Page 1

INSTRUCTION

MANUAL

GENERAL

RADIO

Page 2

Contents

SPEC1 FlCATlONS

TABLE OF CONTENTS

-

INTRODUCTION

SECTION

INSTALLATION - SECTION

OPERATING PROCEDURE -SECTION

APPLICATIONS - SECTION

PRINCIPLES OF OPERATION - SECTION

SERVICE AND MAINTENANCE - SECTION

WARRANTY

We warrant that each new instrument manufactured and sold by us is free from

defects in material and workmanship and that, properly used, it

accordance with applicable specifications for a period of two years after original

shipment. Any instrument or component that is found within the two-year period

not to meet these standards after examination by our factory, District Office, or

authorized repair agency personnel will be repaired or, at our option, replaced

without charge, except for tubesor batteries that have given normal service.

1

2

3

4

5

6

will perform in full

@GENERAL RADIO COMPANY

Concord, Massachusetts,

Form

1362-01 00-8

January, 1971

I

D-B552

U.S.A.

01742

1967

Page 3

SPECIFICATIONS

Frequency Range:

Tuned Circuit:

Frequency Accuracy:

Warmup Frequency Drift:

Frequency Control:

300°, with a slow-motion drive of about 9 turns.

over

Output Power (into

Type 1267 or 1264 Power Supply, 200

220 to 920 MHz.

Butterfly, with no sliding contacts.

k

1%.

0.2% typical total.

A

four-inch dial with calibration

50

ohms):

At least 160 mW with

mW with Type

1269 Power Supply.

Output System:

A coupling loop feeds a waveguidebelow-cut-off attenuator calibrated over an 80-dB range

with 5-dB scale divisions, relative attenuation. Additional uncalibrated range

is

provided. Output adjust-

ment and locking GR 874 output connector are at the

front of the instrument.

Modulation:

An external audio-frequency plate modulator may be connected to the front panel MOD jack.

The modulation impedance

is

approximately 3 kn.

sinewave of 20 V rms, amplitude will produce ap-

A

proximately

1000

Hz

1311 Audio Oscillator

30%

amplitude modulation. For 400

Hz.

and other audio frequency modulation the Type

is

recommended. The Type 1263

Amplitude-Regulating Power Supply can be used for

1-kHz square-wave modulation, the Type 1264 Modulating Power Supply for square-wave

,or pulse modula-

tion.

Power Supply:

Four types of power supplies are rec-

ommended; the choice depends on the intended ap-

plication. Refer to Table of Accessories, paragraph

1.5.

Tube:

One Y-1266.

Mounting:

Accessories Available:

Dimensions:

(205 by

Net Weight:

Rack-bench cabinet.

Refer to paragraph 1.5.

Width

8,

height 7-5/8, depth 9 1/2 inches

195 by 240 mm). See outline below.

8 pounds (3,6 kg).

GR 874 Patent No. 2,548,457.

Figure

1-1.

Panel view of Type

1362

UHF

Oscillator with accessories

.

Page 4

TABLE

OF

CONTENTS

Section 1 INTRODUCTION

1.1

Purpose

1.2 Description

1.3 Amplitude Modulation

1.4 Sweep Operation

1.5 Auxiliary Equipment.

Section 2 INSTALLATION

2.1 Connection to Power Supply

2.2 Bench Mounting

2.3 Rack Mounting

2.4 Modulator Connection

2.5 RF Output Connections

Section 3 OPERATING PROCEDURE

3.1 Equipment Turn-On

3.2 Frequency Adjustment

3.3 Output Adjustment

Section 4 APPLICATIONS

4.1 General

SECTION

1

.

. . .

.

. .

. .

.

. . .

. . . .

.

.

.

. .

. . .

.

.

. . .

. .

. .

. . . .

.

.

. . . .

. . .

. . . . . .

.

. . .

. . . . . . . .

.

.

. .

.

. . . . . .

. . . . . . . .

.

.

. . . . . . . . . . . . . .

. . . . . .

. .

. .

. . . .

. . .

. . . . . . . . . .

. . . .

. . . . . .

. . . . . . . . . . .

. . . . . . . .

. . . .

. . . . . .

. . . . . .

. . . .

. . . . . . .

.

.

.

. . . . .

. . . . . . .

. .

. .

. . . .

.

.

.

.

.

.

.

.

. .

. . . . .

. . .

. . . . . .

. . . . . . . . .

. . .

. .

. .

.

.

.

.

. . . . . . . . . . . .

.

.

. . . . .

. .

4.2 Signal Generator for Receiver Testing.

4.3

1

1

3

3

3

5

5

7

8

8

9

9

9

10

Local Oscillator in a Frequency Converter.

4.4

Transfer Oscillator

4.5 Swept Oscillator

4.6

Observation of Modulation

Section 5 PRINCIPLES OF OPERATION

5.1 General

Circuitry

5.2

Section 6 SERVICE AND MAINTENANCE

6.1

Warranty

6.2

Service

6.3 Minimum Performance Standards

6.4

Trouble Analysis

Removal of Covers.

6.5

6.6 Installation of Oscillator Tube

6.7 Frequency Calibration

6.8

Lubrication.

6.9 Adjustment for Maximum Tube Life

.

. . . .

. . . . .

. . . .

. . . . . . .

. . . . . .

.

. . .

. .

. . . . .

. . . .

. . . . . . . .

. .

.

. . . .

.

. . . .

. . . . . .

. .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

.

. .

.

.

.

. .

.

. .

. .

. .

. .

. .

. .

. .

. . . . . . . . .

. . . . . .

. . . .

. . . . . .

. . .

. .

.

. . .

. . . . .

. .

. .

.

. . .

. .

. . . . . .

.

.

. . . . . . . . .

. . . . . . .

.

.

.

. .

.

.

. .

.

.

.

.

. . . .

.

. . .

.

. .

.

. .

.

. . .

. .

. .

. . . . .

. .

. .

.

. . .

.

. . .

. . .

.

. . .

. . . . . .

.

. . .

10

10

11

11

11

12

12

13

13

13

15

16

18

19

19

19

INTRODUCTION

1.1

PURPOSE.

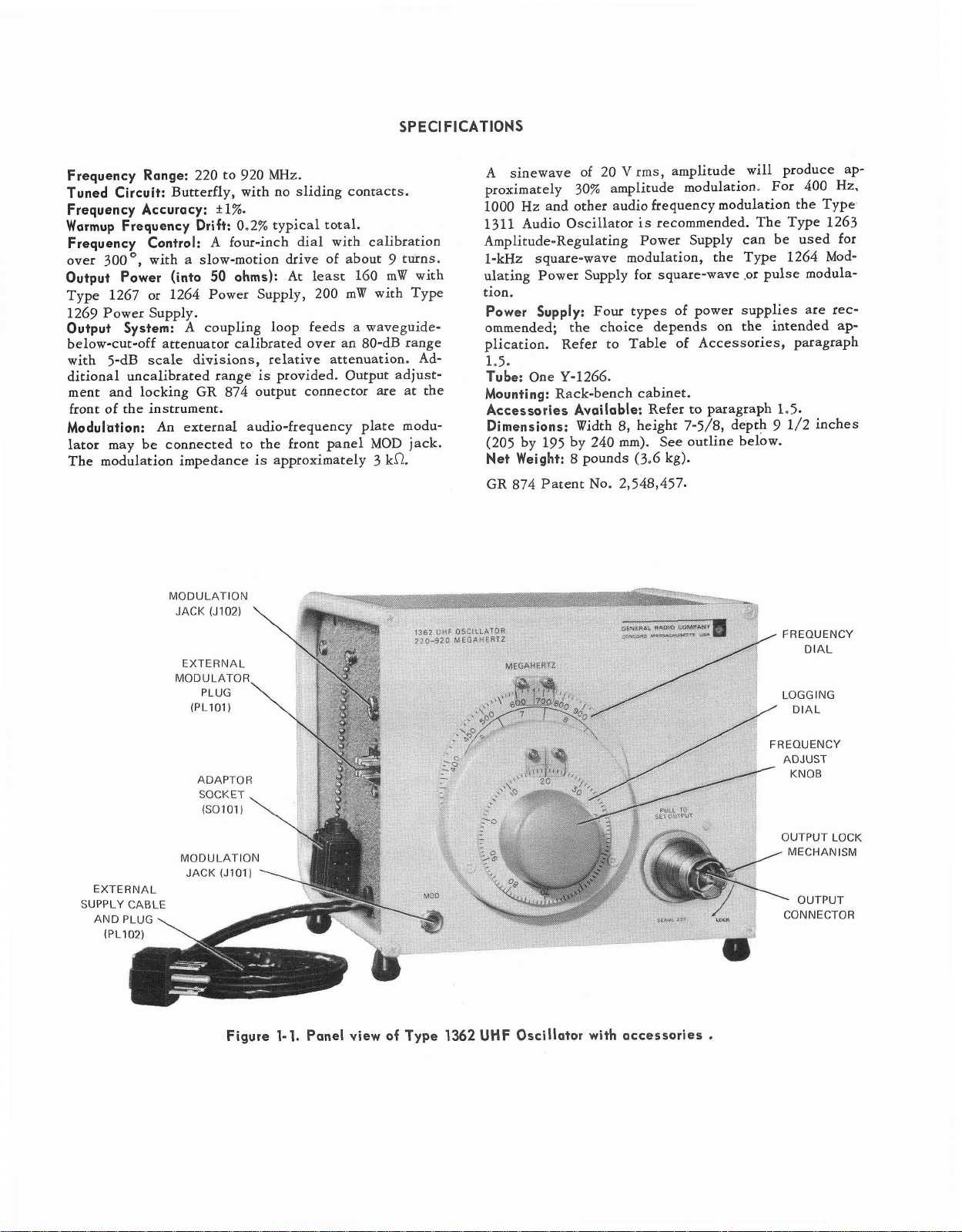

The 1362 UHF Oscillator (Figure 1-1)

eral-purpose oscillator for the radio-frequency laboratory. Covering the calibrated range from 220 to

920

MHz,

this oscillator provides adequate power to

drive bridges, slotted lines, impedance comparators,

and other measuring equipment. The output is brought

through an attenuator, calibrated in relative power

levels, making the oscillator suitable for the testing

of receivers. Direct sine-wave, square-wave, or pulse

is

amplitude modulation

tion free from incidental fm can be obtained with an

external diode modulator. Connected to a mixer, the

oscillator can be used as

erodyne receiver to convert the GR 1236 I-F Amplifier,

or a low-frequency communications receiver, into a

detector for

plitude modulation can be obtained with the GR Type

1264 Modulating Power Supply (Figure 1-2), or leveled

uhf signals. Square-wave and pulse am-

possible. Amplitude modula-

thelocal oscillator in a het-

is

a gen-

output can be obtained with the GR

tude-Regulating Power Supply.

1.2

DESCRIPTION.

1.2.1 GENERAL.

The 1362 Oscillator uses a planar triode and

tuned by a butterfly resonator, to provide wide tuning

range without switching or sliding contacts. For details

refer to paragraph 5.2.

The butterfly rotor

backlash gears by the main dial, turning

vernier drive, whose

100 arbitrary (logging) divisions. Frequency calibra-

is

tion

with the logging scale

special-purpose power supplies, and the measurement

of plate current.

accurate to +I%. Resolution of 0.1% or better

Jacks are provided for modulation, connection of

is

9

turns are each resolved into

is

described in paragraph 3.2.

ppe 1263 Ampli-

is

driven 85' through anti-

330°, and the

INTRODUCTION

1

Page 5

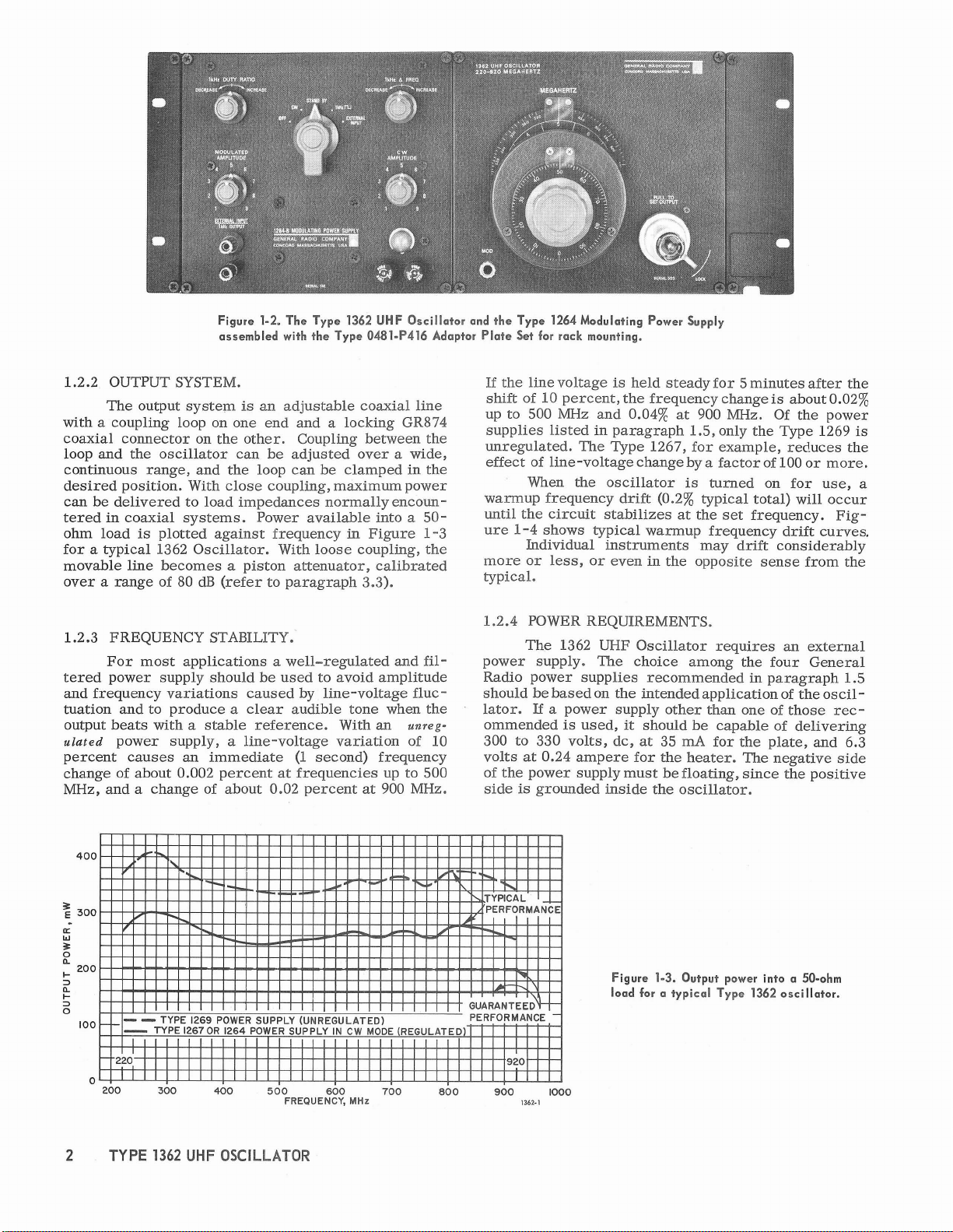

Figure 1-2. The Type 1362

assembled with the Type 0481-P416 Adaptor Plate Set for rack mounting.

UHF

Oscillator and the Type 1264 Modulating Power Supply

1.2.2 OUTPUT SYSTEM.

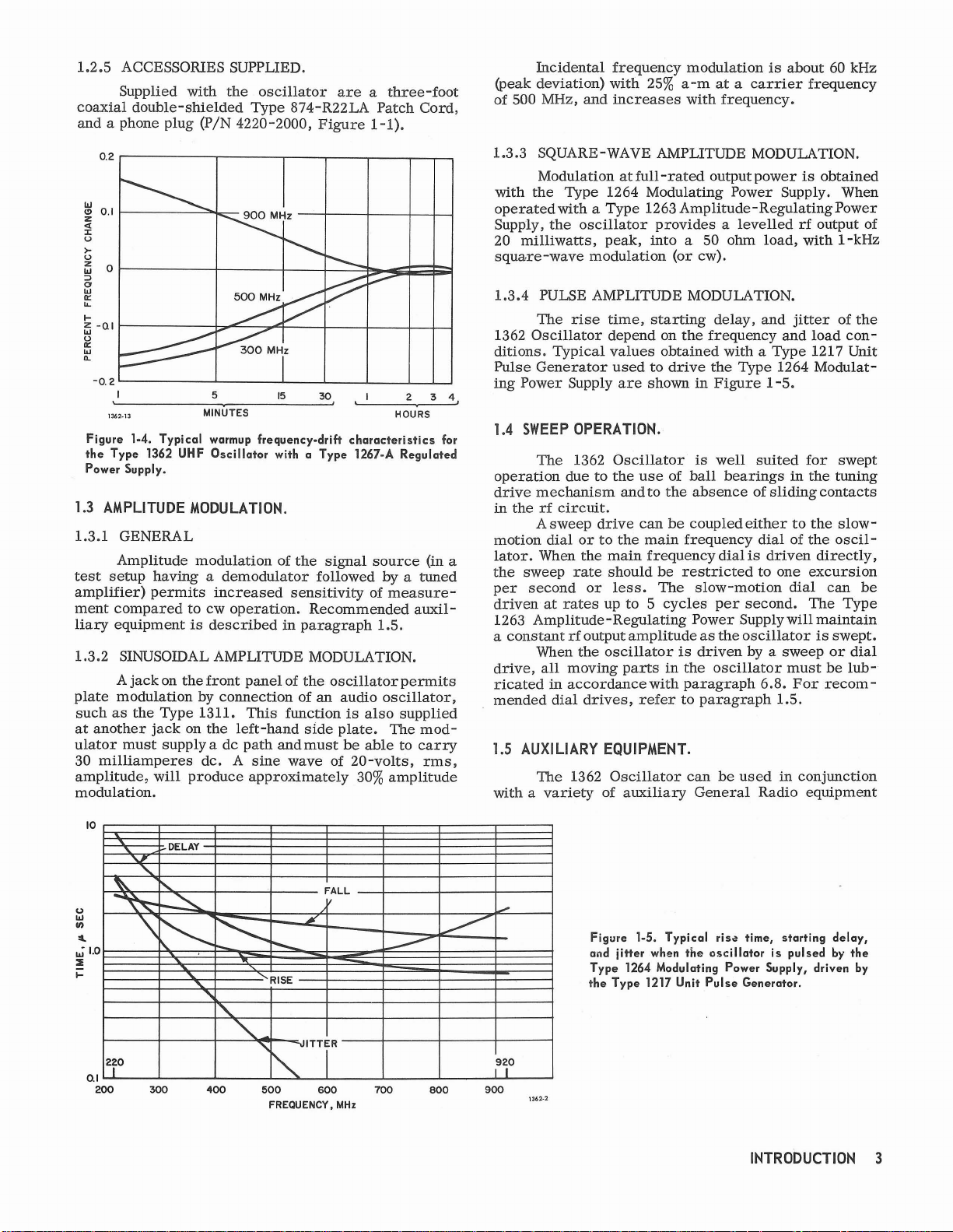

The output system

with a coupling loop on one end and a locking

is

an adjustable coaxial line

GR874

coaxial connector on the other. Coupling between the

loop and the oscillator can be adjusted over a wide,

continuous range, and the loop can be clamped in the

desired position. With close coupling, maximum power

can be delivered to load impedances normally encoun-

tered in coaxial systems. Power available into a

ohm load

is

plotted against frequency in Figure 1-3

50-

for a typical 1362 Oscillator. With loose coupling, the

movable line becomes a piston attenuator, calibrated

over a range of 80

dB

(refer to paragraph 3.3).

1.2.3 FREQUENCY STABILITY.

For most applications a well-regulated and fil-

tered power supply should be used to avoid amplitude

and frequency variations caused by line-voltage fluctuation and to produce a clear audible tone when the

output beats with a stable reference. With an

ulated

power supply, a line-voltage variation of 10

unreg-

percent causes an immediate (1 second) frequency

change of about 0.002 percent at frequencies up to 500

MHz, and a change of about 0.02 percent at 900 MHz.

If the line voltage is held steady for 5 minutes after the

is

shift of 10 percent, the frequency change

about 0.02%

up to 500 MHz and 0.04% at 900 MHz. Of the power

supplies listed in paragraph 1.5, only the

Type 1269 is

unregulated. The Type 1267, for example, reduces the

effect of line-voltage change by a factor of 100 or more.

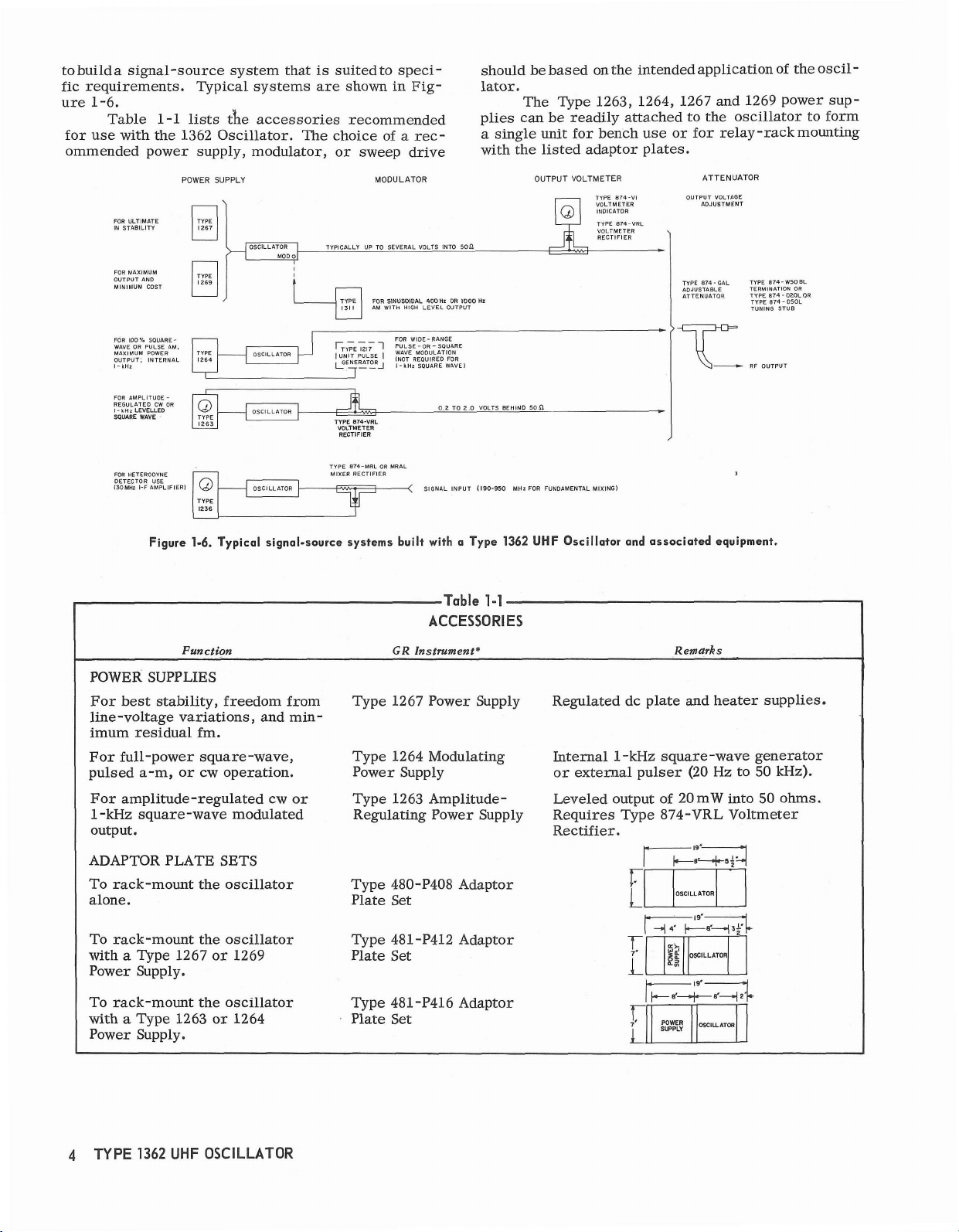

When the oscillator is turned on for use, a

warmup frequency drift (0.2% typical total) will occur

until the circuit stabilizes at the set frequency. Figure 1-4 shows typical

warmup frequency drift curves.

Individual instruments may drift considerably

more or less, or even in the opposite sense from the

typical.

1.2.4 POWER REQUIREMENTS.

The 1362 UHF Oscillator requires an external

power supply. The choice among the four General

Radio power supplies recommended

in

paragraph 1.5

should be based on the intended application of the oscillator.

ommended

300 to 330 volts, dc, at 35

If

a power supply other than one of those rec-

is

used, it should be capable of delivering

mA for the plate, and 6.3

volts at 0.24 ampere for the heater. The negative side

of the power supply must be floating, since the positive

side is grounded inside the oscillator.

400

',

300

(C

W

a

,

200

=I

a

I-

3

0

100

0

200 300 400 500 600 700 800

2

TYPE

1362

UHF

OSCILLATOR

FREQUENCY,

MHz

900 1000

1362.1

Figure 1-3. Output power into a 50-ohm

load for a typical Type 1362 oscillator.

Page 6

1.2.5 ACCESSORIES SUPPLIED. Incidental frequency modulation

Supplied with the oscillator are a three-foot

coaxial double-shielded Tvpe 874 -R22LA Patch Cord,

and a phone plug

(P/N 4220-2000, Figure 1-1).

(peak deviation) with

of 500

MHz,

and

25%- a-m at a carrier frequency

increases

with

frequency.

is

about 60 kHz

0.2

1

I

1362.13

Figure 1-4. Typical warmup frequency-drift characteristics far

the Type 1362 UHF Oscillator with a Type 1267-A Regulated

Power Supply.

1.3

AMPLITUDE MODULATION.

I

5

MINUTES

I

I

I

15

30

1

2

HOURS

3

1.3.1 GENERAL

Amplitude modulation of the signal source (in a

test setup having a demodulator followed by a tuned

amplifier) permits increased sensitivity of measurement compared to cw operation. Recommended

liary equipment is described in paragraph

auxil-

1.5.

1.3.2 SINUSOIDAL AMPLITUDE MODULATION.

A jack on the front panel of the oscillator permits

plate modulation by connection of an audio oscillator,

such as the Type 1311. This function is also supplied

at another jack on the left-hand side plate. The modulator must supply a dc path

andmust be able to carry

30 milliamperes dc. A sine wave of 20-volts, rms,

amplitude, will produce approximately

30% amplitude

modulation.

1.3.3 SQUARE -WAVE AMPLITUDE MODULATION.

Modulation at full-rated output power is obtained

with the

Type 1264 Modulating Power Supply. When

operatedwith a Type 1263 Amplitude-Regulating Power

Supply, the oscillator provides a levelled rf output of

20 milliwatts, peak, into a 50 ohm load, with 1-kHz

square-wave modulation (or cw).

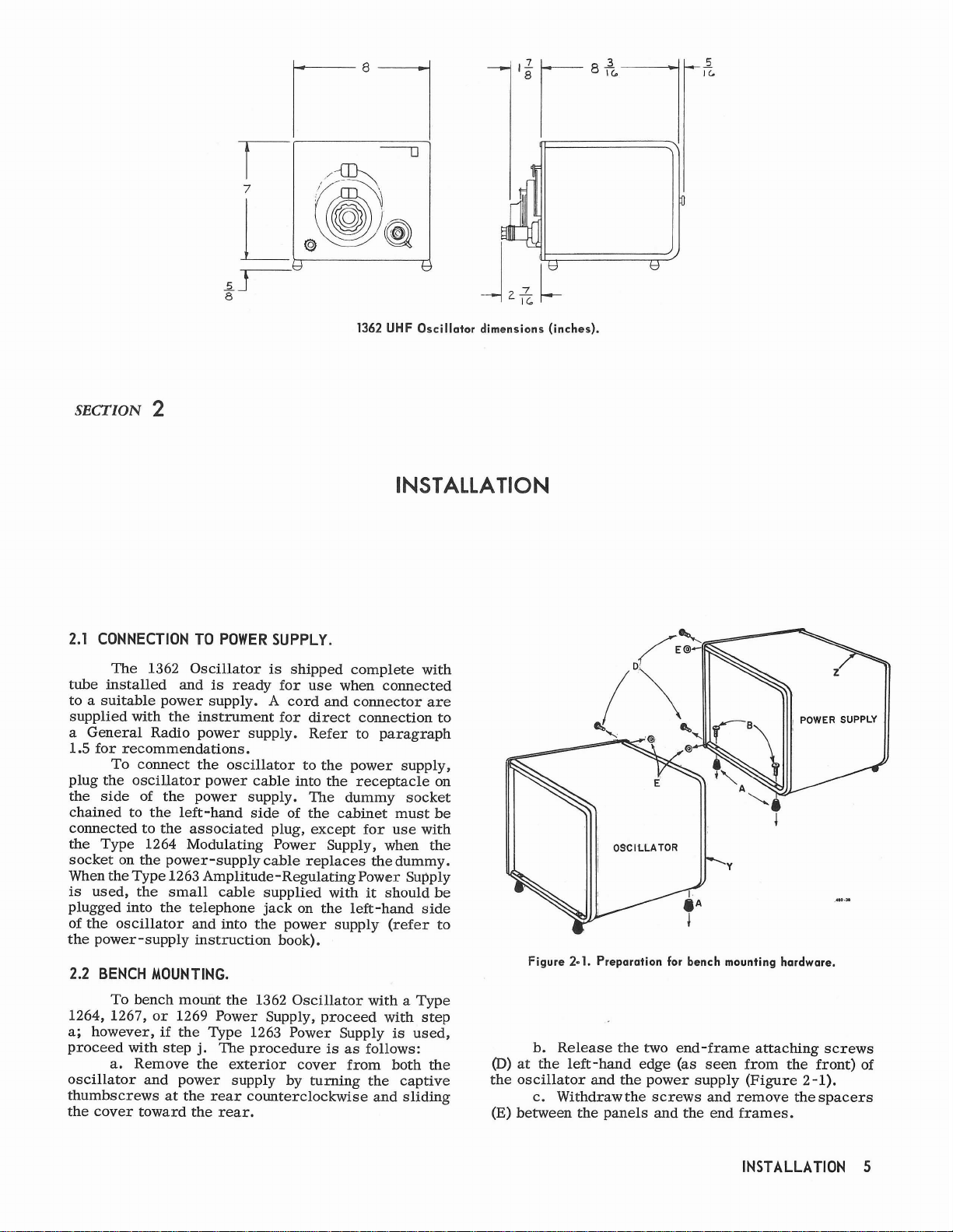

1.3.4 PULSE AMPLITUDE MODULATION.

The rise time, starting delay, and jitter of the

1362 Oscillator depend on the frequency and load con-

ditions. Typical values obtained with a Type 1217 Unit

Pulse Generator used to drive the Type 1264 Modulating Power Supply are shown in Figure 1-5.

4,

1.4

SWEEP OPERATION.

The 1362 Oscillator is well suited for swept

operation due to the use of ball bearings in the tuning

drive mechanism and to the absence of sliding contacts

in the rf circuit.

Asweep drive can be coupledeither to the slowmotion dial or to the main frequency dial of the oscillator. When the main frequency dial is driven directly,

the sweep rate should be restricted to one excursion

per second or less. The slow-motion dial can be

driven at rates up to 5 cycles per second. The

1263 Amplitude-Regulating Power Supply will maintain

a constant rf output amplitude as the oscillator

When the oscillator is driven by a sweep or dial

drive, all moving parts in the oscillator must be lubricated in accordancewith paragraph 6.8. For recommended dial drives, refer to paragraph 1.5.

1.5

AUXILIARY EQUIPMENT.

The 1362 Oscillator can be used in conjunction

with a variety of auxiliary General Radio equipment

is

Type

swept.

I

200

300

400

500

FREQUENCY. MHz

600

700

800

900

1362.2

Figure 1-5. Typical rise time, starting delay,

and iitter when the oscillator is pulsed

Type 1264 Modulating Power Supply, driven by

the

Type 1217 Unit Pulse Generator.

by

the

INTRODUCTION

3

Page 7

tobuilda signal-source system that is suitedto speci-

should be based

fic requirements. Typical systems are shown in Fig- lator.

ure 1-6.

1-1

Table

for use with the 1362 Oscillator. The

lists the accessories recommended

choice of a rec-

ommended power supply, modulator, or sweep drive

MODULATOR OUTPUT VOLTMETER

FOR ULTIMATE

IN

STABILITY

POWER SUPPLY

\

plies can be readily attached to the oscillator to form

a single unit for bench use or for relay-rackmounting

with the listed adaptor plates.

onthe intendedapplicationof the oscil-

The Type 1263, 1264, 1267 and 1269 power sup-

ATTENUATOR

OUTPUT VOLTAGE

ADJUSTMENT

TYPE 874-VRL

-

Figure

-

SINUSOIDAL 400HZ OR lDDD

FOR

131 1

1M

WITH

HlGH LEVEL OUTPUT

TVPE 874-VRL

VOLTMETER

RECTIFIER

TYPE 874-MRL OR MRAL

I

L"T

TVPE

1236

1-6.

w

Typical signal-source systems built with a Type

8

0 2 TO 2.0 VOLT5 BEHIND 508

<

SIGNAL INPUT (190-950

IUDI~

HI

1362

1-1

FOR

MAXIMUM

OUTPUT

AND

MlNlMUM COST

FOR

iOOX SOUARE-

MIIYlMUM POWER OSCILLATOR

OUTPUT, INTERNAL

I-I".

IMPLITUDE

FOR

REGULATED CW OR

FOR

HETEROOINE MIXER RECTIFIER

DETECTOR USE

rlOlW 1-6 AYPLlFEil OSCILLATOR

ACCESSORIES

Function GR Instrument* Remarks

POWER SUPPLIES

For best stability, freedom from Type 1267 Power Supply

line-voltage variations, and minimum residual fm.

For full-power square -wave, Type 1264 Modulating

pulsed a-m, or cw operation. Power Supply

814- GAL

TYPE

AOJUSTIISLE TERMlNDiTlON

ATTENUITOR TYPE 874 -020LOR

-

I

MHz

FOR FUNDAMENTAL MIXING1

UHF

Oscillator and associated equipment.

Regulated dc plate and heater supplies.

Internal

or external pulser

1

-kHz

square-wave generator

(20

Hz to

TYPE

874-

WSO BL

TYPE

874-

TUNING STUB

RF OUTPUT

50

kHz).

OR

D50L

For amplitude-regulated cw or

1

-kHz square-wave modulated

Type 1263 Amplitude-

Regulating Power Supply Requires Type 874-VRL Voltmeter

Leveled output of 20

output. Rectifier.

ADAPTOR PLATE SETS

To rack-mount the oscillator Type 480-P408 Adaptor

alone. Plate Set

To rack-mount the oscillator

Type 481

-P412 Adaptor

with a Type 1267 or 1269 Plate Set

Power supply.

To rack-mount the oscillator

with a Type 1263 or 1264

481

Type

Plate Set

-P416 Adaptor

Power Supply.

4

TYPE

1362

UHF

OSCILLATOR

mW into 50 ohms.

r-&L3

OSCILLATOR

fUII

I-ELqI

mi

L

tkzLIF*T

Page 8

2.1

CONNECTION TO POWER SUPPLY.

1362

UHF

Oscillator dimensions (inches).

INSTALLATION

The 1362 Oscillator

tube installed and

is

to a suitable power supply.

is

shipped complete with

ready for use when connected

A

cord and connector are

supplied with the instrument for direct connection to

a General Radio power supply. Refer to paragraph

1.5 for recommendations.

To connect the oscillator to the power supply,

plug the oscillator power cable into the receptacle on

the side of the power supply. The dummy socket

chained to the left-hand side of the cabinet must be

connected to the associated plug, except for use with

the Type 1264 Modulating Power Supply, when the

socket on the power-supply cable replaces the dummy.

When the Type 1263 Amplitude-Regulating

is

used, the small cable supplied with it should be

Power Supply

plugged into the telephone jack on the left-hand side

of the oscillator and into the power supply (refer to

the power-supply instruction book).

2.2

BENCH MOUNTING.

To bench mount the 1362 Oscillator with a Type

1264, 1267, or 1269 Power Supply, proceed with step

a; however, if the

proceed with step

Type 1263 Power Supply is used,

j.

The procedure

is

as follows:

a. Remove the exterior cover from both the

oscillator and power supply by turning the captive

thumbscrews at the rear counterclockwise and sliding

the cover toward the rear.

POWER SUPPLY

OSCILLATOR

Figure

2-1.

Preparation for bench mounting hardware.

b. Release the two end-frame attaching screws

@)

at the left-hand edge (as seen from the front) of

the oscillator and the power supply (Figure 2-1).

c. Withdraw the screws and remove the spacers

(E)

between the panels and the end frames.

INSTALLATION

5

Page 9

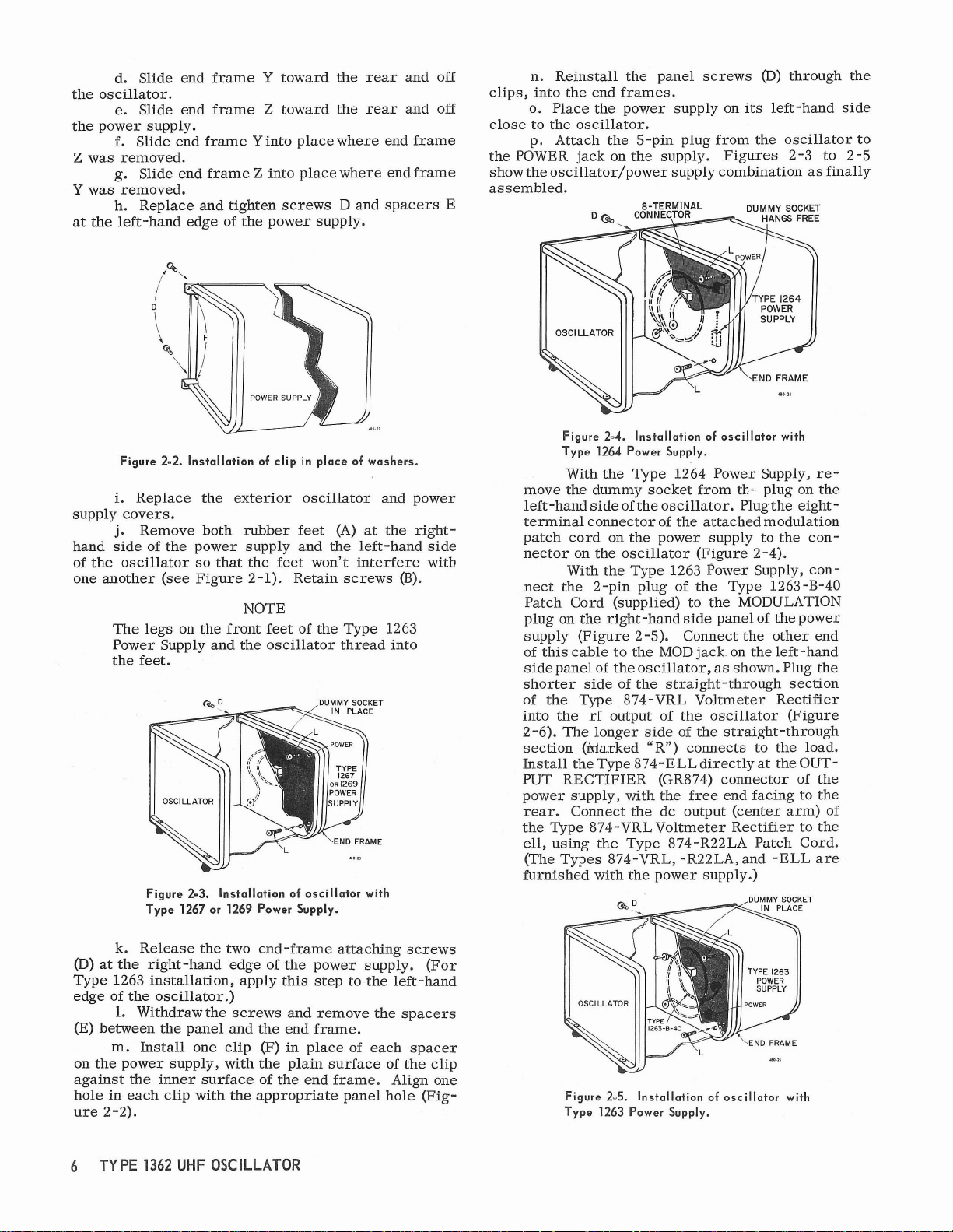

d. Slide end frame Y toward the rear and off

the oscillator.

Z

e. Slide end frame

toward the rear and off

the power supply.

f. Slide end frame

Z

was removed.

g. Slide end frame

Y

was removed.

Y

into place where end frame

Z

into place where endframe

h. Replace and tighten screws D and spacers E

at the left-hand edge of the power supply.

POWER

SUPPLY

Figure 2-2. lnstallation of clip in place of washers.

i.

Replace the exterior oscillator and power

supply covers.

j.

Remove both rubber feet (A) at the right-

hand side of the power supply and the left-hand side

of the oscillator so that the feet won't interfere witb

one another (see Figure 2-1). Retain screws

(B).

NOTE

The legs on the front feet of the Type 1263

Power Supply and the oscillator thread into

the feet.

Figure 2-3. lnstallation of oscillator with

Type 1267 or 1269 Power Supply.

(D)

n. Reinstall the panel screws

through the

clips, into the end frames.

o. Place the power supply on its left-hand side

close to the oscillator.

p.

Attach the 5-pin plug from the oscillator to

the POWER jack on the supply. Figures 2-3 to 2-5

show the

oscillator/power supply combination as finally

assembled.

Figure 2-4. lnstallation of oscillator with

Type 1264 Power Supply.

With the Type 1264 Power Supply, remove the dummy socket from

left-hand side of the oscillator.

tk. plug on the

Plugthe eightterminal connector of the attached modulation

patch cord on the power supply to the connector on the oscillator (Figure 2-4).

With the Type 1263 Power Supply, connect the 2-pin plug of the Type 1263-B-40

Patch Cord (supplied) to the MODULATION

plug on the right -hand side panel of the power

supply (Figure 2-5). Connect the other end

of this cable to the MOD jack on the left-hand

side panel of the oscillator, as shown. Plug the

shorter side of the strajght-through section

of the Type 874-VRL Voltmeter Rectifier

into the

rf

output of the oscillator (Figure

2-6). The longer side of the straight-through

section

(Ma.rked "R") connects to the load.

Install the Type 874-ELLdirectly at the OUTPUT RECTIFIER

(GR874) connector of the

power supply, with the free end facing to the

rear. Connect the dc output (center arm) of

the Type 874-VRLVoltmeter Rectifier to the

ell, using the Type

(The Types 874-VRL,

874-R22LA Patch Cord.

-R22LA, and -ELL are

furnished with the power supply.)

k. Release the two end-frame attaching screws

@)

at the right-hand edge of the power supply. (For

Type 1263 installation, apply this step to the left-hand

edge of the oscillator.)

1. Withdrawthe screws and remove the spacers

(E) between the panel and the end frame.

m. Install one clip (F) in place of each spacer

on the power supply, with the plain surface of the clip

against the inner surface of the end frame. Align one

hole in each clip with the appropriate panel hole (Figure 2-2).

6

TYPE

1362

UHF

OSCILLATOR

Figure 2-5. lnstallation of oscillator with

Type 1263 Power Supply.

Page 10

OSCILLATOR

Figure 2-6. Completion of the control loop

with Type 1263 Power Supply.

d. Install clips (F) on panels

(G),

screws

(Figure 2

lockwashers

-7).

(U)

&I),

and nuts (I) supplied

Figure

rack adaptor plates.

and

2-7.

Subassembly of

(V),

using

q.

Hold the oscillator immediately above the

supply, oriented as it will be in final assembly. Form

the patch cords into flat coils between the side walls

of the instruments.

r.

Lower the oscillator, so that the instruments

slide together, with the exposed ends of the clips (F)

in the supply entering the spacer slots behind the

oscillator front panel.

(D)

s. Reinstall the front-panel screws

in the

oscillator, through the clips, into the end frames.

t. Remove the cover of the oscillator from the

(L)

rear and pass the 10-32 screws

the rear clearance holes (top and

(supplied) through

battom) on the oscil-

lator left-side panel (Figures 2-3 through 2-5).

u. Thread the screws into the matching tapped

holes in the joining wall of the supply.

NOTE

If

the power supply in the combination doesn't

have tapped holes in the joining wall, a No.

10-32 nut and lockwasher will be necessary

for each screw.

v. Tighten all six screws and remountthe oscillator cover. Retain the surplus rubberfeet andattaching hardware, in case it may be desired to restore the

instruments to their original form in the future.

2.3

RACK MOUNTING.

To mount the assembly in a standard 19-inch

relay rack, attach the rack-adaptor set as follows:

e. If the coaxial patch cord is used to bring the

output of the 1362 Oscillator from the front of the

panel to the back, the mounting cup, locked to the con-

nector with a large hex nut, should be reversed to

obtain a neater assembly. The sequence of parts for

is

this method of assembly

f. Install the four 4-40 screws

washers

(Q)

from the front of panel (V) and thread

shown in Figure 2-8.

(P)

with lock-

them into the mounting cup of the patch-cord as-

sembly

assemble the cover plate

(0).

g. If the patch cord assembly

(R) and mount it over the

is

not to be used,

hole (insert, Figure 2-8). To do this, push the spring

into the mounting hole from the front.

Figure 2-8. Mounting of Type

panel connector to face the rear.

874

UNPAINTED

SIDE

OUNTING CUP

h. Remove the outside pairs of front-panel

@)

screws

and spacers (E) from both instruments.

i. Attach panels

(U)

and (V) as shown in Figure

2-9. Install the clips in place of the spacers (E) and

fasten them with the screws

(D).

NOTE

The coaxial patch cord assembly supplied

can be mounted on the appropriate adaptor

plate to bring the rf output from the front of

the oscillator to the back of the panel,

sired.

a. Release the two end-frame attaching screws

@)

at the left-hand edge of the oscillator.

b. Attach oscillator to power supply as described

in paragraph 2.2 starting at step j.

c. Remove the remaining rubber feet from both

instruments.

if

de-

Figure 2-9. Rack installation of oscillator with power supply.

INSTALLATION

7

Page 11

j. Use the 5/8-inch, No. 10-32 screws (W) and

nylon washers

(X)

(supplied) to attach the assembly

to the relay rack. Patch cords connecting front and

rear points (if any) can pass easily through the small

notch at the bottom of panel

2.4

MODULATOR CONNECTION.

An open circuited plug in either of the phone

iacks will stop the oscillator and cause full

power-supply voltage to appear at the terminals.

07).

WARNING

For sinusoidal amplitude modulation the audio

modulation voltage should be inserted at the

MOD

jack on the front panel or at the phone jack on the left

side. Full plate current (about 30

mA) must flow

through the modulating source. A modulation voltage

of about 20 volts is required for 30-percent modulation. The input impedance is about 3000 ohms. The

Type 1311 Audio Oscillator is an economic audio

frequency modulator for the

2.5

RF OUTPUT CONNECTIONS.

uhf oscillator.

With the Type 1264,1267, or 1269 Power Supply,

the oscillator

rf

output may be connected directly to

the equipment under test by means of the three-foot

coaxial cable supplied.

Attenuator pads may help to reduce standing

waves on the cable where the equipment under test

does not provide a good termination. Without padding,

cable resonance effects may be quite pronounced since

the output coupling loop of the oscillator

is

not a

matched source. A low-pass filter may be beneficial

in cases where oscillator harmonics must be kept to

very low values.

When the Type 1263 Amplitude -Regulating Power

Supply is used, care must be taken to avoid damaging

the diode

in

the voltmeter rectifier.

CAUTION

The following connections

made with the power OFF. Before the

is

power

Instruction Manual for proper operat-

ing procedure.

The oscillator

applied, refer to the Type

rf

output should be connected dir-

must

be

1263

ectly to the short end of the Type 874-VRL Voltmeter

Rectifier. The attenuator should be

pushedin and locked; it is not usedto control output level in this system.

The longer end of the rectifier (labelled

"R") contains

a 50-ohm series resistor, which is the effective gen-

rf

erator--source impedance. The levelled

output available at the corresponding connector may now be connected to the equipment under test.

If cables equipped with other connectors are to

be used, a suitable adaptor may be semipermanently

attached to the locking

GR874 output receptacle of the

oscillator. See the table at the rear of this book for a

listing of available adaptors.

8

TYPE

1362

UHF OSCILLATOR

Page 12

SECTION

3

OPERATING PROCEDURE

3.1

EQUIPMENT TURN-ON.

The power switch on any of the recommended

power supplies controls the application of heater power

to the oscillator.

1269 Power Supply, plate voltage is applied by appropriate setting of a standby or function switch.

put is obtainable from the oscillator about 30 seconds

after power is turned on, an interval required for the

heater to come up to temperature.

Do not attempt to operate the oscillator with

the 8-pin plug on the left-side panel disconnected. For good oscillator frequency stability, allow a one-half -hour

Refer to paragraph 1.2.3.

3.2

FREQUENCY ADJUSTMENT.

The calibration accuracy of the frequency dial

is

+1%, but the frequency can be reset by use of the

logging scales to a precision of 1.3 MHz at midscale.

This precision increases to 0.2

and falls off to

tion within the

scale marks, the precision of the setting can be

increased by a factor of at least two, to

midscale.

The inner scale on the main frequency-control

dial serves as the first digit in a three-digit logging

On

all supplies except the Type

Rf

out-

NOTE

warmup period.

MHz

at the low end

2.5

MHz at the high end. By interpola-

1/8-inch interval between the vernier-

+0.1% at

scale, the last two digits being indicated by the vernier

dial. The

one of the lines separating the nine numbered segments,

0

through 8. Combined, the dials furnish 900 dial

settings throughout the range of the oscillator, to per-

mit rapid and precisely repeatable frequency settings.

gears

matically disengages the drive if the vernier knob is

lifted. To restore proper mesh, rotate the main dial

to an intersegment mark, lift up gently on the

and reset the vernier 0 mark.

3.3

OUTPUT ADJUSTMENT.

barrel pushed all the way

the attenuator out. The output lock is activated by

clockwise rotation. The output attenuator is calibrated

at 5-dB intervals over an 80-dB range, and has an additional uncalibrated region near maximum output.

The output power or voltage level at any setting of the

attenuator is

such as "zero", provided that frequency and load impedance are not changed.

be negligible for adjustments of load or attenuator in

the calibrated region of the attenuator, but padding

(refer to paragraph

reduce standing waves in the rf output cable.

0 mark on the vernier corresponds to any

The mesh of the main- and vernier-dial drive

is

maintained by a spring return, which auto-

hob,

Maximum output

known if it is measured at one setting,

Load reaction on the oscillator frequency will

is

obtained with the attenuator

in.

To reduce output, pull

2.5)

may still be desirable to

OPERATING PROCEDURE

9

Page 13

SECTION

4

APPLICATIONS

4.1 GENERAL.

The versatility of the 1362

UHF

Oscillator

is

greatly increased by the large selection of Type 874

coaxial elements available from General Radio Com-

pany. These elements are part of a broad, integrated

line of equipment for measurements of voltage, power,

and standing-wave ratio at very-high and ultra-high

frequencies. Use of the coaxial elements can adapt

the oscillator to various applications in the

radiofrequency laboratory in place of more expensive equipment that

is

not always available.

Five applications are described in detail in the

following paragraphs.

study of the complete list of

included in the

General Radio catalog. Coaxial ele-

Others will be suggested by a

GR874 coaxial elements

ments with locking connectors are preferred over

non-locking ones because of better impedance matching, shielding, mechanical stability, and repeatability.

A condensed list of

GR874 elements appears in the

rear of this manual.

4.2 SIGNAL GENERATOR FOR RECEIVER TESTING.

The ,1362 UHF Oscillator, being a well shielded

power source, can be used as a signal generator to

test receivers if means are available to measure the

output. The Type 874-VRL Voltmeter Rectifier and

the Type 874-VI Voltmeter Indicator are suitable for

this purpose, and should be connected to the oscillator

as

shown in Figure 4-1.

The signal level is established at a convenient

setting of the attenuator, such as -10 dB, and the output

is

measured by a crystal diode in the voltmeter rectifier and indicated on the meter of the voltmeter

indicator. (Means are provided to standardize the

meter indication.) A 50-ohm resistor after the diode

determines the output impedance.

I

Osc~~~~~O~

Figure

with the 1362 Oscillator for use as a standard-signal

generator.

I

voLTEL8.7i%ER

4-1.

Setup of a voltmeter indicator and rectifier

Do not

may be damaged.

apply full output to the rectifier or it

TE'ST

OUTPUT

CAUTION

TYPE 874-VI

VOLTMETER INDICATOR

I

With the above-described arrangement, the maximum available output is several tenths of a volt. The

attenuator calibration covers 80 dB. Shielding of the

oscillator

andof other components is adequate for ac-

curate measurements over .this range.

4.3 LOCAL OSCILLATOR IN A FREQUENCY

CONVERTER.

Connected to a Type 874-MRAL Mixer Rectifier,

the oscillator can provide the local signal in a hetero-

dyne converter to adapt the 1236 I-F Amplifier for

use as a sensitive detector for

uhf signals (see Fig-

ure 4-2). Without additional tuning, the conversion

is

loss

Oscillator as the local oscillator.

about 6

Figure 4-2. Setup of a superheterodyne receiver using the 1362

dB

at an intermediate frequency of

SIGNAL

INPUT

30

13621.5

10

TYPE 1362

UHF

OSCILLATOR

Page 14

I

-,

-*

I

-t

TO

FREQUENCY

.

MEASURING

DEVICE

(OPTIONAL)

.

.

, ,

MHz.

The Type 1236

I-F

Amplifier has a built-in

precision attenuator, a panel meter, which normally

indicates signal level, and a separate built-in power

supply for operating the oscillator. The panel meter,

besides indicating signal level, can also be used to

measure the mixer current (and hence local-oscillator

level).

4.4

TRANSFER OSCILLATOR.

The 1362 Oscillator can be used as a transfer

oscillator to measure the frequency of a microwave

source, or as a heterodyne frequency meter of

flz

accuracy.

Auxiliary equipment required, in addition to a

power supply, includes a

Qpe 1232 Tuned Amplifier

and Null Detector, a Type 874-VQL Voltmeter Detector, a Type

874-G10L Attenuator, a Type 874-R22LA

Patch Cord, and two patch cords such as Type 874-

R22LA for connection to the signal and, if greater

accuracy is desired, to frequency-measuring equip-

in

ment. The necessary connections are shown

4-3.

ure

oscillator should be tuned to zero beat with

The

Fig-

the source at two or more points on the dial, noting

the frequencies of a pair of successive, strong beats.

01)

The harmonic order

can then be determined as

follows:

Let:

fs = the source frequency

fh = the higher frequency of two suc-

cessive, strong beats

f

=

the lower frequency to two successive, strong beats

Figure

4-3.

using the

lator or heterodyne frequency meter.

and the signal frequency,

4.5

SWEPT OSCILLATOR.

The 1362 Oscillator, employed

Setup for frequency measurement,

1362 Oscillator as a transfer oscil-

fd = fh

H

-

f

=

fh/fd (always

fs

=

the difference

an

integer)

,

is:

in

the equipment

setup shown in Figure 4-4, can be used for rapid insertion-loss measurements on

uhf devices. This

is

indicative of a number of applications in which the

oscillator can be operated in a swept-frequency mode.

Long life is assured by the design (ball bearings in

the tuning mechanism) and proper lubrication (refer

to paragraph 1.4 and 1.5).

Use of the Type 1263 Power Supply (which includes the Type 874-VRLVoltmeter Rectifier) ensures

a leveled output from the oscillator throughout the

1

sweep range. The internal

-kHz square-wave mod-

ulator of the power supply permits use of the extremely

sensitive

Qpe 1232 Tuned Amplifier and Null Detector

as the indicator, with an auxiliary output that can drive

X-Y

an

4.6

recorder, if desired.

OBSERVATION OF MODULATION.

The envelope of the amplitude-modulated rf sig-

nal can be displayed on an oscilloscope with the setup

shown in Figure 4-5. Since the detector provides a

negative signal, the use of a scope with polarity in-

is

version

recommended, so that the display will show

increasing voltage upward.

TYPE

1263

AMPLITUDE-

REGULATING

POWER SUPPLY

SWEEP DRIVE

RECTIFIER DETECTOR

Y-AXIS TYPE 1232

'

SIGNAL TUNED

-

$MPLlFlER

NULL DETECTOR

8

Figure

4-4.

Setup for measurement of

insertion

using the

and leveled source.

loss or gain vs frequency

1362 Oscillator as a swept

APPLICATIONS

11

Page 15

OSCILLATOR

MODULATING

OR

POWER

AND

SEPARATE

I

i2424

TYPE

TYPE

*

POWER'SUPPLY

SUPPLY

MODULATOR

L

-----------------------

Figure 4-5. Setup for observation of modulation envelope.

874G6L

ATTENUATOR

OPTIONAL

-C

SYNCHRONIZATION

874-VQL

DETECTOR

I

y$:t$k

*,

I-

TYPE

-c

TERMINATION

OSCILLOSCOPE

874-W50BL

50-OHM

I

J

SECTION

5

PRINCIPLES OF OPERATION

5.1 GENERAL.

The Type 1362 UHF Oscillator is avacuum-tube

oscillator intended for use as a general-purpose laboratory rf source. Its frequency range, which extends

from 220 to 920 MHz, is tuned with a single control,

without band switching. Frequency setting is indicated

on a large, easy-to-read, engraved dial, individually

calibrated to give

The oscillator is capable of delivering

in excess of 160 milliwatts into 50 ohms over its

frequency range. Power-supply, modulation, and output-calibration circuitry have been omitted from the

instrument, in order to leave the user the greatest

possible latitude of choice to arrange the oscillator

in a system that meets his particular needs.

5.2 CIRCUITRY.

5.2.1 TUBE CIRCUIT.

The oscillator uses the General Electric type

Y

-1266 metal-and-ceramic, planar, triode tube (Figure 5-1). The tube is designed to operate with 6.3

volts and 0.24 amperes on the heater and a maximum

plate voltage of 350 volts.

The tube is used in a Colpitts circuit (Figure

5-2) with the plate and grid connected to the tuned

circuit

LC101. The feedback is determined by the

inter-electrode capacitances of the tube, with addi-

21% accuracy.

rf

power

Figure 5-1. Type Y-1266

oscillator tube, outline

drawing.

tional cathode-to-plate capacitance, C105, built into

its mount.

LClOl

C105

C106

It-

Figure 5-2. Elementary schematic diagram of

the 1362

5.2.2 TUNING.

The 1362 Oscillator uses a butterfly tuning cir-

cuit, which combines a variable air capacitor and a

variable inductor in a single unit with no sliding contacts. Inductance varies from 10

quency end of the tuning range to 4

frequency end, and capacitance varies from 50

7

pF.

5.2.3 OUTPUT COUPLING.

Radio-frequency power is coupled from one of

the inductive parts of the butterflyto a loop at one end

short air line having the output connector at the

of a

other end.

tor is provided by permitting the air line to slide

ially in a suitable tube.

Maximum output is obtained with the loop in

close to the butterfly, reduced output with the loop

retracted. Reasonably linear and frequency

tive attenuator calibration is possible only while the

loop is withdrawn beyond the

tion extends over a range of 80 dB from that point.

UHF

Oscillator.

nH at the low-fre-

nH at the high-

A

waveguide-below-cutoff (piston) attenua-

-insensi

zero-dB mark. Calibra-

pF to

ax-

-

12 TYPE

1362

UHF OSCILLATOR

Page 16

SECTION

6

SERVICE

AND MAINTENANCE

6.1 WARRANTY. 6.3 MINIMUM PERFORMANCE STANDARDS.

We warrant that each new instrument manufac- 6.3.1

tured and sold by us is free from defects in material

and workmanship, and that, properly used, it will per-

form in full accordance with applicable specifications

for a period of two years after original shipment. Any

instrument or component that is found within the

year period not to meet these standards after examination by our factory, District Office, or authorized

repair agency personnel will be repaired or, at our

option, replaced without charge, except for tubes or

batteries that have given normal service.

Typical life of the

hours. Tubes are guaranteed for

months; replacement for defective tubes will be made

on a prorated basis within this period.

6.2

SERVICE.

The two-year warranty stated above attests the

quality of materials andworkmanship in our products.

When difficulties do occur, our service engineers will

assist in any way possible.

eliminated by use of the following service instructions,

please write or phone our Service Department (see

rear cover), giving full information of the trouble and

of steps taken to remedy it. Be sure to mention the

type and serial numbers of the instrument.

Before returning an instrument to General Radio

for service, please write to our Service Department

or nearest District Office, requesting a Returned

Material Tag. Use of this tag will ensure proper

handling and identification. For instruments not covered by the warranty, a purchase order should be

forwarded to avoid unnecessary delay.

5pe Y-1266 tube is 2000

1000 hours or 12

If

the difficulty cannot be

two-

the harmonically related output of another signal

GENERAL.

The following paragraphs contain necessary in-

formation on means to determine rapidly that the

oscillator is performing within specifications. The

procedures given will be useful to instrument-standards

laboratories and equivalently equipped service facili-

ties, to perform routine calibration checks on properly

functioning instruments and to determine that a repaired instrument has been restored to proper operation. The procedures that follow immediately apply to

bench checks that use only front-panel controls and

externally available test points

assembly

in Table 6-1.

6.3.2 OPERATING CHECK.

milliameter into either MOD jack

measure the plate current of

dicated by a gradual variation of the plate current

as the oscillator

Maximum plate current normally occurs near the

high end of the tuning range and should be 25 to 35

for

6.3.3 FREQUENCY CHECK.

of the main tuning dial is within the specified

accuracy is to compare the oscillator rf output with

source. The signals are combined in a broadband

is

neither required nor recommended).

A

list of recommended test equipment appears

To check the dc operating conditions, plug a dc

is

tuned over its frequency range.

CW

operation with a 300-volt power supply.

One method of

determining that the calibration

(i.e., instrument dis-

0101 or J102) and

V101. Oscillation is in-

mA

?I%

SERVICE AND MAINTENANCE 13

Page 17

GR

Type

(or

equivalent) Name

Table

6-1

RECOMMENDED TEST EQUIPMENT

Function

I

1264

1215

1267 Power Supply (Regulated) For 1215 Oscillator.

1191-2 Frequency Measuring Furnish digital indication of signal-source output frequency.

1232 Null Detector, tunable to Null indicator for frequency measurements.

1862 Megohmmeter Measure butterfly rotor isolation with high potential.

-

-

874-R22LA Patch Cord To interconnect system components.

874-R34 Patch Cord To connect GR 874-VI into a system.

74-W50BL Termination, 50 -ohm

8

874

-TPDL Power Divider Means of balanced coaxial interconnection.

8 74

-VI- Voltmeter Indicator Measures output voltage of oscillator.

874-VQL Coaxial Crystal Detector

874-G101 Coaxial Attenuator Pads,

-G20L 10 dB and 20 dB

or

Modulating Power Supply

Oscillator,50 to 250 MHz

Assembly, dc to 500 MHz

1-kHz,

Voltohmeter, 20 ka/V, Measure voltage and resistance values.

minimum

Microwave power meter, Measure rf power output of oscillator.

+3% accuracy

1

pV sensitivity

Power and modulate oscillator for frequency, output, and

modulation measurements.

Furnish strong reference signal to measure oscillator frequency.

Terminate rf system for noise and modulated-output measurements.

Used to generate harmonics of reference signal and mix these

with oscillator output. Also used to detect the rf envelope

in modulation.

Reduce oscillator output to protect sensitive measuring instruments.

14

TYPE

FREQUENCY MEASURING

POWER SUPPLY

POWER SUPPLY

1362

UHF OSCILLATOR

p-

ASSEMBLY

TYPE 1215

OSCILLATOR

TYPE 1267

REGULATED

-

OSCILLATOR

TYPE 1264

MODULATING

-p

-

Figure

calibration

TYPE 874-TPDL

COAXIAL

POWER DIVIDER

6-1.

Setup to check frequency

of

the Type

1362

1

TYPE 874 -VQL

VOLTMETER

DETECTOR

t

Oscillator.

-

TYPE 1232

AMPLIFYING

INDICATOR

116b10

Page 18

crystal detector and the resultant output is observed

on a sensitive null detector serving as a beat indicator.

Refer to Figure 6-1 for the test set-up and proceed

as follows:

a. Connect the 1362 Oscillator to the power

supply, apply power, and allow for a one-half hour

warmup in the STANDBY mode.

b. Apply power to the signal source (Type 1215

Unit Oscillator) and allow for at least one-half hour

warmup. (This should be unmodulated.)

c. Apply power to the Type 1143 Frequency

Measuring Assembly and allow for a one-half hour

wa rmup

.

d. Set the output loop of the 1215 Oscillator

about one-half inch from maximum coupling and tune

carefully to 150 MHz. Observe the frequency indication on the Counter assembly and adjust the

oscillator, as necessary, for at least one significant

figure after the decimal point,

i.e., 150.0

kO.l

MHz.

e. Turn on the 1232 Detector, set its amplifier

in the FLAT

(broadband) mode, its meter for

LOG

indication, and its GAIN control for negligible response (1 division on the meter).

f. Turn the mode switch on the 1264 Power

Supply to CW.

g. Adjust the main tuning dial slowly around

300 MHz, and look for a beat indication (peak response)

on the 1232 Detector. The beat should occur well

within

f1%.

h. Repeat the procedure of step g at 600 MHz

If

and at 900 MHz.

the 1362 Oscillator dial is correct

at these frequencies, it is quite reasonable to assume

that the other engraved lines are accurate to the

specified

+I%.

If

the oscillator frequency calibration is outside

specification, refer to paragraph 6.7 for corrective

action.

6.3.4 POWER OUTPUT CHECK.

To check the available rf power output from the

oscillator, use any suitable rf power meter. Alternatively,a GR Type 874-VI Voltmeter Indicator may be

used with a

GR Type 874-VQL Voltmeter Detector.

The detector will produce a dc current to drive the

indicator, which can be calibrated in volts. The 874VQL Detector introduces no appreciable discontinuity when inserted in a 50-ohm coaxial line and should

be terminated with a 50-ohm load, such as the Type

874-W50BL 50 -ohm Termination.

To make a measurement, set up the equipment

'in Figure 6-2.

as

The use of a GR Type

874-G10L

Attenuator limits the power level to prevent damage

to the diode in the detector. The oscillator output

voltage is measured by suitable adjustments of sensitivityand calibration controls on thevoltmeter indicator. That value in volts must be sauared.

by ten for each 10 dB attenuator

pad inserted

multi~lied

i;

the

system, and divided by the termination resistance in

ohms, to obtain the output power

in

watts. (Example:

Given a measurement of 1.0 volt, a 10 dB pad in the

system, and a 50-ohm load.

Solution:

1.0~ x 10/50=

0.2 watts = 200 milliwatts.) Refer to Figure 1-3 for

guaranteed and typical performance with various

General Radio power supplies.

If

the output power is very low, refer to the

trouble analysis section 6.4.

On

the other hand, if the

output power is slightly below specification, it may be

corrected by adjustment of

R107. Refer to paragraph

6.6, g.

6.4

TROUBLE ANALYSIS.

6.4.1 GENERAL.

If the 1362 Oscillator performs outside of speci-

fication, as determined by use of paragraph 6.3, the

procedures below can be used to isolate the trouble to

a defective assembly or part. Suggestions for trouble

analysis are given in Tables 6-2 and 6-3. The former

is based on operating parameters, the latter on cold

resistances. (Refer to Figures 6-3 and 6-4 and to the

schematic diagram, Figure 6-8, at the

endof the book.)

Instructions for adjustment and repair are given in

subsequent paragraphs of Section 6.

6.4.2 DETAILS OF TROUBLE ANALYSIS.

If

the oscillator is weak, and the analysis sug-

gested

in

Tables 6-2 and 6-3 show no defects except

low plate current and high cathode voltage, the tube

has a defective (worn-out) cathode. Proceed to paragraph 6.6.

If

oscillation ceases and restarts very abruptly

as the tuning dial is rotated, recheck Table 6-3, step

k several times. The

be used, applying 500 volts to the test.

Type 1862 Megohmmeter may

If

there is a

short-circuit caused by a loose piece of material

between rotor and stator, its behavior may be erratic

and difficult to analyze.

a short-circuit

is

the result

If

of bent plates, the malfunction will be repeatable and

the instrument should be serviced as described in

paragraph 6.2.

OSCILLATOR

-

TYPE 1264 50-OHM TERMINATION

MODULATING

POWER SUPPLY

I

Figure

TYPE 874-VI

6-2.

Setup to check output level of the Type

I

TYPE

1362

874-W50BL

oscillator.

SERVICE AND MAINTENANCE

15

Page 19

I

SteQ Measurement

Plate current

a

and phone plug)

Table

6-2

CURRENT

Ibv

use of) Test Points Indication Comments

(50-mA dc meter

MODulation jack on panel

0101, Figure 6-4)

AND VOLTAGE ANALYSIS*

0 mA Check power supply

18 to 35

varies with tuning

mA steady Open grid

18

22

mA fixed when No oscillation. (Sustuning dial is

rotated short circuit from

mA Short circuit from

42

mA,

and connections.

Check voltages.

Normal

pect

grid to cathode.)

plate to cathode.

(Check resistances.)

I

LC101 shorted or

b Cathode voltage (300-Vdc meter)

c Heater voltage (10-V dc or ac

I

1

*Power supply: Type

RE

meter depending on power

supply)

1267,

shield cover in place.

or

1264

set to cw with

"Ground" or sub-panel

(+);

orange wire at C107

(-)

or R105

FLlOl to FL102 (Figure

6 -5)

amplitude control clockwise.

(Figure 6-4)

NOTE

Ifmeasurements are

attem~tedon this oscillator with power on and the rf shield cover

removed, one may expect the instrument in

good repair to oscillate over most of its tuning range but to deviate appreciably from

specified frequency calibration and output

power level.

When the oscillator

paired, avisual inspection

is

being serviced and re-

is

appropriate. All soldered

joints should be secure, mechanical fasteners tight,

dial-drive mechanism operating smoothly without backlash, and the tiny damping resistors on the rotor secure

and unbroken. For lubrication, refer to paragraph 6.8.

6.5

REMOVAL OF COVERS.

6.5.1 GENERAL.

When it becomes necessary to carry the trouble

analysis beyond step "a" in either Table 6-2 or 6-3,

the exterior

and c" in Table 6-2 must be made with the

cover will have to be removed. Steps "b

rf

shield

cover in place; however, the rf shield cover will have

to be removed to perform steps

"b through 1" inTable

6-3 and to replace the oscillator tube (V101).

6.5.2 REMOVAL OF EXTERIOR COVER.

To remove the exterior cover, loosen the captive

thumb screws that hold the exterior cover on by ro-

0

V

Less than 75

75 to 160 V, Normal

varies with tuning

300 V

0

V

6.5 V

Lack of voltage from

power supply or

grounded cathode circuit.

Suspect C107 (Set up

V

both steps a and b,

disconnect

Open circuit to cathode or

"dead" tube (check heater

Lack of voltage from power

supply (check connections,

resistances)

Normal

go to

(If

Table

PL101.)

300 V in step b

6-3, step

a)

)

tating them counter-clockwise (as seenfrom the rear).

Slide the cover off the rear of the instrument.

6.5.3 REMOVAL OF RF SHIELD COVER.

To remove the rf shield cover proceed as follows:

a. Remove the snap button from the right side

of the instrument (Figure 6-5). This is done by pushing out the button from the inside with a blunt tool,

such as the end of a small screwdriver handle.

b. Insert a Phillips-head screwdriver through

by

the hole left

1/4-inch screw in the rf shield cover.

6-32,

the snap button and remove the No.

c. Unscrew the two captive No. 10-32 Phillips-

head screws on opposite sides of the shield cover.

Unscrew several turns at a time, alternating between

screws.

d. Slide the rf shield cover off. Figure 6-4

identifies the major interior components.

CAUTION

The positions of parts in the rf section are

critical. Do not move any port unless it is

fective. When a part must be replaced, install

the new one in the some position and orientation, with the same lengths of leads and lead

dress.

.

.

de-

16 TYPE 1362 UHF OSCILLATOR

Page 20

Figure

6-3.

Interior rear view of Type 1362 Oscillator with shield cover removed.

-

JIOI

Figure

6-4.

Interior top view of Type 1362 Oscillator with shield cover removed.

SERVICE AND MAINTENANCE

17

Page 21

7

Step

a

b

c

d

e

f

g

h

i

j

k

1

Measurement

(by

use of)

Heater (ohmmeter)

Cathode string

(ohmmeter)

C107 (ohmmeter)

Modulation circuit

(ohmmeter)

Cathode to grid

(ohmmeter)

Grid to plate

(ohmmeter)

Cathode to plate

(ohmmeter)

L104 (ohmmeter)

Butterfly rotor

(megohmmeter)

Heater to cathode

(ohmmeter)

Table 6-3

RESISTANCE ANALYSIS

CAUTION - Turn

Test Points

Pins 13 and 14 of PL102

(Figure 6-8)

AT101; AT102 (Figure

6-3)

PL102, pin 16; orange

wire at

R105 or C107

(Figures 6-4, 6-8)

Orange wire at R105 or

C107; AT103 (Figures

6-3, 6-4)

C107 terminals (Figure

6-4)

WARNING

C107 may be charged;

short it out first.

PL102, pin 15; Ground

(Figure 6-8)

AT103; AT104

(Figure 6-3)

AT104; AT107

(Figures 6-3, 6-4)

AT103; AT107

(Figures 6-3, 6-4)

AT107; AT108

(Figures 6-3, 6-4)

AT107; LC101

rotor (Figures 6-3, 6-4)

FL101; FL103

(Figure 6-3, 6-4, 6-5)

a1

I

power OFF.

Indication

10

m

C0

5.5 to 8.2 k52

33

Low

100 kfi

0

52

m

0 fi

1

kQ

0

52

m

0

52

~0

0

a

a

(over

whole tuning

range)

1

m52

a,

52

52

a

a

52

52

52

52

Comments

Normal

Open circuit (Go to step b)

in

Open heater

tube

(See paragraph 6.6)

Normal

Normal

Leaky or shorted

Normal

Normal

Fault in

J101,5102, or SO101

Suspect tube (V101)

Normal

C106 or C104 shorted

Normal

Short in

VlOl or C105

Normal

Normal

Normal

Normal

Check

SO101

Conditions:

plug

6.6

INSTALLATION OF OSCILLATOR TUBE.

When it

PL102

(5-pin plug) floating,

and

socket) connected, no phone plugs.

is

necessary to replace the Type Y-1266

S0101-PL101

(8-pin

tube, proceed as follows (Figure 6-6):

CAUTION

all

Turn

power OFF.

a. Remove the covers as described in para-

graph 6.5.

b. Remove the two plate-clamp-mounting screws,

and withdraw the tube from the heater socket.

c. Loosen the plate-clamp screw and withdraw

the tube from the plate clamp.

d. Plug replacement tube into heater socket,

using care not to snag the grid fingers on the smaller

(cathode) flange of the tube. Be sure that the tube is

fully seated, and that the two grid fingers are making

contact.

18

TYPE

1362 UHF OSCILLATOR

e. Slip the plate clamp over the plate terminal

and secure the assembly to the butterfly capacitor by

means of original hardware.

f.

Tighten the plate-clamp screw, making sure

that tube is still fully seated in heater socket. Replace

the

rf

shield cover and tighten its 3 screws.

g. Connect a 0-50 milliameter at the MOD jack;

apply power using a 1267 Power Supply; set the dial

to 920 MHz; connect a 50-ohm load to the output connector; push the attenuator in; allow 5 minutes for

a

warm-up. Adjust R107 with

Figure 6-3) for 30

mA 23 mA plate current. (The

current may be set higher to provide more

output at the expense of reduced tube

screwdriver (refer to

rf

power

life;conversely,

for economy, refer to paragraph 6.9.)

h. Restore frequency calibration if necessary,

in accordance with paragraph 6.7.

Page 22

Figure

6-5.

Interior right-side view with shield cover in ,place (right side of cabinet removed).

6.7

FREQUENCY CALIBRATION.

Replacement of the oscillator tube may affect

frequency calibration. This can be checked by the

method described in paragraph 6.3.3, during which

process the shield cover must be in place with all

three screws tight, and the output loop withdrawn at

least to the zero-dB mark. If necessary, remove the

shield cover

and set the trimmer capacitor C104 by

rotation (not bending) to make the output signal frequency agree with the dial calibration at any convenient frequency above 800 MHz. To free

C104, tempor-

arily loosen the plate clamp screw slightly.

If there is inadequate range to reach 920 MHz by

rotating

back tabs

C104, it may be necessary to bend the feed-

(C105

A,

B)

as well. Moving each tab away

from the tube raises the top frequency of the oscillator,

but the feedback tabs, unlike

C104, also affect the

power output at the low-frequency end of the tuning

range.

6.8

LUBRICATION.

Proper lubrication consists of occasional light

grease on the gears behind the panel and the dial assembly. (Remove only the dust cover and the two screws

is

near the vernier knob.) Lubrication

important when the oscillator is driven by

particularly

a

sweep

or dial drive.

6.9

ADJUSTMENT FOR MAXIMUM TUBE LIFE.

Longest tube life will be obtained by the use of

regulated plate and heater voltages as supplied by the

1263, 1264, or 1267 power supplies. When the 1269

(unregulated) power supply is used, tube life can be

prolonged at the expense of maximum power output by

readjusting R107 to reduce plate current as far as

possible, normally to 31 or 32

mA. (Refer to para-

graph 6.6, step g.)

-GRID

CONTACT

PLATE CLAMP

CLAMP

PLATE CLAMP

SCREW (YO-80)

1362.12

Figure

6-6.

Details of oscillator-tube mounting.

SERVICE AND MAINTENANCE

19

Page 23

From

Federal Supply Cods

(Name

to Cods) and

FEDERALMANUFACTURERSCODE

for

Monufacturors Cataloging Handbooks H4-1

H4-2

(Code

10

Nome)

os

supplemented through

June,

1967.

Code Monufocturers Nome and Address

Jones Mfg. Co., Chicago, Illinois

Walsco Electronics Corp., Los Angeles, Calif.

Aerovox Corp., New

Alden Products Co., Brockton, Mass.

Allen-Bradley, Co., Milwaukee, Wisc.

Texas Instruments, Inc., Dallas, Texas

Ferroxcube Corp. of America,

Lab.

Fenwal

Amphenol ~lectrbnics Corp., ~roadview, Ill.

Fastex Division of 111. Tool Works,

G. E. Semiconductor Products

Grayhurne, Yonkers, N. Y. 10701

Pyrofilm Resistor Co., Cedar Knolls, N. J.

Clairex Coro.. New York, N. Y.

Arrow, ~art'&d ~e~eman Electric Co.,

Motorola Semi-conduct Product,

Engineered Electronics Co., Inc.,

Barber-Colman Co.,

Wakefield Eng., Inc., Wakefield, Mass. 01880

Eagle Signal Div. of E. W. Bliss Co.,

Avnet Corp., Culver City, Calif. 90230

Fairchild Camera and Instrument Coro..

Birtcher Corp., No. Los Angeles, Calif.

American Semiconductor Corp., Arlington

Bodine Corp., Bridgeport, Conn. 06605

Bodine Electric Co., Chicago,

Continental Device Corp., Hawthorne, Calif.

State Labs Inc., N. Y., N.

Amphenol Corp., Borg Inst. Div.,

Vemaline Prod. Co., Franklin Lakes, N.

General Electric Semiconductor, Buffalo, N. Y.

Burgess Battery Co., Freeport,

Burndy Corp., Nomalk, Corn. 06852

Chandler Evans Corp., W. Hartford, Conn.

Teledyn Inc., Crystalonics Div.,

RCA Commercial Receiving Tube and Semi-

Mfg. Co. Inc., Dover, N.,H. 03820

Clarostat

Dickson Electronics Corp., Scottsdale, Ariz.

Solitrone Devices,

I'M Semiconductors, W. Palm Beach, Florida

Cornell Dubilier Electric Co., Newark N. J.

Coming Glass Works, Coming, N. Y.

General Instrument Corp., Hicksville, N. Y.

In,

Semiconductor Div. of Int. T. and T,

Cutler-Hammer Inc., Milwaukee, Wisc. 53233

Spruce Pine Mica Co., Spruce Pine, N. C.

Mfz. Co.. Indeoendence. Kansas 67301

Electra

Fafnir

~eaFin~

G. E. Schenectady, N. Y. 12305

G. E., Electronic Comp., Syracuse, N. Y.

G. E. (Lamp Div), Nela Park, Cleveland, Ohio

General Radio Co.. W. Concord. Mass 01781

American Zettler

Hayman Mfg. Co., Ken~lworth, N. J.

Hoffman Electronics CorD., El Monte. Callf.

International Business

Jensen Mfg. Co., Chicago, Ill. 60638

Constanta Co. of Canada

P. R. Mallory and Co. Inc., Indianapolis, Ind.

Marlin-Rockwell Corp., Jarnestown, N. Y.

Honeywell Inc., Minneapolis, Minn. 55408

Muter Co., Chicago,

National Co. Inc., Melrose, Mass. 02176

Norma-Hoffman Bearings Corp.,

RCA, New York, N. Y.

Raytheon Mfg. Co., Waltham, Mass. 02154

Bedford, Mass.

Saugerties, N. Y. 12477

Inc.. Morton Grove. Ill.

Des Plaines,

Syracuse, N. Y.

Hartford, Conn. 06106

Phoenix, Ariz. 85008

Santa Ana, Calif. 92702

Rockford, 111. 61101

Baraboo, Wisc.

Mountain View, Calif.

Ill. 60004

Heights,

Y.

Delavan, Wisc. 53115

Cambridge, Mass.

conductor Div., Woodridge, N.J.

Tappan, N. Y. 10983

Lawrence, Mass.

CO.,

N~W

~riton; Conn.

kc., Costa Mesa, Calif.

~achines, Armonk,N.Y.

L~mited.

Montreal 19, Quebec

Ill. 60638

Stanford, Conn. 06904

Ill. 60016

Deot.,

li20l

10001

Ill. 60618

10003

Ill.

02140

Code

Monofocturers Nome and Address

53021

Sangamo Electric Co., Springfield, Ill. 62705

54294

Shallcross Mfg. Co., Selma, N. C.

Shure Brothers, Inc., Evanston,

Sprague Electric Co., N. Adams, Mass.

Thomas and Betts Co., Elizabeth, N. J. 07207

TRW Inc. (Accessories Div), Cleveland, Ohio

Torrington Mfg. Co., Torrington, Conn.

Union Carbide Corp., New York, N.

United-Carr Fastener Corp., Boston, Mass.

Victoreen Instrument Co.. Inc..

Ward Leonard Electric

Westinghouse (Lamp Div), Bloomfield, N. J.

Weston Instruments, Weston-Newark,

Atlantic-India Rubber Works, Inc.,

Amoerite Co.. Union Citv. N.

el den

Bronson, Homer D., Co., Beacon Falls, Corn.

Canfield, H.

Bussman Mfe. Div. of McGraw Edison Co..

Centralab, Inc., Milwaukee,

Continental Carbon Co., Inc., New York. N. Y.

Cot0 Coil Co. kc., ~ro;idence, R. I.

Chicago Miniature Lamp Works, Chicago, Ill.

.

.

J.

Cinch Mfg. Co. and Howard B. Jones Div.,

Darnell Corp., Ltd., Downey, Cahf. 90241

Electro Motive Mfg. Co., Willmington, Conn.

Nytronics

Dialieht Co.. Brooklvn. N. Y. 11237

~enezal ~nstrument'cdrp., Capacitor Div.,

Drake

Hugh H.

Elastic Stop Nut Corp., Union, N.

Erie Technological Products Inc., Erie, Penn.

Amperex Electronics Co., Hicksville, N. Y.

Carling Electric Co., W. Hartford, Conn.

Elco Resistor Co., New York, N. Y.

J. F. D. Electronics Corp., Brooklyn, N. Y.

Heinemann Electric Co., Trenton, N. J.

Industrial Condenser Corp., Chicago,

E.

F.

IRC Inc., Philadelphia, Penn. 19108

Kulka Electric Corp., Mt. Vernon, N. Y.

Linden and Co., Providence,

Littelfuse, Inc., Des Plaines, Ill. 60016

Lord

James

Mueller Electric Co., Cleveland, Ohio 44114

National Tube Co.,

Oak Mfg. Co., Crystal Lake,

Patton MacGuyer Co., Providence,

Pass-Seymour, Syracuse, N.

Plerce Roberts Rubber Co., Trenton, N. J.

Positive Lockwasher Co., Newark

Ray-0-Vac Co., Madison, Wisc.

TRW, Electronic Component Div.,

General Instruments Corn.. Brooklvn. N. Y.

Shakeproof Div. of

Sigma Instruments Inc., S. Braintree, Mass.

StackDole Carbon Co.. St. Marvs. Penn.

t inner man

RCA, Commercial Receiving Tube and SemiWiremold Co., Hartford. Conn. 06110

Zierick Mfg.

Prestole Fastener Div. Bishop and Babcock

Vickers Inc. Electric Prod. Div..

Electronic

Motorola

Standard Oil

Bourns Inc., Riverside, Calif. 92506

Air Filter Corp., Milwaukee, Wisc. 53218

~leveland,'~hio'

Newark, N. J.

Chicago,

Mfg. do., ~hica~o,.111."60644

0.

Co., Clifton Forge, Va. 24422

Louls, Mo.

St.

Chicago,

Inc., Berkeley Heights, N. J. 07922

Newark, N.

We. Co.. Chicago. Ill. 60656

64,

I&.,

PhiGdelphia, Penn. 19144

Johnson Co., Waseca, Minn. 56093

Mfg. Co., Erie, Pem. 16512

Millen Mfg. Co., Malden,Mass. 02148

Pittsburg, Penn.

Camden, N. J. 08103

Ill. ~dol works;

Elgin, Ill. 60120

Products, kc., cl&eiand, Ohio

conductor Div., Harrison, N. J.

CO.,

New Rochelle, N.

Corp., Toledo, Ohio

Loms, Mo.

St.

Industr~es Assoc., Washmgton, D.C.

Inc., Franklin Park, Ill. 60131

CO.,

Lafeyette, Ld.

Co.,

Mt. Vernon,

Ill. 60607

I.

WISC. 53212

Ill. 60624

J. 07104

R. I.

Ill.

Y.

Ill.

07087

J.

R.

,

N. J.

Y.

07083

111.

I.

'

Y.

10017

'

Code

Monufocturers Nome ond Address

Hammarlund Co. Inc.. New York. N. Y.

80583

Beclanan Instruments; Inc., Fullerton, Calif.

Grayhill Jnc., LaGrange, Ill. 60525

WE. Corp., Stirling, N.

Isolantite

~~eGfications

Military

Joint Army-Navy Specifications

Columhus Electronics Corp., Yonkers, N. Y.

Filton Co., Flushing, L. I., N. Y

Barry Controls Div. of Barry Wright Corp.,

N.

Y.

Sylvania Electric Products, Inc., (Electronic

Indiana Pattern and Model Works,

Switchcraft Inc., Chicago,

Metals and Controls Inc., Attleboro, Mass.

Milwaukee Resistor Co., Milwaukee, Wisc.

Carr Fastener Co.. Cambridee. Mass.

Victory

Bearing Specialty Co.,

Solar Electric Corn.. Warren. Penn.

Union Carbide

TRW Capacitor Div.,

Lehigh Metal Products Corp.,

TA Mfg. Corp., Los Angeles, Calif.

Precision Metal Products of Malden Inc.,

RCA (Electrical Component and Devices)

Cutler-Hammer Inc., Lincoln, Ill.

Gould Nat. Batteries Inc., Trenton, N. J.

Cornell Dubilier Electric Corp.,

K

and G Mfg. Co., New York, N.

Holtzer. Cabot Cor~.. Boston. Mass.

United Transformer Co., Chicago, Ill.

Mallory Capacitor Co., Indianapolis, Ind.

Westinghouse Electric Corp., Boston, Mass.

Hardware Products Co., Reading, Penn. 19602

Continental Wire Corp., York, Penn. 17405

I'M Cannon Electric Inc., Salem, Mass.

Iohanson

Chandler c;, Wethersfleld, coin. Oh109

Dale Elecrronics Inc., Columbus, Nebr.

Elco Corp., Willow Grove,

General Instruments, Inc., Dallas, Texas

Iloncywell Inc., Freeport, Ill.

Electra Insulation

Edgerton, Germeshausen and Grier,

Sylvania Electric Products, Inc.,

Cramer Products Co., New York, N. Y. 10013

Raytheon Co. Components Div., Quincy, Mass.

Tung Sol Electric Inc., Newark, N.

Garde Mfg. Co., Cumberland, R. I.

Alco Electronics Mfg. Co., Lawrence, Mass.

Continental Connector Corp., Woodside, N. Y.

Vitramon, Inc., Bridgeport, Conn.

Methode Mfg. Co., Chicago,

General Electric Co., Schenectady, N. Y.

Ansconda American Brass Co.,

Hi-Q Div. of Aerovox Corp.,

Texas Instruments Inc., Dallas, Texas 75209

Thordarson-Meissner

Microwave Associates Inc., Burlington, Mass.

Military Standards

CBS Electronics Div. of Columbia Broadcast-

Sealectro Corp.,

North Hills Electronics Inc., Glen Cove, N. Y.

Transitron Electronics Corp., Melrose, Mass.

Atlee Corp., Wmchester, Mass. 01890

Delevan Electronics Corp., E. Aurora, N. Y.

Watertown, Mass.

Tube Div.), Emporium, Penn.

~n~ineering Corp (I~ECO),

Springfield, N.

San

COG.;

New

Ogallala, Nebr.

Cambridge, Mass. 02140

Stoneham, Mass. 02180

Harrison, N.

Fuquay-Varina, N. C.

. .

Mfp. Co., Boonton, N.

Corp.,

Long Island, N. Y.

Boston, Mass.

Woburn, Mass.

Torrington, Conn.

DIV. of McGuire,

Mt. Carmel, Ill.

ing Systems, Danvers, Mass.

Mamaroneck: N. Y. 10544

J.

07980

-

LaPort, Ind.

Ill. 60630

J.

07081

Francisco, Calif.

YO;^,

N. Y. 10017

J.

Y.

1.

07005

Pem.

Woods~de.

J.

Ill.

Orlean, N.

Y.

20

TYPE

1362

UHF

OSCILLATOR

Page 24

Re/. Des.

Pinure

6-7

Description

Slider to raise front of instrument

Rubber feet

Screw, binder head, 10-32, 3/8 in.

Screw, binder head, 6-32, 3/8 in.