Flintec LDU 68.2 User Manual

m

b

Y

e

T

e

m

e

C

U

N

s

6

n

t

8

M

8

1

n

&

A

A

G

8

.

Load

ell Digi

izing U

it

yp

LD

TECH

U 6

ICAL

.1

NU

6

L

.2

Fir

ware Ver

Hardwar

Flintec G

Bemanns

74909 Me

GERMAN

www.flint

bH

ruch 9

ckesheim

c.com

Version

Docume

ion 68.1

8.101.5.v

t No. G1

1.v.4.00 o

.3.00 & 68

9 Rev12

higher

.201.5 v.3

B

.00

Table of Contents:

1. Safety Instructions .................................................................................................................................... 4

2. Declaration of Conformity ........................................................................................................................ 5

3. Introduction and Specifications ............................................................................................................... 6

4. Communications and Getting started ..................................................................................................... 7

4.1. Serial Interface ......................................................................................................................................... 7

4.2. Command Language ................................................................................................................................ 7

4.3. Baud Rate / Device Address .................................................................................................................... 8

4.4. Getting Started ......................................................................................................................................... 8

5. Hardware and Wiring ................................................................................................................................. 9

5.1. Wiring ....................................................................................................................................................... 9

5.2. With Unit Adapter UA 77.1 (RS232) ........................................................................................................ 9

5.3. With Unit Adapter UA 73.2 (RS422 / RS485 Full-/Half-Duplex) .............................................................. 9

5.4. Terminal Configuration ........................................................................................................................... 10

5.5. Load Cell Connection ............................................................................................................................. 10

6. Calibration and Calibration Sequence ................................................................................................... 11

7. Commands – Overview ........................................................................................................................... 12

8. Commands Description .......................................................................................................................... 13

8.1. System Diagnosis Commands – ID, IV, IS, SR, RS .............................................................................. 13

8.1.1. ID Get Device Identity ................................................................................................................................... 13

8.1.2. IV Get Firmware Version ............................................................................................................................... 13

8.1.3. IS Get Device Status ..................................................................................................................................... 13

8.1.4. SR Reset LDU XX.X Firmware ...................................................................................................................... 13

8.1.5. RS Read Serial Number ................................................................................................................................ 13

8.2. Calibration Commands – CE, CM, DS, DP, CZ, CG, ZT, ZI, FD, CS .................................................... 14

8.2.1. CE Read TAC* Counter / Open Calibration Sequence ................................................................................. 14

8.2.2. CM Set Maximum Output Value ..................................................................................................................... 14

8.2.3. DS Set Display Step Size .............................................................................................................................. 14

8.2.4. DP Set Decimal Point Position ...................................................................................................................... 14

8.2.5. CZ Set Calibration Zero Point ....................................................................................................................... 14

8.2.6. CG Set Calibration Gain (Span) ..................................................................................................................... 15

8.2.7. ZT Enable / Disable Zero Tracking ................................................................................................................ 15

8.2.8. ZI Initial Zero Range ...................................................................................................................................... 15

8.2.9. FD Reset to Factory Default Settings ............................................................................................................ 15

8.2.10. CS Save the Calibration Data ....................................................................................................................... 15

8.3. Motion Detection Commands – NR, NT ................................................................................................. 16

8.3.1. NR Set No-motion Range ............................................................................................................................... 16

8.3.2. NT Set No-motion Time Period ..................................................................................................................... 16

8.4. Filter Setting Commands – FL, FF, UR .................................................................................................. 17

8.4.1. FL Filter Settings ........................................................................................................................................... 17

8.4.2. FF Moving Average ....................................................................................................................................... 17

8.4.3. UR Update Rate ............................................................................................................................................. 17

8.5. Taring and Zeroing Commands – SZ, RZ, ST, RT ................................................................................ 18

8.5.1. SZ Set Zero ................................................................................................................................................... 18

8.5.2. RZ Reset Zero Point...................................................................................................................................... 18

8.5.3. ST Set Tare ................................................................................................................................................... 18

8.5.4. RT Reset Tare ............................................................................................................................................... 18

8.6. Output Commands – GG, GN, GT, GS, GF, GW, GA ........................................................................... 19

8.6.1. GG Get Gross Value ...................................................................................................................................... 19

8.6.2. GN Get Net Value .......................................................................................................................................... 19

8.6.3. GT Get Tare Value ........................................................................................................................................ 19

8.6.4. GS Get ADC Sample Value ........................................................................................................................... 19

8.6.5. GF Get Filtered Value ................................................................................................................................... 19

8.6.6. GW Get Data String “Net, Gross and Status“ ................................................................................................. 19

8.6.7. GA Get Triggered Average Value .................................................................................................................. 19

LDU 68.1 & 68.2 Technical Manual, Rev. 12 January 2010

Page 2 of 28

8.7.

Auto–transmit Commands – SG, SN, SF, SW, SA ................................................................................ 20

8.7.1. SG Send Gross Value continuously ............................................................................................................... 20

8.7.2. SN Send Net Value continuously .................................................................................................................. 20

8.7.3. SF Send Filtered Value continuously (Display Mode only) ............................................................................ 20

8.7.4. SW Send Data String “Net, Gross and Status“ continuously .......................................................................... 20

8.7.5. SA Send Triggered Average Value automatically ......................................................................................... 20

8.8. Commands for External I/O Control – IN, IO, IM ................................................................................... 21

8.8.1. IN Read the Status of the Input Channels ..................................................................................................... 21

8.8.2. IO Read / Set the Status of the Output Channels .......................................................................................... 21

8.8.3. IM Control of the logic outputs by the host application .................................................................................. 21

8.9. Setpoint Output Commands – Sn, Hn, An ............................................................................................. 22

8.9.1. S0 / S1 Setpoint Value ................................................................................................................................... 22

8.9.2. H0 / H1 Setpoint Hysteresis and Switching Action ......................................................................................... 22

8.9.3. A0 / A1 Allocation of Gros or Net Value ......................................................................................................... 22

8.10. Communication Setup Commands – AD, BR, CL, DX, TD, OP ......................................................... 23

8.10.1. AD Device Address ........................................................................................................................................ 23

8.10.2. BR Baud Rate ................................................................................................................................................ 23

8.10.3. CL Close Device Address n .......................................................................................................................... 23

8.10.4. DX Half-duplex or Full-duplex ....................................................................................................................... 23

8.10.5. TD Transmission Delay ................................................................................................................................. 23

8.10.6. OP Open Device ............................................................................................................................................ 23

8.11. Save Calibration and Setup Data Commands – CS, WP, SS, GI, PI ................................................ 24

8.11.1. WP Save the Setup Parameters .................................................................................................................... 24

8.11.2. SS Schaltpunkt-Parameter sichern ............................................................................................................... 24

8.11.3. GI Save an Image File from the EEPROM .................................................................................................... 24

8.11.4. PI Download an Image File to the EEPROM ................................................................................................. 24

8.12. Trigger Commands – SD, MT, GA, TE, TR, TL, SA ........................................................................... 25

8.12.1. SD Start Delay Time...................................................................................................................................... 25

8.12.2. MT Measuring Time ....................................................................................................................................... 25

8.12.3. GA Get Triggered Average Value .................................................................................................................. 25

8.12.4. TE Trigger Edge ............................................................................................................................................ 25

8.12.5. TR Software Trigger ...................................................................................................................................... 25

8.12.6. TL Trigger Level ............................................................................................................................................ 26

8.12.7. SA Send Triggered Average Value automatically ......................................................................................... 26

9. Use in “Approved” Applications (LDU 68.1 only) ................................................................................ 27

10. Updates – Firmware Download .............................................................................................................. 28

LDU 68.1 & 68.2 Technical Manual, Rev. 12 January 2010

Page 3 of 28

.

RIGHTS

A

e

t

e

t

I

s

c

o

s

T

©

S

h

L

h

s

n

o

t

o

d

i

o

1

n

a

e

H

A

Y

G

N

A

E

O

O

A

e

r

r

s

t

s

h

d

c

t

o

u

G

h

A

m

s

P

O

O

E

N

E

T

W

S

D

V

n

s

e

f

c

a

a

e

a

n

e

t

e

9

B

n

r

c

n

A

C

P

T

C

W

N

U

e

F

r

a

h

a

a

m

n

e

e

m

c

R

E

R

O

N

O

O

A

M

T

R

e

p

c

s

h

N

e

o

i

s

r

s

f

A

P

T

V

G

Y

U

S

G

m

p

e

s

e

v

c

a

h

d

a

o

e

q

o

n

N

O

A

O

E

R

R

N

S

o

e

o

n

r

o

c

n

O

d

A

M

E

N

N

T

T

R

E

Q

N

f

a

m

f

w

s

t

T

C

O

O

ND LIABI

ITIES

All rights r

No part of

means, m

GmbH

No patent l

precaution

omissions.

herein.

The inform

informed if

the use of

FLINTEC r

Neither FL

losses, co

this produ

FLINTEC

FLINTEC

consumabl

NOTICE:

Copyright

served.

his publicati

chanical, p

iability is as

has been ta

Neither is a

ation herein

any errors

his manual.

eserves the

NTEC nor i

ts, or expen

t or unauth

perating an

hall not be l

e products

he contents

2010-201

on may be r

otocopying,

umed with

ken in the p

y liability a

is believed

ccur. FLINT

right to revi

s affiliates s

ses incurre

rized modifi

maintenan

able agains

ther than th

of this man

by Flintec

produced,

recording, o

espect to th

eparation o

sumed for d

o be both a

EC cannot

e this manu

all be liable

by purchas

ations, rep

e instructio

any damag

se designa

al are subj

mbH, 7490

tored in a r

r otherwise,

use of the

this book,

amages res

curate and

ccept any li

l and alter i

to the purc

r or third p

irs, or alter

ns.

es or proble

ed as Origi

ct to chang

9 Meckeshe

trieval syst

without the

information

LINTEC as

ulting from t

eliable. FLI

bility for dir

ts content w

aser of this

rties as a re

tions to this

s arising fr

al FLINTEC

without not

im, Bemann

m, or trans

rior written

ontained h

umes no re

e use of th

TEC, howe

ct or indire

thout notific

product or t

sult of: acci

product, or f

m the use

Products.

ce.

bruch 9, G

itted in any

permission

rein. While

ponsibility f

informatio

er, would b

t damages

tion at any

ird parties f

ent, misuse

ailure to stri

f any optio

rmany

form or by

f Flintec

very

r errors or

contained

obliged to

esulting fro

time.

r damages,

, or abuse o

tly comply

s or any

ny

be

ith

1.

afety I

CAUTION

instructions

operate, cle

this equipm

ENGINEER

WARNING

EXERCISE

MADE WIT

BODILY H

WARNING

PROPERL

WARNING

SERVICIN

WARNING

COMPONE

LWAYS R

CONNECTI

PRECAUTI

BODILY H

CAUTION

DEVICES.

structi

READ t

carefully. S

n, inspect,

nt from the

ING for part

ONLY

CARE WHE

POWER

RM.

FOR C

GROUND

DISCO

.

BEFOR

TS OR IN

MOVE PO

NS OR DI

NS COUL

RM.

OBSER

ons

is manual

VE this ma

aintain, se

power sour

, informatio

ERMIT QU

N MAKING

N. FAILING

NTINUED

D OUTLET

NECT ALL

CONNEC

ERCONNE

ER AND

CONNECT

RESULT I

E PRECA

EFORE op

ual for futur

rvice, or ta

e before cle

, and servi

LIFIED PE

HECKS, T

TO OBSE

ROTECTI

ONLY. DO

POWER T

ING/DISC

TING WIRI

AIT AT LE

IONS ARE

DAMAGE

TIONS FO

rating or se

e reference.

per with thi

aning or per

e.

SONNEL T

STS AND

VE THESE

N AGAINS

OT REMO

THIS UNIT

NNECTIN

NG BETWE

ST THIRT

ADE. FAIL

O OR DE

HANDLIN

vicing this e

DO NOT all

equipment.

orming mai

SERVICE

DJUSTME

RECAUTI

SHOCK H

E THE GR

BEFORE R

ANY INTE

N ELECT

(30) SECO

RE TO OB

TRUCTION

ELECTRO

quipment. F

ow untraine

ALWAYS D

tenance. C

THIS EQUI

TS THAT

NS CAN R

ZARD CO

UND PRO

MOVING

NAL ELEC

ONIC EQUI

DS BEFO

SERVE TH

OF THE E

STATIC SE

LLOW the

personnel

ISCONNEC

LL FLINTE

PMENT.

UST BE

SULT IN

NECT TO

G.

HE FUSE

RONIC

PMENT

E ANY

SE

UIPMENT

SITIVE

e

o

R

R

LDU 68

.1 & 68.2 Tec

nical Manual

Rev. 12 Ja

uary 2010

Page 4 o

28

.

2.

D

0

a

e

h

u

b

p

t

m

n

e

ä

3

t

A

t

t

e

h

n

A

p

E

h

t

/

t

A

:

g

m

e

e

c

i

e

e

i

R

C

K

D

m

t

o

r

1

c

m

n

p

e

a

n

r

h

c

A

A

u

A

r

n

m

m

t

n

o

r

h

t

m

e

s

e

m

e

g

Pr

k

C

/

n

7

u

e

r

ulawcom

r

A

s

i

e

l

d

c

a

in

fe

m

9

h

r

E

8

e

e

e

5/

e

d

e

n

n

a

y

e

m

ro

n

g

v

g

e

O

r

h

O

(

5

e

y

e

a

n

s

2

0

s

f

eclara

ion of

onfor

ity

Mon

Herst

Ansc

Prod

Das

This

Rich

Parla

zur A

Mitgli

Vertr

89/3

Rich

ktbezeichnun

t/Jahr: month

ller: Manufac

rift:

ddress

ezeichnete P

roduct confir

linie 2004/10

ents und de

gleichung d

dstaaten üb

glichkeit und

6/EWG

linie 2006/95

EG-

EC-

year:

urer:

: Product na

rodukt stimm

s with the foll

8/EG des Eu

s Rates vom

r Rechtsvors

r die elektro

zur Aufhebu

/EG Nieders

onfor

eclara

e:

mit folgende

wing regulati

opäischen

5. Dezembe

hriften der

agnetische

g der Richtlin

annungs-Ric

itätser

ion of

Vorschriften

ns of the Dir

2004

ie

tlinie

lärung

onfor

07

2010

Fli

tec GmbH

mannsbruch

Be

4909 Meckes

DDe

tschland / Ge

LD

U 68.1 / LDU

der Europäis

ctives of the

Di

ective 2004/10

Co

ncil of 15th D

s of the Memb

patibility and r

ective 2006/9

Di

it

eim

any

68.2

hen Richtlini

uropean Co

/EC of the Eu

ember 2004 o

r States relatin

pealing Directi

EC Low Volta

en überein:

munit

opean Parliam

n the approxim

to electromag

e 89/336/EEC

e Directive

nt and of the

tion of the

etic

Die

bsicherung al

Quali

ätsmerkmale

Quali

ätsmanagem

Diese

Erklärung bes

den g

nannten Richtl

Zusic

erung von Eig

Folge

de Normen w

s a

roof of conform

OIML

-76-1

DIN

N 45501

ler produktsp

erfolgt auf B

ent-Systems

heinigt die Übe

nien, beinhaltet

nschaften.

rden zum Nac

ty with the dire

Nicht-Selbsttäti

Non-automatic

Metrologische

nhang B.3: F

nhang C: Ve

zifischen

sis eines zer

ach DIN ISO

einstimmung

jedoch keine

weis der Über

tives following

Waagen – M

weighing syste

spekte nichts

nktionsprüfun

fahren für die

ifizierten

9001.

it

instimmung mit

tandards are fu

trologische un

ms – Metrologi

lbsttätiger Wa

en unter Störe

rüfung derStör

sy

Th

dir

ll

product-relat

tem in accor

s declaration c

ctives, but it is

den Richtlinien

filled:

technische A

al and technic

gen; Deutsche

flüssen

stigkeit gegen

d features ar

ance with IS

rtifies the confo

o promise of c

eingehalten:

forderungen (

l requirements

Fassung EN 4

ochfrequente

e assured by

9001.

rmity with the li

aracteristics.

IML R-76:200

(OIML R-76:20

501:1992

lektromagneti

a quality

ted

Teil 1)

2 Part 1)

che Felder.

LDU 68

.1 & 68.2 Tec

nical Manual

Rev. 12 Ja

uary 2010

Page 5 o

28

3. Introduction and Specifications

The model LDU 68.x is a precise digital amplifier for weighing and force measurements with strain gauge (SG)

sensors. The LDU 68.2 can be used for industrial applications,the LDU 68.1 can be used in legal for trade as

well as for industrial applications. The device features full multi-drop communications capability and can be

programmed via a straightforward ASCII command set.

The LDU XX.X series and the amplifier DAS 72.1 with on-board digital display, use the same command set.

You can connect up to 32 SG amplifiers of either the LDU XX.X series or DAS 72.1 type onto a single RS 485

bus. The LDU 68.x with its accurate A to D converter and an internal sample rate of up to 90 measurement

values per second, is particularly suitable for static or dynamic measurements and control purposes.

Specifications LDU 68.1 LDU 68.2

Accuracy class III Test certificate according OIML R76 10 000 Teile -

Linearity < 0.002 % FS

Excitation

Analogue input range

Minimum input sensitivity 0.1 μV / d

Certified accuracy according OIML R76 1.0 μV / e Resolution > ± 130 000 counts (input); ± 100 000 counts (output)

Conversion rate 90 values/second internal, up to 90 values/second external

Digital filter IIR filter 0.2 to 5 Hz; Bessel; in 8 steps adjustable

Calibration By software via ASCII commands, sehr einfach durchführbar

Communication interface

Standard weighing functions Gross, tare, net, zero, etc.

Digital inputs

Digital outputs 2x open collector outputs, < 30 V DC, max. 200 mA

Temperature effect on zero

Temperature effect on span

Operation temperature range –15 °C to +55 °C –15 °C to +50 °C

Storage temperature range –30 °C to +70 °C

Enclosure

Dimensions and weight

Power supply 12 ... 24 V DC ±10 %, < 60 mA, not galvanically isolated

Available accesoires

EMC OIML R-76:2006 and DIN EN 45 501:1992/AC1993

5 V DC, load cells 350 – 1 150 Ohm (87,5 – 1 150 Ohm at supply

voltage up to max. 12 V DC); 6 wire technique

±11 mV (bipolar; for weighing applications, force and torque

measurements)

RS485 oder RS422; Voll-Duplex oder Halb-Duplex;

9600 ... 115200 Baud; busfähig bis zu 32 Einheiten

2x opto-isolated inputs, 10 ... 30 V DC max. 3 mA,

Status via software

Typical 7 ppm/°K;

max. < 10 ppm/°K

Typical 2 ppm/°K;

max. < 5 ppm/°K

Typical 25 ppm/°K;

max. < 50 ppm/°K

Typical 15 ppm/°K;

max. < 30 ppm/°K

Tinned steel enclosure, IP40 protection,

special IP65 housing on request

82 x 31 x 6 mm, weighs approx. 30 g;

with adaptor board 99 x 41 x 12 mm, approx. 50 g

Adaptor board UA73.2 (RS485 / RS422) or

Adaptor board UA77.1 (inkl. converter RS422/RS232)

LDU 68.1 & 68.2 Technical Manual, Rev. 12 January 2010

Page 6 of 28

4. Communications and Getting started

4.1. Serial Interface

Communicating with the LDU 68.1 digitizer is carried out via the RS422/RS485 port.

The data format is the familiar 8/N/1 structure (8 data bits, no parity, 1 stop bit).

Available baud rates via the RS422/RS485 port are as follows: 9 600, 19 200, 38 400, 57 600 or 115 200 baud.

RS422:

Connection using a 4 wire technique

Point-to-Point connection, i.e. no bus communication possible

Half duplex setup (DX=0)

RS485:

Connection using 2- or 4-wire techniques

Multi-drop connection possible, up to 32 LDU XX.X

Half or Full Duplex (DX=0 or DX=1) possible

(RS232):

The optional adapter board UA 77.1 is available which has an RS485/RS232 converter built in.

4.2. Command Language

The command set of LDU XX.X series is based on a simple ASCII format (2 capital letters). This enables the

user to setup the device, get results or check parameters.

Example: LDU XX.X with the address or channel number 1 is connected via the RS 485 port to a bus system.

You want to get the net weight.

In this manual means: Space “_“ and Enter (CR/LF) ““

Master (PC / SPS) sends Slave (LDU XX.X) responds Meaning

OP 1

OK

GN

N+123.45

Net weight with algebraic sign / floating point

The command OP_2 opens the communication channel to LDU XX.X device #2. Now device #2 acknowledges

that it is active and responds to any commands on the bus. Communication with device #2 will be closed by

another OP command (for another device on the bus e.g. OP_5) or by the command CL_2.

Each OP_X command implies a CL command to all other devices on the bus except device #X. This makes the

address structures easier and the system performance improves.

Open device #1

Device # 1 ready

Get net weight

LDU 68.1 & 68.2 Technical Manual, Rev. 12 January 2010

Page 7 of 28

4.3. Baud Rate / Device Address

Baud Rate:

For baud rate setup use command BR, see chapter 8.10

Factory default: 9 600 baud

Device Address:

For address setup use command AD, see chapter 8.10

Factory default: Address 0

Setting the device address to 0 will set the continuously active mode, where the device becomes permanently

active, and will listen and respond to any command on the bus, without the need for an OP xxx command.

Note: The LDU XX.X series has sets of special solder pads on the under side of the PCB (see chapter 5.1). If

the solder pads are bridged then the LDU will be in a special configuration mode to set up the baud rate and

device address. This function should be used only when baud rate or address is unknown.

After power up, the LDU XX.X will enter a special baud rate search mode – waiting for a space character (0x20)

to be received. The time duration of this character is measured by the LDU and its baud rate timing will be set

accordingly – i.e. the baud rate of the terminal used will be the baud rate used by the LDU subsequently. The

device address will also be set to ”0“

4.4. Getting Started

You will require:

PC or PLC with either a RS422 or RS485 communication port

If using a PC / PLC with RS232 port, a RS422/485 to RS232 converter will be required (option UA 77.1)

Interconnecting cabling - confirm that all relevant pins are used – see the wiring diagram at the end of

this section

A load cell / scale with test weights or a load cell simulator

A 12-24 VDC power supply capable of delivering approximately 100mA for each LDU and load cell

One or more LDU 68.1

A suitable ASCII communication software *

Refer to the following wiring diagram in chapter 5.

* You can easily communicate between a PC and an LDU using programs such as Procomm, Telemate, Kermit

or HyperTerminal (included in Windows).

Also the DOP software with graphical user interface and oscilloscope function, running under Windows

2000/XP is available as freeware. This software is included on the Flintec product CD-ROM (2008 or later).

LDU 68.1 & 68.2 Technical Manual, Rev. 12 January 2010

Page 8 of 28

.

5.

H

W

W

W

h

r

W

r

r

n

1

2

2

2

e

f

ardwa

e and

iring

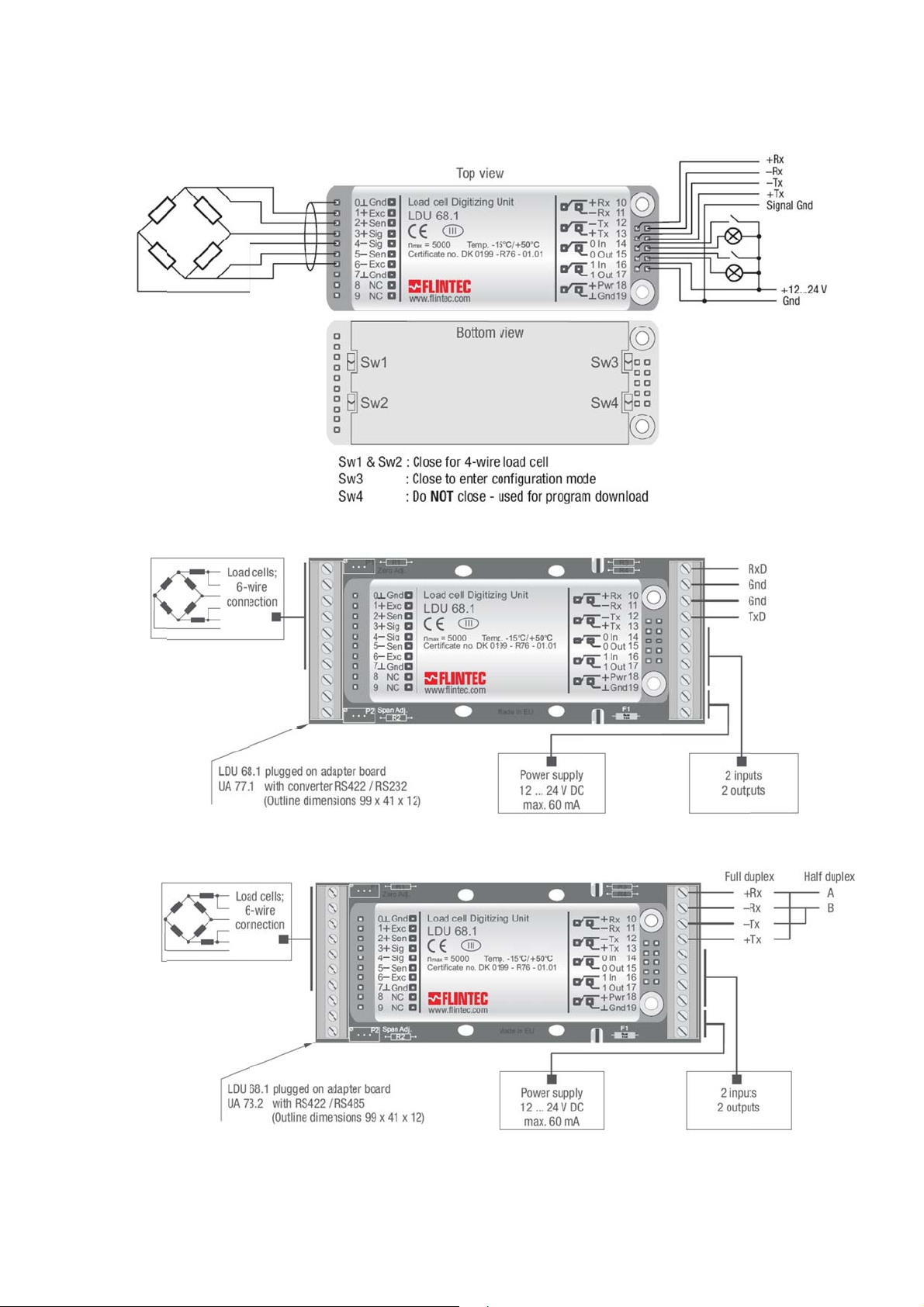

5.1.

5.2.

iring

ith Unit

Adapte

UA 77.

(RS23

)

5.3.

LDU 68

ith Unit

.1 & 68.2 Tec

Adapte

nical Manual

UA 73.

Rev. 12 Ja

(RS42

uary 2010

/ RS485 Full-/Half-Dupl

x)

Page 9 o

28

Loading...

Loading...