Page 1

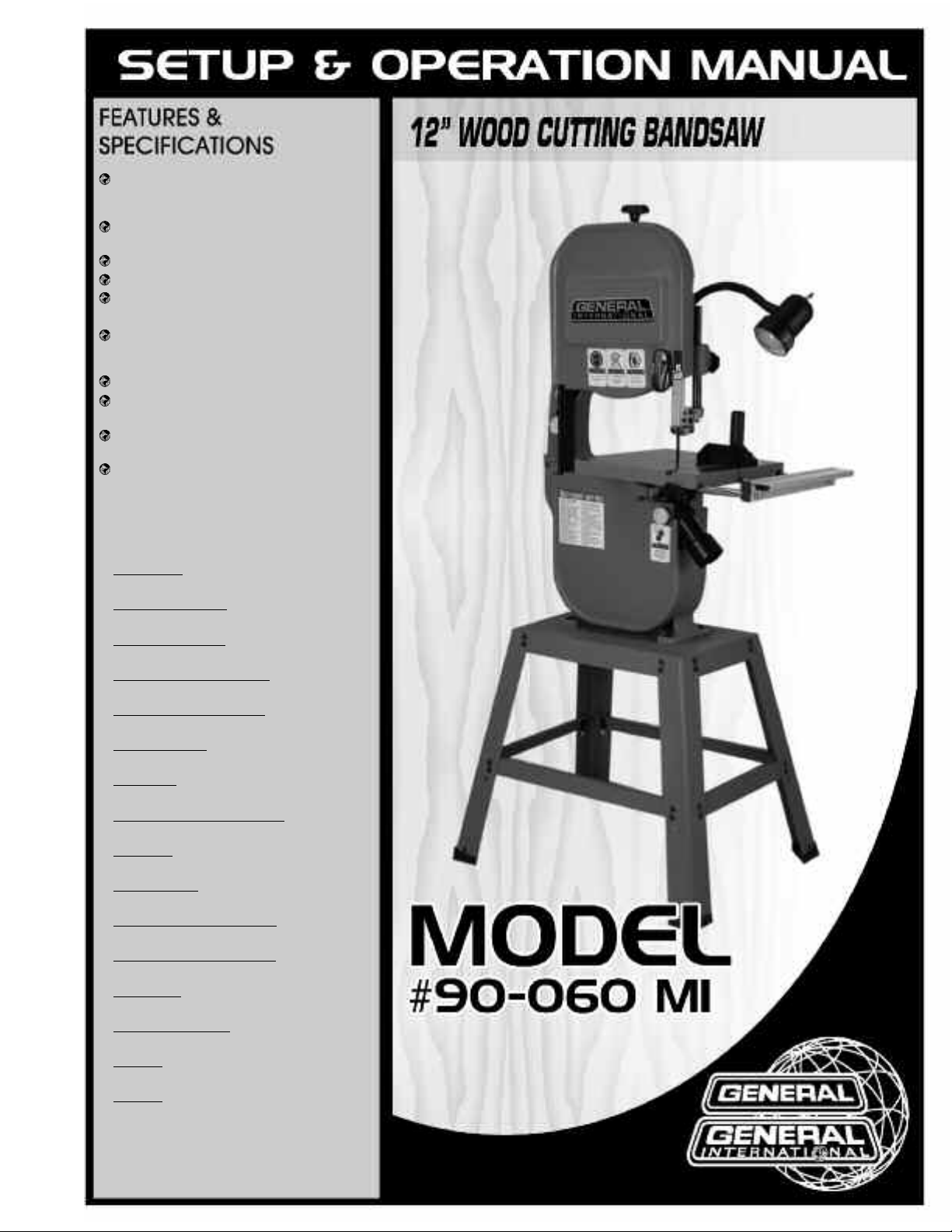

Cast-iron frame & precision balanced

aluminum wheels with replaceable

rubber tires.

2 cutting speeds for excellent results in

either hard or soft wood.

Precision blade guide bearing included.

Aluminum miter gauge with handle.

Large, stable cast iron table and slide out

steel extension wing.

Laser line marker and goose neck style

work light included. (Bulb for work light not

included)

Smooth running, durable 1/2 HP motor.

Safety lock-out switch with removable key

to prevent unauthorized use.

Built-in blade cleaning brush keeps tires

free of dust and chips.

Telescoping extension table with

retractable fence attachment.

WHEEL SIZE

12” (316 mm)

WHEEL SPEEDS (2)

483 & 825 RPM

BLADE SPEEDS (2)

1580 & 2710 FPM (480& 820 MPM)

MAXIMUM BLADE WIDTH

1⁄2” (13 mm)

MINIMUM BLADE WIDTH

1⁄8” (3.2 mm)

BLADE LENGTH

80” (2032 mm)

TABLE SIZE

13” x 13” (330 x 330 mm)

TABLE SIZE WITH EXTENSION

20” x 13” (508 x 330 mm)

TABLE TILT

0° TO 45° (RIGHT)

TABLE HEIGHT

38 3⁄4 (985 mm)

MAXIMUM WIDTH OF CUT

12” (305 mm)

MAXIMUM DEPTH OF CUT

5” (127 mm)

DUST PORT

2 1⁄2” (63 mm)

BASE DIMENSIONS

30” x 21” (710 x 540 mm)

MOTOR

1⁄2 HP, 110 V, 7 A

WEIGHT

154 LBS (70 kg)

REVISION 2 APRIL 09/09

© COPYRIGHT GENERAL INTERNATIONAL 09/2009

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General International model 90-060 Bandsaw.

This bandsaw has been carefully tested and inspected before shipment and if properly used

and maintained, will provide you with years of reliable service. To ensure optimum performance and trouble-free operation, and to get the most from your investment, please take the

time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this unit as well as the set-up, maintenance and identification of its parts and components.

This manual is not intended as a substitute for formal woodworking instruction, nor to offer the

user instruction in the craft of woodworking. If you are not sure about the safety of performing

a certain operation or procedure, do not proceed until you can confirm, from knowledgeable

and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

GENERAL ® INTERNATIONAL WARRANTY

All component parts of General® International machinery are carefully tested and inspected during all stages of

production, and each machine is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of 24

months from date of purchase, any genuine part or parts which, upon examination, prove to be defective in workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

Disclaimer: The information and specifications in this manual per tain to

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements, General

International reserves the right to make changes to components, parts

or features of this unit as deemed necessary, without prior notice and

without obligation to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure that the specifications and information in this manual corresponds with that of the unit

with which it was supplied. However, special orders and “after factory”

modifications may render some or all information in this manual

inapplicable to your machine. Further, as several generations of this

model of bandsaw and several versions of this manual may be in circulation, if you own an earlier or later version of this unit, this manual may

not depict your machine exactly. If you have any doubts or questions

contact your retailer or our support line with the model and serial

number of your unit for clarification.

Page 3

Rules for Safe Operation

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. GENERAL® INTERNATIONAL disclaims any real or implied warranty and holds itself harmless for any injury that may result from improper use of its equipment.

1. Learn the machine’s applications and limitations, as

well as the specific potential hazards particular to this

machine. Follow available safety instructions and

safety rules carefully.

2. Keep working area clean and be sure adequate lighting is available.

3. Do not wear loose clothing, gloves, bracelets, necklaces, or jewellery while operating the bandsaw.Wear

face, eye, ear, respiratory and body protection

devices, as indicated for the operation or environment.

4. Keep hands well away from blades and all moving

parts. Do not clear chips and sawdust away with

hands. Use a brush.

5. Make sure all cutting tools are moving at operation

speed before feeding.

6. Do not feed the material too quickly. The cutting tool

will perform better and be safer working at the rate for

which it was designed.

7. Whenever possible use a dust collector with shaving

hood to minimize health hazards.

8. Never leave the machine with the power on.

9. Stop the feeder before stopping the cutting tool.

14. Do not force the machine. It will do the job better and

be safer at a rate for which it was designed.

15. Keep guards in place and in working order. If a guard

must be removed for maintenance or cleaning make

sure it is properly attached before using the tool

again.

16. Be sure that key and adjusting wrenches have been

removed before turning power on.

17. Use only accessories designed for the machine.

18. Do not work on long stock without adequate support

on the out feed end of the table.

19. Make sure tool is properly grounded. If tool is

equipped with three-prong plug, it should be

plugged into a three-pole electrical receptacle. Never

remove the third prong.

20. Always disconnect tool before servicing and when

changing accessories such as blades, bits, cutters.

21. Make sure that switch is in "OFF" position before plugging in cord.

22. Adjust and position upper and lower blade guides

before starting to cut. Upper blade guide should be

adjusted to approximately 1/8” above the material to

be cut.

10. Keep children away. Make sure that visitors are kept

at a safe distance from the work area.

11. Never stand on tool. Serious injury could occur if the

tool is tipped or if the cutting tool is unintentionally

contacted.

12. Adjust blade tension and tracking before starting to

cut.

13. Use suitable support if stock does not have a flat surface.

23. Hold material firmly against the table.

24. Saw teeth must point down toward the table.

25. Use ONLY recommended accessories. Use of accessories NOT recommended by General International

may result in a risk of injury.

26. Do not use this bandsaw for other than it’s intended

use. If used for other purposes, General International

disclaims any real or implied warranty and holds itself

harmless for any injury, which may result from that use.

Page 4

ELECTRICAL REQUIREMENTS

Before connecting the machine to the power source, verify that the voltage of your power supply corresponds

with the voltage specified on the motor I.D. nameplate. A power source with greater voltage than needed can

result in serious injury to the user as well as damage to the machine. If in doubt, contact a qualified electrician

before connecting to the power source.

This tool is for indoor use only. Do not expose to rain or use in wet or damp locations.

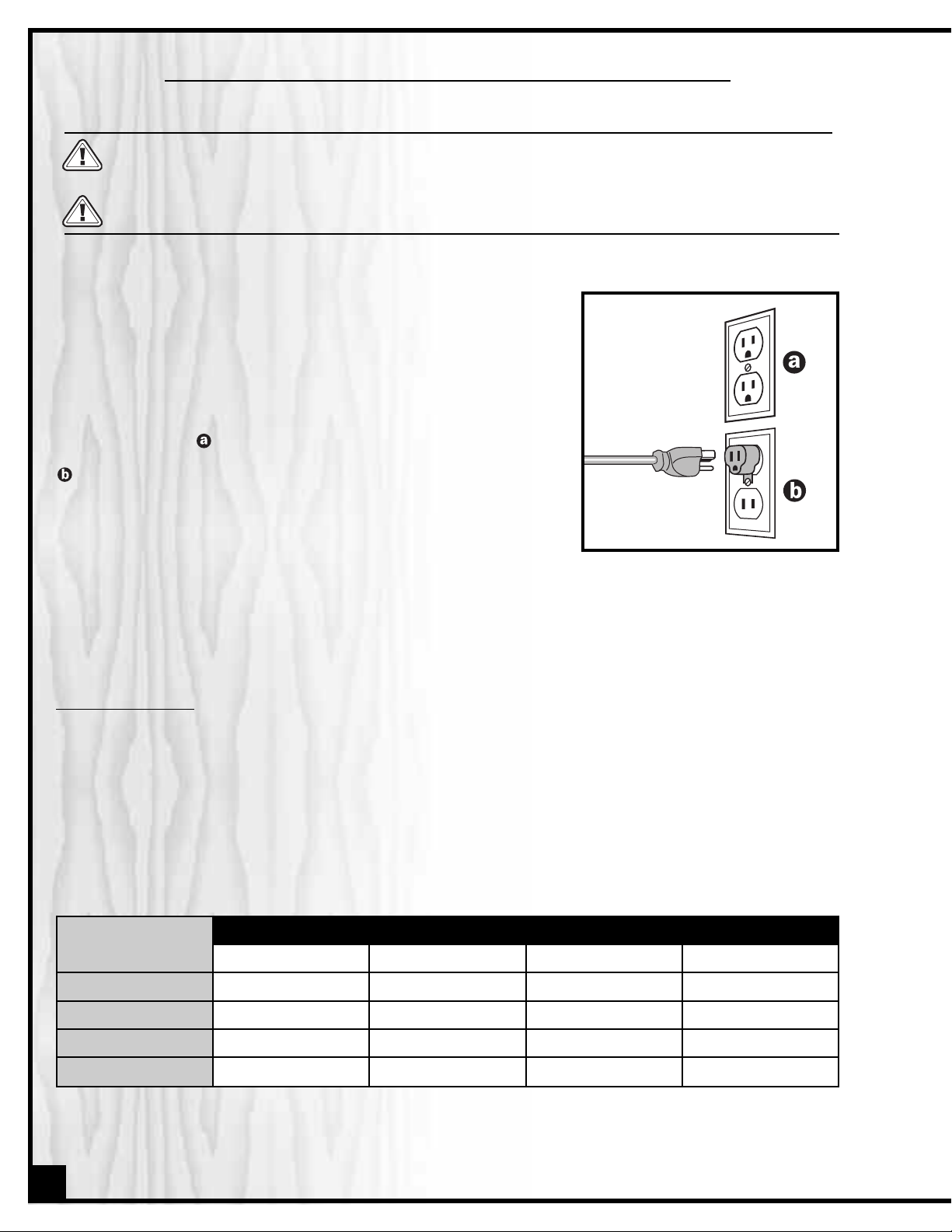

Connect the motor plugs and then plug the bandsaw into a proper

receptacle. Your power tools should be connected to a dedicated

electrical circuit of not less than #12 wire and should be protected with

a 15 amp time lag fuse.

GROUNDING: In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock to. The motor of this

machine is wired for 110V single phase operation and is equipped

with a 3-conductor cord and a 3-prong grounded plug to fit a grounded type receptacle, . Do not remove the 3rd prong (grounding pin)

to make it fit into an old 2-hole wall socket. If an adaptor plug is used,

, it must be attached to the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some areas. Check

your local codes.

DO NOT MODIFY THE PLUG PROVIDED.

If it will not fit your receptacle, have the proper receptacle installed by a qualified electrician.

CHECK with a qualified electrician or service person if you do not completely understand these grounding instructions, or if you are not sure the tool is properly grounded.

EXTENSION CORDS:

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE 3-PRONG GROUNDING PLUGS AND 3-POLE RECEPTACLES THAT ACCEPT

THE TOOLS’ PLUG. REPAIR OR REPLACE A DAMAGED OR WORN POWER CORD OR PLUG IMMEDIATELY.

If you find it necessary to use an extension cord with your machine make sure the cord rating is suitable for the

amperage listed on the motor I.D. plate. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The accompanying chart shows the correct size extension cord to be used based on cord

length and motor I.D. plate amp rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the

heavier the cord.

AMPERES

(AMPS)

25 FEET 50 FEET 100 FEET 150 FEET

EXT E NS I O N C OR D LEN G TH

<6 18 16 16 14

6 TO 10 18 16 14 12

10 TO 12 16 16 14 12

12 TO 16 14 12 NA NA

NA = Not Available

4

Page 5

12” BANDSAW

90-060

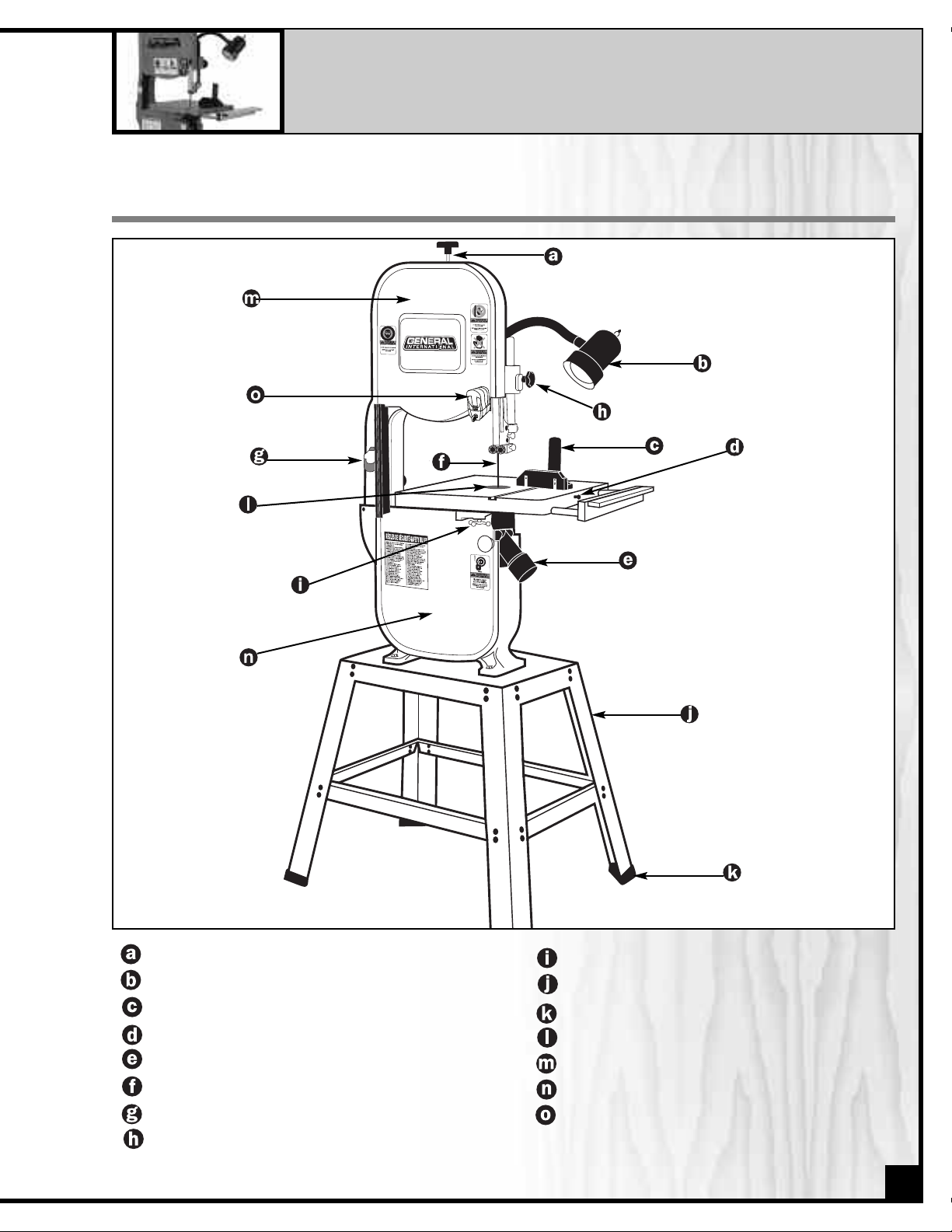

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

BLADE TENSION KNOB

WORK LIGHT

MITER GAUGE

TABLE ALIGNING PIN

DUST PORT

BLADE

ON/OFF SWITCH

UPPER BLADE GUIDE LOCK KNOB

TABLE TILT LOCK KNOB

STAND

FOOT PAD

TABLE INSERT

UPPER WHEEL COVER DOOR

LOWER WHEEL COVER DOOR

LASER LINE MARKER

5

Page 6

UNPACKING & SET UP

ADDITIONAL TOOLS NEEDED

• Philips screwdriver

• Adjustable wrench

• Straightedge

• Extra person for help with lifting

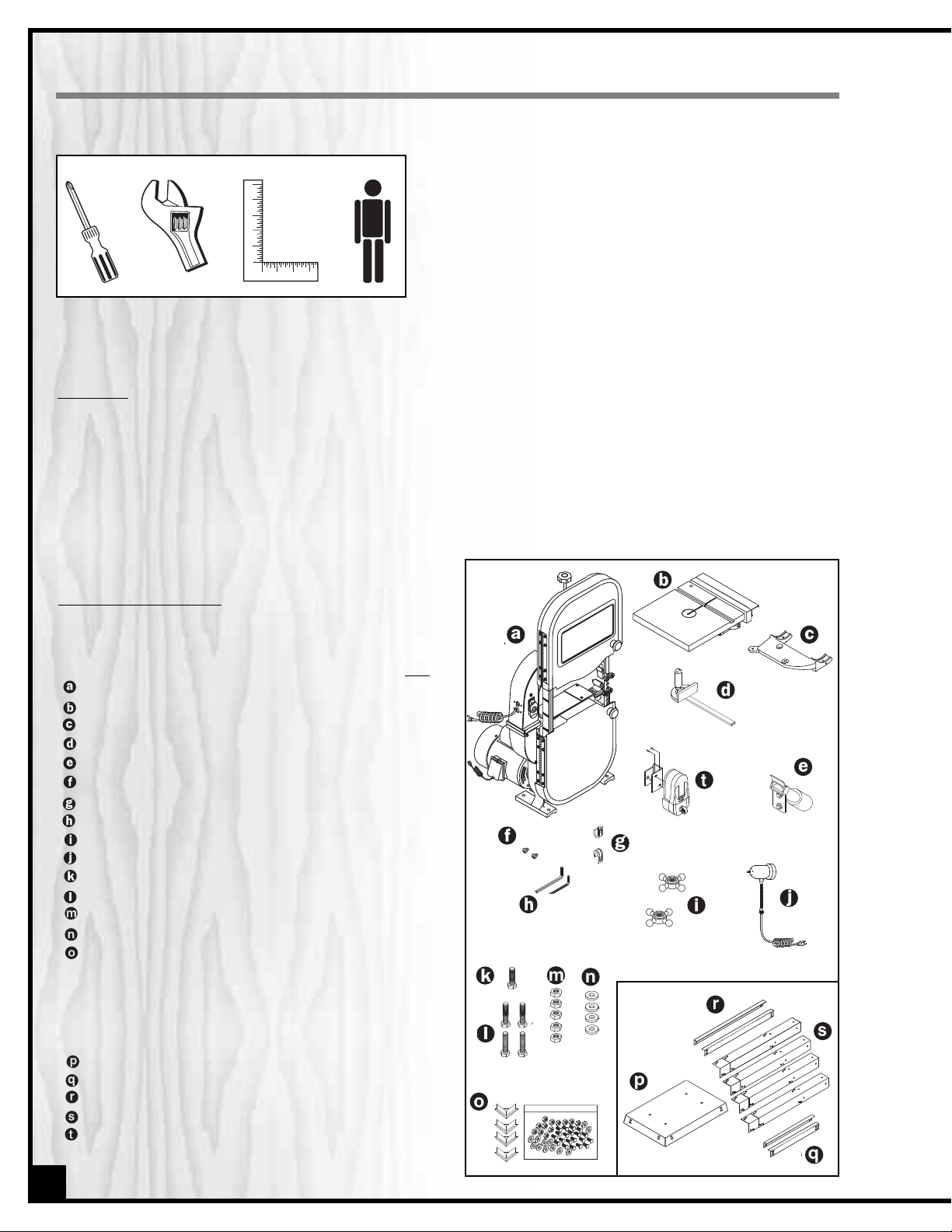

UNPACKING

Carefully unpack and remove the bandsaw and its components from the box and check for missing or damaged

items as per the list of contents below.

Note: Please report any damaged or missing items to your General International distributor immediately.

LIST OF CONTENTS

Once the parts have been removed from the

packaging, you should have the following items:

BANDSAW W/MOTOR . . . . . . . . . . . . . . . . . . . . . . . . .1

TABLE W/EXTENSION WING . . . . . . . . . . . . . . . . . . . . .1

TRUNNION SUPPORT BRACKET . . . . . . . . . . . . . . . . . .1

MITER GAUGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

DUST PORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SCREWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

POWER CORD HOOKS . . . . . . . . . . . . . . . . . . . . . . . .2

ALLEN KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

TABLE TILT LOCK KNOBS . . . . . . . . . . . . . . . . . . . . . . .2

WORK LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

BOLT 5/16” X 1” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

BOLT 5/16” X 1 1/4” . . . . . . . . . . . . . . . . . . . . . . . . . . .4

HEX NUT 5/16” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

LARGE WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

HARDWARE BAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CARRIAGE BOLT . . . . . . . . . . . . . . . . . .3 2

HEX. NUT . . . . . . . . . . . . . . . . . . . . . . . .3 2

WASHER . . . . . . . . . . . . . . . . . . . . . . . .3 2

FOOT PAD . . . . . . . . . . . . . . . . . . . . . . .4

Qty

TOP PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SHORT LOWER BRACKET . . . . . . . . . . . . . . . . . . . . . . .2

LONG LOWER BRACKET . . . . . . . . . . . . . . . . . . . . . . .2

LEG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

LASER LINE MARKER (WITH HARDWARE) . . . . . . . . . .1

6

Page 7

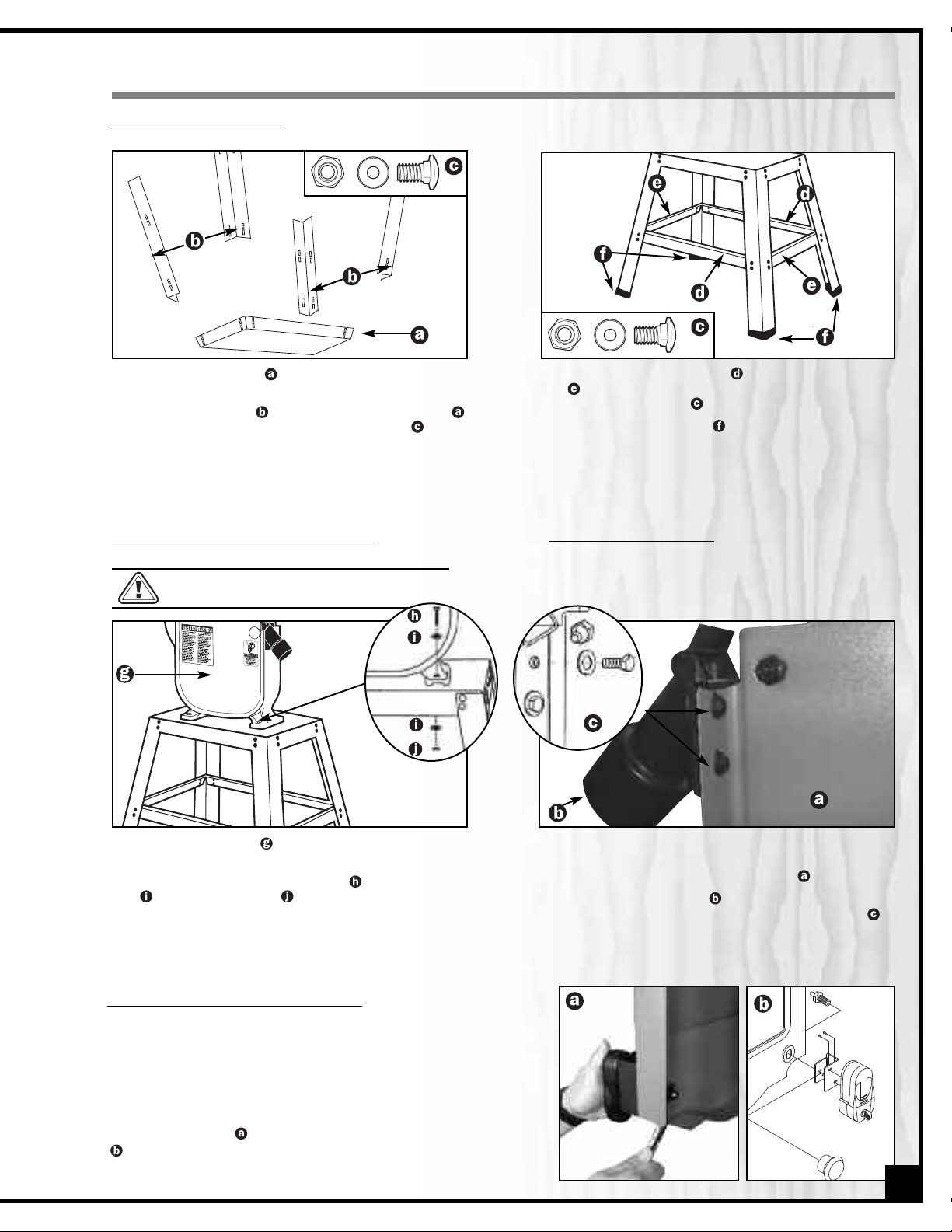

ASSEMBLY INSTRUCTIONS

ASSEMBLING THE STAND

Lay the top plate upside down on a flat sur-

1.

face.

2. Attach the 4 legs to the outside of top plate

using 4 carriage bolts, washers, and nuts

Note: Do not tighten hex nuts until all fasteners are

attached.

ATTACHING THE BANDSAW TO STAND

The bandsaw is heavy. The help of an assistant will be needed to lift the bandsaw.

.

3. Attach 2 long brackets and 2 short brackets

to the inside for the legs, using carriage bolts,

washers, and nuts .

4. Place the foot pads on the bottom of each

leg.

5. Place the stand on a flat surface to square it up

and finally tighten all the nuts.

ATTACHING DUST PORT

The dust port has a 2-1/2” opening

connection to a dust collector (not included).

to accommodate

1. Lift the saw body with the help of an assistant

and place it on the stand.

2. Using 4 long hex head bolts , 8 flat washers

, and 4 hex nuts , secure the bandsaw to

the stand and tighten all mounting bolts.

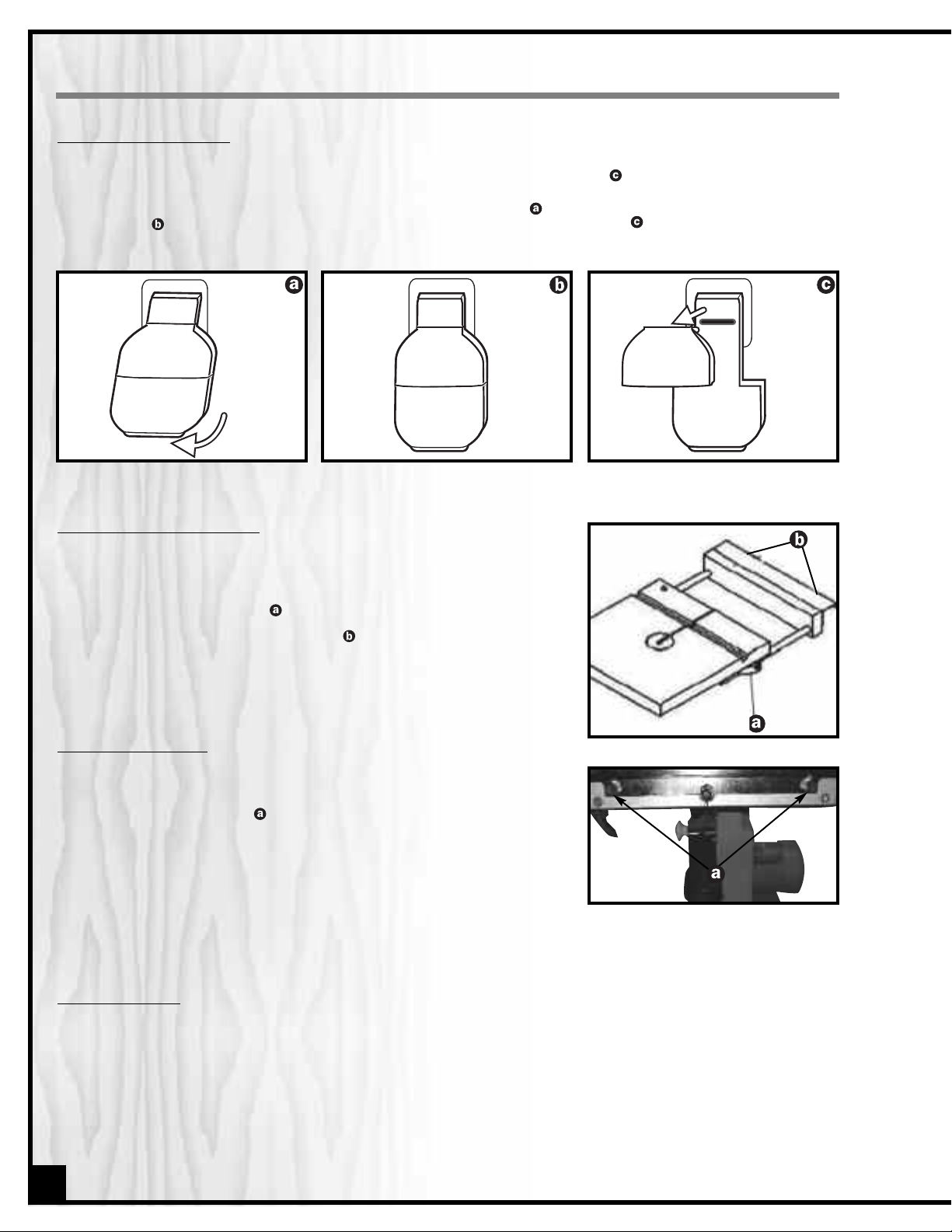

INSTALLING THE LASER LINE MARKER

The door knob and its threaded pin are used as the

fasteners to secure the laser line marker mounting

bracket to the door.

To install the laser line marker on the door, first remove

the door knob and its pin. Then re-install the knob with

its pin through the hole in the laser line markers’

mounting bracket in the order of assembly shown

.

1. Remove the bolts and washers from the dust

port.

2. Open the lower wheel cover door

3. Attach the dust port to the edge of the door

using the same hex head bolts and washers .

4. Tighten the bolts and close the door.

.

7

Page 8

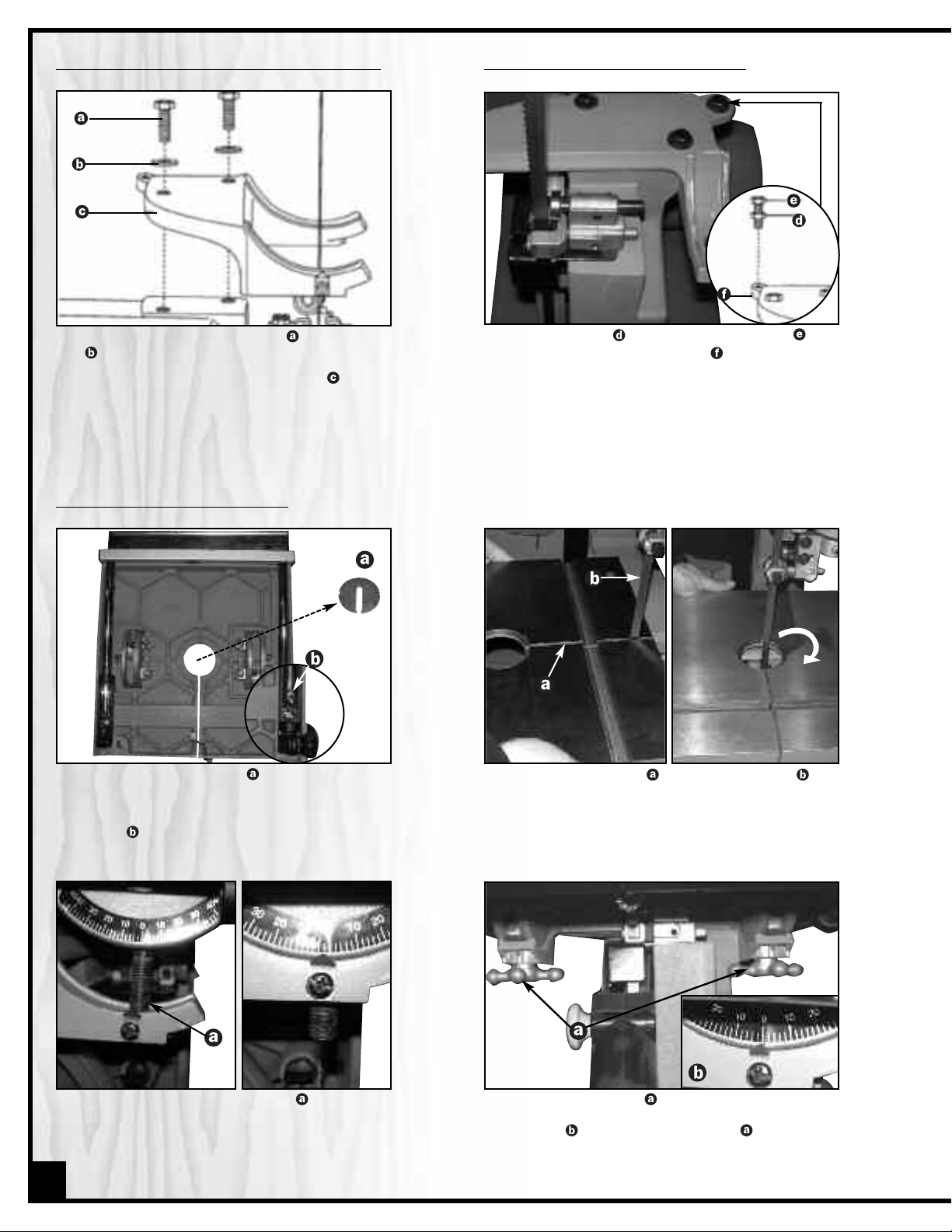

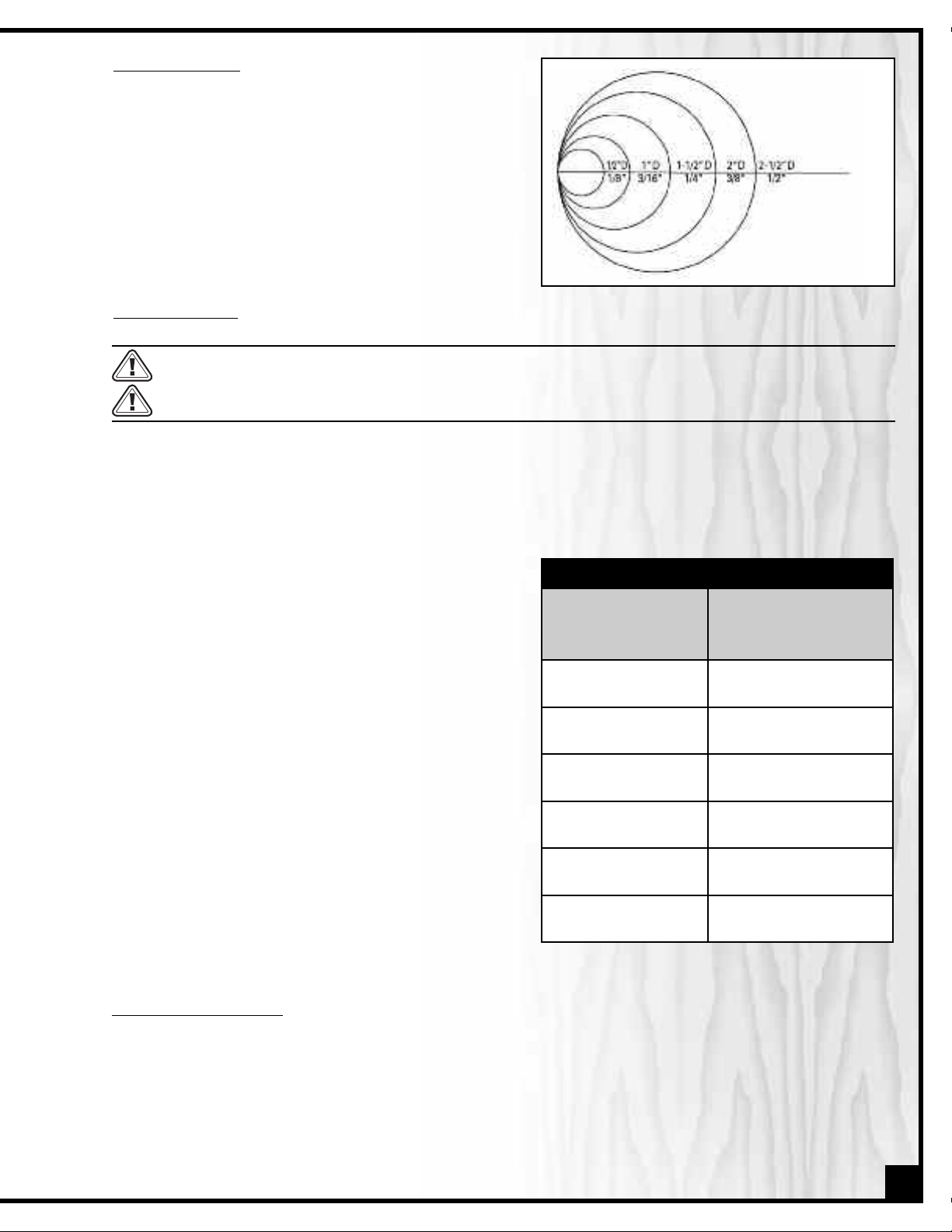

MOUNTING THE TRUNNION SUPPORT BRACKET

INSTALLING 90° TABLE TILT STOP BOLT

1. Remove the 2 hex head bolts and washers

, located on the lower band saw housing.

2. Place the trunnion support bracket on the

saw body, aligning the mounting holes.

3. Place the washers on the hex head bolts, and

insert into the threaded holes, through the

bracket and saw body. Tighten.

INSTALLING THE BANDSAW TABLE

1. Remove the table insert from the table.

2. The extension table must be removed before

placing table onto saw. Unscrew the stopscrew on the rear extension table guide bar

and pull the extension table off of the main

table.

1. Thread the nut onto the table stop bolt and

screw bolt into the rear tab on the trunnion

support bracket. Tighten the nut down onto the

bracket tab.

2. After installing the table, the 90° stop bolt can be

adjusted up or down as needed to “stop” the

table at 90° to the blade.

90° CW

3. Guide the table slot over the saw blade and

rotate 90° clockwise so the slot is perpendicular

to the blade.

4. Slip the 2 table tilt trunnion bolts through the

holes in the trunnion brackets (front & rear) as

shown.

8

5. Place a lock knob on each bolt and adjust

the table, aligning the zero scale mark to the

pointer , then tighten the knobs .

Page 9

bottom

view

MITER GAUGE

6. Re-install the table insert .

7. Insert the table aligning pin in the hole at

the side of the table.

8. Re-install the extension table and re-attach the

stop-screw

.

INSTALLING POWER CORD STORAGE BRACKETS

Attach the power cord brackets to the rear of

the saw, as shown using the 2 Phillips head screws

.

To prevent damage, stow the cord by wrapping it onto the brackets whenever the saw is not

in use.

REMOVING & INSTALLING THE BLADE

Store the miter gauge on the supplied bracket on the

stand as shown.

ATTACHING THE WORK LIGHT

Remove 4 phillips screws from machine body. Install

the work light and the power cord to the machine

body by using 4 phillips screws and tighten.

The worklight uses a standard 110V household lightbulb, 60 Watts - Not Included.

Before replacing or adjusting the blade, make sure the switch is in the “OFF” position and that the power cord is unplugged.

Note: Extension table must be removed when removing/installing the blade. See Step 2 & 8 in INSTALL THE BANDSAW TABLE, pg. 8 & 9.

1. To remove blade, release blade tension by turning

the blade tension knob counter-clockwise until

it stops.

2. Remove the table insert and table aligning pin.

3. Open upper and lower wheel cover doors.

4. Loosen the 2 Phillips screws and remove the

upper blade guard .

5.

Remove the blade from the upper and lower

blade guides. Carefully pull the blade from the

side slot and from the wheels

.

6. Swing the left side of the blade toward you, turning

the blade so it will fit through the slot in the table

and remove.

9

Page 10

Make sure the blade is in the center of the table insert slot before operating.

To install a blade, repeat the previous steps (Pg. 9) in

reverse order, making sure that the blade is installed with

the teeth pointing forward and down as shown.

With the blade installed, re-attach the extension table and

then proceed to “BLADE TENSION ADJUSTMENTS” and

“BLADE TRACKING ADJUSTMENTS” in the “RECOMMENDED

ADJUSTMENTS” section of this manual, Pg. 11.

RECOMMENDED ADJUSTMENTS

Before making any adjustments, make sure that the switch is in the “OFF” position and that the power cord is

unplugged.

TILTING THE TABLE

Proper installation

Improper installation

1. Loosen both table lock knobs underneath the table.

2. Manually tilt the table to the desired angle on the

scale under the table.

3. Tighten the knobs to secure the table at the desired

angle.

ADJUSTING THE 90° TABLE STOP

1. Loosen both table lock knobs underneath the table

and tilt the table to the right.

2. Loosen the nut on the table stop bolt and lower

the stop bolt as far as possible.

3. Place a combination square on the table against

the saw blade.

4. Adjust the tilt of the table left or right until it is 90° to the

blade. Make sure there is no space between the square

and the blade. Tighten the lock knobs .

5. Adjust the table stop bolt up until it touches the

underside of the table.

6. Loosen the lock knobs and verify that the table is resting on the stop bolt .

7 . Check the square to make sure the table is still

90° to the blade. If not, re-adjust the stop bolt as

needed.

8 . When the adjustment is accurate at 90°, tighten down

the nut on the stop bolt , tighten the table lock knobs

and align the pointer to the 0° mark on the angle

indicator scale

.

10

Page 11

BLADE TENSION ADJUSTMENTS

Before making blade tension adjustments, make sure that the switch is in the “OFF” position and that the power

cord is unplugged.

The gauge on the bracket at the rear of the upper

wheel housing indicates the proper tension for the various

blade widths.

1. Set the blade tension gauge to correspond with the

width of the blade in use.

2. Turn the blade tension knob clockwise, raising the

upper wheel to tighten the blade. Turn the knob counter-clockwise to lower the upper wheel, loosening the

blade.

Note: Changes in blade width and the type of material

being cut will have an effect on the blade tension. Too

much or too little tension could break the blade. When

the band saw is not in use, loosen the tension on the

blade, to prolong blade life.

BLADE TRACKING ADJUSTMENTS

Note: The blade must be tensioned properly before

adjusting the tracking.

1. Open the upper wheel cover door and move the

blade guides and support bearings away from

the blade, if necessary. See page 12-13 for bearing

and guide adjustment.

2. Rotate the wheel slowly forward by hand, and check

the position of the blade on the wheel. The blade

should remain centered on the wheel as it turns.

A) If the blade moves toward the front of the wheel, turn

the tracking knob on the back of the band saw

clockwise. This tilts the top of the wheel to the back and

moves the blade toward the center.

B) If the blade moves toward the back edge, turn the

tracking knob counter- clockwise, moving the blade

toward the center.

Note: Turn the tracking knob in 1/2 turn increments,

re-check and adjust again as needed.

CL

Back View

Turn CW

if blade

moves

to front

Turn

CCW if

blade

moves

to back

11

Page 12

ADJUSTING THE BLADE GUARD FOR DEPTH OF CUT

1. Loosen the lock knob and manually move the blade

guard assembly up or down to set the guard to

1/8” - 1/4” above the workpiece.

2. Re-tighten the lock knob, before turning on the saw.

3. Adjust the height of the blade guard to suit the thickness of the workpiece .

UPPER BLADE GUIDE

To avoid injury, make sure that the switch is in the “OFF” position and that the power cord is unplugged.

Note: In the drawing below, the blade guard has been removed for clarity of illustration. To avoid injury, never operate

the bandsaw without all guards in place and in proper working order.

Note: Make sure the blade is tensioned and tracking properly. Adjust the blade guide and support bearings after each

blade tension and tracking adjustment. Whenever the upper blade guide and support bearings are adjusted, the lower

guide and support bearings should also be adjusted.

1. Loosen the set screws and move the roller bearing

as close to the blade as possible without pinching it.

2. Using a feeler gauge, make sure the space between

each bearing and the blade measures 0.02” (the thickness of a dollar bill).

3. Re-tighten the set screws and loosen the side thumb

screw by turning counter-clockwise.

4. Move the blade guide bracket shaft in or out until the

roller bearings are at least 1/32” behind the blade

teeth.

5. The roller bearing must remain behind the blade

teeth during operation to prevent damage to the

blade. Tighten the thumb screw

.

POSITIONING THE UPPER SUPPORT BEARING

Note: The blade support bearing prevents the blade

from moving back too far and damaging the saw teeth

setting.

1. To re-position the support bearing, loosen the thumb

screw .

2. Move the support bearing shaft in or out, until the

bearing is 1/64” behind the blade.

”

3. Tighten the thumb screw .

12

Page 13

LOWER BLADE GUIDES

Note: The lower blade guides and support bearings

should always be adjusted after the blade is tensioned,

tracking is adjusted, and the upper blade guides and

upper support bearings are properly adjusted.

1. Loosen both front hex socket screws with a hex

wrench and move the bearings as close to the sides

of the blade as possible without pinching it.

2. Using the feeler gauge, measure the spaces between

the guide and the blade. Adjust to 0.02”.

3. Tighten the hex screws and loosen the side hex socket screw . Move the guide support bracket in or out

until the guides are at least 1/32” behind the saw teeth.

Tighten the screw.

LOWER SUPPORT BEARING

1. Loosen the bearing hex socket screw with the hex

wrench.

2. Move the blade support bearing shaft in or out until

the support bearing is 1/64” behind the saw blade.

3. Tighten the bearing hex socket screw .

LASER LINE MARKER

This model 90-060 is equipped with a laser line marker, located on the front right side hand of the upper wheel cover door

, allowing you to easily mark a straight cut line on your

workpiece.

Note: Requires two AAA batteries (not included). Slide upwards and remove the battery cover .

Align the laser beam on the blade as follows:

Move ON/OFF switch up to turn the laser marker

1.

on.

Move the beam adjustment knob in any direction

2.

until the beam is aligned with the blade .

PULLEY ALIGNMENT

Note: The pulley alignment has been pre-set and verified

at the factory and should not need re-adjustment. If

adjustment is needed or the belt needs replacing:

1. Place a straight edge in the front groove of both pulleys, behind the blade wheel.

2. Turn the set screw in the side of the motor pulley to

loosen the pulley on the shaft.

ON / OFF SWITCH

ON

CLOSE UP

OFF

BEAM

ADJUSTMENT KNOB

3. Adjust the pulley in or out on the shaft to align the

edges of the two pulleys.

4. When aligned, re-tighten the set screw on the side of the

motor pulley.

13

Page 14

OPERATING INSTRUCTIONS

ON/OFF POWER SWITCH

The bandsaw is equipped with a rocker type ON/OFF switch, located at the left, that is equipped with a lock-out key.

To prevent unwanted or unauthorized start-up or usage remove the lock-out key and store it in a safe place.

To start the bandsaw, insert the lock-out key and pull up the switch . To stop the bandsaw, push down on the

power switch . When the saw comes to a complete stop, remove the lock-out key by gently pulling it outward.

POWER ON

USING THE TABLE EXTENSION

When working with wider or longer work pieces that may need additional support the table extension can be pulled out and locked in place to

provide wider work surface.

1. Loosen the cam lock lever at the front of the table.

2. Pull out and slide the table extension to the required position.

3. Lock down the cam lock lever to secure the table extension in

place.

USING THE RIP FENCE

For more precise straight line cuts there is a retractable rip fence attachment on the end of the table extension.

1. Loosen the 2 lock knobs on the end of the extension table.

2. Raise the rip fence and while holding it in place above the table, retighten the 2 lock knobs.

3. Adjust the positioning of the table extension so that the distance

from the inside face of the rip fence to the blade matches the

required width of cut. Make sure to lock the table extension in place

before starting to cut against the rip fence.

POWER OFF LOCK-OUT KEY

(PREVENTS START-UP WHEN REMOVED)

CUTTING CURVES

• When cutting curves, carefully turn the workpiece so the blade follows without twisting, If the curve is so sharp that

you repeatedly back up and cut new kerf, use a narrower blade, or a blade with more set (teeth further apart).

When a blade has more set, the workpiece turns easier but the cut is rougher.

• When changing a cut, do not withdraw the workpiece from the blade. The blade may get drawn off the wheels.

• To change a cut, turn the workpiece and cut your way out through the waste material area.

• When cutting long curves, make relief cuts as you go along.

14

Page 15

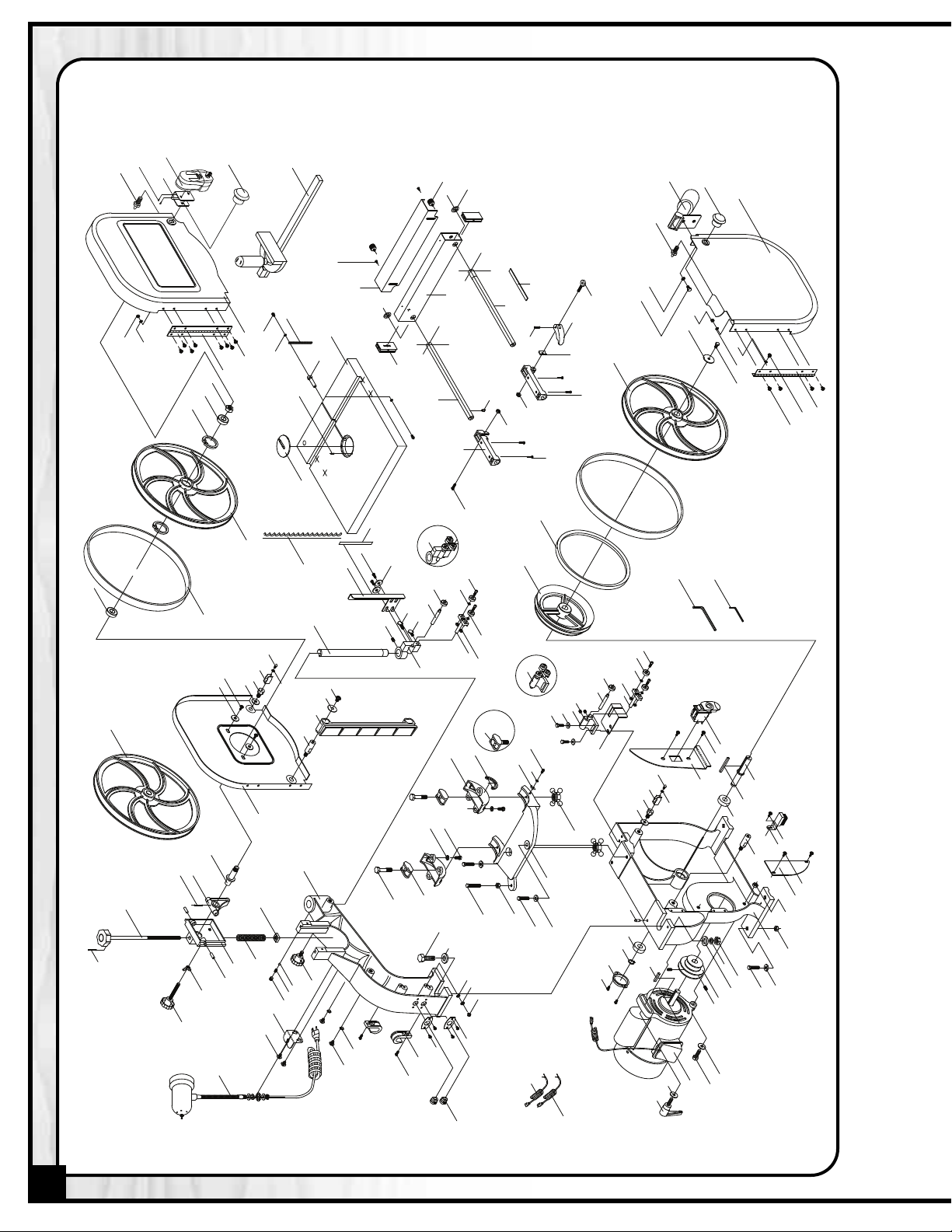

CUTTING CIRCLES

1. Adjust the blade guard assembly to 1/8” above the

workpiece.

2. Use both hands while feeding the work into the blade.

Hold the workpiece firmly against the table. Use gentle

pressure. Do not force the work. Allow the blade to cut.

MIN. CIRCLE

DIAM.

3. The smallest diameter circle that can be cut is determined by the width of the blade. For example, a 1/4”

wide blade will cut a minimum diameter of approximately 1-1/2”.

BLADE WIDTH

BLADE SELECTION

Blade teeth are sharp. Use care when handling a saw blade.

Do not cut ferrous metals with this bandsaw.

There are a variety of different types of bandsaw blades on the market to suit various cutting applications. The accompanying “Blade Selection” chart is provided as a general reference tool; your results may vary based on usage, experience and personal preference. Ask your local tool dealer for suggestions for 80” bandsaw blades in 1/8” to 1/2”

widths, based on what is available in your area.

Some general guideline to consider when choosing bandsaw blades:

• Wider blades with coarse teeth are best suited to cutting

straight lines, re-sawing and for sweeping curves,but will

not turn tight corners. They will cut quickly and aggressively but do have a tendency to bind (or get stuck in

the cut) if turned to sharply.

B L AD E S E L E C TI O N

OPERATION RECOMMENDED BLADE

WIDTH (INCHES)

CROSS CUTTING 1/4, 3/8, 1/2

• Narrower, thinner blades with finer teeth will cut more

slowly but can turn much tighter corners for cutting

more intricate work.

Common causes of blade breakage:

• Poor guide bearing alignment and adjustment.

• Forcing or twisting a wide blade around a short radius.

• Feeding the workpiece too quickly.

• Dull teeth.

• Too much blade tension.

•Setting blade guard assembly too high above the workpiece.

•Lumpy or improperly finished braze or weld on the

blade.

• Continuous running of blade when not cutting.

MITERING 1/4, 3/8, 1/2

BEVELING 1/4, 3/8, 1/2

COMPOUND CUTTING 1/4, 3/8, 1/2

CIRCLE CUTTING SEE “CUTTING CIRCLES”

CURVE CUTTING 1/8, 1/4

SELECTING BLADE SPEED

This bandsaw is equipped with 2 speed settings: High - 2710 Feet Per Minute (FPM) and Low- 1580 FPM, allowing you to

achieve better results by selecting a more appropriate blade speed based on the cutting operation being performed.

Some general guidelines to consider for selecting blade speed:

Thick Material = Slower Speed

Harder or Denser Material = Slower Speed

Blades with Fine Tooth Pitch = Slower Speed

Thin Material = Faster Speed

Soft Material = Faster Speed

Blades with Few Teeth PI = Faster Speed

15

Page 16

CHANGING SPEED SETTING

NEVER make adjustments with the machine running.

1. Loosen the belt tension by turning the tension lock handle

the rear of the saw.

2. Open the lower wheel cover and reposition the V-belt .

A) Changing the speed from 1580 to 2710 FPM:

Remove the belt from the band saw pulley first, and

reposition in the saw pulley groove . Next, remove the belt

from the motor pulley and reposition in the motor pulley

groove .

B) Changing the speed from 2710 to 1580 FPM:

Remove the belt from the motor pulley first, and reposition in the motor pulley groove . Remove the belt from the

saw pulley and reposition in the saw pulley groove .

3. Tighten the belt tension by turning the tension lock handle .

Note: After readjusting belt position and belt tension, check

and readjust the settings for the blade tension and tracking,

guides and bearings (See ADJUSTMENT section on page 11).

at

MOTOR

MAINTENANCE & LUBRICATION

Before performing any maintenance, cleaning, adjusting, or lubricating your band saw, make sure that the switch

is in the “OFF” position and that the power cord is unplugged.

To avoid fire or toxic reaction, never use gasoline, naphtha, acetone, lacquer thinner or similar highly volatile solvents to clean the band saw.

To avoid eye injury from blowing debris, wear safety goggles when blowing out sawdust.

Keep your band saw clean. Sawdust will accumulate under the table, base and in the wheel housings. This could

cause difficulty in the movement of the table when setting up a band saw cut. Frequently blow out or vacuum up the

sawdust.

Do not allow dirt, pitch or gum to build up on the table, the guide, or support bearings. Clean as needed with gum

and pitch remover.

Note: Do not immerse the bearings in the gum and pitch remover. Put a thin coat of paste wax on the table so

that the wood slides easily while cutting.

16

Page 17

TO INSTALL A NEW BELT

1. Open the lower wheel door and loosen the blade tension by turning the blade tension lock knob .

2. Remove the blade from the lower blade wheel.

3. Loosen and remove the hex head bolt and flange

on the lower blade wheel.

4. Remove the lower blade wheel.

5. Turn the belt tension handle on the rear of the saw

housing to loosen the v-belt tension.

6. Remove the v-belt .

7. Check the alignment of the two pulleys.

8. If the edges of the two pulleys are not aligned, see: PULLEY ALIGNMENT on Page 13.

9. Place the new v-belt on the saw pulley and the motor

pulley. See CHANGING SPEED SETTING on Page 16 for

proper belt placement.

10. When positioned properly, tighten the v-belt tension by

turning the tension lock handle.

Note: The pulley belt is properly tensioned when there is

1/2” deflection if pressed in the center between the pulleys.

11. Replace the blade wheel. Push the wheel firmly until it is touching the saw pulley. Replace and tighten the flange

and nut.

12. Reinstall the blade (See INSTALL THE BLADE on page 9).

13. Adjust the blade tension, tracking, and the upper and lower blade guides and bearings before operating the bandsaw. (See pages 11-13)

BLADE WHEEL TIRES

Pitch and sawdust that build up on the tires should be removed with a stiff brush or scraped off with a piece of wood.

NOTE: To avoid damaging the tires do not use a sharp knife or any kind of solvent. When the tires become worn

they should be replaced. When replacing the tires, stretch them around the wheels but do not glue then on.

MOTOR

Frequently blow or vacuum out any sawdust from the motor. Follow lubrication instruction on the motor label.

LUBRICATION

All of the bearings are sealed and permanently lubricated. They require no further lubrication.

Never put lubricants on the blade while it is spinning.

17

Page 18

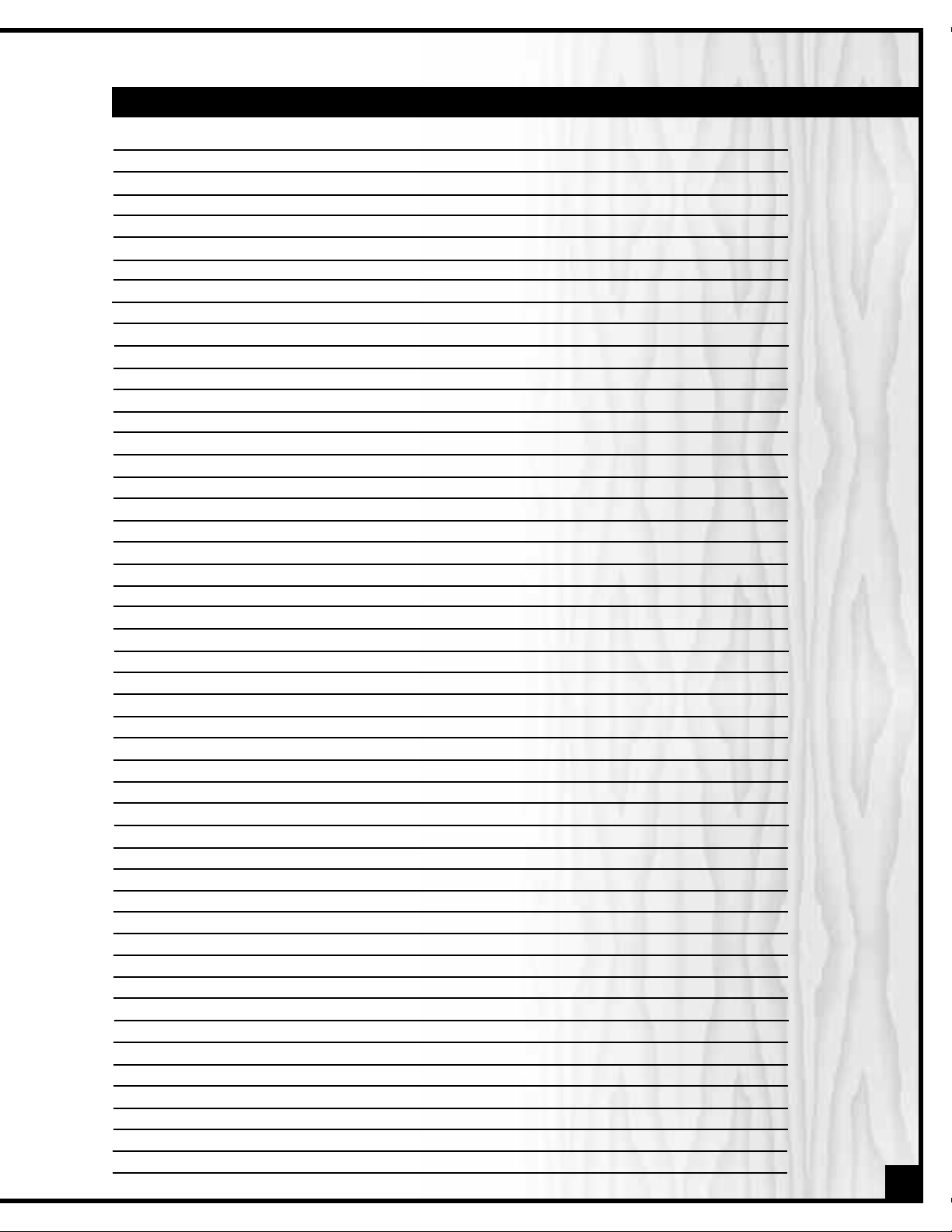

121

117

111

116

109

110

108

82

108

113

107

99

99

83

115

120

119

112

123

128

80

89

87

86

126

85

114

84

99

127

96

107

94

128

100

101

95

91

92

90

97

99

98

93

88

122

63

57

66

77

78

50

4

49

48

47

36

52

64

79

1

54

65

6

43

65

34

71

53

32

46

31

33

35

26

33

45

37

5

65

15

38

81

44

70

39

42

41

65

29

30

28

74

25

24

55

27

56

52

51

124

22

21

23

18

19

20

8

16

17

11

125

65

38

14

68

60

62

61

42

3

40

35

59

67

81

44

58

2

15

42

7

9

9-1

10

63

42

14

69

58

70

39

65

12

13

129-1

134

131

135

130

137

140

136

141

142

139

102

104

105

138

133

106

86

143

144

147

148

72

72

118

73

73

76

75

146

145

65

65

149

150

130-1

130-2

129-4

129-2

129-3

129-5

103

129

151

123

152

153

154

18

Page 19

PARTS LIST - 90-060

PART N0. DESCRIPTION SPECIFICATION QTY

90050-01 1

90050-02 1

90050-03 1

90050-04 1

90050-05 1

90050-06 1

90050-07 1

90050-08 1

90050-09 1

90050-09-1 3 x 30 1

90050-10 1

90050-11 312L 1

90050-12 (V TYPE) 1

90050-13 1

90050-14 2

90050-15 2

90050-16 1

90050-17 1

90050-18 5/16 x 2 1

90050-19 5/16 1

90050-20 2

90050-21 5/16 x 5/16 1

90050-22 1

90050-23 1/4 1

90050-24 5/16 x 1-1/4 1

90050-25 2

90050-26 1

90050-27 2

90050-28 SJT18 x 3C 1

90050-29 SJT18 x 3C 1

90050-30 6N-4 2

90050-31 1

90050-32 S-15 1

90050-33 6202ZZ 2

90050-34 1/4 x 16mm 2

90050-35 3/8 2

90050-36 3" 1

90050-37 1

90050-38 3/8 2

90050-39 2

90050-40 ABS 1

90050-41 4P J9305 1

90050-42 626ZZ 6

90050-43 1

90050-44 2

90050-45 5 x 5 x 54 1

90050-46 5 x 5 x 32.5 1

90050-47 1

90050-48 3/8" x 23 x 2T 1

BASE FRAME

UPPER ARM

REAR UPPER COVER

MOTOR ASSEMBLY W/CORD

FRAME ARM COVER, UPPER

FRAME ARM COVER, LOWER

POST MOUNTING BLOCK

SLIDING BRACKET

UPPER WHEEL SHAFT HINGE

PIN

UPPER WHEEL SHAFT

TENSION ADJUST ASSY W/KNOB

GUIDE POST

BLADE GUARD

BEARING SHAFT

"Y" TYPE BEARING BLOCK

ADJUST SPRING

SQUARE NUT

TRACKING ADJUSTMENT KNOB

BUTTERFLY NUT

PIN

CAP SCREW

SPRING

STEEL BALL

LOCK KNOB

POWER CORD STORAGE BRACKET

LOWER BLADE GUARD

PLATE

POWER CORD W/PLUG

POWER CORD W/INSERT PLUG

STRAIN RELIEF

BEARING COVER

C RING

BEARING

PIN

PIN FIXTURE BOLT

MOTOR PULLEY

LOWER WHEEL SHAFT

HEX. FIXTURE BOLT

DOOR RETAINER CLIP

INNER GUARD

SAFETY SWITCH

BEARING

WHEEL BRUSH ASSY.

STEEL WASHER

KEY

FLAT KEY

KNOB

FLAT WASHER

19

Page 20

PARTS LIST - 90-060

PART N0. DESCRIPTION SPECIFICATION QTY

20

90050-49 3/8" x 1-1/2" 1

90050-50 3/8" x 19 x 2T 1

90050-51 3/4" x 2-1/2" 1

90050-52 3/4" x 46 x 3T 2

90050-53 3/4" 1

90050-54 3/8" 1

90050-55 5mm 2

90050-56 2

90050-57 3/16" x 1/4" 2

90050-58 3/16" x 14 X1T 4

90050-59 5/16"-23 x 2.0mm 2

90050-60 1

90050-61 1/4" x 3/4" 2

90050-62 1/4"x16x2T 2

90050-63 M6 x 10x1T 4

90050-64 M6 x 16 2

90050-65 3/16" x 3/8" 17

90050-66 3/16" x 3/8" 2

90050-67 3/16" x 3/8" 2

90050-68 1/4" x 1/4" 2

90050-69 1/4" x 1/2" 1

90050-70 3/16" x 1/4" 2

90050-71 3/4" 1

90050-72 M6 4

90050-73 M6 x 20L 4

90050-74 3/16" x 1/2" 2

90050-75 M6 x 16L 1

90050-76 M6 x 10L 1

90050-77 5/16" x 1-1/4" 4

90050-78 5/16" x 23 4

90050-79 5/16" 4

90050-80 1

90050-81 3/16" 2

90050-82 1

90050-83 1

90050-84 1

90050-85 80" x 3 / 8" x 0.5mm x 6T 1

90050-86 6002ZZ 2

90050-87 1/2" 1

90050-88 2

90050-89 2

90050-90 M10 x 40 2

90050-91 5/16" 6

90050-92 1/4" x 5/8" 6

90050-93 1

90050-94 M10 2

90050-95 5/16" x 1-1/4" 2

90050-96 5/16" x 18x2T 2

90050-97 1

HEX. SCREW

FLAT WASHER

HEX HEAD BOLT

FLAT WASHER

HEX. NUT

NYLON NUT

SPROCKET WASHER

COPPER WASHER

PHILLIPS HEAD METAL SCREW

STEEL WASHER

STEEL WASHER

LOWER SUPPORT BRACKET

HEX. HEAD BOLT

FLAT WASHER

FLAT WASHER

SET SCREW

PHILLIPS HEAD METAL SCREW

PHILLIPS HEAD SCREW

HEADLESS CROSS SCREW

SET SCREW

SET SCREW

PHILLIPS HEAD SCREW

LOCK WASHER

NUT

CAP SCREW

PHILLIPS HEAD METAL SCREW

THUMB SCREW

THUMB SCREW

HEX HEAD BOLT

FLAT WASHER

NUT

DUST PORT

LOCK WASHER

LOWER DOOR HINGE

LOWER WHEEL WASHER

UPPER DOOR HINGE

BLADE

BEARING

HEX. NUT

TRUNNION

TRUNNION CLAMPING SHOE

HEX HEAD BOLT

LOCK WASHER

HEX HEAD BOLT

SCALE

TABLE TILT LOCK KNOB

HEX HEAD BOLT

FLAT WASHER

POINTER

Page 21

PARTS LIST - 90-060

PART N0. DESCRIPTION SPECIFICATION QTY

90050-98 3/16" x 3/8" 1

90050-99 3/16" 17

90050-100 5/16" x 1" 1

90050-101 5/16" 1

90050-102 1

90050-103 1

90050-104 1

90050-105 1

90050-106 1

90050-107 3/16" 12

90050-108 3/16" x 1/4" 12

90050-109 1/4" x 5/8" 1

90050-110 3/16" x 3/8" 4

90050-111 1

90050-112 1

90050-113 1

90050-114 1

90050-115 1

90050-116 2

90050-117 3 mm 1

90050-118 5 mm 1

90050-119 2

90050-120 1/4" x 3/8" 2

90050-121 1

90050-122 2

90050-123 3/8" 2

90050-124 1

90050-125 1

90050-126 A-26 1

90050-127 1

90050-128 2

90050-129 1

90050-129-1 1

90050-129-2 1

90050-129-3 M5 x 25L 1

90050-129-4 M5 1

90050-129-5 5 x 20L 1

90050-130 1

90050-130-1 M5 x 20 1

90050-130-2 M5 1

90050-131 M6 x 10L 4

90050-132 2

90050-133 5/8" x 282L x 1.4T 1

90050-134 5/8" x282L x 1.4T 1

90050-135 3/16" x 1/4" 1

90050-136 330.2L x 20 x 40 x 1.2T 1

90050-137 20 x 40 2

90050-138 1/4" x 3/4" 2

90050-139 1

PHILLIPS HEAD SCREW

LOCK WASHER

HEX. HEAD BOLT

HEX. NUT

TABLE

TABLE PIN

SPRING PIN

TABLE INSERT

MITER GAUGE ASSY.

NUT

PHILLIPS HEAD METAL SCREW

HEX HEAD BOLT

PHILLIPS HEAD METAL SCREW

PULLEY

LOWER DOOR

UPPER DOOR

UPPER WHEEL

LOWER WHEEL

TIRE

ALLEN KEY

ALLEN KEY

FLAT WASHER

HEX HEAD BOLT

UPPER WHEEL ASSEMBLY

TRUNNION CLAMP ASSEMBLY

DOOR KNOB

LOWER BLADE GUIDE ASSY.

UPPER BLADE GUIDE ASS'Y

V-BELT

TRUNNION BRACKET

SPRING CLIP

FRONT EXTENSION BRACKET

KNOB

CLAMPING PLATE

THUMB SCREW

NYLON FLANGE NUT

PIN

REAR EXTENSION BRACKET

PHILLIPS HEAD SCREW

NYLON NUT

PHILLIPS HEAD SCREW

NUT

REAR EXTENSION TUBE

FRONT EXTENSION TUBE

PHILLIPS HEAD SCREW

TABLE EXTENSION BODY

TUBE CAP

CAP SCREW

FENCE

21

Page 22

PARTS LIST - 90-060

PART N0. DESCRIPTION SPECIFICATION QTY

NOTE

90050-140 M4x10L 2

90050-141 3/8" x 20 x 2T 2

90050-142 1

90050-143 R-32 2

90050-144 3 x 20 1

90050-145 2

90050-146 3/16" x 1/4" 2

90050-147 1

90050-148 1/4" 2

90050-149 1

90050-150 1

90050-151 1

90060-152 1

90060-153 1

90060-154 M3 x 8 MM 2

LOCK KNOB

FLAT WASHER

SCALE

C-RING

PIN

CORD CLIP

PHILLIPS HEAD METAL SCREW

CHAIN

LOCK WASHER

WORKLIGHT MOUNTING BRACKET

WORKLIGHT ASSEMBLY

SCALE FOR BLADE GUARD

LASER LINE MARKER

MOUNTING BRACKET

PHILLIPS SCREW

22

Page 23

10

4

1

7

8

9

5

6

3

2

STAND

PARTS LIST - 90-060 - STAND

PART N0. DESCRIPTION SPECIFICATION QTY

90050-01S 1

90050-02S 4

90050-03S 2

90050-04S 2

90050-05S 1

90050-06S 3/16 x 1/4" 2

90050-07S 5/16" 32

90050-08S 3/16 x 18 x 2 32

90050-09S 32

90050-10S 4

TOP PLATE

LEG

LOWER BRACKET (LONG)

LOWER BRACKET (SHORT)

MITER GAUGE STORAGE

SCREW

NUT

FLAT WASHER

CARRIAGE BOLT

FOOT PAD

23

Page 24

90-060

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

Tel.: (514) 326-1161

Fax : (514) 326-5565

Parts & Service

Fax : (514) 326-5555 Order Desk

orderdesk@general.ca

www.general.ca

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and part number. Also a brief description of each item and quantity

desired.

Loading...

Loading...