Page 1

GETINGE 86-SERIES

INSTALLATION MANUAL

502606400

SEV0 725 001-

Page 2

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 2 of 20

Contents

FOREWORD ____________________________________________3

SAFETY REGULATIONS _________________________________4

General safety regulations ___________________________________ 4

The machine must be assembled and installed: ________________ 4

When the work is complete, check that _______________________ 5

Product liability ____________________________________________ 5

Attention symbols __________________________________________ 5

INSTALLATION __________________________________________6

Wall-mounted model ________________________________________ 7

Connecting electric power ___________________________________ 8

Alternative connection arrangements _________________________ 9

Connecting water, steam, waste and dryer ____________________ 10

Function check ____________________________________________ 13

TECHNICAL DATA _______________________________________ 15

Water quality - washer disinfectors _______________________18

Page 3

FOREWORD

This user manual is intended for users of Getinge 86-series washer disinfectors.

The instruction manual describes the design and operation of the machine and the maintenance for which the user is responsible. The purpose of the information in the manual

is to ensure safe operation and optimum efciency.

Before using the machine for the rst time, users must have read this instruction manual

and familiarized themselves with the operation of the machine and its safety instructions.

To conform to EN ISO 15883, the items must be placed in the proper accessories,

recommended by Getinge Disinfection AB.

The customer is responsible for ensuring that an Installation Qualication, an Operating

Qualication and a Performance Qualication according to EN ISO 15883 are carried

out before the product goes into service.

The information in this manual describes the machine as dispatched from Getinge.

There may be differences due to customization.

The machine is accompanied by the following documentation:

• User manual

Read the user manual before using the machine.

• Installation manual (this book)

• Technical manual

• Spare parts list

Getinge reserves the right to change the specication and design without prior notice.

The information in this manual was up to date on the date of issue of the manual.

© Copyright

The content of this manual must not be copied, in

whole or in part, without the written consent of Getinge.

Page 3 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 4

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 4 of 20

SAFETY REGULATIONS

This machine has been designed with a number of built-in safety devices.

To avoid injury, it is highly important not to bypass or disable these safety devices.

If the equipment is used in a manner that was not specied by the manufacturer, the

safety equipment on the machine may not be fully effective.

Operators and maintenance personnel must undergo safety training for the machine.

All personnel who handle chemicals for washing and disinfection must understand the

washing process, possible health hazards and ways of detecting leaks of toxic chemicals.

Operators and maintenance personnel must undergo regular training in the operation and

maintenance of the equipment. There must be a documented list of personnel who have been

trained on the machine. Trained personal must be tested to verify the training programme.

The equipment must be used in accordance with the safety instructions below.

If in doubt, contact a representative of the reseller without delay.

Important

Take care when handling the chemical agents used in the machine.

•

Read the instructions on the pack or contact the manufacturer before using the ma-

•

chine for instructions about:

- what to do if the substance comes into contact with the eyes or skin or if vapors

are inhaled.

- storage of packs and sorting of empty packs for disposal.

The machine must be connected in accordance with the instructions given in the

•

installation manual.

The machine may only be used by adults.

•

Installation and servicing may only be done by personnel trained for this machine.

•

Never bypass door safety switches.

•

Leaks in the system caused by worn seals in the door, for example, must be re-

•

paired immediately.

Before doing any repair or servicing work, the personnel concerned must study the

•

relevant handbooks and service manuals.

Before any welding is done on or close to the machine, all cables connected to the

•

control system via connectors and sockets must be disconnected.

Before doing any servicing or maintenance work on the machine, isolate it from the

•

electric power supply and drain all tanks.

Do not wash down or hose down the machine with water.

•

Take care when using corrosive substances.

•

Observe safety measures for steam and hot water.

•

The electrical cabinet may only be opened by authorized and trained personnel.

•

Spare parts must be obtained only via Getinge EDC.

•

The machine must be assembled and installed:

by qualied personnel.

•

in accordance with current local regulations and rules.

•

Warning:

To avoid the risk of back injury, this equipment should be assembled and

installed by two people.

Page 5

When the work is complete, check that

all parts have been installed in accordance with the installation instructions

•

all screws have been properly tightened

•

there are no sharp edges on any parts that may come into contact with people

•

all hoses, pipes and connections are intact and free from defects

•

all the functions of the machine are working properly. Adjust if necessary.

•

Carry out an Installation Qualication, an Operating Qualication and a Performance

Qualication according to ISO 15883 before putting the machine into service.

Incorrect use may result in damage and injury.

Product liability

Any modication or incorrect use of the equipment without the approval of Getinge Disinfection AB invalidates Getinge Disinfection AB´s product liability.

This product was manufactured by:

GETINGE DISINFECTION AB

Ljungadalsgatan 11

Box 1505

351 15 Växjö

Sweden

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that we

use the following special symbols to draw attention to them. The symbols and designs

used are:

This symbol indicates a warning in the text of the manual. It warns of a hazard

that may lead to more or less severe injury and in certain cases mortal danger. It also highlights warnings to avoid damage to equipment.

Page 5 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 6

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 6 of 20

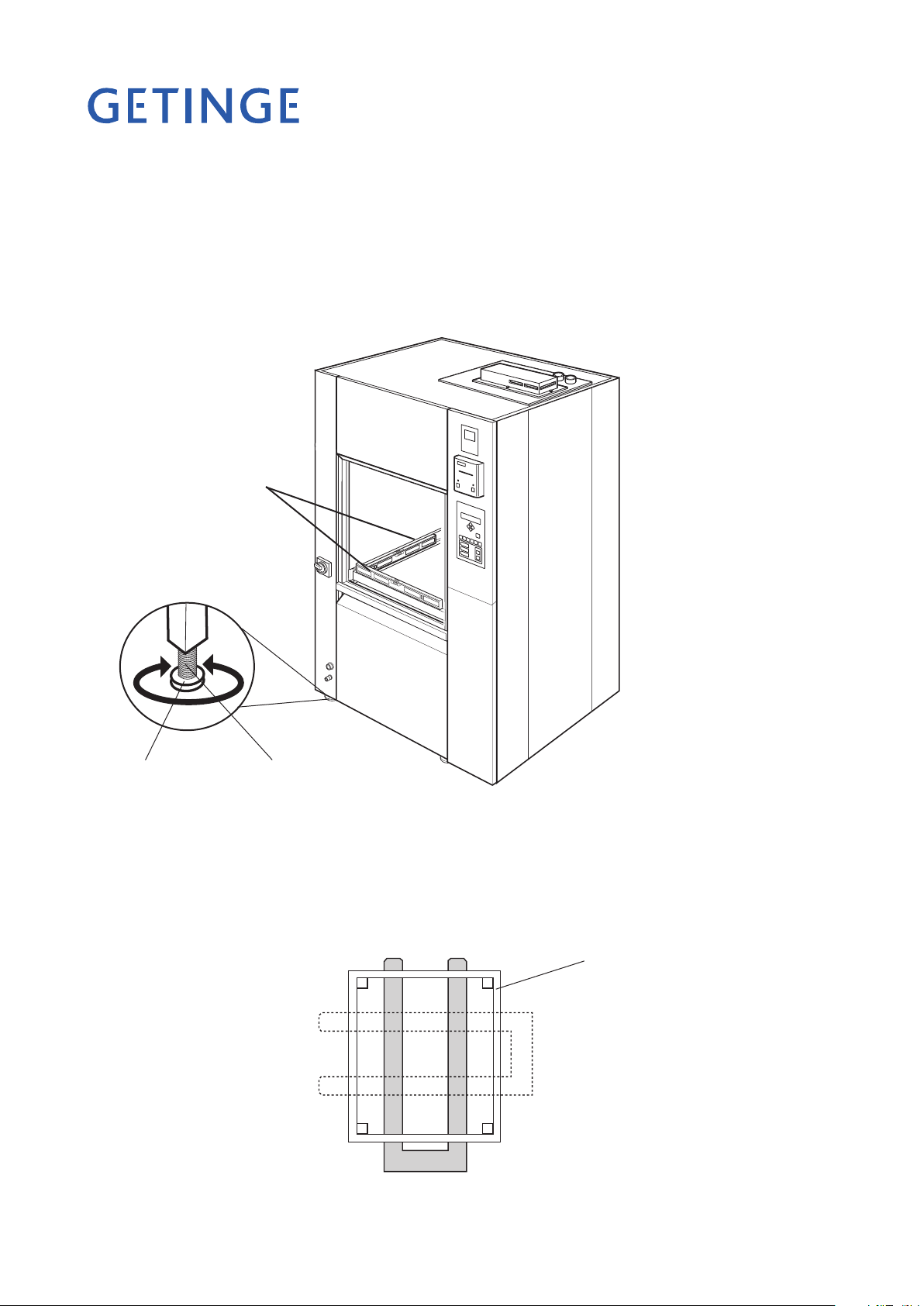

INSTALLATION

The oor where the machine is to stand must be at and level within ±5 mm.

•

Pull the machine (on a transport pallet) to the location where it will be installed.

•

Lift the machine off the pallet.

•

Position the machine at the chosen location and adjust the feet so that the machine

•

is stable.

Level the

machine with

a spirit level.

V1472

Adjusting screwFoot plate

Figure 1. Adjustment

Using a spirit level, check as shown in Figure 1 that the machine is level within ±2 mm.

•

If you need to move the machine by using a pallet truck:

position the pallet truck forks as shown in Figure 2 so as not to damage the machine.

•

Bottom frame

V318

Figure 2. Positioning the pallet truck forks.

Page 7

Wall-mounted model

If the machine has double doors and is to be mounted in a wall, the distance be-

•

tween machine and wall must be 15 mm.

If machines are to be installed next to each other they must be adjusted to the same

•

height on installation.

Where a plinth plate is used, the height from the oor to the underside of the ma-

•

chine must be at least 100 mm.

Set the machine horizontal with a spirit level on the side of the machine and adjust

•

with the feet.

For the loading trolley to work in all the machines, the oor in front of them must

•

be at and level.

Figure 3. Installation in a wall

Service area

V1475

Page 7 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 8

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 8 of 20

Connecting electric power

Installation may only be done by authorized personnel.

Connect electric power to the machine as follows:

Connect the power supply to the electrical connections of the machine; see the dia-

•

gram with alternative connection arrangements.

For easier servicing and maintenance, the supply to the machine should be tted

•

with a lockable isolator with a 3 mm break gap. The isolator must be located in an

easily accessible position on the wall.

It is important that the connection has the correct overcurrent protection. The

correct fuse rating is stated on the type plate.

The main switch on the front of the machine is connected to protective ground (earth)

and to the supply voltage stated on the type plate.

Main switch

Electrical

connection

V1473

Type plate

Figure 4 Electrical connection (see alternative connection arrangements)

Page 9

Alternative connection arrangements

MAIN SWITCH

HUVUDBRYTARE

HAUPTSCHALTER

INTERRUPTEUR ELECTRIQUE

ELECTRICAL CONNECTION

EL-ANSLUTNING

ELEKTROANSCHLUSS

CONNEXION ELECTRIQUE

-Q01

JB01

L1 L1 L1-1 L1 T1 L1-2

L2 L2 L2-1 L2 T2 L2-2

L3 L3 L3-1 L3 T3 L3-2

N N N-1 N N

PE PE PE -1 PE PE

MAIN SWITCH

HUVUDBRYTARE

HAUPTSCHALTER

INTERRUPTEUR ELECTRIQUE

ELECTRICAL CONNECTION

EL-ANSLUTNING

ELEKTROANSCHLUSS

CONNEXION ELECTRIQUE

-Q01

JB01

L1 L1 L1-1 L1 T1 L1-2

L2 L2 L2-1 L2 T2 L2-2

L3 L3 L3-1 L3 T3 L3-2

PE PE PE -1 PE PE

Electrically heated 240/415V 3N+PE, 50Hz 21.1kW 31A FUSE 3x32A 240V 3+PE, 60Hz 21.3kW 54A FUSE 3x60A

230/400V 3N+PE, 50/60Hz 19.7kW 30A FUSE 3x32A 230V 3+PE, 50Hz 19.7kW 54A FUSE 3x63A

220/380V 3N+PE, 50/60Hz 17.9kW 29A FUSE 3x32A 208 3+PE, 60Hz 20.5kW 59A FUSE 3x60A

200V 3+PE, 50/60Hz 19.1kW 58A FUSE 3x63A

Steam-heated 240/415V 3N+PE, 50Hz 6.5kW 14A, FUSE 3x20A 240V 3+PE, 60Hz 6.5kW 23A, FUSE 3x25A

230/400V 3N+PE, 50/60Hz 6.5kW 14A, FUSE 3x20A 230V 3+PE, 50Hz 6.5kW 24A, FUSE 3x25A

220/380V 3N+PE, 50/60Hz 6.5kW 14A, FUSE 3x20A 208V 3+PE, 60Hz 6.5kW 26A, FUSE 3x30A

200V 3+PE, 50/60Hz 6.5kW 27A, FUSE 3x32A

Steam-heated 240/415V 3N+PE, 50Hz 11.4kW 18A, FUSE 3x20A 240V 3+PE, 60Hz 11.5kW 30A, FUSE 3x30A

with booster 230/400V 3N+PE, 50/60Hz 10.7kW 17A, FUSE 3x20A 230V 3+PE, 50Hz 10.7kW 29A, FUSE 3x32A

220/380V 3N+PE, 50/60Hz 9.8kW 16A, FUSE 3x20A 208V 3+PE, 60Hz 11.1kW 33A, FUSE 3x35A

200V 3+PE, 50/60Hz 10.4kW 32A, FUSE 3x32A

Steam-heated & 240/415V 3N+PE, 50Hz 11.4kW 18A, FUSE 3x20A 240V 3+PE, 60Hz 11.5kW 30A, FUSE 3x30A

electrically heated 230/400V 3N+PE, 50/60Hz 10.7kW 17A, FUSE 3x20A 230V 3+PE, 50Hz 10.7kW 29A, FUSE 3x32A

220/380V 3N+PE, 50/60Hz 9.8kW 16A, FUSE 3x20A 208V 3+PE, 60Hz 11.1kW 33A, FUSE 3x35A

200V 3+PE, 50/60Hz 10.4kW 32A, FUSE 3x32A

Steam-heated & 240/415V 3N+PE, 50Hz 21.1kW 31A, FUSE 3x32A 240V 3+PE, 60Hz 21.3kW 54A, FUSE 3x60A

electrically heated 230/400V 3N+PE, 50/60Hz 19.7kW 30A, FUSE 3x32A 230V 3+PE, 50Hz 19.7kW 52A, FUSE 3x63A

with booster 220/380V 3N+PE, 50/60Hz 17.9kW 29A, FUSE 3x32A 208V 3+PE, 60Hz 20.5kW 59A, FUSE 3x60A

200V 3+PE, 50/60Hz 19.1kW 58A, FUSE 3x63A

Page 9 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 10

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 1 0 of 20

Connecting water, steam, waste and dryer

Installation may only be done by authorized personnel.

Provide water and, if required, steam connections with separate stopcocks. Flush

•

out the water and steam pipes that are to be connected to the machine, to prevent

clogging of lters and valves.

Connect the disinfector to cold and hot water and to steam and condensate connec-

•

tions, if used. The connections must meet the following requirements:

Connection Pressure Flow rate

Cold water 3/4” (20 mm) male 100-800 kPa

Hot water 3/4” (20 mm) male 100-800 kPa

Dist. water/

de-ion. water

3/4” (20 mm) male 100-800 kPa*

Steam 1/2” (15 mm) female 300-500 kPa

Condensate 1/2” (15 mm) female

Compressed air 1/2” (15 mm) female 4 to 8 bar

* Where the pressure is lower than 100 kPa a separate feeder pump must be used.

** At chamber depth = 720 mm

*** At chamber depth = 800 mm

Note:

Distilled or de-ionized water must have a conductivity of less than 40 µS/cm.

approx 33 liters/phase**

approx 40 liters/phase***

approx 33 liters/phase**

approx 40 liters/phase***

approx 33 liters/phase***

approx 40 liters/phase***

0.9 to 1.0 kg/min

(300 kPa)

Page 11

Chamber depth 720 mm

Clean side

Soiled side

Chamber depth 800 mm

Clean side

Soiled side

Figure 5. Connecting water, steam, waste and dryer

1. Cold water 350 mm above the oor

2. Hot water 350 mm above the oor

3. Distilled/de-ionized water 350 mm above

the oor

4. Compressed air connection (in/out feeder)

400 mm above the oor

5. Steam connection 350 mm above the oor

6. Condensate connection 350 mm above

the oor

7. Drain connection at oor

8. Dryer exhaust air at roof

9. Electrical connection 350 mm above

the oor

A. No cables or pipes in this area

B. Adjustable within this range

Page 1 1 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 12

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 1 2 of 20

PTFE tape is recommended for sealing the connections.

•

Connect the disinfector to a waste outlet with a capacity of at least 50 litres/min.

•

Connect the waste as shown in Figure 5. Diameter of waste: 50 mm.

Figure 6. Connecting a dryer

Connect air exhaust from dryer (if the machine has a dryer).

•

Air quantity approx 350 m3/h.

V1474

Page 13

Function check

Check that the machine is connected to the correct voltage and the waste, water,

•

steam and condensate connections are correctly connected. Open the valves for

water and steam.

Fill the detergent containers and place alarm sensors in the containers.

•

When starting a new machine, the door can be unlocked and opened with U.

•

With a manually-operated door, the door must be pressed down with the handle

after it has been unlocked. An automatic door opens automatically.

Machines with double doors have a system of interlocks to ensure that only one

•

door can be opened at a time.

The clean-side door can only be opened if the completed process has been ap-

•

proved and the soiled-side door is closed and locked.

If the soiled-side door cannot be opened, check that the clean-side door is closed

•

and locked. If not, proceed as follows:

- Manually-operated door - Close the door and press W.

- Automatically-operated door - Press W.

Place a wash rack in the wash chamber and close the door.

•

Choose a program where dosing is done from all the detergent and rinse-aid con-

•

tainers and start the machine (see the instruction manual).

Check that the machine draws water.

•

Note:

On starting, there must be water in the circulation pump. If there is no water in the pump

the shaft seal may be damaged.

Check that the circulation pump is rotating in the right direction as indicated by the

•

arrow on the pump motor. If not, isolate the power, change the phase sequence at

the electrical connections and restart the machine.

V766

Figure 7. Circulation pump

Check that the dosing pumps work at the right time in accordance with the program

•

description in the instructions for use and that detergent is drawn off.

While the program is running, check that the door(s) cannot be opened.

•

Page 1 3 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 14

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 1 4 of 20

On a machine with manual double doors, check the door locking function when the

•

program is complete as follows:

- If the soiled-side door cannot be opened, check that the clean-side door is closed.

- Open and close the clean side door.

- Press W.

- Open the soiled-side door.

- Check that the clean side door cannot be opened.

Check that there are no water or steam leaks. If necessary, retighten water, steam

•

and waste connections.

Page 15

TECHNICAL DATA

Dimensions

Outside dimensions

Width 1110 mm

Depth

8666, CM303: 910 mm

8668, CM304: 990 mm

Height 1870 mm

Chamber, effective dimension

Chamber depth

8666, CM303 720 mm

8668, CM304 800 mm

Chamber width 665 mm

Chamber height 667 mm

Chamber volume

8666, CM303 300 litres

8668, CM304 340 litres

Weight including water and load.

Total 350-400Kg

Loading per machine foot 0.85 to 0.98 kN (four feet)

Specic area loading 3.4-3.9 kN/m

Floor area loading, machine foot 347 kN/m

2

2

Connections

Water consumption

8666, CM303 33 liters/phase

8668, CM304 40 liters/phase

Cold water

Recommended water quality: Drinking water with max 5°dH

Connection ISO G-3/4

Pressure 100-800 kPa

Flow rate 30 liters/min

Hot water

Recommended water quality: Preheated drinking water with max 5°dH

Temperature 45-60°C (113-140°F)

Connection ISO G-3/4

Pressure 100-800kPa

Flow rate 30 liters/min

Note 1.

The water consumption varies depending on the type of wash trolley and the items.

Note 2.

The water temperature affects the process time. The lower the water temperature, the longer

the process will take.

Note 1.

Note 1.

Note 2.

Page 1 5 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 16

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 1 6 of 20

Distilled/de-ionized water (option)

Recommended water quality: The maximum conductivity is determined by the desired

washing result.

Max temperature 60°C (140°F)

Note 2.

Connection ISO G-3/4

Pressure 100-800 kPa (where the pressure is lower than 100 kPa, a

separate pressure booster pump must be connected. This is

available as an option.)

Flow rate 30 liters/min

Compressed air (option with loader/unloader only)

Connection pressure 4.8 bar

Steam (only for a machine with steam-heated chamber)

Connection ISO G-1/2

Pressure 300-500kPa

Max steam temperature 160 °C (320 °F)

Consumption about 0.9-1.0 kg/min at 300 kPa

Notes 3, 4.

Steam condensate (only for a machine with steam-heated chamber)

Connection ISO G-1/2

Note 4.

Waste outlet

Dimension, out ø50 mm (2”)

Minimum capacity of receiving drain

1. Capacity 40 l/min, max 90 °C (194 °F)

2. Capacity with drain cooling (option) 80 l/min, max 60 °C (140 °F)

Recommended connection dimension 100mm

Evacuation air

Air quantity 350 m3/h approx.

Max temperature: 160 °C (320 °F)

Air humidity 60-100 %

Note 2.

The water temperature affects the process time. The lower the water temperature, the longer

the process will take.

Note 3.

The pressure and temperature of the steam affect the process time. The lower the pressure, the

longer the process will take.

Note 4.

The pressure differential between the supply and return lines must be greater than 100 kP.

Page 17

Other points

Circulation system

Design pressure: 200 kPa

Working pressure: max 130 kPa

Design temperature 160 °C (320 °F)

Working temperature 93°C (199°F)

Electrical connection

See the relevant connection option.

Environmental requirements

Air humidity max 80% at 31 °C (87 °F)

Room temperature 5-40 °C (41-104 °F )

Heat dissipation to the room

Max 4000 W hot air during drying.

Max 1100 W during disinfection at 90 °C (194 °F)

Max external temperature of the machine at 50 °C (123 °F)

Sound level

Table 1 below shows the sound power level as linear octave band values and as co-weighted,

A-weighted sound power level, both equivalent L wA and maximum LwAFmax.

Table 1

Calculated sound power level Lw for the test object, db ref 1 pW.

Octave band frequency (Hz) 125 250 500 1000 2000 4000 8000 LwA LwAFmax

Correction terms (Kok) 67 69 67 67 69 67 70 75 84

The calculated sound power level implies different sound levels LpA in different types of space.

With a larger room volume, the sound level decreases slightly and with a smaller room level it increases slightly. Table 2 below shows three example of what to expect in practice.

Table 2

Calculated sound level LpA for the test object in a 70m3 room, db ref 20 µPa.

Type of

room

Hard to

sound

Normallydamped

Damped Full-cover ceiling absorbent and some furnish-

Description Operator

position*

All surfaces of tile, plaster, concrete or similar,

ie no sound absorbing surfaces and no furniture

Some sound absorption in the form of furniture

and textiles.

ing with tables, chairs and textiles.

74 74

70 69

67 65

3 meters from

the machine

* The term “operator position” means 1 meter from the machine and 1.5 meters above the oor.

Degree of protection

IP21

Page 1 7 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 18

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 1 8 of 20

Water quality - washer disinfectors

The quality of the water used in all stages of cleaning is important for good results.

The water used in each stage must be compatible with:

* The material of which the washer disinfector is made

* The chemicals used in the process

* Process requirements for the various stages of the process

The main factors for good water quality are:

Hardness High hardness will cause limescale deposits in the washer disinfector, lead-

Ionic contaminants A high concentration of ionic contaminants may cause corrosion and pitting

Microbial contaminants The water used should not increase the biological load on the equipment

Sanitary chemicals High concentrations of and high exposure to sanitary chemicals may cause

ing to poor cleaning results.

on stainless steel. Heavy metals such as iron, manganese or copper cause

instruments to tarnish.

that is being treated against micro-organisms and their residual products

which may cause fever-like symptoms when they get into the human body.

corrosion and pitting on stainless steel.

Getinge Disinfection AB therefore recommends that water used in the pre-rinsing, washing and nal rinsing phases should be of drinkable quality in accordance with the guidelines. Detailed information about acceptable water quality can be found in “Guidelines

for Drinking Water Quality 3rd Edition” published by WHO.

Getinge Disinfection AB also recommends following local standards. RO (reverseosmosis) water (or similarly treated water) is used for the nal washing/disinfection

phase.

A typical specication for RO water is:

pH 5.5 to 8

Conductivity <30 µs.cm

-1

TDS <40 mg/l

Maximum hardness <50 mg/l

Chlorine <10 mg/l

Heavy metals <10 mg/l

Phosphates <0.2 mg/l som P2O

Silicates <0.2 mg/l som SiO

5

2

Endotoxins <0.25 EU/ml

Total number of micro-organisms <100 per 100 ml

Further advice should also be obtained from the manufacturers of chemical and medical

equipment.

Where local standards are stricter that Getinge Disinfection AB’s recommendations, they

should be followed. Note that it is the customer’s responsibility to supply the washer

disinfector with suitable water.

Page 19

Page 1 9 of 20

<Doc_I NS><Doc _502606 400><Re l_A><La ng_GB>

Page 20

Australia

Getinge Australia Pty Ltd

154 Lytton Road

Bulimba Qld 4171

info@getinge.com.au

Phone: +61-733 956 311

Belgium

Getinge NV

Nijverheidsstraat 2

BE-2160 Wommelgem

info@getinge.be

Phone: +32-33542865

Canada

Getinge Canada Ltd

1575 South Gateway Road,

Unit C

Mississauga Ontario

L4W 5J1

info@getingecastle.ca

Phone: +1-905 629 8777

China

Getinge (Suzhou) Co. Ltd

Rm. 720, 7/F, Century Financial Tower

No. 1,

Su Hua Road, Suzhou Industrial Park,

Suzhou,

Jiangsu Province

Phone: + (86512) 67621587,

67621589, 67611591

France

Getinge France SAS

BP 49, avenue du Canada

ZA de Courtaboeuf

Les Ulis, FR-91942

getinge.france@getinge.fr

Phone: +33-1 64 86 89 00

Germany

Getinge Van Dijk

Medizintechnik GmbH

Postfach 1125

Boekholter Weg 1B

DE-47628 Straelen

info@getingevandijk.de

Phone: +49-283 491 330

Italy

Getinge S.p.A.

Via dei Buonvisi 61/D

IT-00148 Roma

info@getinge.it

www.getinge.com/it

Phone: +39-06656631

Netherlands

Getinge B.V.

Fruiteniersstraat 27, Zwijndrecht

Postbus 1004

NL-3330 CA Zwijndrecht

info@getinge.nl

Phone: +31-78 610 24 33

South Africa

Getinge South Africa (Pty) Ltd

P O Box 48492

Hercules

Pretoria SA 0002

getinge@mweb.co.za

Phone: +27-123 721 370

Spain

Getinge Iberica SL

P.E. San Fernando, Avda. Castilla 2,

Edif. Francia 1era planta

San Fernando de Henares

Madrid ES-28830

administracion@getinge.es

www.getinge.com

Phone: + 34-916 78 26 26

Sweden

Getinge International AB

P O Box 69

SE-310 44 Getinge

info@getinge.com

Phone: +46-35 15 55 00

Switzerland

Getinge ALFA AG

Weidenweg 17

4310 Rheinfelden

info@alfa.ag

www.getingealfa.ch

Phone: +41-61 836 15 15

Getinge Shanghai Trading Co. Ltd

Unit C, 8/F, Luck Plaza,

300 Xuanhua Road, Shanghai

P.R. China

info@getinge.com.cn

www.getinge.com/cn

Phone: +86 21 5208 1122

Denmark

Getinge Danmark A/S

Firskovvej 23

DK-2800 Lyngby

getinge.danmark@getinge.com

www.getinge.dk

Phone: +45-45 93 27 27

Finland

Getinge Finland Ab

Hallonnäsgatan 23A,

FI-00210 Helsinki

getinge@getinge.fi

Phone: +358-968 241 20

Norway

Getinge Norge AS

Enebakk vn.117.

N-0680 Oslo

info@getinge.no

www.getinge.com/no

Phone: +47-23 03 52 00

Poland

Getinge Poland

Ul. Lirowa 27

02-387 Warszawa

office@getinge.pl

Phone: +48-22 882 06 26

Singapore

Getinge International Far East Pte.

Ltd.

20 Bendemeer Road,

#06-02, Cyberhub Building

Singapore, SG-339914

Phone: + 65 6396 7298

United Kingdom

Getinge UK Ltd

Orchard Way

Calladine Park

Sutton-In-Ashfield

Notts NG 17 1JU

sales@getinge.co.uk

Phone: +44-1623510033

USA

Getinge USA Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133

info@getingeusa.com

www.getingeusa.com

Phone: +1-585 475 9040

www.getinge.com

Loading...

Loading...