Page 1

<

+

SETUP MANUAL

HMI

www.hongdiancnc.com

B-64647EN/01

www.hongdiancnc.com

Page 2

• No part of this manual may be reproduced in any form.

• The design and specifications of this product are subject to change due to

improvements.

The products in this manual are controlled based on Japan's "Foreign Exchange and

Foreign Trade Law".

Furthermore, the product may also be controlled by re-export regulations of the United

States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

This manual attempts to include information as much as possible.

There are, however, a very large number of operations that must not or cannot be

performed, and if the manual contained them all, it would be enormous in volume.

It is, therefore, requested to assume that any functions not described in this manual are

"not equipped in this product."

Program and device names belonging to companies other than FANUC in this manual

include registered trademarks of their respective companies.

However, the ® and ™ marks may be omitted for some of those names.

www.hongdiancnc.com

www.hongdiancnc.com

Page 3

B-64647EN/01

!

!

!

SAFETY PRECAUTIONS

DEFINITION OF WARNING, CAUTION, NOTE, AND MEMO

SAFETY PRECAUTIONS

1

When using FANUC iHMI, you must comply with the instructions written in "SAFETY

PRECAUTIONS".

DEFINITION OF WARNING, CAUTION,

NOTE, AND MEMO

This manual includes safety precautions for protecting the user and preventing

the machine. Precautions are classified into " Warning" and "

damage t

Caution" according to the degree of the risk or severity of damage.

Also, supplementary information is described as "Note" and "Memo".

Read these indications thoroughly before using this product.

WARNING

CAUTION

o

Used if a danger resulting in the death or serious injury of the user is

expected to occur if he or she fails to observe the approved procedure.

Used if a danger resulting in the minor injury of the user or equipment

damage is expected to occur if he or she fails to observe the approved

procedure.

!

2

3

4

5

6

7

8

A1

Used if points to keep in mind not related to WARNING or CAUTION are to

www.hongdiancnc.com

NOTE

MEMO

Read this manual carefully, and store it in a safe place.

*

be indicated.

Used if supplementary explanations for operation or additional information

not related to WARNING or CAUTION are to be indicated.

s-1

A2

Z

www.hongdiancnc.com

Page 4

1

!

!

B-64647EN/01

SAFETY PRECAUTIONS

GENERAL PRECAUTIONS

GENERAL PRECAUTIONS

The following warnings and cautions provide information to be noted when

handing the CNC device for safer use of the machine with the CNC device.

2

3

4

5

6

7

8

A1

WARNING

• Carefully check that data you want to enter is correctly entered before

performing the next operation. Operation with incorrect data may cause

unexpected behavior of the machine, resulting in damage to the work or

machine or injury.

• Carefully check that program command value, offset value, curren

po

tion, and external signal settings, etc. are correct before starting the

si

machine for operation, such as machining the work. Also, perform tria

op

eration, such as using the single block, feed speed override, or machi

ock function, or operating without a tool or work, to carefully check that th

l

machine operates correctly.

• Check that an appropriate feed speed value is specified for the operation.

h

e maximum feed speed is normally limited for each machine. Follow the

T

manual of the machine as well because the optimal speed is differen

de

pending on the operation.

Operation with an incorrect speed may cause unexpected load to t

ma

ine, resulting in damage to the work or machine or injury.

ch

• Before using the tool offset function, carefully check the offset direction a

v

ue. Operation with incorrect data may cause unexpected behavior of

al

chine, resulting in damage to the work or machine or injury.

ma

• Optimal values are set to the CNC and PMC parameters, so they do no

no

mally need to be changed. If you change the parameter for so

r

eason, fully understand its function before change. An incorrect parameter

r

setting may cause unexpected behavior of the machine depending on th

etting value, resulting in damage to the work or machine or injury.

s

t

l

ne

t

he

nd

the

t

me

e

e

www.hongdiancnc.com

A2

• After pressing the power on button, do not touch any key on the keyboard

un

Z

CAUTION

til the screen appears. Some keys are used for maintenance or specia

eration and may cause unexpected behavior.

op

• NC programs, parameters, and variables are stored in the non-volatile

in the CNC device. These data are usually not lost by powering

mory

me

on/off. However, precious data stored in the non-volatile memory may

l

ost due to incorrect operation or may have to be erased due to faul

covery.

re

To recover fast from such an unexpected situation, back up all kinds of

da

a beforehand.

t

• There are some embedded machine operations and screen function

i

talled by machine tool builders (MTB). For how to use them and

ns

precautions, refer to the appropriate manual provided by each

manufacturer.

s-2

www.hongdiancnc.com

l

be

t

s

Page 5

B-64647EN/01

!

SAFETY PRECAUTIONS

GENERAL WARNINGS FOR CNC APPLICATION DEVELOPMENT

0.1

GENERAL WARNINGS FOR CNC

APPLICATION DEVELOPMENT

1

WARNING

Be careful enough for the following warnings when you develop two or more

applications or use networks.

If you neglect them, there is a danger of the user being injured or there is a

r of both the user being injured and the equipment being damaged.

nge

da

1.Be careful enough if you write an identical NC data, an identical PMC data

eries of related data set by two or more above applications including

a s

or

network functions. Because they are executed based on each individual

cycles (in other words, asynchronous cycles), there is a possibility that the

data will be written in an unexpected order.

Therefore, do NOT write above data in the following cases.

- Applications and network functions

- Two or more applications

- Two or more network functions

Data, applications and network functions of interest are listed in below.

r, all may not be listed completely because new features will be

ve

Howe

added in the future.

2.Be careful enough that you must prevent PMC signals in the same by

being written by the following two or more applications including

from

network functions. While an application reads and writes one byte of PMC

signals, other applications may write the same byte.

te

2

3

4

5

6

7

8

A1

www.hongdiancnc.com

3.Be careful enough if you process a PMC signal set that is related to a

tion by using the following two or more applications including network

func

functions. Because they are executed based on each individual cycles (in

other words, asynchronous cycles), there is a possibility that the NC may

receive the PMC signal set in an unexpected order.

4.Generally, when multi-byte data are read or written at once among t

following two or more applications including network functions, the

coherency of the read multi-byte data (in other words, reading all latest

data at once) is not guaranteed. To ensure the coherency of the multi-byte

data, prepare flags to notify the completion of reading or writing process

that is separated from the entity of the data and make the handshaking

process to access the data by using the flags.

s-3

www.hongdiancnc.com

NC

he

A2

Z

Page 6

1

!

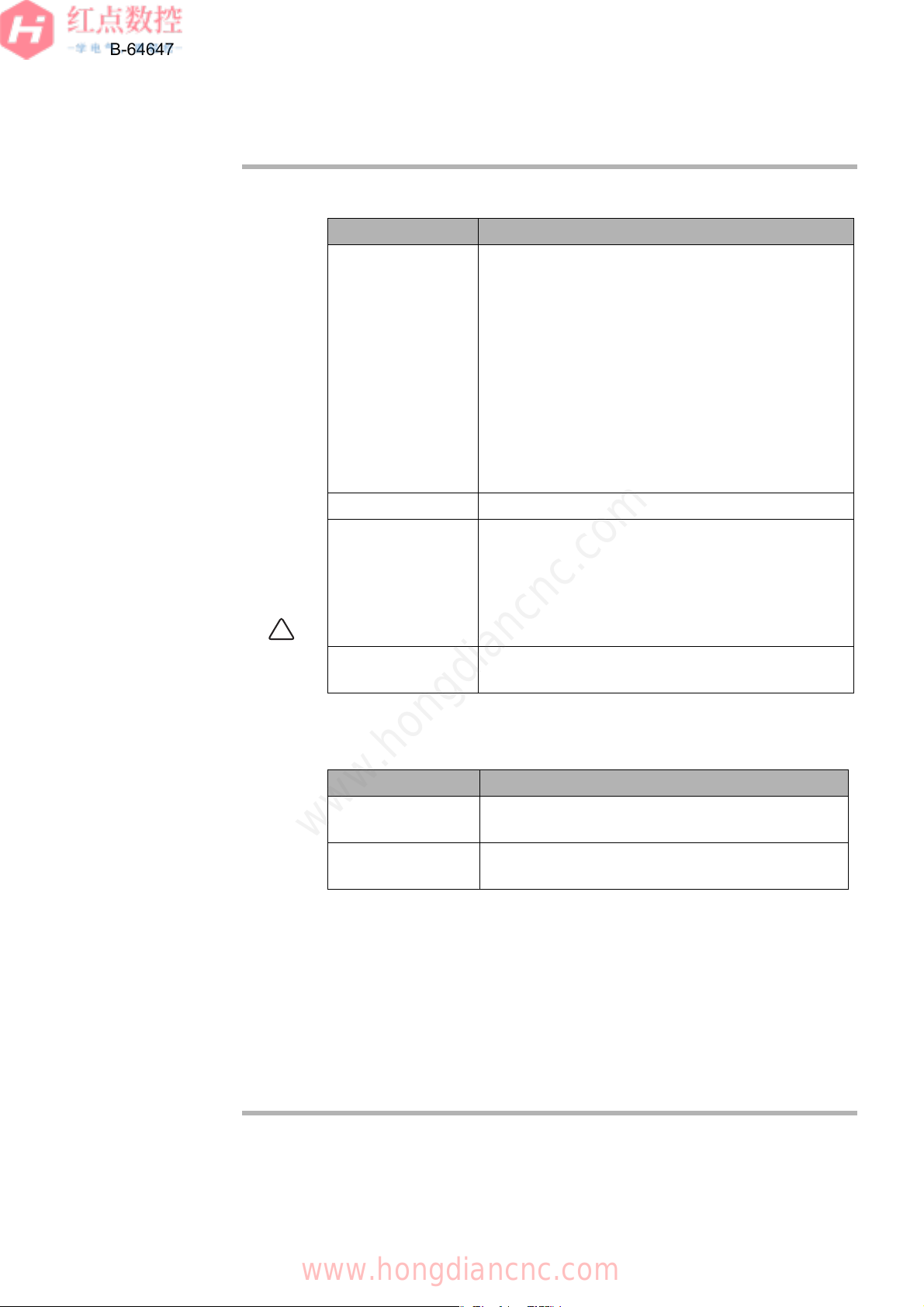

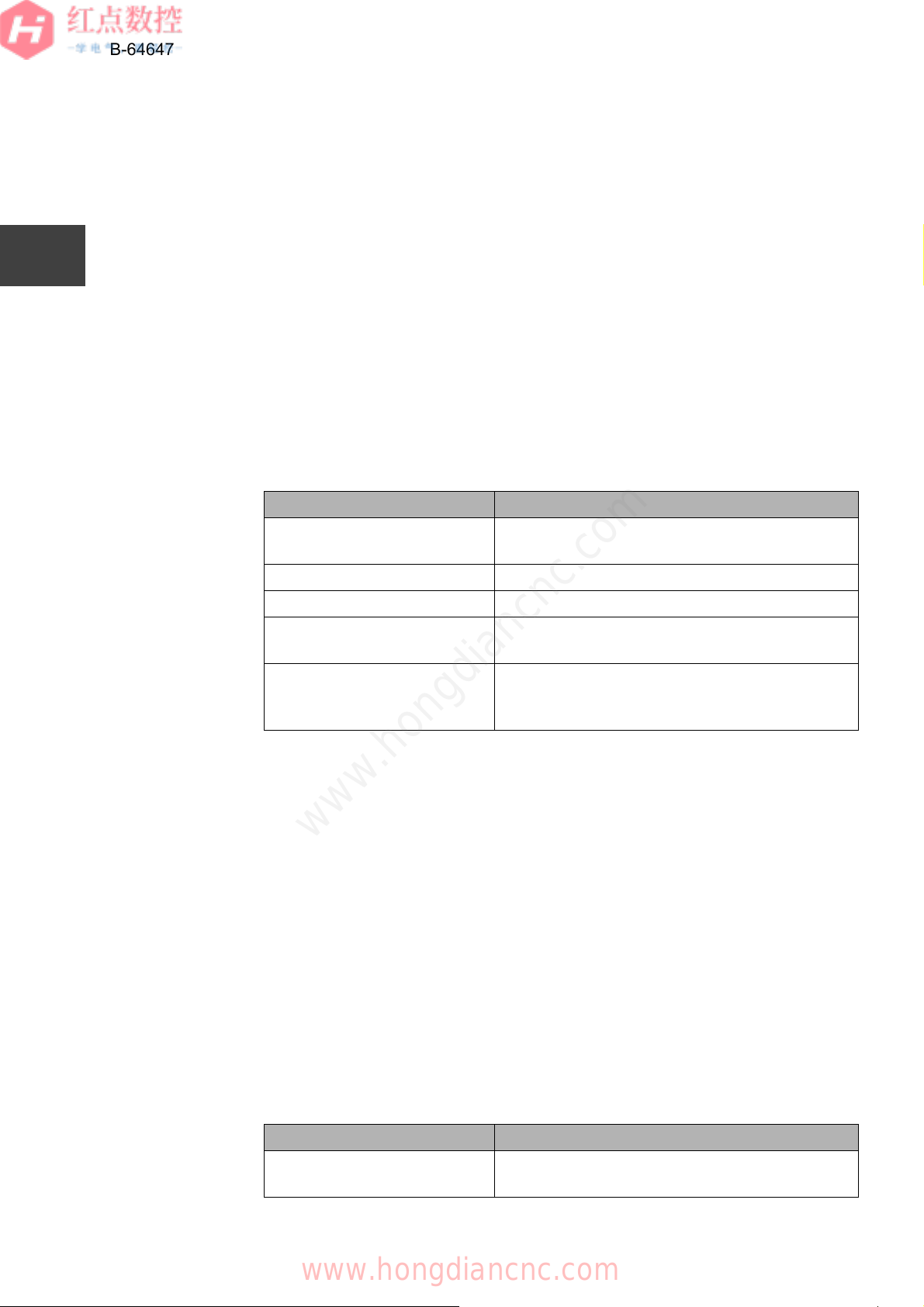

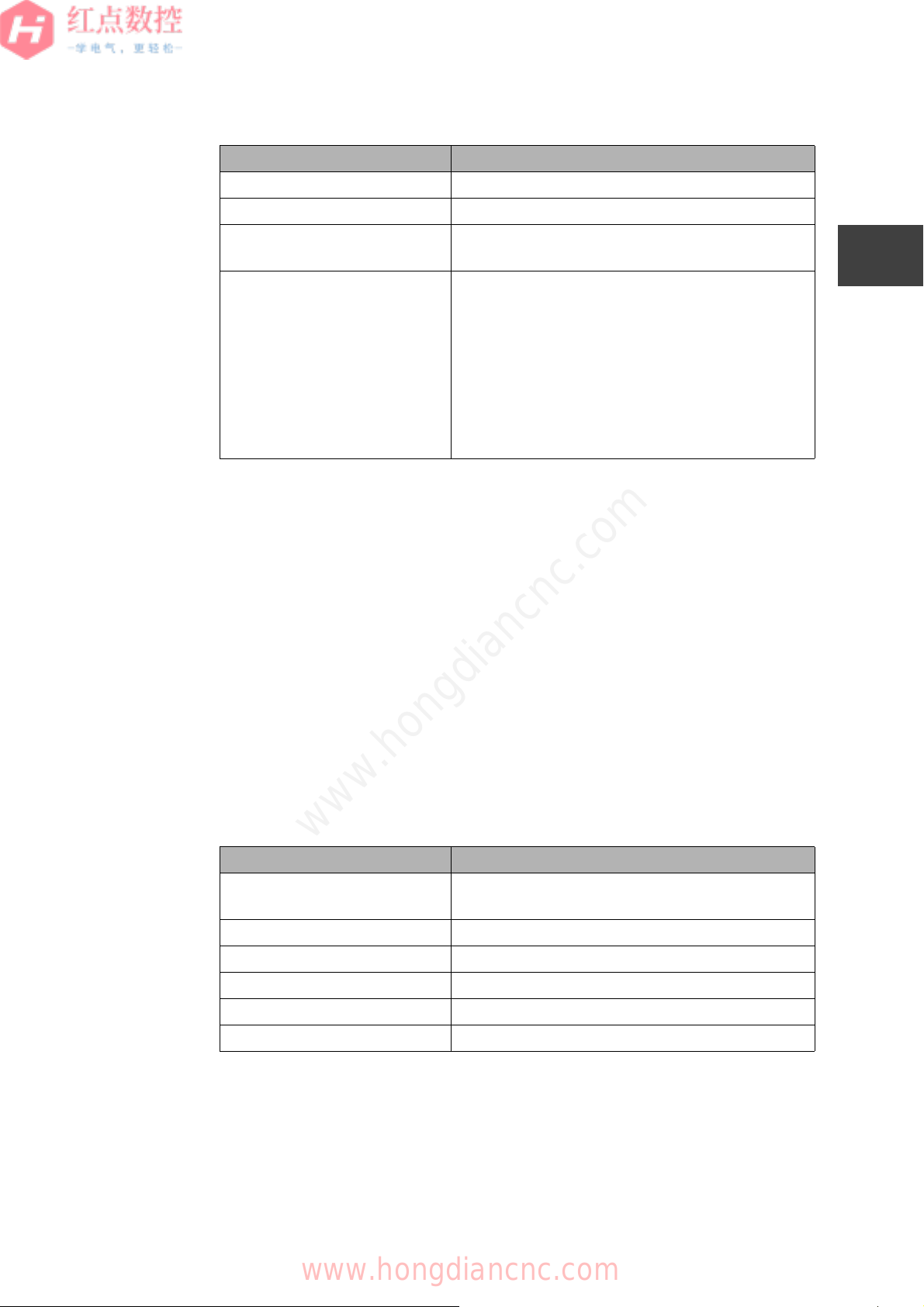

Category Data

General data for NC Parameter, Tool compensation value and related

data,

Work zero offset value and related data,

Workpiece coordinate system shift value and related

data,

Macro variable, P-CODE variable, Program and

related data,

Tool management function data, Tool life

management data,

Error compensation related data ,

Overtravel check (Interference check) related data ,

Software operator’s panel related data

PMC data PMC signal, PMC parameter

Data for Laser,

Punch press or Wire

cut

Tool data for punch press and related data, Safety

zone data and related data, Laser cutting condition

data and related data, Laser oscillator setting data

and related data, Wire consumption compensation

data, Guide position compensation data, Workpiece

leveling data

Other data Parameters for Data Server, Parameters for network

setting

Category Functions

Applications PMC Ladder, Macro Executor, C Language

Executor, FANUC PICTURE, FOCAS2

Network functions FL-net, EtherNet/IP, PROFINET, Modbus/TCP,

PROFIBUS-DP, DeviceNet, CC-Link

2

3

4

B-64647EN/01

SAFETY PRECAUTIONS

GENERAL WARNINGS FOR CNC APPLICATION DEVELOPMENT

Data List Table

5

6

7

8

CAUTION

List Table of Applications and Network Functions

A1

A2

Z

www.hongdiancnc.com

5.CNC has functions that read or write PMC signals in other than the G/F

address. Be careful enough if the above mentioned applications and

network read or write PMC signals used by these functions. When reading

or writing the same PMC signal, applications or CNC functions may work in

an unexpected manner.

As for the CNC functions of interest, refer to the connection manual

(

Function) (B-64483EN-1) ”Appendix B. List of Functions Using PMC

Signals Other Than G/F Address”.

s-4

www.hongdiancnc.com

Page 7

PREFACE

B-64647EN/01

PREFACE

RELATED MANUALS

1

The iHMI consists of applications that support CNC operations and the "Home

screen" that starts each application. The iHMI allows you to customize each

application and add your custom applications to the Home screen. This manual

describes the customization method and specifications of the iHMI.

For details about the iHMI and iHMI applications, see "FANUC iHMI Home Screen

OPERATOR'S MANUAL" (B-64644EN) and "FANUC iHMI CNC Operation Screen

OPERATOR'S MANUAL" (B-64644EN-1).

0.1

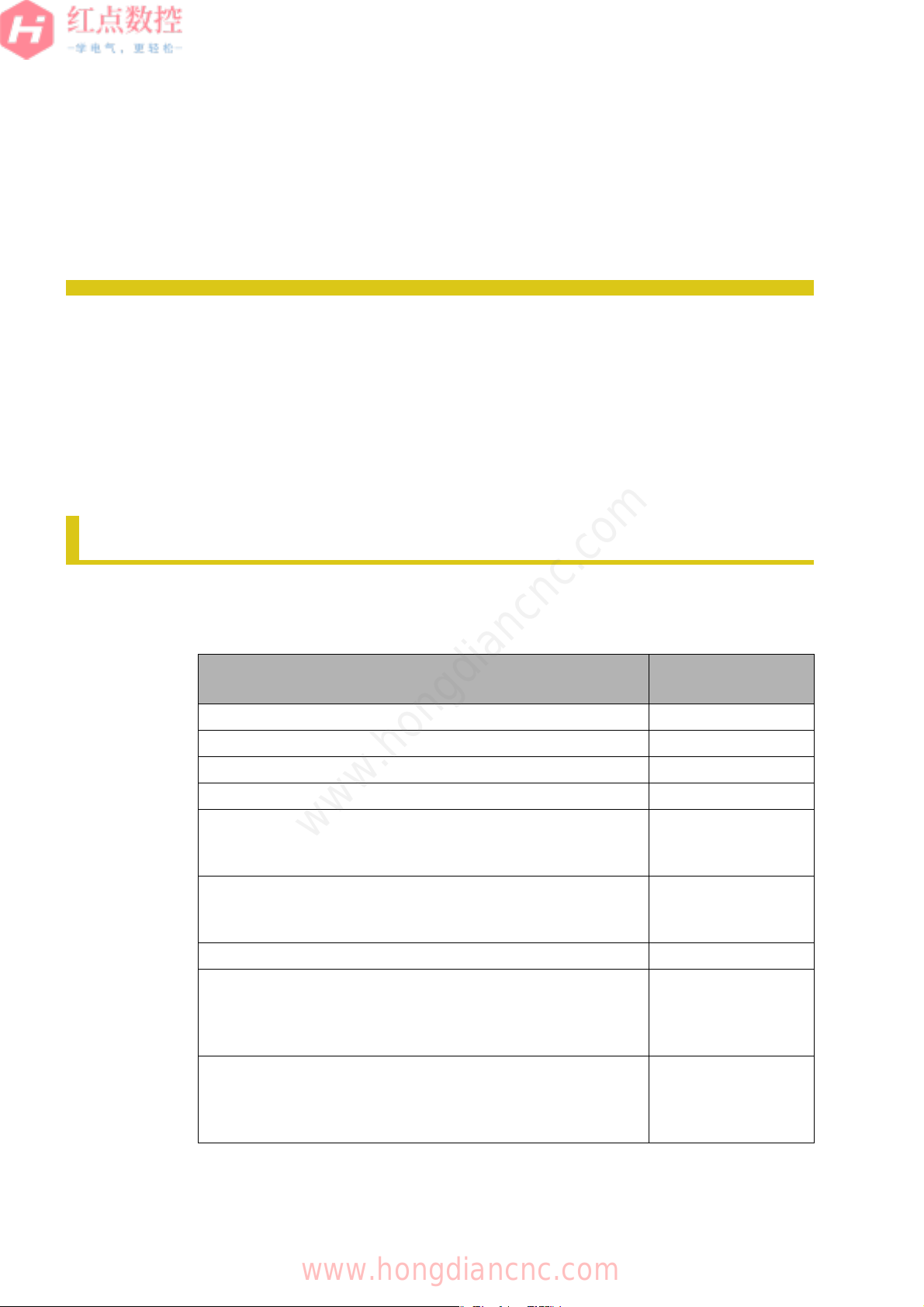

1 RELATED MANUALS

The table below lists related manuals.

Table1 Related Manuals List

Manual name Specification

FANUC iHMI Home Screen OPERATOR'S MANUAL B-64644EN

FANUC iHMI CNC Operation Screen OPERATOR'S MANUAL B-64644EN-1

FANUC iHMI Machining Cycle OPERATOR'S MANUAL B-64644EN-2

FANUC iHMI Set-up Guidance OPERATOR'S MANUAL B-64644JA-3

2

3

4

5

6

7

number

8

A1

FANUC Series 30i-MODEL B

FANUC Series 31i-MODEL B

FANUC Series 32i-MODEL B PARAMETER MANUAL

FANUC Series 30i-MODEL B

FANUC Series 31i-MODEL B

FANUC Series 32i-MODEL B MAINTENANCE MANUAL

FANUC PICTURE OPERATOR'S MANUAL B-66284EN

FANUC Series 30i-MODEL B

FANUC Series 31i-MODEL B

FANUC Series 32i-MODEL B CONNECTION MANUAL

(HARDWARE)

FANUC Series 30i-MODEL B

FANUC Series 31i-MODEL B

FANUC Series 32i-MODEL B CONNECTION MANUAL

(FUNCTION)

www.hongdiancnc.com

p-1

B-64490EN

B-64485EN

B-64483EN

B-64483EN-1

A2

Z

www.hongdiancnc.com

Page 8

1

2

B-64647EN/01

PREFACE

RELATED MANUALS

FANUC Series 30i-MODEL B

FANUC Series 31i-M

FANUC Series 32iMachining Center System OPERATOR'S MANUAL

FANUC Series 30i-MODEL B

FANUC Series 31i-M

FANUC Series 32i-MO

FANUC Series 35i-MO

Manual name Specification

O

DEL B

M

ODEL B Common to Lathe System/

O

DEL B

D

EL B

D

EL B PMC PROGRAMMING MANUAL

B-64484EN

B-64513EN

number

3

4

5

6

7

8

A1

FANUC MANUAL GUIDE i Common to Lathe System/Machining

Center System OPERATOR'S MANUAL

FANUC MANUAL GUIDE i SET-UP GUIDANCE FUNCTIONS

OPERATOR'S MANUAL

FANUC Interactive Programming Function for Complex Lathe

OPERATOR'S MANUAL

CNC Screen Display Function OPERATOR'S MANUAL

B-63874EN

B-63874EN-1

B-64654EN

B-63164EN

A2

Z

www.hongdiancnc.com

p-2

www.hongdiancnc.com

Page 9

CHAPTER CONTENTS

B-64647EN/01

1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2 SETTING UP iHMI APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . .13

3 CREATING A USER APPLICATION . . . . . . . . . . . . . . . . . . . . . . . .185

4 MAINTENENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

5 PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

A APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .313

1

2

3

4

5

A

www.hongdiancnc.com

c-1

www.hongdiancnc.com

Page 10

1

2

3

4

B-64647EN/01

5

6

7

8

A1

A2

Z

www.hongdiancnc.com

c-2

www.hongdiancnc.com

Page 11

TABLE OF CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . s-1

B-64647EN/01

1

2

DEFINITION OF WARNING, CAUTION, NOTE, AND MEMO ...........s-1

GENERAL PRECAUTIONS ................................................................s-2

GENERAL WARNINGS FOR CNC APPLICATION

DEVELOPMENT..................................................................................s-3

PREFACE ............................................................................................... p-1

1 RELATED MANUALS .......................................................................... p-1

1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 iHMI SETUP OVERVIEW ..............................................................2

1.1.1 Setup Overview ................................................................................ 2

1.1.1.1 Customizing applications registered with the iHMI ................... 2

1.1.1.2 Overall iHMI settings ................................................................. 6

1.1.2 Environment Required for iHMI Customization ................................ 8

1.1.2.1 User application ........................................................................ 8

1.1.2.2 FANUC PICTURE ..................................................................... 9

1.1.2.3 Machine alarm diagnosis guidance table ................................ 10

1.1.3 iHMI Hardware Performance Table ................................................ 10

1.2 iHMI MAINTENANCE OVERVIEW .............................................12

2 SETTING UP iHMI APPLICATIONS . . . . . . . . . . . . . . . . . . . . . .13

2.1 iHMI APPLICATION SETUP OVERVIEW ...................................14

2.1.1 iHMI Folder Configuration .............................................................. 14

2.1.1.1 Folder configuration inside the CNC ....................................... 14

2.1.2 Customizable Applications ............................................................. 15

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI ...17

2.2.1 Application Definition File ............................................................... 17

2.2.1.1 Starting an application with a screen specified ....................... 19

2.2.1.2 Starting iHMI applications from shortcuts ............................... 19

2.2.2 iHMI Whole Configuration File ....................................................... 22

2.2.3 Individual Settings Common to the Applications ............................ 24

2.2.3.1 Hiding the vertical soft keys .................................................... 24

2.2.3.2 Setting an animation to be used when a slide is displayed ..... 25

2.3 SETTING UP BASIC FUNCTIONS .............................................27

2.3.1 Customizing the Home Screen ....................................................... 27

2.3.1.1 Changing the background of the home screen ....................... 27

2.3.1.2 Adding a shutdown button ...................................................... 27

www.hongdiancnc.com

3

4

5

6

7

8

A1

A2

Z

c-3

www.hongdiancnc.com

Page 12

1

2

3

4

5

6

7

8

A1

A2

Z

B-64647EN/01

2.3.2 Customizing the Status Display ..................................................... 29

2.3.2.1 Adding status icons and character string display ................... 29

2.3.3 Setting the Machine Alarm Diagnosis ............................................ 36

2.3.3.1 Alarm and operator message types that can be added .......... 36

2.3.3.2 Diagnosable numbers ............................................................. 36

2.3.3.3 Environments required to create failure diagnosis messages 37

2.3.3.4 Machine alarm diagnosis guidance table ............................... 37

2.3.3.5 Creating failure diagnosis messages ...................................... 42

2.3.3.6 Creating different language messages ................................... 50

2.4 SETTING UP THE PLANNING APPLICATION .......................... 54

2.4.1 Setting Up Tool Management Function ......................................... 54

2.4.1.1 NC tool database management .............................................. 54

2.4.1.2 Tool management function customization .............................. 56

2.4.2 Setting Up Cycle Time Estimation Function ................................... 57

2.4.2.1 Application definition file ......................................................... 57

2.4.2.2 Auxiliary function time setting window .................................... 57

2.4.2.3 Adding an auxiliary function time ............................................ 58

2.4.2.4 Changing an auxiliary function time ........................................ 60

2.4.2.5 Deleting an auxiliary function time .......................................... 60

2.5 SETTING UP THE MACHINING APPLICATION ........................ 62

2.5.1 Setting Up the CNC Operation Screen .......................................... 62

2.5.1.1 Configuration file to use the multi-path edit function ............... 62

2.5.1.2 Setting the coordinate axes display and soft key display ....... 64

2.5.1.3 Setting the number of divided areas of the multi-path display 65

2.5.1.4 Hiding the modal G codes ...................................................... 68

2.5.1.5 Settings related to each mode base screen ........................... 68

2.5.1.6 Setting the spindle rotation direction icon display ................... 70

2.5.1.7 Setting the uniform peripheral speed control mode icon

display .................................................................................... 73

2.5.1.8 Setting the traveling direction guide in the JOG, HND, INC,

www.hongdiancnc.com

2.5.1.9 Setting the workpiece coordinates slide ................................. 76

2.5.1.10 Setting the program manager slide ........................................ 77

2.5.1.11 Opening/closing the custom macro variable slide .................. 78

2.5.1.12 Displaying custom macro variable numbers and values ........ 79

2.5.1.13 Editing custom macro variables .............................................. 82

2.5.1.14 Displaying custom macro variable names .............................. 86

2.5.1.15 Conditions to use the machining simulation function .............. 87

2.5.1.16 Configuration file to use the machining simulation function .... 88

2.5.1.17 Machining simulation screen .................................................. 90

2.5.1.18 Configuration file to use the machining cycle creation

2.5.1.19 Display settings of the MEM mode base screen .................... 99

2.5.1.20 Setting program guidance messages ................................... 101

2.5.1.21 Setting up M code input function .......................................... 105

2.5.1.22 Setting up the fixed sentence function .................................. 109

and REF mode base screens ................................................. 74

function ................................................................................... 98

c-4

www.hongdiancnc.com

Page 13

B-64647EN/01

2.5.2 Setting Up the iHMI Machining Cycle ........................................... 113

2.5.3 Setting Up the iHMI Set-up Guidance .......................................... 113

2.5.3.1 Manually setting in the P-CODE variable .............................. 114

2.5.3.2 Setting on the MANUAL GUIDE i screen .............................. 121

2.5.4 Setting Up the Machine Collision Avoidance Function ................. 125

2.5.4.1 Creating a 3D machine model .............................................. 125

2.5.4.2 Setting various settings of the machine collision avoidance

function ................................................................................. 127

2.5.4.3 Setting the common items .................................................... 129

2.5.4.4 Setting the machine configuration ......................................... 131

2.5.4.5 Configuring the individual path settings ................................ 149

2.5.4.6 Preview time of the machine collision avoidance function .... 153

2.5.4.7 Signals available during the execution of the machine

collision avoidance function .................................................. 156

2.6 SETTING UP THE IMPROVEMENT APPLICATION ................159

2.6.1 Importing/Exporting Logs Collected with the Data Logger

Function ........................................................................................ 159

2.6.1.1 Log item configuration file ..................................................... 159

2.6.1.2 Log file .................................................................................. 164

2.6.2 Setting Up the Maintenance Manager .......................................... 166

2.6.2.1 Setting parts placement information ..................................... 167

2.6.2.2 Standard icons list ................................................................. 168

2.6.2.3 Switching maintenance items display ................................... 169

2.6.2.4 Outputting the display switch settings of the maintenance

items ..................................................................................... 170

2.6.2.5 Maintenance items display switch configuration file ............. 170

2.7 SETTING UP THE UTILITY APPLICATION ..............................173

2.7.1 Setting Up the Manual Viewer Function ....................................... 173

2.7.1.1 Manual information configuration file .................................... 173

2.7.1.2 Manual viewer tag list ........................................................... 174

2.7.1.3 Import folder configuration .................................................... 177

2.7.1.4 Naming rules for manual file update ..................................... 178

2.7.2 Setting Up the Web Browser Function ......................................... 179

2.7.2.1 Description of the Web browser configuration file ................. 179

2.7.2.2 Setting the start page ............................................................ 180

2.8 CREATING PROGRAM STORAGE FILES ...............................181

2.8.1 Program Storage Files ................................................................. 181

2.8.2 Creating a Program Storage File (Ncprog.bin) ............................. 181

2.8.3 Program Storage File Edit Library (Ncprog.dll) ............................ 181

www.hongdiancnc.com

1

2

3

4

5

6

7

8

A1

A2

Z

3 CREATING A USER APPLICATION . . . . . . . . . . . . . . . . . . . .185

3.1 OVERVIEW OF CREATING A USER APPLICATION ..............186

3.1.1 Adding an Application to the iHMI ................................................ 186

3.1.2 User Application ........................................................................... 187

3.2 HOW TO CREATE A USER APPLICATION .............................188

3.2.1 Overview of Creating an Application ............................................ 188

c-5

www.hongdiancnc.com

Page 14

1

2

B-64647EN/01

3.2.2 Using the iHMI Library ................................................................. 188

3.2.2.1 Application Manager ............................................................. 189

3.2.2.2 Overlapping the user application with the iHMI application .. 190

3.2.2.3 Starting a specific application from the user application ....... 192

3.2.2.4 Displaying a specific screen when starting the user

application ............................................................................ 194

3.3 CUSTOMIZING A SCREEN WITH FANUC PICTURE ............. 196

3.3.1 Creating a New Operator's Panel Screen .................................... 196

3.3.2 Changing an Operator's Panel Screen ........................................ 199

3.3.3 Simultaneous Display with Another Application ........................... 201

3

4

5

6

7

8

A1

A2

Z

4 MAINTENENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

4.1 DATA BACKUP/RESTORE ...................................................... 206

4.1.1 Starting the Backup Screen ......................................................... 207

4.1.2 Saving Data in a Batch ................................................................ 212

4.1.3 Restoring Data in a Batch ............................................................ 213

4.1.4 Saving Data Individually ............................................................... 214

4.1.5 Restoring Data Individually .......................................................... 214

4.1.6 Displaying the Details of Batch Save and Restore Results ......... 214

4.2 AUTOMATIC DATA BACKUP .................................................. 216

4.2.1 Backing Up to External Memory .................................................. 217

4.2.1.1 List of output text data .......................................................... 218

4.3 HOW TO UPDATE THE SOFTWARE ...................................... 220

4.3.1 Preparation .................................................................................. 220

4.3.1.1 Checking the iHMI version ................................................... 220

4.3.1.2 Checking whether the EWF is enabled/disabled

(for PANEL iH Pro only) ....................................................... 221

4.3.2 Updating the iHMI Basic Software for the PANEL iH .................. 222

4.3.2.1 Folder configuration .............................................................. 222

4.3.2.2 Backing up iHMI data ........................................................... 222

www.hongdiancnc.com

4.3.2.3 Installing the iHMI ................................................................. 223

4.3.2.4 Restoring backed-up iHMI data ............................................ 225

4.3.3 Updating the iHMI Basic Software for the PANEL iH Pro ............ 226

4.3.3.1 Backing up iHMI data ........................................................... 226

4.3.3.2 Disabling the EWF ................................................................ 227

4.3.3.3 Uninstalling the iHMI ............................................................ 228

4.3.3.4 Installing the iHMI ................................................................. 228

4.3.3.5 Restoring backed-up iHMI data ............................................ 228

4.3.3.6 Enabling the EWF ................................................................. 229

c-6

www.hongdiancnc.com

Page 15

B-64647EN/01

5 PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

5.1 PARAMETERS TO DISABLE EDITING OF PROGRAMS ........233

5.2 PARAMETER OF SUBPROGRAM CALLS ...............................238

5.3 PARAMETER OF PROGRAM PROTECTION KEYS ...............239

5.4 PARAMETERS TO DISABLE EDITING IN THE AUTOMATIC

OPERATION STOP STATE ......................................................240

5.5 PARAMETER TO CHANGE THE NUMBER OF DIGITS FOR

PROGRAM NUMBERS .............................................................242

5.6 PARAMETER TO SELECT A DEVICE .....................................243

5.7 PARAMETERS OF THE TROUBLE DIAGNOSIS FUNCTION .244

5.8 PARAMETERS OF THE MACHINING SIMULATION

FUNCTION ................................................................................247

5.9 PARAMETERS OF THE CURRENT POSITION/REMAINING

TRAVEL DISTANCE DISPLAY TILES ......................................251

5.9.1 Parameters to Display Axis Names .............................................. 251

5.9.2 Parameters to Display Extended Axis Names and Subscripts ..... 253

5.9.3 Parameters to Display Coordinate Values ................................... 255

5.9.4 Parameters of Increment System 0.1 nm Display ........................ 257

5.9.5 Parameters of Programmable Diameter/Radius Switching .......... 259

5.9.6 Parameters to Show/Hide Control Axes ....................................... 261

5.9.7 Parameters to Align Control Axes to the Top ............................... 261

5.9.8 Parameters to Change the Order of Displaying Control Axes ...... 262

5.9.9 Parameters to Preset a Workpiece Coordinate System

(Absolute/Overall) ......................................................................... 262

5.10 PARAMETERS OF SERVO LOAD METER DISPLAY ..............264

5.10.1 Parameters to Display Axis Names .............................................. 264

5.10.2 Parameters to Display Extended Axis Names and Subscripts ..... 264

5.10.3 Parameters of Axis Name Switching ............................................ 264

5.10.4 Parameters to Show/Hide Control Axes ....................................... 264

5.10.5 Parameters to Align Control Axes to the Top ............................... 264

5.10.6 Parameters to Change the Order of Displaying Control Axes ...... 265

5.11 PARAMETERS OF MODAL INFORMATION DISPLAY ............266

5.11.1 Parameters of Modal G Codes ..................................................... 266

5.11.2 Parameters of Modal HD.T and NX.T Codes ............................... 268

5.11.3 Parameters of Modal SRPM, SSPM, and SMAX ......................... 271

5.11.4 Parameters of Modal F Codes ..................................................... 271

5.11.5 Parameters of Modal T, D, and H Codes ..................................... 272

5.11.6 Parameters of Modal T Codes ..................................................... 273

5.11.7 Parameters of Modal S Codes ..................................................... 274

5.11.8 Parameters of Modal M Codes (First to Fifth M Codes) ............... 275

5.11.9 Parameters of Modal B Codes (Second Auxiliary Function) ........ 276

5.11.10Parameters of Modal C Codes (Third Auxiliary Function) ........... 279

5.11.11Parameters of Modal A Codes (Fourth Auxiliary Function) ......... 279

5.11.12Parameters of General Modal Information .................................. 280

www.hongdiancnc.com

1

2

3

4

5

6

7

8

A1

A2

Z

c-7

www.hongdiancnc.com

Page 16

1

2

3

4

5

6

7

8

B-64647EN/01

5.12 PARAMETERS OF MACHINING INFORMATION DISPLAY ... 282

5.13 PARAMETER TO DISPLAY FEEDRATE INFORMATION ....... 287

5.13.1 Parameter to Display Feedrate Information ................................. 287

5.13.2 Parameters of the Actual Feedrate Unit ....................................... 287

5.13.3 Parameter to Display the Actual Feedrate ................................... 289

5.13.4 Parameters of the Actual Feedrate Speed Meter ........................ 289

5.14 PARAMETERS OF SPINDLE INFORMATION DISPLAY ........ 291

5.14.1 Parameters of Extended Spindle Names and Subscripts ............ 291

5.14.2 Parameters of the Actual Spindle Speed ..................................... 295

5.14.3 Parameters of the Spindle Speed Meter ...................................... 296

5.14.4 Parameters of the Spindle Load Meter ........................................ 296

5.14.5 Parameters of the Current Load Ratio ......................................... 297

5.15 PARAMETERS OF MACHINING PROGRAM DISPLAY .......... 298

5.15.1 Parameters of Subprogram Calls ................................................. 298

5.15.2 Parameter of Program Content Display ....................................... 300

5.15.3 Parameters of Program Numbers ................................................ 301

5.15.4 Parameters of Display during Program Backward by Manual

Handle Retrace ............................................................................ 302

5.16 PARAMETER OF N NUMBER SEARCH IN A MACHINING

PROGRAM ............................................................................... 304

5.16.1 Parameter of Sequence Numbers ............................................... 304

5.17 PARAMETERS OF SEQUENCE NUMBER STOP ................... 305

5.18 PARAMETERS OF THE CUSTOM MACRO VARIABLE LIST

SLIDE ........................................................................................ 306

5.19 PARAMETERS OF THE MACHINE COLLISION AVOIDANCE

FUNCTION ............................................................................... 308

A1

A2

Z

A APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .313

A.1 APPLICATION IDENTIFIER ID ................................................. 314

A.2 CNC OPERATION SCREEN SWITCHING ID

A.3 MAINTENANCE DISPLAY SWITCHING ID

A.4 MDI KEY CODE MAP FOR iHMI .............................................. 324

A.5 FANUC SCREEN COLOR DEFINITION LIST .......................... 333

A.6 FUNCTION SPECIFICATIONS ................................................ 338

A.7 RESOURCES REQUIRED FOR EACH FUNCTION ................ 344

www.hongdiancnc.com

(SUBJECT VALUE) .................................................................. 315

(SUBJECT VALUE) .................................................................. 316

A.6.1 CncAppClient Function Specifications ......................................... 338

A.6.2 CncAppClient Notification Message ............................................. 342

A.7.1 For PANEL iH .............................................................................. 344

A.7.1.1 Memory usage in the iHMI basic functions ........................... 344

A.7.1.2 Amount of memory that can be used in the MTB application 345

A.7.2 For PANEL iH Pro ........................................................................ 345

A.7.2.1 Memory usage in the iHMI basic functions ........................... 346

A.7.2.2 Memory usage in option functions ........................................ 347

A.7.2.3 Amount of memory that can be used in the MTB application 347

c-8

www.hongdiancnc.com

Page 17

1

1

OVERVIEW

This chapter describes the overview of an environment required to set up the

iHMI and customization.

1.1 iHMI SETUP OVERVIEW ........................................................................ 2

1.2 iHMI MAINTENANCE OVERVIEW......................................................... 12

2

3

4

5

A

www.hongdiancnc.com

www.hongdiancnc.com

Page 18

1

2

3

B-64647EN/01

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

1.1

1.1 iHMI SETUP OVERVIEW

The iHMI allows you to customize iHMI applications and add your custom

applications to the Home screen. There are two types of hardware, FANUC

PANEL iH and FANUC PANEL iH Pro, both of which allow application

customization.

1.1.1 Setup Overview

1.1.1

The iHMI provides the following customization methods according to the machine

equipped with the iHMI or the way of using the operator.

4

5

6

7

8

A1

A2

1.1.1.1 Customizing applications registered with the iHMI

1.1.1.1

Customize each iHMI application. The following shows customization examples:

Status icon/Home screen

You can add an icon to the status at the top of an iHMI application or change the

background color of the Home screen.

Fig. 1.1.1.1 (a) Adding a Status Icon

www.hongdiancnc.com

Z

Fig. 1.1.1.1 (b) Changing the Background of the Home Screen

2

www.hongdiancnc.com

Page 19

B-64647EN/01

Tool Data

+iHMI

Tool Manager

Database

Data loading

Select and group tools

Data storing

Tool library

software

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

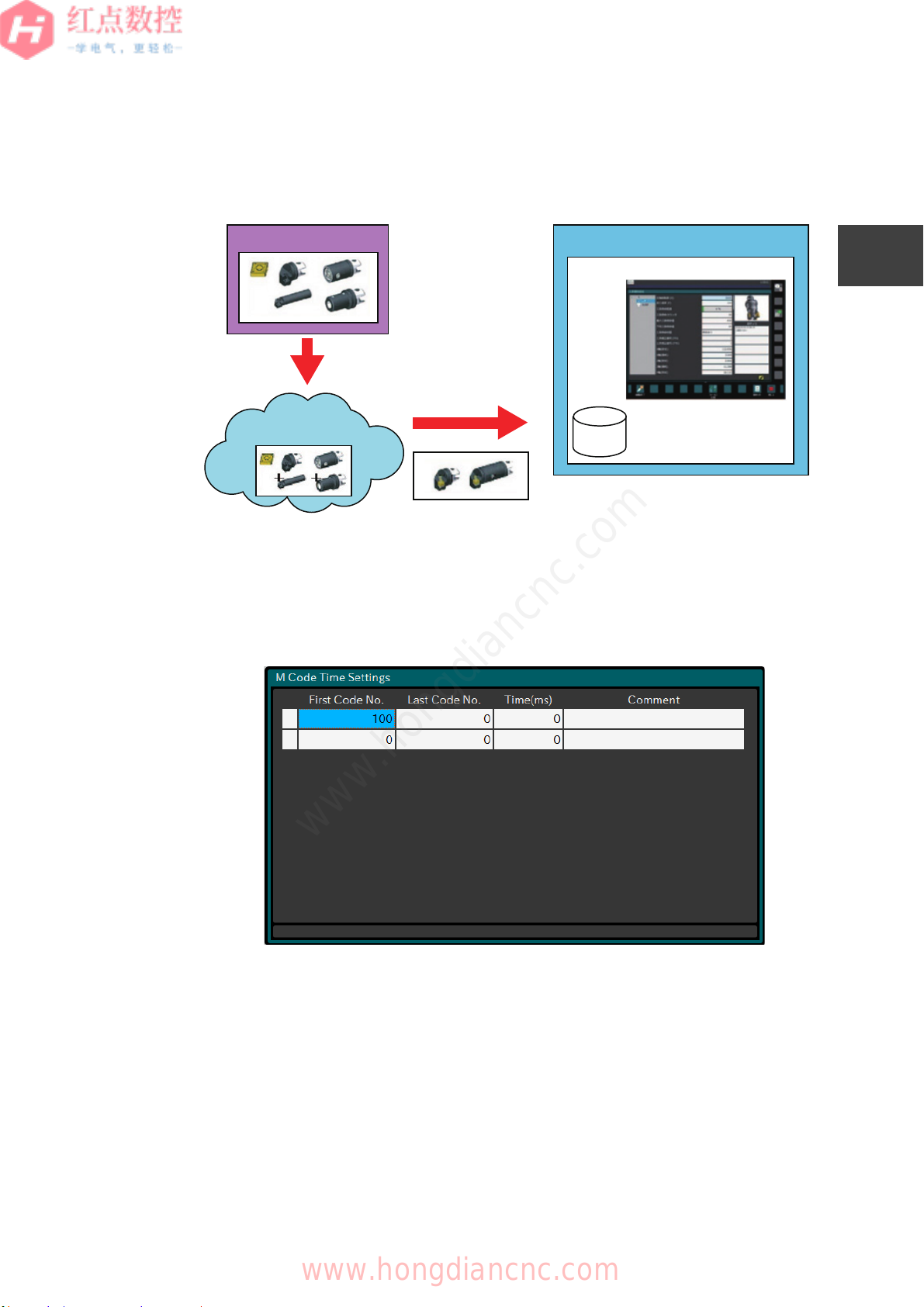

Tool Manager

The Tool Manager allows you to set the options and parameters required for using

the functions and import catalog data.

1

2

3

4

Fig. 1.1.1.1 (c) Flow of Importing Tool Data

Cycle Time Estimation

The Cycle Time Estimation allows you to set the auxiliary function time.

www.hongdiancnc.com

Fig. 1.1.1.1 (d) Auxiliary function time settings

5

6

7

8

A1

A2

Z

www.hongdiancnc.com

3

Page 20

1

Define a

machine model.

Tool definition

VERICUT

2

3

4

B-64647EN/01

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

CNC Operation Screen

The CNC operation screen allows you to configure the settings required for using

the functions. You can also register images to a program.

5

6

7

8

A1

A2

Z

Fig. 1.1.1.1 (e) CNC Operation Screen

Machine Collision Avoidance

The machine collision avoidance allows you to register machine 3D model data

and set the parameters.

www.hongdiancnc.com

Fig. 1.1.1.1 (f) Registering 3D Model Data

4

www.hongdiancnc.com

Page 21

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

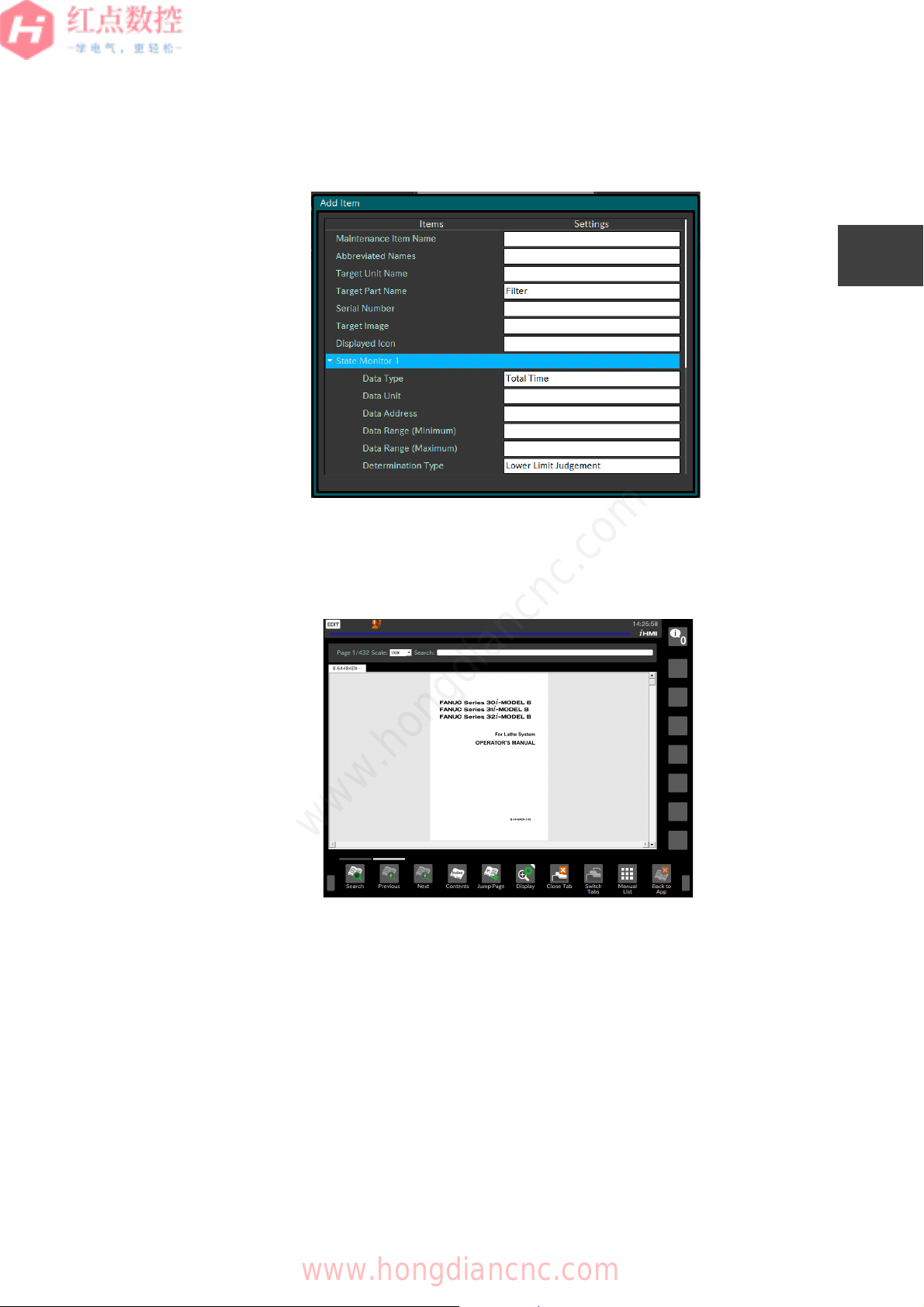

Maintenance Manager

The Maintenance Manager allows you to set the maintenance items.

B-64647EN/01

1

2

3

4

Fig. 1.1.1.1 (g) Setting the Maintenance Items

Manual Viewer

The manual viewer allows you to add a manual and specify whether to protect it.

www.hongdiancnc.com

Fig. 1.1.1.1 (h) Manual Viewer

5

6

7

8

A1

A2

Z

For details on how to customize each application, see " Chapter 2 SETTING UP

iHMI APPLICATIONS ".

5

www.hongdiancnc.com

Page 22

B-64647EN/01

iHMI Home Screen customization example

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

1.1.1.2 Overall iHMI settings

1.1.1.2 -

You can configure the overall iHMI settings. The following shows customization

examples:

1

2

3

4

5

6

7

Adding an Application

You can add an application to the Home screen and start the application.

Fig. 1.1.1.2 (a) Adding an Application

In addition, the following applications can be added to the Home screen:

8

A1

A2

Z

● Applications created with FANUC PICTURE

You can create a machine operator's panel screen using FANUC PICTURE.

www.hongdiancnc.com

Fig. 1.1.1.2 (b) Custom Screen

6

www.hongdiancnc.com

Page 23

B-64647EN/01

Maintenance Manager

Display the last used

application

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

● Custom applications created using C++ or C# (user applications)

You can create a screen using the FOCAS2 library, which allows you to obtain

and set NC information, or the iHMI library, which can control iHMI applications.

1

2

3

4

Fig. 1.1.1.2 (c) User application

For the PANEL iH Pro, you can add general applications, as well as the above

applications. In addition, a small-size iHMI application can be displayed above an

MEMO

application created with the display unit size.

Registering a shortcut key

You can use the shortcut to start an application specified with the function key.

www.hongdiancnc.com

5

6

7

8

A1

A2

Z

Fig. 1.1.1.2 (d) Registering a shortcut key

For details on how to customize, see "2.2 CONFIGURATION FILES THAT

AFFECT THE ENTIRE iHMI" and "3.3 CUSTOMIZING A SCREEN WITH FANUC

PICTURE".

7

www.hongdiancnc.com

Page 24

B-64647EN/01

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

1.1.2 Environment Required for iHMI Customization

1.1.2

This section describes an environment required for iHMI customization.

1

2

3

4

5

6

7

8

1.1.2.1 User application

1.1.2.1

The machine manufacturers can use the SDK and libraries when creating their

own iHMI application.

For PANEL iH Pro

To create an application that runs on the PANEL iH Pro, the following environment

is required.

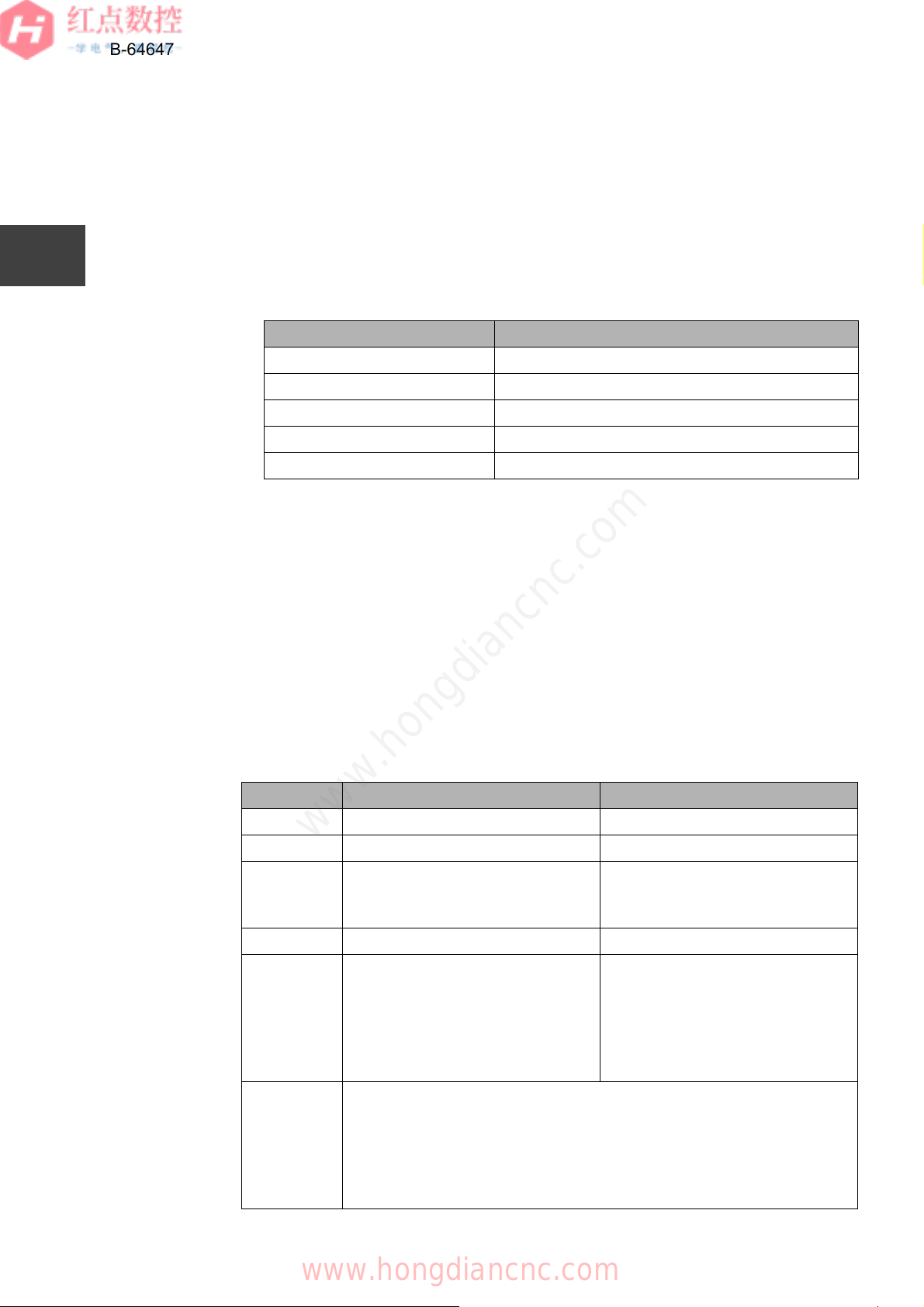

Table 1.1.2.1 (a) Environment Required to Create an Application That Runs on the

PANEL iH Pro

Item Description

Operating system (OS) Microsoft Windows 7 or Microsoft Windows 8

Professional

Memory 1 GB or more (2 GB or more is recommended)

Available hard disk capacity 4.7 GB or more

Display unit resolution 1024 x 768 or higher (1280 x 1024 or higher is

recommended)

Required application • Microsoft Visual Studio 2008 Professional or

Team Editions

• Microsoft Visual Studio 2008 Service Pack 1

A1

A2

Z

You can create an application using the develop languages C/C++, C#, and Visual

Basic .NET.

You can use the following libraries included in "CNC Application Development Kit"

(A08B-9010-J555#ZZ12) as necessary. The libraries can be used in Visual Studio

2008 or later.

• FOCAS2 library

• iHMI library

For PANEL iH

To create an application that runs on the PANEL iH, the following environment is

required.

Table 1.1.2.1 (b) Environment Required to Create an Application That Runs on

www.hongdiancnc.com

the PANEL iH

Item Description

Operating system (OS) Microsoft Windows 7 or Microsoft Windows 8

Professional

8

www.hongdiancnc.com

Page 25

B-64647EN/01

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

Item Description

Memory 1 GB or more (2 GB or more is recommended)

Available hard disk capacity 4.7 GB or more

Display unit resolution 1024 x 768 or higher (1280 x 1024 or higher is

recommended)

Required application • Microsoft Visual Studio 2008 Professional or

Team Editions

• Microsoft Visual Studio 2008 Service Pack 1

• Visual Studio 2008 update for Windows

Embedded Compact 7

• Windows Embedded Compact 7 ATL Update for

Visual Studio 2008 SP1

• FANUC SDK for Windows Embedded Compact 7

(*1)

*1: You can create an application using the develop languages C/C++, C#, and

Visual Basic .NET included in "iHMI Application SDK for PANEL iH" (A08B9110-J713#ZZ11).

1

2

3

4

5

You can use the following libraries included in "iHMI Application SDK for PANEL

iH" (A08B-9110-J713#ZZ11) as necessary.

• Standard library (FISLIB)

• FOCAS2 library

• iHMI library

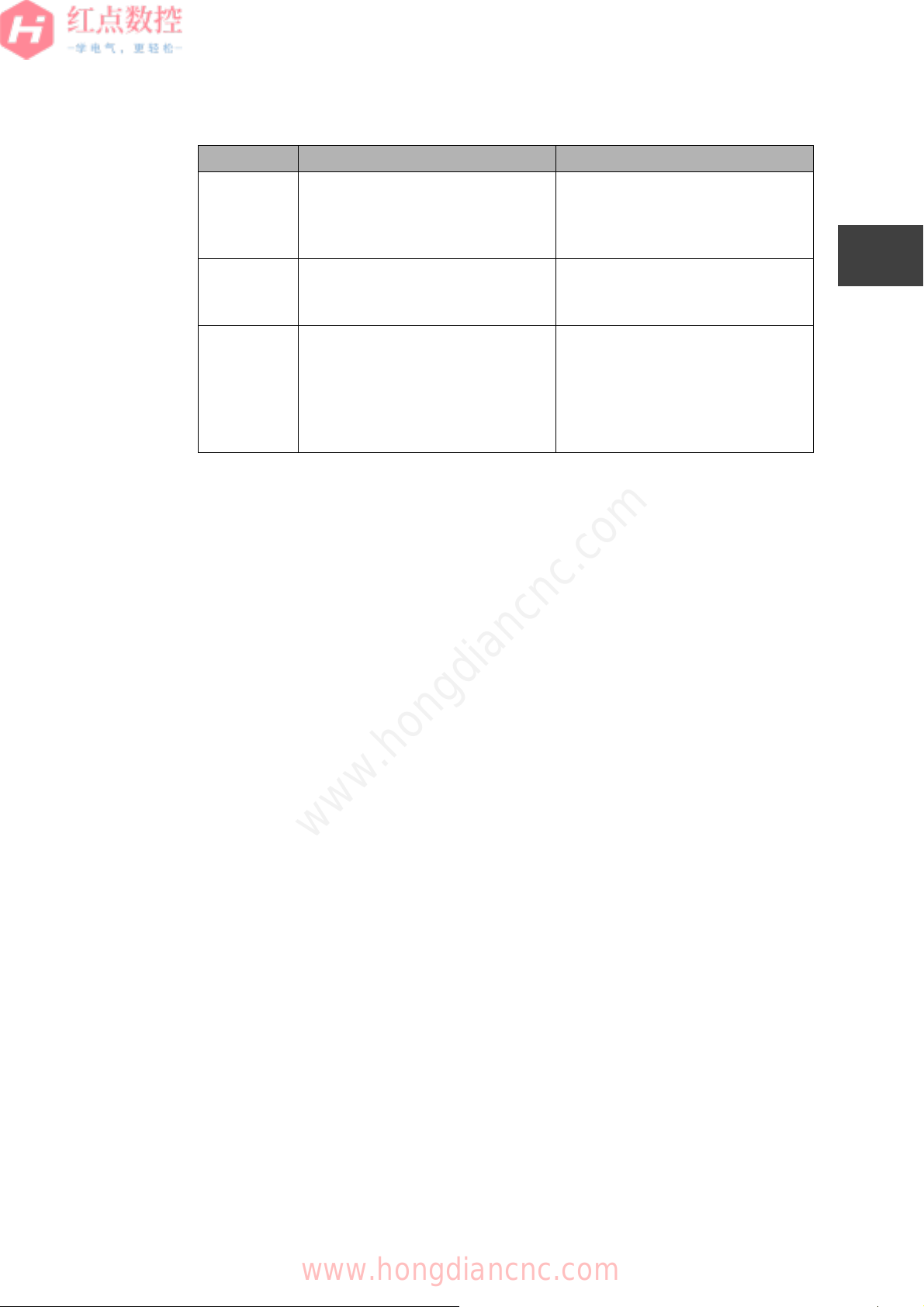

1.1.2.2 FANUC PICTURE

1.1.2.2

To create a screen using FANUC PICTURE, the following environment is required.

Table 1.1.2.2 Environment Required for FANUC PICTURE

www.hongdiancnc.com

Item Description

Operating system (OS) Microsoft Windows 7, Microsoft Windows 8, or

Memory 4 GB or more

Available hard disk capacity 64MB or more

Display unit resolution 1280 x 960 or higher

Peripheral device CF card, USB flash drive

Required application Internet Explorer (version 9.0 or later)

6

7

8

A1

A2

Microsoft Windows 10

Z

For both PANEL iH Pro and PANEL iH, software included in "CNC Application

Development Kit" (A08B-9010-J555#ZZ12) is used to create a screen.

9

www.hongdiancnc.com

Page 26

B-64647EN/01

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

1.1.2.3 Machine alarm diagnosis guidance table

1.1.2.3

The machine alarm diagnosis guidance table allows you to create alarm diagnosis

function data in the iHMI Information Center. To use the machine alarm diagnosis

guidance table, the following environment is required.

1

2

3

4

5

6

7

Table 1.1.2.3 Environment Required for Machine Alarm Diagnosis Guidance

Table

Item Description

Operating system (OS) Microsoft Windows 7 or Microsoft Windows 8

Memory 1GB or more

Available hard disk capacity 128MB or more

Peripheral device CF card, USB flash drive

Required application Microsoft Excel 2007 or Microsoft Excel 2010

The machine alarm diagnosis guidance table is included in both "CNC Application

Development Kit" (A08B-9010-J555#ZZ12) and "iHMI Application SDK for PANEL

iH" (A08B-9110-J713#ZZ11).

1.1.3 iHMI Hardware Performance Table

1.1.3

There are two types of hardware, FANUC PANEL iH and FANUC PANEL iH Pro.

The performance of each type is as follows:

8

A1

A2

Z

Table 1.1.3 Performance of PANEL iH and PANEL iH Pro

Item PANEL iH PANEL iH Pro

OS Windows Embedded Compact 7 Windows Embedded Standard 7

CPU ARM Core i

General

Windows

application

Shutdown Not required Required

Memory Main memory: 1 GB

Display 10.4 inch color TFT LCD (800 x 600),

www.hongdiancnc.com

None Can be used after operation is

verified

SSD type

File memory: 2 to 16 GB compact

flash card

16.0 inch color TFT LCD (1024 x 768), or

19.0 inch color TFT LCD (1280 x 1024)

32-bit full color

MDI keys (QWERTY layout, ONGP layout)

Soft keys or touch panel

C drive (13 GB)

D drive (All areas after C drive)

HDD type

C drive (500GB)

D drive (None)

10

www.hongdiancnc.com

Page 27

B-64647EN/01

CHAPTER 1 OVERVIEW

1.1 iHMI SETUP OVERVIEW

Item PANEL iH PA NEL iH Pro

Ports PCMCIA x 1 (*1)

Ethernet (10BASE-TX)

USB2.0 x 2

Serial port (RS-232C) x 2 (*2)

OS standard

software

Software

provided by

FANUC

*1 Only the PC card provided by FANUC can be used.

*2 For the display integrated unit, the ports are shared with the CNC. While they

are used by the CNC, applications cannot be used.

Internet Explorer 7 for Windows

Embedded

.NET Compact Framework 3.5

HSSB driver

MDI key driver

FOCAS2 library

iHMI (including the CNC screen

display function)

PCMCIA x 1

Ethernet (100BASE-TX)

USB2.0 x 4

Serial port (RS-232C) x 2

Internet Explorer 8.0

Windows Media Player 12.0

.NET Framework 2.0/3.0/3.5/4.5

HSSB driver

MDI key driver

Hardware monitoring driver

FOCAS1/2 library

iHMI (including the CNC screen

display function)

1

2

3

4

5

6

www.hongdiancnc.com

7

8

A1

A2

Z

11

www.hongdiancnc.com

Page 28

1

2

3

4

B-64647EN/01

CHAPTER 1 OVERVIEW

1.2 iHMI MAINTENANCE OVERVIEW

1.2

1.2 iHMI MAINTENANCE OVERVIEW

The iHMI maintenance functions include the iHMI batch backup function, which

saves all data files created with the iHMI function and general data created by the

machine manufacturer or users to an external device. For details, see

BACKUP/RESTORE".

In addition, you can update the software by updating the iHMI basic function

software. For details, see

"4.3 HOW TO UPDATE THE SOFTWARE".

"4.1 DATA

5

6

7

8

A1

A2

Z

www.hongdiancnc.com

12

www.hongdiancnc.com

Page 29

SETTING UP iHMI

1

2

APPLICATIONS

This section describes how to set up each iHMI application.

2.1 iHMI APPLICATION SETUP OVERVIEW ............................................ 14

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI ............. 17

2.3 SETTING UP BASIC FUNCTIONS ........................................................ 27

2.4 SETTING UP THE PLANNING APPLICATION...................................... 54

2.5 SETTING UP THE MACHINING APPLICATION.................................... 62

2.6 SETTING UP THE IMPROVEMENT APPLICATION............................ 159

2.7 SETTING UP THE UTILITY APPLICATION......................................... 173

2.8 CREATING PROGRAM STORAGE FILES .......................................... 181

2

3

4

5

A

www.hongdiancnc.com

www.hongdiancnc.com

Page 30

B-64647EN/01

//CNC_MEM

SYSTEM

MTB1

MTB2

USER

PATH1

LIBRARY

Program storage memory

inside the CNC

(5) System folder

(4) Folder 1 (dedicated to

machine manufacturer)

(3)Folder 2 (dedicated to

machine manufacturer)

(2) Common program

folder

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.1 iHMI APPLICATION SETUP OVERVIEW

2.1

2.1 iHMI APPLICATION SETUP OVER-

VIEW

1

2

3

4

5

6

7

8

A1

You can customize the functions of iHMI applications, add applications to the

Home screen, and change the background.

2.1.1 iHMI Folder Configuration

2.1.1

iHMI application folder

iHMI applications are stored in the following locations. (These folders may be

described as "%APPPATH%" in this document.)

For PANEL iH

\Storage Card\FANUC\iHMI

For PANEL iH Pro

C:\Program Files (x86)\FANUC\iHMI

iHMI data folder

iHMI data are stored in the following locations. (These folders may be described

as "%APPDATA%" in this document.)

For PANEL iH

\Storage Card2\FANUC\iHMI

For PANEL iH Pro

For PANEL iH Pro (SSD): D:\FANUC\iHMI

For PANEL iH Pro (HDD): C:\ProgramData\FANUC\iHMI

A2

Z

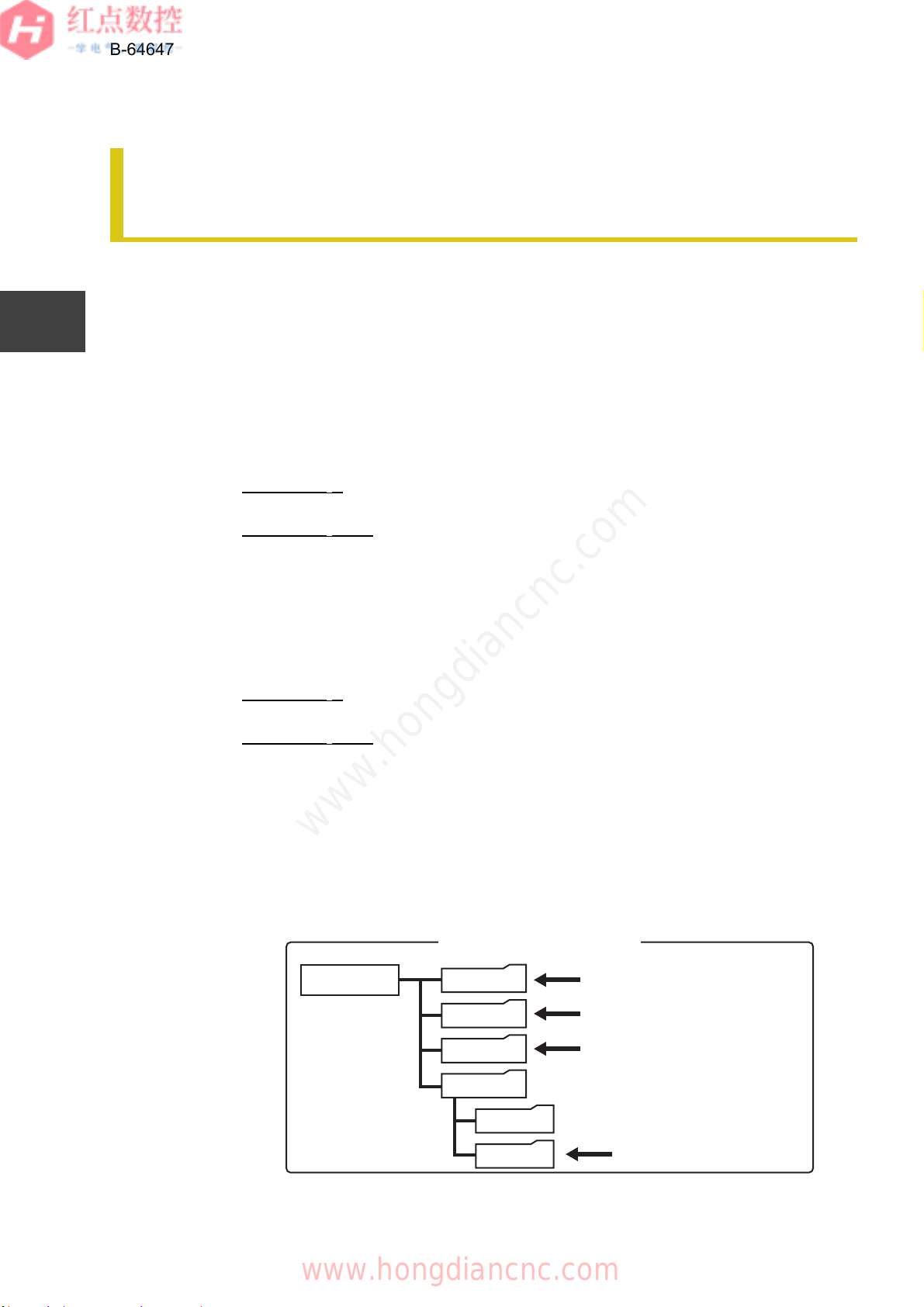

2.1.1.1 Folder configuration inside the CNC

2.1.1.1

The folder configuration inside the CNC is shown below. Data required for each

customization are stored the folders (3) and (4).

www.hongdiancnc.com

Fig. 2.1.1.1 Folder configuration inside the CNC

www.hongdiancnc.com

14

Page 31

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.1 iHMI APPLICATION SETUP OVERVIEW

• With the parameter (No. 3457), you can set whether to enable searching in the

MEMO

folders (2) to (5) shown in the figure above. For details about the parameters,

see "FANUC Series 30i/31i/32i-MODEL B PARAMETER MANUAL" (B64490EN).

1

2.1.2 Customizable Applications

2.1.2

The following shows customizable iHMI applications:

Table 2.1.2 Application List

Application name Customization overview Icon

Tool Manager Allows you to add a function to manage tool

information required at production sites.

Cycle Time Estimation

(Option)

NC OPERATION Allows you to edit, change setups, and

Machine Collision

Avoidance (Option)

Lathe Conversation

(Option)

www.hongdiancnc.com

Data Logger Allows you to import/export logs collected with

Allows you to set an auxiliary function time to

estimate an accurate cycle time.

execute programs in the CNC screen.

Allows you to set signals to be used while the

machine collision avoidance function is being

executed.

Allows you to create an NC program only by

entering blank and part geometries and

determining a machining process.

For details, see "FANUC Interactive

Programming Function for Complex Lathe

OPERATOR'S MANUAL" (B-64654EN).

the data logger function.

2

3

4

5

6

7

8

A1

A2

Z

Maintenance Manager Allows you to switch the display of manage

maintenance information, such as consumable

life management and abnormality detection,

and to output switching settings.

Manual Viewer Allows you to import manual information.

15

www.hongdiancnc.com

Page 32

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.1 iHMI APPLICATION SETUP OVERVIEW

Application name Customization overview Icon

WEB BROWSER Allows you to set the start page of the Web

browser.

1

2

3

4

5

6

7

Maintenance Display Displays the conventional NC screen.

For details, see "CNC Screen Display Function

OPERATOR'S MANUAL" (B-63164EN).

8

A1

A2

Z

www.hongdiancnc.com

16

www.hongdiancnc.com

Page 33

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

2.2

2.2 CONFIGURATION FILES THAT

AFFECT THE ENTIRE iHMI

B-64647EN/01

Configuration files that affect the entire iHMI are of three types such as:

• Application definition file (XML file)

• iHMI whole configuration file (XML file)

• File for individual settings common to the applications (INI format file)

2.2.1 Application Definition File

2.2.1

The application definition file (apps-general.xml) is stored in the iHMI data folder

(%APPDATA% folder). By changing this file, the following operations can be

performed.

- Adding an application to the Home screen

- Changing the initial display screen after power-on

- Changing the Home screen

Adding an application to the Home screen

Add the following description of the <entry> tag to the application definition file.

1

2

3

4

5

6

7

<entry>

<name>CNC</name>

<category>Machining</category>

<caption>

<en>CNC</en>

<ja>CNC</ja>

</caption>

<file>%APPPATH%\NcOperation\NcOperation.exe</file>

<image>%APPPATH%\Resources\NcOperation.svg</image>

</entry>

The following are details of the descriptions between the <entry> and </entry>

tags.

XML tag Description

<name> Identifier ID (Set not to be duplicated)

<category> Category where the application belongs (select Planning, Machining,

<caption> Application name displayed in the Home screen

<file> Absolute path of the application execution file (exe)

www.hongdiancnc.com

Table 2.2.1 (a) Description in the <entry> Tag

Improvement, or Utility)

8

A1

A2

Z

<image> Absolute path of the application icon file (png, bmp, svg)

17

www.hongdiancnc.com

Page 34

1

2

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

XML tag Description

<current> Current path of the application

<parameters> Parameters passed when the application is started

<subject> Character string (up to 63 characters, nullable) passed when the

application is called.

The following options can be set for the <entry> tag.

Table 2.2.1 (b) Description of Each Option

3

4

5

6

7

8

A1

A2

Option Description

startup Starts the application when Application Manager is started.

nomenu Does not display the application on the Home screen menu.

waitregister Starts the application in synchronization with Application

Manager.

alwaysvisible Does not hide the application even if it goes to background.

The application name can be described in each language by adding the following

<[language]> tag to the <caption> tag.

Table 2.2.1 (c) Languages Used in the <[language]> Tag

<[language]>

Tag

<en> English <da> Danish <bg> Bulgarian

<ja> Japanese <pt> Portuguese <ro> Romanian

<de> German <pl> Polish <sk> Slovak

<fr> French <hu> Hungarian <fi> Finnish

<cht>

<it> Italian <cs> Czech <id> Indonesian

Language name

Traditional

www.hongdiancnc.com

Chinese

<[language]>

Tag

<sv> Swedish <vi> Vietnamese

Language name

<[language]>

Tag

Language name

Z

<ko> Korean <chs>

<es> Spanish <ru> Russian

<nl> Dutch <tr> Turkish

An application is added to the Home screen by adding the <entry> tag description

to the XML file.

Changing the initial display screen after power-on

Set the value of the <name> tag for an application you want to display as the initial

display screen to the "first" option of the <apps> tag.

Example:

18

Simplified

Chinese

<sl> Slovene

www.hongdiancnc.com

Page 35

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

<apps first=" CNCOPERA ">

Changing the Home screen

Set the value of the <name> tag for an application you want to display as the

Home screen to the "home" option of the <apps> tag.

Example:

1

<apps home=" MainMenu ">

2.2.1.1 Starting an application with a screen specified

2.2.1.1

2.2.1.2 Starting iHMI applications from shortcuts

2.2.1.2

To start an application with a screen specified, add the <subject> tag. For subject

values that can be specified in the CNC operation screen and maintenance

display, see "

and ""A.3 MAINTENANCE DISPLAY SWITCHING ID (subject VALUE)"".

You can add multiple <subject> tags with different values to one application. In

such a case, the <name> tags must have the same value.

MEMO

You can start specified applications from the shortcuts on iHMI. The following

shortcut startup settings are available.

• Starting applications from the shortcuts

• Registering multiple shortcut keys

"A.2 CNC OPERATION SCREEN SWITCHING ID (subject VALUE)""

2

3

4

5

6

7

8

• Disabling the shortcut function for specific applications

www.hongdiancnc.com

Screen transition

When you press a shortcut key, an application registered to the shortcut starts up.

Pressing the shortcut key again displays the last used application.

Example: Shortcut key: <CUSTOM1> key, shortcut application: "Maintenance

Manager"

A1

A2

Z

19

www.hongdiancnc.com

Page 36

1

Maintenance Manager

Display the last used

application

Start the shortcut application

2

3

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

4

5

6

7

8

A1

A2

Z

Fig. 2.2.1.2 Screen transition

An application with the shortcut function disabled is not switched to another as

shown above.

NOTE

How to define a shortcut key

You can define a shortcut key by adding a shortcut definition to the configuration

file (apps-general.xml).

Add the <shortcuts> tag below the <apps> tag in the configuration file. Put

shortcut key information between <shortcuts> and </shortcuts>. Shortcut key

information needs to be provided in the <entry> tag for each shortcut key added.

The following is a list of tags included between <shortcuts> and </shortcuts>.

www.hongdiancnc.com

Table 2.2.1.2 Description in the <shortcuts> tag

XML tag Requir

ed

<entry> ○ <key>

Child

element

<name>

<subject>

Description

Put shortcut information.

You can add the invalidname attribute.

invalidname: Specify the identifier ID of an

application for which you want to disable the

shortcut. If you want to disable the shortcut

function for more than one application, separate

the IDs by ",".

www.hongdiancnc.com

20

Page 37

B-64647EN/01

NOTE

• The <POS> key cannot be selected

because it is used for Information

Center display.

• If you select keys other than the

above, the definition will be invalid.

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

XML tag Requir

ed

<key> ○ None Specify a shortcut key.

<name> ○ None Application identifier ID.

Child

element

Description

The following are the keys that can be specified

as a shortcut:

PROG: <PROG> key

OFFSET: <OFFSET> key

MESSAGE: <MESSAGE> key

SYSTEM: <SYSTEM> key

GRAPH: <GRAPH> key

CUSTOM1: <CUSTOM1> key

CUSTOM2: <CUSTOM2> key

Enter the identifier ID of an application you want

to display when pressing the shortcut key

specified in <key>.

1

2

3

4

5

6

<subject> × None Character string (up to 63 characters, nullable)

passed when the application is called.

Description example of the configuration file

The following shows a description example of apps-general.xml for executing the

following operations.

• "App02" is displayed when the <PROG> function key is pressed.

• "App03" is displayed when the <CUSTOM1> function key is pressed. While

"App01" is displayed, the shortcut is disabled.

www.hongdiancnc.com

7

8

A1

A2

Z

21

www.hongdiancnc.com

Page 38

1

2

3

4

5

6

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

<?xml version="1.0" encoding="UTF-16"?>

<apps home="MainMenu" info="AppMgr">

<entry>

<name>App01</name>

...

</entry>

<entry>

<name>App02</name>

...

</entry>

<entry>

<name>App03</name>

...

</entry>

<shortcuts>

<entry>

<key>PROG</key>

<name>App02</name>

<subject>open,Main</ subject >

</entry>

<entry invalidname="App01">

<key>CUSTOM1</key>

<name>App03</name>

</entry>

</shortcuts>

</apps>

Add <PROG> to

shortcut key

Add <CUSTOM1> to

shortcut key

7

8

A1

A2

Z

2.2.2 iHMI Whole Configuration File

2.2.2

You can change the settings for startup, and the display position and size of an

iHMI application by modifying the XML file (settings.xml).

Startup settings for an iHMI application

You can change the startup settings for an iHMI application by modifying the XML

file (settings.xml) stored in the %APPPATH% folder.

The XML file has the following description, and you can change the settings by

modifying the description.

<settings>

...

<time>

<sync>yes</sync>

<timeout>0.0</timeout>

</time>

<display taskbar="hide"/>

</settings>

www.hongdiancnc.com

22

www.hongdiancnc.com

Page 39

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

The following describes tag descriptions.

Table 2.2.2 (a) Description in the Tags

XML tag Description

<time> Time settings

<sync> If "yes" is set, the application is synchronized with the NC.

B-64647EN/01

1

<timeout> Set the timeout time when the application is started.

<display> Display settings. If taskbar="hide" is set, the taskbar is hidden.

Setting the display position and size of an iHMI application

You can change the display position and size of an iHMI application by modifying

the XML file (settings-general.xml) stored in the iHMI data folder (%APPDATA%

folder).

The XML file has the following description, and you can change the settings of the

display position and size by modifying the description.

<settings>

...

<display>

<inchx10>150</inchx10>

<x>0</x>

<y>0</y>

</display>

</settings>

The following describes tag descriptions.

2

3

4

5

6

7

8

Table 2.2.2 (b) Description in the Tags

XML tag Description

<display> Display settings.

<inchx10> Set the application display size. The value is ten times the display size

<x> Set the application display position (x-coordinate on the upper left

<y> Set the application display position (y-coordinate on the upper left

www.hongdiancnc.com

(select 104, 150, or 190).

corner).

corner).

A1

A2

Z

23

www.hongdiancnc.com

Page 40

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

2.2.3 Individual Settings Common to the Applications

2.2.3

You can make settings common to the applications.

1

2

3

4

5

6

7

8

2.2.3.1 Hiding the vertical soft keys

2.2.3.1

The screen can be configured so that the vertical soft keys are hidden when an

application starts up. If you set the vertical soft keys to be hidden, the display area

of the main screen will be expanded to the full horizontal width.

Fig. 2.2.3.1 (a) Hiding the vertical soft keys

In this case, a slide cannot be displayed. The slide can be displayed by receiving a

notification from outside of an application.

On the slide, the display area size is the same as that for when the vertical soft

keys are set to be displayed. Note, however, that the slide is centered in the

screen horizontal direction.

A1

A2

Z

www.hongdiancnc.com

Fig. 2.2.3.1 (b) Hiding the vertical soft keys (slide)

Configuration file

Values loaded from the configuration file at application startup determine whether

to display or hide the vertical soft keys.

24

www.hongdiancnc.com

Page 41

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

The configuration file is prepared for each application and loaded at application

startup.

In the configuration file, you can describe whether to show/hide the vertical soft

keys. If you make settings to show the soft keys, the screen will be configured to

display the vertical soft keys. If you make settings to hide the keys, the screen will

be configured not to display the vertical soft keys. By default, the soft keys are set

to be shown.

The vertical soft keys are displayed when:

• Incorrect setting values are described.

• The setting item of whether to use the vertical soft keys is not described.

MEMO

• No configuration file is present.

The configuration file specifications are as follows.

1

2

3

4

Table 2.2.3.1 Configuration file specifications

Item Description

Path %APPDATA%\MTB\Application name\Setting\setting_data.txt

Format Windows INI file format

* The INI file is a file where various settings of Windows

applications are saved.

Section name VSoftKey_104

Key name USE_VSOFTKEY

Value (displayed) YES

Value (hidden) NO

Description example:

[VSoftKey_104]

USE_VSOFTKEY=YES

• Displaying or hiding the vertical soft keys will be determined at startup. This

NOTE

cannot be changed after startup.

www.hongdiancnc.com

5

6

7

8

A1

A2

Z

2.2.3.2 Setting an animation to be used when a slide is displayed

2.2.3.2

In the configuration application and configuration file, you can set whether to use

an animation when a slide is displayed.

The settings of the configuration file are prioritized over those of the configuration

application.

25

www.hongdiancnc.com

Page 42

1

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.2 CONFIGURATION FILES THAT AFFECT THE ENTIRE iHMI

The settings of the configuration application are reflected when:

• Incorrect setting values are described in the configuration file.

• The setting item is not described in the configuration file.

MEMO

• No configuration file is present.

2

3

4

5

6

7

8

A1

A2

The configuration file specifications are as follows.

Table 2.2.3.2 Configuration file specifications

Item Description

Path %APPDATA%\MTB\Application name\Setting\setting_data.txt

Format Windows INI file format

* The INI file is a file where various settings of Windows

applications are saved.

Section name Slide_screen

Key name ANIMATION

Value (used) ON

Value (not used) OFF

Description example:

[Slide_screen]

ANIMATION=ON

• The setting of whether to use an animation set in the configuration file will be

MEMO

determined at startup. This cannot be changed after startup. If settings are

made in the configuration file, any setting change in the configuration

application will be ignored.

www.hongdiancnc.com

Z

26

www.hongdiancnc.com

Page 43

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.3 SETTING UP BASIC FUNCTIONS

2.3

2.3 SETTING UP BASIC FUNCTIONS

You can: (1) change the background color of the Home screen; (2) add buttons to

application menus; and (3) add status icons to the iHMI status display area. Also,

you can additionally display failure diagnosis messages on the Information Center.

2.3.1 Customizing the Home Screen

2.3.1

2.3.1.1 Changing the background of the home screen

2.3.1.1

You can:

- Change the background of the Home screen.

- Add a shutdown button on the Home screen.

To change the background of the Home screen, add an image file (svg, png)

called "BG" to the following location.

B-64647EN/01

1

2

3

4

5

%APPDATA%\MTB\Home

Fig. 2.3.1.1 Changing the Background of the Home Screen

www.hongdiancnc.com

If there are multiple image files called "BG" in the folder, the priority of a file to be

used as the background is in order of svg and png. If there is no image file, the

default background is used.

2.3.1.2 Adding a shutdown button

2.3.1.2

For PANEL iH Pro, you can add a shutdown button on an application menu by

modifying the description of the XML file (settings-general.xml) stored in the

following location.

6

7

8

A1

A2

Z

%APPDATA%\settings-general.xml

Add the following tag in the <settings> tag of settings-general.xml.

27

www.hongdiancnc.com

Page 44

B-64647EN/01

Shutdown

button

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.3 SETTING UP BASIC FUNCTIONS

Table 2.3.1.2 (a) Tag to be included between <settings> and </settings>

XML tag Description

<home> Specify information related to the Home screen.

1

2

3

4

5

6

7

Table 2.3.1.2 (b) Tag to be included between <home> and </home>

XML tag Description

<shutdown> Specify whether to display or hide the shutdown button. If "show"

is specified, the shutdown button will be displayed on the

application menu. By default setting, the shutdown button is not

displayed.

Setting example:

<settings>

...

<home>

<shutdown>show</shutdown>

</home>

</settings>

8

A1

A2

Z

www.hongdiancnc.com

Fig. 2.3.1.2 Shutdown button

• For shutdown button operation, see "FANUC iHMI Home Screen OPERATOR'S

MEMO

MANUAL" (B-64644EN).

28

www.hongdiancnc.com

Page 45

CHAPTER 2 SETTING UP iHMI APPLICATIONS

Standard status

Additional icon display

Additional character string

display

Additional character string display

2.3 SETTING UP BASIC FUNCTIONS

2.3.2 Customizing the Status Display

2.3.2

You can add status icons to the iHMI status display area.

B-64647EN/01

2.3.2.1 Adding status icons and character string display

2.3.2.1

The iHMI status display area can include machine manufacturer specific icons,

such as coolant, interlock, and machine warnings. Also, machine specific

information, such as numeric value display for temperature, can be displayed. The

machine manufacturer-specific icon and character string displays can be switched

by the PMC bit signal or byte signal.

These display items are left-aligned on the right side of the standard status

display.

Fig. 2.3.2.1 (a) Status display (top row)

Alternatively, they appear left-aligned on the bottom row of the status display area

(for 15" or 19" displays).

1

2

3

4

5

6

7

Fig. 2.3.2.1 (b) Status display (bottom row)

www.hongdiancnc.com

To display icons or character strings, create an XML file (file name: status.xml)

and define the PMC signal and display items in this file.

Store the created XML file in the following location.

%APPDATA%

Maximum number of displayed items

The following table shows the width of the display area for each display unit size

and maximum number of displayed items per row (for display items of size 24 x 24

dots).

8

A1

A2

Z

www.hongdiancnc.com

29

Page 46

B-64647EN/01

CHAPTER 2 SETTING UP iHMI APPLICATIONS

2.3 SETTING UP BASIC FUNCTIONS

Table 2.3.2.1 (a) Maximum number of displayed items

1

2

3

4

5

6

7

8

A1

A2

Display unit size Width of display

area

10.4" 449 dots 16

15" 640 dots 23

19" 896 dots 32

Format of status.xml

The format of status.xml is as follows.

● </status/signals> tags

Specify PMC data to be displayed in the </status/signals> tags.

Table 2.3.2.1 (b) Description between the <signals> and </ signals> tags

XML tag, attribute Description

<pmc> tag Specify the PMC address for the input data.

Examples: 1:R1000, 3:R1000

name attribute Specify the input data name with a character string.

Examples: toolno, spload, etc.