General 747l Owner's Manual

ENGLISH INSTALLATION INSTRUCTIONS

1

PRECAUTION: The installer should be an experienced service technician. Disconnect electrical power before

beginning installation. Do not install where temperatures fall below 32 degrees F or where plenum temperatures

exceed 200 degrees F.

GENERALAire

RESIDENTIAL AIR TREATMENT PRODUCTS

FOR INSTALLATION ON

THE HORIZONTAL SUPPLY

DUCT OF ANY FORCED

WARM AIR FURNACE

INST ALL ER: PLEASE FILL OUT AND MAIL GUARANTEE CARD AFTER INSTALLATION

IS COMPLETE. LEAVE INSTALLATION

INSTRUCTIONS WITH HOME OWNER

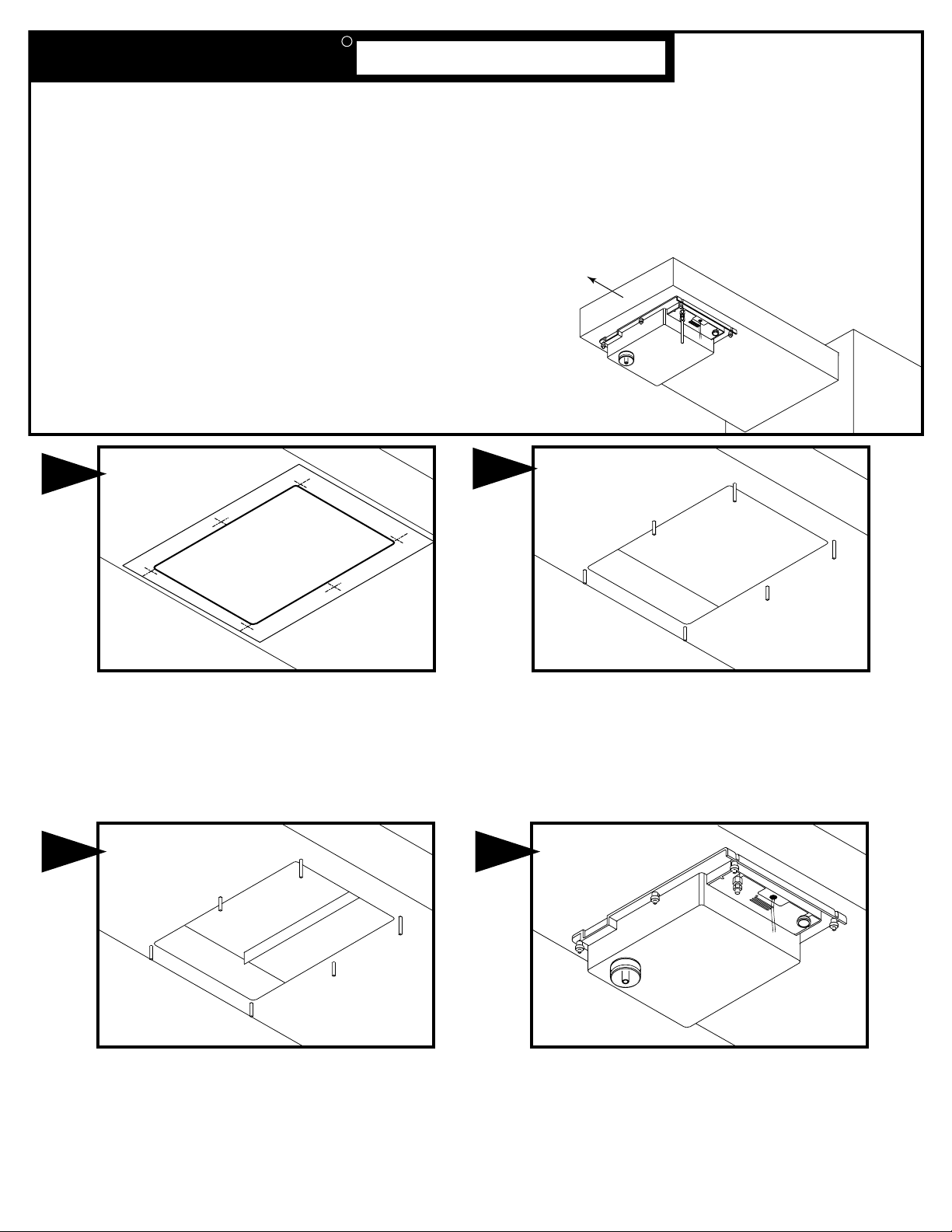

INSTALLATION: The humidifier may be mounted on the

horizontal warm air duct only.

See Typical Installation.

The following illustrations show steps for installing the

humidifier on the horizontal supply duct of a forced warm

air furnace. For maximum output, install the humidifier

perpendicular to the air flow as shown. On supply ducts

less than 16" wide the humidifier may be mounted parallel

to the air flow, but will have reduced evaporative output.

2

MODEL 747-L

DUCT MOUNT

DRUM HUMIDIFIER

R

3

Install the right angle metal baffle on the upper inside surface

of 8" or deeper supply ducts. Position the baffle 1" upstream

from the centerline of the rotating drum. Mark and drill two

1/8" holes. Mount the baffle with the two sheet metal screws

provided. For maximum evaporative output the 2" leg of the

baffle should extend down.

Place humidifier on the mounting studs and fasten in place

with the six thumb nuts supplied.

4

Select a location on the bottom surface of the warm air supply

duct for mounting the humidifier. The mounting position

should be at least 24" from the vertical supply plenum. Apply

the mounting template.

Center punch and drill the 6 mounting holes with a 1/4" drill.

Cut out center section of template. Remove remaining

template. Place mounting bracket inside duct with the 6

mounting studs down through the 1/4" holes. THE LONG

STUDS HOLD THE MOTOR END OF THE HUMIDIFIER.

Push two flat push-nuts on the central studs to hold the

mounting bracket in place.

Top Of Template

TEMPLATE FOR INSTALLING

GENERAL "747-L" HUMI

D

IFIE

R

4.

T

IG

H

TE

N

S

C

R

EW

S

A

N

D A

D

JU

S

T

H

U

M

ID

IF

IE

R

U

N

T

IL

L

E

V

E

L

.

5.

R

E

M

A

R

K

F

O

U

R

RE

M

A

I

NIN

G

HO

LE

S

I

F

N

E

C

E

S

S

ARY

.

6

. R

E

M

O

VE

HU

M

ID

IF

I

ER

,

D

R

IL

L

R

E

M

A

IN

I

NG

HO

LE

S

AN

D

C

U

T

O

U

T

C

E

N

TE

R

SE

CT

IO

N

O

F

T

E

M

P

L

AT

E

.

CUT ON THIS LINE

TE

M

P

LA

T

E

N

O. 10

4

2

-2

5

F

O

L

L

O

W

IN

ST

RU

CT

IO

N

S

P

A

C

K

E

D

W

IT

H

H

U

M

ID

IF

IE

R

1.

RE

M

O

VE

P

R

O

T

E

CT

I

V

E

P

A

P

E

R

FR

O

M

B

AC

K

O

F

T

E

M

P

LA

T

E

A

N

D

S

TI

C

K

I

N

LEV

E

L P

O

S

I

TI

O

N

.

2.

C

E

N

TE

R

P

U

NC

H

A

N

D

D

R

IL

L T

H

E

F

O

U

R

S

ID

E

M

O

U

N

T

IN

G

H

O

LE

S

W

I

T

H

A

1

/8

" D

IA

.

D

RI

L

L

.

3. HA

N

G

H

UM

I

DI

FI

E

R

F

R

O

M

F

O

U

R

S

ID

E

S

CR

E

W

S

A

N

D

I

NS

T

A

LL

D

RA

IN

P

AN

,

E

V

A

P

O

R

A

TO

R

P

A

D

A

N

D

D

IS

T

R

IBU

T

O

R

T

R

O

UG

H.

WARM AIR

5

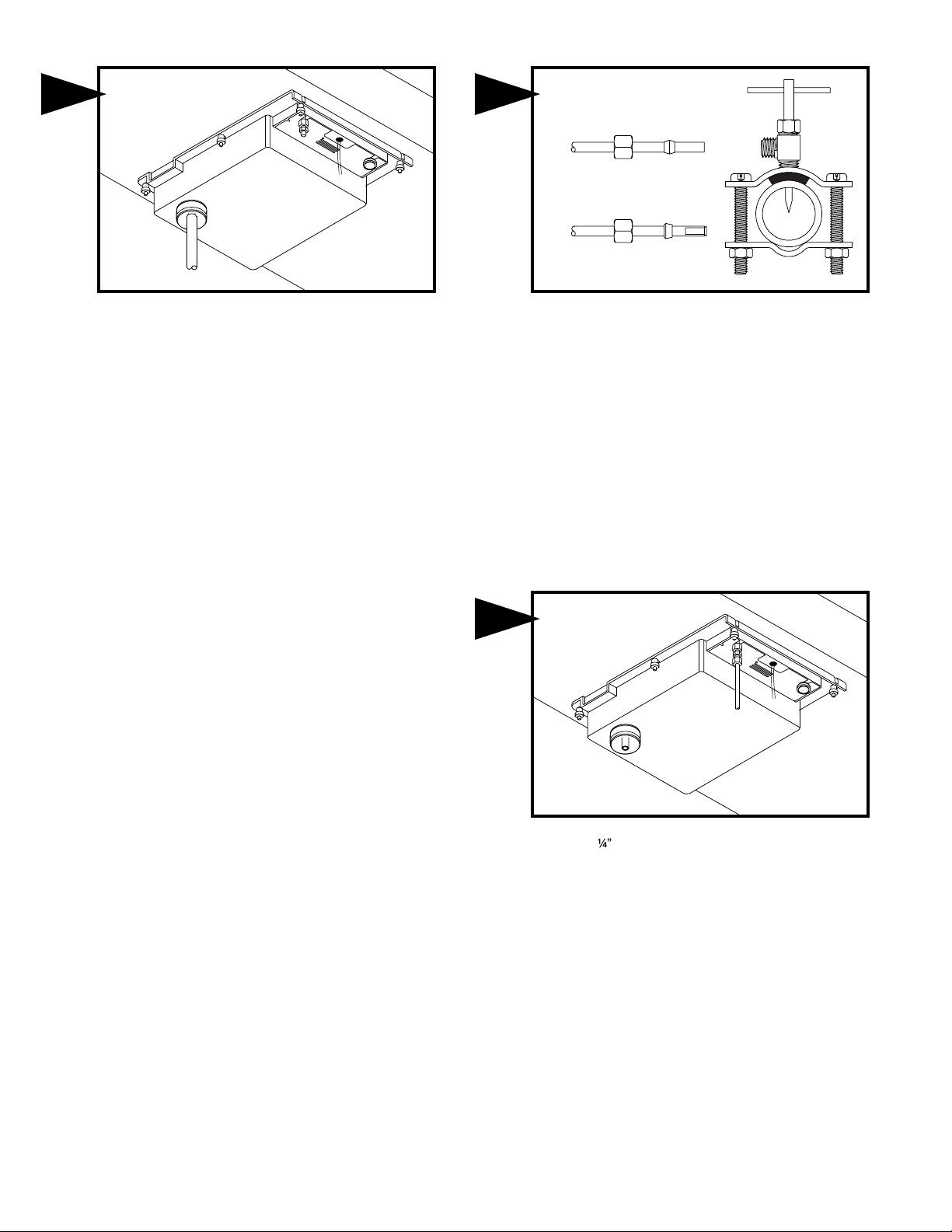

NOTE: If overflow protection is required, slide 5/8" I.D. vinyl

tube (Pt. No. 1099-16) over quick-drain spout and run to

suitable drain connection. Use a strain relief clamp within 36"

of humidifier to prevent drain tube from pulling on quick-drain.

Drain tube is not supplied with humidifier but is available in 5,

15 and 100 foot lengths.

6

COPPER

TUBING

PLASTIC

TUBING

Mount the self tapping saddle valve on either a cold or a hot

water pipe. A side or top mount is best to avoid clogging

from pipe sediment. Connect 1/4” O.D. tubing to the saddle

valve. Copper tubing requires a brass compression nut and

brass sleeve. Plastic tubing requires a brass insert inside the

tubing, a plastic sleeve on the outside with a brass

compression nut.

NOTE: DO NOT USE PLASTIC TUBING ON HOT WATER

OR IN CONTACT WITH ANY HOT PLENUM SURFACE OR

DUCT. INSTALLATION OF THIS SADDLE VALVE MUST

MEET OR EXCEED LOCAL CODES AND ORDINANCES.

SADDLE VALVE INSTALLATION INSTRUCTIONS

Copper Pipe

1. Retract piercing pin into valve body by turning handle

counterclockwise.

2. Screw valve body into upper bracket and tighten.

3. Place rubber gasket over piercing pin.

4. Assemble saddle valve over copper pipe using enclosed screws,

nuts and lower bracket.

5. Tighten screws evenly and firmly. Brackets should be parallel.

6. Complete compression connection to saddle valve outlet.

7. Turn handle clockwise to pierce tubing and close saddle valve.

8. Turn handle counterclockwise to

several seconds to flush dirt from pipe and tubing.

Steel, Brass or Hard Plastic Pipe

1. Shut off water supply and drain pipe.

2. Turn handle clockwise to expose piercing pin and close saddle valve.

3. Place rubber gasket over piercing pin.

4. Drill 1/8" hole in pipe using a hand crank drill to avoid shock hazard.

5. Assemble saddle valve over steel, brass or hard plastic pipe using

enclosed screws, nuts and lower bracket.

6. Tighten screws evenly and firmly. Brackets should be parallel.

7. Complete compression connection to saddle valve outlet.

8. Turn handle counterclockwise to

several seconds to flush dirt from pipe and tubing.

Threaded Pipe Fittings

1. Turn handle clockwise to expose piercing pin and close saddle valve.

2. Seal valve body threads using pipe tape or sealant.

3. Install valve into 1/8" NPT fitting.

4. Complete compression connection to saddle valve outlet.

5. Turn handle counterclockwise to

several seconds to flush dirt from pipe and tubing.

open saddle valve, leave open for

open saddle valve, leave open for

open saddle valve, leave open for

7

Connect the water supply tubing to the humidifier. Copper

tubing requires a brass compression nut and brass sleeve.

Plastic tubing requires a brass insert inside the tubing, a

plastic sleeve on the outside with a brass compression nut.

DO NOT USE PLASTIC TUBING IN CONTACT WITH

ANY HOT PLENUM SURFACE OR DUCT. IF USING

PLASTIC TUBING, USE TUBE SUPPORT PROVIDED.

Loading...

Loading...