Page 1

®

SUBMERSIBLE WATER PUMP FTP 400 D3

SUBMERSIBLE WATER PUMP

Translation of the original instructions

ZUIVER WATER-DOMPELPOMP

Vertaling van de originele gebruiksaanwijzing

POMPE À EAU CLAIRE IMMERGÉE

Traduction des instructions d‘origine

KLARWASSER-TAUCHPUMPE

Originalbetriebsanleitung

IAN 109771

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Avant de lire le mode d‘emploi, ouvrez la page contenant les illustrations et familiarisez-vous ensuite avec

toutes les fonctions de l‘appareil.

Vouw vóór het lezen de pagina met de afbeeldingen open en maak u vertrouwd met alle functies van het

apparaat.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Translation of the original instructions Page 4

FR / BE Traduction des instructions d‘origine Page 17

NL / BE Vertaling van de originele gebruiksaanwijzing Pagina 31

DE / AT / CH Originalbetriebsanleitung Seite 45

Page 3

7

10

1

10

11

7

12

9

8

56

4

½’’

¾’’

1’’

G 1 ½’’

2

3

13

8

13

9

10

12

5

8

7

1 ½’’

6

6

10

7

11a

11

11b

12

4a4b4

Page 4

GB IE

Content

Introduction .................................4

Special instructions for safe

operating .....................................5

Areas of Application ....................5

General Description ......................5

Scope of Delivery ..............................5

Overview ......................................... 6

Functional description ........................6

Technical Data ..............................6

Performance data ..............................6

Notes on Safety ...........................7

Symbols in the manual ....................... 7

Explanation of symbols ...................... 7

General notes on safety .....................7

Start-up .......................................9

Assembly .........................................9

Connection of the pressure line ...........9

To erect/suspend ..............................9

Controls before operational start-up ...10

Operation ..................................10

Mains connection ............................10

Switching on and off .......................10

Automatic mode..............................10

Manual mode/at suction ................ 11

Maintenance and Cleaning .........11

General cleaning instructions ............11

To replace the backow stop ............11

Clean pump pedestal ......................12

Storage ......................................12

Waste Disposal and

Environmental Protection ...........12

Replacement parts/Accessories ..13

Faults - Causes - Remedies .........14

Guarantee .................................15

Repair Service ............................16

Service-Center ............................16

Importer ....................................16

Translation of the original

EC declaration of conformity ......59

Exploded Drawing .....................61

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has

been checked for quality and subjected

to a nal inspection. The functionality of

your equipment is therefore guaranteed. It

cannot be ruled out that residual quantities

of water or lubricants will remain on or in

the equipment/hose lines in isolated cases.

This is not a fault or defect and it represents no cause for concern.

The operating instructions constitute

part of this product. They contain

important information on safety, use

and disposal.

Before using the product, familiarise

yourself with all of the operating

and safety instructions. Use the

product only as described and for

the applications specied.

Keep this manual safely and in the

event that the product is passed on,

hand over all documents to the third

party.

4

Page 5

GB IE

Special instructions for

safe operating

• The equipment is not to be operated if there are people in the

water. There is a risk of electric

shock.

• Connect the equipment only

to a socket with a residual cur

rent protection device (residual

current circuit breaker) with a

rated current of not more than

30mA; minimum fuse 6 am

peres.

• If the power cable for this

equipment is damaged, it must

be replaced by the manufac

turer, a customer service agent

of the same or a similarly quali

ed person in order to prevent

hazards.

•

This appliance can be used

by children aged from 8 years

and above and persons with

reduced physical, sensory or

mental capabilities or lack of experience and knowledge if they

have been given supervision or

instruction concerning use of the

appliance in a safe way and understand the hazards involved.

Children shall not play with the

appliance. Cleaning and user

maintenance shall not be made

by children without supervision.

• Children should be supervised

to ensure that they do not play

with the appliance.

-

-

• Contamination of the liquid can

occur when the lubricant leaks

out.

• See further information in the

section on “Maintenance and

cleaning”.

Areas of Application

-

The submersible water pump acquired by

you is designed for pumping water with a

maximum temperature of 35°C.

This pump can be used e.g. to empty basins and tanks.

The pump is not suitable for commercial

use. Commercial use will invalidate the

guarantee.

The operator or user is responsible for accidents or damage to other people or their

-

property. The manufacturer shall not be

liable for damages caused by use other

than for which the equipment is intended

or by incorrect operation.

General Description

The illustration of the principal

functioning parts can be found

on the front foldout page.

Scope of Delivery

Carefully unpack the appliance and check

that it is complete. Dispose of the packaging material correctly.

- Submersible water pump (pump)

- Angle adapter + adapter with hose

connection

- 8m nylon rope

- Instructional manual

5

Page 6

GB IE

m

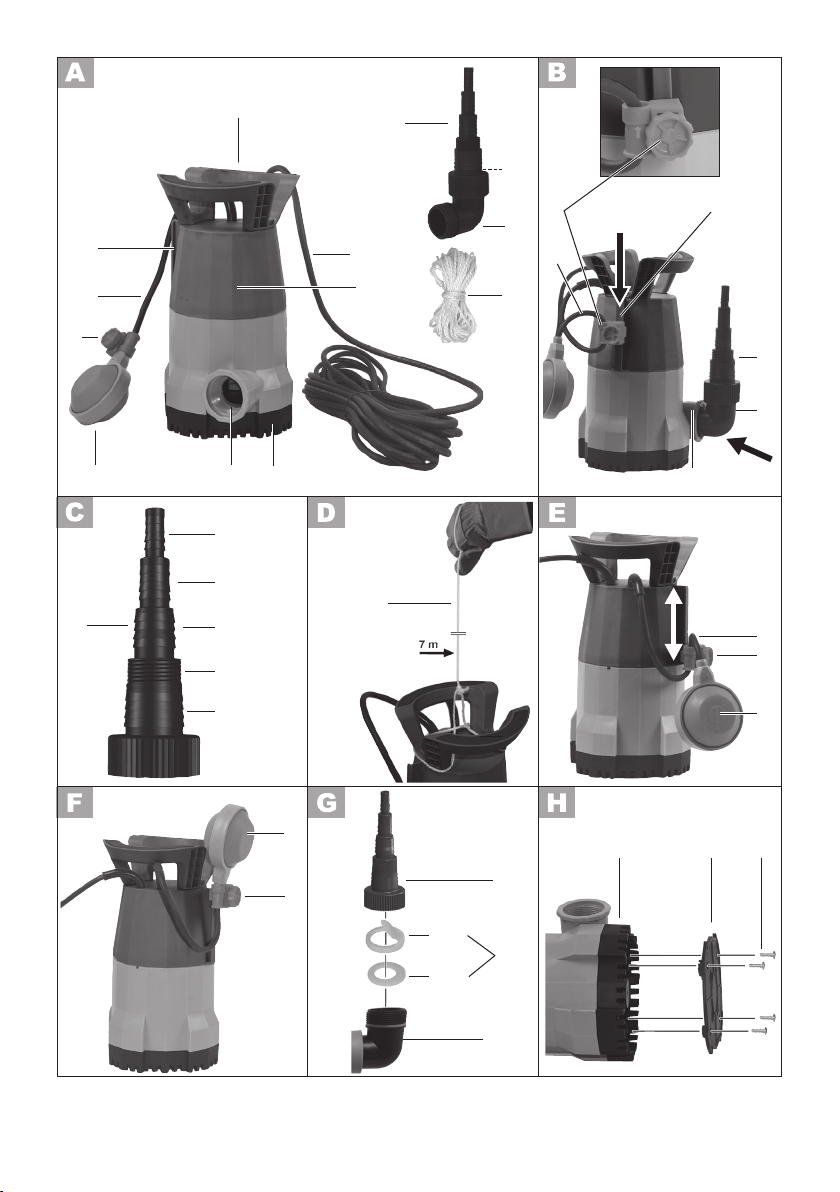

Overview

1 Carrying handle

2 Mains cable

3 Pump casing

4 Pump pedestal

5 Pump output

6 Float switch

7 Float switch height-adjustment

8 Float switch cable

9 Float switch guideway

10 Adapter with hose connection

11 backow stop (11a) with seal

(11b) (not visible)

12 Angle adapter

13 8 m nylon rope

4a 4 screws, pump pedestal

4b Cover plate, pump pedestal

Functional description

The pump is tted with a oat switch,

which automatically switches the equipment on or off.

In case of overload, the pump is switched

off by the integrated thermal protection

switch. After cooling, the motor restarts

automatically.

In addition, the pump also has a backow

stop that prevents water from owing back,

for example during an interruption in the

power supply.

Technical Data

Submersible water pump ........ FTP 400 D3

Mains connection ............ 230 V~, 50 Hz

Power consumption .....................400 W

Max. discharge rate (Qmax) ...10000 l/h

Max. discharge head (Hmax) ............ 7 m

Max. depth of immersion ..................7 m

Max. water temperature (Tmax) .......35°C

Hose connection .............½“, ¾“, 1“, 1 ½“

(13mm,19mm, 25mm, 38mm)

Tap connection with

interior thread ............. G1 ½“ (44,9mm)

Max. foreign body size ................ø 5 mm

Mains cable ..................................10 m

Weight (incl. accessories) .. approx. 4.0 kg

Safety class ..........................................I

Degree of protection ........................ IPX8

Technical and optical changes can be carried out in the course of further development

without notice. All dimensions, references

and information of this instruction manual are

therefore without guarantee. Legal claims,

which are made on the basis of the instruction

manual, cannot thus be considered as valid.

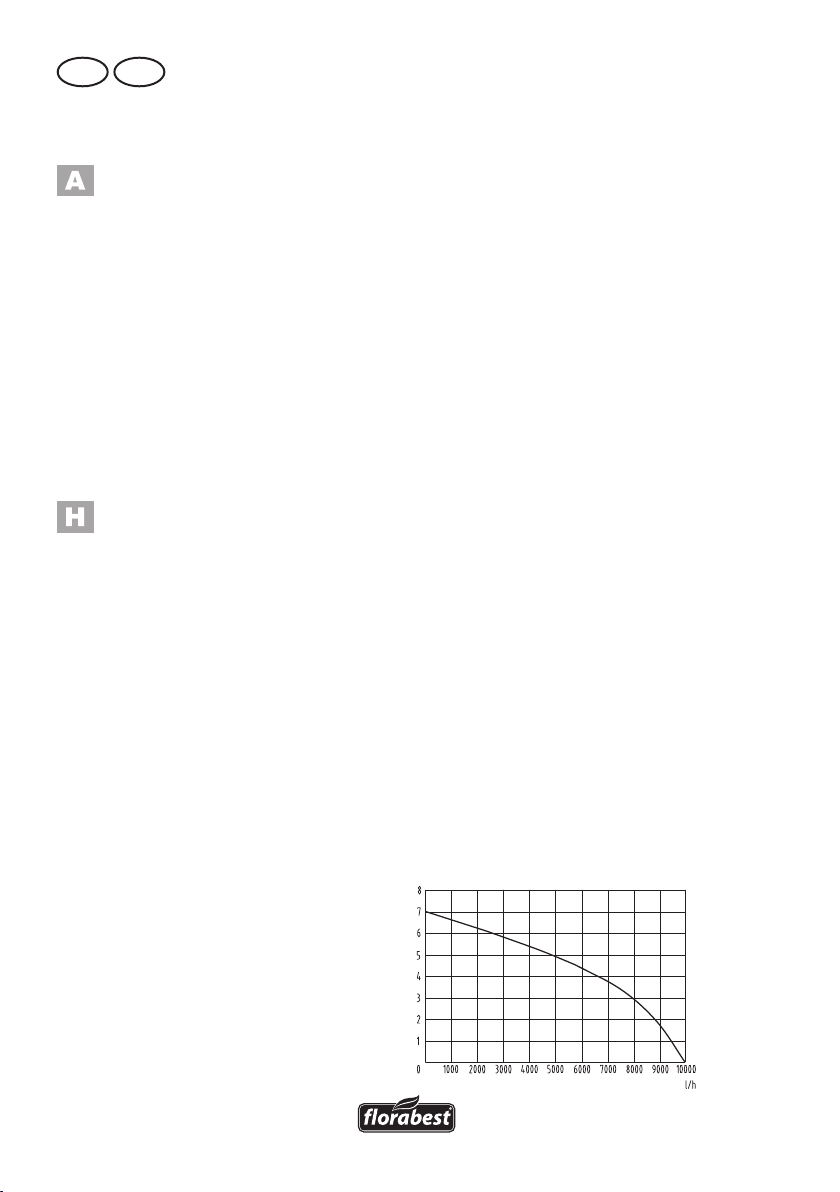

Performance data

The measurement of the maximum performance data takes place under optimal con-

ditions, such as a straight, direct exit. The

angle piece and backow stop may reduce

performance.

6

Page 7

GB IE

7 m

Notes on Safety

Symbols in the manual

Warning symbols (the danger

can be explained at the place

of the exclamation mark)

with information on damage

and injury prevention.

Instruction symbols (the instruction

can be explained at the place of

the exclamation mark) with information on preventing damage.

Help symbols with information on

improving tool handling.

Explanation of symbols

Caution! Not suitable for water

with a high sand content!

Read and follow the operating in-

structions provided for the device!

Attention: Remove the plug from the

socket as soon as the power lead is

damaged or cut.

Greatest possible operating immer-

sion depth.

Electric appliances should not be

disposed of in the domestic garbage.

General notes on safety

This section deals with the basic safety

regulations to be observed when working

with the machine.

Working with the equipment:

Caution: to avoid accidents and in-

juries:

• People who are unfamiliar with the

operating instructions are not permitted

to use the equipment. Local regulations

or bylaws may determine the minimum

age for using the device.

• Wear sturdy footwear to protect against

electric shock.

• Should there be people in the water,

do not operate the equipment. Risk of

electric shock!

• Take appropriate measures to keep children away from the equipment whilst it

is running. There is a risk of injury!

• Do not use the equipment in the vicinity

of ammable liquids or gases. Nonobservance will result in a risk of re or

explosion.

• The transportation of aggressive, abrasive (grinding effect), corrosive, combustible (e.g. motor fuels) or explosive

liquids, salt water, cleaning agents and

foodstuffs is not permitted. The temperature of the liquid being transported must

not exceed 35°C.

• Store the equipment in a dry place and

out of reach of children.

Caution! To avoid damage to the

equipment and any possible person

injury resulting from this:

• Do not work with damaged or incomplete equipment, or with equipment that

has been converted without the approval of the manufacturer. Before initial operation, have a specialist check that the

required electrical protection measures

are in place.

• Monitor the equipment during opera-

7

Page 8

GB IE

tion (particularly in residential spaces,

in order to detect automatic switching

off or dry running of the pumps in time.

Regularly check the function of the oat

switch (see chapter “initial operation“).

Non-observance will invalidate all guarantee and liability claims.

• Please note that the pump is not suitable

for continuous operation (e.g. for watercourses in garden ponds). Check the

equipment regularly for correct functioning.

• Note that the lubricants used in the

equipment may cause damage or contamination if they escape. Do not use

the pump in garden ponds with sh

stocks or valuable plants.

• Do not carry or x the equipment by the

cable or pressure line.

• Protect the equipment from frost and

from running dry.

• Use only original accessories and do not

carry out conversion work on the equipment.

• Please read the notes in the operating

instructions on the topic of “maintenance

and cleaning”. Any measures above

and beyond these, particularly opening

the equipment, are to be carried out by

an electrician. In the case of repairs,

always contact our service centre.

Electrical safety:

Caution: to avoid accidents and inju-

ries from electric shocks:

• The equipment is not to be operated if

there are people in the water. There is a

risk of electric shock.

• After erection, the mains plug must be

freely accessible when the equipment is

in operation.

• Before operating your new pump, have

a specialist check:

- The earthing, the protective multiple

earthing; the residual current circuit

breaking must be compliant with

the safety regulations of the energy

supply company and function without fault,

- The protection of the electrical plug

connections from the wet.

• If there is a risk of ooding, x the

plug connections in an area that is safe

from ooding.

• Ensure that the mains voltage matches

the specications on the rating plate.

• The electrical installation shall be ac-

cording to national wiring rules.

• Before each use, check the equipment,

cable and plug for damage. Defective cables are not to be repaired, but

rather replaced by new ones. Have

damage on your equipment repaired

by an authorised specialist.

• Do not pull the plug from the socket by

the cable. Protect the cable from heat,

oil and sharp edges.

• Do not carry or x the equipment by

the cable.

• Use only extension cables that are protected from spray water and designed

for outdoor use. Always fully unroll a

cable drum before use. Check the cable for damage.

• Disconnect the mains plug from the

socket before all work on the equipment, in case of leaks in the water

system, during work breaks, and when

not in use.

• The cross-section of mains connection

lines must be no smaller than rubber hose lines with the designation

H05RN8-F. The line must be 10 m

long. The exible lead cross-section

of the extension cord must at least

2.5mm

2

.

8

Page 9

GB IE

Start-up

Assembly

To screw-on the adapter:

1. Screw the angle adapter (12)

and the adapter with the hose

connection (10) onto the pump

outlet (5).

Tomounttheoatswitch

height adjustment

2. Loosen the screw of the oat

switch height adjustment (7) and

push the adjustment over the

oat switch guideway (9). Check

that the oat switch cable (8)

moves upward (arrow

up) (see „Operation“).

Connection of the pressure

line

The installation of the submersible water

pump is implemented either

- with xed pipe or

- with exible hose line

to point

The measurement of the maximum

performance data takes place

under optimal conditions, such as

a straight, direct exit. The angle

adapter (

stopper (

To increase pump output, the backow

stopper (11) may be taken out of the angle

adapter (12) (see

stopper”). This is particularly recommended for hose connections smaller than

1“. Please bear in mind that the water may

then ow back during pumping, or in the

event of a power cut.

12) and the backow

11) may reduce output.

“replacing backow

To erect/suspend

The pump can be erected or sus-

pended in the water.

The cord (

delivery contents may be used to

suspend and/or extract the pump.

The pump shaft should have the dimensions 40 x 40 x 50cm at least, so that the

oat switch can move freely.

13) contained in the

• If using a ½” hose, attach the

hose over the pump’s hose connection (10) and fasten it with a

hose clamp if necessary.

• To use a ¾”, 1“ or 1½” hose,

cut off the connection above and

attach the hose over the correct

connection (xing with a hose

clamp).

• To use a tap adaptor (IG1½“)

to connect external hose connection systems, cut off the three top

connections directly above the

G1½“ tube thread.

Fix the nylon rope (13) onto the car-

rying handle (1).

Ensure that the equipment is

not hung up or held by the

mains cable. There is a risk

of electric shock from damaged mains cables.

Note that, over time, dirt and sand

may collect on the bottom of the

shaft, which could damage the

pump.

We recommend placing the pump

on a brick or a grid.

9

Page 10

GB IE

If the water level is too low, the silt

in the shaft can quickly dry out and

impede the pump when warming

up.

Controls before operational

start-up

• Check that the oat switch is

working (see chapter: “Operation“).

• Check that the pump is resting

on the pit base

• Check that the pressure line has

been attached properly

• Check the proper status of the

electrical plug socket and make

sure that the plug socket is sufciently fused (at least 6 A). Insert the pump plug into the plug

socket and the pump is ready for

operation.

• Make sure that moisture or water

never come in contact with the

mains connection.There is a risk

of electrocution.

Operation

Mains connection

Switching on and off

1. Insert the plug in the socket. The pump

starts working immediately.

The pump immediately starts running

when the swimming switch is in the

correct position (see „Automatic operation“ and „Manual operation“).

2. To switch off, withdraw the plug from

the socket. The pump stops.

If the water level is too low, the

oat switch will automatically

switch off the pump.

Supervise the appliance while it is

in operation in order to be immediately aware if the automatic cut-out

operates or the pump runs dry, to

limit any damage to a minimum.

Automatic mode

In automatic mode, the oat switch ( 6)

automatically switches the pump on or off.

In the case of stationary installation,

check regularly (no less then once

every three months) that the oat

switch (

6) is working.

The submersible water pump acquired by

you is already provided with an grounded

plug. The equipment is designed for con-

nection to an earthed wall socket with a

residual current operated device (RCD

switch) at 230 V ~ 50Hz.

Only start to operate the device

after all the above conditions have

been observed.

10

The On/Off switch point of the oat switch

(

6) is innitely variable:

Loosen the screw in the oat switch

height adjustment (5) and move it

to the desired position.

Check the oat switch ( 6).

- It must be positioned so that it

can lift and lower freely. The

switching point heights “On” and

“Off” must be easy to reach.

Page 11

GB IE

Check this by placing the pump

into a vessel lled with water

and lift the oat switch (

carefully by hand and then lower it again. In this case, you can

see whether the pump switches

on and off.

- Also ensure that the separation

distance between the oat switch

(6) head and the oat switch

height adjustment (5) is not too

small. In the case of a separation distance which is too small,

trouble-free functioning cannot

be guaranteed.

- During the adjustment of the oat

switch (

oat switch does not contact the

oor before the pump switches

off.

The pump run dry if too long a

oat switch cable (

particularly if the oat switch height

adjustment (

(see „Operational start-up“).

6), ensure that the

5) is not installed

6)

3) is chosen,

Manual mode/at suction

In manual mode, the pump does not switch

off automatically, as the oat switch (

is bypassed.

Position the oat switch (6) vertical-

ly upward in the oat switch height

adjustment (5).

6)

Maintenance and

Cleaning

Clean and maintain your equipment regu-

larly. This will guarantee its performance

and long durability.

Ask our service centre to car-

ry out any work that is not

described in these instructions. Use only original parts.

There is a risk of injury!

Pull out the power plug before

every maintenance operation. There

is a risk of electrocution or of injury

from moving parts.

General cleaning instructions

• In case of transport for utilization in

different locations, the pump must be

cleaned with clear water after every

use.

• In case of stationary installation, the

function of the oat switch (

to be checked regularly (at the latest

every three months).

• With a water jet, remove uff and

brous particles which are possibly

present in the pump casing (

• Clean precipitation from the oat

switch (

• Regularly remove sludge from the pit

base (at the latest every 3 months) and

also clean the shaft walls

6) with clear water.

6) is

3).

Monitor the pump constantly when

in manual mode. Switch the pump

off immediately (disconnect from

the mains) if no more water is being pumped. There is a risk of damage if the pump runs dry.

To replace the backow stop

Replace a defective backow stop (see

“Replacement parts/Accessories”).

11

Page 12

GB IE

1. Unscrew the adapter with the

hose connection (10) on the

angle adapter (12) and remove

the backow stop (11a) and seal

(11b).

2. Insert the seal (11b) into the

back ow stop (11a).

3. Set the backow stop (11) be-

tween the angle adapter (12)

and the adapter with the hose

connection (10) in such a manner that the stop is opened in

the owing direction and closed

against the owing direction.

Clean pump pedestal

Always remove the mains plug be-

fore working on the device.

Moving parts create the risk of elec-

trocution or injury.

Dirt on the underside of the pump can be

removed after removing the cover plate

(4b) on the pump pedestal (4):

1. Loosen the 4 screws (4a) on the

underside of the pump pedestal

(4) and remove the cover (4b).

2. Remove the dirt from the underside of the pump with running

water. Do not use your ngers.

3. Screw the cover plate (4b) back

on.

Storage

• Clean the pump before storage.

• Store the appliance in a dry, frost-free

place, and where children cannot gain

access to it.

• When the pump is not to be used for

a longer period, it must be thoroughly

cleaned after its last use, and before it

is next used. Otherwise there may be

problems in starting the pump, caused

by deposits and residues.

Waste Disposal

and Environmental

Protection

Be environmentally friendly. Return the

tool, accessories and packaging to a recy-

cling centre when you have nished with

them.

Electric appliances should not be

disposed of in the domestic garbage.

Hand the tool in at a recycling centre. The

plastics and metal parts can be separated

and recycled. Ask your Service Center

about this. Defective units returned to us

will be disposed of for free.

Any measures above and beyond these, particularly opening the equipment, are to be

carried out by an electrician. In the case of

repairs, always contact our service centre.

12

Page 13

GB IE

Replacement parts/Accessories

Spare parts and accessories can be obtained at

www.grizzly-service.eu

If you do not have internet access, please contact the Service Centre via telephone

(see “Service-Center” page 16). Please have the order number mentioned below ready.

Item Item Description Order

Instruction Exploded number

manual drawing

4a 40 Screw set for pump pedestal 91101225

4b 39 Cover plate, pump pedestal 91101224

10/11 35/41 Adapter with hose connection,

with backow stop 91101246

12 34 Angle adapter 91101245

The backow stop is subject to wear; its replacement is not covered by guarantee.

13

Page 14

GB IE

Faults - Causes - Remedies

Faults Causes Remedies

Pump does not start

Pumps has no discharge

Pump does not switch

off

Flow rate insufcient

- Mains voltage is not applied

- Float switch (

switch

- Pump pedestal (

grating blocked

- Reduces pump performance,

through severely contaminated water and additions in

the water which produce a

grinding effect

- Backow stop (

incorrectly tted or faulty

- Float switch cannot drop - Set up pumps correctly on the

- Pump pedestal (

grating blocked

- Reduces pump performance,

through severely contaminated water and additions in

the water which produce a

grinding effect

- Backow stop (

incorrectly tted or faulty

- Backow stop (

duces pump performance

6) does not

4) inlet

11) is

4) inlet

11) is

11) re-

- Check mains voltage

- Bring oat switch into higher

position

- Use a water jet to clean the

pump pedestal inlet grating

- Clean pump

- Check the backow stop’s

connection. Change it if

necessary (see “Maintenance

and Cleaning”)

pit base

- Use a water jet to clean the

pump pedestal inlet grating

- Clean pump

- Check the backow stop’s

connection. Change it if

necessary (see “Maintenance

and Cleaning”)

- Remove the backow stop

from the angle adapter (

12) (see “Start-up”)

Pump switches off

after a short period

14

- Motor contactor disconnects

the pumps because of water

pollution that is too severe.

- Water temperature too high,

motor contactor breaks

- Pull out power plug and

clean the pump as well as

shaft

- Note maximum water temperature of 35°C!

Page 15

GB IE

Guarantee

Dear Customer,

This equipment is provided with a 3-year

guarantee from the date of purchase.

In case of defects, you have statutory rights

against the seller of the product. These

statutory rights are not restricted by our

guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect occurs

within three years of the date of purchase

of this product, we will repair or replace –

at our choice – the product for you free of

charge. This guarantee requires the defective equipment and proof of purchase to be

presented within the three-year period with

a brief written description of what constitutes

the defect and when it occurred.

If the defect is covered by our guarantee, you

will receive either the repaired product or a

new product. No new guarantee period begins on repair or replacement of the product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced

in accordance with strict quality guidelines

and conscientiously checked prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts that

are subject to normal wear and may therefore be considered as wearing parts (e.g.

backow stop, sealing ring) or to cover

damage to breakable parts (e.g. switches,

batteries, or parts made of glass).

This guarantee shall be invalid if the product has been damaged, used incorrectly or

not maintained. Precise adherence to all of

the instructions specied in the operating

manual is required for proper use of the

product. Intended uses and actions against

which the operating manual advises or

warns must be categorically avoided.

The product is designed only for private

and not commercial use. The guarantee

will be invalidated in case of misuse or

improper handling, use of force, or interventions not undertaken by our authorised

service branch.

In the case of pumping water containing sand or aggressive liquids or other

incorrect, non-design-appropriate use, as

well as in case of non-observance of the

operating manual, application of force in

use or inappropriate or insufcient maintenance, no guarantee claim exists, since

seals, impeller wheel, motor or other parts

are damaged by this. Also, sewage water

pumps are not suitable for the pumping of

abrasive materials (sand, stone).

Note: submersible pumps are drainage

pumps. This kind of pump is constructed

with the purpose of transporting or removing a certain volume of water – depending

on its output category – as quickly as possible. Submersible pumps are not intended

as irrigation (for example, in garden ir-

rigation systems) or as constant water-ow

pumps (such as in articial streams or or-

namental fountains). Inappropriate use will

15

Page 16

GB IE

invalidate the warranty.

Periodically check that the oat switch is

operational. Warranty and liability claims

will be void in case on non-compliance or

if the pump runs dry.

In particular, the guarantee is likewise void

in the case of employment of the sewage

water pumps without base plate or (this

applies for all pumps) in case of damages

which are caused by supporting on or sus-

pending from the mains cable. The pumps

must not be run dry or exposed to frost.

Processing in Case of Guarantee

To ensure quick handling of you issue,

please follow the following directions:

• Please have the receipt and identication number (IAN 109771) ready as

proof of purchase for all enquiries.

• Please nd the item number on the rating plate.

• Should functional errors or other defects occur, please initially contact the

service department specied below by

telephone or by e-mail. You will then

receive further information on the processing of your complaint.

• After consultation with our customer

service, a product recorded as defective can be sent postage paid to the

service address communicated to you,

with the proof of purchase (receipt)

and specication of what constitutes

the defect and when it occurred. In order to avoid acceptance problems and

additional costs, please be sure to use

only the address communicated to you.

Ensure that the consignment is not sent

carriage forward or by bulky goods,

express or other special freight. Please

send the equipment inc. all accessories

supplied at the time of purchase and

ensure adequate, safe transport packaging.

Repair Service

For a charge, repairs not covered by the

guarantee can be carried out by our ser-

vice branch, which will be happy to issue

a cost estimate for you.

We can handle only equipment that has

been sent with adequate packaging and

postage.

Attention: Please send your equipment to

our service branch in clean condition and

with an indication of the defect.

Equipment sent carriage forward or by

bulky goods, express or other special

freight will not be accepted.

We will dispose of your defective devices

free of charge when you send them to us.

Service-Center

Service Great Britain

GB

Tel.: 0871 5000 720

(£ 0.10/Min.)

E-Mail: grizzly@lidl.co.uk

IAN 109771

Service Ireland

IE

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: grizzly@lidl.ie

IAN 109771

Importer

Please note that the following address is

not a service address. Please initially con-

tact the service centre specied above.

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

63762 Großostheim, Germany

www.grizzly-service.eu

16

Page 17

FR BE

Sommaire

Introduction ...............................17

Consignes particulières pour une

utilisation en toute sécurité .........17

Fins d’utilisation ......................... 18

Description générale ..................18

Volume de la livraison ..................... 18

Vue synoptique ............................... 19

Description du fonctionnement .......... 19

Détails techniques ...................... 19

Performances .................................. 20

Instructions de sécurité ............... 20

Symboles utilisés dans le mode

d’emploi ........................................20

Explication des symboles et des avis de

sécurité .......................................... 20

Consignes générales de sécurité ....... 20

Mise en service ..........................22

Instructions de montage ................... 22

Raccordement de la conduite forcée .. 22

Mettre en place/accrocher ............... 23

Contrôls devant la mise en marche .... 23

Service .......................................24

Le raccordement au réseau ............... 24

Mise en marche et arrêt ................... 24

Mode automatique .......................... 24

Mode manuel/Aspiration à plat ........ 25

Entretien et nettoyage ................ 25

Travaux d’entretien et de nettoyage

généraux ....................................... 25

Remplacement du clapet de non-retour ..25

Nettoyage du pied de la pompe ....... 26

Stockage ....................................26

Protection de l’environnement .... 26

Pièces de rechange/Accessoires .. 27

Dépannage ................................ 28

Garantie ....................................29

Service Réparations ...................30

Service-Center ............................ 30

Importeur .................................. 30

Traduction de la déclaration de

conformité CE originale ..............60

Vue éclatée ................................61

Introduction

Toutes nos félicitations pour l’achat de

votre nouvel appareil. Vous avez ainsi

choisi un produit de qualité supérieure.

La qualité de l’appareil a été vériée

pendant la production et il a été soumis

à un contrôle nal. Le fonctionnement de

votre appareil est donc ainsi garanti. Il

n’est pas à exclure que dans certains cas

isolés, il demeure dans l’appareil, ou dans

les tuyauteries exibles, des quantités résiduelles d’eau ou de lubriants industriels.

Ceci n’est pas un défaut ou un vice et on

ne doit pas s’inquiéter à ce sujet.

La notice d’utilisation fait partie de

ce produit. Elle contient des instruc-

tions importantes pour la sécurité,

l’utilisation et l’élimination des

déchets. Avant d’utiliser ce produit,

lisez attentivement les consignes

d’emploi et de sécurité. N’utilisez le

produit que tel que décrit et unique-

ment pour les domaines d’emploi

indiqués.

Conservez cette notice et remet-

tez-la avec tous les documents si

vous cédez le produit à un tiers.

Consignes particulières

pour une utilisation en

toute sécurité

• L’appareil ne doit pas être utili-

sé si des personnes se trouvent

dans l’eau (p. ex. en cas des

travaux de nettoyage ou de

maintenance aux piscines). Il

existe un danger par choc élec

trique.

-

17

Page 18

FR BE

•

Branchez l‘appareil seulement

sur une prise de courant avec

un dispositif de protection de

courant de défaut (commutateur

FI) avec un courant de référence

d‘un maximum de 30 mA ; pro

-

tection au moins 6 ampères.

• Si le câble d’alimentation est

endommagé, il doit être rempla

cé par le fabricant, son service

après vente ou des personnes

de qualication similaire an

d’éviter un danger.

• Cet appareil peut être utilisé par

des enfants à partir de 8ans

et plus et par des personnes

ayant des capacités physiques,

sensorielles ou mentales réduites

ou un manque d’expérience et

de connaissances à condition

qu’elles aient reçu une supervi

sion ou des instructions concernant I’utilisation de I’appareil

en toute sécurité et qu’elles com

prennent les dangers encourus.

Les enfants ne doivent pas jouer

avec l’appareil. Le nettoyage

et I’entretien par I’usager ne

doivent pas être effectués par

des enfants sans surveillance.

• Il convient de surveiller les en-

fants pour s’assurer qu’ils ne

jouent pas avec l’appareil.

• La pollution du liquide peut pro-

venir d’une fuite de lubriants.

• Respectez les autres consignes

abordées dans le chapitre «

Maintenance et nettoyage ».

Fins d’utilisation

La pompe à eau immergée est conçue pour

pomper de l‘eau jusqu‘à une température

maximale de 35°C.

Elle est adaptée, par exemple, pour pomper et transvaser depuis un bassin vers des

conteneurs et de l‘eau d‘une cave inondée.

Cet appareil n’est pas adapté à une utilisa-

-

tion industrielle. Toute utilisation industrielle

met n à la garantie.

L‘opérateur ou l‘utilisateur est responsable

des accidents ou des dégâts sur les per-

sonnes et sur les biens.

Le fabricant n‘est pas responsable des

dégâts qui ont été causés par un usage

contraire aux prescriptions ou par une

utilisation non conforme.

Description générale

Vous trouverez les illustrations

sur la page de rabat avant.

Volume de la livraison

-

Déballez l’appareil et vériez que la livraison est complète. Evacuez le matériel

d’emballage comme il se doit.

- Pompe

- Adaptateur d‘angle et adaptateur avec

raccord de tuyau

- 8 m de câble de nylon

- Mode d’emploi

18

Page 19

FR BE

Vue synoptique

1 Poignée

2 Conduite de réseau

3 Boîtier de la pompe

4 Pied de la pompe

5 Sortie de pompe

6 Interrupteur à otteur complet

7 Réglage en hauteur de l’interrup-

teur à otteur

8 Câble d’interrupteur à otteur

9 Asservissement d’interrupteur à

otteur

10 Adaptateur avec raccord de

tuyau

11 Clapet de non-retour (11a) avec

joint (11b) (non visible)

12 Adaptateur d‘angle

13 8 m de câble de nylon

4a 4 vis, pied de la pompe

4b Plaque de protection, pied de la

pompe

Description du

fonctionnement

La pompe est équipée d’une commande à

otteur qui la met automatiquement en ou

hors circuit, en fonction du niveau d’eau.

En cas de surcharge, la pompe est arrêtée

par le disjoncteur thermique incorporé.

Après refroidissement, le moteur redémarre

tout seul.

La pompe est de plus équipée d’un clapet

anti-retour qui empêche l’eau de reuer,

par exemple lors d’une panne de courant.

Détails techniques

Type ............................ FTP 400 D3

Raccordement au réseau ...230 V~, 50 Hz

Puissance ................................... 400 W

Max. ux de pompage (Qmax) ..10000 l/h

Max. hauteur de pompage (Hmax) .... 7 m

Profondeur d’immersion max. ............ 7 m

Max. température de l’eau (Tmax) ... 35° C

Raccord de tuyau .......... ½“, ¾“, 1“, 1 ½“

(13mm,19mm, 25mm, 38mm)

Raccord de robinet avec

let intérieur ...............G1 ½“ (44,9mm)

Corps étrangers max. ................. Ø 5 mm

Conduite de réseau ........................ 10 m

Poids (y compris accessoires) ... env. 4,0 kg

Classe de protection .............................. I

Mode de protection ..........................IPX8

Des modications techniques et optiques

en vue d’un perfectionnement sont pos-

sibles sans notication préalable. C’est

pourquoi toutes les dimensions, informa-

tions, remarques et déclarations mentionnées dans ce manuel sont sans engagement de notre part. Par conséquent, des

prétentions à des revendications juridiques

qui se basent sur le manuel d’instructions

d’emploi seront sans effet.

19

Page 20

FR BE

m

7 m

Performances

La mesure des données de performance

maximales dans des conditions optimales

se fait comme une sortie directe droite.

L’adaptateur d’angle peut réduire la puissance de l‘appareil.

Instructions de sécurité

Symboles utilisés dans le

mode d’emploi

Symbole de danger et indica-

tions relatives à la prévention

de dommages corporels ou

matériels.

Symbole d’interdiction (l’interdiction

est précisée à la place des guillemets) et indications relatives à la

prévention de dommages.

Symboles de remarque et informa-

tions permettant une meilleure utilisation de l‘appareil.

Explication des symboles et

des avis de sécurité

Attention!

Non approprié pour l’eau très

sableuse !

Lisez et respectez le mode d’emploi

de l’appareil.

Attention! Si le câble de réseau est

détérioré ou coupé, tirez immédiatement la che de la prise de cou-

rant.

Profondeur d’immersion maximale

Les machines n’ont pas leur place

dans les ordures ménagères.

Consignes générales de

sécurité

Cette section traite des principales normes

de sécurité lors de travaux avec l‘appareil.

Travaux avec l‘appareil :

Prudence : vous éviterez ainsi acci-

dents et blessures :

• Les personnes qui ne connaissent pas le

mode d‘emploi ne doivent pas utiliser

l‘appareil. Il se peut que des disposi-

tions locales xent l’âge minimum de

l‘utilisateur.

• Portez des chaussures de sécurité an

d’être isolé des éventuelles décharges

électriques.

• Prenez toutes les mesures appropriées

pour tenir les enfants éloignés de l‘ap-

pareil lorsque celui-ci fonctionne. Vous

risquez de vous blesser.

20

Page 21

FR BE

• N‘utilisez pas l‘appareil à proximité de

liquides inammables ou de gaz. En

cas d‘inobservation de cette consigne, il

y a risque d‘incendie ou d‘explosion.

• L‘utilisation de liquides agressifs, abra-

sifs (ayant un effet déclencheur), décapants, inammables (par exemple des

carburants pour moteur) ou explosifs,

d‘eau salée, de produits de nettoyage

et alimentaires est interdite. La température du liquide pompé ne peut pas

dépasser 35 °C.

• Conservez l‘appareil dans un endroit

sec et hors de portée des enfants.

Prudence! Vous évitez ainsi d‘en-

dommager l‘appareil et les éventuelles conséquences pouvant affec-

ter les personnes :

• Ne travaillez pas avec un appareil

endommagé, incomplet ou sans consentement du fabricant de l‘appareil si

celui-ci a été modié. Avant la mise en

service, faites contrôler par un spécialiste que les mesures de protection électriques exigées sont disponibles.

• Contrôlez l‘appareil pendant son exploitation (notamment dans les locaux d‘habitation) pour détecter à temps la déconnexion automatique ou un fonctionnement à vide de la pompe. Contrôlez

régulièrement le fonctionnement de

l‘interrupteur ottant (cf. chapitre « Mise

en service »). L‘inobservation de cette

consigne met n aux droits de garantie

et à la responsabilité.

• Veuillez ne pas oublier que la pompe

n‘est pas adaptée à une exploitation

en continu (par exemple pour des cours

d‘eau, dans des étangs). Contrôlez

régulièrement le bon fonctionnement de

l‘appareil.

• N‘oubliez pas que l‘appareil utilise

des lubriants, lesquels en cas de fuite,

peuvent s‘écouler et causer des dom-

mages ou des pollutions. Ne placez pas

la pompe dans des étangs contenant

des poissons ou des plantes de valeur.

• Ne portez pas ou ne xez pas l‘appareil par le câble ou le tuyau de refoule-

ment.

• Protégez l‘appareil du gel et du fonctionnement à sec.

• Utilisez seulement des accessoires d‘ori-

gine et ne modiez pas l‘appareil.

• En ce qui concerne le thème « Mainte-

nance et nettoyage », veuillez lire les

instructions du mode d‘emploi. Toutes

les tâches concernant ce sujet, en parti-

culier l‘ouverture de l‘appareil, doivent

être exécutées un électricien de métier.

En cas de réparation, adressez vous

toujours à notre service après-vente.

Sécurité électrique :

Prudence : vous éviterez ainsi les

blessures et les accidents dus au

choc électrique :

• Lorsque l‘appareil fonctionne après

avoir été mis en place, la che de secteur doit être accessible.

• Avant que vous ne mettiez en service

votre nouvelle pompe, faites contrôler

par un professionnel :

- que la mise à la terre, la liaison au

neutre, le circuit de protection de

courant de défaut correspondent

aux normes de sécurité des entreprises d‘approvisionnement en éner-

gie et fonctionnent correctement,

- que les raccordements électriques

sont protégés de l‘humidité.

21

Page 22

FR BE

• En cas de risque d‘inondation les rac-

cordements doivent être situés dans une

zone à l‘abri des inondations. Danger

de décharge électrique.

• Faites attention à ce que la tension de

réseau corresponde aux indications de

la plaque signalétique.

• Avant toute utilisation, contrôlez l‘appa-

reil, le câble et la prise pour détecter

tout dommage. Les câbles défectueux

ne peuvent pas être réparés mais

doivent être échangés contre de nouveaux. Faites réparer les dommages

survenus à votre appareil par un spécialiste autorisé.

• N‘utilisez pas le câble pour tirer sur la

prise de courant. Protégez le câble de

la chaleur, de l‘huile et des bords coupants.

• Ne portez pas ou ne xez pas l‘appareil par le câble.

• Utilisez seulement des câbles de prolongation qui sont étanches aux jets d‘eau

et prévus pour être utilisés en plein air.

Avant utilisation, déroulez toujours la

totalité du câble. Contrôlez le câble an

de détecter tout dommage.

• Avant tout travail sur l’appareil, en

cas de non-étanchéité dans le système

d’eau, pendant les pauses et en cas de

non utilisation, retirez la che secteur

de la prise de courant.

• Les conduites d‘alimentation ne doivent

pas avoir de plus petite coupe transver-

sale que des câbles sous caoutchouc

avec la marque H05RN8-F. La longueur

de ligne doit être de 10 m. La section

du toron de la rallonge doit être égale

ou supérieure à 2,5 mm

2

.

Mise en service

Instructions de montage

Visser l’adaptateur

1. Vissez l‘adaptateur d‘angle (12)

et l‘adaptateur avec raccord de

tuyau (10) sur la sortie de pompe

(5).

Monter le réglage en hau-

teur pour l’interrupteur à

otteur

2. Desserrez la vis de réglage en

hauteur de l’interrupteur à otteur

(7) et poussez celui-ci dans la di-

rection de l’interrupteur à otteur

(9). De plus, le câble d’interrupteur à otteur (8) doit être dirigé

vers le haut (la èche

orientée vers le haut) (voir «Ser-

vice»).

Raccordement de la conduite

forcée

L’installation de la pompe à eau immergée

est effectuée:

- soit sur une tuyauterie xe

- soit sur des tuyaux exibles

• Si vous utilisez un tuyau en ½“,

emboîtez-le sur l’adaptateur

avec raccord de tuyau (10) de

la pompe et xez-le à l’aide d’un

collier de serrage.

• Si vous utilisez un tuyau en ¾“,

1“ ou 1½“, coupez l’embout pla-

cé au-dessus et emboîtez ensuite

le tuyau sur l’embout correspondant (xation avec collier de ser-

rage).

doit être

22

Page 23

FR BE

• Si vous utilisez une pièce de

robinet (IG1½“) pour le raccordement de systèmes d’embouts de

tuyaux externes, coupez les trois

embouts supérieurs juste au-dessus du letage du tube G1½ “.

La mesure des données de perfor-

mance maximales dans des conditions optimales se fait comme une

sortie directe droite. L’adaptateur

d’angle (

tour (

puissance.

Il est possible de retirer le clapet de non-retour (11) de l’adaptateur (12) pour augmenter la puissance de la pompe (voir

«remplacement du clapet de non-retour»).

Ceci est notamment recommandé pour les

embouts de tuyaux inférieurs à 1“. Tenez

compte du fait que le reux de l’eau peut

toutefois éventuellement survenir en cas

de coupure de courant ou de panne des

pompes.

12) et clapet de non-re-

11) peuvent réduire la

Mettre en place/accrocher

La pompe peut être placée ou ac-

crochée dans l’eau. Pour accrocher

et / ou tirer la pompe, vous pouvez

utiliser le câble (

dans le volume de la livraison.

Il serait préférable que la fosse de la

pompe ait les dimensions suivantes:

40 x 40 x 50 cm an que l’interrupteur à

otteur puisse se déplacer librement.

13) contenu

Faites attention à ce qu‘en

aucun cas l‘appareil ne soit

xéoususpenduparlecâble

d‘alimentation secteur. Il y a

alors danger d‘une décharge

électriqueparlescâbles

d‘alimentation secteur endommagés.

Faites attention qu‘avec le temps,

il n‘y ait pas de saleté ou de sable

qui s‘accumule dans le puits, ce qui

pourrait endommager la pompe.

Nous recommandons de placer la

pompe sur une brique ou sur une

grille.

Si la surface du plan d‘eau est trop

petite, la vase présente dans le

puits peut se dessécher rapidement

et empêcher la pompe de fonctionner.

Contrôls devant la mise en

marche

• Contrôlez le fonctionnement de

l’interrupteur à otteur (voir «Service»).

• Vériez que la pompe est bien

posée sur le sol de la fosse.

• Vériez que la conduite forcée est

montée correctement.

• Vériez que la prise électrique est

en bon état (au moins de 6A).

• Evitez que la pompe fonctionne à

sec. Il y a le risque d’une électrocution.

Fixez le câble de nylon (13) à la

poignée de transport (1).

23

Page 24

FR BE

Service

Le raccordement au réseau

La pompe que vous avez acquise est déjà

munie d’un interrupteur de sécurité. L’appa-

reil a été conçu pour un raccordement à un

socle de prise de courant de sécurité avec

un dispositif de protection par courant

de défaut (commutateur FI) avec 230 V ~

50Hz.

Ne mettez l’appareil en marche

que sous respect de tous les points

précités.

Mise en marche et arrêt

1. Branchez le câble d’alimentation dans

la prise de courant. La pompe démarre

immédiatement.

La pompe démarre immédiatement

lorsque l‘interrupteur ottant se trouve

dans la position correcte (voir « Mode

automatique » et « Mode manuel »).

2. Pour débrancher, retirer le connecteur

de la prise de courant. La pompe s’arrête.

Si le niveau de l‘eau est trop faible,

le commutateur ottant arrête automatiquement la pompe.

Surveillez l’appareil pendant son

fonctionnement an de constater,

en temps utile, une marche à sec de

la pompe et éviter ainsi des dommages.

Mode automatique

En mode automatique, l’interrupteur à

otteur (

s’arrête automatiquement.

6) de la pompe s’enclenche et

En cas d’installation stationnaire,

l’interrupteur à otteur (

être contrôlé régulièrement (au plus

tard tous les trois mois).

Le point de commutation Marche/Arrêt

de l‘interrupteur à otteur (

réglé de manière continue :

Desserrez la vis de réglage en hau-

teur de l‘interrupteur à otteur (7) et

positionnez celui-ci dans la position

souhaitée.

Contrôlez l’interrupteur à otteur

(

6).

- Il doit être positionné de telle

sorte qu’il puisse se lever et

s’abaisser librement. La hauteur du point de commutation

«Marche» et la hauteur du point

de commutation «Arrêt» doivent

pouvoir être atteints facilement.

Vériez en plaçant la pompe

dans un récipient rempli d’eau

et soulever avec précaution l’interrupteur à otteur à la main et

ensuite le laisser retomber. Ce

faisant, vous pouvez remarquer

si la pompe se met en marche ou

s’arrête.

- Veillez à ce que l’espace entre

l’interrupteur à otteur (6) et le

réglage en hauteur de l’interrupteur à otteur (7) ne soit pas trop

réduit. Si l’espace est trop réduit, le

fonctionnement sans faille n’est pas

garanti.

- Lors du réglage de l’interrupteur

à otteur (6), veillez à ce que

celui-ci ne touche pas le sol avant

l’arrêt de la pompe.

6) doit

6) peut être

24

Page 25

FR BE

Il existe un danger de fonctionne-

ment à sec, si le câble d’interrupteur à otteur (

en particulier si le réglage en hauteur de l’interrupteur à otteur (

7) n’est pas monté (voir la « mise

en service »).

8) est trop long,

Mode manuel/Aspiration à

plat

En mode manuel, la pompe ne s’arrête pas

automatiquement car l’interrupteur à otteur (

6) est dérivé.

Positionnez l’interrupteur à otteur

(6) verticalement vers le haut dans

le réglage en hauteur de l’interrupteur à otteur (7).

En mode manuel, observez la

pompe en permanence. Arrêtez

immédiatement la pompe (retirer la

che de secteur) si aucune eau n’est

plus pompée. Si la pompe travaille

à sec, vous risquez de l’endommager.

Entretien et nettoyage

La pompe est un produit de qualité ayant

fait ses preuves et qui a été soumis a un

contrôle nal sévère. Toutefois, pour augmenter la longévité, nous recommandons

un contrôle et un entretien réguliers.

Si vous faites exécuter des

travaux qui ne sont pas

décrits dans cette directive,

adressez vous à notre service

après-vente. Utilisez seulement des pièces d‘origine.

Vous risquez de vous blesser.

Débrancher la pompe avant

chaque travail d’entretien. Il y danger d’un choc électrique ou le danger de se blesser par des pièces en

mouvement.

Travaux d’entretien et de

nettoyage généraux

• En cas d’utilisation mobile, la pompe

doit être nettoyée à l’eau claire après

chaque utilisation.

• En cas d’utilisation xe, il faut vérier la

fonction de l’interrupteur à otteur (

6) régulièrement (au plus tard tous les

trois mois).

• Enlever les bres et peluches se trouvant

éventuellement dans le boîtier de la

pompe (

• Eliminer les dépôts sur l’interrupteur à

otteur (

• Nettoyer régulièrement (au plus tard

tous les trois mois) la boue se trouvant

sur le sol de la fosse et sur les parois de

la fosse.

3) avec un jet d’eau.

6) à l’eau claire.

Remplacement du clapet de

non-retour

Échangez un clapet de anti-retour défectueux (voir «Pièces de rechange/Acces-

soires»).

1. Dévissez l’adaptateur raccordé à

la tuyauterie (10) sur l’adaptateur

coudé (12) et retirez le clapet de

anti-retour (11a) ainsi que le joint

(11b).

2. Insérez le joint (11b) dans le cla-

pet de non-retour (11a).

3. Placez le clapet de non-retour

(11) avec le raccordement de

tuyau (10) entre l’adaptateur

25

Page 26

FR BE

angulaire (12) et l’adaptateur de

telle sorte que la soupape s’ouvre

dans la direction du ux et se

ferme dans la direction opposée

au ux.

Nettoyage du pied de la

pompe

Avant d’effectuer un travail sur l’ap-

pareil, débranchez-le de la che de

contact.

Il existe un risque d’électrocution

ou un risque de blessures par les

pièces amovibles.

Les saletés se trouvant en dessous de la

pompe peuvent être éliminées après enlè-

vement de la plaque de protection (4b) du

pied de la pompe (4) :

1. Dévissez les 4 vis (4a) sur le des-

sous du pied de la pompe (4) et

enlevez la plaque de protection

(4b).

2. Éliminez les saletés en dessous de

la pompe à l’aide d’un jet d’eau.

N’utilisez pas vos doigts pour

cela.

3. Revissez la plaque de protection

(4b).

Tous les travaux qui ne sont pas décrits

ici, en particulier l‘ouverture de la pompe

doivent être exécutés par un électricien

professionnel. Pour toute réparation, adres-

sez-vous toujours à notre service aprèsvente

Stockage

• Nettoyez la pompe avant de la stocker.

• Conservez la pompe au sec, à l’abri du

gel et hors de portée des enfants.

• Si vous n’avez pas utilisé la pompe

pendant une longue période, il faut la

nettoyer à fond après la dernière utilisation et avant toute nouvelle utilisation,

sinon les dépôts et les résidus peuvent

entraîner des problèmes de démarrage.

Protection de l’environnement

Respectez la réglementation relative à la

protection de l’environnement (recyclage)

pour l’élimination de l’appareil, des accessoires et de l’emballage.

Les appareils ne font pas partie des

ordures ménagères.

Déposez l’appareil à un point de recyclage. Les pièces de plastique et de métal

utilisées peuvent être triées selon leur

nature et être ainsi recyclées. Demandez

conseil sur ce point à notre centre de services.

Nous exécutons gratuitement l’élimination

des déchets de vos appareils renvoyés

défectueux.

26

Page 27

FR BE

Pièces de rechange/Accessoires

Vous obtiendrez des pièces de rechange

et des accessoires à l’adresse www.grizzly-service.eu.

Si vous ne disposez d’aucun accès Internet, veuillez téléphoner au centre de SAV

(voir «Service-Center» page 30). Veuillez tenir prêts les numéros de commande indiqués

ci-dessous.

Position Position Désignation n° de

Notice Vue commande

d‘utilisation éclatée

4a 40 Kit de vis pour le pied de la pompe 91101225

4b 39 Plaque de protection, pied de la pompe 91101224

10/11 35/41 Adaptateur avec raccord de tuyau,

avec clapet de non-retour 91101246

12 34 Adaptateur d‘angle 91101245

Etant une pièce d’usure, le clapet de non-retour n’est pas remplacé sous garantie.

27

Page 28

FR BE

Dépannage

Pannes Causes Aide

La pompe ne

démarre pas

La pompe ne

pompe pas

La pompe ne

s’arrête pas

Flux insufsant

- pas de tension de réseau

- l’interrupteur à otteur (

ne se met pas en marche

- grille d‘entrée du pied (

bouchée

- performance de la pompe

réduite à cause de quantités

d‘eau souillées et émerisées

- clapet de non-retour (

mal monté ou défectueux

- l‘interrupteur à otteur ne

peut pas descendre

- grille d‘entrée du pied (

bouchée

- performance de la pompe

réduite à cause de quantités

d‘eau souillées et émerisées

- clapet de non-retour (

mal monté ou défectueux

- clapet de non-retour (

réduit la puissance de pompage

11)

11)

11)

- vérier la tension du réseau

6)

- placer l‘interrupteur à otteur à

une hauteur plus élevée

4)

- nettoyer au jet d‘eau la grille

d‘entrée du pied

- nettoyer la pompe

- Contrôler la position du clapet

de non-retour et éventuellement

le remplacer

(voir «Entretien et nettoyage»)

- placer la pompe correctement

sur le sol de la fosse

4)

- nettoyer au jet d‘eau la grille

d‘entrée du pied

- nettoyer la pompe

- contrôler la position du clapet de

non-retour et éventuellement le

remplacer

(voir «Entretien et nettoyage»)

- Retirer le clapet de non-retour de

l’adaptateur (

(voir «Mise en service»)

12)

La pompe s’arrête

après un bref

temps de marche

28

- la protection du moteur

stoppe la pompe à cause de

salissures trop importantes

- température de l‘eau trop élevée, la protection du moteur

stoppe

- débrancher et nettoyer la

pompe et la fosse

- respecter la température maximale de 35° C!

Page 29

FR BE

Garantie

Chère cliente, cher client, ce produit bénécie d’une garantie de 3ans, valable à comp-

ter de la date d’achat. En cas de manques

constatés sur ce produit, vous disposez des

droits légaux contre le vendeur du produit.

Ces droits légaux ne sont pas limités par

notre garantie présentée par la suite.

Conditions de garantie

Le délai de garantie débute avec la date

d’achat. Veuillez conserver soigneusement

le ticket de caisse original. En effet, ce do-

cument vous sera réclamé comme preuve

d’achat.

Si un défaut de matériel ou un défaut de

fabrication se présente au cours des trois

ans suivant la date d’achat de ce produit,

nous réparons gratuitement ou remplaçons

ce produit - selon notre choix. Cette garantie

suppose que l’appareil défectueux et le justicatif d’achat (ticket de caisse) nous soient

présentés durant cette période de trois ans et

que la nature du manque et la manière dont

celui-ci est apparu soient explicités par écrit

dans un bref courrier.

Si le défaut est couvert par notre garantie, le

produit vous sera retourné, réparé ou remplacé par un neuf. Aucune nouvelle période de

garantie ne débute à la date de la réparation ou de l’échange du produit.

Indépendamment de la garantie commer-

ciale souscrite, le vendeur reste tenu des

défauts de conformité du bien et des vices

rédhibitoires dans les conditions prévues aux

articles L211-4 et suivants du Code de la

consommation et aux articles 1641 et suivants du Code Civil.

Durée de garantie et demande légale en dommages-intérêts

La durée de garantie n’est pas prolongée

par la garantie. Ce point s’applique aussi

aux pièces remplacées et réparées. Les dom-

mages et les manques éventuellement constatés dès l’achat doivent immédiatement être

signalés après le déballage. A l’expiration du

délai de garantie les réparations occasion-

nelles sont à la charge de l’acheteur.

Volume de la garantie

L’appareil a été fabriqué avec soin, selon de

sévères directives de qualité et il a été entièrement contrôlé avant la livraison.

La garantie s’applique aux défauts de matériel

ou aux défauts de fabrication. Cette garantie

ne s’étend pas aux parties du produit qui sont

exposées à une usure normale et peuvent être

donc considérées comme des pièces d’usure

(par exemple le clapet de non-retour, le bague

d’étanchéité) ou pour des dommages affectant

les parties fragiles (par exemple les commutateurs, l’accumulateur).

Cette garantie prend n si le produit endommagé n’a pas été utilisé ou entretenu d’une façon conforme. Pour une utilisation appropriée

du produit, il faut impérativement respecter

toutes les instructions citées dans le manuel de

l’opérateur. Les actions et les domaines d’utilisation déconseillés dans la notice d’utilisation

ou vis-à-vis desquels une mise en garde est

émise, doivent absolument être évités.

En cas de pompage d’eau sableuse ou de

liquides corrosifs ou d’autres utilisations incorrectes, les droits de garantie ne sont pas

valables car les joints, la roue de roulement, le

moteur ou d’autres pièces peuvent être endom-

magés. Les pompes également ne sont pas

destinées au pompage de matériaux abrasifs

(sable, cailloux).

Attention : Les pompes sont des pompes

de drainage. L’installation d’une pompe à

immersion a pour but d’extraire, voire de

pomper le plus rapidement possible un certain

volume d’eau dans le cadre de sa catégorie.

Les pompes à immersion ne conviennent pas

comme pompes d’irrigation (par ex. pour l’ir-

29

Page 30

FR BE

rigation du jardin) ou comme pompes à fonctionnement constant (par ex. pour les cours de

ruisseaux ou les fontaines d’étangs). Le droit

de garantie prend n en cas d’une utilisation

non conforme à la destination.

Contrôlez régulièrement le fonctionnement de

l’interrupteur à otteur. En cas d’emploi non

conforme ou de fonctionnement à sec de la

pompe, vous perdez les droits de la garantie.

Marche à suivre dans le cas de

garantie

Pour garantir un traitement rapide de votre

demande, veuillez suivre les instructions suivantes :

• Tenez vous prêt à présenter, sur demande,

le ticket de caisse et le numéro d’identication (IAN109771) comme preuve d’achat.

• Vous trouverez le numéro d’article sur la

plaque signalétique.

• Si des pannes de fonctionnement ou

d’autres manques apparaissent, prenez

d’abord contact, par téléphone ou par

e-Mail, avec le service après-vente dont

les coordonnées sont indiquées ci-dessous.

Vous recevrez alors des renseignements

supplémentaires sur le déroulement de

votre réclamation.

• En cas de produit défectueux vous pouvez,

après contact avec notre service clients,

envoyer le produit, franco de port à

l’adresse de service après-vente indiquée,

accompagné du justicatif d’achat (ticket de

caisse) et en indiquant quelle est la nature

du défaut et quand celui-ci s’est produit.

Pour éviter des problèmes d’acceptation

et des frais supplémentaires, utilisez ab-

solument seulement l’adresse qui vous est

donnée. Assurez-vous que l’expédition ne

se fait pas en port dû, comme marchandises encombrantes, envoi express ou autre

taxe spéciale. Veuillez renvoyer l’appareil,

y compris tous les accessoires livrés lors de

l’achat et prenez toute mesure pour avoir

un emballage de transport sufsamment sûr.

Service Réparations

Vous pouvez, contre paiement, faire exécuter par notre service, des réparations qui ne

font pas partie de la garantie. Nous vous

enverrons volontiers un devis estimatif.

Nous ne pouvons traiter que des appareils

qui ont été correctement emballés et qui ont

envoyés sufsamment affranchis.

Attention: veuillez renvoyer à notre agence

de service votre appareil nettoyé et avec

une note indiquant le défaut constaté.

Les appareils envoyés en port dû - comme

marchandises encombrantes, en envoi ex-

press ou avec toute autre taxe spéciale ne

seront pas acceptés.

Nous exécutons gratuitement la mise aux déchets de vos appareils défectueux renvoyés.

Service-Center

Service France

FR

Tel.: 0800 919270

E-Mail: grizzly@lidl.fr

IAN 109771

Service Belgique/

BE

Service België

Tel.: 070 270 171

(0,15 EUR/Min.)

E-Mail: grizzly@lidl.be

IAN 109771

Importeur

Veuillez noter que l’adresse suivante n’est

pas une adresse de service après-vente.

Contactez d’abord le service après-vente

cité plus haut.

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

63762 Großostheim, Allemagne

www.grizzly-service.eu

30

Page 31

NL BE

Inhoud

Inleiding ....................................31

Bzondereaanwzingenvooreen

veiligbedrf ..............................32

Gebruiksdoel ............................. 32

Algemenebeschrving ............... 32

Omvang van de levering ................ 32

Overzicht ..................................... 33

Toepassingsgebieden ..................... 33

Technische gegevens ..................33

Prestatievermogen .........................33

Veiligheidsvoorschriften ............. 34

Symbolen in de gebruiksaanwzing .. 34

Verklaring van symbolen ................ 34

Algemene veiligheidsvoorschriften ... 34

Ingebruikname ..........................36

Montagehandleiding ..................... 36

Aansluiting van de persleiding ........ 36

Installatie/ophangen ...................... 36

Kontroles voor ingebruikname ......... 37

Bediening ..................................37

Netaansluiting............................... 37

In- en uitschakelen ......................... 37

Automatische werking .................... 37

Handmatige werking/

vlakke afzuiging ............................ 38

Onderhoud en Reiniging ............38

Algemene reinigings- en onderhouds-

werkzaamheden ............................ 39

Terugstroomklep vervangen ............ 39

Voetdeel reinigen .......................... 39

Opslag .......................................39

Afvalverwerking/

milieubescherming ..................... 40

Reserveonderdelen/accessoires .. 40

Foutopsporing ............................41

Garantie ....................................42

Reparatieservice ........................43

Service-Center ............................ 44

Importeur .................................. 44

Vertaling van de originele

CE-conformiteitsverklaring .........60

Explosietekening ........................61

Inleiding

Hartelk gefeliciteerd met de aankoop van

uw nieuw apparaat. Daarmee hebt u voor

een hoogwaardig product gekozen.

Dit apparaat werd tdens de productie op

kwaliteit gecontroleerd en aan een eindcontrole onderworpen. De functionaliteit

van uw apparaat is bgevolg verzekerd. Er

kan niet uitgesloten worden dat er zich in

specieke gevallen aan of in het apparaat

resp. in slangleidingen resthoeveelheden

water of smeerstoffen bevinden. Dit duidt

niet op een gebrek of defect en is geen

reden tot bezorgdheid.

De gebruiksaanwzing vormt een

bestanddeel van dit product. Ze

omvat belangrke aanwzingen

voor veiligheid, gebruik en afval-

verwdering. Maak u vóór het

gebruik van het product met alle

bedienings- en veiligheidsinstructies

vertrouwd. Gebruik het product uitsluitend zoals beschreven en voor

de aangegeven toepassingsgebieden. Bewaar de handleiding goed

en overhandig alle documenten b

het doorgeven van het product mee

aan derden.

31

Page 32

NL BE

Bzondere aanwzingen

voor een veilig bedrf

• Indien er zich personen in het

water bevinden, mag het ap

paraat niet bediend worden. Er

bestaat gevaar door een elektri

sche schok.

• Sluit het apparaat uitsluitend op

een contactdoos met lekstroom

beschermingsinrichting (differentieelschakelaar) met een toegekende stroom van maximaal

30 mA aan; zekering minstens

6ampère.

• Als het netsnoer van dit appa

raat beschadigd wordt, moet het

door de fabrikant of door zn

klantenserviceafdeling of door

een gelkwaardig gekwaliceer

de persoon vervangen worden

om gevaren te vermden.

•

Dit apparaat kan door kinderen

vanaf 8 jaar en ouder en tevens

door personen met verminderde

fysieke, zintuiglke of mentale

capaciteiten of met een gebrek

aan ervaring en kennis gebruikt

worden wanneer ze onder toezicht staan of met het oog op

het gebruik van het apparaat

geïnstrueerd werden en zich van

de daaruit resulterende gevaren

bewust zn. Kinderen mogen niet

met het apparaat spelen. Reiniging en gebruikersonderhoud

mogen niet door kinderen zonder

toezicht doorgevoerd worden.

-

-

-

• Kinderen dienen onder toezicht

te staan om te vrwaren dat ze

niet met het apparaat spelen.

• Vervuiling van de vloeistof

kan optreden door uittredende

smeermiddelen.

• Neem ook de aanwzingen in

het hoofdstuk “Onderhoud en

reiniging” in acht.

Gebruiksdoel

De zuiver water-dompelpomp is een afvoerpomp en voor het transport van water

tot een temperatuur van max. 35°C bestemd.

Ze is bvoorbeeld geschikt voor het over-

en wegpompen van bekkens en reservoirs.

Dit apparaat is niet geschikt voor com-

mercieel gebruik. B commercieel gebruik

-

vervalt de garantie.

De operator of gebruiker is voor schade

aan andere mensen of aan hun eigen-

dom verantwoordelk. De fabrikant is niet

aansprakelk voor beschadigingen, die

door een niet-reglementair voorgeschreven

gebruik of door een foutieve bediening

veroorzaakt werden.

Algemene beschrving

De afbeeldingen kunt u vinden

op de voorste uitklappagina.

Omvang van de levering

Pak het apparaat uit en controleer, of de

inhoud volledig is. Zorg voor een regle-

mentair voorgeschreven afvalverwdering

van het verpakkingsmateriaal.

32

Page 33

NL BE

m

- Zuiver water-dompelpomp (pomp)

- Hoekadapter + adapter met slangaansluiting

- 8 m touw

- Gebruiksaanwzing

Overzicht

1 Transporthandvat

2 Netspanning

3 Pompbehuizing

4 Voetdeel

5 Pompuitgang

6 Drfschakelaar

7 Hoogteverstelling drfschakelaar

8 Kabel voor de drfschakelaar

9 Drfschakelaar-geleiding

10 Adapter met slangaansluiting

11 Terugstroomklep met afdichting

(niet zichtbaar)

12 Hoekadapter

13 8 m nylonkabel

4a 4 shroeven, voetdeel

4b Afdekplaat, voetdeel

Toepassingsgebieden

De pomp is uitgerust met een drfschakeling, die het apparaat afhankelk van het

waterpeil automatisch in- of uitschakelt.

B overbelasting word de pomp door de

ingebouwde thermische veiligheidsschakelaar uitgeschakeld. Na afkoeling start de

motor weer automatisch.

Daarenboven heeft de pomp een terugstroomklep, die het terugstromen van het

water bv. b een stroomuitval verhindert.

Technische gegevens

Zuiver water-dompelpomp ....... FTP 400 D3

Netspanning ................... 230 V~, 50 Hz

Prestatievermogen ........................400 W

Hoeveelheid water max.

(Qmax) .................................. 10000 l/h

Bereikbare hoogte max. (Hmax) ..........7 m

Zo diep mogelke ligging ..................7 m

Watertemperatuur max. (Tmax) ........35° C

Aansluiting slang ........... ½“, ¾“, 1“, 1 ½“

(13mm,19mm, 25mm, 38mm)

Aansluiting kraanstuk

met binnendraad ...........G1 ½“ (44,9mm)

Vreemde voorwerpen max. ......... Ø 5 mm

Netspanning ..................................10 m

Gewicht (incl. alle onderdelen) ... ca. 4,0 kg

Beschermingsniveau .............................. I