Page 1

with HART®

ValveSight™ Diagnostics DTM Manual

Logix® MD+ Positioners

Page 2

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Table of Contents

LOGIX MD+ .................................................................... 3

QUICK START GUIDE ................................................... 4

S

YSTEM REQUIREMENT

DTM I

NSTALLATION

C

REATE A FIELD NETWORK

DTM L

ICENSING

..................................................................................................... 6

......................................................................................................... 8

.............................................................................................. 10

............................................................................................................ 16

BASIC DASHBOARD ................................................... 17

ADVANCED DASHBOARD .......................................... 20

ANNUNCIATOR PANELS ............................................ 25

A

LARMS ANNUNCIATOR

M

ANAGEMENT ANNUNCIATOR

E

VENT HISTORY

.................................................................................................. 26

........................................................................................ 43

............................................................................................................. 55

HEALTH ....................................................................... 58

V

ALVE HEALTH

P

OSITIONER HEALTH

A

CTUATOR HEALTH

C

ONTROL HEALTH

T

RAINING

.............................................................................................................. 59

Friction .............................................................................................................. 64

Bellows Cycles & Travel ................................................................................... 72

....................................................................................................... 76

Teperature & Humidity .................................................................................... 82

Pilot Relay ........................................................................................................ 84

Piezo Voltage .................................................. ................................................. 88

........................................................................................................ 90

Actuator Pnuematic Leak ................................................................................. 94

Supply Pressure ................................................................................................ 97

Actuation Ratio .............................................................................................. 100

Actuator Cycles & Travel ................................................................................ 102

........................................................................................................ 106

Deviation ........................................................................................................ 110

Position Alerts ................................................................................................ 113

Command Frequency ..................................................................................... 116

Command Amplitude ..................................................................................... 119

Position Frequency ......................................................................................... 122

Position Amplitude ......................................................................................... 125

................................................................................................................... 128

ON-LINE DIAGNOSTICS ............................................ 130

D

ATA MONITOR

T

RENDS

C

ONTINUOUS STROKE TEST

.......................................................................................................... 131

...................................................................................................................... 137

............................................................................................ 142

OFF-LINE DIAGNOSTICS .......................................... 144

R

AMP TEST

© Flowserve Corporation 2

................................................................................................................. 145

Ramp Compare ............................................................................................... 155

Page 3

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

S

TEP TEST

................................................................................................................... 160

Step Test Compare ......................................................................................... 167

HDRL T

EST

................................................................................................................. 171

HDRL Compare ............................................................................................... 179

P

ARTIAL STROKE TEST

Partial Stroke Compare .................................................................................. 189

Partial Stroke Schedule .................................................................................. 193

................................................................................................... 183

FCD- LGENSF0014-00

CALIBRATION ........................................................... 195

S

ENSOR CALIBRATION

C

OMMAND CALIBRATION

C

ALIBRATION ERRORS

................................................................................................... 196

.............................................................................................. 202

................................................................................................... 206

CONFIGURATION ...................................................... 213

C

ONFIGURATION MANAGEMENT

DTM L

ICENSE MANAGEMENT

P

OSITIONER UPGRADE MANAGEMENT

P

OSITIONER UPGRADE

L

OCAL INTERFACE

C

ONTROL

.................................................................................................................... 237

Position Shutoff .............................................................................................. 238

Soft Limits ....................................................................................................... 240

Positioner Gain ............................................................................................... 242

Pressure Control ............................................................................................. 245

Stroke Characterization ................................................................................. 247

I

NFORMATION

Actuator ......................................................................................................... 260

Valve Body ...................................................................................................... 262

Valve Trim ...................................................................................................... 264

Positioner & HART® Information ................................................................... 266

C

ARD SLOT

U

NITS

................................................................................................................. 268

Multi-Function Card ....................................................................................... 269

........................................................................................................................ 277

.................................................................................................. 229

......................................................................................................... 231

Stroke Characterization (Custom) ................................................................... 254

............................................................................................................. 259

Analog Output Calibration ............................................................................... 271

Discrete Output (DO) ........................................................................................ 275

.................................................................................... 214

........................................................................................ 223

............................................................................ 225

© Flowserve Corporation 3

Page 4

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

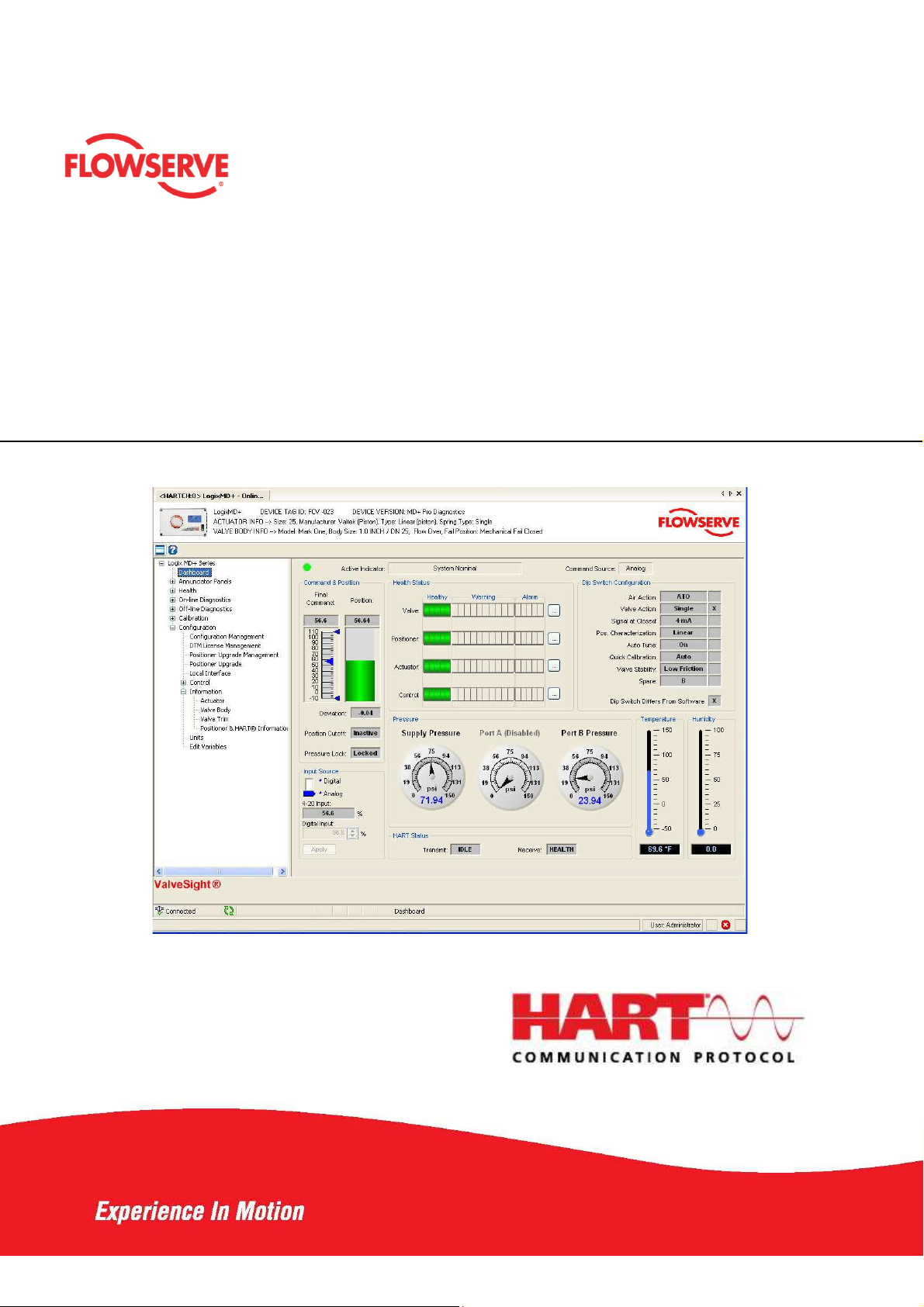

Welcome to the Logix MD+

Welcome to the Flowserve ValveSight® DTM for the Logix MD+ series digital

positioners. This package offers unparalleled functionality for configuring, calibrating,

maintaining and diagnosing control valve operation.

This package follows the standard FDT/DTM conventions. The Frame application

controls the menu bar at the top of the page and the Frame connection tree at the far

left of the frame window.

The DTM application contains a menu tree on the left side showing the available

pages for configuring, calibrating, maintaining and diagnosing control valve operation.

At the top of the DTM window, the device tag is shown, and some basic information

for the actuator and valve that is currently connected to the system.

The bar right below the device information contains two icons, one to toggle the menu

bar on and off and the other to show this help.

At the bottom of the page below the Flowserve logo is an icon indicating the status of

the connection to the field device. If the icon has a green check and the tow plugs

touching it indicates that communications are taking place and the device shown at

the top of the page is online. Two green arrows to the right of the connection symbol

are visible when the DTM is requesting information from the device.

© Flowserve Corporation 4

Page 5

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Quick Start Guide

GENERAL INFORMATION

This Document

This document details the installation and functions of the ValveSight® Device Type

Manager (ValveSight DTM) for the Logix® MD+ series of digital positioners including

the Logix 520MD+.

Qualified Personnel

Qualified personnel are people who, on account of their training, experience and

instruction and their knowledge of relevant standards, specifications, accident

prevention regulations and operating conditions, have been authorized by those

responsible for the safety of the plant to perform the necessary work and who can

recognize and avoid possible dangers.

Additionally, product users and maintenance personnel should thoroughly review the

Logix MD+ Series Digital Positioner Instruction, Operation, Maintenance and Safety

Manual prior to installing, operating, or performing maintenance on the valve or

positioner.

System Disclaimer

The installation instructions herein show an example of how to install, navigate, or

commission the ValveSight Logix MD+ DTM in a WINDOWS 7 64 bit operating

system, using the fdtCONTAINER FRAME Application. Any variation of operating

system and/or FRAME application may result in a different procedure to install,

operate, or commission the ValveSight Software.

Terms Concerning Safety

The safety terms DANGER, CAUTION and NOTE are used in these instructions to

highlight particular dangers and/or to provide additional information on aspects that

may not be readily apparent.

To avoid possible injury to personnel or damage to valve parts, DANGER and

CAUTION notes must be strictly followed. Modifying this product, substituting nonfactory parts or using maintenance procedures other than outlined could drastically

affect performance and be hazardous to personnel and equipment, and may void

existing warranties.

NOTE: indicates and provides additional technical information, which may not be very

obvious even to qualified personnel.

CAUTION: Indicates that minor personal injury and/or property damage can occur if

proper precautions are not taken.

© Flowserve Corporation 5

Page 6

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

DANGER: Indicates that death, severe personal injury and/or substantial property

damage can occur if proper precautions are not taken.

Compliance with other, not particularly emphasized notes, with regard to transport,

assembly, operation and maintenance and with regard to technical documentation

(e.g., in the operating instruction, product documentation or on the product itself) is

essential, in order to avoid faults, which in themselves might directly or indirectly

cause severe personal injury or property damage.

© Flowserve Corporation 6

Page 7

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

System Requirement

Computer System

The ValveSight® DTM has been successfully tested with the following Operating

System with a minimum of 512 M RAM:

• Windows XP

• Windows 7

Power Supply

• Non-filtered, 4-20 mA

Modem

• IFAC HART Modem

• Viator RS 232 Serial HART Modem

• UX Multiplexor

Communication DTM

• CodeWrite COMM DTM

• M&M – OEM HART COMM DTM (recommended)

• Yokogawa COMM DTM

• ABB COMM DTM

FRAMES

The ValveSight Logix MD+ DTM has been successfully tested in the following FRAME

Applications:

• fdtCONTAINER FRAME Application

• PactWare (Point to Point) FRAME Application

DD Testing

The DD has been successfully tested on the following system components:

• HART Tokenizer Version 6

• SDC-625

• 475 HandHeld

Certifications

• Logix MD+ DTM Certification with FDT Group will be performed after field trial

tests.

• DD Certification with the HART foundation will be performed after field trial

tests.

System Assumptions

This Quick Start Guide document will assume that you already have the FRAME

Application and Communication DTM installed.

© Flowserve Corporation 7

Page 8

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

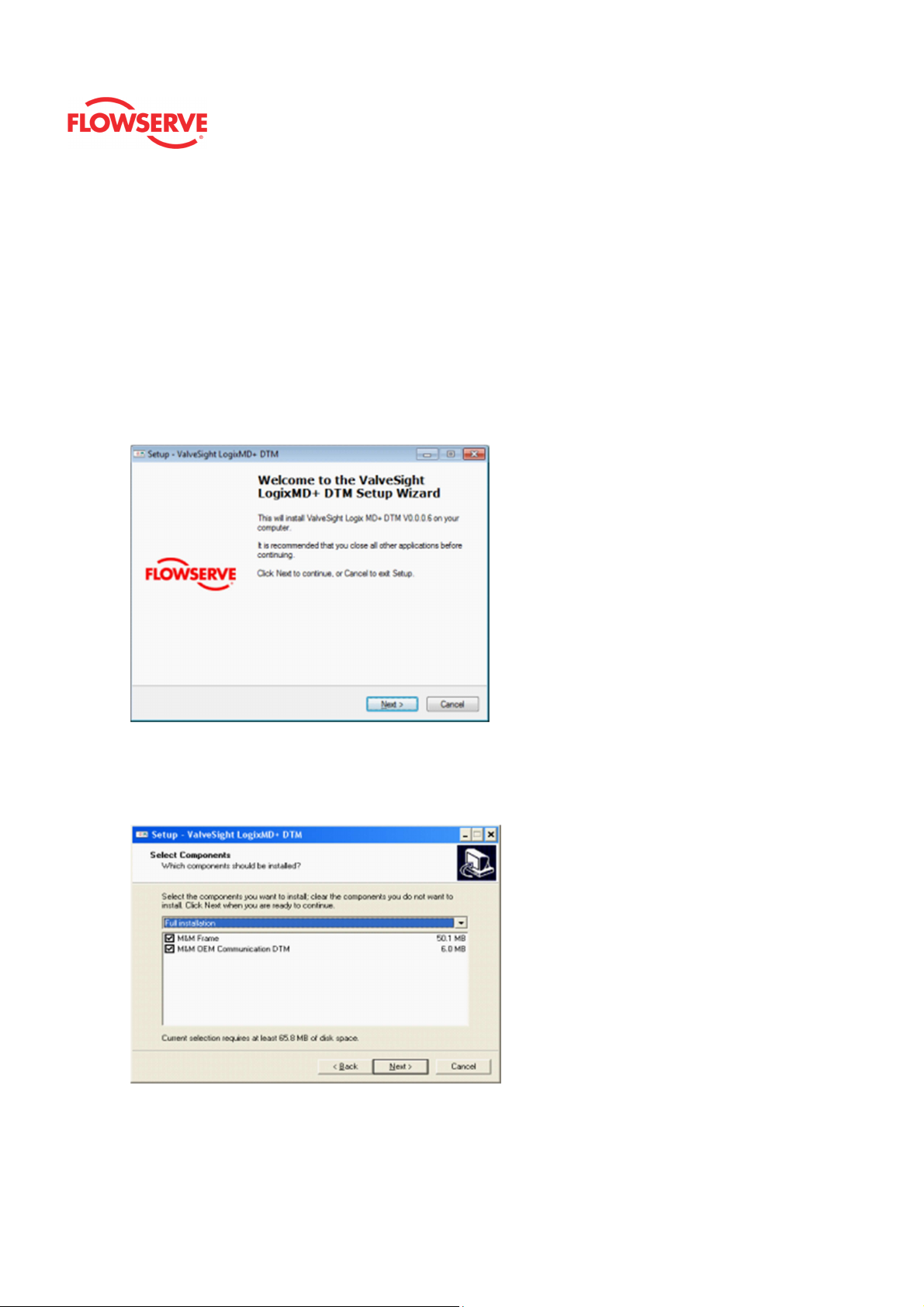

DTM Installation

Please log in to the Flowserve FTP Site (ftp://fcdftp) or open the CD to download the

Logix MD+ ValveSight DTM, FdtCONTAINER, or HART COMM DTM Installs. These

installs will allow you to install the ValveSight Logix MD+ DTM, FRAME application,

and COMM DTM respectively.

NOTE: This document will ONLY cover the installation of the Logix 520MD+

ValveSight DTM.

Follow the installation instructions

Frame and COMM DTM Install

If you do not have the FRAME Application or the HART Communication DTM

installed, check the two boxes below and follow the installation instruction for both

Frame and Communication DTM, else uncheck the already installed component.

Runtime Libraries

The ValveSight installation will check to see if the computer already has the

necessary Microsoft Libraries, else it will prompt you to install the Libraries. Select

© Flowserve Corporation 8

Page 9

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

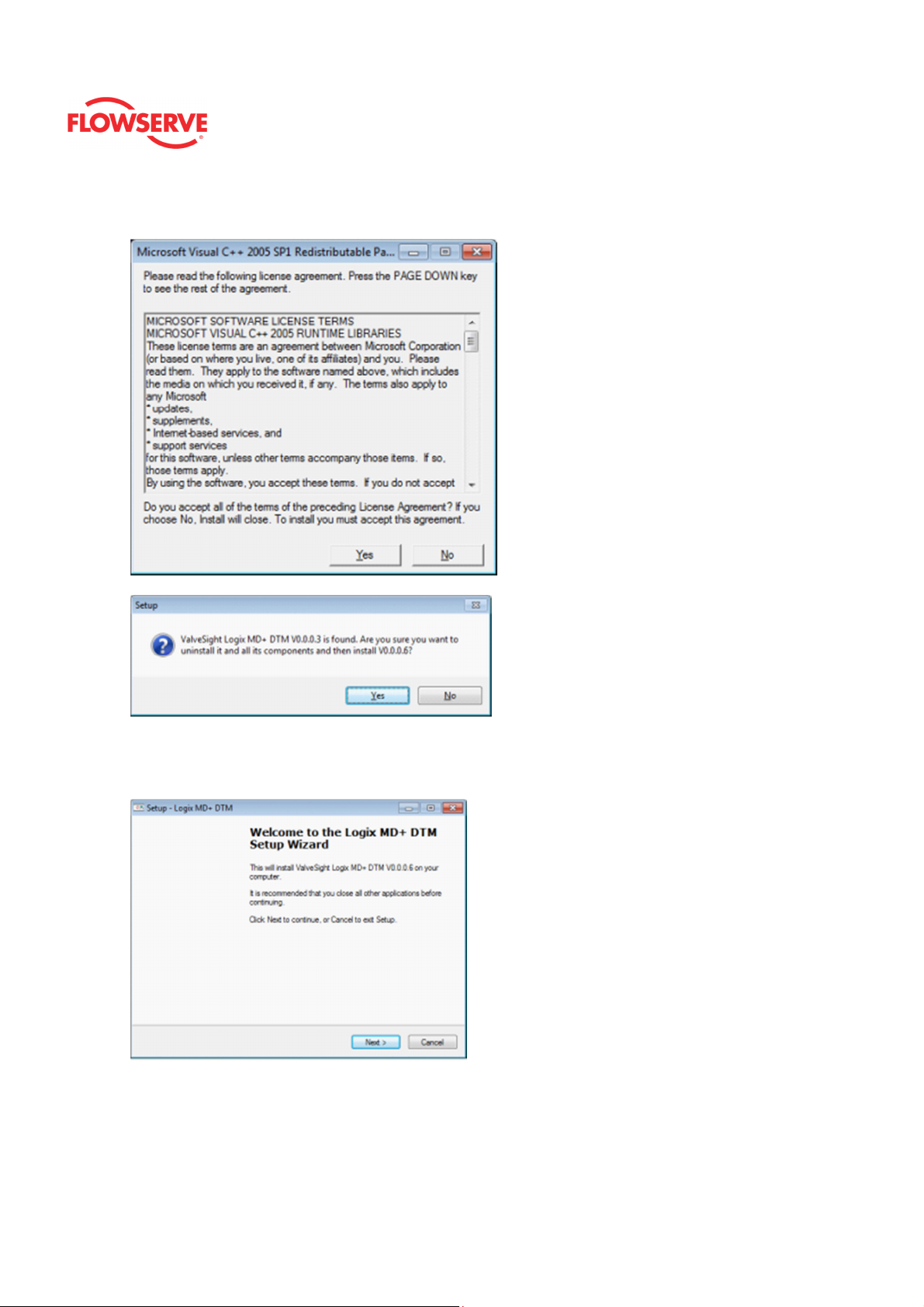

“Yes” on the following pages.

FCD- LGENSF0014-00

Resuming ValveSight Install

Once the install complete the installation and the Dongle and the Microsoft Runtime

Libraries it will resume the installation of the DTM. Click Next

Accept the Agreement

Read and accept the agreement, then click next.

© Flowserve Corporation 9

Page 10

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Select DTM destination

Browse and select the location where the DTM will install:

FCD- LGENSF0014-00

Follow and complete the installation as prompted.

© Flowserve Corporation

10

Page 11

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Create a Field Network

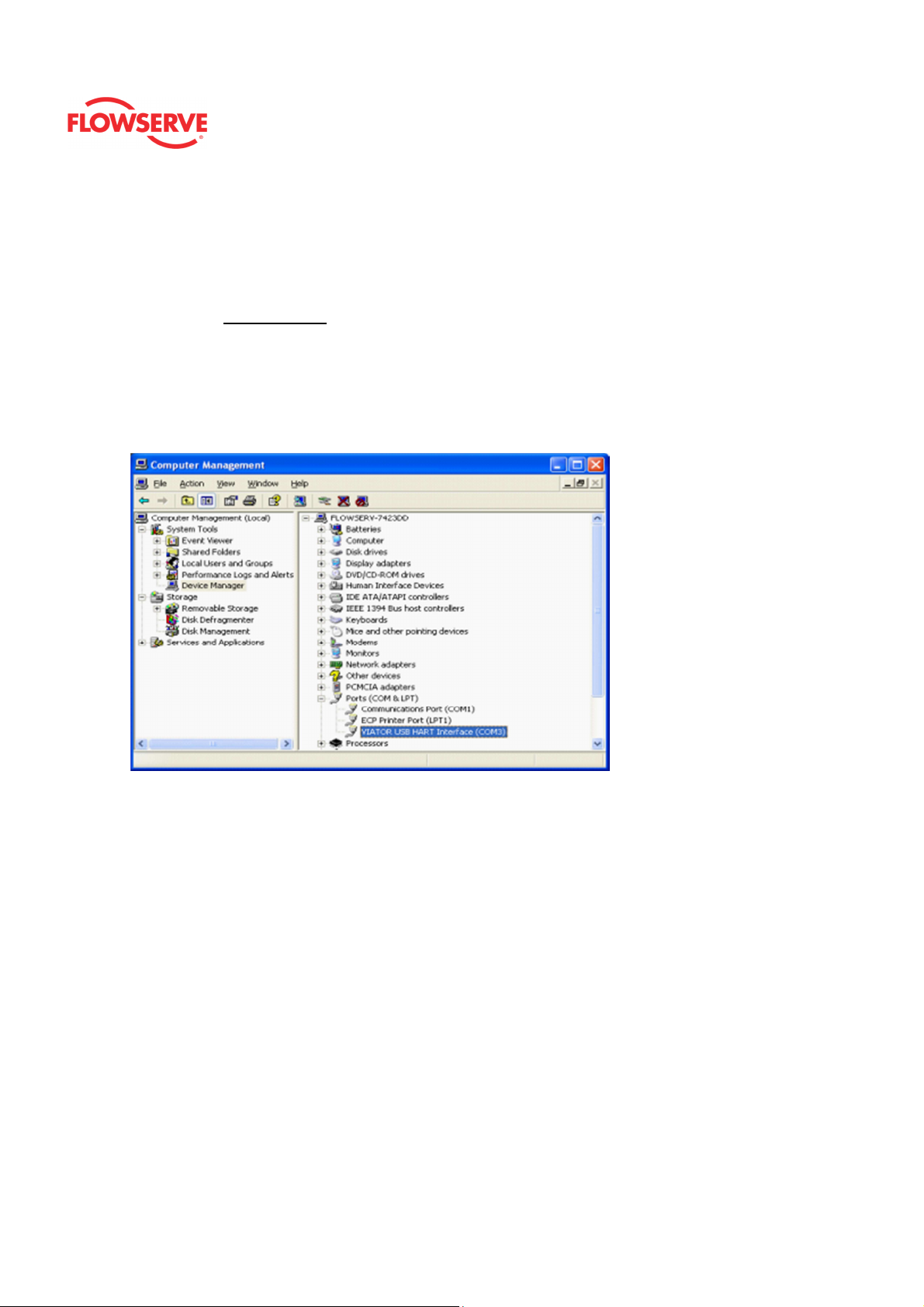

HART Modem

• If the modem is a serial port, move on to the next step

• The USB Modem requires that you install the driver for it. Make sure you

remember what slot you put the USB Driver, in case you unplug and plug in a

different slot you will need to install the driver for the different slot.

• Right Click on My Computer and select Manage.

• Click on Device Manager and select Ports

• Check what port the modem was installed

FCD- LGENSF0014-00

Create a Field Network

The remainder of the Quick Start Guide will give instructions on how to create a Field

Network using the fdtCONTAINER FRAME Application.

Device Catalog

Double click on the FDT Container, which is the M&M • Frame to open it. You will see

a widow on the right of the page called “Device Catalog”. At the bottom of the page,

click on Update. This should allow the Frame to identify both the COMM DTM and the

ValveSight DTM.

© Flowserve Corporation

11

Page 12

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

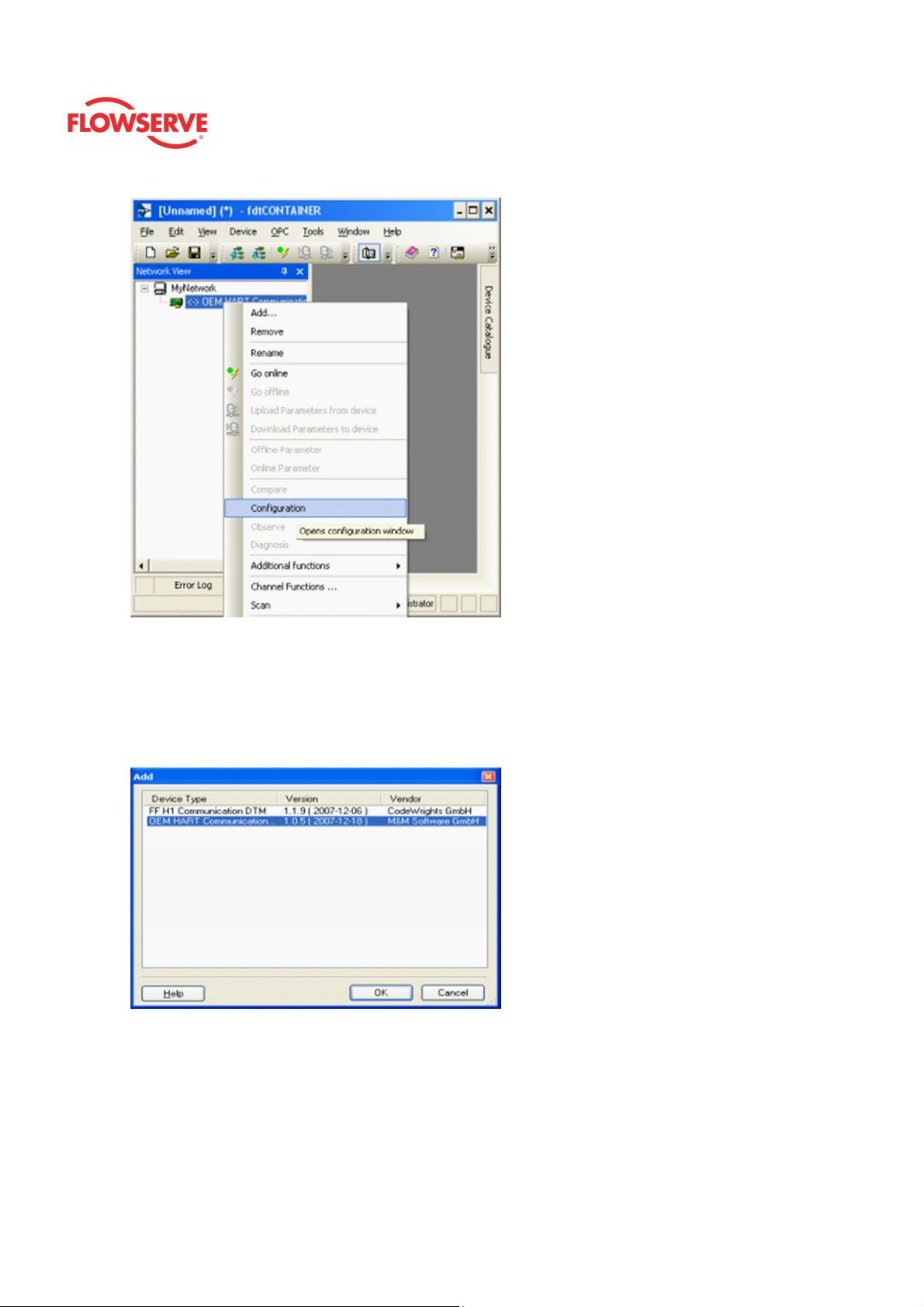

Add the COMM DTM

On the left side of the page you will see a window “Network View”. Right click on the

My Network icon. Select “Add…”

To configure the communication port, right click the OEM HART Communication DTM

in the “Network Views” window. Select “Configuration”.

© Flowserve Corporation

12

Page 13

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Set Port Address

• Select the correct port where the modem is installed.

• Check with the modem manufacturer to select the correct “Access Mode”.

• Under the “Communications Mode”, set the correct “Access Mode”

• Click the Apply or Ok button to apply modem configuration changes.

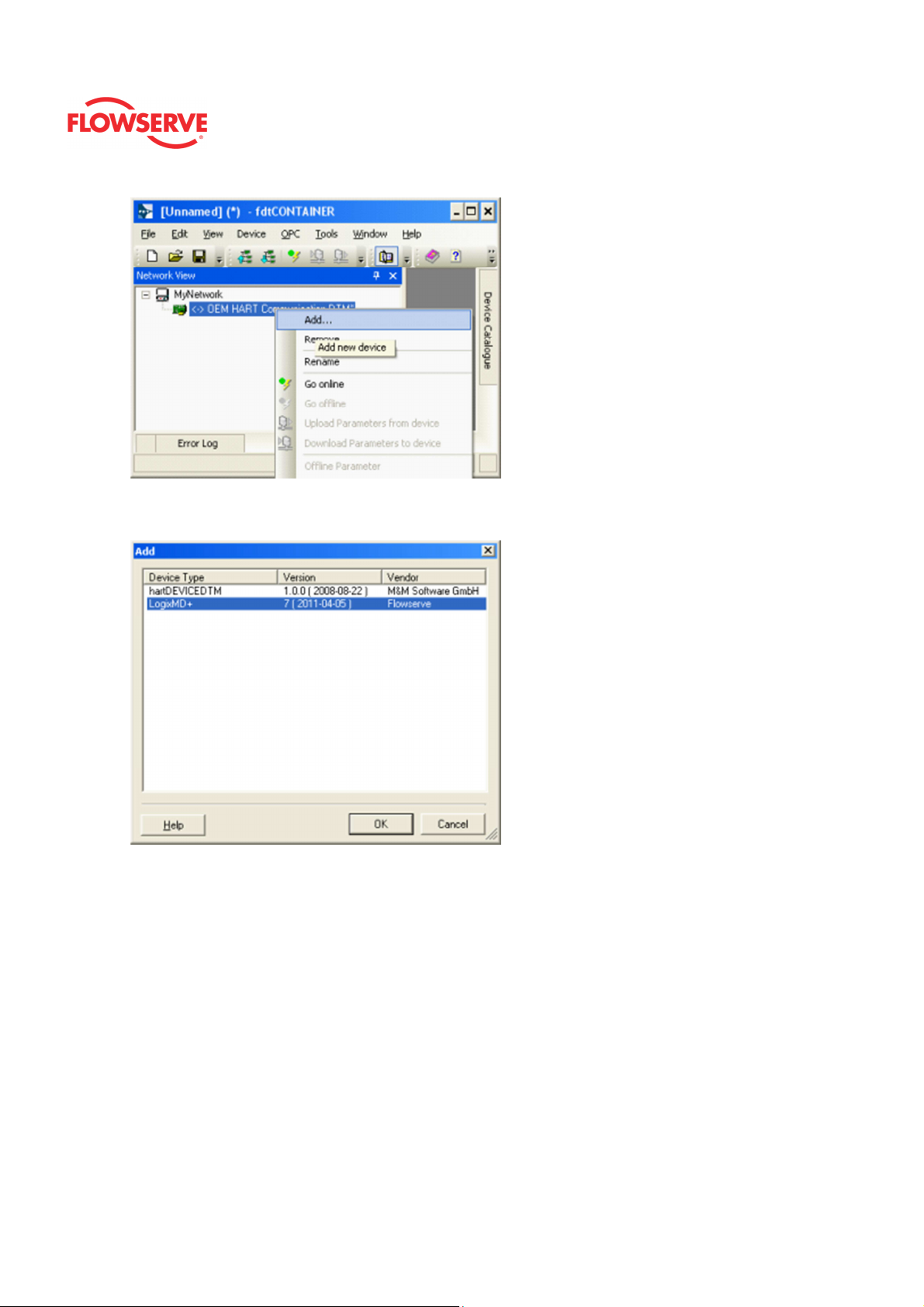

Add ValveSight Logix MD+ DTM

To add the ValveSight Logix MD+ DTM, right click on the OEM HART Communication

DTM in the “Network Views” window and select “Add”.

© Flowserve Corporation

13

Page 14

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Select the “LogixMD+”

FCD- LGENSF0014-00

Optional: Save the project to your desktop or somewhere easy to remember. This will

save you time so you do not have to create a field network in the future.

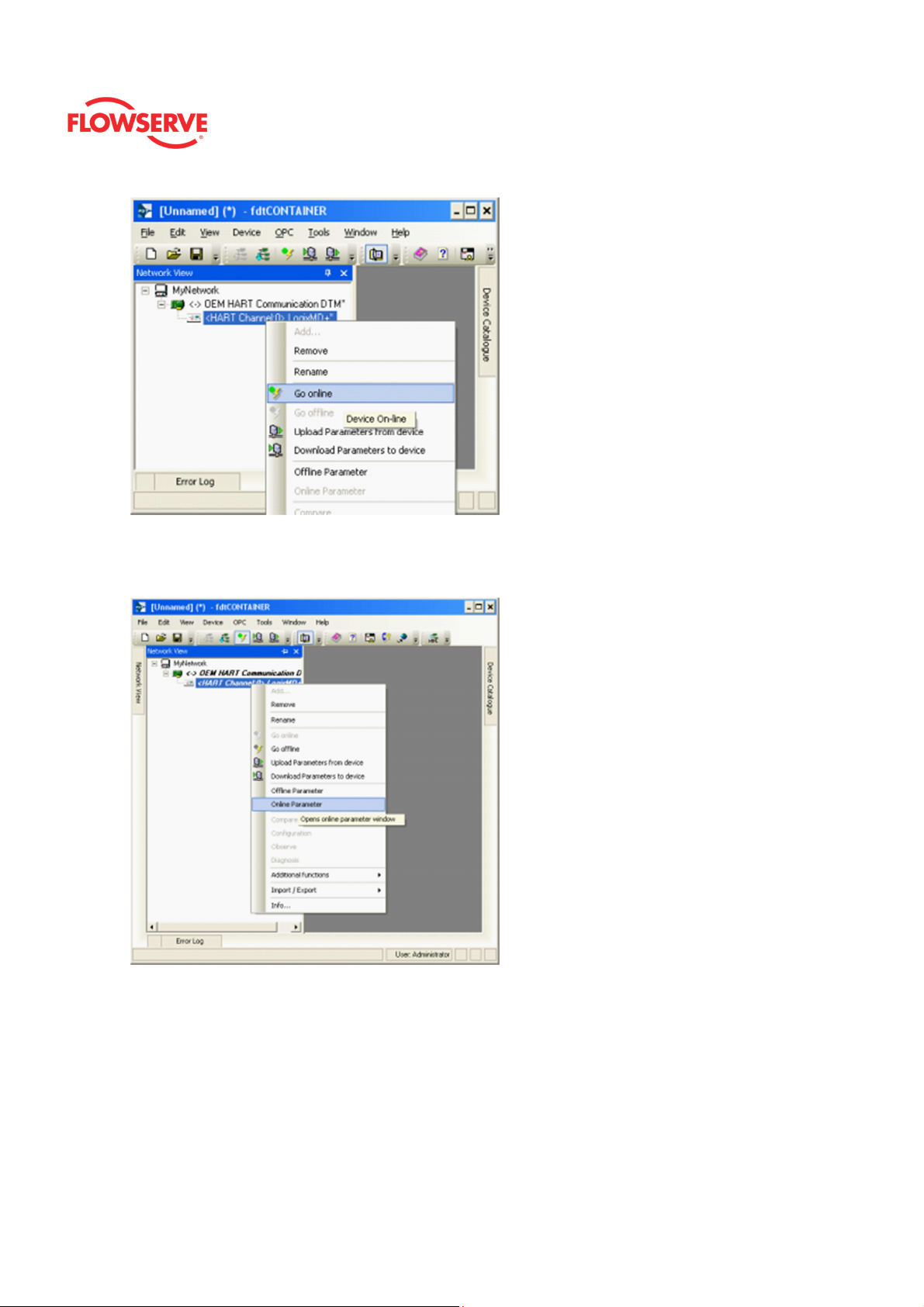

Starting the ValveSight MD+ DTM

To launch the ValveSight DTM, ensure the modem is connected to a device and the

device is powered on.

Right click on the “HART Channel 0> LogixMD+” and select “Go Online”

© Flowserve Corporation

14

Page 15

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Double click the “HART Channel 0> LogixMD+”, or right click and select Online

Parameter

Troubleshooting

If communications is not established:

1. Verify the HART modem is functional. Some HART modems will report a positive

self-check, but still be non-functional.

2. If another primary master is connected in the system, use a communication DTM

other than the M&M fdtCONTAINER. This communication DTM does not support a

primary master other than itself.

© Flowserve Corporation

15

Page 16

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

DANGER: Using certain features of the DTM can result in valve movement and the

inability to operate the valve until the operation is complete. Notify proper personnel

that the valve may stroke, and make sure the valve is properly isolated before

proceeding.

© Flowserve Corporation

16

Page 17

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

DTM Licensing

License ValveSight

To take advantage of the full diagnostic capabilities of ValveSight®, license the

Advanced ValveSight DTM for the Logix MD+.

Steps to license the Advance DTM:

1. In the menu tree, select “Configuration” -> “DTM License Management”

2. Write “beta” in the “Feature code:” (make sure it is all lower case)

3. Click the “Activate / Deactivate”

NOTE: The ValveSight Advance License will only apply to the specific PC.

© Flowserve Corporation

17

Page 18

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

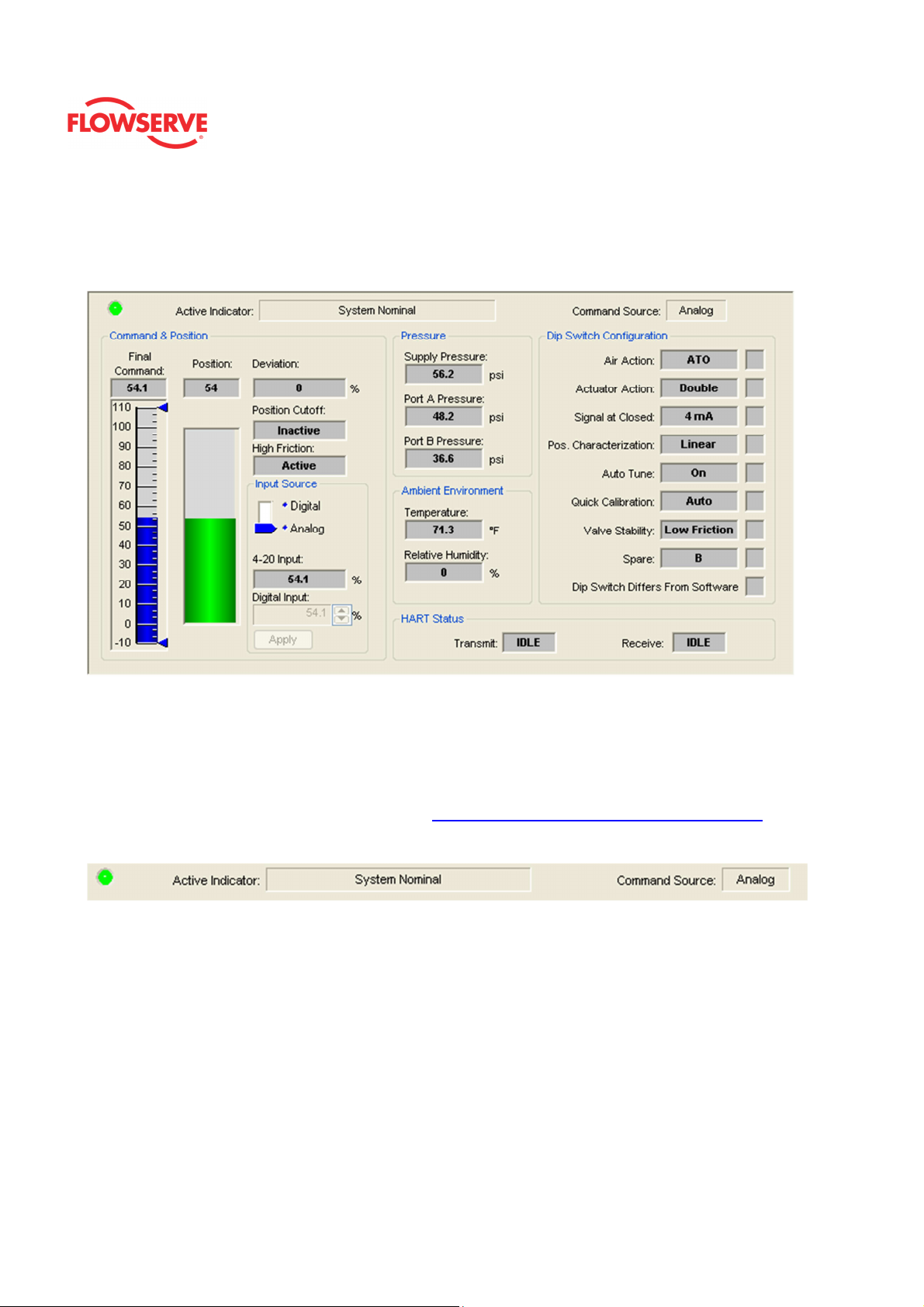

Basic Dashboard

The Basic Dashboard is a high level view of the status of the positioner. It is the main view

of the ValveSight® DTM.

Status Area

The Active Indicator area shows the status of the most relevant active indicator. The color

of the "LED light" corresponds to the Active Indicator and the first color of the blink code

sequence on the positioner. Generally green indicates no immediate issues. Yellow

indicates a developing issue. Red indicates the ability to control may be compromised. A

detailed list of the indicators is given in the Alarm Congfiguraion - Alarm Annunicator page.

The Command Source field indicates weather the positioner is being controlled by digital or

an analog (4-20 mA) command source.

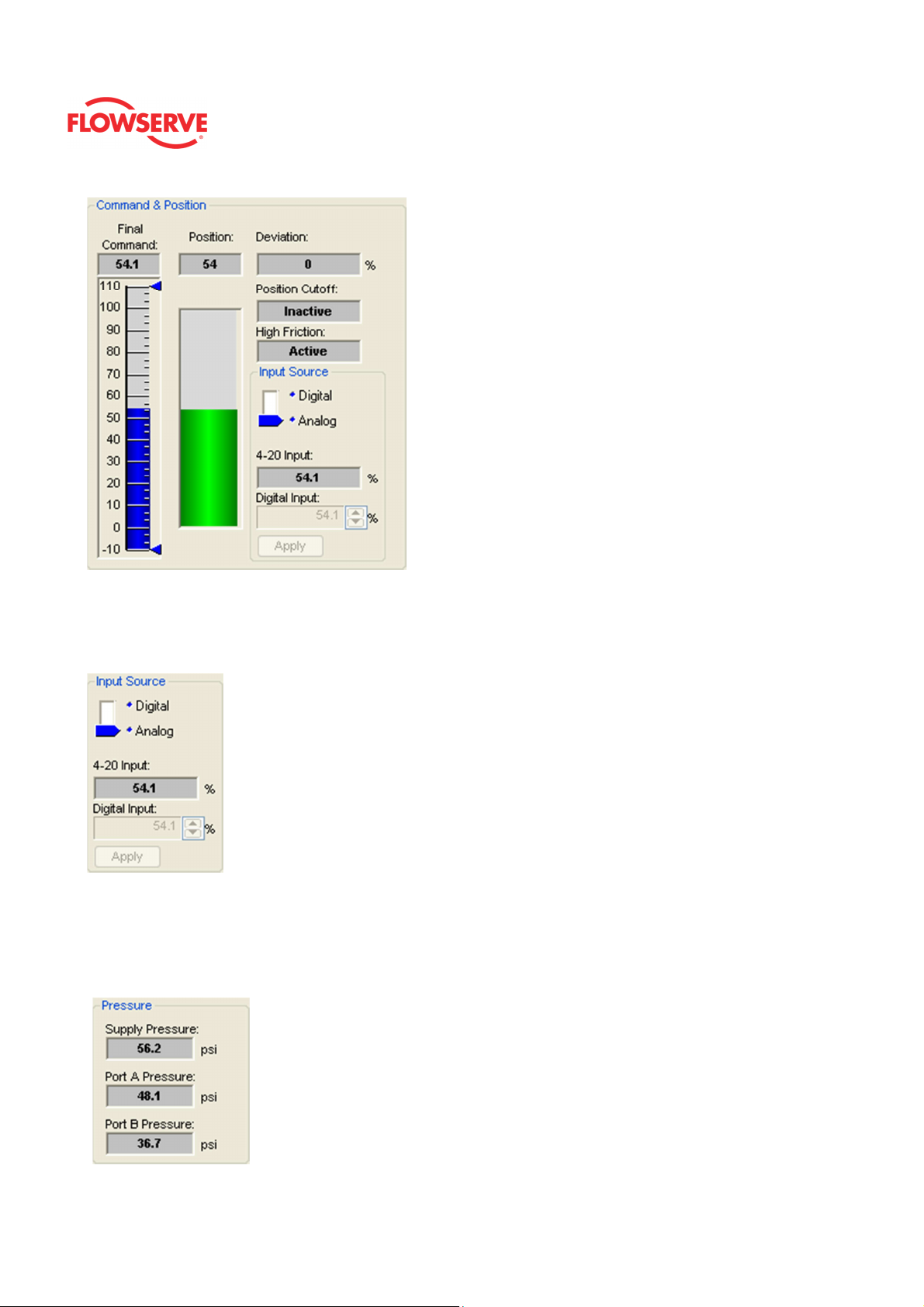

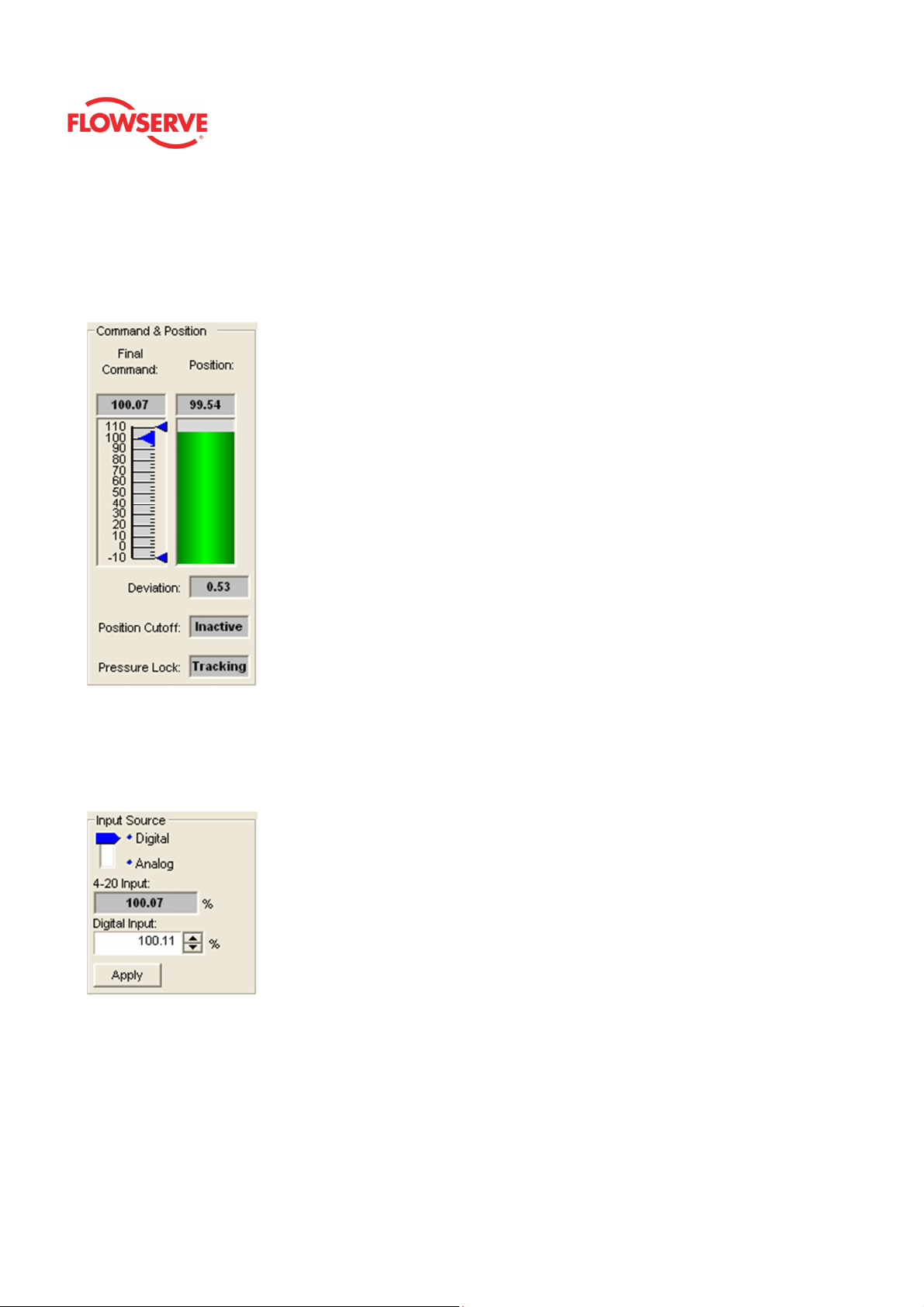

Command and Position

This area contains a graphical representations of the valve command and position. The

blue bar tracks the final command value (after adjustments for characterization curves).

The green position bar indicates the current measured position of the valve. The smaller

pointers show the settings of the travel alert settings (these can be changed on the Travel

Alerts page located under Alarms/Alerts). Grayed out zones at the top or bottom of the

graphs indicate the settings of soft travel limits.

© Flowserve Corporation

18

Page 19

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Input Source

Select the analog or digital control mode. In analog mode, the positioner will position the

valve according to the 4-20 mA supplied current. In digital mode, the positioner will position

according to the value entered in the Digital Input field.

Pressure

Supply, port A and port B pressures are seen in this box. If the Supply Pressure field is

yellow or red, there is a problem with the supply pressure to the positioner. The fields in the

Pressure box are only active if the positioner is upgraded to have Advanced or Pro

diagnostics.

© Flowserve Corporation

19

Page 20

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

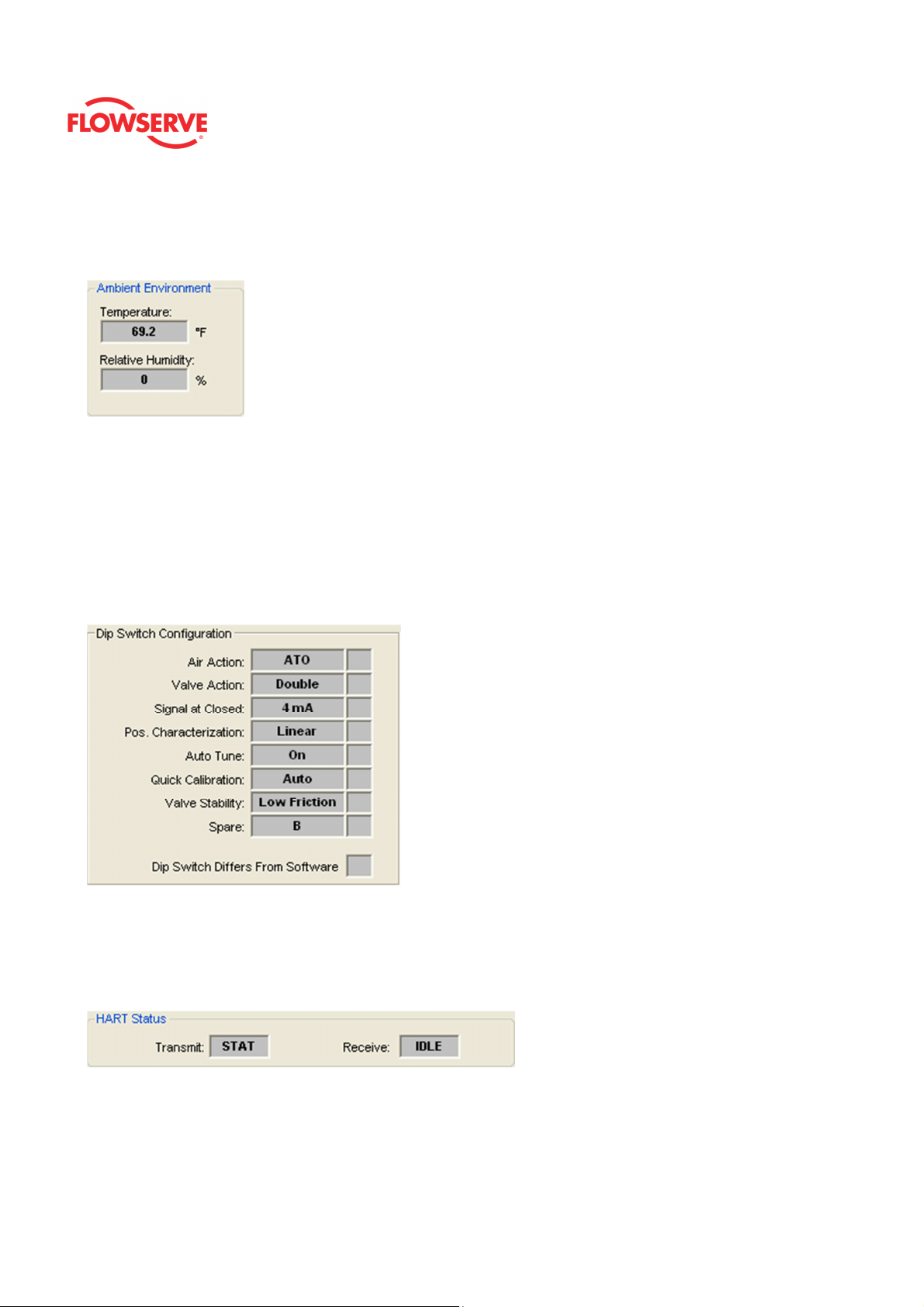

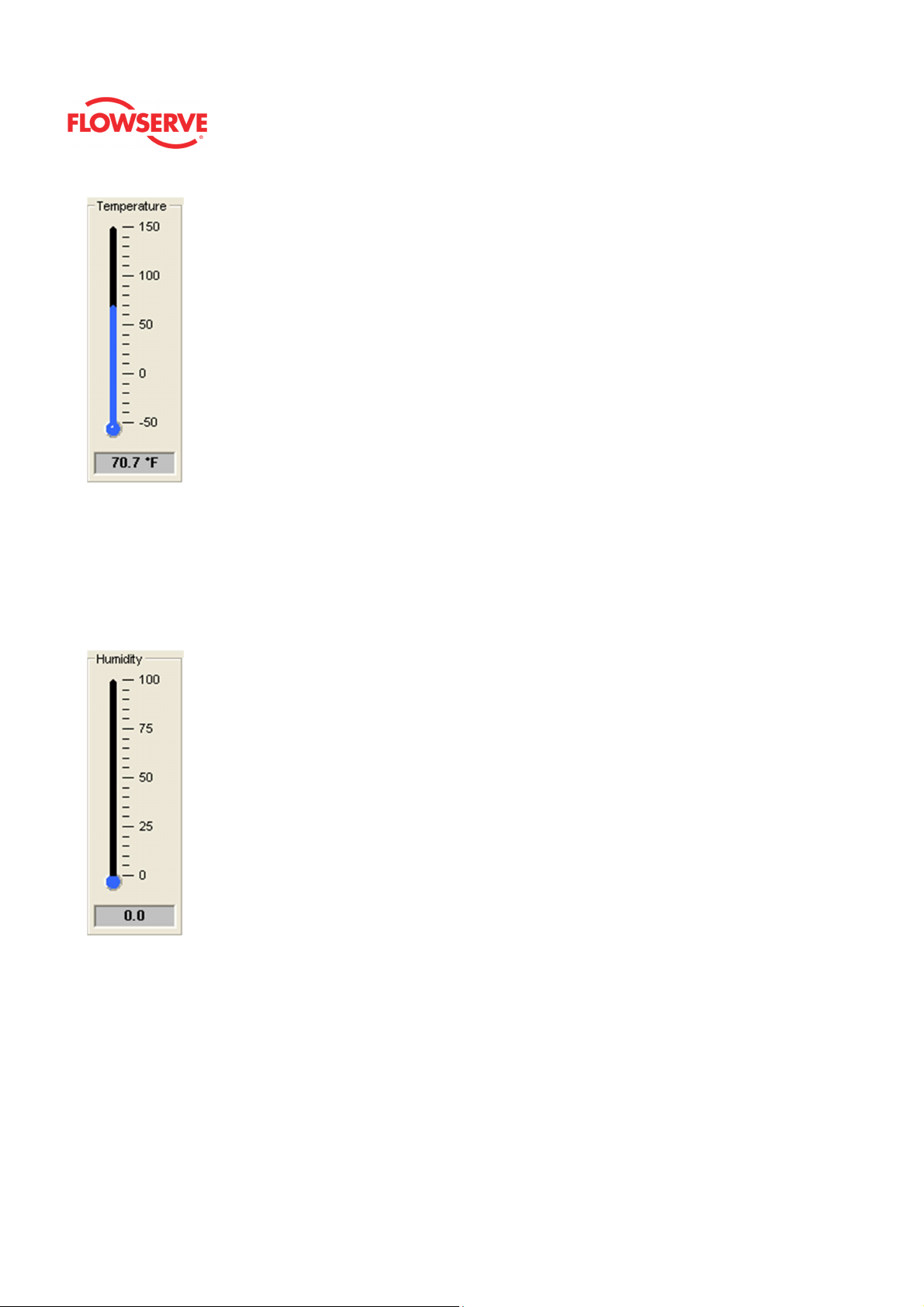

Ambient Temperature

The temperature and relative humidity inside the positioner are shown here. The units for

temperature can be changed in the Positioner Configuration - Units page.

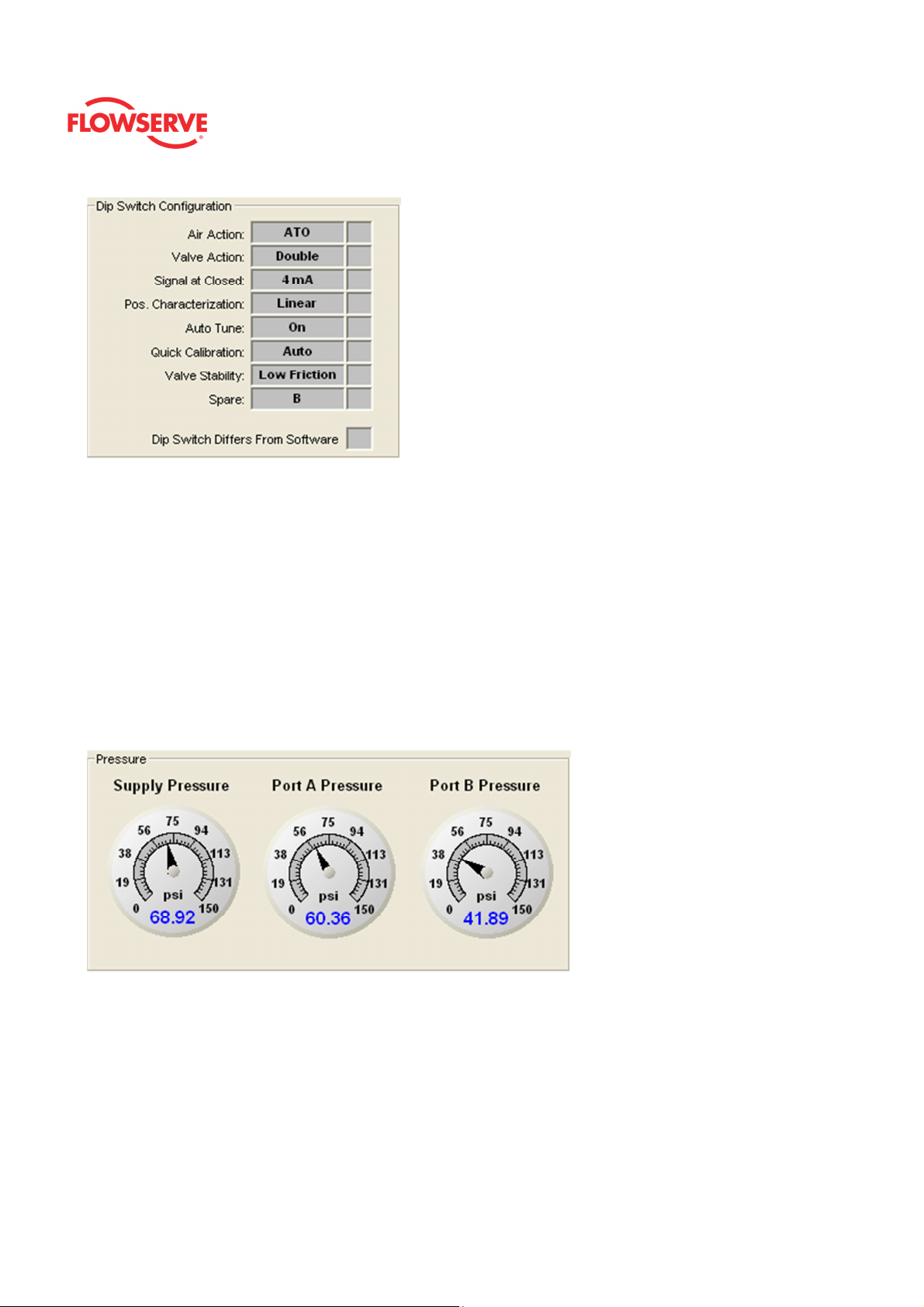

Dip Switch Configuration

The box shows the current configuration of the DIP switches on the front of the positioner.

These switches should be set on the positioner before calibration. The configuration that is

set by the DIP switches can be overridden in the software using the DTM. (See the

Basic/Local Interface page of the DTM). If this is the case, an X will be shown in the box to

the right of the item. Be careful when changing the configuration in software because

performing a position calibration (Quick-Cal) will reset the configuration according to the

physical DIP switch settings. See you instructions for the positioner for a detailed

explanation of the switches.

HART Status

Communication with the DTM is displayed here. The Transmit field displays a data packet

transmitted to the positioner. The Receive field shows data packets received from the

positioner. These are constantly updating. If they appear static, there may be a problem

with communications.

© Flowserve Corporation

20

Page 21

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

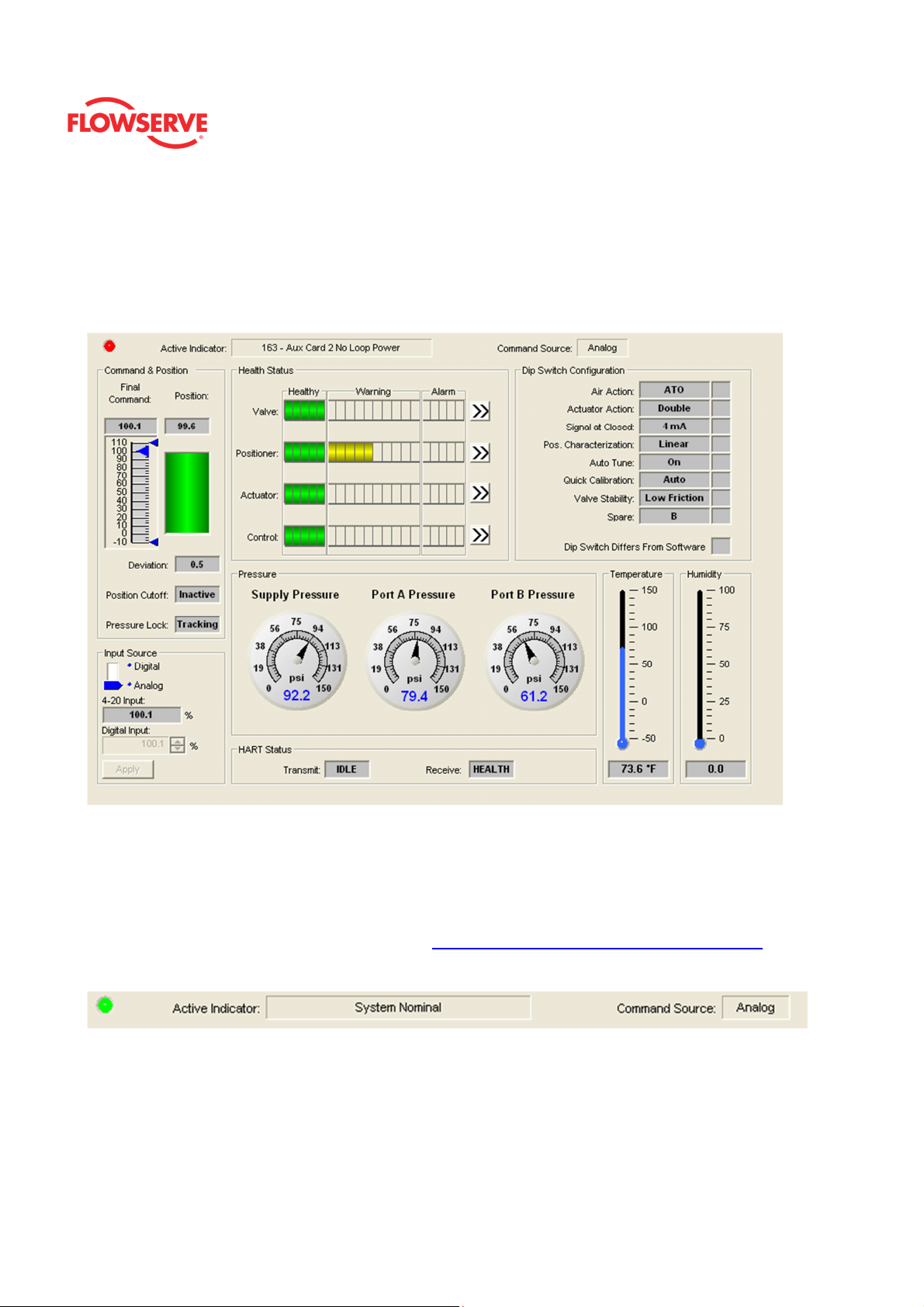

Advanced Dashboard

The Dashboard view is the main diagnostic view of the ValveSight® DTM. Generally, the

color green signifies a healthy condition, yellow signifies some degradation has taken

place, and red signifies a problem that needs to be addressed right away. You can identify

problems right away by observing any red areas on this page.

Status Area

The Active Indicator area shows the status of the most relevant active indicator. The color

of the "LED light" corresponds to the Active Indicator and the first color of the blink code

sequence on the positioner. Generally green indicates no immediate issues. Yellow

indicates a developing issue. Red indicates the ability to control may be compromised. A

detailed list of the indicators is given in the Alarm Congfiguraion - Alarm Annunicator page.

The Command Source field indicates weather the positioner is being controlled by digital or

an analog (4-20 mA) command source.

Command and Position

This area contains a graphical representations of the valve command and position. The

blue pointer tracks the final command value after adjustments for characterization curves,

Soft Limits, and Tight Shut Off. The green position bar indicates the current measured

position of the valve. The smaller pointers show the settings of the travel alert settings

(these can be changed on the Travel Alerts page located under Alarms/Alerts). Grayed out

© Flowserve Corporation

21

Page 22

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

zones at the top or bottom of the graphs indicate the settings of Soft Limits. The command

chart also displays the settings for travel limits and position Tight Shut Off (Minimum

Position Cut Off (MPC)) limits. If the positioner has been configured for Tight Shut Off this

will show up in the field below the position bar. The Pressure Lock field indicates if the

positioner is locked on a steady command by controlling the pressures, or tracking a

moving command signal.

Input Source

The command source can be changed to analog or digital mode. In analog mode, the

positioner will position the valve according to the 4-20 mA supplied current. In digital mode,

the positioner will position the valve according to the value entered in the Digital Input field.

HART Status

The status of HART communication with the DTM is displayed here. The Transmit field

displays a data packet transmitted to the positioner. The Receive field shows data packets

received from the positioner. These are constantly updating. If they appear static, there

may be a problem with communications.

© Flowserve Corporation

22

Page 23

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Health Status

The Health Status box has health indication bars for Valve, Position, Actuator, and Control

which are displayed in 4 bar graphs in the center of the dashboard. These are powerful,

visual diagnostic tools. Information from all of the diagnostic indications are rolled up into

these health bars. As the graphs turn color (from green to yellow to red) they indicate

developing issues. The health of the four key components of a control valve can be

identified quickly by looking at the color of the bar. If the bars only show green then

everything is operating within normal limits and no further action is required. If the bar is

partially yellow it is pointing out a degraded condition. The further the bar goes to the right

the more serious the degradation. If the bar is red then action should be taken immediately

because the ability to control may be compromised. To learn more about any of the 4

health areas, click the double arrows ( ) button at the end of the bar. This leads to the

detailed health status page for that particular item.

NOTE: Health Status bars are only available with the Advanced ValveSight® license

viewing positioners with Advanced or Pro diagnostics. See the licensing and upgrade

pages under Positioner Configuration in the DTM for more information.

Dip Switch Configuration

The box shows the current configuration of the DIP switches on the front of the positioner.

These switches should be set on the positioner before calibration. The configuration that is

set by the DIP switches can be overridden in the software using the DTM. (See the

Basic/Local Interface page of the DTM). If this is the case, an X will be shown in the box to

the right of the item. Be careful when changing the configuration in software because

performing a position calibration (Quick-Cal) will reset the configuration according to the

physical DIP switch settings. See you instructions for the positioner for a detailed

explanation of the switches.

© Flowserve Corporation

23

Page 24

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Pressure

Pressure values are shown here. The units for pressure can be changed in the Positioner

Configuration - Units page. The pressure gages for Port 1 and Port 2 read directly from the

pressure sensors in the positioner. For single acting configurations, the Port 2 gage is not

be active. Should the DTM view a device with no pressure sensors, all 3 gauges will be

inactive. Pressure sensors are calibrated in the factory. A pressure calibration is not

required unless there has been sever pressure or thermal stress on the positioner. See the

Calibration - Sensor Calibration page.

NOTE: Pressure gauges are only available while viewing positioners with Advanced or Pro

diagnostics. See the Positioner Upgrade page under Positioner Configuration in the DTM

for more information.

Temperature

This gage shows the temperature on the circuit board in the positioner. The units for

temperature can be changed in the Positioner Configuration - Units page.

© Flowserve Corporation

24

Page 25

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Humidity

This gage shows the Humidity on the circuit board inside the positioner. Since the

positioner should be run with a dry air supply, this value should be near zero most of the

time. Elevated humidity inside the positioner may significantly shorten the life of the

positioner. Sensor accuracy is +/-10% RH. The sensors are calibrated in the factory. No

other calibration is required.

© Flowserve Corporation

25

Page 26

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Annunciator Panels

Annunciator Panels allow quick viewing of the current state and history of diagnostic

indicators and allows masking of alarms, warnings and alerts. This selection automatically

redirects to the Alarms Annunciator page.

© Flowserve Corporation

26

Page 27

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

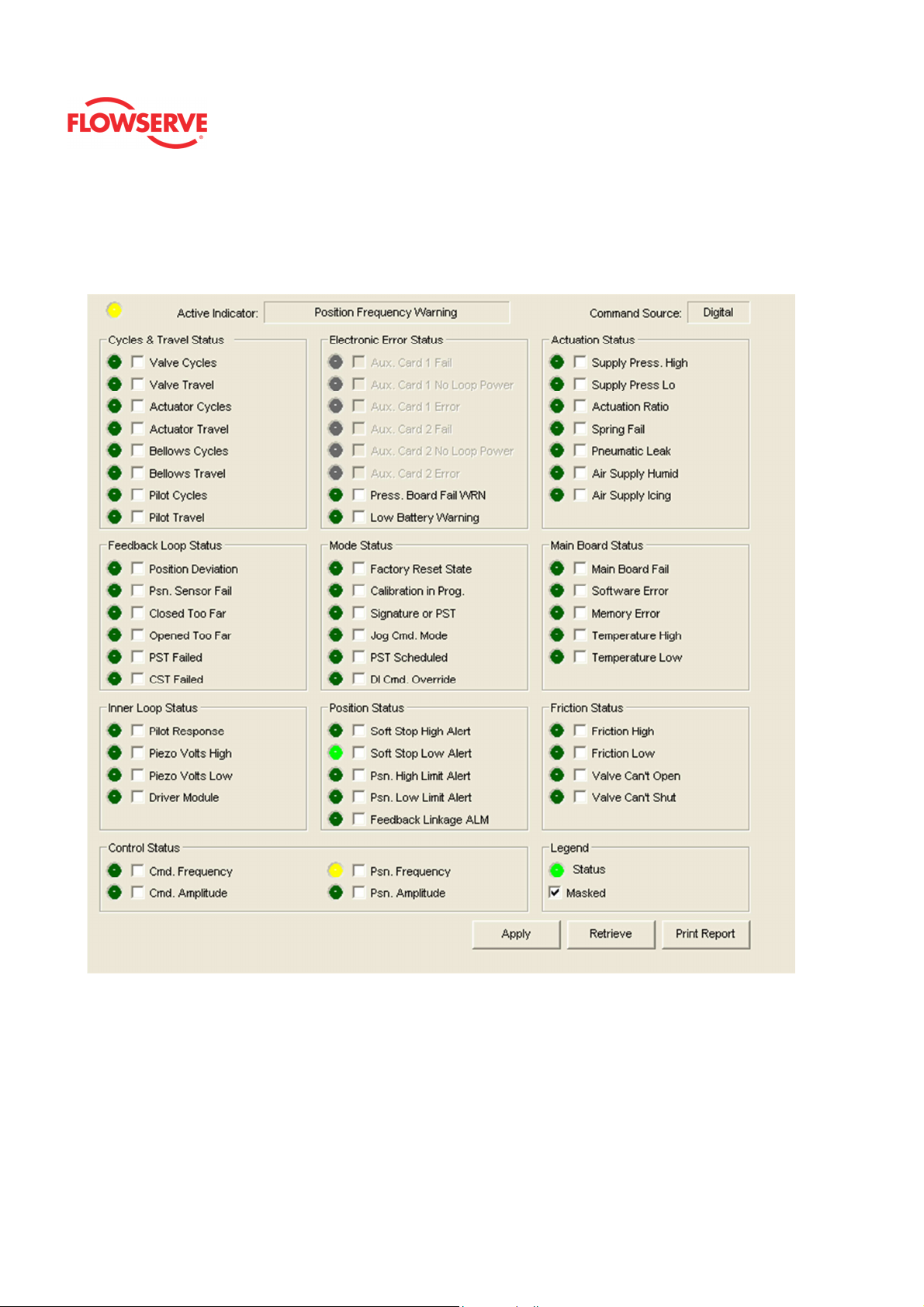

Alarms Annunciator

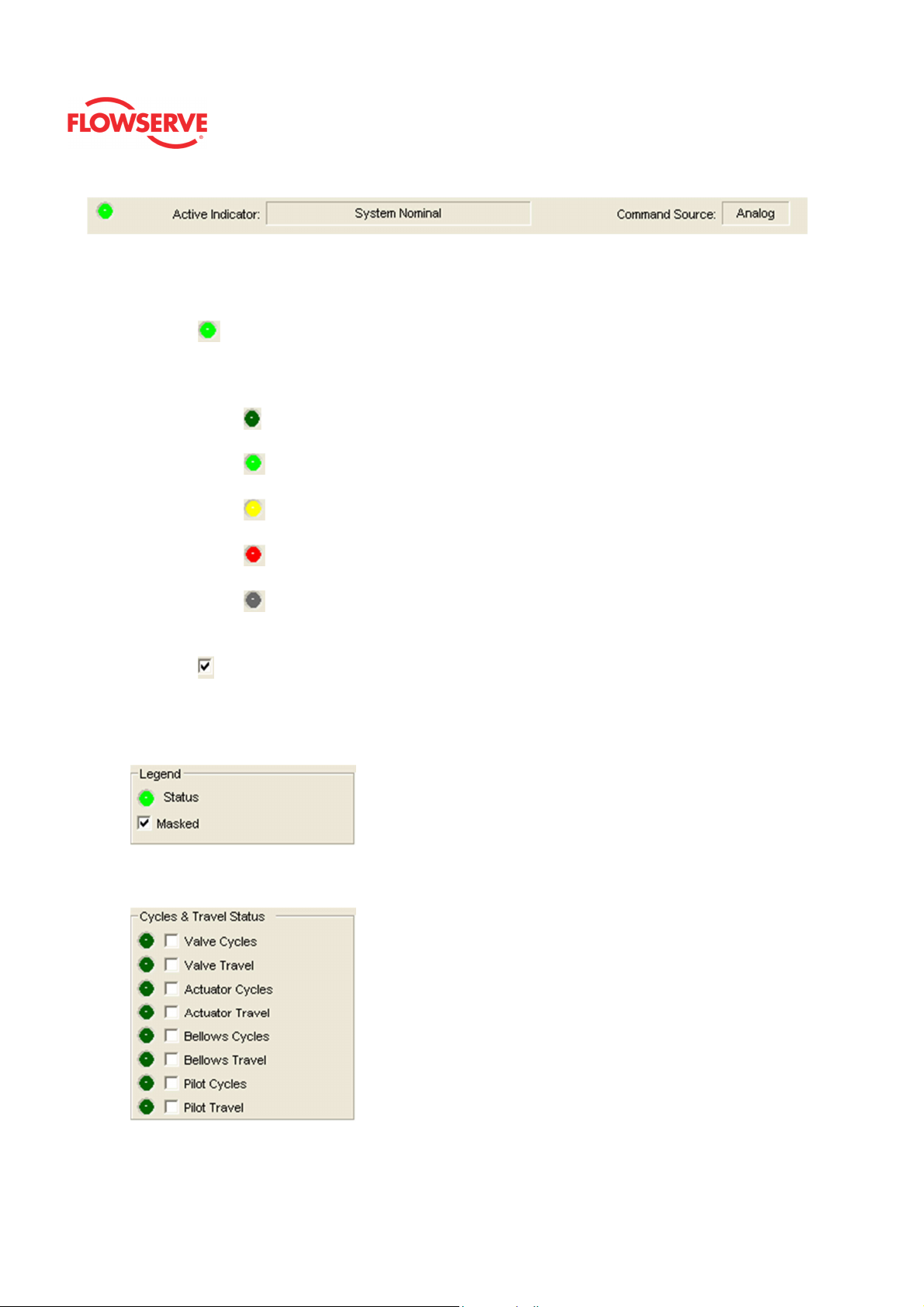

The Alarm Annunciator page displays the status of all

diagnostic indicators. The status is shown in by the indicator "light". The checkboxes allow

masking of indicators.

Status Area

The Active Indicator area shows the status of the most relevant active indicator. The color

of the "LED light" corresponds to the Active Indicator and the first color of the blink code

sequence on the positioner. Generally green indicates no immediate issues. Yellow

indicates a developing issue. Red indicates the ability to control may be compromised. A

detailed list of the indicators is given below. The Command Source field indicates weather

the positioner is being controlled by digital or an analog (4-20 mA) command source.

© Flowserve Corporation

27

Page 28

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Legend

Each indicator group box may contain the following components:

• An "LED light" indicates health status. Warning and alarm limits (set by the

user in many cases) determine the conditions when the color will turn from

green to yellow to red. The most sever of the indicators on this page will be

shown in the health bar on the Dashboard.

• Dark Green circle indicates a healthy condition where no attention is

needed.

• Light Green indicates an occurrence of a normal activity that does

not affect the health of the valve system.

• Yellow circle indicates that an active warning, alert or mode is

present.

• Red circle indicates that an active alarm or state is present that

could seriously limit the operation of the valve.

• Gray circle indicates that the feature or condition is not available

because the configuration of the hardware or software does not support

it.

• A checkbox indicates the masked status. Check to mask. If a particular

indicator is masked, it will not be shown in the active indicator field at the top

of each screen, affect the status of the health bars on the main dashboard, be

sent in command 48, or be seen on the blinking LEDs on the positioner. It

will however continue to show on this page.

FCD- LGENSF0014-00

Cycles & Travel Status

Valve Cycles

• Definition: The valve cycle limit has been exceeded.

© Flowserve Corporation

28

Page 29

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Implications: Each cycle represents two reversals of the direction of

valve movement. The cycle counting criterion and count limit are set by

the user to track the usage of the valve.

• Possible Solutions: Follow routine procedures for maintenance when

the limit is reached such as checking the packing tightness, and

checking linkages for wear, misalignment, and tightness. After

maintenance, reset the cycle accumulator.

Valve Travel

• Definition: The total accumulated valve travel limit has been

exceeded.

• Implications: The travel is accumulated in both directions. The travel

counting criterion and limit are set by the user to track the usage of the

valve.

• Possible Solutions: Follow routine procedures for maintenance when

the limit is reached such as checking the packing tightness, and

checking linkages for wear, misalignment, and tightness. After

maintenance, reset the travel accumulator.

Actuator Cycles

• Definition: The actuator cycle limit has been exceeded.

• Implications: Each cycle represents two reversals of the direction of

valve movement. The cycle counting criterion and count limit are set by

the user to track the usage of the valve.

• Possible Solutions: Follow routine procedures for maintenance when

the limit is reached such as checking the actuator seals and

lubrication. After maintenance, reset the travel accumulator.

Actuator Travel

• Definition: The total accumulated actuator travel limit has been

exceeded.

• Implications: The travel is accumulated in both directions. The travel

counting criterion and limit are set by the user to track the usage of the

valve.

• Possible Solutions: Follow routine procedures for maintenance when

the limit is reached such as checking the actuator seals and

lubrication. After maintenance, reset the travel accumulator.

Bellows Cycles

• Definition: The bellows cycle limit has been exceeded.

• Implications: The bellows may be reaching the end of its fatigue

life. Each cycle represents two reversals of the direction of bellows

movement. The cycle counting criterion and count limit are set by the

user to track the usage of the valve.

• Possible Solutions: Follow routine procedures for maintenance when

the limit is reached such as checking bellows for cracking or

leaking. After maintenance, reset the cycle accumulator.

Bellows Travel

• Definition: The bellows cycle limit has been exceeded.

FCD- LGENSF0014-00

© Flowserve Corporation

29

Page 30

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Implications: The bellows may be reaching the end of its fatigue

life. Each cycle represents two reversals of the direction of valve

movement. The cycle counting criterion and count limit are set by the

user to track the usage of the valve.

• Possible Solutions: Follow routine procedures for maintenance when

the limit is reached such as checking bellows for cracking or

leaking. After maintenance, reset the cycle accumulator.

Pilot Cycle

• Definition: The pilot relay cycle limit set by the user has been

exceeded.

• Implications: The pilot relay cycles indicate the activity level of the pilot

relay as it maintains a valve’s position. Excessive cycles can contribute

to a worn relay which can lead to high air consumption.

• Possible Solutions: Inspect for high air consumption and signs of

wear.

Pilot Travel

• Definition: The total accumulated pilot relay travel (% of full relay span)

set by the user has been exceeded.

• Implications: The pilot relay travel indicates the activity level of the

relay as it maintains a valve’s position. Excessive travel can contribute

to a worn pilot relay which can lead to high air consumption.

• Possible Solutions: Inspect for high air consumption and signs of

wear.

Feedback Loop Status

FCD- LGENSF0014-00

Position Deviation

• Definition: The device is not controlling at the set point.

• Implications: The difference between the command and the actual

position has been greater than the user-set limit for longer than a userset time.

• Possible Solutions: Review active alarms and warnings to find root

causes of this alarm. The deviation settings can be changed in the

Valve Health page of the DTM.

Position Sensor Fail

• Definition: The feedback arm may be disconnected from the valve

assembly.

• Implications: The feedback arm may be disconnected from the valve

assembly or the sensor has failed.

© Flowserve Corporation

30

Page 31

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Possible Solutions: Check the feedback arm linkage. Recalibrate. If

the problem persists return the unit for repair.

Closed Too Far

• Definition: The valve has closed farther than it did at the last

calibration.

• Implications: While the valve was in use, it closed farther than it did at

the last calibration by 0.5%.

• Possible Solutions: Check the feedback arm linkage and ensure the

valve stem connection is tight. Recalibrate the stroke. If the process

cannot be interrupted a service technician may be able to adjust the

calibration.

Opened Too Far

• Definition: The valve has opened farther than it did at the last

calibration.

• Implications: While the valve was in use, it opened farther than it did at

the last calibration by 0.5%.

• Possible Solutions: Check the feedback arm linkage and ensure the

valve stem connection is tight. Recalibrate the stroke. If the process

cannot be interrupted a service technician may be able to adjust the

calibration.

PST Failed -

• Definition: Measured times or forces during the last partial stroke test

did not pass the criteria set by the user.

• Implications: This may be an indication of corrosion build-up on the

valve stem or in the actuator, low or restricted supply pressure, or a

sticking positioner relay.

• Possible Solutions: This warning will clear upon completion of a

successful partial stroke test.

CST Failed

• Definition: During the continuous stroke test, the valve did not move

after 5 consecutive attempts.

• Implications: This could mean the valve has increased friction, a

change in process load or inadequate supply pressure.

• Possible Solutions: Check friction, supply pressure and other alarms

or warnings that would indicate difficulty in moving the valve. Check

packing, and air supply. The warning will clear when the CST function

is turned off or when a successful attempt to move the valve occurs.

Inner Loop Status

FCD- LGENSF0014-00

© Flowserve Corporation

31

Page 32

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Pilot Response

• Definition: The pilot relay is sticking or slow to respond.

• Implications: This affects the responsiveness, increases the chance of

limit cycling and excessive air consumption. The pilot relay is part of the

inner loop and consists of the driver module assembly with piezo (I-P

relay) which is coupled to the spool valve or poppet. The value of this

indicator corresponds with inner loop lag. Delayed response can be

caused by a partially clogged piezo or debris, oil, corrosion, or ice on

the spool, or low supply pressure.

• Possible Solutions: Check response of the valve. If OK, adjust Pilot

Relay Response limits. Check supply pressure. Check the spool or

poppet for debris, oil, corrosion, ice on the spool. Clean or replace the

spool or poppet assembly. Replace the piezo or driver module

assembly. Maintain a clean, water-free air/gas supply.

Piezo Volts High

• Definition: The voltage driving the piezo is above the warning limit.

• Implications: This could indicate an error with the relay or the main

board. This may result from an extended period of inactivity, but in this

case should not persist for more than 30 minutes when the valve is

controlling. The positioner may still be functioning, but have reduced

performance under some circumstances.

• Possible Solutions: Ensure the supply pressure is not low. If alarm

persists for more than 30 minutes, the Piezo assembly is

damaged. Replace the pilot relay.

Piezo Volts Low

• Definition: The voltage to the piezo is too low.

• Implications: The piezo may be damaged. This may prevent the

proper failure position upon loss of signal/power. This condition may

occur briefly on an air-to-close valve that is held for long periods of time

in the closed position, or an air-to-open valve held in the open position.

• Possible Solutions: Ensure the supply pressure is not low. If alarm

persists for more than 30 minutes, the Piezo assembly is

damaged. Replace the pilot relay.

Driver Module

• Definition: Driver module alarm.

• Implications: The pilot relay can't open, the pilot relay can't shut, or the

Hall sensor circuit has failed.

• Possible Solutions: Check the internal wiring connections. Replace

the pilot relay.

Control Status

FCD- LGENSF0014-00

Command Frequency

© Flowserve Corporation

32

Page 33

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Definition: The frequency of the command signal is above the warning

or alarm limit. This could mean the control loop is oscillating faster than

normal.

• Possible Solutions: Verify the limits are set at an appropriate level.

Review the control loop parameters and equipment. Adjust as

necessary.

Command Amplitude

• Definition: The amplitude of the command signal is above the warning

or alarm limit. This could mean the control loop has larger swings than

desirable.

• Possible Solutions: Verify the limits are set at an appropriate level.

Review the control loop parameters and equipment. Adjust as

necessary.

Position Frequency

• Definition: The frequency of the position signal is above the warning or

alarm limit. The positioner is controlling the position of the valve with

rapid corrections.

• Possible Solutions: Verify the limits are set at an appropriate level.

Adjust the selectable Gain switch to a lower setting or use the "Hi

Friction" setting. Perform a QUICK-CAL which sets the gains based on

valve response. Check for high friction. If the problem persists replace

the relay.

Position Amplitude

• Definition: The amplitude of the position signal is above the warning

limit. The positioner is controlling the position of the valve with large

corrections.

• Possible Solutions: Verify the limits are set at an appropriate level.

Adjust the selectable Gain switch to a lower setting or use the "Hi

Friction" setting. Perform a QUICK-CAL which sets the gains based on

valve response. Check for high friction. If the problem persists replace

the relay.

Electronic Error Status

FCD- LGENSF0014-00

Aux. Card 1 Fail

• Definition: Auxiliary Card 1 is not communicating.

• Possible Solutions: Check auxiliary card connection to the main

© Flowserve Corporation

33

Page 34

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

board. If the problem persists, replace the card.

Aux. Card 1 No Loop Power

• Definition: Auxiliary Card 1 has no loop current.

• Possible Solutions: Check auxiliary card connection to loop current. If

the problem persists, replace the card.

Aux. Card 1 Error

• Definition: Auxiliary Card 1 has an electrical problem.

• Possible Solutions: MFC: Check auxiliary loop wiring and ensure

adequate compliance voltage. Replace card if condition persists

Aux. Card 2 Fail

• Definition: Auxiliary Card 1 is not communicating.

• Possible Solutions: Check auxiliary card connection to the main

board. If the problem persists, replace the card.

Aux. Card 2 No Loop Power - Auxiliary Card 2 has no loop current

• Definition: Auxiliary Card 2 has no loop current.

• Possible Solutions: Check auxiliary card connection to loop current. If

the problem persists, replace the card.

Aux. Card 2 Error

• Definition: Auxiliary Card 2 has an electrical problem.

• Possible Solutions: MFC: Check auxiliary loop wiring and ensure

adequate compliance voltage. Replace card if condition persists

Pressure Board Fail Warning

• Definition: One or more pressure sensors may have failed.

• Possible Solutions: Check the supply pressure to ensure it is between

1.3 and 10.3 bar (19 and 150 PSI). Check the pressure sensor board

connections. Recalibrate the pressure sensors. If the problem persists,

replace the pressure sensor board.

Low Battery Warning

• Definition: The battery for the real time clock is low.

• Implications: The battery is designed for a 15+ year life with the

positioner unpowered. The battery is not required for the positioner to

control properly, but is used only to maintain the time and date upon

loss of power. The time and date affect the time stamps of alarms,

warnings and other events. This warning could be caused by rapidly

power cycling the positioner.

• Possible Solutions: The battery is not replaceable. Verify or reset the

time and date. Replace the main board if the problem persists for

several days.

Mode Status

© Flowserve Corporation

34

Page 35

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Factory Reset State

• Definition: The positioner is in factory reset state.

• Implications: Calibration is required to enable control.

• Possible Solutions: Perform a Stroke Calibration (QUICK-CAL).

Calibration in Progress

• Definition: A calibration is in progress.

• Possible Solutions: The calibration can be canceled from the Sensor

Calibration page of the DTM, from the handheld, or by briefly pressing

the BACK button.

Signature or PST

• Definition: The positioner is in Out Of Service (OOS) mode because a

test or signature has been initiated. These include Step Test, Ramp

Test, or Partial Stroke Test.

• Possible Solutions: Signatures and tests can be defined, initiated, and

cancelled through the Off-Line Diagnostics pages of the DTM.

Jog Command Mode

• Definition: The positioner has been placed in a local override mode

where the valve can only be stroked using the UP and DOWN buttons.

• Implications: The positioner will not respond to analog or digital input

commands from HART.

• Possible Solutions: Control the valve using the UP and DOWN

buttons. This mode may be cancelled by briefly pushing the QUICKCAL/ACCEPT button.

PST Scheduled

• Definition: The schedule established by the user shows that a partial

stroke test is due.

• Possible Solutions: Follow internal procedures to initiate a partial

stroke test (PST). A partial stroke test will cause the valve to move

suddenly and the positioner will not respond to commands while the

PST is in progress. See the Partial Stroke Test page of the DTM to

verify PST settings.

DI Command Override

• Definition: The Multi-Function Card has been configured as a Discrete

Input (DI) and to override the input command, positioning the valve at a

preconfigured set point. The DI signal is active and the positioner is

attempting to control the valve at the set point.

• Possible Solutions: Configure the DI function and set point using the

menu, a handheld or the Multi-Function Card Configuration page of the

FCD- LGENSF0014-00

© Flowserve Corporation

35

Page 36

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

DTM.

Position Status

Soft Stop High Alert

• Definition: The Final Command would move the valve beyond the

user-set Soft Limit, but the internal software is holding the position at

the limit.

• Implications: The function is similar to a mechanical limit stop except it

is not active if the unit is un-powered.

• Possible Solutions: If more travel is needed, reset the Soft Limits. If

not, adjust the Final Command signal back into the specified range.

Soft Stop Low Alert

• Definition: The Final Command would move the valve beyond the

user-set Soft Limit, but the internal software is holding the position at

the limit.

• Implications: The function is similar to a mechanical limit stop except it

is not active if the unit is un-powered.

• Possible Solutions: If more travel is needed, reset the Soft Limits. If

not, adjust the Final Command signal back into the specified range.

Position High Limit Alert

• Definition: The position has reached or is exceeding a user defined

upper position indicator.

• Implications: This is similar to a limit switch indicator.

• Possible Solutions: Set the limit to a higher value if more travel is

needed, or adjust the command signal back in the specified range.

Position Low Limit Alert

• Definition: The position has reached or is exceeding a user defined

lower position indicator similar to a limit switch indicator.

• Implications: This is similar to a limit switch indicator.

• Possible Solutions: Set the limit to a lower value if more travel is

needed, or adjust the command signal back in the specified range.

Feedback Linkage Alarm

• Definition: The feedback linkage is broken or the position feedback

POT is out of range.

• Possible Solutions: Fix broken linkage or adjust feedback arm until full

motion is within the range of the POT.

Actuation Status

FCD- LGENSF0014-00

© Flowserve Corporation

36

Page 37

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Supply Pressure High

• Definition: The supply pressure is above the user set warning limit.

• Implications: Supply pressure that exceeds the maximum rating on the

actuator can become a potential hazard.

• Possible Solutions: Regulate the supply pressure at the positioner

below the maximum limit recommended for your actuator. Recalibrate

pressure sensors. Check the pressure sensor board

connections. Replace pressure sensor board if necessary.

Supply Pressure Low

• Definition: The supply pressure is below the user set warning or alarm

limit.

• Implications: Low supply pressure can cause poor valve response or

positioner failure. The minimum recommended supply pressure for

proper operation is 1.3 bar (19 PSI).

• Possible Solutions: Regulate the supply pressure at the positioner

above 1.3 bar (19 PSI). Ensure system air/gas supply is

adequate. Repair kinked or restricted supply tubing. Check for

pneumatic leaks in the actuator and actuator tubing. Recalibrate

pressure sensors. Check the pressure sensor board connections and

replace pressure sensor board if necessary.

Actuation Ratio

• Definition: The force required to control the system is close to the

maximum available force.

• Implications: Actuation Ratio is based on the ratio of available force to

the required force to fully actuate. Control may be lost if this ratio

reaches 100%. It is affected by the process load, friction, spring force,

and available supply pressure.

• Possible Solutions: Increase the supply pressure. Reduce the

friction. Check the actuator spring. Resize the actuator. Adjust user

set limits.

Spring Fail

• Definition: Upon loss of air supply, the valve may not move to the fail-

safe position.

• Implications: The spring alone is not adequate to overcome the friction

and process load in the system. The system is relying on pneumatic

force to actuate in the direction the spring is pushing. The failsafe

FCD- LGENSF0014-00

© Flowserve Corporation

37

Page 38

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

spring may have failed, or it was not sized properly for the application.

Friction or process load may have increased.

• Possible Solutions: Repair or replace actuator spring. Check for high

friction. Reduce process load.

Pneumatic Leak

• Definition: The positioner has detected a leak in the actuation

assembly.

• Implications: Leakage from the actuator can cause decreased

responsiveness and excessive air/gas consumption.

• Possible Solutions: Repair pneumatic leaks at the tubing junctions

and actuator seals. Check spool valve for excessive wear.

Air Supply Humid

• Definition: The supply gas has high relative humidity which can lead to

condensation on electronic components and failure of electronic

functions.

• Possible Solutions: Ensure supply gas is clean and dry. Check and

clean the regulator filter.

Air Supply Icing

• Definition: The supply gas has high relative humidity and the

temperature is close to 0 °C (32 °F). Under these conditions ice may

form in the pilot relay causing diminished or total loss of position

control.

• Possible Solutions: Ensure supply gas is clean and dry. Check and

clean the regulator filter.

Main Board Status

FCD- LGENSF0014-00

Main Board Fail

• Definition: There has been an oscillator fault, position sensor ADC

failure, supply voltage error, reference voltage error, shunt voltage error,

or piezo voltage error.

• Possible Solutions: This may be caused by transient conditions. If the

error persists, replace the main board.

Software Error

• Definition: There has been a watch dog time out, stack overflow

warning, or CPU usage warning.

• Possible Solutions: If the problem persists, perform a factory reset. If

it still persists, reprogram or replace the main board.

Memory Error

© Flowserve Corporation

38

Page 39

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Definition: The microprocessor's memory has a problem.

• Possible Solutions: Error may clear with time. If error persists, cycle

power and complete a QUICK-CAL. If the error still persists, perform a

factory reset, reprogram or replace the main circuit board.

Temperature High

• Definition: The temperature of the internal electronics has exceeded

the manufacturer set limit of 85°C (176°F). High temperature may affect

performance or limit the life of the positioner.

• Possible Solutions: Regulate the temperature of the positioner by

shading or cooling supply gas. If the temperature reading is in error,

replace the main board.

Temperature Low

• Definition: The temperature of the internal electronics has exceeded

the manufacture set limit of -40°C (-40°F). Low temperature may inhibit

responsiveness and accuracy.

• Possible Solutions: Regulate the temperature of the positioner. If the

temperature reading is in error, replace the main circuit board.

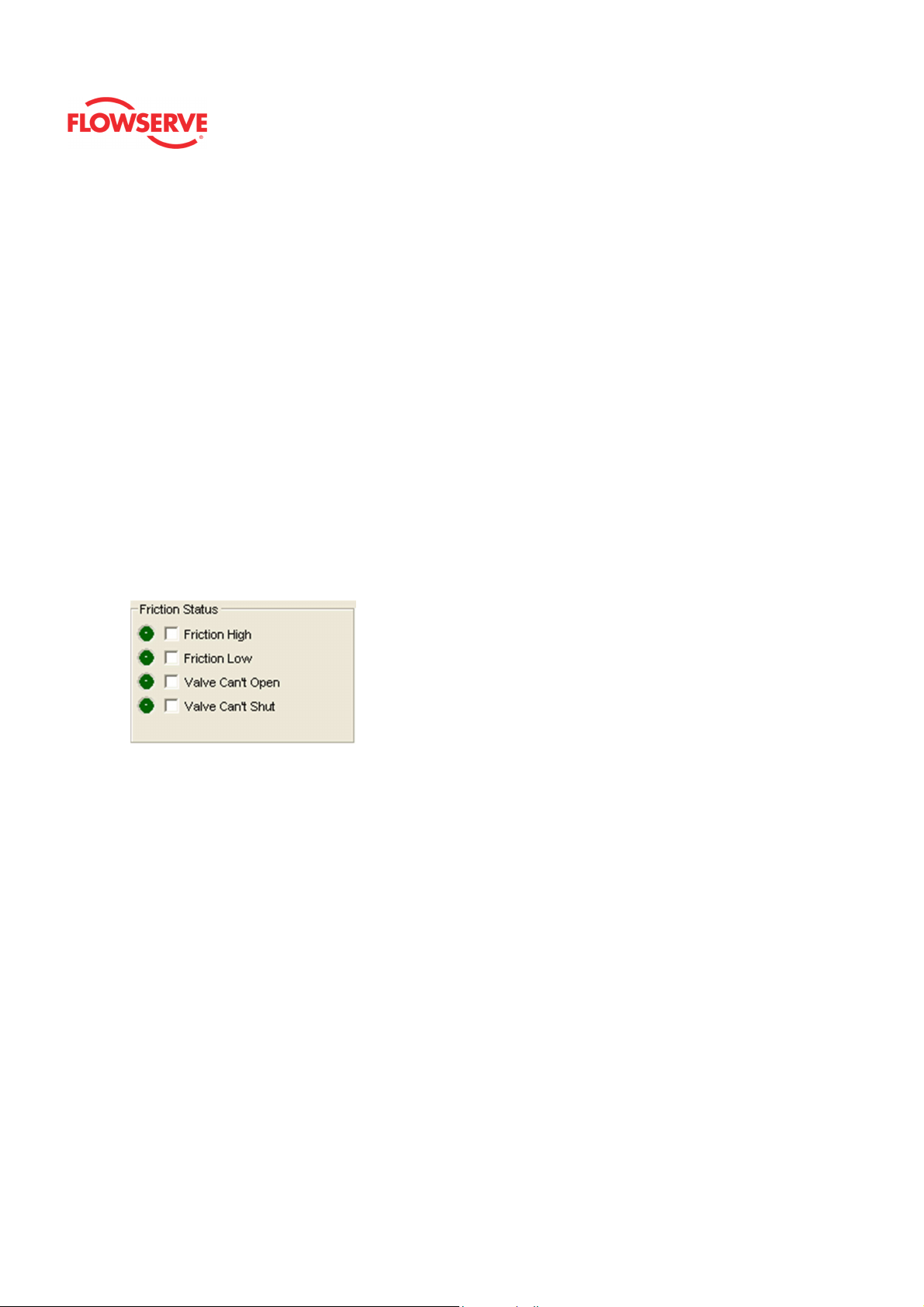

Friction Status

FCD- LGENSF0014-00

Friction High

• Definition: The valve and actuator friction has passed the user set

• Implications: High friction can cause loop oscillations, poor position

• Possible Solutions: Determine if the friction is significantly interfering

Friction Low

• Definition: The friction has passed below the user set limit.

• Implications: Low friction is an indication of improperly loaded packing

limit.

control, jerky motion, or valve sticking. It can be caused by build-up

from the process on the stem, trim or seat , by a failing bearing or

guides in the valve and actuator, galling of the trim or stem, excessively

tightened packing, linkages, or other valve or actuator mechanical

issues.

with the valve control. If not, consider increasing the friction warning

limit. Consider the following to reduce friction: Stroke the valve to clear

off build-up. Clear any external mechanical obstruction, loosen the

packing, clean the stem, repair or replace the actuator. Highly localized

friction or very jerky travel can indicate internal galling. Repair or

replace internal valve components.

and, in severe cases, can be an indication of the process fluid leaking at

© Flowserve Corporation

39

Page 40

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

the valve stem.

• Possible Solutions: Check for packing leak. Tighten or replace the

valve packing.

Valve Can't Open

• Definition: Pressure has been applied (or removed) to open the valve,

but the valve is not opening.

• Implications: This may be caused by excessive friction.

• Possible Solutions: Verify adequate supply pressure is applied. Verify

the feedback linkage is connected. View the friction trends if

available. Consider the following: Clear any external or internal

mechanical obstruction, loosen the packing, clean the stem, repair or

replace the actuator, repair the valve if galling is suspected.

Valve Can't Shut

• Definition: Pressure has been removed (or applied) to close the valve,

but the valve is not closing.

• Implications: This may be caused by excessive friction.

• Possible Solutions: Verify adequate supply pressure is applied. Verify

the feedback linkage is connected. View the friction trends if

available. Consider the following: Clear any external or internal

mechanical obstruction, loosen the packing, clean the stem, repair or

replace the actuator, repair the valve if galling is suspected.

Action Buttons

The Apply button will save changes to the connected device.

FCD- LGENSF0014-00

The Retrieve button will retrieve the latest information from the device.

The Print Report button will print a report to default printer (see example below).

Information includes:

• Information about the connected device

• The active status of the alarms, warnings and alerts.

• The masked status.

• The current value (where applicable).

• The value threshold (where applicable).

NOTE: It is possible to print the report to save to a PDF file. Instructions:

1. Download and install the free version of PDFCreator.

2. Install the PDFCreator

3. Set PDFCreator as the default Printer

© Flowserve Corporation

40

Page 41

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

4. Click Print Report and save the report to a pdf file in your computer.

© Flowserve Corporation

41

Page 42

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

© Flowserve Corporation

42

Page 43

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

© Flowserve Corporation

43

Page 44

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Management Annunciator

The Management Annunciator page displays all modes, setup, configuration and calibration

errors and their current status. If a particular indicator is not wanted then a check in the box

for a particular item will mask that item and it will not be shown in the active indicator field at

the top of each page nor will it affect the status of the health bar on the main dashboard

view.

Status Area

The Active Indicator area shows the status of the most relevant active indicator. The color

of the "LED light" corresponds to the Active Indicator and the first color of the blink code

sequence on the positioner. Generally green indicates no immediate issues. Yellow

indicates a developing issue. Red indicates the ability to control may be compromised. A

detailed list of the indicators is given in the Alarm Congfiguraion - Alarm Annunicator page.

The Command Source field indicates weather the positioner is being controlled by digital or

an analog (4-20 mA) command source.

Legend

Each indicator group box may contain the following components:

•

© Flowserve Corporation

An "LED light" indicates health status. Warning and alarm limits (set by the

44

Page 45

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

user in many cases) determine the conditions when the color will turn from

green to yellow to red. The most sever of the indicators on this page will be

shown in the health bar on the Dashboard.

• Dark Green circle indicates a healthy condition where no attention is

needed.

• Light Green indicates an occurrence of a normal activity that does

not affect the health of the valve system.

• Yellow circle indicates that an active warning, alert or mode is

present.

• Red circle indicates that an active alarm or state is present that

could seriously limit the operation of the valve.

• Gray circle indicates that the feature or condition is not available

because the configuration of the hardware or software does not support

it.

• A checkbox indicates the masked status. Check to mask. If a particular

indicator is masked, it will not be shown in the active indicator field at the top

of each screen, affect the status of the health bars on the main dashboard, be

sent in command 48, or be seen on the blinking LEDs on the positioner. It

will however continue to show on this page.

Start Up Status

Initializing

• Definition: The positioner has powered up and is displaying a blink

sequence 3 times.

• Possible Solutions: Wait for 3 blink sequences to complete.

Stroke Calibration Required

• Definition: A factory reset was performed and the positioner has not

yet been calibrated. The unit will not respond to commands and will

remain in the fail-safe position until a calibration is successfully

completed.

• Possible Solutions: Perform a Stroke Calibration (QUICK-CAL) by

holding the QUICK-CAL/ACCEPT button down for 3 seconds, or

perform a Pressure or Friction calibration if desired. See the Calibration

section of the IOM for warnings.

Pressure Calibration Required

© Flowserve Corporation

45

Page 46

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Definition: A Factory Pressure Calibration has not been performed.

Unlike a regular pressure sensor calibration, a Factory Pressure

Calibration saves the calibration values to memory, making them

available should a factory reset be performed. Proper pressure sensor

calibration is required for proper pressure sensing and diagnostics.

Calibration values from a regular pressure sensor calibration will be lost

when a factory reset is performed. Typically no pressure calibration is

required with a new positioner.

• Possible Solutions: After replacing a main board or a pressure sensor

board, perform a Factory Pressure Calibration. To do this, see the

Pressure Sensor Board Removal and Installation section of the IOM.

Friction Calibration Required

• Definition: No friction calibration has been performed since the last

factory reset. The friction calibration determines a preliminary friction

value, spring forces and direction and other information used for proper

diagnostics. If no friction calibration is performed, the positioner will

soon determine the operating friction, but other diagnostic information

will be missing.

• Possible Solutions: Perform a Friction Calibration using the display

menu, handheld, or Sensor Calibration page of the DTM. See the

Calibration section of the IOM for warnings.

Mode Status

FCD- LGENSF0014-00

Digital Command Mode

• Definition: The input command is set by a digital HART command

instead of the 4-20 mA signal.

• Possible Solutions: The input command source can be changed back

to the 4-20 mA signal by using a handheld, the Dashboard page of the

DTM, or performing a manual Command Reset. Perform the

Command Reset during a QUICK-CAL by holding both the UP and

DOWN buttons and briefly pressing the QUICK-CAL/ACCEPT button.

A new QUICK-CAL must be performed after resetting.

© Flowserve Corporation

46

Page 47

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Tight Shut Off Mode

• Definition: - (Also called MPC.) The Final Command is beyond the user

set limit for the tight shutoff feature and the positioner is applying full

actuator pressure to close (or open) the valve. This is a normal

condition for all valves when closed. The factory default setting triggers

this at command signals below 1%. This indication may also occur on 3

way valves at both ends of travel if the upper Tight Shut Off value has

been set.

• Possible Solutions: If tight shutoff is not desired reset the tight shutoff

limits or adjust the command signal inside of the specified Tight Shut

Off values.

Pressure Control Lock

• Definition: The pressures are held constant (locked), improving the

stability of the valve position. When the position of the valve gets very

close to the commanded position, the positioning algorithm will change

to pressure control. The point at which the pressure control is locked

depends on the Valve Stability switch on the positioner. When the

switch is set to “Lo Friction”, the locking point is self-adjusting to

optimize accuracy. When the switch is set to “Hi Friction” and the

deviation is smaller than +/- 1.0% (default), the pressure “locks”. The

High Friction window size can be changed to optimize the response for

valves and actuators with high friction levels. This setting slightly slows

the response and will normally stop limit cycling that can occur on high

friction valves.

• Possible Solutions: If "Hi Friction" is set and this indicator never

comes on, the error band limits may need to be adjusted using the

Pressure Control page of the DTM or the Display Menu. Use the Valve

Stability Configuration Switch to toggle the Valve Stability from "Lo

Friction" to "Hi Friction" mode. A QUICK-CAL must be performed to

apply the switch settings. If a QUICK-CAL cannot be performed, use

the DTM to activate and set the "Hi Friction" window setting. .

CST Mode (Continuous Stroke Test Mode)

• Definition: When there is no variation in the command input, this

feature is deliberately moving the valve as little as possible in order to

perform diagnostics and ensure the valve is functioning.

• Possible Solutions: If more stability is required, turn off Continuous

Stroke Test mode, or configure the rate of travel, period, and allowable

movement using the Continuous Stroke page of the DTM.

Training Mode

• Definition: The positioner is gathering data for a certain period of time.

This data can be used in the DTM to help set reasonable limits for

diagnostic warnings and alarms.

• Possible Solutions: Training has no effect on control. Allow the

training to finish if the process conditions are typical. Or start the

training over if new process conditions have been applied. See the

Training Mode page in the DTM for configuration.

FCD- LGENSF0014-00

© Flowserve Corporation

47

Page 48

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

Training Complete

• Definition: The positioner has finished gathering data for the specified

amount of time. This data can now be used to benchmark typical

conditions.

• Possible Solutions: Data is available to set more meaningful

diagnostic warning and alarm limits.

Event Captured

• Definition: A user-defined condition was met and a data file was

generated to show conditions at the time of the event.

• Possible Solutions: Use the Event Capture page of the DTM to view

the data captured during the event.

Local Interface Enabled

• Definition: Control and configuration features are locked at the

positioner's local interface. This is to prevent unauthorized or

accidental adjustments. The buttons can still be used to view

information on the LCD. The status code is only present for a short

time when the user attempts to make a change through the display

menu.

• Possible Solutions: The DTM's Local Interface page is used to unlock

the local interface, turn this feature on and off, and to set the PIN. For

temporary access, a Personal Identification Number (PIN) can be

entered from the positioner if an LCD is installed.

Squawk Mode

• Definition: A user has set the positioner to flash a special sequence so

that it can be visually located.

• Possible Solutions: This mode is cancelled if one of the following

occurs: 1) The QUICK-CAL/ACCEPT button is briefly pressed. 2) The

Squawk mode is selected again remotely. 3) More than one hour has

passed since the command was issued.

Backup Control Mode

• Definition: The positioner is controlling the position based on actuator

pressures instead of the feedback POT.

• Possible Solutions: The feedback linkage is probably broken or the

feedback arm needs to be rotated because the POT is out of range.

Calibration Error Status

FCD- LGENSF0014-00

© Flowserve Corporation

48

Page 49

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

FCD- LGENSF0014-00

Position Range Small

• Definition: During calibration, the range of motion of the position

feedback arm was too small for optimum performance.

• Possible Solutions: Check for loose linkages and/or adjust the

feedback pin to a position closer to the follower arm pivot to create a

larger angle of rotation and recalibrate. The minimum angle of rotation

should be greater than 15 degrees. Briefly pressing the QUICKCAL/ACCEPT button acknowledges this condition and the positioner

will operate using the short stroke calibration if otherwise a good

calibration.

Position < ADC Range

• Definition: During calibration, the feedback sensor moved beyond its

range of operation at the 0% (closed) position.

• Possible Solutions: Adjust the positioner mounting, linkage or

feedback potentiometer to move the position sensor back into range

then restart the calibration.

Position > ADC Range

• Definition: During calibration, the feedback sensor moved beyond its

range of operation at the 100% (open) position.

• Possible Solutions: To correct the condition, adjust the positioner

mounting, linkage or feedback potentiometer to move the position

sensor back into range then restart the calibration.

No Motion Time Out

• Definition: During a stroke calibration, there was no valve motion

detected. Because some valves are quite large, this indicator can take

up to 9 minutes to detect an error.

© Flowserve Corporation

49

Page 50

ValveSight™ Diagnostics DTM Manual for Logix MD+ Positioner with HART®

• Possible Solutions: Check linkages and air supply to make sure the

system is properly connected. If the time out occurred because the

actuator is very large then simply retry the QUICK-CAL and the

positioner will automatically adjust for a larger actuator by doubling the

time allowed for movement. This error may be cleared by briefly

pushing the QUICK-CAL/ACCEPT.

Settle Time Out

• Definition: During calibration, the position feedback sensor showed

movement, but did not settle.

• Possible Solutions: Check for loose linkages or a loose positioner

sensor. This error may appear on some very small actuators during the

initial calibration. Recalibrating may clear the problem, or this error may

be cleared by briefly pushing the QUICK-CAL/ACCEPT button.

ILO Time Out

• Definition: During calibration the Inner Loop Offset (ILO) value did not

settle. This could result in less accurate positioning.

• Possible Solutions: Repeat the stroke calibration to get a more

accurate ILO value. To proceed using the less accurate ILO value, this

error may be cleared by briefly pushing the QUICK-CAL/ACCEPT

button. Lowering the setting on the gain selection switch may help if the

actuator is unstable during the calibration.

AO Range Small

• Definition: During an Analog Output Calibration the difference between

the milliamp signal at 0% and the milliamp signal at 100% was too

small.

• Possible Solutions: Recalibrate making sure to use a larger difference

between signal limits. This notification can be cleared by briefly

pressing the QUICK-CAL/ACCEPT button.

Command Range Small

• Definition: During a Command Loop Calibration, the difference

between the signal at 0% and the signal at 100% was too small. The

system is designed to accept a difference greater than 5 mA.

• Possible Solutions: Recalibrate making sure to use a larger

difference between command signal limits. The difference must exceed

5 mA.

Command < ADC Range

• Definition: During Command Loop Calibration, the 0% signal was out

of the Analog to Digital Converter (ADC) range.

• Possible Solutions: The system is designed to accept a signal that is

above 10 ADC counts. Recalibrate making sure the ADC counts are

above that limit.

Command > ADC Range

• Definition: During Command Loop Calibration, the 100% signal was