Page 1

Device Description User Manual

Logix® MD+ Positioners with HART®

Page 2

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

CONTENTS

DD MENU CHART .................................. 3

GENERAL INFORMATION ....................... 6

INTRODUCTION .......................................................................... 6

QUALIFIED PERSONNEL ................................................................ 6

USING THIS DOCUMENT .............................................................. 6

TERMS CONCERNING SAFETY ........................................................ 6

1 LONG TAG ..................................... 7

2 TAG ............................................... 7

3* FULL INITIAL SETUP ....................... 7

3 STATUS ......................................... 7

3.1 PRIORITY ALARM ............................................................. 7

3.2 COMMAND DATA ............................................................ 7

3.3 PRESSURES ..................................................................... 7

3.4 HOUR METERS ................................................................ 7

3.5 TEMPERATURE HISTORY .................................................... 7

3.6 HEALTH DATA ................................................................. 8

3.7 DIAGNOSTIC VALUES ........................................................ 8

8 AUXILIARY CARDS ........................ 20

8.1 AUXILIARY CARD 1 ID ..................................................... 20

8.2 AUXILIARY CARD 1 TYPE .................................................. 20

8.3 AUXILIARY CARD 1 DI SETUP ........................................... 20

8.4 AUXILIARY CARD 1 DO TRIGGER ....................................... 20

8.5 CALIBRATE MFC 1 ANALOG OUT ...................................... 21

8.6 AUXILIARY CARD 2 ID ..................................................... 21

8.7 AUXILIARY CARD 2 TYPE .................................................. 21

8.8 AUXILIARY CARD 2 DI SETUP ........................................... 22

8.9 AUXILIARY CARD 2 DO TRIGGER ....................................... 22

8.10 CALIBRATE MFC 2 ANALOG OUT ...................................... 23

4 ALERTS AND ALARMS .................... 9

4.1 EVENTS HISTORY .............................................................. 9

4.2 CURRENT ALARMS ........................................................... 9

4.3 STATUS BYTES ................................................................. 9

5 STROKE TESTS ............................ 11

5.1 PARTIAL STROKE TEST ..................................................... 11

5.2 CONTINUOUS STROKE TEST ............................................. 11

6 CALIBRATION .............................. 12

6.1 CALIBRATE SENSORS ....................................................... 12

6.2 CALIBRATE COMMAND INPUT .......................................... 12

6.3 CALIBRATION DATES AND TIMES ....................................... 12

6.4 CALIBRATE MFC ANALOG OUT 1 ..................................... 12

6.5 CALIBRATE MFC ANALOG OUT 2 ..................................... 12

6.6 CALIBRATION STATUS ..................................................... 12

7 CONFIGURATION ......................... 13

7.1 RESET FACTORY DEFAULTS .............................................. 13

7.2 DEVICE INFORMATION .................................................... 13

7.3 CONTROL CONFIG .......................................................... 14

7.4 ALERTS / ALARMS CONFIG .............................................. 16

7.5 USER PREFERENCES ........................................................ 19

7.6 BURST MODE ................................................................ 20

© Flowserve Corporation 2

Page 3

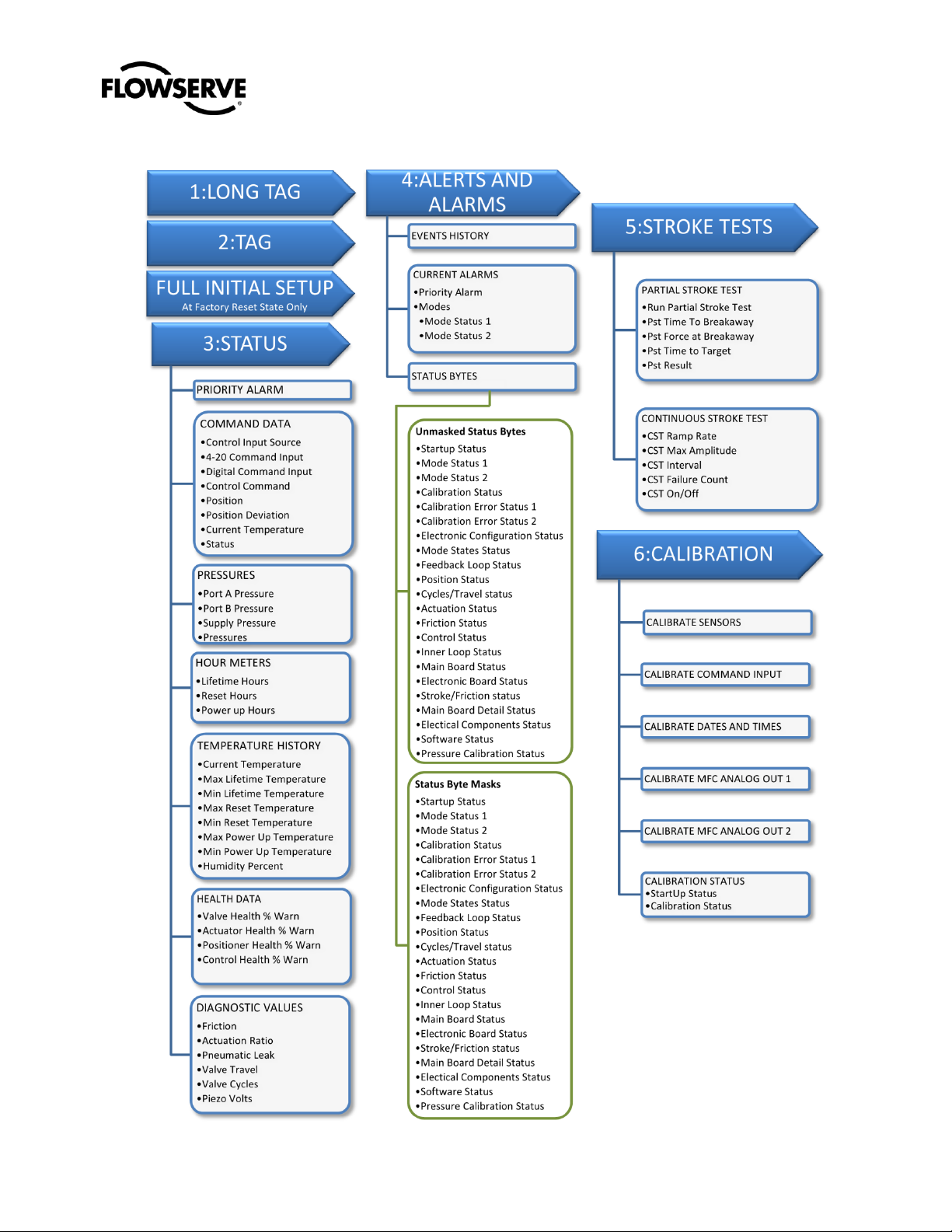

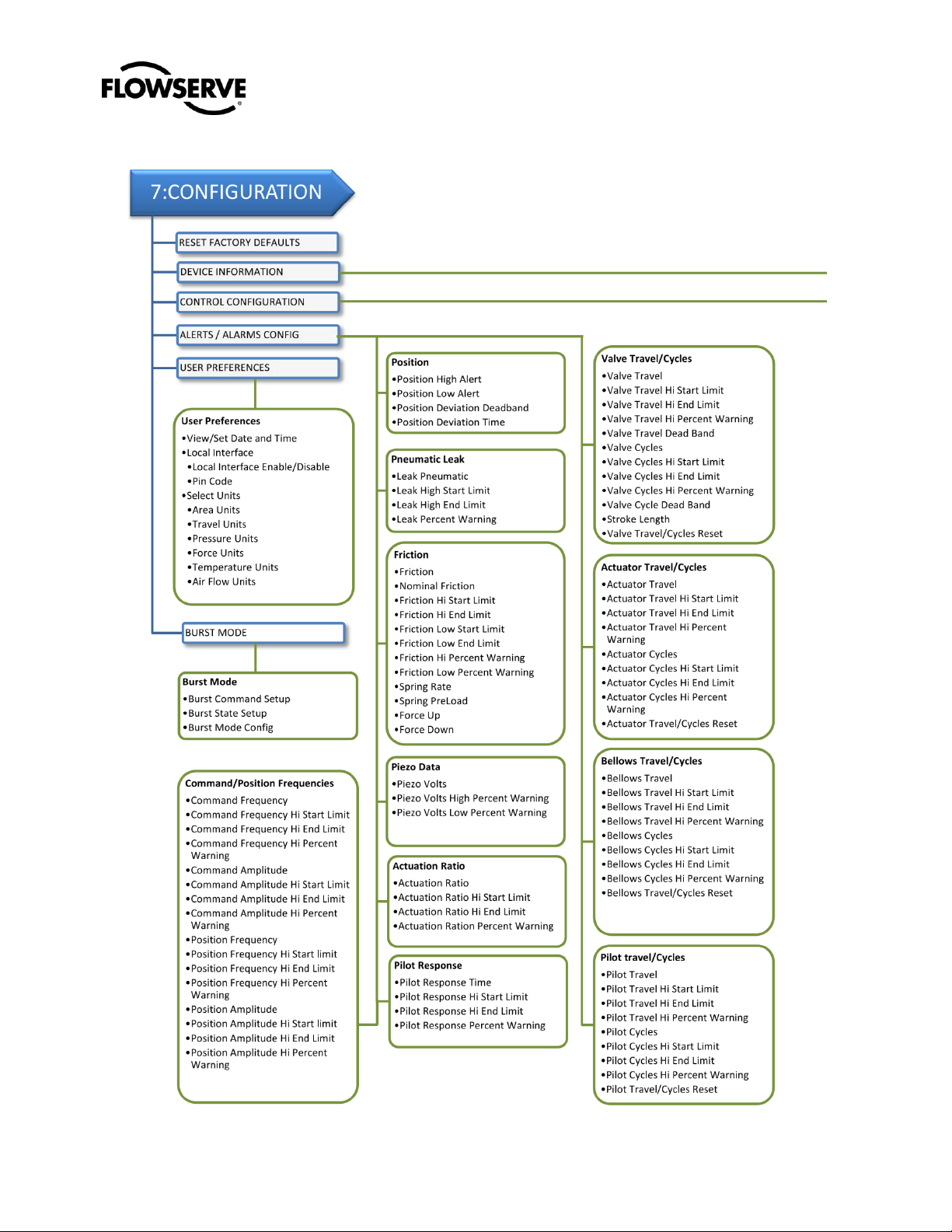

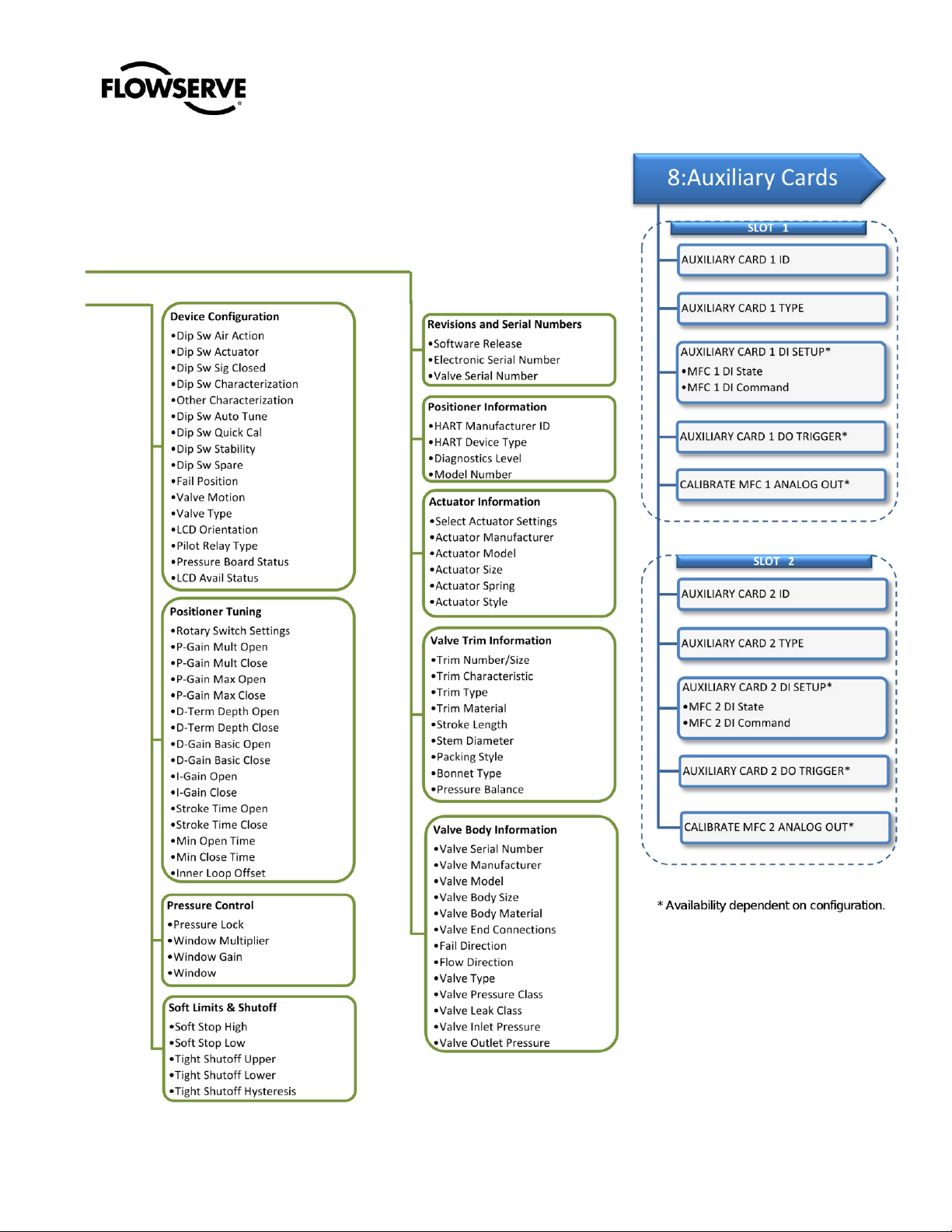

DD MENU CHART

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

© Flowserve Corporation 3

Page 4

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

© Flowserve Corporation 4

Page 5

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

© Flowserve Corporation 5

Page 6

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

GENERAL INFORMATION

Introduction

This document provides detailed information about the

function of the Logix 520MD+ Device Description (DD). The

DD follows the protocol provided by the HART

Communication Foundation. For more information about

downloading, installing and using HART DDs, visit

http://www.hartcomm.org/

Qualified Personnel

Qualified personnel are people who, on account of their

training, experience, instruction and their knowledge of

relevant standards, specifications, accident prevention

regulations and operating conditions, have been authorized

by those responsible for the safety of the plant to perform the

necessary work and who can recognize and avoid possible

dangers.

In using this software, the position and operation of the

related valves can be affected. Product users and

maintenance personnel should thoroughly review the effects

of any functions before applying those functions.

Using This Document

The features listed below are numbered to correspond to

their location in the DD menu tree. Some menu items may

not be available depending on positioner upgrade status and

the presence of auxiliary cards.

Terms Concerning Safety

The safety terms DANGER, CAUTION and NOTE are used

in these instructions to highlight particular dangers and/or to

provide additional information on aspects that may not be

readily apparent.

To avoid possible injury to personnel or damage to valve

parts, DANGER and CAUTION notes must be strictly

followed. Modifying this product, substituting non-factory

parts or using maintenance procedures other than outlined

could drastically affect performance and be hazardous to

personnel and equipment, and may void existing warranties.

NOTE: indicates and provides additional technical

information, which may not be very obvious even to qualified

personnel.

CAUTION: Indicates that minor personal injury and/or

property damage can occur if proper precautions are not

taken.

DANGER: Indicates that death, severe personal injury

and/or substantial property damage can occur if proper

precautions are not taken.

© Flowserve Corporation 6

Page 7

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

1 LONG TAG

Set the HART long tag. (For HART 6 only.)

2 TAG

Set the HART tag.

3* FULL INITIAL SETUP

Set basic values and perform calibrations required for

positioner to control.

*This menu item is only available when the positioner in in

Factory Reset state.

3 STATUS

View basic information about the current status of the

positioner including basic on-line diagnostics.

3.1 Priority Alarm

View the highest priority alarm. For a complete list of current

alarms, see Alarms and Alerts.

3.2 Command Data

View command and position information.

3.2.1 Control Input Source

Select either analog or digital command input source.

3.2.2 4-20 Command Input

View the analog command input value.

3.2.3 Digital Command Input

Set the digital command input value.

3.2.4 Control Command

View the final command after Characterization, Soft Limits,

and Tight Shut-Off effects are applied.

3.2.5 Position

View the position of the valve.

3.2.6 Position Deviation

View the difference between the Control (Final) Command

and the Position.

3.2.7 Current Temperature

The temperature of the positioner’s main circuit board.

3.2.8 Current Humidity

The humidity of the positioner’s main circuit board in relative

percent (RH).

3.3 Pressures

View the pressure sensor values. Advanced or Pro

diagnostics are required.

3.3.1 Port A Pressure

View the pressure at port A.

3.3.2 Port B Pressure

View the pressure at port B.

3.3.3 Supply Pressure

View the supply pressure.

3.3.4 Pressures

View a graph of Port A, Port B, and Supply pressures. (EDD

only.)

3.4 Hour Meters

View the number of hours the positioner has been in

operation.

3.4.1 Lifetime Hours

View the total number of hours the positioner has been in

operation.

3.4.2 Reset Hours

View the number of hours the positioner has been in

operation since the last factory reset was performed.

3.4.3 Power up Hours

View the number of hours the positioner has been in

operation since the last time it was powered up.

3.5 Temperature History

View the positioner temperature and humidity information.

3.5.1 Current Temperature

View the current temperature inside the positioner.

3.5.2 Max Lifetime Temperature

View the maximum temperature the positioner has ever

seen.

3.5.3 Min Lifetime Temperature

View the minimum temperature the positioner has ever seen.

3.5.4 Max Reset Temperature

View the maximum temperature the positioner has seen

since the last factory reset was performed.

3.5.5 Min Reset Temperature

© Flowserve Corporation 7

Page 8

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

View the minimum temperature the positioner has seen since

the last factory reset was performed.

3.5.6 Max Power Up Temperature

View the maximum temperature the positioner has seen

since the last time the positioner was powered up.

3.5.7 Min Power Up Temperature

View the minimum temperature the positioner has seen since

the last time the positioner was powered up.

3.5.8 Humidity Percent

View the current relative humidity inside the positioner.

3.6 Health Data

View the warning level for each category. The 520MD+

positioner monitors the conditions that affect the ability of the

valve to respond. As these conditions worsen, a warning

level is shown. A low value such as 0% indicates no

warning. A high value such as 90% indicates the ability to

control may be impaired soon. A value of 100 indicates that

the valve may no longer be responsive.

3.6.1 Valve Health % Warning

The warning value from 0 to 100% based on warnings and

alarms related to valve health such as friction. A lower value

indicates less serious issues.

View the pneumatic leakage of the actuator. This value does

not include normal air consumption.

3.7.4 Valve Travel

View the amount the valve has traveled in percent of total

stroke length.

3.7.5 Valve Cycles

View the number of cycles the valve has travelled. This is

the number of times the valve has changed directions twice.

3.7.6 Piezo Volts

View the voltage supplied to the piezo element in the

positioner's pilot relay. This should typically be between 0

and 24 VDC.

3.6.2 Actuator Health % Warning

The warning value from 0 to 100% based on warnings and

alarms related to actuator health such as supply pressure. A

lower value indicates less serious issues.

3.6.3 Positioner Health % Warning

The warning value from 0 to 100% based on warnings and

alarms related to positioner health such as circuit board

malfunction. A lower value indicates less serious issues.

3.6.4 Control Health % Warning

The warning value from 0 to 100% based on warnings and

alarms related to control health such as deviation. A lower

value indicates less serious issues.

3.7 Diagnostic Values

View basic diagnostic information. Pro diagnostics are

required.

3.7.1 Friction

View the friction of the valve and actuator assembly.

3.7.2 Actuation Ratio

View the effort required to move the valve in the direction that

compresses the spring. The ratio is the force required to

overcome friction, spring, and process load forces over the

force available from the current supply pressure.

3.7.3 Pneumatic Leak

© Flowserve Corporation 8

Page 9

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

4 ALERTS AND ALARMS

View and manage alerts and alarms.

4.1 Events History

View the complete list of events (alarms, calibrations etc.).

The latest event is shown first. Select OK to view previous

events.

4.2 Current Alarms

View the current status of all alarms.

4.2.1 Priority Alarm

View the top priority alarm. Other alarms may be active.

This alarm may be the root of the issue.

4.2.2 Modes

View the modes or behavior configurations of the positioner.

4.2.2.1 Mode Status 1 View the status of Digital Command, Tight Shut Off, Pressure

Control, Soft Stop, and Backup Control modes.

4.2.2.2 Mode Status 2 View the status of Continuous Stroke Test, Training In

Progress, Training Complete, Event Capture, Local Interface

Lock, and Squawk modes.

4.3 Status Bytes

View a comprehensive list of status indicators. Mask

unwanted alerts and alarms.

4.3.1 Unmasked Status Bytes

View the condition of each status indicator before masking.

Masking prevents specific alerts and alarms from being

included in the command 48 feedback.

4.3.1.1 Startup Status View status of Power ON, Initializing, Stroke Calibration

Required, Pressure Calibration Required, and Friction

Calibration Required.

4.3.1.2 Mode Status 1 View status of Digital Command Mode, Tight Shut Off Mode,

Pressure Control Locked, Soft Stop High Limit Alert, and Soft

Stop Low Limit Alert.

4.3.1.3 Mode Status 2 View status of Continuous Stroke Test Mode, Training Mode

In Progress, Training Mode Completed, Event Captured,

Local Interface Off, and Squawk Mode.

4.3.1.4 Calibration Status View status of Stroke Calibration in Progress, Setting Inner

Loop Offset, Pressure Calibration in Progress, Friction

Calibration in Progress, Command Input Calibration in

Progress, Analog Output Calibration In Progress, and Jog

Calibration Set 100% Position.

4.3.1.5 Calibration Error Status 1 View status of Position Range Too Small, Position Sensor

Below ADC Range, Position Sensor Above ADC Range, No

Motion Time Out, Settle Time Out, and Inner Loop Offset

Time Out.

4.3.1.6 Calibration Error Status 2 View status of Analog Output Range Too Small, Command

Input Range Too Small, Command Input Below ADC Range,

Command Input Above ADC Range, Stroke Shift, Stroke

Span Increase , and Stroke Span Decrease .

4.3.1.7 Electronic Configuration Status View status of Aux Card 1 Present, Aux Card 2 Present,

Pressure Sensor Board Present, and LCD Present.

4.3.1.8 Mode States Status View status of Factory Reset State, Calibration in Progress,

Signature or Partial Stroke Test in Progress, Jog Command

Mode, Partial Stroke Test Scheduled, and DI Command

Override.

4.3.1.9 Feedback Loop Status View status of Position Deviation Alarm, Position Sensor

Failure Alarm, Valve Opened Too Far Warning, Valve Closed

Too Far Warning, Backlash Warning, Backlash Alarm, Partial

Stroke Test Failed Warning, and Continuous Stroke Test

Failed Warning.

4.3.1.10 Position Status View status of Position High Limit Alert, Position Low Limit

Alert and Feedback Linkage Alarm.

4.3.1.11 Cycles/Travel status View status of Valve Cycles Warning, Valve Travel Warning,

Actuator Cycles Warning, Actuator Travel Warning, Bellows

Cycles Warning, Bellows Travel Warning, Pilot Relay Cycles

Warning, and Pilot Relay Travel Warning.

4.3.1.12 Actuation Status View status of Supply Pressure High Warning, Supply

Pressure Low Warning, Supply Pressure Low Alarm,

Actuation Ratio Warning, Spring Unable to Fail Safe

Warning, Pneumatic Leak Warning, Air Supply Humid

Warning, and Air Supply Icing Warning.

4.3.1.13 Friction Status View status of Friction High Warning, Friction High Alarm,

Friction Low Warning, Friction Low Alarm, Valve Can't Open

Alarm, and Valve Can't Shut Alarm.

4.3.1.14 Control Status View status of Command Frequency Warning, Command

Frequency Alarm, Command Amplitude Warning, Command

Amplitude Alarm, Position Frequency Warning, Position

Frequency Alarm, Position Amplitude Warning, and Position

Amplitude Alarm.

© Flowserve Corporation 9

Page 10

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

4.3.1.15 Inner Loop Status View status of Pilot Relay Response Warning, Pilot Relay

Response Alarm, Piezo Voltage High Warning, Piezo Voltage

High Alarm, Piezo Voltage Low Warning, Piezo Voltage Low

Alarm, and Driver Module Alarm.

4.3.1.16 Main Board Status View status of Main Board Electronic Failure Warning,

Software Error Warning, Memory Error Warning,

Temperature High Warning, and Temperature Low Warning.

4.3.1.17 Electronic Board Status View status of Aux Card 1 Failure Warning, Aux Card 2

Failure Warning, Aux Card 1 No Loop Power, Aux Card 2 No

Loop Power, Aux Card 1 Error, Aux Card 2 Error, Pressure

Sensor Board Failure Warning, and Low Battery Warning.

4.3.1.18 Stroke/Friction status View status of Reversed Spring, Insufficient Spring, and No

Spring.

4.3.1.19 Main Board Status View status of Humidity Sensor Failure, Oscillator Fault,

Position Sensor ADC Failure, Supply Voltage Error,

Reference Voltage Error, Shunt Voltage Error, and Piezo

Voltage Error.

4.3.1.20 Electrical Components Status View status of Pilot Can't Open, Pilot Can't Shut, Hall Sensor

Failure, and ILO Out Of Range.

4.3.1.21 Software Status View status of NVMEM CRC Error, RAM Error, RAM CRC

Error, FLASH CRC Error, Watch Dog Time Out, Stack

Overflow Warning, CPU Usage Warning, and Firmware

Update Applied.

4.3.1.22 Pressure Calibration Status View status of Port S Out Of Range, Port A Out Of Range,

Port B Out Of Range, Port S Range too Small, Port A Range

too Small, Port B Range too Small, and Pressure Sensor

Failure.

4.3.2 Status Byte Masks

Mask status indicators from appearing in command 48. This

applies only to warnings, alarms and alerts that affect the

health of the system.

4.3.2.1 Startup Status Mask Power ON, Initializing, Stroke Calibration Required,

Pressure Calibration Required, and Friction Calibration

Required.

4.3.2.2 Mode Status 1 Mask Digital Command Mode, Tight Shut Off Mode, Pressure

Control Locked, Soft Stop High Limit Alert, and Soft Stop Low

Limit Alert.

4.3.2.3 Mode Status 2

Mask Continuous Stroke Test Mode, Training Mode In

Progress, Training Mode Completed, Event Captured, Local

Interface Off, and Squawk Mode.

4.3.2.4 Calibration Status Mask Stroke Calibration in Progress, Setting Inner Loop

Offset, Pressure Calibration in Progress, Friction Calibration

in Progress, Command Input Calibration in Progress, Analog

Output Calibration In Progress, and Jog Calibration Set

100% Position.

4.3.2.5 Calibration Error Status 1 Mask Position Range Too Small, Position Sensor Below ADC

Range, Position Sensor Above ADC Range, No Motion Time

Out, Settle Time Out, and Inner Loop Offset Time Out.

4.3.2.6 Calibration Error Status 2 Mask Analog Output Range Too Small, Command Input

Range Too Small, Command Input Below ADC Range,

Command Input Above ADC Range, Stroke Shift, Stroke

Span Increase , and Stroke Span Decrease.

4.3.2.7 Electronic Configuration Status Mask Aux Card 1 Present, Aux Card 2 Present, Pressure

Sensor Board Present, and LCD Present.

4.3.2.8 Mode States Status Mask Factory Reset State, Calibration in Progress, Signature

or Partial Stroke Test in Progress, Jog Command Mode,

Partial Stroke Test Scheduled, and DI Command Override.

4.3.2.9 Feedback Loop Status Mask Position Deviation Alarm, Position Sensor Failure

Alarm, Valve Opened Too Far Warning, Valve Closed Too

Far Warning, Backlash Warning, Backlash Alarm, Partial

Stroke Test Failed Warning, and Continuous Stroke Test

Failed Warning.

4.3.2.10 Position Status Mask Position High Limit Alert, Position Low Limit Alert and

Feedback Linkage Alarm.

4.3.2.11 Cycles/Travel status Mask Valve Cycles Warning, Valve Travel Warning, Actuator

Cycles Warning, Actuator Travel Warning, Bellows Cycles

Warning, Bellows Travel Warning, Pilot Relay Cycles

Warning, and Pilot Relay Travel Warning.

4.3.2.12 Actuation Status Mask Supply Pressure High Warning, Supply Pressure Low

Warning, Supply Pressure Low Alarm, Actuation Ratio

Warning, Spring Unable to Fail Safe Warning, Pneumatic

Leak Warning, Air Supply Humid Warning, and Air Supply

Icing Warning.

4.3.2.13 Friction Status Mask Friction High Warning, Friction High Alarm, Friction

Low Warning, Friction Low Alarm, Valve Can't Open Alarm,

and Valve Can't Shut Alarm.

4.3.2.14 Control Status

© Flowserve Corporation 10

Page 11

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

Mask Command Frequency Warning, Command Frequency

Alarm, Command Amplitude Warning, Command Amplitude

Alarm, Position Frequency Warning, Position Frequency

Alarm, Position Amplitude Warning, and Position Amplitude

Alarm.

4.3.2.15 Inner Loop Status Mask Pilot Relay Response Warning, Pilot Relay Response

Alarm, Piezo Voltage High Warning, Piezo Voltage High

Alarm, Piezo Voltage Low Warning, Piezo Voltage Low

Alarm, and Driver Module Alarm.

4.3.2.16 Main Board Status Mask Main Board Electronic Failure Warning, Software Error

Warning, Memory Error Warning, Temperature High

Warning, and Temperature Low Warning.

4.3.2.17 Electronic Board Status Mask Aux Card 1 Failure Warning, Aux Card 2 Failure

Warning, Aux Card 1 No Loop Power, Aux Card 2 No Loop

Power, Aux Card 1 Error, Aux Card 2 Error, Pressure Sensor

Board Failure Warning, and Low Battery Warning.

4.3.2.18 Stroke/Friction status Mask Reversed Spring, Insufficient Spring, and No Spring.

4.3.2.19 Main Board Status Mask Humidity Sensor Failure, Oscillator Fault, Position

Sensor ADC Failure, Supply Voltage Error, Reference

Voltage Error, Shunt Voltage Error, and Piezo Voltage Error.

4.3.2.20 Electrical Components Status Mask Pilot Can't Open, Pilot Can't Shut, Hall Sensor Failure,

and ILO Out Of Range.

4.3.2.21 Software Status Mask NVMEM CRC Error, RAM Error, RAM CRC Error,

FLASH CRC Error, Watch Dog Time Out, Stack Overflow

Warning, CPU Usage Warning, and Firmware Update

Applied.

4.3.2.22 Pressure Calibration Status Mask Port S Out Of Range, Port A Out Of Range, Port B Out

Of Range, Port S Range too Small, Port A Range too Small,

Port B Range too Small, and Pressure Sensor Failure.

5 STROKE TESTS

Run a partial stroke tests and view results. Configure the

continuous stroke test.

DANGER: Using this feature will result in valve movement

and the inability to operate the valve until the operation is

complete. Notify proper personnel that the valve may

stroke, and make sure the valve is properly isolated before

proceeding.

5.1 Partial Stroke Test

Run a partial stroke tests and view results.

5.1.1 Run Partial Stroke Test

Start a partial stroke test. Warning: The PST will cause valve

movement.

5.1.2 PST Time To Breakaway

View the time required for the valve to begin movement.

5.1.3 PST Force at Breakaway

View the force recorded when the valve began to move. This

force is valid for slow ramps only.

5.1.4 PST Time to Target

View the time taken for the position to come within 2% of the

final command after the initial change in command.

5.1.5 PST Result

View the pass/fail result of the last partial stroke test.

5.2 Continuous Stroke Test

Configure the continuous stroke test (CST). This feature is

NOT recommended for processes requiring highly accurate

positioning, or for valves that are frequently adjusting

position. The CST function superimposes a small,

continuous bi-directional ramp over the input command. By

constantly moving the valve, additional diagnostic data can

be gathered that would otherwise be unavailable with a

constant input command. The superimposed ramp reverses

when the valve moves.

5.2.1 CST Ramp Rate

Set the rate of the superimposed ramp in percent/second.

5.2.2 CST Max Amplitude

Set the maximum ramp amplitude. The valve position will not

always follow the full ramp amplitude. If the valve moves

before the full ramp amplitude is reached, the superimposed

ramp command will be reversed, edging the valve the other

way. This way the actual movement of the valve is

minimized.

5.2.3 CST Interval

Set the amount of time (in seconds) the positioner should

wait between ramping attempts.

5.2.4 CST Failure Count

© Flowserve Corporation 11

Page 12

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

View the number of times the valve failed to move at the end

of a ramp.

5.2.5 CST On/Off

Turn CST on or off. Warning: The CST will cause small

periodic valve movements.

6 CALIBRATION

Calibrate all aspects of the positioner.

6.1 Calibrate Sensors

Calibrate the stroke, pressure sensors, friction feature, or all

of them in one operation using the "Triple" calibration.

6.2 Calibrate Command Input

Calibrate the analog command input. Typically this will be 4

to 20 mA. However, a split range can be set also.

DANGER: Using this feature will result in valve movement

and the inability to operate the valve until the operation is

complete. Notify proper personnel that the valve may

stroke, and make sure the valve is properly isolated before

proceeding.

6.3 Calibration Dates and Times

View a history of previous calibration dates and times.

6.4 Calibrate MFC Analog Out 1

Calibrate the analog output. A multi-function card (MFC)

must be installed in slot 1 and configured for the AO function.

6.5 Calibrate MFC Analog Out 2

Calibrate the analog output. A multi-function card (MFC)

must be installed in slot 2 and configured for the AO function.

6.6 Calibration Status

View details about the calibration flags.

6.6.1 StartUp Status

View the state of the positioner including Power ON,

Initializing, Stroke Calibration Required, Pressure Calibration

Required, and Friction Calibration Required.

6.6.2 Calibration Status

View the state of the positioner including Stroke Calibration in

Progress, Setting Inner Loop Offset, Pressure Calibration in

Progress, Friction Calibration in Progress, Command Input

Calibration in Progress, Analog Output Calibration In

Progress, and Jog Calibration Set 100% Position.

© Flowserve Corporation 12

Page 13

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

7 CONFIGURATION

View and set the configuration of the system.

7.1 Reset Factory Defaults

Reset all values back to the default state. This will affect the

positioner behavior and configuration settings will be reset.

After a factory reset, the positioner will need to be configured

and stroke calibration will need to be performed.

DANGER: Using this feature will result in valve movement

and the inability to operate the valve until the positioner is

calibrated. Notify proper personnel that the valve may

stroke, and make sure the valve is properly isolated before

proceeding.

7.2 Device Information

View the information about the system .

7.2.1 Revisions and Serial Numbers

View information about the system revisions and serial

numbers.

7.2.1.1 Software Release View the software version number.

7.2.1.2 Electronic Serial Number View the serial number assigned to the positioner. This

number is listed on the positioner label.

7.2.1.3 Valve Serial Number View the valve serial number. This number is entered by the

user. See Valve Information.

7.2.2 Positioner Information

View information about HART and the positioner.

7.2.2.1 HART Manufacturer ID View the positioner manufacturer.

7.2.2.2 HART Device Type View HART device type of the positioner.

7.2.2.3 Diagnostics Level View the diagnostic level of the positioner. Three levels are

possible - Standard, Advanced, and Pro.

7.2.2.4 Model Number View the positioner model number.

7.2.3 Actuator Information

View and set information about the actuators.

7.2.3.1 Select Actuator Settings Select actuators from a list to automatically look up and store

some of the actuator information.

7.2.3.2 Actuator Manufacturer Select the actuator manufacturer from a list.

7.2.3.3 Actuator Model Select the actuator model from a list.

7.2.3.4 Actuator Size Select the actuator size. Selecting the area of the actuator is

important for some of the diagnostics that deal with force,

such as the friction values.

7.2.3.5 Actuator Spring Select the actuator spring type from a list.

7.2.3.6 Actuator Style Select the actuator style from a list.

7.2.4 Valve Trim Information

View and set information about the valve trim.

7.2.4.1 Trim Number/Size Set the Trim Number/Size.

7.2.4.2 Trim Characteristic Set the Trim Characteristic.

7.2.4.3 Trim Type Set the Trim Type.

7.2.4.4 Trim Material Set the Trim Material.

7.2.4.5 Stroke Length Set the Stroke Length.

7.2.4.6 Stem Diameter Set the Stem Diameter.

7.2.4.7 Packing Style Set the Packing Style.

7.2.4.8 Bonnet Type Set the Bonnet Type.

7.2.4.9 Pressure Balance Set the Pressure Balance.

7.2.5 7.2.5.0 - Valve Body Information

View and set information about the valve body.

7.2.5.1 Valve Serial Number Set the Valve Serial Number.

7.2.5.2 Valve Manufacturer Set the Valve Manufacturer.

7.2.5.3 Valve Model Set the Valve Model.

7.2.5.4 Valve Body Size

© Flowserve Corporation 13

Page 14

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

Set the Valve Body Size.

7.2.5.5 Valve Body Material Set the Valve Body Material.

7.2.5.6 Valve End Connections Set the Valve End Connections.

7.2.5.7 Fail Direction Set the direction the valve is tubed to fail upon loss of

pressure.

7.2.5.8 Flow Direction Set if flow direction.

7.2.5.9 Valve Type Set rotary or linear.

7.2.5.10 Valve Pressure Class Set the Valve Pressure Class.

7.2.5.11 Valve Leak Class Set the Valve Leak Class.

7.2.5.12 Valve Inlet Pressure Set the Valve Inlet Pressure.

7.2.5.13 Valve Outlet Pressure Set the Valve Outlet Pressure.

7.3 Control Config

Set parameters the affect the control of the valve. Warning:

Adjusting the control configuration will affect the way the

valve position is controlled.

7.3.1 Device Configuration

Override DIP switch settings, reverse the LCD, set fail

position, view relay type

DANGER: Changing the DIP Switch settings can affect

how the valve controls and may cause sudden valve

movement. Notify proper personnel that the valve may

stroke, and make sure the valve is properly isolated before

proceeding.

7.3.1.1 Dip Sw Air Action Override the DIP switch on the positioner to change the Air

Action. Select Air to Open or Air to Close.

7.3.1.2 Dip Sw Actuator Override the DIP switch on the positioner to change the

Actuator action. Select Double or Single. This is only

applicable for positioners with double acting relay modules.

7.3.1.3 Dip Sw Sig Closed Override the DIP switch on the positioner to change the

Signal at Closed. Select 4 mA or 20 mA.

7.3.1.4 Dip Sw Characterization Override the DIP switch on the positioner to change the

Characterization. Select Linear or Other. If Other is

selected, choose a characterization curve using "Other

Characterization" below.

7.3.1.5 Other Characterization If the Characterization Dip Switch is set to "Other", select the

desired characterization curve. The Custom curve has a

default of equal percent for linear valves.

7.3.1.6 Dip Sw Auto Tune Override the DIP switch on the positioner to change the Auto

Tune setting. Select On or Off. Selecting On enables an

auto tune feature that will automatically determine the

positioner gain settings during a Quick-Cal. Selecting Off

tells the positioner to use the factory preset tuning levels

determined by the gain selector switch.

7.3.1.7 Dip Sw Quick Cal Override the DIP switch on the positioner to change the

Quick Cal mode. Select Auto or Jog. Select Auto under

most circumstances. Select Jog if there is no hard stop on

the valve at the 100% open position. When performing a

Quick-Cal, the 100% position can be manually set.

7.3.1.8 Dip Sw Stability Override the DIP switch on the positioner to change the

Valve Stability. Select Low Friction or High Friction. Placing

the switch to Lo Friction optimizes the response for low

friction, high performance control valves. Placing the switch

to the right optimizes the response for valves and actuators

with high friction levels.

7.3.1.9 Dip Sw Spare The Spare DIP typically has no function and is reserved for

special features.

7.3.1.10 Fail Direction Record the fail direction. Select Closed or Open. This entry

does not affect the function of the positioner or the fail

position of the valve. It is only a label.

7.3.1.11 Flow Direction Record the flow direction. Select Over, Under or Other. This

should represent the configuration of the valve.

7.3.1.12 Valve Type Record the valve type. Select Linear or Rotary. This entry

does not affect the function of the positioner. It is only a

label.

7.3.1.13 LCD Orientation Select the LCD orientation. Select Normal or Reversed.

Reversed will flip the LDC display upside down.

7.3.1.14 Pilot Relay Type View the pilot relay type. Spool relays have higher capacity.

Poppet relays have lower air consumption.

7.3.1.15 Pressure Board Status

© Flowserve Corporation 14

Page 15

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

View if the pressure sensor board is installed.

7.3.1.16 LCD Avail Status View if the LCD is installed.

7.3.2 Positioner Tuning

View and adjust tuning parameters

DANGER: Changing the tuning parameters can affect how

the valve controls and may cause sudden valve movement.

Notify proper personnel that the valve may stroke, and make

sure the valve is properly isolated before proceeding.

7.3.2.1 Rotary Switch Settings View the rotary switch setting. This is a live manual tune

selector. Use this as a first option when adjusting the tuning.

7.3.2.2 P-Gain Mult Open Adjust the proportional gain multiplier in the open direction.

Use caution when adjusting gain settings. Small changes

can cause the valve position to go unstable.

7.3.2.3 P-Gain Mult Close Adjust the proportional gain multiplier in the close direction.

Use caution when adjusting gain settings. Small changes

can cause the valve position to go unstable.

7.3.2.4 P-Gain Max Open Adjust the maximum proportional gain setting in the open

direction. Use caution when adjusting gain settings. Small

changes can cause the valve position to go unstable.

7.3.2.5 P-Gain Max Close Adjust the maximum proportional gain setting in the close

direction. Use caution when adjusting gain settings. Small

changes can cause the valve position to go unstable.

7.3.2.6 D-Term Depth Open Adjust the derivative gain depth in the open direction. Use

caution when adjusting gain settings. Small changes can

cause the valve position to go unstable.

7.3.2.7 D-Term Depth Close Adjust the derivative gain depth in the close direction. Use

caution when adjusting gain settings. Small changes can

cause the valve position to go unstable.

7.3.2.8 D-Gain Basic Open Adjust the basic derivative gain in the open direction. Use

caution when adjusting gain settings. Small changes can

cause the valve position to go unstable.

7.3.2.9 D-Gain Basic Close Adjust the basic derivative gain in the close direction. Use

caution when adjusting gain settings. Small changes can

cause the valve position to go unstable.

7.3.2.10 I-Gain Open Adjust the integral gain in the open direction. Use caution

when adjusting gain settings. Small changes can cause the

valve position to go unstable.

7.3.2.11 I-Gain Close Adjust the integral gain in the close direction. Use caution

when adjusting gain settings. Small changes can cause the

valve position to go unstable.

7.3.2.12 Stroke Time Open Adjust the stroke time in the open direction. This time is

determined at calibration. A smaller stroke time will increase

the responsiveness in the open direction.

7.3.2.13 Stroke Time Close Adjust the stroke time in the close direction. This time is

determined at calibration. A smaller stroke time will increase

the responsiveness in the close direction.

7.3.2.14 Min Open Time Set the minimum open time. This is a speed limit for any

movement of the valve in the open direction. The maximum

rate will be 100% / Min Open Time.

7.3.2.15 Min Close Time Set the minimum close time. This is a speed limit for any

movement of the valve in the close direction. The maximum

rate will be 100% / Min Close Time.

7.3.2.16 Inner Loop Offset Set the Inner Loop Offset. This is automatically determined

at calibration. Do not adjust this unless the positioner is not

responding and the current value is not between 30% and

70%.

7.3.3 Pressure Control

View and set the pressure control lock parameters. When the

Valve Stability DIP switch is set to High Friction and the

deviation is less than the Window value, the position will be

locked based on pressure control rather than position

feedback. When the Valve Stability DIP switch is set to Low

Friction, the pressure window is automatically optimized to be

as small as possible.

7.3.3.1 Pressure Lock View the status of the pressure lock.

7.3.3.2 Window Multiplier Set the window multiplier value for automatic optimization of

the pressure control window when the Valve Stability DIP

switch is set to Low Friction. Typically this value does not

need adjustment.

7.3.3.3 Window Gain Set the window gain value for automatic optimization of the

pressure control window when the Valve Stability DIP switch

is set to Low Friction. Typically this value does not need

adjustment.

7.3.3.4 Window Set the size pressure control window when the Valve Stability

DIP switch is set to Hi Friction. A larger window will stop

valve oscillations caused by very high friction. A smaller

window will allow more accurate valve positioning.

© Flowserve Corporation 15

Page 16

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

7.3.4 Soft Limits & Shutoff

Set Soft Limits that stop the valve from traveling beyond a set

point. Set Shutoff limits that cause full pressure to close or

open the valve.

7.3.4.1 Soft Stop High Set the maximum valve position the final command will allow,

regardless of the analog or digital input command. This is

similar to placing a physical block on the valve stem to limit

the amount the valve can open.

7.3.4.2 Soft Stop Low Set the minimum valve position the final command will allow,

regardless of the analog or digital input command. This is

similar to placing a physical block on the valve stem to limit

the amount the valve can close.

7.3.4.3 Tight Shutoff Upper Set the upper command limit that will trigger the positioner to

apply full supply pressure in the open direction. For

example, after setting the Tight Shutoff Upper to 95%, if the

positioner receives any input command greater than 95%, full

supply pressure will be applied to open the valve.

7.3.4.4 Tight Shutoff Lower Set the lower command limit that will trigger the positioner to

apply full supply pressure in the close direction. For

example, after setting the Tight Shutoff Upper to 5%, if the

positioner receives any input command less than 5%, full

supply pressure will be applied to close the valve.

7.3.4.5 Tight Shutoff Hysteresis Enter the amount the command must backtrack in order for

the positioner to return to regular control. For example, it the

Tight Shutoff Upper is set to 90%, and Tight Shutoff

Hysteresis is set at 2%. The command must return from

90% to 88% in order for the positioner to control normally.

This is to prevent an oscillation in and out of Tight Shutoff

mode.

7.4 Alerts / Alarms Config

View and set alarm and alert limits.

7.4.1 Position

View and set alarm and alert limits regarding position.

7.4.1.1 Position High Alert Set the upper limit at which an alert will be sounded. The

valve will be allowed to continue travel beyond this point.

7.4.1.2 Position Low Alert Set the lower limit at which an alert will be sounded. The

valve will be allowed to continue travel beyond this point.

7.4.1.3 Position Deviation Dead band Set the amount of allowable deviation before sounding the

Position Deviation alarm. The deviation must remain for the

time set in the Position Deviation Time parameter.

7.4.1.4 Position Deviation Time Set the amount of allowable time before sounding the

Position Deviation alarm. The deviation must be outside of

the deviation limit set in the Position Deviation Dead Band

parameter.

7.4.2 Pneumatic Leak

View and set pneumatic leak limits.

7.4.2.1 Leak Pneumatic View the amount of pneumatic leak beyond normal air

consumption. This feature requires Pro diagnostics.

7.4.2.2 Leak High Start Limit Set the pneumatic leak limit at which a warning will appear.

7.4.2.3 Leak High End Limit Set the pneumatic leak limit at which a warning will show full

severity.

7.4.2.4 Leak Percent Warning View the severity of the pneumatic leak warning based on the

Start and End limits.

7.4.3 Friction

View and set friction limits. This feature requires Pro

diagnostics.

7.4.3.1 Friction View the friction of the valve and actuator assembly.

7.4.3.2 Nominal Friction View the last saved friction value.

7.4.3.3 Friction Hi Start Limit Set the high friction limit at which a warning will appear.

7.4.3.4 Friction Hi End Limit Set the high friction limit at which a warning will show full

severity.

7.4.3.5 Friction Low Start Limit Set the low friction limit at which a warning will appear.

7.4.3.6 Friction Low End Limit Set the low friction limit at which a warning will show full

severity.

7.4.3.7 Friction Hi Percent Warning View the severity of the high friction warning based on the

Start and End limits.

7.4.3.8 Friction Low Percent Warning View the severity of the low friction warning based on the

Start and End limits.

7.4.3.9 Force Up at 15 Percent View the force required to move the valve up at 15% position.

7.4.3.10 Force Down at 15 Percent

© Flowserve Corporation 16

Page 17

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

View the force required to move the valve down at 15%

position.

7.4.3.11 Force Up at 85 Percent View the force required to move the valve up at 85% position.

7.4.3.12 Force Down at 85 Percent View the force required to move the valve down at 85%

position.

7.4.3.13 Spring Rate View the calculated spring rate which is the force change

over the full stroke. A negative value indicates the spring is

pushing the valve in the close direction.

7.4.3.14 Spring Pre Load View the estimated force of the spring at the close position.

A negative value indicates the spring is pushing the valve in

the close direction.

7.4.3.15 Force Up View the force required to move the valve up under the most

recent conditions.

7.4.3.16 Force Down View the force required to move the valve down under the

most recent conditions.

7.4.4 Piezo Data

View piezo data. The piezo is a small valve in the positioner

that is controlled electronically and drives the pilot relay.

7.4.4.1 Piezo Command 1 Avg View the average piezo command (1st aspect).

7.4.4.2 Piezo Command 2 Avg View the average piezo command (2nd aspect).

7.4.4.3 Piezo Volts 1 Avg View the average actual piezo voltage (1st aspect).

7.4.4.4 Piezo Volts 2 Avg View the average actual piezo voltage (2nd aspect).

7.4.4.5 Piezo Volts View current piezo voltage.

7.4.4.6 Piezo Volts High Percent Warning Set the limit at which an Piezo Voltage High warning will

appear.

7.4.4.7 Piezo Volts Low Percent Warning Set the limit at which a Piezo Voltage Low warning will

appear.

7.4.5 Actuation Ratio

View and set the Actuation Ratio alarm limits. The Actuation

Ratio is the force required to actuate the valve as a

percentage of the total force available. The value is an

estimate of the force that would be required to move the

valve to the end of travel, fully compressing the actuator

spring(s). It is affected by the process load, friction, spring

force, and available supply pressure. This feature requires

Pro diagnostics.

7.4.5.1 Actuation Ratio View the current value of the Actuation Ratio.

7.4.5.2 Actuation Ratio Hi Start Limit Set the limit at which an Actuation Ratio warning will appear.

7.4.5.3 Actuation Ratio Hi End Limit Set the limit at which an Actuation Ratio warning will show

full severity.

7.4.5.4 Actuation Ration Percent Warning View the severity of the Actuation Ratio warning based on

the Start and End limits.

7.4.6 Pilot Response

View and set the Pilot Response warning limits. The pilot

response is a measure of how rapidly the pilot relay is

following the pilot relay command. Longer times indicate

slower response. This feature requires Pro diagnostics.

7.4.6.1 Pilot Response Time View the current value of the pilot response time. This is a

measure of how rapidly the pilot relay is following the pilot

relay command.

7.4.6.2 Pilot Response Hi Start Limit Set the limit at which the Pilot Response warning will appear.

7.4.6.3 Pilot Response Hi End Limit Set the limit at which the Pilot Response warning will show

full severity.

7.4.6.4 Pilot Response Percent Warning View the severity of the Pilot Response warning based on the

Start and End limits.

7.4.7 Command/Position Frequencies

Set and view parameters associated with the command and

position frequency amplitude. This feature requires Pro

diagnostics.

7.4.7.1 Command Frequency View the typical frequency of the command input cycling In

cycles/hour.

7.4.7.2 Command Frequency Hi Start Limit Set the limit at which the Command Frequency warning will

appear.

7.4.7.3 Command Frequency Hi End Limit Set the limit at which the Command Frequency warning will

show full severity.

7.4.7.4 Command Frequency Hi Percent Warning

© Flowserve Corporation 17

Page 18

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

View the severity of the Command Frequency warning based

on the Start and End limits.

7.4.7.5 Command Amplitude View the typical amplitude of the command input.

7.4.7.6 Command Amplitude Hi Start Limit Set the limit at which the Command Amplitude warning will

appear.

7.4.7.7 Command Amplitude Hi End Limit Set the limit at which the Command Amplitude warning will

show full severity.

7.4.7.8 Command Amplitude Hi Percent Warning View the severity of the Command Amplitude warning based

on the Start and End limits.

7.4.7.9 Position Frequency View the typical frequency of the position cycling in

cycles/hour.

7.4.7.10 Position Frequency Hi Start limit Set the limit at which the Position Frequency warning will

appear.

7.4.7.11 Position Frequency Hi End Limit Set the limit at which the Position Frequency warning will

show full severity.

7.4.7.12 Position Frequency Hi Percent Warning View the severity of the Position Frequency warning based

on the Start and End limits.

7.4.7.13 Position Amplitude View the typical amplitude of the valve position.

7.4.7.14 Position Amplitude Hi Start limit Set the limit at which the Position Amplitude warning will

appear.

7.4.7.15 Position Amplitude Hi End Limit Set the limit at which the Position Amplitude warning will

show full severity.

7.4.7.16 Position Amplitude Hi Percent Warning View the severity of the Position Amplitude warning based on

the Start and End limits.

7.4.8 Valve travel/Cycles

View and adjust the limits for the valve cycling and travel

warnings.

7.4.8.1 Valve Travel View the total valve travel.

7.4.8.2 Valve Travel Hi Start Limit Set the limit at which the Valve Travel warning will appear.

7.4.8.3 Valve Travel Hi End Limit

Set the limit at which the Valve Travel warning will show full

severity.

7.4.8.4 Valve Travel Hi Percent Warning View the severity of the Valve Travel warning based on the

Start and End limits.

7.4.8.5 Valve Travel Dead Band Set the amount the valve must move in order to begin adding

to the travel total.

7.4.8.6 Valve Cycles View the total valve cycles.

7.4.8.7 Valve Cycles Hi Start Limit Set the limit at which the Valve Cycles warning will appear.

7.4.8.8 Valve Cycles Hi End Limit Set the limit at which the Valve Cycles warning will show full

severity.

7.4.8.9 Valve Cycles Hi Percent Warning View the severity of the Valve Cycles warning based on the

Start and End limits.

7.4.8.10 Valve Cycle Dead Band Set the amount the valve must move in order to begin adding

to the travel and cycle totals.

7.4.8.11 Stroke Length Enter the stroke length of the valve.

7.4.8.12 Valve Travel/Cycles Reset Reset the valve travel or cycle counter.

7.4.9 Actuator Travel/Cycles

View and adjust the limits for the actuator cycling and travel

warnings.

7.4.9.1 Actuator Travel View the total actuator travel.

7.4.9.2 Actuator Travel Hi Start Limit Set the limit at which the Actuator Travel warning will appear.

7.4.9.3 Actuator Travel Hi End Limit Set the limit at which the Actuator Travel warning will show

full severity.

7.4.9.4 Actuator Travel Hi Percent Warning View the severity of the Actuator Travel warning based on

the Start and End limits.

7.4.9.5 Actuator Cycles View the total actuator cycles.

7.4.9.6 Actuator Cycles Hi Start Limit Set the limit at which the Actuator Cycles warning will

appear.

7.4.9.7 Actuator Cycles Hi End Limit

© Flowserve Corporation 18

Page 19

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

Set the limit at which the Actuator Cycles warning will show

full severity.

7.4.9.8 Actuator Cycles Hi Percent Warning View the severity of the Actuator Cycles warning based on

the Start and End limits.

7.4.9.9 - Actuator Travel/Cycles Reset Reset the actuator travel or cycle counter.

7.4.10 Bellows Travel/Cycles

View and adjust the limits for the bellows cycling and travel

warnings.

7.4.10.1 Bellows Travel View the total bellows travel.

7.4.10.2 Bellows Travel Hi Start Limit Set the limit at which the Bellows Travel warning will appear.

7.4.10.3 Bellows Travel Hi End Limit Set the limit at which the Bellows Travel warning will show

full severity.

7.4.10.4 Bellows Travel Hi Percent Warning View the severity of the Bellows Travel warning based on the

Start and End limits.

7.4.10.5 Bellows Cycles View the total bellows cycles.

7.4.10.6 Bellows Cycles Hi Start Limit Set the limit at which the Bellows Cycles warning will appear.

7.4.10.7 Bellows Cycles Hi End Limit Set the limit at which the Bellows Cycles warning will show

full severity.

7.4.10.8 Bellows Cycles Hi Percent Warning View the severity of the Bellows Cycles warning based on the

Start and End limits.

7.4.10.9 Bellows Travel/Cycles Reset Reset the bellows travel or cycle counter.

7.4.11 Pilot travel/Cycles

View and adjust the limits for the pilot relay cycling and travel

warnings.

7.4.11.1 Pilot Travel View the total pilot relay travel.

7.4.11.2 Pilot Travel Hi Start Limit Set the limit at which the Pilot Relay Travel warning will

appear.

7.4.11.3 Pilot Travel Hi End Limit Set the limit at which the Pilot Relay Travel warning will show

full severity.

7.4.11.4 Pilot Travel Hi Percent Warning View the severity of the Pilot Relay Travel warning based on

the Start and End limits.

7.4.11.5 Pilot Cycles View the total pilot relay cycles.

7.4.11.6 Pilot Cycles Hi Start Limit Set the limit at which the Pilot Relay Cycles warning will

appear.

7.4.11.7 Pilot Cycles Hi End Limit Set the limit at which the Pilot Relay Cycles warning will

show full severity.

7.4.11.8 Pilot Cycles Hi Percent Warning View the severity of the Pilot Relay Cycles warning based on

the Start and End limits.

7.4.11.9 Pilot Travel/Cycles Reset Reset the pilot relay travel or cycle counter.

7.5 User Preferences

View and set user preferences such as date, interface lock,

and units.

7.5.1 View/Set Date and Time

View and set the positioner date and time.

7.5.2 Local Interface

Lock the local interface of the positioner and set a pin code.

Locking the local interface prevents unauthorized changes

from taking place at the positioner's button panel that affect

the control or configuration of the positioner.

7.5.2.1 Local Interface Enable/Disable Lock the local interface so that no adjustments can be made

to the control or configuration of the positioner using the

buttons on the positioner without a pin code. The gain switch

will still be responsive.

7.5.2.2 Pin Code Set a pin code to allow access to modify positioner control

and configuration parameters at the positioner's local

interface.

7.5.3 Select Units

Set desired units.

7.5.3.1 Area Units Set area units (in2, cm2)

7.5.3.2 Travel Units Set travel units (%)

7.5.3.3 Pressure Units Set pressure units (psi, bar, kg/cm2, kPa)

7.5.3.4 Force Units

© Flowserve Corporation 19

Page 20

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

Set force units (lbf, kg, N)

7.5.3.5 Temperature Units Set temperature units (degrees F, degrees C)

7.5.3.6 Air Flow Units Set the air flow units (scfm, slpm, slph, Nm3/hr)

7.6 Burst Mode

Change burst mode settings and activate burst mode.

7.6.1 Burst Command Setup

Set burst mode to use command 1, 2, 3, 9, 33, or 48.

7.6.2 Burst State Setup

Select out of the following burst mode variables.

Command (mA)

Command % (Analog)

Command % (Digital)

Command %

Command % Target

Position %

Deviation %

Pilot Command %

Pilot Position %

Temperature User

Actuation Ratio

Pilot Response Time (T86)

Pneumatic Leak

Pressure Supply

Pressure Deviation

Pressure Port A

Pressure Port B

Friction

7.6.3 Burst Mode Configuration

Turn Burst mode on or off.

8 AUXILIARY CARDS

Manage auxiliary card configuration and view status. These

menus change based on the presence of and configuration of

the auxiliary cards.

8.1 Auxiliary Card 1 ID

View the auxiliary card present in slot 1. This feature is only

present if an auxiliary card is in slot 1.

8.2 Auxiliary Card 1 Type

View and set the type configuration of the auxiliary card

present in slot 1. This feature is only present if an auxiliary

card is in slot 1.

DANGER: Discrete input settings affect the valve

movement by initiating a PST or moving to a set point

according to the voltage supplied to the MFC. Verify

connections and notify proper personnel that the valve may

stroke, and make sure the valve is properly isolated before

proceeding.

8.3 Auxiliary Card 1 DI Setup

If the card in slot 1 is a Discrete Input, configure the settings.

8.3.1 MFC 1 DI State

Select the action when the DI state is triggered. Discrete

input settings affect the valve movement by initiating a PST

or moving to a set point according to the voltage supplied to

the MFC. Verify connections before proceeding.

8.3.2 MFC 1 DI Command

If the DI action is Command Override, set the desired

position where the valve should move when the DI state is

triggered.

8.4 Auxiliary Card 1 DO Trigger

If the card in slot 1 is a Discrete Output, configure the

settings.

8.4.1 Startup Status

Select DO in slot 1 to trigger on Power ON, Initializing, Stroke

Calibration Required, Pressure Calibration Required, and

Friction Calibration Required.

8.4.2 Mode Status 1

Select DO in slot 1 to trigger on Digital Command Mode,

Tight Shut Off Mode, Pressure Control Locked, Soft Stop

High Limit Alert, and Soft Stop Low Limit Alert.

8.4.3 Mode Status 2

Select DO in slot 1 to trigger on Continuous Stroke Test

Mode, Training Mode In Progress, Training Mode Completed,

Event Captured, Local Interface Off, and Squawk Mode.

8.4.4 Cal Status

Select DO in slot 1 to trigger on Stroke Calibration in

Progress, Setting Inner Loop Offset, Pressure Calibration in

Progress, Friction Calibration in Progress, Command Input

© Flowserve Corporation 20

Page 21

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

Calibration in Progress, Analog Output Calibration In

Progress, and Jog Calibration Set 100% Position.

8.4.5 Cal Error Status 1

Select DO in slot 1 to trigger on Position Range Too Small,

Position Sensor Below ADC Range, Position Sensor Above

ADC Range, No Motion Time Out, Settle Time Out, and Inner

Loop Offset Time Out.

8.4.6 Cal Error Status 2

Select DO in slot 1 to trigger on Analog Output Range Too

Small, Command Input Range Too Small, Command Input

Below ADC Range, Command Input Above ADC Range,

Stroke Shift, Stroke Span Increase , and Stroke Span

Decrease.

8.4.7 Electronic Configuration Status

Select DO in slot 1 to trigger on Aux Card 1 Present, Aux

Card 2 Present, Pressure Sensor Board Present, and LCD

Present.

8.4.8 Mode States Status

Select DO in slot 1 to trigger on Factory Reset State,

Calibration in Progress, Signature or Partial Stroke Test in

Progress, Jog Command Mode, Partial Stroke Test

Scheduled, and DI Command Override.

8.4.9 Feedback Loop Status

Select DO in slot 1 to trigger on Position Deviation Alarm,

Position Sensor Failure Alarm, Valve Opened Too Far

Warning, Valve Closed Too Far Warning, Backlash Warning,

Backlash Alarm, Partial Stroke Test Failed Warning, and

Continuous Stroke Test Failed Warning.

8.4.10 Position Status

Select DO in slot 1 to trigger on Position High Limit Alert,

Position Low Limit Alert and Feedback Linkage Alarm.

8.4.11 Cycles/Travel Status

Select DO in slot 1 to trigger on Valve Cycles Warning, Valve

Travel Warning, Actuator Cycles Warning, Actuator Travel

Warning, Bellows Cycles Warning, Bellows Travel Warning,

Pilot Relay Cycles Warning, and Pilot Relay Travel Warning.

8.4.12 Actuation Status

Select DO in slot 1 to trigger on Supply Pressure High

Warning, Supply Pressure Low Warning, Supply Pressure

Low Alarm, Actuation Ratio Warning, Spring Unable to Fail

Safe Warning, Pneumatic Leak Warning, Air Supply Humid

Warning, and Air Supply Icing Warning.

8.4.13 Friction Status

Select DO in slot 1 to trigger on Friction High Warning,

Friction High Alarm, Friction Low Warning, Friction Low

Alarm, Valve Can't Open Alarm, and Valve Can't Shut Alarm.

8.4.14 Control Status

Select DO in slot 1 to trigger on Command Frequency

Warning, Command Frequency Alarm, Command Amplitude

Warning, Command Amplitude Alarm, Position Frequency

Warning, Position Frequency Alarm, Position Amplitude

Warning, and Position Amplitude Alarm.

8.4.15 Inner Loop Status

Select DO in slot 1 to trigger on Pilot Relay Response

Warning, Pilot Relay Response Alarm, Piezo Voltage High

Warning, Piezo Voltage High Alarm, Piezo Voltage Low

Warning, Piezo Voltage Low Alarm, and Driver Module

Alarm.

8.4.16 Main Board Status

Select DO in slot 1 to trigger on Main Board Electronic

Failure Warning, Software Error Warning, Memory Error

Warning, Temperature High Warning, and Temperature Low

Warning.

8.4.17 Electronic Board Status

Select DO in slot 1 to trigger on Aux Card 1 Failure Warning,

Aux Card 2 Failure Warning, Aux Card 1 No Loop Power,

Aux Card 2 No Loop Power, Aux Card 1 Error, Aux Card 2

Error, Pressure Sensor Board Failure Warning, and Low

Battery Warning.

8.4.18 Stroke/Friction Status

Select DO in slot 1 to trigger on Reversed Spring, Insufficient

Spring, and No Spring.

8.4.19 Main Board Status

Select DO in slot 1 to trigger on Humidity Sensor Failure,

Oscillator Fault, Position Sensor ADC Failure, Supply

Voltage Error, Reference Voltage Error, Shunt Voltage Error,

and Piezo Voltage Error.

8.4.20 Electronic Comp Status

Select DO in slot 1 to trigger on Pilot Can't Open, Pilot Can't

Shut, Hall Sensor Failure, and ILO Out Of Range.

8.4.21 Software Status

Select DO in slot 1 to trigger on NVMEM CRC Error, RAM

Error, RAM CRC Error, FLASH CRC Error, Watch Dog Time

Out, Stack Overflow Warning, CPU Usage Warning, and

Firmware Update Applied.

8.4.22 Press Cal Status

Select DO in slot 1 to trigger on Port S Out Of Range, Port A

Out Of Range, Port B Out Of Range, Port S Range too

Small, Port A Range too Small, Port B Range too Small, and

Pressure Sensor Failure.

8.5 Calibrate MFC 1 Analog Out

If the card in slot 1 is an Analog Output, perform an analog

output calibration.

8.6 Auxiliary Card 2 ID

View the auxiliary card present in slot 2. This feature is only

present if there is an auxiliary card in slot 2.

8.7 Auxiliary Card 2 Type

© Flowserve Corporation 21

Page 22

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

View and set the type configuration of the auxiliary card

present in slot 2. This feature is only present if there is an

auxiliary card in slot 2.

DANGER: Discrete input settings affect the valve

movement by initiating a PST or moving to a set point

according to the voltage supplied to the MFC. Verify

connections and notify proper personnel that the valve may

stroke, and make sure the valve is properly isolated before

proceeding.

8.8 Auxiliary Card 2 DI Setup

If the card in slot 2 is a Discrete Input, configure the settings

8.8.1 MFC 2 DI State

Select the action when the DI state is triggered. Discrete

input settings affect the valve movement by initiating a PST

or moving to a set point according to the voltage supplied to

the MFC. Verify connections before proceeding.

8.8.2 MFC 2 DI Command

If the DI action is Command Override, set the desired

position where the valve should move when the DI state is

triggered.

8.9 Auxiliary Card 2 DO Trigger

If the card in slot 2 is a Discrete Output, configure the

settings.

8.9.1 Startup Status

Select DO in slot 2 to trigger on Power ON, Initializing, Stroke

Calibration Required, Pressure Calibration Required, and

Friction Calibration Required.

8.9.2 Mode Status 1

Select DO in slot 2 to trigger on Digital Command Mode,

Tight Shut Off Mode, Pressure Control Locked, Soft Stop

High Limit Alert, and Soft Stop Low Limit Alert.

8.9.3 Mode Status 2

Select DO in slot 2 to trigger on Continuous Stroke Test

Mode, Training Mode In Progress, Training Mode Completed,

Event Captured, Local Interface Off, and Squawk Mode.

8.9.4 Cal Status

Select DO in slot 2 to trigger on Stroke Calibration in

Progress, Setting Inner Loop Offset, Pressure Calibration in

Progress, Friction Calibration in Progress, Command Input

Calibration in Progress, Analog Output Calibration In

Progress, and Jog Calibration Set 100% Position.

8.9.5 Cal Error Status 1

Select DO in slot 2 to trigger on Position Range Too Small,

Position Sensor Below ADC Range, Position Sensor Above

ADC Range, No Motion Time Out, Settle Time Out, and Inner

Loop Offset Time Out.

8.9.6 Cal Error Status 2

Select DO in slot 2 to trigger on Analog Output Range Too

Small, Command Input Range Too Small, Command Input

Below ADC Range, Command Input Above ADC Range,

Stroke Shift, Stroke Span Increase , and Stroke Span

Decrease.

8.9.7 Electronic Configuration Status

Select DO in slot 2 to trigger o nAux Card 1 Present, Aux

Card 2 Present, Pressure Sensor Board Present, and LCD

Present.

8.9.8 Mode States Status

Select DO in slot 2 to trigger on Factory Reset State,

Calibration in Progress, Signature or Partial Stroke Test in

Progress, Jog Command Mode, Partial Stroke Test

Scheduled, and DI Command Override.

8.9.9 Feedback Loop Status

Select DO in slot 2 to trigger on Position Deviation Alarm,

Position Sensor Failure Alarm, Valve Opened Too Far

Warning, Valve Closed Too Far Warning, Backlash Warning,

Backlash Alarm, Partial Stroke Test Failed Warning, and

Continuous Stroke Test Failed Warning.

8.9.10 Position Status

Select DO in slot 2 to trigger on Position High Limit Alert,

Position Low Limit Alert and Feedback Linkage Alarm.

8.9.11 Cycles/Travel Status

Select DO in slot 2 to trigger on Valve Cycles Warning, Valve

Travel Warning, Actuator Cycles Warning, Actuator Travel

Warning, Bellows Cycles Warning, Bellows Travel Warning,

Pilot Relay Cycles Warning, and Pilot Relay Travel Warning.

8.9.12 Actuation Status

Select DO in slot 2 to trigger on Supply Pressure High

Warning, Supply Pressure Low Warning, Supply Pressure

Low Alarm, Actuation Ratio Warning, Spring Unable to Fail

Safe Warning, Pneumatic Leak Warning, Air Supply Humid

Warning, and Air Supply Icing Warning.

8.9.13 Friction Status

Select DO in slot 2 to trigger on Friction High Warning,

Friction High Alarm, Friction Low Warning, Friction Low

Alarm, Valve Can't Open Alarm, and Valve Can't Shut Alarm.

8.9.14 Control Status

Select DO in slot 2 to trigger on Command Frequency

Warning, Command Frequency Alarm, Command Amplitude

Warning, Command Amplitude Alarm, Position Frequency

Warning, Position Frequency Alarm, Position Amplitude

Warning, and Position Amplitude Alarm.

8.9.15 Inner Loop Status

Select DO in slot 2 to trigger on Pilot Relay Response

Warning, Pilot Relay Response Alarm, Piezo Voltage High

Warning, Piezo Voltage High Alarm, Piezo Voltage Low

Warning, Piezo Voltage Low Alarm, and Driver Module

Alarm.

© Flowserve Corporation 22

Page 23

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

8.9.16 Main Board Status

Select DO in slot 2 to trigger on Main Board Electronic

Failure Warning, Software Error Warning, Memory Error

Warning, Temperature High Warning, and Temperature Low

Warning.

8.9.17 Electronic Board Status

Select DO in slot 2 to trigger on Aux Card 1 Failure Warning,

Aux Card 2 Failure Warning, Aux Card 1 No Loop Power,

Aux Card 2 No Loop Power, Aux Card 1 Error, Aux Card 2

Error, Pressure Sensor Board Failure Warning, and Low

Battery Warning.

8.9.18 Stroke/Friction Status

Select DO in slot 2 to trigger on Reversed Spring, Insufficient

Spring, and No Spring.

8.9.19 Main Board Status

Select DO in slot 2 to trigger on Humidity Sensor Failure,

Oscillator Fault, Position Sensor ADC Failure, Supply

Voltage Error, Reference Voltage Error, Shunt Voltage Error,

and Piezo Voltage Error.

8.9.20 Electronic Comp Status

Select DO in slot 2 to trigger on Pilot Can't Open, Pilot Can't

Shut, Hall Sensor Failure, and ILO Out Of Range.

8.9.21 Software Status

Select DO in slot 2 to trigger on NVMEM CRC Error, RAM

Error, RAM CRC Error, FLASH CRC Error, Watch Dog Time

Out, Stack Overflow Warning, CPU Usage Warning, and

Firmware Update Applied.

8.9.22 Press Cal Status

Select DO in slot 2 to trigger on Port S Out Of Range, Port A

Out Of Range, Port B Out Of Range, Port S Range too

Small, Port A Range too Small, Port B Range too Small, and

Pressure Sensor Failure.

8.10 Calibrate MFC 2 Analog Out

If the card in slot 2 is an Analog Output, perform an analog

output calibration.

© Flowserve Corporation 23

Page 24

DD User Manual - Logix® 520MD+ Series Digital Positioner FCD-LGENSF0013-01

Bulletin FCD-LGENSF0013-01

To find your local Flowserve representative please use

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve

Flowserve Headquarters

the Sales Support Locator System found at

www.flowserve.com

Or call

Europe +43 (0) 4242 41181 999

North America (801) 489-2300

Asia + (65) 6879 8900

product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware

that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve can provide

general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate

responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and

understand the (INSERT OFFICIAL USER INSTRUCTION TITLE) instructions included with the product, and train its employees and contractors in the

safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and

should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a

warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is continually improving and

upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any

question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

© 2010 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

5215 N. O'Connor Blvd. Suite 2300

Irving, Tx. 75039

Phone: +1 972 443 6500

Flowserve Corporation

Flow Control

1350 N. Mt. Springs Parkway

Springville, UT 84663 USA

Phone: 801 489 8611

Fax: 801 489 3719

Flowserve S.A.S.

12, avenue du Quebec

B.P. 645

91965 Courtaboeuf Cedex France

Phone: 33 (0) 1 60 92 32 51

Fax: 33 (0) 1 60 92 32 99

Flowserve Pte Ltd.

12 Tuas Avenue 20

Singapore 638824

Singapore

Phone: 65 6868 4600

Fax: 65 6862 4940

Flowserve Australia Pty Ltd.

14 Dalmore Drive

Scoresby, Victoria 3179 Australia

Phone: 61 7 32686866

Fax: 61 7 32685466

Flowserve Ltda .

Rua Tocantins, 128

São Caetano do Sul, SP 09580-130

Brazil

Phone: 55 11 2169 6300

Fax: 55 11 2169 6313

Flowserve (Austria) gmbH

Control Valves - Villach

Operation Kasernengasse 6

9500 Villach Austria

Phone: +43 (0)4242 41181 0

Fax: +43 (0)4242 41181 50

Flowserve (China)

585, Hanwei Plaza

7 Guanghau Road

Beijing, China 100004

Phone: +86 10 6561 1900

Flowserve India Controls

Pvt. Ltd Plot # 4, 1A, E.P.I.P,

Whitefield Bangalore Kamataka

India 560 066

Phone: +91 80 284 10 289

Fax: +91 80 284 10 286

Flowserve Essen gmbH

Manderscheidtstr. 19

45141 Essen Germany

Phone: +49 (0)201 8919 5

Fax: +49 (0)201 8919 662

Kämmer Valves inc.

1300 Parkway View Drive

Pittsburgh, Pa 15205 USA

Tel.: +1 412 787 8803

Fax: +1 412 787 1944

NAF Ab

Gelbgjutaregatan 2

SE-581 87 Linköping Sweden

Phone: +46 (0)13 31 61 00

Fax: +46 (0)13 13 60 54

© Flowserve Corporation 24

Loading...

Loading...