Page 1

1. This product may be used for model airplane or surface use if on the correct frequency.

The product described in this manual is subject to regulations of the Ministry of

Radio/Telecommunications and is restricted under Japanese law to such purposes.

2. Exportation precautions

(a) When this product is exported from Japan, its use is to be approved by the Radio Law of

the country of destination.

(b) Use of this product with other than models may be restricted by Export and Trade

Control Regulations. An application for export approval must be submitted.

3. Modification, adjustment, and replacement of parts

Futaba is not responsible for unauthorized modification, adjustment, and replacement of

parts of this product.

This device complies with part 15 of the FCC rules. Operation is subject to the following

two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause

undesired operation.

The RBRCTM SEAL on the (easily removable) nickel-cadmium battery contained in Futaba

products indicates that Futaba Corporation of America is voluntarily participating in an

industry program to collect and recycle these batteries at the end of their useful lives, when

taken out of service within the United States. The RBRC

TM

program provides a convenient

alternative to placing used nickel-cadmium batteries into the trash or municipal waste which

is illegal in some areas.

Futaba Corporation of America's payments to RBRC

TM

makes it easy for you to return the

spent battery to Futaba for recycling purposes. You may also contact your local recycling

center for information on where to return the spent battery. Please call 1-800-8-BATTERY

for information on Ni-Cd battery recycling in your area. Futaba Corporation of America's

involvement in this program is part of its commitment to protecting our environment and

conserving natural resources.

NOTE: Our instruction manuals need to encourage our customers to return

spent batteries to Futaba or a local recycling center in order to keep a healthy

environment.

RBRC

TM

is a trademark of the Rechargeable Battery Recycling Corporation.

Pay special attention to the safety at the parts of this manual that are indicated by the

following marks.

:Procedures which may lead to a dangerous condition and cause death or

serious injury to the user if not carried out properly.

:Procedures which may lead to a dangerous condition or cause death or

serious injury to the user if not carried out properly, or p r ocedures where the probability of

superficial injury or physical damage is high.

:Procedures where the possibility of serious injury to the user is small, but

there is a danger of injury, or physical damage, if not carried out properly.

Symbol:

; Prohibited

; Mandatory

Page 2

I

NSTRUCTION

M

ANUAL

6XAs / 6XHs

FOR AIRCRAFT / HELICOPTERS

FM/PCM SYSTEM, 6 CHANNELS

Futaba Corporation

Page 3

INTRODUCTION

Thank you for purchasing a Futaba® 6XAs/6XHs series digital proportional R/C system.

This system is extremely versatile and may be used by both beginners and experts. In order for

you to make the best use of your system and to fly safely, please read this manual carefully. If

you have any difficulties while using your system, please consult the manual, your hobby dealer,

or Futaba. This product is to be used for sport and recreational flying of radio-control models

only. Futaba is not responsible for the results of use of this product by the customer or for any

alteration of this product, including modification or incorporation into other devices by third

parties. Modification will void any warranty and is done at owner’s risk..

Your T6XAs or T6XHs system includes the following components:

• T6XAs/T6XHs Transmitter. May be programmed for planes or helicopters, both with

special mixing function, 6 model memories. (Transmitting frequency: 29, 35, 36, 40, 41, 50,

60 or 72 Mhz band)

• R127DF or R116FB Receiver (FM system). R138DP or R148DP Receiver (PCM system).

(Receiving frequency: 29, 35, 36, 40, 41, 50, 60 or 72 Mhz band)

• Servos, S3003 with mounting hardware and servo arm assortment (or S148 Servo)

• Receiver battery (or Battery Box)

• Switch harness with charging jack

• Aileron extension cord (use to easily connect to an aileron servo in a detachable wing)

• AC battery charger

• Owner’s Manual

Owner’s Manual

This manual is not just a translation — it has been carefully written from scratch to be as

helpful to you, the new owner, as possible. There are many pages of setup procedures,

examples, explanations, and trimming instructions. If you feel that any corrections or

clarifications should be made, please jot them down on a piece of paper and send them to the

factory. The information contained in this manual is subject to change without notice due to

possible changes in manufacturing procedures or updates.

“Futaba” is a registered trademark of the Futaba Corporation of America.

Manual text copyright ©1996 by Don Edberg, Dynamic Modelling Co. All rights reserved

– ii –

Page 4

TABLE OF CONTENTS

Introduction to the T6XAs/T6XHs System.........................................................................1

ACRO Transmitter Controls and Switch Identification......................................................2

ACRO & HELI Transmitter Switch Functions ...................................................................2

Charging the Ni-Cd Battery.................................................................................................3

Operating With The Trainer Cord .......................................................................................3

Adjusting Stick Length & Tension......................................................................................4

Changing Transmitter Mode................................................................................................5

Reversing The Throttle Stick...............................................................................................5

ACRO Receiver and Servo Connections.............................................................................6

Radio Installation Precautions.............................................................................................7

Airplane Frequencies (U.S.A.) ............................................................................................9

Transmitter Displays and Programming Keys...................................................................10

Warning Displays ..............................................................................................................11

Safety Precautions (DO NOT operate without reading)....................................................12

AIRCRAFT FUNCTIONS INDEX (ACRO Menu) 13

Aircraft (ACRO) Functions Diagram................................................................................14

Aircraft Setup Example (Pattern model) ...........................................................................15

Pattern Aircraft Trimming Chart.......................................................................................22

ATV................Adjustable Travel Volume.........................................................................24

D/R ................Dual Rates..................................................................................................25

EXP...............Exponential Settings..................................................................................26

REV...............Servo Reverse............................................................................................27

STRM............Subtrim......................................................................................................27

FLPR.............Flaperon (combined flaps & ailerons).......................................................28

FLTR.............Flap trim.....................................................................................................29

ABRK ............Airbrake settings........................................................................................30

VTAL.............V-tail mixing..............................................................................................31

ELVN.............Elevon mixing (tailless models) ................................................................32

1->4...............Rudder Coupling........................................................................................33

6->2...............Flap -> Elevator mixing.............................................................................34

2->6...............Elevator -> Flap mixing.............................................................................35

PMX1, 2........Programmable Mixer #1, #2......................................................................35

F/S.................Failsafe function (only in PCM mode)......................................................37

PARA ............Parameter menu .........................................................................................38

REST.............Data Reset..................................................................................................38

– iii –

Page 5

DRSW........... Dual Rate Switch Select............................................................................39

ACRO........... Acrobatic model mode.............................................................................. 39

HELI..............Helicopter model mode.............................................................................39

MOD............. Modulation (FM/PPM or PCM)................................................................ 40

COPY ........... Data Copy ................................................................................................. 40

TMEM........... Trim Memory............................................................................................ 41

MODL........... Model select.............................................................................................. 42

HELICOPTER SECTION INDEX 43

Helicopter (HELI) Functions Index.................................................................................. 43

Helicopter Function Menu Diagram................................................................................. 43

Helicopter Transmitter Controls and Switch Identification..............................................44

Helicopter Setup Instructions............................................................................................ 45

Helicopter Trimming Chart............................................................................................... 48

PI-N, I, H...... Pitch Rate (Normal, Idle-Up, Hovering)................................................... 49

HV-T ............. Hovering Throttle...................................................................................... 49

IDLE.............. Idle-Up function........................................................................................ 50

HOLD............ Throttle Hold............................................................................................. 51

REVO ........... Revolution mixing..................................................................................... 51

R-OF............. Rudder Offset............................................................................................ 52

HV-P............. Hovering Pitch .......................................................................................... 53

SWSH........... Swashplate Type & AFR .......................................................................... 53

Glossary............................................................................................................................ 55

Data Recording Sheets: ACRO, HELI.......................................................................... 56

Factory Repair Service................................................................................................... 57

– iv –

Page 6

Introduction to the 6XAs/6XHs Systems

TRANSMITTER

The versatile T6XAs/T6XHs

PCM1024 multi-function 6-channel

transmitter may be used with any Futaba

FM/PPM receiver! In addition, your system

will work with Futaba PCM1024 receivers

when you select the built-in PCM

transmission option. The liquid-crystal

display panel allows rapid data input into its

easy-to-read LCD display.

The T6XAs/T6XHs system comes

complete with programming for ACRO

(aircraft) and HELI (helicopter) mixing and

can accommodate virtually any model

configuration. The compact, ergonomicallydesigned transmitter holds completely

independent memories for six different

models.

The T6XAs/T6XHs features a new

stick design which provides an improved

feel. The sticks’ length and tension may be

adjusted. Switches are provided for dual

rate (D/R), programmable mixers (PMX),

and other functions. For those learning to

fly, the transmitter has “buddy-box”

capability where a second transmitter may

be used by an experienced pilot as an

instructor. [The trainer cord is sold

separately.]

Standard programming features

include servo reversing for all channels,

ATV on all channels, dual rates,

exponential, and fail safe on all channels

(PCM transmission only). In addition, the

T6XAs/T6XHs features a number of handy

mixing features applicable to all types of

flying models. For aircraft, the extensive

preprogrammed mixing features include:

flaperon, V-tail, elevon, airbrake, elevator ->

flap, and flap -> elevator. Helicopter

features include hovering pitch and throttle,

revolution mixing, swashplate type

selection, and rudder offset. [Note: the

T6XAs/T6XHs may be used for sailplanes.

For these we recommend Futaba’s System 8,

which contains extensive sailplane

programming.]

Transmitter Specifications:

Operating system: 2-stick, 6 channels,

PCM1024 system

Modulation: FM/PPM or PCM, switchable

Power supply: 9.6V Ni-Cd battery

Current drain: 250mA

RECEIVER

The R127DF seven-channel receiver

included with your system is a compact

high-sensitivity narrow-band unit, providing

superior range and performance.

Receiver Specifications (FP-

R127DF)

Type: FM, Dual conversion

Intermediate frequencies: 455kHz, 10.7MHz

Power requirement: 4.8V or 6V Ni-Cd battery

Current drain: 14mA @ 4.8V

Size: 1.39x2.52x0.82” (35.3x64.0x20.8mm)

Weight: 1.5oz (42.5g)

Receiver Battery

4-cell NR-4J (NR-4RB for heli version)

Capacity: 500mAH (1,000mAH for NR-4RB)

Weight: 3.3oz/94g (3.9oz/111g for NR-4RB)

SERVO SPECIFICATIONS

Servo type: S3003 (Standard)

Control system: Pulse width control, 1.52ms

neutral

Power requirement: 4.8V (from receiver)

Output torque: 44.4oz-in (3.2kg-cm)

Operating speed: 0.23sec/60°

Size: 1.59x0.78x1.41” (40.4x19.8x36mm)

Weight: 1.3oz (37.2g)

*Specifications and ratings are subject to change without notice.

– 1 –

Page 7

– 2 –

Page 8

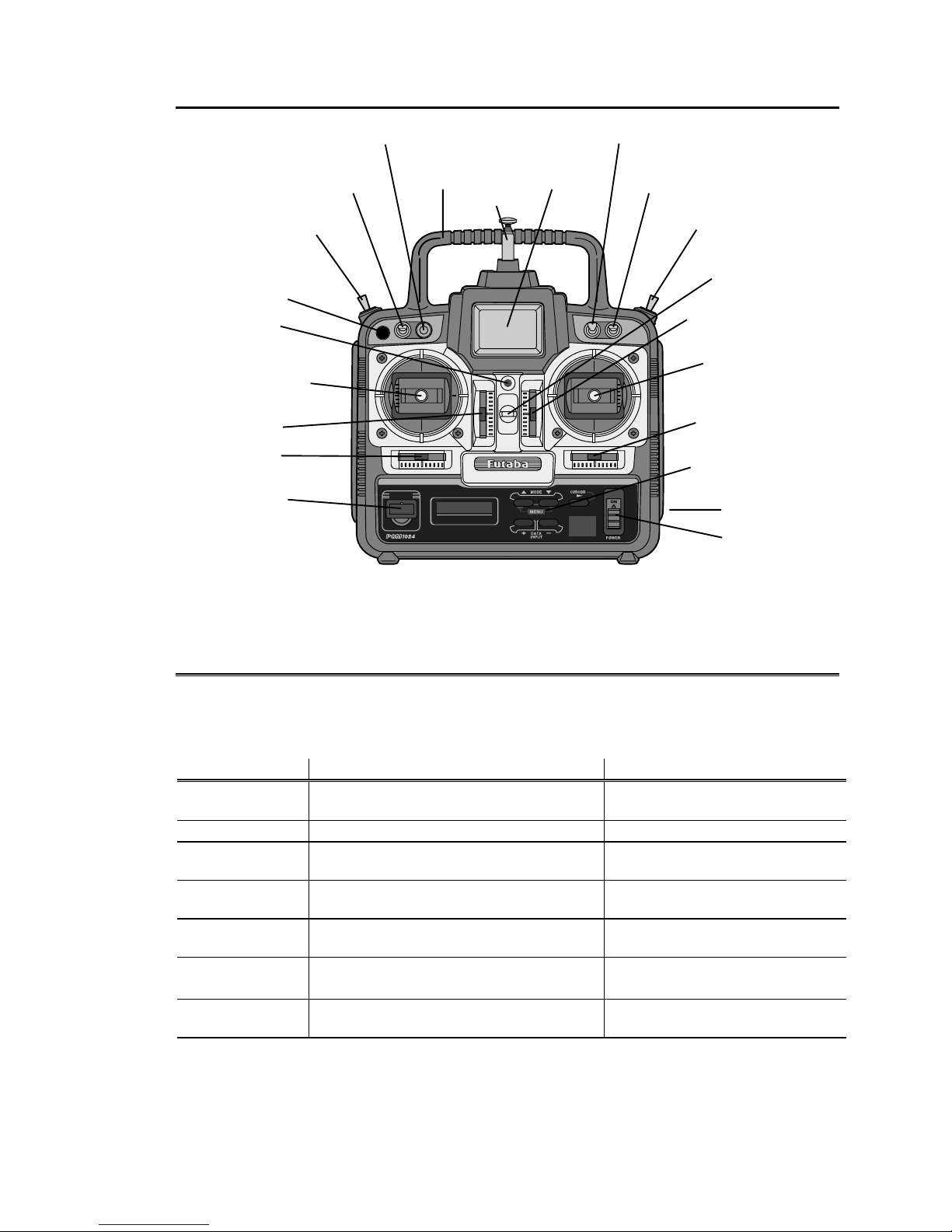

TRANSMITTER CONTROLS – AIRCRAFT (T6XAs System)

FUTABAFLIGHTCOMFORT NARROWBANDTECHNOLOGY

Elevator Dual

Rate Switch (A)

Flap Knob (Ch. 6)

Aileron Dual

Rate Switch (C)

Airbrake Switch (B)

Antenna

Landing Gear

Switch (Ch. 5,

Sw. E)

Elev -> Flap

Mixing Switch

(D)

Carrying

Handle

Liquid-Crystal

Display

Trainer Pushbutton Switch

ON indicator

light

Rudder / Throttle

Stick

Throttle Trim

Rudder Trim

Crystal Cover

Neckstrap Hook

Elevator Trim Lever

Aileron / Elevator

Stick

Aileron Trim Lever

Programming Keys

Charging Jack

On-Off Switch

X'TAL

T6XH

COMPUTER RADIO

PCM / PPM SELECTABLE

Fun to Fly

This figure shows the default assignments for a Mode 2 aircraft system as supplied by the factory.

SWITCH ASSIGNMENT TABLE

The functions activated by the switches and knobs for a Mode 2 transmitter are shown in the

table below. Note that some of the functions will not operate until activated in the mixing

menus. For a Mode 1 transmitter, elevator and throttle are reversed, as are switches D and E.

Switch / Knob ACRO HELI

Switch A

Up = Elevator Dual Rate 1;

Down = PMX1 & PMX2 on; Elev D/R 2

Up = Elevator Dual Rate 1;

Down = Elev D/R 2

Switch B

Down = Airbrake on Gyro sensitivity (if desired)

Switch C

Up = Aileron Dual Rate 1

Down = Aileron Dual Rate 2

Up = Aileron Dual Rate 1

Down = Aileron Dual Rate 2

Switch D

Forward = 2 -> 6 (Elev -> Flap) on Forward = Throttle Hold on, and

REVO off

Switch E

Landing Gear Forward = Idle-up on, Rudder

offset on, and REVO off

Switch F

(Push-button)

Trainer Trainer

CH6 knob

Flap or Flap trim if flaperon function

(FLPR) on

Hovering Pitch

– 3 –

Page 9

CHARGING THE Ni-Cd BATTERIES

1. Connect the transmitter charging cord into the charging socket (on the right of the case,

when facing the front) and airborne Ni-Cd batteries to the receiver connector on the

charger.

2. Plug the charger into a wall socket.

3. The charger’s LEDs should light, indicating charging current is flowing. The batteries

should be left on charge for about 15 hours.

Only charge the batteries with the charger supplied with

your system. The use of a fast charger may damage the batteries by overheating and

dramatically reduce their lifetime.

You should fully discharge your system’s batteries

periodically to prevent a condition called “memory.” For example,

if you only make two flights each session, or you regularly use only a small amount of the

batteries’ capacity, the memory effect can reduce the actual capacity even if the battery is

fully charged. You can cycle your batteries with a commercial cycling unit, or by leaving the

system on and exercising the servos by moving the transmitter sticks. Cycling should be

done every one to two months, even during the winter or periods of long storage. Keep track

of the batteries’ capacity during cycling; if there is a noticeable change, you may need to

replace the batteries.

NOTE: If you need to remove or replace the transmitter battery, do not pull on its wires to

remove it. Instead, gently pull on the connector’s plastic housing where it plugs in to the

transmitter.

Operating With The Trainer Cord

An optional training cord is available from your dealer. The cord may be used to help

a beginning pilot learn to fly easily by allowing a second transmitter, operated by an

experienced instructor, to be connected to this system. The instructor may override the

beginning pilot at any time to bring the model back under safe control. For training, the

T6XAs/ T6XHs transmitter may be connected to another T6XAs/XHs system, as well as to

any 4VF, 6VA Skysport, 6XA, Super 7, System 8, or 9Z series transmitter.

To use the trainer cord:

1. Set up both the student’s and instructor’s transmitters to have identical trim and control

motions. If the instructor’s transmitter is on a different frequency than the student’s, use

the student’s as the master transmitter and the other as the student’s.

– 4 –

Page 10

2. Set the student transmitter modulation mode to PPM. Collapse the student’s antenna, and

fully extend the instructor’s antenna. Remove the RF module from the transmitter held

by the student (if it is a module-type transmitter).

3. Plug one end of the trainer cord into each

transmitter, with power switched off. The trainer

jack is in the center of the rear face of the

transmitter. Do not force, the connector is keyed.

4. Turn on the instructor’s transmitter. DO NOT turn

on the student transmitter power. Move the controls

on the instructor’s transmitter, and verify each

control moves the proper direction. Now verify that

the student’s trims and control travels match the instructor’s by using the trainer button

and switching back and forth while leaving the control sticks and trims alone, then

moving the control sticks.

5. The instructor’s transmitter has normal control over the model unless the trainer button is

pushed, when the student’s has control. If control is lost, the instructor should release the

trainer button and resume controlling the model.

OTHER T6XAS/XHS ADJUSTMENTS

Adjustable length non-slip control sticks

You may change the length of the

control sticks to make your transmitter more

comfortable to hold and operate. To lengthen

or shorten your transmitter’s sticks, first unlock

the stick tip by holding locking piece B and turning stick tip A counterclockwise. Next,

move the locking piece B up or down (to lengthen or shorten). When the length feels

comfortable, lock the position by turning locking piece B counterclockwise.

Stick lever tension adjustment

You may adjust the stick tension of your

sticks to provide the “feel” that you like for

flying. To adjust your springs, you’ll have to

remove the rear case of the transmitter. Using a

screwdriver, remove the four screws that hold

the transmitter’s rear cover into position, and put them in a safe place. Gently ease off the

transmitter’s rear cover. You may wish to unplug the battery wire. Carefully rotate the rear

of the case you you have access to the rear of the sticks. Now you’ll see the view shown.

Using a small screwdriver, rotate the adjusting screw for each stick for the desired

spring tension. The tension increases when the adjusting screw is turned clockwise, and

– 5 –

Page 11

decreases for counterclockwise motion. When you are satisfied with the spring tensions, you

may close the transmitter. Very carefully reinstall the rear cover. When the cover is properly

in place, tighten the four screws.

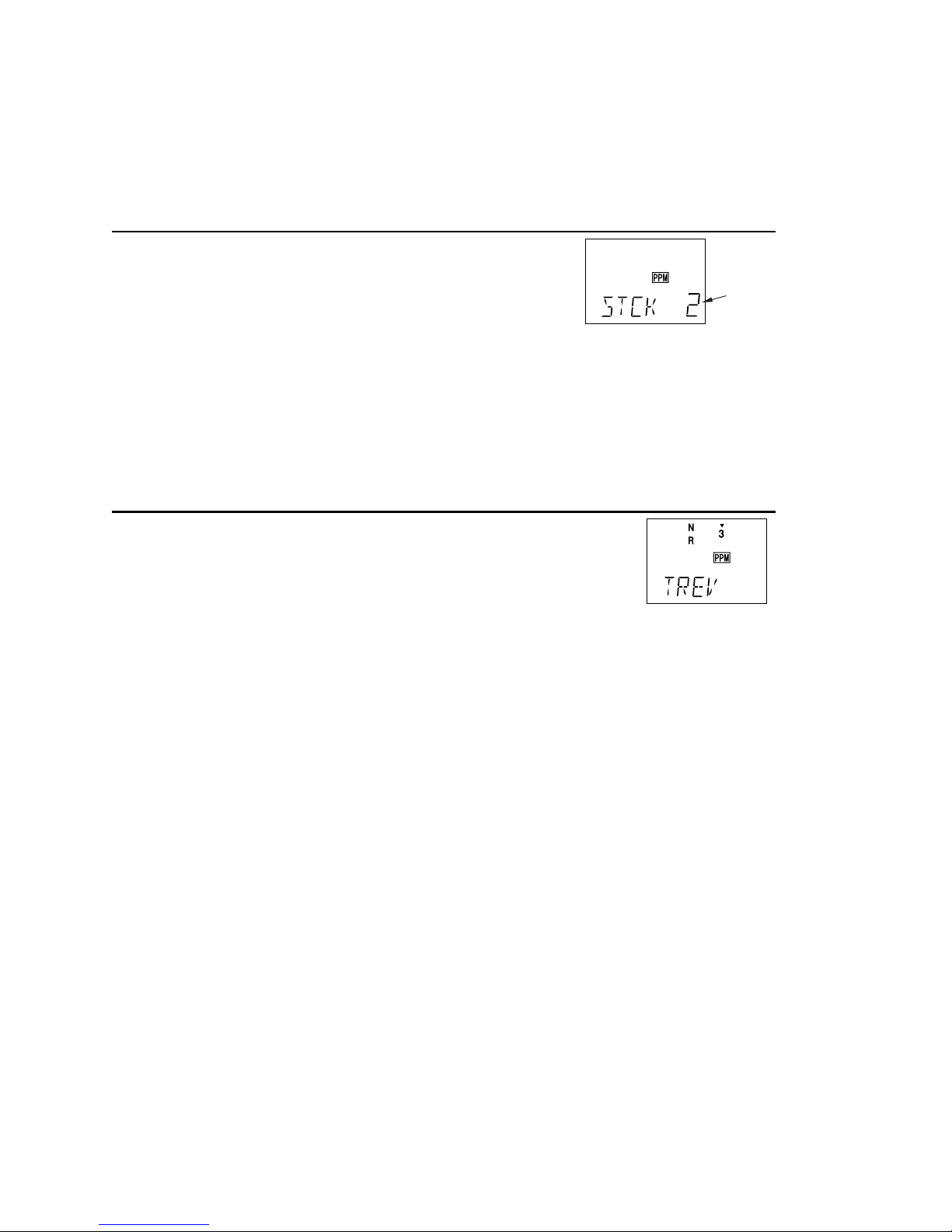

Changing the T6XAs/Hs transmitter’s mode

flashing

If you wish to change the mode of the transmitter, say

from mode 1 to mode 2, turn on the transmitter holding the two

MODE buttons down. You’ll see a display “STCK X,” where X

is a number representing the current transmitter mode. Press the

plus (+) or minus (–) DATA INPUT key to change the mode number as desired. You’ll see the

effect of you changes when you next turn on your transmitter. In some cases, you’ll have to

swap the throttle detent mechanism with the elevator centering mechanism. This can be done

by Futaba.

Reversing the throttle stick’s action

If for some reason you wish to reverse the action of the throttle

stick (for example, to get throttle trim at the top of the stick’s travel), you

may reverse it by turning on the transmitter holding the two MODE

buttons down, then pressing either of the MODE buttons to get to the

TREV menu. You may then use the (+) or (–) keys to switch between normal and reversed

functioning.

– 6 –

Page 12

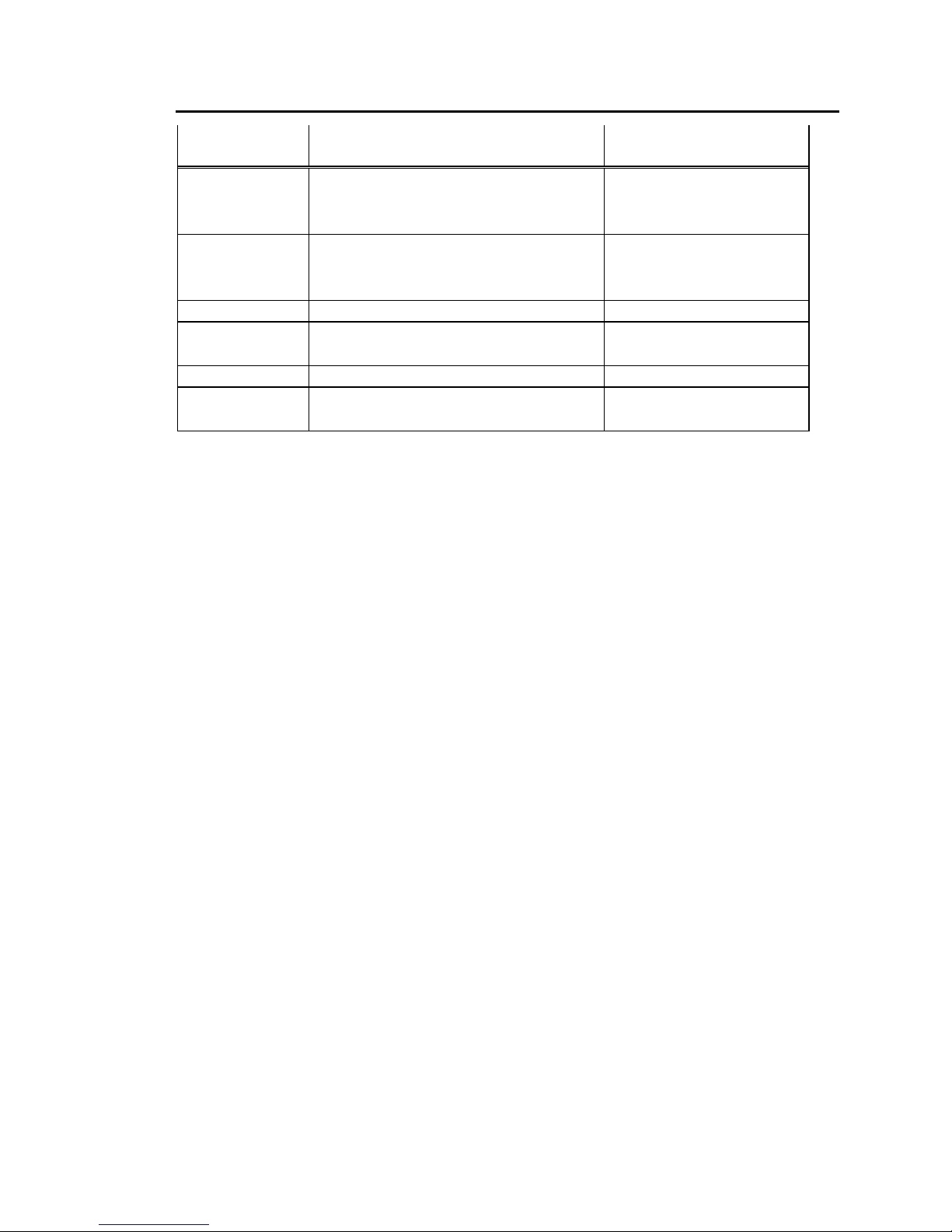

RECEIVER AND SERVO CONNECTIONS

Receiver output

channel

Aircraft

(ACRO)

Helicopter

(HELI)

1 Right aileron or

combined right flap + aileron

*

or

right elevon

†

(tailless)

Aileron

2 Elevator or

V-tail

‡

right side or

left elevon

†

(tailless)

Elevator

3 Throttle Throttle

4 Rudder or

V-tail

‡

left side

Rudder

5 Landing Gear Gyro sensitivity

6 Flap or

combined Left flap + aileron

*

Pitch

Multiple entries indicate that the servo function varies with the selected programming (*=FLPR mode,

†

=ELVN mode, ‡=VTAL mode). Outputs with no mixing functions are shown first.

The diagram below shows the default servo connections for a model using the ACRO

mode (only three or four servos are included in the T6XAs system). Two possible model

formats are shown on the ACRO contents page. Suggested helicopter connections are given

within the helicopter setup example.

– 7 –

Page 13

RADIO INSTALLATION

While you are installing the battery, receiver, and servos into your model’s fuselage, please

pay attention to the following guidelines:

Servo Notes

Mounting

Use the supplied rubber grommets when you mount each servo.

Be sure not to overtighten the screws. If any portion of the servo case

directly contacts the fuselage or the servo rails, the rubber grommets will not attenuate

vibration, which can cause mechanical wear and servo failure.

Servo Throw

Once you have installed the servos, operate each one over

its full travel and check that the pushrod and output arms do

not bind or collide with each other, even at extreme trim

settings. Check to see that each control linkage does not require undue force to move (if

you hear a servo buzzing when there is no transmitter control motion, most likely there is too

much friction in the control or pushrod). Even though the servo will tolerate loads like this,

they will drain the battery pack much more rapidly.

Switch Harness Installation

When you are ready to install the switch harness, remove the switch cover and use it as a

template to cut screw holes and a rectangular hole slightly larger than the full stroke of the

switch. Choose a switch location on the opposite side of the fuselage from the engine

exhaust, and choose a location where it can’t be inadvertently turned on or off during

handling or storage. Install the switch so that it moves without restriction and “snaps” from

ON to OFF and vice versa.

Receiver Notes

Antenna

DO NOT cut or coil the receiver antenna wire. It is normal for the

receiver antenna to be longer than the fuselage.

DO NOT cut it or fold it back on itself – cutting or folding changes

the electrical length of the antenna and may reduce range. Secure the antenna to the top of

– 8 –

Page 14

the vertical fin or the tailboom, and let the excess length trail behind the aircraft (be sure it

cannot tangle with the tail rotor on a helicopter).

You may run the antenna inside of a non-metallic housing within the fuselage, but range may

suffer if the antenna is located near metal pushrods or cables. Be sure to perform a range

check before flying. With the antenna collapsed, you should be able to walk 20 - 30 paces

from the model without losing control or seeing “jitter” in the servos.

Connectors

When you insert servo or battery connectors into the

receiver, note that each plastic housing has an alignment tab.

Be sure the alignment tab is oriented properly before

inserting the connector. To remove a connector from the

receiver, pull on the connector housing rather than the wires.

Using The Aileron Extension

If your aileron servo (or others) are located too far away

to plug into the receiver, use an aileron extension cord to

extend the length of the servo lead. Additional extension cords of varying

lengths are available from your hobby dealer or Futaba.

Vibration and Waterproofing

The receiver contains precision electronic parts. Be sure to avoid vibration, shock, and

temperature extremes.

For protection, wrap the receiver in foam rubber or other

vibration-absorbing materials. It’s also a good idea to waterproof the receiver

by placing it in a plastic bag and securing the open end of the bag with a rubber band before

wrapping it with foam. If you accidentally get moisture inside the receiver, you may

experience intermittent operation or a crash.

– 9 –

Page 15

Airplane Frequencies

The following frequencies and channel numbers may be used for flying aircraft in the U.S.:

72 MHz band

Ch. No. MHz 36 72.510

12 72.030 37 72.530

13 72.050 38 72.550

14 72.070 39 72.570

15 72.090 40 72.590

16 72.110 41 72.610

17 72.130 42 72.630

18 72.150 43 72.650

19 72.170 44 72.670

20 72.190 45 72.690

21 72.210 46 72.710

22 72.230 47 72.730

23 72.250 48 72.750

24 72.270 49 72.770

25 72.290 50 72.790

26 72.310 51 72.810

27 72.330 52 72.830

28 72.350 53 72.850

29 72.370 54 72.870

30 72.390 55 72.890

31 72.410 56 72.910

32 72.430 57 72.930

33 72.450 58 72.950

34 72.470 59 72.970

35 72.490 60 72.990

Installing your frequency number

indicator:

It’s very important that you display

your transmitting channel number at all times.

To install your indicator, peel off the channel

number’s backing sheet, and carefully stick

the numbers to both sides of the number

holder. Now you can snap the number holder

onto the lower portion of the antenna as

shown in the figure – use the clip that fits

more snugly on your antenna. You may wish

to cut off the other, unused clip on the

indicator.

– 10 –

Page 16

TRANSMITTER DISPLAYS & BUTTONS

When you first turn on your transmitter, the screen shown below appears on the LCD

display. Before flying, or even starting the engine, BE SURE that the model number appearing

in the lower right of the display matches the model that you are about to fly! If you don’t, servos

may be reversed, and travels and trims will be wrong, leading to an immediate crash. (If you

have trouble remembering which model memory to use, write them on a small piece of tape

affixed to the front of the transmitter.)

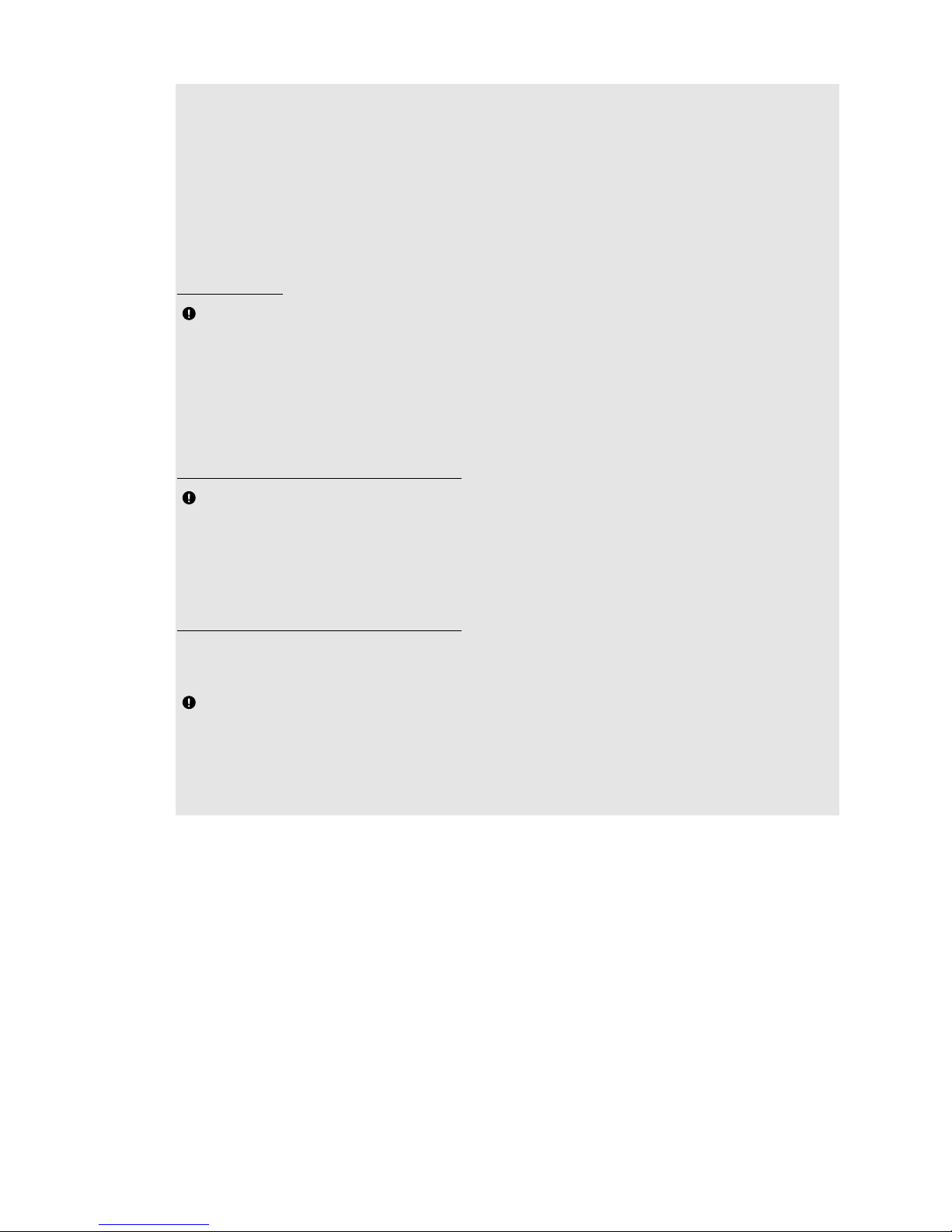

Startup Screen (appears when system is first turned on)

Modulation

indicator

PPM shown

Edit keys

Battery voltage

(Alarm goes off at 8.5V)

MODE keys - use to

select desired function

while programming

DATA INPUT keys - use

these to input numbers or

settings

Current model memory

Model 1 shown

Press these two

keys to enter the

programming

menu

CURSOR key - use to

step through menu and

select item to be set or

changed in the screen

– 11 –

Page 17

WARNING DISPLAYS

Your transmitter is designed to warn you about several potential problems that may occur,

including low battery voltage and switching on with mixing functions active. Each display has a

unique sound associated with it, as described below.

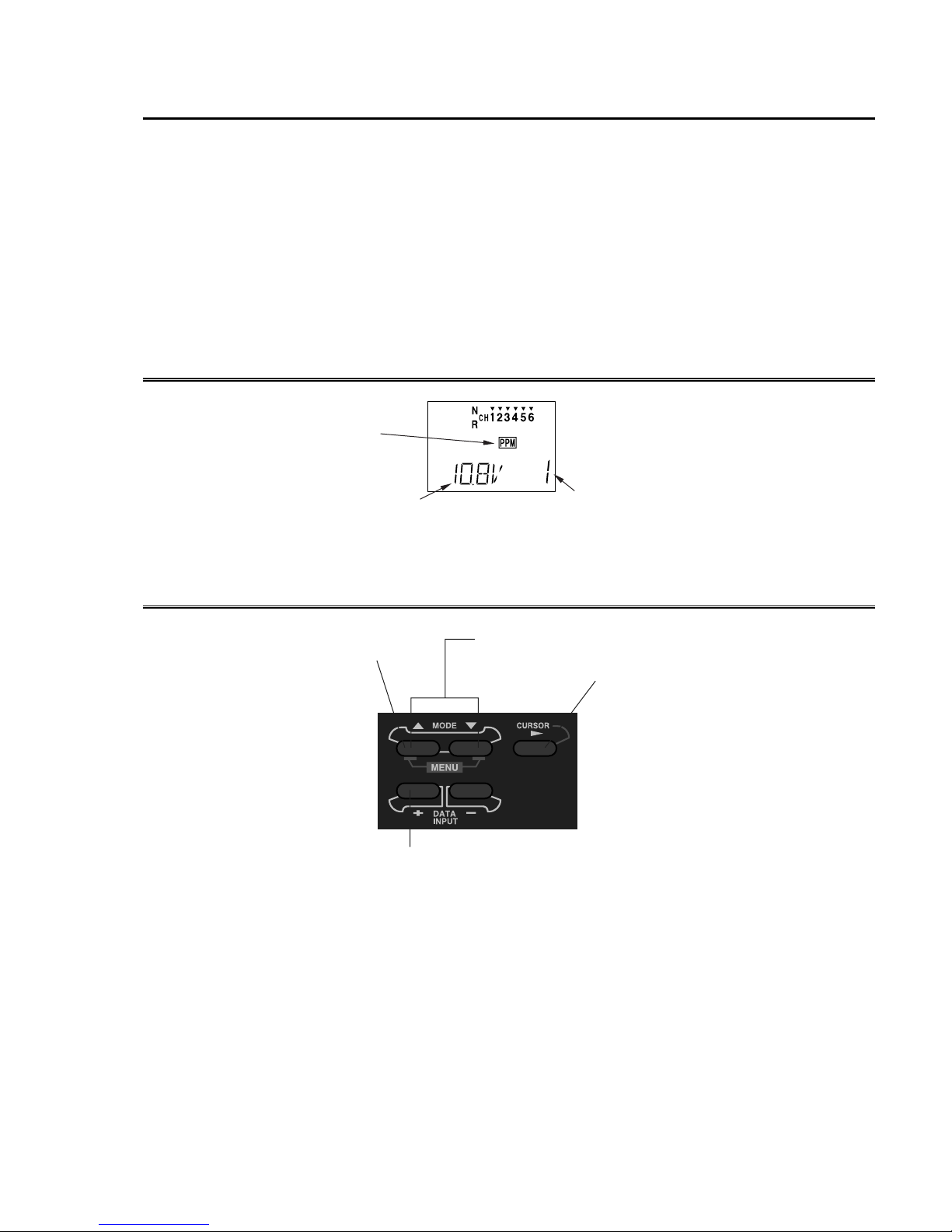

Low battery

The LOW BATTERY warning is displayed

flashing

when the transmitter battery voltage drops below

Warning sound: Beep beep beep —

(beeping does not stop

until transmitter is

turned off)

Backup error

Warning sound: Beep beep beep beep

(repeated)

Mixer warning

8.5V.

LAND YOUR MODEL AS SOON AS

POSSIBLE BEFORE LOSS OF CONTROL

DUE TO A DEAD BATTERY.

The BACKUP ERROR warning occurs when

the transmitter memory is lost for any reason. If

this occurs, all of the data will be reset when the

power is turned on again.

DO NOT FLY when this message is

displayed – all programming has been erased

and is not available. Return your transmitter

to Futaba for service.

flashing

Warning sound: beep beep beep pause

(repeated)

The MIXER warning is displayed to alert you

whenever you turn on the transmitter with any of

the mixing switches active. This warning will

disappear when the offending switch or control is

deactivated. At power-up, warnings will be

issued for the following switches:

ACRO: Airbrake

HELI: Throttle hold, idle-up

– 12 –

Page 18

Flying Safety

To ensure the safety of yourself and others, please observe the following precautions:

Ni-cd Battery

Charge the Batteries! Don't forget to recharge the batteries before each flying session. A battery low

in charge will soon die, causing loss of control and a crash. Plug in the charger that comes in this system

and hook up the transmitter and airborne batteries the day before a planned flying session. When you

begin your flying session, keep track of how long the system’s been used, and monitor the transmitter’s

voltage display. Quit flying long before your batteries become low.

On-field charging of your batteries with a field charger is not recommended. A fast-charger may

overcharge the Ni-Cd batteries, causing overheating and a premature failure.

Flying field

We recommend that you fly at a recognized model airplane flying field. You can find model clubs

and fields by asking your nearest hobby dealer, or contacting the Academy of Model Aeronautics.

Always pay particular attention to the flying field’s rules, as well as the presence and location of

spectators, the wind direction, and any obstacles on the field. Be very careful flying in areas near power

lines, tall buildings, or communication facilities as there may be radio interference in their vicinity. If

you must fly at a site that is not a club field, be sure there are no other modelers flying within a two-mile

range, or you may lose control of your aircraft.

Once you arrive at the flying field …

Before flying, be sure that the frequency you intend to fly with is not in use, and secure any

frequency control device (pin, tag, etc.) for that frequency before turning on your transmitter. Never

believe that it’s possible to fly two or more models on the same frequency at the same time. Even though

there are different types of modulation (AM, FM, PCM), only one model may be flown on a single

frequency.

When you are ready to fly your model, position the throttle stick to its low speed position, or do

whatever is necessary to command your motor NOT to run. Then, you may turn on the transmitter power

followed by the receiver power. When you have finished flying, begin by turning off the receiver power,

then turn off the transmitter power. If you do not follow these procedures, you may damage your servos

or control surfaces, flood your motor, or in the case of electric-powered models, the motor may

unexpectedly turn on and cause a severe injury.

Before starting the engine, fully retract the transmitter antenna, power up the transmitter and receiver,

and check to be sure that the servos follow the movement of the sticks. If a servo operates abnormally,

don’t attempt to fly until you determine the cause of the problem. We recommend that you range-check

your system before each flying session. Have an observer verify that the system works with the

transmitter about 30 paces away with the transmitter antenna collapsed. Finally, before starting the

engine, be sure to check that the transmitter model memory is correct for the chosen model, and (for PCM

receivers only) that the fail safe system functions properly when the transmitter is shut off.

While you’re getting ready to fly, if you place your transmitter on the ground, be sure that the wind

won’t tip it over. If it is knocked over, the throttle stick may accidentally move causing the engine to race

unexpectedly.

Before taxiing, be sure to extend the transmitter antenna to its full length. A collapsed antenna will

reduce your flying range and may cause a loss of control. It is a good idea to avoid pointing the

transmitter antenna directly at the model at all times, since the signal is weakest in that direction.

Don’t fly in the rain!

Water or moisture may enter the transmitter through the antenna or stick openings and cause erratic

operation or loss of control. If you must fly in wet weather during a contest, be sure to cover your

transmitter with a plastic bag or waterproof barrier.

– 13 –

Page 19

AIRCRAFT (ACRO) MENU FUNCTIONS

*Pages 14 to 42 describe the Basic Menu functions for fixed-wing aircraft, provide a

detailed setup example, and then describe the functions individually. Helicopter

functions may be found in the following section, pages 43 to 54.

Map of ACRO Menu Functions .................................................. 14

Aircraft Setup Example ............................................................... 15

Pattern Aircraft Trimming Chart................................................. 22

ATV............. Adjustable Travel Volume.................................... 24

D/R............... Dual Rates............................................................. 25

EXP Exponential Settings.................................................................... 26

REV ............. Servo Reverse ....................................................... 27

STRM .......... Subtrim.................................................................. 27

FLPR............ Flaperon (combined flaps & ailerons) .................. 28

FLTR............ Flap trim................................................................ 29

ABRK .......... Airbrake settings ................................................... 30

VTAL........... V-tail mixing......................................................... 31

ELVN........... Elevon mixing (tailless models)............................ 32

1 -> 4............ Rudder Coupling................................................... 33

6 -> 2............ Flap -> Elevator mixing........................................ 34

2 -> 6............ Elevator -> Flap mixing........................................ 35

PMX1, 2....... Programmable Mixer #1 & #2 .............................. 35

F/S................ Failsafe function (only in PCM mode) ................. 37

PARA........... Parameter menu..................................................... 38

RSET............ Trim Reset............................................................. 38

DRSW.......... Dual Rate Switch Select........................................ 39

ACRO .......... Acrobatic model mode.......................................... 39

HELI ............ Helicopter model mode......................................... 39

MOD............ Modulation (FM/PPM or PCM)............................ 40

COPY........... Data Copy ............................................................. 40

TMEM ......... Trim Memory........................................................ 41

MODL.......... Model select .......................................................... 42

– 14 –

Page 20

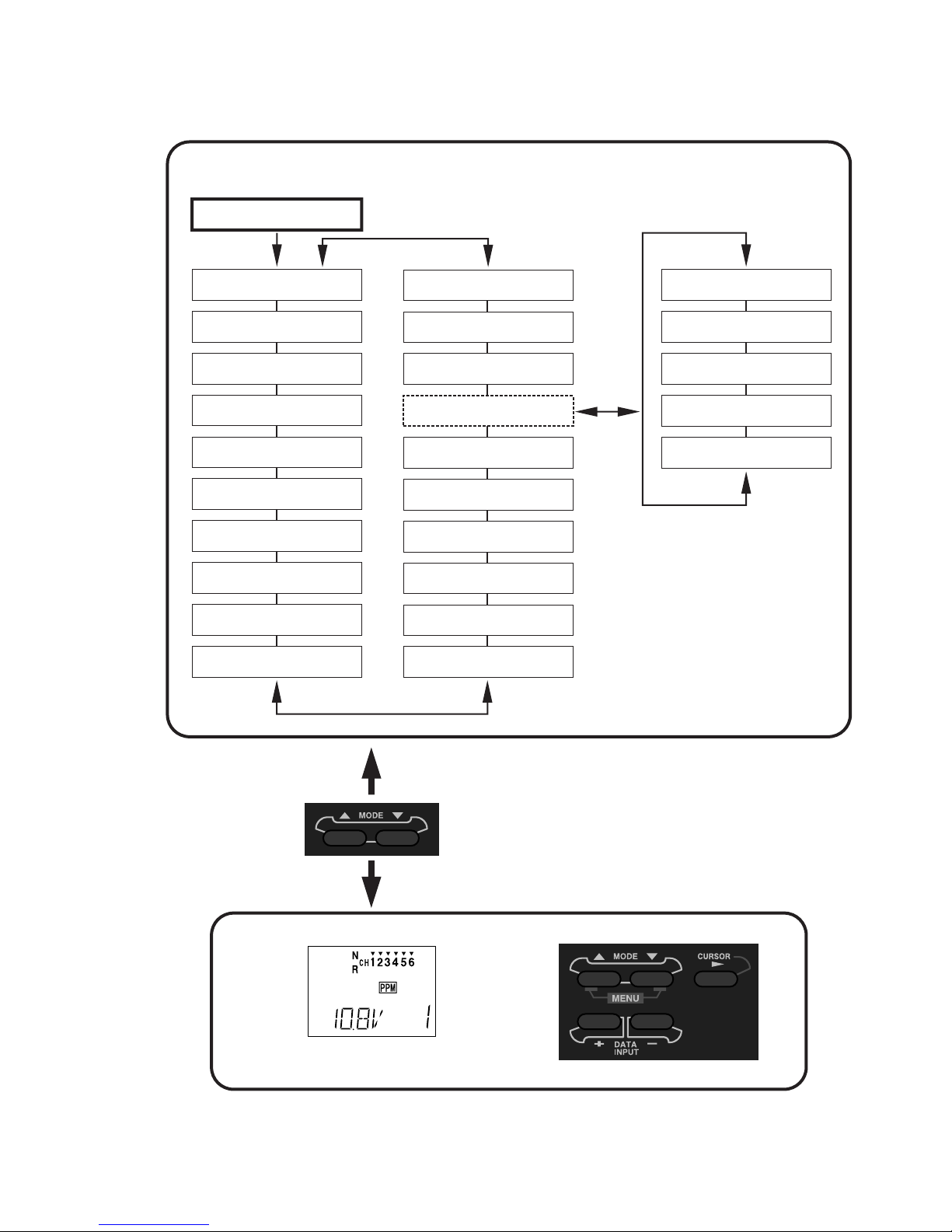

T6XAs/Hs Acro Mode Menu [ACRO]

Normal Display Mode

Press both Mode

Select keys

MAP OF ACRO AIRCRAFT FUNCTIONS

Throw Adjust [ATV]

Dual Rate Set [D/R]

Exponential [EXP]

Servo Reversing [REV]

Sub-Trims [STRM]

Flaperon Mix [FLPR]

Flap Trim [FLTR]

Airbrake [ABRK]

V-Tail Mix [VTAL]

Elevon Mix [ELVN]

Model Select [MODL]

Trim Memory [TMEM]

Copy Model [COPY]

Parameters [PARA]

Failsafe [F/S]*

Prog. Mix 2 [PMX2]

Prog. Mix 1 [PMX1]

Elev -> Flap Mix [2-6]

Flap -> Elev Mix [6-2]

Ail -> Rud Mix [1-4]

Memory Reset [REST]

Dual Rate Sw. [DRSW]

Select Model Type [ACRO]

Select Model Type [HELI]

Modulation: PCM or FM

[MOD C or F]

*Note: Failsafe menu

only appears in PCM

transmission mode.

Screen at Startup

To enter or leave

Menu, press both

MODE keys

simultaneously

– 15 –

Page 21

AIRCRAFT SETUP INSTRUCTIONS (GENERAL 120 CLASS STUNT PLANE)

The aircraft setup procedure presented

below uses a F3A-class model as an example

and assumes that there are two aileron servos,

one in each wing. You may use a similar

procedure to set up your own model, but your

setting’s numbers and percentages will

probably be different.

1. Be sure that all of your servos are plugged

into the proper receiver channels:

CH1 — Aileron (Right aileron*)

its memory number prominently near its onoff switch inside the fuselage.

3. Enter the Parameter (

pressing the down

PARA, p. 38) menu by

MODE key three times.

Press the key three times to select the ACRO

model type (four presses gets the HELI

function). Select ACRO by pressing both

DATA INPUT

appears, again press both

keys. When the flashing “SET”

DATA INPUT keys to

lock it in.

CH2 — Elevator

CH3 — Throttle

CH4 — Rudder

CH5 — Gear

CH6 — Flap (Left aileron*)

* = if FLPR activated

We recommend that you begin your

programming exercise with the servos

installed in the model and connected to the

respective control surfaces. This will enable

you to immediately see the effect of each

programming action we're about to take.

2. Turn on your transmitter and receiver, and

select the desired model memory. To do this,

enter the programming mode by pressing the

two

MODE keys, then press the down MODE

key until “

MODL” appears. Press the CURSOR

key and choose a vacant model memory with

the plus (+) and minus (–)

Select it by pressing the

“SET” is flashing, then press both the

INPUT

keys at once. The figure shows

DATA INPUT keys.

CURSOR key until

DATA

memory #1 being utilized.

flashing

The reason for the separate functions within

the

PARA setup is that these are seldom used,

and the parameter menu provides a convenient

way of bypassing them for most programming

operations.

WARNING: selecting a different model type

will erase the settings in the model memory.

BE SURE you’re in the correct model

memory before selecting a new model type.

4. If your receiver happens to be different

than the transmission mode (as shown it’s

PPM), continue to the modulation (

MOD, p.

40) menu to select the proper mode of

transmission (

and

C is for PCM). This should be set to

F is for FM/PPM transmission,

match your receiver. If you make a change, it

won’t take effect until you cycle the power off

and on again. So if you have changed

modulation, cycle power now.

There are a number of ways to keep track of

which model is in each memory. You may

attach a small piece of white tape to the

transmitter front and write the model's name

along with the model setup number, or you

may use a notebook, or label the model with

flashing

5. If your model has flaperons, turn on the

Flaperon function (FLPR, p. 28) in the menu.

To do this, press one of the

until “

CURSOR key to get the “INH” flashing, then

FLPR” appears in the display. Press the

activate by pressing the plus (+)

MODE buttons

DATA INPUT

– 16 –

Page 22

key (“ON” should appear flashing in the

display).

Connect the right aileron servo to receiver

CH1 and the left aileron servo to receiver

CH6.

Note that you can get differential by adjusting

the up and down motion of the two servos in

the

FLPR

menu. Now we’ll set the servo throw

directions.

6. Now we’ll check that each servo moves the

proper direction, and we’ll use the Reversing

function (

REV, p. 27) if they don’t.

aileron moves the right directions. The

display shows Channel 1 reversed.

7. Next we’ll set the direction of the elevator

servo, channel 2. When you move the righthand stick towards the BOTTOM of the

transmitter, the elevator should move up.

Check to make sure it moves the proper

direction! (More planes are crashed due to

reversed controls than for any other reason.)

flashing

We’ll start by setting the right aileron servo

direction. This is channel 1, and the ‘

1’

should be flashing for this command. When

you move the right-hand stick to the right, the

aileron on the right wing should move

upwards, and the aileron on the left should

move downward. Check that the right aileron

moves the correct way!

If it does not, activate the opposite direction

for the aileron servo by pressing the

INPUT

keys: the PLUS (+) key switches from

DATA

Reversed to Normal, and the MINUS (–) key

switches from Normal to Reversed. In the

display, ‘

N’ for Normal is chosen when the

little triangle is above the channel number,

and ‘

R’ for Reversed is chosen when the little

triangle is below the channel number. Move

the right-hand stick again and verify the right

If the elevator control moves the wrong

direction, move over to Channel 2 by pressing

the

CURSOR key. Now the ‘2’ should be

flashing in the display. Activate the opposite

direction for the elevator servo by pressing the

Minus (–)

DATA INPUT key. Move the right-

hand stick up-and-down again and verify the

elevator moves the right direction.

Now we’ll set the direction of the throttle

servo. When you move the left-hand stick

towards the BOTTOM of the transmitter, the

throttle should close, meaning that the hole in

the carburetor should close. Check to make

sure that the throttle lever on the engine

moves the proper direction!

If the throttle servo moves the wrong

direction, activate the opposite direction for

the throttle servo by pressing the

key. Now the ‘

3’ should be flashing in the

CURSOR

display. Activate the opposite direction for

– 17 –

Page 23

the throttle servo by pressing the Minus (–)

DATA INPUT key. Verify the throttle stick

makes the servo move the carburetor opening

in the correct direction.

8. Now we’ll set the direction of the rudder

servo. When you move the left-hand stick

towards the CENTER of the transmitter (to

the right), the trailing edge or rear rudder

should move to the right. Check to make

sure!

If the rudder moves the wrong direction,

activate the opposite direction by pressing the

Minus (–)

DATA INPUT key. Move the left-

hand stick left-and-right again and verify the

rudder moves the right direction.

12. Now we will set the servo neutrals.

Center all the trims – you can tell when each

is centered because you’ll feel a small

indentation at the center. Once you have

centered all the trims, unscrew the screws

holding the servo arms onto the elevator,

aileron, and rudder (we’ll set the throttle

travel later). You will want to place the servo

arms on the output shaft so they are near

neutral — that is, about 90° to the servo case

sides or, if the servo is mounted sideways, 90°

to the pushrod (sideways mounting is not

recommended). This way you won't run out

of subtrim authority. Remove all the arms

that are in the way or interfere with your

pushrods.

9. If your model has retracts, set the correct

response direction when commanded by the

retract switch, using the same approach.

10. If you’re using a second aileron servo,

you’ll now set the left aileron servo direction

(otherwise skip this and the next step). This is

channel 6, and the ‘

6’ should be flashing for

this command. When you move the righthand stick to the right, the aileron on the left

wing should move downwards. Check that

the left aileron moves the correct way! If it

does not, activate the opposite direction for

the aileron servo by pressing the

DATA INPUT

keys. Move the right-hand stick again and

verify the left aileron moves the proper

directions.

11. Go to the Flap Trim function (

FLTR), and

input a percentage of zero (0). Then press the

CURSOR key and activate the function. This

temporarily disables the flap knob so that you

can set aileron neutrals without regard to the

flap knob position. Later we’ll turn it back

on.

Pushrod

Adjust the clevises on each servo pushrod to

get the position of each control to be as close

as you can to neutral (lined up with the

adjacent portion of wing or tail).

13. Now we’ll set all the subtrims to

electronically set the desired neutral locations.

To do so, get to the

either

MODE SELECT button repeatedly until it

STRM menu by pressing

appears.

Set the right aileron subtrim first. If the little

arrow is not pointing at channel 1, press the

one of the

CURSOR buttons until it is (see

figure). Then, adjust the subtrim amount by

adding or subtracting with the

DATA INPUT

keys. When you have reached a place where

both ailerons match up with the fixed portion

of the wing, you are done. If you can’t get

– 18 –

Page 24

both to match up, then set the subtrim back to

zero and mechanically adjust the clevis to get

as close as you can, then readjust the subtrim

if necessary.

Note 1: you should NOT use subtrims instead

of mechanically adjusting the pushrods to be

close. This is because you can reduce the

travel of the radio, especially if you have to

set the subtrim near 100%. As we stated

before, get the pushrods close mechanically

first, then use the subtrim adjustment to get it

just right.

16. Repeat the subtrim adjustment with the

rudder, gear, and 2nd aileron channels. As

before, first set them mechanically, then

adjust the electronic settings. Be sure you

have selected CH4, CH5, or CH6 respectively.

17. Now we’ll go through and set the servo

travels for each channel. This is both helpful

and important, because you can set the throw

of each servo, in each direction, so that there

is no binding. Binding is important because it

causes very high current drain, and can lead to

a battery dying prematurely.

Note 2: if you mess up the number you’ve

entered or find the percentage the wrong

direction, you can get back to zero quickly by

pressing BOTH the

DATA INPUT keys

simultaneously.

14. Repeat the subtrim adjustment with the

elevator servo (Ch 2). First set the pushrod

length mechanically to get as close to neutral

as possible, then set the subtrim to get the

elevator lined up to be parallel with the

stabilizer portion. For full-flying surfaces, use

an incidence meter or another method to get

the incidence angle recommended by the kit

manufacturer or model designer.

15. For the throttle, we recommend not

setting a subtrim at this time. You will use the

trim tab on the transmitter for idle and

shutting off the motor, after the throw

adjustments are done. You can then set the

throttle subtrim with the STRM command.

The T6XAs/T6XHs automatically provides a

special function called Adjustable Travel

Limit. This function makes the trim work at

low throttle levels, but disables it at high

throttle. Most people set up their engines to

idle with the throttle trim near center, and

have the engine quit when they move the trim

to the bottom position. You’ll set this up later

in the Travel volume settings.

To set travels, get to the

pressing the

MODE SELECT button repeatedly

ATV menu by

until it appears. In sequence, we’ll set Right

aileron right travel, right aileron left travel, up

and down elevator travels, right and left

rudder travels, open and closed throttle

positions, and left aileron travels.

Changes to

"L/D" with AIL

stick motion

flashing

When you reach the ATV menu, you’ll see the

screen as shown. The channel indicator is

below numeral 1 for right aileron, the percent

symbol will be flashing, and you’ll notice that

you can change the

L/D indicator to R/U (or

vice versa) by moving the aileron (right) stick.

You are about to see that this is how you set

the travel directions independently for each

stick motion.

18. To set the RIGHT aileron motion, move

the aileron stick all the way to the right and

hold it. The letters “

R/U” should appear next

to the flashing percent sign, meaning you are

setting either Right or Up travel (with ailerons

it’s right or left only, but the display is set up

to use the same indicators for elevator and

throttle, thus the dual meanings for the

letters). Now if your servo is stalled or

binding, you’ll hear a buzzing sound. Hit the

minus

DATA INPUT key until the buzzing

stops. If the servo is not buzzing, leave the

setting at 100%. Choose a location on the

– 19 –

Page 25

servo arm so that the throw is adjusted in the

90-100% range.

19. To set the right aileron’s LEFT motion,

move the aileron stick all the way to the left

and hold it. The letters “

L/D” should appear

next to the flashing percent sign (as shown in

the figure above). Again listen and hit the

minus

DATA INPUT key until the buzzing

stops. If the servo is not buzzing, leave the

setting at 100%. You may wish to increase or

decrease this number depending on how

rapidly the model rolls to the left. One

possible setting is roughly 9/16” (14-15 mm)

travel in both directions. (Remember, you’re

only setting the right aileron if you have the

flaperon function turned on. You set the other

aileron’s travel in channel 6’s ATV.)

20. To set the UP elevator motion, press on

the

CURSOR

key until the indicator moves

underneath channel 2, as shown. Now move

the right stick all the way to the transmitter

bottom and hold it. The letters “

R/U” should

appear next to the flashing percent sign (as

shown in the figure above). Again listen for a

buzzing sound to indicate the servo is stalling,

and hit the minus

DATA INPUT key until the

buzzing stops. If the servo is not buzzing,

leave the setting at 100%. You may wish to

increase or decrease this number depending on

how tightly the model does an inside loop (or

whether it snap rolls when it shouldn’t).

Changes to

"L/D" with AIL

stick motion

flashing

21. Repeat the previous step for DOWN

elevator by moving the stick all the way to the

top of the transmitter, full “down” elevator.

Check for binding and adjust the percentage

as before. The elevator settings should be

adjusted so that the elevator travel is roughly

9/16” (15 mm).

22. To set the throttle position at IDLE, press

on the

CURSOR key until the indicator moves

underneath channel 3. Now move the throttle

stick all the way to the transmitter bottom and

hold it. The letters “

R/U” should appear next

to the flashing percent sign. Listen for a

buzzing sound to indicate the servo is stalling,

and hit the minus

DATA INPUT

key until the

buzzing stops. If the servo is not buzzing,

leave the setting at 100% or increase it as

necessary to fully close the throttle. You may

wish to increase or decrease this number

depending on whether you can shut off the

engine using throttle at idle and the trim tab.

23. To set the FULL throttle position, move

the throttle stick all the way to the transmitter

top and hold it. The letters “

L/D” should

appear next to the flashing percent sign.

[Notice that the T6XAs/XHs transmitter

thinks of throttle stick positions to the reverse

of the way it seems, in that with the throttle

stick fully forwards — “up” towards the

transmitter top, is the Down position.] Listen

for a buzzing sound to indicate the servo is

stalling, and hit the minus

DATA INPUT key

until the buzzing stops. If the servo is not

buzzing, leave the setting at 100% or change it

as necessary to fully open the throttle.

24. To set the RIGHT rudder motion, press

on the

CURSOR key until the indicator moves

underneath channel 4. Now move the left

stick all the way to the transmitter right and

hold it. The letters “

R/U

” should appear next

to the flashing percent sign. Listen for a

buzzing sound to indicate the rudder servo is

stalling, and hit the minus

DATA INPUT key

until the buzzing stops. If the servo is not

buzzing, leave the setting at 100%. You may

wish to increase or decrease this number

depending on how strongly the model reacts

when the rudder is deflected. Now move the

stick to the left side, and repeat the setting

procedure for left rudder. The rudder travel

should be set to roughly 45 degrees on both

sides.

23. In the same manner as described above,

be sure to set

ATV values for channels 5

(landing gear) and 6 (second aileron), if you

have either.

– 20 –

Page 26

If you wish to have the flaps operate with the

CH6 knob, go back to the

FLTR menu and

input a number greater than zero. Adjust the

number to get the desired amount of flap

travel as you turn the knob.

If you wish to have differential in your

flaperons, go to the flaperon menu and reduce

the number to something less than 100%. If

you choose 0%, you’ll get only up aileron

motion.

24. One more basic function that you will

find extremely useful is the trim memory

function. This is used after the model is

trimmed out and flying the way you like.

Unless you build perfectly, after test flying

and trimming one or more of the trim tabs will

be off-center. This is not a problem if you are

only flying one model with the T6XAs/XHs

transmitter and you never accidentally move

one or more of the trim tabs, but if you have

several models in memory or do accidentally

move on or more of the tabs, all the trims

could be different. The trim memory function

solves this problem by memorizing the offsets

for each model in memory.

To use the Trim Memory function, press on

the

MODE SELECT button until TMEM appears

on the menu. You will see the display shown.

Trim memory is quite easy to use: with the

trim tabs in the desired position, simply press

both

DATA INPUT keys at the same time, and

the trim positions are stored. Now, however,

you must move the trims back to their neutral

position, or else the offsets will be doubled,

and you don’t want that. Simply move the

tabs until you feel the detent at each one’s

center. If you do this with each of the models

stored in memory, you will know the model is

trimmed when the trims are centered. [Note

that the throttle trim position is not memorized

if you are in the

ATL mode. This is so you can

always use the trim to shut the motor off.

flashing

Resetting Trim Memory: if you want to zero

out the trim memory, you have to go to the

TMEM

setting menu, and observe the marks

over or under the channel numbers 1 2 4. If

the trim memory has a non-zero value

(meaning you memorized a trim setting), a

little triangle will appear over the

corresponding channel. Now move the trim

tab for that channel until the triangle

disappears — this is the nominal neutral trim.

Repeat for the other channel numbers. When

you've done all three, hit the

DATA INPUT keys

simultaneously, then center the trim tabs.

You've initialized the trims.

25. Aileron Dual Rate setting (D/R, p. 25).

You can use the dual rate function to reduce

the aileron and elevator travel in flight by

flipping one or two switches. Press a

SELECT

key repeatedly until the

D/R

MODE

menu

appears, as shown.

lower arrow

indicates

lower switch

setting

flashing

Dual rates are typically used to reduce a

model’s sensitivity, but they can also be used

to increase it.

To set the aileron dual rate (although this is

set for CH1, it affects both ailerons if the

flaperon function is active), move the arrow

by pressing the

CURSOR key until the little

arrow is under or over the numeral 1. Now

move the aileron D/R switch up or down,

noticing the position of the arrow. You can

set two dual rates, one for each switch

position. By pressing the

DATA INPUT keys,

you can add or subtract from the numerical

value displayed. Note that you may pick a

value anywhere from 0% to 120% (120% is

larger than the normal amount, so if you do

this be careful not to exceed servo travel limits

and cause stalling or excess current drain). If

– 21 –

Page 27

you quickly want to get back to the default

100%, press both

DATA INPUT keys

simultaneously. We suggest using an initial

value of 75%, which will limit the aileron

travel to roughly 7/16” (11 mm).

NOTE: if you set the dual rate to 0%, you will

have ZERO CONTROL AUTHORITY when

the switch is in that position. DON’T DO IT!

26. Elevator dual rate setting: press the

CURSOR key one time to get the little arrows

above or below the numeral 2. Now set the

elevator dual rates in the same way you set the

ailerons. Adjust the up elevator travel to be

about 15/32” (12 mm) and the down elevator

travel to 17/32” (13 mm).

travel so that there is minimal trim change

when the airbrake switch is operated.

Press the

MODE SELECT button until the ABRK

window appears, as shown. The default is for

the airbrake mode to be inhibited, as shown.

To activate, press the

“

INH” is flashing, then press the (+) key.

Set mode with

DATA INPUT

keys:

+ = Activate

- = Inhibit

CURSOR

key until the

Now press the CURSOR

key one time, and the

percent symbol will flash. You may input the

amount of offset for the elevator (the arrow

should be under the numeral

2) at this time.

This should be set from -7% to -10% (-10% is

the default setting).

27. There is an option on the T6XAs/XHs

which allows you to put both dual rate

switches on the aileron D/R switch, or to keep

them on separate switches. This option is the

second item located in the

PARA menu.

If you choose the ‘2’ option as shown, both

dual rates will be operated by the aileron dual

rate switch. If you choose the ‘

1’ option, the

two D/Rs will operate off their individual

switches. We suggest the ‘

2’ option as it’s

one less switch to keep track of.

28. Airbrake (

ABRK, p. 30): an airbrake effect

is obtained by raising both ailerons (or

dropping the flaps) and adding elevator to

trim. This high-drag configuration makes the

landing approach steeper to help make safe

landings in small fields. With this function, it

is possible to lose some aileron effectiveness

so test the airbrake effect at altitude before

trying it on a landing approach. You should

spend some time fine adjusting the elevator

Press the

CURSOR key one more time, and

you may now input the CH6 setting. The rates

may vary considerably for different models,

but for initial settings choose the flap rate to

be (+)50-55%.

OFF side

ON side

AIR BRAKE

ON or OFF indicates

Airbrake switch position.

Increase or decrease

amount of travel with

DATA INPUT keys

29. Failsafe settings: we recommend that you

set the Fail Safe function (

F/S, p. 37) to move

the throttle to idle if interference is

experienced. Note that the failsafe function

only operates in the PCM transmission mode.

30. 2->6 Mixing: you may couple elevator to

flaps for tighter corners in the elevator-to-flap

mixer (2 -> 6, p. 35). Get to the

then activate it by pressing the

2->6 menu,

CURSOR key,

then the (+). Pull up elevator and verify that

the flaps go down. If they go the wrong

direction, reverse them by pressing the (+) or

– 22 –

Page 28

(–) keys until they do go the right direction.

Then press the

CURSOR key again, and the

percent indicator will flash. Now you may

input the percentage of mixing. Start out with

10-20% and increase it until the corners in

your loops are square enough.

31. Programmable mixers: now take

advantage of your system’s custom

programming capabilities. You may use

programmable mixers (

PMXI or PMX2, p. 35)

to get rid of unwanted tendencies (for

example, pitching up during knife-edge flight.

For pitching during knife-edge, you want to

apply up or down elevator when you are using

full rudder to sustain knife-edge. Thus, the

master channel is rudder, and the slave is

elevator.

To program this mixing, first get to the

window. Press the

CURSOR key once, then

press the (+) to activate it (a flashing

OFF

will appear, depending on the position of

PMXI

ON or

the Elev D/R switch, which turns mixer #1 on

and off).

little arrow is under the numeral 2, indicating

CH2 (elevator) is the slave channel.

Now, you’ll define the mixing direction. If

your model pitches up with knife edge, you’ll

want to input down elevator for rudder going

both directions. Move the rudder stick to one

side and see which way the elevator moves; if

incorrect, press the

press the

DATA INPUT keys until it moves

CURSOR key once, then

down. Repeat this by moving the rudder stick

to the other side. You’ll end up with a plus

sign for one rudder direction, and minus for

the other direction.

Finally you may input the amount of elevator

mixing on both sides by pressing the

CURSOR key, then the (+) or (–) keys until a

small amount of mixing has been assigned.

Repeat this by moving the rudder stick to the

other side and verifying that the numbers

match for both directions.

Be sure you understand how to use the Elev

D/R to switch to turn the mixer on and off,

since you won’t want this mixing on during

normal flight, only during knife-edge. Later,

after you fly the model you may fine tune the

amount of elevator travel so that the pitching

tendency is eliminated.

Next, press the

the

DATA INPUT key until the little arrow is

CURSOR key once, then press

over the numeral 4, indicating CH4 (rudder) is

the master channel. Press the

once, then press the

DATA INPUT key until the

CURSOR key

The sky’s the limit — you’ll enjoy using your

T6XAs/XHs system!

Pattern Aircraft Flight Trimming Chart

The following chart may be used to systematically set up and trim a model for straight flight and

aerobatic maneuvers. Please note that for best results, trimming should be done in near-calm

conditions. Before you decide to make a change, be sure to try the test several times before

making adjustments. If any changes are made, go back through the previous steps and verify

that they are not also affected. If they are, make further adjustments as necessary.

To test for … Test Procedure Observations Adjustments

1. Control

neutrals

Fly the model straight and

level

Use the transmitter trims for hands-off

straight & level flight.

Change electronic subtrims or

adjust clevises to center

transmitter trims.

– 23 –

Page 29

2. Control throws Fly the model and apply full

deflection of each control in

turn

3. Decalage Power off vertical dive

(crosswind if any). Release

controls when model vertical

(elevator trim must be neutral)

4. Center of

Gravity

5. Tip weight

(coarse

adjustment)

6. Side Thrust &

Warped Wing

7. Up/Down

Thrust

8. Tip weight

(fine adjustment)

9. Aileron

differential

Method 1: Roll into near

vertically-banked turn.

Method 2: Roll model inverted

Fly model straight & level

upright. Check aileron trim

maintains level wings. Roll

model inverted, wings level.

Release aileron stick.

Fly model away from you into

any wind. Pull it into a

vertical climb, watch for

deviations as it slows down.

Fly the model on normal path

into any wind, parallel to strip,

at a distance of around 100

meters from you (elevator trim

should be neutral as per Test

3). Pull it into a vertical climb

& neutralize elevator

Method 1: fly the model as per

Test 6 and pull into a

reasonably small diameter

loop (one loop only)

Method 2: fly the model as per

Test 6 and then push into an

outside loop (one only, fairly

tight)

Method 1: fly model toward

you & pull into a vertical

climb before it reaches

you. Neutralize controls,

then half-roll the model.

Method 2: fly model on

normal pass and do three or

more rolls

Method 3: fly the model

straight and level and

gently rock the aileron

stick back and forth

Check the response of each control

• Aileron high-rate: 3 rolls in 4 seconds;

low-rate: 3 rolls/6 sec

• Elevator high-rate: to give a smooth

square corner; low-rate gives approx.

130 ft diameter loop

• Rudder: high-rate 30-35° for stall

turns; low rate maintains knife-edge

A. Model continues straight down

B. Model starts to pull out (nose up)?

C. Model starts to tuck in (nose down)?

A1. Nose drops

B1. Tail drops

A2. Lots of forward stick (down

elevator) required to maintain level

flight

B2. No forward stick (down elevator)

required to maintain level flight, or

model climbs

A. Model does not drop a wing.

B. Left wing drops.

C. Right wing drops.

A. Model continues straight up.

B. Model veers left

C. Model veers right

D. Model rolls right

A. Model continues straight up

B. Model pitches up (goes toward top of

model)

C. Model pitches down (goes toward

bottom of model)

A. Model comes out with wings level

B. Model comes out right wing low

C. Model comes out left wing low

A. No heading changes

B. Heading change opposite to roll

command (i.e. heading veers left

after right roll)

C. Heading change in direction of roll

command

A. Roll axis on model centerline

B. Roll axis off to same side of model

as roll command (i.e. right roll, roll

axis off right wing tip)

C. Roll axis off to opposite side of

model as roll command

A. Model flies straight ahead without

yawing

B. Model yaws away from roll

command (i.e. right roll, yaw left)

C. Model yaws towards roll command

(i.e. right roll, yaw right)

Change ATV (for high rates),

and Dual Rate settings (for

low rates) to achieve desired

responses.

A. No adjustment

B. Reduce incidence

C. Increase incidence

A. Add weight to tail

B. Add weight to nose

A. No adjustment

B. Add weight to right tip.

C. Add weight to left tip.

A. No adjustment

B. Add right thrust

C. Reduce right thrust

D. Put trim tab under left

wing tip *

A. No adjustment

B. Add down thrust

C. Reduce down thrust

A. No adjustment necessary

B. Add weight to left tip

C. Add weight to right tip

A. Differential settings OK

B. Increase differential

C. Decrease differential

A. Differential settings OK

B. Increase differential

C. Decrease differential

A. Differential settings OK

B. Increase differential

C. Decrease differential

– 24 –

Page 30

10. Dihedral Method 1: Fly the model on

normal pass and roll into

knife-edge flight; maintain

flight with top rudder (do this

test in both left & right knifeedge flight)

Method 2: Apply rudder in

level flight

11. Elevator

alignment (for

models with

independent

elevator halves)

12. Pitching in

knife-edge flight

*Trim tab is 3/16” x 3/4” x 4” trailing edge stock, placed just in front of aileron on bottom, pointed end forward.

Fly the model as in Test 6 and

pull up into an inside loop.

Roll it inverted and repeat the

above by pushing it up into an

outside loop.

Fly the model as in Test 10 A. There is no pitch up or down

A. Model has no tendency to roll

B. Model rolls in direction of applied

rudder

C. Model rolls in opposite direction in

both tests

A. No rolling tendency when elevator

applied

B. Model rolls in same direction in both

tests — halves misaligned.

C. Model rolls opposite directions in

both tests. One elevator half has

more throw than the other (model

rolls to side with most throw).

B. The nose pitches up (the model

climbs laterally)

C. Nose pitches down (model dives

laterally)

A. Dihedral OK

B1. Reduce dihedral

B2. Use mixer to produce

aileron opposing rudder

travel (start with 10%)

C1. Increase dihedral

C2. Mix ailerons with rudder

direction 10%

A. Elevators in correct

alignment

B. Either raise one half, or

lower the other

C. Reduce throw on one side,

or increase throw on the

other.

A. No adjustment needed

B. Alternate cures:

1) move CG aft;

2) increase incidence;

3) droop ailerons;

4) mix down elevator with

rudder

C. Reverse ‘B’ above

– 25 –

Page 31

ATV — Adjustable Travel Volume

ATV

The

function is used to set (or limit) the travel of each servo, and may

be set independently between a value of 10% and 120% for each travel

direction. At a 100% setting, the throw of the servo for full stick motion is

approximately 40° for channels 1 – 4 and approximately 55° for channels 5 – 6. Reducing the

percentage settings reduces the total servo throw in that direction. The

ATV

function is normally

used to prevent any servos from binding at the ends of their travel.

Setting ATV values on your system:

1. Enter the programming mode, and get to the

ATV

screen with the up or

down arrow keys. The channel indicator is below numeral 1 for ailerons,

the percent symbol will be flashing, and you’ll notice that you can change

the L/D indicator to R/U (or vice versa) by moving the aileron (right) stick.

In Steps 2 & 3 you will see how you set the travel directions independently for each stick (or

knob or gear switch) motion.

2. To set the RIGHT aileron motion, move the aileron stick all the way to the right and hold it.

The letters “R/U” should appear next to the flashing percent sign, meaning you are setting

either Right or Up travel (with ailerons it’s right or left only, but the display is set up to use