Page 1

B-64305EN/03 APPENDIX A.ALARM LIST

A ALARM LIST

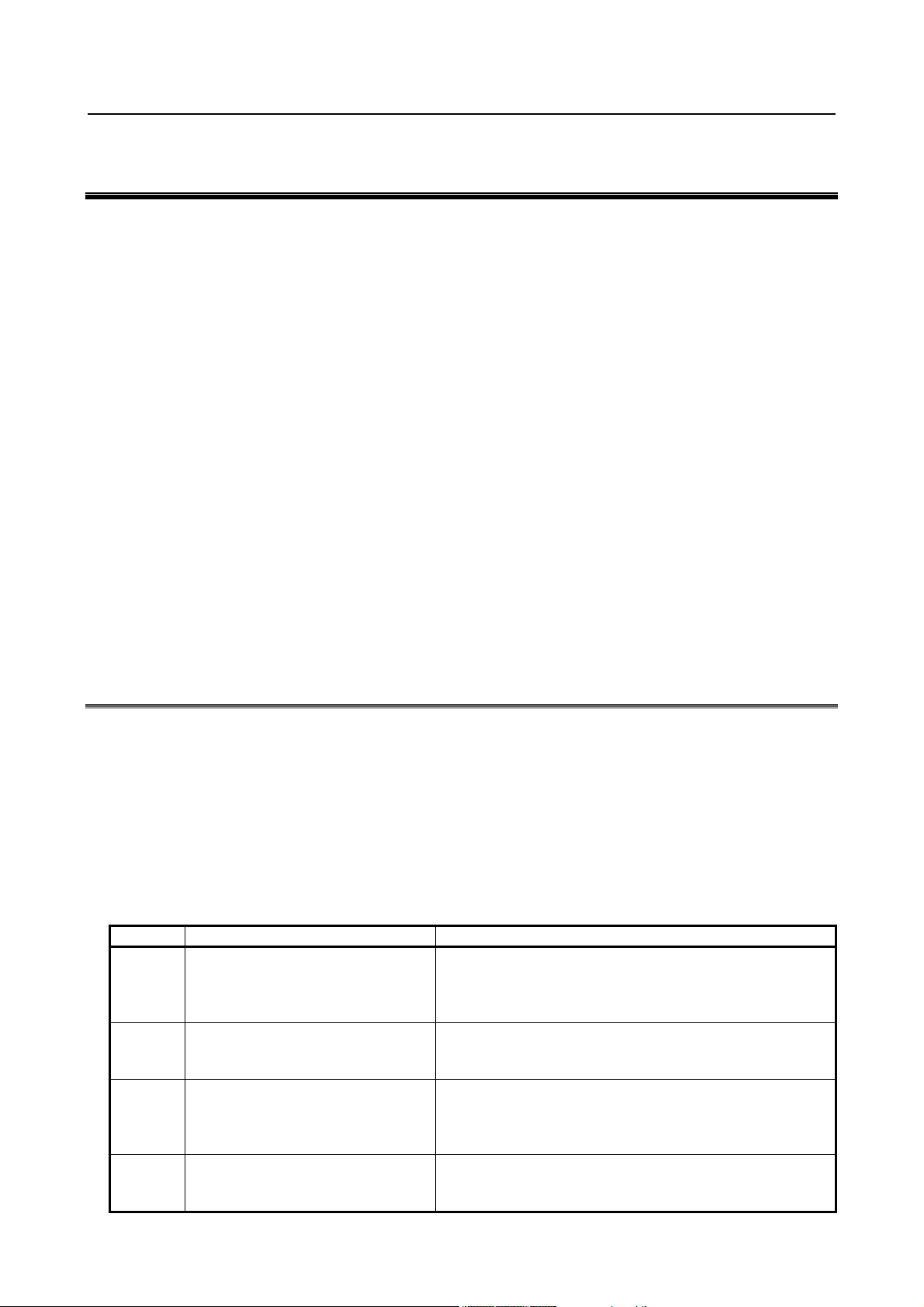

Appendix A, "ALARM LIST", consists of the following sections:

A.1 ALARM LIST (CNC).......................................................................................................................435

(1) Alarms on program and operation (PS alarm) .............................................................................435

(2) Background edit alarms (BG alarm)............................................................................................ 435

(3) Communication alarms (SR alarm).............................................................................................435

(4) Parameter writing alarm (SW alarm)...........................................................................................460

(5) Servo alarms (SV alarm) .............................................................................................................460

(6) Overtravel alarms (OT alarm) .....................................................................................................465

(7) Memory file alarms (IO alarm)....................................................................................................466

(8) Alarms requiring power to be turned off (PW alarm) .................................................................466

(9) Spindle alarms (SP alarm)...........................................................................................................467

(10) Overheat alarms (OH alarm) .....................................................................................................469

(11) Other alarms (DS alarm)............................................................................................................469

(12) Malfunction prevention function alarms (IE alarm)..................................................................473

A.2 ALARM LIST (PMC).......................................................................................................................473

A.2.1 Messages That May Be Displayed on the PMC Alarm Screen ............................................473

A.2.2 PMC System Alarm Messages..............................................................................................477

A.2.3 Operation Errors ...................................................................................................................480

A.2.4 I/O Communication Error Messages ....................................................................................491

A.3 ALARM LIST (SERIAL SPINDLE)................................................................................................495

A.4 ERROR CODES (SERIAL SPINDLE) ............................................................................................503

A.1 ALARM LIST (CNC)

(1) Alarms on program and operation (PS alarm)

(2) Background edit alarms (BG alarm)

(3) Communication alarms (SR alarm)

Alarm numbers are common to all these alarm types.

Depending on the state, an alarm is displayed as in the following examples:

PS"alarm number" Example: PS0003

BG"alarm number"

SR"alarm number" Example: SR0001

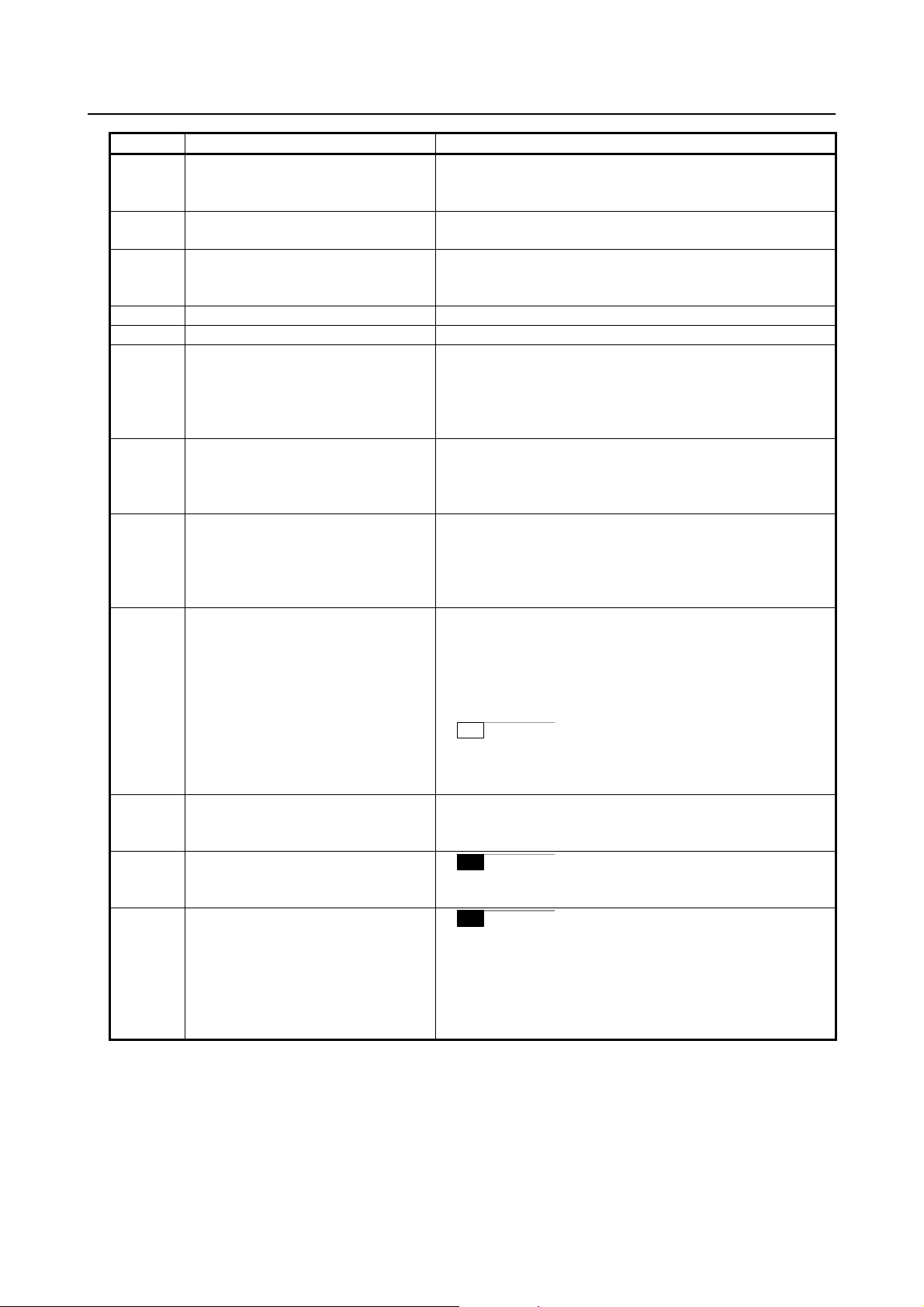

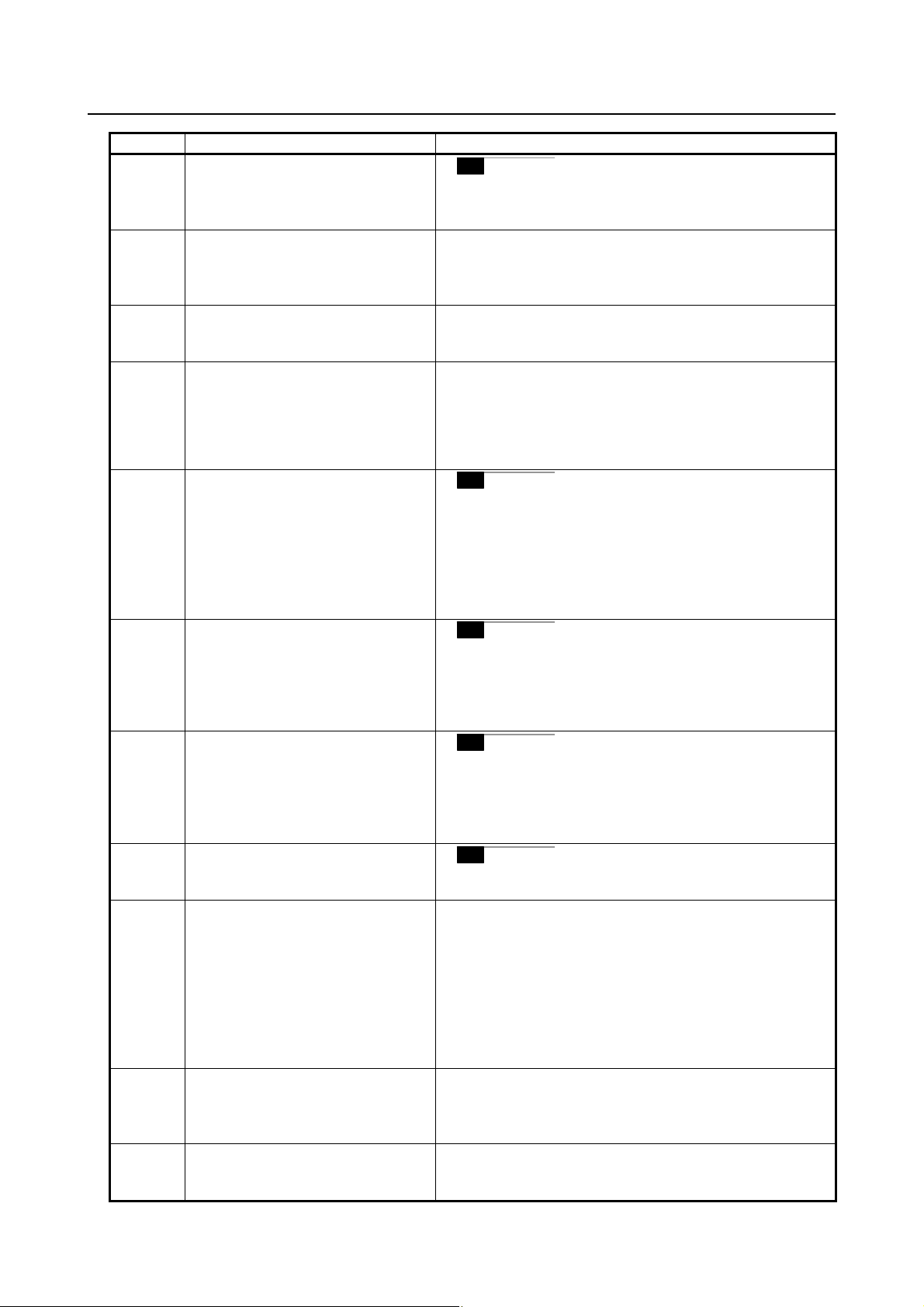

Number Message Description

0001 TH ERROR A TH error was detected during reading from an input device.

0002 TV ERROR An error was detected during the single–block TV error.

0003 TOO MANY DIGIT Data entered with more digits than permitted in the NC

0004 ADDRESS NOT FOUND NC word(s) address + numerical value not in word format.

Example: BG0085

The read code that caused the TH error and how many

statements it is from the block can be verified in the

diagnostics screen.

The TV check can be suppressed by setting TVC parameter

No. 0000#0 to “0”.

instruction word.

The number of permissible digits varies according to the

function and the word.

This alarm is also generated when a custom macro does not

contain a reserved word, or does not conform to the syntax.

- 435 -

Page 2

A.ALARM LIST APPENDIX B-64305EN/03

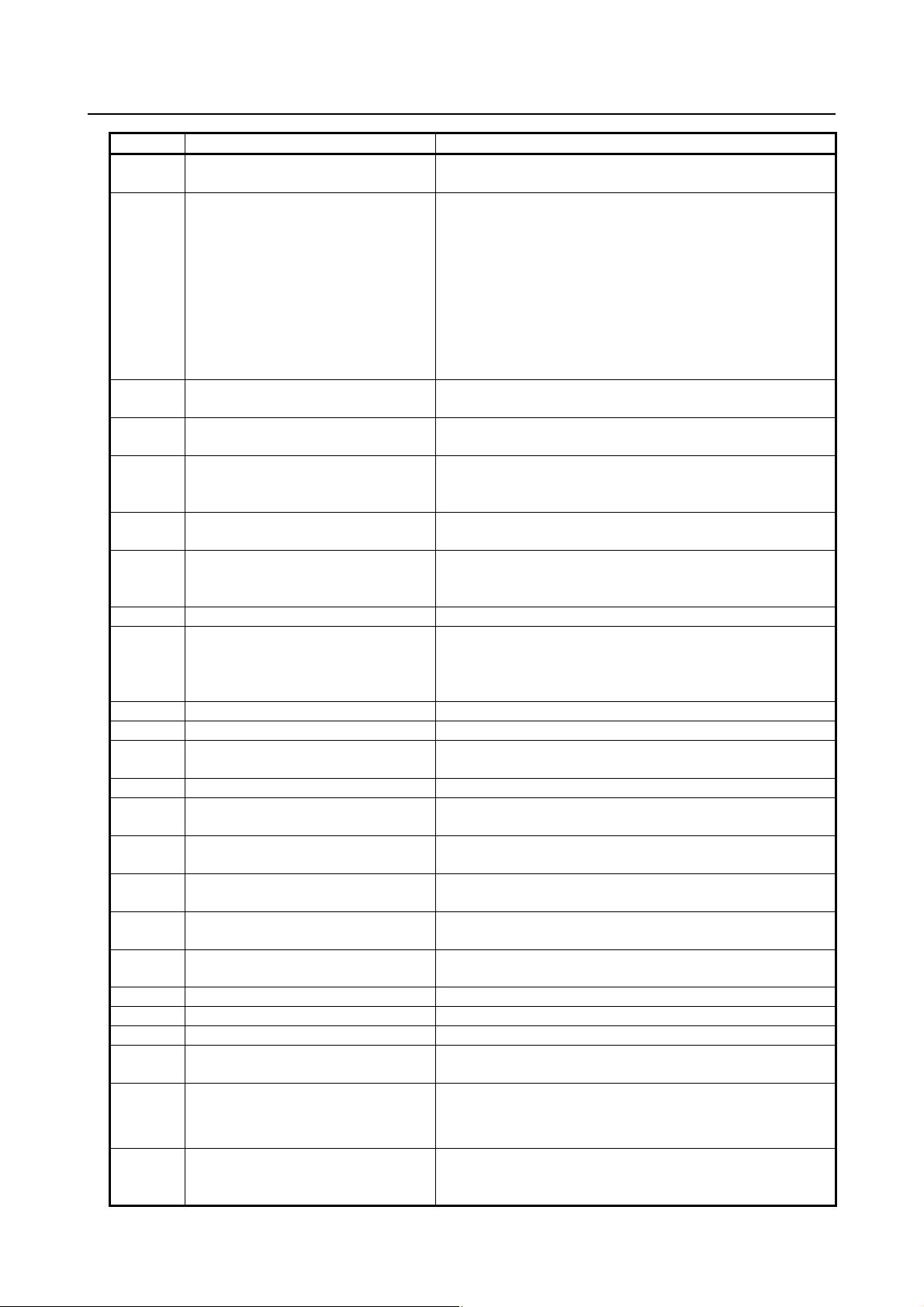

Number Message Description

0005 NO DATA AFTER ADDRESS NC word(s) address + numerical value not in word format.

This alarm is also generated when a custom macro does not

contain a reserved word, or does not conform to the syntax.

0006 ILLEGAL USE OF MINUS SIGN A minus sign (–) was specified at an NC instruction word or

system variable where no minus signal may be specified.

0007 ILLEGAL USE OF DECIMAL POINT A decimal point (.) was specified at an address where no

decimal point may be specified, or two decimal points were

specified.

0009 IMPROPER NC-ADDRESS An illegal address was specified, or parameter 1020 is not set.

0010 IMPROPER G-CODE An unusable G code is specified.

0011 FEED ZERO ( COMMAND ) The cutting feedrate instructed by an F code has been set to

0.

This alarm is also generated if the F code instructed for the S

code is set extremely small in a rigid tapping instruction as the

tool cannot cut at the programmed lead.

0015 TOO MANY SIMULTANEOUS AXES A move command was specified for more axes than can be

controlled by simultaneous axis control.

Either divide the number of programmed move axes into two

blocks.

0020 OVER TOLERANCE OF RADIUS An arc was specified for which the difference in the radius at

the start and end points exceeds the value set in parameter

No. 3410. Check arc center codes I, J and K in the program.

The tool path when parameter No. 3410 is set to a large value

is spiral.

0021 ILLEGAL PLANE SELECT The plane selection instructions G17 to G19 are in error.

Reprogram so that same 3 basic parallel axes are not

specified simultaneously.

This alarm is also generated when an axis that should not be

specified for plane machining is specified, for example, for

circular interpolation.

T

In the 0i -TD, the helical interpolation option is needed to

enable the specification of 3 or more axes for the G02/G03

block.

0022 R OR I,J,K COMMAND NOT FOUND The command for circular interpolation lacks arc radius R or

coordinate I, J, or K of the distance between the start point to

the center of the arc.

M

0025 CIRCLE CUT IN RAPID (F0)

F0 (rapid traverse in one-digit F code feed or inverse feed)

was specified during circular interpolation (G02, G03).

M

0027 NO AXES COMMANDED IN

G43/G44

No axis is specified in G43 and G44 blocks for the tool length

offset type C.

Offset is not canceled but another axis is offset for the tool

length offset type C.

Multiple axes were specified for the same block when the tool

length compensation type is C.

- 436 -

Page 3

B-64305EN/03 APPENDIX A.ALARM LIST

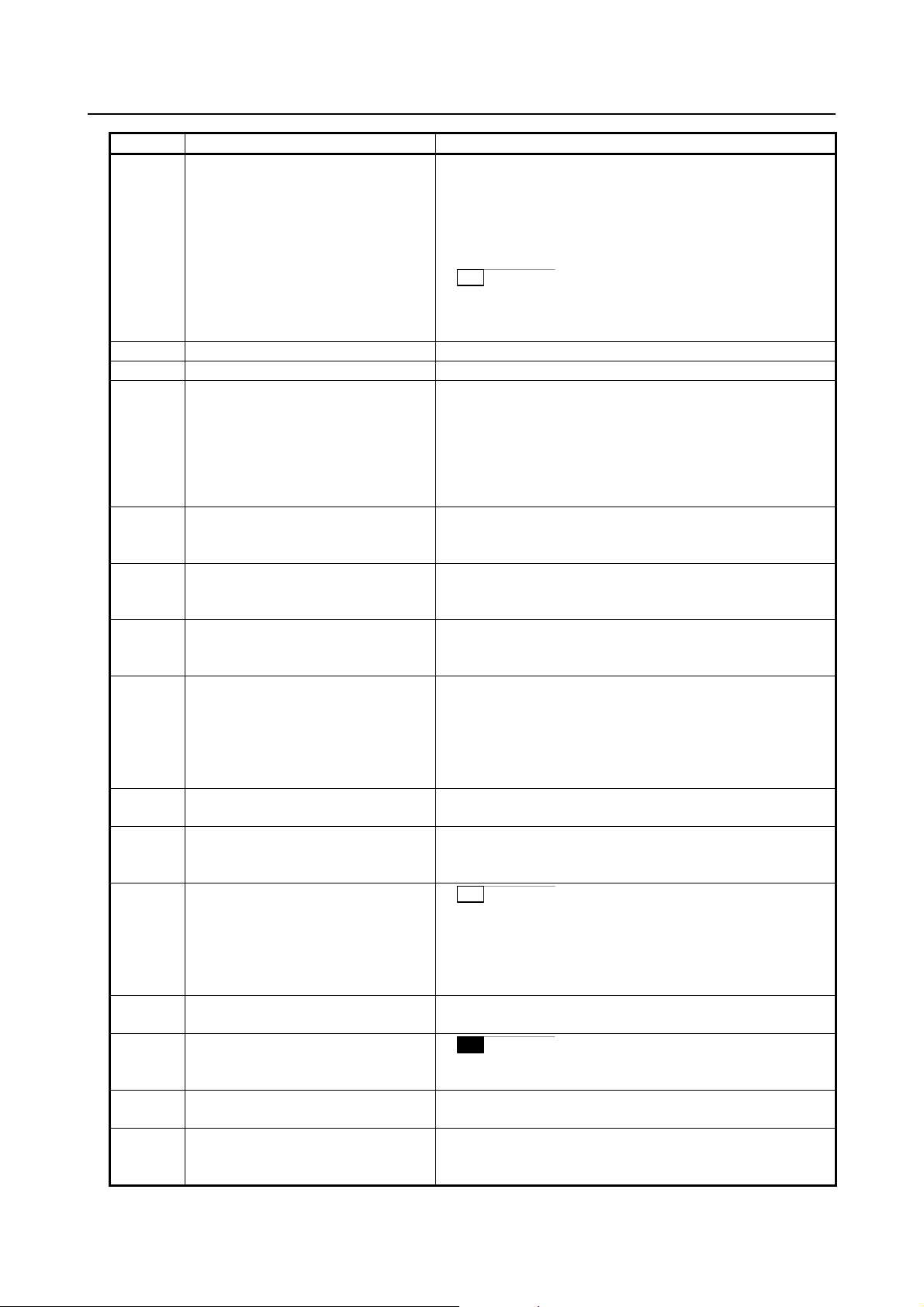

Number Message Description

0028 ILLEGAL PLANE SELECT The plane selection instructions G17 to G19 are in error.

Reprogram so that same 3 basic parallel axes are not

specified simultaneously.

This alarm is also generated when an axis that should not be

specified for plane machining is specified, for example, for

circular interpolation.

T

i -TD, the helical interpolation option is needed to

In the 0

enable the specification of 3 or more axes for the G02/G03

block.

0029 ILLEGAL OFFSET VALUE Illegal offset No.

0030 ILLEGAL OFFSET NUMBER An illegal offset No. was specified.

0031 ILLEGAL P COMMAND IN G10

Data input for the L No. of G10 or the corresponding function

is not enabled.

A data setting address such as P or R is not specified.

An address command not concerned with data setting was

specified. An address varies with the L No.

The sign or decimal point of the specified address is in error,

or the specified address is out of range.

0032 ILLEGAL OFFSET VALUE IN G10 In setting an offset amount by G10 or in writing an offset

amount by system variables, the offset amount was

excessive.

0033 NO INTERSECTION AT G41/G42 The intersection cannot be obtained by the intersection

calculation in tool radius/tool nose radius compensation.

Modify the program.

0034 ONLY G00/G01 ALLOWED IN

STUP/EXT BLK

An attempt was made to perform a start-up or cancel of cutter

compensation or tool nose radius compensation not in the

G00/G01 mode. Modify the program.

0035 CAN NOT COMMANDED G31 1) G31 cannot be specified. This alarm is generated when a

G code (such as for tool radius/tool nose radius

compensation) of group 07 is not canceled.

2) A torque limit skip was not specified in a torque limit skip

command (G31P98 or P99). Specify the torque limit skip in

the PMC window or the like.

0037 CAN NOT CHANGE PLANE IN

G41/G42

0038 INTERFERENCE IN CIRCULAR

BLOCK

The compensation plane G17/G18/G19 was changed during

cutter or tool-nose radius compensation. Modify the program.

Overcutting will occur in tool radius/tool nose radius

compensation because the arc start point or end point

coincides with the arc center. Modify the program.

0039 CHF/CNR NOT ALLOWED IN

G41,G42

T

Chamfering or corner R was specified with a start-up, a

cancel, or switching between G41 and G42 in G41 and G42

commands (tool nose radius compensation). The program

may cause overcutting to occur in chamfering or corner R.

Modify the program.

0041 INTERFERENCE IN G41/G42 In tool radius/tool nose radius compensation, excessive

cutting may occur. Modify the program.

M

0042 G45/G48 NOT ALLOWED IN CRC

Tool offset (G45 to G48) is commanded in tool radius

compensation mode. Modify the program.

0044 G27-G30 NOT ALLOWED IN FIXED

CYC

0045 ADDRESS Q NOT FOUND

(G73/G83)

One of G27 to G30 (G29 is only for the M series) is

commanded in canned cycle mode. Modify the program.

In a high-speed peck drilling cycle or peck drilling cycle, the

amount of each-time cutting is not specified by address Q, or

Q0 is specified. Modify the program.

- 437 -

Page 4

A.ALARM LIST APPENDIX B-64305EN/03

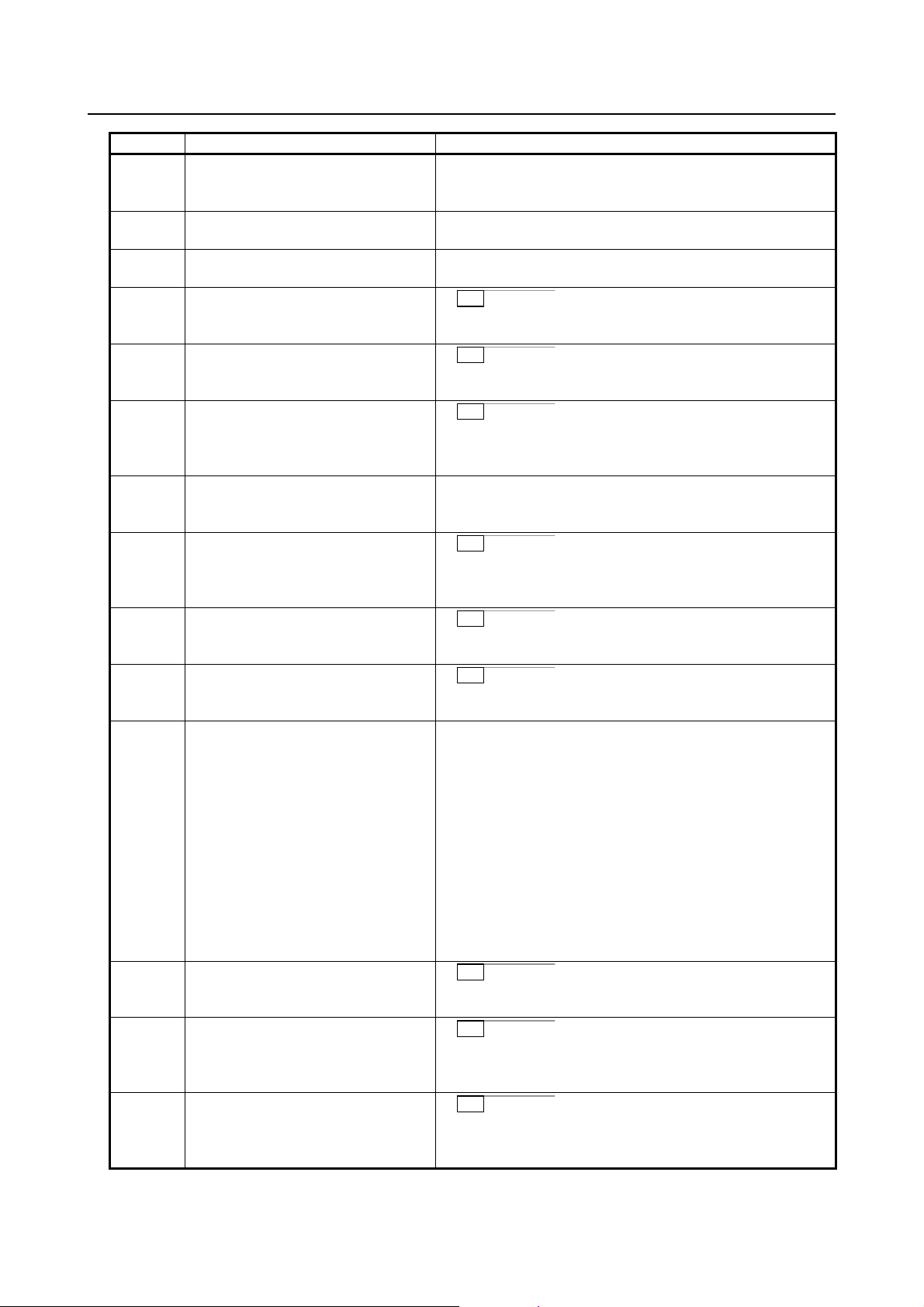

Number Message Description

0046 ILLEGAL REFERENCE RETURN

COMMAND

0050 CHF/CNR NOT ALLOWED IN THRD

BLK

0051 MISSING MOVE AFTER CNR/CHF The travel or travel distance is incorrect in the block next to

0052 CODE IS NOT G01 AFTER

CHF/CNR

0053 TOO MANY ADDRESS COMMANDS

0054 NO TAPER ALLOWED AFTER

CHF/CNR

0055 MISSING MOVE VALUE IN

CHF/CNR

0056 NO END POINT & ANGLE IN

CHF/CNR

0057 NO SOLUTION OF BLOCK END

0058 END POINT NOT FOUND

0060 SEQUENCE NUMBER NOT FOUND [External data input/output]

0061 P OR Q COMMAND IS NOT IN THE

MULTIPLE REPETIVE CYCLES

BLOCK

0062 THE CUTTING AMOUNT IS

ILLEGAL IN THE ROUGH CUTTING

CYCLE

0063 THE BLOCK OF A SPECIFIED

SEQUENCE NUMBER IS NOT

FOUND

A command for a return to the second, third or fourth

reference position is error. (The address P command is in

error.)

The chamfering or corner R block is specified in a threading

block. Modify the program.

the chamfering or corner R. Modify the program.

T

The block next to the chamfering or corner R block is not G01

(or vertical line). Modify the program.

T

In the chamfering and corner R commands, two or more of I,

J, K and R are specified.

T

A block in which chamfering in the specified angle or the

corner R was specified includes a taper command. Modify the

program.

The travel distance specified in the chamfering or corner R

block is smaller than the amount of the chamfering or corner

R. Modify the program.

T

In direct dimension drawing programming, both an end point

and an angle were specified in the block next to the block in

which only an angle was specified (Aa). Modify the program.

T

Block end point is not calculated correctly in direct dimension

drawing programming. Modify the program.

T

Block end point is not found in direct dimension drawing

programming. Modify the program.

The specified number could not be found for program

number and sequence number searches.

A request was issued for input/output of an offset amount for

tool data, but a tool number has never been entered after

power-up. The tool data corresponding to the entered tool

number could not be found.

[External workpiece number search]

The program corresponding to the specified workpiece

number could not be found.

[Program restart]

In the program restart sequence number specification, the

specified sequence number could not be found.

T

Address P or Q is not specified in multiple repetitive cycle

(G70, G71, G72, or G73) command.

T

A zero or a negative value was specified in a multiple

repetitive canned rough-cutting cycle (G71 or G72) as the

depth of cut.

T

The sequence number specified by addresses P and Q in

multiple repetitive cycle (G70, G71, G72, or G73) command

cannot be searched.

- 438 -

Page 5

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0064 THE FINISHING SHAPE IS NOT A

MONOTONOUS CHANGE(FIRST

AXES)

T

In a shape program for the multiple repetitive canned

rough-cutting cycle (G71 or G72), the command for the first

plane axis was not a monotonous increase or decrease.

0065 G00/G01 IS NOT IN THE FIRST

BLOCK OF SHAPE PROGRAM

T

In the first block of the shape program specified by P of the

multiple repetitive canned cycle (G70, G71, G72, or G73),

G00 or G01 was not specified.

0066 UNAVAILABLE COMMAND IS IN

THE MULTIPLE REPETIVE CYCLES

BLOCK

0067 THE MULTIPLE REPETIVE CYCLES

IS NOT IN THE PART PROGRAM

STORAGE

0069 LAST BLOCK OF SHAPE

PROGRAM IS AN ILLEGAL

COMMAND

T

An unavailable command was found in a multiple repetitive

canned cycle (G70, G71, G72, or G73) command block.

T

A multiple repetitive canned cycle (G70, G71, G72, or G73)

command is not registered in a tape memory area.

T

In a shape program in the multiple repetitive canned cycle

(G70, G71, G72, or G73), a command for the chamfering or

corner R in the last block is terminated in the middle.

0070 NO PROGRAM SPACE IN MEMORY The memory area is insufficient.

Delete any unnecessary programs, then retry.

0071 DATA NOT FOUND 1) The address to be searched was not found.

2) The program with specified program number was not found

in program number search.

3) In the program restart block number specification, the

specified block number could not be found.

Check the data.

0072 DATA NOT FOUND The number of programs to be stored exceeded 400 (1-path

system) or 800 (2-path system of T series). Delete

unnecessary programs and execute program registration

again.

0073 PROGRAM NUMBER ALREADY IN

USE

The commanded program number has already been used.

Change the program number or delete unnecessary programs

and execute program registration again.

0074 PROGRAM NUMBER ALREADY IN

USE

The program number is other than 1 to 9999. Modify the

program number.

0075 PROTECT An attempt was made to register a program whose number

was protected.

In program matching, the password for the encoded program

was not correct.

An attempt was made to select a program being edited in the

background as the main program.

An attempt was made to call a program being edited in the

background as a subprogram.

0076 PROGRAM NOT FOUND The specified program is not found in the subprogram call or

macro call.

The M, G, or T codes are called by a P instruction other than

that in an M98, M198, G65, G66, or interrupt type custom

macro, and a program is called by a specific address.

This alarm is also generated when a program is not found by

these calls.

0077 TOO MANY SUB,MACRO NESTING The total number of subprogram and macro calls exceeds the

permissible range.

Another subprogram call was executed during an external

memory subprogram call.

- 439 -

Page 6

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

0078 SEQUENCE NUMBER NOT FOUND The specified sequence No. was not found during sequence

number search.

The sequence No. specified as the jump destination in

GOTO–– and M99P–– was not found.

0079 PROGRAM NOT MATCH The program in memory does not match the program stored

on tape.

Multiple programs cannot be matched continuously when bit 6

(NPE) of parameter No. 3201 is set to “1”.

Set bit 6 (NPE) of parameter No. 3201 to “0” before executing

a match.

M

0080 G37 MEASURING POSITION

REACHED SIGNAL IS NOT

PROPERLY INPUT

0081 G37 OFFSET NO. UNASSIGNED

0082 G37 SPECIFIED WITH H CODE

0083 G37 IMPROPER AXIS COMMAND

0085 OVERRUN ERROR The next character was received from the I/O device

When the tool length measurement function (G37) is

performed, a measuring position reached signal goes 1 in

front of the area determined by the ε value specified in

parameter No.6254. Alternatively, the signal does not go 1.

T

When the automatic tool compensation function (G36, G37)

is used, a measuring position reached signals (XAE1, XAE2)

does not go 1 within the range determined by the ε value

specified in parameters Nos.6254 and 6255.

M

The tool length measurement function (G37) is specified

without specifying an H code.

Correct the program.

T

The automatic tool compensation function (G36, G37) is

specified without specifying an T code.

Correct the program.

M

The tool length measurement function (G37) is specified

together with an H code in the same block.

Correct the program.

T

The automatic tool compensation function (G36, G37) is

specified together with an T code in the same block.

Correct the program.

M

An error has been found in axis specification of the tool

length measurement function (G37). Alternatively, a move

command is specified as an incremental command.

Correct the program.

T

An error has been found in axis specification of the

automatic tool compensation function (G36, G37).

Alternatively, a command is specified as an incremental

command.

Correct the program.

connected to reader/punch interface 1 before it could read a

previously received character.

An overrun, parity error, or framing error occurred during the

reading by reader/punch interface 1. The number of bits in

the entered data, the baud rate setting, or the I/O unit

specification number is incorrect.

- 440 -

Page 7

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0086

DR OFF During I/O process by reader/punch interface 1, the data set

ready input signal of the I/O device (DR) was OFF. Possible

causes are an I/O device not turn on, a broken cable, and a

defective printed circuit board.

0087

BUFFER OVERFLOW During a read by reader/punch interface 1, although a read

stop command was issued, more than 10 characters were

input. The I/O device or printed circuit board was defective.

0090 REFERENCE RETURN

INCOMPLETE

1) The reference position return cannot be performed

normally because the reference position return start point

is too close to the reference position or the speed is too

slow. Separate the start point far enough from the

reference position, or specify a sufficiently fast speed for

reference position return.

2) An attempt was made to set the zero position for the

absolute position detector by return to the reference

position when it was impossible to set the zero point.

Rotate the motor manually at least one turn, and set the

zero position of the absolute position detector after turning

the CNC and servo amplifier off and then on again.

0091 MANUAL REFERENCE POSITION

RETURN IS NOT PERFORMED IN

FEED HOLD

Manual return to the reference position cannot be performed

when automatic operation is halted. Perform the manual

return to the reference position when automatic operation is

stopped or reset.

0092 ZERO RETURN CHECK (G27)

ERROR

The axis specified in G27 has not returned to reference

position.

Reprogram so that the axis returns to reference position.

0094 P TYPE NOT ALLOWED (COORD

CHG)

P type cannot be specified when the program is restarted.

(After the automatic operation was interrupted, the coordinate

system setting operation was performed.) Perform the correct

operation according to the User's manual.

0095 P TYPE NOT ALLOWED (EXT OFS

CHG)

P type cannot be specified when the program is restarted.

(After the automatic operation was interrupted, the external

workpiece origin offset amount changed.) Perform the correct

operation according to the User's manual.

0096 P TYPE NOT ALLOWED (WRK OFS

CHG)

P type cannot be specified when the program is restarted.

(After the automatic operation was interrupted, the workpiece

origin offset amount changed.) Perform the correct operation

according to the User's manual.

0097 P TYPE NOT ALLOWED (AUTO

EXEC)

P type cannot be directed when the program is restarted.

(After power ON or alarms 0094 to 0097 reset, no automatic

operation is performed.) Perform automatic operation.

0099 MDI EXEC NOT ALLOWED AFT.

SEARCH

0109 FORMAT ERROR IN G08

After completion of search in program restart, a move

command is given with MDI.

T

A value other than 0 or 1 was specified after P in the G08

code, or no value was specified.

0110 OVERFLOW :INTEGER An integer went out of range during arithmetic calculations.

0111 OVERFLOW :FLOATING A decimal point (floating point number format data) went out

of range during arithmetic calculations.

0112 ZERO DIVIDE An attempt was made to divide by zero in a custom macro.

0113 IMPROPER COMMAND A function which cannot be used in custom macro is

commanded. Modify the program.

0114 ILLEGAL EXPRESSION FORMAT The format used in an expression in a custom macro

statement is in error. The parameter tape format is in error.

0115 VARIABLE NO. OUT OF RANGE A number that cannot be used for a local variable, common

variable, or system variable in a custom macro is specified.

- 441 -

Page 8

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

0116 WRITE PROTECTED VARIABLE An attempt was made in a custom macro to use on the left

side of an expression a variable that can only be used on the

right side of an expression.

0118 TOO MANY BRACKET NESTING Too many brackets “[ ]” were nested in a custom macro.

The nesting level including function brackets is 5.

0119 ARGUMENT VALUE OUT OF

RANGE

0122 TOO MANY MACRO NESTING Too many macro calls were nested in a custom macro.

0123 ILLEGAL MODE FOR

GOTO/WHILE/DO

0124 MISSING END STATEMENT The END instruction corresponding to the DO instruction was

0125 MACRO STATEMENT FORMAT

ERROR

0126 ILLEGAL LOOP NUMBER DO and END Nos. in a custom macro are in error, or exceed

0127 DUPLICATE NC,MACRO

STATEMENT

0128 ILLEGAL MACRO SEQUENCE

NUMBER

0129 USE 'G' AS ARGUMENT G is used as an argument in a custom macro call. G cannot

0130 NC AND PMC AXIS ARE

CONFLICTED

0136 SPOS AXIS - OTHER AXIS SAME

TIME

0137 M-CODE & MOVE CMD IN SAME

BLK.

0139 CANNOT CHANGE PMC CONTROL

AXIS

0140 PROGRAM NUMBER ALREADY IN

USE

0142 ILLEGAL SCALE RATE

0143 COMMAND DATA OVERFLOW An overflow occurred in the storage length of the CNC internal

0144 ILLEGAL PLANE SELECTED

The value of an argument in a custom macro function is out of

range.

A GOTO statement or WHILE–DO statement was found in the

main program in the MDI or DNC mode.

missing in a custom macro.

The format used in a macro statement in a custom macro is in

error.

the permissible range (valid range: 1 to 3).

An NC statement and macro statement were specified in the

same block.

The specified sequence No. could not be found for sequence

number search.

The sequence No. specified as the jump destination in

GOTO-- and M99P-- could not be found.

be used as an argument.

The NC command and the PMC axis control command were

conflicted. Modify the program or ladder.

T

The M code for spindle positioning and an axis address not for

a spindle positioning axis were specified simultaneously.

Alternatively, the axis addresses of a spindle positioning axis

and non-spindle positioning axis were specified

simultaneously in the spindle positioning mode.

T

The M code for spindle positioning and the axis address of a

spindle positioning axis were specified simultaneously.

The PMC axis was selected for the axis for which the PMC

axis is being controlled.

In the background, an attempt was made to select or delete

the program being selected in the foreground. Perform the

correct operation for the background edition.

M

The scaling rate is 0 times or 10000 times or more.

Modify the setting of the scaling rate. (G51P_ … or

G51I_J_K_ … or parameter No. 5411 or 5421)

data. This alarm is also generated when the result of internal

calculation of scaling (M series), coordinate rotation (M

series), and cylindrical interpolation overflows the data

storage. It also is generated during input of the manual

intervention amount.

M

The coordinate rotation plane and arc or cutter compensation

plane must be the same. Modify the program.

- 442 -

Page 9

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0145 ILLEGAL USE OF G12.1/G13.1

T

The axis No. of plane selection parameter No. 5460 (linear

axis) and No. 5461(axis of rotation) in the polar coordinate

interpolation mode is out of range (1 to number of controlled

axes).

0146 ILLEGAL USE OF G-CODE

T

The G code must be G40 modal when the polar coordinate

interpolation mode is set or canceled.

An illegal G code was specified while in the polar coordinate

interpolation mode.

Only the following G codes can be specified in this mode.

G01,G02,G03,G04,G40,G41,G42,G65,G66,G67,

(G90 and G91 for the G code system B or C),

G98,G99

M

0148 SETTING ERROR

Automatic corner override deceleration rate is out of the

settable range of judgement angle. Modify the parameters

Nos.1710 to 1714.

0149

FORMAT ERROR IN G10L3

In registration (G10L3 to G11) of tool life management data,

an address other than Q1, Q2, P1, and P2 or an unusable

address was specified.

0150 ILLEGAL LIFE GROUP NUMBER The tool group number exceeded the maximum allowable

value. The tool group number (P after specification of G10

L3;) or the group number given by the tool life management T

code in a machining program.

0151 GROUP NOT FOUND AT LIFE DATA The tool group specified in a machining program is not set in

tool life management data.

0152 OVER MAXIMUM TOOL NUMBER The number of tools registered in one group exceeded the

maximum allowable registration tool number.

0153 T-CODE NOT FOUND In registration of tool life data, a block in which the T code

needs to be specified does not include the T code.

Alternatively, in tool exchange method D, M06 is specified

solely. Modify the program.

0154 NOT USING TOOL IN LIFE GROUP The H99 command, D99 command, or the H/D code set by

parameters Nos. 13265 and 13266 was specified when no

tool belonging to a group is used.

0155 ILLEGAL T-CODE COMMAND In a machining program, the T code specified in the same

block as M06 does not correspond to the group in current use.

Modify the program.

0156 P/L COMMAND NOT FOUND The P and L commands are not specified in the beginning of a

program for setting a tool group. Modify the program.

0157 TOO MANY TOOL GROUPS In registration of tool life management data, the group setting

command block counts of P (group number) and L (tool life)

exceeded the maximum group count.

0158 TOOL LIFE VALUE OUT OF RANGE The life value that is being set is too large. Change the

setting.

0159 ILLEGAL TOOL LIFE DATA Tool life management data is corrupted for some reason.

Register the tool data in the tool group or the tool data in the

group again by G10L3; or MDI input.

0160 MISMATCH WAITING M-CODE A waiting M-code is in error.

Different waiting M codes are specified for paths 1 and 2.

0163 ILLEGAL COMMAND IN G68/G69

T

G68 and G69 are not independently commanded in balance

cut.

0169 ILLEGAL TOOL GEOMETRY DATA

T

Incorrect tool figure data in interference check. Set correct

data, or select correct tool figure data.

- 443 -

Page 10

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

0175 ILLEGAL G07.1 AXIS An axis which cannot perform cylindrical interpolation was

specified. More than one axis was specified in a G07.1 block.

An attempt was made to cancel cylindrical interpolation for an

axis that was not in the cylindrical interpolation mode.

In cylindrical interpolation mode, to specify circular

interpolation including a rotation axis (when bit 0 (ROT) of

parameter No. 1006 is 1 and parameter No. 1260 is set), the

value of rotation axis parameter No. 1022 must not be 0 but 5,

6, or 7 for parallel axis specification.

0176 ILLEGAL G-CODE USE(G07.1

MODE)

0190 ILLEGAL AXIS SELECTED (G96) An illegal value was specified in P in a G96 block or

0194 SPINDLE COMMAND IN

SYNCHRO-MODE

0197 C-AXIS COMMANDED IN SPINDLE

MODE

0199 MACRO WORD UNDEFINED Undefined macro word was used. Modify the custom macro.

0200 ILLEGAL S CODE COMMAND In the rigid tap, an S value was out of range or was not

0201 FEEDRATE NOT FOUND IN RIGID

TAP

0202 POSITION LSI OVERFLOW In the rigid tap, spindle distribution value is too large. (System

0203 PROGRAM MISS AT RIGID

TAPPING

0204 ILLEGAL AXIS OPERATION In the rigid tap, an axis movement is specified between the

0205 RIGID MODE DI SIGNAL OFF Although a rigid M code (M29) is specified in rigid tapping, the

0206 CAN NOT CHANGE PLANE (RIGID

TAP)

0207 RIGID DATA MISMATCH The specified distance was too short or too long in rigid

A G code was specified that cannot be specified in the

cylindrical interpolation mode. This alarm also is generated

when an 01 group G code was in the G00 modal or code G00

was instructed.

Cancel the cylindrical interpolation mode before instructing

code G00.

parameter No. 3770.

T

A Cs contour control mode, spindle positioning command, or

rigid tapping mode was specified during the spindle

synchronous control mode.

M

A Cs contour control mode or rigid tapping mode was

specified during the spindle synchronous control mode or

simple spindle synchronous control mode.

The program specified a movement along the Cs-axis when

the Cs contour control switching signal was off.

specified. The parameters Nos. 5241 to 5243 setting is an S

value which can be specified for the rigid tap.

Correct the parameters or modify the program.

The command F code for a cutting feedrate is a zero.

If the value of F command is much smaller than that of the S

command, when a rigid tap command is specified, this alarm

is generated. This is because cutting is not possible by the

lead specified by the program.

error)

In the rigid tap, position for a rigid M code (M29) or an S

command is incorrect. Modify the program.

rigid M code (M29) block and G84 (or G74) block. Modify the

program.

rigid mode DI signal (DGN G061.0) is not ON during

execution of the G84 (or G74) block. Check the PMC ladder

diagram to find the reason why the DI signal is not turned on.

Plane changeover was instructed in the rigid mode. Modify the

program.

tapping.

- 444 -

Page 11

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0210 CAN NOT COMMAND M198/M99 1) The execution of an M198 or M99 command was attempted

during scheduled operation. Alternatively, the execution of

an M198 command was attempted during DNC operation.

Modify the program.

T

2) The execution of an M99 command was attempted by an

interrupt macro during pocket machining in a multiple

repetitive canned cycle.

0213 ILLEGAL COMMAND IN

SYNCHRO-MODE

In feed axis control , the following errors occurred during the

synchronous operation.

1) The program issued the move command to the slave axis.

2) The program issued the manual operation to the slave

axis.

3) The program issued the automatic reference position

return command without specifying the manual reference

position return after the power was turned on.

0214 ILLEGAL COMMAND IN

SYNCHRO-MODE

Coordinate system is set or tool length compensation (M

series) of the shift type is executed in the synchronous control.

Correct the program.

0217 DUPLICATE G51.2(COMMANDS)

T

G51.2 is further commanded in the G51.2 mode. Modify the

program.

0218 NOT FOUND P/Q COMMAND

T

P or Q is not commanded in the G51.2 block, or the command

value is out of the range. Modify the program. For a polygon

turning between spindles, more information as to why this

alarm occurred is indicated in DGN No. 471.

0219 COMMAND G51.2/G50.2

INDEPENDENTLY

T

G51.2 and 50.2 were specified in the same block for other

commands. Modify the program in another block.

0220 ILLEGAL COMMAND IN

SYNCHR-MODE

In the synchronous operation, movement is commanded by

the NC program or PMC axis control interface for the

synchronous axis. Modify the program or check the PMC

ladder.

0221 ILLEGAL COMMAND IN

SYNCHR-MODE

T

Polygon machining synchronous operation and Cs axis

contour control or balance cutting are executed at a time.

Modify the program.

0222 DNC OP. NOT ALLOWED IN

BG-EDIT

Input and output are executed at a time in the background

edition. Execute a correct operation.

0224 ZERO RETURN NOT FINISHED 1) A reference position return has not been performed

before the start of automatic operation.

(Only when bit 0 (ZRNx) of parameter No. 1005 is 0)

Perform a reference position return.

T

2) A command was specified for a spindle positioning axis

not in the spindle positioning mode.

Perform spindle orientation.

0230 R CODE NOT FOUND

M

Cut depth R is not specified in the block including G161.

Alternatively, the value specified for R is negative.

Modify the program.

0231 ILLEGAL FORMAT IN G10 L52 Errors occurred in the specified format at the

programmable-parameter input.

0232 TOO MANY HELICAL AXIS

COMMAND

Three or more axes were specified as helical axes in the

helical interpolation mode.

- 445 -

Page 12

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

0233 DEVICE BUSY When an attempt was made to use a unit such as that

connected via the RS-232-C interface, other users were using

it.

0245 T-CODE NOT ALLOWED IN THIS

BLOCK

0247 THE MISTAKE IS FOUND IN THE

OUTPUT CODE OF DATA.

0250 TOOL CHANGE ILLEGAL Z AXIS

COMMAND

0251 TOOL CHANGE ILLEGAL T

COMMAND

0300 ILLEGAL COMMAND IN SCALING An illegal G code was specified during scaling. Modify the

0301 RESETTING OF REFERENCE

RETURN IS INHIBITED

0302 SETTING THE REFERENCE

POSITION WITHOUT DOG IS NOT

PERFORMED

0304 G28 IS COMMANDED WITHOUT

ZERO RETURN

0305 INTERMEDIATE POSITION IS NOT

ASSIGNED

0306 MISMATCH AXIS WITH CNR/CHF

0307 CAN NOT START REFERENCE

RETURN WITH MECHANICAL

STOPPER SETTING

0310 FILE NOT FOUND The specified file could not be found during a subprogram or

0311 CALLED BY FILE NAME FORMAT

ERROR

0312 ILLEGAL COMMAND IN DIRECT

DRAWING DIMENSIONS

PROGRAMMING

0313 ILLEGAL LEAD COMMAND

One of the G codes, G04,G10,G28,G29 (M series),G30,G50

(T series), and G53, which cannot be specified in the same

block as a T code, was specified with a T code.

When an encrypted program is output, EIA is set for the

output code. Specify ISO.

A Z-axis move command was performed in the same block for

M06 command.

An unusable T code was specified in M06Txx.

program.

Although bit 0 (IDGx) of parameter No. 1012 was set to 1 to

inhibit the reference position from being set again for a return

to the reference position without a dog, an attempt was made

to perform a manual return to the reference position.

The reference position could not be set for a return to the

reference position without a dog. Possible causes are:

- The axis was not moved in the direction of a return to the

reference position for jog feeding.

- The axis was moved in the direction opposite to the direction

of a manual return to the reference position.

Although a reference position was not set, an automatic return

to the reference position (G28) was commanded.

M

Although a G28 (automatic return to the reference position) or

G30 (return to the second, third, or fourth reference position)

command was not issued after power-up, G29 (return from the

reference position) was commanded.

T

The correspondence between the moving axis and the I, J, or

K command is incorrect in a block in which chamfering is

specified.

An attempt was made to set a butt-type reference position for

an axis for which to use the function to set a reference

position without a dog.

macro call.

An invalid format was specified to call a subprogram or macro

using a file name.

T

Direct input of drawing dimensions was commanded in an

invalid format.

An attempt was made to specify an invalid G code during

direct input of drawing dimensions.

Two or more blocks not to be moved exist in consecutive

commands that specify direct input of drawing dimensions.

Although non-use of commas (,) (parameter No. 3405#4 = 1)

was specified for direct input of drawing dimensions, a comma

was specified.

T

The variable-lead threading increment specified in address K

exceeds the specified maximum value in variable-lead

threading. Or, a negative lead value was specified.

- 446 -

Page 13

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0314 ILLEGAL SETTING OF POLYGONAL

AXIS

T

An axis was specified invalidly in polygon turning.

For polygon turning:

1) A tool rotation axis is not specified.

(Parameter No. 7610)

For polygon turning between spindles:

1) Valid spindles are not specified.

(Parameters Nos. 7640 to 7643)

2) A spindle other than the serial spindle.

3) A spindle is not connected.

0315 ILLEGAL NOSE ANGLE COMMAND

IS IN THE THREAD CUTTING

CYCLE

0316 ILLEGAL CUTTING AMOUNT IS IN

THE THREAD CUTTING CYCLE

T

An invalid tool tip angle is specified in a multiple repetitive

canned threading cycle (G76).

T

An minimum depth of cut higher than the thread height is

specified in a multiple repetitive canned threading cycle (G76).

0317 ILLEGAL THREAD COMMAND IS IN

THE THREAD CUTTING CYCLE

T

A zero or a negative value is specified in a multiple repetitive

canned threading cycle (G76) as the thread height or the

depth of cut.

0318 ILLEGAL RELIEF AMOUNT IS IN

THE DRILLING CYCLE

T

Although an escape directions is set in a multiple repetitive

canned cutting-off cycle (G74 or G75), a negative value is

specified for Δd.

0319 THE END POINT COMMAND IS

ILLEGAL IN THE DRILLING CYCLE

T

Although the Δi or Δk travel distance is set to 0 in a multiple

repetitive canned cutting-off cycle (G74 or G75), a value other

than 0 us specified for a U or W.

0320 ILLEGAL MOVEMENT

AMOUNT/CUTTING AMOUNT IS IN

THE DRILLING CYCLE

T

A negative value is specified in a multiple repetitive canned

cutting-off cycle (G74 or G75) as Δi or Δk (travel distance/the

depth of cut).

0321 ILLEGAL REPEATED TIME IS IN

THE PATTERN REPEATING CYCLE

T

A zero or a negative value is specified in a multiple repetitive

canned closed loop cycle (G73) as a repeated time.

0322 FINISHING SHAPE WHICH OVER

OF STARTING POINT

T

An invalid shape which is over the cycle starting point is

specified in a shape program for a multiple repetitive canned

rough-cutting cycle (G71 or G72).

0323 THE FIRST BLOCK OF SHAPE

PROGRAM IS A COMMAND OF

TYPE II

T

Type II is specified in the first block of the shape program

specified by P in a multiple repetitive canned rough-cutting

cycle (G71 or G72). For G71, Z(W) is specified. For G72, X(U)

is specified.

0324 THE INTERRUPTION TYPE MACRO

WAS DONE IN THE MULTIPLE

REPETIVE CYCLES

0325 UNAVAILABLE COMMAND IS IN

SHAPE PROGRAM

T

An interruption type macro was issued during the multiple

repetitive canned cycle (G70, G71, G72, or G73).

T

An usable command was issued in a shape program for a

multiple repetitive canned cycle (G70, G71, G72, or G73).

0326 LAST BLOCK OF SHAPE

PROGRAM IS A DIRECT DRAWING

DIMENSIONS

T

In a shape program in the multiple repetitive canned cycle

(G70, G71, G72, or G73), a command for direct input of

drawing dimensions in the last block is terminated in the

middle.

- 447 -

Page 14

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

0327 MODAL THAT MULTIPLE

REPETIVE CYCLES CANNOT BE

DONE

0328 ILLEGAL WORK POSITION IS IN

THE TOOL NOSE RADIUS

COMPENSATION

0329 THE FINISHING SHAPE IS NOT A

MONOTONOUS CHANGE(SECOND

AXES)

0330 ILLEGAL AXIS COMMAND IS IN

THE TURNING CANNED CYCLE

0334 OFFSET IS OUT OF EFFECTIVE

RANGE

0336 TOOL COMPENSATION

COMMANDED MORE TWO AXES

0337 EXCESS MAXIMUM INCREMENTAL

VALUE

0338 ILLEGAL EXEC SEQ OF BLOCK An incorrect value was detected in a check sum.

0345 TOOL CHANGE ILLEGAL Z AXIS

POS

0346 TOOL CHANGE ILLEGAL TOOL

NUM

0347 TOOL CHANGE ILLEGAL

COMMAND IN SAME BLK.

0348 TOOL CHANGE Z AXIS POS NOT

ESTABLISHED

0349 TOOL CHANGE SPINDLE NOT

STOP

0350 PARAMETER OF THE INDEX OF

THE SYNCHRONOUS CONTROL

AXIS SET ERROR.

0351 BECAUSE THE AXIS IS MOVING,

THE SYNC CONTROL IS CAN'T BE

USED.

0352 SYNCHRONOUS CONTROL AXIS

COMPOSITION ERROR.

T

A multiple repetitive canned cycle (G70, G71, G72, or G73)

was commanded in a modal state in which a multiple

repetitive canned cycle could not be commanded.

T

The specification for the blank side for a tool nose radius

compensation (G41 or G42) is incorrect in a multiple repetitive

canned cycle (G71 or G72).

T

In a shape program for the multiple repetitive canned

rough-cutting cycle (G71 or G72), the command of the second

plane axis was not a monotonous increase or decrease.

T

An axis other than the plane is specified n a canned

cycle(G90, G92, or G94).

An offset data which was out of the effective range was

specified. (malfunction prevention function)

M

For a tool length compensation C, an attempt was made to

command the offset to other axes without canceling the offset.

Or, for a tool length compensation C, multiple axes are

specified in G43 or G44 block.

The command value exceeded the maximum amount of

incremental. (malfunction prevention function)

(malfunction prevention function)

A tool change position on the Z-axis is incorrect.

A tool number for tool change is incorrect.

Tool changing is commanded twice or more in the same

block.

A tool change spindle on the Z-axis is not set.

A tool change spindle stop is not stopped.

T

An illegal synchronous control axis number (parameter No.

8180) is set.

T

While the axis being subject to synchronous control was

moving, an attempt was made to start or cancel the

synchronous control by a synchronous control axis selection

signal.

T

This error occurred when:

1) An attempt was made to perform synchronous control for

the axis during a synchronization, composite, or

superimposed control.

2) An attempt was made to synchronize a further

great-grandchild for a parent-child-grandchild relation.

3) An attempt was made to operate synchronous control

although a parent-child-grandchild relation was not set.

- 448 -

Page 15

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0353 THE INSTRUCTION WAS DONE

FOR THE AXIS WHICH WAS NOT

ABLE TO MOVE.

T

This error occurred when:

1) A move command was executed for an axis for which bit 7

(NUMx) of parameter No. 8163 was 1.

2) A move command was executed for a slave axis in

synchronous control.

3) A move command was executed for an axis for which bit 7

(MUMx) of parameter No. 8162 was 1 in composite control.

0354 THE G28 WAS INSTRUCTED IN

WITH THE REF POS NOT FIXED IN

SYNC MODE

T

This error occurred when G28 was specified to the master

axis being parking during synchronous control, but an axis

reference position is not set for the slave axis.

0355 PARAMETER OF THE INDEX OF

THE COMPOSITE CONTROL AXIS

SET ERROR.

0356 BECAUSE THE AXIS IS MOVING,

THE COMP CONTROL IS CAN'T BE

USED.

T

An illegal composite control axis number (parameter No.

8183) is specified.

T

While the axis being subject to composite control was moving,

an attempt was made to start or cancel the composite control

by a composite control axis selection signal.

0357 COMPOSITE CONTROL AXIS

COMPOSITION ERROR.

T

This error occurred when an attempt was made to perform

composite control for the axis during a synchronous,

composite, or superimposed control.

0359 THE G28 WAS INSTRUCTED IN

WITH THE REF POS NOT FIXED IN

COMP MODE

T

This error occurred when G28 was specified to the composite

axis during composite control, but a reference position is not

set to the other part of the composition.

0360 PARAMETER OF THE INDEX OF

THE SUPERPOS CONTROL AXIS

SET ERROR.

0361

BECAUSE THE AXIS IS MOVING,

THE SUPERPOS CONTROL IS

CAN'T BE USED.

T

An illegal superimposed control axis number (parameter No.

8186) is specified.

T

While the axis being subject to superimposed control was

moving, an attempt was made to start or cancel the

superimposed control by a superimposed control axis

selection signal.

0362 SUPERPOSITION CONTROL AXIS

COMPOSITION ERROR.

T

This error occurred when:

1) An attempt was made to perform superimposed control for

the axis during a synchronous, composite, or

superimposed control.

2) An attempt was made to synchronize a further

great-grandchild for a parent-child-grandchild relation.

0363 THE G28 WAS INSTRUCTED IN TO

THE SUPERPOS CONTROL SLAVE

AXIS.

0364 THE G53 WAS INSTRUCTED IN TO

THE SUPERPOS CONTROL SLAVE

AXIS.

0365 TOO MANY MAXIMUM SV/SP AXIS

NUMBER PER PATH

T

This error occurred when G28 was specified to the

superimposed control slave axis during superimposed control.

T

This error occurred when G53 was specified to the slave axis

being moved during superimposed control.

The number of controlled axes or spindles to be used in one

path is not set correctly. Check parameters No. 981 and No.

982. If this alarm is generated, the emergency stop state

cannot be released.

0369 G31 FORMAT ERROR 1) No axis is specified or two or more axes are specified in

the torque limit switch instruction (G31P98/P99).

2) G31P90 cannot be specified.

- 449 -

Page 16

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

0370 G31P/G04Q ERROR 1) The specified address P value for G31 is out of range. The

address P range is 1 to 4 in a multistage skip function.

2) The specified address Q value for G04 is out of range. The

address Q range is 1 to 4 in a multistage skip function.

3) P1-4 for G31, or Q1-4 for G04 was commanded without a

multistage skip function option.

T

4) In G72 or G74 in grinding canned cycles, the specified

address P value is out of range. Address P ranges from 1

to 4 in the multistage skip function. P1-4 was specified in

G72 or G74 even though the multistage skip function

option is not present.

0372 REFERENCE RETURN

INCOMPLETE

An attempt was made to perform an automatic return to the

reference position on the orthogonal axis before the

completion of a return to the reference position on the angular

axis. However, this attempt failed because a manual return to

the reference position during angular axis control or an

automatic return to the reference position after power-up was

not commanded. First, return to the reference position on the

angular axis, then return to the reference position on the

orthogonal axis.

0373 ILLEGAL HIGH-SPEED SKIP

SIGNAL

In the skip commands (G31, G31P1 to G31P4) and dwell

commands (G04, G04Q1 to G04Q4), the same high-speed

signal is selected in different paths.

0375 CAN NOT ANGULAR

CONTROL(SYNC:MIX:OVL)

Angular axis control is disabled for this axis configuration.

1) All related axes in angular axis control are not in

synchronous control mode. Alternatively, settings must be

made to provide synchronous control between angular

axes, and also between orthogonal axes.

2) All related axes in angular axis control are not in composite

control mode. Alternatively, settings must be made to

provide composite control between angular axes, and also

between orthogonal axes.

3) The related axes in angular axis control are in

superimposed control mode.

0376 SERIAL DCL: ILLEGAL

PARAMETER

1) When bit 1 of parameter No. 1815 is set to “1”, bit 3 of

parameter No. 2002 is set to “0”

2) The absolute-position detection function is enabled.

(Bit 5 (APCx) of parameter No.1815 is set to “1”. )

0412 ILLEGAL G CODE An unusable G code was used.

0445

ILLEGAL AXIS OPERATION

T

The positioning command was issued in the speed control

mode. Check the SV speed control mode signal (Fn521).

0446

ILLEGAL COMMAND IN

G96.1/G96.2/G96.3/G96.4

T

G96.1, G96.2, G96.3, and G96.4 are specified in the block

that includes other commands. Modify the program.

0447

ILLEGAL SETTING DATA The spindle controlled with the servo motor is not set

correctly. Check the parameters for the function of spindle

control with the servo motor.

0455

ILLEGAL COMMAND IN GRINDING In grinding canned cycles:

M

1) The signs of the I, J, and K commands do not match.

2) The amount of travel of the grinding axis is not specified.

- 450 -

Page 17

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

0456

ILLEGAL PARAMETER IN

GRINDING

Parameters related to grinding canned cycles are incorrectly

set. Probable causes are given below.

1) The axis number of the grinding axis is incorrectly set

(parameters Nos. 5176 to 5179).

M

2) The axis number of the dressing axis is incorrectly set

(parameters Nos. 5180 to 5183).

3) The axis numbers of the cut axis, grinding axis, and

dressing axis (only for the M series) overlap.

0601 ILLEGAL AXIS OPERATION FOR

SERVO MOTOR SPINDLE

0602 ILLEGAL AXIS OPERATION FOR

LIVE TOOL AXIS

A move command is executer for the spindle controlled with

the servomotor. Modify the program.

The spindle controlled with the serve motor is not selected

correctly.

1001 AXIS CONTROL MODE ILLEGAL The axis control mode is illegal.

1013 ILLEGAL POS. OF PROGRAM NO. Address O or N is specified where it must not (After the macro

statement etc.).

1014 ILLEGAL FORMAT OF PROGRAM

Address O or N is not followed by a number.

NO.

1016 EOB NOT FOUND EOB (End of Block) code is missing at the end of a program

input in the MDI mode.

1077 PROGRAM IN USE An attempt was made in the foreground to execute a program

being edited in the background.

The currently edited program cannot be executed, so end

editing and restart program execution.

1079 PROGRAM FILE NOT FOUND The program of the specified file No. is not registered in an

external device. (external device subprogram call)

1080 DUPLICATE DEVICE SUB

PROGRAM CALL

Another external device subprogram call was made from a

subprogram after the subprogram called by the external

device subprogram call.

1081 EXT DEVICE SUB PROGRAM CALL

MODE ERROR

The external device subprogram call is not possible in this

mode.

1091 DUPLICATE SUB-CALL WORD More than one subprogram call instruction was specified in

the same block.

1092 DUPLICATE MACRO-CALL WORD More than one macro call instruction was specified in the

same block.

1093 DUPLICATE NC-WORD & M99 An address other than O, N, P or L was specified in the same

block as M99 during the macro modal call state.

1095 TOO MANY TYPE-2 ARGUMENT More than ten sets of I, J and K arguments were specified in

the type–II arguments (A, B, C, I, J, K, I, J, K, ...) for custom

macros.

1096 ILLEGAL VARIABLE NAME An illegal variable name was specified. A code that cannot be

specified as a variable name was specified. The command of

[#_OFSxx] does not match the type (A or C) of tool

compensation memory in current use.

1097 TOO LONG VARIABLE NAME The specified variable name is too long.

1098 NO VARIABLE NAME The specified variable name cannot be used as it is not

registered.

1099 ILLLEGAL SUFFIX [ ] A suffix was not specified to a variable name that required a

suffix enclosed by [ ].

A suffix was specified to a variable name that did not require a

suffix enclosed by [ ].

The value enclosed by the specified [ ] was out of range.

1100 CANCEL WITHOUT MODAL CALL Call mode cancel (G67) was specified even though macro

continuous–state call mode (G66) was not in effect.

- 451 -

Page 18

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

1101 ILLEGAL CNC STATEMENT IRT. An interrupt was made in a state where a custom macro

interrupt containing a move instruction could not be executed.

1115 READ PROTECTED VARIABLE An attempt was made in a custom macro to use on the right

side of an expression a variable that can only be used on the

left side of an expression.

1120 ILLEGAL ARGUMENT FORMAT The specified argument in the argument function (ATAN,

POW) is in error.

1124 MISSING DO STATEMENT The DO instruction corresponding to the END instruction was

missing in a custom macro.

1125 ILLEGAL EXPRESSION FORMAT The description of the expression in a custom macro

statement contains an error.

A parameter program format error.

The screen displayed to enter periodic maintenance data or

item selection menu (machine) data does not match the data

type.

1128 SEQUENCE NUMBER OUT OF

RANGE

1131 MISSING OPEN BRACKET The number of left brackets ([) is less than the number of right

1132 MISSING CLOSE BRACKET The number of right brackets (]) is less than the number of left

1133 MISSING '=' An equal sign (=) is missing in the arithmetic calculation

1134 MISSING ',' A delimiter (,) is missing in a custom macro statement.

1137 IF STATEMENT FORMAT ERROR The format used in the IF statement in a custom macro is in

1138 WHILE STATEMENT FORMAT

ERROR

1139 SETVN STATEMENT FORMAT

ERROR

1141 ILLEGAL CHARACTER IN VAR.

NAME

1142 TOO LONG V-NAME (SETVN) The variable name used in a SETVN statement in a custom

1143 BPRNT/DPRNT STATEMENT

FORMAT ERROR

1144 G10 FORMAT ERROR Data input for the L No. of G10 or the corresponding function

1160

COMMAND DATA OVERFLOW An overflow occurred in the position data within the CNC.

1180 ALL PARALLEL AXES IN PARKING

1196 ILLEGAL DRILLING AXIS

SELECTED

The jump destination sequence No. in a custom macro

statement GOTO instruction was out of range (valid range: 1

to 99999).

brackets (]) in a custom macro statement.

brackets ([) in a custom macro statement.

instruction in a custom macro statement.

error.

The format used in the WHILE statement in a custom macro is

in error.

The format used in the SETVN statement in a custom macro

is in error.

The SETVN statement in a custom macro contacts a

character that cannot be used in a variable name.

macro exceeds 8 characters.

The format used in the BPRINT statement or DPRINT

statement is in error.

is not enabled.

Data setting address P or R is not specified.

An address not relating to the data setting is specified. Which

address to specify varies according to the L No.

The sign, decimal point or range of the specified address are

in error.

This alarm is also generated if the target position of a

command exceeds the maximum stroke as a result of

calculation such as coordinate conversion, offset, or

introduction of a manual intervention amount.

T

All of the axis specified for automatic operation are parked.

An illegal axis was specified for drilling in a canned cycle for

drilling.

In the G code command block in a canned cycle, a Z point is

not specified for the drilling axis.

- 452 -

Page 19

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

1200 PULSCODER INVALID ZERO

RETURN

The grid position could not be calculated during grid reference

position return using the grid system as the one–revolution

signal was not received before leaving the deceleration dog.

This alarm is also generated when the tool does not reach a

feedrate that exceeds the servo error amount preset to

parameter No. 1836 before the deceleration limit switch is left

(deceleration signal *DEC returns to “1”).

M

1202 NO F COMMAND AT G93

F codes in the inverse time specification mode (G93) are not

handled as modal, and must be specified in individual blocks.

1223 ILLEGAL SPINDLE SELECT An attempt was made to execute an instruction that uses the

spindle although the spindle to be controlled has not been set

correctly.

1298 ILLEGAL INCH/METRIC

An error occurred during inch/metric switching.

CONVERSION

1300 ILLEGAL ADDRESS The axis No. address was specified even though the

parameter is not an axis–type while loading parameters or

pitch error compensation data from a tape or by entry of the

G10 parameter.

Axis No. cannot be specified in pitch error compensation data.

1301 MISSING ADDRESS The axis No. was not specified even though the parameter is

an axis–type while loading parameters or pitch error

compensation data from a tape or by entry of the G10

parameter.

Or, data No. address N, or setting data address P or R are not

specified.

1302 ILLEGAL DATA NUMBER A non–existent data No. was found while loading parameters

or pitch error compensation data from a tape or by entry of the

G10 parameter.

This alarm is also generated when illegal word values are

found.

1303 ILLEGAL AXIS NUMBER An axis No. address exceeding the maximum number of

controlled axes was found while loading parameters from a

tape or by entry of the G10 parameter.

1304 TOO MANY DIGIT Data with too many digits was found while loading parameters

or pitch error compensation data from a tape.

1305 DATA OUT OF RANGE Out–of–range data was found while loading parameters or

pitch error compensation data from a tape.

The values of the data setting addresses corresponding to L

Nos. during data input by G10 was out of range.

This alarm is also generated when NC programming words

contain out–of–range values.

1306 MISSING AXIS NUMBER A parameter which requires an axis to be specified was found

without an axis No. (address A) while loading parameters from

a tape.

1307 ILLEGAL USE OF MINUS SIGN Data with an illegal sign was found while loading parameters

or pitch error compensation data from a tape, or by entry of

the G10 parameter. A sign was specified to an address that

does not support the use of signs.

1308 MISSING DATA An address not followed by a numeric value was found while

loading parameters or pitch error compensation data from a

tape.

1329 ILLEGAL MACHINE GROUP

NUMBER

An machine group No. address exceeding the maximum

number of controlled machine groups was found while loading

parameters from a tape or by entry of the G10 parameter.

- 453 -

Page 20

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

1330 ILLEGAL SPINDLE NUMBER An spindle No. address exceeding the maximum number of

controlled spindles was found while loading parameters from a

tape or by entry of the G10 parameter.

1331 ILLEGAL PATH NUMBER An path No. address exceeding the maximum number of

controlled path was found while loading parameters from a

tape or by entry of the G10 parameter.

1332 DATA WRITE LOCK ERROR Could not load data while loading parameters, pitch error

compensation data and work coordinate data from tape.

1333 DATA WRITE ERROR Could not write data while loading data from tape.

1470

G40.1 –G42.1 PARAMETER MISS

1508 DUPLICATE M-CODE (INDEX

TABLE REVERSING)

1509 DUPLICATE M-CODE (SPOS AXIS

ORIENTATION)

1510 DUPLICATE M-CODE (SPOS AXIS

POSITIONING)

1511 DUPLICATE M-CODE (SPOS AXIS

RELEASE)

1533 ADDRESS F UNDERFLOW (G95) The feedrate for the hole drilling axis calculated from the F

1534 ADDRESS F OVERFLOW (G95) The feedrate for the hole drilling axis calculated from the F

1537 ADDRESS F UNDERFLOW

(OVERRIDE)

1538 ADDRESS F OVERFLOW

(OVERRIDE)

1541 S-CODE ZERO “0” has been instructed as the S code.

1543 ILLEGAL GEAR SETTING

1544 S-CODE OVER MAX The S command exceeds the maximum spindle rotation

1548 ILLGAL AXIS MODE The spindle positioning (T series) axis/Cs contour control axis

1561 ILLEGAL INDEXING ANGLE

1564 INDEX TABLE AXIS – OTHER AXIS

SAME TIME

M

A parameter setting related to normal direction control is

illegal.

The axis number of a normal direction controlled axis is set in

parameter No. 5480, but that axis number is in the range of

the number of controlled axes.

The axis set as a normal direction controlled axis is not set as

a rotation axis (ROTx, bit 0 of parameter No. 1006) = 1 and

No.1022=0).

Set the feedrate at which to insert rotation about a normal

direction controlled axis in parameter No. 5481, in the range

of 1 to 15000 mm/min.

M

A function to which the same code as this M code is set

exists. (index table indexing)

T

A function to which the same code as this M code is set

exists. (spindle positioning, orientation)

T

A function to which the same code as this M code is set

exists. (spindle positioning, positioning)

T

A function to which the same code as this M code is set

exists. (spindle positioning, mode cancel)

and S codes is too slow in the feed per single rotation mode.

and S codes is too fast in the feed per single rotation mode.

The speed obtained by applying override to the F instruction is

too slow.

The speed obtained by applying override to the F instruction is

too fast.

T

The gear ratio between the spindle and position coder, or the

set position coder number of pulses is illegal in the spindle

positioning function.

number.

was specified during switching of the controlled axis mode.

M

The specified angle of rotation is not an integer multiple of the

minimum indexing angle.

M

The index table indexing axis and another axis have been

specified in the same block.

- 454 -

Page 21

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

M

1567 INDEX TABLE AXIS DUPLICATE

AXIS COMMAND

Index table indexing was specified during axis movement or

on an axis for which the index table indexing sequence was

not completed.

1590 TH ERROR A TH error was detected during reading from an input device.

The read code that caused the TH error and how many

statements it is from the block can be verified in the

diagnostics screen.

1591 TV ERROR An error was detected during the single–block TV error.

The TV check can be suppressed by setting bit 0 (TVC) of

parameter No. 0000 to “0”.

1592 END OF RECORD The EOR (End of Record) code is specified in the middle of a

block.

This alarm is also generated when the percentage at the end

of the NC program is read.

For the program restart function, this alarm is generated if a

specified block is not found.

M

1593 EGB PARAMETER SETTING

ERROR

Error in setting a parameter related to the EGB

1) The setting of SYN, bit 0 of parameter No. 2011, is not

correct.

2) The slave axis specified with G81 is not set as a rotation

axis. (ROT, bit 0 of parameter No. 1006)

3) Number of pulses per rotation (Parameter (No. 7772 or No.

7773) is not set.)

M

1594 EGB FORMAT ERROR

Error in the format of the block of an EGB command

1) T (number of teeth) is not specified in the G81 block.

2) In the G81 block, the data specified for one of T, L, P, and

Q is out of its valid range.

3) n the G81 block, only one of P and Q is specified.

M

1595 ILL-COMMAND IN EGB MODE

During synchronization with the EGB, a command that must

not be issued is issued.

1) Slave axis command using G27, G28, G29, G30, G33,

G53, etc.

2) Inch/metric conversion command using G20, G21, etc.

M

1596 EGB OVERFLOW

An overflow occurred in the calculation of the synchronization

coefficient.

1805 ILLEGAL COMMAND [I/O Device]

An attempt was made to specify an illegal command during

I/O processing on an I/O device.

[G30 Reference Position Return]

The address P numbers for specifying the 2nd, 3rd, and 4th

reference position returns are not 2, 3, and 4.

[Single Rotation Dwell]

The specified spindle rotation is “0” when single rotation

dwell is specified.

1806 DEVICE TYPE MISS MATCH An operation not possible on the I/O device that is currently

selected in the setting was specified.

This alarm is also generated when file rewind is instructed

even though the I/O device is not a FANUC Cassette.

1807 PARAMETER SETTING ERROR An illegal I/O interface is specified.

The external I/O device and baud rate, stop bit and protocol

selection settings are erroneous.

- 455 -

Page 22

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

1808 DEVICE DOUBLE OPENED An attempt was made to open a device that is being

accessed.

1820

1823 FRAMING ERROR(1) The stop bit of the character received from the I/O device

1830 DR OFF(2) The data set ready input signal DR of the I/O device

1832 OVERRUN ERROR(2) The next character was received from the I/O device

1833 FRAMING ERROR(2) The stop bit of the character received from the I/O device

1834 BUFFER OVERFLOW(2) The NC received more than 10 characters of data from the I/O

1912 V-DEVICE DRIVER ERROR (OPEN) An error occurred during device driver control.

1960 ACCESS ERROR (MEMORY CARD) Illegal memory card accessing

1961 NOT READY (MEMORY CARD) The memory card is not ready.

1962 CARD FULL (MEMORY CARD) The memory card has run out of space.

1963 CARD PROTECTED (MEMORY

1964 NOT MOUNTED (MEMORY CARD) The memory card could not be mounted.

1965 DIRECTORY FULL (MEMORY

1966 FILE NOT FOUND (MEMORY

1967 FILE PROTECTED (MEMORY

1968 ILLEGAL FILE NAME (MEMORY

1969 ILLEGAL FORMAT (MEMORY

1970 ILLEGAL CARD (MEMORY CARD) This memory card cannot be handled.

1971 ERASE ERROR (MEMORY CARD) An error occurred during memory card erase.

1972 BATTERY LOW (MEMORY CARD) The memory card battery is low.

1973 FILE ALREADY EXIST A file having the same name already exists on the memory

2032 EMBEDDED ETHERNET/DATA

2051 #200-#499ILLEGAL P-CODE

ILLEGAL DI SIGNAL STATE 1) An each axis workpiece coordinate system preset signal

was turned “1” in the state in which all axes on the path

including the axis on which to perform preset with the each

axis workpiece coordinate system were not stopped or in

which a command was in execution.

2) When the M code for performing preset with an each axis

workpiece coordinate system preset signal is specified, the

each axis workpiece coordinate system preset signal is not

input.

3) The auxiliary function lock is enabled.

connected to reader/punch interface 1 was not detected.

connected to reader/punch interface 2 turned OFF.

connected to reader/punch interface 2 before it could read a

previously received character.

connected to reader/punch interface 2 was not detected.

device connected to reader/punch interface 2 even though the

NC sent a stop code (DC3) during data reception.

This alarm is also generated during reading when reading is

executed up to the end of the file without detection of the EOR

code.

The memory card is write–protected.

CARD)

The file could not be generated in the root directory for the

CARD)

CARD)

CARD)

CARD)

CARD)

SERVER ERROR

MACRO COMMON INPUT(NO

OPTION)

memory card.

The specified file could not be found on the memory card.

The memory card is write–protected.

Illegal memory card file name

Check the file name.

card.

An error was returned in the built-in Ethernet/data server

function.

For details, see the error message screen of the built-in

Ethernet or data server.

An attempt was made to enter a custom macro common

variable not existing in the system.

- 456 -

Page 23

B-64305EN/03 APPENDIX A.ALARM LIST

Number Message Description

2052 #500-#549P-CODE MACRO

COMMON SELECT(CANNOT USE

SETVN)

2053 P-CODE VARIABLE NUMBER IS

OUTSIDE OF RANGE

2054 EXTENDED P-CODE VARIABLE

NUMBER IS OUTSIDE OF RANGE

The variable name cannot be entered.

The SETVN command cannot be used with the P-CODE

macro common variables #500 to #549.

An attempt was made to enter a P-CODE-only variable not

existing in the system.

An attempt was made to enter an extended P-CODE-only

variable not existing in the system.

4010 ILLEGAL REAL VALUE OF OBUF : The real value for a output buffer is in error.

5006 TOO MANY WORD IN ONE BLOCK The number of words in a block exceeds the maximum. The

maximum is 26 words. However, this figure varies according

to NC options. Divide the instruction word into two blocks.

5007 TOO LARGE DISTANCE Due to compensation, point of intersection calculation,

interpolation or similar reasons, a movement distance that

exceeds the maximum permissible distance was specified.

Check the programmed coordinates or compensation

amounts.

5009 PARAMETER ZERO (DRY RUN) The dry run feedrate parameter No. 1410 or maximum cutting

feedrate parameter No. 1430 for each axis has been set to 0.

5010 END OF RECORD The EOR (End of Record) code is specified in the middle of a

block. This alarm is also generated when the percentage at

the end of the NC program is read.

5011 PARAMETER ZERO (CUT MAX) The maximum cutting feedrate parameter No. 1430 has been

set to 0.

5014 TRACE DATA NOT FOUND A transfer could not be made because of no trace data.

5016 ILLEGAL COMBINATION OF M

CODES

M codes which belonged to the same group were specified in

a block. Alternatively, an M code which must be specified

without other M codes in the block was specified in a block

with other M codes.

5018 POLYGON SPINDLE SPEED

ERROR

T

In G51.2 mode, the speed of the spindle or polygon

synchronous axis either exceeds the clamp value or is too

small. The specified rotation speed ratio thus cannot be

maintained.

For polygon turning between spindles:

More information as to why this alarm occurred is indicated in

DGN No. 471.

5020 PARAMETER OF RESTART ERROR

An invalid value is set in parameter No. 7310, which specifies

the axis order in which the tool is moved along axes to the

machining restart position in dry run. A value ranging from 1 to

the number of controlled axes may be set in this parameter.

M

5046 ILLEGAL PARAMETER (S-COMP)

The setting of a parameter related to simple straightness

compensation contains an error.

Possible causes include:

1) A non-existent axis number is set in a moving or

compensation axis parameter.

2) The simple straightness compensation point numbers do

not have correct magnitude relationships.

3) No simple straightness compensation point is found

between the furthest pitch error compensation point in the

negative region and that in the positive region.

4) The compensation per compensation point is either too

large or too small.

5064 DIFFERRENT AXIS UNIT Circular interpolation has been specified on a plane consisting

of axes having different increment systems.

- 457 -

Page 24

A.ALARM LIST APPENDIX B-64305EN/03

Number Message Description

5065 DIFFERRENT AXIS UNIT(PMC

AXIS)

5073 NO DECIMAL POINT No decimal point has been specified for an address requiring

5074 ADDRESS DUPLICATION ERROR The same address has been specified two or more times in a

5110 IMPROPER G-CODE (AICC MODE) An unspecifiable G code was specified in the advanced

5131 NC COMMAND IS NOT

COMPATIBLE

5195

DIRECTION CAN NOT BE JUDGED

5220 REFERENCE POINT ADJUSTMENT

MODE

5257 G41/G42 NOT ALLOWED IN MDI

MODE

5303 TOUCH PANEL ERROR The touch panel is not connected correctly, or the touch panel

Axes having different increment systems have been specified

in the same DI/DO group for PMC axis control. Modify the

setting of parameter No. 8010.

a decimal point.