Friedrich EP24G33, EP12G33, EP18G33 User Manual

Service Manual

Compact Programmable

Models 2009 2008

CP-14-18-24-ServMan (04-09)

TECHNICAL SUPPORT CONTACT INFORMATION

FRIEDRICH AIR CONDITIONING CO.

Post Office Box 1540 · San Antonio, Texas 78295-1540

4200 N. Pan Am Expressway · San Antonio, Texas 78218-5212 (210) 357-4400 · FAX (210) 357-4490

www.friedrich.com

Printed in the U.S.A.

Table Of Contents |

|

Important Safety Information ........................................................................................................................................ |

2-4 |

Introduction ...................................................................................................................................................................... |

4 |

Unit Identification ............................................................................................................................................................. |

5 |

Electrical Data .............................................................................................................................................................. |

6-7 |

Specifications and Performance Data .......................................................................................................................... |

8-9 |

Functional Components Definitions ............................................................................................................................... |

10 |

Air Conditioner Use ........................................................................................................................................................ |

10 |

How to Operate the Friedrich CP Room Air Conditioner ........................................................................................... |

11-12 |

Refrigeration Sequence of Operation ............................................................................................................................. |

13 |

Sealed Refrigeration System Repairs ....................................................................................................................... |

14-17 |

Method of Charging/Repairs ........................................................................................................................................... |

15 |

. |

|

Metering Device ............................................................................................................................................................... |

18 |

Compressor Checks ................................................................................................................................................... |

18-22 |

Routine Maintenance ................................................................................................................................................. |

23-24 |

Troubleshooting ......................................................................................................................................................... |

25-28 |

Wiring Diagrams for 2009 Models .................................................................................................................................. |

29 |

Wiring Diagrams for 2008 Models .................................................................................................................................. |

30 |

Parts for 2009 Models ............................................................................................................................................... |

31-34 |

Parts for 2008 Models ............................................................................................................................................... |

35-37 |

Warranty ......................................................................................................................................................................... |

38 |

1

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualified service technician who is familiar with the safety procedures required for installation and repair, and who is equipped with the proper tools and test instruments required to service this product.

Installation or repairs made by unqualified persons can result in subjecting the unqualified person making such repairs as well as the persons being served by the equipment to hazards resulting in injury or electrical shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be encountered. If you install or perform service on equipment, it is your responsibility to read and obey these warnings to guard against any bodily injury or property damage which may result to you or others.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is a safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING” or “CAUTION”. These words mean:

WARNING

WARNING

CAUTION

CAUTION

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what will happen if the instructions are not followed.

A message to alert you of potential property damage will have the NOTICE word “NOTICE”. Potential property damage can occur if instructions

are not followed.

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL HAZARDS:

•Unplug and/or disconnect all electrical power to the unit before performing inspections, maintenance, or service.

•Make sure to follow proper lockout/tag out procedures.

•Always work in the company of a qualified assistant if possible.

•Capacitors, even when disconnected from the electrical power source, retain an electrical charge potential capable of causing electric shock or electrocution.

•Handle, discharge, and test capacitors according to safe, established, standards, and approved procedures.

•Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary to test or troubleshoot equipment with the power on to the unit.

2

•Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel, and sleeve on the room side of the air conditioning unit while cleaning.

•Electrical component malfunction caused by water could result in electric shock or other electrically unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

•Never operate the A/C unit with wet hands.

•Use air conditioner on a single dedicated circuit within the specified amperage rating.

•Use on a properly grounded outlet only.

•Do not remove ground prong of plug.

•Do not cut or modify the power supply cord.

•Do not use extension cords with the unit.

•Follow all safety precautions and use proper and adequate protective safety aids such as: gloves, goggles, clothing, adequately insulated tools, and testing equipment etc.

•Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

REFRIGERATION SYSTEM HAZARDS:

•Use approved standard refrigerant recovering procedures and equipment to relieve pressure before opening system for repair.

•Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor to moderate injury.

•Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s flame or hot surfaces can cause serious burns.

•Make sure to protect personal and surrounding property with fire proof materials.

•Have a fire extinguisher at hand while using a torch.

•Provide adequate ventilation to vent off toxic fumes, and work with a qualified assistant whenever possible.

•Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for leaks, flushing etc.

•Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves, safety glasses, clothing etc.

•Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

MECHANICAL HAZARDS:

•Extreme care, proper judgment and all safety procedures must be followed when testing, troubleshooting, handling, or working around unit with moving and/or rotating parts.

•Be careful when, handling and working around exposed edges and corners of sleeve, chassis, and other unit components especially the sharp fins of the indoor and outdoor coils.

•Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.

•Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

3

PROPERTY DAMAGE HAZARDS

FIRE DAMAGE HAZARDS:

•Read the Installation/Operation Manual for this air conditioning unit prior to operating.

•Use air conditioner on a single dedicated circuit within the specified amperage rating.

•Connect to a properly grounded outlet only.

•Do not remove ground prong of plug.

•Do not cut or modify the power supply cord.

•Do not use extension cords with the unit.

•Failure to follow these instructions can result in fire and minor to serious property damage.

WATER DAMAGE HAZARDS:

•Improper installation maintenance, or servicing of the air conditioner unit, or not following the above Safety Warnings can result in water damage to personal items or property.

•Insure that the unit has a sufficient pitch to the outside to allow water to drain from the unit.

•Do not drill holes in the bottom of the drain pan or the underside of the unit.

•Failure to follow these instructions can result in result in damage to the unit and/or minor to serious property damage.

INTRODUCTION

This service manual is designed to be used in conjunction with the installation manuals provided with each unit.

This service manual was written to assist the professional HVAC service technician to quickly and accurately diagnose and repair any malfunctions of this product.

This manual, therefore, will deal with all subjects in a general nature. (i.e. All text will pertain to all models).

IMPORTANT: It will be necessary for you to accurately identify the unit you are servicing, so you can be certain of a proper diagnosis and repair.

(See Unit Identification.)

Cabinet

Air inlet louver

Front grille

|

|

|

|

|

|

|

|

|

|

|

|

Front intake grille |

|

||

|

|||

Air filter |

Power cord |

||

(behind front intake grille) |

|||

|

|||

|

|

Control panel cover |

|

4

Unit Identification

Model Number Code

C P 08 E 1 0

COMPACT

PROGRAMMABLE

3rd and 4th Digit - Approximate

BTU/HR (Cooling)

Heating BTU/Hr capacity listed in the Specification/Performance Data Section

RAC Serial Number Identification Guide

7th Digit – Options

0 = Straight Cool & Heat Pump Models

6th Digit – Voltage

1 = 115 Volts

3 = 230-208 Volts

5th Digit

Alphabetical Modifier

Serial Number |

|

|

L |

H |

G |

K |

00001 |

|

Decade Manufactured |

|

|

|

|

|

|

||

L=0 |

C=3 |

F=6 |

J=9 |

|

|

|

Production Run Number |

|

A=1 |

D=4 |

G=7 |

|

|

|

|

|

|

B=2 |

E=5 |

H=8 |

|

|

|

|

|

Product Line |

|

|

|

|

|

|

|||

Year Manufactured |

|

|

|

|

|

|||

A=1 |

D=4 |

G=7 |

K=0 |

|

|

|

K = RAC |

|

B=2 |

E=5 |

H=8 |

|

|

|

|

|

|

C=3 |

F=6 |

J=9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Month Manufactured |

|

|

|

|

|

|

||

A=Jan |

D=Apr |

G=Jul |

|

K=Oct |

|

|

|

|

B=Feb |

E=May H=Aug |

L=Nov |

|

|

|

|

||

C=Mar |

F=Jun |

J=Sept |

M=Dec |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

electrical DATA

WARNING

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or installation.

All electrical connections and wiring MUST be installedbyaqualifiedelectricianandconformto the National Electrical Code and all local codes which have jurisdiction.

Failure to do so can result in personal injury or death.

|

NOTICE |

|

|

FIRE HAZARD |

|

|

Not following the above WARNING could result in fire or |

|

|

electically unsafe conditions which could cause moderate |

|

|

or serious property damage. |

|

|

Read, understand and follow the above warning. |

|

|

|

|

Wire Size |

Use ONLY wiring size recommended for single outlet branch circuit. |

|

Fuse/Circuit Breaker |

Use ONLY the correct HACR type and size fuse/circuit breaker. Read electrical ratings on unit’s |

|

|

rating plate. Proper circuit protection is the responsibiity of the homeowner. |

|

Grounding |

Unit MUST be grounded from branch circuit through service cord to unit, or through separate |

|

|

ground wire provided on permanently connected units. Be sure that branch circuit or general |

|

|

purpose outlet is grounded. Ground wire must be connected to ground screw located in lower |

|

|

right corner of air conditioner when air conditioner is in cabinet. (CP 14, 18, 24) |

|

Receptacle |

The field supplied outlet must match plug on service cord and be within reach of service cord. |

|

|

Do NOT alter the service cord or plug. Do NOT use an extension cord. Refer to the table above |

|

|

for proper receptacle and fuse type. |

|

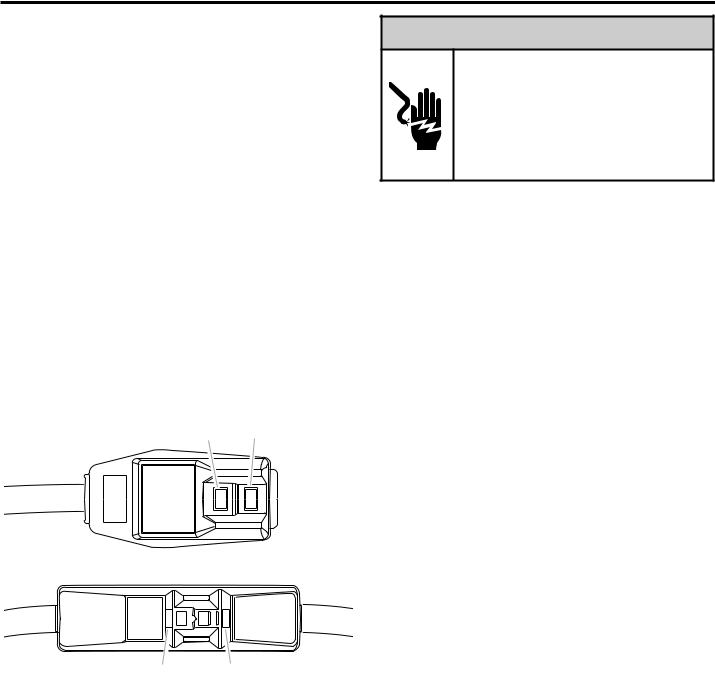

Plug/Outlet/Circuit Rating

|

Circuit Rating |

Plug Face |

Power Cord |

Wall Outlet |

||||||

Model |

Breaker or T-D Fuse |

(NEMA#) |

Length (ft.) |

Appearance |

||||||

|

|

|

|

|

|

|

|

|

|

|

CP14 |

125V - 15A |

5 - 15P |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

CP18 |

250V - 15A |

6 - 15P |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

CP24 |

250V - 20A |

6 - 20P |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

6

Recommended grounding method

This air conditioner must be grounded. This air conditioner is equipped with a power supply cord having a grounded 3 prong plug. To minimize possible shock hazard, the cord must be plugged into a mating, grounded 3 prong outlet, groundedinaccordancewithalllocalcodesandordinances. If a mating outlet is not available, it is the customer’s responsibility to have a properly grounded 3 prong outlet installed by a qualified electrical component installer.

It is the customer’s responsibility:

To contact a qualified electrical installer, and to assure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/NFPA 70 - latest edition, and all local codes and ordinances.

Copies of the standards listed may be obtained from:

National Fire Protection Association One Batterymarch Park

Quincy, MA 02269

Power Supply Cord

NOTE: Your unit’s device may differ from the ones shown.

B A

TEST |

RESET |

TEST |

RESET |

BA

A.Reset button

B.Test button

This room air conditioner is equipped with a power supply cord required by UL. This power supply cord contains state-of-the-art electronics that sense leakage current. If the cord is crushed, the electronics detect leakage current and power will be disconnected in a fraction of a second.

WARNING

WARNING

ELECTRICAL SHOCK HAZARD

Plug into a grounded 3 prong outlet.

Do not remove powercord ground prong. Do not use a plug adapter.

Do not use an extension cord. Failure to follow these instructions can result in death, fire, or electrical shock.

To test your power supply cord:

1.Plug power supply cord into a grounded 3 prong outlet.

2.Press RESET.

3.Press TEST (listen for click; Reset button will trip and pop out).

4.Press and release RESET (listen for click; Reset butto will latch and remain in). The power supply cord is ready for operation.

NOTES:

The Reset button must be pushed in for proper operation.

The power supply cord must be replaced if it fails to trip when the test button is pressed or if it fails to reset.

Do not use the power supply cord as an off/on switch. The power supply cord is designed as a protective device.

A damaged power supply cord must be replaced with a new power supply cord obtained from the product manufacturer and must not be repaired.

The power supply cord contains no user serviceable parts. Opening the tamper-resistant case voids all warranty and performance claims.

7

Specifications for 2009 models

Model |

|

CP14E10 |

CP18E30 |

CP24E30 |

||

Function |

|

COOLING |

COOLING |

COOLING |

||

Rated Voltage |

115V |

208~230V |

208~230V |

|||

Rated Frequency |

60Hz |

60Hz |

60Hz |

|

||

Total Capacity (W/Btu/h) |

14700(Btu/h) |

18000 /18450(Btu/h) |

/ |

(Btu/h) |

||

Power Input (W) |

1370 |

1680/1730 |

2660/2690 |

|||

Rated Input (W) |

1757W |

2259W |

3295W |

|

||

Rated Current (A) |

17.61A |

9.02A |

15A |

|

||

Air Flow Volume (CFM) (H/M/L) |

798/730/696 |

968/918/866 |

1002/950/866 |

|||

Dehumidifying Volume (pints/h) |

5.28 |

5.92 |

9.93 |

|

||

EER |

|

10.8 |

10.8 / 10.8 |

9.4 / 9.4 |

|

|

|

Fan Type-Piece |

Centrifugal flow fan – 1 |

Centrifugal flow fan – 1 |

Centrifugal flow fan – 1 |

||

|

Diameter-Length (inch) |

8.82 X 4.31 |

8.82 X 4.31 |

8.82 X 4.31 |

||

Indoor |

Evaporator |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

||

Side |

Pipe Diameter (inches) |

.276 |

.276 |

.276 |

|

|

|

Coil length (l) x height (H) x |

422 X 381 X 25.4 |

422 X 381 X 25.4 |

422 X 381 X 25.4 |

||

|

coil width (L) |

|||||

|

|

|

|

|

||

|

Compressor Type |

Rotary |

Rotary |

Rotary |

|

|

|

L.R.A. (A) |

61 |

42 |

60 |

|

|

|

Compressor RLA(A) |

11.5 |

7.5 |

11.2/10.7 |

||

|

Compressor Power Input(W) |

1060 |

1606 |

2310/2390 |

||

Outdoor |

Overload Protector |

External |

Internal |

Internal |

|

|

Throttling Method |

Capillary |

Capillary |

Capillary |

|||

Side |

|

|

|

|

|

|

Starting Method |

Capacitor |

Capacitor |

Capacitor |

|||

|

||||||

|

Working Temp Range ( F) |

50°-115° |

50°-115° |

50°-115° |

||

|

Condenser |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

||

|

Fan Type-Piece |

Axial fan –1 |

Axial fan –1 |

Axial fan –1 |

||

|

Fan Diameter (inches) |

15.59 |

15.59 |

15.59 |

|

|

Fan Motor Speed (rpm) (H/M/L) |

900/780/730 |

1000/900/800 |

1060/970/820 |

|||

Output of Fan Motor (W) |

205 |

297 |

320 |

|

||

Fan Motor RLA(A) |

1.78 |

1.29 |

1.39 |

|

||

Fan Motor Capacitor (uF) |

15 |

7 |

7 |

|

||

Permissible Excessive Operating |

|

|

|

|

||

Pressure for the Discharge |

300 |

300 |

300 |

|

||

Side(PSI) |

|

|||||

|

|

|

|

|||

|

|

|

|

|

|

|

Permissible Excessive Operating |

150 |

150 |

150 |

|

||

Pressure for the Suction Side(PSI) |

|

|||||

|

|

|

|

|||

Dimension (W/H/D) |

17½ X 26 X 27⅝ |

17½ X 26 X 29¾ |

17½ X 26 X 29¾ |

|||

Net Weight |

121 |

141 |

165 |

|

||

Refrigerant Charge (oz) |

R22/28.57 |

R22/32.10 |

R22/37.04 |

|||

Performance Data

|

EVAP. AIR TEMP. |

CONDENSER |

|

|

|

|

OPERATING |

ELECTRICAL RATINGS |

R-22 REF. |

|

BREAKER |

||||||

PERFORMANCE |

DEG. F |

Discharge |

Suction |

Super |

|

PRESSURES |

|

FUSE |

|||||||||

|

|

|

|

|

|

|

|||||||||||

|

|

TEMPERATURE |

Sub-Cooling |

|

|

|

|

|

|

|

Voltage |

|

|||||

DATA* Cooling |

Discharge |

Temp. |

DEG. F |

Temp |

Temp |

Heat |

|

Suction |

Discharge |

Amps |

Amps |

|

Locked |

Charge in |

|

60 Hertz |

|

|

Air |

Drop F. |

|

|

|

|

|

Cool |

Heat |

|

Rotor Amps |

OZ. |

|

Amps |

|||

|

|

|

|

|

|

|

|

|

|

||||||||

CP14N10 |

59 |

21 |

118 |

173 |

56 |

41 |

54 |

78 |

267 |

12.1 |

/ |

58 |

26.5 |

115 |

15 |

||

CP18N30 |

58 |

22 |

119 |

173 |

66 |

52 |

55 |

77 |

269 |

8.3 |

/ |

38.9/42.4 |

27.9 |

230 |

15 |

||

57 |

23 |

119 |

172 |

66 |

52 |

55 |

77 |

269 |

8.5 |

/ |

208 |

||||||

|

|

|

|

|

|||||||||||||

CP24N30 |

57 |

23 |

117 |

197 |

60 |

44 |

50 |

75 |

264 |

12.3 |

/ |

|

56A(230V) |

33.5 |

230 |

20 |

|

56 |

24 |

117 |

195 |

57 |

44 |

50 |

75 |

264 |

13.1 |

/ |

|

208 |

|||||

|

|

|

|

|

|||||||||||||

*Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity.

8

Specifications for 2008 models

Model |

|

CP14N10 |

CP18N30 |

CP24N30 |

|

Function |

|

COOLING |

COOLING |

COOLING |

|

Rated Voltage |

115V |

230V/208V~ |

230V/208V~ |

||

Rated Frequency |

60Hz |

60Hz |

60Hz |

||

Total Capacity (W/Btu/h) |

14000(Btu/h) |

18000 /17600(Btu/h) |

23500/23100(Btu/h) |

||

Power Input (W) |

1430 |

1850/1810 |

2740/2710 |

||

Rated Input (W) |

1540W |

2478W |

3538W |

||

Rated Current (A) |

15A |

12.57A |

18.09A |

||

Air Flow Volume (CFM) (H/M/L) |

458.8 |

458.8 |

617.6 |

||

Dehumidifying Volume (pints/h) |

3.38 |

4.65 |

8.46 |

||

EER |

|

9.8 |

9.7 / 9.7 |

8.6 / 8.5 |

|

|

Fan Type-Piece |

Centrifugal flow fan – 1 |

Centrifugal flow fan – 1 |

Centrifugal flow fan – 1 |

|

|

Diameter-Length (inch) |

7.93 X 4.31 |

7.93 X 4.31 |

8.82 X 4.31 |

|

Indoor |

Evaporator |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

|

Side |

Pipe Diameter (inches) |

0.276 |

0.276 |

0.276 |

|

|

Coil length (l) x height (H) x |

16.61 X 15 X 1 |

16.61 X 15 X 1 |

16.61 X 15 X 1 |

|

|

coil width (L) |

||||

|

|

|

|

||

|

Compressor Type |

Rotary |

Rotary |

Rotary |

|

|

L.R.A. (A) |

58 |

42 |

56 |

|

|

Compressor RLA(A) |

10.9 |

7.45 |

11.7/11.0 |

|

|

Compressor Power Input(W) |

1182 |

1700 |

2425/2480 |

|

Outdoor |

Overload Protector |

External |

External |

Internal |

|

Throttling Method |

Capillary |

Capillary |

Capillary |

||

Side |

|

|

|

|

|

Starting Method |

Capacitor |

Capacitor |

Capacitor |

||

|

|||||

|

Working Temp Range ( F) |

50°-115° |

50°-115° |

50°-115° |

|

|

Condenser |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

Aluminum fin-copper tube |

|

|

Fan Type-Piece |

Axial fan –1 |

Axial fan –1 |

Axial fan –1 |

|

|

Fan Diameter (inches) |

15.59 |

15.59 |

15.59 |

|

Fan Motor Speed (rpm) (H/M/L) |

900/780/730 |

900/780/730 |

1000/900/800 |

||

Output of Fan Motor (W) |

200 |

200 |

190 |

||

Fan Motor RLA(A) |

3 |

1.45 |

1.35 |

||

Fan Motor Capacitor (uF) |

15 |

7 |

7 |

||

Permissible Excessive Operating |

|

|

|

||

Pressure for the Discharge |

300 |

300 |

300 |

||

Side(PSI) |

|||||

|

|

|

|||

|

|

|

|

|

|

Permissible Excessive Operating |

150 |

150 |

150 |

||

Pressure for the Suction Side(PSI) |

|||||

|

|

|

|||

Dimension (W/H/D) |

17½ X 26 X 27⅝ |

17½ X 26 X 27⅝ |

17½ X 26 X 29¾ |

||

Net Weight |

121 |

141 |

165 |

||

Refrigerant Charge (oz) |

R22/26.46 |

R22/27.87 |

R22/33.51 |

||

Performance Data

|

EVAP. AIR TEMP. |

CONDENSER |

|

|

|

|

OPERATING |

ELECTRICAL RATINGS |

R-22 REF. |

|

BREAKER |

|||||

PERFORMANCE |

DEG. F |

Discharge |

Suction |

Super |

|

PRESSURES |

|

FUSE |

||||||||

|

|

|

|

|

|

|||||||||||

|

|

TEMPERATURE |

Sub-Cooling |

|

|

|

|

|

|

Voltage |

|

|||||

DATA* Cooling |

Discharge |

Temp. |

DEG. F |

Temp |

Temp |

Heat |

|

Suction |

Discharge |

Amps |

Amps |

Locked |

Charge in |

|

60 Hertz |

|

|

Air |

Drop F. |

|

|

|

|

|

Cool |

Heat |

Rotor Amps |

OZ. |

|

Amps |

|||

|

|

|

|

|

|

|

|

|

||||||||

CP14N10 |

59 |

21 |

118 |

173 |

56 |

41 |

54 |

78 |

267 |

12.1 |

/ |

58 |

26.5 |

115 |

15 |

|

CP18N30 |

58 |

22 |

119 |

173 |

66 |

52 |

55 |

77 |

269 |

8.3 |

/ |

38.9/42.4 |

27.9 |

230 |

15 |

|

57 |

23 |

119 |

172 |

66 |

52 |

55 |

77 |

269 |

8.5 |

/ |

208 |

|||||

|

|

|

|

|||||||||||||

CP24N30 |

57 |

23 |

117 |

197 |

60 |

44 |

50 |

75 |

264 |

12.3 |

/ |

56A(230V) |

33.5 |

230 |

20 |

|

56 |

24 |

117 |

195 |

57 |

44 |

50 |

75 |

264 |

13.1 |

/ |

208 |

|||||

|

|

|

|

|||||||||||||

*Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity.

9

COMPONENT DEFINITIONS

A. Mechanical components

Vent door

Exhausts stale room air outside.

Plenum assembly

Diffuser with directional louvers used to direct the conditioned airflow.

Blower wheel

Attaches to the indoor side of the fan motor shaft and is used for distributing unconditioned, room side air through the heat exchanger and delivering conditioned air into the room.

Slinger fan blade

Attaches to the outdoor side of the fan motor shaft and is used to move outside air through the condenser coil, while slinging condensate water out of the base pan and onto the condenser coil, thus lowering the temperature and pressures within the coil.

B. Electrical components

Thermistor

A sensor that automatically responds to temperature changes.

Capacitor

Reduces line current and steadies the voltage supply, while greatly improving the torque characteristics of the fan motor and compressor motor.

MoneySaver® switch

Used to regulate the operation of the fan motor and the compressor or to turn the unit off. For troubleshooting, refer to the wiring diagrams and schematics in the back of this service manual.

Fan Motor

Dual-shafted fan motor operates the indoor blower wheel and the condenser fan blade simultaneously.

C. Hermetic components

Compressor

Motorized device used to compress refrigerant through the sealed system.

Capillary tube

A cylindrical meter device used to evenly distribute the flow of refrigerant to the heat exchangers (coils).

AIR CONDITIONER USE

Operating the air conditioner properly helps you to obtain the best possible results.

This section explains proper air conditioner operation.

IMPORTANT:

If you turn off the air conditioner, wait at least 3 minutes before turning it back on. This prevents the air conditioner from blowing a fuse or tripping a circuit breaker.

Do not try to operate your air conditioner in the cooling mode when outside temperature is below 65°F (18°C). The inside evaporator coil will freeze up, and the air conditioner will not operate properly.

NOTE: In the event of a power failure, your air conditioner will operate at the previous settings when the power is restored.

10

How to operate the Friedrich room air conditioner

Money |

AutoSwing |

|

Timer |

Saver® |

|

||

|

|

|

|

|

0F |

|

|

|

|

|

Temp/Hour |

POWER |

Hr. |

|

|

|

|

|

|

Cool |

|

High |

|

|

Mode |

Med |

Fan Speed |

Fan Only |

|

Low |

|

1. Press POWER to turn on air conditioner.

POWER

NOTE: When the unit is turned on, it will display the previous settings for the Mode, Fan Speed and temperature.

Temperature

Press, or press and hold, the plus button to raise the temperature 1º until it reaches 86ºF (30ºC).

0F

Temp/Hour

Hr.

Press, or press and hold, the minus button to lower the temperature 1º until it reaches 64ºF (18ºC).

Timer Delay

To set the Timer for a 1- to 24-hour delay untilthe air conditioner turns o (the air conditioner must be On):

1. Press TIMER. Indicator light will ash.

Timer

2.Choose mode. See “Mode.”

3.Choose fan speed. See “Fan Speed.”

4.Choose temperature. See “Temperature.”

Mode

1.Press and hold MODE.

2.Choose Cool or Fan mode

Cool—Cools room. Press FAN SPEED to choose fan speed. Then adjust the temperature by pressing the up or down arrow buttons.

Fan—Operates the fan at High speed, without cooling. The display shows “FO” (fan only).

Money Saver®

Money Saver — Turns fan to low speed when room temperature reaches the temperature setting on the thermostat.

Cool |

Money |

Mode |

|

Fan Only |

Saver® |

|

Fan Speed

NOTE: The FanSpeed button will operate only when the Cool or Power Saver mode ha s been selected.

1.Press and hold FAN SPEED until you see the indicator light for the desired setting.

2.Choose High, Medium or Low.

High

High

Med |

Fan Speed |

Low

Low

2.Press the plus or minus button to change the delay time fro 1 to 24 hours.

3.Press TIMER or wait 10 seconds. Indicator light will remain on.

To set the Timer delay for a 1- to 24-hour delay until the air conditioner turns on, keeping previous settings:

1.Turn o air conditioner.

2.Press TIMER. Indicator light will ash.

3.Press the plus or minus button to change the delay time fro 1 to 24 hours.

4.Press TIMER or wait 10 seconds. Indicator light will remain on.

To set the Timer delay for a 1- to 24-hour delay until the air conditioner turns on, changing previous settings:

1.Turn on air conditioner.

2.Adjust MODE to desired setting.

3. Adjust FAN SPEED to High, Medium or Low.

4.Adjust temperature between 64ºF (18ºC) and 86ºF (30ºC).

5.Turn o air conditioner.

6.Press TIMER. Indicator light will ash.

7.Press the plus or minus button to change delay time from 1 24 hours.

8.Press TIMER or wait 10 seconds.

To clear Timer delay program

NOTE: Air conditioner can be either on or o .

Press and hold TIMER for 3 seconds. Indicator light will turn o

To see the time remaining(inhours)

1.Press TIMER once after it has been set.

2.While the display is showing the remaining time, you can press the plus or minus button to increase or decrease the time.

11

To operate air conditioner with remote control

NOTE: Remote control may vary in appearance.

NOTE: Two AAA batteries (included) power the remote control. Replace batteries after 6 months of use, or when the remote control starts to lose power.

To turn the air conditioner on or o :

Press POWER.

To select the mode:

Press COOL, FAN or $ SAVER

To select the fan speed:

Press FAN SPEED for High, Medium or Low.

To raise the temperature:

Press the plus button to raise the temperature. Each time you press or hold the plus button, the temperature will go up 1º until it reaches 86°F (30°C).

To lower the temperature:

Press the minus button to lower the temperature. Each time you press or hold the minus button, the temperature will go down 1º until it reaches 64°F (18°C).

To set Timer for a 1- to 24-hour delay before air conditioner is turned o (air conditioner must be On):

1.Press TIMER. Indicator light on air conditioner control panel will ash.

2.Press the plus or minus button to change the delay time from 1 to 24 hours.

3.Press TIMER again or wait 10 seconds. Indicator light on air conditioner control panel will remain on.

To set Timer to turn on air conditioner, keeping previous settings:

1.Turn o air conditioner.

2.Press TIMER. Indicator light on air conditioner control panel will ash.

3.Press the plus or minus button to change delay time (1 to 24 hours).

4.Press TIMER again or wait 10 seconds. Indicator light on air conditioner control panel will remain on.

To set Timer to turn on air conditioner, changing the previous settings:

1.Turn on air conditioner.

2.Adjust Mode to Cool, Fan Only, or Power Saver.

3.Adjust Fan Speed to High, Medium or Low.

4.Adjust temperature between 64°F (18ºC) and 86°F (30ºC).

5.Turn o air conditioner.

6.Press TIMER. Indicator light on air conditioner control panel will ash.

7.Press the plus or minus button to change delay time (1 to 24 hours).

8.Press TIMER again or wait 10 seconds. Indicator light on air conditioner control panel will remain on.

12

Loading...

Loading...