Goodman GPC1524M41, GPC1530M41, GPC1536M41, GPC1542M41, GPC1548M41 Installation Manual

...

INSTALLATION INSTRUCTIONS

FOR SELF-CONTAINED PACKAGE

HEAT PUMP UNITS

*PC/*PH15 “M” SERIES

Affix this manual and Users Information Manual adjacent to the unit.

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

ATTENTION INSTALLING PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation Manual. Observe all safety warnings. During installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

These installation instructions cover the outdoor installation of self contained package air conditioners and heating units. See the Specification Sheets applicable to your model for information regarding accessories.

*NOTE: Please contact your distributor or our website for the applicable

Specification Sheets referred to in this manual.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

is a registered trademark of Maytag Corporation or its related companies and is used under license to Goodman Company, L.P., Houston, TX. All rights reserved.

IO-394B 05/12

Goodman Manufacturing Company, L.P. 5151 San Felipe, Suite 500, Houston, TX 77056 www.goodmanmfg.com www.amana-hac.com

© 2010 - 2012 Goodman Manufacturing Company, L.P.

INDEX |

|

TO THE INSTALLER .............................................................................................................................................. |

4 |

IMPORTANT NOTE TO THE HOMEOWNER REGARDING PRODUCT WARRANTY ..................................................................... |

4 |

SHIPPING INSPECTION ...................................................................................................................................................... |

4 |

REPLACEMENT PARTS ....................................................................................................................................................... |

4 |

ORDERING PARTS .............................................................................................................................................. |

4 |

SAFETY INSTRUCTIONS ..................................................................................................................................................... |

4 |

CODES AND REGULATIONS ............................................................................................................................................... |

5 |

EPA REGULATIONS ............................................................................................................................................ |

5 |

NATIONAL CODES ............................................................................................................................................... |

5 |

MAJOR COMPONENTS ....................................................................................................................................................... |

5 |

PRE-INSTALLATION CHECKS ............................................................................................................................................. |

5 |

CLEARANCES AND ACCESSIBILITY ........................................................................................................................... |

5 |

UNIT LOCATION ................................................................................................................................................... |

5 |

GROUND LEVEL PRE-INSTALLATION DETAILS ............................................................................................................ |

5 |

ROOF TOP PRE-INSTALLATION DETAILS .................................................................................................................. |

6 |

ROOF CURB INSTALLATIONS ONLY ......................................................................................................................... |

6 |

RIGGING DETAILS ............................................................................................................................................... |

6 |

CIRCULATING AIR AND FILTERS ....................................................................................................................................... |

7 |

AIR FLOW CONVERSION ....................................................................................................................................... |

7 |

DUCT WORK ....................................................................................................................................................... |

7 |

FILTERS ............................................................................................................................................................ |

7 |

PIPING ................................................................................................................................................................................. |

8 |

CONDENSATE DRAIN ........................................................................................................................................... |

8 |

WIRING ................................................................................................................................................................................ |

8 |

HIGH VOLTAGE WIRING ........................................................................................................................................ |

8 |

LOW VOLTAGE WIRING ........................................................................................................................................ |

8 |

INTERNAL WIRING ............................................................................................................................................... |

8 |

STARTUP, ADJUSTMENTS, AND CHECKS ......................................................................................................................... |

9 |

COOLING START-UP PROCEDURES ........................................................................................................................ |

9 |

HEAT PUMP START-UP PROCEDURE ...................................................................................................................... |

9 |

FINAL SYSTEM CHECKS ...................................................................................................................................... |

9 |

COMPONENTS .................................................................................................................................................................... |

9 |

CONTACTOR ....................................................................................................................................................... |

9 |

CRANKCASE HEATER .......................................................................................................................................... |

9 |

CONDENSER MOTOR ........................................................................................................................................... |

9 |

COMPRESSOR ................................................................................................................................................. |

10 |

CONTACTOR RELAY ........................................................................................................................................... |

10 |

DEFROST CONTROL .......................................................................................................................................... |

10 |

OUTDOOR THERMOSTAT ..................................................................................................................................... |

10 |

REVERSING VALVE COIL ................................................................................................................................... |

10 |

INDOOR BLOWER MOTOR ................................................................................................................................... |

10 |

HEAT PUMP OPERATION .................................................................................................................................................. |

10 |

COOLING CYCLE .............................................................................................................................................. |

10 |

HEATING CYCLE ............................................................................................................................................... |

10 |

DEFROST CONTROL ........................................................................................................................................... |

11 |

AIR FLOW MEASUREMENT AND ADJUSTMENT .......................................................................................................... |

12 |

AIR FLOW ADJUSTMENTS FOR INDOOR BLOWER MOTOR .......................................................................................... |

12 |

2

APH DIP SWITCH FUNCTIONS ............................................................................................................................ |

12 |

APH CFM DELIVERY AND ADJUSTMENTS ............................................................................................................ |

12 |

APH THERMOSTAT “FAN ONLY” MODE .............................................................................................................. |

12 |

APH HUMIDITY CONTROL .................................................................................................................................. |

12 |

APH TWO-STAGE HEATING ............................................................................................................................... |

12 |

APH THERMOSTAT WIRING ................................................................................................................................ |

12 |

EXPANSION VALVE (TXV) SYSTEM ..................................................................................................................... |

13 |

HEAT PUMP - HEATING CYCLE ........................................................................................................................... |

14 |

ELECTRICAL ADJUSTMENTS ........................................................................................................................................... |

14 |

MAINTENANCE .................................................................................................................................................................. |

15 |

SERVICE ............................................................................................................................................................................ |

15 |

COMMON CAUSES OF UNSATISFACTORY OPERATION OF HEAT PUMP ON THE HEATING CYCLE ........................................ |

15 |

INADEQUATE AIR VOLUME THROUGH INDOOR COIL ............................................................................................... |

15 |

OUTSIDE AIR INTO RETURN DUCT ..................................................................................................................... |

15 |

UNDERCHARGE .............................................................................................................................................. |

15 |

POOR “TERMINATING” SENSOR CONTACT ........................................................................................................... |

15 |

MALFUNCTIONING REVERSING VALVE - THIS MAY BE DUE TO: ................................................................................ |

15 |

APPENDIX ......................................................................................................................................................................... |

16 |

TROUBLESHOOTING CHART ................................................................................................................................. |

17 |

GPH15 BLOWER PERFORMANCE DATA ............................................................................................................... |

18 |

GPC15 BLOWER PERFORMANCE DATA ............................................................................................................... |

20 |

APH15 BLOWER PERFORMANCE DATA ............................................................................................................... |

21 |

APH15 CFM OUTPUT AND DIP SWITCH SETTINGS .............................................................................................. |

22 |

CFM OUTPUT FOR DIP SWITCH COMBINATIONS 1-2 (ELECTRIC HEAT) .................................................................. |

22 |

DIP SWITCH SETTINGS FOR SINGLE AND TWO-STAGE THERMOSTATS ...................................................................... |

22 |

CFM OUTPUT FOR DIP SWITCH COMBINATIONS 5-6 (COOLING/HEATING). ............................................................. |

22 |

ADJUSTMENTS THROUGH DIP SWITCH COMBINATIONS 7-8 .................................................................................... |

22 |

DIMENSIONS & MINIMUM CLEARANCES ............................................................................................................. |

23 |

3

TO THE INSTALLER

Carefully read all instructions for the installation prior to installing unit. Make sure each step or procedure is understood and any special considerations are taken into account before starting installation. Assemble all tools, hardware and supplies needed to complete the installation. Some items may need to be purchased locally. After deciding where to install unit, closely look the location over - both the inside and outside of home. Note any potential obstacles or problems that might be encountered as noted in this manual. Choose a more suitable location if necessary.

IMPORTANT NOTE: If a crankcase heater is used, the unit should be energized 24 hours prior to compressor start up to ensure crankcase heater has sufficiently warmed the compressor. Compressor damage may occur if this step is not followed.

IMPORTANT NOTE TO THE OWNER REGARDING PRODUCT

WARRANTY

Your warranty certificate is supplied as a separate document with the unit installed by your contractor. Read the limited warranty certificate carefully to determine what is and is not covered and keep the warranty certificate in a safe place. If you are unable to locate the warranty certificate please contact your installing contractor or contact customer service (877- 254-4729) to obtain a copy.

To receive the 10-year Parts Limited Warranty, online registration must be completed within 60 days of installation. Online registration is not required in California or Quebec.

Complete warranty details available from your local dealer or, for Goodman® brand products, visit www.goodmanmfg.com, and for Amana® brand products, visit www.amana-hac.com.

IMPORTANT: To register your Goodman® brand unit, go to www.goodmanmfg.com and click “Warranty Registration”. Complete registration as prompted.

To register your Amana® brand unit, go to www.amana-hac.com and click “Warranty Registration”. Complete registration as prompted.

Product limited warranty certificates for models currently in production can be viewed at www.goodmanmfg.com or www.amanahac.com. If your model is not currently in production or does not appear on the website, please contact your installing contractor or contact customer service (877-254-4729) to obtain a copy of your warranty certificate.

Each product overview page contains a Product Warranty link; by clicking on it you will be able to view the limited warranty coverage for that specific product. To view warranty registration information, click on the Product Warranty text on the left navigation panel on the home page of each website. The Online Product Registration pages are located in this same section.

Before using this manual, check the serial plate for proper model identification.

The installation and servicing of this equipment must be performed by qualified, experienced technicians only.

SHIPPING INSPECTION

Upon receiving the unit, inspect it for damage from shipment. Claims for damage, either shipping or concealed, should be filed immediately with the shipping company. Check the unit model number, specifications, electrical characteristics and accessories to determine if they are correct. In the event an incorrect unit is shipped, it must be returned to the supplier and must NOT be installed. The manufacturer assumes no responsibility for installation of incorrectly shipped units.

REPLACEMENT PARTS

ORDERING PARTS

When reporting shortages or damages, or ordering repair parts, give the complete unit model and serial numbers as stamped on the unit’s nameplate.

Replacement parts for this appliance are available through your contractor or local distributor. For the location of your nearest distributor, consult the white business pages, the yellow page section of the local telephone book or contact:

CONSUMER AFFAIRS

GOODMAN MANUFACTURING COMPANY, L.P.

7401 SECURITY WAY

HOUSTON, TEXAS 77040 877-254-4729

SAFETY INSTRUCTIONS

The following symbols and labels are used throughout this manual to indicate immediate or potential safety hazards. It is the owner’s and installer’s responsibility to read and comply with all safety information and instructions accompanying these symbols. Failure to heed safety information increases the risk of personal injury, property damage, and/or product damage.

4

CODES AND REGULATIONS

The *PH/C M-series heat pumps are designed for OUTDOOR USE ONLY. *PH M-Series is available in cooling capacities of 2, 2.5 3, 4 and 5 nominal tons of cooling. The GPC is only available in 2 thru 4 ton. Optional field installed heat kits are available in 5,8,10,15 and 20 kW. The units can be easily installed in manufactured or modular homes with existing high-static duct work. The units can also be easily converted to accommodate a plenum for normal or low-static applications. The *PH/C M-series are self contained packaged units so the only connections needed for installation are the supply and return ducts, the line and low voltage wiring and drain connection. Rated performance is achieved after 72 hours of operation. The units are ETL listed and AHRI certified.

The information on the rating plate is in compliance with the FTC & DOE rating for single phase units.

EPA REGULATIONS

IMPORTANT: THE UNITED STATES ENVIRONMENTAL PROTECTION AGENCY (EPA) HAS ISSUED VARIOUS REGULATIONS REGARDING THE INTRODUCTION AND DISPOSAL OF REFRIGERANTS IN THIS UNIT. FAILURE TO FOLLOW THESE REGULATIONS MAY HARM THE ENVIRONMENT AND CAN LEAD TO THE IMPOSITION OF SUBSTANTIAL FINES. BECAUSE REGULATIONS MAY VARY DUE TO PASSAGE OF NEW LAWS, WE SUGGEST A CERTIFIED TECHNICIAN PERFORM ANY WORK

DONE ON THIS UNIT. SHOULD YOU HAVE ANY QUESTIONS PLEASE CONTACT THE LOCAL OFFICE OF THE EPA.

NATIONAL CODES

This product is designed and manufactured to permit installation in accordance with National Codes. It is the installer’s responsibility to install the product in accordance with National Codes and/or prevailing local codes and regulations.

MAJOR COMPONENTS

The unit includes a hermetically sealed refrigerating system (consisting of a compressor, condenser coil, evaporator coil with flowrator), an indoor blower, a condenser fan and all necessary internal electrical wiring. The heat pump also includes a reversing valve, solenoid, defrost thermostat and control and loss of charge protection. The system is factoryevacuated, charged and performance tested. Refrigerant amount and type are indicated on rating plate.

PRE-INSTALLATION CHECKS

Before attempting any installation, the following points should be considered:

•Structural strength of supporting members

•Clearances and provision for servicing

•Power supply and wiring

•Air duct connections

•Drain facilities and connections

•Location may be on any four sides of a home, manufactured or modular, to minimize noise

CLEARANCES AND ACCESSIBILITY

The unit is designed to be located outside the building with unobstructed condenser air inlet and discharge. Additionally, the unit must be situated to permit access for service and installation. Condenser air enters from three sides. Air discharges upward from the top of the unit. Refrigerant gauge connections are made on the right side of the unit as you face the compressor compartment. Electrical connections can be made either on the right, bottom or duct panel side of the unit. The best and most common application is for the unit to be located 10” from wall (4” minimum) with the connection side facing the wall. This “close to the wall” application minimizes exposed wiring.

Close to the wall application assures free, unobstructed air to the other two sides. In more confined application spaces, such as corners provide a minimum 12” clearance on all air inlet sides. Allow 36” minimum for service access to the compressor compartment and controls. The top of the unit should be completely unobstructed. If units are to be located under an overhang, there should be a minimum of 48” clearance and provisions made to deflect the warm discharge air out from the overhang.

UNIT LOCATION

Consider the affect of outdoor fan noise on conditioned space and any adjacent occupied space. It is recommended that the unit be placed so that condenser air discharge does not blow toward windows less than 25 feet away. Consideration should also be given to shade and unit appearance.

Heat pumps require special location consideration in areas of heavy snow accumulation and/or areas with prolonged continuous subfreezing temperatures. Heat pump unit bases have holes under the outdoor coil to permit drainage of defrost water accumulation. The unit must be situated to permit free unobstructed drainage of the defrost water and ice. A minimum 2" clearance under the outdoor coil is required in the milder climates.

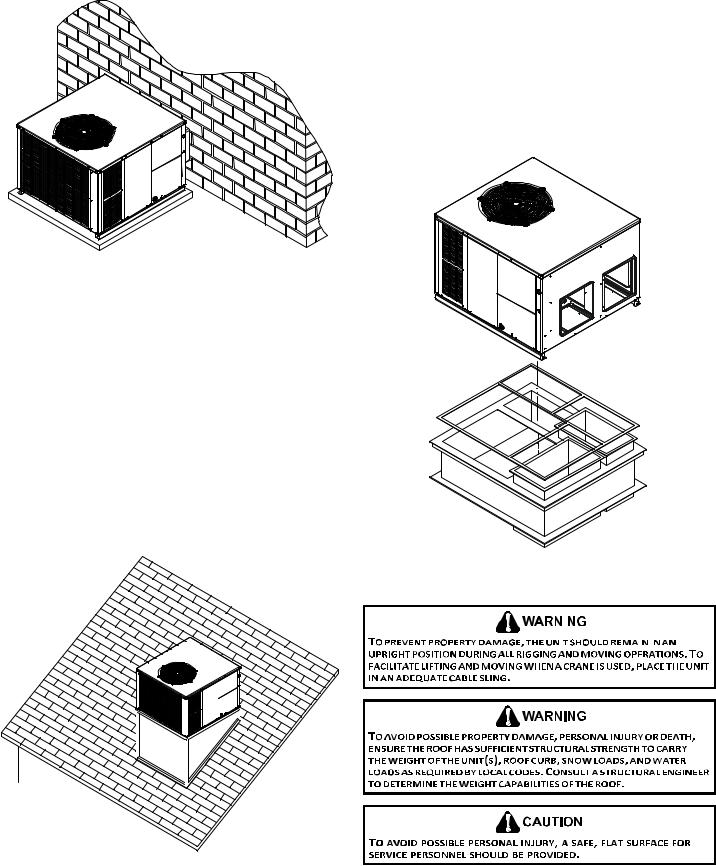

GROUND LEVEL PRE-INSTALLATION DETAILS

The unit should be set on a solid, level foundation - preferably a concrete slab at least 4 inches thick. The slab should be above ground level and surrounded by a graveled area for good drainage. Any slab used as a unit’s foundation should not adjoin the building as it is possible that sound and vibration may be transmitted to the structure.

5

ROOF CURB INSTALLATIONS ONLY

NOTE: Sufficient structural support must be determined prior to locating and mounting the curb and package unit.

Curb insulation, cant strips, flashing and general roofing material are furnished by the contractor.

Curbing must be installed in compliance with the National Roofing Contractors Association Manual. Construct duct work using current industry guidelines. The duct work must be placed into the roof curb before mounting the package unit.

Ground Level Installation

ROOF TOP PRE-INSTALLATION DETAILS

Ensure that the roof is weather tight and allows proper drainage of condensation. Use steel or treated wood beams as unit support for load distribution.

NOTE: To ensure proper condensate drainage, unit must be installed in a level position.

• To avoid possible property damage or personal injury, the roof must have sufficient structural strength to carry the weight of the unit(s) and snow or water loads as required by local codes. Consult a structural engineer to determine the weight capabilities of the roof.

• The unit may be installed directly on wood floors or on Class A, Class B, or Class C roof covering material.

• To avoid possible personal injury, a safe, flat surface for service personnel should be provided.

Roof Curb Installation

RIGGING DETAILS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IMPORTANT: If using bottom discharge with roof curb, duct |

||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

||||||||

RooftopInstallation |

|

work should be attached to the curb prior to installing the unit. |

||||||||||||

|

Lower unit carefully onto roof mounting curb. While rigging |

|||||||||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

unit, center of gravity will cause condenser end to be lower |

||||||

|

|

|

|

|

|

|

|

than supply air end. |

||||||

6

Rigging

CIRCULATING AIR AND FILTERS

AIR FLOW CONVERSION

Units can easily be converted from horizontal to down discharge air flow delivery. In down discharge or high static installations, the installer should measure the total external static and review the blower performance charts before performing the installation. In some installations it will be necessary to change the blower speed to provide proper air flow.

Horizontal Air Flow

Single phase models are shipped without horizontal duct covers. If needed, these kits may be ordered through Goodman’s Service Parts department.

Return

Supply

Remove these panels for downflow duct applications

Duct Cover Installation

Down Discharge Applications

Cut insulation around bottom openings and remove panels from the bottom of the unit, saving the screws holding the panels in place.

NOTE: Single phase models require installation of horizontal duct kit #20464501PDGK (medium chassis) and #20464502PDGK (large chassis).

DUCT WORK

Duct systems and register sizes must be properly designed for the C.F.M. and external static pressure rating of the unit. Duct work should be designed in accordance with the recommended methods of Air Conditioning Contractors of America Manual D (Residential) or Manual Q (Commercial). All duct work exposed to the outdoors must include a weatherproof barrier and adequate insulation.

A duct system should be installed in accordance with Standards of the National Board of Fire Underwriters for the Installation of Air Conditioning, Warm Air Heating and Ventilating Systems. Pamphlets No. 90A and 90B.

The supply duct from the unit through a wall may be installed without clearance. However, minimum unit clearances as shown in the Appendix must be maintained. The supply duct should be provided with an access panel large enough to inspect the air chamber downstream of the heat exchanger. A cover should be tightly attached to prevent air leaks.

For duct flange dimensions on the unit refer to the Unit Dimension illustration in the Appendix.

For down discharge applications, the duct work should be attached to the roof curb prior to installing the unit. Duct work dimensions are shown in the roof curb installation manual.

If desired, supply and return duct connections to the unit may be made with flexible connections to reduce possible unit operating sound transmission.

FILTERS

Filters are not provided with unit and must be supplied and externally installed in the return duct system by the installer. A field-installed filter grille is recommended for easy and convenient access to the filters for periodic inspection and cleaning. When installing filters, ensure the air flow arrows on the filter are pointing toward the circulator blower.

Refer to the unit filter size chart below for filter size information.

MINIMUM FILTER SIZE

NOMINAL SIZE (INCHES) |

NOMINAL AREA (SQ. FT.) |

10x20 |

1.4 |

14x20 |

1.9 |

14x25 |

2.4 |

15x20 |

2.1 |

16x20 |

2.2 |

16x25 |

2.8 |

20x20 |

2.8 |

20x25 |

3.5 |

25x25 |

4.3 |

NOTE: Filters must have adequate face area for the rated quantity of the unit. See the air delivery table below for recommended filter size. Size the filters in accordance with their manufacturer recommendations. Throwaway filters must be sized for a maximum face velocity of 300 feet per minute.

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Area |

Feet |

6 |

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Filter |

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

||

5 |

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

IL |

|

|

|

|

|

|

|

|

|

|

||||

Square |

|

|

|

|

|

|

|

|

EF |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

R |

|

|||

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

||||

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

T |

|

|

|||

Nominal |

|

|

|

|

|

S |

|

|

|

|

|

|

|

|

|

IL |

|

|

|

|||

4 |

|

|

|

|

|

|

|

|

|

|

|

|

T |

F |

|

|

|

|

||||

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

P |

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|||||

|

IS |

|

|

|

|

|

|

|

|

|

NE |

|

|

|

|

|

|

|||||

|

D |

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

M |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

||

|

3 |

|

|

|

|

|

|

|

|

P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

1000 |

|

|

1500 |

2000 |

|

2500 |

|

3000 |

3500 |

||||||||||

|

|

500 |

|

|

|

|

||||||||||||||||

Airflow - SCFM

7

PIPING

CONDENSATE DRAIN

The condensate drain connection of the evaporator is a half coupling of ¾” N.P.T. A trap must be provided to have proper condensate drainage.

Unit |

2" Minimum |

Drain |

|

Connection |

3" Minimum |

|

|

Flexible |

|

Tubing-Hose |

A Positive Liquid Seal |

Or Pipe |

Is Required |

Install condensate drain trap as shown. Use ¾ “ drain connection size or larger. Do not operate without trap. Unit must be level or slightly inclined toward drain.

WIRING

NOTE: All wiring should be made in accordance with the National Electrical Code.

Consult your local Power Company to determine the availability of sufficient power to operate the unit. Check the voltage, frequency, and phase at the power supply to ensure it corresponds to the unit’s RATED VOLTAGE REQUIREMENT.

In accordance with the N.E.C. or local codes, install a branch circuit fused disconnect near the unit. Determine wire sizes and overcurrent protection from the unit nameplate ampacity and in accordance with the Minimum Filter Size or the N.E.C. The wiring should never be sized smaller than is recommended by either of these two sources.

Fuses smaller than that recommended on the rating plate could result in unnecessary fuse failure or service calls. The use of protective devices of larger size than indicated could result in extensive damage to the equipment. The manufacturer bears no responsibility for damage caused to equipment as result of the use of larger than is recommended size protective devices.

All units have undergone a run test prior to packaging for shipment. This equipment has been started at minimum rated voltage and checked for satisfactory operation. Do not attempt to operate this unit if the voltage is not within the minimum and maximum voltages shown on nameplate.

All exterior wiring must be within approved weatherproof conduit. The unit must be permanently grounded in accordance with local codes, or in absence of local codes, with N.E.C. ANSI/ NFPA NO. 70-1984 or latest edition by using ground lug in the control box.

Fuses or HACR type circuit breakers may be used where codes permit.

IMPORTANT NOTE: Some single phase units are equipped with a single-pole contactor. Exercise caution when servicing as only one leg of the power supply is broken with the contractor.

HIGH VOLTAGE WIRING

•Single Phase. Connect two leads to terminals L1 & L2 in the electrical control section, using wire sizes specified in wiring table.

LOW VOLTAGE WIRING

•Heat Pumps. Connect 24V wires from the thermostat to the corresponding wires in the control box using No. 18 AWG as follows:

|

GPC15 |

|

|

24 -60 |

|

|

|

Terminal |

Thermostat |

|

|||

|

Red |

|

|

R (24V) |

|

|

|

Green |

|

|

G (fan) |

|

|

|

White |

|

W1 (heat*) |

|

||

|

Brown |

|

W2 (heat*) |

|

||

|

Yellow |

|

|

Y (cool) |

|

|

|

Blue |

C (24V Common) |

|

|||

|

|

|

|

|

||

[A/G]PH15 |

24 - 43 |

|

|

49 - 60 |

||

Terminal |

Thermostat |

|

|

Thermostat |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Red |

R (24V) |

|

|

|

R (24V) |

|

Green |

G (fan) |

|

|

|

G (fan) |

|

Orange |

O (rev. valve) |

|

|

O (rev. valve) |

||

White |

W1 (heat, 2nd) |

|

|

W1 (heat. 2nd)* |

||

Brown |

W2 (heat, 3rd) |

|

|

W2 (heat, 3rd)* |

||

Purple |

Not used |

|

|

|

Y1 (Low cool) |

|

Yellow |

Y (cool) |

|

|

|

Y2 (Hi cool) |

|

Blue |

C (24V Common) |

|

C (24V Common) |

|||

Thermostats must be set to energize "G" during cooling. This is default on most all thermostats.

*Optional field installed heat connections.

*PH1549 - *PH1560 have two-stage cooling and require two-stage heat/cool with optional third stage electric heat thermostat.

INTERNAL WIRING

A diagram detailing the internal wiring of this unit is located on the electrical box cover. If any of the original wire supplied with the appliance must be replaced, the wire gauge and insulation must be the same as the original wiring.

Transformer is wired for 230 volts on the 208/230 models. See wiring diagram for 208 volt wiring.

1.For branch circuit wiring (main power supply to unit disconnect), the minimum wire size for the length of run can be determined using the circuit ampacity found on the unit rating plate and the table below. From the unit disconnect to the unit, the smallest wire size allowable may be used for the ampacity, as the disconnect must be in sight of the unit.

BRANCH CIRCUIT AMPACITY |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

SUPPLY WIRE LENGTH - |

|

|

|

|

|

|

|

|

FEET |

|

|

|

|

|

|

|

|

200 |

6 |

4 |

4 |

4 |

3 |

3 |

2 |

2 |

150 |

8 |

6 |

6 |

4 |

4 |

4 |

3 |

3 |

100 |

10 |

8 |

8 |

6 |

6 |

6 |

4 |

4 |

50 |

14 |

12 |

10 |

10 |

8 |

8 |

6 |

6 |

2.Wire size based on 60°C rated wire insulation and 30°C Ambient Temperature (86°F).

3.For more than three conductors in a raceway or cable, see the N.E.C. for derating the ampacity of each conductor.

8

Loading...

Loading...