Page 1

*

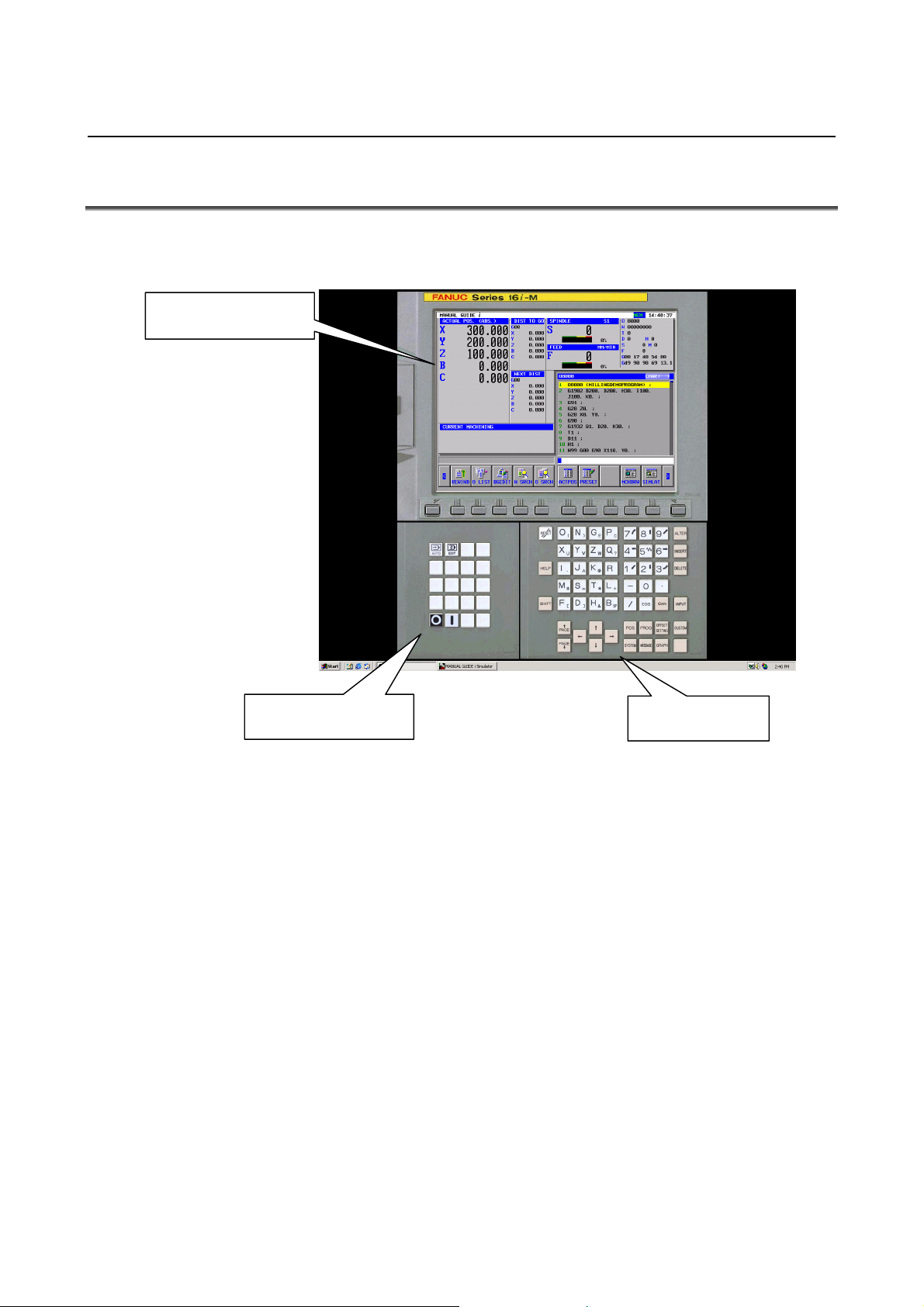

FANUC MANUAL GUIDE

OPERATOR’S MANUAL

B-63874EN/05

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B-63874EN/05 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

When using a machine equipped with the FANUC MANUAL GUIDE i,

be sure to observe the following safety precautions.

s-1

Page 4

SAFETY PRECAUTIONS B-63874EN/05

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to the degree of the risk or the

severity of damage.

Also, supplementary information is described as Note.

Read the Warning, Caution, and Note thoroughly before attempting to

use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-63874EN/05 SAFETY PRECAUTIONS

1.2 GENERAL WARNINGS AND CAUTIONS

To ensure safety while using a machine featuring the MANUAL

GUIDE i function, observe the following precautions:

WARNING

1 Confirm, on the screen, that the data has been entered

correctly before proceeding to the next operation.

Attempting operation with incorrect data may cause the

tool to strike the workpiece or machine, possibly

breaking the tool or machine or injuring the operator.

2 Before starting the machine using the tool compensation

function, carefully determine the direction of

compensation and the compensation value, and ensure

that the tool will not strike the workpiece or machine.

Otherwise the tool or machine may be damaged or the

operator may be injured.

3 When using constant surface speed control, set the

maximum rotating speed of the spindle to a value that is

allowed for the workpiece and workpiece hold unit.

Otherwise, the workpiece or hold unit may be removed

by centrifugal force to damage the tool machine or injure

the operator.

4 Set all necessary parameters and data items before

starting MANUAL GUIDE i operations. Note that if the

cutting conditions are not suitable for the workpiece, the

tool may be damaged or the operator may be injured.

5 After creating a machining program using MANUAL

GUIDE i functions, do no run the machine on that

program immediately. Instead, confirm every step of the

resultant program, and make sure that the tool path and

machining operation are correct and that the tool will not

strike the workpiece or machine. Before starting

production machining, run the machine with no

workpiece attached to the machine to make sure that the

tool will not strike a workpiece or the machine. If the tool

strikes the machine and/or work-piece, the tool and/or

machine may be damaged, and even injuries the

operator.

CAUTION

After pressing the power-on button, do not touch any

keys on the keyboard until the initial screen appears.

Some keys are used for maintenance or special

operations such that pressing such a key may cause an

unexpected operation.

s-3

Page 6

Page 7

B-63874EN/05 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

I. GENERAL

1 OVERVIEW OF THIS MANUAL..............................................................3

2 READ AT FIRST .....................................................................................4

3 ALL-IN-ONE SCREEN ............................................................................9

4 SYMBOLS USED ..................................................................................12

5 NOTES ON CREATING PROGRAMS ..................................................13

6 MANUAL GUIDE i SIMULATOR FOR THE PERSONAL

COMPUTER ..........................................................................................16

6.1 OPERATING ENVIRONMENT ....................................................................17

6.1.1 Product Components ..............................................................................................17

6.1.2 Operating Environment ..........................................................................................17

6.2 METHOD OF INSTALLATION..................................................................... 18

6.3 SIMULATION CNC SELECTION.................................................................21

6.4 FULL-SCREEN DISPLAY............................................................................ 22

6.5 PARAMETER ..............................................................................................23

6.6 RESTRICTIONS ON USE ........................................................................... 23

6.7 NOTES ........................................................................................................ 24

6.8 SIMULATOR DEFINITION FILE FORMAT.................................................. 25

6.8.1 Comment ................................................................................................................25

6.8.2 Section....................................................................................................................25

6.8.3 Key ......................................................................................................................25

6.8.3.1 [Simulator_MachineSetting_MaxNumber] section............................................................................. 26

6.8.3.2 [Simulator_MachineSettingn] section .................................................................................................26

6.9 DISPLAY DATA ini FILE FORMAT.............................................................. 29

6.9.1 Comment ................................................................................................................29

6.9.2 Section....................................................................................................................29

6.9.3 Key ......................................................................................................................30

6.9.3.1 [settings] section................................................................................................................................... 30

6.9.3.2 [frame_mainscreen] section .................................................................................................................31

6.9.3.3 [cnctitle] section ................................................................................................................................... 32

6.9.3.4 [softkey] section ...................................................................................................................................33

6.9.3.5 [frame_mdikey] section........................................................................................................................ 34

6.9.3.6 [mdikey] section ................................................................................................................................... 35

6.9.3.7 [frame_functionkey] section ................................................................................................................36

6.9.3.8 [functionkey] section............................................................................................................................ 37

6.9.3.9 Information to be passed when a button is pressed ............................................................................. 38

c-1

Page 8

TABLE OF CONTENTS B-63874EN/05

II. OPERATION

1 OVERVIEW OF THE PROCEDURE .....................................................43

1.1 MAIN FEATURES OF MANUAL GUIDE i ................................................... 44

2 MACHINING PROGRAM FORMAT ......................................................46

3 EDITING MACHINING PROGRAMS ....................................................48

3.1 MACHINING PROGRAM WINDOW AND EIDITNG .................................... 49

3.2 CREATING MACHINING PROGRAMS....................................................... 51

3.3 EDITING IN A PROGRAM LIST .................................................................. 52

3.4 SEARCHING FOR A MACHINING PROGRAM TO BE EDITED.................54

3.5 BASIC EDITING OPERATIONS OF PART PROGRAM .............................. 55

3.5.1 Entering a Word (INSERT key).............................................................................55

3.5.2 Modifying a Word (ALTER key)...........................................................................55

3.5.3 Modifying the Numeric Value of a Word (ALTER key) .......................................55

3.5.4 Deleting a Word (DELETE key)............................................................................56

3.5.5 Modifying a Block (ALTER key) ..........................................................................56

3.5.6 Deleting a Block (DELETE key) ...........................................................................56

3.5.7 Changing the Program Number (ALTER key) ......................................................56

3.6 SEARCH (FORWARD AND BACKWARD).................................................. 57

3.7 CUT ............................................................................................................. 58

3.8 COPY ..........................................................................................................58

3.9 PASTE......................................................................................................... 59

3.10 DELETE....................................................................................................... 59

3.11 KEY-IN PASTE ............................................................................................ 60

3.12 UNDO, REDO..............................................................................................61

3.13 M-CODE MENU........................................................................................... 62

3.14 FIXED FORM SENTENCE INSERTION...................................................... 64

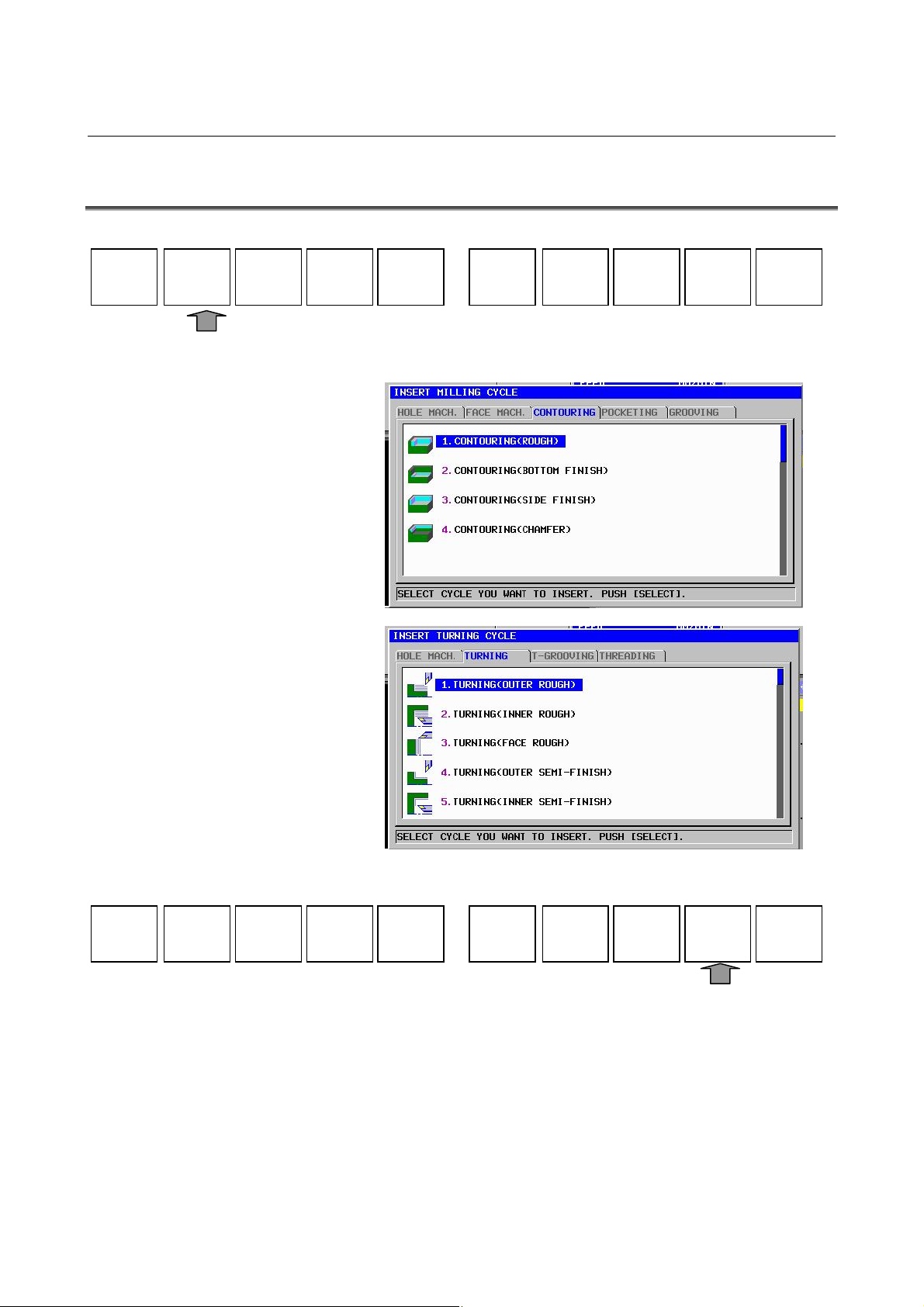

4 EDITING CYCLE MACHINING OPERATIONS.....................................66

4.1 ENTERING THE START COMMAND ......................................................... 67

4.2 SELECTING A CYCLE MACHINING TYPE ................................................69

4.3 ENTERING CYCLE MACHINING DATA ..................................................... 71

4.4 SELECTING FIGURES ............................................................................... 73

4.5 ENTERING FIXED FORM FIGURE DATA FOR CYCLE MACHINING ....... 75

4.6 ENTERING ARBITRARY FIGURE DATA FOR CYCLE MACHINING......... 78

4.7 ENTERING CONTOUR PROGRAMS ......................................................... 81

4.8 ENTERING THE END COMMAND.............................................................. 83

4.9 CHANGING CYCLE MACHINING AND FIGURE DATA ............................. 83

c-2

Page 9

B-63874EN/05 TABLE OF CONTENTS

5 DETAILED DESCRIPTIONS ABOUT ENTERING ARBITRARY

FIGURES...............................................................................................84

5.1 INCREMENTAL PROGRAMMING .............................................................. 85

5.1.1 Arbitrary Figures for the XY Plane........................................................................86

5.2 ARBITRARY FIGURES FOR THE YZ PLANE ............................................97

5.3 ARBITRARY FIGURES FOR THE POLAR COORDINATE

INTERPOLATION PLANE (XC PLANE) .................................................... 107

5.4 ARBITRARY FIGURES FOR THE CYLINDRICAL SURFACE

(ZC PLANE)...............................................................................................118

5.5 ARBITRARY FIGURES FOR TURNING (ZX PLANE)............................... 129

5.6 ARBITRARY FIGURE COPY FUNCTIONS...............................................140

5.6.1 Selecting an Arbitrary Figure Copy Function ......................................................140

5.6.2 Copy Condition Input Screen ...............................................................................141

5.6.3 Executing Arbitrary Figure Copy Operation........................................................145

5.6.4 Figure after Arbitrary Figure Copy Execution .....................................................147

5.6.5 Notes on Arbitrary Figure Copy Operation..........................................................147

6 OPERATIONS IN THE MEM MODE ...................................................148

6.1 REWINDING A MACHINING PROGRAM ................................................. 149

6.2 EDITING WITH THE MACHINING PROGRAM LIST ................................149

6.3 SEARHING FOR A SEQUENCE NUMBER IN A PROGRAM ................... 150

6.4 SELECTING A PROGRAM FOR MACHINING OPERATION.................... 150

6.5 CHANGING THE CURRENT POSITION DISPLAY................................... 150

6.6 PRESETTING RELATIVE COORDINATES ..............................................151

6.7 DISPLAYING MEASUREMENT RESULTS............................................... 152

6.8 DISPLAYING THE MACHINING SIMULATION WINDOW ........................ 152

6.9 DISPLAYING THE DRAWING-DURING-MACHINING WINDOW ............. 152

6.10 BG EDITING.............................................................................................. 153

6.11 NC PROGRAM CONVERSION ................................................................. 153

6.12 NEXT-BLOCK DISPLAY FUNCTION ........................................................ 154

6.13 PROGRAM RESTART FUNCTION ........................................................... 156

6.13.1 [P TYPE] Soft-key ...............................................................................................156

6.13.2 [Q TYPE] Soft-key...............................................................................................157

7 OPERATIONS IN THE MDI MODE ..................................................... 158

8 OPERATIONS IN THE MANUAL MODE (HANDLE AND JOG) ........160

9 MACHINING SIMULATION AND DRAWING DURING MACHINING. 161

9.1 DRAWING DURING MACHINING (TOOL PATH) ..................................... 163

c-3

Page 10

TABLE OF CONTENTS B-63874EN/05

9.1.1 Program Selection Operation and Other Operations in Drawing during

Machining.............................................................................................................164

9.1.2 Selecting Whether to Display the Tool Path or Not in Drawing during

Machining.............................................................................................................165

9.1.3 Scaling, Movement, and Other Operations in Drawing during Machining..........165

9.2 MACHINING SIMULATION (TOOL PATH) (FOR Series 16i/18i/21i)........ 168

9.2.1 Program Selection Operation and Other Operations in Machining Simulation

(Tool Path)............................................................................................................170

9.2.2 Execution Operations in Machining Simulation (Tool Path) ...............................170

9.2.3 Scaling, Movement, and Other Operations in Machining Simulation

(Tool Path)............................................................................................................171

9.3 MACHINING SIMULATION (ANIMATED) (FOR Series 16i/18i/21i).......... 172

9.3.1 Program Selection Operation and Other Operations in Machining Simulation

(Animated)............................................................................................................174

9.3.2 Execution Operations in Machining Simulation (Animated)...............................174

9.3.3 Scaling, Movement, and Other Operations in Machining Simulation

(Animated)............................................................................................................175

9.3.4 Notes on Machining Simulation...........................................................................175

9.4 MACHINING SIMULATION (TOOL PATH) (FOR Series 30i).................... 177

9.4.1 Program Selection Operation and Other Operations in Machining Simulation

(Tool Path)............................................................................................................181

9.4.2 Execution Operations in Machining Simulation (Tool Path) ...............................182

9.4.3 Scaling, Movement, and Other Operations in Machining Simulation

(Tool Path)............................................................................................................182

9.5 MACHINING SIMULATION (ANIMATED) (FOR Series 30i) ..................... 183

9.5.1 Program Selection Operation and Other Operations in Machining Simulation

(Animated)............................................................................................................183

9.5.2 Execution Operations in Machining Simulation (Animated)...............................183

9.5.3 Scaling, Movement, and Other Operations in Machining Simulation

(Animated)............................................................................................................184

9.6 DATA HANDLED DURING MACHINING SIMULATION (FOR Series 30i) 185

9.7 FUNCTIONS OPERATING DIFFERENTLY BETWEEN MACHINING

SIMULATION AND AUTOMATIC OPERATION (FOR Series 30i) ............ 186

9.7.1 Functions That Cannot Be Used for Machining Simulation ................................187

9.7.2 Functions That Can Be Used for Machining Simulation (Milling System) .........187

9.8 CHANGING WORKPIECE COORDINATE DURING MACHINING

SIMULATION (ANIMATION, TOOL PATH DRAWING) ............................. 188

9.9 SETTING OF DATA FOR ANIMATION ..................................................... 190

9.10 SPINDLE MOVEMENT ANIMATION FOR AUTOMATIC LATHES ...........217

9.10.1 Function................................................................................................................217

9.10.2 Start Command of Reflection...............................................................................217

9.10.3 End Command of Reflection................................................................................218

c-4

Page 11

B-63874EN/05 TABLE OF CONTENTS

9.10.4 Simulation and Actual Working of the Machine..................................................219

10 SETTING DATA .................................................................................. 222

10.1 SETTING THE WORKPIECE COORDINATE DATA................................. 223

10.1.1 [MEASUR] Soft Key ...........................................................................................225

10.1.2 [+INPUT] Soft Key..............................................................................................226

10.2 SETTING TOOL OFFSET DATA...............................................................228

10.2.1 [MEASUR] Soft Key ...........................................................................................230

10.2.2 [+INPUT] Soft Key..............................................................................................231

10.2.3 [INP.C.] Soft Key.................................................................................................232

10.3 REGISTERING FIXED FORM SENTENCES ............................................ 233

10.3.1 Registering a New Fixed Form Sentence .............................................................236

10.3.2 Modifying a Fixed Form Sentence.......................................................................238

10.3.3 Deleting a Fixed Form Sentence ..........................................................................239

10.3.4 Initialization to Standard Fixed Form Sentences..................................................239

11 BACKGROUND EDITING................................................................... 240

11.1 STARTING BACKGROUND EDITING ...................................................... 241

11.2 ENDING BACKGROUND EDITING........................................................... 242

11.3 OPERATIONS DURING BACKGROUND EDITING .................................. 242

12 NC PROGRAM CONVERSION FUNCTION ....................................... 243

12.1 BASIC SPECIFICATIONS ......................................................................... 244

12.2 OPERATING THE NC PROGRAM CONVERSION FUNCTION ...............246

12.3 RESTRICTIONS ........................................................................................ 249

13 TOOL DATA BASE FUNCTION .........................................................251

13.1 SETTING OF TOOL OFFSET DATA.........................................................252

13.2 SETTING OF TOOL DATA........................................................................ 253

13.2.1 Setting of Tool Type ............................................................................................253

13.2.2 Editing of Tool Name...........................................................................................254

13.2.3 Setting of Tool Set................................................................................................254

13.2.4 Entering of Tool Data...........................................................................................254

13.2.5 Cutting Edge angle of Tool Data Base Function..................................................255

13.2.6 Initializing of Tool Data .......................................................................................256

13.3 SELECTING TOOL DATA AT PROGRAM ENTERING............................. 257

13.4 SETTING OF TOOL GRAPHIC DATA....................................................... 258

13.4.1 Tool Graphic Data ................................................................................................258

13.5 ACCESSING TOOL DATA BASE FUNCTION ..........................................259

13.5.1 Basic Specifications .............................................................................................259

13.5.2 System Variables..................................................................................................260

13.5.3 Reading.................................................................................................................261

13.5.4 Writing .................................................................................................................261

c-5

Page 12

TABLE OF CONTENTS B-63874EN/05

13.5.5 Copying ................................................................................................................261

13.5.6 Initialization .........................................................................................................262

13.5.7 Initialization of All Tool Data ..............................................................................262

14 EDITING OF FREE FIGURE AND FIXED FORM FIGURE OF

SUBPROGRAM FORM....................................................................... 263

14.1 EDITING A FREE FORM FIGURE SUBPROGRAM .................................264

14.2 WARNING MESSAGE............................................................................... 267

14.3 EDITING A FIXED FORM FIGURE SUBPROGRAM ................................267

15 SHORTCUT KEY OPERATIONS........................................................268

15.1 SHORTCUTS FOR VARIOUS CONFIRMATION OPERATIONS.............. 269

15.2 SHORTCUTS FOR RANGE SELECTION................................................. 269

15.3 SHORTCUTS FOR COPY OPERATION................................................... 269

15.4 SHORTCUTS FOR CUT OPERATION ..................................................... 269

15.5 SHORTCUTS FOR THE BASE SCREEN SOFT KEYS ............................270

15.6 SHORTCUT FOR STARTING THE CYCLE CHANGE SCREEN .............. 270

15.7 SHORTCUTS FOR THE MENU SELECTION SCREEN ........................... 270

15.8 SHORTCUTS FOR THE REGULAR PROGRAM INSERTION SCREEN.. 270

15.9 SHORTCUTS FOR THE M CODE INSERTION SCREEN ........................ 271

15.10 SHORTCUTS FOR THE PROGRAM LIST SCREEN ................................ 271

15.11 SHORTCUTS FOR THE PROGRAM CREATION SCREEN ..................... 271

15.12 SHORTCUTS FOR THE COMMENT EDITING SCREEN ......................... 271

15.13 SHORTCUTS FOR THE SEARCH SCREEN ............................................ 271

15.14 SHORTCUTS FOR THE CYCLE INPUT SCREEN ...................................272

15.15 SHORTCUT FOR THE WORKPIECE COORDINATE SYSTEM

SETTING SCREEN ................................................................................... 272

15.16 SHORTCUT FOR THE TOOL OFFSET SETTING SCREEN .................... 272

15.17 SHORTCUTS FOR THE REGULAR PROGRAM REGISTRATION

SCREEN.................................................................................................... 272

15.18 SHORTCUTS FOR THE CREATION SCREEN FOR REGULAR

PROGRAM REGISTRATION .................................................................... 273

15.19 SHORTCUTS FOR THE ALTER SCREEN FOR REGULAR PROGRAM

REGISTRATION........................................................................................ 273

15.20 SHORTCUTS FOR THE PRESET SCREEN............................................. 273

15.21 SHORTCUT FEEDRATE THE MEASUREMENT RESULT SCREEN ....... 273

15.22 SHORTCUT FOR THE MANUAL MEASUREMENT SCREEN..................273

15.23 SHORTCUT FOR VARIOUS SETTING SCREENS .................................. 273

15.24 SHORTCUTS FOR THE FREE FIGURE MAIN SCREEN ......................... 274

c-6

Page 13

B-63874EN/05 TABLE OF CONTENTS

15.25 SHORTCUTS FOR THE FREE FIGURE INPUT SCREEN ....................... 274

15.26 SHORTCUTS FOR THE FREE FIGURE CREATION SCREEN ............... 274

16 HELP SCREEN ................................................................................... 275

17 MEMORY CARD INPUT/OUTPUT FUNCTION .................................. 277

17.1 MEMORY CARD INPUT/OUTPUT OF PART PROGRAM ........................ 278

17.1.1 Memory Card Input/Output Screen of Part Program............................................278

17.1.2 Memory Card Output Operation for Part Program...............................................279

17.1.3 Memory Card Input Operation for Part Program .................................................282

17.1.4 File Format Allowed for Memory Card Input/Output..........................................283

17.2 MEMORY CARD INPUT/OUTPUT OF TOOL DATA................................. 284

17.2.1 Memory Card Input/Output Screen of Tool Data.................................................284

17.2.2 Memory Card Output Operation for Tool Data....................................................285

17.2.3 Memory Card Input Operation for Tool Data ......................................................286

17.2.4 Data Format..........................................................................................................286

17.3 MEMORY CARD INPUT/OUTPUT OF FIXED FORM SENTENCES ........ 287

17.3.1 Memory Card Input/Output Screen of Fixed Form Sentences.............................287

17.3.2 Output Fixed Form Sentences ..............................................................................288

17.3.3 Input Fixed Form Sentences.................................................................................289

17.3.4 Format of Fixed Form Sentences .........................................................................289

18 HANDLING LARGE PROGRAMS ......................................................290

18.1 SETTING A MAXIMUM PROGRAM SIZE THAT CAN BE HANDLED ...... 291

18.2 HANDLING A PROGRAM LARGER THAN THE MAXIMUM

ALLOWABLE SIZE .................................................................................... 292

19 CALCULATOR FUNCTION ................................................................ 294

19.1 CALCULATOR FUNCTION ....................................................................... 295

20 AUTOMATIC SETTING OF INITIAL VALUE DATA ........................... 298

20.1 AUTOMATIC SETTING OF INITIAL VALUES ON THE INPUT DATA

SCREEN.................................................................................................... 299

20.2 AUTOMATIC TOOL DEFINITION BLOCK COPY .....................................299

21 SUPPORT FOR FOLDER MANAGEMENT (FOR Series 30i ONLY) 300

21.1 PROGRAM LIST SCREEN........................................................................ 301

21.1.1 Data Displayed in the Program List .....................................................................301

21.1.2 Operations Added for the Program List Screen....................................................302

21.1.3 Support for the Data Server..................................................................................303

21.2 MEMORY CARD I/O SCREEN..................................................................304

21.3 SUBPROGRAM TAB ON THE CYCLE FIGURE SELECTION SCREEN .. 304

21.4 OUTPUT OF AN ARBITRARY FIGURE AS A SUBPROGRAM ................ 304

c-7

Page 14

TABLE OF CONTENTS B-63874EN/05

21.5 DISPLAY OF ARBITRARY FIGURES OF M98 SUBPROGRAMS ............ 305

22 SCREEN HARD COPY ....................................................................... 306

23 DISPLAYING MACHINING TIME (FOR Series 16i/18i/21i ONLY) ... 307

23.1 FORMAT OF MACHINING TIME DATA .................................................... 308

23.2 OPERATION FOR INSERTING MACHINING TIME.................................. 309

23.3 DISPLAY MACHINING TIME..................................................................... 311

24 PROGRAM COORDINATE SYSTEM CHANGING FUNCTION AND

TOOL OFFSET MEMORY CHANGING FUNCTION...........................312

24.1 PROGRAM COORDINATE SYSTEM CHANGING FUNCTION................ 313

24.1.1 COORDINATE SYSTEM SELECTION COMMAND ......................................313

24.1.2 COORDINATE OF ARBITRARY FIGURES (XZ, ZC, ZY PLANE) ...............315

24.1.3 MACHINING SIMULATION.............................................................................316

24.1.4 STATUS DIPLAY ...............................................................................................317

24.2 TOOL OFFSET MEMORY CHANGING FUNCTION ................................. 318

24.2.1 TOOL OFFSET DATA WINDOW .....................................................................318

24.2.2 WORKPIECE SHIFT OFFSET DATA WINDOW.............................................320

24.3 SET-UP GUIDANCE FUNCTIONS............................................................ 321

24.3.1 MANUAL MEASUREMENT .............................................................................321

24.3.2 MEASUREMENT CYCLE..................................................................................321

24.3.3 MEASUREMENT RESULT DISPLAY SCREEN .............................................321

24.4 CAUTIONS ................................................................................................ 322

III. CYCLE MACHINING TYPES

1 MILLING .............................................................................................. 325

1.1 HOLE MACHINING BY MILLING ..............................................................335

1.1.1 Hole Machining Type Block ................................................................................335

1.1.2 Hole Position Block (XY Plane) ..........................................................................351

1.1.3 Hole Position Block (YZ Plane)...........................................................................359

1.1.4 Hole Position Block (XC Plane and End Face)....................................................360

1.1.5 Hole Position Block (ZC Plane and Cylindrical Surface) ....................................362

1.1.6 Hole Position Block (XA Plane and Cylindrical Surface) ...................................362

1.2 HOLE MACHINING BY TURNING (WITH THE TOOL ROTATED) ........... 363

1.2.1 Machining Type Blocks for Hole Machining by Turning

(with the Tool Rotated) ........................................................................................363

1.3 FACING ..................................................................................................... 370

1.3.1 Machining Type Blocks for Facing......................................................................370

1.3.2 Fixed Form Figure Blocks for Facing (XY Plane)...............................................376

1.3.3 Fixed Form Figure Blocks for Facing (YZ Plane, XC Plane)..............................379

1.3.4 Arbitrary Figure Blocks for Facing (XY Plane)...................................................380

1.3.5 Arbitrary Figure Blocks for Facing (YZ Plane, XC Plane, ZC Plane, XA Plane)381

c-8

Page 15

B-63874EN/05 TABLE OF CONTENTS

1.4 CONTOURING .......................................................................................... 382

1.4.1 Machining Type Blocks for Contouring ..............................................................382

1.4.2 Fixed Form Figure Blocks for Contouring (XY Plane)........................................403

1.4.3 Fixed Form Figure Blocks for Contouring (YZ Plane, XC Plane).......................406

1.4.4 Arbitrary Figure Blocks for Contouring (XY Plane) ...........................................407

1.4.5 Arbitrary Figure Blocks for Contouring

(YZ Plane, XC Plane, ZC Plane, XA Plane) ........................................................409

1.5 EMBOSS MACHINING.............................................................................. 410

1.5.1 Machining Type Blocks for Emboss machining ..................................................410

1.5.2 Arbitrary Figure Blocks for Emboss machining (XY Plane) ...............................420

1.5.3 Arbitrary Figure Blocks for Emboss machining

(YZ Plane, XC Plane, ZC Plane, XA plane) ........................................................421

1.6 POCKETING.............................................................................................. 422

1.6.1 Machining Type Blocks for Pocketing.................................................................422

1.6.2 Fixed Form Figure Blocks for Pocketing (XY Plane)..........................................435

1.6.3 Fixed Form Figure Blocks for Pocketing (YZ Plane, XC Plane).........................438

1.6.4 Arbitrary Figure Blocks for Pocketing (XY Plane)..............................................439

1.6.5 Arbitrary Figure Blocks for Pocketing

(YZ Plane, XC Plane, ZC Plane, XA Plane) ........................................................441

1.7 GROOVING............................................................................................... 442

1.7.1 Machining Type Blocks for Grooving .................................................................442

1.7.2 Fixed Form Figure Blocks for Grooving (XY Plane) ..........................................457

1.7.3 Fixed Form Figure Blocks for Grooving (YZ Plane, XC Plane)..........................462

1.7.4 Arbitrary Figure Blocks for Grooving (XY Plane) ..............................................463

1.7.5 Arbitrary Figure Blocks for Grooving

(YZ Plane, XC Plane, ZC Plane, XA Plane) ........................................................464

1.8 C-AXIS GROOVING .................................................................................. 465

1.8.1 Machining Type Blocks for C-axis Grooving ......................................................465

1.8.2 Figure Blocks for C-axis Grooving and A-axis Grooving ...................................467

1.9 REAR END FACING BY MILLING............................................................. 472

1.9.1 Rear End Facing ...................................................................................................472

1.10 ADDRESS SETTING OF ROTATION AXIS .............................................. 474

1.10.1 Support for C-Axis Machining with Rotation Axis .............................................474

1.11 C AXIS CLAMPING M CODE OUTPUT .................................................... 476

1.11.1 Outline..................................................................................................................476

1.11.2 Value of M Code Output ......................................................................................476

1.11.3 Distinction between Main and Sub Spindle .........................................................477

1.11.4 Position of M Code Output ..................................................................................477

2 TURNING ............................................................................................480

2.1 HOLE MACHINING (WORKPIECE ROTATION).......................................483

2.1.1 Machining Type Blocks for Hole Machining (Workpiece Rotation)...................483

2.2 TURNING .................................................................................................. 488

c-9

Page 16

TABLE OF CONTENTS B-63874EN/05

2.2.1 Machining Type Blocks for Turning....................................................................488

2.2.2 Arbitrary Figure Blocks for Turning ....................................................................516

2.3 TURNING GROOVING.............................................................................. 517

2.3.1 Machining Type Blocks for Turning Grooving ...................................................517

2.3.2 Fixed Form Figure Blocks for Turning Grooving................................................544

2.4 THREADING.............................................................................................. 559

2.4.1 Machining Type Blocks for Threading ................................................................559

2.4.2 Fixed Form Figure Blocks for Threading.............................................................564

2.5 REAR END FACING BY TURNING........................................................... 569

2.5.1 Rear End Facing ...................................................................................................569

3 SLANT FACE MACHINING (COORDINATE CONVERSION)............571

3.1 SUPPORTABLE MACHINE CONFIGURATION........................................ 572

3.2 SLANT FACE MACHINING COMMAND

(COORDINATE CONVERSION) ...............................................................573

IV. MULTI-PATH LATHE FUNCTIONS

(FOR Series 16i/18i/21i ONLY)

1 MULTI-PATH LATHE APPLICATION................................................. 581

1.1 PREPARATION ......................................................................................... 582

1.1.1 Machine Configuration Setting ............................................................................582

1.1.2 Set Icon for Selected Turret..................................................................................583

1.2 OPERATIONS OF MULTI-PATH LATHE .................................................. 584

1.2.1 Changing Screens for Each Path ..........................................................................584

1.2.1.1 Changing by a soft-key ...................................................................................................................... 584

1.2.1.2 Changing by a switch on a machine operator’s panel ....................................................................... 584

1.3 ANIMATION FOR MULTI-PATH LATHE ................................................... 585

1.3.1 Tool Path Drawing During Machining and Tool Path Machining Simulation.....585

1.3.2 Machining Simulation (Animation) .....................................................................586

1.4 MACHINING SIMULATION FOR EACH PATH .........................................587

1.5 OTHERS.................................................................................................... 589

2 SIMULTANEOUS ALL PATH DISPLAY / EDITING FUNCTION........ 590

2.1 OUTLINE ................................................................................................... 591

2.2 DETAILS.................................................................................................... 592

2.2.1 How to Start .........................................................................................................592

2.2.2 How to Finish .......................................................................................................592

2.3 SCREEN CONFIGURATION.....................................................................593

2.3.1 Display Position of Each Path ..............................................................................593

2.3.2 Status Display Part ...............................................................................................594

2.3.3 Current Position Display Part...............................................................................595

2.3.4 Program Display Part ...........................................................................................595

c-10

Page 17

B-63874EN/05 TABLE OF CONTENTS

2.4 HOW TO SELECT PATH .......................................................................... 596

2.5 OTHERS.................................................................................................... 596

3 PROCESS LIST EDITING FUNCTION ...............................................597

3.1 PREPARATION ......................................................................................... 598

3.1.1 Parameter..............................................................................................................598

3.2 START AND END OPERATIONS .............................................................599

3.2.1 Start ....................................................................................................................599

3.2.2 End ....................................................................................................................600

3.3 DISPLAY CONTENTS............................................................................... 601

3.3.1 Cell ....................................................................................................................601

3.3.2 Current Cell ..........................................................................................................601

3.3.3 Spindle..................................................................................................................602

3.3.4 Turret ....................................................................................................................602

3.3.5 Waiting Line.........................................................................................................602

3.3.6 Transfer ................................................................................................................603

3.4 BASIC OPERATIONS ............................................................................... 604

3.4.1 Basic Operations...................................................................................................604

3.5 EDITING OPEARTIONS............................................................................ 605

3.5.1 Insertion of a Cell.................................................................................................606

3.5.2 Deletion of a Cell .................................................................................................607

3.5.3 Copying of a Cell .................................................................................................609

3.5.4 Moving of a Cell ..................................................................................................611

3.5.5 Modification of Process Name .............................................................................614

3.5.6 Program Edit.........................................................................................................615

3.5.7 Assign of Waiting.................................................................................................617

3.5.8 Release of Waiting ...............................................................................................620

3.5.9 Assign of Transfer ................................................................................................622

3.5.10 Release Transfer ...................................................................................................624

3.5.11 Addition of Optional Block Skip for Each Path Program Check.........................626

3.5.12 Deletion of Optional Block Skip for Each Path Program Check .........................628

3.6 DEALING OF THE PART PROGRAM WITH UNFITTED TO PROCESS

LIST FORM ............................................................................................... 629

3.7 FORMAT ................................................................................................... 631

3.8 OTHERS.................................................................................................... 631

V. TOOL MANAGEMENT FUNCTION

(FOR Series 16i/18i/21i ONLY)

1 ASSOCIATING TOOL NUMBERS WITH OFFSET NUMBERS .........635

1.1 SELECTING THE SCREEN FOR ASSOCIATING A TOOL NUMBER

WITH A OFFSET NUMBER....................................................................... 636

c-11

Page 18

TABLE OF CONTENTS B-63874EN/05

1.2 SCREEN DISPLAY ITEMS........................................................................637

1.3 DISABLE WARNING MESSAGE............................................................... 638

2 VIEWING AND SETTING TOOL OFFSET VALUES .......................... 639

2.1 SELECTING THE TOOL NUMBER-BY-TOOL NUMBER TOOL OFFSET

SETTING SCREEN ................................................................................... 640

2.2 SCREEN DISPLAY ITEMS........................................................................641

2.3 TOOL OFFSET..........................................................................................643

2.4 NOTES ...................................................................................................... 644

2.5 DISABLE WARNING MESSAGE............................................................... 647

3 VIEWING AND SETTING TOOL MANAGEMENT DATA ................... 648

3.1 SELECTING THE TOOL MANAGEMENT DATA SETTING SCREEN ...... 649

3.2 MAGAZINE DATA SCREENS (MAGAZINE 1 TO 4) ................................. 650

3.2.1 Screen Display Items............................................................................................650

3.2.2 Displayed Warning Messages ..............................................................................651

3.3 SPINDLE AND STANDBY POSITION TOOL DISPLAY SCREEN ............ 652

3.3.1 Screen Display Items............................................................................................652

3.3.2 Displayed Warning Messages ..............................................................................653

4 VIEWING AND SETTING LIFE MANAGEMENT DATA ..................... 654

4.1 SELECTING THE LIFE MANAGEMENT DATA SETTING SCREEN ........ 655

4.2 SCREEN DISPLAY ITEMS........................................................................656

4.3 CHANGING TOOL PRIORITY................................................................... 658

4.4 UPDATING LIFE VALUES DISPLAYED ON THE TOOL LIFE DATA

SCREEN.................................................................................................... 659

4.4.1 Operation..............................................................................................................659

4.5 GROUP NUMBER LIST DISPLAY ............................................................661

4.6 DISPLAY OF GROUP NUMBER LIST ......................................................663

4.6.1 Display Life States of Group................................................................................663

4.6.2 Restore Group Life...............................................................................................665

4.7 DISPLAYED WARNING MESSAGES ....................................................... 666

4.8 SETTING THE LIFE NOTICE FLAG.......................................................... 666

5 TOOL LIFE DATA LIST SCREEN ......................................................667

5.1 SELECTING THE LIFE MANAGEMENT DATA LIST SCREEN ................ 668

5.2 LIFE MANAGEMENT DATA LIST SCREEN.............................................. 669

6 MODAL DISPLAY OF OFFSET TYPES ............................................. 672

6.1 SCREEN DISPLAY ITEMS........................................................................673

c-12

Page 19

B-63874EN/05 TABLE OF CONTENTS

6.2 DISPLAYED OFFSET TYPES

(SET BY THE MACHINE TOOL BUILDER)............................................... 674

7 DISPLAY TOOL MANAGEMENT DATA OF CNC STANDARD SCREEN

.............................................................................................................675

7.1 OPERATION.............................................................................................. 676

8 OTHERS..............................................................................................678

8.1 RETURN TO MENU SCREEN ..................................................................679

8.1.1 Return to SETTINGS Menu Screen.....................................................................679

8.2 INHIBITION OF EDITING TOOL MANAGEMENT DATA AT CNC

STANDARD SCREEN ............................................................................... 681

8.2.1 Operations ............................................................................................................681

8.3 USING TOOL MANAGEMENT DATA .......................................................681

VI. EXAMPLE OF PROGRAMMING OPERATION

1 EXPLANATORY NOTES .................................................................... 685

2 LATHE.................................................................................................686

2.1 SETTING TOOL OFFSET DATA...............................................................687

2.1.1 Setting of Z-axis Offset Data................................................................................688

2.1.2 Setting of X-axis Offset Data ...............................................................................690

2.2 SETTING OF WORKPIECE COORDINATE SYSTEM SHIFT DATA ........ 691

2.3 PREPARING OF THE FIXED FORM SENTENCE MENU......................... 693

2.3.1 Entering the Fixed Form Sentence for Turning Machining .................................693

2.3.2 Entering of the Fixed Form Sentence for Milling Machining..............................694

2.4 SETTING OF TOOL DATA........................................................................ 695

2.5 CREATING OF PART PROGRAM ............................................................ 696

2.5.1 Creating New Part Program..................................................................................696

2.5.2 Operations of “START” Menu.............................................................................697

2.5.2.1 Entering blank form data....................................................................................................................697

2.5.3 Entering Tool Changing and Spindle Rotating Blocks for Turning Machining ..698

2.5.3.1 Entering in ISO-code form directly.................................................................................................... 698

2.5.3.2 Entering by fixed form sentence menu ..............................................................................................698

2.5.4 Entering Outer Roughing Process ........................................................................699

2.5.4.1 Entering outer roughing cycle block .................................................................................................. 699

2.5.4.2 Entering figure for outer roughing..................................................................................................... 701

2.5.5 Entering Tool Changing and Spindle Rotation Blocks for Outer Finishing in

ISO-code Form.....................................................................................................704

2.5.6 Entering Outer Finishing Cycle Machining Process ............................................705

2.5.6.1 Entering figure for outer finishing cycle block..................................................................................705

2.5.6.2 Entering figure for outer finishing.....................................................................................................706

2.5.6.3 Entering releasing motion blocks in ISO-code form .........................................................................706

2.5.7 Entering Tool Changing and Spindle Rotating Blocks for C-axis Drilling..........707

c-13

Page 20

TABLE OF CONTENTS B-63874EN/05

2.5.7.1 Entering in ISO-code form directly.................................................................................................... 707

2.5.7.2 Entering by fixed form sentence menu ..............................................................................................707

2.5.8 Entering C-axis Drilling Process..........................................................................708

2.5.8.1 Entering C-axis drilling cycle block ..................................................................................................708

2.5.8.2 Entering hole position block .............................................................................................................. 709

2.5.9 Operations in the “END” Menu ...........................................................................710

2.5.9.1 Entering in ISO-code form directly.................................................................................................... 710

2.5.9.2 Entering by fixed form sentence menu ..............................................................................................710

2.6 CHECKING OF THE PART PROGRAM.................................................... 711

2.6.1 Checking by Animation........................................................................................711

3 MACHINING CENTER ........................................................................ 712

3.1 SETTING OF TOOL LENGTH OFFSET DATA ......................................... 713

3.2 SETTING OF WORKPIECE ORIGIN OFFSET VALUE............................. 715

3.3 PREPARING OF THE FIXED FORM SENTENCE MENU......................... 717

3.3.1 Entering the Fixed Form Sentence for Milling.....................................................717

3.4 SETTING OF THE TOOL DATA................................................................ 718

3.5 CREATING OF PART PROGRAM ............................................................ 719

3.5.1 Creating New Part Program..................................................................................719

3.5.2 Operations of “START” Menu.............................................................................720

3.5.2.1 Entering blank form data....................................................................................................................720

3.5.3 Entering Tool Changing and Spindle Rotating Blocks for Roughing Flat End

Mill ....................................................................................................................721

3.5.3.1 Entering in ISO-code form directly.................................................................................................... 721

3.5.3.2 Entering by fixed form sentence menu ..............................................................................................721

3.5.4 Entering Outer Wall Contouring Process.............................................................722

3.5.4.1 Entering outer wall contouring (rough) cycle block.......................................................................... 722

3.5.4.2 Entering figure for outer wall contouring (rough)............................................................................. 723

3.5.5 Entering Pocket Roughing Process ......................................................................724

3.5.5.1 Entering pocket roughing cycle block ............................................................................................... 724

3.5.5.2 Entering figure for pocket roughing ..................................................................................................726

3.5.6 Entering Tool Changing and Spindle Rotating Blocks for Finishing Flat End

Mill ....................................................................................................................731

3.5.6.1 Entering in ISO-code form directly.................................................................................................... 731

3.5.6.2 Entering by fixed form sentence menu ..............................................................................................731

3.5.7 Entering Pocket Bottom and Side Finishing Process ...........................................732

3.5.7.1 Entering pocket bottom finishing cycle block ...................................................................................732

3.5.7.2 Entering figure for pocket bottom finishing ...................................................................................... 733

3.5.7.3 Entering pocket side finishing cycle block ........................................................................................734

3.5.7.4 Entering figure for pocket side finishing...........................................................................................735

3.5.8 Entering Tool Changing and Spindle Rotating Blocks for Drill ..........................736

3.5.8.1 Entering in ISO-code form directly.................................................................................................... 736

3.5.8.2 Entering by fixed form sentence menu ..............................................................................................736

3.5.9 Entering Drilling Process .....................................................................................737

3.5.9.1 Entering drilling cycle block.............................................................................................................. 737

3.5.9.2 Entering hole position block .............................................................................................................. 738

3.5.10 Operations in the “END” Menu ...........................................................................739

3.5.10.1 Entering in ISO-code form directly.................................................................................................... 739

3.5.10.2 Entering by fixed form sentence menu ..............................................................................................739

c-14

Page 21

B-63874EN/05 TABLE OF CONTENTS

3.6 CHECKING OF THE PART PROGRAM.................................................... 740

3.6.1 Checking by Animation........................................................................................740

APPENDIX

A PARAMETERS.................................................................................... 743

A.1 REQUIRED PARAMETERS ...................................................................... 744

A.1.1 Parameters Required for Basic Options................................................................744

A.1.2 Parameters Required for Machining Simulation ..................................................745

A.1.3 Parameters Required for Other Options except Basic Option

(For Series 30i only).............................................................................................746

A.2 BASIC PARAMETERS .............................................................................. 747

A.2.1 Settings for the Color Palette for Screen Display (No.2) .....................................747

A.2.2 Parameters for Operations in General ..................................................................748

A.2.3 Parameters for the Axial Configuration of the Machine ......................................752

A.2.4 Settings for Spindle Status Display ......................................................................753

A.2.5 Setting for the Display Language .........................................................................753

A.2.6 Settings for Graphic Display ................................................................................754

A.2.7 Settings for Machining Simulation Axes .............................................................755

A.2.8 Settings for Subprogram Selection Screens .........................................................756

A.2.9 Settings for the Color Palette for Screen Display.................................................757

A.2.10 Settings for the Color Palette for Icon Display ....................................................759

A.2.11 Settings for the Color Palette for Guide Display..................................................761

A.2.12 Settings for Tool Path Drawing Colors ................................................................763

A.2.13 Settings for Machining Simulation Animation Colors.........................................763

A.2.14 Settings for Path Colors During Tool Path Plotting .............................................764

A.2.15 Settings for the Allocation of Startup Function Keys ..........................................765

A.2.16 Settings for Current Position Display...................................................................768

A.2.17 Settings for F Load Meter Compensation ............................................................769

A.2.18 Settings for Tool Management Functions ............................................................770

A.2.19 Settings for Arbitrary Figures...............................................................................771

A.2.20 Other Parameters ..................................................................................................772

A.2.21 Settings for Operations in General (All Common Path).......................................773

A.2.22 Settings for Operations in General (For Series 30i) .............................................775

A.2.23 Settings for Operations in General (For Multi C Executor) .................................775

A.2.24 Settings for Operations in General (Each Path) ...................................................776

A.2.25 Settings for Operations in General (All Common Path).......................................776

A.2.26 Settings for Arbitrary Figures(XA Plane) ............................................................777

A.3 PARAMETERS FOR MILLING CYCLE MACHINING................................ 778

A.3.1 Parameters for Milling Cycles in General ............................................................778

A.3.2 Parameters for Facing Cycles ...............................................................................783

A.3.3 Parameters for Contouring Cycles........................................................................784

A.3.4 Parameters for Pocketing Cycles..........................................................................787

A.3.5 Parameters for Grooving Cycles ..........................................................................792

c-15

Page 22

TABLE OF CONTENTS B-63874EN/05

A.4 PARAMETERS FOR TURNING CYCLE OPTIONS .................................. 795

A.4.1 Parameters Common to Turning Cycles...............................................................795

A.4.2 Parameters for Turning Cycle Machining ............................................................797

A.4.3 Parameters for Threading Cycles .........................................................................798

A.4.4 Parameter for Turning and Grooving Cycles .......................................................801

A.4.5 Parameters for Program Coordinate System Changing Function and Tool

Offset Memory Changing Function .....................................................................802

A.4.6 Parameters for Machining Simulation (Animated) ..............................................804

A.4.7 Parameter for Machining Simulation (Animated) ................................................816

A.4.8 Parameters for Multi-path Lathe Function ...........................................................817

A.4.9 Parameters for Icon of Path Number Display.......................................................819

A.4.10 Other Parameters ..................................................................................................820

B ALARMS .............................................................................................821

C MANUAL GUIDE i SETUP METHOD .................................................826

C.1 GENERAL ................................................................................................. 827

C.2 HARDWARE..............................................................................................827

C.3 SOFTWARE .............................................................................................. 828

C.3.1 Lathe (Series 16i/18i/21i).....................................................................................828

C.3.2 Machining Center (Series 16i/18i/21i) .................................................................829

C.3.3 Lathe or Machining Center (Series 30i) ...............................................................830

C.3.4 Lathe with Compound Machining Function (Series 16i/18i/21i).........................831

C.3.5 Other Machines (Series 16i/18i/21i) ....................................................................831

C.3.6 Other Machines (Series 30i).................................................................................832

C.3.7 Note ....................................................................................................................832

C.4 PARAMETER SETTING ............................................................................ 833

C.4.1 Lathe ....................................................................................................................833

C.4.2 Machining Center.................................................................................................839

C.4.3 Other Machines ....................................................................................................842

C.5 M CODE OUTPUTED DURING CYCLE EXECUTING.............................. 843

C.5.1 M code for Rigid Tapping ....................................................................................843

C.5.2 M code for Clamping and Unclamping Rotate Axis as “C”.................................844

C.6 OPTIONAL FUNCTIONS AVAILABLE ...................................................... 846

C.6.1 Lathe (Series 16i/18i/21i).....................................................................................846

C.6.2 Machining Center (Series 16i/18i/21i) .................................................................846

C.6.3 Lathe, Machining Center (Series 30i) ..................................................................846

c-16

Page 23

I. GENERAL

Page 24

Page 25

B-63874EN/05 GENERAL 1.OVERVIEW OF THIS MANUAL

1 OVERVIEW OF THIS MANUAL

This manual describes the functions of "MANUAL GUIDE i" for the

Series 16i/18i/21i-MODEL B or Series 30i-MODEL A and the

MANUAL GUIDE i simulator for the personal computer.

For other functions, refer to the operator’s manual for the Series

16i/18i/21i-MODEL B or Series 30i-MODEL A.

The specifications and usage of MANUAL GUIDE i may vary

according to the specifications of the operator’s panel of a machine

tool. Be sure to read the manual provided by the machine tool builder.

The functions of the CNC machine tool system are determined not

only by the CNC, but by the combination of the machine tool, the

power magnetic circuit in the machine tool, the servo system, the CNC,

and the operator’s panel.

It is impossible to cover all possible combinations of all functions,

programming methods, and operations in a single manual.

This manual explains only the MANUAL GUIDE i operations

provided for the CNC. For individual CNC machine tools, refer to

applicable manuals from the machine tool builders.

This manual explains as many detailed functions as possible. However,

it is not possible to describe all of the items which cannot be done or

which the operator must not do. Therefore, please assume that

functions other than those described in this manual cannot be

performed.

Detailed information and special conditions are explained in notes.

The readers may encounter new technical terms in the notes not

previously defined or described. In this case, read this manual through

first, then review the details.

NOTE

MANUAL GUIDE i has options for supporting

milling and turning cycles, animated simulation, and

set-up guidance. This manual covers these

functions assuming that your machine has all these

functions. However, your machine may not actually

be provided with some of these functions.

Refer to the manual published by the machine tool

builder of your machine for details.

- 3 -

Page 26

2.READ AT FIRST GENERAL B-63874EN/05

2 READ AT FIRST

In this chapter, you will find the explanation of the place where you

should refer to when you operate MANUAL GUIDE i.

When trying to use a machine equipped with the FANUC MANUAL

GUIDE i, be sure to observe the safety precautions written in this

manual with sufficient caution.

What is MANUAL GUIDE i ?

MANUAL GUIDE i is the operation guidance to support an operator

on many situations such as creating a part program, checking by

machining simulation, set-up and actual machining. These operations

can be done on the only one screen.

ISO code form is adopted as the part program format, it is widely used

on many CNC machine tools, furthermore, machining cycles, which

can realize complicated machining motions by simple programming,

are provided.

As to the outline of MANUAL GUIDE i, refer to the following part.

• Features

II 1.1 MAIN FEATURES OF MANUAL GUIDE i

• Displaying screens

I 3. ALL-IN-ONE SCREEN

What kind of machines can be supported?

MANUAL GUIDE i can be used for lathe, machining center and

compound machine including the following machine configurations.

• Lathe

From 1-path to 3-path lathe, which includes Y-axis and tool

inclining axis.

• Machining center

Machining center including workpiece rotating table and tool

inclining axis.

• Compound machine

Compound machine with capability of both lathe machining and

milling.

MANUAL GUIDE i has operation ability common to the above

machines. So, you can operate on same screen commonly on the

above machine excepting machining cycles and tool offset data setting

which are used for each machine exclusively.

- 4 -

Page 27

B-63874EN/05 GENERAL 2.READ AT FIRST

How to install MANUAL GUIDE i to CNC

In ordinary case, MANAUL GUIDE i is installed in an CNC and

prepared by MTB such as parameter setting. In that case, you can use

MANUAL GUIDE i as it is.

However, by some reasons, there is a case such like you must install

MANUAL GUIDE i into CNC and set necessary parameter by

yourself.

In order to support you in that case, parameter setting and set-up

guidance explanations are prepared.

• Explanations for the operations for installing MANUAL GUIDE

i into CNC newly.

• Appendix A. PARAMETER

• Appendix C. MANUAL GUIDE i SETUP METHOD

How to begin to operate MANUAL GUIDE i

In order to display the screen of MANUAL GUIDE i, press some

function button on the MDI panel of CNC. As to which function

button should be used, refer to the manual made by MTB because it

depends on the parameter No.14794 and 14795 setting.

NOTE

MANUAL GUIDE i operations cannot be done during

background editing mode of CNC program screen.

How to create a part program

In order to create a part program on MANUAL GUIDE i, refer to the

following part,

• General operations flow of programming

VI. EXAMPLE OF PROGRAMMING OPERATION:

For lathe and machining center respectively, series of

operations from setting up such as offset data to creating a

part program and its checking are explained.

• Basic operations of part program editing

II 3. EDITING MACHINING PROGRAMS:

Various editing operations, which are used for the part

program in form of ISO code, are explained.

• Details of machining cycles

II 4. EDITING CYCLE MACHINING OPERATIONS

II 5. DETAILED DESCRIPTIONS ABOUT ENTERING

ARBITRARY FIGURES:

Operations of various machining cycles, which can be used

for realizing complicated machining, are explained.

In the ISO code form part program, similar programs are used

frequently such as toll changing and spindle rotation. MANUAL

GUIDE i supports those frequently used operations by the fixed form

- 5 -

Page 28

2.READ AT FIRST GENERAL B-63874EN/05

sentence function. Fixed form sentences, programming template, are

made in advance and can be used by selecting from the menu during

programming operations. In to details, refer to the following part.

• Making and using of fixed form sentence

II 3.14. FIXED FORM SENTENCE INSERTION

II 10.3. REGISTERING FIXED FORM SENTENCES

How to check the created part program

As to the operations for checking the created part program on

MANUAL GUIDE i, refer to the following part.

• Checking the part program

II 9. OPERATIONS IN MACHINING SIMULATION:

Operations of checking the part program by using

machining simulation, animation or tool path drawing, are

explained. And also, checking the tool path drawing of

actual motions during machining is explained.

How to set the data needed for machining

In order to execute actual machining, tool offset data and workpiece

coordinate data setting must be done in advance. These data are

prepared as CNC standard function, but these data can be entered by

using MANUAL GUIDE i too.

• Setting of tool offset data and workpiece coordinate data

II 10.1 SETTING THE WORKPIECE COORDINATE DATA

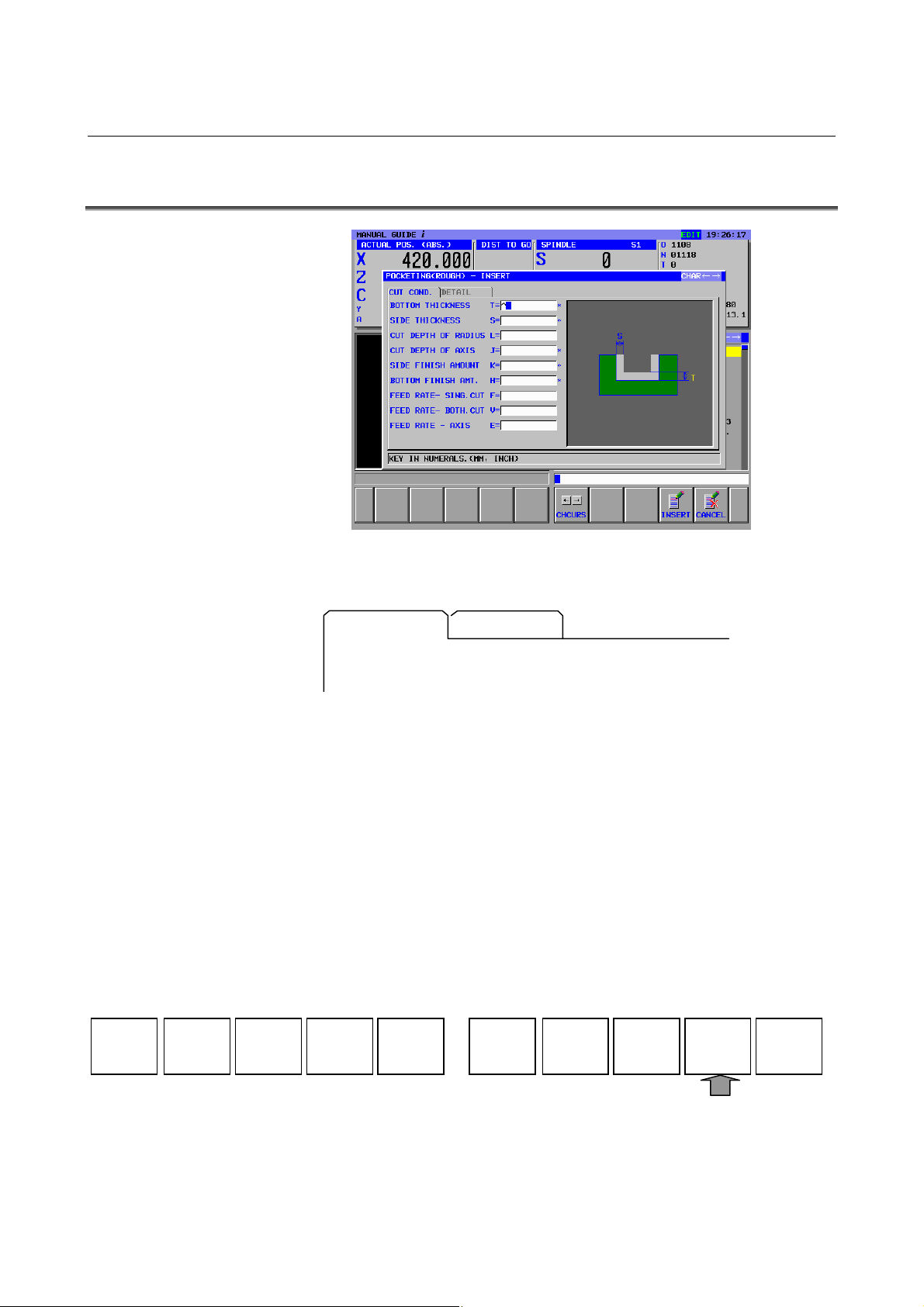

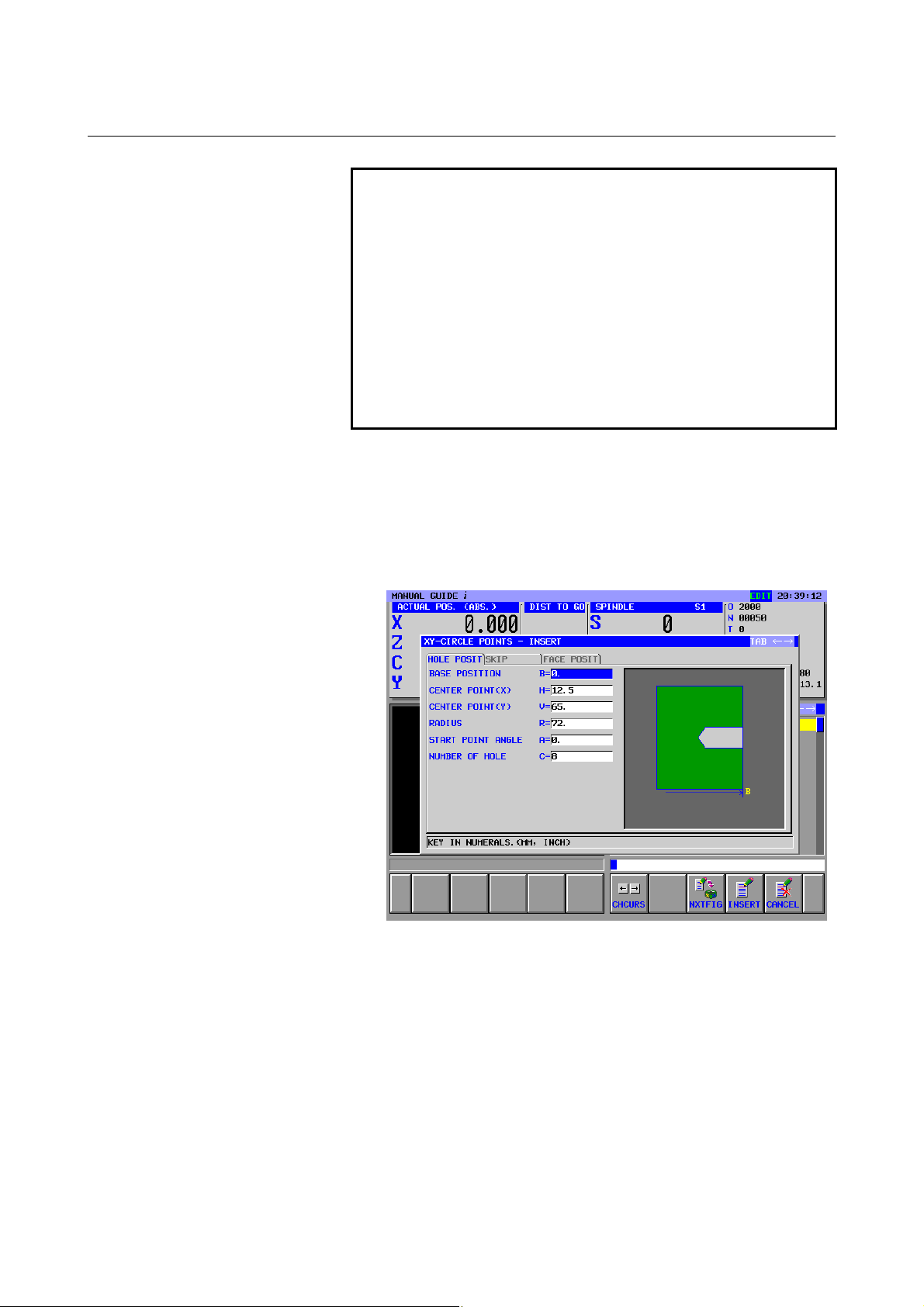

II 10.2 SETTING TOOL OFFSET DATA: