Page 1

OPERATING

INSTRUCTIONS

Decomat 8666Operating instructions

9908

Decomat

8666

Serial no. 81511-

4996863-04

0301

1

Produced: 1999

Page 2

Contents

Operating instructionsDecomat 8666

Safety rules________________________________________________3

General safety rules _______________________________________ 3

Power cut-off device ______________________________________ 3

Caution symbols _________________________________________ 3

Decomat 8666 ______________________________________________4

Programming device ______________________________________ 5

Door function ___________________________________________ 5

Manually controlled door _______________________________ 6

Automatically controlled door ____________________________ 6

Dispenser system ________________________________________ 6

Drying _________________________________________________ 6

Operation _________________________________________________ 7

Error indication ____________________________________________8

Red lamp lights __________________________________________ 8

Error messages __________________________________________ 8

Error codes (F-Codes) _____________________________________ 9

Acknowledgement of error code _____________________________ 9

Maintenance ______________________________________________ 10

Daily _________________________________________________ 1 0

If necessary ____________________________________________ 10

The washing chamber _________________________________ 10

The exterior _________________________________________ 1 0

Standard programs _________________________________________11

Machine for hospitals, without drying function ________________ 11

Machine for hospitals, with drying function ___________________ 12

Machine for laboratories, without drying function ______________ 13

Machine for laboratories, with drying function _________________ 14

Standard program _______________________________________ 15

Program printout __________________________________________16

9908

2

Page 3

Safety rules

This machine is designed with a number of integrated safety devices. To avoid

personal injury it is essential that the safety devices are not bypassed or in any

other way put out of action.

General safety rules

• The machine should be connected according to the instructions.

• The machine may not by used by juveniles.

• Installation work and servicing should be carried out by staff trained to use

this machine.

• The door switch on the machine may not be bypassed under any

circumstances.

• Leakage in the system, eg, due to worn lid gasket, must be repaired

immediately.

• Personnel concerned must study valid handbooks and service manuals prior

to any repairs or service work.

• All plug-in leads must be unplugged from all of the circuit boards of the

control system before any welding on or close to the dishwasher is started.

• The machine may not be sprayed with water.

• Caution must be observed when using corrosive detergents.

• Safety precautions must be observed when using hot water or steam.

Decomat 8666Operating instructions

Power cut-off device

The machine can be provided with a separate main switch in the power supply

line, easily accessible on the wall.

Caution symbols

This manual contains certain warnings, instructions and advice of such

importance that they are particularly emphasized. The configuration and use of

the appertaining symbols are as follows:

This symbol indicates a warning in the text. It gives warning of

dangers which could lead to minor or major injury to the person

and even to a fatality.

It is also used in warnings to avoid damage to the machine.

9908

3

Page 4

Decomat 8666

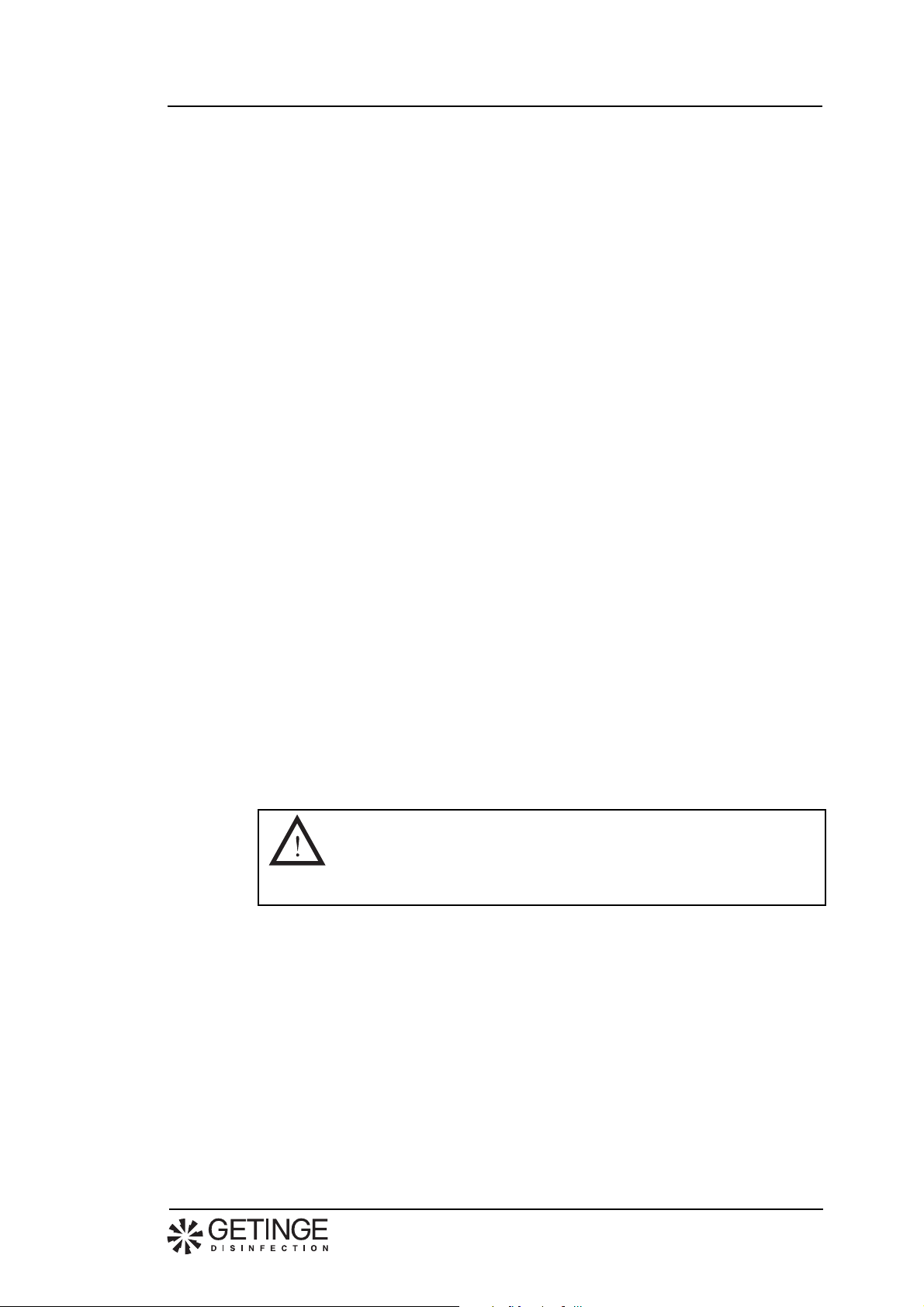

The Decomat 8666 is a fully automatic washer disinfector for the cleaning and

disinfecting of contaminated dishware in hospitals, laboratories and the

pharmaceutical industry.

The machine is provided with three spray arms and can be equipped with a

variety of accessories for different cleaning requirements. These accessories are

presented in a separate accessories catalogue.

Several options are available with regard to installation to suit the range of use

intended:

• Electric or steam heating.

• Connection of distilled or deionized water.

• With or without built-in drying system.

• Single or double doors.

• Extra dispenser pumps, eg, to permit chemical disinfection of heat sensitive

goods.

• Loader/Unloader

• Automatic program select (set by basket)

• Audio-signal for end of cycle, error code, etc.

Decomat 8666 is tested and approved in compliance with the recommendations

of SPRI (Swedish Planning and Rationalization Institute of the Health and Social

Services) and BGA.

Operating instructionsDecomat 8666

9908

4

V770

Page 5

Programming device

The machine is fitted with an electronic programmable device which can contain

a maximum of 60 different programs. Six of these programs can be chosen using

the program selection buttons.

A number of standard programs are included in the programming device on

delivery (see section, Standard programs). These programs can be modified to

suit individual customer requirements. Furthermore, completely new individual

programs can be programmed directly into the machine from the machine control

panel. If desired, the whole or parts of a standard program can be used as the

basis for programming.

Programming may only be carried out by authorized personnel.

Door function

Decomat A 8666 is provided with either one or two doors. Doors are of the

vertical sliding type.

The doors can be equipped with motors for automatic opening and closing. The

doors have efficient anti-crushing protection.

Decomat 8666Operating instructions

Clean side

V398

Machines with double doors are fitted with an interlocking system that allows

only one door to be open at a time. This means that the door on the clean side

must be closed and latched by pressing the “DOOR” button before the door on

the soiled side can be opened.

On pressing the START button, the door is locked and a yellow lamp flashes

(process ON) for about 10 seconds. If the START button is pressed again during

this “alert” period the door on the soiled side will be unlocked and it can then be

opened by hand or automatically.

The doors can be locked or unlocked individually by entering the test program

(access code required).

Soiled side

Clean

side

9908

5

Page 6

Manually controlled door

On closing the door by hand and pressing the START button, the door will lock

automatically, the yellow lamp will flash and the program starts.

When the program is completed, a green lamp will light on both sides (if fitted

with two doors) and the door on the clean side will unlock. The green lamp will go

out when the door is opened by hand. If fitted with two doors, the door on the

clean side must be closed, and locked with the DOOR button before the door on

the soiled side can be opened.

Automatically controlled door

On pressing the START button, the door will close and lock automatically, the

yellow lamp will flash and the program starts.

When the program is completed, a green lamp will light on both sides (if fitted

with two doors) and the door on the clean side will automatically open. The green

lamp will go out on both sides when the door is fully open. If fitted with two

doors, the door on the clean side must be closed with the DOOR button before

the door on the soiled side opens automatically.

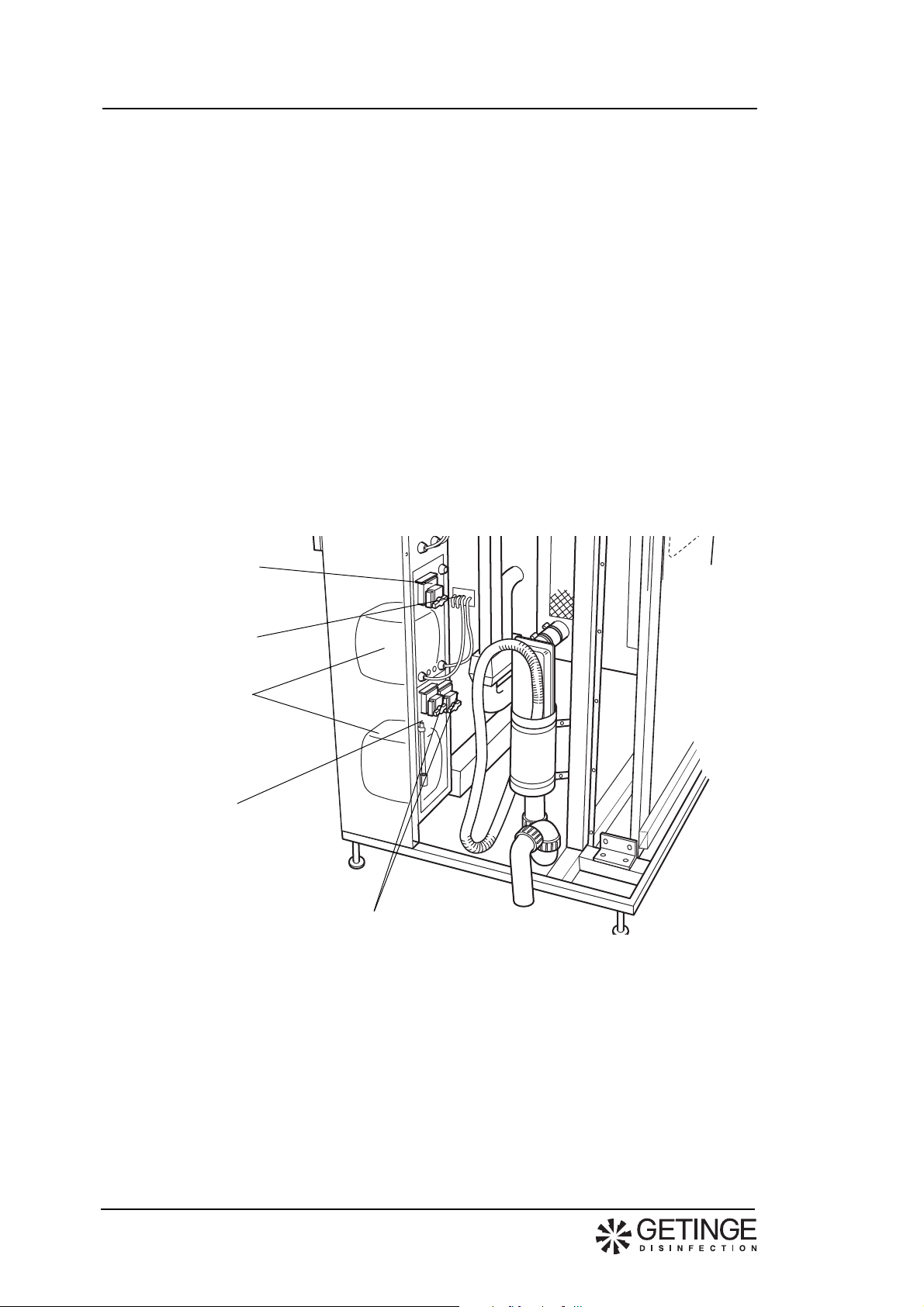

Dispenser system

In its standard version the machine has two different dispenser systems. One

Operating instructionsDecomat 8666

Dispenser pump

Dispenser tube

connections to

Detergent/

Empty bottle

V775

Dispenser pumps

system for alkaline detergent and one system for rinse-aid or acidic detergent.

The size of the dispenser dose can be individually set for each program and each

separate part of the program.

The machine cannot be started if the detergent bottle is empty. The message

”FILL DETERGENT” will be displayed when the detergent bottle becomes

empty.

A third dispenser system can be installed if required, eg, for chemical

disinfection of heat-sensitive dishware.

Drying

9908

6

If the machine is not provided with drying, it is recommended that the dishware

is dried in a separate dryer cabinet.

Page 7

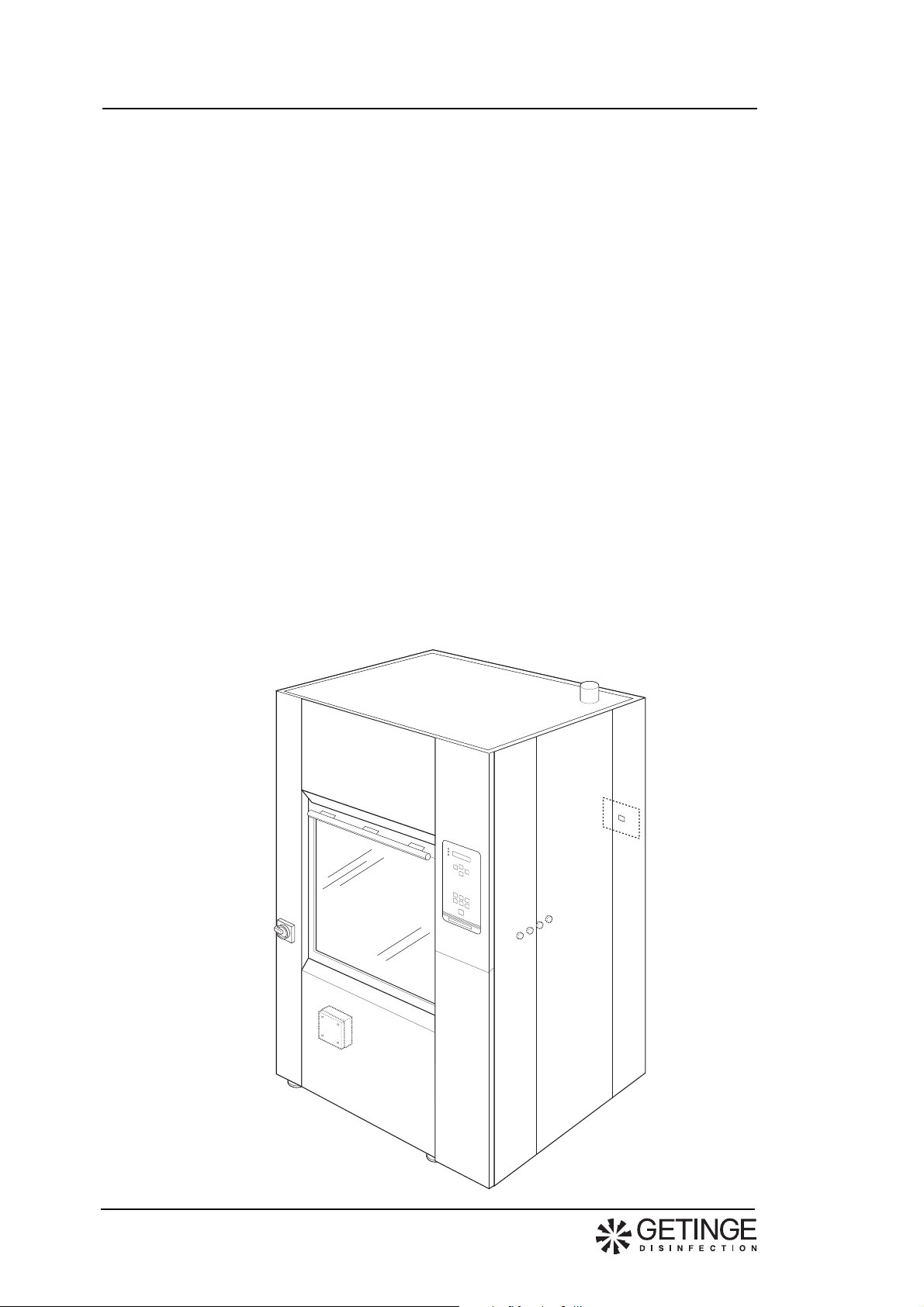

Operation

Decomat 8666Operating instructions

Before starting: Selected program

During process: Program phase (eg, ”Rinsing”)

Yellow: Process in progress

Green: Process completed

Red: Not disinfected

Actual temperature

in washing chamber

Program selection

buttons

Washing program

start button

L

Rinsing P01

M

047°C 00:30

K

I

ABC

DEF

L

H

K

J

G

Program number

Remaining

program time

Programming buttons (see

”Service instructions”)

• Place the dishware in the trolley and roll it into the machine. How to arrange

the dishware on the trolley is demonstrated in the goods arrangement chart.

• Ensure that the spray arms can rotate freely without touching the dishware.

Close the door.

• Choose a program using the program selector buttons A- F. The upper line

of the display will then show the name and number of the program chosen. If

no program is available under the program button that was chosen, the

message ”NOT PROGRAMMED” will be displayed.

• Press the Gbutton. The yellow lamp will light throughout the program

sequence, and the current phase of the program, eg, ”Rinsing”, the actual

temperature and the remaining program time will be displayed.

• On completion of the program, the green lamp will light and the door will be

unlocked (door on the cleaned side if fitted with two doors).

• Empty the machine (and close the door on the cleaned side if fitted with two

doors).

• If the same program is to be repeated it is not necessary to press a program

selector button, just press the Gbutton.

• The yellow lamp will flash for 10 seconds when the Gbuttom is pressed.

During this period the program can be interrupted by pressing Gonce more.

Note.

The display window goes dark after 30 minutes and i automatically

activated again on starting or when choosing a program.

9908

7

Page 8

Error indication

Red lamp: Not disinfected

Error message or error code

L

P01

M

Fill detergent 1

K

H

I

J

ABC

DEF

G

Operating instructionsDecomat 8666

L

K

Red lamp lights

If the red lamp lights at K, this is an indication that disinfection is aborted

because the temperature is too low. Contact maintenance personnel.

Error messages

Error messages are displayed in clear text. The machine cannot be started until

the error is rectified. The following error messages can occur:

CHOOSE PROGRAM Gbutton has been pressed before

NOT PROGRAMMED No program available for the program

CLOSE THE DOOR Gbutton pressed while door is open.

FILL DETERGENT 1 Detergent bottle 1 is empty and the

FILL DETERGENT 2 Detergent bottle 2 is empty and the

FILL DETERGENT 3 Detergent bottle 3 is empty and the

V337

P01

Fill detergent 1

choosing a program.

button A- Fchosen.

Gbutton has been pressed.

Gbutton has been pressed.

Gbutton has been pressed.

9908

8

Note.

When the error message ”Fill detergent” appers, there is always

sufficient detergent left for one program.

Page 9

Error codes (F-Codes)

Error code: 05

The error codes indicate a serious malfunction in the washing sequence. Such

errors must be attended to by authorized personnel.

The following error codes can appear:

Code Fault Comments

1 Filling with water too slow Water level sensor not activated within 10

2 Heating of water too slow Water not heated 10°C from initial

3 Draining not working. Water level sensor still activated at end of

4 Drying air temperature too low. Air temperature below 62°C after 15

5 Faulty temperature sensor. Displayed temperature below 0°C or

7 Motor circuit breaker triggered. Motor circuit breaker for the circulation

8 Door malfunction, soiled side. Sensor “Door closed” in lock not activated.

9 Door malfunction, clean side. Sensor “Door closed” in lock not activated.

10 Error when filling economy tank. Level sensor in tank not actuated within two

11 Error when emptying economy tank Level sensor in tank still actuated when

12 Water leakage in drying section. Level sensor in drying section activated

Decomat 8666Operating instructions

minutes from commencement of filling.

temperature within 8 minutes from

commencement of heating.

programmed draining period.

minutes drying.

above 110 °C.

pump is triggered.

minutes of starting to fill the economy tank.

emptying time has expired.

while circulation pump is running.

Acknowledgement of error code

After rectifying an error, press the Gbutton for at least 5 seconds to reset the

code.

9908

9

Page 10

Maintenance

Operating instructionsDecomat 8666

V773

Daily

• Check that no object has fallen to the bottom of the washing chamber and is

• Ensure that the spray arms can rotate freely. Ensure that the holes in the

• Remove and clean the coarse filter in the bottom of the flushing chamber.

• Check that there is detergent/rinse aid in the containers.

• Ensure that the dishware rack docks properly against the water connections.

If necessary

The washing chamber

The washing chamber should be kept free of limescale deposits. Remove

remaining deposits by spraying on a normal acid-based detergent. Then run a

program to cleanse the washing chamber (if the correct dosage of descaling

compound is used, this should not normally be necessary).

The exterior

The front and side walls can be cleaned and disinfected with an alcohol-based

detergent, surgical spirit, or normal detergent. The control panel can be cleaned

in the same way.

Remove marks with ordinary stain-remover for stainless steel.

If the disinfector is used without automatic descaling, the steam generator must

be checked regularly for limescale deposits.

left lying there.

spray arms are not clogged.

Clean the spray arms as required by unscrewing the centre nut, lift off the arm

and flush clean. Ensure that the spray arm rotates freely after refitting.

9908

10

Page 11

Standard programs

5

10 15 20 25 30 50454035

10

100

90

80

70

60

50

40

30

20

Min

°C

Dos 2

Dos 1

Kv

Vv

Vv Vv

3

5 8

The following pages show the programs that are included in the machine on

delivery. The programs will vary depending on the initial range of use intended

and the equipment fitted.

Machine for hospitals, without drying function

Decomat 8666Operating instructions

100

100

90

80

70

60

50

40

30

20

10

°C

1 OP-BGA (A+B)

90

80

70

Dos 1

60

50

40

30

1

20

10

KvVvKv

3

10 15 20 25 30 50454035

5

Vv

Dos 2

5 6 8

Min

Vv VvVv

V354

2 AN-BGA (A+B)

V415

3 OP-BGA (A)

°C

Dos 1

3

1

5

Kv

Vv

Vv

Dos 2

5 6 8

Min

10 15 20 25 30 50454035

Vv VvVv

V355

4 , 5 and 6 Not programmed

Program phases

9908

1 Pre rinse 1

2 Pre rinse 2

3 Washing

4 Neutralizing

5 After rinse 1

6 After rinse 2

7 After rinse 3

8 Final rinse

9 Drying

11

Page 12

Machine for hospitals, with drying function

Operating instructionsDecomat 8666

100

1 OP-BGA (A+B)

°C

100

90

80

70

60

50

40

30

20

10

100

°C

90

80

70

Dos 1

60

50

40

30

20

10

5

Kv

3

10 15 20 25 30 50454035

Dos 2

4 5 8

Min

Vv VvVv

V464

3 OP-BGA (A)

°C

90

80

70

60

Dos 1

50

40

30

1

20

10

5

Kv

Kv

Vv

Vv

Dos 2

3

4 5 8

10 15 20 25 30 50454035

VvVv

Vv

Min

V466

°C

100

90

80

70

60

50

40

30

20

10

Kv Drying

2 AN-BGA (A+B)

Dos 2

Dos 1

3

1

5

Kv

Vv VvVv

Vv

4 5 8

10 15 20 25 30 50454035

Vv

4 OP-BGA (A+B)-T

Dos 2

Dos 1

3

10 15 20 25 30 60454035

5

4 5 8

Vv VvVv

Min

V465

9

Min

V467

100

°C

90

80

70

60

50

40

30

1

20

10

Kv

Vv

9908

12

5 AN-BGA (A+B)+T

Dos 2

Dos 1

3

4 5 8

10 15 20 25 30 804035

5

Vv VvVv

Vv

1 Pre rinse 1

2 Pre rinse 2

3 Washing

4 Neutralizing

5 After rinse 1

9

Min

Drying

V468

Program phases

6 After rinse 2

7 After rinse 3

8 Final rinse

9 Drying

6 OP-BGA (A) -SHORT+T

°C

100

90

80

70

Dos 1

60

50

40

30

20

10

5

Kv

Vv

Dos 2

3

4 5 8

10 15 20 25 30 50454035

VvVv

Vv Drying

9

Min

V469

Page 13

Machine for laboratories, without drying function

5

10 15 20 25 30 50454035

10

100

90

80

70

60

50

40

30

20

Min

°C

55

60 65 70

75

Kv

Vv

Vv

Vv

43 5

Dos 2

Dos 1

Kv

Dv

1

6 8

Dv

Decomat 8666Operating instructions

1 SHORT LAB

°C

100

90

80

70

60

Dos 1

50

40

30

20

10

1

5

Kv VvVv

Dos 2

4

3

10 15 20 25 30 50454035

85

Vv Dv

Min

55

G222

2 LONG LAB

G223

3 TEST TUBES

°C

100

90

80

70

60

Dos 2

50

40

30

20

10

1

5

Vv

Vv

Kv

10 15 20 25 30 50454035

3 6

Vv

Dos 2

43 5 7

Vv

Vv Kv

Vv Dv

8

60 65 70

55

Min

75

G224

4 , 5 and 6 Not programmed

Program phases

1 Pre rinse 1

2 Pre rinse 2

3 Washing

9908

4 Neutralizing

5 After rinse 1

6 After rinse 2

7 After rinse 3

8 Final rinse

9 Drying

13

Page 14

Machine for laboratories, with drying function

Operating instructionsDecomat 8666

1 SHORT LAB

°C

100

90

80

70

60

Dos 1

50

40

30

20

10

1

5

Kv VvVv

Dos 2

4

3

10 15 20 25 30 50454035

85

Vv Dv

Min

55

G222

°C

100

90

80

70

60

50

40

30

20

10

1

Kv

Vv

3 TEST TUBES

°C

100

90

80

70

60

Dos 2

50

40

30

20

10

1

10 15 20 25 30 50454035

5

Vv

Vv

Kv

3 6

Vv

Dos 2

43 5 7

Vv

Vv Kv

Vv Dv

8

60 65 70

55

Min

75

2 LONG LAB

Dos 1

5

Vv

Dos 2

43 5

6 8

10 15 20 25 30 50454035

Dv

Dv

Vv

Kv

4 SHORT LAB +T

°C

100

90

80

70

60

Dos 1

50

40

30

20

10

1

5

Kv VvVv

Dos 2

3

4

85

10 15 20 25 30 50454035

Vv Dv

Drying

9

55

60 65 70

55

Min

75

G223

Min

G224

5 LONG LAB +T

°C

100

90

80

70

60

Dos 1

50

40

30

20

10

1

5

Kv

Vv

Vv

Dos 2

43 5

6 8

10 15 20 25 30 50454035

Vv

Kv

Dv

Dv

Drying

9

60 65 70

55

Min

75

°C

100

90

80

70

60

50

40

30

20

10

6 TEST TUBES +T

Vv

Dos 2

43 5 7

3 6

Vv Kv

8

Vv

Vv Dv

Dos 2

1

10 15 20 25 30 50454035

5

Vv

Kv

Kv

55

Drying

9

60 65 70

G227

G226

Min

75

G228

Program phases

6 After rinse 2

7 After rinse 3

8 Final rinse

9 Drying

9908

1 Pre rinse 1

2 Pre rinse 2

3 Washing

4 Neutralizing

5 After rinse 1

14

Page 15

Decomat 8666Operating instructions

g

g

g

g

g

g

Standard program

The indicated cycle time is depending on both water pressure and temperature.

Sektion 1 - Hospital programs according to SPRI

Hospital validated programs due to SPRI-guidelines with disinfection at 90°C/1 min

(SPRI = Swedish Institute for Hospital Planning and Rationalizing)

margorPemitelkyCemaNecnamrofrepdnaesopruP

10P'72POstnemurtsnI

20P'81TROHS-POstnemurtsnideliossseldnaslisnetU

30P'72NAgnibutcitehtseanA

40P'81SOD-LCXE-NAgnibutcitehtseanAylppustnegretedtuohtiw

50P'74T-PO02+10Pgniyrdnim

60P'83T-TROHS-POgniyrdnim02+20P

70P'76T-NAgniyrdnim04+30P

80P'85T-SOD-LCXE-NAgniyrdnim04+40P

90P'02NIM02-Tgniyrdnim02

-

Sektion 2 - Hospital programs according to BGA

Hospital validated programs due to BGA-guidelines with disinfection BGA (A) at 90°C/1 min and BGA

(A+B) at 93°C/10min

(BGA = German Federal Institute of Health)

p

margorPemitelkyCemaNecnamrofrepdnaesopruP

02P'62PO)A(AGB-stnemurtsnI

12P'42-PO)A(AGBTROHSstnemurtsnideliossseldnaslisnetU

22P'03NA)A(AGB-gnibutcitehtseanA

32P'14)B+A(AGB-POtnemurtsnIs

42P'34)B+A(AGB-NAgnibutcitehtseanA

52P'72MEHC-SOC°06taseohs-PO.g.e,sdoogevitisnestaeH

62P'64T-)A(AGB-POgniyrdnim02+12P

72P'44

82P'07T-)A(AGB-NAgniyrdnim04+22P

92P'55T-)B+A(AGB-POgniyrdnim02+72P

03P'38T-)B+A(AGB-NAgniyrdnim04+42P

13P'74T-MEHC-SOgniyrdnim02+52P

23P'02NIM02-T02m gniyrdni

33P'83)B+A(MYZNE

43P'87T)B+A(MYZNE

93P-53Pt

T

idel

-TROHS)A(AGB-PO

gniyrdnim02+12P

orplaudividnirof

nimmar

Sektion 3 - Laboratory glassware programs

margorPemitelkyCemaNecnamrofrepdnaesopruP

04P'03BALTROHS

14P'83BALGNOL

24P'55SEBUTTSET

34P'75SETTEPIP

44P'05TBALTROHS

54P'85TBALGNOL

64P'57TSEBUTTSET

74P'86T-4BAL

94P-84Ptgidelgnimmargorplaudividnirof

15P-05Ptarekcolb5431iniMtamoceDroF

06P-25Pt

idel

orplaudividnirof

nimmar

9908

15

Page 16

Program printout

Example of a printout for a program is illustrated below. The program P01 OP,

which is programmed on program selection key A, is used in the examples.

Program printout

Operating instructionsDecomat 8666

9908

16

Page 17

Decomat 8666Operating instructions

9908

17

Page 18

This product is manufactured by:

GETINGE DISINFECTION AB, Ljungadalsgatan 11, Box 1505, 351 15 Växjö, Sweden

Loading...

Loading...