Page 1

+

FANUC MANUAL GUIDE

Common to Lathe System/Machining Center System

OPERATOR'S MANUAL

B-63874EN/11

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

B-63874EN/11 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

When using machines incorporating FANUC MANUAL GUIDE i, be sure to observe the descriptions

herein.

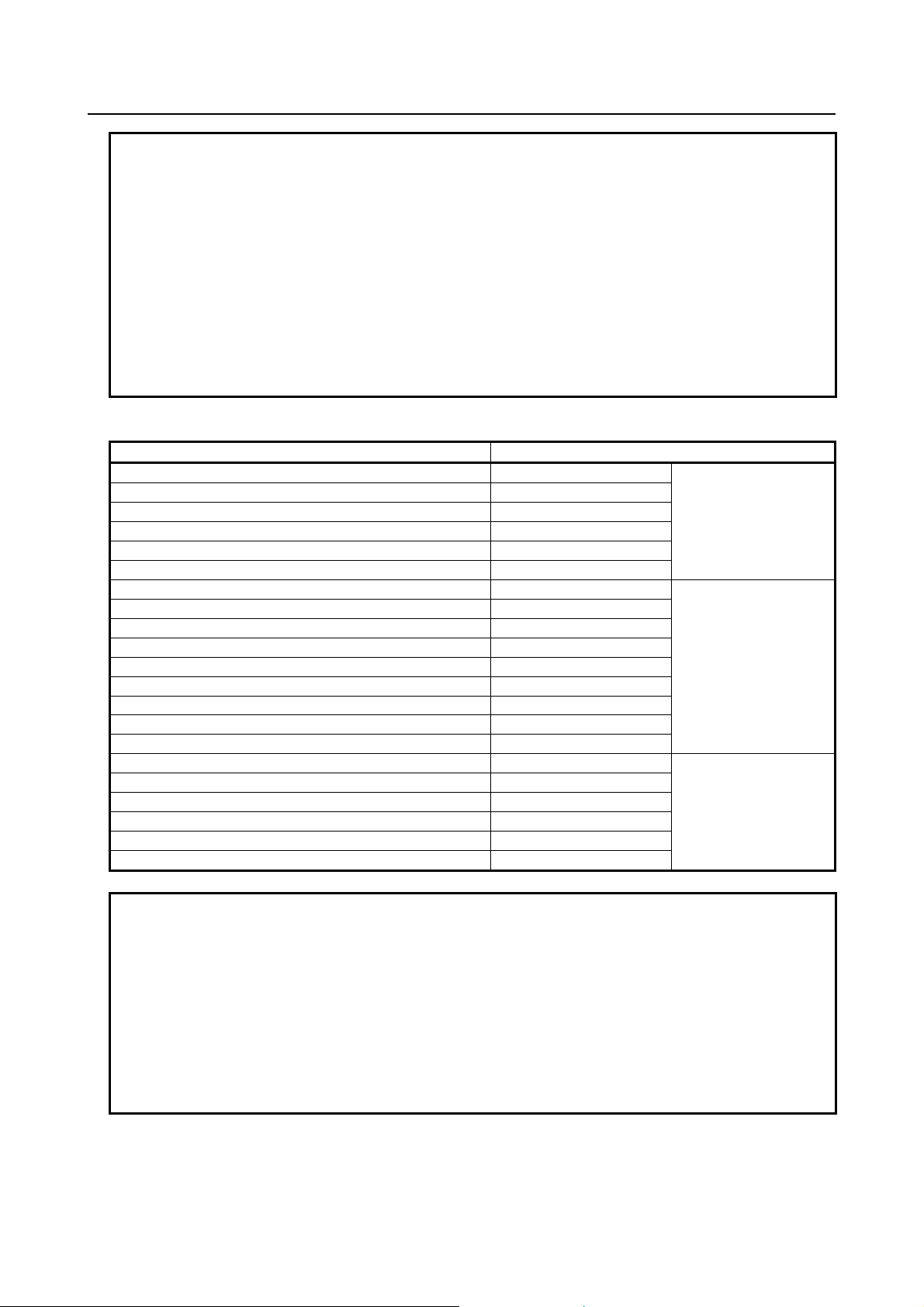

Contents

DEFINITION OF WARNING, CAUTION, AND NOTE.........................................................................s-1

GENERAL WARNINGS AND CAUTIONS

OVERVIEW OF THIS MANUAL

SYMBOLS USED

FORMAT OF PROGRAMS TO BE USED

......................................................................................................................................s-3

............................................................................................................s-2

............................................................................................s-1

..............................................................................................s-3

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to the degree of the risk or the severity of

damage.

Also, supplementary information is described as Note.

Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

damage of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

- Read this manual carefully, and store it in a safe place.

GENERAL WARNINGS AND CAUTIONS

To ensure safety while using a machine featuring the MANUAL GUIDE i function, observe the following

precautions:

WARNING

1 Confirm, on the screen, that the data has been entered correctly before

proceeding to the next operation. Attempting operation with incorrect data may

cause the tool to strike the workpiece or machine, possibly breaking the tool or

machine or injuring the operator.

2 Before starting the machine using the tool compensation function, carefully

determine the direction of compensation and the compensation value, and

ensure that the tool will not strike the workpiece or machine. Otherwise the tool

or machine may be damaged or the operator may be injured.

s-1

Page 4

SAFETY PRECAUTIONS B-63874EN/11

WARNING

3 When using constant surface speed control, set the maximum rotating speed of

the spindle to a value that is allowed for the workpiece and workpiece hold unit.

Otherwise, the workpiece or hold unit may be removed by centrifugal force to

damage the tool machine or injure the operator.

4 Set all necessary parameters and data items before starting MANUAL GUIDE i

operations. Note that if the cutting conditions are not suitable for the workpiece,

the tool may be damaged or the operator may be injured.

5 After creating a machining program using MANUAL GUIDE i functions, do no

run the machine on that program immediately. Instead, confirm every step of the

resultant program, and make sure that the tool path and machining operation are

correct and that the tool will not strike the workpiece or machine. Before starting

production machining, run the machine with no workpiece attached to the

machine to make sure that the tool will not strike a workpiece or the machine. If

the tool strikes the machine and/or work-piece, the tool and/or machine may be

damaged, and even injuries the operator.

CAUTION

After pressing the power-on button, do not touch any keys on the keyboard until

the initial screen appears. Some keys are used for maintenance or special

operations such that pressing such a key may cause an unexpected operation.

OVERVIEW OF THIS MANUAL

This manual describes the functions of MANUAL GUIDE i for the Series 0i-MODEL F, 0i-MODEL D,

MODEL C, Series 16i/18i/21i-MODEL B, Series 30i/31i/32i-MODEL A or Series 30i/31i/32i-MODEL

B.

For other functions, refer to the operator’s manual for the Series 0i-MODEL F, 0i-MODEL D, MODEL C,

Series 16i/18i/21i-MODEL B, Series 30i/31i/32i-MODEL A, or Series 30i/31i/32i-MODEL B.

The specifications and usage of MANUAL GUIDE i may vary according to the specifications of the

operator’s panel of a machine tool. Be sure to read the manual provided by the machine tool builder.

The functions of the CNC machine tool system are determined not only by the CNC, but by the

combination of the machine tool, the power magnetic circuit in the machine tool, the servo system, the

CNC, and the operator’s panel.

It is impossible to cover all possible combinations of all functions, programming methods, and operations

in a single manual.

This manual explains only the MANUAL GUIDE i operations provided for the CNC. For individual CNC

machine tools, refer to applicable manuals from the machine tool builders.

This manual explains as many detailed functions as possible. However, it is not possible to describe all of

the items which cannot be done or which the operator must not do. Therefore, please assume that

functions other than those described in this manual cannot be performed.

Detailed information and special conditions are explained in notes. The readers may encounter new

technical terms in the notes not previously defined or described. In this case, read through this manual

first, then review the details.

s-2

Page 5

B-63874EN/11 SAFETY PRECAUTIONS

SYMBOLS USED

In this manual, the following conventions are used for keys.

(1) Function keys are represented by enclosing their names between the special characters < and >:

Example) <PROGRM>, <OFSET>

(2) The numbers to be input by Numeral keys are indicated as it is.

Example) 12.345

(3) Similarly to functions keys, the input (INPUT) and editing keys are represented by enclosing their

names between the special characters < and >:

Example) 12.345 <INPUT>, <ALTER>

(4) Soft-keys are enclosed in brackets [ ]:

Example) [LIST], [LINE]

(5) The cursor move keys are indicated by the following symbols :

Example) <↑>, <↓>, <←>, <→>

(6) The page change keys are indicated by the following symbols :

Example) <↑ PAGE>, <PAGE ↓>

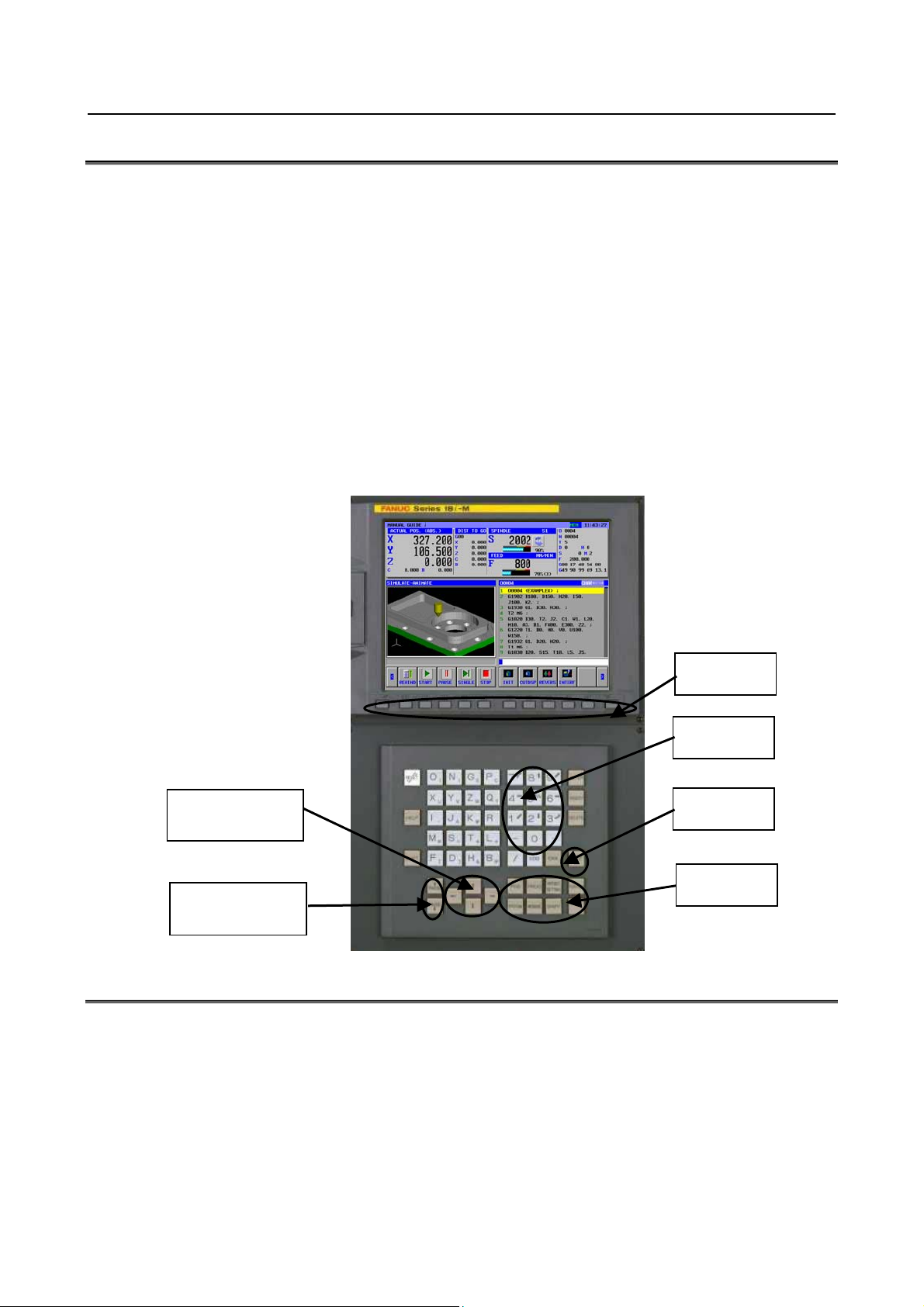

Soft Keys

Numeral keys

Cursor move keys

(or cursor keys)

Page change keys

(or page keys)

INPUT key

Function keys

FORMAT OF PROGRAMS TO BE USED

The ISO code format, which is in wide use for CNC machine tools, is used on machining programs used

with MANUAL GUIDE i. In addition, G4-digit machining cycles are used to implement advanced

machining operations.

G4-digit machining cycles can be input and edited easily using a menu window, which enables machining

data to be entered interactively.

When a machining program is being edited, an address at which the cursor is placed is explained at the

bottom of the screen.

s-3

Page 6

SAFETY PRECAUTIONS B-63874EN/11

1. Word

The term “word” refers to a minimum unit in NC machining programs. It is represented using a

combination of an address (one of letters A to Z), some of digits 0 to 9, an arithmetic symbol (+ or -),

and/or a decimal point.

The “address” represents the meaning of numeric data, such as a machine movement axis

2. Cursor

The term “cursor” used with machining programs refers to a display portion where a string of

characters is shown against a yellow background. This portion is referred to as “cursor-selected

display portion”. This is the place where an actual editing action is made during machining program

editing.

Either of the following two items can be cursor-selected.

<1> 1 block

When the cursor is shifted to the beginning of the next block by pressing the cursor move key

<→>, the entire block is selected.

When the cursor is placed at the address of the beginning of a certain block, pressing the cursor

move key <←> causes the entire block to be selected.

When a block is already selected, pressing the cursor move key <↑> or <↓> causes the block,

respectively, following or preceding the block of interest to be selected.

<2> 1 word

When a whole block is selected, pressing the cursor move key <←> or <→> causes a word to

be selected. Each time the cursor move key <←> or <→> is pressed, a new word is selected.

When a word in a certain block is selected, pressing the cursor move key <↑> or <↓> causes

the same-number address in the block, respectively, following or preceding the block of interest

to be selected.

NOTE

1 On a screen where numeric data, such as offset data or cycle machining data, is

input directly, the term “cursor” refers to a data portion enclosed in a blue frame.

2 A data portion enclosed in a blue frame is referred to as “cursor-selected data

item”. Once numeric data is keyed in with numeric keys, pressing the <INPUT>

key causes the numeric data to be input as the data item of interest.

3 Pressing the cursor move key <←>, <↑>, <↓>, or <→> causes a new data item

to be selected.

s-4

Page 7

B-63874EN/11 PREFACE

PREFACE

This manual is configured as follows:

Explanations about the document contents

SAFETY PRECAUTIONS

Describes the rules you should observe so that you can safely use machines incorporating FANUC

MANUAL GUIDE i.

PREFACE

Explains how this document is configured. It also lists applicable CNC units and related documents.

Part I, “WHAT IS MANUAL GUIDE i?”

Describes the features of MANUAL GUIDE i.

Part II, “BASIC SCREEN AND OPERATION”

Describes the configuration of the MANUAL GUIDE i screen. It also explains all basic operations,

from creating machining programs in ISO code format to running machine tools using the programs.

Part III, “CONVENIENT FUNCTIONS”

Explains convenient functions that will help create and run programs.

Part IV, “MACHINING CYCLE”

Explains how to program machining cycles offered by MANUAL GUIDE i.

Part V, “MULTI-PATH LATHE FUNCTIONS (OPTION)”

Explains how to program functions for multipath lathes.

Part VI, “OTHER FUNCTIONS”

Describes the program coordinate system switching, tool management, and other functions usable

with MANUAL GUIDE i.

APPENDIX

Provides information (such as examples of creating and running programs, alarms, and parameter

setting) which machine operators can reference when operating MANUAL GUIDE i.

APPENDIX (FOR MACHINE TOOL BUILDER)

Provides information (such as MANUAL GUIDE i startup procedure and customization) which

machine tool builders will need in using MANUAL GUIDE i.

Applicable models

This manual can be used with the following models.

The abbreviated names may be used.

- FANUC Series 30i/31i/32i-MODEL A

Product name Abbreviation

FANUC Series 30i-MODEL A 30i –A Series 30i

FANUC Series 31i-MODEL A 31i –A

FANUC Series 31i-MODEL A5 31i –A5

FANUC Series 32i-MODEL A 32i –A Series 32i

- FANUC Series 30i/31i/32i-MODEL B

Product name Abbreviation

FANUC Series 30i-MODEL B 30i –B Series 30i

FANUC Series 31i-MODEL B 31i –B

FANUC Series 31i-MODEL B5 31i –B5

FANUC Series 32i-MODEL B 32i –B Series 32i

Series 31i

Series 31i

p-1

Page 8

PREFACE B-63874EN/11

NOTE

1 For an explanatory purpose, the following descriptions may be used according to

the types of path control used:

T series: For the lathe system

•

M series: For the machining center system

•

2 Unless otherwise stated, the model names Series 30i, Series 31i, and Series 32i

used in this document sometimes collectively refer to the models mentioned

above except for item 3 below.

3 Some functions described in this manual may not be applied to some products.

For details, refer to the DESCRIPTIONS (B-63942EN) related to applied CNC.

4 MANUAL GUIDE i is not available in Series 30i-MODEL A or MODEL B with 5

paths or over.

- FANUC Series 16i/18i/160i/180i/160is/180is-MODEL B

Product name Abbreviation

FANUC Series 16i-TB 16i-TB

FANUC Series 16i-MB 16i-MB

FANUC Series 160i-TB 160i-TB

FANUC Series 160i-MB 160i-MB

FANUC Series 160is-TB 160is-TB

FANUC Series 160is-MB 160is-MB

FANUC Series 18i-TB 18i-TB

FANUC Series 18i-MB5 18i-MB5

FANUC Series 18i-MB 18i-MB

FANUC Series 180i-TB 180i-TB

FANUC Series 180i-MB5 180i-MB5

FANUC Series 180i-MB 180i-MB

FANUC Series 180is-TB 180is-TB

FANUC Series 180is-MB5 180is-MB5

FANUC Series 180is-MB 180is-MB

FANUC Series 21i-TB 21i-TB

FANUC Series 21i-MB 21i-MB

FANUC Series 210i-TB 210i-TB

FANUC Series 210i-MB 210i-MB

FANUC Series 210is-TB 210is-TB

FANUC Series 210is-MB 210is-MB

Series 16i

Series 18i

Series 21i

NOTE

1 For an explanatory purpose, the following descriptions may be used according to

the types of path control used:

T series: For the lathe system

•

M series: For the machining center system

•

2 Unless otherwise stated, the model names Series 16i, Series 18i, and Series 21i

used in this document sometimes collectively refer to the models mentioned

above except for item 3 below.

3 Some functions described in this manual may not be applied to some products.

For details, refer to the DESCRIPTIONS (B-63532EN) related to applied CNC.

p-2

Page 9

B-63874EN/11 PREFACE

- FANUC Series 0i–MODEL F

Product name Abbreviation

FANUC Series 0i-TF 0i-TF

FANUC Series 0i-MF 0i-MF

Series 0i-F

- FANUC Series 0i–MODEL D

Product name Abbreviation

FANUC Series 0i-TD 0i-TD

FANUC Series 0i-MD 0i-MD

Series 0i-D

- FANUC Series 0i–MODEL C

Product name Abbreviation

FANUC Series 0i-TC 0i-TC

FANUC Series 0i-TTC 0i-TTC

FANUC Series 0i-MC 0i-MC

Series 0i-C

NOTE

1 For an explanatory purpose, the following descriptions may be used according to

the types of path control used:

T series: For the lathe system

•

M series: For the machining center system

•

2 Unless otherwise stated, the model names Series 0i used in this document

sometimes collectively refer to the models mentioned above except for item 3

below.

3 Some functions described in this manual may not be applied to some products.

For details, refer to the DESCRIPTIONS (B-64112EN, B-64302EN) related to

applied CNC.

Related manuals

- Manuals related to MANUAL GUIDE i

The table below lists manuals related to MANUAL GUIDE i.

Manual name Specification Number

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-63874EN *

OPERATOR’S MANUAL (For Machining Center System) B-63874EN-2

OPERATOR’S MANUAL (SET-UP GUIDANCE FUNCTIONS) B-63874EN-1

(*) In the table, this manual is marked with an asterisk (*).

- Manuals related to FANUC Series 30i/31i/32i-MODEL A

Manual name Specification Number

DESCRIPTIONS B-63942EN

CONNECTION MANUAL (HARDWARE)

CONNECTION MANUAL (FUNCTION)

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-63944EN

OPERATOR’S MANUAL (For Lathe System) B-63944EN-1

OPERATOR’S MANUAL (For Machining Center System) B-63944EN-2

MAINTENANCE MANUAL B-63945EN

PARAMETER MANUAL B-65950EN

B-63943EN

B-63943EN-1

p-3

Page 10

PREFACE B-63874EN/11

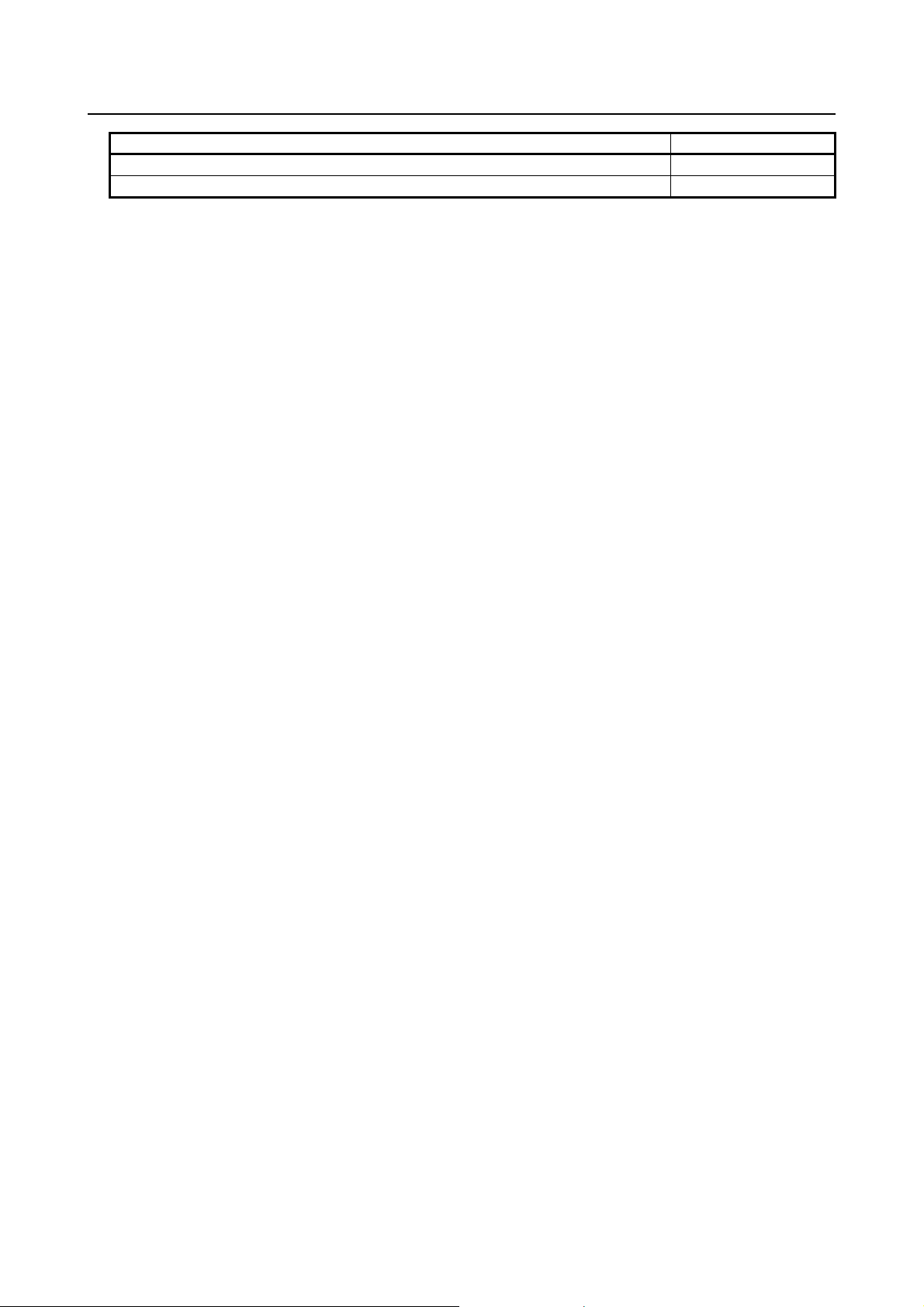

- Manuals related to FANUC Series 30i/31i/32i-MODEL B

Manual name Specification Number

DESCRIPTIONS B-64482EN

CONNECTION MANUAL (HARDWARE)

CONNECTION MANUAL (FUNCTION)

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64484EN

OPERATOR’S MANUAL (For Lathe System) B-64484EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64484EN-2

MAINTENANCE MANUAL B-64485EN

PARAMETER MANUAL B-64490EN

B-64483EN

B-64483EN-1

- Manuals related to FANUC Series 16i/18i/160i/180i/160is/180is-MODEL B

Manual name

DESCRIPTIONS B-63522EN

CONNECTION MANUAL (HARDWARE) B-63523EN

CONNECTION MANUAL (FUNCTION) B-63523EN-1

OPERATOR’S MANUAL (For Lathe System) B-63524EN

OPERATOR’S MANUAL (For Machining Center System) B-63534EN

MAINTENANCE MANUAL B-63525EN

PARAMETER MANUAL B-63530EN

Specification Number

- Manuals related to FANUC Series 0i–MODEL F

Manual name Specification Number

DESCRIPTIONS B-64602EN

CONNECTION MANUAL (HARDWARE) B-64603EN

CONNECTION MANUAL (FUNCTION) B-64603EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64604EN

OPERATOR’S MANUAL (For Lathe System) B-64604EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64604EN-2

MAINTENANCE MANUAL B-64605EN

PARAMETER MANUAL B-64610EN

- Manuals related to FANUC Series 0i–MODEL D

Manual name Specification Number

DESCRIPTIONS B-64302EN

CONNECTION MANUAL (HARDWARE) B-64303EN

CONNECTION MANUAL (FUNCTION) B-64303EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System) B-64304EN

OPERATOR’S MANUAL (For Lathe System) B-64304EN-1

OPERATOR’S MANUAL (For Machining Center System) B-64304EN-2

MAINTENANCE MANUAL B-64305EN

PARAMETER MANUAL B-64310EN

START-UP MANUAL B-64304EN-3

- Manuals related to FANUC Series 0i–MODEL C

Manual name Specification Number

DESCRIPTIONS B-64112EN

CONNECTION MANUAL (HARDWARE)

CONNECTION MANUAL (FUNCTION)

Series 0i-TC OPERATOR’S MANUAL

Series 0i-MC OPERATOR’S MANUAL

Series 0i-TTC OPERATOR’S MANUAL

B-64113EN

B-64113EN-1

B-64114EN

B-64124EN

B-64284EN

p-4

Page 11

B-63874EN/11 PREFACE

Manual name Specification Number

MAINTENANCE MANUAL B-64115EN

PARAMETER MANUAL B-64120EN

p-5

Page 12

Page 13

B-63874EN/11 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE.............................................s-1

GENERAL WARNINGS AND CAUTIONS...............................................................s-1

OVERVIEW OF THIS MANUAL..............................................................................s-2

SYMBOLS USED....................................................................................................s-3

FORMAT OF PROGRAMS TO BE USED...............................................................s-3

PREFACE....................................................................................................p-1

I. WHAT IS MANUAL GUIDE i?

1 WHAT IS MANUAL GUIDE i?................................................................3

1.1 WHAT IS MANUAL GUIDE i?........................................................................3

1.2 MAIN FEATURES OF MANUAL GUIDE i .....................................................3

II. BASIC SCREEN AND OPERATION

1 BASIC SCREEN......................................................................................7

2 EDITING PROGRAMS..........................................................................10

2.1 PROGRAM WINDOW AND EDITING .........................................................10

2.2 CREATING MACHINING PROGRAMS.......................................................10

2.3 EDITING IN A PROGRAM LIST..................................................................11

2.3.1 Simultaneous Deletion of Multiple Programs ........................................................12

2.3.2 Managing Program List Folder (for Series 30i/31i/32i Only)................................12

2.3.2.1 What is displayed in the program list?............................................................... 12

2.3.2.2 Operations added to the program list window................................................... 13

2.3.2.3 Supporting data server operations .....................................................................13

2.4 SEARCHING FOR A MACHINING PROGRAM TO BE EDITED.................14

2.5 PROGRAM NUMBER O8-DIGIT FUNCTION..............................................14

2.6 BASIC EDITING OPERATIONS OF PART PROGRAM..............................14

2.6.1 Entering a Word (<INSERT> key) ........................................................................14

2.6.2 Modifying a Word (<ALTER> key) ......................................................................15

2.6.3 Modifying the Numeric Value of a Word (<ALTER> key)...................................15

2.6.4 Deleting a Word (<DELETE> key) .......................................................................15

2.6.5 Modifying a Block (<ALTER> key)......................................................................15

2.6.6 Deleting a Block (<DELETE> key).......................................................................15

2.6.7 Changing the Program Number (ALTER key).......................................................15

2.7 SEARCH (FORWARD AND BACKWARD)..................................................15

2.7.1 Simultaneous String Search Function of Multi Programs......................................16

2.7.1.1 Mode to use this function .................................................................................. 16

2.7.1.2 Program window where search is executed.......................................................16

2.7.1.3 Changing search mode....................................................................................... 16

2.7.1.4 Execute simultaneous string search of multi programs ..................................... 17

2.8 CUT.............................................................................................................17

2.9 COPY ..........................................................................................................18

2.10 PASTE.........................................................................................................18

2.11 DELETE.......................................................................................................18

c-1

Page 14

TABLE OF CONTENTS B-63874EN/11

2.12 KEY-IN PASTE............................................................................................18

2.13 REPLACING WORD....................................................................................19

2.13.1 Replacing a Word...................................................................................................19

2.13.2 Replace All Words .................................................................................................19

2.13.3 Replaced Words .....................................................................................................20

2.13.4 Note........................................................................................................................21

2.14 UNDO, REDO..............................................................................................22

2.15 MULTI PART PROGRAM EDITING FUNCTION

(For only Series30i /31i /32i /0i-F/0i-D)......................................................22

2.15.1 Start of Multi Part Program Editing Function........................................................22

2.15.2 Operation of Display Program Selection................................................................22

2.15.3 Display of Multi Part Program Editing Screen.......................................................23

2.15.4 Opening and Shutting of Program Window...........................................................24

2.15.5 Switching Target of Editing Program.....................................................................24

2.15.6 End of Multi Part Program Editing Function of Programs.....................................25

2.15.7 Operation of Switching to CNC Screen .................................................................25

2.15.8 Operation of Changing Path...................................................................................25

2.15.9 Operation of Changing Mode.................................................................................26

2.15.10 About the Maintenance of Displayed Program Information ..................................26

2.15.11 Restrictions.............................................................................................................26

2.16 M-CODE MENU...........................................................................................26

2.17 FIXED FORM SENTENCE INSERTION......................................................27

2.17.1 Fixed Form Sentence..............................................................................................27

2.17.2 Start Command.......................................................................................................28

2.17.3 End Command........................................................................................................29

2.18 REGISTERING FIXED FORM SENTENCES..............................................29

2.18.1 Registering a New Fixed Form Sentence...............................................................30

2.18.2 Modifying a Fixed Form Sentence.........................................................................30

2.18.3 Deleting a Fixed Form Sentence ............................................................................31

2.18.4 Initialization to Standard Fixed Form Sentences....................................................31

2.18.5 Extension of Fixed Form Sentences

(For only Series 30i/31i/32i-B, Series 0i-F/0i-D)...................................................32

2.18.5.1 Parameter...........................................................................................................32

2.19 BACKGROUND EDITING ...........................................................................32

2.19.1 Starting Background Editing..................................................................................32

2.19.2 Ending Background Editing...................................................................................32

2.19.3 Operations During Background Editing.................................................................33

2.20 NOTES ON CREATING PROGRAMS.........................................................33

2.20.1 General Notes on Machining Programs .................................................................33

3 MACHINING SIMULATION...................................................................34

3.1 EDITING WITH THE PROGRAM LIST........................................................34

3.2 SEARCHING FOR A SEQUENCE NUMBER IN A PROGRAM...................35

3.3 SELECTING A PROGRAM FOR MACHINING SIMULATION.....................35

3.4 REWINDING A PROGRAM.........................................................................35

3.5 SETTING OF DATA FOR MACHINING SIMULATION................................35

3.6 MACHINING SIMULATION DISPLAY.........................................................48

3.6.1 Machining Simulation (Tool Path) (for Series 0i-C/16i/18i/21i)...........................48

3.6.1.1 Starting and stopping simulation....................................................................... 49

3.6.1.2 Scaling, movement, and other operations.......................................................... 50

3.6.2 Machining Simulation (Animated Drawing) (FOR Series 0i-C /16i/18i/21i)........50

3.6.2.1 Starting and stopping machining simulation......................................................51

c-2

Page 15

B-63874EN/11 TABLE OF CONTENTS

3.6.2.2 Scaling, movement, and other operations.......................................................... 52

3.6.3 Machining Simulation (Tool Path Drawing) (for Series 0i-F/0i-D/ 30i/31i/32i) ...52

3.6.3.1 Starting and stopping machining simulation......................................................54

3.6.3.2 Scaling, movement, and other operations.......................................................... 55

3.6.4 Machining Simulation (Animated Drawing) (for Series 0i-F/0i-D/ 30i/31i/32i)...55

3.6.4.1 Starting and stopping machining simulation......................................................55

3.6.4.2 Scaling, movement, and other operations.......................................................... 56

3.6.5 Data Handled during Machining Simulation (for Series 0i-F/0i-D/ 30i/31i/32i)...56

3.6.6 Functions Operating Differently between Machining Simulation and Automatic

Operation (for Series 0i-F/0i-D/ 30i/31i/32i).........................................................57

3.6.6.1 Functions that cannot be used for machining simulation...................................57

3.6.6.2 Functions that can be used for machining simulation (M series) ...................... 58

3.6.7 Changing Workpiece Coordinate During Machining Simulation (Animation,

Tool Path Drawing)................................................................................................58

3.6.8 Machining Simulation Screen on 15 inch LCD (Tool Path)

(for Series 30i/31i/32i, Series 0i-F)........................................................................59

3.6.8.1 Operations at machining simulation screen....................................................... 59

3.6.8.2 Operations at drawing during machining screen ............................................... 59

3.7 CHECK Y AXIS VALUE AT THE MACHINING SIMULATION OF THE

TURNING CYCLE .......................................................................................60

3.8 A WARNING MESSAGE WHEN A RESIDUAL CUTTING PART

REMAINS....................................................................................................60

3.9 MACHINING SIMULATION SPEED CHANGE FUNCTION.........................60

3.9.1 Operation on Machining Simulation Screen ..........................................................60

3.10 BLANK CUTOUT DISPLAY IN ANIMATED SIMULATION..........................62

3.10.1 Operation................................................................................................................62

3.10.2 Available Blank Figures for Blank Cutout Display ...............................................62

3.11 DISPLAYING MACHINING TIME................................................................63

3.11.1 Format of Machining Time Data............................................................................63

3.11.2 Operation for Inserting Machining Time ...............................................................63

3.11.3 Display Machining Time........................................................................................64

3.12 LARGE WINDOW DISPLAY OF MACHINING SIMULATION (ANIMATED

DRAWING) (For Series 30i/31i/32i–B only) ................................................64

3.12.1 Changing Window Size of Machining Simulation (Animated Drawing) ..............64

3.12.2 Restrictions on Large Window Display .................................................................65

3.13 2 WINDOWS MACHINING SIMULATION

(For only Series 0i-F/30i/31i/32i–B).............................................................65

3.13.1 Changing Window of Machining Simulation.........................................................65

3.13.2 Selecting Active Window.......................................................................................66

3.13.3 Restrictions on 2 Windows Display.......................................................................66

3.14 NOTES........................................................................................................66

3.14.1 Notes on Machining Simulation.............................................................................66

3.14.2 Tool size in Machining Simulation ........................................................................67

4 PROGRAM OPERATION......................................................................68

4.1 SELECTING A PROGRAM FOR OPERATION...........................................68

4.2 REWINDING A PROGRAM.........................................................................68

4.3 DISPLAYING THE DRAWING-DURING-MACHINING................................69

4.3.1 Program Selection Operation and Other Operations in Drawing during

Machining...............................................................................................................70

4.3.2 Selecting Whether to Display the Tool Path or Not in Drawing during

Machining...............................................................................................................70

c-3

Page 16

TABLE OF CONTENTS B-63874EN/11

4.3.3 Scaling, Movement, and Other Operations in Drawing during Machining............70

4.4 CHANGING THE CURRENT POSITION DISPLAY.....................................72

4.5 PRESETTING RELATIVE COORDINATES ................................................72

4.6 NEXT-BLOCK DISPLAY FUNCTION..........................................................72

4.7 FEEDRATE DISPLAY .................................................................................73

4.8 DISPLAYING 3-DIMENSIONAL INTERFERENCE CHECK STATUS (FOR

Series 0i-F/30i/31i/32i ONLY)....................................................................73

4.9 DISPLAYING THE ROTATION SPEED OF A SERVO MOTOR-DRIVEN

MILLING AXIS.............................................................................................73

4.9.1 Conditions for Using This Function.......................................................................74

4.9.2 About the “SPINDLE” Display Block ...................................................................74

4.9.2.1 Path 1 display window (10.4-inch screen)......................................................... 74

4.9.2.2 Path 1 display window (15-inch screen)............................................................ 75

4.9.2.3 Simultaneous multipath display window (10.4-inch screen).............................76

4.9.2.4 Simultaneous multipath display window (15-inch screen)................................77

4.9.2.5 Machining simulation and NC statement conversion windows

(10.4-inch screen).............................................................................................. 78

4.9.2.6 Machining simulation and NC statement conversion windows

(15-inch screen)................................................................................................. 78

4.9.2.7 Re-threading window ........................................................................................ 78

4.9.3 “CURRENT POSITION” Display Block...............................................................79

4.9.4 “FEED” Display Block ..........................................................................................79

4.9.5 Details of Actual Rotation Speed Shown in the SPINDLE Display Block............79

4.9.6 Details of Load Ratio (%) Shown in the SPINDLE Display Block ....................... 80

4.10 DISPLAYING THE SPINDLE-POSITION AND STANDBY-POSITION

TOOL NUMBERS (FOR Series 30i/31i/32i ONLY) .....................................81

4.10.1 Displaying the Spindle-Position Tool Number ......................................................81

4.10.2 Displaying the Standby-Position Tool Number .....................................................81

4.11 G54.4 MODAL DISPLAY.............................................................................81

4.11.1 DETAIL..................................................................................................................82

4.11.2 NOTE .....................................................................................................................82

4.12 COMMENT DISPLAY DURING MACHINING..............................................83

4.12.1 Format of Comment Display G code G2900..........................................................83

4.12.2 Notes.......................................................................................................................84

4.13 OPERATION RESTART CONFIRMATION FUNCIOTN AFTER EDITING

PROGRAM (FOR Series 30i/31i/32i)..........................................................84

4.13.1 Operation Restart Confirmation Screen .................................................................84

4.13.2 Editing Function during Single Block Stop ...........................................................84

4.13.3 Operation Restart Confirmation in Multi Path System ..........................................85

4.13.4 Parameter................................................................................................................85

5 EDITING AND OPERATION OF MDI PROGRAMS..............................86

6 MANUAL OPERATION.........................................................................87

7 SETTING THE WORKPIECE COORDINATE DATA............................88

7.1 SOFT KEY [MEASUR].................................................................................88

7.2 SOFT KEY [+INPUT]...................................................................................88

7.3 CALCULATING METHOD OF MEASURING OF SETTING WORKPIECE

COORDINATE DATA (for Series 0i-F/0i-D/30i/31i/32i)...............................89

7.3.1 Outline....................................................................................................................89

7.3.1.1 In case of Series 0i-D......................................................................................... 89

c-4

Page 17

B-63874EN/11 TABLE OF CONTENTS

7.3.1.2 In case of Series 0i-F/30i/31i/32i-A/B...............................................................90

7.3.2 Parameter Setting ...................................................................................................90

8 SETTINGS RELATED TO TOOLS........................................................91

8.1 SETTING TOOL OFFSET DATA.................................................................91

8.1.1 Softkeys Icons for the Direction of the Imaginary Tool Nose ...............................91

8.1.1.1 How to specify icons ......................................................................................... 91

8.1.1.2 If program coordinate system/offset memory switching is enabled ..................92

8.1.2 Soft Key [MEASUR] .............................................................................................92

8.1.3 Soft Key [+INPUT]................................................................................................92

8.1.4 Soft Key [INP.C.]...................................................................................................92

8.2 SPECIFYING TOOL FIGURE DIMENSION DATA......................................93

8.2.1 Overview................................................................................................................93

8.2.2 Setting of Tool Type ..............................................................................................93

8.2.3 Editing of Tool Name.............................................................................................94

8.2.4 Setting of Tool Set..................................................................................................94

8.2.5 Setting of Tool Data ...............................................................................................94

8.2.6 Cutting Edge Angle................................................................................................95

8.2.7 Initializing of Tool Data.........................................................................................96

8.2.8 Displaying Tool Icons ............................................................................................96

8.2.9 Shortcut to the Tool Figure Dimension Data Setting Window ..............................97

8.3 TOOL INFORMATION DISPLAY.................................................................97

8.3.1 Displaying Screen...................................................................................................97

8.3.2 Tool Information Display.......................................................................................98

8.3.3 Notes when Commanding Offset Number by D Code...........................................98

8.4 COMBINING A TOOL DATABASE WITH THE TOOL MANAGEMENT

FUNCTION..................................................................................................98

8.4.1 Tool Management Data Window ...........................................................................98

8.4.2 Tool Management Data Tab...................................................................................99

8.4.2.1 Tool management data....................................................................................... 99

8.4.2.2 Spindle rotation speed and feedrate...................................................................99

8.4.2.3 Tool offset........................................................................................................100

8.4.2.4 Customization data..........................................................................................100

8.4.3 Customizing Tool Management Data Displays....................................................100

8.4.4 Magazine Management Table Tab .......................................................................100

8.4.5 Tool Offset Tab ....................................................................................................101

8.4.6 Tool Information Tab...........................................................................................101

8.4.7 Outputting Tool Management Data to the Memory Card ....................................101

8.4.8 Inputting Tool Management Data from the Memory Card ..................................101

III. CONVENIENT FUNCTIONS

1 CONTOUR PROGRAMMING..............................................................105

2 MEMORY CARD INPUT/OUTPUT FUNCTION..................................106

2.1 MEMORY CARD INPUT/OUTPUT OF PROGRAM...................................106

2.1.1 Memory Card Input/Output Screen of Program...................................................106

2.1.2 Memory Card Output Operation for Program......................................................107

2.1.3 Memory Card Input Operation for Program.........................................................108

2.1.4 File Format Allowed for Memory Card Input/Output..........................................109

2.1.5 Notes.....................................................................................................................109

2.2 MEMORY CARD INPUT/OUTPUT OF TOOL DATA.................................110

2.2.1 Memory Card Input/Output Screen of Tool Data.................................................110

2.2.2 Memory Card Output Operation for Tool Data....................................................110

c-5

Page 18

TABLE OF CONTENTS B-63874EN/11

2.2.3 Memory Card Input Operation for Tool Data ......................................................110

2.2.4 Data Format..........................................................................................................110

2.3 MEMORY CARD INPUT/OUTPUT OF OFFSET DATA (FOR Series

16i/18i/21i/30i/31i/32i)...............................................................................111

2.3.1 Output Operation..................................................................................................111

2.3.2 Input Operation.....................................................................................................112

2.3.3 Notes.....................................................................................................................112

2.4 MEMORY CARD INPUT/OUTPUT OF FIXED FORM SENTENCES........112

2.4.1 Memory Card Input/Output Screen of Fixed Form Sentences.............................112

2.4.2 Output Operation for Fixed Form Sentences........................................................113

2.4.3 Input Operation for Fixed Form Sentences ..........................................................113

2.4.4 Format of Fixed Form Sentences .........................................................................113

3 USB MEMORY INPUT/OUTPUT FUNCTION (for Series 0i-F/0i-D,

30i/31i/32i-B)......................................................................................114

3.1 USB MEMORY INPUT/OUTPUT OF PROGRAM .....................................114

3.1.1 USB Memory Input/Output Screen of Program...................................................114

3.1.2 USB Memory Output Operation for Program......................................................115

3.1.3 USB Memory Input Operation for Program.........................................................116

3.1.4 File Format Allowed for USB Memory Input/Output..........................................116

3.1.5 Notes.....................................................................................................................117

4 PROGRAM RESTART FUNCTION.....................................................118

4.1 RESTART METHOD .................................................................................118

4.1.1 Soft-key [P TYPE] ...............................................................................................118

4.1.2 Soft-key [Q TYPE]...............................................................................................119

4.2 PROGRAM RESTART IN MACHINING CYCLE (For only

Series30i/31i/32i-A/B, 0i-F/0i-D) ...............................................................119

5 CALCULATOR FUNCTION ................................................................120

5.1 APPLICATIONS.........................................................................................120

5.2 CALCULATION METHODS.......................................................................120

5.3 TRIGONOMETRIC FUNCTIONS (SINE, COSINE, TANGENT, ARCSINE,

ARCCOSINE, ARCTANGENT)..................................................................120

5.4 SQUARE ROOT........................................................................................121

5.5 EXPONENTIAL FUNCTIONS....................................................................121

5.6 LOGARITHMIC FUNCTIONS (COMMON LOGARITHM, NATURAL

LOGARITHM)............................................................................................121

5.7 ABSOLUTE VALUE...................................................................................121

5.8 ROUNDING...............................................................................................122

5.9 DISCARDING............................................................................................122

5.10 CIRCLE RATIO..........................................................................................122

6 SHORTCUT KEY OPERATIONS........................................................123

6.1 SHORTCUTS FOR VARIOUS CONFIRMATION OPERATIONS..............123

6.2 SHORTCUTS FOR RANGE SELECTION.................................................123

6.3 SHORTCUTS FOR COPY OPERATION...................................................123

6.4 SHORTCUTS FOR CUT OPERATION .....................................................123

6.5 SHORTCUTS FOR THE BASE SCREEN SOFT KEYS ............................123

6.6 SHORTCUT FOR STARTING THE CYCLE CHANGE SCREEN..............124

c-6

Page 19

B-63874EN/11 TABLE OF CONTENTS

6.7 SHORTCUTS FOR THE MENU SELECTION SCREEN...........................124

6.8 SHORTCUTS FOR THE REGULAR PROGRAM INSERTION SCREEN..124

6.9 SHORTCUTS FOR THE M CODE INSERTION SCREEN........................124

6.10 SHORTCUTS FOR THE PROGRAM LIST SCREEN................................124

6.11 INVALIDATION OF SHORTCUT KEY OPERATIONS ..............................125

6.11.1 Operation of Shortcut Key ...................................................................................125

6.12 SHORTCUTS FOR THE PROGRAM CREATION SCREEN.....................125

6.13 SHORTCUTS FOR THE COMMENT EDITING SCREEN.........................125

6.14 SHORTCUTS FOR THE SEARCH SCREEN............................................125

6.15 SHORTCUTS FOR THE CYCLE INPUT SCREEN ...................................125

6.16 SHORTCUT FOR THE WORKPIECE COORDINATE SYSTEM SETTING

SCREEN....................................................................................................126

6.17 SHORTCUT FOR THE TOOL OFFSET SETTING SCREEN....................126

6.18 SHORTCUTS FOR THE REGULAR PROGRAM REGISTRATION

SCREEN....................................................................................................126

6.19 SHORTCUTS FOR THE CREATION SCREEN FOR REGULAR

PROGRAM REGISTRATION ....................................................................126

6.20 SHORTCUTS FOR THE ALTER SCREEN FOR REGULAR PROGRAM

REGISTRATION........................................................................................126

6.21 SHORTCUTS FOR THE PRESET SCREEN.............................................127

6.22 SHORTCUT FOR THE MEASUREMENT RESULT SCREEN ..................127

6.23 SHORTCUT FOR THE MANUAL MEASUREMENT SCREEN..................127

6.24 SHORTCUT FOR VARIOUS SETTING SCREENS ..................................127

6.25 SHORTCUTS FOR THE FREE FIGURE MAIN SCREEN.........................127

6.26 SHORTCUTS FOR THE FREE FIGURE INPUT SCREEN.......................127

6.27 SHORTCUTS FOR THE FREE FIGURE CREATION SCREEN ...............128

7 INPUT OF DIRECTION ALONG THE LAYOUT OF NUMERIC

KEYS...................................................................................................129

8 HELP SCREEN ...................................................................................130

9 OPERATION NAVIGATING FUNCTION ............................................131

9.1 START METHOD FOR OPERATION NAVIGATING.................................131

9.1.1 First Method of Start (“SELECT NAVIGATION” window is displayed)...........131

9.1.2 Second Method of Start (“SELECT NAVIGATION” window isn’t displayed)..131

9.2 OPERATION WHILE NAVIGATION IS EFFECTIVE.................................132

9.3 THE METHOD TO FINISH OPERATION NAVIGATING...........................132

9.4 OPERATION WHEN STANDARD OPERATION NAVIGATING DATA

ARE USED ................................................................................................132

10 ADVANCED GUIDANCE FUNCTION

(for only Series 0i-F/30i/31i/32i-B) ...................................................134

10.1 DECOMPOSED CYCLE DISPLAY............................................................134

10.1.1 Method of Displaying the Decomposed Cycle Display Screen ...........................134

10.1.2 Condition..............................................................................................................135

10.1.3 Restriction ............................................................................................................135

10.2 INPUT DATA CHECK BY SIMULATION...................................................135

10.2.1 Condition..............................................................................................................136

c-7

Page 20

TABLE OF CONTENTS B-63874EN/11

10.2.2 Operational Procedure..........................................................................................136

10.2.3 Available Screen...................................................................................................136

10.2.4 Execution Range of Input Data Check by Simulation..........................................137

10.3 HELP WINDOW ACCORDING TO EACH SCREEN.................................138

10.3.1 Outline..................................................................................................................138

10.3.2 Condition..............................................................................................................139

10.3.3 Restriction ............................................................................................................139

10.4 COOPERATION WITH ANIMATED SOFTWARE THAT IS OPERATED

WITH PANEL i...........................................................................................139

10.4.1 Outline..................................................................................................................139

10.4.2 Condition..............................................................................................................139

10.4.3 Operation..............................................................................................................141

10.4.4 Restriction ............................................................................................................142

IV. MACHINING CYCLE

1 OVERVIEW .........................................................................................145

1.1 SELECTING A MACHINING CYCLE TYPE ..............................................145

1.2 ENTERING MACHINING CYCLE DATA ...................................................146

1.3 SELECTING FIGURES .............................................................................147

1.4 ENTERING FIXED FORM FIGURE DATA................................................149

1.5 ENTERING ARBITRARY FIGURE DATA..................................................150

1.6 CHANGING MACHINING CYCLE AND FIGURE DATA ...........................152

1.7 NOTES ON CREATING PROGRAMS.......................................................152

2 TURNING CYCLE ...............................................................................154

2.1 HOLE MACHINING (WORKPIECE ROTATION).......................................157

2.1.1 Machining Command...........................................................................................157

2.1.2 Specifying Pecking Clearance of Drill Cycle for Lathe in Input Window

(for only Series 30i/31i/32i-A/B, 0i-TF/0i-TD) ...................................................163

2.1.2.1 Parameter setting to use this function.............................................................. 163

2.1.2.2 Format of drill cycle ........................................................................................ 163

2.2 TURNING ..................................................................................................164

2.2.1 Machining Command...........................................................................................164

2.2.2 Arbitrary Figure (ZX Plane).................................................................................187

2.2.3 Conical Boring Cycle ...........................................................................................189

2.2.4 Optimization of the Cutting Direction in Finish Turning.....................................196

2.2.5 Go past amount in End Face Finishing.................................................................202

2.2.6 Continuous Machining of Roughing and Finishing .............................................203

2.2.7 Improvement of Excessive Amount of Travel in Turning Cycle.........................204

2.2.7.1 Target machining cycle.................................................................................... 204

2.2.7.2 Condition that this function is enabled ............................................................204

2.2.7.3 Example of machining.....................................................................................204

2.2.8 The Restriction of Turning Cycle When Input Values of Z-axis and X-axis

Clearances are Different.......................................................................................205

2.2.9 Restrictions...........................................................................................................205

2.3 TURNING GROOVING..............................................................................207

2.3.1 Machining Cycle ..................................................................................................207

2.3.2 Restrictions on Target Figures..............................................................................216

2.3.3 Fixed Form Figure (ZX Plane).............................................................................217

2.3.4 Turning Groove Cycle by Using Button Tool......................................................223

2.3.5 Automatic Adjustment of Escape Amount for Turning Grooving Cycle.............223

2.3.5.1 Machining cycles.............................................................................................223

c-8

Page 21

B-63874EN/11 TABLE OF CONTENTS

2.3.5.2 Tool path.......................................................................................................... 224

2.4 THREADING..............................................................................................225

2.4.1 Machining Command...........................................................................................225

2.4.2 Fixed Form Figure................................................................................................229

2.5 REAR END FACING BY TURNING...........................................................235

2.6 RESIDUAL MACHINING BY TURNING ....................................................236

2.6.1 Outline of the Residual Machining Cycle ............................................................236

2.6.2 Cycle Selection Screen.........................................................................................237

2.6.3 Cycle Input Screen ...............................................................................................237

2.6.4 Motion of Outer Surface Residual Roughing (G1160) ........................................238

2.6.5 Motion of Machining Other than Outer Surface Residual Roughing (G1160) ....242

2.6.6 Finish Turning Using G41/G42............................................................................242

2.7 POLYGON TURNING CYCLE...................................................................243

2.7.1 Input Items of Polygon Turning Cycle.................................................................243

2.7.2 Inserting Polygon Turning Cycle Command........................................................244

2.7.3 Tool Path of Polygon Turning..............................................................................245

2.7.4 Tool Kind Setting.................................................................................................247

2.7.5 Direction of Imaginary Tool Nose Setting ...........................................................247

2.7.6 Simulation during Polygon Turning Cycle ..........................................................247

3 C-AXIS AND A-AXIS MACHINING CYCLE ........................................248

3.1 C-AXIS AND A-AXIS GROOVING.............................................................249

3.1.1 Machining Command...........................................................................................249

3.1.2 Figure Blocks for C-axis and A-axis Grooving....................................................250

3.2 CYCLE RETRACT MOTION......................................................................254

3.3 C-AXIS MACHINING WITH ROTATION AXIS...........................................254

3.3.1 Support for C-Axis Machining with Rotation Axis .............................................254

3.4 C-AXIS AND A-AXIS CLAMPING M CODE OUTPUT...............................255

3.4.1 Outline..................................................................................................................255

3.4.2 Specifying the Clamping Method.........................................................................256

3.4.3 Value of M Code Output......................................................................................256

3.4.4 Distinction between Main and Sub Spindle .........................................................256

3.4.5 Position of M Code Output (When Hard Clamping is Selected) .........................256

3.4.6 Position of M Code Output (When Soft Clamping is Selected)...........................259

3.4.7 Position of M Code Output (When Suppression of Clamp Output is Selected)...260

4 MILLING..............................................................................................261

4.1 HOLE MACHINING ...................................................................................269

4.1.1 Machining Command (Tool Rotation: M Series).................................................269

4.1.2 Machining Command (Tool Rotation: T Series)..................................................277

4.1.3 Figure (XY Plane) ................................................................................................280

4.1.4 Figure (YZ/XC Plane)..........................................................................................284

4.1.5 Specifying Pecking Clearance / Return Amount of Drill Cycle for Machining

Center in Input Window (for only Series 30i/31i/32i-A/B, 0i-MF/0i-MD).........286

4.1.5.1 Parameter setting to use this function.............................................................. 286

4.1.5.2 Format of drill cycle ........................................................................................ 287

4.1.6 C axis Hole on End Face (Random Points) - Cartesian Coordinates Input

Cycle.....................................................................................................................287

4.1.6.1 Input items of C axis hole on end face (random points) - cartesian

coordinates (G1574)........................................................................................287

4.1.7 C axis Hole on End face (GRID) - Cartesian Coordinates Input Cycle (For only

Series 30i/31i/32iB, 0i-F/0i-D).............................................................................288

4.1.7.1 Input items of C-axis hole on end face (Grid) – cartesian coordinates

(G1576)............................................................................................................288

c-9

Page 22

TABLE OF CONTENTS B-63874EN/11

4.2 FACING.....................................................................................................289

4.2.1 Machining Command...........................................................................................289

4.2.2 Fixed Form Figure Blocks (XY Plane) ................................................................292

4.2.3 Fixed Form Figure (YZ Plane, XC Plane)............................................................294

4.2.4 Arbitrary Figure (XY Plane) ................................................................................295

4.2.5 Arbitrary Figure (YZ/XC/ZC/XA Plane) .............................................................295

4.3 CONTOURING..........................................................................................296

4.3.1 Machining Command...........................................................................................296

4.3.2 Fixed Form Figure (XY Plane).............................................................................310

4.3.3 Fixed Form Figure (YZ/XC Plane) ......................................................................311

4.3.4 Arbitrary Figure (XY Plane) ................................................................................312

4.3.5 Arbitrary Figure (YZ/XC/ZC/XA Plane) .............................................................313

4.4 EMBOSS MACHINING..............................................................................314

4.4.1 Machining Command...........................................................................................315

4.4.2 Arbitrary Figure (XY Plane) ................................................................................318

4.4.3 Arbitrary Figure (YZ/XC/ZC/XA plane) .............................................................319

4.5 POCKETING..............................................................................................320

4.5.1 Machining Command...........................................................................................320

4.5.2 Improvement of Checking Cutting Condition for Pocketing (Rough) and

Emboss Machining (Rough).................................................................................330

4.5.2.1 PARAMETER................................................................................................. 330

4.5.3 Fixed Form Figure (XY Plane).............................................................................330

4.5.4 Fixed Form Figure (YZ/XC Plane) ......................................................................331

4.5.5 Arbitrary Figure (XY Plane) ................................................................................332

4.5.6 Arbitrary Figure (YZ/XC/ZC/XA Plane) .............................................................333

4.5.7 Pocket Residual Machining Cycle (for only Series 30i/31i/32i-B, 0i-F/0i-D).....334

4.5.7.1 Outline.............................................................................................................334

4.5.7.2 Condition.........................................................................................................334

4.5.7.3 Operation.........................................................................................................334

4.5.7.4 Format of pocket residual machining cycle command ....................................335

4.5.7.5 Tool path.......................................................................................................... 336

4.5.7.6 Restrictions...................................................................................................... 337

4.6 GROOVING...............................................................................................339

4.6.1 Machining Command...........................................................................................339

4.6.2 Fixed Form Figure (XY Plane).............................................................................348

4.6.3 Fixed Form Figure (YZ/XC Plane) ......................................................................350

4.6.4 XC-plane Circumferential Groove Figure............................................................351

4.6.5 Arbitrary Figure (XY Plane) ................................................................................354

4.6.6 Arbitrary Figure (YZ/XC/ZC/XA Plane) .............................................................355

4.7 ENGRAVING CYCLE................................................................................356

4.7.1 Operation..............................................................................................................356

4.7.2 Input Item.............................................................................................................357

4.7.3 Enable Characters.................................................................................................359

4.7.4 Format of G4 Digit Cycle for Engraving Cycle ...................................................359

4.7.5 Tool Path of Engraving Cycle..............................................................................359

4.7.6 Restrictions...........................................................................................................360

4.8 THREAD MILLING CYCLE........................................................................361

4.8.1 Screens and Operations ........................................................................................361

4.8.2 Input Items of Thread Milling..............................................................................362

4.8.3 Specifiable Combinations of Figure.....................................................................363

4.8.4 Tool Kind .............................................................................................................363

4.8.5 Basic Motions of Tool..........................................................................................363

4.8.6 Machining Type ...................................................................................................364

4.8.7 Pattern of Tool Path..............................................................................................365

c-10

Page 23

B-63874EN/11 TABLE OF CONTENTS

4.8.8 Tool Path (Machining Type 1) .............................................................................365

4.8.9 Tool Path (Machining Type 2) .............................................................................366

4.8.10 Tool Path (Machining Type 3).............................................................................367

4.8.11 Machining Simulation Screen ..............................................................................368

4.8.12 Parameters............................................................................................................368

4.9 OUTER THREAD MILLING CYCLE..........................................................369

4.9.1 Machining Types..................................................................................................369

4.9.2 Method of Program Creation................................................................................370

4.9.3 Outer Thread Milling Cycle Command................................................................371

4.9.4 Tool Type.............................................................................................................372

4.9.5 Machining Simulation..........................................................................................372

4.9.6 Drawing-During-Machining.................................................................................373

4.9.7 Parameters............................................................................................................373

4.9.8 Alarms..................................................................................................................373

4.10 REAR END FACING BY MILLING.............................................................375

4.10.1 Rear End Facing...................................................................................................375

4.11 MIRROR / ROTATION / SCALING / FIGURE COPY COMMAND.............376

4.11.1 Coordinate Conversion (Mirror Image)................................................................377

4.11.2 Coordinate Conversion (Rotation) .......................................................................377

4.11.3 Scaling..................................................................................................................378

4.11.4 Figure Copy (Rotation Copy/ Parallel Copy).......................................................379

4.11.5 Parameter..............................................................................................................380

4.12 COORDINATE SYSTEM CONVERSION CYCLE.....................................381

4.12.1 Supportable Machine Configuration ....................................................................381

4.12.2 Slant Face Machining Command (Coordinate Conversion).................................382

4.13 TILTED WORKING PLANE INDEXING FUNCTION (FOR Series 30i/31i,

Series 0i-MF/0i-MD)..................................................................................384

4.13.1 Operation..............................................................................................................384

4.13.2 Tilted Working Plane Input Screen by Euler’s Angle..........................................385

4.13.3 Tilted Working Plane Input Screen by Roll-Pitch-Yaw.......................................386

4.13.4 Tilted Working Plane Input Screen by Three Points............................................386

4.13.5 Tilted Working Plane Input Screen by Two Vectors ...........................................387

4.13.6 Tilted Working Plane Input Screen by Projection Angles ...................................388

4.13.7 Tilted Working Plane Input Screen by Tool Axis Direction................................388

4.13.8 Tilted Working Plane Input Screen by Tilted Plane Cancel.................................388

4.13.9 Restriction of Machining Simulation ................................................................... 389

4.14 MILLING BY ROTATING A WORKPIECE ABOUT THE Y-AXIS...............389

4.14.1 Machining Type ...................................................................................................389

4.14.2 Figure ...................................................................................................................390

4.14.3 Machining Simulation..........................................................................................392

5 ENTERING ARBITRARY FIGURES...................................................393

5.1 ENTERING ARBITRARY FIGURE DATA..................................................393

5.1.1 Arbitrary Figures for the XY Plane......................................................................394

5.1.2 Arbitrary Figures for the YZ Plane ......................................................................399

5.1.3 Arbitrary Figures for the Polar Coordinate Interpolation Plane (XC Plane)........400

5.1.4 Arbitrary Figures for the Cylindrical Surface (ZC Plane)....................................401

5.1.5 Arbitrary Figures for Turning (ZX Plane)............................................................401

5.2 ARC SPECIFICATION BY CENTRAL ANGLE..........................................407

5.2.1 Operations ............................................................................................................407

5.2.2 Input Items............................................................................................................408

5.2.3 Enable Arbitrary Figures......................................................................................408

c-11

Page 24

TABLE OF CONTENTS B-63874EN/11

5.3 ENLARGEMENT AND REDUCTION ON THE ARBITRARY FIGURE

INPUT SCREEN........................................................................................408

5.3.1 Machining Simulation Screen ..............................................................................409

5.3.2 Arbitrary Figure Input Screen ..............................................................................409