General 4172, 4170, 4162, 4165, 4152 Owner's Manual

Operation And Maintenance Manual

SSCB-7 SERIES

SEMI-FLUSH CEILING MOUNTED

ELECTRONIC AIR CLEANER

IMPORTANT: PLEASE READ MANUAL BEFORE INSTALLING,

OPERATING, CLEANING OR SERVICING UNIT

IMPORTANT: Please read entire instructions before

installing the Electronic Air Cleaner.

CONTENTS

SAFETY CONSIDERATIONS 2

WHAT THE ELECTRONIC AIR CLEANER DOES 2

BENEFITS 2

HOW IT WORKS 2

MAJOR COMPONENTS 3

INSTALLATION 3-4

Mounting 3

Wiring 4

OPERATION & MAINTENANCE 4

Operation Check 4

Maintenance Schedule 4

Cleaning 4

SERVICE 5-7

Testing For High Voltage At Power Board 5

Measuring High Voltage At Power Board 5

Replacing A Performance Light 5

Replacing A Power Board 5

Testing The 24 V Transformer 6

Replacing The 24 V Transformer 6

Setting Voltage Of Power Board 6

Setting Approximate Voltage Without High Voltage Meter 6

Testing For Voltage at The Cell 6

Testing Cell For Bad Contacts 7

Testing Cell With An Ohmmeter 7

Replacing A Tungsten Wire 7

Replacing A Fan Motor 7

REMOTE SWITCH CONTROL 7

Electrical Schematic 8

TROUBLESHOOTING GUIDE 9

Exploded View 10

Parts List 10

Technical Data and Dimensions 11

WARRANTY 12

Certified for shock and electrical fire hazard only.

SAFETY CONSIDERATIONS

Read and follow instructions carefully. Follow all local

electrical codes during installation. All wiring must

conform to local and national electrical codes. Improper

wiring or installation may damage the Air Cleaner.

Understand the signal words WARNING and

CAUTION which are present in the Installation, Operation

& Service Instructions.

WARNING and CAUTION signifies a hazard which

could result in property damage, personal injury or death.

Installation and servicing of Electronic Air Cleaners

can be hazardous. Only trained and qualified service

personnel should install, repair, or service Electronic

Air Cleaners.

Untrained personnel can perform the basic

maintenance functions of cleaning and replacing

filters.

When working on air cleaning equipment, observe

precautions in the manual, labels attached to the unit,

and other safety precautions that may apply. Follow

all safety codes. Wear safety glasses and work

gloves.

WHAT THE ELECTRONIC AIR CLEANER DOES

Your High Efficiency Electronic Air Cleaner has been

designed to remove tobacco smoke particles, cooking

smoke and grease, atmospheric dust, coal dust,

insecticide dust, mites, pollen, mold spores, fungi,

bacteria, viruses and more down to 0.01 micron (0.01

micron = 1/2,540,000 of an inch).

BENEFITS

Helps clear up a smokey environment quickly, so

customers can dine more comfortably.

Helps employees reduce suffering from irritated eyes,

nasal congestion and respiratory problems that lead

to absenteeism.

Helps prevent damaging black and greasy particles

from staining ceilings, walls and furnishings, reducing

the amount of housekeeping and redecorating costs.

Helps to lower energy bills by recycling air rather than

exhausting expensive heated or cooled air.

HOW IT WORKS

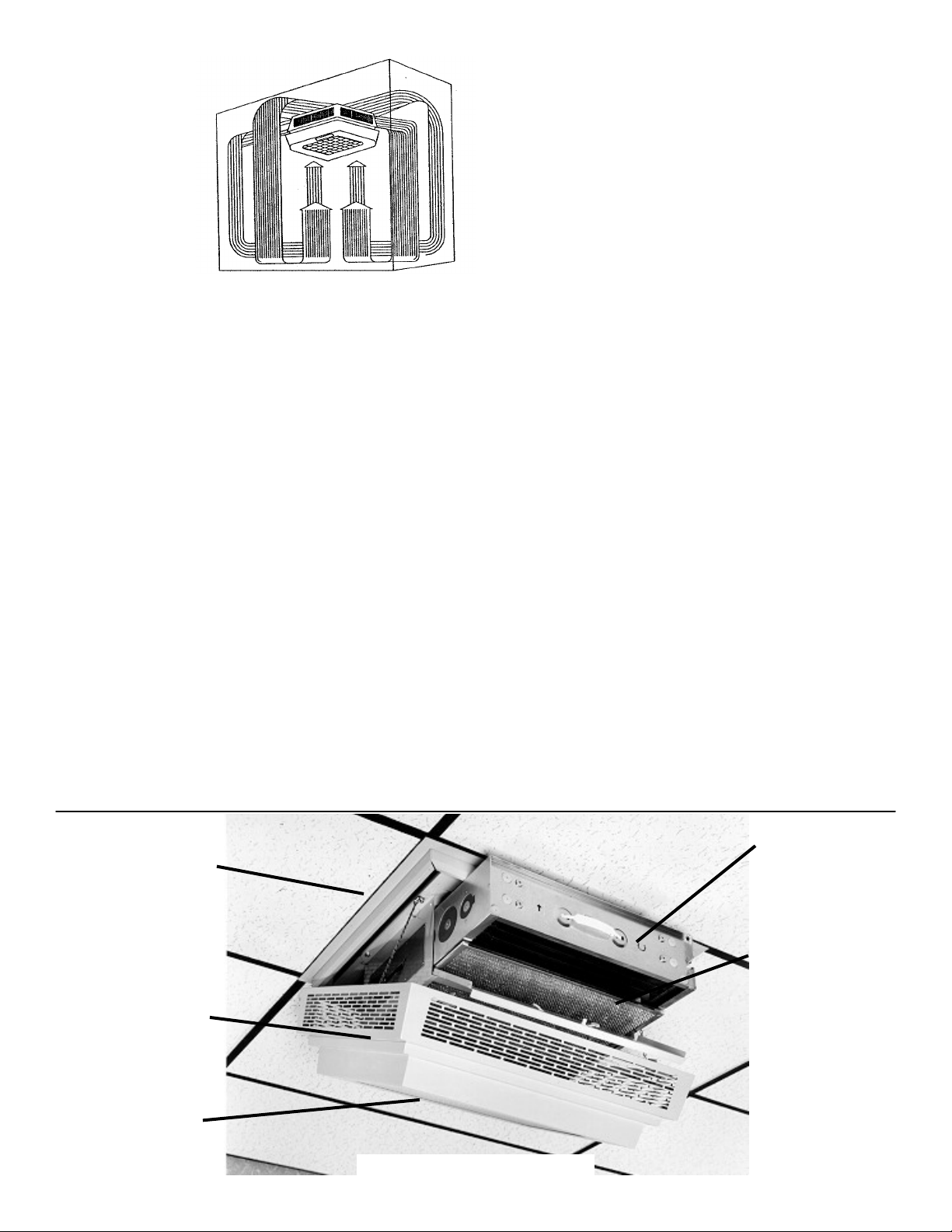

This Air Cleaner works on the principle of

"Electrostatic Precipitation". Millions of airborne pollutants

are drawn through the intake grill on the bottom of the Air

Cleaner and first pass through a Prefilter which removes

all large visible particles such as lint. Next, smaller

particles move to a two-stage electrostatic Collecting Cell

where they are given a powerful positive charge by the

ionizing wires. Charged particles then move into the

collecting area where they are attracted to a series of

grounded plates. Pollutants are held in this section like a

magnet until washed away during cleaning. Clean air is

then dispersed from the side grills in four directions

allowing superior air flow circulation.

1 Dirty Air

1 Dirty Air

2 Prefilter

2 Prefilter

3 Charging

3 Charging

Section

Section

4 Collecting Cell

4 Collecting Cell

Plates

Plates

5 Clean Air

5 Clean Air

WARNING

Before beginning any installation or modification, be

certain that the main line electrical disconnect switch is

in OFF position. Electric shock could result. Tag

disconnect switch with suitable warning labels.

2

2

Fig. 1 — Electrostatic Precipitation

Fig. 1 — Electrostatic Precipitation

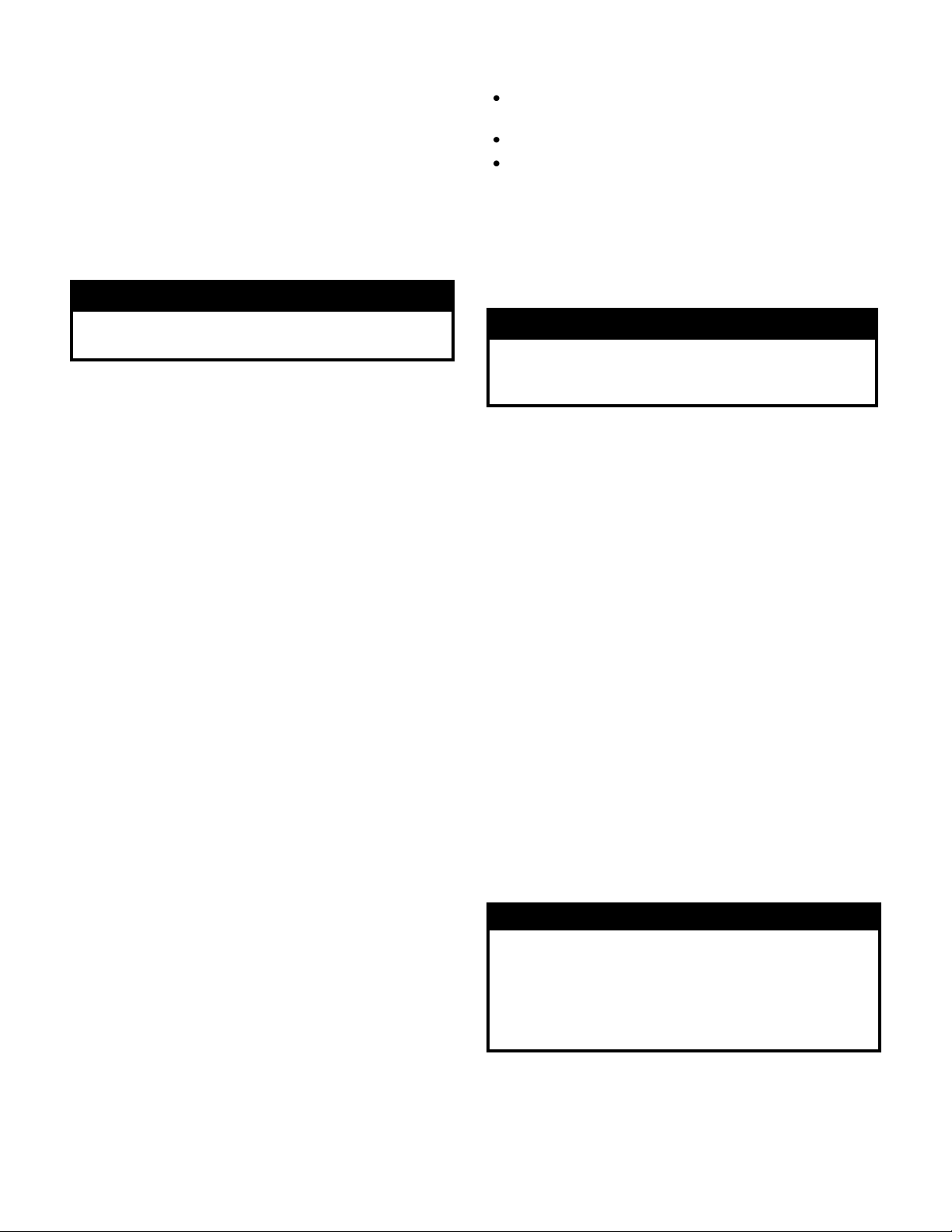

The Air Cleaner

creates a circular air

flow pattern which

never allows air to

rest at the ceiling.

Fig. 2 — Coanda Air Flow

MAJOR COMPONENTS

Description

The Electronic Air Cleaner is approximately 24 x 28 x

15 in (61 x 71 x 38 cm) with 6 in (15.2 cm) of the unit

above the ceiling. The cover and exhaust grill which

remain below the ceiling are hinged to allow access to the

cell and power board. The unit is rated at 700 CFM (1190

m3/hr) on the highest speed setting.

Cabinet

The cabinet is constructed of 20 gauge steel. The

external parts have a tough powder-coated, scratchresistant finish. Access to the collecting cell, power box

and prefilter is made by releasing the latches of the cover

and allowing it to swing down.

The cover is interlocked to cut power to the unit when

opened.

Prefilter

The washable prefilter measuring 12.5 x 20 in (31.75

x 50.8 cm) is constructed of multi-layers of aluminum

mesh for maximum filtration of large particles.

Collecting Cell

The dual voltage collecting cell is constructed of

heavy gauge aluminum to resist rust and damage. The

first stage, the ionizing section, is charged at

Blower and motor are

hidden above ceiling tiles

for space conservation.

Advantageous for low

ceiling applications where

a larger unit would be

obstructive.

Hinged cover provides

convenient access to grill,

prefilter, collecting cell and

electrical compartment.

Safety interlock cuts power

when cover is opened.

Rear hinges permit smooth

release of cover for easy

installation.

Removable intake grill for

easy cleaning.

approximately 7500 VDC. The collecting plates are

alternately grounded and charged at 5000 VDC. The

arrow on the cells indicates the direction of air flow which

must point up towards the fan motor.

Motor and Fan Blade

The motor is 1/33 HP, 1050 RPM, 3-speed, controlled

by a 3-position slide switch. The motor is thermally

protected. The fan blade is 14 in (35.5 cm) with a 20o

pitch.

Electrical Compartment

The removable power box contains the speed control,

system switch, high voltage power board, and

performance indicator light.

The interlock switch is located in the cabinet

body near the wiring compartment.

INSTALLATION

1. Read instructions carefully. Failure to do so may

result in product damage or injury.

2. Make sure the sizing is correct for your application.

3. Installation should be done by a knowledgeable

technician.

4. After installation, check out operation as provided in

these instructions.

Mounting

1. Remove the unit from the box and lay the unit on its

back, grill side up.

2. Release the grill by pushing the levers, located in the

exhaust grill, toward each other and lift up.

4. Remove the ‘S’ hook from each chain, tilt cover up

until the cover releases from the back hinges.

5. Remove the cell and prefilter from the unit.

6. Holes are provided in the cabinet to accommodate

5/16 in (8 mm) threaded rod. Threaded rod can be

attached to the angle iron which is laid across the

joists, by drilling holes through these supports. Pass

threaded rod up through the supports and secure with

two nuts and washers. This will allow adjustment of

Heavy duty collecting

cell captures airborne

pollutants and simply

washes clean.

Washable, aluminum

mesh prefilter catches

lint and large particles

before they enter

collecting cell.

3-speed fan control

(not shown) allows

adjustment of air flow

to activity level in room.

Fig. 3— Components

3

the unit so that the flange is flush with the underside

of the ceiling.

Leave enough room around the Air Cleaner for

removal of collecting cell and prefilter.

7. Replace the cell, prefilter and cover. Hook up the

safety chain to the cover.

Do not hang the unit with chain only. This will not

give the unit the necessary stability when removing

the cells or servicing the unit.

Wiring

WARNING

The frequency of cleaning will vary from one environment

to another. The following is an average wash cycle:

Stores, Offices, Computer & Conference Rooms = 4

Weeks

Cafeterias, Restaurants, Lounges = 3-4 Weeks

Bars, Bingo halls = 1-3 Weeks

The unit should be checked on a regular basis to

determine the frequency of cleaning required in each

location and a cleaning schedule established.

Cleaning

Electrical shock can cause injury or death. Be certain

main line disconnect switch is off before wiring.

All wiring must comply with applicable codes and

standards. See unit rating label for correct voltage and

amperage.

1. Two knockouts are provided, one on top and one on

the side of the unit, adjacent to the wiring

compartment. For convenience, a wall switch may be

installed near the Air Cleaner, in series with the

power source, to turn the unit on and off.

2. Remove the cover of the wiring compartment to

locate the input leads and ground stud. The Air

Cleaner must be grounded for proper operation and

safety.

3. Once the unit is mounted and wired, the cover can be

replaced on the hinge and the chain replaced on the

"S" hooks. Close the cover by sliding the levers

toward the center and pushing the cover up into

place. Release levers to lock the cover into place.

For information on wiring the remote switch

control see page 7.

OPERATION & MAINTENANCE

Operation Check

1. With the cell and prefilter in place and the cover

closed, turn the system switch ON.

2. Adjust the fan speed with the slide switch. Insure the

unit functions on all speeds.

3. The performance light should be ON, which indicates

the power board is functioning properly.

4. If the unit is not functioning properly see the

"Troubleshooting Guide"

When the Air Cleaner is new it may arc or periodically

make "snapping sounds". A slight odor of ozone may be

noticeable. The arcing and odor are due to rough edges

and burrs on the cell. These symptoms will disappear

during the first few weeks of normal operation. The ozone

levels are well below government standards for indoor air

concentration.

Maintenance Schedule

The collecting cell and prefilter must be cleaned on a

regular basis for the unit to function at its peak efficiency.

CAUTION

Make sure Air Cleaner switch is OFF before

performing any maintenance or removing any

components.

1. Turn off the system switch and wait 15 seconds for

high voltage to dissipate.

2. Open the cover and cell access door and remove

collecting cell and prefilter. Cell plates are sharp.

Handle with care.

3. Place cell in tub and spray completely with DAX

Detergent, allowing detergent to run down both sides

of plates and ionizing wires. Let sit for 5 minutes.

Rinse cell well with hot water (140ºF / 60ºC

maximum). Repeat washing process if necessary.

4. If dirt or nicotine remains on plates, let cell soak in hot

soapy water for 30 minutes. Never use any

instrument to clean the cell, as this may damage

the ionizing wires or bend cell plates.

5. Spray prefilter with DAX Detergent and rinse well.

6. To dry cell, tilt on 45º angle against wall with the

arrow pointing sideways. Allow to dry completely for

10-24 hours. Place in sunlight for faster drying time.

7. When the cell and prefilter are dry, place them back

into the unit. The arrow on the cell points up. The red

fiberboard on the cell should line up with the contacts

in the cabinet. Close door and cover. If the cell arcs

when the switch is turned on or if the performance

light does not come on, then the cell may be still wet.

Allow more time for drying.

CAUTION

Damage to cell may occur if improperly handled or

washed. Do not wash cell in a dishwasher. Never

use any object to clean between the cell plates, as this

may cause damage to plates or ionizing wires. Never

place cell in oven to dry. The edges of the cell may be

sharp - handle with care.

The use of DAX Detergent is strongly recommended

for cleaning as it is a heavy-duty solution used expressly

for removal of accumulated pollutants on cell plates. If

used as directed, DAX will not harm aluminum or steel.

Any problem arising out of the use of another cleaning

agent will void the warranty. Do not use detergents that

4

Loading...

Loading...