Page 1

1M23N23002

3PL-2.4G

3-channel, FHSS

Radio control system

for Cars

INSTRUCTION MANUAL

Digital Proportional R/C System

R

Page 2

Thank you for purchasing a Futaba FHSS 3PL 2.4GHz system.

This system is based on the combination of the newly developed 2.4GHz transmitter

and its corresponding receiver. Before using your 3PL 2.4GHz system, read this manual

carefully and use your R/C set safely.

After reading this manual, store it in a safe place.

FHSS 3PL 2.4GHz system

• 2.4GHzSS (Spread Spectrum) radio communication system

• Frequency channel setting unnecessary: Sifting the channels within the 2.4GHz band automatically, this

system minimizes the interference from other 2.4GHz system.

• Accepts no unwanted signals by using ID code

• Built-in antenna (T3PL-2.4G transmitter)

Application, Export, and Modification

1. This product may be used for models only. It is not intended for use in any application other than the

control of models for hobby and recreational purposes.

2. Exportation precautions:

(a) When this product is exported from the country of manufacture, its use is to be approved by the laws

governing the country of destination concerning devices that emit radio frequencies. If this product is

then re-exported to other countries, it may be subject to restrictions on such export. Prior approval of the

appropriate goverment authorities may be required. If you have purchased this product from an exporter

outside your country, and not the authorized Futaba distributor in your country, please contact the seller

immediately to determine if such export regulations have been met.

(b) Use of this product with other than models may be restricted by Export and Trade Control Regulations,

and an application for export approval must be submitted.

3. Modification, adjustment, and replacement of parts: Futaba is not responsible for unauthorized

modification, adjustment, and replacement of parts on this product. Any such changes may void the

warranty.

Compliance Information Statement (for U.S.A.)

This device, trade name Futaba Corporation of America, model number R2004GF, complies with part 15 of

the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation.

The party responsible for this device's compliance is:

3002 N Apollo Drive Suite 1, Champaign, IL 61822 U.S.A.

TEL (217)398-8970 or E-mail: support@futaba-rc.com (Support)

TEL (217)398-0007 or E-mail: service@futaba-rc.com (Service)

Battery Recycling (for U.S.A.)

The RBRCTM SEAL on the (easily removable) nickel-cadmium battery contained in Futaba

products indicates that Futaba Corporation of America is voluntarily participating in an

industry program to collect and recycle these batteries at the end of their useful lives, when

taken out of service within the United States. The RBRC

alternative to placing used nickel-cadmium batteries into the trash or municipal waste system, which is

illegal in some areas.

You may contact your local recycling center for information on where to return the spent battery. Please

call 1-800-8-BATTERY for information on Ni-Cd battery recycling in your area. Futaba Corporation

of America's involvement in this program is part of its commitment to protecting our environment and

conserving natural resources.

RBRCTM is a trademark of the Rechargeable Battery Recycling Corporation.

TM

program provides a convenient

Page 3

Table of Contents

Safety Precautions ............................. 4

Definition of Symbols ............................................................ 4

2.4GHz System Precautions ................................................. 4

Operation Precautions .......................................................... 5

Storage and Disposal Safety Precautions ........................... 6

Other Safety Precautions ...................................................... 7

Before Operation ................................ 8

System Contents .................................................................... 8

Nomenclature / Handling ....................................................... 9

Assembly / Adjustment ..................... 12

Receiver and Servo Connection ......................................... 12

Receiver Antenna Installation ............................................. 12

Assembly Precautions ........................................................ 13

How to Link Transmitter and Receiver ............................... 14

Transmitter Set-Up Procedures .......................................... 15

3PL-2.4G Functions ........................... 16

Steering Trim (TRM-CH1) ..................................................... 16

Throttle Trim (TRM-CH2) ...................................................... 16

Steering Dual Rates (D/R-CH1) ........................................... 16

Model Selection/Model Reset (MDL) .................................. 17

Steering Servo Reversing (REV-CH1) ................................ 17

Throttle Servo Reversing (REV-CH2) ................................. 17

Channel-3 Servo Reversing (REV-CH3) ............................. 17

Channel-4 Servo Reversing (REV-CH4) ............................. 17

Steering End Point Adjustment (EPA-CH1) ....................... 18

Throttle End Point Adjustment (EPA-CH2) ........................ 18

Channel-3 End Point Adjustment (EPA-CH3) .................... 18

Channel-4 End Point Adjustment (EPA-CH4) .................... 19

ABS function (ABS-CH2) ..................................................... 19

Model Name (NAME) ............................................................ 19

4WS/BRK Mixing Selection (SMX) ...................................... 19

Channel-4 Trim (TRM-4) ....................................................... 20

Throttle Fail Safe Function .................................................. 20

MC230CR/MC330CR ............................................................ 21

Safety

Precautions

Before

Operation

Assembly /

Adjustment

3PL-2.4G

Functions

Function

Map

Reference

Function Map .................................... 22

*Each function is easily selected with the SELECT key and set with the digital trim DT1/DT2.

Reference .......................................... 24

Ratings .................................................................................. 24

Troubleshooting ................................................................... 25

Error Displays ...................................................................... 26

When Requesting Repair .................................................... 27

Warning: This product contains a chemical known to cause cancer and birth defects (or

other reproductive harm).

3

Page 4

Safety Precautions

For your safety as well as that of others, please read this manual thoroughly prior to

installation and operation of your digital proportional R/C system.

Definition of Symbols

The following defines the symbols used in this manual.

Explanation of Symbols

DANGER

n

WARNING

n

CAUTION

n

Procedures which may lead to a dangerous condition and cause death or

serious injury to the user if not carried out properly.

Procedures which may lead to a dangerous condition or cause death or

serious injury to the user if not carried out properly, or procedures where

the probability of superficial injury or physical damage is high.

Procedures where the possibility of serious injury to the user is small, but

there is a danger of injury, or physical damage, if not carried out properly.

Explanation of Graphic Symbols

Indicates an operation that prompts a warning (including Caution).

n

Indicates an operation that must not be performed.

l

Indicates an operation that always must be performed.

j

2.4GHz System Precautions

WARNING

n

Do not cover/hold the built-in antenna part of T3PL-2.4G transmitter by your hand during

l

running. Do not put any conductive plate/sticker on the antenna part.

Otherwise, the operating range may become shorter.

Do not perform the linking procedure when motor's main wire is connected or the engine is

l

operating as it may result in serious injury.

While the linking is done, please cycle receiver power and check if the receiver to be linked

j

is really under the control of the transmitter to be linked.

Always use R2004GF under 6.0V NiCd battery or regulated output from your ESC.

j

Using dry cell batteries may cause malfunction.

Be sure that when using an ESC's regulated output, the capacity of the ESC meets your

usage condition.

In order to maintain complete control of your car/boat it is important that it remains visible

j

at all times. Running behind large objects is not suggested. Doing so may result in the

reduction of the quality of the radio frequency link to the model.

4 Safety Precautions

Page 5

Operation Precautions

WARNING

n

When using a Ni-cad battery to power your system, always charge and check the battery

j

voltage prior to operation. Should the battery discharge below the minimum voltage level,

control will be lost.

Prior to operation always perform a range test. Even one abnormality in the R/C system

j

may cause loss of control.

[Range Test Procedure]

Have a friend hold the model, or place it on a stand where the wheels or prop cannot come

in contact with any object. Operate from a distance of about 100 feet. Be sure to check the

movement of each servo to make sure it follows the movement of the steering wheel and

throttle trigger. If the servos do not follow the commands from the transmitter or any type of

interference is detected, Do Not operate the model.

Never operate in the rain or run through puddles.

l

The transmitter, receiver, batteries and most servos and speed controls are not waterproof.

Contact with any type of moisture or immersion in water or snow will cause damage along

with possible loss of control. Should any type of moisture enter any component of the system, immediately stop using the R/C system and return it to our service center for inspection.

Do not operate when visibility is limited.

l

Should you lose sight of the model, a collision or other dangerous situation may occur.

Do not operate near people or roads.

l

Do not operate on any pond when boats are present.

Do not operate near high tension power lines or communication broadcasting antennas.

Prior to the operation of any model, be sure the area you plan to use is safe. Be aware of

all objects that may be in the path of your model. Do not operate the model where people

or any type of moveable object could stray in the path of your model. Control loss due to

interference, component failure, loss of sight or low battery voltage could result in serious

injury to yourself and others as well as damage to your model.

Do not operate when you are tired, not feeling well or under the influence of alcohol or

l

drugs.

Your judgment is impaired and could result in a dangerous situation that may cause serious

injury to yourself and others.

(Turning on the power switches)

j

Always check the throttle trigger on the transmitter to be sure it is at the neutral position.

1. Turn on the transmitter power switch.

2. Turn on the receiver or speed control power switch.

(Turning off the power switches)

Always be sure the engine is not running or the motor is stopped.

1. Turn off the receiver or speed control power switch.

2. Then turn off the transmitter power switch.

If the power switches are turned off in the opposite order the model may unexpectedly run

out of control and cause a very dangerous situation.

Safety Precautions

5

Page 6

Make all adjustments to the radio control system with the engine not running, or the electric

j

motor disconnected.

If the engine is running or the motor is connected while adjustments are made, the model

may run out of control.

Remove the main battery source from electric powered models when they are not being

j

used.

Should you accidentally leave the receiver switch on, the model could run out of control.

(Fail safe function)

j

Before running (cruising), check the fail safe function.

Check Method:

Before starting the engine, check the fail safe function as follows:

1. Turn on the transmitter and receiver power switches.

2. Turn off the transmitter power switch.

3. Check if the fail safe function moves the servos to the preset position when reception fails.

The fail safe function is a safety feature that minimizes set damage by moving the servos

to a preset position when reception fails. However, if set to a dangerous position, it has the

opposite effect.

Setting example: Throttle idle or brake position

Do not touch the engine, motor, speed control or any part of the model that will generate

l

heat while running.

Touching hot parts will result in serious burns.

CAUTION

n

When the charger is not in use, disconnect it from the outlet. This will prevent accidents,

j

overheating and short circuits.

Storage and Disposal Safety Precautions

WARNING

n

At the end of a day's operation, store the system with NiCd battery discharged. Be sure to

j

recharge the system before it is used again.

You should fully discharge your system's batteries periodically to prevent a condition called

"memory". For example, if you only make two runs in a day or you regularly use a small

amount of a battery's capacity, the memory effect can reduce the actual capacity even if

the battery is charged for the recommended amount of time.

Do not throw a Ni-cad battery into a fire. Do not disassemble or attempt to repair a Ni-cad

l

battery pack.

Overheating, damage and acid leakage may lead to burns, loss of eyesight as well as numerous other types of injuries. The electrolyte in Ni-cad batteries is a strong alkali. Should

you get even the smallest amount of the electrolyte in your eyes, Do Not rub, wash immediately with water, and seek medical attention at once. The electrolyte can cause blindness. If

electrolyte comes in contact with your skin or clothes, wash with water immediately.

Do not leave the radio system or models within the reach of small children.

l

A small child may accidentally operate the system. This could cause a dangerous situation

6 Safety Precautions

Page 7

and injuries. NiCd batteries can be very dangerous when mishandled and cause chemical

damage.

CAUTION

n

Do not store your R/C system where it will be exposed to the following conditions.

l

s%XTREMEHEATORCOLDNESS

s$IRECTSUNLIGHT

s7HEREHUMIDITYISHIGH

s7HEREVIBRATIONISPREVALENT

s7HEREDUSTISPREVALENT

s7HERETHEREISSTEAMANDCONDENSATION

Storing your R/C system under adverse conditions could cause deformation and numerous

other problems with operation.

If the system will not be used for a long period of time, remove the batteries from the model

j

and store in a cool, dry place.

If the batteries are left in the model, electrolyte may leak and damage the model.

<NiCd Battery Recycling>

A used NiCd battery is valuable resource. Insulate the battery terminals and dispose of the battery by taking

it to a battery recycling center.

Other Safety Precautions

CAUTION

n

When operating two or more models at the same time, have a third person act as a spotter.

j

They will be in charge of safety and you should follow their instructions.

Beginners should receive instructions regarding safety and operation from an experienced

j

modeler.

Always use only genuine Futaba transmitters, receivers, servos, and electronic speed

j

controls, along with other optional parts and components.

Futaba will not be held responsible for damages caused by other than genuine Futaba

parts and components. Use only genuine Futaba parts and components listed in the instruction manual and catalog.

Do not short circuit the Ni-cad battery terminals.

l

Short circuiting the terminals will lead to sparks and overheating and could cause a fire and

burns as well.

Do not expose plastic parts to fuel, motor spray, waste oil or exhaust.

l

The fuel, motor spray, waste oil and exhaust will penetrate and damage the plastic.

<NiCd Battery Electrolyte>

The electrolyte in NiCd batteries is a strong alkali. Should you get even the smallest amount of the

electrolyte in your eyes, DO NOT RUB. Wash immediately with water and seek medical attention at once.

The electrolyte can cause blindness. If electrolyte comes in contact with your skin or clothes, wash with

water immediately.

Safety Precautions

7

Page 8

Before Operation

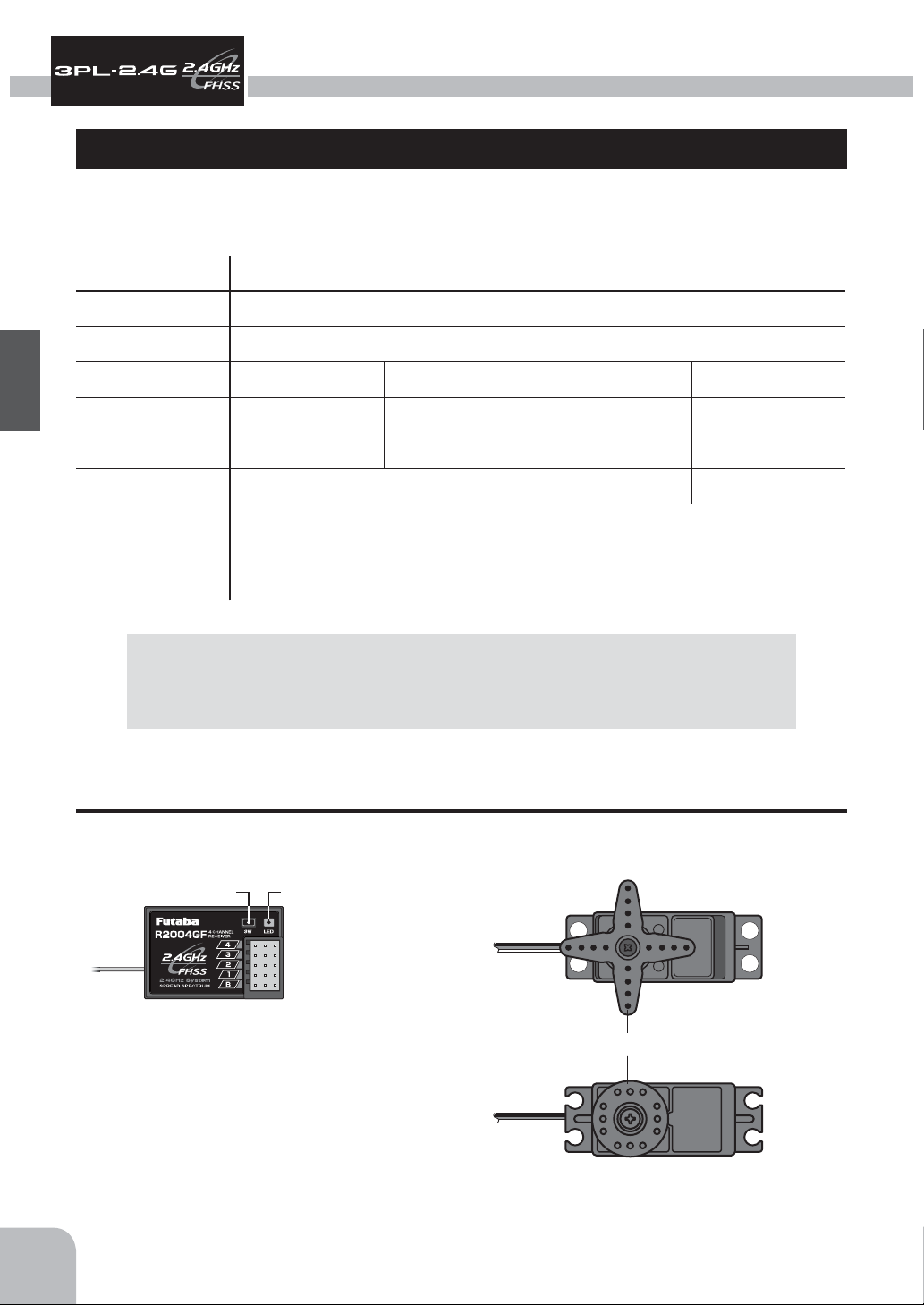

System Contents

After opening the container, check the contents for the following items. The contents will

vary with the system purchased.

3PL-2.4GHz System Contents

Transmitter

Receiver

Servo

E.S.C.

Switch

Miscellaneous

NOTE: This Futaba FHSS system, including the T3PL-2.4G transmitter and

R2004GF receiver, does not work with current Futaba FASST™ systems. Please

use the T3PL-2.4G and R2004GF in pairs. Futaba FASST™ systems and FHSS

system are not compatible.

----- S3003 (x2) S3003 (x1) S3050 (x1)

----- -----

SSW-GS (x1) ----- -----

*Servo mounting hardware and servo horns (only w/servo set)

T3PL-2.4G (x1)

R2004GF (x1)

MC230CR or

MC330CR (x1)

Mini Screwdriver

MC330CR (x1)

Receiver R2004GF

Link Switch LED

Connectors

"4" : Channel-4 Servo (CH4)

"3" : Channel-3 Servo (CH3)

"2" : Throttle Servo (CH2)

"1" : Steering Servo (CH1)

"B": Power connector

8 Before Operation

Servo S3003/S3050

Mounting

Servo Horn

Flange

Page 9

Nomenclature / Handling

Transmitter T3PL-2.4G

Steering Trim Lever (DT1)

Adjusts the steering in small increments so

the model will run straight.

Throttle Trim Lever (DT2)

Adjusts the throttle in small increments so the

model will not move at neutral.

LCD screen

Power switch turned on: Beep confirmation

sound is generated and the model name is

displayed for about two seconds and then

the initial screen appears.

(Initial screen)

'y number display

'!!y voltage display

Power Switch

When slid upward,

the power is turned on.

Channel 3 Switch

Turn channel 3 servo to left

or right.

Grip Handle

(*1)

(*1)

WARNING

n

As with all radio frequency

j

transmissions, the strongest area

of signal transmission is from

the sides of the antenna(builtin). As such, the antenna (arrow

direction) should not be pointed

directly at the model.

Antenna (Built-in)

The antenna is inside of this part.

Select Button

Press the Select button to select the

desired function screen.

Steering Wheel

Turn model to left or right.

Throttle Trigger

Control the speed of the model and movement

forward and backward.

Steering Dual Rate Lever (D/R)

Adjust the vehicle's steering sensitivity across

the entire range.

(*1)

(*1)

Digital trim DT1, DT2, and D/R operation

Push the lever to the left or right (up or down).

The current position is displayed on the LCD screen for about two seconds.

Each step is indicated by a tone. When the trim exceeds the maximum trim

adjustment range, the beep tone will change and the servo will not move

any further. Remember, the trims are digital so the position of each trim is

remembered for each model separately.

WARNING

n

Do not cover/hold the built-in antenna part of T3PL-2.4G transmitter

l

by your hand during running.

Do not put any conductive plate/sticker on the antenna part.

Otherwise, the operating range may become shorter.

Before Operation

9

Page 10

Battery Replacement Method

CAUTION

n

(4 AA size batteries)

Remove the battery cover from

the transmitter by sliding it in the

1

direction of the arrow in the figure.

Remove the used batteries.

2

Load the new AA size batteries.

Pay very close attention to the

3

polarity markings and reinsert

accordingly.

Slide the battery cover back onto

4

the case.

Always be sure you reinsert the

j

batteries in the correct polarity order.

If the batteries are loaded incorrectly ,

the transmitter may be damaged.

When the transmitter will not be used

j

for any short or long period of time,

always remove the batteries.

If the batteries do happen to leak , clean

the battery case and contacts thoroughly. Make sure the contacts are free of

corrosion.

Check:

Turn the power switch on the transmitter

to the ON position. Check the battery

voltage display on the LCD screen.

If the voltage is low, check the batteries

for insufficient contact in the case or

incorrect battery polarity.

Low Battery Alarm:

If the transmitter battery voltage drops

below 4.2V an alarm will sound and

"LOW" will be displayed on the LCD

screen.

The low battery alarm is meant to be

a safety feature only. Do NOT operate

your radio below 4.5V. Always shut your

radio off as soon as possible after the

low battery warning tone to avoid loss of

control.

10 Before Operation

Page 11

E.S.C. MC230CR / MC330CR

Checker LED

Pushbutton

switch

MC230CR/MC330CR

Power switch

Applicable motors

(Number of turns is criteria.)

•Use the MC230CR with a motor with 20T or more turns.

•Use the MC330CR with a motor with 13T or more turns.

*If a motor with a number of turns smaller than the above is used, the heat

protector and overcurrent protection circuit may operate. The number of turns

of the motor is one criteria only. Depending on the running conditions, the

protection circuit may operate even if the condition above is satisfied.

(Orange)

(Blue)

(Black)

Motor connector

Connects to the motor.

(Orange) is positive. (Blue) is negative.

If the motor rotates in the wrong

direction, reverse the connections.

Nicd battery connector

Connects to the running Nicd battery.

(Red)

(Red) is positive. (Black) is negative.

Nicd battery 6~7 cells (7.2~8.4V)

Receiver connector

Connects to the receiver throttle channel.

Miniature screwdriver

Accessory. Use to press the

pushbutton switch.

Before Operation

11

Page 12

Assembly / Adjustment

Receiver and Servo Connection

As you connect the receiver, servos and other components, do so in accordance with the

"Assembly Precautions".

Connections when an E.S.C. MC230CR or MC330CR is used.

Connects to Motor

Connects to Battery

E.S.C.

Power Switch

(CH4)

(CH2)

(CH3)

Channel 4 Servo

Channel 3 Servo

Receiver

Gas Powered Model

Receiver

To Receiver

Battery

Power Switch

(CH1)

(CH4)

(CH3)

(CH2)

(B)

(CH1)

Steering Servo

Channel 4 Servo

Channel 3 Servo

Throttle Servo

Steering Servo

Receiver Antenna Installation

Install the R2004GF receiver on the car as follows:

Note: The operating range may become shorter, depending on where the

receiver and the antenna are mounted.

Antenna

tube

Antenna

WARNING

n

Install the antenna in the higher place as shown in the figure.

j

Keep the antenna as far away from the motor, ESC and other

noise sources as possible.

Put the antenna in the antenna tube to protect it.

Do not cut the antenna.

l

Do not bend the coaxial cable. Doing so causes damage.

12 Assembly / Adjustment

Coaxial

cable

R2004GF

Page 13

Assembly Precautions

WARNING

n

Check the receiver, servos, and battery connectors, to be sure they are firmly connected.

j

If a connector is not fully inserted, vibration may cause the connector to work loose while

the model is operating. This will result in loss of control.

Operate each servo horn over its full stroke and check to see that the linkage does not bind

j

or is not too loose.

Excessive force applied to the servo horn by binding or poor installation may lead to servo

problems and result in loss of control.

(Electric Cars and Boats)

j

Isolate the receiver from vibration by attaching to the chassis or mounting plate with thick

double sided tape.

(Gas Powered Cars and Boats)

Isolate the receiver from vibration by wrapping it in foam rubber or similar type cushioning

material. Protect the unit from water damage by placing it in a plastic bag or waterproof radio box.

The receiver contains precision electronic parts. These parts are vulnerable to vibration and

shock. Any contact with moisture (water or condensation) may cause receiver malfunction

and loss of control.

Keep all devices that emit high frequency noise, such as motors, batteries, and wiring

j

that handles heavy current loads, at least 1/2 inch away from the receiver and the receiver

antenna.

High frequency noise will cause a decrease in operating range and could cause loss of

control.

Install electronic speed control heat sinks as well as other components that conduct

j

electricity so they cannot come in contact with aluminum, carbon fiber or other materials

that conduct electricity.

If, for example, the speed control came loose while the model was running and touched an

aluminum chassis, a short circuit may occur that would cause irreparable damage to the

system as well as loss of control.

Noise suppression capacitors should be installed on almost all motors.

j

If the proper capacitors are not installed, high frequency noise will reduce range and cause

loss of control along with various other problems.

Inspect all linkage installations and any point where metal could come in contact with other

j

metal parts. Make sure these parts do not touch other metal parts under vibration.

Should a linkage or other metal parts come in contact with other metal parts under vibration, the high frequency noise generated by this contact will cause interference and possible loss of control.

CAUTION

n

Do Not disassemble any part of this system that is not specified in the instruction manual.

l

Futaba will not be responsible for any damage due to improper disassembly of any part of

the radio control system.

Assembly / Adjustment

13

Page 14

How to link the transmitter and the receiver

Each transmitter has an individually assigned, unique ID code. In order to start operation,

the receiver must be linked with the ID code of the transmitter with which it is being

paired. Once the link is made, the ID code is stored in the receiver and no further linking

is necessary unless the receiver needs to be used with another transmitter. (For T/R set,

the link is already done at factory.)

Link procedure

Bring the transmitter and the receiver close

to each other, within one meter.

1

Turn on the transmitter and the receiver.

2

Push and hold the Link Switch of the

3

receiver.

When the link is complete, the LED in the

4

receiver changes to solid green.

*Please refer the table below for LED status vs receiver's condition.

Link Switch LED

LED status vs receiver's condition:

No signal reception Red : On

Receiving signals Green: On

Receiving signals, but ID is unmatched. Green: Blink

14 Assembly / Adjustment

Page 15

Transmitter Set-Up Procedures

*When making these setting adjustments, do so with the motor disconnected or

the engine not running.

(Preparations)

Select the model memory that is not used and reset it to the initial values with the model

selection and model reset functions.

Model Selection Model Reset

Model number

(1 - 0)

Model name

(Selection key)

Servo Horn Installation Instructions

Connect the receiver, servos, and other components and then

1

turn on the power switches to the transmitter and receiver.

*Both servos will move to the neutral position.

At this time install the servo horn in the manner described in

2

the instruction manual provided with the model this system

will be used in.

Reversing The Servo Operation Direction

Should the servo operate in the opposite

direction required for your application, reverse

the direction with the servo reversing.

E.S.C. MC230CR / MC330CR

Push the DT2 lever up or down

for about one second.

All data stored in the current

selected model memory is

erased.

Steering Servo Reverse

NOR: Normal

REV: Reverse

Throttle Servo Reverse

NOR: Normal

REV: Reverse

(Selection key)

(Selection key)

NEUTRAL, HIGH, AND BRAKE MAX POINTS SETTINGS

Set the steering angle adjustment function (ATV) to

100% and the ABS function and acceleration function

to OFF using the transmitter throttle channel function.

If the steering angle is too large or the ABS and acceleration

functions are on, erroneous operation may occur.

Before setting each point, set the transmitter throttle channel trim to neutral.

Turn on the power in transmitter -> amp order.

1

Transmitter throttle operation

(Pushbutton switch operation) (Checker LED)

*When using the ABS function, after setting up

the MC230CR / MC330CR, stop the reverse

function, then turn on the ABS function. If the

ABS function is on, the MC231CR / MC331CR

cannot be set up correctly.

MC230CR /MC330CR

2

Neutral point

setting

N

・Neutral state

・Press the pushbutton switch.

(0.5 secs or longer)

(Confirmation beep sounds)

・Continuous single blink

3

High point

setting

Full High

・Full high state

N

・Press the pushbutton switch.

(Confirmation beep sounds)

・Continuous double blink

4

Brake MAX

point setting

* Since the data is read at the end of setting of all points, the points cannot be set independently.

* If the amp power was turned off during setting, the setting points cannot be memorized. (The previous settings are retained.)

* The confirmation beep sounds only when the motor was connected.

N

・Full brake state

Full brake

・Press the pushbutton switch.

(Confirmation beep sounds.)

・If the LED goes out,

setting is complete.

Assembly / Adjustment

If the LED does not go off

but blinks rapidly, setting

was not performed

normally. Repeat setting

from "Neutral point

setting".

・Continuous rapid blink

15

Page 16

3PL-2.4G Functions

(

)

Steering Trim (TRM-CH1)

Steering neutral adjustments can be made by moving the Steering trim

Steering Trim

knob to the left or right.

Racers Tip

When you install a servo, always check to be sure the servo is at its neutral

(L25 - 0 - R25)

position. Adjust the servo horn hole position and linkage so both are parallel.

When a servo saver is used, place it as close to center position as possible. Be

sure the steering trim on the transmitter is at the neutral position.

Trim Operation And Maximum Travel

Changing the trim can affect the overall settings. When

adjustments are made with the trims, recheck your installation

Servo Saver

Direct Servo Saver Horn

90° 90°

Parallel

for maximum travel. (Steering EPA right side and left side).

When Trim usage is extreme

If it takes most of your trim movement to get a servo to the neutral position, reposition

the servo horn or servo saver on the servo and inspect your linkage installation.

Throttle Trim (TRM-CH2)

Throttle neutral adjustments can be made moving the throttle trim to the

left or right.

Racers Tip

When using an electronic speed control, set the throttle trim to neutral

and make adjustments to the speed control. On a gas powered model, set

the trim to neutral and adjust the linkage to the point where the carburetor

is fully closed in accordance with the engine instruction manual.

Throttle Trim

(B25 - 0 - F25)

Trim Operation and Travel

Trim adjustments will affect the overall servo travel. Check the brake

side (backward) movement when changes are made.

When trim movement is extreme

If you use most of the trim movement to get the servo to the neutral

position, recenter the servo horn closer to the neutral position and

inspect your throttle linkage.

Steering Dual Rates (D/R-CH1)

Use this function to adjust the steering travel of your model. If the

model understeers (push) while cornering, add steering by pressing the

upper side of the D/R button. When the model oversteers (loose), take

away steering by pressing the lower side of the D/R button.

• This function can not be used when 4WS mixing is activated.

16 3PL-2.4G Functions

Carburetor Fully Closed

(Drum Type)

Slide Type

Steering D/R

(30 - 100%)

Page 17

Model Selection/Model Reset (MDL)

The model selection selects the desired model memory from the 10 model memories

stored within the transmitter, and the model reset erases all data stored in a specific model

memory.

Model Selection Model Reset

Push the DT2 lever up or down

Model number

(1 - 0)

Model name

(Selection key)

for about one second.

All data stored in the current

selected model memory is

erased.

Steering Servo Reversing (REV-CH1)

This function reverses the rotation direction of

the Steering servo.

When the trim position deviates from the

center, the deviation will be on the opposite

side when the servo is reversed.

Throttle Servo Reversing (REV-CH2)

This function reverses the rotation direction of

the throttle servo.

When the trim position deviates from the

center, the deviation will be on the opposite

side when the servo is reversed.

Channel-3 Servo Reversing (REV-CH3)

This function reverses the rotation direction of

the channel-3 servo.

Steering Servo Reverse

NOR: Normal

REV: Reverse

(Selection key)

Throttle Servo Reverse

NOR: Normal

REV: Reverse

(Selection key)

Channel-3 Servo Reverse

NOR: Normal

REV: Reverse

(Selection key)

Channel-4 Servo Reversing (REV-CH4)

(This setting screen is displayed when 4WS mixing or Brake mixing is activated.)

This function reverses the rotation direction of

the channel-4 servo.

Channel-4 Servo Reverse

NOR: Normal

REV: Reverse

When the trim position deviates from the

center, the deviation will be on the opposite

side when the servo is reversed.

3PL-2.4G Functions

(Selection key)

17

Page 18

Steering End Point Adjustment (EPA-CH1)

Use this function to limit the servo

movement to the left or right. The

servo travel to each side can be

independently adjusted. This

feature will compensate for any

difference in right or left turning

angles or radius due to the

characteristics of your model.

WARNING

n

Be sure that the steering linkage does not bind or come in contact with any

j

suspension parts or arms. If unreasonable force is applied to the servo, the

servo may be damaged and result in loss of control.

Throttle End Point Adjustment (EPA-CH2)

This function is used to adjust the

forward and brake side servo

travel. Each direction can be

adjusted independent of each

other. Use this feature to set the

throttle servo travel.

WARNING

n

Steering EPA

Range: 0 - 120%

(Left side) (Right side)

Adjust the travel of the servo

while operating the steering

wheel each way.

Throttle EPA

Range: 0 - 120%

(Forward side)

Adjust the travel of the servo

while operating the throttle

trigger each way.

(Brake side)

Be sure that your throttle linkage does not apply excessive force to the servo.

j

If your linkage installation causes an unreasonable amount of force to be

applied to the servo, the servo may be damaged and result in loss of control.

Channel-3 End Point Adjustment (EPA-CH3)

Use this function to limit the servo

movement to the left or right. The

servo travel to each side can be

independently adjusted.

WARNING

n

Be sure that the linkage does not bind or come in contact with any parts

j

or arms. If unreasonable force is applied to the servo, the servo may be

damaged and result in loss of control.

18

3PL-2.4G Functions

Channel-3 EPA

Range: 0 - 120%

Adjust the travel of the servo

while operating the channel-3

switch each way.

(Left side) (Right side)

Page 19

Channel-4 End Point Adjustment (EPA-CH4)

(This setting screen is displayed when 4WS mixing or Brake mixing is activated.)

Use this function to limit the servo

movement to the left or right. The

servo travel to each side can be

independently adjusted.

WARNING

n

Be sure that the linkage

j

does not bind or come in

contact with any parts or

arms. If unreasonable force

is applied to the servo, the

servo may be damaged and

result in loss of control.

ABS function (ABS-CH2)

This function simulates a full size

car's antilock braking by pulsing

the brake on and off rapidly.

Model stops as rapidly as possible

without skidding.

• The cycle speed can be selected from FST/MID/SLW.

Channel-4 EPA

Range: 0 - 120%

(Left side) (Right side)

ABS function

(4WS function)

Adjust the travel of the servo

while operating the steering

wheel each way.

(BRK function)

Adjust the travel of the servo

while operating the trigger

to the brake side.

ABS Cycle Speed

OFF: Inhibited

FST: Active (fast)

MID: Active (middle)

SLW: Active (slow)

(Brake side)

(Selection key)

Model Name (NAME)

This function provides a

3-character name for each of the

model memories in the transmitter

to easily select the correct setup

for the model currently in use.

• Clearly label each model for easy selection.

4WS/BRK Mixing Selection (SMX)

Either 4WS mixing function or

Brake mixing function can be

selected on this screen.

Model Name

Model number

(1 - 0)

Model name

(Selection key)

Special Mixing Selection

(2 seconds)

INH: Inhibited

4WS: 4WS mixing

BRK: Brake mixing for second brake

(Selection key)

(Selection key)

3PL-2.4G Functions

19

Page 20

4WS Mixing (4WS)

This mixing is used with Crawler and other 4WS specification cars. The 1st channel

controls the front side steering and the 4th channel controls the rear side steering.

• The operation mode of the front and rear wheels can be switched by the steering D/R lever (D/R). By pressing the lever up

or down, reverse phase (up side) and same phase (down side) can be switched.

• Linkage at 4WS function selection

1. After connecting the linkage, use the servo reverse function to change the direction of operation of the front and rear

wheels so that it is the same mode as the operation mode (reverse phase/same phase) being selected.

2. Thereafter, use the end point adjuster to adjust the left and right steering angles.

Brake Mixing (BRK)

Use this mixing when the front and rear brakes must be adjusted independently, such as

in 1/5GP cars, etc. This mixing uses the 2nd channel to control the rear brakes and the 4th

channel to control the front brakes.

• When braking, mixing is applied to 2nd channel and to 4th channel.

• The set value of A.B.S. function is reflected.

Channel-4 Trim (TRM-4)

(This setting screen is displayed when 4WS mixing or Brake mixing is activated.)

At 4WS mixing function:

Channel-4 Trim

The neutral adjustments of the

rear steering servo can be made by

moving the steering trim (DT1) to

the left or right.

(4WS mixing) (Brake mixing)

Range:

L25 - 0 - R25

B25 - 0 - F25

At brake mixing function:

The neutral adjustments of the front brake servo can be made by moving the steering trim

(DT1) to the left or right.

Throttle Fail Safe Function

This function moves the throttle

servo to a preset position when the

receiver cannot receive the signal

from the transmitter for some

reason.

When the signal from the

transmitter can be received again,

this function automatically resets.

Throttle F/S Function

OFF: Inhibited

***%: F/S position

F/S position setting

Push the DT2 lever up or down for about

one second while operating the throttle

trigger to the desired position.

Setting example: Throttle idle or brake

position

(Selection key)

20

*For gasoline engine cars, it is recommended that the fail safe position be set to the direction that applies the brakes.

3PL-2.4G Functions

Page 21

MC230CR/MC330CR

CANCELLING THE REVERSE FUNCTION

The amp reverse function can be cancelled by the following method so that the model can be used even in races

that prohibit reverse running. (Brake operation only)

(Pushbutton switch operation) (Power switch)

1

Reverse

function

cancellation

the pushbutton switch,

BRAKE/REVERSE OPERATING INSTRUCTIONS

Operation can be switched to reverse operation by returning the throttle trigger (or throttle stick) from the brake

position to the neutral position.

PROTECTION CIRCUIT OPERATION

The following protection circuits are built into the MC230CR / MC330CR. When a protection circuit operates,

remove the cause before operating the model again.

Overcurrent

protection

Heat protector

Low voltage

operation

MC230CR / MC330CR

* When desired, you can enable the cancelled reverse

function by repeating the operation shown at the left.

While pressing

When an overcurrent flows due to an output short circuit, etc., the overcurrent protection circuit automatically

limits the current to protect the FET.

Remove the cause of the short circuit, etc. before operating the model again.

When abnormal heating of the FET due to an overload, etc. is detected, the heat protector operates so that

the speed is gradually reduced.

When the FET temperature drops, the heat protector automatically resets. However, remove the cause

of the overheating before operating the model again.

When the Nicd battery voltage drops, this function limits the motor output current and ensures steering operation.

After the speed drops, immediately recover the vehicle.

ON

set the power switch to ON.

(The reverse function is switched alternately.)

CHECKER LED DISPLAY

The amp operates linearly in proportion to the amount of forward, reverse, and brake operation. The amp operating

state can be checked with the checker LED as shown below.

Operation

(Reverse operation set)

Amp power ON

(Only brake operation set)

High point

Forward

Neutral point

Reverse

/brake

Brake MAX point

(Amp power left on alarm)

When the transmitter power

was turned off first.

* Confirmation beep only sounds when the motor was connected.

Single blink

(Single confirmation beep)

Double blink

(Two confirmation beeps)

Blinks. (Confirmation

beep also sounds.)

Checker LED display

Off

*Becomes brighter nearer the high

On

point.

Off

On

*Becomes brighter nearer the

brake MAX point.

Off

*Not used with PCM receivers.

*When the transmitter is OFF, this function is

not performed in environments such that the

servo operates erroneously.

3PL-2.4G Functions

21

Page 22

Function Map

Power switch turned on

Digital trim DT1, DT2, and D/R display

The current position is displayed on the LCD screen for about two seconds

when each digital trim is operated.

Steering Trim Throttle Trim Steering D/R

The current model name

is displayed for about

two seconds.

(Initial Screen)

s0RESSTHESELECTBUTTONTOSELECTTHEDESIREDFUNCTIONSCREEN

s0RESSITFORABOUTTWOSECONDSTORETURNTOTHEINITIALSCREEN

Model Selection

Steering Servo Reverse

Throttle Servo Reverse

Channel-3 Servo Reverse

INH (Special Mix) ACT

Channel-4 Servo Reverse

(L25 - 0 - R25)

Model number

(1 - 0)

Model name

NOR: Normal

REV: Reverse

NOR: Normal

REV: Reverse

NOR: Normal

REV: Reverse

(B25 - 0 - F25)

(Selection key)

(Selection key)

(Selection key)

(Selection key)

(30 - 100%)

Model Reset

Push the DT2 lever up or down

for about one second.

All data stored in the current

selected model memory is

erased.

s$4AND$4OPERATEONLY

ASTHEDATAINPUTKEYSIN

THEPROGRAMMINGMODE

4HESEDONOTOPERATE AS

THETRIMLEVERS

22

Function Map

NOR: Normal

REV: Reverse

(Selection key)

Page 23

Steering EPA

Range: 0 - 120%

(Left side) (Right side)

Throttle EPA

Range: 0 - 120%

(Forward side)

Channel-3 EPA

Range: 0 - 120%

(Left side) (Right side)

INH (Special Mix) ACT

Channel-4 EPA

Range: 0 - 120%

(Left side: 4WD)

(Right side: 4WD, Brake side: BRK)

ABS function

ABS Cycle Speed

OFF: Inhibited

FST: Active (fast)

MID: Active (middle)

SLW: Active (slow)

(Brake side)

(Selection key)

Adjust the travel of the servo while operating

the steering wheel each way.

Adjust the travel of the servo while

operating the throttle trigger each way.

Adjust the travel of the servo while

operating the channel-3 switch each way.

Adjust the travel of the servo while

operating the steering wheel or throttle

trigger each way.

Model Name

Model number

(1 - 0)

Model name

(Selection key)

Special Mixing Selection

INH: Inhibited

4WS: 4WS mixing

BRK: Brake mixing

(2 seconds)

INH (Special Mix) ACT

(Selection key)

Channel-4 Trim

Range:

(4WS mixing) (Brake mixing)

L25 - 0 - R25

B25 - 0 - F25

Throttle F/S Function F/S position setting

OFF: Inhibited

***%: F/S position

(Selection key)

(Selection key)

Push the DT2 lever up or down for

about one second while operating the

throttle trigger to the desired position.

Setting example: Throttle idle or brake

position

To Initial Screen

s!LWAYSRETURNTOTHEINITIALSCREENAFTERTHESETTING

Function Map

23

Page 24

Reference

*Specifications and ratings are subject to change without prior notice.

Ratings

Communication method:

One-way operation system

Maximum operating range:

80m (Optimum condition)

For safety:

F/S (Throttle), ID (About 4 billion ways of pair

identifications)

Transmitter T3PL-2.4G

(FHSS system, wheel type, 3+1 channels)

*The 4th channel is used for mixing functions only.

Transmitting frequency:

2.4GHz band

Power requirement:

(Dry cell battery) Penlight x 4(6V)

Current drain:

100mA or less

Transmission antenna:

1/2λ di-pole (Built-in)

Receiver R2004GF:

(FHSS system, 4 channels)

Power requirement:

4.8V or 6V NiCd battery

Size:

26x39x10mm (excluding a projection part)

Weight:

14g

Servo S3003

(Standard servo)

Power requirement:

6V (common with receiver)

Current drain:

8mA (at 6V / Idle)

Output torque:

4.1kg-cm (57in.-oz.) at 6V

Operating speed:

0.19sec/60 degree at 6V

Size:

40.4x19.8x36mm (1.59x0.78x1.42in.)

Weight:

37.2g (1.31oz.)

NOTE: This Futaba FHSS system, including the T3PL-

2.4G transmitter and R2004GF receiver, does not work

with current Futaba FASST™ systems. Please use the

T3PL-2.4G and R2004GF in pairs. Futaba FASST systems and FHSS systems are not compatible.

Servo S3050

(Standard digital servo)

Power requirement:

6V (common with receiver)

Current drain:

8mA (at 6V / Idle)

Output torque:

6.5kg-cm (90.3oz.-in.) at 6V

Operating speed:

0.16sec/60 degree at 6V

Size:

40.0x20.0x38.1mm (1.57x0.79x1.50in.)

Weight:

49g (1.72oz.)

E.S.C. MC230CR / MC330CR

(Electronic speed control)

Operating system:

Forward, reverse, and brake operations are all

linear.

Power requirement:

Nicd battery 6-7 cells (7.2 to 8.4V)

PWM frequency:

1.5kHz (fixed)

Setting:

One-touch input by pushbutton switch. Set data is

saved to built-in EEPROM.

Current capacity (FET rating):

Forward=90A/200A, reverse=45A/100A

Size:

27.1x33.3x12.8mm (1.07x1.31x0.50in.)

(excluding protruding parts)

Silicon cord gauge size:

AWG16/AWG14 equivalent

Weight:

44/45g (1.55/1.59oz.)

(including connectors and switches)

BEC voltage:

6.0V

24

Reference

Page 25

Troubleshooting

If your system fails to operate or you experience a short range problem or erratic control,

check the table below for possible causes. If after you have followed the suggestions

listed the problem is not corrected, return the system to our service department for

inspection and repair.

(Item Check)

Transmitter

Battery

Dead battery Change the batteries.

Batteries inserted incorrectly. Reload the batteries in accordance with the

polarity markings

Faulty contact

contact

Dirty contacts Clean the contacts and check for corrosion.

Check to see if the contacts are bent and not making good

Receiver

Battery

Dead battery Replace or recharge

Wrong polarity Check connections

Antenna

Near other wiring Move away from wiring

Was antenna cut Request repair

Is the antenna installed correctly Refer to the receiver installation.

Monitor LED

Check the LED of the receiver.

Refer to the "How to link the transmitter and the receiver".

Connector connections

Wiring incorrect Insert all connectors firmly

Loose connections Push the connector in firmly

Linkage

Binding or loose Adjust the linkage in model

Is movement stiff Adjust linkage in model

Motor (Electric powered)

Noise problems Install capacitors on motor

Reference

25

Page 26

Error Displays

Low Battery Alarm

If the transmitter battery voltage drops to 4.2V or less, an audible alarm will sound

and "LOW v" will be displayed on the LCD screen.

LCD screen:

WARNING

n

When a low battery alarm is generated, cease operation

j

immediately and retrieve the model. If the battery goes dead

while in operation, you will lose control.

Backup Error

If the data is lost for an unknown reason, an audible alarm will sound and "ERR" will be

displayed on the LCD screen.

LCD screen:

WARNING

n

When a backup error is generated, immediately stop using the

j

system and request repair from the Futaba Service Center. If

you continue to use the system, the transmitter may malfunction

and cause loss of control.

RF Error

If the RF circuit fails for an unknown reason, an audible alarm will sound and "RF" will

be displayed on the LCD screen. Please request repair from the Futaba Service Center.

LCD screen:

26

Reference

Page 27

When requesting repair

Before requesting repair, read this instruction again and recheck your system. Should the

problems continue, request as follows.

(Information needed for repair)

Describe the problem in as much detail as possible and send the letter along with the

system in question.

• Symptom (Including the conditions and when the problem occurred)

• R/C System (Send transmitter, receiver and servos)

• Model (Type of model, brand name and model number or kit name)

• Detailed packing list (Make a list of all items sent in for repair)

• Your name, address and telephone number.

(Warranty)

Read the Warranty card.

• When requesting warranty service, send the card or some type of dated proof of

purchase.

Hobby Services (U.S. only)

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822 U.S.A.

Phone: (217) 398-0007

www.hobbyservices.com

©Copyright 2010. No part of this manual may be reproduced in any form without prior permission. The contents of this manual are subject

to change without prior notice. While this manual has been carefully written, there may be inadvertent errors or omissions. Please contact

our service center if you feel that any corrections or clarifications should be made.

FUTABA CORPORATION Phone: +81 475 32 6982, Facsimile: +81 475 32 6983

1080 Yabutsuka, Chosei-mura, Chosei-gun, Chiba 299-4395, Japan

1M23N23002 ©FUTABA CORPORATION 2010, 7 (1)

Reference

27

Page 28

R

Loading...

Loading...