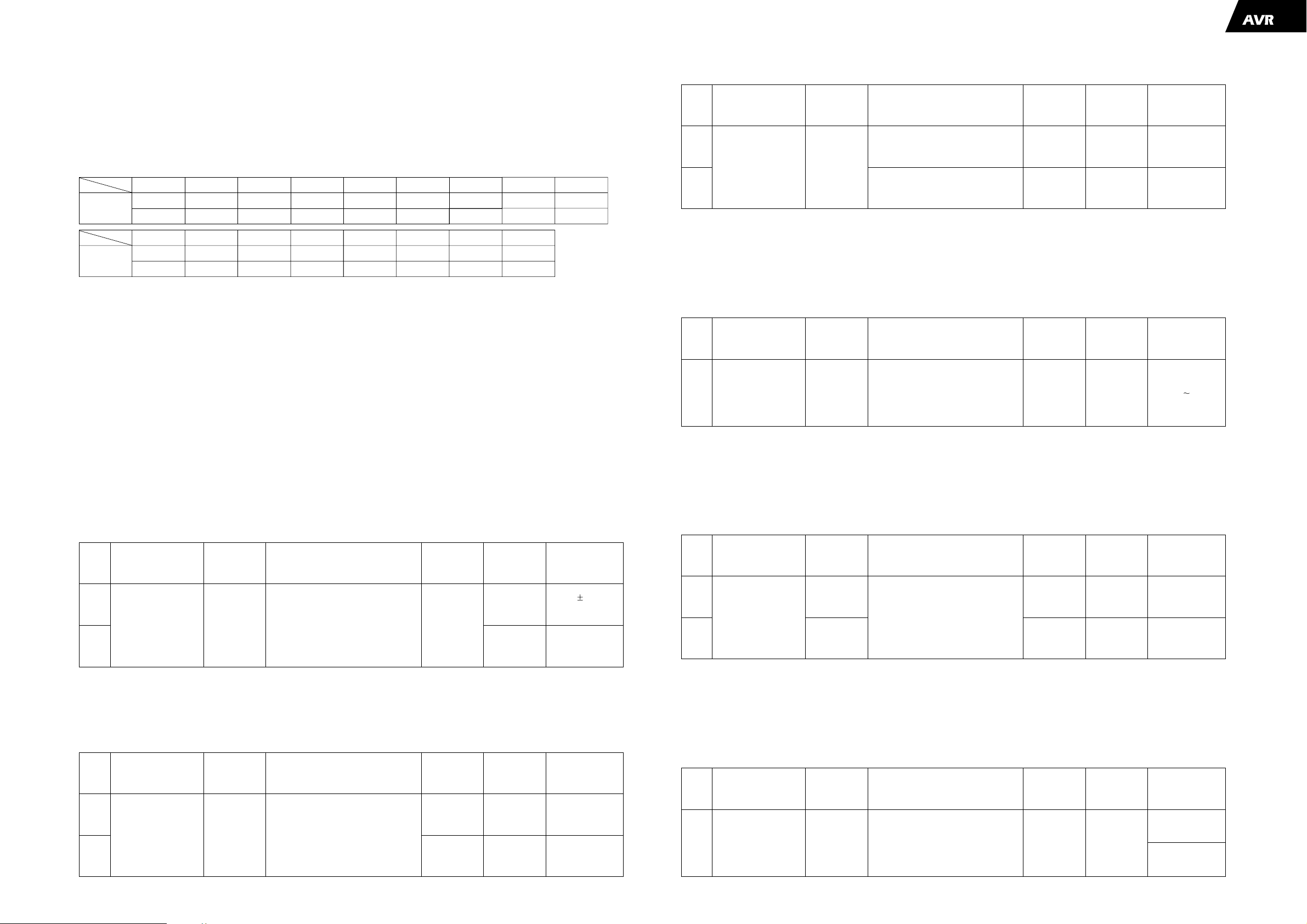

8. Main Amp ldling current Adjustment

(1) SET CONDITION

1) SEMI VOLUME POSITION at MAIN/SURROUND AMP Board; CENTER

MAIN : VR401, VR402, VR501

SURROUND : VR601, VR602

2) NO signal / NO LOAD

3) AC LINE VOLTAGE : 120V/60Hz, 230V/50Hz

Source Signal Output Level and

Modulation

1000uV/m(60dBu)

400Hz

MOD.30%

Reception

Frequency

999kHz

(230,230RDS)

1000kHz(120)

AUTO SCAN

Adjustment

Point

VR802

Only

Confirm

Adjustment

Value

"TUNED"

indicate on

VFD

"TUNED"

indicate on

VFD

(1) SET CONDITION

1) SEMI VOLUME POSITION at MAIN/SURROUND AMP Board; CENTER

MAIN : VR403, VR404, VR502

SURROUND : VR603, VR604

2) NO signal / NO LOAD

3) AC LINE VOLTAGE : 120V/60Hz, 230V/50Hz

(2) After turning on the unit, keep it over than 5MIN. (Keep the Power/Drive TR as normal temperature)

(3) Adjust the voltage value of primary & secondary of wafer to be 10mV by rotating the semi-volume

of each channel to the right

CHANNEL ADJUSTMENT MEASUREMENT OTHERS

FRONT-L ch

FRONT-R ch

CENTER ch

SURROUND-L ch

SURROUND-R ch

VR403

VR404

VR502

VR603

Vr604

JK401

JK402

JK501

JK601

JK601

VOLAGE

0mV

0mV

0mV

0mV

0mV

(2) After turning on the unit, keep it over than 5MIN. (Keep the Power/Drive TR as normal temperature)

(3) Adjust the voltage value of primary & secondary of wafer to be 10mV by rotating the semi-volume

of each channel to the right

CHANNEL ADJUSTMENT MEASUREMENT OTHERS

FRONT-L ch

FRONT-R ch

CENTER ch

SURROUND-L ch

SURROUND-R ch

(4) CAUTION

1) In case that POWER TR or DREVE TR is needed to be replaced for repairing, the corresponding channel

should be adjusted again

* FRONT AMP : Q433~Q440

* CENTER AMP : Q517~Q520

* SURROUND AMP : Q633~Q640

VR401

VR402

VR501

VR601

VR602

WA401

WA402

WA501

WA601

WA602

VOLAGE

10 3mV

10 3mV

10 3mV

10 3mV

10 3mV

R401:22.7mA

R472:22.7mA

R501:22.7mA

R601:22.7mA

R602:22.7mA

(4) CAUTION

1) In case that POWER TR or DREVE TR is needed to be replaced for repairing, the corresponding channel

should be adjusted again

* FRONT AMP : Q401~Q440, Q411~Q414

* CENTER AMP : Q501, Q502, Q506, Q507

* SURROUND AMP : Q601~Q604, Q611~Q614

10. Cautions for main Amp adjustment

(1) At MAIN/SURROUND BOARD, use the below condensors after discharging for sufficent time

for preventing possible damage from electrical spark.

MAIN BOARD C481, C482 (10000/63V, 8200uF/63V)

SURROUND BOARD C691, C692 (6800/63V, 6800uF/50V)

(2) The checker for MAIN/SURROUND BOARD should have the discharging circuit.

Discharge over 30sec. through (407ohm 10w) resistor after turning off

-10-

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

harman/kardon Service Bulletin

Service bulletin # H/K2000-02 Rev1 January 2001 Warranty labor rate: MAJOR repair

To: All harman/kardon Service Centers

Models: AVR300, AVR500

Subject: Random Noise, Erratic Output in DTS Mode

In the event you receive an AVR300 or AVR500 receiver with the complaint “there is distortion, random

noise or gaps in the program material when in the DTS mode”, perform the following procedure:

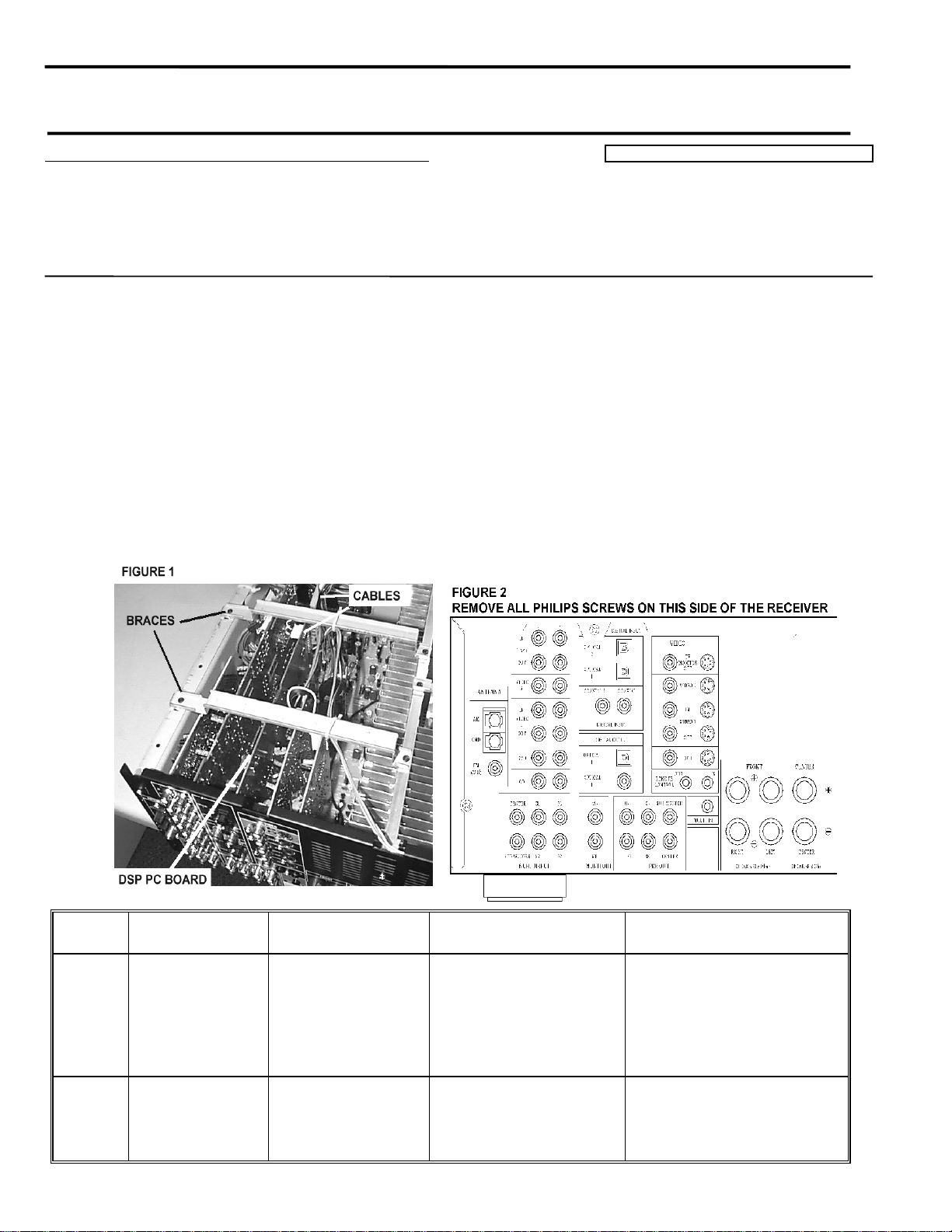

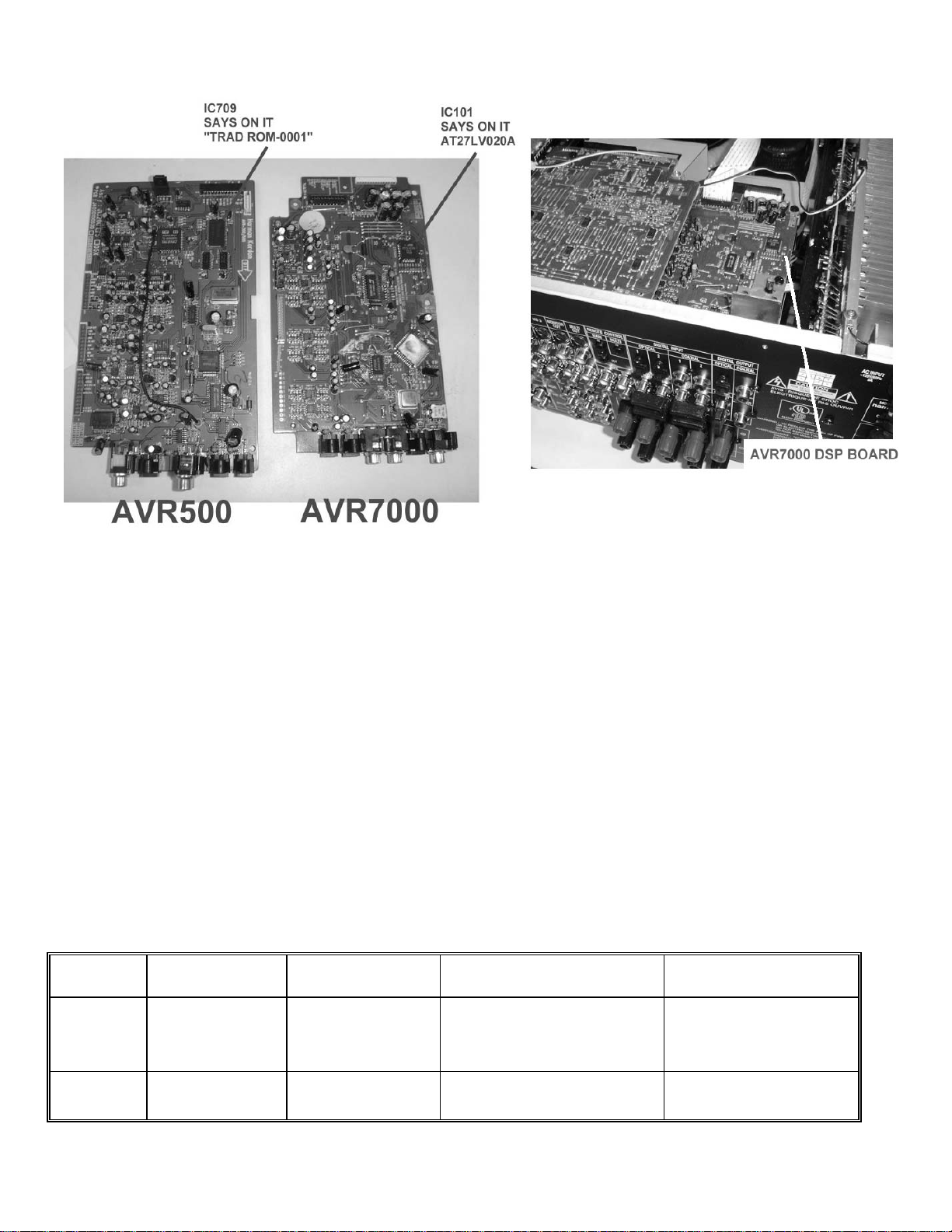

REMOVAL AND MODIFICATION OF THE DSP BOARD

1) Remove the top cover, (14) Black Phillips screws.

2) Locate the DSP PC Board; Figure 1. Remove the two metal braces at the top of the unit. If necessary, cut

the cable ties attached to the braces to move any wires away from the area.

3) Pull the white 22 conductor ribbon cable at the rear of the DSP PC Board straight out of its receptacle.

4) Unplug the white 5 conductor molex cable at the top of the DSP PC Board.

5) Remove the (33) plated Phillips screws on the left side of the rear backplate; see Figure 2. Do not remove

any additional screws on the right side. If using a power tool, use care and minimum effort to avoid damaging

the various plastic receptacles.

6) Remove all three black plastic plugs that cover the optical inputs at the rear of the DSP PC Board.

7) Pull on the left side of the rear backplate, away from the receiver chassis; you should be able to pull it away

enough to allow the DSP PC Board to be pulled straight up and out of the receiver.

8) Proceed with the modifications on page 2.

1

Model Serial Number

120V

AVR300

AVR500

AVR300

AVR500

TH0001-01000

To

TH0001-13886

TH0002-01000

To

TH0002-10460

TH0001-13887

Or higher

TH0002-10461

Or higher

Serial Number

230V RDS

TH0005-01000

To

TH0005-03317

TH0006-01000

To

TH0006-02795

TH0005-03318

Or higher

TH0006-02796

Or higher

STATUS ACTION

Random Noise, Erratic

Output or Gaps in Program

Material when in DTS Mode

Modified by factory NONE REQUIRED

Modifications to DSP Board:

Add ground wire;

Change R756 & R755

from 600W resistor or Capacitor

to 33W resistor

17

Page 18

Models: AVR300, AVR500 Subject: Random Noise, Erratic Output in DTS Mode

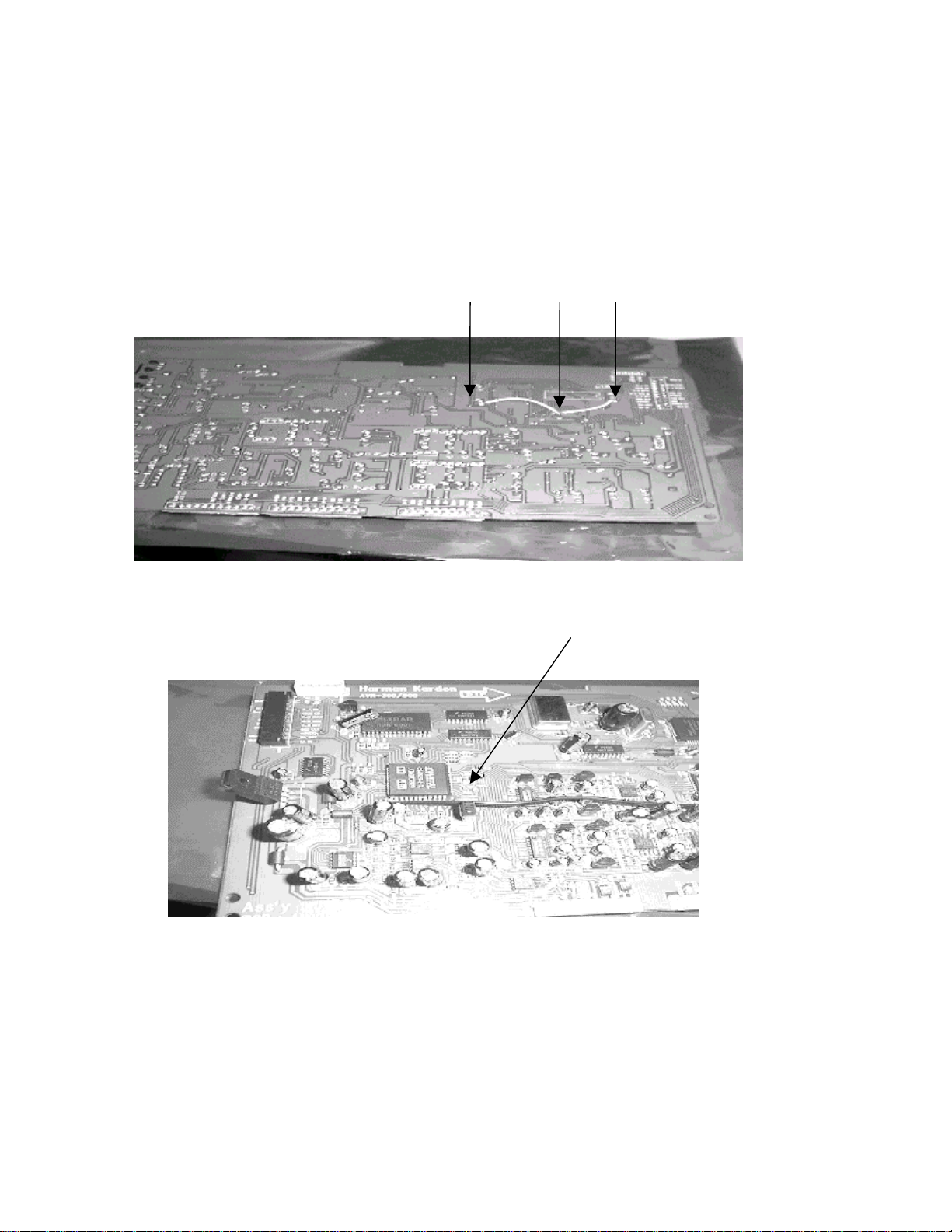

9) Ground Reinforcement:

Using an insulated 16AWG wire, Connect Negative sides of the following capacitors on the bottom side of the

PCB as shown below. Negative side of each cap will have a white mark on the component side of the PCB.

A. Negative polarity of C746 Elec Cap (1uF/50V) in the proximity of ROM IC709

B. Negative polarity of C749 Elec Cap (1uF/50V) in the proximity of IC708 DSP IC

C. Negative polarity of C744 Elec Cap (1uF/50V) in the proximity of IC710 74VHC574

C B A

2

10) Replace:

R756 & R755. Original parts may be 600W resistors, or Capacitors. Change both to 33W 1/10W

SMD resistors (h/k part#

11) Replace DSP PC Board back into its (3) receptacle plugs atop the MAIN PCB.

12) Replace all screws, braces, and any cable ties that were cut during disassembly. Before tightening the

screws, make sure all PCB’s and their RCA jacks are firmly seated in their respective holes in the rear

backplate. If using a power tool, use care and minimum effort to avoid damaging the various plastic

receptacles.

13) Plug both the 22 conductor ribbon cable and the 5 conductor molex cable back into their receptacles.

14) Replace the top cover and optical plugs.

15) Test unit by powering up the receiver and playing a source with DTS encoded material; confirm the complaint

of Random Noise or Erratic Output is no longer occurring.

292-33.2). See location below.

18

Page 19

harman/kardon Service Bulletin

Service bulletin # H/K2000-04 Rev1 February 2003

AVR500 MAJOR repair

To: All harman/kardon Service Centers AVR7000 MINOR repair

Models: AVR500/AVR7000

Subject: Noise in Logic 7 Mode

In the event you receive an AVR500 or AVR7000 receiver with the complaint “There is crackling, noise,

or distortion coming from my loudspeakers when my receiver is in the Logic 7 mode with certain

program material playing”, perform the following procedure:

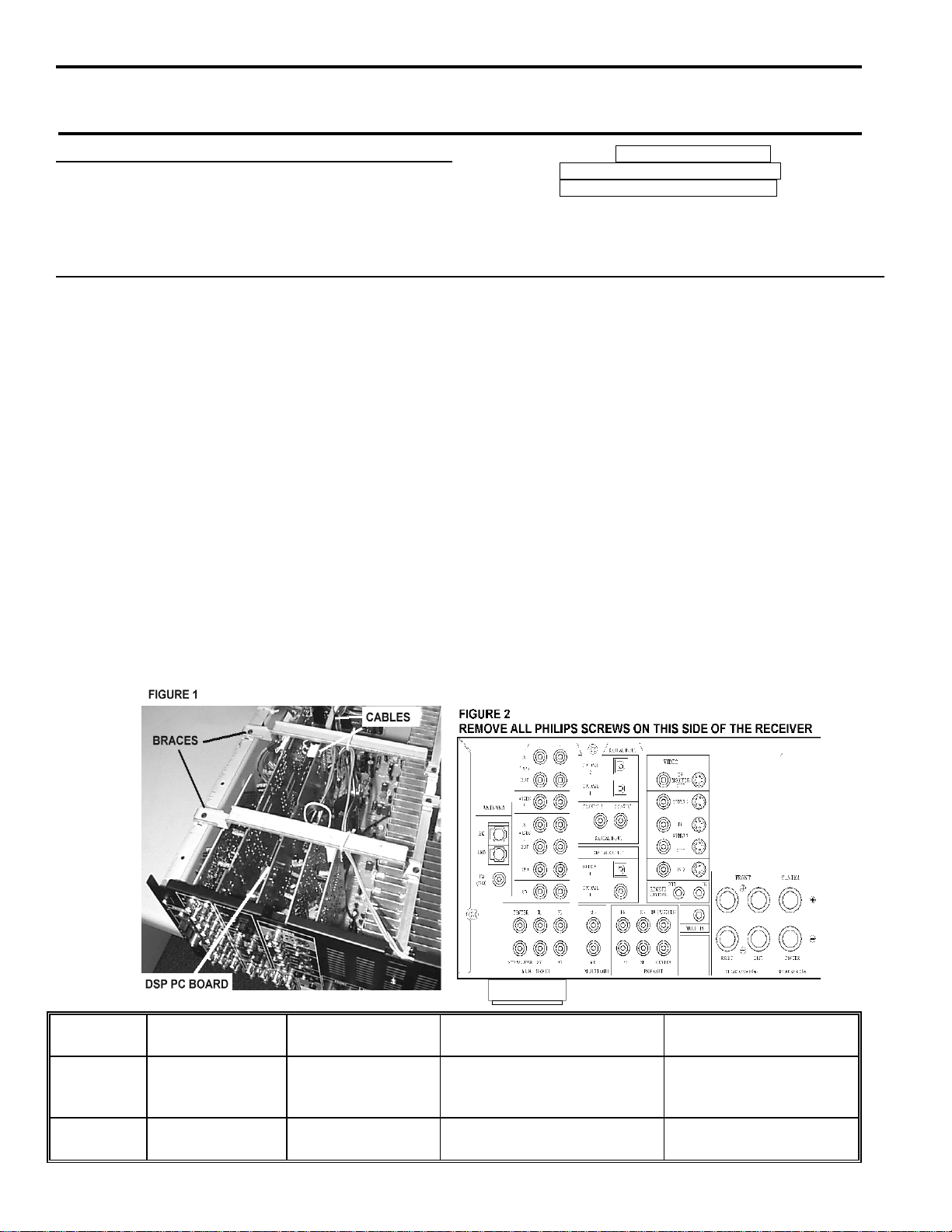

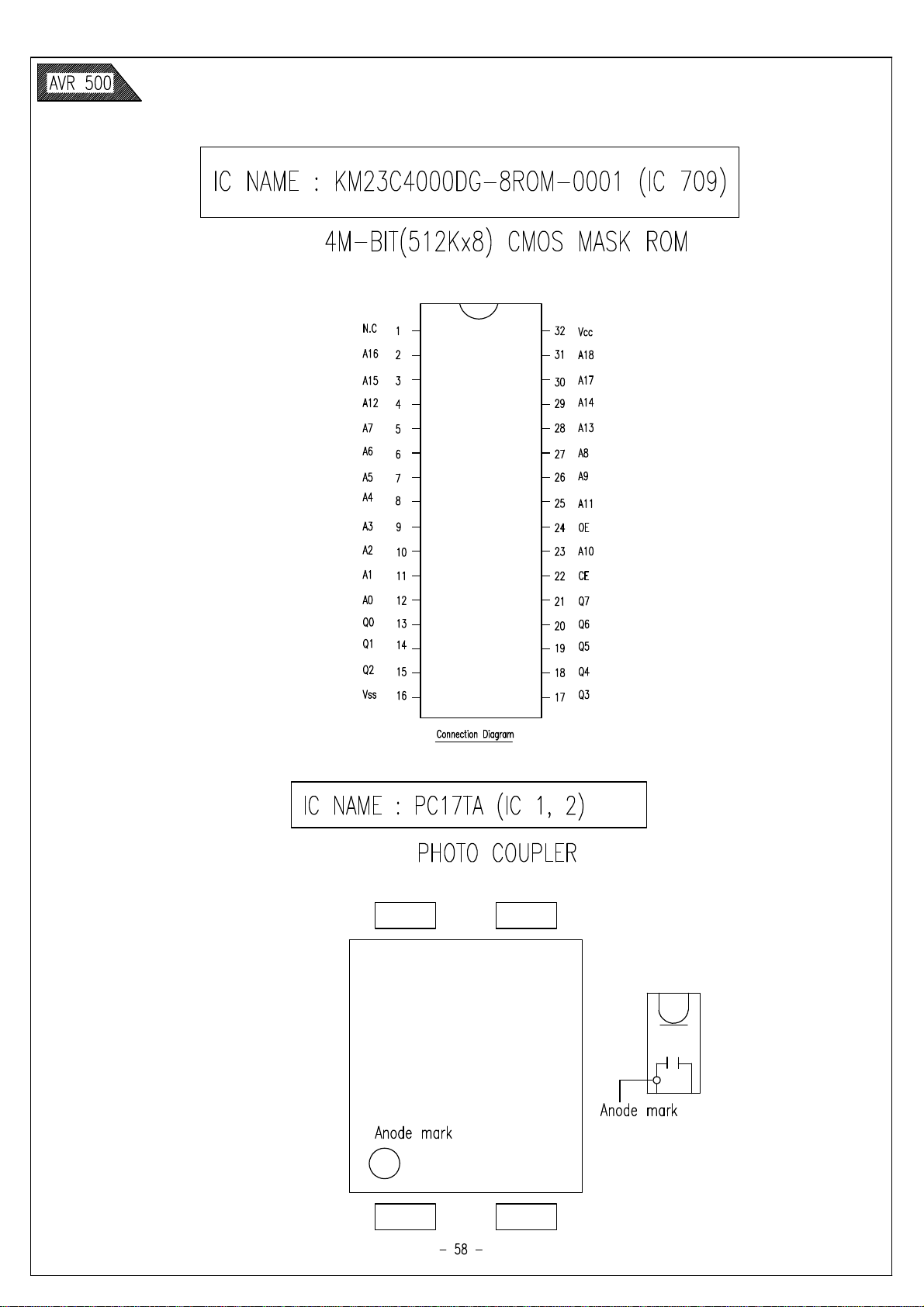

AVR500 ONLY: REMOVAL AND MODIFICATION OF THE DSP BOARD (replace IC709 TRAD ROM-0001)

WARNING: FOLLOW PROPER STATIC CONTROL PROCEDURES and use caution during the removal of the

DSP board, and during installation of new IC709 to prevent damage.

1) Remove the top cover, (14) Black Phillips screws at the sides and rear of the unit.

2) Locate the DSP PC Board; Figure 1. Remove the two metal braces at the top of the unit. If necessary, cut

the cable ties attached to the braces to move any wires away from the area.

3) Pull the white 22 conductor ribbon cable at the rear of the DSP PC Board straight out of its receptacle.

4) Unplug the white 5 conductor molex cable at the top of the DSP PC Board.

5) Remove the (33) plated Phillips screws on the left side of the rear backplate; see Figure 2. Do not remove

any additional screws on the right side. If using a power tool, use care and minimum effort to avoid

damaging the various plastic receptacles.

6) Remove all three black plastic plugs that cover the optical inputs at the rear of the DSP PC Board.

7) Pull on the left side of the rear backplate, away from the receiver chassis; you should be able to pull it away

enough to allow the DSP PC Board to be pulled straight up and out of the receiver.

8) Unsolder IC709 TRAD ROM-0001 and replace with hk part# J21310030011. See illustration on following

page for location on PCB.

Warranty labor rate:

Model Serial Number

120V

AVR500

AVR500

TH0002-01000

To

TH0002-14977

TH0002-14978 or

higher

Serial Number

230V RDS

TH0006-01000

To

TH0006-05105

TH0006-05106 or

higher

STATUS

Noise in Logic 7 Mode

Modified by factory

19

ACTION

Replace IC709

TRAD ROM-0001

NONE REQUIRED

Page 20

Location of IC upgrade for the AVR500/AVR7000:

9) Replace DSP PC Board back into its (3) receptacle plugs atop the MAIN PCB.

10) Replace all screws, braces, and any cable ties that were cut during disassembly. Before tightening the

screws, make sure all PCB’s and their RCA jacks are firmly seated in their respective holes in the rear

backplate. If using a power tool, use care and minimum effort to avoid damaging the various plastic

receptacles.

11) Plug both the 22 conductor ribbon cable and the 5 conductor molex cable back into their receptacles.

12) Replace the top cover and optical plugs.

13) Test unit by powering up the receiver and playing a music source in the Logic 7 mode.

AVR7000 ONLY: MODIFICATION OF THE DSP BOARD (replace IC101 AT27LV020A)

WARNING: FOLLOW PROPER STATIC CONTROL PROCEDURES and use caution during the installation of

new IC101 to prevent damage.

1) Remove the top cover, (16) Black Phillips screws at the sides and rear of the unit.

2) Locate the DSP PC Board and IC101 with the illustrations above.

3) Unsolder IC101 AT27LV020A and replace with hk part# 55172540AVR7000. See illustration above for

location on PCB.

4) Replace top cover and all Phillips screws.

5) Test unit by powering up the receiver and playing a music source in the Logic 7 mode.

Model Serial Number

120V

AVR7000

AVR7000

TH0003-01000

To

TH0003-05222

TH0003-05223

Or higher

Serial Number

230V RDS

Modified by factory

Modified by factory

STATUS

Noise in Logic 7 Mode

Modified by factory

NONE REQUIRED

ACTION

Replace IC101

AT27LV020A

20

Page 21

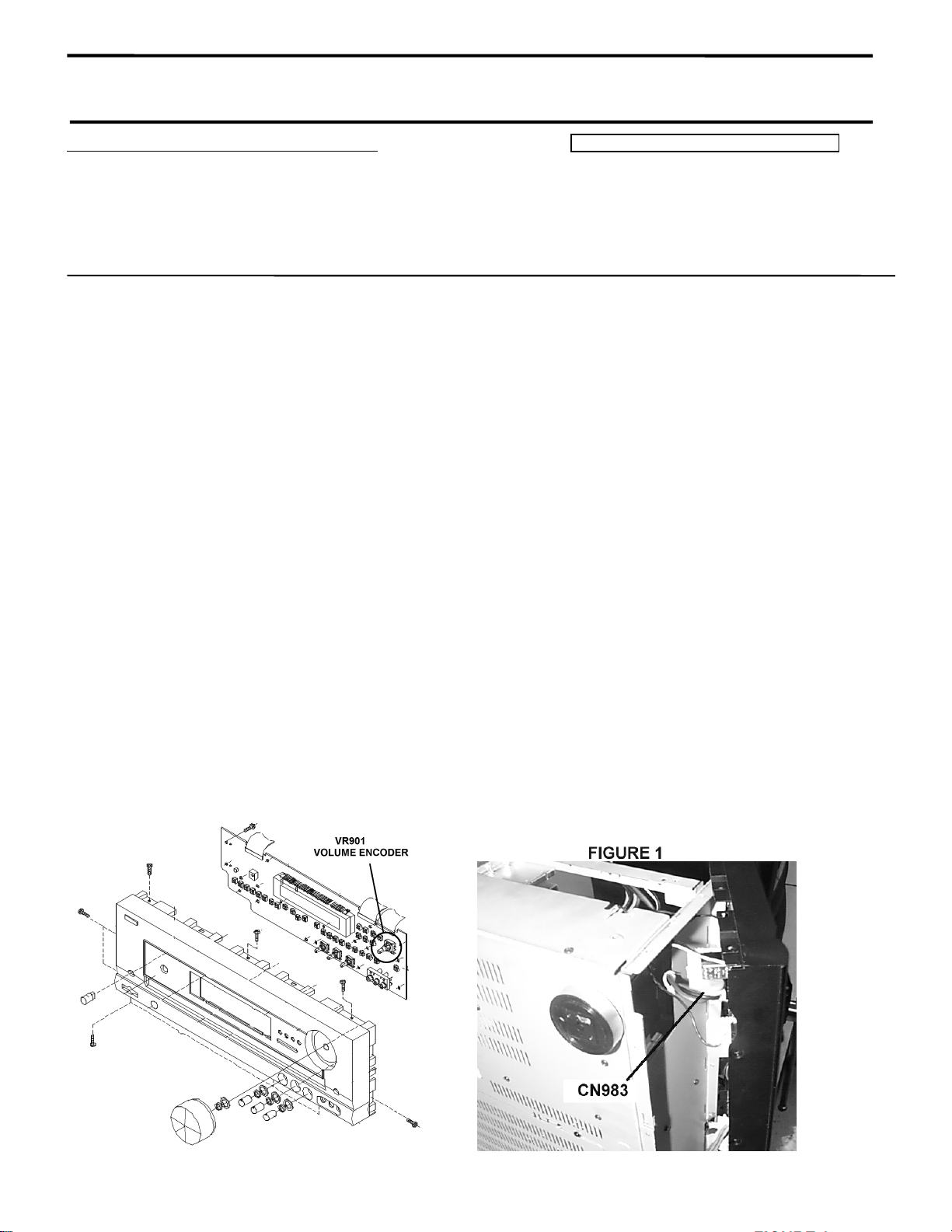

harman/kardon Service Bulletin

Service bulletin # H/K2000-05 May 2000 Warranty labor rate: MAJOR repair

To: All harman/kardon Service Centers

Models: AVR300, AVR500

Subject: Volume Level Changes

On early versions of the AVR300 or AVR500 the volume level may change by itself, or when the volume knob

is tapped. This may happen on an occasional random basis and depends on where the volume control knob is

positioned after a volume adjustment. During a running production change, new volume encoders were

installed.

In the event you receive an AVR300 or AVR500 with the complaint “The volume on my receiver

changes by itself”, perform the following procedure:

REPLACE VR901 VOLUME ENCODER

1) Remove the top cover, (14) Black Phillips screws.

2) Remove the (11) Black Phillips screws holding the plastic front panel to the chassis.

3) Remove the single Phillips screw on both right & left side of the chassis with a dual black ground wire.

4) Remove the volume, bass, treble and balance knobs by pulling them straight off.

5) Remove the single nut holding the volume encoder to the front panel.

6) Pull the loaded front panel off the chassis; cut any plastic cable ties necessary to fully disengage it

7) Lift and set the receiver on its right side for the remainder of the procedure.

8) Remove molex connector CN983 at the power switch; see Figure 1.

9) Pull the front panel as far away as the remaining connecting wires will allow.

10) Unsolder the connections at the rear of the front PCB to the volume encoder.

11) Using a “stubby” Phillips screwdriver, remove the (19) Black Phillips screws holding the front PCB to the

front panel; two plated screws at the rear of the headphone jack also must be removed.

12) Pull the front PCB away from the front panel.

13) Remove and replace the volume encoder with h/k part# J32612050102; resolder the new encoder in place.

14) Replace the front PCB and reassemble the receiver in reverse order, following the instructions above.

Replace all cable ties that were cut, and reattach any connectors that were unplugged. Make sure the two

ground wires on both sides of the receiver are reattached.

15) Power up receiver, and test volume control to assure it no longer changes settings by itself, or when the

volume knob is tapped.

21

Page 22

Models: AVR300, AVR500 Subject: Volume Level Changes

Model Serial Number

120V

AVR300

AVR500

AVR300

AVR500

TH0001-01000

To

TH0001-08402

TH0002-01000

To

TH0002-05565

TH0001-08403

Or higher

TH0002-05566

Or higher

Serial Number

230V RDS STATUS ACTION

TH0005-01000

To

TH0005-01001

TH0006-01000

To

TH0006-01001

TH0005-01002

Or higher

TH0006-01002

Or higher

Volume level changes by

itself or when volume

knob is tapped

Modified by factory NONE REQUIRED

Change VR901

Rotary encoder

22

Page 23

DISASSEMBLY PROCEDUREDISASSEMBLY PROCEDURE

1. Removingthe top cover, and

Removescrews

2. Removingthe front panel, and

Removescrews

4. Removingthe main PCBblock, and

Removescrews

5. Removingthe power PCBblock, and

Remove

3. Removingthe rear panel, and

Removescrews

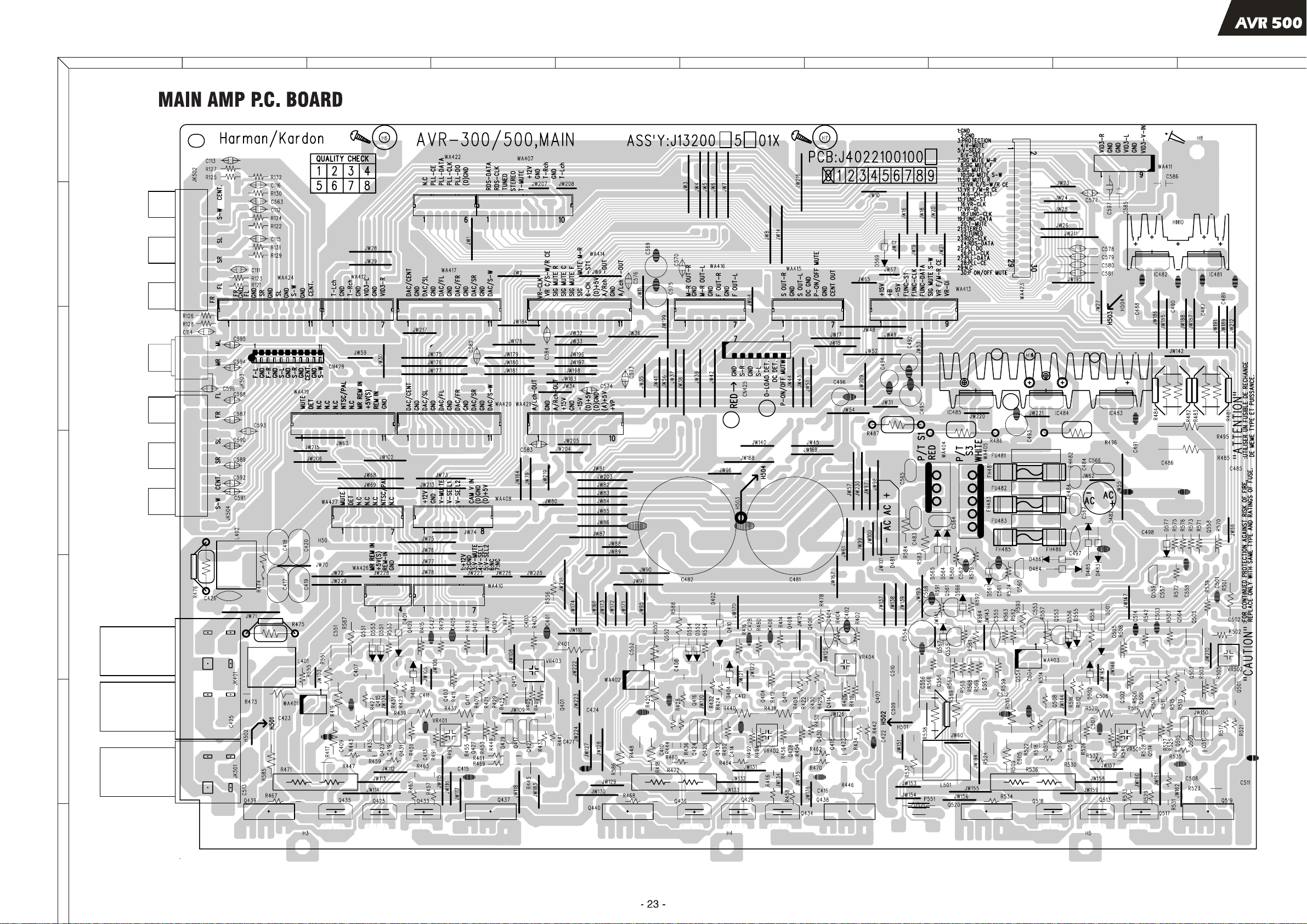

MAIN AMP PCB BLOCKMAIN AMP PCB BLOCK

1. Removeall of the screwson Rearpanel.

2. Removethe Rearpanel.

3. RemovePCBBrk t and Guide

4. Removeall of the screwsthat connect with main Assy.

5. Removethe Main PCBblock.

POWER PCB BLOCKPOWER PCB BLOCK

1. RemovePCBBrk t and Guide

2. Remove4 screwsfor Power PCBmounting

3. Removethe POWERPCBblock.

SUB PCB BLOCKSUB PCB BLOCK

1. Remove4 screwson Rearpanel.

2. Removethe Rearpanel.

3. RemovePCBBrk t and Guide

4. Removethe SUBPCBblock.

Brk t from Main Assy.

Brk t from Main Assy.

Brk t from Main Assy.

6. Removingthe sub PCBblock, and

Removescrews

FRONT PCB BLOCKFRONT PCB BLOCK

1. RemoveMain

2. Removevolume and rotary knob from the front

3. Removeall of the screwson back sideof Front function PCB.

4. Removethe Front function PCB.

Assy.

Assy.

23

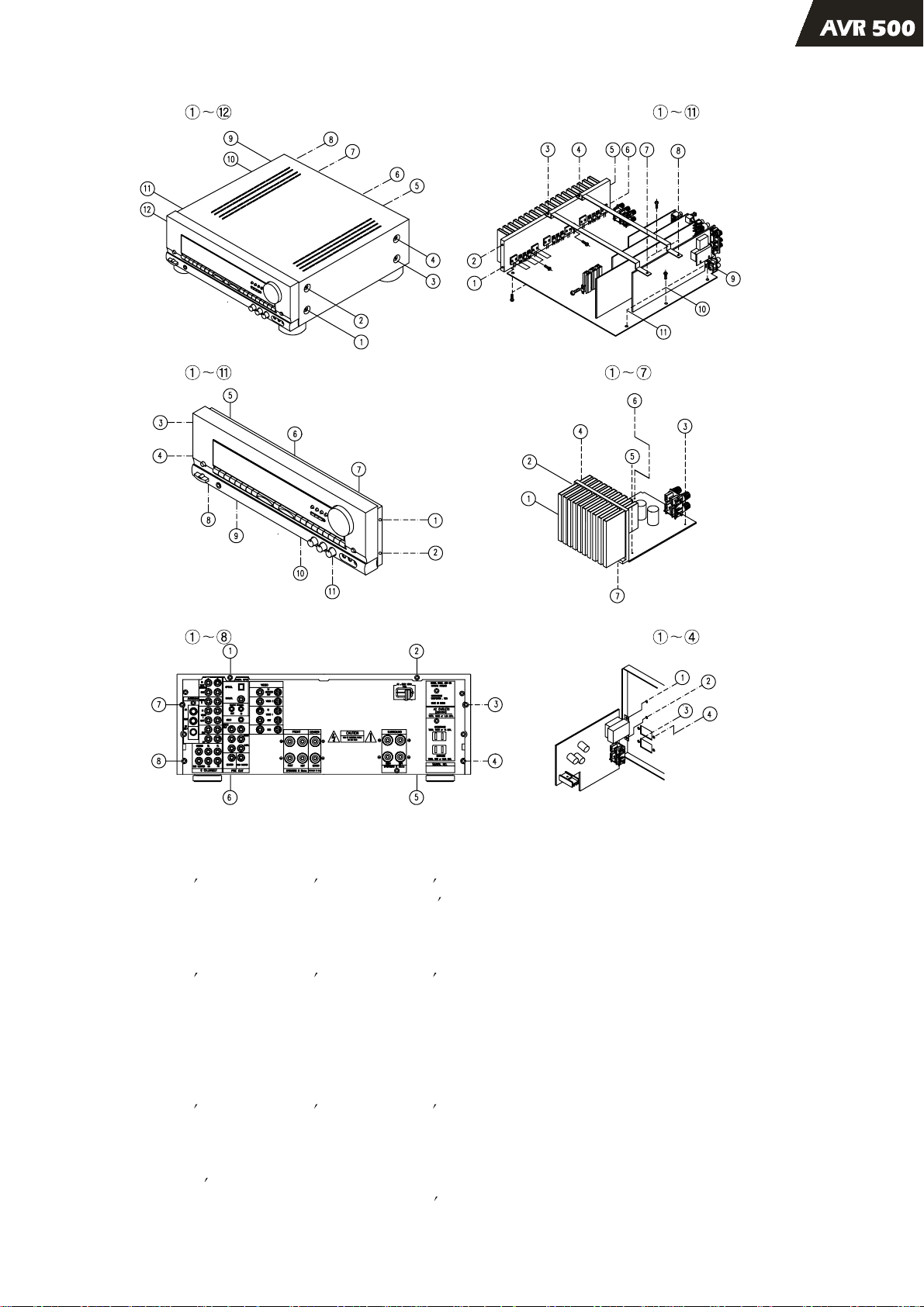

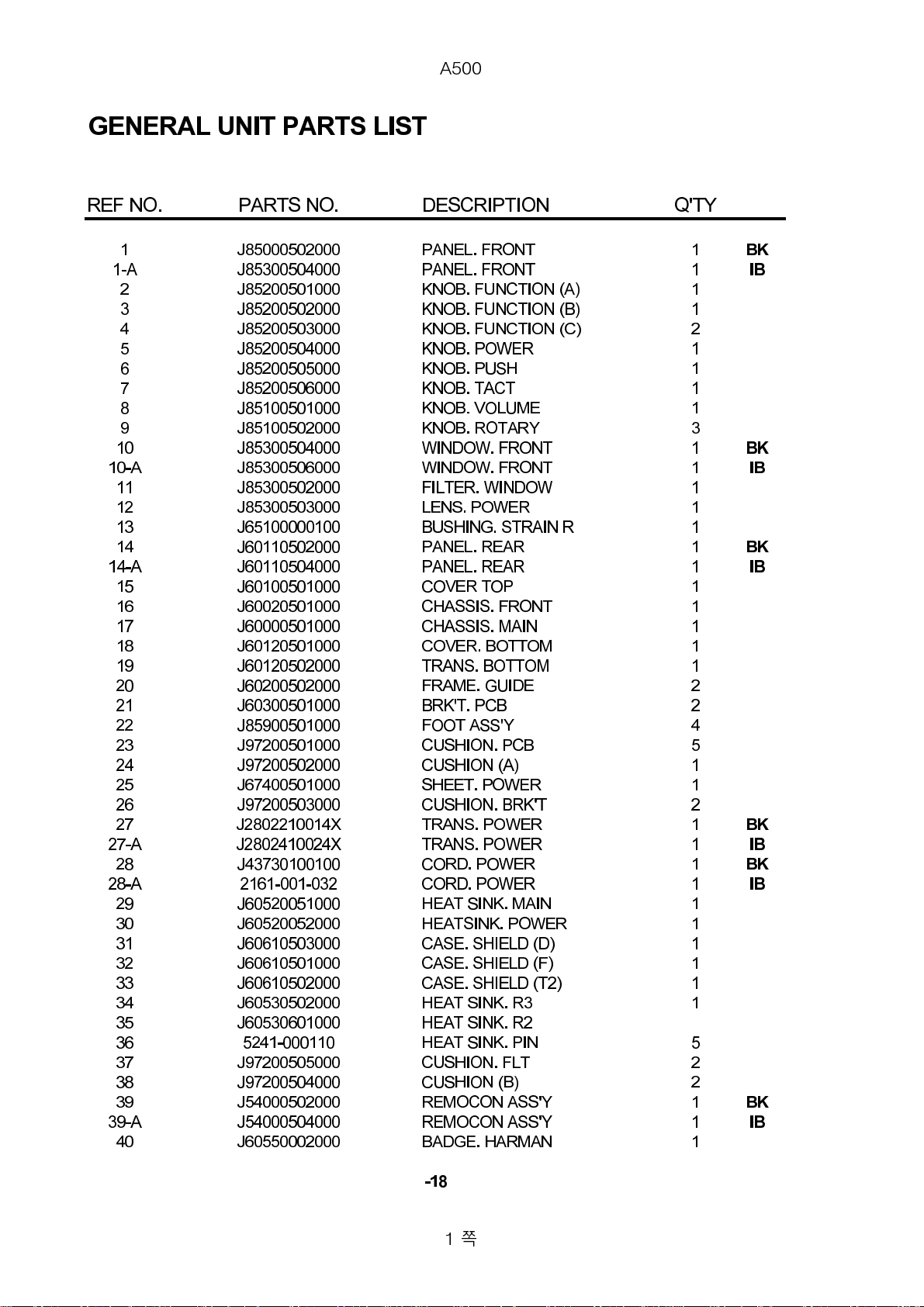

Page 24

24

Page 25

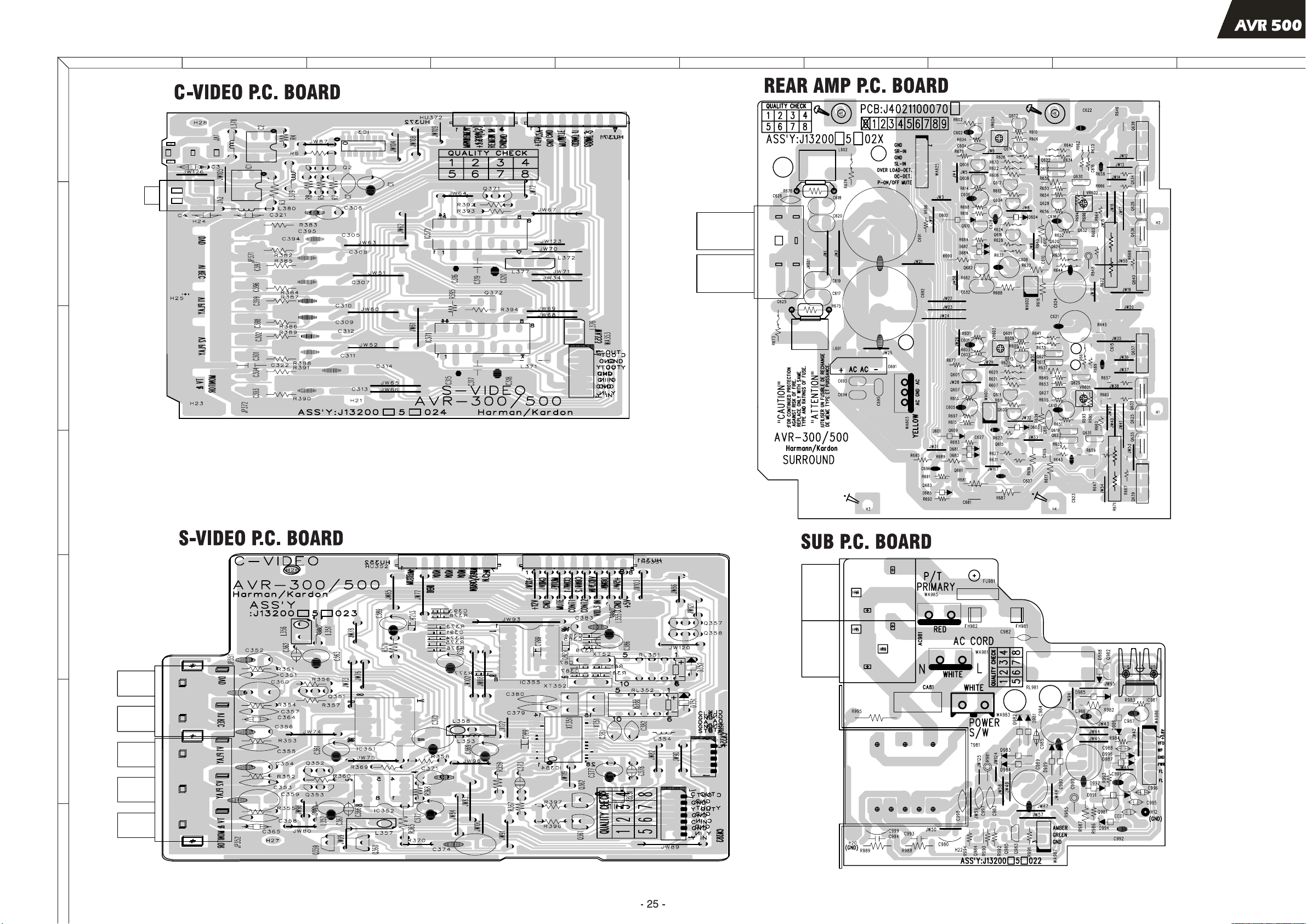

25

Page 26

26

Page 27

B C D E F G H I JA

27

1

2

3

4

5

6

7

Page 28

B C D E F G H I JA

28

1

2

3

4

5

6

7

Page 29

B C D E F G H I JA

29

1

2

3

4

5

6

7

Page 30

B C D E F G H I JA

30

1

2

3

4

5

6

7

Page 31

B C D E F G H I JA

31

1

2

3

4

5

6

7

Page 32

ELECTRIC PART LIST(500Serise) DSP P.C BOARD

32

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

J1320045205X DSP P.C. BOARD

J1320045105X DSP P.C. BOARD

IB

BK L 704 J2631200010X HC3550 9.4ohm AXIAL

INTEGRATED CIRCUITs

IC 1 J2142930002X 74VHCT04SJX HEX INVERT L 707 J2631200010X HC3550 9.4ohm AXIAL

IC 2 J2120012001X NJM4558M OP-AMP L 708 J2631200010X HC3550 9.4ohm AXIAL

IC 701 J2120012002X NJM072M OP-AMP L 709 J2631200010X HC3550 9.4ohm AXIAL

IC 702 J2120012002X NJM072M OP-AMP L 821 J2631200010X HC3550 9.4ohm AXIAL

IC 703 J2133926002X CS5360-KS A/D CONVERTER

IC 704 J2142930001X 74VHC153SJX MULTIPLEXER R 6 J2631300174X HB-1T2012-601 CHIP

IC 705 J2129012001X NJU6324M QUARTZ OSC R 7 J2631300174X HB-1T2012-601 CHIP

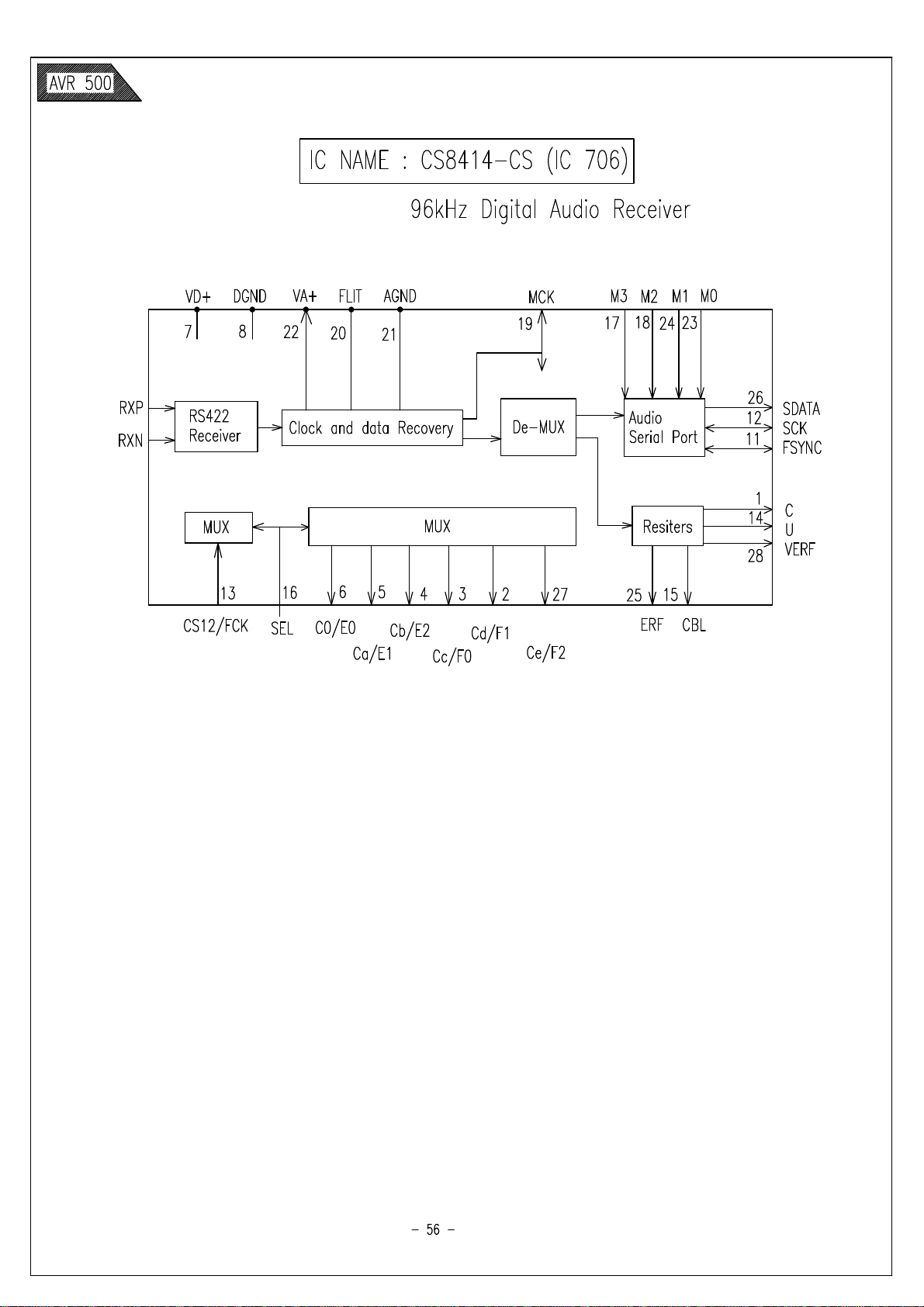

IC 706 J2136926001X CS8414-CS DIGITAL AUDIO Rx. R 13 J2631300184X HB-1T2012-202 CHIP

IC 707 J2142930003X 74VHCT244SJX OCTAL NON-INVERT R 14 J2631300174X HB-1T2012-601 CHIP

IC 708 J2135326003X CS492604D DECODER R 15 J2631300174X HB-1T2012-601 CHIP

IC 709 J2131003001X KM23C4000DG-8 ROM-0001 R 17 J2631300174X HB-1T2012-601 CHIP

IC 709 J2131328002X AT27C040-100JC ROM OTP R 18 J2631300174X HB-1T2012-601 CHIP

IC 710 J2142930004X 74VHCT574SJX OCTAL D-FILP FLOP R 19 J2631300174X HB-1T2012-601 CHIP

IC 711 J2142930004X 74VHCT574SJX OCTAL D-FILP FLOP R 109 J2631300174X HB-1T2012-601 CHIP

IC 712 J2132321002X HD404354A52H MCU-0002 R 731 J2631300174X HB-1T2012-601 CHIP

IC 712 J2132321001X HD407A435PH SUB-u-COM OTP R 732 J2631300174X HB-1T2012-601 CHIP

IC 713 J2133926003X CS4341-KS D/A CONVERTER R 734 J2631300174X HB-1T2012-601 CHIP

IC 714 J2133926003X CS4341-KS D/A CONVERTER R 755 J2631300174X HB-1T2012-601 CHIP

IC 715 J2133926003X CS4341-KS D/A CONVERTER R 756 J2631300174X HB-1T2012-601 CHIP

IC 716 J2120012002X NJM072M OP-AMP R 760 J2631300174X HB-1T2012-601 CHIP

IC 717 J2120012002X NJM072M OP-AMP R 767 J2631300174X HB-1T2012-601 CHIP

IC 718 J2120012002X NJM072M OP-AMP R 781 J2631300174X HB-1T2012-601 CHIP

IC 719 J2142930006X 74VHCU04MX HEX INVERT R 782 J2631300174X HB-1T2012-601 CHIP

IC 720 J2112504001X BA033T REGULATOR 3.3V R 785 J2631300174X HB-1T2012-601 CHIP

IC 722 J2120012001X NJM4558M OP-AMP R 799 J2631300174X HB-1T2012-601 CHIP

IC 723 J2120012001X NJM4558M OP-AMP R 800 J2631300174X HB-1T2012-601 CHIP

IC 724 J2120012001X NJM4558M OP-AMP R 817 J2631300174X HB-1T2012-601 CHIP

IC 725 J2120012001X NJM4558M OP-AMP R 818 J2631300174X HB-1T2012-601 CHIP

TRANSISTORs

Q 703 J2021000201X KTA1266-Y PNP R 853 J2631300174X HB-1T2012-601 CHIP

Q 704 J2021220101X KRC101M NPN R 854 J2631300174X HB-1T2012-601 CHIP

Q 705 J2021200101X KRA101M PNP R 869 J2631300174X HB-1T2012-601 CHIP

Q 706 J2021060001X KTD1302-B NPN R 870 J2631300174X HB-1T2012-601 CHIP

Q 707 J2021060001X KTD1302-B NPN

Q 708 J2021220101X KRC101M NPN

Q 709 J2021200101X KRA101M PNP R 822 J3013561320X 1/5W CARBON 560W-J

Q 710 J2021060001X KTD1302-B NPN

Q 711 J2021060001X KTD1302-B NPN R 1 J3024101120X 1/10W CHIP 100W-J

Q 712 J2021220101X KRC101M NPN R 2 J3024222120X 1/10W CHIP 2K2W-J

Q 713 J2021200101X KRA101M PNP R 3 J3024473120X 1/10W CHIP 47KW-J

Q 714 J2021060001X KTD1302-B NPN R 4 J3024473120X 1/10W CHIP 47KW-J

Q 715 J2021060001X KTD1302-B NPN R 5 J3024222120X 1/10W CHIP 2K2W-J

Q 716 J2021220301X KRC103M NPN R 8 J3024472120X 1/10W CHIP 4K7W-J

DIODEs

D 705 J2221010100X 1SS133 SW. R 11 J3024474120X 1/10W CHIP 470KW-J

D 706 J2221010100X 1SS133 SW. R 12 J3024474120X 1/10W CHIP 470KW-J

COILs

L 701 J2616247020X AXIAL LAL02 47uH-K R 703 J3024103120X 1/10W CHIP 10KW-J

L 702 J2616247020X AXIAL LAL02 47uH-K R 704 J3024103120X 1/10W CHIP 10KW-J

J2616247020X AXIAL LAL02 47uH-K R 705 J3024103120X 1/10W CHIP 10KW-J

BEADs

L 705 J2631200010X HC3550 9.4ohm AXIAL

L 706 J2631200010X HC3550 9.4ohm AXIAL

R 839 J2631300174X HB-1T2012-601 CHIP

R 840 J2631300174X HB-1T2012-601 CHIP

RESISTORs

R 9 J3024472120X 1/10W CHIP 4K7W-J

R 10 J3024101120X 1/10W CHIP 100W-J

R 701 J3024203120X 1/10W CHIP 20KW-J

R 702 J3024203120X 1/10W CHIP 20KW-J

Page 33

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

33

R 706 J3024103120X 1/10W CHIP 10KW-J R 788 J3024103120X 1/10W CHIP 10KW-J

R 707 J3024473120X 1/10W CHIP 47KW-J R 789 J3024103120X 1/10W CHIP 10KW-J

R 708 J3024473120X 1/10W CHIP 47KW-J R 790 J3024223120X 1/10W CHIP 22KW-J

R 709 J3024103120X 1/10W CHIP 10KW-J R 791 J3024223120X 1/10W CHIP 22KW-J

R 710 J3024103120X 1/10W CHIP 10KW-J R 792 J3024101120X 1/10W CHIP 100W-J

R 711 J3024151120X 1/10W CHIP 150W-J R 793 J3024103120X 1/10W CHIP 10KW-J

R 712 J3024151120X 1/10W CHIP 150W-J R 794 J3024103120X 1/10W CHIP 10KW-J

R 713 J3024151120X 1/10W CHIP 150W-J R 795 J3024122120X 1/10W CHIP 1K2W-J

R 714 J3024151120X 1/10W CHIP 150W-J R 796 J3024122120X 1/10W CHIP 1K2W-J

R 715 J3024100120X 1/10W CHIP 10W-J R 797 J3024203120X 1/10W CHIP 20KW-J

R 716 J3024100120X 1/10W CHIP 10W-J R 798 J3024203120X 1/10W CHIP 20KW-J

R 717 J3024101120X 1/10W CHIP 100W-J R 801 J3024473120X 1/10W CHIP 47KW-J

R 718 J3024101120X 1/10W CHIP 100W-J R 802 J3024473120X 1/10W CHIP 47KW-J

R 719 J3024750120X 1/10W CHIP 75W-J R 804 J3024561120X 1/10W CHIP 560W-J

R 720 J3024750120X 1/10W CHIP 75W-J R 805 J3024561120X 1/10W CHIP 560W-J

R 735 J3024471120X 1/10W CHIP 470W-J R 806 J3024103120X 1/10W CHIP 10KW-J

R 736 J3024103120X 1/10W CHIP 10KW-J R 807 J3024103120X 1/10W CHIP 10KW-J

R 737 J3024103120X 1/10W CHIP 10KW-J R 808 J3024223120X 1/10W CHIP 22KW-J

R 738 J3024103120X 1/10W CHIP 10KW-J R 809 J3024223120X 1/10W CHIP 22KW-J

R 739 J3024103120X 1/10W CHIP 10KW-J R 810 J3024101120X 1/10W CHIP 100W-J

R 740 J3024103120X 1/10W CHIP 10KW-J R 811 J3024103120X 1/10W CHIP 10KW-J

R 741 J3024103120X 1/10W CHIP 10KW-J R 812 J3024103120X 1/10W CHIP 10KW-J

R 742 J3024103120X 1/10W CHIP 10KW-J R 813 J3024122120X 1/10W CHIP 1K2W-J

R 743 J3024103120X 1/10W CHIP 10KW-J R 814 J3024122120X 1/10W CHIP 1K2W-J

R 744 J3024103120X 1/10W CHIP 10KW-J R 815 J3024203120X 1/10W CHIP 20KW-J

R 745 J3024103120X 1/10W CHIP 10KW-J R 816 J3024203120X 1/10W CHIP 20KW-J

R 746 J3024103120X 1/10W CHIP 10KW-J R 819 J3024473120X 1/10W CHIP 47KW-J

R 747 J3024472120X 1/10W CHIP 4K7W-J R 820 J3024473120X 1/10W CHIP 47KW-J

R 748 J3024473120X 1/10W CHIP 47KW-J R 827 J3024123120X 1/10W CHIP 12KW-J

R 749 J3024473120X 1/10W CHIP 47KW-J R 828 J3024123120X 1/10W CHIP 12KW-J

R 750 J3024473120X 1/10W CHIP 47KW-J R 829 J3024223120X 1/10W CHIP 22KW-J

R 751 J3024473120X 1/10W CHIP 47KW-J R 831 J3024224120X 1/10W CHIP 220KW-J

R 752 J3024100120X 1/10W CHIP 10W-J R 832 J3024224120X 1/10W CHIP 220KW-J

R 753 J3024222120X 1/10W CHIP 2K2W-J R 833 J3024123120X 1/10W CHIP 12KW-J

R 754 J3024103120X 1/10W CHIP 10KW-J R 834 J3024123120X 1/10W CHIP 12KW-J

R 757 J3024103120X 1/10W CHIP 10KW-J R 835 J3024123120X 1/10W CHIP 12KW-J

R 758 J3024472120X 1/10W CHIP 4K7W-J R 836 J3024123120X 1/10W CHIP 12KW-J

R 759 J3024103120X 1/10W CHIP 10KW-J R 837 J3024473120X 1/10W CHIP 47KW-J

R 761 J3024105120X 1/10W CHIP 1MW-J R 838 J3024473120X 1/10W CHIP 47KW-J

R 763 J3024473120X 1/10W CHIP 47KW-J R 845 J3024123120X 1/10W CHIP 12KW-J

R 764 J3024222120X 1/10W CHIP 2K2W-J R 846 J3024123120X 1/10W CHIP 12KW-J

R 765 J3024182120X 1/10W CHIP 1K8W-J R 847 J3024223120X 1/10W CHIP 22KW-J

R 766 J3024181120X 1/10W CHIP 180W-J R 848 J3024223120X 1/10W CHIP 22KW-J

R 768 J3024561120X 1/10W CHIP 560W-J R 849 J3024101120X 1/10W CHIP 100W-J

R 769 J3024561120X 1/10W CHIP 560W-J R 850 J3024101120X 1/10W CHIP 100W-J

R 770 J3024103120X 1/10W CHIP 10KW-J R 851 J3024224120X 1/10W CHIP 220KW-J

R 771 J3024103120X 1/10W CHIP 10KW-J R 852 J3024224120X 1/10W CHIP 220KW-J

R 772 J3024223120X 1/10W CHIP 22KW-J R 859 J3024123120X 1/10W CHIP 12KW-J

R 773 J3024223120X 1/10W CHIP 22KW-J R 860 J3024242120X 1/10W CHIP 2K4W-J

R 774 J3024101120X 1/10W CHIP 100W-J R 861 J3024223120X 1/10W CHIP 22KW-J

R 775 J3024103120X 1/10W CHIP 10KW-J R 862 J3024243120X 1/10W CHIP 24KW-J

R 776 J3024103120X 1/10W CHIP 10KW-J R 863 J3024224120X 1/10W CHIP 220KW-J

R 777 J3024122120X 1/10W CHIP 1K2W-J R 864 J3024224120X 1/10W CHIP 220KW-J

R 778 J3024122120X 1/10W CHIP 1K2W-J R 865 J3024101120X 1/10W CHIP 100W-J

R 779 J3024203120X 1/10W CHIP 20KW-J R 866 J3024101120X 1/10W CHIP 100W-J

R 780 J3024203120X 1/10W CHIP 20KW-J R 867 J3024203120X 1/10W CHIP 20KW-J

R 783 J3024473120X 1/10W CHIP 47KW-J R 868 J3024203120X 1/10W CHIP 20KW-J

R 784 J3024473120X 1/10W CHIP 47KW-J R 930 J3024223120X 1/10W CHIP 22KW-J

R 786 J3024561120X 1/10W CHIP 560W-J

R 787 J3024561120X 1/10W CHIP 560W-J

Page 34

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

34

CAPACITORs

C 6 J3442110041X ELEC/CHIP 16V 10uF-K C 828 J3470147041X ELEC 25V 47uF-M

C 7 J3442110041X ELEC/CHIP 16V 10uF-K C 832 J3470110971X ELEC 50V 1uF-M

C 3 J3471610971X ELEC 50V 1uF-M C 836 J3470110071X ELEC 50V 10uF-M

C 4 J3471622041X ELEC 25V 22uF-M C 839 J3470110216X ELEC 6.3V 1000uF-M

C 701 J3470110071X ELEC 50V 10uF-M C 843 J3471647971X ELEC 50V 4.7uF-M

C 702 J3470110071X ELEC 50V 10uF-M C 844 J3471647971X ELEC 50V 4.7uF-M

C 711 J3470147041X ELEC 25V 47uF-M C 845 J3471647971X ELEC 50V 4.7uF-M

C 712 J3470147041X ELEC 25V 47uF-M C 846 J3471647971X ELEC 50V 4.7uF-M

C 715 J3470110971X ELEC 50V 1uF-M C 847 J3470147041X ELEC 25V 47uF-M

C 717 J3470110971X ELEC 50V 1uF-M C 848 J3470147041X ELEC 25V 47uF-M

C 727 J3470110216X ELEC 6.3V 1000uF-M C 853 J3471647971X ELEC 50V 4.7uF-M

C 729 J3471610971X ELEC 50V 1uF-M C 854 J3471647971X ELEC 50V 4.7uF-M

C 731 J3470110216X ELEC 6.3V 1000uF-M C 855 J3470147041X ELEC 25V 47uF-M

C 735 J3470110971X ELEC 50V 1uF-M C 856 J3470147041X ELEC 25V 47uF-M

C 738 J3470110216X ELEC 6.3V 1000uF-M C 861 J3471647971X ELEC 50V 4.7uF-M

C 741 J3470110971X ELEC 50V 1uF-M C 862 J3471647971X ELEC 50V 4.7uF-M

C 742 J3471610971X ELEC 50V 1uF-M C 863 J3471647971X ELEC 50V 4.7uF-M

C 744 J3471610971X ELEC 50V 1uF-M C 864 J3471610031X ELEC 16V 10uF-M

C 746 J3470110971X ELEC 50V 1uF-M C 865 J3471610031X ELEC 16V 10uF-M

C 749 J3471610971X ELEC 50V 1uF-M C 866 J3470147041X ELEC 25V 47uF-M

C 750 J3471610971X ELEC 50V 1uF-M C 867 J3470147041X ELEC 25V 47uF-M

C 753 J3471610971X ELEC 50V 1uF-M C 872 J3470110971X ELEC 50V 1uF-M

C 755 J3471647031X ELEC 16V 47uF-M

C 756 J3471622971X ELEC 50V 2.2uF-M C 11 J3523104540X CERA/DISC F 25V 0.1uF-Z

C 758 J3471610971X ELEC 50V 1uF-M C 840 J3523104540X CERA/DISC F 25V 0.1uF-Z

C 761 J3470110971X ELEC 50V 1uF-M

C 763 J3470110971X ELEC 50V 1uF-M C 2 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 766 J3471610971X ELEC 50V 1uF-M C 5 J3525103170X CERA/CHIP B 50V 0.01uF-K

C 768 J3471610971X ELEC 50V 1uF-M C 8 J3515101270X CERA/CHIP CH 50V 100pF-J

C 770 J3471610971X ELEC 50V 1uF-M C 9 J3515101270X CERA/CHIP CH 50V 100pF-J

C 771 J3471633971X ELEC 50V 3.3uF-M C 10 J3515101270X CERA/CHIP CH 50V 100pF-J

C 772 J3471633971X ELEC 50V 3.3uF-M C 12 J3515101270X CERA/CHIP CH 50V 100pF-J

C 775 J3471610031X ELEC 16V 10uF-M C 13 J3515101270X CERA/CHIP CH 50V 100pF-J

C 776 J3471610031X ELEC 16V 10uF-M C 703 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 781 J3471610031X ELEC 16V 10uF-M C 704 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 782 J3471610031X ELEC 16V 10uF-M C 705 J3515470270X CERA/CHIP CH 50V 47pF-J

C 783 J3470147041X ELEC 25V 47uF-M C 706 J3515470270X CERA/CHIP CH 50V 47pF-J

C 784 J3470147041X ELEC 25V 47uF-M C 707 J3515100270X CERA/CHIP CH 50V 10pF-D

C 788 J3471610971X ELEC 50V 1uF-M C 708 J3515100270X CERA/CHIP CH 50V 10pF-D

C 790 J3471610971X ELEC 50V 1uF-M C 709 J3525222170X CERA/CHIP B 50V 2200pF-K

C 792 J3471610971X ELEC 50V 1uF-M C 710 J3525222170X CERA/CHIP B 50V 2200pF-K

C 793 J3471633971X ELEC 50V 3.3uF-M C 713 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 794 J3471633971X ELEC 50V 3.3uF-M C 714 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 797 J3471610031X ELEC 16V 10uF-M C 716 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 798 J3471610031X ELEC 16V 10uF-M C 718 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 803 J3471610031X ELEC 16V 10uF-M C 719 J3525103170X CERA/CHIP B 50V 0.01uF-K

C 804 J3471610031X ELEC 16V 10uF-M C 720 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 805 J3470147041X ELEC 25V 47uF-M C 721 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 806 J3470147041X ELEC 25V 47uF-M C 722 J3525103170X CERA/CHIP B 50V 0.01uF-K

C 810 J3471610971X ELEC 50V 1uF-M C 723 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 812 J3471610971X ELEC 50V 1uF-M C 724 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 814 J3471610971X ELEC 50V 1uF-M C 725 J3525103170X CERA/CHIP B 50V 0.01uF-K

C 815 J3471633971X ELEC 50V 3.3uF-M C 726 J3525103170X CERA/CHIP B 50V 0.01uF-K

C 816 J3471633971X ELEC 50V 3.3uF-M C 728 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 819 J3471610031X ELEC 16V 10uF-M C 730 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 820 J3471610031X ELEC 16V 10uF-M C 732 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 825 J3471610031X ELEC 16V 10uF-M C 733 J3515150270X CERA/CHIP CH 50V 15pF-J

C 826 J3471610031X ELEC 16V 10uF-M C 734 J3525103170X CERA/CHIP B 50V 0.01uF-K

C 827 J3470147041X ELEC 25V 47uF-M

C 834 J3470110971X ELEC 50V 1uF-M

Page 35

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

35

C 736 J3525104540X CERA/CHIP F 25V 0.1uF-Z C 1 J3681224731X MET POLYCARBO 63V 0.22uF-J

C 739 J3525104540X CERA/CHIP F 25V 0.1uF-Z C 737 J3640683220X MET POLY/RA 63V 0.068uF-J

C 740 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 743 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 745 J3525104540X CERA/CHIP F 25V 0.1uF-Z HU 1 J4423341160X 2.5mm 11P JE605-11

C 747 J3525104540X CERA/CHIP F 25V 0.1uF-Z HU 720 J4423341160X 2.5mm 11P JE605-11

C 748 J3525104540X CERA/CHIP F 25V 0.1uF-Z HU 721 J4423341060X 2.5mm 10P JE605-10

C 751 J3525104540X CERA/CHIP F 25V 0.1uF-Z WA 702 J4422112220X 1.25mm 22P 8370-227

C 752 J3525104540X CERA/CHIP F 25V 0.1uF-Z WA 703 J4420040500X 2.5mm 5P 5267-05A

C 754 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 757 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 759 J3515220270X CERA/CHIP CH 50V 22pF X 1 J43199011729 1P,1007#22(HI-WAP),170m/m

C 760 J3515220270X CERA/CHIP CH 50V 22pF

C 762 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 764 J3525104540X CERA/CHIP F 25V 0.1uF-Z JA 701 J2123806001X TORX178A OPTIC Rx

C 765 J3525104540X CERA/CHIP F 25V 0.1uF-Z JA 702 J2123806001X TORX178A OPTIC Rx

C 767 J3525104540X CERA/CHIP F 25V 0.1uF-Z JA 703 J44302201101 JW-1609RS

C 769 J3525104540X CERA/CHIP F 25V 0.1uF-Z JA 704 J2123806002X TOTX178 OPTIC Tx

C 773 J3525123170X CERA/CHIP B 50V 0.012uF-K JA 705 J44302101102 JW-1409S

C 774 J3525123170X CERA/CHIP B 50V 0.012uF-K RL 701 J5513300002X P-12 MEISEI 12V RELAY

C 777 J3525562170X CERA/CHIP B 50V 5600pF-K X 701 J3914010015X 12.288MHz SCO-K1-12288 OSC

C 778 J3525562170X CERA/CHIP B 50V 5600pF-K X 702 J3913010045X 5MHz 30pF X-TAL

C 779 J3515221270X CERA/CHIP CH 50V 220pF-J

C 780 J3515221270X CERA/CHIP CH 50V 220pF-J

C 785 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 786 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 787 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 789 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 791 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 795 J3525123170X CERA/CHIP B 50V 0.012uF-K

C 796 J3525123170X CERA/CHIP B 50V 0.012uF-K

C 799 J3525562170X CERA/CHIP B 50V 5600pF-K

C 800 J3525562170X CERA/CHIP B 50V 5600pF-K

C 801 J3515221270X CERA/CHIP CH 50V 220pF-J

C 802 J3515221270X CERA/CHIP CH 50V 220pF-J

C 807 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 808 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 809 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 811 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 813 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 817 J3525123170X CERA/CHIP B 50V 0.012uF-K

C 818 J3525334540X CERA/CHIP F 25V 0.33uF-Z

C 821 J3525562170X CERA/CHIP B 50V 5600pF-K

C 822 J3525562170X CERA/CHIP B 50V 5600pF-K

C 823 J3515221270X CERA/CHIP CH 50V 220pF-J

C 824 J3515221270X CERA/CHIP CH 50V 220pF-J

C 829 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 830 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 831 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 833 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 835 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 837 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 838 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 849 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 850 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 857 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 858 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 868 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 869 J3525104540X CERA/CHIP F 25V 0.1uF-Z

C 871 J3525104540X CERA/CHIP F 25V 0.1uF-Z

WAFERs

WIREs

MISCELLANIES

2P RCA JACK

1P RCA JACK

Page 36

ELECTRIC PART LIST(500Serise) INPUT P.C. BOARD

TRANSISTORs

36

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

J1320045203X

J1320045103X

INPUT P.C. BOARD

INPUT P.C. BOARD

INTEGRATED CIRCUITs

IC 101

J2121712002X NJU7312AM

IC 102

J2121712003X NJU7313AM

J2120012001X NJM4558M OP-AMP

IC 103

J2120012001X NJM4558M OP-AMP

IC 104

IC 105

J2121712001X NJU7311AM

IC 106

J2115211003X LC7536

J2120012001X NJM4558M OP-AMP

IC 107

J2120012001X NJM4558M OP-AMP

IC 108

IC 109

J2115211003X LC7536

J2120012001X NJM4558M OP-AMP

IC 110

J2120012001X NJM4558M OP-AMP

IC 111

J2120012001X NJM4558M OP-AMP

IC 112

IC 113

J2121712001X NJU7311AM

IC 114

J2115211003X LC7536

J2120012001X NJM4558M OP-AMP

IC 115

J2120012001X NJM4558M OP-AMP

IC 116

IC 117

J2115211003X LC7536

J2120012001X NJM4558M OP-AMP

IC 118

J2120012001X NJM4558M OP-AMP

IC 119

J2120012001X NJM4558M OP-AMP

IC 120

J2120012001X NJM4558M OP-AMP

IC 121

J2120012001X NJM4558M OP-AMP

IC 122

J2120012001X NJM4558M OP-AMP

IC 123

J2120012001X NJM4558M OP-AMP

IC 124

Q 110 J2021000201X KTA1266-Y PNP

Q 111 J2021000201X KTA1266-Y PNP

Q 112 J2021000201X KTA1266-Y PNP

Q 113 J2021000201X KTA1266-Y PNP

Q 114 J2021000201X KTA1266-Y PNP R 123

J20210600011 KTD1302-B NPN R 124

Q 115

J20210600011 KTD1302-B NPN

Q 116

J2021060001X KTD1302-B NPN

Q 117

J2021060001X KTD1302-B NPN

Q 118

J2021060001X KTD1302-B NPN

Q 119

J2021060001X KTD1302-B NPN R 129 J3024183120X

Q 120

J2021060001X KTD1302-B NPN

Q 121

J2021060001X KTD1302-B NPN

Q 122

J2021060001X KTD1302-B NPN

Q 123

J2021060001X KTD1302-B NPN

Q 124

J2021060001X KTD1302-B NPN

Q 125

J2021060001X KTD1302-B NPN

Q 126

J2021060001X KTD1302-B NPN

Q 127

J2021060001X KTD1302-B NPN

Q 128

J2021060001X KTD1302-B NPN

Q 129

J2021060001X KTD1302-B NPN R 139 J3024224120X

Q 130

Q 131

J2021220201X KRC102M

Q 132

J2021220201X KRC102M

Q 133

J2021200301X KRA103M

Q 134

J2021200301X KRA103M

Q 135

J2021200301X KRA103M

Q 136

J2021200301X KRA103M

Q 137

J2021200301X KRA103M

FUNC. SW. Q 142

FUNC. SW.

FUNC. SW.

ELEC. VR.

ELEC. VR.

FUNC. SW.

ELEC. VR.

ELEC. VR.

IB Q 138

BK Q 139

Q 140

Q 141

D 101

D 102

D 103

R 101

R 102

R 103

R 104

R 105

R 106

R 107

R 108

R 109

R 110

R 111

R 112

R 113

R 114

R 115

R 116

R 117

R 118 J3024331120X 1/10W CHIP 330W-J

R 119

R 120

R 121

R 122

R 125

R 126

R 127

R 128 J3024223120X 1/10W CHIP 22KW-J

R 130

R 131

R 132 J3024223120X 1/10W CHIP 22KW-J

R 133

R 134

R 135

R 136

R 137

R 138

NPN R 140 J3024224120X

NPN

PNP

PNP

PNP

PNP

PNP

R 141

R 142

R 143

R 144

R 145

R 146

J2021220101X KRC101M

J2021220101X KRC101M

J2021220101X KRC101M

J2021220101X KRC101M

J2021220101X KRC101M

NPN

NPN

NPN

NPN

NPN

DIODEs

J2221010100X 1SS133 SW.

J2221010100X 1SS133 SW.

J2221010100X 1SS133 SW.

RESISTORs

J3024331120X

J3024331120X

J3024474120X

J3024474120X

J3024331120X

J3024331120X

J3024474120X

J3024474120X

J3024331120X

J3024331120X

J3024474120X

J3024474120X

J3024331120X

J3024331120X

J3024474120X

J3024474120X

J3024331120X

J3024474120X

J3024474120X

J3024102120X

J3024433120X

J3024822120X 1/10W CHIP 8K2W-J

J3024822120X 1/10W CHIP 8K2W-J

J3024433120X

J3024331120X

J3024331120X

J3024331120X

J3024331120X

J3024101120X

J3024101120X

J3024474120X

J3024474120X

J3024101120X

J3024101120X

J3024101120X

J3024101120X

J3024474120X

J3024474120X

J3024101120X

J3024101120X

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 330W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 1KW-J

1/10W CHIP 43KW-J

1/10W CHIP 43KW-J

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 18KW-J

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

Page 37

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

37

R 147 J3024224120X

R 148 J3024224120X

J3024101120X

R 149

J3024101120X

R 150

R 151 J3024224120X

R 152 J3024224120X

J3024101120X

R 153

J3024101120X

R 154

R 155 J3024224120X

R 156 J3024224120X

J3024101120X

R 157

J3024101120X

R 158

J3024474120X

R 159

J3024474120X

R 160

R 161

J3024152120X 1/10W CHIP 1K5W-J

R 162

J3024152120X 1/10W CHIP 1K5W-J

R 163 J3024224120X

R 164 J3024224120X

J3024101120X

R 165

J3024101120X

R 166

J3024474120X

R 167

J3024474120X

R 168

R 169

J3024152120X 1/10W CHIP 1K5W-J

R 170

J3024152120X 1/10W CHIP 1K5W-J

R 171 J3024224120X

R 172 J3024224120X

J3024101120X

R 173

J3024101120X

R 174

R 175 J3024224120X

R 176 J3024224120X

J3024101120X

R 177

J3024101120X

R 178

R 179 J3024224120X

R 180 J3024224120X

J3024101120X

R 181

J3024101120X

R 182

J3024101120X

R 183

J3024101120X

R 184

J3024101120X

R 185

J3024101120X

R 186

R 187

J3024104120X 1/10W CHIP 100KW-J R 252

R 188

J3024104120X 1/10W CHIP 100KW-J R 253

J3024222120X

R 189

J3024222120X

R 190

J3024222120X

R 191

J3024222120X

R 192

J3024102120X

R 193

J3024102120X

R 194

J3024102120X

R 195

J3024102120X

R 196

J3024102120X

R 197

J3024102120X

R 198

J3024102120X

R 199

R 200

J3024229120X 1/10W CHIP 2R2W-J R 268

R 201

J3024229120X 1/10W CHIP 2R2W-J R 269

J3024222120X

R 202

J3024222120X

R 203

J3024222120X

R 204

J3024222120X

R 205

R 206 J3024224120X

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J R 213

1/10W CHIP 100W-J R 214

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J R 217

1/10W CHIP 100W-J R 218

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 470KW-J

1/10W CHIP 470KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J R 237

1/10W CHIP 100W-J R 238

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J R 241

1/10W CHIP 100W-J R 242

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J R 245

1/10W CHIP 100W-J R 246

1/10W CHIP 100W-J R 247

1/10W CHIP 100W-J R 248

1/10W CHIP 100W-J R 249

1/10W CHIP 100W-J R 250

1/10W CHIP 100W-J R 251

1/10W CHIP 2K2W-J R 254

1/10W CHIP 2K2W-J R 255

1/10W CHIP 2K2W-J R 256

1/10W CHIP 2K2W-J

1/10W CHIP 1KW-J R 261

1/10W CHIP 1KW-J R 262

1/10W CHIP 1KW-J R 263

1/10W CHIP 1KW-J R 264

1/10W CHIP 1KW-J R 265

1/10W CHIP 1KW-J R 266

1/10W CHIP 1KW-J R 267

1/10W CHIP 2K2W-J R 270

1/10W CHIP 2K2W-J R 271

1/10W CHIP 2K2W-J R 272

1/10W CHIP 2K2W-J R 273

1/10W CHIP 220KW-J R 274

R 207 J3024224120X

R 208 J3024224120X

R 209 J3024224120X

R 210 J3024472120X

R 211 J3024472120X

R 212 J3024203120X

J3024101120X

J3024101120X

R 215 J3024224120X

R 216 J3024224120X

J3024101120X

J3024101120X

R 219 J3024224120X

R 220 J3024224120X

R 221 J3024224120X

R 222 J3024224120X

R 223 J3024224120X

R 224 J3024224120X

R 225 J3024224120X

R 226 J3024224120X

R 227 J3024224120X

R 228 J3024224120X

R 234

J3024822120X 1/10W CHIP 8K2W-J

R 235

J3024822120X 1/10W CHIP 8K2W-J

R 236

J3024123120X 1/10W CHIP 12KW-J

J3024101120X

J3024101120X

R 239 J3024224120X

R 240 J3024224120X

J3024101120X

J3024101120X

R 243 J3024224120X

R 244 J3024224120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

R 260

J3024123120X 1/10W CHIP 12KW-J

J3024102120X

J3024102120X

J3024102120X

J3024473120X

J3024473120X

J3024473120X

J3024102120X

J3024102120X

J3024102120X

J3024473120X

J3024473120X

J3024473120X

J3024102120X

J3024102120X

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 4K7W-J

1/10W CHIP 4K7W-J

1/10W CHIP 20KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J

Page 38

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

38

J3024102120X

R 275

J3024473120X

R 276

J3024473120X

R 277

J3024473120X

R 278

J3024102120X

R 279

J3024102120X

R 280

J3024102120X

R 281

J3024473120X

R 282

J3024473120X

R 283

J3024473120X

R 284

J3024102120X

R 285

J3024102120X

R 286

J3024102120X

R 287

J3024473120X

R 288

J3024473120X

R 289

J3024473120X

R 290

J3024102120X

R 291

J3024102120X

R 292

J3024102120X

R 293

J3024473120X

R 294

J3024473120X

R 295

J3024473120X

R 296

J3024102120X

R 297

J3024102120X

R 298

J3024102120X

R 299

J3024473120X

R 300

J3024473120X

R 301

J3024473120X

R 302

J3024102120X

R 303

J3024102120X

R 304

J3024102120X

R 305

J3024473120X

R 306

J3024473120X

R 307

J3024473120X

R 308

R 309 J3024203120X

R 310 J3024203120X

R 311 J3024203120X

R 312

J3024124120X 1/10W CHIP 120KW-J

R 313

J3024124120X 1/10W CHIP 120KW-J

J3024479120X

R 314

J3024479120X

R 315

J3024479120X

R 316

J3024479120X

R 317

J3024479120X

R 318

J3024479120X

R 319

J3024479120X

R 320

J3024479120X

R 321

J3024479120X

R 322

J3024479120X

R 323

J3024479120X

R 324

J3024479120X

R 325

J3024479120X

R 326

J3024479120X

R 327

J3024479120X

R 328

J3024479120X

R 329

J3024479120X

R 330

J3024479120X

R 331

J3024479120X

R 332

R 333 J3024183120X

J3024331120X

R 334

1/10W CHIP 1KW-J R 335

1/10W CHIP 47KW-J R 336 J3024223120X 1/10W CHIP 22KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J R 338 J3024223120X 1/10W CHIP 22KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J R 340

1/10W CHIP 1KW-J R 341

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J R 346

1/10W CHIP 1KW-J R 347

1/10W CHIP 47KW-J R 348 J3024333120X 1/10W CHIP 33KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 1KW-J R 351 J3024333120X 1/10W CHIP 33KW-J

1/10W CHIP 1KW-J R 352

1/10W CHIP 1KW-J R 353

1/10W CHIP 47KW-J R 354 J3024223120X 1/10W CHIP 22KW-J

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J R 356

1/10W CHIP 1KW-J R 357

1/10W CHIP 1KW-J R 358

1/10W CHIP 1KW-J R 359

1/10W CHIP 47KW-J R 360

1/10W CHIP 47KW-J R 361

1/10W CHIP 47KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J R 364 J3024000120X 1/10W CHIP

1/10W CHIP 1KW-J R 365

1/10W CHIP 47KW-J R 366

1/10W CHIP 47KW-J

1/10W CHIP 47KW-J

1/10W CHIP 20KW-J R 371 J3024000120X 1/10W CHIP

1/10W CHIP 20KW-J R 372 J3024000120X 1/10W CHIP

1/10W CHIP 20KW-J R 373 J3024000120X 1/10W CHIP

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J R 380

1/10W CHIP 4R7W-J R 381

1/10W CHIP 4R7W-J R 382

1/10W CHIP 4R7W-J R 383

1/10W CHIP 4R7W-J R 384

1/10W CHIP 4R7W-J R 385

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J R 389

1/10W CHIP 4R7W-J R 390

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J R 396

1/10W CHIP 4R7W-J R 397

1/10W CHIP 4R7W-J R 398

1/10W CHIP 4R7W-J R 399

1/10W CHIP 4R7W-J R 400

1/10W CHIP 18KW-J R 401

1/10W CHIP 330W-J R 402

J3024331120X

R 337 J3024183120X

R 339 J3024183120X

J3024101120X

J3024101120X

R 342 J3024224120X

R 343 J3024224120X

R 344 J3024224120X

R 345 J3024224120X

J3024102120X

J3024102120X

R 349

J3024752120X 1/10W CHIP 7K5W-J

R 350

J3024752120X 1/10W CHIP 7K5W-J

J3024331120X

J3024331120X

R 355 J3024183120X

J3024479120X

J3024479120X

J3024479120X

J3024479120X

J3024101120X

J3024101120X

R 362 J3024224120X

R 363 J3024224120X

J3024101120X

J3024101120X

R 367 J3024224120X

R 368 J3024224120X

R 375 J3024224120X

R 376 J3024224120X

R 378 J3024224120X

R 379 J3024224120X

J3024101120X

J3024101120X

J3024101120X

J3024101120X

J3024101120X

J3024101120X

R 386 J3024224120X

R 387 J3024224120X

J3024101120X

J3024101120X

R 391 J3024224120X

R 392 J3024224120X

J3024222120X

J3024222120X

J3024222120X

J3024222120X

J3024479120X

J3024479120X

J3024479120X

1/10W CHIP 330W-J

1/10W CHIP 18KW-J

1/10W CHIP 18KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 1KW-J

1/10W CHIP 1KW-J

1/10W CHIP 330W-J

1/10W CHIP 330W-J

1/10W CHIP 18KW-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 100W-J

1/10W CHIP 100W-J

1/10W CHIP 220KW-J

1/10W CHIP 220KW-J

1/10W CHIP 2K2W-J

1/10W CHIP 2K2W-J

1/10W CHIP 2K2W-J

1/10W CHIP 2K2W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

1/10W CHIP 4R7W-J

0W-J

0W-J

0W-J

0W-J

Page 39

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

39

J3024479120X

R 403

J3024479120X

R 404

R 405 J3024183120X

R 406 J3024183120X

1/10W CHIP 4R7W-J C 237

1/10W CHIP 4R7W-J C 240

1/10W CHIP 18KW-J C 241

1/10W CHIP 18KW-J C 242

CAPACITORs

C 117 J3470147971X ELEC 50V 4.7uF-M

C 118 J3470147971X ELEC 50V 4.7uF-M

J3470647931X ELEC 16V 4.7uF-M

C 119

J3470647931X ELEC 16V 4.7uF-M

C 120

C 121 J3470147971X ELEC 50V 4.7uF-M

C 122 J3470147971X ELEC 50V 4.7uF-M

J3470647931X ELEC 16V 4.7uF-M

C 123

J3470647931X ELEC 16V 4.7uF-M

C 124

J3470647931X ELEC 16V 4.7uF-M

C 125

J3470647931X ELEC 16V 4.7uF-M

C 126

J3470647931X ELEC 16V 4.7uF-M

C 127

J3470647931X ELEC 16V 4.7uF-M

C 128

J3470647931X ELEC 16V 4.7uF-M

C 129

J3470647931X ELEC 16V 4.7uF-M

C 130

J3470647931X ELEC 16V 4.7uF-M

C 131

J3470647931X ELEC 16V 4.7uF-M

C 132

J3470647931X ELEC 16V 4.7uF-M

C 145

J3470647931X ELEC 16V 4.7uF-M

C 146

J3470647931X ELEC 16V 4.7uF-M

C 147

J3470647931X ELEC 16V 4.7uF-M

C 148

J3470647931X ELEC 16V 4.7uF-M C 280 J3470147971X ELEC 50V 4.7uF-M

C 149

J34706479311 ELEC 16V 4.7uF-M C 281 J3470147971X ELEC 50V 4.7uF-M

C 150

J3470647931X ELEC 16V 4.7uF-M

C 151

J3470647931X ELEC 16V 4.7uF-M

C 152

J3470647931X ELEC 16V 4.7uF-M

C 153

J3470647931X ELEC 16V 4.7uF-M

C 154

C 155 J3470147971X ELEC 50V 4.7uF-M

C 156 J3470147971X ELEC 50V 4.7uF-M

J34701470411 ELEC 25V 47uF-M C 288 J3470147971X ELEC 50V 4.7uF-M

C 157

J34701470411 ELEC 25V 47uF-M C 289 J3470147971X ELEC 50V 4.7uF-M

C 158

J34701470411 ELEC 25V 47uF-M

C 159

J3470147041X ELEC 25V 47uF-M

C 160

J3470147041X ELEC 25V 47uF-M

C 161

C 163 J3470147971X ELEC 50V 4.7uF-M

J3470647931X ELEC 16V 4.7uF-M

C 164

C 165 J3470147971X ELEC 50V 4.7uF-M

C 166 J3470147971X ELEC 50V 4.7uF-M

J34701470411 ELEC 25V 47uF-M

C 197

J34701470411 ELEC 25V 47uF-M

C 198

J3470147041X ELEC 25V 47uF-M

C 201

J34701470411 ELEC 25V 47uF-M

C 202

J3470147041X ELEC 25V 47uF-M

C 205

J3470147041X ELEC 25V 47uF-M C 302 J3471647931X ELEC 16V 4.7uF-M

C 206

J34701470411 ELEC 25V 47uF-M

C 209

J34701470411 ELEC 25V 47uF-M

C 210

J34701470411 ELEC 25V 47uF-M

C 225

J34701470411 ELEC 25V 47uF-M

C 227

J3470147041X ELEC 25V 47uF-M

C 229

J34701470411 ELEC 25V 47uF-M

C 231

J34701470411 ELEC 25V 47uF-M

C 232

J34701470411 ELEC 25V 47uF-M

C 233

J34701470411 ELEC 25V 47uF-M C 101 J3515121270X

C 234

J34701470411 ELEC 25V 47uF-M C 102 J3515121270X

C 235

J34701470411 ELEC 25V 47uF-M C 103 J3515121270X

C 236

J34701470411 ELEC 25V 47uF-M

J3470147041X ELEC 25V 47uF-M

J3470147041X ELEC 25V 47uF-M

J34701470411 ELEC 25V 47uF-M

J34701470411 ELEC 25V 47uF-M

C 243

J34701470411 ELEC 25V 47uF-M

C 244

J3470147041X ELEC 25V 47uF-M

C 245

J34701470411 ELEC 25V 47uF-M

C 246

J3470147041X ELEC 25V 47uF-M

C 247

J3470147041X ELEC 25V 47uF-M

C 248

J3470147041X ELEC 25V 47uF-M

C 249

J34701470411 ELEC 25V 47uF-M

C 250

C 264 J34701101311

C 265 J34701101311

C 266 J3470610031X

C 267 J3470610031X

C 268 J3470610031X

C 269 J3470610031X

C 270 J3470610031X

C 271 J3470610031X

C 272 J3470610031X

C 273 J3470610031X

J3470647931X ELEC 16V 4.7uF-M

C 276

J3470647931X ELEC 16V 4.7uF-M

C 277

J3470647931X ELEC 16V 4.7uF-M

C 278

J3470647931X ELEC 16V 4.7uF-M

C 279

J3470647931X ELEC 16V 4.7uF-M

C 282

J3470647931X ELEC 16V 4.7uF-M

C 283

J34706479311 ELEC 16V 4.7uF-M

C 284

J3470647931X ELEC 16V 4.7uF-M

C 285

J3470647931X ELEC 16V 4.7uF-M

C 286

J3470647931X ELEC 16V 4.7uF-M

C 287

J3470647931X ELEC 16V 4.7uF-M

C 290

J3470647931X ELEC 16V 4.7uF-M

C 291

J3470647931X ELEC 16V 4.7uF-M

C 292

J3470647931X ELEC 16V 4.7uF-M

C 293

J3470647931X ELEC 16V 4.7uF-M

C 294

J3470647931X ELEC 16V 4.7uF-M

C 295

J3470647931X ELEC 16V 4.7uF-M

C 296

J3470647931X ELEC 16V 4.7uF-M

C 297

J3470647931X ELEC 16V 4.7uF-M

C 298

J3470647931X ELEC 16V 4.7uF-M

C 299

J3470647931X ELEC 16V 4.7uF-M

C 300

J3470647931X ELEC 16V 4.7uF-M

C 301

J34706479311 ELEC 16V 4.7uF-M

C 303

J34701470411 ELEC 25V 47uF-M

C 304

J34701470411 ELEC 25V 47uF-M

C 306

J34701470411 ELEC 25V 47uF-M

C 308

J34701470411 ELEC 25V 47uF-M

C 310

J34701470411 ELEC 25V 47uF-M

C 312

J34701470411 ELEC 25V 47uF-M

C 314

ELEC 16V 100uF-M

ELEC 16V 100uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

ELEC 16V 10uF-M

CERA/CHIP

CERA/CHIP

CERA/CHIP

CH 50V 120pF-J

CH 50V 120pF-J

CH 50V 120pF-J

Page 40

REF NO. PART NO. DESCRIPTION REF NO. PART NO. DESCRIPTION

40

C 104 J3515121270X

C 105 J3515121270X

C 106 J3515121270X

C 107 J3515121270X

C 108 J3515121270X

C 109 J3515121270X

C 110 J3515121270X

C 167

J3515470270X CERA/CHIP

C 168

J3515470270X CERA/CHIP

J3515471170X

C 173

J3515471170X

C 174

J3515471170X

C 175

J3515471170X

C 176

J3515471170X

C 177

J3515471170X

C 178

J3515471170X

C 179

J3515471170X

C 180

J3515471170X

C 181

J3515471170X

C 182

J3515471170X

C 183

J3515471170X

C 184

J3515471170X

C 185

J3515471170X

C 186

J3515471170X

C 187

J3515471170X

C 188

J3515471170X

C 189

J3515471170X

C 190

J3515471170X

C 191

J3515471170X

C 192

J3515471170X

C 193

J3515471170X

C 194

J3515471170X

C 195

J3515471170X

C 196

J3525104540X

C 199

J3525104540X

C 200

J3525104540X

C 203

J3525104540X

C 204

J3525104540X

C 207

J3525104540X

C 208

J3525104540X

C 211

J3525104540X

C 212

J3525104540X

C 213

J3525104540X

C 214

J3525104540X

C 215

J3525104540X

C 216

J3525104540X

C 217

J3525104540X

C 218

J3525104540X

C 219

J3525104540X

C 220

J3525104540X

C 221

J3525104540X

C 222

J3525104540X

C 223

J3525104540X

C 224

J3525104540X

C 226

J3525104540X

C 228

J3525104540X

C 230

C 238

J3515270270X CERA/CHIP

C 239

J3515270270X CERA/CHIP

J3525104540X

C 251

J3525104540X

C 252

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CERA/CHIP

CH 50V 120pF-J