Page 1

FANUC Series 0+-MODEL F

CONNECTION MANUAL (HARDWARE)

B-64603EN/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan is subject to an export license by the

government of Japan. Furthermore, the product may also be controlled by re-export

regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

The products in this manual are manufactured under strict quality control. However, when

using any of the products in a facility in which a serious accident or loss is predicted due to

a failure of the product, install a safety device.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

B-64603EN/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Described below are the safety precautions regarding the control units and those peripheral units

explained herein. The safety precautions must be observed in order to use these units safely.

Because exchanging, as well as performing daily maintenance operations on, the control units and those

peripheral units explained herein may incur diverse dangers, you cannot be involved in such work unless

you have been sufficiently trained for safety.

Some safety precautions may not apply to your control units or peripheral units explained herein because

the units have no corresponding function. If this is the case, skip reading those precautions.

As for safety precautions regarding machine tools, refer to the respective machine manuals provided by

the machine tool builders.

Before starting to operate machines for check purposes, be sure to read the manuals provided by the

machine tool builders and FANUC and sufficiently understand their descriptions.

Contents

DEFINITION OF WARNING, CAUTION, AND NOTE.........................................................................s-1

WARNINGS AND CAUTIONS REGARDING MOUNTING, WIRING, AND EXCHANGING..........s-2

WARNINGS AND CAUTIONS REGARDING DESIGNING.................................................................s-4

WARNINGS, CAUTIONS, AND NOTES REGARDING DAILY MAINTENANCE............................s-5

NOTE REGARDING KOREAN KC MARK ..........................................................................................s-5

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

SAFETY PRECAUTIONS B-64603EN/01

WARNINGS AND CAUTIONS REGARDING MOUNTING, WIRING, AND EXCHANGING

WARNING

1 Before starting mounting, wiring, and exchanging, be sure to shut off externally

supplied power. Otherwise, electrical shocks, breakdown, and blowout may

occur.

If a control unit is turned off but other units are not, it is likely that power may be

supplied to servo units, resulting in the units being damaged and workers getting

an electrical shock when the units are exchanged.

2 Voltage lingers in servo and spindle amplifiers for a while even after power has

been turned off, resulting in workers possibly getting an electrical shock when

the workers touch them. Before starting to exchange these amplifiers, wait for 20

minutes after power has been turned off.

3 Be sure to ground your control units and peripheral units in accordance with your

national grounding standards (protective grounding class C or stricter).

Otherwise, electrical shocks, breakdown, and blowout may occur.

4 In order to prevent damage that may be caused by static electricity, wear a

grounding wrist strap or take a similar protective measure before starting to

touch a printed-circuit board or unit or attach a cable.

Static electricity from human bodies can damage electrical circuits.

5 In unit replacement, specify the same settings and parameters in the newly

installed unit as those for the one removed. (For details, refer to the respective

manuals for the units.)

Operating the newly installed unit with incorrect settings or parameters will cause

the machine to behave unexpectedly, possibly leading to a damaged workpiece

or machine or injury.

6 If you notice an apparent hardware fault, such as abnormal noise, abnormal

odor, smoke, ignition, or abnormal heat, in the hardware while power is being

supplied to it, shut it off at once. These faults can cause fire, breakdown,

blowout, and malfunction.

7 The radiating fins of control units, servo amplifiers, spindle amplifiers, and other

devices can remain very hot for a while after power has been turned off, making

you get burned if you touch them. Before starting to work on them, wait and

make sure they are cool.

8 When exchanging heavy stuff, you should do so together with two or more

people.

If you try to exchange heavy stuff all by yourself, you may drop it and get hurt.

9 Wiring work in the control units and peripheral units must be done only after they

have been installed. Otherwise, electrical shocks can occur.

10 Be careful not to damage cables. Otherwise, electrical shocks can occur.

11 When working, wear suitable clothes with safety taken into account. Otherwise,

injury and electrical shocks can occur.

12 Do not work with your hands wet. Otherwise, electrical shocks and damage to

electrical circuits can occur.

s-2

Page 5

B-64603EN/01 SAFETY PRECAUTIONS

CAUTION

Failing to observe any caution stated below can lead to fire, breakdown, blowout,

and malfunction.

1 Do not attach the units directly to any flammable object or install the units near

any flammable object.

2 Do not allow any foreign matter (such as a screw, metal chip, or coolant) to get

in the units.

3 Handle the units and printed-circuit boards gently because they are precision

devices. Be careful not to drop them or give a high impact to them.

4 Lay signal wires away from power wires as stated in this manual.

5 When fastening each unit or wire, be sure to observe the screw tightening torque

specified for them. If screws are tightened too weakly or too strongly, it is likely

that the unit may drop, break, or malfunction, or the wire may be short-circuited.

Do not forget to tighten all necessary screw.

6 Do not block any cooling fan air inlet or outlet. For units having no cooling fan,

allow space for natural convection cooling above and below them.

7 Be careful not to make an incorrect wiring or connection. Be sure to attach wires

and cables to their respective corresponding terminals and connectors.

8 Confirm equipment’s electrical rating stated herein. Do not apply any unspecified

voltage to the equipment.

9 Do not confuse voltage polarity. Carefully confirm the arrangement of connector

pins.

10 When making a cable assembly, press-mount, crimp, or solder the wires, using

the tool specified by the cable manufacturer.

11 Use printed-circuit boards and peripheral units that match your control unit.

12 When mounting the units, pay attention to their mass.

13 When detaching a cable from a unit, hold the connector rather than the cable.

When attaching a cable, be sure to fit its connector to the connector pins

securely. For connectors having a lock mechanism, be sure to lock them

securely.

14 As for the shielding wires of the cables specified herein, securely ground them,

using, for example, cable clamps.

15 Always use wires whose length, diameter, heat resistance, and flex resistance

match their use.

s-3

Page 6

SAFETY PRECAUTIONS B-64603EN/01

WARNINGS AND CAUTIONS REGARDING DESIGNING

WARNING

1 When designing, be sure to observe all rules stated in this document and any

related manuals. Otherwise, it is likely that failure and malfunction may occur.

2 Failures in the control units and I/O units as well as input power abnormality and

communication failures can hamper the normal operation of these I/O units.

Design each I/O unit in such a way that the machine can operate safely, for

example, by providing an external safety circuit to the I/O unit so that no accident

will occur even if the I/O unit fails to operate normally.

The DO function of each I/O unit has been designed in such a way that, if a

system alarm is issued in the control unit that controls the I/O unit or the power

of the control unit or the I/O unit is turned off, the DO function of all the I/O units

is turned off. However, it is not guaranteed that the DO function is surely turned

off. So, it is requested that, if a signal regarding safety is involved, a safety circuit

external to each I/O unit must be configured. Using the dual check safety

function makes it possible to detect a single fault in a portion related to safety.

For details of the dual check safety function, refer to the FANUC Series

30i/31i/32i-MODEL B Dual Check Safety Connection Manual (B-64483EN-2).

3 Install each control unit, display unit, MDI unit, and machine operator panel in

such a place that neither cutting chip nor coolant will spatter to them. Otherwise,

damage or malfunction may occur.

4 Coolants containing sulfur or chlorine at a high activation level, oil-free coolants

called synthetic, and water-soluble coolants at a high alkali level, in particular,

can largely affect the CNC and peripheral units. Please note that, even if

consideration is taken to protect them from direct exposure to these coolants,

the following trouble is likely to occur.

Coolants containing sulfur or chlorine at a high activation level

•

Some coolants containing sulfur or chlorine are at an extremely high activity

level. If such a coolant adheres to the CNC or peripheral units, it reacts

chemically with a material, such as resin, of equipment, possibly leading to

corrosion or deterioration. If it gets in the CNC or peripheral units, it corrodes

metals, such as copper and silver, used as component materials, possibly

leading to a defective component.

Synthetic-type coolants having a high permeability

•

Some synthetic-type coolants whose lubricating component is, for example,

PAG (polyalkylene glycol) have an extremely high permeability. If such a

coolant is used even in equipment having a high closeness, it can readily flow

into the CNC or peripheral units through, for example, gaskets. It is likely that,

if the coolant gets in the CNC or a peripheral unit, it may deteriorate the

insulation and damage the components.

Water-soluble coolants at a high alkali level

•

Some coolants whose pH is increased using alkanolamine are so strong

alkali that its standard dilution will lead to pH10 or higher. If such a coolant

spatters over the surface of the CNC or peripheral unit, it reacts chemically

with a material, such as resin, possibly leading to corrosion or deterioration.

s-4

Page 7

B-64603EN/01 SAFETY PRECAUTIONS

WARNINGS, CAUTIONS, AND NOTES REGARDING DAILY MAINTENANCE

WARNING

Battery replacement

Do not replace batteries unless you have been well informed of maintenance

work and safety.

When opening the cabinet and replacing batteries, be careful not to touch any

high-voltage circuit (marked with

and covered with an electric shock

prevention cover).

When the electric shock prevention cover has been removed, you will get an

electric shock if you touch any high-voltage circuit.

WARNING

Fuse replacement

Before replacing a blown fuse, it is necessary to remove the cause of the blown

fuse.

So, do not replace fuses unless you have been well informed of maintenance

work and safety.

When opening the cabinet and replacing fuses, be careful not to touch any

high-voltage circuit (marked with

and covered with an electric shock

prevention cover).

When the electric shock prevention cover has been removed, you will get an

electric shock if you touch any high-voltage circuit.

CAUTION

Handle the batteries gently. Do not drop them or give a strong impact to them.

NOTE

Each control unit uses batteries, because it must hold data, such as programs,

offset values, and parameters even when AC power for it is off.

Back up the data (programs, offset values, and parameters) regularly.

If the battery voltage becomes low, a low battery voltage alarm is displayed on

the machine operator’s panel or screen.

Once the battery voltage alarm has been displayed, replace the batteries within

one week. Otherwise, the memory contents may be lost.

For the battery replacement procedure, see Section 4.4, “Batteries”. Recollect or

discard old batteries in the way your local autonomous community specifies.

NOTE REGARDING KOREAN KC MARK

NOTE

This equipment is industrial (Class A) electromagnetic wave suitability equipment

and seller or user should take notice of it, and this equipment is to be used in the

places except for home.

이 기기는 업무용(A급) 전자파적합기기로서 판 매자 또는 사용자는 이 점을 주의하시기 바라며

가정외의 지역에서 사용하는 것을 목적으로 합니다

s-5

.

,

Page 8

Page 9

B-64603EN/01 PREFACE

PREFACE

This manual describes the information, that is, electrical and structural specifications, needed in

connecting machine tools to the control and peripheral units stated below. The manual covers the range

shown on the total connection diagrams mentioned in Chapter 2. The manual briefly describes the units

that are used in common with the FANUC control units, such as FANUC I/O units, FANUC PANEL

and servo motors. It also gives supplementary information for use of these units with the control units.

For detailed specifications, refer to the manuals of these components.

For options not covered in this manual, also refer to the manuals of these components.

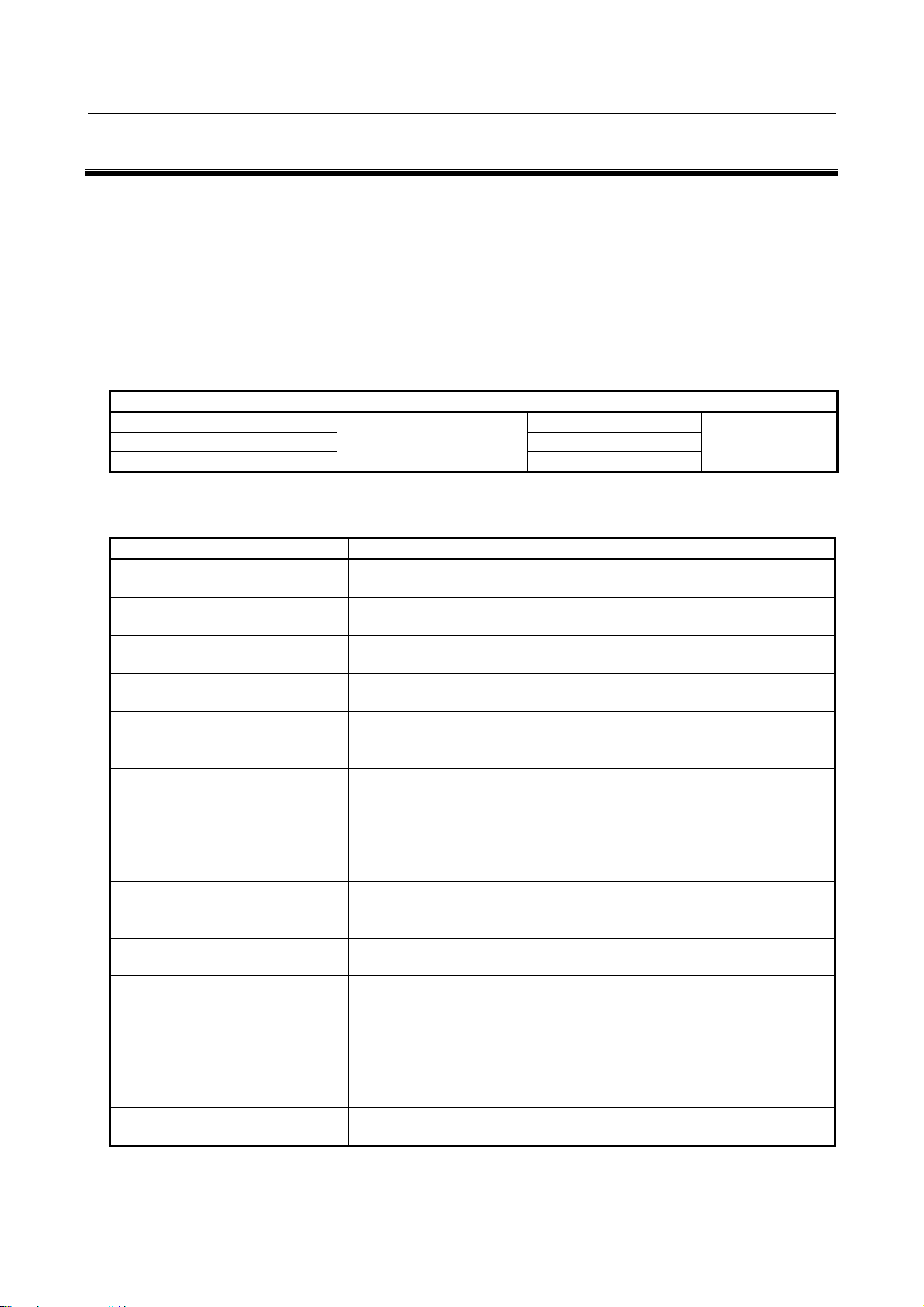

Applicable models

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 0i– TF 0i–TF

FANUC Series 0i– MF 0i–MF

FANUC Series 0i– PF

0i–F

0i–PF

Series 0i

Organization of this manuals

This manual consists of chapters 1 to 12 and appendixes at the end of the book.

Chapter and title Contents

Chapter 1

CONFIGURATION

Chapter 2

TOTAL CONNECTION DAIGRAMS

Chapter 3

INSTALLATION

Chapter 4

POWER SUPPLAY CONNECTION

Chapter 5

CONNECTION TO CNC

PERIOHERALS

Chapter 6

SERVO AND SPINDLE

INTERFACES

Chapter 7

CONNECTION TO FANUC I/O Link

i

Chapter 8

UNITS CONNECTED TO FANUC

I/O Link i

Chapter 9

STOP AND EMERGENCY STOP

Chapter 10

CONNECTION TO OTHER

NETWORKS

Chapter 11

CONNECTION WITH THE FANUC

PANEL i AND COMMERCIAL

PERSONAL COMPUTERS

Chapter 12

PANEL i

Provides general information related to the connection, as well as an

introduction to detailed information.

Describes how to connect peripheral units.

Describes the installation requirements for using.

Describes how to make connections related to the power supply.

Describes how to connect the peripheral devices.

Describes how to connect the 30i–B series to servo or spindle amplifiers.

Also explains how to connect separate detector interface units.

Describes how to connect machine interface I/O units using the FANUC I/O

Link i.

Describes major units that correspond to the FANUC I/O Link i.

Describes how to handle the emergency stop signal.

A lot of important information regarding safety is included. Be sure to read It.

Describes how to connect to networks.

Describes how to connect to the FANUC PANEL i or a commercial personal

computer, using the high-speed serial bus (HSSB) or Ethernet.

Describes how to connect a PANEL i.

i,

p-1

Page 10

PREFACE B-64603EN/01

Chapter and title Contents

APPENDIX A) OUTLINE DRAWINGS OF UNITS AND CONNECTORS

B) 20-PIN INTERFACE CONNECTORS AND CABLES

C) CONNECTION CABLE (SUPPLIED FROM US)

D) OPTICAL FIBER CABLE

E) MEMORY CARD INTERFACE

Related manuals of 0i-F

The following table lists the manuals related to 0i-F. This manual is indicated by an asterisk(*).

Table 1 Related manuals

Manual name Specification number

DESCRIPTIONS B-64602EN

CONNECTION MANUAL (HARDWARE) B-64603EN *

CONNECTION MANUAL (FUNCTION) B-64603EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64604EN

OPERATOR’S MANUAL (For Lathe System) B-64604EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64604EN-2

MAINTENANCE MANUAL B-64605EN

PARAMETER MANUAL B-64610EN

0i-PF CONNECTION MANUAL (FUNCTION)

0i-PF OPERATOR’S MANUAL

0i-PF PARAMETER MANUAL

Programming

Macro Executor PROGRAMMING MANUAL B-63943EN-2

Macro Compiler PROGRAMMING MANUAL B-66263EN

C Language Executor PROGRAMMING MANUAL B-63943EN-3

PMC

PMC PROGRAMMING MANUAL B-64513EN

Network

PROFIBUS-DP Board CONNECTION MANUAL B-63993EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64014EN

DeviceNet Board CONNECTION MANUAL B-64043EN

FL-net Board CONNECTION MANUAL B-64163EN

CC-Link Board CONNECTION MANUAL B-64463EN

Industrial Ethernet CONNECTION MANUAL B-64013EN

Operation guidance function

MANUAL GUIDE i

(Common to Lathe System/Machining Center System) OPERATOR’S MANUAL

MANUAL GUIDE i (For Machining Center System) OPERATOR’S MANUAL

MANUAL GUIDE i (Set-up Guidance Functions) OPERATOR’S MANUAL

Dual Check Safety

Dual Check Safety CONNECTION MANUAL B-64483EN-2

B-64623EN

B-64624EN

B-64630EN

B-63874EN

B-63874EN-2

B-63874EN-1

p-2

Page 11

B-64603EN/01 PREFACE

Related manuals of SERVO MOTOR αis/αi/βis/βi series

The following table lists the manuals related to SERVO MOTOR αis/αi/βis/βi series

Manual name Specification number

FANUC AC SERVO MOTOR αi series DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS

FANUC AC SERVO MOTOR βi series DESCRIPTIONS

FANUC AC SPINDLE MOTOR βi series DESCRIPTIONS

FANUC SERVO AMPLIFIER αi series DESCRIPTIONS

FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

FANUC SERVO MOTOR αis series

FANUC SERVO MOTOR αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series

MAINTENANCE MANUAL

FANUC SERVO MOTOR βis series

FANUC AC SPINDLE MOTOR βi series

FANUC SERVO AMPLIFIER βi series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βi series

FANUC LINEAR MOTOR LiS series

FANUC SYNCHRONOUS BUILT-IN SERVO MOTOR DiS series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series

FANUC AC SPINDLE MOTOR βi series

BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

B-65262EN

B-65272EN

B-65302EN

B-65312EN

B-65282EN

B-65322EN

B-65285EN

B-65325EN

B-65270EN

B-65280EN

Related manuals of FANUC PANEL i

The following table lists the manuals related to FANUC PANEL i.

Manual name Specification number

FANUC PANEL i CONNECTION AND MAINTENANCE MANUAL

B-64223EN

Related manuals of FANUC I/O Unit

The following table lists the manuals related to FANUC I/O Unit.

Manual name Specification number

FANUC I/O Unit-MODEL A CONNECTION AND MAINTENANCE MANUAL B-61813E

FANUC I/O Unit-MODEL B CONNECTION AND MAINTENANCE MANUAL B-62163E

Handy Machine Operator’s Panel CONNECTION MANUAL B-63753EN

Training

• FANUC runs FANUC Training Center to train those who will be involved in the connection,

maintenance, and operation of FANUC products. It is recommended to attend the class so you will

be able to use the products effectively.

Visit the following web site for detailed descriptions of its curriculum.

http://www.fanuc.co.jp/

p-3

Page 12

Page 13

B-64603EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE.............................................s-1

WARNINGS AND CAUTIONS REGARDING MOUNTING, WIRING, AND

EXCHANGING............................................................................................s-2

WARNINGS AND CAUTIONS REGARDING DESIGNING.....................................s-4

WARNINGS, CAUTIONS, AND NOTES REGARDING DAILY MAINTENANCE ....s-5

NOTE REGARDING KOREAN KC MARK ..............................................................s-5

PREFACE....................................................................................................p-1

1 CONFIGURATION ..................................................................................1

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT NAMES..............1

1.1.1 Configurations of LCD-mounted Type Control Units .............................................1

1.1.2 Configurations of Optional Boards ..........................................................................5

1.2 HARDWARE OVERVIEW..............................................................................6

1.2.1 LCD-mounted Type Control Unit Overview ...........................................................6

2 TOTAL CONNECTION DIAGRAMS.......................................................7

3 INSTALLATION ....................................................................................10

3.1 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CABINET...............10

3.1.1 Environmental Conditions outside the Cabinet......................................................10

3.1.2 Installation Conditions of the Control Unit............................................................10

3.2 CAUTIONS REGARDING THE INSTALLATION DESIGN OF MACHINE

TOOL POWER MAGNETICS CABINETS ...................................................11

3.3 THERMAL DESIGN OF THE MACHINE TOOL MAGNETIC CABINET......14

3.3.1 Temperature Rise within the Machine Tool Magnetic Cabinet..............................14

3.3.2 Heat Output of Each Unit.......................................................................................14

3.3.3 Thermal Design of Operator's Panel.......................................................................15

3.4 COUNTERMEASURES AGAINST NOISE AND GROUNDING ..................16

3.4.1 Grounding as Noise Suppression Measures ...........................................................17

3.4.1.1 Grounding methods ...........................................................................................17

3.4.1.2 Cabinet............................................................................................................... 18

3.4.2 Protective Ground (Grounding for Protection against Indirect Contact) ...............21

3.4.3 Connecting the Ground Terminal of the Control Unit ...........................................22

3.4.4 Separating Signal Lines..........................................................................................23

3.4.5 Noise Suppressor....................................................................................................25

3.4.6 Cable Clamp and Shield Processing.......................................................................26

3.4.7 Lightning Surge Absorber Installation...................................................................28

3.5 INSTALLING THE CONTROL UNIT............................................................30

3.5.1 Installing the LCD-mounted Type Control Unit....................................................30

3.6 TIGHTENING TORQUE FOR FASTENING UNITS AND GROUND

TERMINALS................................................................................................31

3.7 DUSTPROOF MEASURES FOR CABINETS AND PENDANT BOXES......31

3.8 LCD PROTECTION COVER .......................................................................34

3.9 ATTACHING SCREW CAPS.......................................................................34

3.10 INSTALLATION CONDITION FOR UL RECOGNITION..............................35

c-1

Page 14

TABLE OF CONTENTS B-64603EN/01

4 POWER SUPPLY CONNECTION.........................................................36

4.1 24 VDC POWER (INSULATION AC/DC CONVERTOR).............................36

4.1.1 Connecting 24 VDC Power....................................................................................36

4.1.2 24 VDC Power Supply Specification.....................................................................38

4.1.3 Power Capacity of 24 VDC Power Supplies..........................................................40

4.2 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT.............41

4.2.1 Power-on Sequence................................................................................................41

4.2.2 Power-off Sequence ...............................................................................................42

4.3 CABLE FOR POWER SUPPLY TO CONTROL UNIT.................................44

4.4 BATTERIES.................................................................................................44

4.4.1 Battery for Memory Backup in the Control Unit (3 VDC) ....................................44

4.4.1.1 Replacing the lithium battery............................................................................. 45

4.4.1.2 Replacing commercially available alkaline dry cells (size D)...........................46

4.4.2 Battery for Separate Absolute Pulsecoders (6VDC) ..............................................48

4.4.3 Battery for Absolute Pulse Coder Built into the Motor (6VDC)............................49

5 CONNECTION TO CNC PERIPHERALS .............................................50

5.1 CONNECTION BETWEEN THE LCD-MOUNTED TYPE CONTROL UNIT

AND MDI UNIT............................................................................................50

5.1.1 Overview................................................................................................................50

5.1.2 Connection with the MDI Unit...............................................................................51

5.1.3 Key Layout of MDI Unit........................................................................................53

5.1.4 Keyboard Cover .....................................................................................................55

5.2 CONNECTION WITH INPUT/OUTPUT DEVICES ......................................56

5.2.1 Overview................................................................................................................56

5.2.2 Connecting I/O Devices .........................................................................................56

5.2.3 RS232-C Serial Port...............................................................................................57

5.2.4 RS232-C Interface Specification............................................................................59

5.3 CONNECTING THE HIGH-SPEED SKIP (HDI)...........................................66

5.3.1 Connecting the High-speed Skip (HDI).................................................................66

5.3.2 Input Signal Rules for the High-speed Skip (HDI) ................................................67

5.4 LINKING THE ETHERNET INTERFACE.....................................................68

5.4.1 Connection to the Ethernet Interface......................................................................68

5.4.2 Specification of Twisted-Pair Cable.......................................................................70

5.4.3 Network Installation...............................................................................................72

5.4.4 Ethernet Connector Panel.......................................................................................73

5.5 USB PORT ..................................................................................................77

6 SERVO AND SPINDLE INTERFACES.................................................79

6.1 OVERVIEW .................................................................................................79

6.2 Interface to the Amplifiers............................................................................80

6.2.1 Number of Units That Can Be Connected..............................................................81

6.3 SEPARATE DETECTOR INTERFACE........................................................82

6.3.1 Overview................................................................................................................82

6.3.2 Connection Diagram...............................................................................................83

6.3.3 Separate Detector Interface Unit Specification ......................................................84

6.3.4 Connection of Power Supply..................................................................................84

6.3.5 Separate Detector Interface (Digital Input)............................................................86

6.3.5.1 FANUC serial interface..................................................................................... 86

6.3.5.2 Parallel interface................................................................................................ 87

6.3.5.3 Input Signal Requirements (Parallel interface).................................................. 88

6.3.6 Overview of the Analog Basic Unit .......................................................................90

c-2

Page 15

B-64603EN/01 TABLE OF CONTENTS

6.3.7 Connection Diagrams of an Analog Basic Unit .....................................................91

6.3.8 Separate Detector Interface (Analog Input)............................................................93

6.3.8.1 Analog 1Vp-p Interface..................................................................................... 93

6.3.8.2 Input signal requirements (analog 1Vp-p interface)..........................................94

6.3.8.3 Method for checking the encoder signals.......................................................... 95

6.3.9 Connection of Battery for Absolute Position Detector........................................... 96

6.3.10 Connection Between the Basic Unit and Additional Unit......................................98

6.3.11 Connector Locations...............................................................................................98

6.3.12 Installation............................................................................................................100

6.3.13 Notes on Installing a Separate Detector Interface Unit........................................101

7 CONNECTION TO FANUC I/O Link i.................................................103

7.1 OVERVIEW ...............................................................................................103

7.2 CONNECTION...........................................................................................104

7.2.1 Connection of I/O Link i by Electric Cable..........................................................105

7.2.2 Connection of FANUC I/O Link i by Optical Fiber Cable ..................................106

7.2.3 Connection When Multiple Channels of the I/O Link i is Used ..........................108

7.3 ASSIGNMENT FOR I/O UNITS.................................................................112

7.3.1 Assignment of Signals..........................................................................................112

7.3.2 Fixed Signals........................................................................................................112

7.3.3 Status Alarm.........................................................................................................113

7.4 MANUAL PULSE GENERATOR ...............................................................114

7.4.1 Manual Pulse Generator Connection....................................................................114

7.4.2 Cable Length for Manual Pulse Generator...........................................................115

7.4.3 Manual Pulse Generator Signal Specifications ....................................................115

7.5 POWER SUPPLY......................................................................................116

8 UNITS CONNECTED TO FANUC I/O Link i ......................................117

8.1 GENERAL UNITS......................................................................................117

8.2 CONNECTION OF I/O MODULE FOR CONNECTOR PANEL .................121

8.2.1 Configuration .......................................................................................................121

8.2.2 Connection Diagram.............................................................................................122

8.2.3 Module Specifications..........................................................................................123

8.2.4 Connection of the Basic Module, and Extension Modules A and B....................125

8.2.4.1 Connector pin arrangement..............................................................................125

8.2.4.2 DI (Input Signal) Connection ..........................................................................126

8.2.4.3 DO (Output Signal) Connection...................................................................... 128

8.2.4.4 DI/DO Signal Specifications ........................................................................... 129

8.2.5 Connection of Extension Module C (2A Output Module)...................................131

8.2.5.1 Connector pin arrangement..............................................................................131

8.2.5.2 2A Output Signal Connection.......................................................................... 132

8.2.5.3 2A output signal specifications........................................................................ 133

8.2.6 Connection of Extension Module D (Analog Input Module)...............................133

8.2.6.1 Analog Input Connector Pin Allocation ..........................................................133

8.2.6.2 Analog Input Signal Connections....................................................................134

8.2.6.3 Analog Input Signal Specifications .................................................................135

8.2.6.4 Channel selection and A/D conversion data....................................................135

8.2.7 Manual Pulse Generator Connection....................................................................138

8.2.8 Connection of Basic and Extension Modules.......................................................138

8.2.9 Module Installation...............................................................................................139

8.2.10 Other Notes...........................................................................................................144

8.2.11 Rotary Switch Setting...........................................................................................146

8.2.12 Connection of the Grounding Terminal of the Module........................................148

8.2.13 Terminal Conversion Adapter..............................................................................149

c-3

Page 16

TABLE OF CONTENTS B-64603EN/01

8.2.13.1 Connection diagram......................................................................................... 150

8.2.13.2 Component names ........................................................................................... 151

8.2.13.3 External view and dimensions......................................................................... 154

8.2.13.4 Installation .......................................................................................................155

8.2.13.5 Cable connection to the terminal block ........................................................... 156

8.2.13.6 Connection.......................................................................................................158

8.3 CONNECTION OF I/O MODULE FOR OPERATOR'S PANEL (FOR

MATRIX INPUT)........................................................................................163

8.3.1 Overall Connection Diagram................................................................................163

8.3.2 Power Connection ................................................................................................164

8.3.3 DI/DO Connector Pin Arrangement.....................................................................165

8.3.4 DI (General-purpose Input Signal) Connection ...................................................166

8.3.5 DI (Matrix Input Signal) Connection...................................................................168

8.3.6 DO (Output Signal) Connection...........................................................................169

8.3.7 Manual Pulse Generator Connection....................................................................172

8.3.8 External View.......................................................................................................173

8.3.9 Specifications .......................................................................................................174

8.3.10 Other Notes...........................................................................................................176

8.3.11 Connection of the Grounding Terminal of the Module........................................178

8.4 CONNECTION OF I/O MODULE FOR OPERATOR'S PANEL AND I/O

MODULE FOR POWER MAGNETICS CABINET......................................179

8.4.1 Overall Connection Diagram................................................................................179

8.4.2 Power Connection ................................................................................................180

8.4.3 DI/DO Connector Pin Arrangement.....................................................................181

8.4.4 DI (General-purpose Input Signal) Connection ...................................................182

8.4.5 DO (Output Signal) Connection...........................................................................186

8.4.6 Manual Pulse Generator Connection....................................................................187

8.4.7 External View.......................................................................................................188

8.4.8 Specifications .......................................................................................................189

8.4.9 Other Notes...........................................................................................................191

8.4.10 Connection of the Grounding Terminal of the Module........................................193

8.5 CONNECTION OF I/O MODULE TYPE-2 FOR CONNECTOR PANEL....194

8.5.1 Configuration .......................................................................................................194

8.5.2 Connector Layout Diagram..................................................................................195

8.5.3 Connection Diagram.............................................................................................196

8.5.4 Module Specifications..........................................................................................197

8.5.5 DI/DO Connector Pin Assignment.......................................................................198

8.5.6 DI (Input Signal) Connection...............................................................................199

8.5.7 DO (Output Signal) Connection...........................................................................206

8.5.8 DI/DO Signal Specifications................................................................................210

8.5.9 Power Supply Connection....................................................................................211

8.5.10 Manual Pulse Generator Connection....................................................................211

8.5.11 Connection between Modules..............................................................................211

8.5.12 Unit Dimensions...................................................................................................213

8.5.13 Mounting the Module...........................................................................................214

8.5.14 Connector Panel Printed Circuit Board................................................................215

8.5.15 Other Notes...........................................................................................................218

8.5.16 Connection of the Grounding Terminal of the Module........................................220

8.6 CONNECTION OF TERMINAL TYPE I/O MODULE.................................221

8.6.1 Overview..............................................................................................................221

8.6.2 Module Specifications..........................................................................................222

8.6.2.1 Types of modules.............................................................................................222

8.6.2.2 Installation conditions...................................................................................... 223

8.6.2.3 I/O signal specifications .................................................................................. 223

c-4

Page 17

B-64603EN/01 TABLE OF CONTENTS

8.6.2.4 Power supply rating......................................................................................... 226

8.6.2.5 Heat dissipation ............................................................................................... 226

8.6.2.6 Weight ............................................................................................................. 226

8.6.2.7 Applicable wire................................................................................................227

8.6.3 External View and Dimensions............................................................................228

8.6.3.1 Dimensions (common to the modules)............................................................ 228

8.6.3.2 Dimensions in a maximum configuration (one basic module + three

extension modules).......................................................................................... 228

8.6.3.3 Component names ........................................................................................... 229

8.6.4 Installation............................................................................................................232

8.6.5 Connection ...........................................................................................................234

8.6.5.1 Overall connection diagram............................................................................. 234

8.6.5.2 Power connection ............................................................................................ 235

8.6.5.3 Signal assignment on terminal blocks..............................................................236

8.6.5.4 DI/DO connection............................................................................................239

8.6.5.5 Manual pulse generator connection................................................................. 246

8.6.5.6 Inter-module connection..................................................................................246

8.6.5.7 Cable connection to a terminal block .............................................................. 247

8.6.5.8 Detaching a terminal block..............................................................................248

8.6.5.9 Connection of the ground terminal.................................................................. 249

8.6.6 Settings.................................................................................................................250

8.6.6.1 Address map....................................................................................................250

8.6.6.2 Channel selection and A/D conversion data for extension module D.............251

8.6.6.3 Channel selection and D/A conversion data for extension module E.............. 253

DO alarm detection........................................................................................................... 254

8.6.6.4 Setting the rotary switch.................................................................................. 256

8.6.7 Others ...................................................................................................................257

8.6.7.1 Method of common pin expansion..................................................................257

8.6.7.2 Parallel DO (output signal) connection ........................................................... 259

8.7 I/O Link CONNECTION UNIT....................................................................260

8.7.1 Overview..............................................................................................................260

8.7.2 Specification.........................................................................................................261

8.7.3 Installation............................................................................................................263

8.7.4 Connection ...........................................................................................................266

8.7.4.1 I/O Link connection.........................................................................................266

8.7.4.2 Power connection ............................................................................................ 267

8.8 CONNECTION TO MACHINE OPERATOR'S PANEL ..............................268

8.8.1 Overview..............................................................................................................268

8.8.2 Total Connection Diagram...................................................................................271

8.8.3 DI/DO Address Map ............................................................................................274

8.8.4 Each Connections.................................................................................................276

8.8.4.1 Pin assignment.................................................................................................276

8.8.4.2 Power supply connection.................................................................................280

8.8.4.3 I/O Link i connection....................................................................................... 281

8.8.4.4 Using the channel 2 of I/O Link i .................................................................... 281

8.8.4.5 Emergency stop signal connection .................................................................. 284

8.8.4.6 Power ON/OFF control signal connection.......................................................285

8.8.4.7 General-purpose DI signal connection ............................................................ 287

8.8.4.8 General-purpose DO signal connection...........................................................293

8.8.5 Manual Pulse Generator.......................................................................................295

8.8.5.1 Manual pulse generator connection................................................................. 295

8.8.5.2 Pendant type manual pulse generator connection............................................295

8.8.6 Connector (on the cable side) specifications........................................................297

8.8.7 DI/DO Addresses for the Keyboard .....................................................................297

8.8.8 Code Output for the Rotary Switch......................................................................299

8.8.9 Outline..................................................................................................................300

c-5

Page 18

TABLE OF CONTENTS B-64603EN/01

8.8.9.1 Outline of main panel ......................................................................................300

8.8.9.2 Outline of Safety machine operator’s panel.....................................................301

8.8.9.3 Outline of Safety machine operator’s panel type B.........................................302

8.8.9.4 Outline of sub panel AA..................................................................................303

8.8.9.5 Outline of sub panel D.....................................................................................304

8.8.9.6 Connector locations of main panel ..................................................................305

8.8.9.7 Connector locations of safety machine operator’s panel................................. 305

8.8.9.8 Connector locations of safety machine operator’s panel type B......................306

8.8.10 Specifications of the Machine Operator’s Panel..................................................306

8.8.10.1 Installation conditions...................................................................................... 306

8.8.10.2 Order specification...........................................................................................306

8.8.10.3 Main panel specification..................................................................................307

8.8.10.4 Safety machine operator’s panel and safety machine operator’s panel type B

specification.....................................................................................................307

8.8.10.5 Sub panel AA, D specification ........................................................................ 308

8.8.10.6 Power supply specification.............................................................................. 308

8.8.10.7 Heat output ...................................................................................................... 308

8.8.10.8 General-purpose DI signal definition .............................................................. 308

8.8.10.9 General-purpose DO signal definition.............................................................309

8.8.11 Keyboard..............................................................................................................309

8.8.11.1 Meaning of key symbols.................................................................................. 309

8.8.11.2 Detachable key top on the main panel............................................................. 311

8.8.11.3 Keyboard cover................................................................................................311

8.8.12 DO (Output Signal) Error Detection .................................................................... 312

8.9 CONNECTION OF OPERATOR'S PANEL CONNECTION UNIT

(SOURCE DO)...........................................................................................314

8.9.1 Overall Connection Diagram................................................................................314

8.9.2 Power Connection ................................................................................................314

8.9.3 DI/DO Connector Pin Arrangement.....................................................................315

8.9.4 DI (Input Signal) Connection...............................................................................316

8.9.5 DO (Output Signal) Connection...........................................................................323

8.9.6 External View.......................................................................................................327

8.9.7 Specifications .......................................................................................................327

8.9.8 Other Notes...........................................................................................................329

8.10 CONNECTION OF SAFETY IO UNIT........................................................331

8.10.1 Overview..............................................................................................................331

8.10.2 Total connection diagram.....................................................................................331

8.10.3 Power supply connection......................................................................................332

8.10.4 I/O Link i Connection...........................................................................................332

8.10.5 DI/DO Address.....................................................................................................333

8.10.6 Pin assignment of DI/DO.....................................................................................334

8.10.7 DI/DO connection ................................................................................................335

8.10.8 Outline of Safety IO Unit.....................................................................................343

8.10.9 Connector locations of Safety IO Unit.................................................................344

8.10.10 Color labels for connectors of Safety IO Unit......................................................345

8.10.11 Connector specification of Safety IO Unit...........................................................346

8.10.12 Specifications of Safety IO Unit...........................................................................346

8.10.13 DO (Output Signal) Error Detection....................................................................348

8.11 CONNECTION OF I/O MODULE FOR OPERATOR’S PANEL

SUPPORTING SAFETY FUNCTION.........................................................349

8.11.1 Overview..............................................................................................................349

8.11.2 Connection Diagram.............................................................................................349

8.11.3 Power Connection ................................................................................................350

8.11.4 DI/DO Address Map ............................................................................................351

8.11.5 DI/DO Connector Pin Arrangement.....................................................................353

c-6

Page 19

B-64603EN/01 TABLE OF CONTENTS

8.11.6 DI(General-purpose Input Signal)Connection................................................355

8.11.7 DO (Output Signal) Connection...........................................................................358

8.11.8 Manual pulse generator Connection.....................................................................359

8.11.9 External View.......................................................................................................360

8.11.10 Specifications .......................................................................................................361

8.11.11 DO (output signal) Error Detection......................................................................362

8.12 I/O UNIT FOR POWER MAGNETICS CABINET.......................................363

8.12.1 Overall Connection Diagram................................................................................363

8.12.2 Power Connection ................................................................................................364

8.12.3 DI/DO Connector Pin Arrangement.....................................................................365

8.12.4 DI(General-purpose Input Signal)Connection .....................................................366

8.12.5 DO(Output Signal) Connection............................................................................373

8.12.6 Manual Pulse Generator Connection....................................................................377

8.12.7 External View.......................................................................................................377

8.12.8 GND Cable Connection........................................................................................378

8.12.9 Specifications .......................................................................................................379

8.12.10 Other Notes...........................................................................................................381

9 STOP AND EMERGENCY STOP .......................................................383

9.1 STOP MODES...........................................................................................383

9.2 SHUTTING OFF THE MOTOR POWER...................................................383

9.3 STOPPING THE SPINDLE MOTOR .........................................................384

9.4 STOPPING THE SERVO MOTOR............................................................384

9.5 EMERGENCY STOP SIGNAL...................................................................385

9.6 CAUTIONS ABOUT MULTI-PATH CONTROL..........................................389

10 CONNECTION TO OTHER NETWORKS ...........................................390

11 CONNECTION WITH FANUC PANEL i AND COMMERCIAL

PERSONAL COMPUTERS.................................................................391

11.1 OVERVIEW ...............................................................................................391

11.2 CAUTIONS................................................................................................391

11.3 CONNECTION USING THE HIGH-SPEED SERIAL BUS (HSSB)............391

11.3.1 Overview..............................................................................................................391

11.3.2 Connection Diagram.............................................................................................392

11.3.3 Specifications of a Commercial PC......................................................................392

11.3.4 Installation Environment......................................................................................393

11.3.5 Handling Precautions ...........................................................................................393

11.3.6 Procedure for Installing Personal Computer Interface Boards.............................393

11.3.7 Cable Connection .................................................................................................394

11.4 CONNECTION USING Ethernet................................................................395

11.4.1 Overview..............................................................................................................395

11.4.2 Connection Diagram.............................................................................................395

12 PANEL i ..............................................................................................396

APPENDIX

A OUTLINE DRAWINGS OF UNITS AND CONNECTORS...................399

B 20-PIN INTERFACE CONNECTORS AND CABLES.........................432

B.1 BOARD-MOUNTED CONNECTORS........................................................432

c-7

Page 20

TABLE OF CONTENTS B-64603EN/01

B.1.1 Vertical-type Connectors......................................................................................432

B.1.2 Straight and Right-angled Connectors (for Spring and Screw-fixing Connector

Housings) .............................................................................................................432

B.2 CABLE CONNECTORS ............................................................................433

B.2.1 Strand Wire Press-mount Connector....................................................................433

B.2.2 Soldering Type Connector....................................................................................434

B.3 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND

CABLES ....................................................................................................435

B.3.1 Recommended Connectors...................................................................................436

B.3.2 Applicable Cables.................................................................................................436

C CONNECTION CABLE (SUPPLIED FROM US).................................443

D OPTICAL FIBER CABLE....................................................................446

E MEMORY CARD INTERFACE............................................................456

F HOW TO ATTACH THE KEYBOARD COVER...................................458

c-8

Page 21

B-64603EN/01 1.CONFIGURATION

1 CONFIGURATION

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT

NAMES

The LCD-mounted type is one having both control and indicator sections in it. Each unit has different

composition. Described below is the configuration of type. This manual focuses on how to attach the

connectors shown in the configuration diagrams to device.

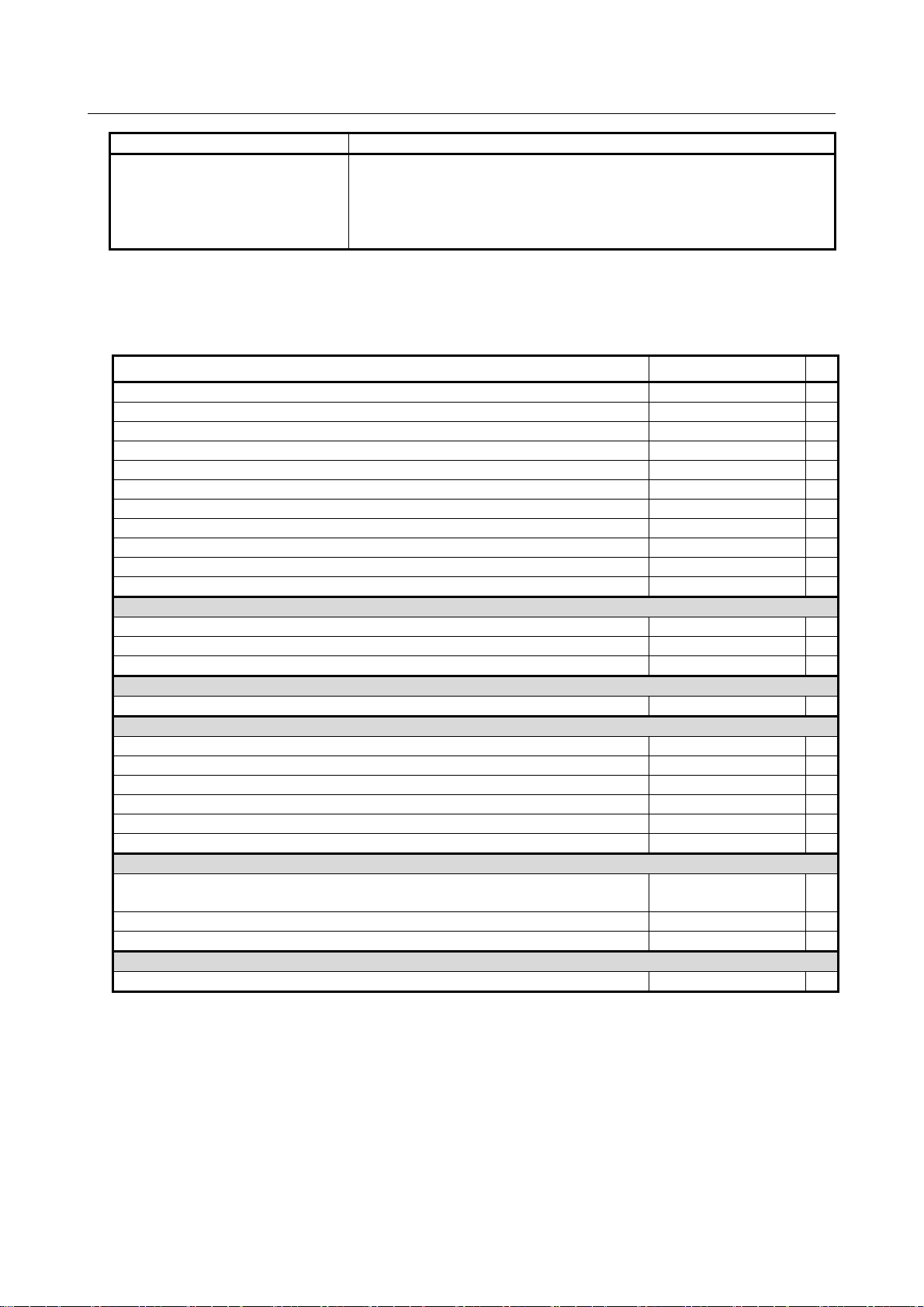

1.1.1 Configurations of LCD-mounted Type Control Units

LCD-mounted type control units

Basic

unit

Basic unit

A

Basic unit

G

CAUTION

The touch panel is a device designed to be operated by touching directly its

screen. Touch panel is possible to be operated with the gloves or bare hand. It is

possible to get a better operating feeling when using a FANUC-supplied

exclusive touch panel pen (A02B-0236-K111).

Please be careful not to press too strongly when operating with a finger. There is

a risk that internal circuit of the touch panel fails or the glass cracks.

If you press the screen with the pointed pen or sharp tool like a driver, it may

cause failure or the surface of the display may be scratched. Be sure to keep

away from such improper use.

CAUTION

Do not poke the surface of the display with a sharp tool like a driver, or hit

strongly with a something hard like a grip of driver. It may cause failure or the

surface of the display may be scratched.

Screen

size

8.4"

10.4"

15"

Touch

panel

Without

With

Without

With

Without

With

(horizontal)

(vertical)

(horizontal)

(vertical)

Separate

(horizontal/ver

Separate

(horizontal/

vertical)

MDI

With

With

With

With

tical)

Number of

option slots

Without

2

Without

2

Without

2

Without

2

Without

2

Without

2

Without

2

Without

2

Number of

horizontal soft keys

5+2 without

10+2 (8+1)or Without

10+2 8+1

Number of vertical

soft keys

- 1 -

Page 22

1.CONFIGURATION B-64603EN/01

NOTE

The indicators having a touch panel has a protection sheet attached to its front

surface. Explanations about how to replace the protection sheet, refer to the

FANUC Series 0i-MODEL F Maintenance Manual (B-64605EN).

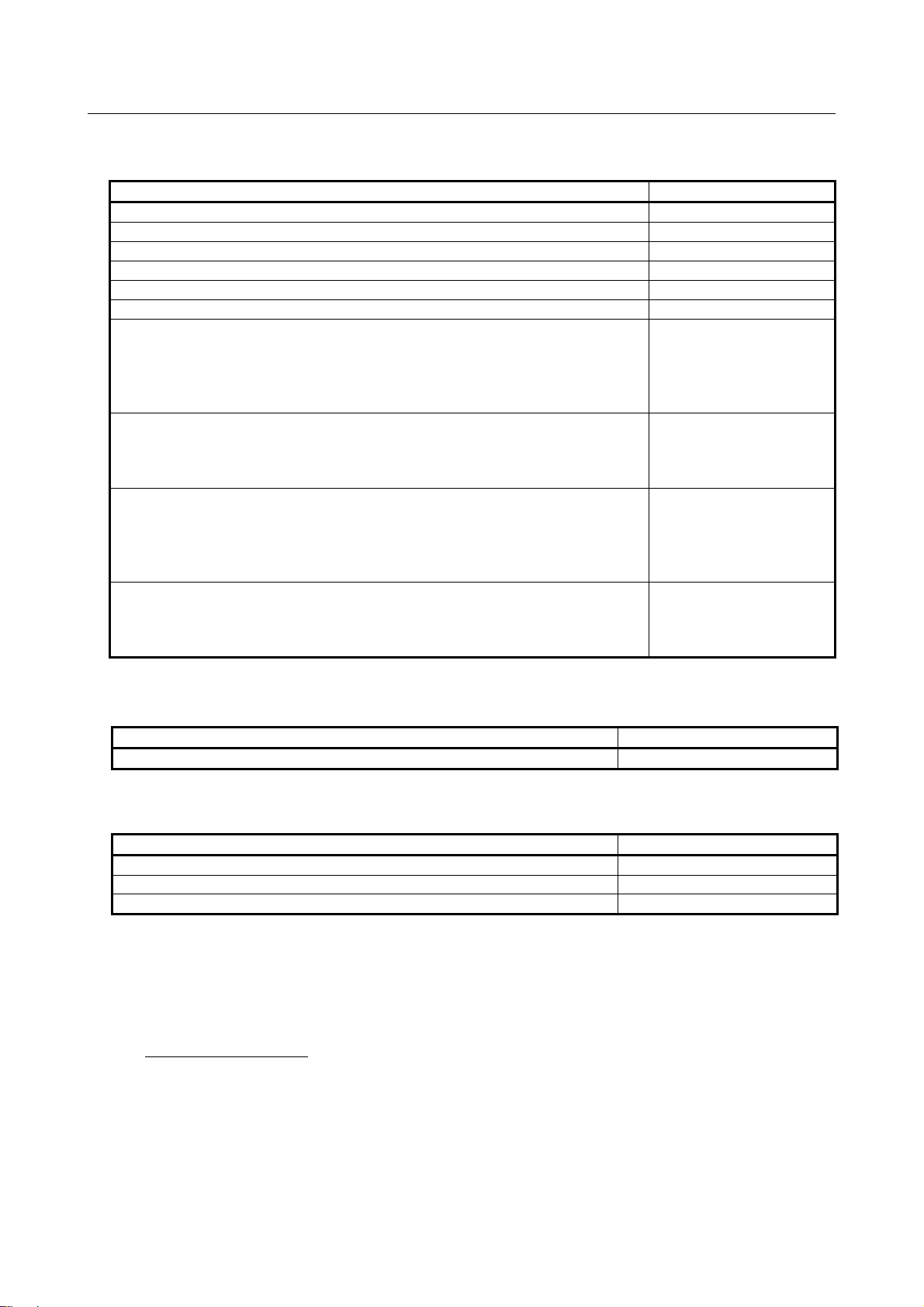

10.4” LC D unit (f ront view)

Liquid-crystal

display

Mem ory card

interface

USB port

Horiz ont a l s oft

keys

Vertical soft

keys

NOTE

1 This figure shows the 10.4” LCD-mounted control unit as viewed from the front.

The basic configuration of the other control unit models is the same, as viewed

from the front.

2 The LCD (liquid-crystal display) has been fabricated using an extreme precision

technology. However, some of their pixels may fail to light or stay constantly

lighting because of their characteristics. Please be forewarned that these

phenomena are not faults.

- 2 -

Page 23

B-64603EN/01 1.CONFIGURATION

r

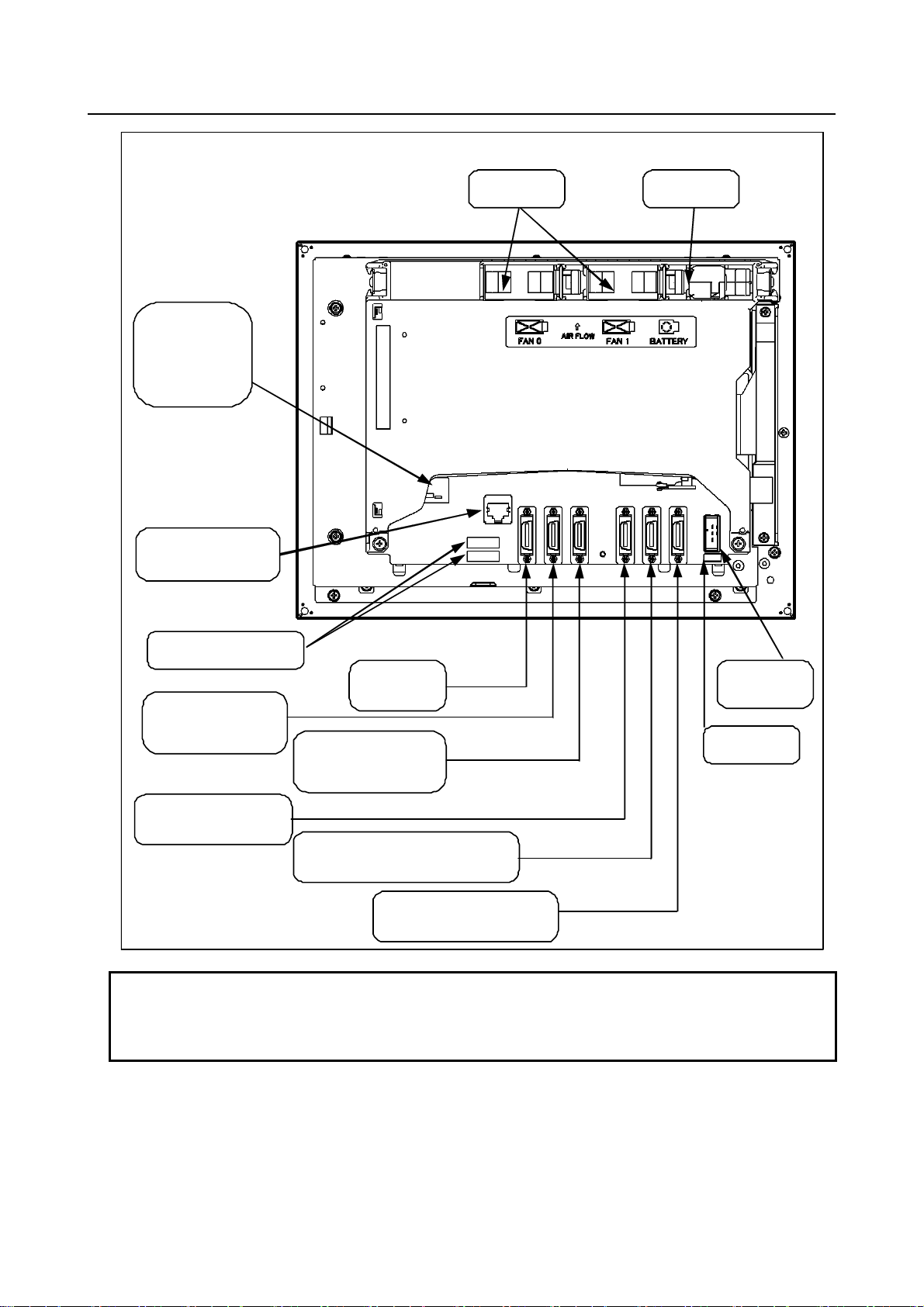

Basic unit A (rear view)

FSSB interface

connector

[COP10A]

Etherne t connec t or

(Embedded Ethernet )

[CD38A]

Fan unit

Battery

Soft key connect ors

Power supply

connector

[CP1 ]

Fuse

I/O devic e inter face

connector (RS-232C)

[JD36A]

High-speed skip

connector

[JA40]

MDI c onnect or

[JA2]

I/O dev i ce inte r face

connector (RS-232C)

[JD36B]

I/ O Link i or I/O Link connector

[JD51A]

Posit ion co der connec to

[JA41]

NOTE

1 This figure shows an LCD-mounted control unit having no option slot as viewed

from the rear.

2 The numbers in brackets [] in the figures are connector numbers.

- 3 -

Page 24

1.CONFIGURATION B-64603EN/01

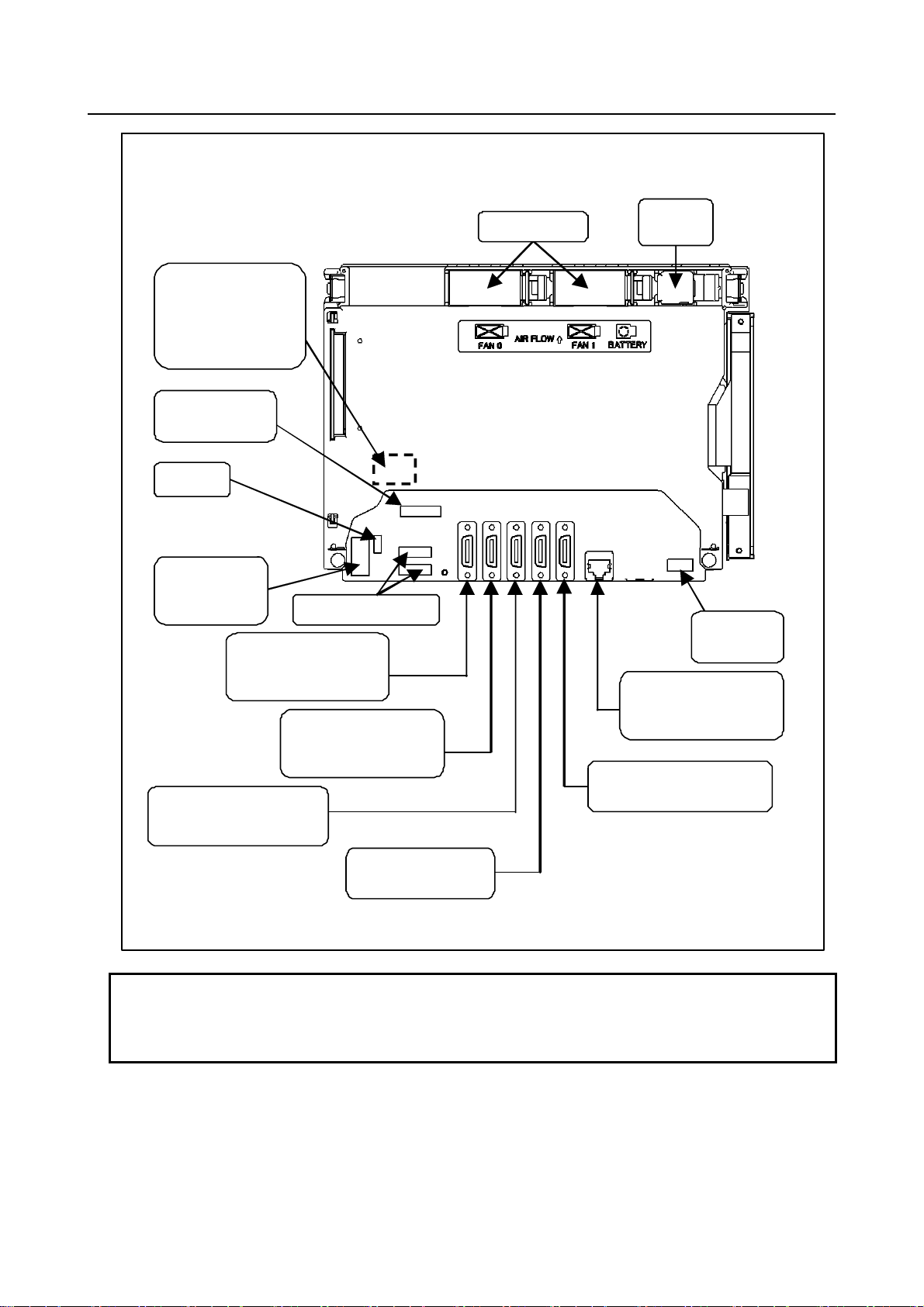

Basic unit G (rear view)

FSSB interface

connector

[COP10A-1]

MDI connector

[CA55]

Fuse

Power supply

connector

[CPD16A]

I/O devic e interface

connec t or (RS-232C )

[JD56A]

High-s peed s ki p conn ector

[JA40]

Soft key connect ors

I/O device interface

connec t or (R S-232C )

[JD36A]

Fan unit

Battery

USB port

[CD41P]

Ethernet connector

(Embedded Ethernet )

[CD38S]

Po sition c oder connec t or

[JA41]

I/O Link i connector

[JD51A]

NOTE

1 This figure shows an LCD-mounted control unit having no option slot as viewed

from the rear.

2 The numbers in brackets [] in the figures are connector numbers.

- 4 -

Page 25

B-64603EN/01 1.CONFIGURATION

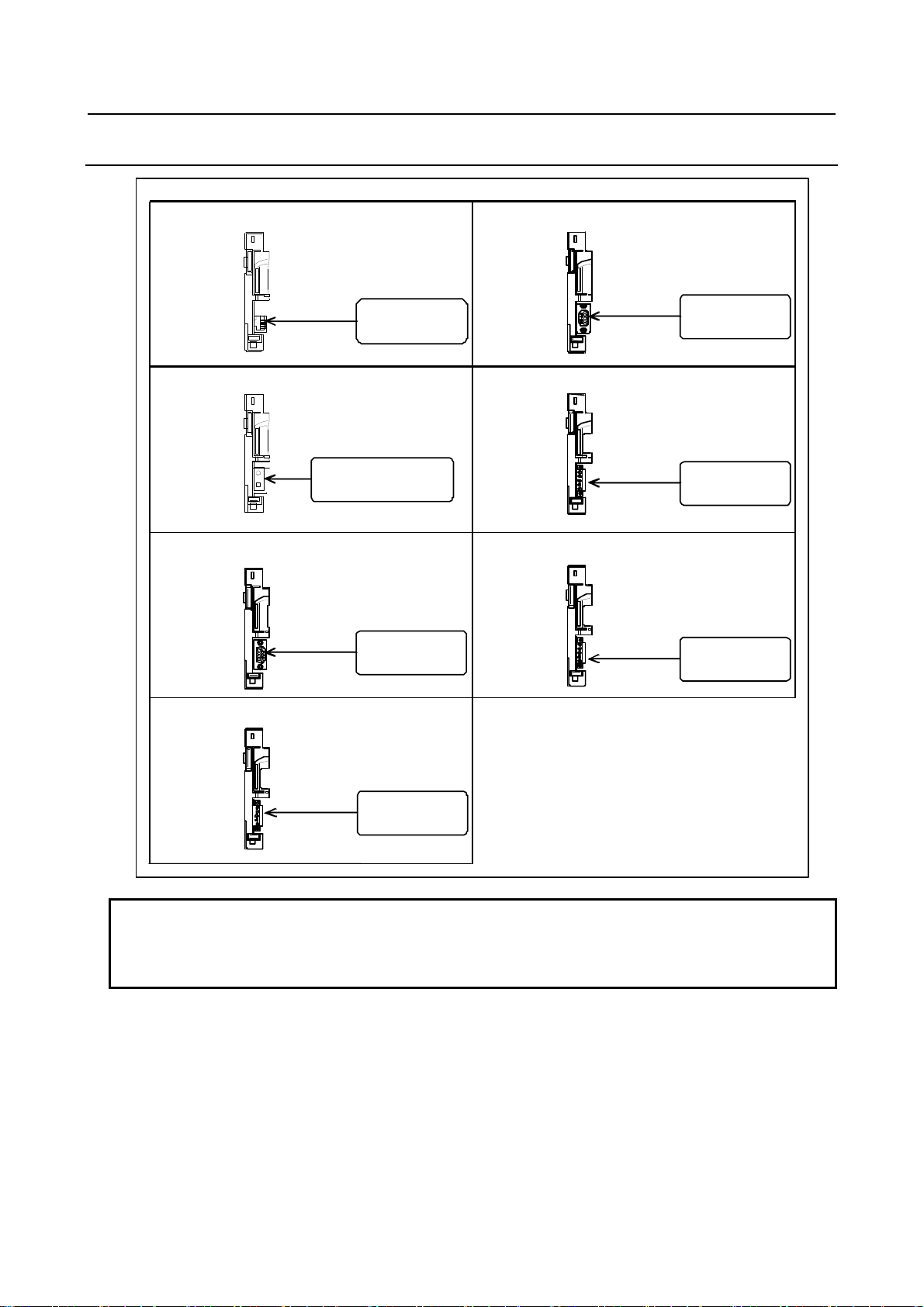

1.1.2 Configurations of Optional Boards

F ast Ethe rne t boar d

PROF I B US -DP sl ave b oa rd

HSSB interface board

For HSSB interface

[COP21N]

PROFIBUS-DP master b oard

CC-Li n k remote device stati on boar d

For Ethernet

[CD38R]

For Profibus

[CN1]

For Profibus

[CN2 ]

Devi ceN et master board

For DeviceNet

[TB L]

Devi ceN et sl ave b oa rd

For DeviceNet

[TBL]

For CC-Link

[CT1 ]

NOTE

The numbers in brackets [] in the figures are connector numbers.

The Fast Ethernet board may be used also as data server or FL-net functions,

depending on the settings of parameters.

- 5 -

Page 26

1.CONFIGURATION B-64603EN/01

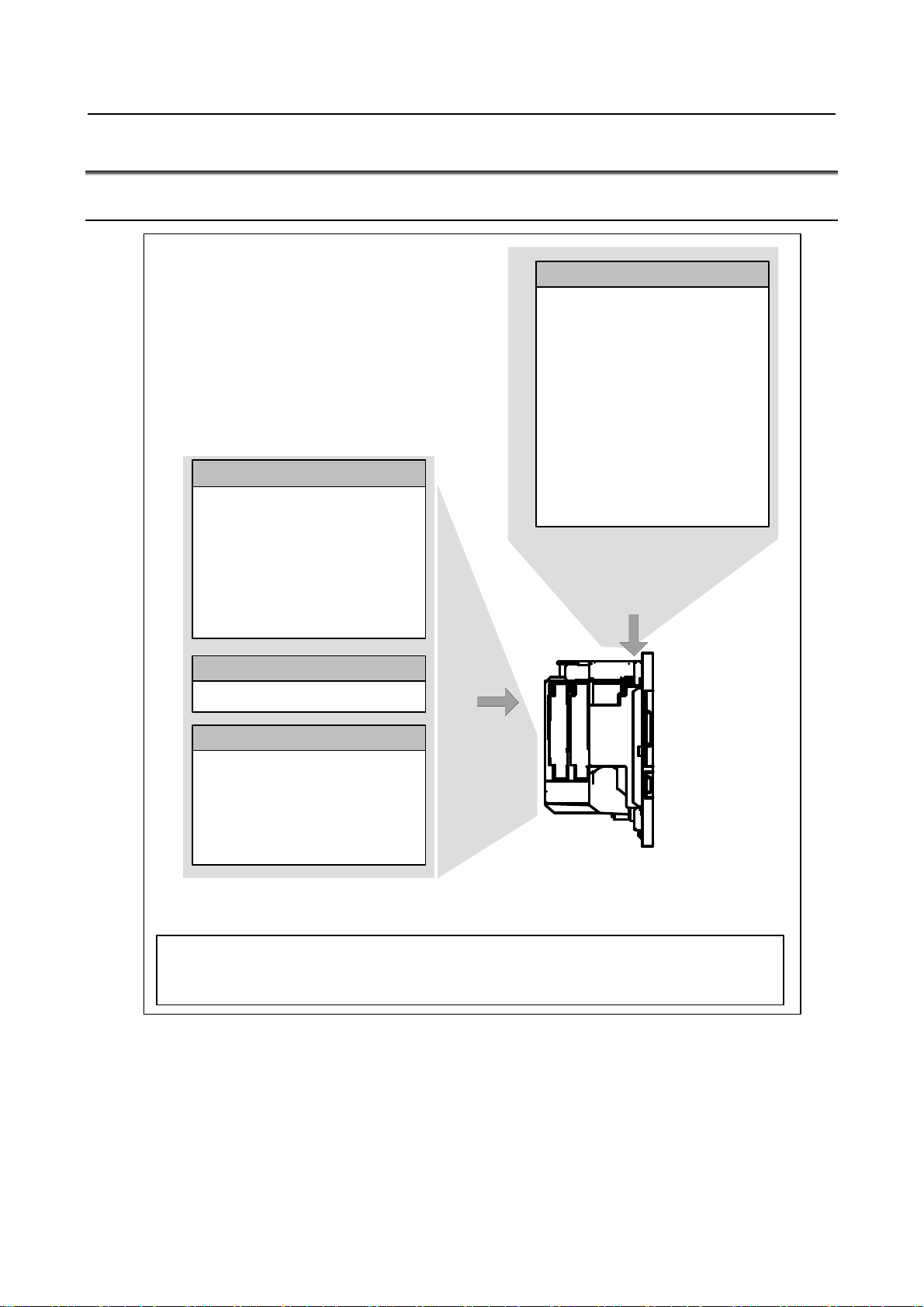

1.2 HARDWARE OVERVIEW

1.2.1 LCD-mounted Type Control Unit Overview

Main board

- C PU for co ntrollin g CNC

- Power supply

- Ax is contro l functio n

- MDI I/F

- I/O Link i con trol function

- Analog output

- Position coder

- PM C cont rol functi on

- High-speed skip (HDI)

Fast E thernet board

Fas t Ethernet fu nction

Data server function

FL-net function

EtherNet/IP

master/slave function

PROFINET

master/slave function

Modbus/T CP func tion

- RS-232C I/ F

- Me mory card I/F

- USB I/ F

- Ethernet funct ion

B asic system

HSSB interface board

High-speed serial bus interface

Various ty pes of network b oard s

PROFIBUS-DP master board

PROFIBUS-DP s lave board

Devi ceNet maste r board

DeviceNet slave board

CC-Link remote device station boar d

Note

1 On a unit with optional slots , as many optional boards as the slots can be m ounted.

note2

Options

Unit without opti onal slots

or

Unit hav ing two optiona l slots

- 6 -

Page 27

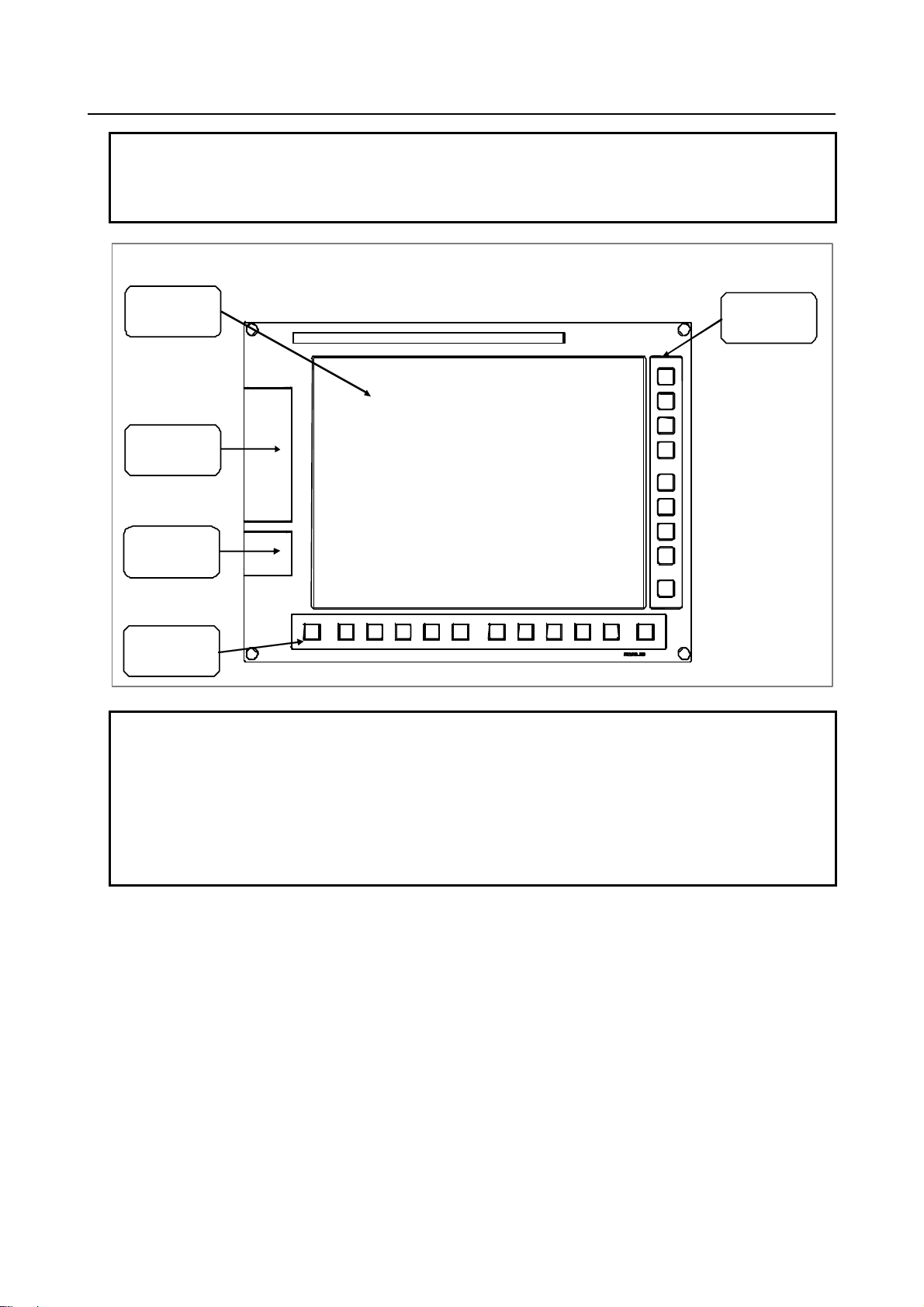

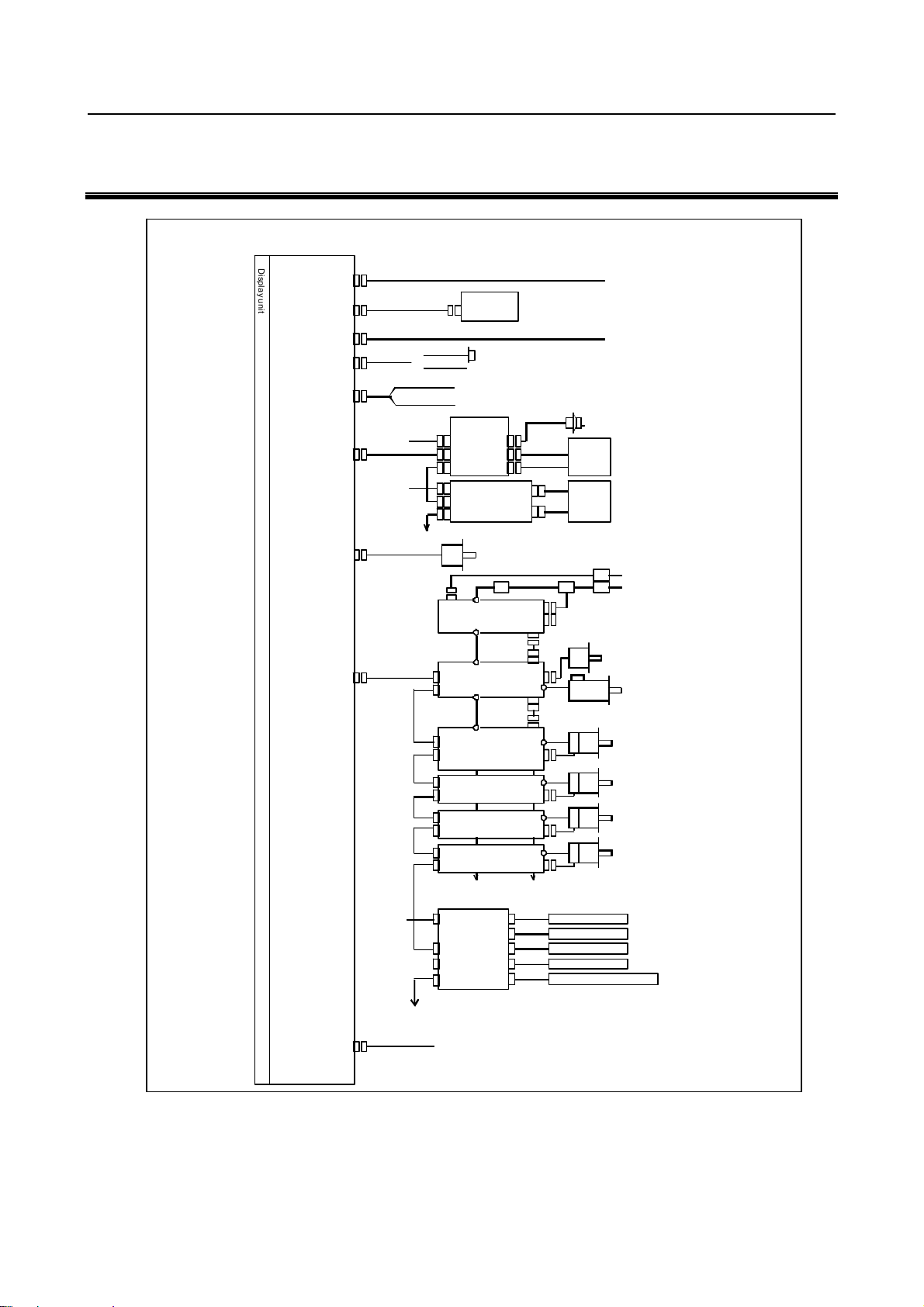

B-64603EN/01 2.TOTAL CONNECTION DIAGRAMS

A

y

A

A

JA4A

scale, axis

p

y

A

2 TOTAL CONNECTION DIAGRAMS

10.4”LCD unit and 8.4”LCD/MDI unit

D

Main board

i

s

24V-IN(CP1)

l

a

u

n

i

t

MDI(JA2)

MDI unit

CK27

24 VDC power supply

R232C-1(JD36A)

R232C-2(JD36B)

A-OUT&HDI(JA40)

I/O Link i

(JD51A)

P0S(JA41)

FSSB(COP10A)

{

DC24V

DC24V

((In this figure, a 1-axisamplifier is used.)

DC24V JF101

RS-232C I/Odevice

To uch panel

nalog output for tool drives

High-speed skip input

Distributed

I/O board

CPD1

A3

D1B

D1A

Distributed

CPD1

I/O board

JD1B

I/O unit, etc

JD1A

Position coder

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

Separate detector interface unit 1

CP11A

JF102

COP10B

JF103

JF104

COP10A

CNF1

RS-232C I/O device

Manual pulse generator

Operator's

panel

Power

magnetics

cabinet

Circuit breaker

C reac to r

MCC

αi PS

αi SP

αi SV

αiSV

αi SV

αi SV

Position coder

Serial spindle motor

Linear

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

bsolute scale batt er

(Required only when an absolute scale is used)

DC24V

Circuit breaker

Servo mo tor

Servo mo tor

Servo mo tor

Servo mo tor

1

C200V

ETHERNET(CD38A)

To separate detector interface unit 2

Ethernet

- 7 -

Page 28

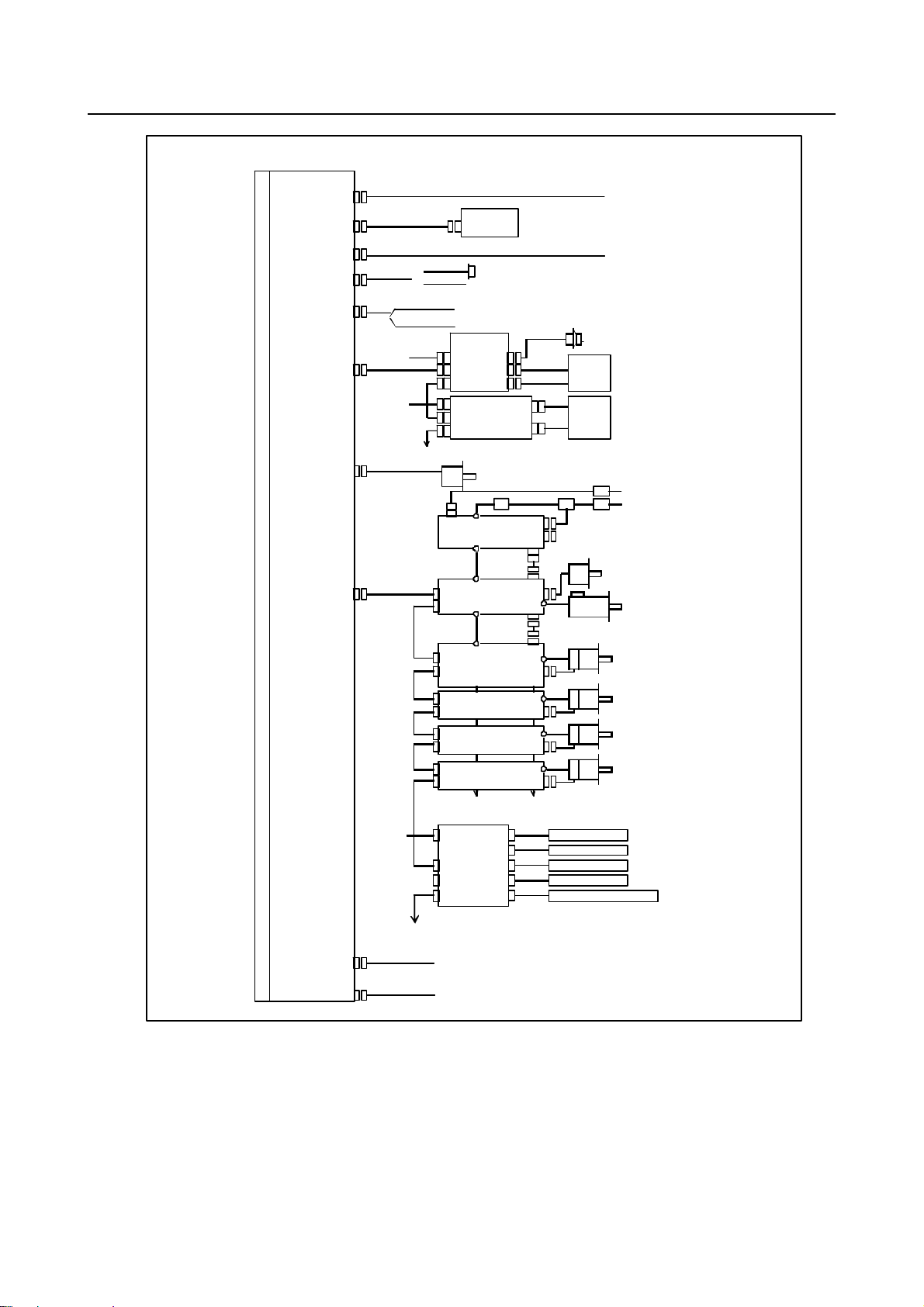

2.TOTAL CONNECTION DIAGRAMS B-64603EN/01

A

A

A

A

ear scale, axis

p

y

A

)

y

15”LCD uni t

Dis

Main board

la

unit

24V-IN(CPD16A

MDI(CA55)

MDI unit

24VDC power supply

R232C-1(JD56A)

R232C-2(JD36A)

A-OUT&HDI(JA40)

(JD51A)

I/O Link i

POS(JA41)

FSSB(COP10A)

RS-232C I/O device

{

DC24V

DC24V

(In this figure, a 1-axisamplifier is used.)

DC24V

RS-232C I/O device

Touch panel

nalog output for tool drives

High-speed skip input

Distributed

I//O board

CPD1

A3

D1B

D1A

Distribute

CPD1

JD1B

JD1A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

Separate detector interface unit 1

CP11A

COP10B

COP10A

CNF1

I/O board

I/O unit, etc

Position coder

C reac to r

αi PS

αi SP

αi SV

αiSV

αi SV

αi SV

JF101

JF102

JF103

JF104

JA4

Lin

Linear scale, axis 2

Linear scale, axis 3

Linear sc al e , axi s 4

(Required only when an absolute scale is used)

Manual pulse generator

Operator’s

panel

Power

magnetics

cabinet

Circuit breaker

MCC

Circuit breaker

Position coder

Serial spindle motor

Servo mo tor

Servo mo tor

Servo mo tor

Servo mo tor

1

bsolute scale batt ery

DC24V

C200V

ETHERNET(CD38S)

USB(CD41P

To separate detector interface unit 2

Ethernet (Embedded Ethernet)

USB memor

- 8 -

Page 29

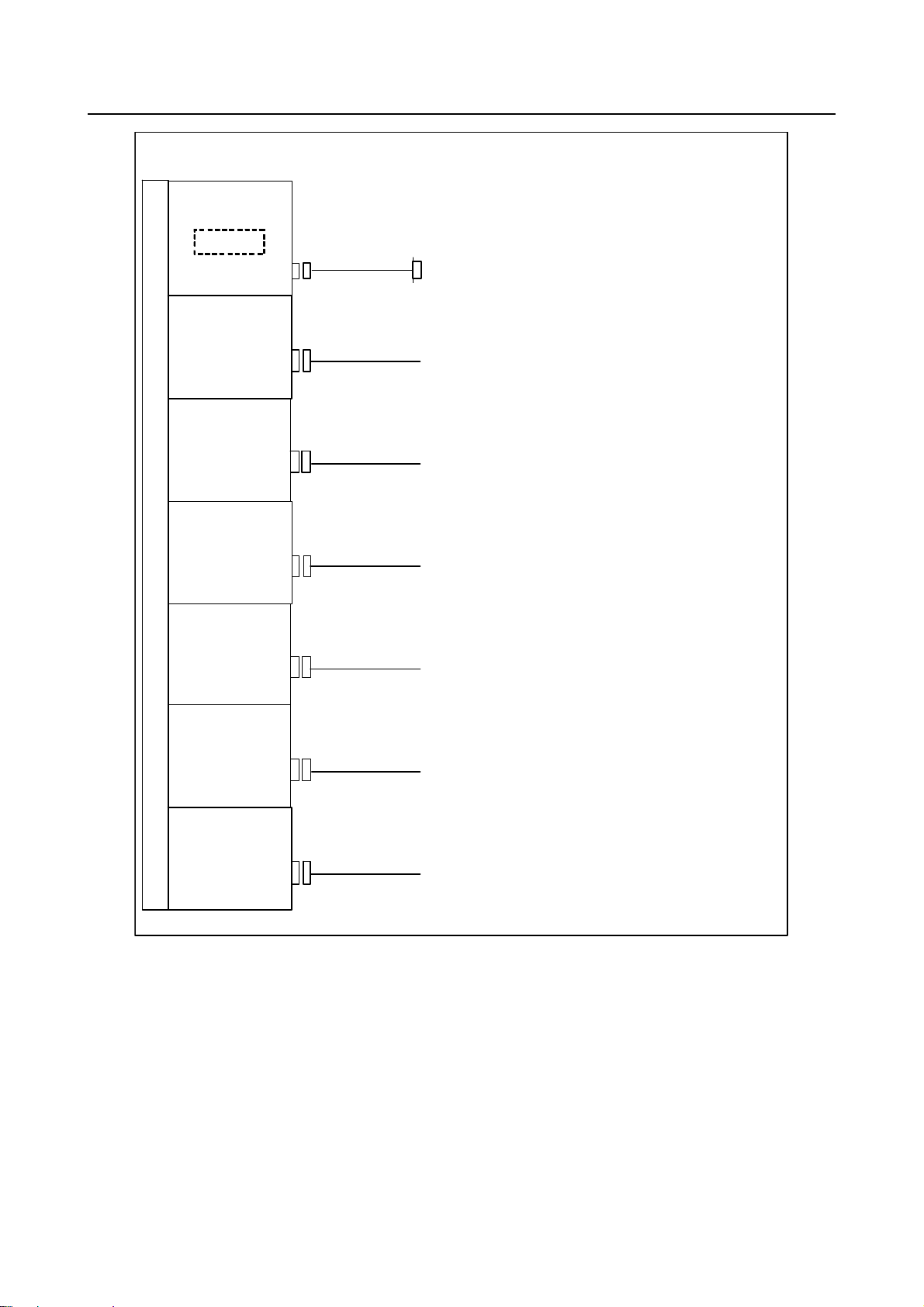

B-64603EN/01 2.TOTAL CONNECTION DIAGRAMS

When optional boards are provided

Optional slot

Fast Ethernet board

Memory c ard

ETHERNET(CD38R)

HSSB interface board

HSSB(COP21A)

PROFIBUS-DP

m aste r boar d

PROFI(CN1)

PROFIBUS-DP

slave board

PROFI(CN2)

DeviceNet

m aste r boar d

DVNET(TBL)

Use a compact flash card purchased from FANUC

E ther net or FL-net ,and so on

PANEL i

or Per sonal Computer

Other cont rol unit

or PROFIBUS device

Other cont rol unit

or PROFIBUS device

Other cont rol unit

or Devi ceNet device

DeviceNet

slave board

DVNET(TBL)

CC-Link remote

device sta tio n board

CCLNK(CT1)

Other cont rol unit

or Devi ceNet device

CC-Lin k devic e

- 9 -

Page 30

3.INSTALLATION B-64603EN/01

3 INSTALLATION

3.1 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE

CABINET

3.1.1 Environmental Conditions outside the Cabinet

The control unit and the peripheral units have been designed on the assumption that they are housed in

closed cabinets. In this manual "cabinet" refers to the following:

• Cabinet manufactured by the machine tool builder for housing the control unit or peripheral units;

• Operation pendant, manufactured by the machine tool builder, for housing the MDI unit, or

operator's panel.

• Equivalent to the above.

The following table lists the environmental conditions required in installing these cabinets. Section 3.3 of

this connection manual explains the design conditions regarding installation of cabinets that will meet the

environmental conditions.

Ambient

temperature of

the cabinet

Humidity

Vibration

Meters above

sea level

Environment

Operating 0°C to 45°C

Nonoperating (including storage

and transportation)

Temperature change 0.3°C/minute or less

Normal 75%RH or less, no condensation

Short period (less than 1 month) 95%RH or less, no condensation

Operating 4.9m/s2 (0.5G) or less

Nonoperating (including storage

and transportation)

Operating Up to 1000 m

Nonoperating (including storage

and transportation)

Normal machine shop environment

(The environment must be considered if the cabinets are in a

location where the density of dust, coolant, organic solvent,

and/or corrosive gas is relatively high.)

-20°C to 60°C

2

9.8m/s

(1.0G) or less

(see Note 1 in the Subsec. 3.1.2.)

Up to 12000 m

3.1.2 Installation Conditions of the Control Unit

Condition LCD-mounted type control unit and display unit

Operating 0°C to 58°C

Ambient

temperature

Humidity

Nonoperating (including storage

and transportation)

Temperature change 0.3°C/minute or less

Normal 75%RH or less, no condensation

Short period (less than 1 month) 95%RH or less, no condensation

- 10 -

-20°C to 60°C

Page 31

B-64603EN/01 3.INSTALLATION

Condition LCD-mounted type control unit and display unit

4.9m/s2 (0.5G) or less

FANUC’s evaluation test was conducted under the following

conditions complying with IEC 60068-2-6.

10 to 58Hz: 0.075mm (amplitude)

58 to 500Hz: 9.8m/s

Direction of vibration: Each of the X, Y, and Z directions

Number of sweep cycles: 10

Coolant, lubricant, or cutting chips shall not be sprinkled

directly over the CNC or servo unit. No corrosive gas shall be

allowed.

2

(1.0G)

2

9.8m/s

(1.0G) or less

Up to 12000m

(Note 1)

Vibration

Meters above