Page 1

Dirty Water Submersible Pump FTS 1100 B2

®

Dirty Wa ter

SubmerSible PumP

Translation of original operation manual

DränkPumP för SmutSvatten

Översättning av bruksanvisning i original

SchmutzWaSSer-tauchPumPe

Originalbetriebsanleitung

JäteveDen uPPoPumPPu

Alkuperäisen käyttöohjeen käännös

SPilDevanDS-D ykPumPe

Oversættelse af den originale driftsvejledning

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista kuvallinen sivu esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut bildsidan och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 11

SE Bruksanvisning och säkerhetsanvisningar Sidan 17

DK Brugs- og sikkerhedsanvisninger Side 23

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 29

Page 3

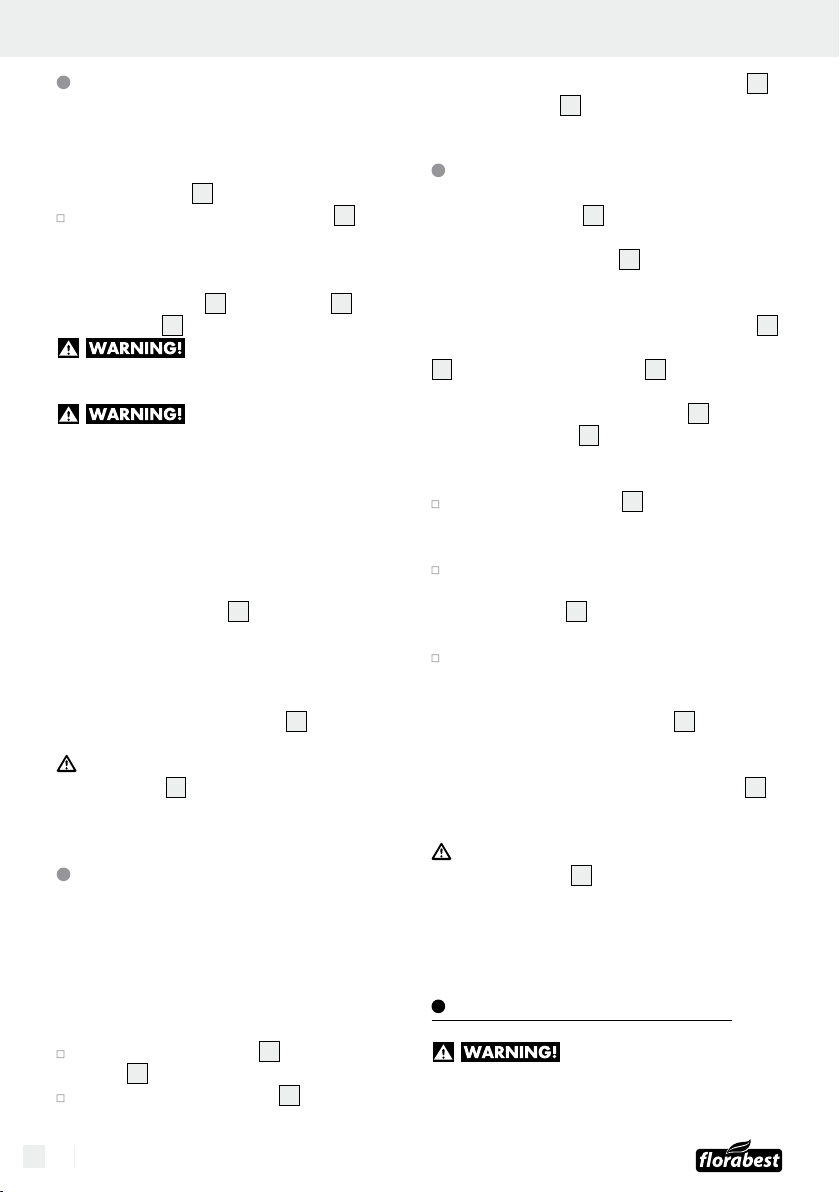

9

1

8

12

11

10

7

6 5

2

3

4

a Cb

9

8

4 11

13

10

6 5

Page 4

Page 5

Table of contents

Introduction

Proper use .........................................................................................................................Page 6

Features and equipment .................................................................................................. Page 6

Included items .................................................................................................................. Page 6

Technical data .................................................................................................................. Page 6

General safety advice ....................................................................................... Page 6

Safety advice relating specifically to submersible pumps ............................................. Page 7

Further safety advice relating to submersible pumps .....................................................Page 7

Preparing for use .................................................................................................. Page 7

Standing up or suspending the device ........................................................................... Page 8

Connecting the discharge hose or pipe ......................................................................... Page 8

Attaching the float switch ................................................................................................ Page 8

Maintenance and cleaning ............................................................................ Page 8

Cleaning the impeller .......................................................................................................Page 9

Service ............................................................................................................................ Page 9

Warranty ......................................................................................................................Page 9

Disposal ......................................................................................................................... Page 10

Declaration of Conformity / Manufacturer.......................................Page 10

®

5 GB/IE

Page 6

Dirty Water Submersible Pump

FTS 1100 B2

Introduction

Please make sure you familiarise yourself

fully with the way the device works be-

fore you use it for the first time and that

you understand how to handle electrical devices.

To help you do this, please read the following operating instructions. Keep these instructions in a safe

place. If you pass the device on to anyone else,

please ensure that you also pass on all the documentation.

Proper use

This submersible dirty water pump is intended for

pumping out and delivering water, including dirty

water with a maximum particle size of 35 mm (with

reducer max. 19 mm), at a maximum water temperature of + 35 °C. Examples of use include recirculating or pumping out water in pools and containers,

flooded cellars or for extracting water from wells or

chambers. Any other use or modification to the device shall be considered as improper use and could

give rise to considerable risk of accident. Not suitable for continuous operation. Not for commercial

use.

Included items

1 Dirty Water Submersible Pump FTS 1100 B2

1 Angle adapter

1 Reducer

1 Rope (8 m)

1 Operating instructions

Technical data

Submersible dirty water pump FTS 1100

Rated voltage: 230 V∼, 50 Hz

Rated power consumption: 1100 W

Protection class: I

IP rating: IPX8

Water temperature: Max. 35 °C

Max. particle size: 35 mm

Max. submersion depth: Hmax. 8 m

Max. flow rate: Qmax 20000 l/h

Max. delivery head: 8 m

Switching point “On”: approx. 520 mm

Switching point “Off”: approx. 230 mm

Hose connection: 25 mm (1“),

38 mm (1 ½“)

Length of mains lead: 10 m

Weight: approx. 6.8 kg

General safety advice

(EN 60335-1)

B2

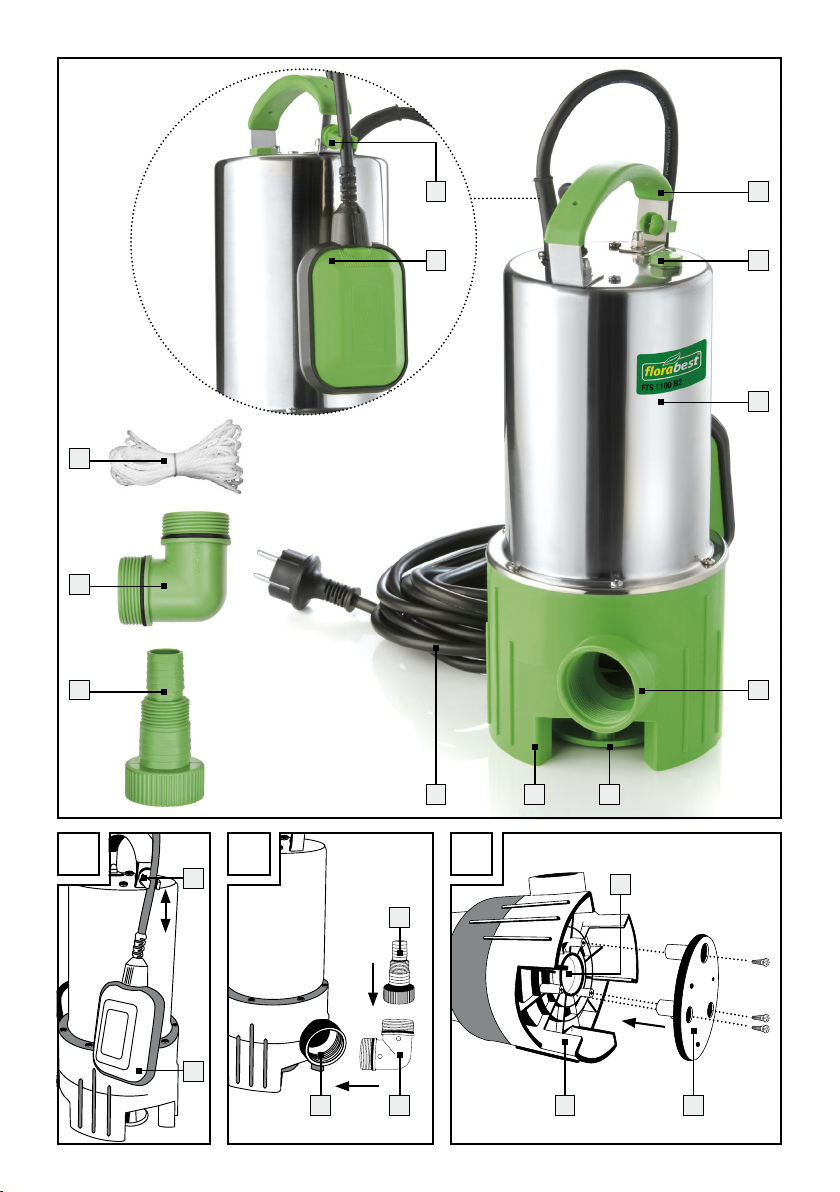

Features and equipment

1

Handle

2

Air bleed mechanism

3

Pump housing

4

Pump outlet

5

Base plate

6

Foot

7

Mains connection lead

8

Float switch

9

Float switch pivot clip

10

Reducer

11

Angle adapter

12

Rope

13

Impeller

6 GB/IE

This device is not intended to be used by per

(including children) with restricted physical,

sensory or mental abilities or with insufficient

experience and / or knowledge, unless they are

supervised by a person who is responsible for

their safety or they have received instruction on

how to use the device from such a responsible

person.

Children should be supervised in order to en

that they do not play with the device. Take the

appropriate precautions to keep children away

from the device.

sons

sure

®

Page 7

General safety advice / Preparing for use

Safety advice relating

specifically to submersible

pumps

RISK TO LIFE FROM ELECTRIC

SHOCK! Do not use the device if

there are people in the water. Ensure

that the electrical plug-in connector is positioned

where it cannot be reached by the water. Otherwise there is a risk of loss of life through electric shock.

Do not use the mains lead or the

hose for any purpose for which it

was not intended, e.g. to carry the

product, to hang it up or to pull the mains plug

out of the mains socket. Keep the mains lead

away from heat, oil, sharp edges or moving

parts of the device. Damaged or tangled mains

leads increase the risk of electric shock.

Please note that health and employment authori-

ties, water supply and other similar bodies in

countries may impose additional requirements.

Connect the device through a residual current

device (RCD) with a maximum trip current of

30 mA.

When not in use always ensure that electrical

devices are kept out of reach of children. Do

not let anyone use the device if he or she is not

familiar with it or has not read the instructions

and advice. Electrical power tools are dangerous

when they are used by inexperienced people.

many

When working with the device, please take

note of the maximum operating depth of 8 m.

Otherwise damage to the device could occur.

Please note that the device uses lubricant. If it

leaks then damage or contamination could occur. Therefore do not use the device in garden

ponds containing fish or valuable plants.

In the interest of safety, do not allow children,

young persons under the age of 16 or any person who is not familiar with these operating instructions to use this device.

Pay attention to the device while it is operating

so that you are aware in good time of the pump

switching off automatically or running dry.

Check regularly that the float switch is working

properly (see the section on “Preparing for use”.

Always check the device for damage before use.

Do not operate the pump continuously, e.g. for

circulating water in garden ponds. It is not designed for continuous operation. Otherwise a

reduction in the service life of the device could

occur.

Protect the device from frost. Store the submers-

ible dirty water pump in a frost-free place.

Never leave the device unattended. Otherwise

damage to the device could occur.

Use original accessories only. Do not carry out

any repairs to the device. This way you will ensure that the device remains safe to use.

The device must be opened only by an electrician

or similar expert. In the event of a repair being

necessary, please contact our Service Centre.

Further safety advice

relating to submersible

pumps (EN 60335-2-41)

Do not use for sand-water mixtures. Otherwise

damage to the device could occur.

Do not pump aggressive, abrasive (capable of

removing coatings), corrosive, combustible or

explosive liquids, brine, cleaning agents or

foodstuffs. Otherwise a risk to health, material

damage or damage to the device could occur.

When pumping, ensure that the water tempera-

ture is less than 35 °C. Otherwise damage to

the device could occur.

®

Preparing for use

Note: You can install this submersible pump in a

fixed position, i.e. it can be permanently fastened

in place (e.g. for regularly circulating or pumping

out water in pools or containers). If you wish to install your submersible pump in a fixed position, you

may have to seek the further advice of a suitable

specialist.

7 GB/IE

Page 8

Preparing for use / Maintenance and cleaning Maintenance and cleaning / Service / Warranty

Standing up or suspending

the device

Note: The pump chamber should have minimum

dimensions of 40 x 40 x 50 cm (W x D x H) to allow the float switch

8

to move freely.

Suspend the device from the handle 1 or

stand it on the bottom or supporting surface.

Otherwise damage to the device could occur.

Note: You can suspend the pump safely using

the supplied rope

the handle

12

. Loop the rope 12 around

1

and fasten it with a double knot.

ATTENTION! Never suspend

the device from the hose. Otherwise damage

to the device could occur.

ATTENTION! Check the state

of the device occasionally while it is working.

Dirt and sand may build up over time on the

bottom or supporting surface, which could

damage the pump. If the water level in the

chamber is too low, any sludge present could

quickly dry out and prevent the pump from

starting.

Note: The submersible pump has an automatic

air bleed mechanism

2

. This mechanism allows

any air to escape from the device as soon as

the device is submerged in water. If the submersible pump is not completely submerged in

water during operation, then water may escape

from the air bleed mechanism

2

. This does not

indicate that the device is defective.

ATTENTION! Do not screw off the air bleed

mechanism

2

, otherwise damage to the de-

vice may occur.

Connecting the discharge

hose or pipe

Note: The water can be pumped out through a

fixed pipe or a flexible hose.

The hose may block if the particle size is greater

than 35 mm, or 19 mm with the reducer fitted, (see

the section on “Maintenance and cleaning”).

Screw the angle adapter 11 on to the pump

4

outlet

Pull a hose over the reducer 10 and fix it in

place with a hose clamp. Or you can use a

8 GB/IE

(see Fig. B).

threaded connector on the angle adapter 11

or the reducer

10

.

Attaching the float switch

Note: The float switch 8 is set up to allow the

to be used immediately. In the case of a permanent

installation, the float switch

8

must be checked

regularly (at least every three months) to see that it

is working properly.

The on and off switching point of the float switch

can be set by altering the position of the float switch

8

in the float switch pivot clip 9 (see Fig. A).

The following principles apply here: The longer the

length of the cable of the float switch

float switch pivot clip

9

to the float, the higher the

on and off switching point will be.

Position the float switch 8 so that the “ON”

and “OFF” switch point level is achieved easily

and with little force.

Check that it is working properly i.e. stand the

pump in water in a vessel, then carefully raise

the float switch

8

by hand and then let it fall

again. Check that the pump switches on and off.

To bring the submersible pump into use, plug

the mains plug into a suitable mains socket.

Depending on the set switch point level and

the water level, the float switch

8

automatically on or off as appropriate.

Note: Ensure that the distance between the float

switch head and the float switch pivot clip 9 is

not too short. If the distance is too short, the

switch may not work properly.

ATTENTION! When making the setting ensure

that float switch

8

does not come into contact

with the bottom or supporting surface before the

pump switches off. Otherwise there is the risk that

the pump may run dry and become damaged.

pump

8

from the

switches

8

Maintenance and cleaning

RISK OF LOSS OF LIFE AND

INJURY! Before you carry out any work on the

device, always pull the mains plug out of the mains

socket.

®

Page 9

Maintenance and cleaning / Service / Warranty

If the pump is not permanently installed, clean

it with clean water after every use.

Check regularly that the float switch 8 is work-

ing properly on permanently installed devices

(at least once every three months).

Use a jet of water to remove any fluff and fibrous

particles that may have attached themselves to

the pump housing.

Remove any deposits from the float switch 8

with clean water.

Remove sludge from the bottom of the chamber

(at least every three months) and clean the walls.

Thoroughly clean the pump if it has not been

used for an extended period. The pump may

be difficult to start if deposits and residues are

allowed to form.

Use a cloth to clean the outside of the housing

- never use petrol, solvents or cleaners. Otherwise damage to the device could occur.

Cleaning the impeller

Note: If the impeller 13 becomes dirty or blocked,

you can clean it using the pump outlet

screwing off the base plate

5

To do this, screw off the angle adapter 11 from

the pump outlet

4

.

Remove the 3 screws from the underside of the

pump housing 3 and take off the base plate 5.

Clean the impeller 13 with clean water.

To reassemble the device, proceed in reverse

order.

Note: Any other tasks on the pump, in particular opening the pump, must be carried out by

an electrician or similar expert. In the event of

a repair being necessary, please contact our

Service Centre.

4

(see Fig. C).

or by

If the plug or lead

needs to be replaced, always have

the replacement carried out by the

manufacturer or its service centre. This

will ensure that your device remains safe to use.

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

Service

Have your device

repaired at the service centre or by

qualified specialist personnel using

original manufacturer parts only. This

will ensure that your device remains safe to use.

®

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP/Min.)

e-mail: kompernass@lidl.gb

IAN 69518

9 GB/IE

Page 10

Warranty / Disposal / Declaration of Conformity / Manufacturer Sisällysluettelo

IE

Service Ireland

Tel: 1890 930 034

(0,08 EUR/Min. (peak)

0,06 EUR/Min. (off peak))

e-mail: kompernass@lidl.ie

IAN 69518

Disposal

The packaging is wholly composed of

environmentally-friendly materials that

can be disposed of at a local recycling

centre.

Do not dispose of electrical

devices with the household

rubbish!

In accordance with European Directive 2002 / 96 / EC

(covering waste electrical and electronic equipment)

and its transposition into national legislation, worn

out electrical power tools must be collected sepa

and taken for environmentally compatible recycling.

rately

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, the person responsible for

documents: Mr Semi Uguzlu, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following standards, normative

documents and EU directives:

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

Applicable harmonized standards

EN 60335-2-41:2003+A1:04

EN 62233:2008, EK1 337-07:2007

EN 60335-1:2002+A11, A1:04+A12,A2:

06+A13:08, EN 55014-1:2006/+A1:2009

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006/+A1:2009/+A2:2009

EN 61000-3-3:2008

Type / Device description:

Dirty Water Submersible Pump FTS 1100 B2

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

10 GB/IE

Date of manufacture (DOM): 10–2011

Serial number: IAN 69518

Bochum, 31.10.2011

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications in the course of further development.

®

Page 11

Sisällysluettelo

Johdanto

Määräystenmukainen käyttö .............................................................................................Sivu 12

Varustus ..............................................................................................................................Sivu 12

Toimitukseen kuuluu ...........................................................................................................Sivu 12

Tekniset tiedot .....................................................................................................................Sivu 12

Yleiset turvallisuusohjeet .................................................................................Sivu 12

Uppopumppujen laitekohtaiset turvallisuusohjeet ............................................................Sivu 13

Muut relevantit uppopumppujen turvallisuusohjeet .........................................................Sivu 13

Käyttöönotto

Laitteen sijoitus / ripustus ....................................................................................................Sivu 13

Tyhjennysjohdon liittäminen...............................................................................................Sivu 14

Uimurikytkimen asennus.....................................................................................................Sivu 14

Huolto ja puhdistus ................................................................................................Sivu 14

Siipirattaan puhdistus .........................................................................................................Sivu 15

Huolto................................................................................................................................Sivu 15

Takuu .................................................................................................................................Sivu 15

Hävittäminen ..............................................................................................................Sivu 15

Vaatimustenmukaisuusvakuutus / Valmistaja ...............................Sivu 16

®

11 FI

Page 12

Jäteveden uppopumppu

FTS 1100 B2

Johdanto

Tutustu ennen ensimmäistä käyttöönottoa laitteen kaikkiin toimintoihin ja ota

selvää, miten sähkötyökaluja käsitellään.

Lue tätä varten seuraava käyttöohje läpi. Säilytä

tämä käyttöohje. Anna kaikki dokumentit mukaan,

jos luovutat laitteen edelleen.

Määräystenmukainen käyttö

Tämä jätevesiuppopumppu on tarkoitettu veden ja

j

äteveden pumppaamiseen ja siirtoon maksimi 35 mm:n

hiukkaskoolla (supistuskappale max. 19 mm) ja veden

lämpötilan ollessa max. + 35 °C. Se on tarkoitettu

esimerkiksi altaiden ja säiliöiden, kellareiden tulvavesien poisto- ja tyhjennyspumppaamiseen sekä vedenottoon kaivoista ja kuiluista. Kaikki muunlainen

käyttö tai muutosten teko laitteeseen on määräystenvastaista ja voi aiheuttaa huomattavia tapaturmavaaroja. Pumppu ei sovellu jatkuvaan käyttöön.

Se ei ole tarkoitettu kaupalliseen käyttöön.

Toimitukseen kuuluu

1 jäteveden uppopumppu FTS 1100 B2

1 kulma-adapteri

1 supistuskappale

1 köysi (8 m)

1 käyttöohje

Tekniset tiedot

Jätevesiuppopumppu FTS 1100 B2

Nimellisjännite: 230 V∼, 50 Hz

Nimellisottoteho: 1100 W

Suojausluokka: I

Kotelointiluokka: IPX8

Veden lämpötila: max. 35 °C

Max. hiukkaskoko: 35 mm

Max. upotussyvyys Hmax. 8 m

Max. tuotto: Qmax 20000 l/h

Max. nostokorkeus: 8 m

Kytkentäpisteen korkeus ”Päällä”: n. 520 mm

Kytkentäpisteen korkeus ”Pois”: n. 230 mm

Letkuliitäntä: 25 mm (1“),

38 mm (1 ½“)

Verkkojohdon pituus: 10 m

Paino: n. 6,8 kg

Varustus

1

Kahva

2

Ilmanpoistolaite

3

Pumpunpesä

4

Pumpun poistoaukko

5

Pohjalevy

6

Jalkaosa

7

Verkkoliitäntäjohto

8

Uimurikytkin

9

Uimurikytkimen pidike

10

Supistuskappale

11

Kulma-adapteri

12

Köysi

13

Siipiratas

12 FI

Yleiset turvallisuusohjeet

(EN 60335-1)

Tämä laite ei ole tarkoitettu sellaisten henkilöi-

den (lapset mukaan luettuina) käyttöön, joiden

fyysinen, aistimuksellinen tai henkinen kunto

rajoittunut tai joilla ei ole kokemusta / tietoja

teen käytöstä. He saavat käyttää laitetta ainoastaan turvallisuudesta vastuussa olevan henkilön

valvonnassa tai jos tämä on antanut heille

opastusta laitteen käytössä.

Lapsia on valvottava ja pidettävä huoli siitä, ett-

eivät he pääse leikkimään laitteen kanssa. Pidä

lapset sopivilla toimenpiteillä loitolla käynnissä

olevasta laitteesta.

on

lait-

®

Page 13

Yleiset turvallisuusohjeet / Käyttöönotto

Uppopumppujen

laitekohtaiset

turvallisuusohjeet

HENGENVAARALLINEN SÄH-

KÖISKUN VAARA! Laitetta ei

saa käyttää, mikäli vedessä on samanaikaisesti ihmisiä. Varmista, että sähköiset

pistokeliitännät on asennettu alueelle, johon ei

pääse tulvimaan vettä. Muussa tapauksessa

sähköisku voi aiheuttaa hengenvaaran.

Älä koskaan käytä johtoa tai letkua

sähkölaitteen kantamiseen tai ripu-

stamiseen, älä myöskään vedä pistoketta johdon avulla ulos pistorasiasta. Älä altista

johtoa kuumuudelle ja öljylle, varo teräviä reunoja ja laitteen liikkuvia osia. Vaurioitunut tai

sotkeutunut johto lisää sähköiskun vaaraa.

Huomautamme, että monissa maissa kansalliset

terveys- ja työsuojeluviranomaiset, vesihuolto ja

vastaavat virastot asettavat lisävaatimuksia.

Liitä laite vikavirta (FI)-suojakytkimellä maksimi

30 mA laukaisuvirtaan.

Kun et käytä sähkölaitteita, säilytä ne lasten

ulottumattomissa. Älä anna laitetta henkilöiden

käyttöön, jotka eivät ole perehtyneet sen toimintaan tai eivät ole lukeneet tätä ohjetta. Sähkötyökalut ovat vaarallisia, jos kokemattomat

henkilöt käyttävät niitä.

Huomaa, että laitteessa käytetään voiteluainetta.

Tämä voi vuotaessaan

likaantumista. Älä tästä syystä käytä laitetta

puutarhalammissa, joissa on kaloja tai arvokkaita kasveja.

Turvallisuussyistä eivät lapset eivätkä alle

16-vuotiaat tai henkilöt, jotka eivät ole tutustuneet laitteen käyttöohjeisiin, saa käyttää tätä

laitetta.

Valvo laitetta käytön aikana, jotta voit tunnistaa

automaattisen poiskytkennän tai

käynnin

ajoissa. Tarkista säännöllisesti uimurikytkimen toiminto (katso kappale

”Käyttöönotto”).

Tarkista laite aina ennen jokaista käyttöönottoa

ettei siinä ole vaurioita.

Älä käytä pumppua jatkuvassa käytössä esimer-

kiksi puutarhalammikoiden veden kierrättämiseen.

Se ei ole

käytössä

Suojaa laite pakkaselta. Varastoi jätevesiuppo-

pumppu jäätymiseltä suojattuun paikkaan.

Älä anna laitteen käydä kuivana.

Laite voi muuten vaurioitua

Käytä vain alkuperäisiä osia. Älä tee mitään

muutoksia laitteeseen. Tällä taataan, että laitteen turvallisuus säilyy.

Anna sähköalan ammattimiehen suorittaa lait-

teen avaaminen. Käänny korjaustapauksessa

huoltopalvelumme puoleen.

tarkoitettu tällaiseen käyttöön. Tällaisessa

laitteen käyttöikä lyhenee.

aiheuttaa vaurioita tai

pumpun kuiva-

Muut relevantit

uppopumppujen

turvallisuusohjeet

(EN 60335-2-41)

Älä käytä hiekkavedessä. Laite voi muuten

vaurioitua

Älä pumppua aggressiivisia, abrassiivisia (hiovia),

syövyttäviä, paloherkkiä tai räjähtäviä nesteitä,

suolavettä, puhdistusaineita tai elintarvikkeita.

Näistä voi aiheutua terveydellisiä vaaroja, aineellisia vauriota tai laitteen vaurioituminen.

Pumpattavan veden lämpötilan on oltava alle

35 °C. Laite voi muuten vaurioitua.

Tarkista laitteella työskennellessäsi, että mak-

simi käyttöupotussyvyys on 8 m. Muuten laite

voi vaurioitua.

®

Käyttöönotto

Huomautus: Voit asentaa tämän uppopumpun

myös kiinteästi

aina samassa paikassa (esim. altaiden ja säiliöiden

säännölliseen tyhjennyspumppaukseen). Mikäli haluat asentaa uppopumpun kiinteästi, pyydä tarvittaessa lisätietoja alan asiatuntijalta.

, toisin sanoen se voi olla kiinnitettynä

Laitteen sijoitus / ripustus

Huomautus: Pumpun kuillun mittojen tulisi olla

vähintään 40 x 40 x 50 cm (l x s x k), jotta uimuri-

8

kytkin

voi liikkua vapaasti.

13 FI

Page 14

Ripusta laite kahvasta 1 tai aseta se pohjaan.

Laite voi muuten vaurioitua.

Huomautus: Voit pumpun turvalliseen ripustamiseen käyttää toimitukseen kuuluvaa köyttä

Kierrä tätä varten köysi

kiinnitä se

kaksoissolmulla.

12

ympäri

kahvan 1 ja

12

HUOMIO! Älä koskaan ripusta

laitetta letkusta. Laite voi muuten vaurioitua.

HUOMIO! Tarkista töiden

aikana silloin tällöin laitteen kunto. Pohjaan voi

ajan kuluessa kerääntyä likaa ja hiekkaa, mikä

voi vaurioittaa pumpun. Mikäli vedenpinnan

korkeus on alhainen, kuilussa oleva liete voi kuivua nopeasti ja estää pumpun käynnistymisen.

Huomautus: Uppopumppu on varustettu automaattisella ilmanpoistolaitteella

2

. Tämän

kautta laitteesta poistuu siinä mahdollisesti vielä

oleva ilma, kun upotat sen veteen. Ellet upota

uppopumppua käytön aikana kokonaan veteen,

vettä voi vuotaa ulos ilmanpoistolaitteesta

2

Tässä ei ole kyse viasta.

HUOMIO! Älä ruuvaa ilmanpoistolaitetta 2

irti, laite voi vaurioitua.

Tyhjennysjohdon liittäminen

Huomautus: Tyhjennyspumppaus voidaan suorit-

taa joko kiinteällä putki- tai joustavalla letkujohdolla.

Mikäli hiukkaskoko on yli 35 mm tai 19 mm supistuskappaleessa, letku voi tukkeutua (katso myös

kappale “Huolto ja puhdistus“).

Ruuvaa kulma-adapteri 11 pumpun poistoauk-

4

koon

(katso kuva B).

Pistä letku supistus

letkun

kiristimellä. Käytä vaihtoehtoisesti ruuvilii-

täntää kulma-adapterilla

10

leella

.

kappaleelle 10 ja kiinnitä se

11

tai supistuskappa-

Uimurikytkimen asennus

Huomautus: Uimurikytkin 8 on säädetty niin,

välitön käyttöönotto on mahdollinen.

nuksessa

uimuri

kytkimen 8 toiminto on tarkistettava

Kiinteässä asen-

säännöllisesti (vähintään joka kolmas kuukausi

Uimurikytkimen 8 päälle- ja poiskytkentäpistettä

14 FI

että

).

voidaan säätää uimurikytkimen 8 asentoa muuttamalla uimurikytkimen pidikkeestä

9

(katso kuva A).

Tässä pätee: Mitä enemmän välystä on uimuri

8

.

johdossa uimurikytkimen pidikkeen 9 takana,

sitä korkeampi on päälle- ja poiskytkentäkorkeus.

Paikoita uimurikytkin 8 niin, että kytkentäpisteen

korkeus ”PÄÄLLE“ ja ”POIS“ voidaan saavuttaa

helposti vain vähän voimaa käyttäen.

Tarkista sen toiminto asettamalla pumppu vedellä

täytettyyn astiaan, kohottamalla uimurikytkintä 8

varovasti käsin ja laskemalla se tämän jälkeen

taas alas. Tällöin voit nähdä kytkeytyykö pumppu

päälle vai pois.

Pistä uppopumpun

käyttöönottoa varten verkkopistoke sopivaan pistorasiaan. Riippuen asete

kytkentäpisteen korkeudesta ja vedenpinnan

korkeudesta uimurikytkin

8

kytkeytyy auto-

maattisesti päälle tai pois.

.

Huomautus: Tarkista ettei uimurikytkimen

pään ja uimurikytkimen pidikkeen

liian pieni. Mikäli etäisyys on liian pieni, moitteetonta toimintoa ei voida taata.

HUOMIO! Pidä huoli siitä, ettei uimurikytkin 8

kosketa pohjaa ennen kuin pumppu on kytketty

pois. Muuten on olemassa kuivakäynnin vaara

ja laite voi vaurioitua.

Huolto ja puhdistus

HENGEN- JA LOUKKAAN-

TUMISVAARA! Irrota aina verkkopistoke pistora-

siasta ennen kuin ryhdyt töihin laitteella.

Puhdista laite, jota ei ole asennettu kiinteästi

jokaisen käytön jälkeen puhtaalla vedellä.

Tarkista kiinteästi asennetuissa laitteissa sään-

nöllisesti uimurikytkimen

joka kolmas kuukausi).

Poista vesiruiskulla nukka ja kuituhiukkaset, jotka

mahdollisesti ovat kiinnittyneet pumpunpesään.

Poista kerrostumat uimurikytkimeltä 8 puh-

taalla vedellä.

Poista kuilun pohjasta liete säännöllisesti (vähin-

tään joka 3 kuukausi) ja puhdista kuilun seinät.

Puhdista pumppu perusteellisesti ellei sitä ole

käytetty pitempään aikaan. Kerrostumat ja jää

voivat muuten aiheuttaa käynnistysvaikeuksia.

8

toiminto (vähintään

kytkimen

9

väli ole

tusta

mät

®

Page 15

Huolto ja puhdistus / Huolto / Takuu / Hävittäminen

Käytä pesän puhdistukseen liinaa, älä missään

tapauksessa käytä bensiiniä, liuottimia äläkä

puhdistusaineita. Laite voi muuten vaurioitua

Siipirattaan puhdistus

Huomautus: Mikäli siipipyörä 13 on likainen tai

juuttunut kiinni, voit puhdistaa sen pumpun poistoau-

4

kosta

tai ruuvaamalla pohjalevy 5 irti (katso

kuva C).

Ruuvaa tätä varten kulma-adapteri 11 irti pum-

pun poistoaukosta

4

.

Poista 3 ruuvia pumpunpesän 3 alapuolelta

ja ota pohjalevy

Puhdista siipiratas 13 puhtaalla vedellä

5

pois.

.

Kokoa päinvastaisessa järjestyksessä.

Huomautus: Kaikki tämän yli menevät toimenpiteet, erityisesti pumpun avaaminen on

annettava asiantuntijan tehtäväksi. Käänny

korjaustapauksessa aina huoltopalvelumme

puoleen.

Huolto

liikkeen tai sähköliikkeen korjattav

Korjauksissa saa käyttää vain alkuperäisiä varaosia. Laitteesi säilyy näin

turvallisena.

verkkojohdon saa vaihtaa vain laitteen valmistaja tai sen valtuuttama

huoltoliike. Laitteesi säilyy näin turvallisena.

Anna laitteet huolto-

aksi.

Laitteen pistokkeen tai

Takuu koskee ainoastaan materiaali- ja valmistusvirheitä, ei kuitenkaan kuljetusvaurioita, kuluvia osia tai

herkästi vaurioituvien osien, esim. kytkinten tai akkujen

vaurioita. Tuote on tarkoitettu ainoastaan yksityiseen,

ei kaupalliseen käyttöön.

Väärä tai asiaton käyttö, väkivallan käyttö ja muiden

kuin valtuutetun huoltopisteen suorittamat korjaukset

aiheuttavat takuun raukeamisen. Tämä takuu ei rajoita kuluttajan lakisääteisiä oikeuksia.

Takuukorjaus ei pidennä takuuaikaa. Tämä koskee

myös vaihdettuja ja korjattuja osia. Mahdollisista jo

ostettaessa olemassa olevista vahingoista ja puutteista on ilmoitettava välittömästi pakkauksesta purkamisen jälkeen, kuitenkin viimeistään kaksi päivää

ostopäiväyksen jälkeen. Takuuajan jälkeen suoritetut

korjaukset ovat maksullisia.

FI

Huolto Suomi

Tel.: 010309 3582

e-mail: kompernass@lidl.fi

IAN 69518

Hävittäminen

Pakkaus on valmistettu ympäristöystävällisistä kierrätettävistä materiaaleista.

Älä heitä sähkölaitteita talousjätteisiin!

Takuu

Laitteen takuu on 3 vuotta ostopäivästä.

Laite on valmistettu huolellisesti ja tarkistettu tarkasti ennen toimitusta. Säilytä

ostokuitti todisteeksi takuun voimassaolosta. Ota takuutapauksessa puhelimitse

yhteyttä huoltopisteeseesi. Vain näin

voidaan taata tuotteesi maksuton lähettäminen huoltoon.

®

Sähkölaitteiden hävittämistä koskevan EU-normin

2002 / 96 / EC mukaan käytöstä poistettuja sähkölaitteita hävitettäessä on huolehdittava materiaalien

erottelusta ja kierrätyksestä.

Lisätietoja antavat mm. paikalliset ympäristöviranomaiset.

15 FI

Page 16

Hävittäminen / Vaatimustenmukaisuusvakuutus / Valmistaja Innehållsförteckning

Vaatimustenmukaisuus-

vakuutus / Valmista ja

Me, Kompernaß GmbH, dokumentoinnista vastaava:

herra Semi Uguzlu, Burgstr. 21, D-44867 Bochum,

Saksa, vakuutamme täten, että tämä tuote vastaa

seuraavia standardeja, normatiivisia dokumentteja

ja EY-direktiivejä

Pienjännitedirektiivi

(2006 / 95 / EC)

Elektromagneettista yhteensopivuutta

koskevat direktiivit

(2004 / 108 / EC)

Sovelletut harmonisoidut normit

EN 60335-2-41:2003+A1:04

EN 62233:2008, EK1 337-07:2007

EN 60335-1:2002+A11, A1:04+A12,A2:

06+A13:08, EN 55014-1:2006/+A1:2009

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006/+A1:2009/+A2:2009

EN 61000-3-3:2008

Tyyppi / Laitekuvaus:

Jäteveden uppopumppu FTS 1100 B2

Date of manufacture (DOM): 10–2011

Sarjanumero: IAN 69518

Bochum, 31.10.2011

Semi Uguzlu

- Laatumanageri -

Pidätämme oikeuden muutoksiin.

16 FI

®

Page 17

Innehållsförteckning

Inledning

Avsedd användning ........................................................................................................Sidan 18

De olika delarna .............................................................................................................Sidan 18

Leveransens omfattning ..................................................................................................Sidan 18

Tekniska data ..................................................................................................................Sidan 18

Allmänna säkerhetsanvis ningar ............................................................. Sidan 18

Produktspecifika säkerhetsanvisningar för dränkbara pumpar ....................................Sidan 19

Ytterligare relevanta säkerhetsanvisningar för dränkbara pumpar .............................Sidan 19

Användning

Ställa upp / hänga upp produkt .....................................................................................Sidan 19

Ansluta pumpslangen .....................................................................................................Sidan 20

Montera flottör ................................................................................................................Sidan 20

Underhåll och rengöring ................................................................................Sidan 20

Rengöra fläkt ...................................................................................................................Sidan 21

Service ...........................................................................................................................Sidan 21

Garanti ..........................................................................................................................Sidan 21

Avfallshantering ...................................................................................................Sidan 21

Konformitetsdeklaration / Tillverkarintyg ......................................Sidan 22

®

17 SE

Page 18

Dränkpump FTS 1100 B2 för

smutsvatten

Inledning

Innan du börjar använda produkten gör

dig ovillkorligen förtrogen med de olika

funktionerna och informera dig om hur

man hanterar med elprodukten. Läs nedanstående

bruksanvisning. Spara denna bruksanvisning. Se till

att bruksanvisningen alltid finns tillgänglig även vid

vidare användning av tredje man.

Avsedd användning

D

enna dränkbara smutsvattenpump är avsedd för

att pumpa

med maximal partikelstorlek på 35 mm (reducer

max. 19 mm) och vattentemperatur på max. + 35 °C.

Den är t.ex. avsedd för att pumpa om eller pumpa

ur bassänger och behållare, översvämmande källare och pumpa bort vatten ur brunnar och schakt.

Varje annan användning gäller som icke avsedd

användning och kan medföra allvarliga olycksfallsrisker. Endast lämplig för konstant användning. Inte

avsedd för kommersiellt bruk.

och transportera vatten och smutsvatten

stycke

Leveransens omfattning

1 dränkpump FTS 1100 B2 för smutsvatten

1 vinkeladapter

1 reducerstycke

1 lina (8 m)

1 bruksanvisning

Tekniska data

Dränkbar smutsvattenpump FTS 1100 B2

Märkspänning: 230 V∼, 50 Hz

Effekt: 1100 W

Skyddsklass: I

Skyddstyp: IPX8

Vattentemperatur: max. 35 °C

Max. partikelstorlek: 35 mm

Max. sänkdjup: Hmax. 8 m

Max. pumpmängd: Qmax 20000 l/h

Max. pumphöjd: 8 m

Kopplingspunkthöjd ”TILL“: ca. 520 mm

Kopplingspunkthöjd ”FRÅN“: ca. 230 mm

Slanganslutning: 25 mm (1“),

38 mm (1 ½“)

Nätkabellängd: 10 m

Vikt: ca. 6,8 kg

De olika delarna

1

Handtag

2

Avluftningsanordning

3

Pumphus

4

Pumputgång

5

Bottenplatta

6

Bottendel

7

Nätanslutningskabel

8

Flottör

9

Flottörkoppling

10

Reducerstycke

11

Vinkeladapter

12

Lina

13

Fläkt

18 SE

Allmänna säkerhetsanvisningar (EN 60335-1)

Barn och personer med bristande kunskaper

och eller erfarenhet samt personer med nedsatta

fysiska, motoriska hinder, handikappade personer eller barn skall om möjligt inte använda

produkten utan uppsikt eller handledning av

säkerhetsansvarig person.

Barn skall hållas under uppsikt och får absolut

inte använda produkten som leksak. Vidtag

lämpliga åtgärder för att hålla barn borta från

aktiv produkt.

®

Page 19

Allmänna säkerhetsanvis ningar / Användning

Produktspecifika

säkerhetsanvisningar för

dränkbara pumpar

LIVSFARA FÖR ELSTÖTAR! An-

vänd inte produkten om det befinner

sig personer i vattnet. Säkerställ att

alla elektriska anslutningar finns i ett översvämningssäkert område. Risk för personskador p.g.a.

elstötar föreligger.

Använd inte kabeln eller slangen för

något de inte är avsedda för genom

att använda dessa för att bära eller

hänga upp apparaten och dra inte i kabeln eller

slangen för att dra ut stickkontakten ur eluttaget.

Se till att kabeln inte utsätts för värme, olja,

kanter eller rörliga apparatdelar. Skadade eller

snodda kablar ökar risken för elstötar.

Observera att i många länder gäller ytterligare

från nationella hälso- och arbetsskyddsmyndigheter, vattenleverantörer och liknande myndigheter.

Anslut produkten via en jordfelsbrytare med

maximalt 30 mA utlösningsström.

Förvara elektrisk utrustning som inte används

utom räckhåll för barn. Låt inte personer använda

verktyget utan att de känner till användningen e

har läst användningsinstruktionerna. Elverktyg

är farliga om oerfarna personer använder dem.

skarpa

ller

Observera att produkten använder smörjmedel.

Detta kan medföra

läcker ut.

gårdsdammar med fisk eller värdefulla plantor.

Produkten får av säkerhetsskäl inte användas

av barn eller ungdomar under 16 år eller personer som inte läst denna bruksanvisning.

Håll produkten under uppsikt under användning

för att upptäcka automatisk avstängning eller

tomkörning av pumpen i tid.

funktion regelbundet (se kapitel „Användning“).

Kontrollera produkten på skador före varje an-

vändning.

Använd inte pumpen kontinuerligt t.ex. för vat-

tenfall i trädgårdsdammar. Den är

för detta driftssätt. Annnars

tens användningstid.

Frostskydda produkten. Förvara den dränkbara

pumpen för smutsvatten på frostfri plats.

Låt inte produkten torrköra.

Risk för produktskador föreligger.

Använd endast original-tillbehör. Förändra inte

produkten. Detta säkerställer säkerheten för

produkten.

Låt endast behörig elektriker öppna produkten.

Kontakta kundtjänst om reparation är nödvändig.

Använd därför inte produkten i träd-

skador eller smuts

Kontrollera flottörens

förkortas produk-

om det

inte avsedd

Användning

Ytterligare relevanta

säkerhetsanvisningar

för dränkbara pumpar

(EN 60335-2-41)

Använd inte i sandigt vatten. Risk för produktska-

dor föreligger.

Pumpa inga aggressiva, abrasiva (slipande),

frätande, brännbara eller explosiva vätskor,

saltvatten, rengöringsmedel eller livsmedel.

Hälsorisker, risk för materialskador och produktskador föreligger.

Se till att vattentemperaturen ligger under 35 °C

vid användning. Risk för produktskador föreligger.

Observera detmaximala driftssänkdjupet på

8 m när du arbetar med produkten. Risk för

produktskador föreligger.

®

Obs: Du kan även installera denna dränkbara pump

statio

närt, dvs du kan montera den fast på en plats

(t.ex. för att regelbundet pumpa om eller ur bassänger och behållare). Om du vill installera den

dränkbara pumpen stationärt, kontakta eventuellt

behörig elektriker för ytterligare information.

Ställa upp / hänga upp

produkt

Obs: Pumpschaktet måste minst hålla måtten 40 x

40 x 50 cm (B x D x H) så att flottören

sig fritt.

Häng upp produkten i handtaget 1 eller ställ

på marken. Risk för produktskador föreligger.

8

kan rör

den

19 SE

Page 20

Obs: Använd medlevererad lina 12 för att

hänga upp pumpen säkert. Lägg linan

handtaget 1 och sätt fast med

12

om

en dubbelknut.

OBSERVERA! Häng aldrig upp

produkten i slangen. Risk för produktskador fö-

religger.

OBSERVERA! Kontrollera

tillståndet för produkten regelbundet under ar-

betet. Smuts och sand kan samlas i botten under

användningen, detta kan skada pumpen. Slammet som finns i schaktet kan torka snabbt om

vattenytan är låg och förhindra att pumpen

startar.

Obs: Den dränkbara pumpen har en automatisk avluftningsanordning

2

. Via denna försvinner eventuell befintlig luft ur produkten när

den dränks i vatten. Om du inte sänker ner den

dränkbara pumpen helt i vattnet, kan vatten

rinna genom avluftningsanordningen

2

. Detta

är dock ingen fel utan helt normalt.

OBSERVERA! Skruva inte av avluftningsanord-

2

ningen

, risk för produktskador föreligger.

Ansluta pumpslangen

Obs: Pumpen kan användas med fast rör eller

flexibel slang.

Slangen kan blockeras om partikelstorleken är större

än 35 mm resp. 19 mm för recuderstycket (se även

kapitel “Underhåll och rengöring“).

Skruva fast vinkeladaptern 11 på pumput-

gången

Sätt fast en slang över recuder

fäst med en slangklämma.

skruvförbindelse på vinkeladaptern

reducerstycket

4

(se bild B).

10

stycket 10 och

Använd alternativt en

.

11

resp. på

Montera flottör

Obs: Flottören 8 är inställd för omedelbar använd-

ning. Vid

funktion kontrolleras regelbundet (var tredje månad)

Flottörens 8 TILL- resp. FRÅN-kopplingspunkter kan

förändras med flottörens

lingen

stationär installation måste

8

position i flottörklopp-

9

(se bild A).

flottörens

8

Därvid gäller: Ju mer spel för flottorens

bakom flottörkopplingen

9

, desto högre TILL- resp.

8 kabel

FRÅN-kopplingshöjd.

Positionera flottören 8 så att kopplingspunk-

terna “TILL“ och “FRÅN“ kan aktiveras lätt utan

större kraft.

Kontrollera funktionen genom att ställa pumpen

i ett vattenfyllt kar, lyft flottören

8

försiktigt för

hand och sänk den igen. Pumpen startar och

stänger av.

Anslut den dränkbara pumpens nätkontakt till

lämpligt vägguttag för användning. Beroende

på inställd kopplingshöjd och vattennivå, kopplar flottören

8

automatiskt TILL resp. FRÅN.

Obs: Observera att avståndet mellan flottörhuvudet och flottörkopplingen

9

inte är för kort.

Ett för kort avstånd ger inte felfri funktion.

OBSERVERA! Observera vid flottörens 8 in-

ställning att den inte rör marken innan pumpen

stängs av. Risk för torrkörning och produktskador.

Underhåll och rengöring

RISK FÖR LIVSFARLIGA

SKADOR OCH PERSONSKADOR! Dra alltid

ut nätkontakten ur vägguttaget innan arbeten görs

på produkten.

Ren produkten med rent vatten efter varje an-

vändning.

Kontrollera flottörens 8 funktion på stationärt in-

stallerad produkt regelbundet (var tredje månad).

Ta bort ludd och fiberpartiklar som ev. fastnat i

pumphuset med vattenstråle.

Ta bort avlagringar på flottören 8 med rent

vatten.

Ta bort slam i botten regelbundet (var tredje

månad) och rengör även väggarna.

Rengör pumpen noga om den inte skall använ

under längre tid. Startsvårigheter kan annars

förekomma pga avlagringar och rester.

Använd en duk för rengöring, använd inte ben-

.

sin, lösningsmedel eller rengöringsmedel. Risk

för produktskador föreligger.

das

20 SE

®

Page 21

Underhåll och rengöring / Service / Garanti / Avfallshantering

Rengöra fläkt

Obs: Om fläkten 13 är smutsig eller blockerad kan

den rengöras via pumputgången

att skruva loss bottenplattan

Skruva av vinkeladaptern 11 på pumput-

gången

Ta bort de 3 skruvarna på pumphusets 3 un-

dersida och ta bort bottenplattan

Rengör fläkten 13 med rent vatten

Montera i omvänd ordning.

Obs: Alla därutöver nödvändiga åtgärder

skall utföras av behörig elektriker. Kontakta alltid kundtjänst om reparation är nödvändig.

4

.

4

5

(se bild C).

eller genom

5

.

.

Service

elektriker reparera utrustningen och

använd endast reservdelar i original.

Därmed säkerställs verktygets säkerhet.

eller kundtjänst byta nätkontakt eller

nätsladd. Därmed säkerställs verktygets

säkerhet.

Låt endast behörig

Låt alltid tillverkaren

serade servicefilial upphör garantin att gälla. Den lagstadgade garantin begränsas inte av denna garanti.

Garantitiden förlängs inte för att man utnyttjar garantiförmånerna. Det gäller även för utbytta eller

reparerade delar. Eventuella skador och brister som

upptäcks redan vid köpet måste anmälas omedelbart efter uppackningen, dock senast två dagar ef

inköpsdatum. När garantitiden är slut måste man

betala för eventuella reparationer.

SE

Service Sverige

Tel.: 0770 930739

e-mail: kompernass@lidl.se

ter

IAN 69518

FI

Service Suomi

Tel.: 010309 3582

e-mail: kompernass@lidl.fi

IAN 69518

Avfallshantering

Garanti

För den här apparaten lämnar vi tre års

garanti från och med inköpsdatum. Den

här apparaten har tillverkats med omsorg

och genomgått en noggrann kontroll innan

leveransen. Var god bevara kassakvittot

som köpbevis. Vi ber dig att kontakta ditt

serviceställe per telefon vid garantifall. Endast då kan produkten skickas in fraktfritt.

Garantin gäller bara för bara för material- eller fabrikationsfel, den täcker inte transportskador, förslitningsdelar eller skador på ömtåliga delar som t ex

brytare och batterier. Produkten är endast avsedd

privat bruk och får inte användas yrkesmässigt.

Vid missbruk och felaktig behandling, användande

av våld och vid ingrepp som inte gjorts av vår auktori-

®

för

Förpackningen består av miljövänligt

material som kan avfallshanteras vid

lokala återvinningsställen.

Kasta inte elprodukter i hus-

hållssoporna!

Enligt EU-direktiv 2002 / 96 / EC gällande Begagnad elektrisk och elektronisk utrustning skall trasiga

eller begagnade elverktyg avfallshanteras separat

och tillföras återvinningen enligt gällande miljölagstiftning.

Kontakta miljökontoret på din ort för vidare information om avfallshantering av förbrukad utrustning.

21 SE

Page 22

Konformitetsdeklaration /Tillverkarintyg Indholdsfortegnelse

Konformitetsdeklaration /

Tillverkarintyg

Vi, Kompernaß GmbH, dokumentansvarig: Herr

Semi Uguzlu, Burgstr. 21, D-44867 Bochum, Tyskland, förklarar härmed att detta produkt motsvarar

följande normer, normade dokument och EU-direktiv:

Lågspänningsdirektiv

(2006 / 95 / EC)

Elektromagnetisk kompatibilitet

(2004 / 108 / EC)

använda harmoniserade normer

EN 60335-2-41:2003+A1:04

EN 62233:2008, EK1 337-07:2007

EN 60335-1:2002+A11, A1:04+A12,A2:

06+A13:08, EN 55014-1:2006/+A1:2009

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006/+A1:2009/+A2:2009

EN 61000-3-3:2008

Typ / beteckning:

Dränkpump FTS 1100 B2 för smutsvatten

Date of manufacture (DOM): 10–2011

Serienummer: IAN 69518

Bochum, 31.10.2011

Semi Uguzlu

- Kvalitetsmanager -

Rätt till tekniska ändringar för fortsatt

produktutveckling förbehålles.

22 SE

®

Page 23

Indholdsfortegnelse

Indledning

Brug efter bestemmelsen ....................................................................................................Side 24

Udstyr ..................................................................................................................................Side 24

Leveringsomfang ................................................................................................................Side 24

Tekniske specifikationer .....................................................................................................Side 24

Generelle sikkerhedshen visninger ..........................................................Side 24

Apparatspecifikke Sikkerhedshenvisninger for dykkerpumper ........................................Side 25

Yderligere, relevante sikkerhedshenvisninger for dykkerpumpen ...................................Side 25

Ibrugtagning ...............................................................................................................Side 25

Apparatet stilles / hænges op ...........................................................................................Side 26

Pumpeledning tilsluttes .......................................................................................................Side 26

Flydeafbryder anbringes ...................................................................................................Side 26

Vedligeholdelse og rensning ........................................................................Side 26

Vingehjul renses .................................................................................................................Side 27

Service ..............................................................................................................................Side 27

Garanti .............................................................................................................................Side 27

Bortskaffelse ...............................................................................................................Side 27

Konformitetserklæring / Fremstiller ........................................................Side 28

®

23 DK

Page 24

Spildevands-dykpumpe FTS 1100 B2

Indledning

Gør dig inden første ibrugtagning fortrolig med apparatet og informer dig om

den rigtige håndtering af el-apparater.

Læs til dette formål den efterfølgende betjeningsvejledning. Opbevar denne vejledning godt. Udlever

alle dokumenter, når apparatet gives videre til

tredje mand.

Brug efter bestemmelsen

D

enne spildevands-dykkerpumpe er beregnet til

bortpump

med en maksimal partikelstørrelse på 35 mm (overgangsstykke maks. 19 mm) og vandtemperatur på

maks. 35 °C. Den er for eksempel beregnet til omog udpumpning af kar og beholdere, oversvømmede

kældre samt vandoptagning fra brønde og skakte.

Enhver anden anvendelse eller ændring på apparatet gælder som ikke hensigtsmæssig og skjuler

alvorlige risici for ulykker. Ikke egnet til døgndrift.

Ikke til erhvervsmæssig brug.

ning og udvinding af vand og spildevand

Leveringsomfang

1 spildevands-dykpumpe FTS 1100 B2

1 vinkeladapter

1 overgangsstykke

1 reb (8 m)

1 betjeningsvejledning

Tekniske specifikationer

Spildevands-dykkerpumpe FTS 1100 B2

Nominel kapacitet: 230 V∼, 50 Hz

Nominel optagelse: 1100 W

Beskyttelsesklasse: I

Beskyttelsesart: IPX8

Vandtemperatur : maks. 35 °C

MAks. partikelstørrelse: 35 mm

Maks. dykkedybde: Hmax. 8 m

Maks. transportkapacitet: Qmax 20000 l/h

Maks. transporthøjde: 8 m

Afbryderpunkthøjde ”Tænd”: ca. 520 mm

Afbryderpunkthøjde ”Sluk”: ca. 230 mm

Slangetilslutning: 25 mm (1“),

38 mm (1 ½“)

Strømkabellængde: 10 m

Vægt: ca. 6,8 kg

Udstyr

1

håndtag

2

ventilationsmekanisme

3

pumpehus

4

pumpeudgang

5

bundplade

6

foddel

7

strømtilslutningskabel

8

flydeafbryder

9

flydeafbryder-raster

10

overgangsstykke

11

vinkeladapter

12

reb

13

vingehjul

24 DK

Generelle sikkerhedshenvisninger (EN 60335-1)

Dette apparat er ikke beregnet til at blive brugt

af personer (inklusive børn) med indskrænkede

fysiske, sensoriske eller mentale ev

manglende erfaring og / eller mang

medmindre de er under opsyn af en person,

som er ansvarlig for vedkommendes sikkerhed

eller har fået anvisninger om hvordan apparatet benyttes af samme.

Børn bør være under opsyn, for at sikre, at de

ikke leger med apparatet. Sørg for egnede foranstaltninger, for at holde børn væk fra det kørende apparat.

ner eller

lende viden,

®

Page 25

Generelle sikkerhedshen visninger / Ibrugtagning

Apparatspecifikke

Sikkerhedshenvisninger

for dykkerpumper

LIVSFARE GRUNDET ELEKTRISK

STØD! Brug apparatet ikke, hvis der

befinder sig personer i vandet. Det

skal sikres, at elektriske stikforbindelser er anbragt

i et område, som er sikret mod oversvømmelse.

Ellers er der livsfare grundet elektrisk stød.

Brug ikke kablet eller slangen mod

deres formål til at bære det elek-

triske apparat, til at hænge det op

eller til at trække elstikket ud af stikdåsen. Ledningen skal holdes på afstand af varme, olie,

skarpe kanter eller dele af apparatet, der er i

bevægelse. Beskadigede eller forsnoede ledninger forhøjer risikoen for elektrisk stød.

Der gøres opmærksomt på, at der i mange

lande vedtages yderligere krav af nationale

sundheds- og arbejdstilsynsstyrelser, vandforsyningsstyrelser og lignende styrelser.

Tilslut apparatet over et fejlstrøms (FI)-beskyttelses-

relæs med maksimal udløsningsstrøm på 30 mA.

Elektriske apparater, der ikke er i brug, skal op-

bevares uden for børns rækkevidde. Lad ikke

personer benyttet apparatet, hvis de ikke er fortrolige med det eller ikke har læst disse anvisninger. Elektrisk værktøj er farligt, hvis det

benyttes af uerfarne personer.

Vær under arbejdet med apparatet opmærksom

på den maksimale driftsdykkedybde på 8 m.

Ellers kan det resultere i skader på apparatet.

Vær opmærksom på, at apparatet bruger smø-

remidler. Disse kan ved udløb resultere i

digelser og tilsmudsninger. Indsæt derfor ikke

apparatet i havebassiner med fiskebestand eller

værdifulde planter.

Af sikkerhedsgrunde må børn og unge under

16 år samt personer, som ikke er fortrolig med

betjeningsvejledningen, ikke bruge dette apparat.

Observer apparatet mens det er i drift, for at

genkende automatisk slukning eller

tørløben i ti

bryderens funktion (se kapitel ”Ibrugtagning”).

Kontroller apparatet inden hvert brug for even-

tuelle beskadigelser.

Brug pumpen ikke i døgndrift f. eks. til vandløb

eller havebassiner. Den er

driftsart. El

Beskyt apparatet mod frost. Lager spildevands-

dykkerpumpen på et frostsikkert sted.

Lad ikke apparatet køre uden pumbar væske.

Ellers kan det resultere i skader på apparatet.

Brug kun original-tilbehør. Gennemfør ingen

ombygninger på apparatet. På den måde sikres, at apparatets sikkerhed holdes vedlige.

Lad åbning af apparatet gennemføres af en el-

specialist. I tilfælde af reparation henvende dig

til vores service-center.

de. Kontroller regelmæssigt flydeaf-

ikke beregnet til denne

lers forkortes apparatets levetid.

beska-

pumpens

Yderligere, relevante

sikkerhedshenvisninger

for dykkerpumpen

(EN 60335-2-41)

Må ikke bruges til sandet vand. Ellers kan det

resultere i skader på apparatet.

Udvind ingen aggressive, abrasive (smerglende),

ætsende, brandbare eller eksplosive væsker,

saltvand, rensemidler eller fødevarer. Ellers er

der sundhedsrisici, risiko for materiel skade og

skader på apparatet.

Sørg ved udvindingen for, at vandtemperaturen

er lavere end 35 °C. Ellers kan det resultere i

skader på apparatet.

®

Ibrugtagning

Bemærk: Denne spildevands-dykkerpumpe kan

også installeres statio

vedvarende på et sted (f. eks. til regelmæssig omog udpumpning af bassiner og beholdere). Hvis du

vil installere din dykkerpumpe stationært, henvend

dig i givet fald til en specialist for yderligere informationer.

nært, dvs. den kan monteres

25 DK

Page 26

Apparatet stilles / hænges op

Flydeafbryder anbringes

Bemærk: Pumpeskakten skal have mindst målene

40 x 40 x 50 cm (B x D x H) , så flydeafbryderen 8

kan bevæges frit.

Hæng apparatet op i håndtaget 1 eller stil

den på gulvet / jorden. Ellers kan det resultere i

skader på apparatet.

Bemærk: Til sikker ophængning af apparatet

kan det medleverede reb

til dette formål rebet

og fastgør det ved hjælp af

12

også bruges. Slyng

12

omkring

en doppelknude.

håndtaget 1

OBS! Hæng aldrig apparatet

op i slangen. Ellers kan det resultere i skader

på apparatet.

OBS! Kontroller under arbejdet

en gang imellem apparatets tilstand. I løbet af

tiden kan der samles snavs og sand i bunden,

som kan beskadige pumpen. For lav vandstand

kan hurtigt udtørre slammen, som befinder sig i

skakten, og hindre pumpen i at gå i gang.

Bemærk: Dykkerpumpen er udstyret med en

automatisk ventilationsmekanisme

2

. Over

denne undviger luft, som eventuelt stadig befinder sig i apparatet, så snart det dykkes i vand.

Hvis dykkerpumpen ved brug ikke dykkes helt i

vand, kan der træde vand ud af ventilationsmekanismen

OBS! Spæd ikke ventilationsmekanismen 2

2

. Det er ikke nogen defekt.

af,

ellers kan det resultere i skader på apparatet.

Pumpeledning tilsluttes

Bemærk: Pumpningen kan foregå ved hjælp af

en fast rør- eller fleksibel slangeforbindelse.

Ved en partikelstørrelse på mere end 35 mm hhv.

19 mm ved overgangsstykket kan slangen stoppes

til (se også kapitlet “Vedligeholdelse og rensning“).

Spænd vinkeladapteren 11 på pumpeudgan-

4

gen

(se illust. B).

Sæt en slange over overgangs

fastgør den ved hjælp af et slange

Brug alternativt en skrueforbindelse på vinkeladapteren

11

hhv. på overgangsstykket 10.

stykket 10 og

spændebånd.

Bemærk: Flydeafbryderen 8 er indstillet, så en

øjeblikkelige ibrugtagning er mulig. Ved

installering skal

flyde

afbryderens funktion 8 kon-

trolleres regelmæssigt (senest hver tredje måned

stationær

).

Tænd- hhv. sluk-afbryderpunktet på flydeafbryderen 8

9

, desto

8

8

kan indstilles ved ændring af flydeafbryderens

position i flydeafbryder-rasteret

9

(se illust. A).

Derved gælder: Jo mere spil flydeafbryderens

kabel har bagved flydeafbryder-rasteret

højere bliver tænd- hhv. sluk-højden.

Positioner flydeafbryderen 8 på en sådan

at afbryderpunkthøjden for ”TÆND” eller

måde,

”SLUK”

kan nås nemt og med kun lidt kraft.

Kontroller dens funktion, idet du stiller pumpen

i en beholder, som er fyldt med vand, løfter flydeafbryderen

8

forsigtigt med hånden og efterfølgende sænker den igen. Derved kan du se,

om pumpen tændes hhv. slukkes.

Sæt til ibrugtagning dykkerpumpens s

en egnet stikkontakt

. Alt efter indstillet afbryder-

punkthøjde tændes hhv. slukkes flydeafbryde

8

automatisk.

trømstik i

ren

Bemærk: Sørg for, at afstanden imellem flydeafbryderhoved og flydeafbryder-rasteret

9

ikke er for lille. Ved for lille afstand kan en upåklagelig funktion ikke garanteres.

OBS! Sørg ved indstillingen for, at flydeafbry-

8

deren

ikke rører bunden inden pumpen

slukkes. Ellers er der risiko for, at pumpen kører

uden væske og på den måde for en beskadigelse på apparatet.

Vedligeholdelse og rensning

LIVSFARE OG RISIKO FOR

TILSKADEKOMST! Strømstikket trækkes altid ud

af stikkontakten, inden arbejder på apparatet gennemføres.

Rens apparater, som ikke er installeret statio

med klart vand efter hvert brug.

Kontroller ved stationært installerede apparater

regelmæssigt flydeafbryderens

8

(senest hver trdje måned).

nært,

funktion

26 DK

®

Page 27

Vedligeholdelse og rensning / Service / Garanti / Bortskaffelse

Fjern fnug og fiberagtige partikler, som eventu-

elt har sat sig fast i pumpehuset, ved hjælp af

en vandstråle.

Fjern aflejringer på flydeafbryderen 8 ved

hjælp af klart vand.

Befri skaktbunden regelmæssigt for slam (senest

hver tredje måned) og rens også skaktvæggene.

Rens pumpen grundigt, hvis denne ikke blev brugt

i et længere tidsrum. Ellers kan det på grund af

aflejringer og rester komme til startproblemer.

Brug til rensning af huset en klud og under ingen

omstændigheder benzin, løsningsmidler eller

rensemidler. Ellers kan det resultere i skader på

apparatet.

Vingehjul renses

Bemærk: Ved tilsmudsning og blokering af vinge-

hjulet 13 kan du rense dette over pumpeudgangen 4

eller ved at skrue bundpladen

Skru til dette formål vinkeladapteren 11 på

pumpeudgangen

Fjern de 3 skruer på pumpehusets 3 underside

og tag bundpladen

Rens vingehjulet 13 med klart van

Gå frem i omvendt rækkefølge, når den samles.

Bemærk: Alle foranstaltninger, som går ud

over, især åbning af pumpning, skal udføres af

en el-specialist. I tilfælde af reparation henvend

dig altid til vores service-center.

5

af (se illust. C).

4

af.

5

af.

d.

Service

Deres apparater bør

De kun lade reparere hos serviceafdelingen eller af en fagmand og kun

med originale reservedele. På den måde

er der garanti for at apparatets sikkerhed bevares.

Stik eller ledning må

altid kun udføres af apparatets producent eller dennes kundetjeneste. På

den måde er der garanti for at apparatets sikkerhed bevares.

Garanti

På denne donkraft får du 3 års garanti

fra købsdatoen. Apparatet er produceret

omhyggeligt og inden levering afprøvet

samvittighedsfuldt. Opbevar kassebonen

som bevis for købet. I garantitilfælde be

du kontakte service-afdelingen telefonisk.

På denne måde kan gratis indsendelse af

varen garanteres.

Garantiydelsen gælder kun for materiale- eller fabrikationsfejl, men ikke for transportskader, sliddele

eller skader på skrøbelige dele som f.eks. kontakter

eller batterier. Produktet er kun beregnet til privat

og ikke til erhvervsmæssigt brug.

Ved misbrug og uhensigtsmæssig behandling, anvendelse af vold og ved indgreb, som ikke er foretaget

af vores autoriserede service-afdeling, ophører garantien. Dine juridiske rettigheder indskrænkes ikke

ved denne garanti.

Garantiperioden forlænges ikke på grund af produktansvaret. Det gælder også for udskiftede og

reparerede dele. Eventuelle skader og mangler, som

allerede findes ved køb, skal straks anmeldes efter

udpakning og senest to dage efter købsdatoen. Når

garantiperioden er udløbet, skal udgifterne til reparationer betales normalt.

DK

Service Danmark

Tel.: 32 710005

e-mail: kompernass@lidl.dk

des

IAN 69518

Bortskaffelse

Emballagen består af mljøvenlige

materialer og kan smides ud på de

lokale genbrugsstationer.

El-apparater må ikke kastes i

husholdningsaffald!

®

27 DK

Page 28

Bortskaffelse / Konformitetserklæring / Fremstiller Inhaltsverzeichnis

I henhold til Europæisk direktiv 2002 / 96 / EC om

udtjente elektriske apparater og dets omsætning til

national lov skal brugte elektriske redskaber indsamles særskilt og bringes til miljvenlig genindvinding.

Mulighederne for at komme af med et udtjent apparat kan De få at vide hos de lokale myndigheder.

Konformitetserklæring /

Fremstiller

Vi, Kompernaß GmbH, ansvarlig for dokumenter:

Semi Uguzlu, Burgstr. 21, D-44867 Bochum, Tyskla

erklærer hermed, at dette produkt stemmer overens

med de følgende normer, normative dokumenter og

EF-retningslinjer:

EF-lavspændingsdirektiv

(2006 / 95 / EC)

Elektromagnetisk fordragelighed

(2004 / 108 / EC)

Anvendte harmoniserede standarder

EN 60335-2-41:2003+A1:04

EN 62233:2008, EK1 337-07:2007

EN 60335-1:2002+A11, A1:04+A12,A2:

06+A13:08, EN 55014-1:2006/+A1:2009

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006/+A1:2009/+A2:2009

EN 61000-3-3:2008

Type / apparatbetegnelse:

Spildevands-dykpumpe FTS 1100 B2

nd,

28 DK

Date of manufacture (DOM): 10–2011

Serienummer: IAN 69518

Bochum, 31.10.2011

Semi Uguzlu

- Kvalitetsmanager -

Tekniske ændringer af hensyn til den videre

udvikling forbeholdes.

®

Page 29

Inhaltsverzeichnis

Einleitung

Bestimmungsgemäßer Gebrauch ....................................................................................Seite 30

Ausstattung ....................................................................................................................... Seite 30

Lieferumfang ..................................................................................................................... Seite 30

Technische Daten ............................................................................................................. Seite 30

Allgemeine Sicherheits hinweise ............................................................... Seite 30

Gerätespezifische Sicherheitshinweise für Tauchpumpen ............................................. Seite 31

Weitere, relevante Sicherheitshinweise für Tauchpumpen ............................................ Seite 31

Inbetriebnahme ...................................................................................................... Seite 31

Gerät aufstellen / aufhängen .......................................................................................... Seite 32

Abpump-Leitung anschließen .......................................................................................... Seite 32

Schwimmschalter anbringen ...........................................................................................Seite 32

Wartung und Reinigung

Flügelrad reinigen ............................................................................................................ Seite 33

Service ............................................................................................................................ Seite 33

Garantie ........................................................................................................................ Seite 33

Entsorgung .................................................................................................................. Seite 34

Konformitätserklärung / Hersteller ....................................................... Seite 35

®

29 DE/AT/CH

Page 30

Einleitung / Allgemeine Sicherheitshinweise Allgemeine Sicherheitshinweise / Inbetriebnahme

Schmutzwasser-Tauchpumpe

FTS 1100 B2

Einleitung

Machen Sie sich vor der ersten Inbetriebnahme mit den Funktionen des Gerätes

vertraut und informieren Sie sich über den

Umgang mit Elektrogeräten. Lesen Sie hierzu die

nachfolgende Bedienungsanleitung. Bewahren Sie

diese Anleitung auf. Händigen Sie alle Unterlagen

bei Weitergabe des Gerätes an Dritte aus.

Bestimmungsgemäßer Gebrauch

D

iese Schmutzwasser-Tauchpumpe ist zum Abpump

und Fördern von Wasser und Schmutzwasser mit

einer maximalen Partikelgröße von 35 mm (Reduzierstück max. 19 mm) und Wassertemperatur von

max. + 35 °C bestimmt. Sie ist beispielsweise zum

Um- und Auspumpen von Becken und Behältern,

überfluteten Kellern sowie zur Wasserentnahme aus

Brunnen und Schächten vorgesehen. Jede andere

Verwendung oder Veränderung des Geräts gilt als

nicht bestimmungsgemäß und birgt erhebliche Unfallgefahren. Nicht für den Dauerbetrieb geeignet.

Nicht zum gewerblichen Gebrauch.

Lieferumfang

1 Schmutzwasser-Tauchpumpe FTS 1100 B2

1 Winkeladapter

1 Reduzierstück

1 Seil (8 m)

1 Bedienungsanleitung

Technische Daten

Schmutzwasser-Tauchpumpe FTS 1100 B2

Nennspannung: 230 V∼, 50 Hz

Nennaufnahme: 1100 W

Schutzklasse: I

Schutzart: IPX8

Wassertemperatur: max. 35 °C

Max. Partikelgröße: 35 mm

en

Max. Eintauchtiefe: Hmax. 8 m

Max. Fördermenge: Qmax 20000 l/h

Max. Förderhöhe: 8 m

Schaltpunkthöhe „Ein“: ca. 520 mm

Schaltpunkthöhe „Aus“: ca. 230 mm

Schl aucha nschl uss: 25 mm (1“), 38 mm (1 ½“)

Netzkabellänge: 10 m

Gewicht: ca. 6,8 kg

Allgemeine Sicherheitshinweise (EN 60335-1)

Ausstattung

1

Griff

2

Entlüftungsvorrichtung

3

Pumpengehäuse

4

Pumpenausgang

5

Bodenplatte

6

Fußteil

7

Netzanschlusskabel

8

Schwimmschalter

9

Schwimmschalter-Rasterung

10

Reduzierstück

11

Winkeladapter

12

Seil

13

Flügelrad

30 DE/AT/CH

Dieses Gerät ist nicht dafür bestimmt, durch Per-

sonen (einschließlich Kinder) mit eingeschränkten

physischen, sensorischen oder geistigen Fähigkeiten oder mangels Erfahrung und / oder mange

Wissen benutzt zu werden, es sei denn, sie

werden durch eine für ihre Sicherheit zuständige Person beaufsichtigt oder erhielten von ihr

Anweisungen, wie das Gerät zu benutzen ist.

Kinder sollten beaufsichtigt werden, um sicher-

zustellen, dass sie nicht mit dem Gerät spielen.

Ergreifen Sie geeignete Maßnahmen, um Kinder

vom laufenden Gerät fernzuhalten.

ls

®

Page 31

Gerätespezifische

Sicherheitshinweise

für Tauchpumpen

LEBENSGEFAHR DURCH ELEK-

TRISCHEN SCHLAG! Benutzen

Sie das Gerät nicht, wenn sich Personen im Wasser befinden. Stellen Sie sicher,

dass elektrische Steckverbindungen in einem

überflutungssicheren Bereich angebracht sind.

Andernfalls besteht Lebensgefahr durch elektrischen Schlag.

Zweckentfremden Sie das Kabel

den Schlauch nicht, um das Elektro-

gerät zu tragen, aufzuhängen oder

um den Stecker aus der Steckdose zu ziehen.

Halten Sie das Kabel fern von Hitze, Öl, scharfen

Kanten oder sich bewegenden Geräteteilen.

Beschädigte oder verwickelte Kabel erhöhen

das Risiko eines elektrischen Schlages.

Es wird darauf hingewiesen, dass in vielen

Ländern zusätzliche Anforderungen durch die

nationalen Gesundheits- und Arbeitsschutzbehörden, die Wasserversorgungen und ähnliche

Behörden erlassen werden.

Schließen Sie das Gerät über einen Fehler-

strom (FI)-Schutzschalter mit maximal 30 mA

Auslösestrom an.

Bewahren Sie unbenutzte Elektrogeräte außer-

halb der Reichweite von Kindern auf. Lassen Sie

Personen das Gerät nicht benutzen, die mit die

nicht vertraut sind oder diese Anweisungen nicht

gelesen haben. Elektrowerkzeuge sind gefährlich,

wenn sie von unerfahrenen Personen benutzt

werden.

oder

sem

Weitere, relevante

Sicherheitshinweise für

Tauchpumpen

(EN 60335-2-41)